Page 1

®

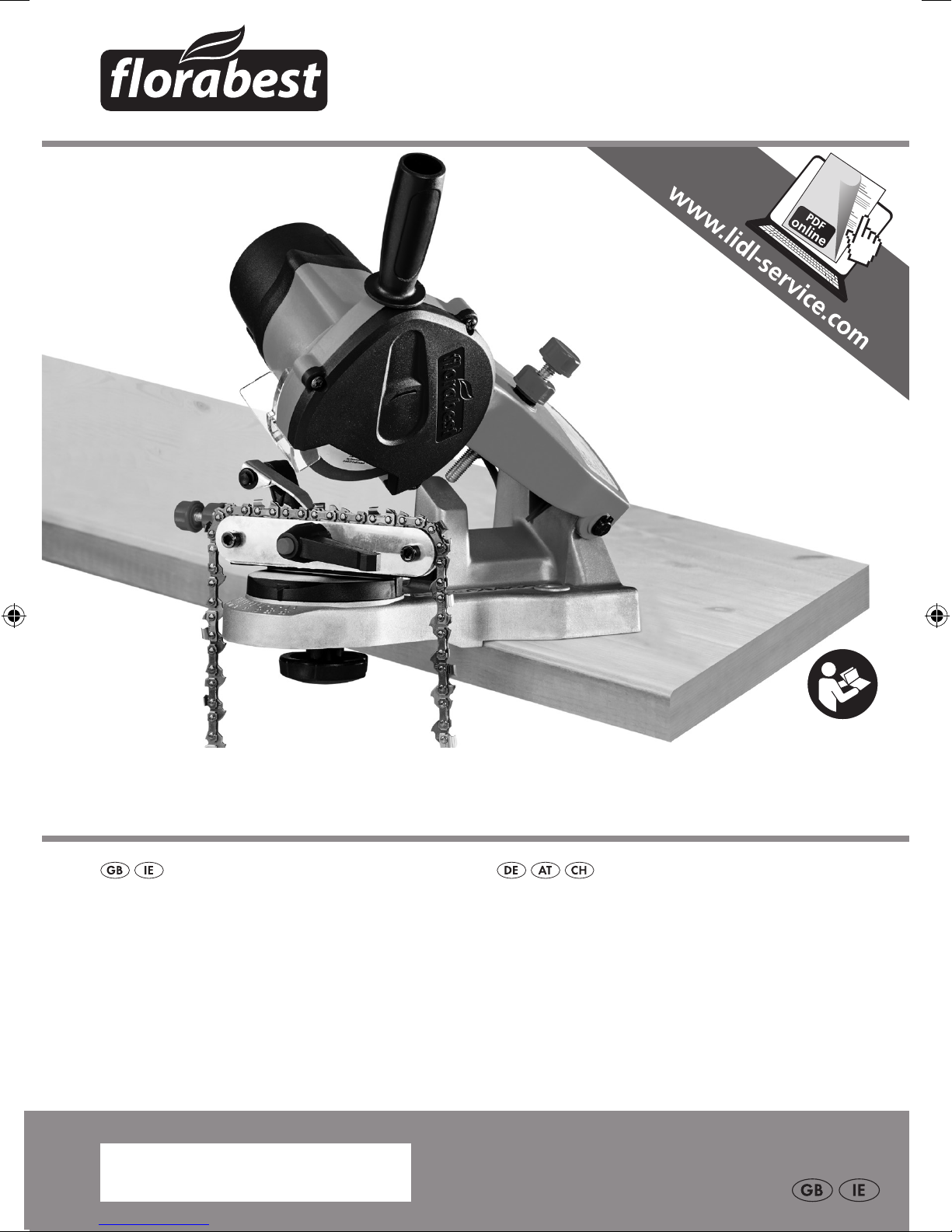

Chain Sharpener FSG 85 B1

Chain Sharpener

Translation of the original instructions

IAN 109774

KettenSChärFGerät

Originalbetriebsanleitung

Page 2

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Translation of the original instructions Page 4

DE / AT / CH Originalbetriebsanleitung Seite 17

Page 3

1 3

2

4

5

6

7

8

9

9

8

4

6

8

10

12

2

25

26

22

16

17

24b

23

24a

13

12

11

10

14

15

16

17

18

20

19

21

1a

1b

Page 4

4

GB IE

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has

been checked for quality and subjected

to a nal inspection. The functionality of

your equipment is therefore guaranteed. It

cannot be ruled out that residual quantities

of water or lubricants will remain on or in

the equipment/hose lines in isolated cases.

This is not a fault or defect and it represents no cause for concern.

The operating instructions constitute

part of this product. They contain

important information on safety, use

and disposal.

Before using the product, familiarise

yourself with all of the operating

and safety instructions. Use the

product only as described and for

the applications specied.

Keep this manual safely and in the

event that the product is passed on,

hand over all documents to the third

party.

Intended use

The chain sharpener is suitable for sharpening the standard saw chain types.

The equipment is not designed for any other type of application (e.g. grinding with a

coolant liquid, grinding other work pieces

or materials such as asbestos, which are

hazardous to health).

The equipment is intended for use in the

eld of DIY. It is not designed for commer-

cial use.

The equipment is designed for use by

adults. Young people under the age of 16

Content

Introduction .................................4

Intended use ................................ 4

General description ...................... 5

Scope of delivery ............................. 5

Function description..........................5

Summary ........................................ 5

Technical specications .................6

Safety Instructions........................6

Safety instructions/symbols on the

equipment ....................................... 7

Symbols in the manual ...................... 7

General safety instructions ................ 7

Further Safety Instructions .................. 9

Installation .................................10

Operation .................................. 10

Working with the equipment ............ 10

Switching on and off ...................... 11

Sharpening the saw chain ................ 11

Maintenance and cleaning .........13

Cleaning ....................................... 13

Changing the grinding disk ............. 13

Storage ......................................14

Waste disposal and

environmental protection ...........14

Replacement parts/accessories ...14

Guarantee .................................15

Repair Service ............................ 16

Service-Center ............................ 16

Importer .................................... 16

Translation of the original

EC declaration of conformity ......32

Exploded Drawing .....................33

Page 5

5

GB IE

are permitted to use the equipment only

under supervision.

The manufacturer shall not be liable for

damages caused by use other than for the

intended purpose or by incorrect operation.

General description

The illustrations can be found

on the front and rear fold-out

pages.

Scope of delivery

Unpack the equipment and check that it is

complete. Dispose of the packaging material correctly.

- Chain sharpener with grinding disk

installed

- Handle

- Chain clamping unit and locking screw

- Adjusting screw and washer

- Two screws, nuts and washers for

mounting on the worktop

- Instruction Manual

Function description

Prior to rst starting the appliance, rmly

mount it on a worktop. It is driven by an

electric motor with protection against overheating and restart for added safety.

The rake angle is easily adjustable between -35° and +35° using a rotary

disk. The chain guide rail has a variably

adjustable stopper. To sharpen, swivel the

grinding head. The equipment is tted with

a protective screen in order to protect the

user.

For the function of the operating parts,

please refer to the descriptions below.

