GAS RANGES

PROFESSIONAL

RGV-488, RGV-485GD, RGV-66, RGV-05, RGV-04

INSTALLATION GUIDE

US CA

!

WARNING!

SAFETY AND WARNINGS

!

WARNING!

If the information in this guide is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

NEVER use this appliance as a space

heater to heat or warm the room. Doing

so may result in carbon monoxide

poisoning and overheating of the

appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone.

• Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

Never operate the top surface cooking

section of this appliance unattended.

• Failure to follow this warning statement

could result in fire, explosion or burn

hazard that could cause property damage,

personal injury or death.

• If a fire should occur, keep away from the

appliance and immediately call your fire

department.

an oil/grease fire with water

Do not attempt to extinguish

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

2

SAFETY AND WARNINGS

!

WARNING!

Electric Shock Hazard

Failure to follow this advice may result in

electrical shock or death.

• Before carrying out any work on the electrical

section of the appliance, it must be disconnected

from the mains electricitysupply.

• Connection to a good ground wiring system is

absolutely essential and mandatory.

• Alterations to the domestic wiring system must

only be made by a qualified electrician.

!

WARNING!

Tip Hazard

Failure to follow this advice may result in

death or seriousburns.

• To reduce the risk of tipping the appliance, the

appliance must be secured by properly installed

anti-tip device packed with the appliance.

!

WARNING!

Weight Hazard

Failure to follow this advice may result in

damage or personalinjury.

• Proper equipment and adequate manpower must

be used in moving the range to avoid personal

injury or damage to the unit or the floor. The unit

is heavy and rests on adjustable steellegs.

• Two persons are required to move the product

safely to the installation location.

• 30" product weight: 408lb (185kg)

• 36" product weight: 440lb (200kg)

• 48" product weight: 604-640lb (274-290kg)

!

WARNING!

Cut Hazard

Failure to use caution could result in injury.

• Take care: some edges are sharp.

• A child or adult can tip the range and be killed.

• Install the anti-tip device to the structure by

fastening the supplied bracket to the floor and

wall following the instructions for installing the

anti-tip device.

• Engage the anti-tip device.

• Re-engage the anti-tip device if the range

ismoved.

3

SAFETY AND WARNINGS

READ AND SAVE THIS GUIDE

WARNING!

To reduce the risk of fire, injury to persons or damage when using the appliance, follow the

important safety instructions listed below. Read all the guidance before using the appliance.

Servicing

z

Do not repair or replace any part of the appliance unless specifically recommended in

the user guide. All other servicing should be undertaken by a Fisher & Paykel trained and

supported service technician or qualified person.

z

Technicians must disconnect the power supply before servicing this appliance.

z

Please make this information available to the person installing the appliance.

z

This appliance must be installed and connected to the mains power supply only by a

suitably qualified person according to these installation instructions and in compliance

with any applicable local building and electricity regulations. Failuretoinstall the

appliance correctly could invalidate any warranty or liability claims.

Gas Requirements

z

Be sure that the unit being installed is set up for the kind of gas being used. The gasrange

is shipped from the factory set and adjusted for Natural Gas or LP (propane), depending

on the specific model ordered. Verify that the range is compatible with the gas at the

installation site before proceeding further.

z

Returnrange to dealer if the unit is not set for site gas supply.

General

z

The appliance must not be installed behind a decorative door in order to

avoid overheating.

z

The range must be grounded.

z

Installation must comply with your local building and electricity regulations.

z

Ensure the installer shows the customer where the gas supply shut-off valve is located.

z

A circuit breaker is recommended.

z

If the power supply cable is damaged, it must be replaced by the manufacturer, itsservice

agent or similarly qualified person in order to avoid a hazard.

z

Do not use adaptors, reducers or branching devices to connect the oven to

themainselectricity supply, as they can cause overheating and burning.

z

Improper installation, adjustment alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance instructions

thoroughly before using, installing or servicing this appliance.

z

A risk of the appliance tipping over exists if the appliance is not installed in accordance

with installation instructions.

z

DO NOT obstruct the flow of combustion or ventilation air to the appliance.

Besureafresh air supply is available.

z

Check local building codes for the proper method of range installation. Localcodesvary.

Installation, electrical connections, and grounding must comply with all applicable codes.

In the absence of local codes, the range should be installed in accordance with the latest

edition of National Fuel Gas Code ANSI Z223.1 and National Electrical Code ANSI / NFPA 70.

z

In Canada: Installation must be in accordance with the current CAN/CGA B149.1&2 Gas

Installation codes and/or local codes. Electrical installation must be in accordance with the

current CSA C22.1 Canadian Electrical Codes Part 1 and/or local codes.

z

Do not lift the range by the door handle. Doing so may damage the product.

z

Before use, ensure all doors are correctly installed.

z

Always keep the appliance area clear and free from combustible materials, gasoline and

other flammable vapors and liquids.

