Page 1

DESCRIPTION

Worcester Controls/McCANNA ACCESS I and M Series 39 actuators

are pneumatic quarter-turn valve actuators. The solenoid and limit

switches for the ACCESS I are integral to the actuator end cap, while

the ACCESS M is a separate factory-mounted enclosure containing

the solenoid and limit switches. The design utilizes a double-rack,

single-pinion concept, with each rack integrally cast to a piston. Both

pistons are supported and centered by large, stainless steel guide

rods. In double-acting units, both pistons are pressurized on both

strokes of the actuator. Ambient temperature range of ACCESS unit is

0°F minimum to 160°F maximum.

Standard units feature an extended top shaft for manual override

capabilities and a completely modular design which allows simple

attachment of a variety of accessories. The units feature a control

block (with spool valve) which properly directs supply air to the

actuator. The control block provides independently adjustable speed

control for both opening and closing strokes of the actuator on

double-acting units, and for the closing stroke on spring-return units

(standard mounting configuration). The units can also be supplied

with an air connection block (in place of control block) for when there

is no solenoid valve integral with unit.

a WARNING: SERIES 39 ACTUATORS ARE ELECTRO-MECHANICAL

DEVICES SUBJECT TO NORMAL WEAR AND TEAR. ACTUATOR LIFE IS

DEPENDENT UPON APPLICATION AND ENVIRONMENTAL

CONDITIONS. IF APPLIED IN HAZARDOUS SERVICES, SUCH AS BUT

NOT LIMITED TO MEDIA TEMPERATURE EXTREMES, TOXINS,

FLAMMABLES, OR OTHER SERVICES WHERE IMPROPER OR

INCOMPLETE OPERATION COULD PRODUCE A SAFETY HAZARD, IT IS

INCUMBENT UPON THE SYSTEM DESIGNER AND THE USER TO

PROVIDE PROPER WARNING DEVICES SUCH AS TEMPERATURE

SENSORS, OXYGEN SENSORS AND FLOW SENSORS. FLOWSERVE

ALSO RECOMMENDS THAT THE INTEGRAL LIMIT SWITCHES BE USED

FOR MONITORING AND/OR ELECTRICAL INTERLOCK.

CAUTIONS: When actuator is installed in outdoor conditions, water

can enter the exhaust hole(s) of the control block or air connection

blocks, and then freeze. Flowserve suggests a cover be used, or

mount the actuator such that the block exhaust hole(s) will not fill

with water.

Flowserve recommends that all products which must be stored

prior to installation be stored indoors, in an environment suitable

for human occupancy. Do not store product in areas where

exposure to relative humidity above 85%, acid or alkali fumes,

radia tion above normal background, ultraviolet light, or

temperatures above 120°F or below 40°F may occur. Do not store

within 50 feet of any source of ozone.

IMPORTANT: INCLUDED IN ALL 39 ACTUATOR ACCESSORY AND

REPAIR KITS IS A REBUILD/ACCESSORY ADDITION LABEL, WHICH

IS TO BE MARKED WITH A PERMANENT MARKER AND THEN

APPLIED TO THE ACTUATOR AFTER AN ACCESSORY KIT HAS BEEN

INSTALLED OR AN ACTUATOR HAS BEEN REPAIRED.

All ACCESS M units have four threaded tamper proof plugs installed

over the enclosure mounting machine screws. No attempt should be

made to remove these plugs. If it becomes necessary to remove

enclosure from actuator end cap, consult Flowserve.

INSTALLATION

NOTE: The Series 39 actuator is normally installed with its major axis

parallel to the pipe line (this is mandatory when mounting actuator to

90° V1 diverter/three-way (D44 & T44) valves and CPT valves. The

actuator can be oriented above, beside or beneath the valve without

affecting its operation.

Sizes 10–35 Rev. R6 actuators may come with an ISO locating ring

used for optional ISO mounting.

A. Determine mode of operation desired (normally open or normally

closed) of the valve.

B. Determine desired quadrant for bracket attachment and direction

of mounting of actuator (in-line or cross-line).

C. Attach mounting bracket to actuator using four (4) cap screws

and lockwashers provided in mounting kit. To avoid any damage

to the Series 39 actuator body, ONLY the proper length screws

supplied with the mounting kit should be used. For

1

/

4"– 2" top-

mount style valves, attach bracket such that bracket nameplate

will be to side of valve.

For mounting to 818/828 Series valves insert ISO locating ring

into groove on bottom of actuator before attaching to bracket.

FCD WCAIM2028-01

(Part 15908)

Worcester Controls 10, 15, 20 ACCESS I

and 10-40 ACCESS M 39 Actuators Intrinsically Safe

Installation, Operation and Maintenance Instructions

Page 2

2 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

NOTE: Ring can be permanently held in groove by applying Loctite

to ring before inserting in groove.

D. Attach bracket/actuator assembly to valve as follows:

CAUTION: Ball valves can trap pressurized media in the cavity. If

it is necessary to remove any valve body bolts, stem nuts, or

remove valve from the line, and if the valve is or has been in

operation, make sure there is NO pressure to or in the valve and

operate valve one full cycle. However, the valves listed below

do not require the removal of any valve body bolts or removal of

valve from line in order to mount actuator.

1. Rotate valve ball and stem to position necessary to achieve

desired operation. If any valve information is marked on stop

plate or handle, it will be necessary to transfer this

information to the bracket nameplate

2. For

1

/

4"– 2" 44, and

1

/

2"– 2" WK70/WK74,

1

/

4"–1

1

/

2" 59 and

1

/

2"–1

1

/

2"

H71 Series top-mount style valves and

1

/

2"– 2" 51/52,

1

/

2"–1

1

/

2"

82/83 Series valves with high-cycle stem packing as standard,

remove handle nut, lockwasher, handle, separate stop plate (if

any), retaining nut and stop pin(s). Add the two additional

Belleville washers with their larger diameter sides touching

each other. Add the self-locking nut to the stem and tighten

while holding the stem flats with wrench. Tighten until

Belleville washers are flat, the nut will “bottom”, and then

back nut off

1

/

3 of a turn. The two additional Belleville washers

and the self-locking nut are included in the mounting kit.

CAUTION: The self-locking stem nut is difficult to tighten,

and must fully flatten Belleville washers before backing off.

For 2" 59, H71, 82/83, and 2

1

/

2" 45, 82/83 series valves, and

valves 3" and larger with square stem, remove handle

assembly (if any), retaining nut, stop and stop screws.

Replace with valve stem spacer or, if valve has graphite stem

packing, with two Belleville washers (except 8", 10" 82/83 and

10" 51/52), and replace retaining nut.

NOTE: Belleville washers are installed with their larger

diameter sides touching each other. Do not use stem spacer

when Belleville washers are used. Using a wrench to prevent

stem from turning, tighten retaining nut until stem packing is

fully compressed or Bellevilles, if used, are fully flattened,

then back off nut

1

/

6 turn. Excessive tightening causes higher

torque and shorter seal life.

NOTE: Large valves with V51 high-cycle stem packing option

installed, identified by two Belleville washers installed and

handle assembly, stop and stop screws removed, and

818/828 Series Valves do not require stem area disassembly.