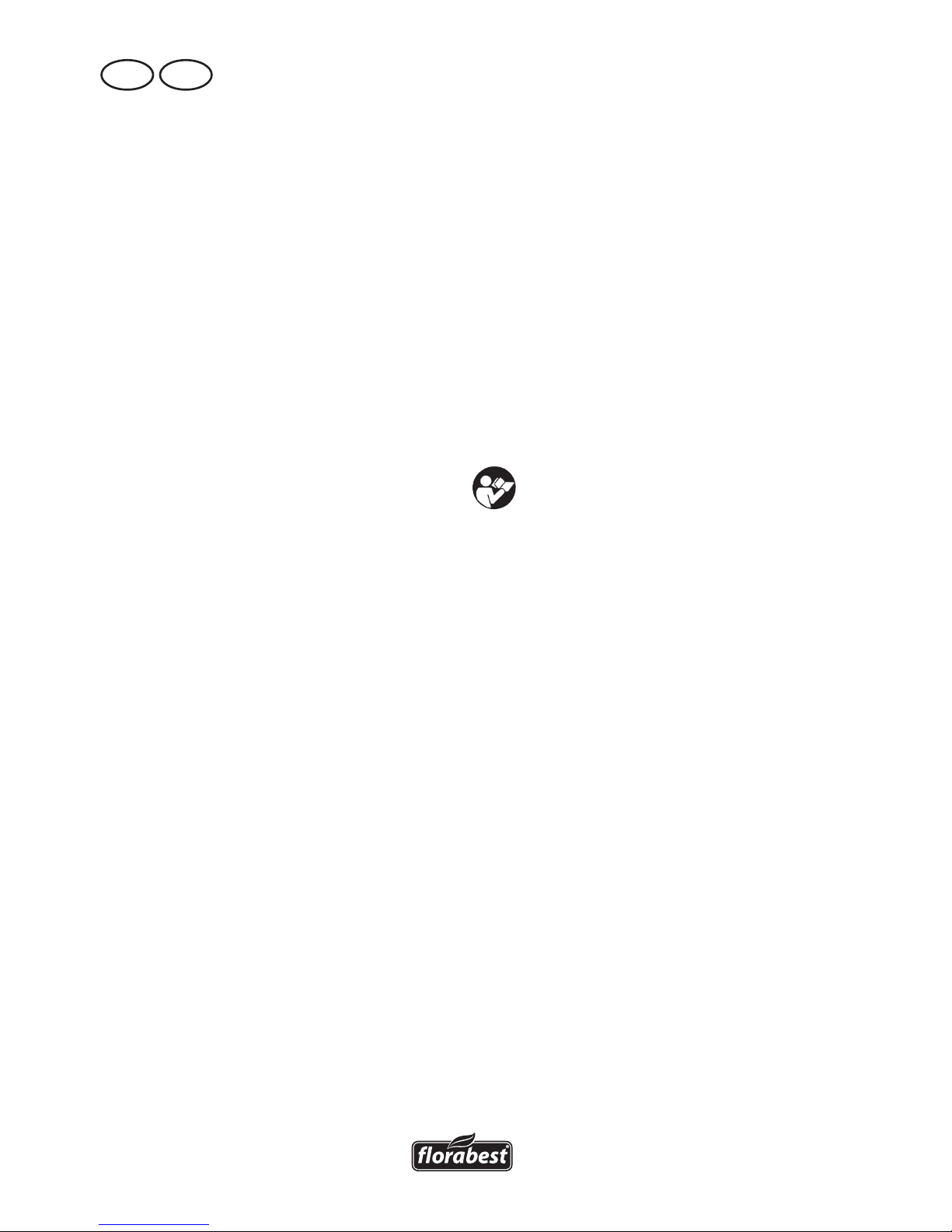

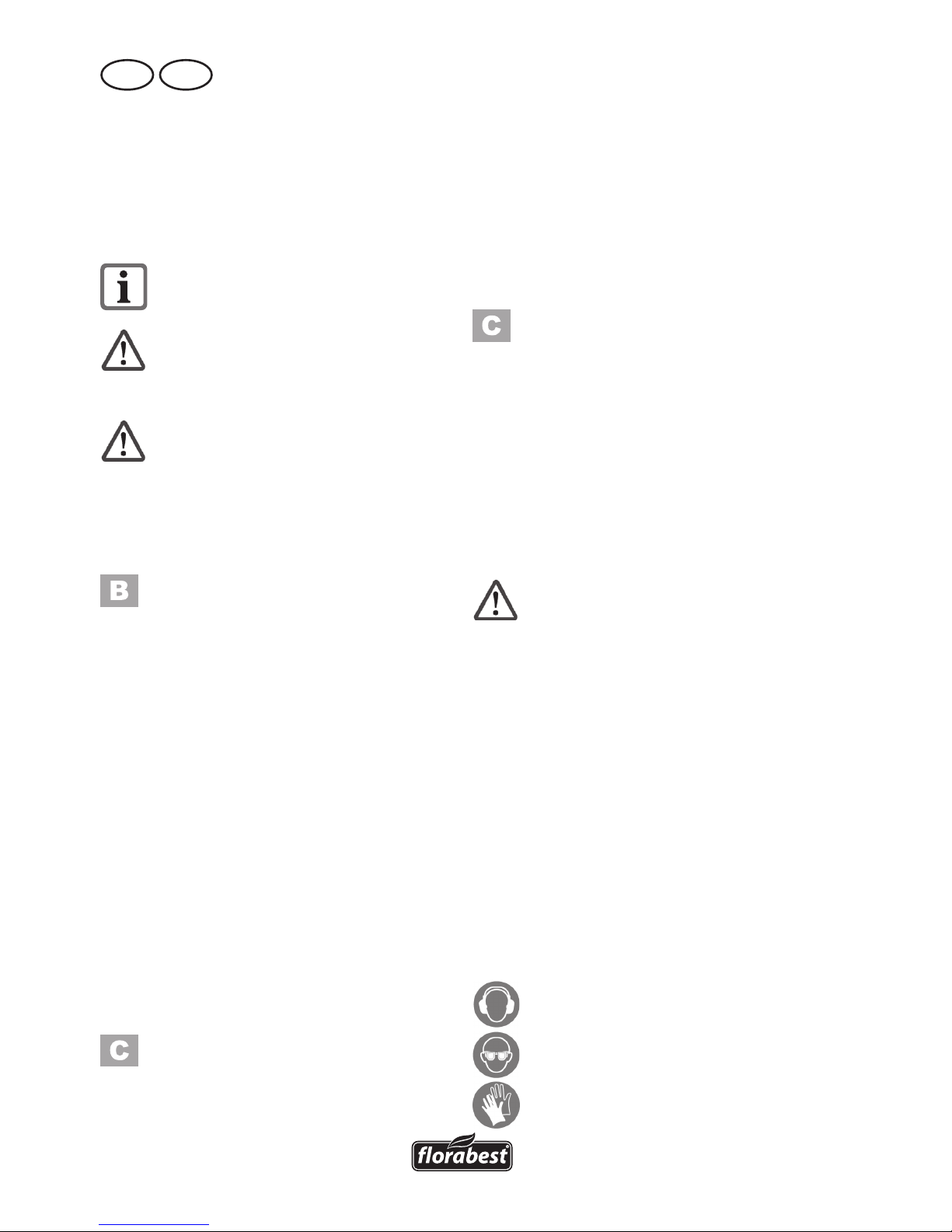

Summary

1 On / off switch

1a On switch

1b Off switch

2 Grinding head

3 Grinding disk cover

4 Handle

5 Fixing screws for grinding disk

cover

6 Adjusting screw and adjusting nut

for depth stopper

7 Guide rail

8 Grinding plinth

9 Stop notches

10 Locking screw for chain clamping

unit

11 Scale for rake angle (+35° to -35°)

12 Chain clamping unit and rotary

disk

13 Chain tensioning and clamping

lever

14 Chain feed adjusting screw and

adjusting nut

15 Stopper

16 Cable hook (not shown)

17 Mains cable

18 Grinding disk and grinding disk

nut (not shown)

19 LED-lamp (not shown)

20 Protective screen

21 Ventilation openings (not shown)

22 Worktop

23 2 screws (for mounting on the

worktop)

24a

2 washers (for mounting on the

worktop)

24b 2 nuts (for mounting on the worktop)

25 Washer (for adjusting screw)

26 Mounting nut (for adjusting screw)

27 Cutting tooth (chain saw)

28 Depth limiter lug (chain saw)

Page 6

6

GB IE

Technical specications

Chain sharpener ............FSG 85 B1

Nominal input voltage ........ 230 V~, 50 Hz

Power consumption ............... max. 85 W

(S2: 15 min)**

Rated resting period ...........approx. 5 min

Safety class .....................................

II

Mechanical rating .......................... IP 20

Idle-running speed n

0

................5000 min

-1

Disk speed .................... max. 27.8 m/s*

Adjustment angle .............. 35° left / right

For saw chains

with link sizes ... 6.35 / 8.255 / 9.52 mm

(1/4“ / 0.325“ / 3/8“)

Dimensions grinding disk

external diameter ...................Ø 104 mm

diameter of bore ......................Ø 22 mm

thickness .................................3.2 mm

Weight (incl. accessories) .. approx. 2.6 kg

Sound pressure level

(L

PA

) .........................83 dB(A); KPA=3 dB

Sound power level (L

WA

)

measured ............... 96 dB(A); K

WA

=3 dB

guaranteed ...........................99 dB(A)

Vibration (a

h

) ......... 3.05 m/s

2,

K=1.5 m/s

2

* The grinding disk must be able to withstand

a circulation speed of minimum 27.8 m/s.

Is the max. rotation speed on the grinding

disk too small in contrast to the appliance the

grinding disk can break.

** Do not operate the equipment for longer

than 15 minutes without interruption; then

take a rest break of 5 minutes.

Technical and optical changes may be

undertaken in the course of further development without notice. All dimensions,

references and information in this instruction manual are therefore not guaranteed.

Legal claims made on the basis of the

instruction manual can therefore not be

considered as valid.

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to compare one power tool to another.

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning:

The vibration emission value may

differ during actual use of the

power tool from the stated value

depending on the manner in which

the power tool is used.

Safety precautions aimed at protecting the user should be based on

estimated exposure under actual

usage conditions (all parts of the

operating cycle are to be considered, including, for example, times

during which the power tool is

turned off and times when the tool

is turned on but is running idle).

Safety Instructions

WARNING!

When using power tools, observe

the following basic safety measures

for the prevention of electric shocks

and the risk of injury and re.

Page 7

7

GB IE

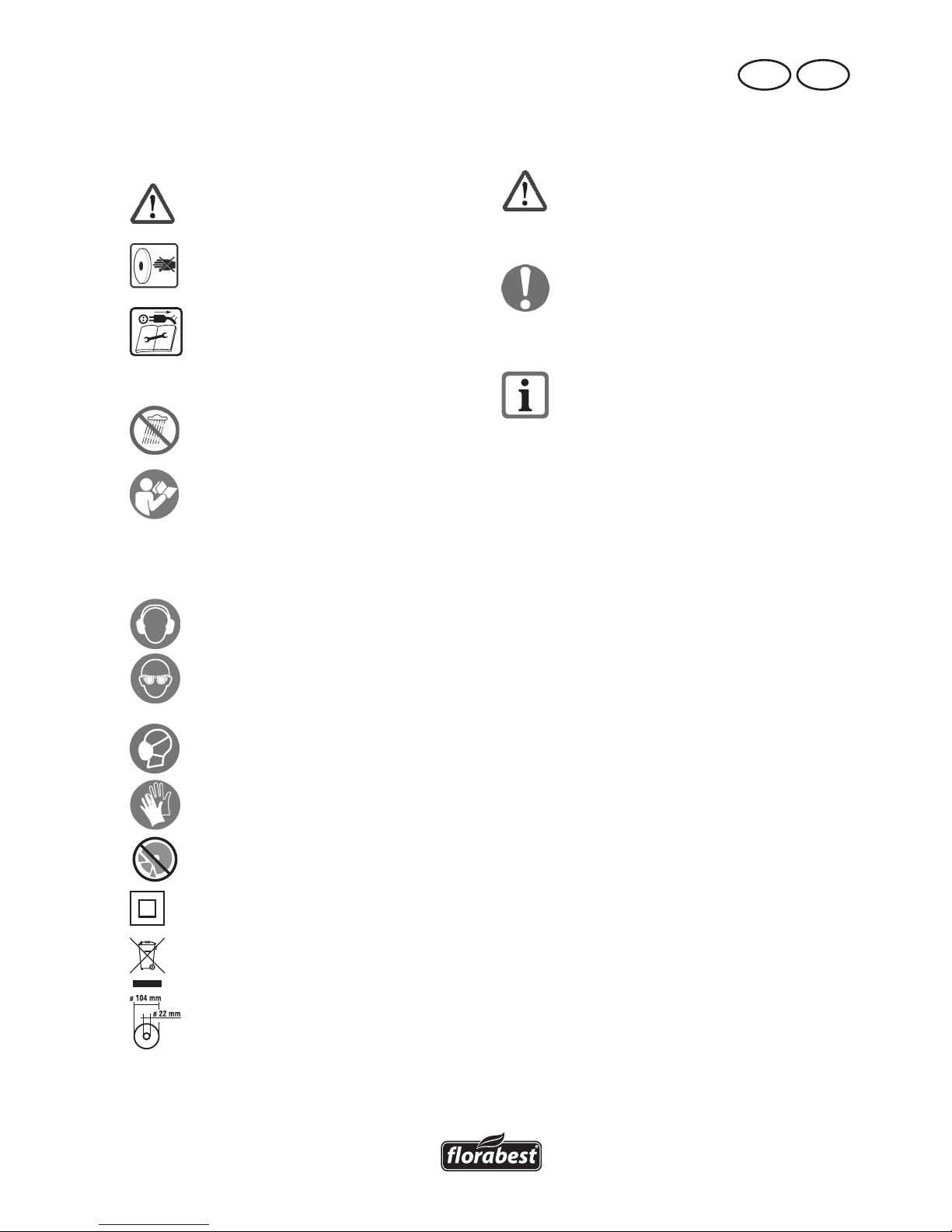

Safety instructions/symbols

on the equipment

Warning!

Risk of injury from the rotating tool!

Keep hands away.

Risk of electric shock!

Disconnect from the mains before

carrying out maintenance and repair work.

Do not expose the unit to rain.

Read and observe the operating

instructions pertaining to the equipment.

Also observe the safety instructions

for your chainsaw and replacement

saw chain.

Risk of injury!

Wear ear, eye and hand protection!

Wear breathing protection.

Risk of cuts!

Wear cut-resistant gloves.

Never use faulty grinding disks.

Safety class II

Do not dispose of electrical equip-

ment in household waste.

Dimensions grinding disk

Symbols in the manual

Warning symbols with in-

formation on damage and

injury prevention.

Instruction symbols (the instruction is

explained at the place of the exclamation mark) with information on

preventing damage.

Help symbols with information on

improving tool handling.

General safety instructions

• This device can be used by individuals

with reduced physical, sensory or mental capabilities or a lack of experience

or knowledge if they are supervised or

have been instructed in how to use the

device safely and understand the associated dangers. Children must not play

with the device.

Safe operation:

• Keep work area clear.

Cluttered areas and benches invite in-

juries.

• Consider work area environ-

ment.

- Do not expose tools to rain. Do not

use tools in damp or wet locations.

