Fisher & Paykel OR90SDBGFPX1 Product Manual

Freestanding cooker

OR90SDBGFPX models

Installation instructions

and User guide

NZ AU

Contents

1

Safety and warnings

Installation instructions

First use

Setting the clock

Using your oven

Cooking functions

Cooking guide

Using the rotisserie

Using the electronic timer

Automatic cooking

Using your gas cooktop

Care and cleaning

Using the Self Clean function

Troubleshooting

Warranty and service

2

8

21

22

23

26

28

30

32

33

34

38

54

57

59

Important!

SAVE THESE INSTRUCTIONS

The models shown in this User Guide may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please go to our website www.fisherpaykel.com or

contact your local Fisher & Paykel dealer.

2

Safety and warnings

Installation

WARNING!

Electrical Shock Hazard

Always disconnect the cooker from the mains electricity supply before

carrying out any maintenance operations or repairs.

Failure to follow this advice may result in death or electrical shock.

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

Important safety instructions

General

To avoid hazard, follow these instructions carefully before installing or using this product.

Please make this information available to the person installing the product as it could reduce

your installation costs.

These products are registered:

in New Zealand at www.energysafety.govt.nz

in Australia with AGA at www.aga.asn.au

This appliance must be installed in accordance with these installation instructions, local

gas fitting regulations, municipal building codes, water supply regulations, electrical wiring

regulations, AS/NZS5601.1:2010 - Gas Installations and any other relevant statutory regulations.

Failure to install the cooker correctly could invalidate any warranty or liability claims.

Some appliances have a protective film. Remove this film before using the cooker.

Do not modify this appliance.

Do not operate your appliance by means of an external timer or separate remote-control system.

This appliance is to be installed and serviced only by an authorised person.

Safety and warnings

Electrical

This cooker is to be installed and connected to the electricity supply only by an authorised person.

If the installation requires alterations to the domestic electrical system, call a qualified

electrician. The electrician should also check that the electrical system is suitable for the

electricity drawn by the cooker.

The appliance must be connected to the mains electricity supply, checking that the voltage

corresponds to the value given in the rating plate and that the electrical cable sections can

withstand the load specified on the plate.

A suitable disconnection switch must be incorporated in the permanent wiring, mounted and

positioned to comply with the local wiring rules and regulations. The switch must be of an

approved type installed in the fixed wiring and provide a 3 mm air gap contact separation in all

poles in accordance with the local wiring rules.

In Australia and New Zealand, a switch of the approved type with a 3 mm air gap must be

installed in the active (phase) conductor of the fixed wiring.

The switch must always be accessible.

The power supply cable must not touch any hot parts and must be positioned so that it does not

exceed 75

To connect the cooker to the mains electricity supply, do not use adapters, reducers or branching

devices as they can cause overheating and burning.

This cooker must be connected to a suitable double pole control unit adjacent to the cooker. No

diversity can be applied to this control unit.

If the electrical supply cord is damaged, it must only be replaced by an authorised person.

This cooker must be connected to electrical supply using V105 insulated cable.

The cooker must be earthed.

O

C at any point.

3

Power supply

220-240V~ 3450W 50Hz - 15A (230V)

4

Safety and warnings

Operation

Your freestanding cooker has been carefully designed to operate safely during normal cooking

procedures. Please keep the following guidelines in mind when you are using it:

WARNING!

Explosion Hazard

Do not store flammable materials such as gasoline near the cooktop.

Do not store flammable material in the oven or storage compartment.

Do not spray aerosols near the cooktop during use.

Failure to follow this advice may result in death or serious injury.

Electrical Shock Hazard

Switch the cooker off at the wall before replacing fuses or the oven lamp.

Failure to do so may result in death or electrical shock.

WARNING!

WARNING!

Hot Surface Hazard

Accessible parts may become hot when this cooker is in use.

To avoid burns and scalds keep children away.

Do not touch hot surfaces inside the oven.

Use oven mitts or other protection when handling hot surfaces such as oven

shelves or dishes.

Take care when opening the oven door.

Let hot air or steam escape before removing or replacing food.

Do not touch the cooktop components, burners, pan supports or the base

when hot.

Before cleaning, turn the cooker off and make sure it is cool.

Follow the instructions on starting a Self Clean cycle . Items made from

combustible material (for example wood, fabric, plastic) may catch fire if left

in the oven during a Self Clean cycle.

Failure to follow this advice could result in burns and scalds.

Safety and warnings

Important safety instructions

Never leave the appliance unattended when in use. Boilover causes smoking and greasy

spillovers that may ignite.

Isolating switch: make sure this cooker is connected to a circuit which incorporates an isolating

switch providing full disconnection from the power supply.

Household appliances are not intended to be played with by children.

Children of less than 8 years old must be kept away from the appliance unless continuously

supervised. This appliance can be used by children aged from 8 years and above, and persons

with reduced physical, sensory or mental capabilities or lack of experience and knowledge, if

they have been given supervision or instruction concerning the use of the appliance in a safe way

and they understand the hazards involved. Cleaning and user maintenance shall not be done by

children without supervision.

Do not store things children might want above the oven. Children could be burned or injured

while climbing on the oven to retrieve items.

Safe food handling: leave food in the oven for as short a time as possible before and after

cooking. This is to avoid contamination by organisms which may cause food poisoning. Take

particular care during warmer weather.

Do not place aluminium foil, dishes, trays, water or ice on the oven floor during cooking as this

will irreversibly damage the enamel.

Do not line the walls with aluminium foil.

Do not stand on the door, or place heavy objects on it.

Do not use harsh abrasive cleaners or sharp metal scrapers to clean the oven door glass since

they scratch the surface, which may result in shattering of the glass.

Do not use a steam cleaner to clean any part of the cooker.

Do not use an asbestos mat or decorative covers between the flame and the saucepan as this may

cause serious damage to your cooktop.

Do not store flammable items in the oven or storage drawer.

5

6

Safety and warnings

Operation

Important safety instructions

Do not place aluminium foil or plastic dishes on the cooktop burners.

Do not let large saucepans or frying pans overlap the bench as this can deflect heat onto your

benchtop and damage the surface.

Do not let large saucepans, frying pans or woks push any other pans aside. This could make them

unstable or deflect heat onto your benchtop and damage the surface.