For

1

/

2"– 2" 94 valves, remove handle (if any). Do not remove

gland plate or gland bolts.

For 3" and larger 94 and 2" and larger E818/828 valves,

remove handle assembly, stop, and spacer (if any). Do not

remove gland plate or gland bolts.

For 2" and larger 818/828 valves, remove handle assembly,

locking plates and hardware, and stop screw (if any). Do NOT

remove stop plate (2"– 6" sizes) or spacer (8" size).

3. Center coupling on valve stem.

4. Lower mounting bracket/actuator assembly over coupling and

onto valve, making sure that male actuator shaft engages slot

in coupling.

5. Secure bracket to valve using cap screws and lockwashers, or

bolts and nuts provided in mounting kit. Tighten securely. For

1

/

2"– 2" top mount style valves, bracket nameplate will be to

side of valve.

Install set screws (if any) in the coupling and tighten securely.

6. Determine if mode of operation is as desired; if not:

a. Double-Acting Actuators

- Mount the actuator 90° from

normal mounting (see last paragraph in D.6.b for size 25

and larger actuators). On 10–20 sizes, the actuator may

also be inverted, yielding the opposite mode.

b. Spring-Return Actuators

- The normal method of

mounting is to have the actuator in line with the pipe line

and the valve and actuator in the FAIL-CLOSED position.

For FAIL-CLOSED cross-line operation with 10–20 sizes,

invert actuator and cross-line mount actuator to pipe line.

For FAIL-OPEN in-line operation with 10–20 sizes, invert

actuator. (NOTE: If in-line coupling is used, actuator does

not need to be inverted). Rotate the valve ball and stem

90°, so coupling lines up with actuator shaft. Mount

actuator in line with the pipe line. See Electrical

Connection Section for proper wiring information.

For FAIL-OPEN cross-line operation with 10–20 sizes,

rotate the valve ball and stem 90°, so coupling lines up

with actuator shaft. Mount actuator cross line to pipe line.

See Electrical Connection Section for proper wiring

information.

On sizes 25 and larger double-acting and spring-return

actuators the output shaft is square. This allows selection

of either mode of operation by indexing the coupling

(including valve ball and stem) 90° to the actuator shaft,

while keeping the actuator in an in-line orientation. Crossline mounting, if desired, requires a special bracket,

except for the 818/828 Series valves.

7. Determine position indication. Buttons on position indicator

are set up to show valve closed on in-line mounting, i.e.,

pistons together in actuator. If different indication is required:

a) Check which visual indication is required.

b) Check that indicator, when located on actuator shaft, will

show correct indication.

c) To change indication, push out (remove) red and white

buttons and reassemble in opposite positions (this step is

only necessary on 10–20 sizes).

d) Locate indicator on actuator shaft flats. Press firmly until

location nibs snap into recess on actuator shaft.

Flow Control

Worcester Controls

Page 3

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 3

AIR SUPPLY AND

ELECTRICAL INSTALLATION

A. 1. Air Supply:

The Series 39 Actuator is factory lubricated. For optimum

operation, the use of filtered and lubricated air is

recommended.

2. Air Supply Pressure:

Intrinsically Safe versions of double-acting actuators require

40–100 psig supply air. Spring-return actuators require

80–100 psig supply air. Spring-return actuators can also be

set up to operate on supply air pressures ranging from 40–80

psig by using fewer springs. See “Rebuilding Instructions”,

Spring-Return Actuator, for proper number and location of

springs for reduced supply air pressures.

3. Air Supply Connection:

Connect air supply to

1

/

4" NPT connection on control block. For

units with no integral solenoid valve, air connection block has

two

1

/

4" NPT connections for inlet air (only one used for

spring-return units).

4. Recommended Tubing Sizes:

In order to provide sufficient flow of supply air to the Series

39 actuator, the following tubing sizes are recommended:

Actuator Size Runs Up To 4 ft. Long Runs Over 4 ft. Long

10, 15, 20, 25

1

/

8"

1

/

4"

30 and larger

1

/

4"

3

/

8"

5. Air Consumption:

The following chart shows the amount of pressurized (80

psig) air consumed per stroke in cubic feet. To determine the

total amount of air consumed per complete cycle for doubleacting actuators, simply add the volumes for both the opening

and closing strokes together; for spring-return units, the total

volume of air consumed is the volume shown for the opening

stroke.

Actuator Size

Stroke 1039 1539 2039 2539 3039 3339 3539 4039

Open .04 .08 .16 .28 .43 .65 .90 1.26

Close .05 .09 .17 .30 .47 1.10 1.27 1.43

6. Electrical Supply:

Make electrical connections in accordance with the wiring

diagram on the inside of cover or appropriate wiring diagram

in Section B.4.

