Page 1

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile: 801 489 2228

Automation Business Unit www.flowserve.com Email: actuators@flowserve.com

AS-I Bus Card for BUSwitch and UltraSwitch Enclosures

Introduction

Flowserve’s BUSwitch™ uses the AS-I Bus

communication prot ocol to operate pneumatic valve

actuators and m onitor/r ep o r t the ir p os ition. The AS-I

card may be provided in Flowserve’s Aviator

enclosure with integrated solenoid valve or in our

UltraSwitch™ enclosures for use with external

solenoid valves.

Principles of Operation

BUSwitch™ utilizes two dis crete outputs to en ergize

solenoid valves, which operate rotary pneumatic

actuators. For spring return and double acting

applications with a desired fail position (open or

closed). Output one ( 1) is used to operate a singl e

pilot. For applic ations requiring fail in last posi tion,

both output one (1) and out put two (2) are us ed with

a “dual coil” pilot configuration.

Actuator position is sensed with two limit switches.

BUSwitch™ communicates the state of these lim its

into the master as input one (1) and input two (2)

A 2-wire cable using the AS-I (166 kb/s) protocol

provides communication and power to the AS-I

Communication Board. This card operates from

29.5 to 31.6 VDC.

Printed Circuit Board Specifications

Power requirements

XA0244

Communications Card

Temperature

Operational -55 °F to +185 °F

Storage -55 °F to +250 °F

29.5 to 31.6 VDC

(-48 °C to +85 °C)

(-48 °C to +120 °C)

AS-I Bus Information

ID Code (describes device behavior)

ID 0001 Binary

This code is specific to

Flowserve’s AS-I board and is

stored in non-volatile memory

I/O Code (describes type of I/O

implemented)

Type OUT OUT IN IN

I\D 1011 Binary

This code is also stored in nonvolatile memory.

Start-up Guide

1. Following the instructions in “Mechanical

Installation,” install the BUSwitch™ onto a

pneumatic actuator and turn supply air on.

2. Following the instructions in “Electrical

connections,” connect AS-I bus.

3. Bring up control software used for AS-I

implementation.

4. Turn power onto AS-I bus.

5. Using output 1 value parameter (and output 2 for

dual coil mode), stroke the valve (Discrete 0 =

de-energized; Discrete 1 = energized) and set

limit switches, r eferring to “ Adjustment of S witch

Cams” section. Circuit board mounted LED’s

light when switches are tripped.

6.

This is the minim um c onfiguratio n to oper ate the

actuator and read valve positio n

Mechanical Installation

Installation is best performed with Flowserve

NAMUR mounting kits. These kits allow direct

mounting of the BUSwitch™ shaft to the actuator

pinion without a coupl er. The NAMUR mount ing kits

will work with any actuator conforming to the

instructions, NAMUR standard for accessory

mounting hole locations and pinion dimensions.

Simply attach the bracket to actuator and

BUSwitch™ to the bracket with the included

fasteners. The BUSwitch™ shaft features an

integral alignment pin that engages the tapped

pinion hole. Flowserve a lso offers a full line of nonNAMUR mounting kits.