Saucepan handles may be hot to touch. Ensure saucepan handles do not

overhang other gas burners that are on. Keep handles out of reach of children.

If the electrical supply cord is damaged, it must only be replaced by an authorised person.

This cooker is not to be used as a space heater, especially if it is installed in marine craft or in a

caravan.

The use of a gas cooking appliance results in the production of heat and moisture in the room in

which it is installed. Ensure the kitchen is well ventilated. Keep natural ventilation holes open or

install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening

of a window, or more effective ventilation, for example increasing the level of mechanical

ventilation where present.

Safety and warnings

Operation

Important safety instructions

Never leave the appliance unattended when in use. Boilover causes smoking and greasy

spillovers that may ignite.

Wear proper apparel. Do not wear loose fitting or hanging garments when using the appliance.

They could ignite or melt if they touch an element or hot surface and you could be burned.

Always keep oven vents unobstructed.

Use only dry oven mitts or potholders. Moist or damp potholders on hot surfaces could result in

burns from steam. Do not let potholders touch hot areas or heating elements. Do not use a towel

or a bulky cloth for a potholder. It could catch fire.

Caution. Hot air can blow from the vent at the top of the oven as part of the oven’s cooling

system.

Placement of oven shelves: always position shelves in the desired location before preheating

the oven. If a shelf must be removed while the oven is hot, do not let the oven mitts or potholder

contact hot heating elements in the oven or the base of the oven.

Before starting a Self Clean cycle, remove oven shelves, side racks, and all other cookware/

utensils, and wipe up large food spills or grease deposits.

Before starting a Self Clean cycle, make sure you move any pet birds to another, closed and well-

ventilated room. Some pet birds are extremely sensitive to the fumes given off during a Self Clean

cycle, and may die if left in the same room as the oven during such a cycle.

During a Self Clean cycle, the oven reaches higher temperatures than it does for cooking. Under

such conditions, the surfaces may get hotter than usual and children should be kept away.

7

8

Installation instructionsInstallation instructions

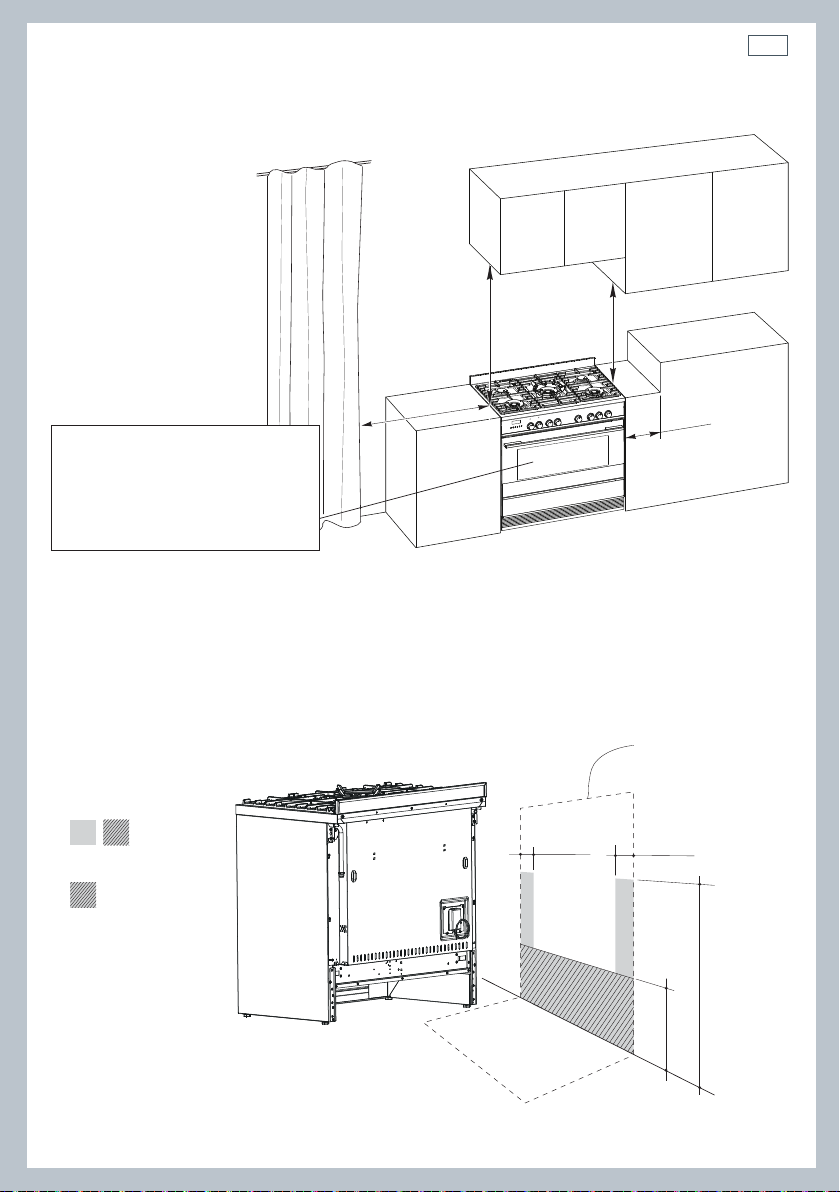

Dimensions and clearances

Installation clearances and protection of combustible surfaces shall comply with the current

local regulations eg. AS/NZS5601.1:2010 Gas Installations code. Installation shall comply with

the dimensions in Fig. 1, bearing in mind the following requirements:

Overhead Clearances

In no case shall the clearance above the highest part of the cooker be less than 600 mm or, for

an overhead exhaust fan, 750 mm. AII other downward-facing combustible surfaces less than

600 mm above the cooker surface shall be protected for the full width of the cooking surface in

accordance with the standards noted above. In no case shall the clearance be less than 450 mm.

Rear and Side Clearances

Where the distance from the periphery of the nearest burner to any vertical combustible surface

is less than 200 mm, the surface shall be protected in accordance with the standards to a height

of not less than 150 mm above the cooking surface for the full width or depth of the cooking

surface.

Where the distance from the periphery of the nearest burner to any horizontal combustible

surface is less than 200 mm, the horizontal surface shall be more than 10 mm below the

surface of the cooking surface, or the horizontal surface shall be above the pan support (see

requirements for vertical combustible surfaces above).