Water entering a power tool will increase the risk of electric shock.

- Keep work area well lit.

- Do not use tools in the presence of

ammable liquids or gases.

Power tools create sparks which may

ignite the dust or fumes.

• Guard against electric shock.

Avoid body contact with earthed or

grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

Page 8

8

GB IE

• Keep other persons away.

Do not let persons, especially children,

not involved in the work touch the tool

or the extension cord and keep them

away from the work area.

• Store idle tools. When not in use,

tools should be stored in a dry lockedup place, out of reach of children.

• Do not force the tool. It will do

the job better and safer at the rate for

which it was intended.

• Use the right tool.

- Do not force small tools to do the job

of a heavy duty tool.

- Do not use tools for purposes not

intended; for example do not use circular saws to cut tree limbs or logs.

Use of the power tool for operations dif-

ferent from those intended could result in

a hazardous situation.

• Dress properly.

- Do not wear loose clothing or jewellery, they can be caught in moving

parts.

- Anti-slip footwear is recommended

when working outdoors.

- Wear protective hair covering to contain long hair.

• Use protective equipment.

- Use safety glasses.

- Use face or dust mask if working operations create dust.

• Connect dust extraction equip-

ment. If the tool is provided for the

connection of dust extraction and collecting equipment, ensure these are

connected and properly used.

• Do not abuse the cord. Never

yank the cord do disconnect it from the

socket. Keep the cord away from heat,

oil and sham edges.

• Secure work. Where possible use

clamps or a vice to hold the work. It is

safer than using your hand.

• Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

• Maintain tools with care.

Many accidents are caused by poorly

maintained power tools.

- Keep cutting tools sharp and clean

for better and safer performance.

- Follow instruction for lubricating and

changing accessories.

- Inspect tool cords periodically and if

damaged have them repaired by an

authorized service facility.

- Inspect extension cords periodically

and replace if damaged.

- Keep handles dry, clean and free

from oil and grease.

• Disconnect tools. When not in use,

before servicing and when changing

accessories disconnect tools from the

power supply. Such preventive safety

measures reduce the risk of starting the

power tool accidentaIly.

• Remove adjusting keys and

wrenches. Form the habit of checking to see that keys and adjusting

wrenches are removed from the tool

before turning it on. A wrench or a key

left attached to a rotating part of the

power tool may result in personal injury.

• Avoid unintentional starting.

Ensure switch is in “off” position when

plugging in.

• Use outdoor extension leads.

When the tool is used outdoors, use

only extension cords intended for outdoor use and so marked.

• Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while you are

tired or under the inuence of drugs,

alcohol or medication. A moment of

Page 9

9

GB IE

inattention white operating power tools

may result in serious personal injury.

• Check damaged parts. This will

ensure that the safety of the power tool

is maintained.

- Before further use of tool, it should be

carefully checked to determine that it

will operate properly and perform its

intended function.

- Check for alignment of moving parts,

binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation.

- A guard or other part that is damaged should be properly repaired or

replaced by an authorized service

centre unless otherwise indicated in

this instruction manual.

- Have defective switches replaced by

an authorized service centre.

- Do not use the tool if the switch does

not turn it on and off.

There is a risk of injury.

• Warning.

The use of any accessory or attach-

ment other than one recommended in

this instruction manual may present a

risk of personal injury.

• Have your tool repaired by a

qualied person. This electric tool

complies with the relevant safety rules.

Repairs should only be carried out by

qualied persons using original spare

parts, otherwise this may result in considerable danger to the user.

• If the supply cord of this power tool

is damaged, it must be replaced by

a specially prepared cord available

through the service organization.

Further Safety Instructions

• Connect the device only to a power

point with a residual current protective

device (RCD) with a measured residual

current of not more than 30 mA.

• Keep the mains cable and extension

cable away from the grinding disk and

saw chain. In the event that it is damaged or severed, immediately disconnect the plug from the socket.

Do not touch the cable before it has

been disconnected from the mains.

Risk of electric shock.

• Before use, carry out a visual inspection of the grinding disk. Do not

use grinding disks that are spalled,

cracked or otherwise damaged. Replace a worn grinding disk.

• Never operate the device without the

visual protection disk.

• Do not work with the device if you

are tired or after the consumption of

alcohol or tablets. Always take a break

from the work in good time.

• Do not use the device in an explosive

atmosphere or where sparks could

cause re, explosion etc. Failure to observe this will result in a risk of re or

explosion.

• Keep your hands away from the grinding disk and chain teeth when the

device is in use. Do not move the chain

by hand. This will cause a risk of injury.

• Never place your ngers between the

grinding disk and rotary disk or between the grinding disk and protection

disk. This will cause a risk of crushing.

• The chain becomes hot during grind-

ing. Do not touch the machined location, as there is a risk of being burnt.

• Use only grinding disks recommended

by the manufacturer. Do not use saw

blades.

• Switch off the device and disconnect at

the plug

- to release a jammed insertion tool,

Page 10

10

GB IE

from the chain clamping unit (12).

7. Place the chain clamping unit

(12) on the grinding plinth (8)

and x it using the locking screw

(10).

8. Snap the mains lead (17) into the

cable hook (16).

Screwing on the adjusting

screw:

9. Place the enclosed washer (25)

on the adjusting screw (6).

10. Screw the adjusting screw (6)

onto the securing nut (26) xed

into the grinding head (2).

Operation

Working with the equipment

Caution! Risk of injury!

- Use only grinding disks and accessories recommended by the manu-

facturer. The use of other insertion

tools and other accessories may

cause risk of injury.

- Never operate the device without

the visual protection disk.

- Do not use saw blades.

- Check the grinding disk before

use: check the distance between

the protective screen and the

grinding disk.

- Do not use broken, cracked or oth-

erwise damaged grinding disks.

- Switch on the equipment only

when it is safely installed on the

work surface.

Risk of injury!

Wear ear, eye and hand protection!

When working with the saw chain,

wear cut resistant gloves and an

- if the connecting cable is damaged

or tangled,

- in the case of unusual noises.

Installation

Always use the M10x70 screws

from the package to mount the unit.

Make sure to leave enough

room for working and that

nobody else is put at risk.

Always use screws of suf-

cient length and thickness

to mount the device on the

work surface, in order to

prevent loss of control of the

device.

Installing the appliance:

- Thickness of the table edge: 15 - 30 mm.

- Drill diameter: 10.5 mm.

- Size of screw: M10

1. Use the stop notches (9) to cor-

rectly place the appliance on the

worktop (22). Make sure that the

grinding plinth (8) protrudes beyond the edge of the table.

2. Use a pen to mark the drill holes

and remove the appliance.

3. Drill two holes into the worktop

(22).

4. Using the enclosed screws (23),

washers (24a) and nuts (24b),

screw the grinding plinth in place

on the worktop.

Assembling the grinder:

5. Screw the handle (4) into the

grinding head (2).

6. Remove the locking screw (10)

Page 11

11

GB IE

apron if necessary, to avoid incision injuries.

Keep hands away from the grinding

disk and chain teeth when the equipment is in use. Do not move the chain

by hand. There is a risk of injury.

Switching on and off

Ensure that the mains voltage

matches the specications on the

rating plate.

Connect the equipment to the mains.

1. To switch on, press the “I” On switch

(green) and the device starts up (see

1a).

2. To switch off, press the “0” Off switch

(red) and the device switches off (see

1b).

The disk will continue to

run after the equipment is

switched off. There is a risk

of injury.

Protection against overheating and

restart:

The unit will not automatically restart following an automatic cutout due to overload.

To restart the grinder, press the “I” On switch

(green) and the device starts up (see

1a).

Test run:

Before starting work and after each

change of grinding disk, carry out a test

run of at least 30 seconds with no load.

Switch off the equipment immediately if the

disk runs lumpy, substantial vibrations occur, or abnormal noises are generated.

Sharpening the saw chain

When working with the saw chain,

keep clean the ventilation openings

(see “Maintenance and cleaning”).

In case of a blockage, switch off

the equipment and disconnect from

the mains. Only then should the

blockage be removed.

An incorrectly sharpened

saw chain may damage the

chain the increase the risk of

the saw jumping back.

Ensure that the chain is

aligned accurately.

Observe the correct rake angle and minimum dimensions

of the saw chain. Remove as

little material as possible.

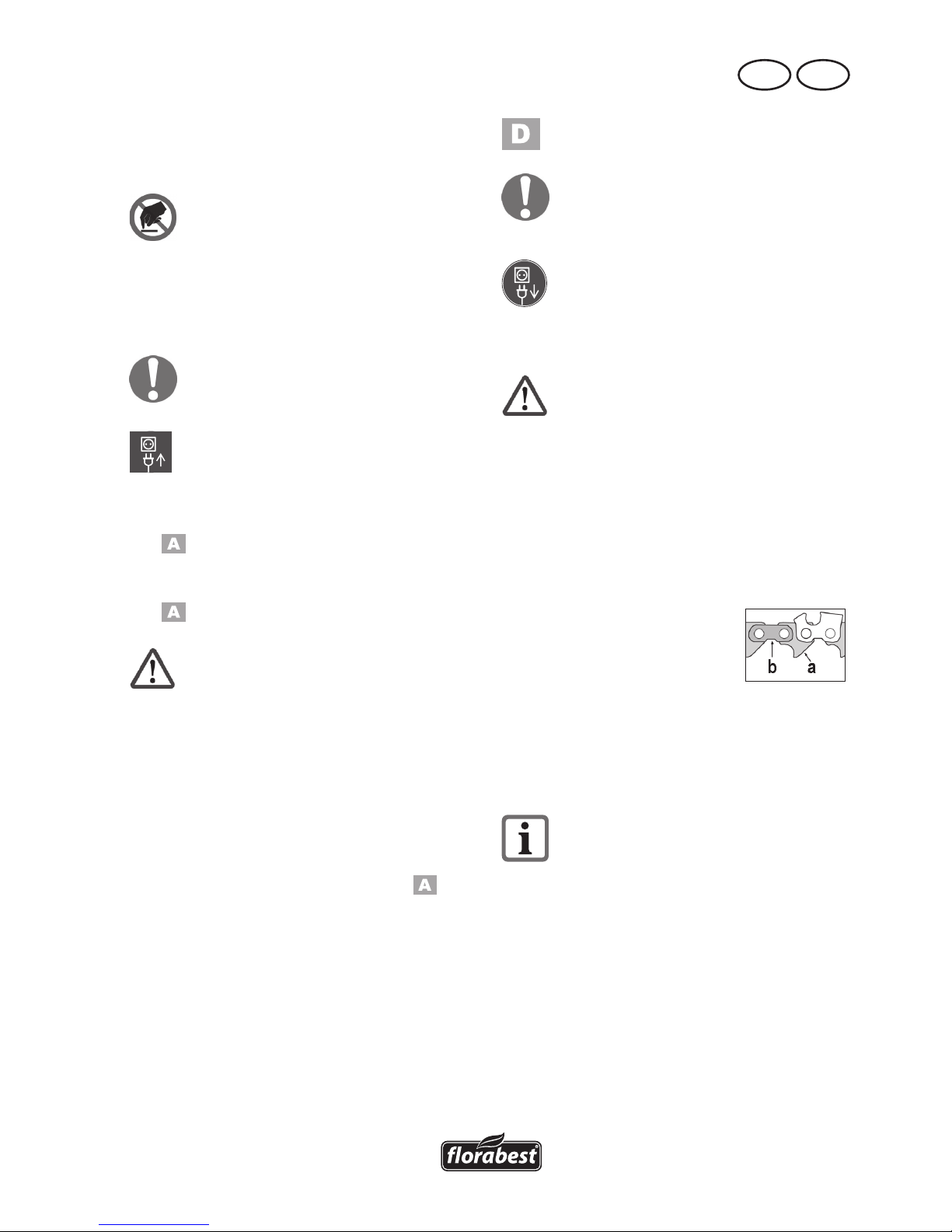

Do not grind in

drive (a) or connecting (b) links,

otherwise the saw

chain may rupture.