4

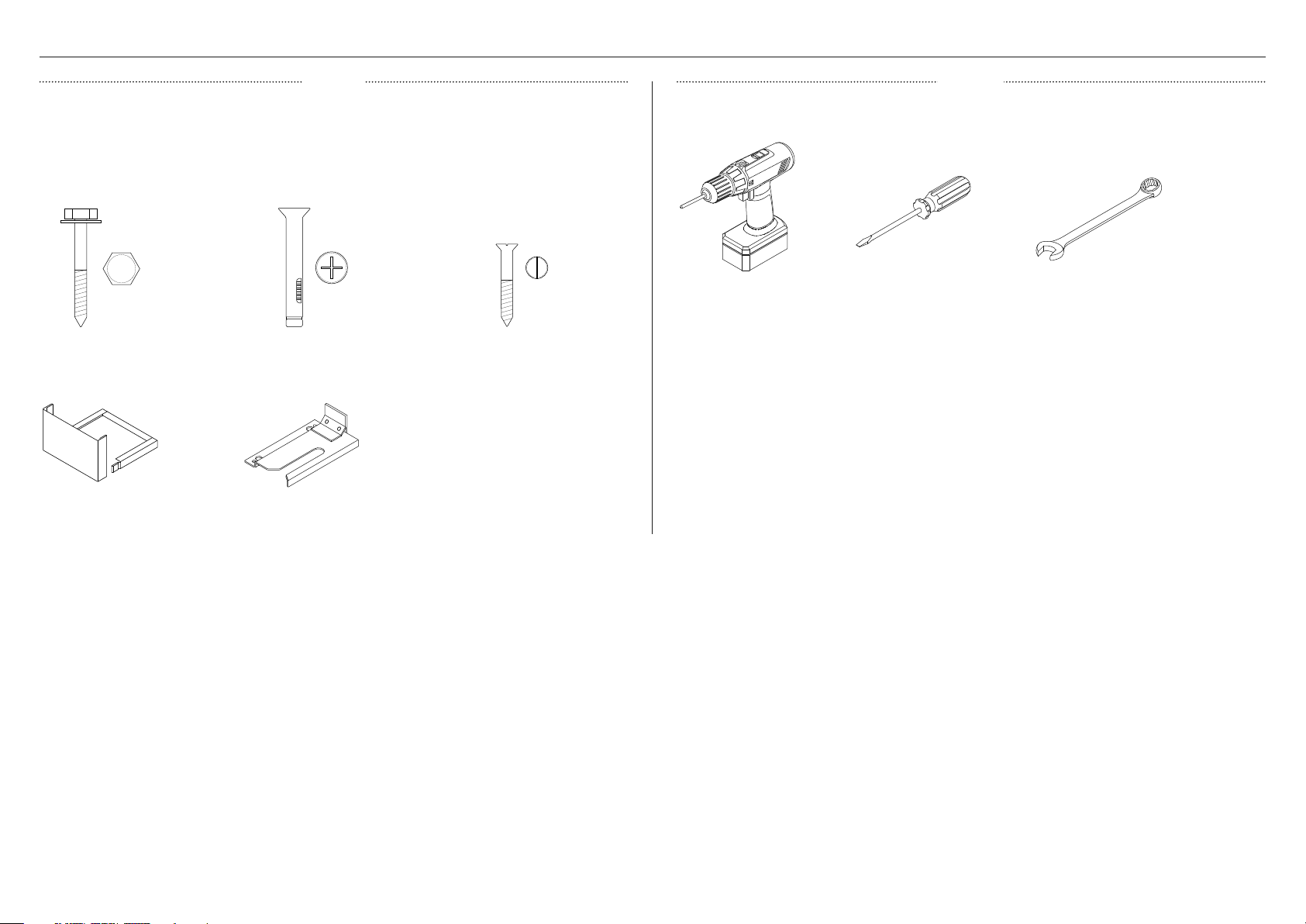

COMPONENTS REQUIRED

PARTS TOOLS

z

Keep all packing materials until the unit has been inspected.

z

Inspect the product to ensure there is no shipping damage. If any damage is detected

contact the dealer or retailer you bought the product from to report the damage.

z

Fisher & Paykel is not responsible for shipping damage.

Supplied

Not supplied

Lag bolts and washers (2)

Foot cover sets (2)

5/16" x 1 1/2" sleeve anchors (2)

Anti-tip bracket (2)

#10 x 2" wood screws (4)

Powered driver

Flat-head screw driver

15/16" spanner (2)