Protection of combustible surfaces

The standards above specify that, where required, protection shall ensure that the surface

temperature of combustible surfaces does not exceed 65°C above room temperature.

Do not install the cooker near flammable materials (eg curtains).

Installation instructions

j

9

500 mm

Cooker overall dimensions [mm]

•

height:

•

product width: 897

•

depth: 600

•

cavity width 900

min 897 - max 910

Locating the area for gas and electrical connection

Area for gas

connection

Area for electrical

connection

750 mm

70 mm

450 mm

200 mm

Fig. 1 Dimensions and

distances from cooker

Dotted line showing

the position of the

cooker when installed

70 mm

Fig. 2 Area for gas and electrical connections

240 mm (*)

(*) Depending on

feet ad

450 mm (*)

ustment

10

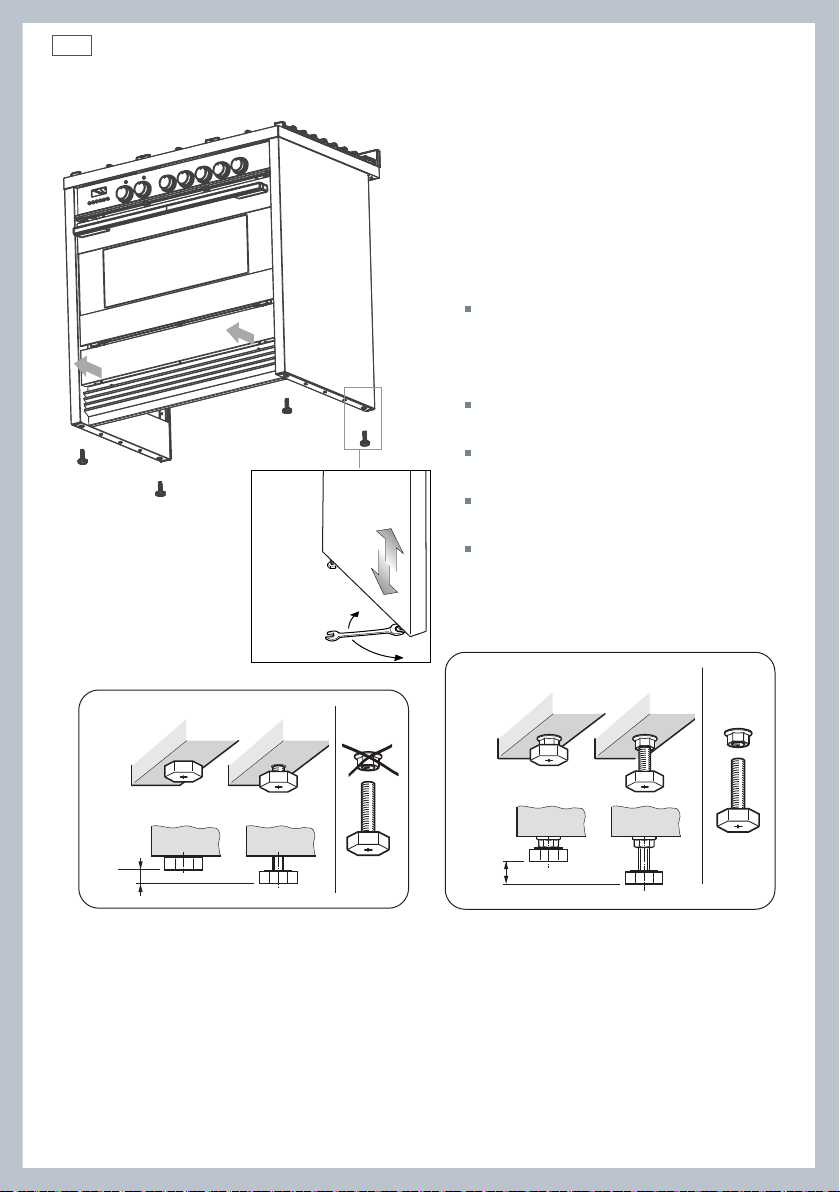

Installation instructionsInstallation instructions

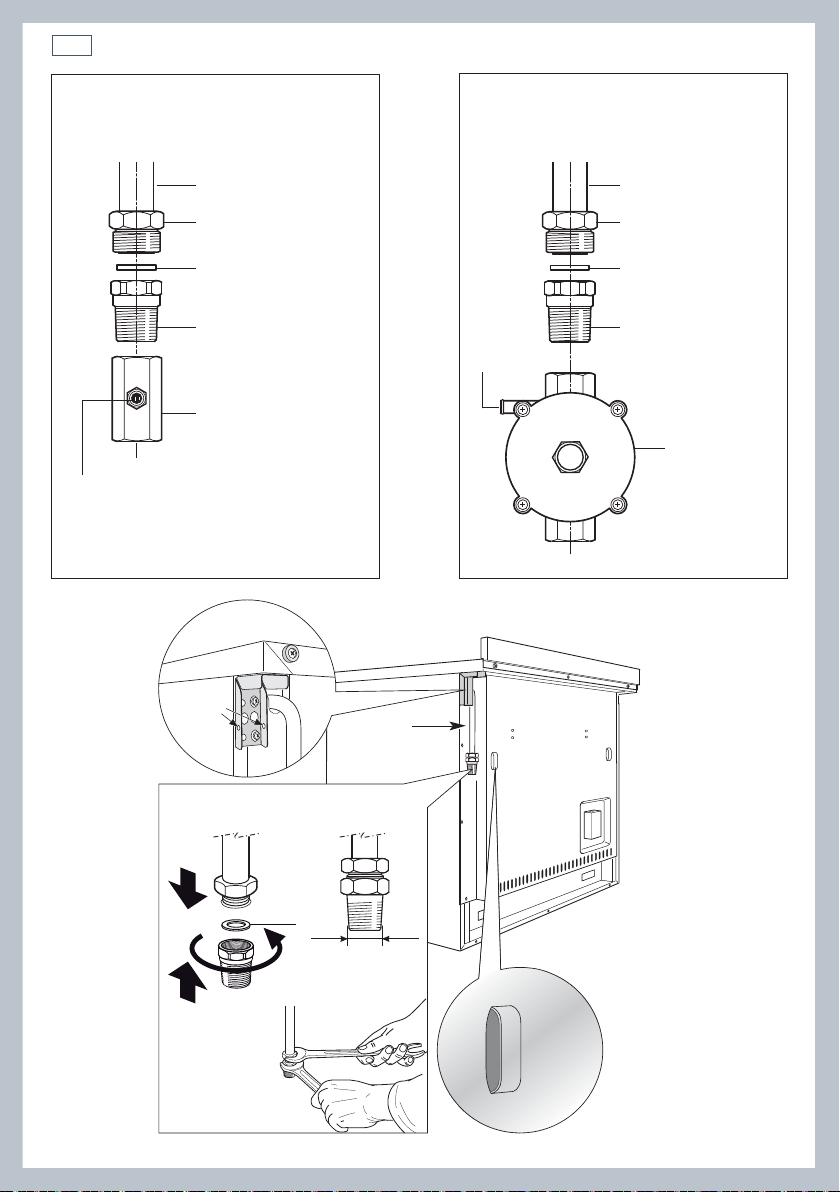

Fig. 3a Screw/unscrew the

feet to get the required height

Levelling the cooker

Important!

Using the supplied adjustable feet is

MANDATORY. For safety reasons and to

ensure adequate ventilation, the cooker

chassis MUST NOT sit directly on the floor, a

plinth, or other support surface.

For ease of installation, first remove

the kickstrip. To remove the kickstrip,

unscrew the two screws holding it in

place.

The cooker is already fitted with four

levelling feet.

Level the cooker by screwing or

unscrewing the feet.

Make sure you follow the instructions in

Figs. 3a, 3b, and 3c.

Note: nuts are supplied with the cooker

in a separate kit.

Do not refit the kickstrip until you have

installed the anti-tip bracket.

0

+ 8

mm

Fig. 3b Do not use the supplied nuts for height

adjustments between 0 and 8 mm

+ 8

mm

+ 13

mm

height adjustments between 8 and 13 mm

Fig. 3c Use the supplied nuts for

Dotted line showing the position

of the cooker when installed