In the event of non-observance, there is a risk of accidents when handling the

chainsaw.

Instructions for sharpening

• Clean the saw chain before you sharpen it. Use a brush or cloth to remove

oily wood chips or residual oil.

• After sharpening, all cutting links must

be of equal length and width.

• The chain is worn and must be replaced with a new saw chain if only

approx. 4 mm of cutting tooth remain.

Inserting the saw chain:

1. To open the chain guide, turn the

Page 12

12

GB IE

clamping lever (13) anticlockwise. You

must rst return the clamping lever to

its home position several times.

The clamping lever unlocks by pulling

it outward, returning it to the home position and allowing it to snap back in.

2. Place the saw chain in the chain guide

(7). Ensure that the cutting edges face

the grinding disk (18).

3. Flap down the chain stop (15) and pull

the saw chain back until the cutting

tooth (27) to be sharpened contacts the

stop (see gure

).

Adjusting the sharpening angle:

4. Loosen the locking

screw (10) and use the

scale (11) on the rotary

disk of the chain clamping

unit (12) to set the correct

sharpening angle α.

Tighten the locking screw.

Adjust the sharpening angle ac-

cording to the manufacturer’s speci-

cations.

Adjusting the stop:

5. Turn off the motor and pull down the

grinding head (2) by the handle (4).

6. Turn the chain feed adjusting screw

(14a) to move the cutting tooth (27)

towards the grinding disk (18) until

they make contact (see gure

).

Tighten the adjusting nut (14b) to lock

the adjusting screw (14a).

7. Turn the clamping lever (13) clockwise

to tighten the chain links in the chain

guide (7) (see 1.).

8. Turn the adjusting screw (6a) to set the

depth stopper such that the grinding

disk (18) contacts the tooth root (see

gure

). Tighten the adjusting

nut (6b) to set the grinding depth.

Sharpen:

9. Switch on the equipment (see “switching on and off “).

10. By putting gentle pressure on the han-

dle (4), move the grinding head (2)

upwards and sharpen the cutting tooth.

Do not allow the grinding disk (18)

to slow down to standstill. This is pre-

vented by reducing the pressing force

early enough.

11. Switch off the equipment to move the

chain onwards.

Loosen the clamping lever (13) and

tighten the next chain link to be sharpened in the chain guide (7) using

the adjusted chain stop (15) and the

clamping lever.

Start by sharpening the teeth on

one side of the chain. Then adjust

the rake angle and sharpen the

teeth on the other side.

Check the depth limiter distance

(see image

):

The cutting links, which comprise a cutting

tooth (27) and a depth limiter lug (28), are

the sawing parts of the chain. The height

distance between these two is determined

by depth limiter distance A.

1. After every third sharpening process,

check depth limiter distance A against

the saw chain manufacturer’s specications.

2. Use a at le to le down the height of

the depth limiter lug (28) and, after resetting, round off the depth limiter lug

a little. The original shape must remain

intact.

Page 13

13

GB IE

Maintenance and

cleaning

Disconnect the plug before adjust-

ment, maintenance or repair.

Have any work not described

in these instructions carried

out by a specialist workshop.

Use only original components.

Allow the equipment to cool

before carrying out any maintenance and cleaning work.

There is a risk of burns.

Before each use, check the equipment for

obvious defects such as loose, worn or damaged components and check that screws or

other parts are sitting correctly. In particular,

check the grinding disk (

18). Replace

damaged parts.

Cleaning

Do not use cleaning agents or sol-

vents. Chemical substances may

attack plastic parts of the equipment.

Never clean the equipment under

running water.

• Clean the equipment thoroughly after

each use.

Clean the ventilation openings (

21)

and the surface of the equipment with

a brush or cloth.

• Clean the guide rail (

7) with a brush.

• In case of heavy dirt, loosen the locking screw for the chain clamping unit

(

10) and remove the chain clamp-

ing unit and rotary disk (

12) for

better access.

We recommended removing the side

plates for cleaning.

Changing the grinding disk

Instructions for changing:

• Never operate the equipment without the protective screen (

20).

• Ensure that the rotation speed

specied on the grinding disk

(

18) is equal to or greater than

the idle-running speed of the appliance. If the max. rotation speed

on the grinding disk is too small

in contrast to the appliance the

grinding disk can break.

Ensure that the disk dimensions t

the equipment.

• Use only fault-free grinding disks

(ring test).

• If the locator hole in a grinding

disk is too small, do not subsequently redrill in order to increase

the size.

• Do not use separated reduction

bushes or adapters in order to

make a grinding disk t where the

hole is too large.

• Do not use saw blades.

• Reassemble the equipment fully

after changing the grinding disk.

Switch off the equipment and dis-

connect from the mains.

Allow the equipment to cool.

1. Loose the 3 xing screws (5) and

take off the grinding disk cover (3).

2. Remove the grinding disk nut

(18b) by hand.

3. Take the grinding disk (18a) off

the adapter.

4. Place a new grinding disk on the

adapter and tighten the grinding

disk nut by hand.

5. Put the grinding disk cover (3)

back on.

Page 14

14

GB IE

Do not tighten the grinding disk nut

too much because this may cause

the grinding disk and nut to break.

6. Test run: Before starting work and af-

ter each change of grinding disk, carry

out a test run of at least 30 seconds

with no load. Switch off the equipment

immediately if the disk runs lumpy, substantial vibrations occur or abnormal

noises are generated.

Storage

• Store the appliance in a dry place well

out of reach of children.

Grinding disks must be stored dry

and upright and are not to be

stacked.

Waste disposal and environmental protection

Be environmentally friendly. Return the

tool, accessories and packaging to a recy-

cling centre when you have nished with

them.

Machines are not to be place with

domestic waste.

Hand over the device at an utilization loca-

tion. The plastic and metal parts employed

can be separated out into pure materials

and recycling can be implemented. Ask

your Service Center about this. Defective

units returned to us will be disposed of for

free.

Replacement parts/accessories

Spare parts and accessories can be obtained at www.grizzly-service.eu

If you do not have internet access, please contact the Service Centre via telephone

(see “Service-Center” page 16). Please have the order number mentioned below ready.

Position Position Description Order

Instruction Exploded number

manual drawing

3 Set 3 Grinding disk cover 91102832

4 Set 4 Handle with screw 91102833

12 Set 1 Chain clamping unit and rotary disk 91102830

18a 33 Grinding disk 30211030

18b/18c Set 2 Grinding disk nut and hub 91102831

Page 15

15

GB IE

Guarantee

Dear Customer, this equipment is provided

with a 3-year guarantee from the date of

purchase. In case of defects, you have statutory rights against the seller of the prod-

uct. These statutory rights are not restricted

by our guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect occurs

within three years of the date of purchase

of this product, we will repair or replace –

at our choice – the product for you free of

charge. This guarantee requires the defective equipment and proof of purchase to be

presented within the three-year period with

a brief written description of what constitutes the defect and when it occurred.

If the defect is covered by our guarantee, you

will receive either the repaired product or a

new product. No new guarantee period begins on repair or replacement of the product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced

in accordance with strict quality guidelines

and conscientiously checked prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts that

are subject to normal wear and may therefore be considered as wearing parts (e.g.

grinding disks, carbon brushes, stopper,

protective screen.) or to cover damage to

breakable parts (e.g. switches, batteries,

or parts made of glass).

This guarantee shall be invalid if the product has been damaged, used incorrectly or

not maintained. Precise adherence to all of

the instructions specied in the operating

manual is required for proper use of the

product. Intended uses and actions against

which the operating manual advises or

warns must be categorically avoided.

The product is designed only for private and

not commercial use. The guarantee will be

invalidated in case of misuse or improper handling, use of force, or interventions not undertaken by our authorised service branch.

Processing in Case of Guarantee

To ensure quick handling of you issue,

please follow the following directions:

• Please have the receipt and identication number (IAN 109774) ready as

proof of purchase for all enquiries.

• Please nd the item number on the rating plate.

• Should functional errors or other defects occur, please initially contact the

service department specied below by

telephone or by e-mail. You will then

receive further information on the processing of your complaint.

• After consultation with our customer

service, a product recorded as defective

can be sent postage paid to the service

address communicated to you, with the

proof of purchase (receipt) and speci-

cation of what constitutes the defect

and when it occurred. In order to avoid

Page 16

16

GB IE

acceptance problems and additional

costs, please be sure to use only the ad-

dress communicated to you. Ensure that

the consignment is not sent carriage

forward or by bulky goods, express or

other special freight. Please send the

equipment inc. all accessories supplied

at the time of purchase and ensure adequate, safe transport packaging.

Repair Service

For a charge, repairs not covered by the

guarantee can be carried out by our service branch, which will be happy to issue

a cost estimate for you. We can handle

only equipment that has been sent with adequate packaging and postage.

Attention: Please send your equipment to

our service branch in clean condition and

with an indication of the defect.

Equipment sent carriage forward or by

bulky goods, express or other special

freight will not be accepted.

We will dispose of your defective devices

free of charge when you send them to us.

Service-Center

Service Great Britain

Tel.: 0871 5000 720 (£ 0.10/

Min.)

E-Mail: grizzly@lidl.co.uk

IAN 109774

Service Ireland

Tel.: 1890 930 034

(0,08 EUR/Min., (peak))

(0,06 EUR/Min., (off peak))

E-Mail: grizzly@lidl.ie

IAN 109774

Importer

Please note that the following address is

not a service address. Please initially con-

tact the service centre specied above.

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

63762 Großostheim

Germany

www.grizzly-service.eu

GB

IE

Page 17

17

DE AT CH

Einleitung

Herzlichen Glückwunsch zum Kauf Ihres

neuen Gerätes. Sie haben sich damit für

ein hochwertiges Gerät entschieden.

Dieses Gerät wurde während der Produktion

auf Qualität geprüft und einer Endkontrolle

unterzogen. Die Funktionsfähigkeit Ihres

Gerätes ist somit sichergestellt. Es ist nicht

auszuschließen, dass sich in Einzelfällen am

oder im Gerät, bzw. in Schlauchleitungen

Restmengen von Wasser oder Schmierstoffen

benden. Dies ist kein Mangel oder Defekt

und kein Grund zur Besorgnis.

Die Betriebsanleitung ist Bestandteil

dieses Gerätes. Sie enthält wichtige

Hinweise für Sicherheit, Gebrauch

und Entsorgung. Machen Sie sich

vor der Benutzung des Gerätes mit

allen Bedien- und Sicherheitshinweisen vertraut. Benutzen Sie das Gerät

nur wie beschrieben und für die

angegebenen Einsatzbereiche.