7. Switch Ratings: 1 amp, 125 VAC

B. ELECTRICAL CONNECTION:

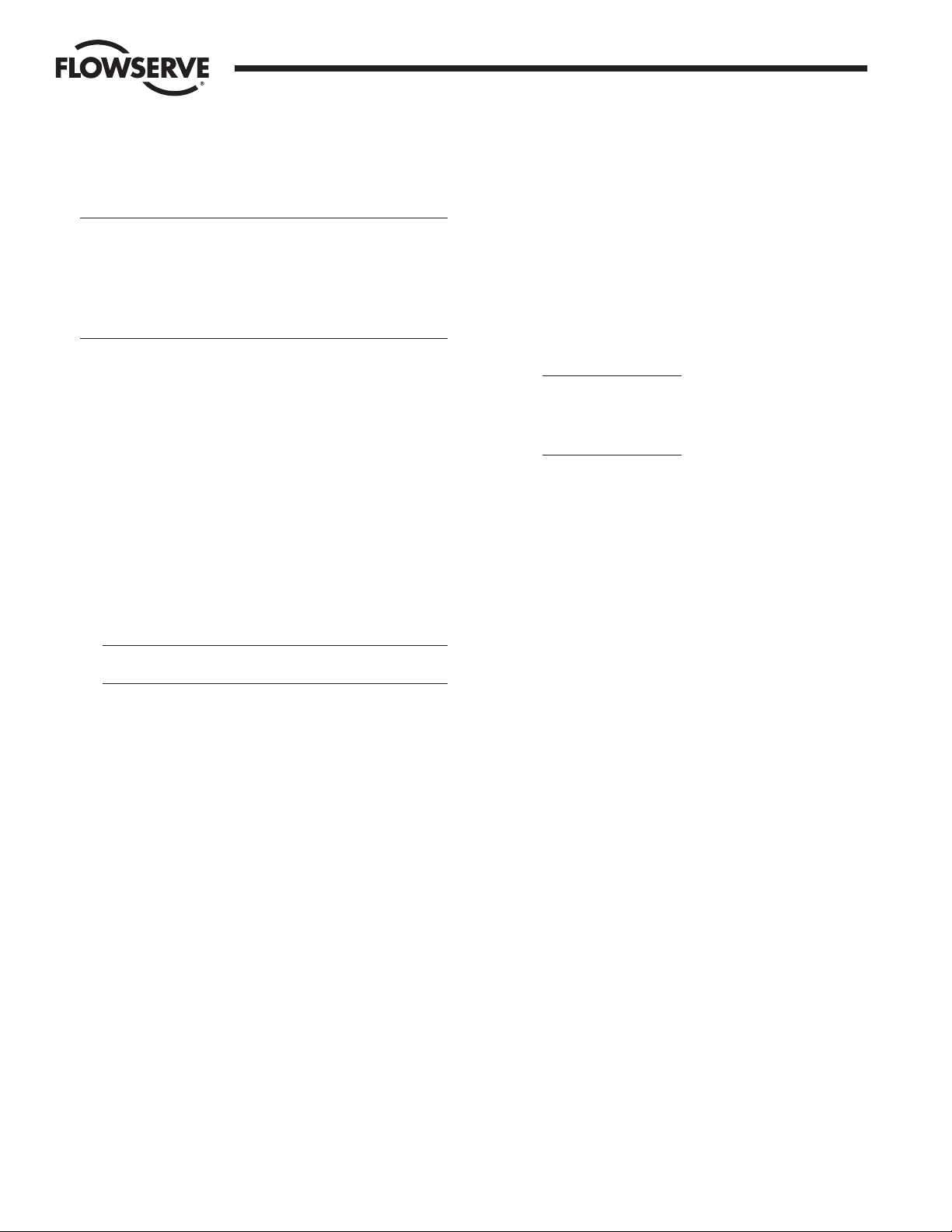

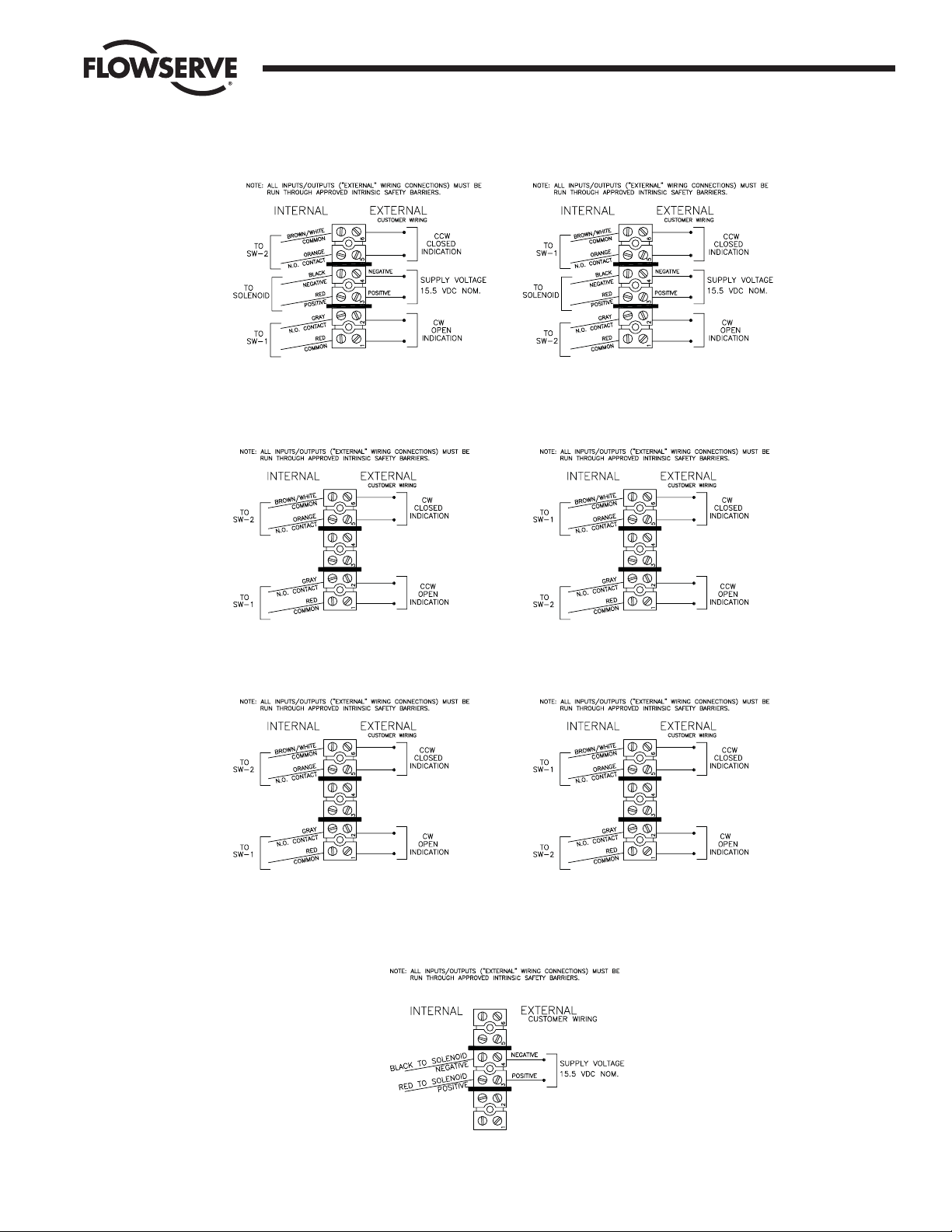

The intrinsically safe versions of the ACCESS I and ACCESS M will

be intrinsically safe when connected through CSA Certified zener

barriers rated 28 volts DC maximum, 300 ohms minimum (for

SW-1 and SW-2 only; refer to paragraph 4 of this section for

intrinsically safe wiring of solenoid), as shown in the wiring

diagrams (Figure 2) below.

IMPORTANT: Shielded cable must be used for each intrinsically

safe circuit (Switch circuits and solenoid circuit) and for zener

barriers, the shield must be connected to a zener barrier ground.

1. The “standard” mounting configuration of the 39 actuator to

the valve is in-line, fail-closed. In this configuration, SW-2, as

described in the wiring diagram and part 3, will give

indication when the actuator is in the closed position, or CW

limit of rotation. SW-1 gives indication of the open position,

or CCW limit of rotation (refer to the appropriate wiring

diagram in figure 2).

NOTE: The CW or CCW rotation of the actuator shaft is

determined when viewing the actuator from the nameplate

side of the actuator while being able to read the nameplate

from left to right.

2. Fail open configuration for sizes 10–20 may be obtained by

either inverting the actuator, using in-line coupling, or

mounting the actuator cross-line. For sizes 25 and larger the

coupling (including valve ball and stem) must be indexed 90°

to the actuator shaft. Refer to Installation Section D.6.b. In

these cases, SW-1 and SW-2 indication will be reversed from

the above but actuator rotation will vary, depending on which

fail-open mounting is used, and wiring shall be done per the

appropriate wiring diagram in figure 3.

Flow Control

Worcester Controls

Figure 1

Figure 2

Page 4

4 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

3. Switches have been factory adjusted, but should be rechecked

after installation. Adjustment is as follows:

a) Switch adjustment for “standard” mounting:

With actuator mounted in “standard” mounting

configuration (see Step 1) set actuator in full-closed

position with the adjustment screw near its loose limit.

Adjust closed position switch SW-2 (see Wiring Diagram)

by tightening the adjustment screw until switch contacts

click. Then tighten adjustment screw one additional turn.