Rear left

foot of cooker

Anti-tilt

bracket

Fitting the anti-tilt bracket

Important!

To restrain the appliance and prevent

it tipping accidentally, the antitilt bracket and restraining plate

supplied must be fitted according to

the instructions below.

1

Drill four 8mm diameter holes for

the fixing screws (two in the wall

and two in the floor-see Fig.4) and

insert the plastic plugs supplied.

Important!

Before drilling the holes, check that you will not

damage any pipes or electrical wires.

2

Attach the anti-tilt bracket to the floor and

rear wall using the four screws supplied, as

shown in Fig. 4.

3

After attaching the anti-tilt bracket securely,

slide the cooker into place. Ensure that the

left rear foot slides under the bracket, as

shown in Fig.4.

4

Access the bracket by removing the drawer

(Fig. 5):

a

Slide out the drawer completely.

b

Press the lever of the left guide rail

down and pull the lever of the right

guide rail up.

c

Holding the levers, disengage and

remove the drawer.

d

If fitted, remove kickstrip

(see ‘Levelling the cooker’)

5

Fix the restraining plate by sliding it into

place and securing it with the fixing screw

and washer supplied. See Fig. 6.

6

Replace the drawer (Fig. 7):

a

Insert the drawer rails into the guide

rails.

b

Gently push the drawer in

completely; the safety catches will

automatically hook.

7

Replace the kickstrip using the two screws.

Important!

Beware of sharp edges when removing or

replacing the drawer.

Installation instructions

Fig. 4 Attaching the

anti-tilt bracket and

sliding the cooker

Fig. 5 Accessing the anti-tilt bracket

by removing the drawer

Restraining plate

Screw & Washer

Fig. 6 Fixing the restraining plate

Fig. 7 Replacing the drawer

11

into place

12

Installation instructionsInstallation instructions

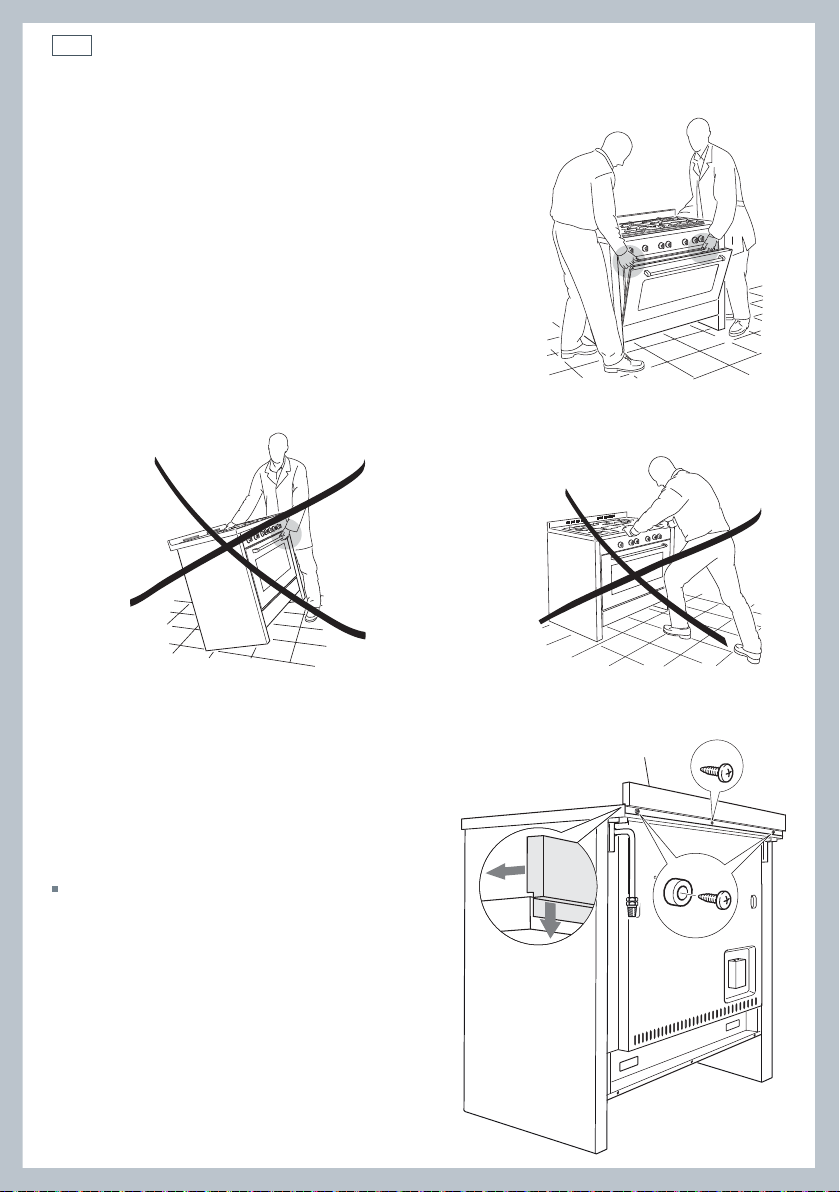

Moving the cooker

Important!