Bewahren Sie die Betriebsanleitung

gut auf und händigen Sie alle Unterlagen bei Weitergabe des Gerätes

an Dritte mit aus.

Bestimmungsgemäße

Verwendung

Das Kettenschärfgerät ist zum Schärfen der

gängigen Sägekettentypen geeignet.

Für alle anderen Anwendungsarten (z.B.

Schleifen mit einer Kühlüssigkeit, Schleifen

anderer Werkstücke oder gesundheitsgefährdender Materialien wie Asbest) ist das

Gerät nicht vorgesehen.

Das Gerät ist für den Einsatz im Heimwerkerbereich bestimmt. Es wurde nicht für

den gewerblichen Dauereinsatz konzipiert.

Das Gerät ist zum Gebrauch durch Erwachsene bestimmt. Jugendliche über

Inhalt

Einleitung ...................................17

Bestimmungsgemäße

Verwendung ..............................17

Allgemeine Beschreibung ...........18

Lieferumfang..................................18

Funktionsbeschreibung ....................18

Übersicht ......................................18

Technische Daten ........................19

Sicherheitshinweise ....................20

Sicherheitshinweise/

Symbole auf dem Gerät ................... 20

Bildzeichen in der Betriebsanleitung ..20

Allgemeine Sicherheitshinweise .......20

Weiterführende Sicherheitshinweise ...23

Montage ....................................24

Bedienung .................................24

Arbeiten mit dem Gerät ..................24

Ein- und Ausschalten ....................... 25

Sägekette schärfen ......................... 25

Wartung und Reinigung .............27

Reinigung .....................................27

Schleifscheibe wechseln .................. 28

Lagerung ...................................28

Entsorgung/Umweltschutz ..........29

Ersatzteile/Zubehör ...................29

Garantie ....................................30

Reparatur-Service ......................31

Service-Center ............................31

Importeur ..................................31

Original EG-Konformitäts-

erklärung ..................................32

Explosionszeichnung ..................33

Page 18

18

DE AT CH

16Jahre dürfen das Gerät nur unter Aufsicht benutzen. Der Hersteller haftet nicht

für Schäden, die durch bestimmungswidrigen Gebrauch oder falsche Bedienung

verursacht wurden.

Allgemeine Beschreibung

Die Abbildungen nden Sie auf

der vorderen und hinteren Ausklappseite.

Lieferumfang

Packen Sie das Gerät aus und kontrollieren

Sie, ob es vollständig ist. Entsorgen Sie

das Verpackungsmaterial ordnungsgemäß.

- Kettenschärfgerät mit montierter Schleifscheibe

- Handgriff

- Kettenspanneinheit mit Feststellschraube

- Stellschraube + Unterlegscheibe

- Zwei Schrauben mit Muttern und Unter-

legscheiben zur Tischbefestigung

- Originalbetriebsanleitung

Funktionsbeschreibung

Das Gerät wird vor der Erstinbetriebnahme

fest auf einer Arbeitsäche montiert. Es

besitzt als Antrieb einen Elektromotor mit

Thermoschutz und Wiederanlaufschutz für

zusätzliche Sicherheit.

Der Schärfwinkel ist bequem von -35° bis

+35° einstellbar. Die Kettenführungsschie-

ne besitzt einen variabel verstellbaren

Anschlag. Das Schärfen erfolgt durch

Schwenken des Schleifkopfes. Zum Schutz

des Anwenders ist das Gerät mit einer

Sichtschutzscheibe versehen.

Die Funktion der Bedienteile entnehmen Sie

bitte den nachfolgenden Beschreibungen.

Übersicht

1 Ein-/Ausschalter

1a Einschalter

1b Ausschalter

2 Schleifkopf

3 Schleifscheiben-Abdeckung

4 Handgriff

5 Befestigungsschrauben für Schleif-

scheiben-Abdeckung

6 Stellschraube und Stellmutter für

den Tiefenanschlag

7 Kettenführungsschiene

8 Schleifsockel

9 Anschlagkerben

10 Feststellschraube für die Ketten-

spanneinheit

11 Skala für Schärfwinkel

(+35° bis -35°)

12 Kettenspanneinheit mit Drehteller

13 Spannhebel zur Kettenxierung

14 Stellschraube und Stellmutter für

den Kettenvorschub

15 Anschlag

16 Kabelhalter (nicht abgebildet)

17 Netzkabel

18 Schleifscheibe mit Schleifscheiben-

Mutter (nicht abgebildet)

19 LED-Lampe (nicht abgebildet)

20 Sichtschutzscheibe

21 Lüftungsöffnungen (nicht abgebil-

det)

22 Arbeitsäche

23 2 Schrauben (zur Tischbefestigung)

24a

2 Unterlegscheiben (zur Tischbe-

festigung)

24b 2 Muttern (zur Tischbefestigung)

25 Unterlegscheibe (für Stellschraube)

26 Befestigungsmutter (für Stellschrau-

be)

27 Schneidezahn (Sägekette)

28 Tiefenbegrenzernase (Sägekette)

Page 19

19

DE AT CH

Technische Daten

Kettenschärfgerät ........... FSG 85 B1

Nenneingangsspannung ...230 V~, 50 Hz

Leistungsaufnahme ................ max. 85 W

(S2: 15 min)**

Bemessungsruhedauer .............. ca. 5 min

Schutzklasse ....................................

II

Schutzart....................................... IP 20

Bemessungs-Leerlaufdrehzahl n

0

.. 5000 min

-1

Scheibengeschwindigkeit .. max. 27,8 m/s*

Einstellwinkel .................. 35° links/rechts

Für Sägeketten mit

Gliedermaß ...... 6,35 / 8,255 / 9,52 mm

(1/4“ / 0,325“ / 3/8“)

Abmessungen Schleifscheibe

Außendurchmesser .............. Ø 104 mm

Lochdurchmesser ................... Ø 22 mm

Stärke ..................................... 3,2 mm

Gewicht (incl. Zubehör) ...........ca. 2,6 kg

Schalldruckpegel

(L

PA

) ..................... 83 dB (A); KPA= 3 dB

Schallleistungspegel (L

WA

)

gemessen ............. 96 dB(A); K

WA

= 3 dB

garantiert .............................. 99 dB(A)

Vibration (a

h

) ........3,05 m/s2; K=1,5 m/s

2

* Die Schleifscheibe muss einer Umlaufge-

schwindigkeit von mind. 27,8 m/s standhalten. Ist die max. Umlaufgeschwindigkeit der

Scheibe im Gegensatz zum Gerät zu klein,

kann diese zerbrechen!

**Kurzzeitbetrieb:Gerätnichtlängerals15Mi-

nuten ununterbrochen betreiben; danach eine

Ruhedauervon5Minuteneinlegen.

Technische und optische Veränderungen

können im Zuge der Weiterentwicklung

ohne Ankündigung vorgenommen werden.

Alle Maße, Hinweise und Angaben dieser

Betriebsanleitung sind deshalb ohne Gewähr. Rechtsansprüche, die aufgrund der

Betriebsanleitung gestellt werden, können

daher nicht geltend gemacht werden.

Der angegebene Schwingungsemissionswert ist nach einem genormten Prüfverfah-

ren gemessen worden und kann zum Vergleich eines Elektrowerkzeugs mit einem

anderen verwendet werden.

Der angegebene Schwingungsemissionswert kann auch zu einer einleitenden

Einschätzung der Aussetzung verwendet

werden.

Warnung: Der Schwingungs-

emissionswert kann sich während

der tatsächlichen Benutzung des

Elektrowerkzeugs von dem Angabewert unterscheiden, abhängig

von der Art und Weise, in der das

Elektrowerkzeug verwendet wird.

Es besteht die Notwendigkeit, Si-

cherheitsmaßnahmen zum Schutz

des Anwenders festzulegen, die

auf einer Abschätzung der Aussetzung während der tatsächlichen

Benutzungsbedingungen beruhen

(hierbei sind alle Anteile des Betriebszyklus zu berücksichtigen,

beispielsweise Zeiten, in denen das

Elektrowerkzeug abgeschaltet ist,

und solche, in denen es zwar eingeschaltet ist, aber ohne Belastung

läuft).

Page 20

20

DE AT CH

Sicherheitshinweise

ACHTUNG!

Beim Gebrauch von Elektrowerk-

zeugen sind zum Schutz gegen

elektrischen Schlag, Verletzungs- und

Brandgefahr folgende grundsätzliche

Sicherheitsmaßnahmen zu beachten.

Sicherheitshinweise/

Symbole auf dem Gerät

Achtung!

Verletzungsgefahr durch sich dre-

hendes Werkzeug! Halten Sie Hände fern.

Gefahr durch elektrischen Schlag!

Ziehen Sie vor Wartungs- und Reparaturarbeiten den Netzstecker

aus der Steckdose.

Gerät nicht dem Regen aussetzen.

Lesen und beachten Sie die zum

Gerät gehörende Betriebsanleitung!

Beachten Sie auch die Sicherheitshinweise Ihrer Kettensäge und

Ersatz-Sägekette.

Verletzungsgefahr!

Tragen Sie Augen- und Gehör-

schutz!

Tragen Sie einen Atemschutz.

Gefahr durch Schnittverletzungen!

Tragen Sie schnittsichere Handschuhe.

Keine defekte Schleifscheibe einset-

zen.

Schutzklasse II

Elektrische Geräte gehören nicht

in den Hausmüll.

Abmessungen Schleifscheibe

Bildzeichen in der Betriebsanleitung

Gefahrenzeichen mit Anga-

ben zur Verhütung von Personen- oder Sachschäden.

Gebotszeichen (anstelle des Aus-

rufungszeichens ist das Gebot

erläutert) mit Angaben zur Verhütung von Schäden.

Hinweiszeichen mit Informationen

zum besseren Umgang mit dem

Gerät.

Allgemeine

Sicherheitshinweise

• Dieses Gerät kann von Personen mit

verringerten physischen, sensorischen

oder mentalen Fähigkeiten oder Man-

gel an Erfahrung und Wissen benutzt

werden, wenn sie beaufsichtigt oder

bezüglich des sicheren Gebrauchs

des Gerätes unterwiesen wurden und

die daraus resultierenden Gefahren

verstehen. Kinder dürfen nicht mit

dem Gerät spielen.

Sicheres Arbeiten:

• Halten Sie Ihren Arbeitsbereich

in Ordnung. Unordnung im Ar-

beitsbereich kann Unfälle zur Folge

haben.

Page 21

21

DE AT CH

• Berücksichtigen Sie Umgebungs-

einüsse.

- Setzen Sie Elektrowerkzeuge nicht

dem Regen aus. Benutzen Sie Elek-

trowerkzeuge nicht in feuchter oder

nasser Umgebung. Das Eindringen

von Wasser in ein Elektrowerkzeug

erhöht das Risiko eines elektrischen

Schlages.

- Sorgen Sie für gute Beleuchtung des

Arbeitsplatzes.

- Benutzen Sie Elektrowerkzeuge nicht,

wo Brand- oder Explosionsgefahr besteht. Elektrowerkzeuge erzeugen Fun-

ken, die den Staub oder die Dämpfe

entzünden können.