5

B

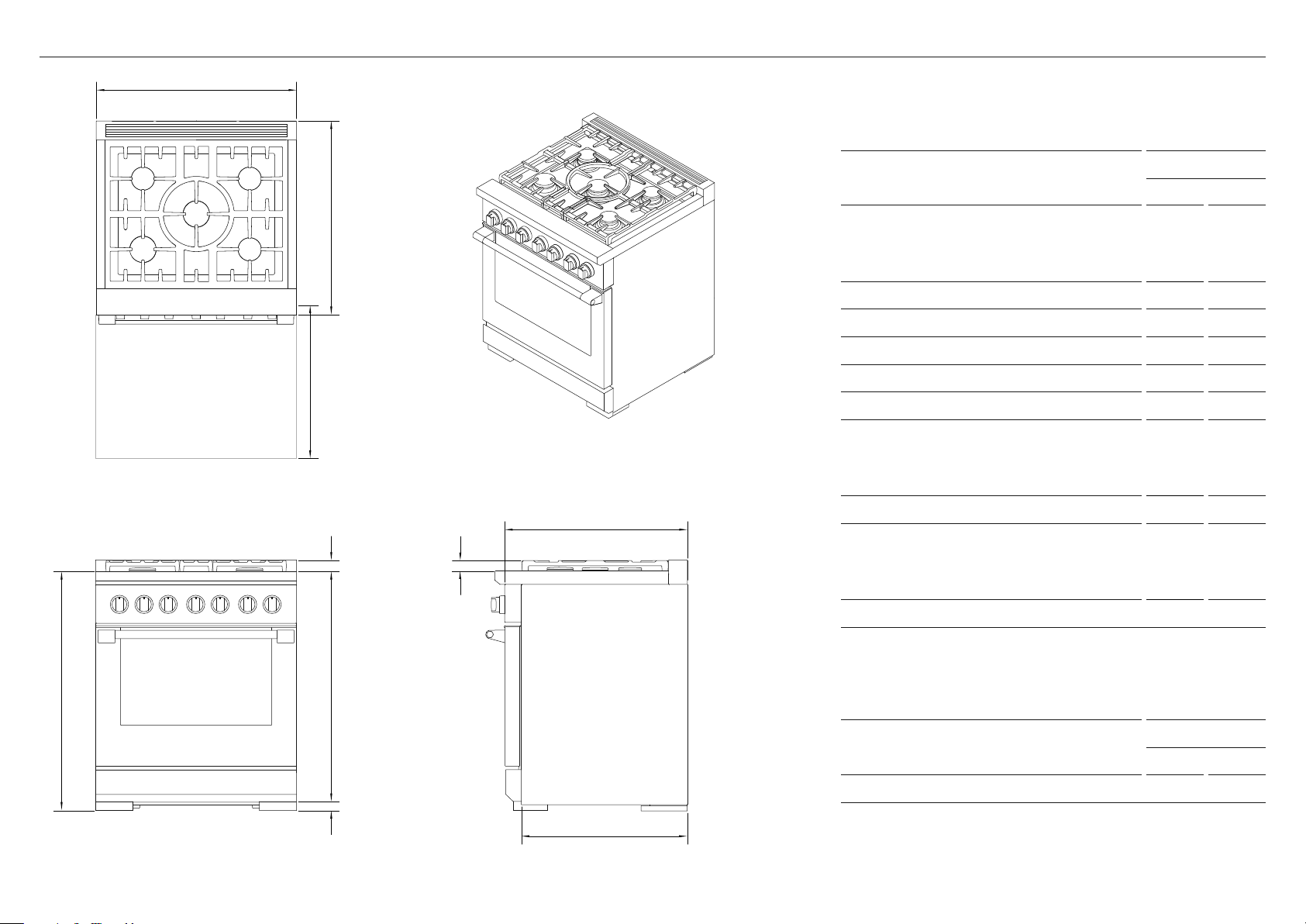

PRODUCT DIMENSIONS — 30" MODELS

A

PLAN

c

J

G F

h

ISOMETRIC

E

PRODUCT DIMENSIONS

30" MODELS

IN MM

A Overall height*

z

Min. (legs fully retracted) 35 3/4 908

z

Max. (legs fully extended) 36 3/4 933

B Overall width 29 7/8 759

C Overall depth 29 1/8 740

D Depth of chassis 25 3/8 644

E Depth from rear to control panel front 27 11/16 703

F Height from cook surface to top of burners 1 9/16 40

G Height from cook surface to top of trim

z

Vent Trim 1 3/4 45

z

Angled Vent Trim*** 3 1/2 90

H Height from cook surface to chassis base 35 1/4 895

I Height of adjustable feet

z

Min. (legs fully retracted) 1/2 13

z

Max. (legs fully extended) 1 1/2 38

J Depth of open door to front control panel 19 1/8 486

*excluding burners and trim

**excluding handle and dials

***purchased separately

PRODUCT WEIGHT

30" MODELS

LB KG

Overall weight (excluding packaging) 408 185

i

D

FRONT PROFILE

6

RGV3 305 model illustrated

Dimensions may vary by ± 2 mm

B

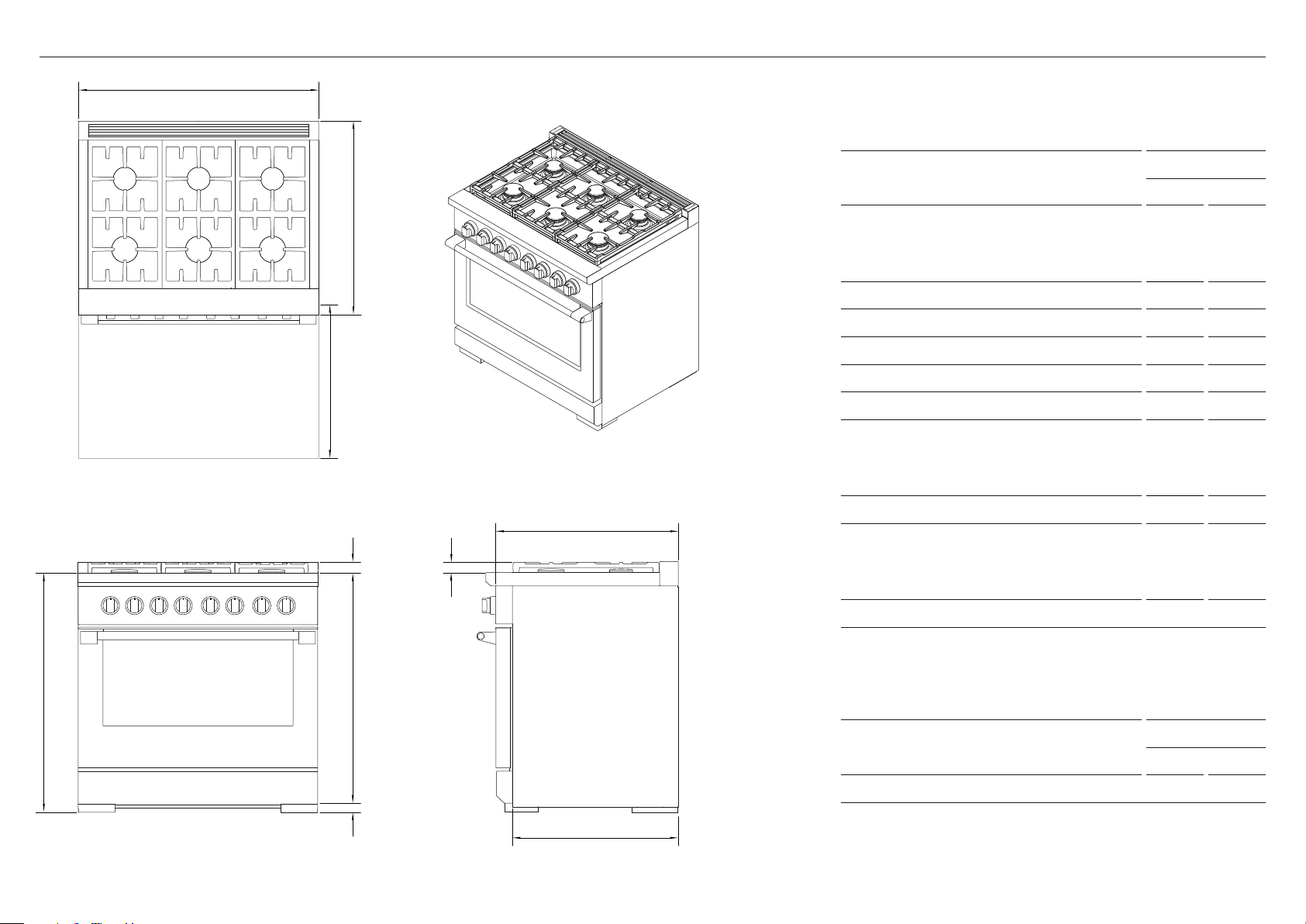

PRODUCT DIMENSIONS — 36" MODELS

A

PLAN

J

c

G

h

F

ISOMETRIC

E

PRODUCT DIMENSIONS

36" MODELS

IN MM

A Overall height*

z

Min. (legs fully retracted) 35 3/4 908

z

Max. (legs fully extended) 36 3/4 933

B Overall width 3 5 7/ 8 911

C Overall depth 29 1/8 740

D Depth of chassis 25 3/8 644

E Depth from rear to control panel front 27 11/16 703

F Height from cook surface to top of burners 1 9/16 40

G Height from cook surface to top of trim

z

Vent Trim 1 3/4 45

z

Angled Vent Trim*** 3 1/2 90

H Height from cook surface to chassis base 35 1/4 895

I Height of adjustable feet

z

Min. (legs fully retracted) 1/2 13

z

Max. (legs fully extended) 1 1/2 38

J Depth of open door to front control panel 19 1/8 486

*excluding burners and trim

**excluding handle and dials

***purchased separately

i

D

FRONT PROFILE

PRODUCT WEIGHT

36" MODELS

LB KG

Overall weight (excluding packaging) 440 200

RGV3 366 model illustrated

Dimensions may vary by ± 2 mm

7

B

PRODUCT DIMENSIONS — 48" MODELS

A

PLAN

J

c

G

h

F

ISOMETRIC

E

PRODUCT DIMENSIONS

48" MODELS

IN MM

A Overall height*

z

Min. (legs fully retracted) 35 3/4 908

z

Max. (legs fully extended) 36 3/4 933

B Overall width 47 7/ 8 1216

C Overall depth 29 1/8 740

D Depth of chassis 25 3/8 644

E Depth from rear to control panel front 27 11/16 703

F Height from cook surface to top of burners 1 9/16 40

G Height from cook surface to top of trim

z

Vent Trim 1 3/4 45

z

Angled Vent Trim*** 3 1/2 90

H Height from cook surface to chassis base 35 1/4 895

I Height of adjustable feet

z

Min. (legs fully retracted) 1/2 13

z

Max. (legs fully extended) 1 1/2 38

J Depth of open door to front control panel 19 1/8 486

*excluding burners and trim

**excluding handle and dials

***purchased separately

PRODUCT WEIGHT

48" MODELS

LB KG

Overall weight (excluding packaging)

604 –