To prevent damaging the adjustable feet or lower

trim, ensure the cooker is always lifted by two

people.

Do not lift the cooker by the door handles.

DO NOT DRAG the cooker. Lift the feet clear of the

floor.

Take extra care not to damage the door sensor (top

left of oven).

Fig. 8 Correctly lifting the cooker

Fig. 9 Incorrectly lifting the cooker

Fixing the backguard

Before installing the cooker, assemble the

backguard “C” .

The backguard “C” can be found packed

at the rear of the cooker.

1

Before assembling, remove any protective

film/adhesive tape.

2

Remove the two spacers “A” and the

screw “B” from the rear of the cooktop.

3

Assemble the backguard as shown and

fix it by screwing the central screw “B”

and the spacers “A”.

Fig. 10 Incorrectly moving the cooker

C

B

A

Fig. 11 Assembling

the backguard

Installation instructions

Connecting the cooker to the gas supply

The gas connection must be carried out by an authorised person according to the relevant

standards.

Before connecting the appliance to the gas main, mount the brass conical adaptor onto the gas

inlet pipe, upon which the washer has been placed (see Fig.s 12-13 following).

Conical adaptor and washer are supplied with the appliance (packed with conversion kit for use

with Natural gas or LPG).

This appliance is suitable for use with Natural gas or LPG. (Check the “gas type” sticker attached

to the appliance).

For Natural gas, connect the gas supply to the gas pressure regulator which is supplied with the

appliance (Fig.13). Adjust the regulator to obtain a test point pressure of 1 kPa with the two semi

rapid burners operating at the maximum.

For LPG, connect the gas supply to the test point adaptor which is supplied with the appliance

(Fig.12). Ensure that the supply pressure is regulated to 2.75 kPa.

The connection must be made at the rear of appliance; the pipe is not to cross the cooker.

IMPORTANT: Use two spanners to tighten or loosen the connecting pipe (Fig.14).

Installation with a flexible hose assembly

If this appliance has to be installed with a hose assembly, the installer shall refer to the network

operator or gas supplier for confirmation of the gas type, if in doubt.

When used with a flexible hose, the connector on the wall should be between 450 mm to 500

mm from the floor and 200 mm to 300 mm from the right-hand side of the appliance as viewed

from the front. The hose connection on the appliance shall face downwards.

It is important that the hose does not come in contact with the metal of the appliance and is

secured as per appropriate gas installation codes. A chain 80% of the length of the flexible gas

hose must be used to prevent stress being applied to the hose. The chain should be attached

securely to the product where shown (see Fig.13), and on the wall.

Flexible hose assemblies should be AS/NZS 1869 Class B or Class D certified. The thread

connection shall be Rp ½ ” (ISO 7-1) male.

13

Important!

After connection the installer must check that the hose is not kinked, subjected to abrasion or permanently

deformed. The installer must check also that the hose is not near or in contact with any hot surfaces.

The hose assembly shall be as short as practicable and comply with relevant AS5601 / NZS5261

requirements.

14

Installation instructions

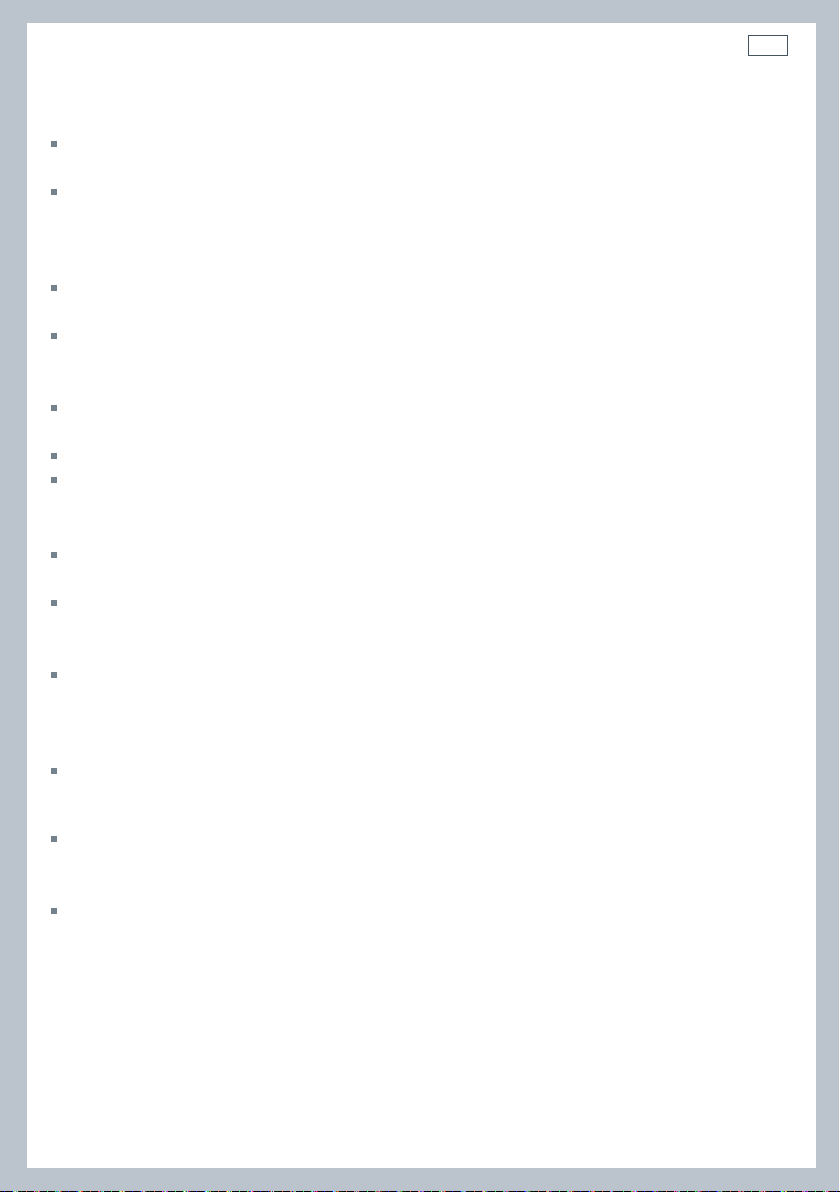

Gas connection for

LPG

Test

point

Gas inlet pipe

Nipple

Washer

Brass conical adaptor

(Thread tight: use

suitable seal)