With air supply to actuator, energize solenoid, if applicable,

cycle to the full-open position and adjust open position

switch SW-1 in the same manner.

b) Switch adjustment for FAIL-OPEN mounting:

With actuator mounted in FAIL-OPEN mounting

configuration (see Step 2) set actuator in full-open position

with the adjustment screw near its loose limit. Adjust open

position switch SW-2 (see Wiring Diagram) by tightening

the adjustment screw until contacts click. Then tighten

adjustment screw one additional turn. With air supply to

actuator, energize solenoid, if applicable, cycle to the fullclosed position and adjust closed position switch SW-1 in

the same manner as SW-2.

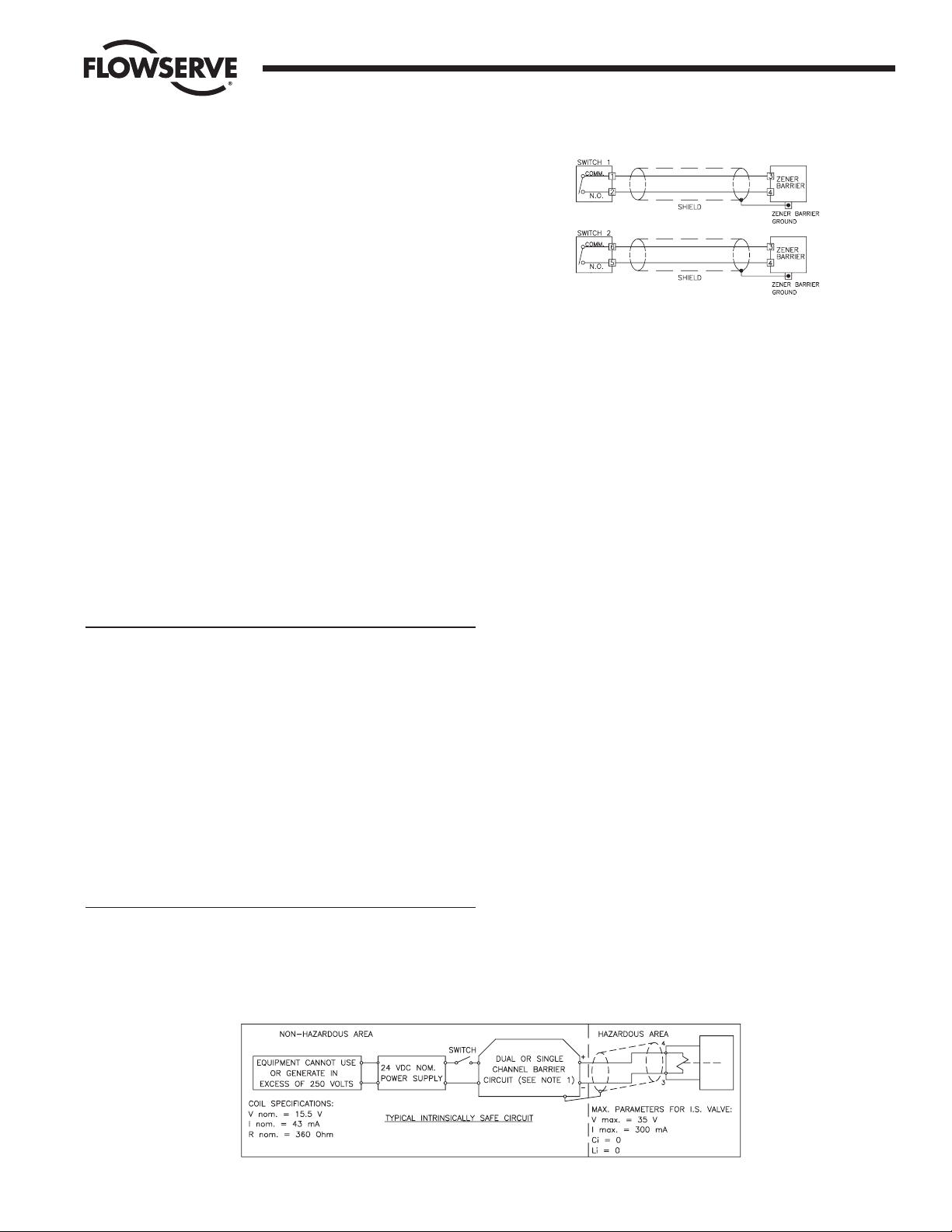

4. Wiring instructions for solenoid and/or limit switches:

The Intrinsically Safe solenoid valve used in the ACCESS is

designed to operate on power levels compatible with Intrinsic

Safety requirements. They are Factory Mutual (FM) approved

for Class I, II and III Groups A, B, C, D, E, F, and G

applications. Entity Approval #OT4A6.AX (NFPA 493; July 19,

1990).

NOTE 1: For barrier interconnection, refer to maximum barrier

output parameters as referenced on the specific barrier

Installation drawing. Connect as follows:

a) V max > Voc of single or Vt of dual channel barrier.

b) I max > Isc of single or It of dual channel barrier

c) Ci + field wiring < Ca of single or dual channel barrier

d) Li + field wiring < La of single or dual channel barrier

For current and wattage values at various input voltages see

table below.

Input Voltage Current Wattage

15.5 VDC 43 mA .7

24 VDC 68 mA 1.63

35 VDC 95 mA 3.3

Make electrical connections in accordance with the

appropriate wiring diagram on inside of cover or the

appropriate diagram in figure 3:

NOTE 2: Installation of Intrinsically Safe Systems is to be done

in accordance with Canadian Electrical Code, Part 1 and

National Electrical Code, Chapter 1.

DEFINITIONS:

Ca-Maximum Allowed Capacitance Li-Maximum Internal Inductance

Ci-Maximum Internal Capacitance Voc-Maximum Output Voltage

I max-Maximum Input Current V max-Maximum Input Voltage

Isc-Maximum Output Current Vt-Voltage Total

La-Maximum Allowed Inductance

Flow Control

Worcester Controls

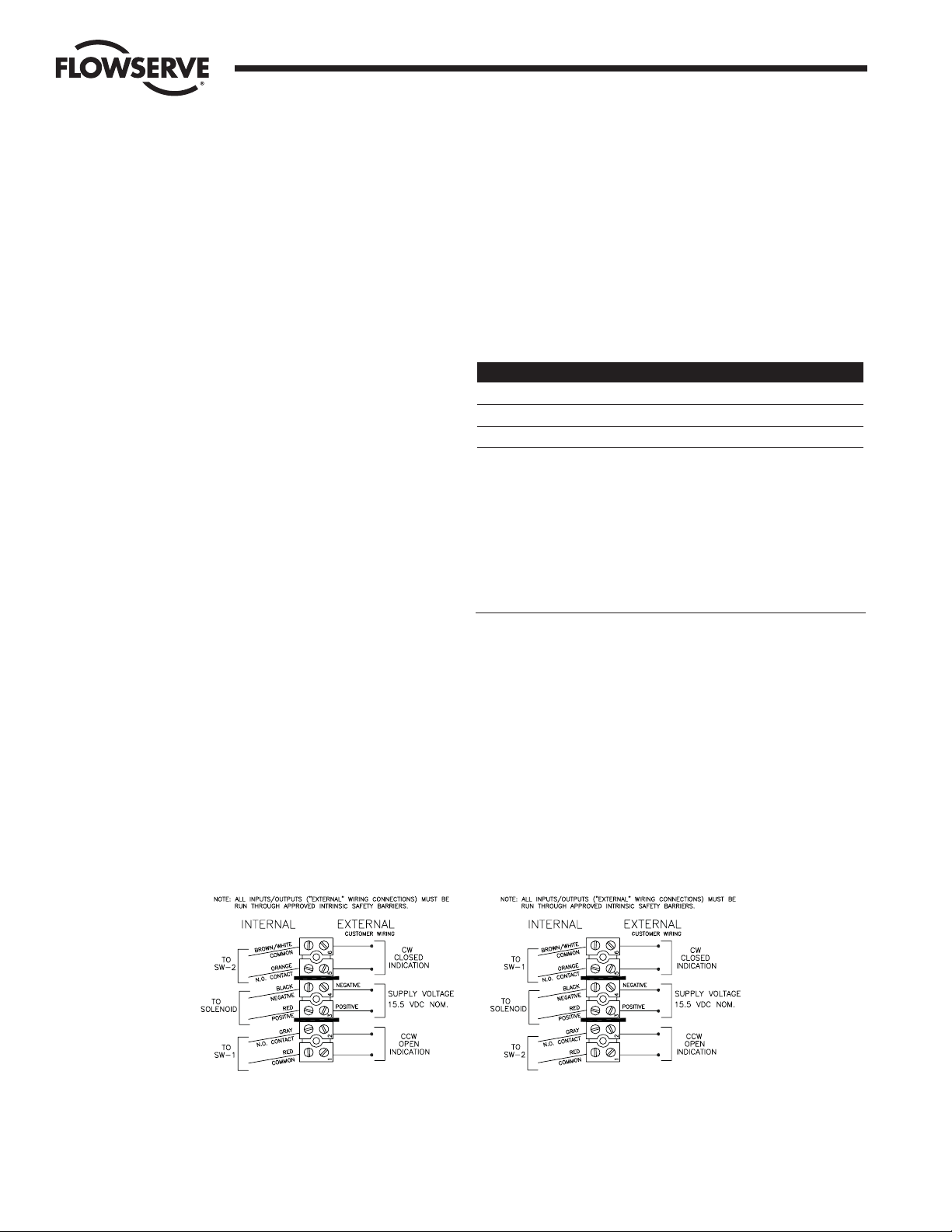

Figure 3

FAIL-CLOSED

(Sizes 10–40 in-line operation)

(Sizes 10–20 in-line, inverted operation)

FAIL-OPEN

(Sizes 25–40 cross-line operation)

Page 5

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 5

Flow Control

Worcester Controls

Figure 3 continued

FAIL-CLOSED

(Sizes 10–20 cross-line, inverted operation)

FAIL-CLOSED

(Sizes 10–40 in-line operation)

(Sizes 25–40 cross-line operation)

No solenoid

FAIL-OPEN

(Sizes 10–20 cross-line operation,

or with in-line coupling)

(Sizes 25–40 in-line operation)

FAIL-OPEN

(Sizes 10–20 in-line, inverted operation)

No solenoid

FAIL-CLOSED

(Sizes 10–20 cross-line,

inverted operation)

No solenoid

(Sizes 10–20 cross-line operation,

(Sizes 25–40 in-line operation)

SOLENOID/NO SWITCHES

FAIL-OPEN

or with in-line coupling)

No solenoid

Page 6

Figure 4

6 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

NOTE 3: The wiring diagrams shown in figure 3 are for specific

actuator positions/operations. For switch indications of other

positions/operations the actuator should be operated, and SW-1 and

SW-2 checked to verify which switch will give the desired indication.

5. Place the lubricated O-ring down over the threaded section of

the housing onto the machined shoulder. The cover must be

threaded onto housing tightly for proper performance. The

assembly is now complete.

NOTE: For units with a metal cover, a light coat of grease (such

as a #1 grease) shall be applied to the cover threads. A minimum

of

1

/

3 the circumference of the threads to be lubricated.

OPERATION

A. Double-Acting with Control Block - Air is supplied to the 1/

4" NPT

port on the block. When the solenoid is energized, the springloaded plunger is withdrawn, allowing the supply air to shift the

spring-loaded spool within the block, which opens the supply

path to the center chamber of the actuator. Air from the end

chambers of the actuator is allowed to pass through the block

and exhaust to atmosphere.

When the solenoid is de-energized, the spring-loaded plunger

blocks the flow of air to the spool seal within the block and the

spool spring shifts the spool within the block to a position which

opens the supply path to the end chambers of the actuator. Air

from the center chamber of the actuator is allowed to pass

through the block and exhaust to the atmosphere.

The actuator is electrically fail-safe. That is, it will reurn to its deenergized position upon electrical failure.

Flow Control

Worcester Controls

Figure 5

Spring-return

Double-acting

Double-acting

Page 7

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 7

The unit has two independently adjustable speed control screws

which can be used to adjust the speed of operation for the

opening and/or closing stroke (see figure 4). If the speed control

screws are too tight, the unit will fail to operate.

NOTE: Speed control screws are shipped from the factory in the

full-open position.

B. Spring-Return with Control Block - Air is supplied to the 1/

4" NPT

port on the block. When the solenoid is energized, the springloaded plunger is withdrawn, allowing the supply air to shift the

spring-loaded spool within the block, which opens the supply

path to the center chamber of the actuator. Air from the end

chambers of the actuator is allowed to pass through the block

and exhaust to atmosphere.

When the solenoid is de-energized, the spring-loaded plunger

blocks the flow of air to the spool within the block and the springloaded spool returns to a position which allows air from the

center chamber of the actuator to pass through the block and

exhaust to atmosphere as the actuator is cycled by the springs in

the end chambers of the actuator. The end chambers are

exhausted to atmosphere at all times.

The actuator is fail-safe. That is, it will return to its de-energized

position upon electrical or pneumatic failure.

The unit has one speed control screw, which can be used to

adjust the speed of operation for the closing stroke (on a FAILCLOSED unit) or opening stroke on a fail open unit, and one port

plugged with a red plastic plug (see figure 4). If the speed control

screw is too tight, the unit will fail to operate.

Note: Speed control screws are shipped from factory in the full-

open position.

CAUTIONS: If converting a double-acting actuator to a springreturn actuator or vice-versa, be sure the correct control block

gasket is used and properly installed (see figure 5 and actuator

exploded view). Do not apply any grease to gasket, it must be

installed dry.

Be sure red plastic plug is installed in plugged port (see figure

4) for spring-return actuators.

C. Double-Acting with No Solenoid and No Control Block - Air is

supplied to the

1

/

4" NPT port on the air connection block to the

center chamber of the actuator through a remotely mounted fourway solenoid (or similar supply system). The other

1

/

4" NPT port

on the air connection block to the end chambers is exhausted

through solenoid (or similar supply system). When solenoid is

de-energized (energized) supply air is now supplied to end

chambers and center chamber is simultaneously exhausted

through solenoid.

D. Spring-Return with No Solenoid and No Control Block - Air is

supplied to the

1

/

4" NPT port on the air connection block to the

center chamber of the actuator through a remotely mounted

solenoid (or similar supply system). The other

1

/

4" NPT port on

the air connection block is the exhaust port for the end

chambers and may be exhausted to atmosphere or through

customer’s system.