640

274 –

290

i

D

FRONT PROFILE

8

RGV3 488 model illustrated

Dimensions may vary by ± 2 mm

CABINETRY DIMENSIONS

30" CABINETRY 36" CABINETRY

D

E

B

A

C

D

E

B

A

C

CABINETRY DIMENSIONS

30" MODELS

INCHES MM

A Max. height

z

Flush with counter 35 3/4 908

z

With levelling legs fully extended 36 3/4 933

B Depth

z

Flush with counter 27 11/16 703

z

Projecting control panel 25 1/8 638

C Width 30 762

D Max. depth of overhead cabinetry 13 330

E Min. width of ventilation hood required 30 762

CABINETRY DIMENSIONS

36" MODELS

INCHES MM

A Max. height

z

Flush with counter 35 3/4 908

z

With levelling legs fully extended 36 3/4 933

B Depth

z

Flush with counter 27 11/16 703

z

Projecting control panel 25 1/8 638

C Width 36 914

D Max. depth of overhead cabinetry 13 330

E Min. width of ventilation hood required 36 914

9

CABINETRY DIMENSIONS

48" CABINETRY CLEARANCES

D

E

The below clearances apply to both wall and island installations for all models.

Ensure the cook surface sits flush or above the adjacent countertop and any openings behind

or under the range are sealed. Flow of combustion and ventilation air must not be obstructed.

B

A

C

48" MODELS

CABINETRY DIMENSIONS

INCHES MM

A Max. height

z

Flush with counter 35 3/4 908

z

With levelling legs fully extended 36 3/4 933

B Depth

z

Flush with counter 27 11/16 703

z

Projecting control panel 25 1/8 638

C Width 48 1219

B

C

A A

C

ALL MODELS

CLEARANCE DIMENSIONS

INCHES MM

A Min. distance from side of range to nearest:

z

vertical combustible surface 12 305

B Min. distance from cook surface to overhead:

z

combustible surface 54 1372

z

combustible covering for ventilation hood 36 914

z

non-combustible surface 30 762

C Min. distance between countertop and cabinet 18 457

D Max. depth of overhead cabinetry 13 330

E Min. width of ventilation hood required 48 1219

10

Non-combustible surfaces: as defined in ‘National Fuel Gas Code’ (ANSI Z223.1, Current Edition). Clearances from noncombustible materials are not part of the ANSI Z21.1 scope and are not certified by UL. Clearances of less than 6" (152mm) must

be approved by the local codes and/or by the local authority having jurisdiction.

VENTILATION REQUIREMENTS

z

Ventilation hoods and blowers are designed for use with single wall ducting, however some local building codes or inspectors may require double wall ducting and/or a damper. Consultlocal

building codes and/or agencies before installing to ensure local requirements are met.

z

Hood blower speeds should be variable to reduce noise and loss of household air. The maximum speed should only be required when using the grill or SELF CLEAN.

z

Due to a high volume of ventilation air, a source of make-up air (outside replacement air) is recommended. This is particularly important for tightly sealed and insulated homes. A reputable

heating and ventilating contractor should be consulted.