Test point adaptor

Test

point

Gas connection for

NATURAL GAS

Gas inlet pipe

Nipple

Washer

Brass conical adaptor

(Thread tight: use

suitable seal)

Gas pressure

regulator

Fig. 13 Natural gas connectionFig. 12 LPG connection

Chain

security

hole

Fitting the brass conical adaptor

Washer

(ISO 7-1) male

Gas

inlet pipe

Rp ½ ”

Chain

security

anchor

Fig. 14 Gas supply inlet

Installation instructions

Leak-testing and flame-testing the cooker

After installing the freestanding cooker and connecting the gas supply:

1

Using a suitable leak detection fluid solution, check each gas connection one at a time by

brushing the solution over the connection.

The presence of bubbles will indicate a leak. If there is a leak, tighten the fitting and then

recheck for leaks.

Important!

2

Adjust the test point pressure or supply pressure to the value that is appropriate for the gas

type.

3

Test the operation of the appliance:

Turn on the appliance gas controls and light each burner individually and in combination.

Check for a well-defined blue flame without any yellow tipping. If any abnormality is

maximum to the minimum position. The flame must not go out. If you need to adjust the

setting, see ‘Adjusting the minimum burner setting’ following.

4

If satisfacfory performance cannot be obtained, the installer shall check the installation and

evident, then check that the burner cap is located properly and the injector nipple is

aligned correctly.

Check the minimum burner setting by quickly rotating the gas control dial from the

notify the local gas supply authority for a gas supply problem, or if it is an appliance problem,

our Customer Service Centre should be called to obtain the nearest authorized Service Agent.

Converting to a different gas type

Do not use a naked flame to test for leaks.

15

This appliance is suitable for use with Natural gas or LPG (check the “gas type” sticker attached

to the appliance). To convert from one gas type to another, you need to replace the injectors,

and then adjust the minimum burning setting.

Replacing the injectors

1

Remove the pan supports and burners from the cooktop.

2

Using a spanner, remove the injectors (shown in Figs. 15-16-17 following) and replace them with

ones according to the gas type (see the ‘Table for the choice of injectors’).

3

Fix the warning label (supplied with the conversion kit) at the back of the cooker, near the gas

inlet connections. This label states that the gas cooktop has been converted for use with LPG/

Natural gas.

Adjusting the minimum burner setting

4

See ‘Adjusting the minimum burner setting’ for instructions.

Important!

If you are converting the cooker from Natural gas to LPG,remove the gas pressure regulator

before connecting the cooker to the gas supply and replace with the test point adaptor supplied

with the conversion kit.

If you are converting the cooker from LPG to Natural gas, remove the test point adaptor before

connecting the cooker to the gas supply and replace with the gas pressure regulator supplied

with the conversion kit.

Notes:

- The burners are designed so that regulation of primary air is not required.