• Schützen Sie sich vor elektrischem Schlag. Vermeiden Sie Kör-

perberührung mit geerdeten Teilen (z.B.

Rohren, Radiatoren, Elektroherden,

Kühlgeräten).

• Halten Sie andere Personen fern.

Lassen Sie andere Personen, insbesondere Kinder, nicht das Elektrowerkzeug

oder das Kabel berühren. Halten Sie sie

von Ihrem Arbeitsbereich fern.

• Bewahren Sie unbenutzte Elektrowerkzeuge sicher auf.

Unbenutzte Elektrowerkzeuge sind an

einem trockenen, hochgelegenen oder

abgeschlossenen Ort, außerhalb der

Reichweite von Kindern, abzulegen. Es

besteht Verletzungsgefahr.

• Überlasten Sie Ihr Elektrowerkzeug nicht. Sie arbeiten besser und

sicherer im angegebenen Leistungsbereich.

• Benutzen Sie das richtige Elektrowerkzeug.

- Verwenden Sie keine leistungsschwachen Maschinen für schwere Arbeiten.

- Benutzen Sie das Elektrowerkzeug

nicht für solche Zwecke, für die es

nicht vorgesehen ist. Benutzen Sie

zum Beispiel keine Handkreissäge

zum Schneiden von Baumästen oder

Holzscheiten.

Der Gebrauch von Elektrowerkzeugen

für andere als die vorgesehenen Anwendungen kann zu gefährlichen Situationen führen.

• Tragen Sie geeignete Kleidung.

- Tragen Sie keine weite Kleidung oder

Schmuck, sie können von beweglichen Teilen erfasst werden.

- Bei Arbeiten im Freien ist rutschfestes

Schuhwerk empfehlenswert.

- Tragen Sie bei langen Haaren ein

Haarnetz.

• Benutzen Sie Schutzausrüstung.

- Tragen Sie eine Schutzbrille. Bei

Nichtbeachtung können Augenverlet-

zungen durch Funken oder Schleifpartikel entstehen.

- Verwenden Sie bei stauberzeugenden

Arbeiten eine Atemmaske.

• Schließen Sie die StaubabsaugEinrichtung an. Falls Anschlüsse zur

Staubabsaugung und Auffangeinrichtung vorhanden sind, überzeugen Sie

sich, dass diese angeschlossen und

richtig benutzt werden.

• Verwenden Sie das Kabel nicht

für Zwecke, für die es nicht bestimmt ist. Benutzen Sie das Kabel

nicht, um den Netzstecker aus der

Steckdose zu ziehen. Schützen Sie das

Kabel vor Hitze, Öl und scharfen Kanten.

Beschädigte oder verwickelte Kabel

erhöhen das Risiko eines elektrischen

Schlages.

• Sichern Sie das Werkstück. Benutzen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzu-

halten. Es ist damit sicherer gehalten als

Page 22

22

DE AT CH

mit Ihrer Hand.

• Vermeiden Sie abnormale Körperhaltung. Sorgen Sie für sicheren

Stand und halten Sie jederzeit das

Gleichgewicht.

Dadurch können Sie das Elektrowerk-

zeug in unerwarteten Situationen besser

kontrollieren.

• Pegen Sie Ihre Werkzeuge mit

Sorgfalt. Viele Unfälle haben ihre

Ursache in schlecht gewarteten Elektro-

werkzeugen.

- Halten Sie die Schneidwerkzeuge

scharf und sauber, um besser und si-

cherer arbeiten zu können.

- Befolgen Sie die Hinweise zur Schmierung und zum Werkzeugwechsel.

- Kontrollieren Sie regelmäßig das

Netzkabel des Elektrowerkzeugs und

lassen Sie dieses bei Beschädigung

von einem anerkannten Fachmann

erneuern.

- Kontrollieren Sie Verlängerungsleitungen regelmäßig und ersetzen Sie

diese, wenn sie beschädigt sind.

- Halten Sie die Handgriffe trocken,

sauber und frei von Öl und Fett.

• Ziehen Sie den Netzstecker aus

der Steckdose bei Nichtgebrauch

des Elektrowerkzeugs, vor der Wartung

und beim Wechsel von Werkzeugen.

Diese Vorsichtsmaßnahme verhindert

den unbeabsichtigten Start des Elektro-

werkzeuges.

• Lassen Sie keine Werkzeugschlüssel stecken. Überprüfen Sie

vor dem Einschalten, dass Schlüssel und

Einstellwerkzeuge entfernt sind.

• Vermeiden Sie unbeabsichtigten

Anlauf. Vergewissern Sie sich, dass

der Schalter beim Einstecken des Steckers in die Steckdose ausgeschaltet ist.

Ein Werkzeug oder Schlüssel, der sich

in einem drehenden Geräteteil bendet,

kann zu Verletzungen führen.

• Benutzen Sie Verlängerungskabel für den Außenbereich.

Verwenden Sie im Freien nur dafür

zugelassene und entsprechend gekenn-

zeichnete Verlängerungskabel.

• Seien Sie aufmerksam, achten

Sie darauf, was Sie tun, und gehen Sie mit Vernunft an die Arbeit mit einem Elektrowerkzeug.

Benutzen Sie kein Elektrowerkzeug, wenn Sie müde sind oder

unter Einuss von Drogen, Alkohol oder Medikamenten stehen.

Ein Moment der Unachtsamkeit beim

Gebrauch des Elektrowerkzeuges kann

zu ernsthaften Verletzungen führen.

• Überprüfen Sie das Elektrowerkzeug auf eventuelle Beschädigungen. Damit wird sichergestellt,

dass die Sicherheit des Elektrowerkzeuges erhalten bleibt.

- Vor weiterem Gebrauch des Elektrowerkzeugs müssen Schutzvorrich-

tungen oder leicht beschädigte Teile

sorgfältig auf ihre einwandfreie und

bestimmungsgemäße Funktion untersucht werden.

- Überprüfen Sie, ob die beweglichen

Teile einwandfrei funktionieren und

nicht klemmen oder ob Teile beschädigt sind. Sämtliche Teile müssen rich-

tig montiert sein und alle Bedingungen

erfüllen, um den einwandfreien Betrieb sicherzustellen.

- Beschädigte Schutzvorrichtungen

und Teile müssen bestimmungsgemäß

durch eine anerkannte Fachwerkstatt

repariert oder ausgewechselt werden,

soweit nichts anderes in der Betriebsanleitung angegeben ist.

- Benutzen Sie keine Elektrowerkzeuge,

Page 23

23

DE AT CH

dem Gebrauch einer Sichtprüfung.

Verwenden Sie keine Schleifscheiben

mit Abplatzungen, Rissen oder anderen

Beschädigungen. Wechseln Sie eine

abgenutzte Schleifscheibe aus.

• Betreiben Sie das Gerät niemals ohne

Sichtschutzscheibe.

• Arbeiten Sie mit dem Gerät nicht, wenn

Sie müde sind oder nach der Einnahme

von Alkohol oder Tabletten. Legen Sie

immer rechtzeitig eine Arbeitspause ein.

• Benutzen Sie das Gerät nicht in explo-

sionsfähiger Atmosphäre oder dort,

wo Funken Feuer, Explosion, usw. verursachen könnten. Bei Nichtbeachtung

besteht Brand- oder Explosionsgefahr.

• Halten Sie Ihre Hände von der Schleif-

scheibe und den Kettenzähnen fern,

wenn das Gerät in Betrieb ist. Bewegen

Sie die Sägekette nicht mit der Hand. Es

besteht Verletzungsgefahr.

• Halten Sie nie die Finger zwischen

Schleifscheibe und Drehteller oder zwischen Schleifscheibe und Schutzschei-

be. Es besteht Gefahr durch Quetschen.

• Die Sägekette wird beim Schleifen heiß.

Nicht an der bearbeiteten Stelle anfas-

sen, es besteht Verbrennungsgefahr.

• Verwenden Sie nur vom Hersteller emp-

fohlene Schleifscheiben. Verwenden Sie

keine Sägeblätter.

• Schalten Sie das Gerät aus und ziehen

Sie den Netzstecker

- zum Lösen eines blockierten Einsatzwerkzeuges,

- wenn die Anschlussleitung beschädigt

oder verheddert ist,

- bei ungewöhnlichen Geräuschen.

bei denen sich der Schalter nicht einund ausschalten lässt. Beschädigte

Schalter müssen bei einer Kundendienstwerkstatt ersetzt werden.

• Achtung! Der Gebrauch anderer Ein-

satzwerkzeuge und anderen Zubehörs

kann eine Verletzungsgefahr für Sie

bedeuten.

• Lassen Sie Ihr Elektrowerkzeug

durch eine Elektrofachkraft reparieren. Dieses Elektrowerkzeug

entspricht den einschlägigen Sicherheitsbestimmungen. Reparaturen dürfen nur

von einer Fachwerkstatt ausgeführt wer-

den, indem Originalersatzteile verwendet werden; andernfalls können Unfälle

für den Benutzer entstehen.

• Wenn die Anschlussleitung dieses Gerätes beschädigt wird,

muss sie durch eine besondere

Anschlussleitung ersetzt werden,

die vom Hersteller oder seinem

Kundendienst erhältlich ist.

Weiterführende Sicherheitshinweise

• Schließen Sie das Gerät nur an eine

Steckdose mit Fehlerstrom-Schutzeinrichtung (FI-Schalter) mit einem Bemessungs-

fehlerstrom von nicht mehr als 30mA

an.

• Halten Sie Netzkabel und Verlängerungskabel von der Schleifscheibe und

der Sägekette fern. Ziehen Sie bei Beschädigung oder Durchschneiden sofort

den Netzstecker aus der Steckdose.

Berühren Sie die Leitung nicht, bevor sie

vom Netz getrennt ist.

Es besteht Gefahr durch elektrischen

Schlag.

• Unterziehen Sie die Schleifscheibe vor

Page 24

24

DE AT CH

Montage

Befestigen Sie das Gerät immer

mit den mitgelieferten Schrauben

(M10x70).

Achten Sie darauf, zum Ar-

beiten genügend Platz zu

haben und andere Personen

nicht zu gefährden.

Befestigen Sie das Gerät im-

mer mittels Schrauben ausreichender Länge und Stärke

auf der Arbeitsäche, um

nicht die Kontrolle über das

Gerät zu verlieren.

Gerät aufstellen:

- Stärke der Tischkante: 15-30mm

- Bohrerdurchmesser: 10,5 mm

- Schraubenstärke: M10

1. Positionieren Sie das Gerät mit

Hilfe der Anschlagkerben (9)

auf der Arbeitsäche (22). Der

Schleifsockel (8) muss dabei über

die Tischkante herausragen.

2. Markieren Sie die Bohrlöcher mit

einem Stift und entfernen Sie das

Gerät wieder.

3. Bohren Sie zwei Bohrlöcher in

die Arbeitsäche (22).

4. Schrauben Sie den Schleifsockel mit Hilfe der beiliegenden

Schrauben (23), Unterlegscheiben (24a) und Muttern (24b) auf

der Arbeitsäche fest.

Kettenschärfgerät

montieren:

5. Schrauben Sie den Handgriff (4)

an den Schleifkopf (2) an.

6. Lösen Sie die Feststellschraube

(10) von der Kettenspanneinheit

(12).