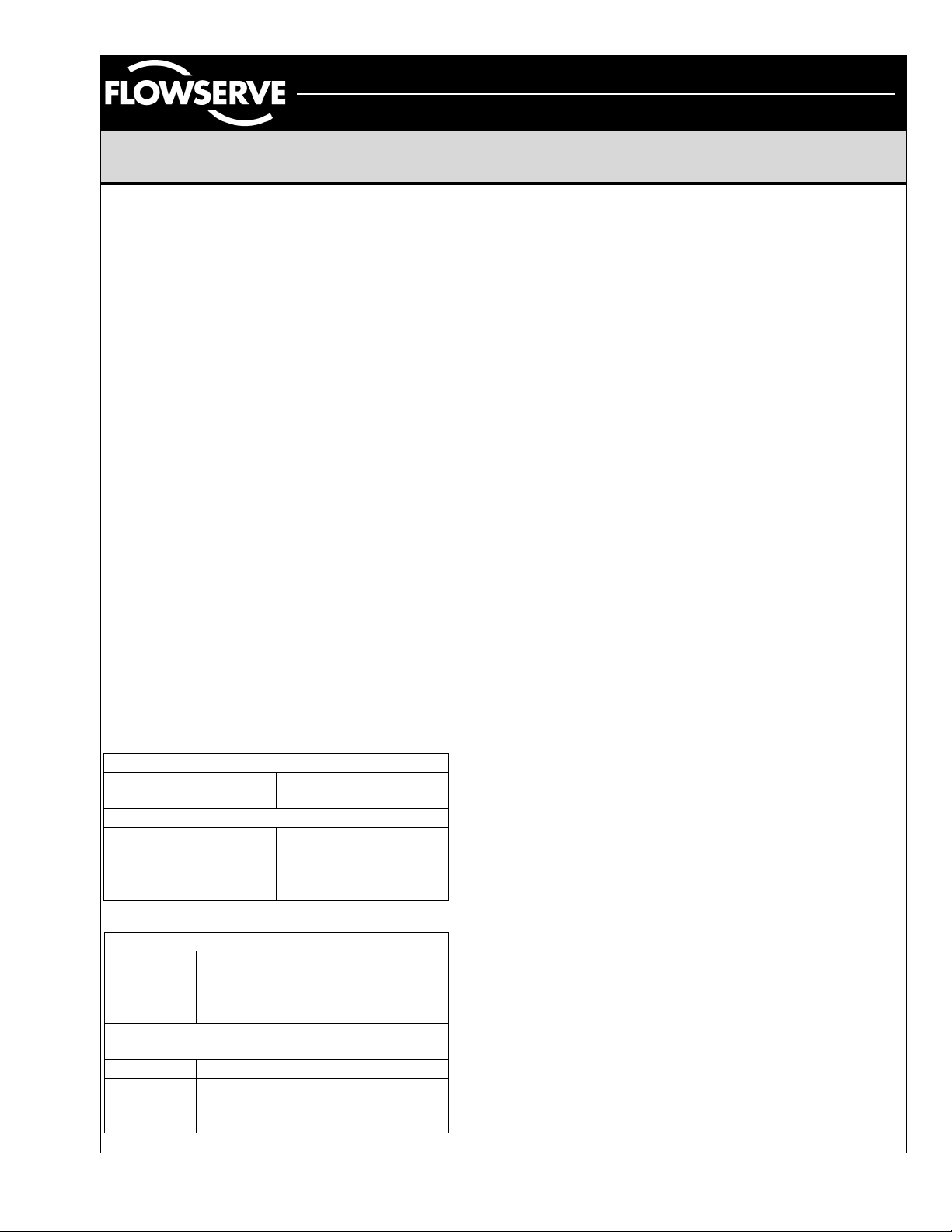

Spool and Tubing Configuration

1. For external solenoid valves, refer to solenoid

valve operating instructions for piping and tubing

configuration. For integrated solenoid valve, a

four-way spool valve is provided. Plug port #2

for 3-way applications (Figure 1). Make sure the

plug is properly configured before installing

tubing.

2. Make sure all air pressure is removed before

installing tubing.

3. Attach tubing according to solenoid valve

manufacturer’s instructions. For integrated

solenoid valve configuration, refer to Figure 1 for

AXAIM025-00 (AUTO-87) 7/01 Page 1 of 4

©2001, Flowserve Corporation, Provo, UT

Page 2

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile: 801 489 2228

Automation Business Unit www.flowserve.com Email: actuators@flowserve.com

spring return or Figure 2 for double acting

applications. Attach supply tubing to Port 1 and

use 3 and 5 for exhaust.

4. To prolong actuator life use only clean, dry plant

air. Lubricated air is not required, although it is

recommended, particularly for high cycle

applications.

Figure 1

Electrical Connections

CAUTION

To prevent ignition of hazardous atmospheres,

keep cover bolts tight while circuits are live.

Disconnect supply circuit before opening.