16

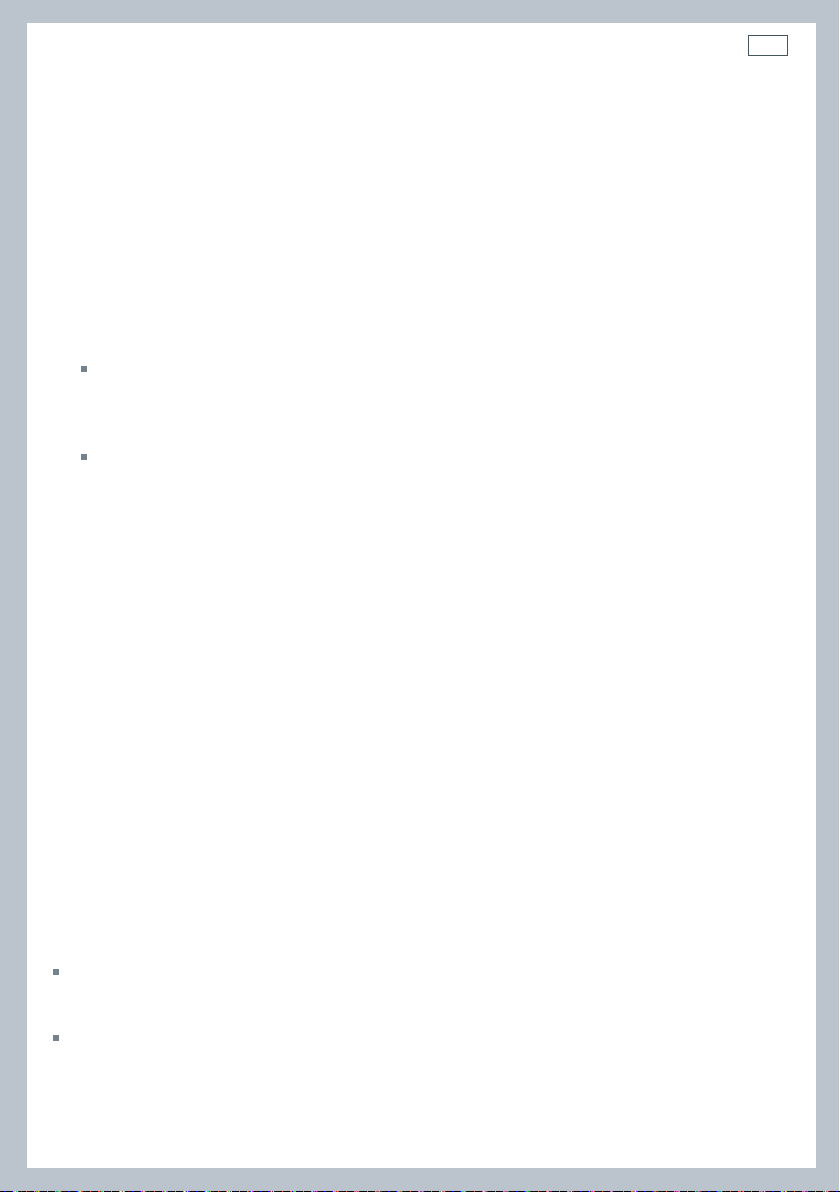

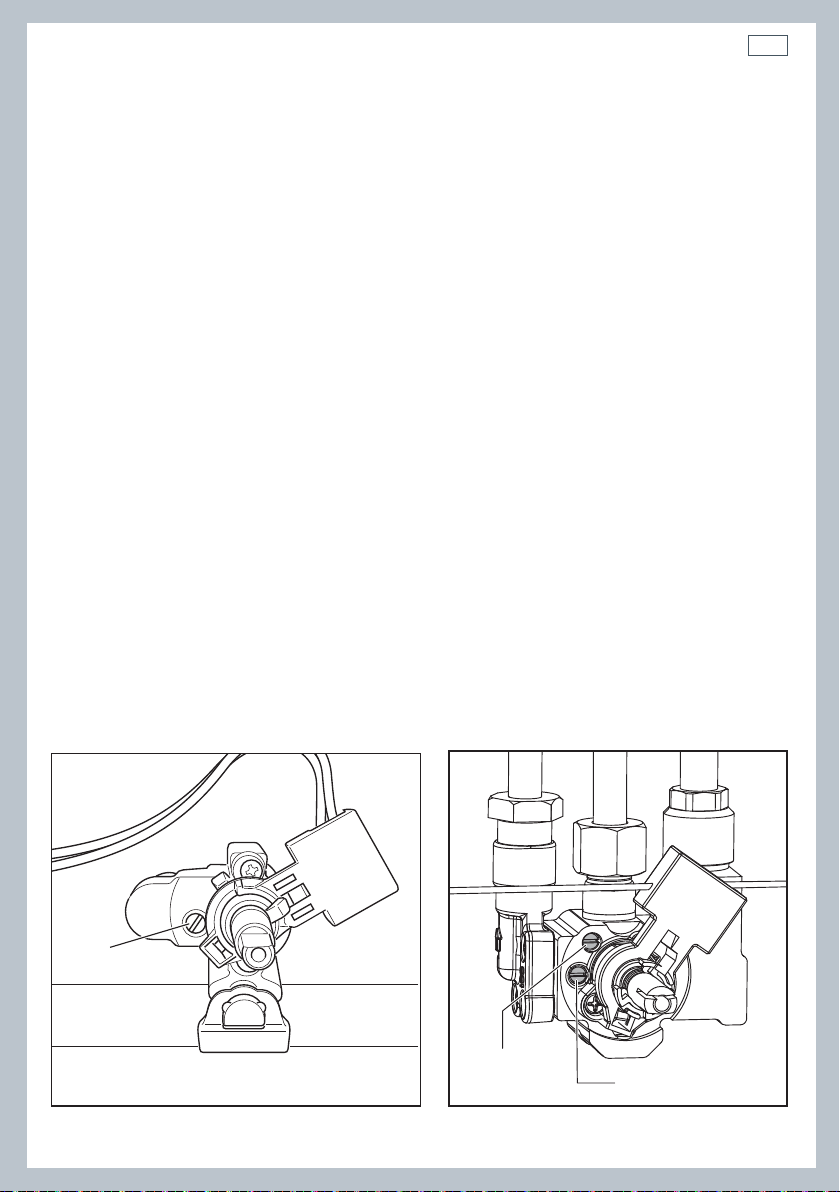

Installation instructions

Injector

Fig. 15 Semi-rapid burner Fig. 16 Triple-ring wok burner

Injector

J

Injector for

Injector for

inner crown

ner crown

J

Injectors for

Injectors for

outer crown

outer crown

J

Fig. 17 Dual burner

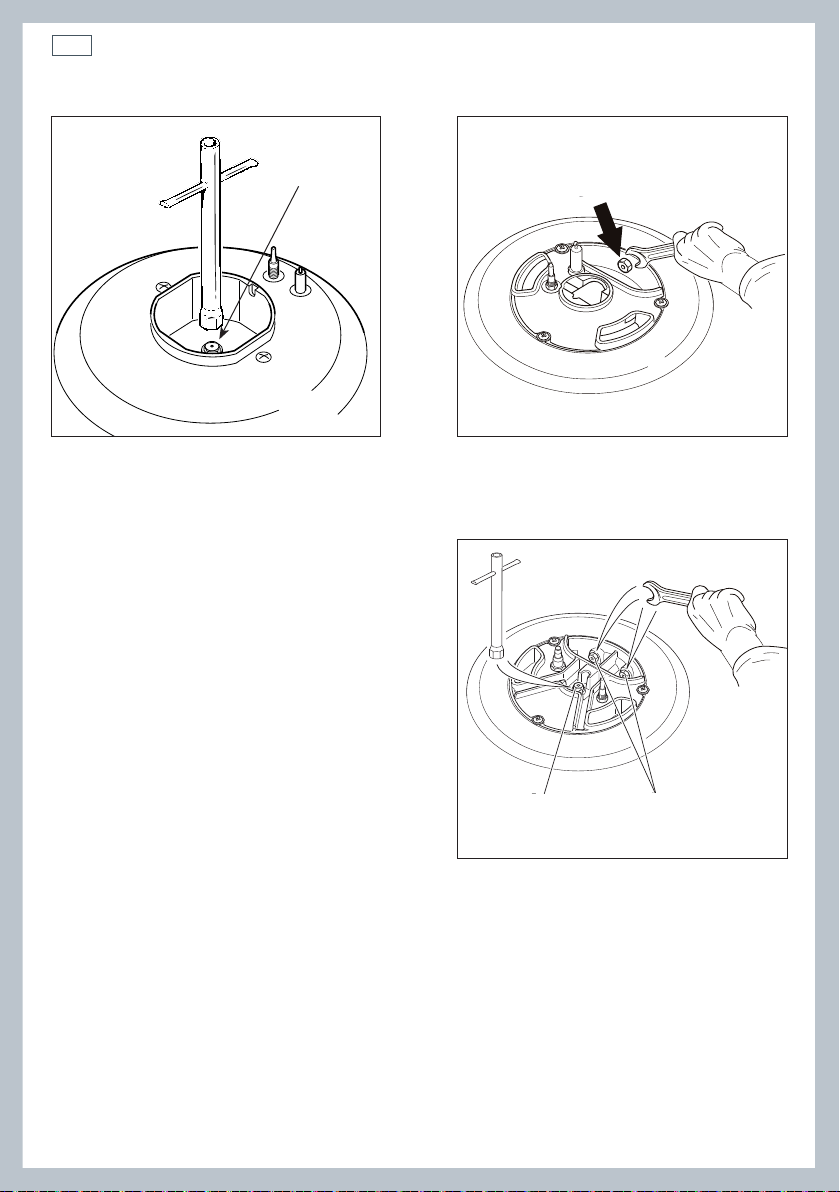

Installation instructions

Adjusting the minimum burner setting

Check whether the flame spreads to all burner ports when the burner is lit with the gas valve set

to the minimum position.

If some ports do not light, increase the minimum gas rate setting. Check whether the burner

remains lit even when the gas valve is turned quickly from the maximum to the minimum

position.

If the burner does not remain lit, increase the minimum gas rate setting.

To adjust the minimum gas rate setting:

Semi-rapid and triple-ring burners:

1

Turn on the burner.

2

Turn the valve to the MINIMUM position.

3

Take off the dial.

4

Using a small flat screwdriver, turn the screw (see Fig. 18) to the correct regulation.

Inside crown of dual burner:

1

Turn on the burner.

2

Turn the valve to the MINIMUM position of the inner crown only.