WALL INSTALLATION ISLAND INSTALLATION

Non-combustible Non-combustibleCombustible Combustible

B b

B B

A A

A A

VENTILATION UNIT WALL INSTALLATION RECOMMENDATIONS

A min. 30" (762mm) max. 42 (762mm)

Hood

B min. 19" (480mm) max. 42 (762mm)

30" Range min. 550 CFM

VENTILATION UNIT ISLAND INSTALLATION RECOMMENDATIONS

A min. 30" (762mm) max. 42 (762mm)

Hood

B min. 19" (480mm) max. 42 (762mm)

30" Range min. 550 CFM

Blower

36" Range min. 550 CFM

48" Range min. 1100 CFM

Blower

36" Range min. 550 CFM

48" Range min. 1100 CFM

11

Non-combustible

BACKGUARD CONSIDERATIONS

BACKGUARD OPTIONSWALL SURFACE

max. 30"

(762mm)

NO BACKGUARD CUSTOM BACKGUARD

min. 6"

(152mm)

made from non-combustible materials

max. 1/2"

(13mm)

LOW THIN BACKGUARD HIGH THIN BACKGUARD

Combustible

RANGE

RANGE MOUNT

LOW BACKGUARD

NO BACKGUARD HIGH THICK BACKGUARD

WALL MOUNT

HIGH BACKGUARD, LOW SHELF

with angled trim

WALL MOUNT

HIGH BACKGUARD, HIGH SHELF

BACKGUARD WIDTH

INCHES MM

30" models BGRV2-1230 BGRV2-3030 BGRV3-3030H 29 7/8 759

36" models BGRV2-1236 BGRV2-3036 BGRV3-3036H 3 5 7/8 911

48" models BGRV2-1248 BGRV2-3048 BGRV3-3048H 4 7 7/ 8 1216

z

Installations against non-combustible surfaces: you may install the range without a backguard or choose any of the three backguards.

z

Installations close to combustible surfaces (above the cooking surface): without a backguard, there must be a min. 6" (152mm) clearance.

z

Installations immediately against combustible surfaces (above the cooking surface): you must purchase and fit the Wall Mount High

Backguard High Shelf and Angled Vent Trim.

z

Non-combustible surfaces: as defined in ‘National Fuel Gas Code’ (ANSI Z223.1, Current Edition). Clearances from non-combustible

materials are not part of the ANSI Z21.1 scope and are not certified by UL. Clearancesofless than 6" (152mm) must be approved by the

Note: Backguards can be purchased separately. All

ranges come fitted with an Integral Vent Trim only.

For more information on Backguard installation, refer to

the separate instructions provided with your backguard.

Backguard Installation Instructions can also be

downloaded from our website, www.fisherpaykel.com

local codes and/or by the local authority having jurisdiction.

12

ELECTRICAL REQUIREMENTS

The electrical supply must be a correctly polarized 120 VAC, 60 Hz, single phase circuit

suitable for the maximum current draw of the model, as detailed in the table below. Verify your

model’s current draw by checking the rating label on the back of the range.

This appliance is factory equipped with a power supply cord with a three-prong grounding

plug (with polarized parallel blades). It must be plugged into a mating grounding-type

receptacle, connected to a correctly polarized 120 VAC.

If the circuit does not have a grounding type receptacle, it is the responsibility and obligation

of the installer to have the existing receptacle changed to a properly grounded and polarized

receptacle in accordance with all applicable local codes and ordinances by a qualified

electrician. In the absence of local codes and ordinances, the receptacle replacement shall be

in accordance with the National Electrical Code.

The third prong should not, under ANY circumstances, be cut or removed.

MODEL MAX. CURRENT DRAW CIRCUIT FREQUENCY

RGV3-488 9 A 15 A 60 HZ

RGV3-485GD 15 A 15 A 60 HZ

RGV3-366 5 A 15 A 60 HZ

RGV3-304 5 A 15 A 60 HZ

RGV3-305 5 A 15 A 60 HZ

A wiring

diagram label

and the rating

label are

attached to

the back of

therange

z

This range must be connected to the mains power supply by a suitably qualified person.

z

This range must be grounded.

z

Always disconnect electric supply cord from the wall outlet or service disconnect before

servicing this appliance.

z

Observe all governing codes and ordinances when grounding, in absence of which, observe

National Electrical Code ANSI/NFPA No. 70.

13

GAS REQUIREMENTS

LP Gas

Connection: 1/2" NPT Minimum 5/8" dia. flex line. SupplyPressure: 11" to 14" W.C.

A regulator is required at the LP source to provide a maximum pressure of 14" W.C.

totherange regulator.

Natural Gas

Connection: 1/2" NPT Minimum 5/8" dia. flex line. SupplyPressure: 6" to 9" W.C.

z

The gas supply line must not protrude beyond the back of the appliance.

z

Ensure the gas supply is turned off at the wall valve before connecting the appliance.

z

Leak-testing of the appliance shall be conducted according to the manufacturer’s

instructions. See guidance on page 17.

z

The appliance must be isolated from the building’s gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig (3.5kPa.). The appliance and its individual

shut-off valve must be disconnected from the gas supply piping system during any pressure

testing of the system at the test pressures in excess of 1/2 psig (3.5kPa.). When checking

the manifold gas pressure, the inlet pressure to the regulator should be at least 7.0" W.C.

fornatural gas or 12.0" W.C. for LP.

z

The flex line for the gas supply must be metal and be approved for appliance use by a

certifying agency (CSA, CGA, or UL). Never use a hose made of rubber or other synthetic

material, as the heat may cause the hose to melt and develop leaks.

z

When hooking up the gas supply from the wall hard pipe to the range hard pipe, installation

length of flex line between range/wall hard piping must accommodate range being pulled

from wall for cleaning or servicing purposes. When range is pulled from wall, no strain

should occur at range or wall hard pipe connections.

The gas supply connections should be made by a qualified technician in accordance with local

codes or ordinances. In the absence of a local code, the installation must conform to the latest

edition of National Fuel Gas Code ANSI Z.223.1 (Warning: this appliance must be installed by a

licensed plumber or gas fitter when within the Commonwealth ofMassachusetts).