When the remotely-mounted solenoid (or similar supply system)

blocks the supply air to the center chamber of the actuator, a

means must be supplied to exhaust this chamber and the actuator

is cycled by the springs in the end chambers.

E. Stroke Times

For stroke times of the ACCESS I and ACCESS M Series 39

actuators with solenoid and control block, consult factory. Times

will be measured in seconds and will represent average times

under 50% load conditions with an air supply pressure of 80

psig. Times will be per stroke for double-acting actuators. For

spring-return actuators, the opening stroke times may be slightly

longer; stroke times for the closing (spring) stroke will be

dependent upon the number of springs used.

Cycle times for customer air supply systems will be dependent

upon customer equipment.

F. Manual Operation

In the event of air failure, the ACCESS I and ACCESS M Series 39

actuators can be cycled manually. This is accomplished by

applying a wrench to the exposed top shaft of the actuator and

turning it in the desired direction.

a WARNING: Care must be taken to ensure that the actuator is

not operated automatically while manual operation is being

performed.

If a routine cycle check is to be performed on an actuator with a

control block, the actuator can be cycled manually by shifting

the spool valve within the control block. This can be done by

pushing the override button in the control block (see figure 4 on

page 6 for location of button). Care must be taken to hold the

spool valve in the desired position until the actuator has

cycled. Provided the air supply is still on, the actuator will

cycle to its original position as soon as the manually applied

pressure on the override button is released.

MAINTENANCE

CAUTION: The actuator must be isolated both pneumatically and

electrically before any maintenance activity is begun.

Periodic checks should be performed to make certain that all

fasteners remain tight. Care should be taken when tightening the end

cap retaining bolts since these fasteners are METRIC. All other

fasteners are UNIFIED IMPERIAL.

All actuators are supplied with sufficient lubrication for their normal

working life. If required, recommended lubrication for all standard

actuators is a #1 grease.

Depending upon the conditions under which the actuator must work,

such as extended-duty, non-compatible operating media or abnormal

operating conditions, periodic replacement of internal seals is

recommended. Repair kits containing all necessary seals can be

obtained through any authorized Flowserve Worcester/McCANNA

Controls distributor.

Flow Control

Worcester Controls

Page 8

8 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

On spring-return actuators, the springs may need replacement after

extended duty since springs may fatigue and break. SPRINGS

SHOULD ALWAYS BE REPLACED IN COMPLETE SETS. Spring kits are

available through any authorized Worcester/McCANNA distributor.

SPARE PARTS

The following are recommended spare parts which should be kept on

hand for Series 39 pneumatic actuators:

Repair Kit(s) - Kits contain all necessary seals,

bearings and instructions.

Spring Kit(s) - For spring-return actuators.

TROUBLESHOOTING

BEFORE DISASSEMBLING ACTUATOR FOR ANY REASON, CONSULT

REBUILDING INSTRUCTIONS CONTAINED IN FOLLOWING SECTION.

A. If actuator does not function, check to ascertain:

1. That valve is free to rotate. This can be done as described

above in Manual Operation.

2. That actuator is the correct size.

3. That speed control screws or exhaust ports are not blocked.

4. That correct voltage is supplied to solenoid.

5. That sufficient air supply is available at inlet to control block.

Inlet pressure to control block should be at least 40 psig for

double-acting, 80 psig for spring-return (unless a reduced

spring complement is installed (fewer springs)). When

checking supply pressure, place gage in line at control block

inlet and monitor gage for unexpected pressure drops.

B. If proper voltage and air pressure have been verified and valve is

free, proceed as follows:

1. Turn on signal voltage. Check solenoid for clicking sound.

2. If no sound is detected, remove air pressure and turn off

signal voltage.

a) Carefully unscrew solenoid and solenoid stem from end

cap.

b) Reapply signal voltage and observe solenoid plunger. If it

does not retract, replace solenoid.

3. Manually override control block. If correct operation is not

obtained, replace the control block.

4. If control block and solenoid are operating correctly, proceed

to Section C below.

C. If the actuator functions but exhibits leakage, or power loss

accompanied by leakage, proceed as follows:

1. Check voltage. Voltage must be within 10% of the specified

voltage (low voltage will cause leakage out of the back of the

solenoid and burn out of the coil).

2. Check air supply. Be certain that no sharp air pressure drops

occur as unit is cycled. Loss of air pressure can cause

incomplete shifting of the spool valves, which results in

bypass leakage and substantial actuator torque losses.

3. If air supply and voltage are adequate, proceed as follows:

a) If leak is at solenoid exhaust port, replace the solenoid.

b) If leak occurs at exhaust ports in the block itself, the

trouble will be in either the spool valve in the block, or at

one of the piston seals of the actuator. A leaking piston

seal will usually leak on either cycle.

If the block is replaced and leakage continues from

the exhaust port, remove the actuator from the valve,

disassemble (per Rebuilding Instructions below) and

check the following:

1) Make sure that all internal porting is free and clear of

any obstructions. End caps, guide rods and the piston

with hole are air-transporting components.

NOTE: The most common problem encountered on 39

actuators is the improper replacement of the piston

with hole, relative to seals in end caps. (See Step 5)

2) Make certain that the actuator has lubrication, and

that there is no solidified grease between the pinion

and the piston racks.

a) If actuator has no lubrication, apply generous

amount of a #1 grease.

b) If solidified grease between the pinion and the

piston racks is present, clean, dry, regrease and

reassemble.

3) Verify that actuator pinion shaft and/or pistons are

not bound. If bound, reassemble per Rebuilding

Instructions.

4) If unit exhibits excessive amounts of backlash, check

teeth on piston racks for wear. If worn, replace piston

assemblies.

5) In spring-return actuators, check for misplaced or

broken springs. If springs are broken, check body

bore for scoring.

a) If springs are broken, replace springs. SPRINGS

SHOULD ALWAYS BE REPLACED IN COMPLETE

SETS.

b) If body bore is scored, replace it. Also, replace

piston O-rings (contained in repair kit).

6) If actuator is free, valve is free and control block (if

used) is shifting air properly, reassemble the actuator

and retest. If unit still fails to operate, consult

Flowserve.

REBUILDING INSTRUCTIONS

NOTE: For identification of all numbered parts discussed below,

consult exploded view of actuator.

After actuator has been repaired, mark rebuild label accordingly and

apply to actuator.

Flow Control

Worcester Controls

Page 9

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 9

ACTUATOR DISASSEMBLY

1. Disconnect the air supply and electrical service to the actuator.

2. Remove the actuator and its mounting bracket from the valve.

(See Caution note.)

CAUTION: Ball valves can trap pressurized media in the cavity.

Isolate the piping system in which the actuator/valve assembly

is mounted and relieve any pressure on the valve. For all the

valves listed in Installation Section D, the actuator bracket can

be removed without loosening or removing any valve body

bolts.

3. Remove the actuator bracket from the actuator to begin repair.

(Note orientation of removed bracket for easy reassembly.)

4. It is not necessary to remove the control block (7A) or air

connection block (7B) to rebuild actuator. However, if it becomes

necessary to remove the block, begin by removing the block bolts

(7D). Use care to retain the block gasket (9A, 9B or 9C).