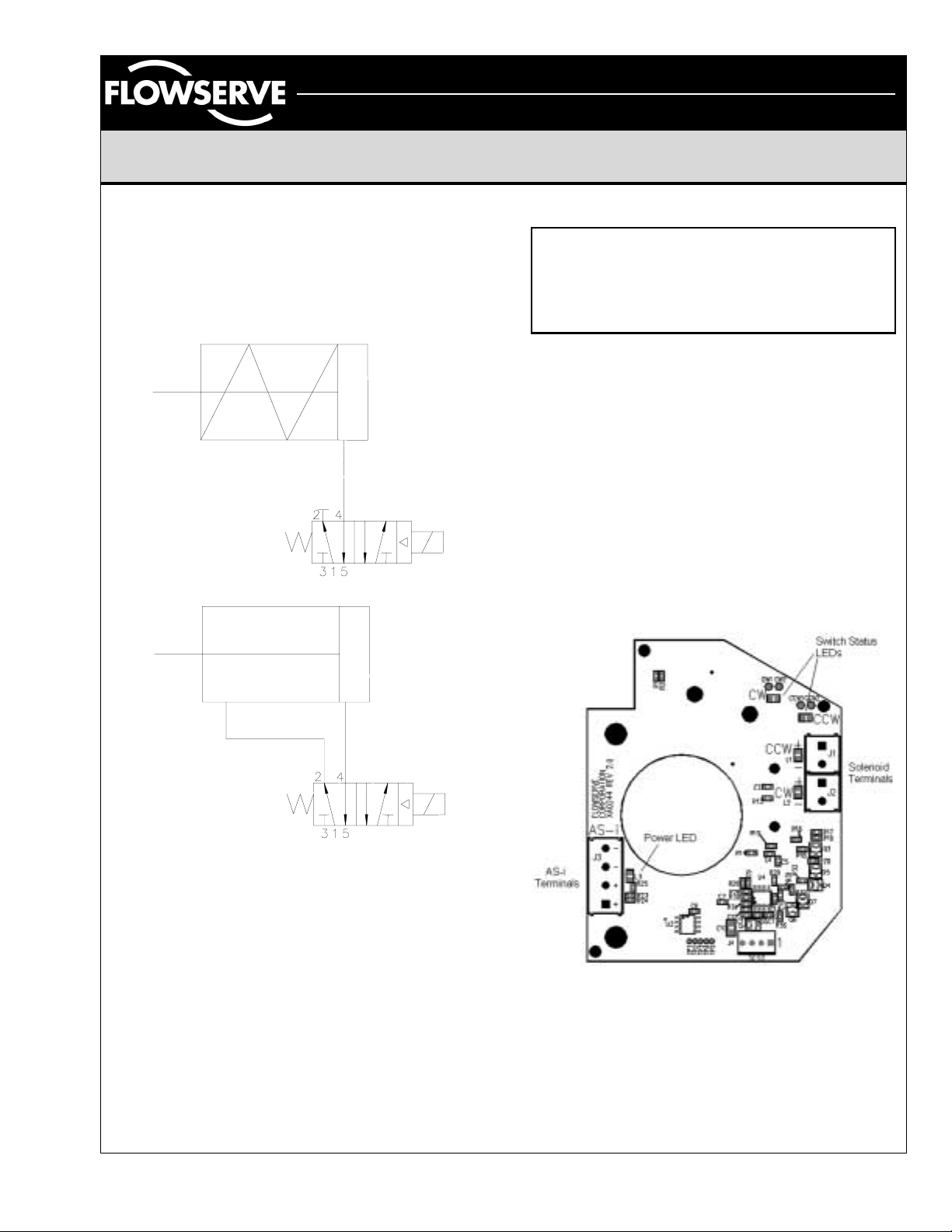

Entry into the BUSwitch™ integrated solenoid

housing is made through three ½” NPT conduit

entries. UltraSwitch enclo sures feature two entries:

¾” NPT for XL and PL series and ½” NPT for GL

series. Figure 3 pro vides terminal locations on the

XA0244 interface card.

Connection of the data cable is made to connector

P3 - observing polarity. Incorrect polarity will not

damage the electronics, but it will prevent

communication. Caution: make sure power is

turned off when making electrical connection.

For hazardous locations, Underwriters Laboratories

(UL) and the National Electric Code (NEC) require

an approved sealing f itting within eighte en inches of

the switch enclosure.

Figure 2

Lubrication

All BUSwitch™ integrated spool valves are prelubricated and will operate dry (with no additional

lubrication). The use of lubricated air will not

interfere with the functioning of the BUSwitch™. If

air lubrication is used, the oils listed below are

popular, easily obtainable, fluids that are

recommended for use with the BUSwitch

integrated spool valve: Gulf Harmon y 47, Mobil DTE

Medium, Shell T ellus 29, Texaco Rondo B, Soh ivis

47 and Sunnis 921. Many other lubricants are

acceptable providing they do not contain det ergents

that will attack Buna N or Viton Seals.