A manual shut-off valve (supplied by the installer) must be installed in an accessible location in

the gas line external to the appliance for the purpose of turning on or shutting off gas to the

appliance. (InMassachusetts such shut-off valves should be approved by the Board of State

Examiners of Plumbers & Gas Fitters.) Theshut-off valve must be located within 6 feet (1.8

meters) of the appliance it serves.

Fisher&Paykel recommends installing the manual shut-off valve in a location readily

accessible by the customer, so that gas to the appliance can be shut off in an emergency

situation. However, the appliance must not be modified to accommodate such placement.

Installer supplied manual

shut-off valve ‘open’ position

To range

To gas supply

Verify the type of gas supplied to the location. The range is shipped from the factory set up

andadjusted for Natural Gas or LP, depending on the specific model ordered.

Verify that the range is compatible with gas supply at the installation site before proceeding

further. Return the range to the dealer if the unit is not set for the gas supplied at the site.

14

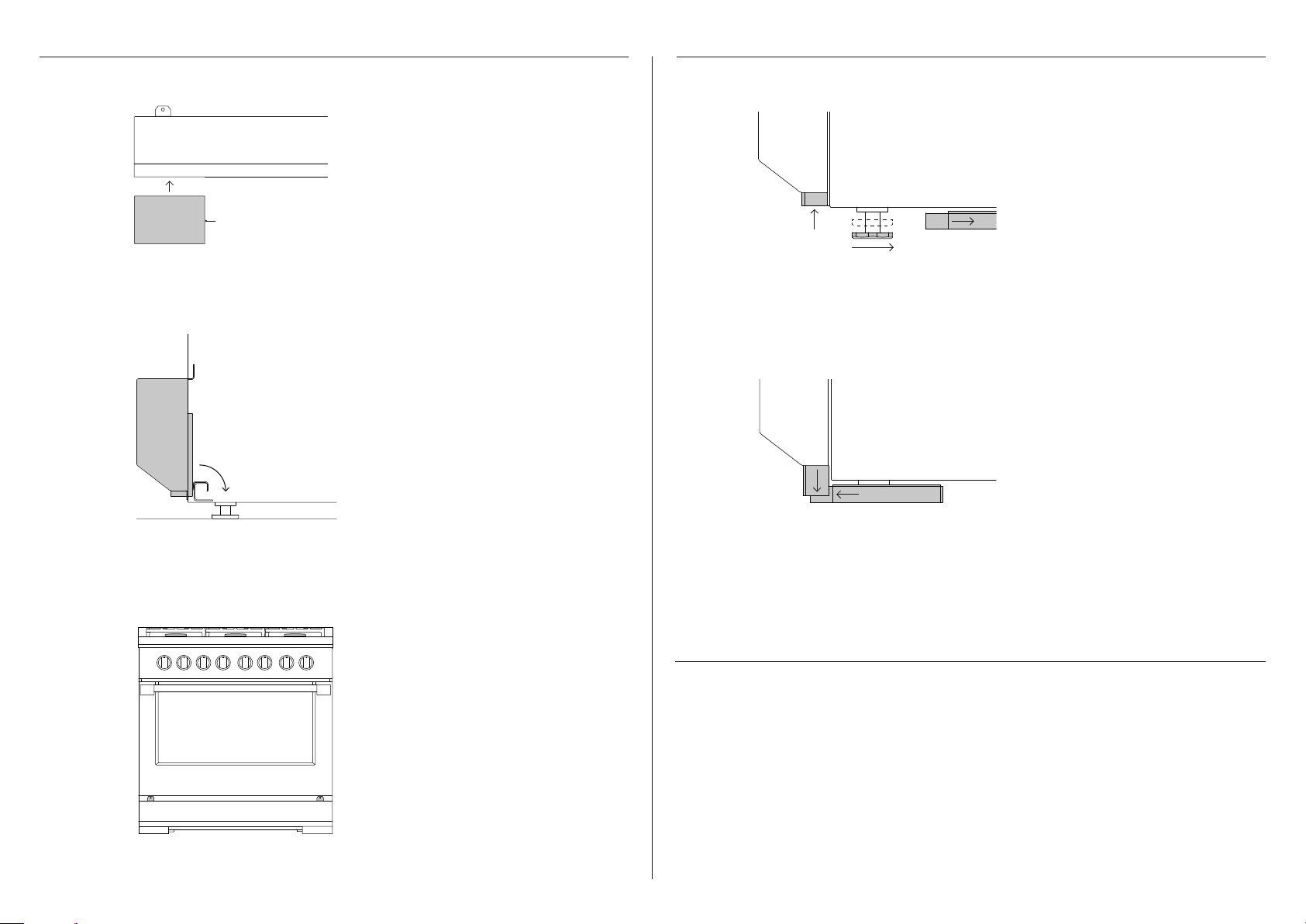

UNPACKING THE RANGE

1. REMOVE TOE KICK

1

FRONT VIEW HINGE DETAIL

2 2

PROFILE VIEW PROFILE VIEW

Remove both screws to detach

the toe kick from the range.

Lift toe kick up and rotate

towards you to remove.

1

3. REMOVE FROM PALLET

2. REMOVE DOORS

Open the door completely and

open the hinge locks fully on

both sides.

Holding the door on both sides,

lift door back up to 45° and

carefully pull the door out and

away from the hinges.

1

2

3

* removal not required if range is secured at rear by brackets.

** model dependant.

Remove front bolts

Remove the two shipping

bolts made visible by

removing the toe kick.

Remove lower guard*

Unscrew the lower guard

panel from the back of

the range to remove.

Remove rear bolts or brackets**

Remove the two shipping bolts

or brackets.

packing sheet

IMPORTANT!

Two people required.

packing sheet

restraining

strap

Before restraining the product to the

hand truck, place two cardboard packing

sheets (shipped with the product)

against both side panels as shown.

Tilt the product and insert hand truck.

DO NOT insert the hand truck to the

front of the product.