5. Each end cap (5A & 5B) is aligned onto the body (1) over a

“foolproof pin”. This ensures that the end caps can only be

assembled to their respective end of the actuator. Remove all four

metric screws (5C) from and remove both end caps. Remove the

two bearings (6A) and O-rings (15A and 15B) from each end cap.

CAUTION: If the actuator is a spring-return model, first

remove two end cap screws diagonally opposite each other,

then lubricate the threads and under the head. Replace the

screws and repeat procedure for the other two screws. Do this

for each end cap, as this will aid reassembly. Now uniformly

loosen all four end cap screws on each end cap two to three

turns at a time, in sequence, to relieve preload of the springs.

On larger actuators with springs use caution when removing

end caps. End cap screws are long enough to allow springs to

relieve before disengaging.

After the screws are removed, gently pry off each end cap, being

careful not to damage the end cap O-rings.

6. The two piston guide rod (4) assemblies can now be removed

from each end of the body and disassembled by removing the

piston set screws (12). Do not interchange piston guide rods (4)

and their respective piston (3). For sizes 10–20 Rev. R6 actuators,

each guide rod and piston may be press fitted together (do not

use set screws) and cannot be disassembled. (To assist

reassembly, mark the body with a line on the side from which the

guide rod using the through-hole is removed). Remove all O-rings

(15B and 15C) and bearings (6B) from pistons (3).

7. The shaft (2A) on sizes 10–20 can only be removed after piston

assemblies are taken out. Remove the position indicator (17) (if

any), the shaft clip (15F) (not a reusable part!) (see Note) and the

stainless steel washer from the top of shaft. Then remove the

shaft through the larger opening in the bottom of the body. The

top bearing (15G) and the O-ring (15D) can now be removed.

Remove the two stainless steel washers (10–35 sizes only) and

thrust bearing (10) from the top of the shaft, the O-ring (15E),

and bearing (15H) from the bottom end.

NOTE: For size 40 model, only a single stainless steel washer is

used and thrust-bearing (10) is not used.

Sizes 25-40 have an anti-ejection ring (15J). This ring does not

have to be removed and it may or may not be included in repair

kits.

NOTE: Some actuators may be using a spiral ring type shaft clip

as shown below.

To remove this clip, engage the lower end of the ring with a flat blade

screwdriver. Using another flat blade screwdriver push the top end of

the clip in the opposite direction. As the clip I.D. expands lift the clip

from the shaft. The installation of a new clip would be the above steps

in reverse and ensuring that the edges of the clip are properly seated

in the shaft groove.

Flow Control

Worcester Controls

Figure 6

Figure 7

IMPORTANT: Note the relative location of the shaft teeth and the

piston assembly’s rack teeth. The above figure is viewed when

looking at the top of the actuator.

IMPORTANT: Align gear teeth on the shaft per Figure 6.

Page 10

10 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

ACTUATOR REASSEMBLY

1. Be sure the actuator surfaces are clean and free of grit and

scratches. If the inside walls of the body are scored, or the guide

rod surfaces are scratched, the actuator will leak after rebuilding.

New parts should be obtained from the factory. Light tracking,

barely detectable to touch, is acceptable.

2. All rebuilding kit O-rings and bearings may now be installed.

Lubricate the standard actuator thoroughly with a #1 grease.

Apply a light film of grease to all O-rings. NOTE: “High-

temperature” actuators and O-rings must be lubricated with Dow

Corning #7 or other equivalent high temperature silicone or

graphite base grease. (Note that kits also contain some parts for

earlier revisions of actuators which will not be needed.)

3. Replace the two split-ring style bearings (6A) and one guide rod

O-ring (15B) in each end cap.

Replace the split-ring style bearing (6B) and guide rod O-ring(s)

(15B) into I.D. groove(s) in each piston (3). Install O-rings (15C)

onto pistons.

4. Replace O-ring (15E) and bearing (15H) (10–40 sizes only) on

the bottom of shaft. On the top of the shaft add the two

stainless steel washers (10–35 sizes only) with the thrust

bearing (10) between them.

NOTE: For size 40 model only, a single stainless steel washer is

used and thrust bearing (10) is not used. Locate the top bearing

(15G) and O-ring (15D) into the body. For sizes 10–35 Rev. R6

actuators, top bearing (15G) is flat, the same as and

interchan

geable with thrust bearing (10). Replace the shaft

through the larger opening in the bottom of the body.

For sizes 25 through 40 actuators, replace anti-ejection ring (15J)

in its groove on the shaft (2B), if removed.

5. Very carefully align the piston guide rod assemblies inside the

body. Keep the pistons square to the body. (This is very important

in the 30 39 actuator where steel set screws can cause internal

body damage if the piston assemblies “cock” inside the actuator

body.)

IMPORTANT: One piston guide rod assembly has a through-hole

drilled in it. It can be easily located by looking down the ends of

both guide rods. This piston assembly must be reassembled,

with its respective guide rod, opposite the nameplate on the

body, as it was removed.

6. Align the shaft so that the teeth on the shaft will “pick-up” the

piston assembly’s rack teeth when turning the top extension of

the shaft clockwise (CW). (See Figure 6.)

IMPORTANT: Proper 90° rotation can only be ensured if the shaft

teeth begin to mesh with the piston assembly’s teeth at the

“proper tooth” between these meshing gear pairs. (See Figure 6.)

7. To ensure proper meshing of teeth, move the shaft 15 to 20

degrees counter-clockwise (CCW) from its normal position when

the piston assemblies are located at the body ends (See Figure 7).

NOTE: The “normal position” of the shaft on 10-20 sizes is whe

n

the top flats are parallel to the main axis of the actuator body. On

the 25-40 sizes the teeth of the shaft will be on the left side of the

actuator when viewed from the ends of the actuator. (See Figure

6.)

8. With the piston assemblies in the body, gently push each piston

into the body. Turn the top shaft extension clockwise (CW). Do

not allow the pistons to “cock”.

At the proper point of engagement between the shaft and piston

assemblies, both piston assemblies will move toward the center

of the body when turning the top shaft extension of the actuator

clockwise (CW).

9. Once the shaft and pistons are properly engaged, ensure that

smooth movement and full closed operation can occur without

moving the pistons out of the actuator body. This is important!

10. Install O-ring (15A) into and replace the actuator end caps, (5A

and 5B), noting that the “foolproof” pin between the body and end

cap mates properly. For spring-return actuators, see spring

installation section before installing end caps.

NOTE: When installing the end cap O-rings, use a small amount of

a general purpose lubricant, such as petroleum jelly, to hold them

in place for ease of assembly and to avoid having them fall and

get pinched.

11. Replace the stainless steel washer over the top shaft extension.

12. VERY IMPORTANT: Install the NEW shaft clip (15F) into its mating

groove on the top shaft extension. (The removed shaft clip is not

to be reu

sed.)

Place the numbered side up on the shaft clip and be certain the

clip is fully seated in its groove. See Note in Step 7 of Actuator

Disassembly for installation of spiral ring type shaft clip (which

newer rebuilding kits will contain).

If control block (7A) or air connection block (7B) was removed:

Properly insert appropriate gasket (9A, 9B or 9C) between control

block or air connection block and end cap (see figure 4 and

actuator exploded view), and attach block securely to end cap. Do

not apply any grease to gasket, it must be installed dry.