7. Setzen Sie die Kettenspanneinheit

(12) auf den Schleifsockel (8) auf

und schrauben diese mit der Fest-

stellschraube (10) fest.

8. Befestigen Sie ggf. das Netzka-

bel (17) im Kabelhalter (16).

Stellschraube montieren:

9. Platzieren Sie die beiliegende

Unterlegscheibe (25) auf der

Stellschraube (6).

10. Schrauben Sie die Stellschraube

(6) auf die im Schleifkopf fest

montierte Befestigungsmutter (26)

auf.

Bedienung

Arbeiten mit dem Gerät

Achtung! Verletzungsgefahr!

- Verwenden Sie nur vom Hersteller empfohlene Schleifscheiben

und Zubehörteile. Der Gebrauch

anderer Einsatzwerkzeuge und

anderen Zubehörs kann eine Ver-

letzungsgefahr für Sie bedeuten.

- Betreiben Sie das Gerät niemals

ohne Sichtschutzscheibe.

- Verwenden Sie keine Sägeblätter.

- Ziehen Sie vor allen Arbeiten an

dem Gerät den Netzstecker.

- Kontrollieren Sie die Schleifscheibe vor ihrer Verwendung:

Prüfen Sie den Abstand zwischen

Sichtschutzscheibe und Schleifscheibe.

- Verwenden Sie keine abgebrochenen, gesprungenen oder

anderweitig beschädigten Schleifscheiben.

Page 25

25

DE AT CH

- Schalten Sie das Gerät erst ein,

wenn es sicher auf der Arbeitsäche montiert ist.

Achtung Verletzungsgefahr!

Tragen Sie Augen- und Gehör-

schutz!

Tragen Sie bei der Arbeit mit der

Sägekette schnittsichere Schutz-

handschuhe und wenn nötig eine

Schürze, um Schnittverletzungen zu

vermeiden.

Halten Sie Ihre Hände von der

Schleifscheibe und den Kettenzähnen fern, wenn das Gerät in Betrieb

ist. Bewegen Sie die Sägekette

nicht mit der Hand. Es besteht Verletzungsgefahr.

Ein- und Ausschalten

Achten Sie darauf, dass die Span-

nung des Netzanschlusses mit

dem Typenschild am Gerät über-

einstimmt.

Schließen Sie das Gerät an die

Netzspannung an.

1. Zum Einschalten drücken Sie den Ein-

schalter „I“ (grün), das Gerät läuft an

(siehe

1a).

2. Zum Ausschalten drücken Sie den Aus-

schalter „0“ (rot), das Gerät schaltet

ab (siehe

1b).

Die Schleifscheibe läuft nach,

nachdem das Gerät abgeschaltet wurde. Es besteht

Verletzungsgefahr.

Thermoschutz mit Wiederanlaufschutz:

Nach einer automatischen Abschaltung

durch Überlastung läuft das Gerät nicht

selbsttätig wieder an.

Zum erneuten Einschalten drücken Sie den

Einschalter „I“ (grün), das Gerät läuft an

(siehe

1a).

Probelauf:

Führen Sie vor dem ersten Arbeiten und nach

jedem Schleifscheibenwechsel einen Probelauf von mindestens 30 Sekunden ohne Belastung durch. Schalten Sie das Gerät sofort

aus, wenn die Schleifscheibe unrund läuft,

beträchtliche Schwingungen auftreten oder

abnorme Geräusche zu hören sind.

Sägekette schärfen

Sorgen Sie beim Arbeiten unter

staubigen Bedingungen für freie

Lüftungsöffnungen (siehe „Wartung

und Reinigung“).

Schalten Sie bei Blockierung das

Gerät ab und ziehen Sie den Netzstecker. Beseitigen Sie erst dann die

Blockierung.

Eine falsch geschärfte Säge-

kette kann zu einer Beschädigung führen und die Rückschlaggefahr der Säge

erhöhen!

Achten Sie auf eine genaue

Justage der Sägekette.

Beachten Sie die richtigen

Schärfwinkel und Mindestmaße der Sägekette. Entfernen

Sie so wenig Material wie

möglich.

Page 26

26

DE AT CH

Schleifen Sie nicht

in Treibglieder (a)

oder Verbindungsglieder (b), die Sägekette kann sonst reißen.

Bei Nichtbeachtung besteht

Unfallgefahr beim Umgang

mit der Kettensäge.

Hinweise zum Schärfen

• Reinigen Sie die Sägekette vor dem

Schärfen. Beseitigen Sie ölhaltige

Holzreste bzw. Ölrückstände mit einem

Pinsel oder Putzlappen.

• Nach dem Schärfen müssen alle

Schneidglieder gleich lang und breit

sein.

• Die Sägekette ist abgenutzt und muss

gegen eine neue Sägekette ersetzt

werden, wenn nur noch ca. 4 mm des

Schneidezahns übrig ist.

Sägekette einlegen:

1. Zum Öffnen der Kettenführungsschiene

drehen Sie den Spannhebel (13) ge-

gen den Uhrzeigersinn. Dazu müssen

Sie den Spannhebel mehrmals in die

Ausgangsposition zurückführen.

Zur Entriegelung des Spannhebels ziehen Sie den Spannhebel nach außen

und lassen ihn nach Zurückführen in

die Ausgangsstellung wieder einrasten.

2. Legen Sie die Sägekette in die Kettenführungsschiene (7) ein. Die Schneid-

kanten müssen zur Schleifscheibe (18)

zeigen.

3. Klappen Sie den Anschlag (15) nach

unten und ziehen Sie die Sägekette

soweit nach hinten, bis der zu schärfende Schneidezahn (27) am Anschlag

anliegt (siehe Bild

).

Schärfwinkel einstellen:

4. Lockern Sie die Feststellschraube (10) und

stellen Sie am Drehteller

der Kettenspanneinheit

(12) den erforderlichen

Schärfwinkel α anhand der Skala (11)

ein. Ziehen Sie die Feststellschraube

wieder an.

Den Schärfwinkel stellen sie nach

Herstellerangaben ein.

Anschlag justieren:

5. Bewegen Sie den Schleifkopf (2) am

Handgriff (4) bei ausgeschaltetem Motor abwärts.

6. Führen Sie mit Hilfe der Stellschraube

für den Kettenvorschub (14a) den

Schneidezahn (27) an die Schleifscheibe (18) heran, bis der Schneidezahn an der Schleifscheibe anliegt

(siehe Bild

). Sichern Sie die

Stellschraube (14a) mit der Stellmutter

(14b).

7. Fixieren Sie die Kettenglieder in der

Kettenführungsschiene (7) durch Dre-

hen des Spannhebels (13) im Uhrzeigersinn (siehe 1.).

8. Stellen Sie den Tiefenanschlag mit Hilfe

der Stellschraube (6a) so ein, dass die

Schleifscheibe (18) den Zahngrund

berührt (siehe Bild

). Sichern Sie

die Schleiftiefe mit der Stellmutter (6b).

Schärfen:

9. Schalten Sie das Gerät ein (siehe „Einund Ausschalten“).

10. Schärfen Sie den Schneidezahn (27),

indem Sie den Schleifkopf (2) durch

sanften Druck auf den Handgriff (4)

abwärts bewegen.

Die Schleifscheibe (18) darf nicht bis

Page 27

27

DE AT CH

zum Stillstand abgebremst werden. Zur

Vermeidung verringern Sie rechtzeitig

den Anpressdruck.

11. Zum Weitertransport der Sägekette

schalten Sie das Gerät aus.

Lösen Sie den Spannhebel (13) und

xieren Sie das nächste zu schärfende

Kettenglied mit Hilfe des justierten An-

schlags (15) und des Spannhebels in

der Kettenführungsschiene (7).

Schärfen Sie zuerst die Zähne einer

Kettenseite. Verstellen Sie dann den

Schärfwinkel und schärfen Sie die

Zähne der anderen Seite.

Tiefenbegrenzer-Abstand prüfen

(siehe Bild

):

Die sägenden Teile der Sägekette sind die

Schneidglieder, die aus einem Schneide-

zahn (27) und einer Tiefenbegrenzernase

(28) bestehen. Der Höhenabstand zwischen diesen beiden bestimmt den Tiefen-

begrenzer-Abstand A.

1. Prüfen Sie nach jedem dritten Schärfen den Tiefenbegrenzer-Abstand A

gemäß den Angaben des SägekettenHerstellers.

2. Feilen Sie die Höhe der Tiefenbegrenzernase (28) mit einer Flachfeile nach

und runden Sie nach dem Zurückset-

zen die Tiefenbegrenzernase etwas

ab. Die ursprüngliche Form muss erhalten bleiben.

Wartung und Reinigung

Ziehen Sie vor jeglicher Einstellung,

Instandhaltung oder Instandsetzung

den Netzstecker.

Lassen Sie Arbeiten, die nicht

in dieser Betriebsanleitung beschrieben sind, von einer Fachwerkstatt durchführen. Verwenden Sie nur Originalteile.

Lassen Sie das Gerät vor allen

Wartungs- und Reinigungsarbeiten abkühlen. Es besteht

Verbrennungsgefahr!

Kontrollieren Sie das Gerät vor jedem

Gebrauch auf offensichtliche Mängel wie

lose, abgenutzte oder beschädigte Teile,

korrekten Sitz von Schrauben oder anderer

Teile. Prüfen Sie insbesondere die Schleifscheibe (

18). Tauschen Sie beschädigte

Teile aus.

Reinigung

Verwenden Sie keine Reinigungs-

bzw. Lösungsmittel. Chemische Substanzen können die Kunststoffteile

des Gerätes angreifen. Reinigen Sie

das Gerät niemals unter ießendem

Wasser.

• Reinigen Sie das Gerät nach jedem Gebrauch gründlich.

Reinigen Sie die Lüftungsöffnungen

(

21) und die Oberäche des Ge-

rätes mit einer weichen Bürste, einem

Pinsel oder einem Tuch.

• Reinigen Sie die Kettenführungsschiene

(

7) mit einer Bürste.

• Bei starken Verunreinigungen lösen Sie

Feststellschraube für die Kettenspan-

Page 28

28

DE AT CH

neinheit ( 10) und entnehmen Sie

die Kettenspanneinheit mit Drehteller

(

12) zwecks besserer Zugänglichkeit.

Wir empfehlen die seitlichen Bleche für

die Reinigung abzunehmen.

Schleifscheibe wechseln

Hinweise zum Wechseln:

• Betreiben Sie das Gerät niemals

ohne Sichtschutzscheibe (

20).

• Vergewissern Sie sich, dass die

auf der Schleifscheibe (

18)

angegebene Drehzahl gleich

oder größer als die BemessungsLeerlaufdrehzahl des Gerätes ist.

Vergewissern Sie sich, dass die

Maße der Schleifscheibe zum

Gerät passen. Ist die max. Umlaufgeschwindigkeit der Scheibe

im Gegensatz zum Gerät zu

klein, kann diese zerbrechen!

• Benutzen Sie nur einwandfreie

Schleifscheiben (Klangprobe).

• Bohren Sie eine zu kleine Aufnahmebohrung der Schleifscheibe

nicht nachträglich auf.

• Verwenden Sie keine getrennten

Reduzierbuchsen oder Adapter,

um Schleifscheiben mit großem

Loch passend zu machen.