AXAIM025-00 (AUTO-87) 7/01 Page 2 of 4

©2001, Flowserve Corporation, Provo, UT

Solenoid to AS-I Interface Card (XA0244 rev 2.0)

Figure 3

Open conduit entries must be closed after

installation using a close-up plug approved for

hazardous locations. Conduit and plugs must fully

engage five threads.

Page 3

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile: 801 489 2228

Automation Business Unit www.flowserve.com Email: actuators@flowserve.com

Special Notes on AS-I cabling

Minimum voltage r equirement for the BU Switch™ is

29.5 VDC supply. The output volt age of the fiel dbus

power supply, the current drawn and the electrical

characteristics of the data cable determine the

maximum distance that a particular segment can

span. With data cable that conforms to the AS-I

cable specified in s ection 5.5.3 of AS-I sp ecification

V2.0 distances of 100 m are guaranteed. If a

shielded cable is used, c onnect the shield to gr ound

at one point only. Multiple grounds can lead to

ground loops whic h can impair the pr oper operation

of the segment. For this r eason, a shield c onnec tion

has not been provided inside the BUSwitch™

housing. Radio frequency grounding at multiple

points through the use of capacitors is not allowed

by the AS-I protocols. For a more thorough

treatment of data cable wiring and aspects of

installation refer to the AS-I specification V 2.0.

Device Initialization

Each new device that is connected to the AS-I

network is recognized within 10ms. Devices are

immediately ready for use when an address is

assigned. Make sure each device to be connected

to a bus segment has a unique address prior to

starting configuration software. This will ensure that

each device is recognized by the system. Duplicate

addresses can result in devices not being

recognized.

Pneumatic Actuator Operation – Single

Coil, Fail Open or Fail Closed

For operation requiring a consistent fail position

(either open or closed), One output is used as

shown in the Single Coil T r uth Table. To reverse the

actuator fail mode for double acting actuators,

reverse actuator ports. To reverse spring-return

actuators, actuator modification is necessary.

Single Coil Truth Table

Output 1 OPEN/CLOSE

0 De-energized

1 Energized

Pneumatic Actuator Operation – Dual

Coil, Fail in Last Position

Dual Coil Operation uses both o utput 1 an d output 2

as shown in the Dual Coil Truth Table.

movement to take place, the Output parameters

must take on opposite values as shown below.

Dual Coil Truth Table

Output 1 Output 2

0 0 No Change No Change

1 0 Energized De-energized

1 1 No Change No Change

0 1 De-energized Energized

OPEN CLOSE

For valve

Adjustment of Switch Cams

1. Loosen five captive cover screws and

remove lid, turning slightly while lifting.

2. Place the actuator in the clock-wise

(CW) position and connect to the ASI bus segment.

3. Push down on the top cam until it

clears the splined coupler, rotating

clockwise until the CW LED is

illuminated (figure 4).

4. Release the cam and insure that it

fully engages the spline.

5. Place the actuator in the counterclockwise (CCW) position.

Figure 4

6. Pull up on the lower cam until it

clears its splined coupler, rotating

counter-clockwise until the CCW LED is

illuminated (figure 4).

AXAIM025-00 (AUTO-87) 7/01 Page 3 of 4

©2001, Flowserve Corporation, Provo, UT

Valve Position Monitoring and Reporting

The BUSwitch™ monitors the status of two limit

switches. SW 1 is the upper switc h and is set to tr ip

when the valve reaches the c losed pos ition. SW 2 is

the lower switch and is s et to trip when the valve is

open.

Truth Table for Switch Values

SW1 SW2 Input 1 Input

2

A A 1 1 Improper switch adj.

A O 1 0 Actuator CLOSED

O A 0 1 Actuator OPENED

O O 0 0 Actuator is moving

A = Activated or Tripped, O = Open or Not Tripped

Meaning

Page 4

Automax Valve Automation Systems

Installation, Operation and Maintenance Instructions

Flowserve Corporation 765 South 100 East Phone: 801 373 3028

Flow Control Division Provo, Utah 84606 Facsimile: 801 489 2228

Automation Business Unit www.flowserve.com Email: actuators@flowserve.com

This page intentionally left blank

AXAIM025-00 (AUTO-87) 7/01 Page 4 of 4

©2001, Flowserve Corporation, Provo, UT

Loading...

Loading...