13. Replace position indicator (17) (if any). See Section D.7 in

Installation Section for proper installation and to determine

position indication.

14. Mark Rebuild/Accessory Addition Label, if included in repair kit,

and apply to actuator.

Flow Control

Worcester Controls

Page 11

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 11

SPRING-RETURN ACTUATOR

1. IMPORTANT: When less than the standard number of springs are

used in each end cap, these springs should be positioned

according to the air supply figures below.

Size 10–40

70 psi - 8 springs - 4 per end cap Remove center spring

60 psi - 8 springs - 4 per end cap Remove center spring

50 psi - 6 springs - 3 per end cap Use 3 on a diagonal

40 psi - 4 springs - 2 per end cap Use 2 in opposite corners

The values listed below are for standard and less than the

standard air pressure as required per the ordering code.

NOTE: Maximum Operating Pressure Does Not Change.

Ordering Code 4 5 6 7 ( )

Supply Pressure (psi) 40 50 60 70 80

Actuator Size End of Spring Torque (in-lb)

10 35 55 75 75 95

15 65 105 145 145 185

20 125 195 265 265 335

25 210 330 450 450 575

30 340 535 730 730 920

33 680 1,070 1,460 1,460 1,850

35 850 1,330 1,815 1,815 2,300

40 1,500 2,240 2,980 2,980 3,740

2. If a spring-return actuator is being repaired due to a failed spring,

REPLACE all the springs in this actuator, as well as any other

parts which may have been damaged.

3. When replacing the springs in a spring-return actuator, place the

springs in the end cap pocket after thoroughly lubricating each

spring. Be generous with lubricant!

4. With the springs pointing up and the end cap on a solid surface,

place the actuator body over the springs and the proper end cap.

(Each end cap can only be mounted to just one end of the

actuator body, as there is a “foolproof” pin in the end cap which

aligns with a hole in the body.)

5. Force the body down and begin by engaging two end cap screws

(5C) by hand through the end cap. Take each end cap screw up in

SMALL and EQUAL turns. Once the end cap is temporarily

secured to the body, turn the actuator over to its normal position

and uniformly take up the four end cap screws. Uniformly load all

the springs to prevent any spring from buckling.

IMPORTANT: Locating nibs are permanently cast into the sizes 25

through 40 actuator piston face. The actuator springs must fit

over these locating nibs on the piston face. Care in following the

above instructions will ensure the proper alignment of the spring

in the actuator body — proper contact with the piston face and

end cap.

6. In a similar manner, as in the previous steps, replace the springs

in the other end of the actuator body.

Flow Control

Worcester Controls

Page 12

12 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

Flow Control

Worcester Controls

ACCESS M EXPLODED VIEW

Page 13

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 13

Flow Control

Worcester Controls

ACCESS I AND 39 ACTUATOR EXPLODED VIEW

Page 14

14 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe WCAIM2028

Flow Control

Worcester Controls

PARTS LISTING

ITEM QTY. DESCRIPTION ITEM QTY. DESCRIPTION

1 1 Actuator Body 12 2 Piston Set Screws (if any)

2A 1 Shaft (10-2039) 13 1 Conduit Plug – Not Shown on ACCESS I

2B 1 Shaft (25-4039) 14 Varies Springs – See Table on page 11

3 2 Pistons 15A 2 End Cap O-Rings

4 2 Guide Rods 15B 6 Guide Rod O-Rings

5A 1 ACCESS I End Cap or ACCESS M Enclosure 15C 2 Piston O-Rings

5B 1 End Cap 15D 1 Top Shaft O-Ring

5C 8 End Cap Screws (Metric) 15E 1 Bottom Shaft O-Ring

5D 1 Cover “Z” 15F 1 Shaft Clip

5E 1 Caution Nameplate “Z” 15G 1 Top Pinion Bearing

5F 1 Cover “W” 15H 1 Bottom Pinion Bearing

5G 1 O-Ring – Cover 15J 1 Anti-Ejection Ring (Sizes 25–40)

5H 1 ACCESS M Endcap 16 1 Wiring Diagram – Not Shown

5J 1 Caution/Wiring Label “W” 17 1 Position Indicator

6A 4 Cap Bearing (Split-Ring Style) 18 2 Drive Screw

6B 2 Piston Bearing (Split-Ring Style) 19 2 Probes

7A 1 Control Block Assembly 20 2 O-Rings – Probe

7B 1 Air Connection Block (No Solenoid) 21 4 Washers – Probe (ACCESS I only)

7C - Not Used 22 2 Retaining Clips – Probe (4 for ACCESS M)

7D 4 Block Bolts 23 2 Spring – Probe (ACCESS I only)

8A 1 Solenoid Assembly 24 1 Terminal Strip

8B 2 Solenoid Exhaust Port Fittings 25 2 Mounting Screws – Terminal Strip

8C 1 Solenoid Exhaust Tubing 26A 1 Limit Switch Assembly – left

8D 1 Solenoid Adapter 26B 1 Limit Switch Assembly – right

8E 2 O-Rings 27 4 Mounting Screws – Limit Switch

9A 1 Gasket – Control Block (Double-Acting) 28 2 Switch Adjustment Screw

9B 1 Gasket – Control Block (Spring-Return) 29 2 Switch Adjustment Spring

9C 1 Gasket – Air Conn. Block (No Solenoid) 30 2 Terminal Strip Dividers

10 1 Thrust-bearing 31 1 Exhaust Port Plug (If No Solenoid)

11 1 Nameplate

To order proper parts, please specify the actuator size, model, and revision number. Use the standard nomenclature listed above.

The rebuilding kits include Items 15A through 15H, 6A and 6B, 10, and S.S. washers. Color of some replacement parts, such as bearings, may

vary from the parts removed.

ADDITIONAL PARTS LISTING (For ACCESS M only)

ITEM QTY. DESCRIPTION ITEM QTY. DESCRIPTION

32 2 Drive Screws 38 2 Flat Washer – Switch

33 1 Bracket-Switch 39 2 Upper Mounting Screw – Enclosure (11/

8" Long)

34 3 Mounting Screws – Switch Bracket 39A 2 Lower Mounting Screw – Enclosure (1" Long)

35 2 Retaining Ring – Switch 40 1 Gasket

36 2 Button – Switch 41 1 Nameplate

37 2 Spring – Switch 42 4 Threaded Tamper Proof Plug

Page 15

WCAIM2028 10, 15, 20 ACCESS I and 10-40 Access M 39 Actuators Intrinsically Safe 15

Flow Control

Worcester Controls

This page intentionally left blank.

Page 16

Flow Control

Worcester Controls

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore

assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation

Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

For more information about Flowserve Corporation, visit www.flowserve.com or call USA 1-800-225-6989.

FLOWSERVE CORPORATION

FLOW CONTROL

1978 Foreman Drive

Cookeville, Tennessee 38501 USA

Phone: 931 432 4021

Facsimile: 931 432 3105

www.flowserve.com

© 2005 Flowserve Corporation, Irving, Texas, USA. Flowserve and Worcester Controls are registered trademarks of Flowserve Corporation. FCD WCAIM2028-01 5/05 Printed in USA.

Loading...

Loading...