• Verwenden Sie keine Sägeblätter.

• Montieren Sie das Gerät nach

dem Schleifscheibenwechsel wieder vollständig.

Schalten Sie das Gerät aus und zie-

hen Sie den Netzstecker.

Lassen Sie das Gerät abkühlen.

1. Lösen Sie die 3 Befestigungs-

schrauben (5) und nehmen Sie

die Schleifscheiben-Abdeckung

(3) ab.

2. Schrauben Sie die Schleifschei-

ben-Mutter (18b) von Hand ab.

3. Nehmen Sie die Schleifscheibe

(18a) von der Aufnahme ab.

4. Setzen Sie die neue Schleifscheibe auf die Aufnahme auf und

schrauben Sie von Hand die

Schleifscheiben-Mutter auf.

5. Schrauben Sie die Schleifschei-

ben-Abdeckung (3) wieder an.

Die Schleifscheiben-Mutter darf

nicht zu fest angezogen werden,

um ein Brechen von Schleifscheibe

und Mutter zu vermeiden

6. Probelauf: Führen Sie vor dem ers-

ten Arbeiten und nach jedem Schleifscheibenwechsel einen Probelauf von

mindestens 30 Sekunden ohne Belastung durch. Schalten Sie das Gerät

sofort aus, wenn die Schleifscheibe

unrund läuft, beträchtliche Schwingungen auftreten oder abnorme Geräu-

sche zu hören sind.

Lagerung

• Bewahren Sie das Gerät an einem

trockenen und staubgeschützten Ort

auf, und außerhalb der Reichweite von

Kindern.

Schleifscheiben müssen trocken und

hochkant aufbewahrt und dürfen

nicht gestapelt werden.

Page 29

29

DE AT CH

Entsorgung/

Umweltschutz

Führen Sie Gerät, Zubehör und Verpackung einer umweltgerechten Wiederverwertung zu.

Elektrische Geräte gehören nicht in

den Hausmüll.

Geben Sie das Gerät an einer Verwertungsstelle ab. Die verwendeten Kunststoff-

und Metallteile können sortenrein getrennt

werden und so einer Wiederverwertung

zugeführt werden. Fragen Sie hierzu unser

Service-Center.

Die Entsorgung Ihrer defekten eingesendeten Geräte führen wir kostenlos durch.

Ersatzteile/Zubehör

Ersatzteile und Zubehör erhalten Sie unter

www.grizzly-shop.de oder www.grizzly-service.eu

Sollten Sie kein Internet haben, so wenden Sie sich bitte telefonisch an das Service-

Center (siehe „Service-Center“ Seite 31). Halten Sie die unten genannte Bestellnummer

bereit.

Position Position Bezeichnung Bestell-Nr.

Betriebs- Explosionsanleitung zeichnung

3 Set 3 Schleifscheiben-Abdeckung 91102832

4 Set 4 Handgriff mit Schraube 91102833

12 Set 1 Kettenspanneinheit mit Drehteller 91102830

18a 33 Schleifscheibe 30211030

18b/18c Set 2 Schleifscheibenmutter und -nabe 91102831

Page 30

30

DE AT CH

Garantie

Sehr geehrte Kundin, sehr geehrter Kunde,

Sie erhalten auf dieses Gerät 3 Jahre Garantie ab Kaufdatum.

Im Falle von Mängeln dieses Gerätes

stehen Ihnen gegen den Verkäufer des

Gerätes gesetzliche Rechte zu. Diese

gesetzlichen Rechte werden durch unsere

im Folgenden dargestellte Garantie nicht

eingeschränkt.

Garantiebedingungen

Die Garantiefrist beginnt mit dem Kauf-

datum. Bitte bewahren Sie den Original-

Kassenbon gut auf. Diese Unterlage wird

als Nachweis für den Kauf benötigt.

Tritt innerhalb von drei Jahren ab dem Kauf-

datum dieses Gerätes ein Material- oder

Fabrikationsfehler auf, wird das Gerät von

uns – nach unserer Wahl – für Sie kostenlos

repariert oder ersetzt. Diese Garantieleistung setzt voraus, dass innerhalb der DreiJahres-Frist das defekte Gerät und der Kaufbeleg (Kassenbon) vorgelegt und schriftlich

kurz beschrieben wird, worin der Mangel

besteht und wann er aufgetreten ist.

Wenn der Defekt von unserer Garantie

gedeckt ist, erhalten Sie das reparierte oder

ein neues Gerät zurück. Mit Reparatur oder

Austausch des Gerätes beginnt kein neuer

Garantiezeitraum.

Garantiezeit und gesetzliche

Mängelansprüche

Die Garantiezeit wird durch die Gewährleistung nicht verlängert. Dies gilt auch

für ersetzte und reparierte Teile. Eventuell

schon beim Kauf vorhandene Schäden und

Mängel müssen sofort nach dem Auspacken gemeldet werden. Nach Ablauf der

Garantiezeit anfallende Reparaturen sind

kostenpichtig.

Garantieumfang

Das Gerät wurde nach strengen Qualitätsrichtlinien sorgfältig produziert und vor

Anlieferung gewissenhaft geprüft.

Die Garantieleistung gilt für Material- oder

Fabrikationsfehler. Diese Garantie erstreckt

sich nicht auf Geräteteile, die normaler Ab-

nutzung ausgesetzt sind und daher als Verschleißteile angesehen werden können (z.B.

Schleifscheiben, Kohlebürsten, Anschlag,

Sichtschutzscheibe) oder für Beschädigungen

an zerbrechlichen Teilen (z.B. Schalter, Akkus oder die aus Glas gefertigt sind).

Diese Garantie verfällt, wenn das Gerät

beschädigt, nicht sachgemäß benutzt oder

nicht gewartet wurde. Für eine sachgemäße

Benutzung des Gerätes sind alle in der Betriebsanleitung aufgeführten Anweisungen

genau einzuhalten. Verwendungszwecke

und Handlungen, von denen in der Betriebsanleitung abgeraten oder vor denen gewarnt wird, sind unbedingt zu vermeiden.

Das Gerät ist lediglich für den privaten

und nicht für den gewerblichen Gebrauch

bestimmt. Bei missbräuchlicher und unsachgemäßer Behandlung, Gewaltanwendung

und bei Eingriffen, die nicht von unserer

autorisierten Service-Niederlassung vorgenommen wurden, erlischt die Garantie.

Abwicklung im Garantiefall

Um eine schnelle Bearbeitung Ihres Anliegens zu gewährleisten, folgen Sie bitte den

folgenden Hinweisen:

• Bitte halten Sie für alle Anfragen den

Kassenbon und die Identikationsnummer (IAN109774) als Nachweis für

den Kauf bereit.

• Die Artikelnummer entnehmen Sie bitte

dem Typenschild.

• Sollten Funktionsfehler oder sonstige

Mängel auftreten, kontaktieren Sie

Page 31

31

DE AT CH

zunächst die nachfolgend benannte

Serviceabteilung telefonisch oder per

E-Mail. Sie erhalten dann weitere Informationen über die Abwicklung Ihrer

Reklamation.

• Ein als defekt erfasstes Gerät können

Sie, nach Rücksprache mit unserem

Kundenservice, unter Beifügung des

Kaufbelegs (Kassenbons) und der

Angabe, worin der Mangel besteht

und wann er aufgetreten ist, für Sie

portofrei an die Ihnen mitgeteilte

Service-Anschrift übersenden. Um Annahmeprobleme und Zusatzkosten zu

vermeiden, benutzen Sie unbedingt nur

die Adresse, die Ihnen mitgeteilt wird.

Stellen Sie sicher, dass der Versand

nicht unfrei, per Sperrgut, Express oder

sonstiger Sonderfracht erfolgt. Senden

Sie das Gerät bitte inkl. aller beim

Kauf mitgelieferten Zubehörteile ein

und sorgen Sie für eine ausreichend

sichere Transportverpackung.

Reparatur-Service

Sie können Reparaturen, die nicht der Garantie unterliegen, gegen Berechnung von

unserer Service-Niederlassung durchführen

lassen. Sie erstellt Ihnen gerne einen Kostenvoranschlag.

Wir können nur Geräte bearbeiten, die

ausreichend verpackt und frankiert eingesandt wurden.

Achtung: Bitte senden Sie Ihr Gerät gereinigt und mit Hinweis auf den Defekt an

unsere Service-Niederlassung.

Unfrei - per Sperrgut, Express oder mit

sonstiger Sonderfracht - eingeschickte Geräte werden nicht angenommen.

Die Entsorgung Ihrer defekten eingesendeten Geräte führen wir kostenlos durch.

Service-Center

Service Deutschland

Tel.: 0800 54 35 111

E-Mail: grizzly@lidl.de

IAN 109774

Service Österreich

Tel.: 0820 201 222

(0,15 EUR/Min.)

E-Mail: grizzly@lidl.at

IAN 109774

Service Schweiz

Tel.: 0842 665566

(0,08 CHF/Min.,

Mobilfunk max. 0,40 CHF/Min.)

E-Mail: grizzly@lidl.ch

IAN 109774

Importeur

Bitte beachten Sie, dass die folgende

Anschrift keine Serviceanschrift ist. Kontaktieren Sie zunächst das oben genannte

Service-Center.

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

D-63762 Großostheim

www.grizzly-service.eu

DE

AT

CH

Page 32

32

DE

AT

Original

EG Konformitäts-

erklärung

Translation of the

original EC declara-

tion of conformity

Hiermit bestätigen wir, dass das

Kettenschärfgerät

Baureihe FSG 85 B1

Seriennummer

201505000001-201505114606

We hereby conrm that the

FSG 85 B1 series

Chain sharpener

serial number

201505000001-201505114606

folgenden einschlägigen EU-Richtlinien in

ihrer jeweils gültigen Fassung entspricht:

conforms with the following applicable re-

levant version of the EU guidelines:

2006/42/EG • 2004/108/EG • 2011/65/EU* 2006/42/EC • 2004/108/EC • 2011/65/EU*

Um die Übereinstimmung zu gewährleisten, wurden folgende harmonisierte

Normen sowie nationale Normen und

Bestimmungen angewendet:

In order to guarantee consistency, the following harmonised standards as well as

national standards and stipulations have

been applied:

EN 61029-2-10/A11:2013 • EN 61029-1/A11:2010

EN 55014-1/A2:2011 • EN 55014-2/A2:2008

EN 61000-3-2/A2:2009 • EN 61000-3-3:2013 • EN 62471:2008

Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt

der Hersteller:

This declaration of conformity is issued

under the sole responsibility of the manufacturer:

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

D-63762 Großostheim, GERMANY

15.05.2015

* Der oben beschriebene Gegenstand der

Erklärung erfüllt die Vorschriften der Richtlinie

2011/65/EU des Europäischen Parlaments und

des Rates vom 8. Juni 2011 zur Beschränkung der

Verwendung bestimmter gefährlicher Stoffe in Elektro- und Elektronikgeräten.

* The object of the declaration described above sa-

tisestheprovisionsofDirective2011/65/EUofthe

European Parliament and the Council of 8 June 2011

on limiting the use of certain harmful substances in

electrical and electronic appliances.

Volker Lappas

(Dokumentationsbevollmächtigter,

Documentation Representative)

CH

GB

Page 33

33