3

Take off the dial.

4

Using a small flat screwdriver, turn the screw (see Fig. 19) to the correct regulation.

Outside crown of dual burner:

1

Turn on the burner.

2

Turn the valve to the MINIMUM position of the inner and outer crowns.

3

Take off the dial.

4

Using a small flat screwdriver, turn the screw (see Fig. 19) to the correct regulation.

17

Note: for LPG, the regulation screw is normally tightened up.

regulation screw

regulation screw

regulation screw

(outside crown)

Fig. 18 Adjusting the minimum burner setting:

semi-rapid and triple-ring wok burner

regulation screw

(inside crown)

Fig. 19 Adjusting the minimum burner setting:

dual burner

18

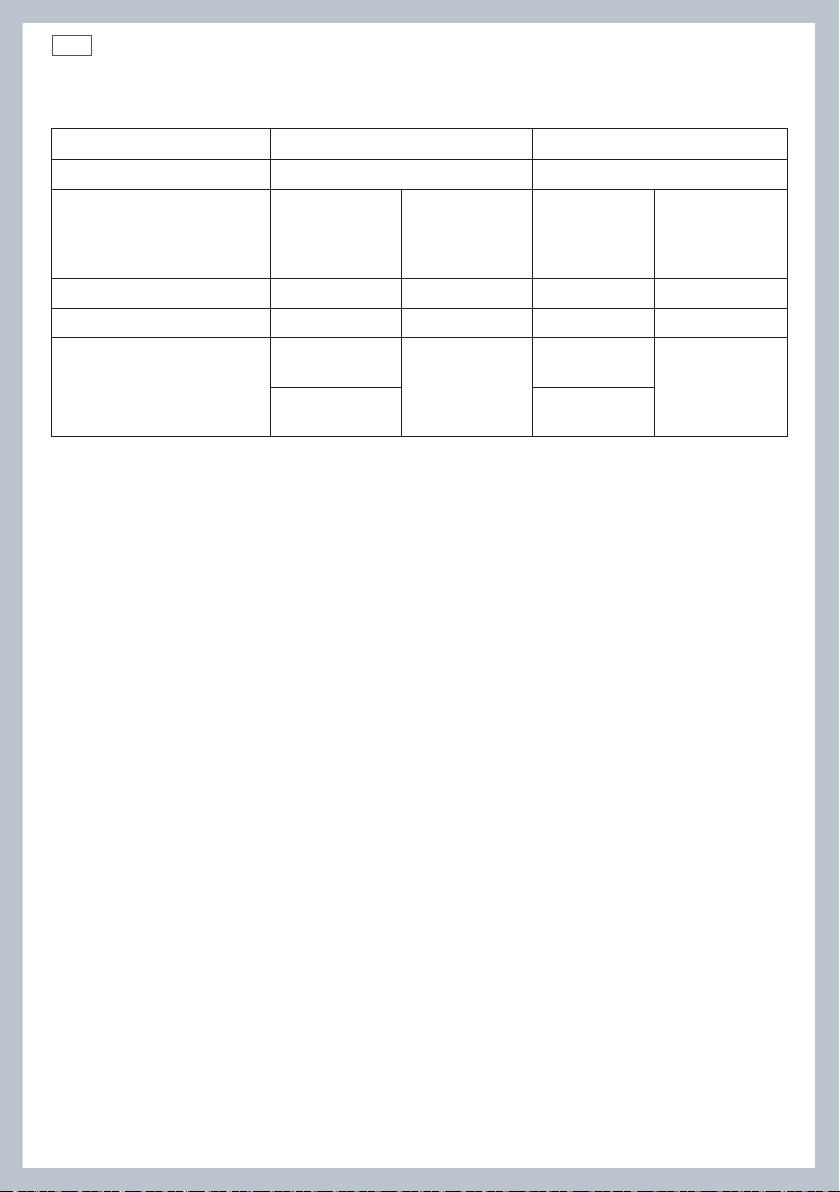

Installation instructions

Natural gas LPG

Test Point Pressure [kPa] 1.0 2.75

BURNER

Semi-rapid

Triple-ring wok

Dual

Injector

Orifice Dia.

[mm]

1.17 6.50 0.70 6.30

1.54 11.88 0.98 12.00

0.76

(inner crown)

1.23 - no.2

(outer crown)

Gas

Consumption

[MJ/h]

16.20

(inner and

outer crowns

operating)

Injector

Orifice Dia.

[mm]

0.50

(inner crown)

0.73 - no.2

(outer crown)

Gas

Consumption

[MJ/h]

16.20

(inner and

outer crowns

operating)

Loading...

Loading...