Restrain the product and packing sheets

to the hand truck using straps and tilt

onto hand truck. Set pallet aside and pull

product to the installation location.

15

TOE KICK INSTALLATION LEVELLING THE RANGE

Insert both foot covers into

1 1

Long hem edge

FRONT VIEW

2 2

CROSS SECTION PROFILE VIEW PROFILE VIEW

the toe kick ensuring the long

hem edge is facing the inside of

the product.

Align the toe kick with side

panels of the range.

Clip into place by rotating and

pushing the bracket down over

the range structure.

To expose both front feet,

slide the interlocking foot

covers out of the way.

Turn feet to adjust the height.

PROFILE VIEW

Replace both sets of covers,

ensuring each set locks together.

PRIOR TO FINAL POSITIONING

z

Ensure the doors and toe kick panel are securely in place, if removed previously.

z

3

16

Check toe kick is flush with the

range and secure using 2 screws.

Ensure any backguard is fitted prior to final positioning. Refer to page 12 for all

backguard options.

z

Ensure all electrical and gas connections have been done as per instructions.

z

Ensure flooring and adjacent cabinetry are also level. To achieve a flush fit of the range to

adjoining countertops, it will be necessary to have level cabinets (front to back, and left to

right across opening of the range).

COOKTOP BURNERS LEAK TESTING

lifting off stable blue flameyellow tip

z

To check that the ignition system operates correctly, light each burner by itself, then all

burners in combination.

z

Check for a well-defined blue flame without any yellow tipping.

z

If any abnormality is evident, check that the burner assembly is located correctly.

z

When installing the burner port ring, align the two locating pins in the bottom side of the

port ring with the locating notch and center holes on the top side of the simmer ring, and

make sure these are properly engaged.

z

Incorrect installation may produce a dangerous flame and result in poor performance.

z

No air shutter adjustment is possible on the cooktop burners. Proper operation is achieved

with factory installed settings for the correct gas type.

z

If proper operation cannot be obtained, contact Customer Care or your nearest

Fisher&Paykel Authorized Service Center.

z

The range must not be used by the customer until proper operation has been achieved.

GAS

ON

z

Ensure all oven and burner knobs are set to OFF before connecting range to gas supply.

z

After final gas connection is made, turn gas supply on and test all connections in gas

supply piping for gas leaks with a soapy water solution.

z

In order to avoid property damage or serious personal injury, never use a Iit match or an

open flame to check for leaks.

If a leak is present: tighten joint or unscrew, apply more joint compound, tighten again and

retest connection for leak.

17

INFRARED BROIL AND OVEN BAKE BURNERS GRILL AND GRIDDLE BURNERS (SOME MODELS ONLY)

Air shutter

Blue flame

z

The oven infrared broiler burner has no air shutter and is not adjustable.

z

It is necessary to operate the oven broiler for 20-30 minutes to eliminate the harsh odor of

the insulation binder. This must be done before using the range for the first time and with

proper ventilation.

z

After approximately 5-8 minutes of operation the burner screen should be glowing red.

z

The oven bake burner has an air shutter and is adjustable.

z

Check for the proper burner flame characteristics and adjust air shutters if necessary.

Burner flames should be blue and stable with no yellow tips, excessive noise or lifting of the

flame from the burner. If any of these conditions exist, check that the air shutter or burner

ports are not blocked.

z

If the condition persists, adjust the air shutter as below:

z

If the flame is too yellow, indicating insufficient air open the shutter to increase air inlet.

z

If the flame is noisy or tends to lift away from the burner, indicating too much air, close the

shutter to reduce air inlet.

z

For warranty coverage, Fisher & Paykel requires that all burner adjustments be made by a

qualified technician at the time of installation. Improper adjustment will void your warranty.

z

Each valve and air shutter is individually tested and adjusted prior to shipment. Normally

adjustment is not required, however, vibration during transit, gas conversion or variations in

the local gas supply may make minor adjustments necessary.

z

Check for the proper burner flame characteristics and adjust air shutters if necessary.

Burner flames should be blue and stable with no yellow tips, excessive noise or lifting of the

flame from the burner. If any of these conditions exist, check that the air shutter or burner

ports are not blocked.

z

If the condition persists, adjust the air shutter as below:

z

If the flame is too yellow, indicating insufficient air open the shutter to increase air inlet.

z

If the flame is noisy or tends to lift away from the burner, indicating too much air, close the

shutter to reduce air inlet.

18

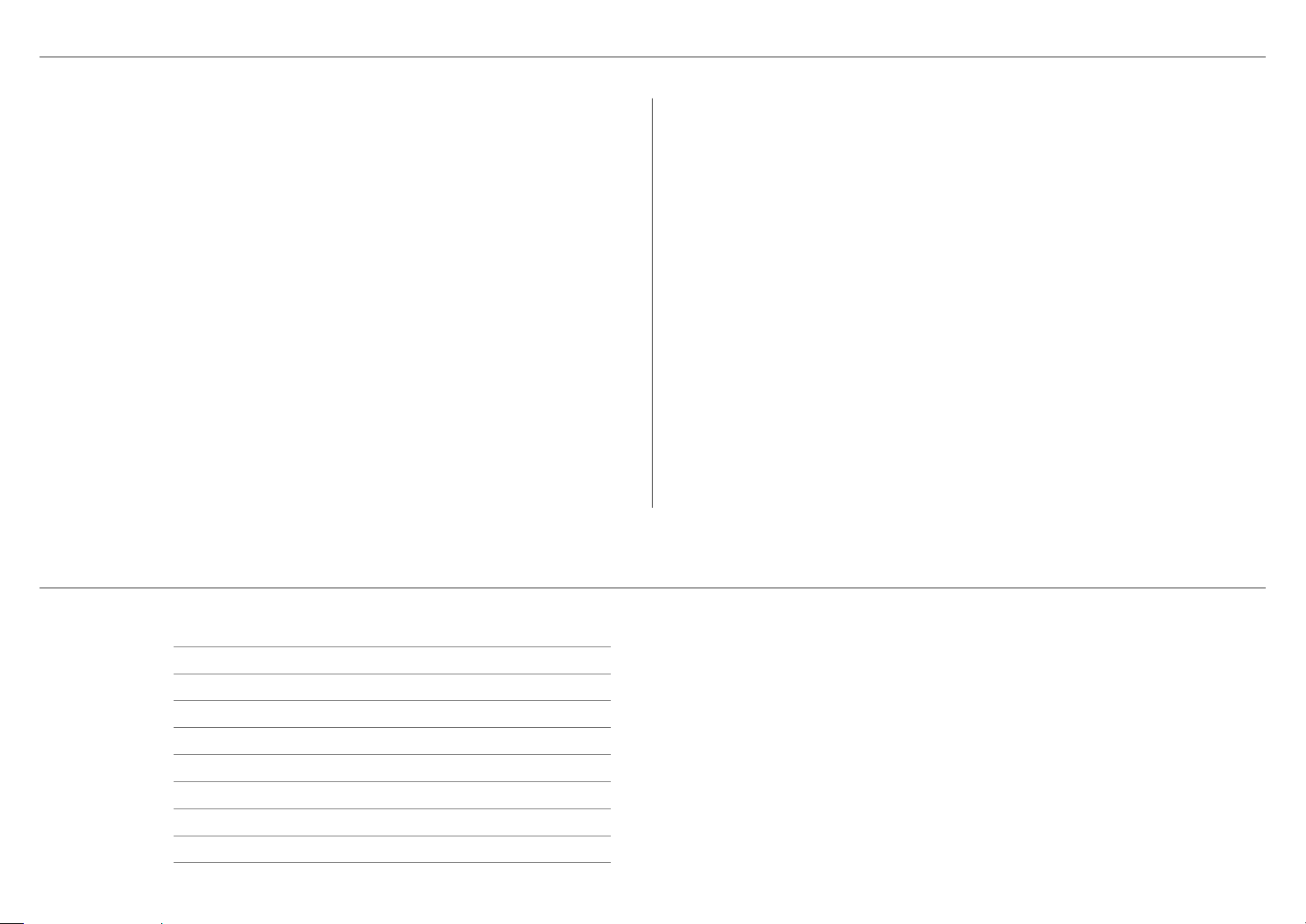

INSTALLING THE ANTI-TIP BRACKET

!

WARNING!

To reduce the risk of tipping the appliance, it must

be secured by properly installed anti-tip device

packed with theappliance.

• A child or adult can tip the range and be killed.

• Install the anti-tip device to the structure by fastening

the supplied bracket to the floor and wall following

the instructions for installing the anti-tip device.

• Engage the anti-tip device.

• Re-engage the anti-tip device if the range is moved.

All ranges must have an anti-tip device correctly installed as per the following instructions. If you pull

the range out from the wall for any reason, make sure that the device is properly engaged when you

push the range back against the wall. If it is not, there is a risk of the range tipping over and causing

injury if you or a child stand, sit or lean on an open oven door.

Instructions are provided for wood and concrete floors. Any other type of construction may require

special installation techniques as deemed necessary to provide adequate fastening of the anti-tip

bracket to the floor and wall. Theuse of this bracket does not preclude tipping of the range when not

properly installed.

Wood substrate

1 Place the bracket against the back wall,

into the right rear corner where

the range is to be located. Leave a 1/2"

(13mm) gap between the wall (or side of

range) and the bracket, as shown.

2 Drill 1/8" diameter pilot holes in the center

of the two small holes. A nail or awl may

be used if a drill is not available.

3 Fasten the bracket securely to the floor

and wall.

Once installed

Check for proper installation of the range and anti-tip bracket by grasping the back of the range

and carefully attempting to tilt it forward.

Concrete or cement substrate

1 Locate the bracket as shown.

2 Using the bracket as a template, drill (x2)

5/16" diameter pilot holes in the center

of the larger holes to a depth of at least

1 3/4".

3 Place the sleeve anchors into the holes

and use a hammer to tap them all the

way in.

4 Tighten the nuts on the sleeve anchors to

fasten the bracket securely to the floor.

Locating the bracket Securing the range

Wood

Concrete

1/2" (13mm)

Right rear foot

slides under bracket

19

TO BE COMPLETED BY THE INSTALLER

GENERAL

Specified clearance maintained.

FINAL CHECKLIST

GAS

Site gas supply iscompatible with range.

Backguard installed if clearance to combustibles behind unit is less than 6" (152mm).

Anti-tip bracket is correctly installed.

Unit is level–front to back and side to side.

Griddle (if equipped) and burner pan supports are level and does not rock.

All packaging materials have been removed. Check below grate and inside the oven.

Oven door hinges seated and door opens and closes properly.

Dials turn correctly and freely.

Burners light satisfactorily, both individually and with other burners operating.

Flame adjustments made if required.

Front toe kick panel in place and two screws are secure.

Complete and keep for safe reference:

LP Connection: 1/2" NPT Minimum 5/8" dia. flex line. SupplyPressure: 11" to 14" W.C.

NG Connection: 1/2" NPT Minimum 5/8" dia. flex line. SupplyPressure: 6" to 9" W.C.

Manual gas shut-off valve installed in an accessible location.

Unit tested and free of gas leaks.

ELECTRICAL

Receptacle with correctly rated and over-current protection is provided for service

cordconnection.

Adequate ground connection.

Model

Serial no.

Purchase date

Purchaser

Dealer address

Installer’s name

Installer’s signature

Installation company

Installation date

20

FISHERPAYKEL.COM

© Fisher & Paykel Appliances 2020. All rights reserved.

The models shown in this guide may not be available in all markets

The product specifications in this guide apply to the specific products and

models described at the date of issue. Under our policy of continuous product

improvement, these specifications may change at any time.

For current details about model and specification availability in your country,

please go to our website or contact your local Fisher&Paykel dealer.

and are subject to change at any time.

59218A 05.20

Loading...

Loading...