AeroCare clothes dryer

Installation instructions

and User guide

US

WARNING!

For your safety the information in

this manual must be followed

to minimize the risk of fire or

explosion or to prevent property

damage, personal injury or death.

—Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

—WHAT TO DO IF YOU SMELL GAS

• Donottrytolightanyappliance.

• Donottouchanyelectricalswitch;do

not use any phone in your building.

• Cleartheroom,buildingorareaofall

occupants.

• Immediatelycallyourgassupplierfrom

a neighbor’s phone. Follow the gas

supplier’s instructions.

• Ifyoucannot reachyourgassupplier,

call the fire department.

—Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

The Governor of California is required to publish a list of substances known to the state of

California to cause cancer or reproductive harm and requires business to warn customers of

potential exposures to such substances.

WARNING!: Gas appliances contain or produce substances, which can cause death, or

serious illness and which are known to the State of California to cause cancer, birth

defects, or other reproductive harm. To reduce the risk from substances in fuel or from fuel

combustion, make sure this appliance is installed, operated, and maintained according to

the manufacturer’s instructions.

In the Commonwealth of Massachusetts

Installation of this appliance must be performed by a contractor, plumber or gasfitter who is

qualified or licensed by the state.

Contents

Introduction 2

Important safety instructions 3

Installation instructions 7

The first time you turn your dryer on 48

Getting started quickly 50

AeroCare controls 52

Sorting and loading 54

Dryer cycles 56

Drying special items 61

Drying cycle options 63

Dryer operation 66

Care labels 68

Drying rack 69

Customizing dryer cycles 70

Changing pre-set options 71

Caring for your dryer 73

Before you call for service

User warnings 76

Fault codes 76

Solving operating problems 77

Solving drying problems 80

Limited warranty 82

How to get service 84

1

Important!

SAVE THESE INSTRUCTIONS

The models shown in this User Guide may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please visit our website listed on the back cover or

contact your local Fisher & Paykel dealer.

2

Introduction

Thank you for buying a Fisher & Paykel AeroCare clothes dryer. We are very proud of this dryer

and trust it will serve you well for many years.

At Fisher & Paykel we aim to provide innovative products that are simple to use, ergonomic,

energy efficient and kind to the environment. Thousands of tonnes of washing and 75 years of

laundry experience have been programmed into your dryer to help give you the best possible

performance.

We have developed this dryer to treat your clothes with the utmost care, drying them gently, so

they will look better for longer. We trust you’ll enjoy the benefits of numerous drying cycles and

options, its extra large capacity and reverse tumbling.

Please take the time to read this User Guide carefully. It will help you to operate and maintain

your new AeroCare dryer. Your safety and the safety of others is very important. Located on your

dryer and throughout this guide are safety messages and instructions; it is important that you

understand and follow them.

We hope you enjoy your new dryer.

Fig.1 AeroCare dryer models

Important!

It is important that this User Guide should be retained with your AeroCare clothes dryer for

future reference. Should the appliance be sold or transferred to another owner, please ensure

that the User Guide is left with the appliance. This will ensure that the new owner can familiarize

themselves with the information and warnings contained within the Guide.

Important safety instructions

Symbols

Symbols will be used in this Guide to highlight when extra care is required. Abide by these at all

times to ensure you and your family are not harmed while operating your dryer.

It is important to always act with caution and use common sense when operating your dryer.

Use only as instructed by the User Guide.

This is the safety alert symbol. This symbol alerts you to hazards that can

present risk of losing life, or hurt you and others.

The safety alert symbol and the word WARNING will precede all safety

messages. This word means:

3

WARNING

All safety messages will identify the hazard, tell you how to reduce the chance of injury,

and tell you what can happen if the instructions are not followed.

You can be at risk of losing your life or being seriously

injured if you don’t follow instructions.

4

Important safety instructions

WARNING!

Electric Shock Hazard

Follow the safety precautions outlined in this User Guide.

Failure to do so can result in death or electrical shock.

Important safety precautions

Read all instructions carefully before using this dryer. Use this dryer only for its intended purpose

as described in this User Guide.

Installation must conform with local codes, or in absence of local codes, with the National Fuel Gas

Code, ANSIZ223.1/NFPA54 or the Canadian Natural Gas and Propane Installation Code, CSAB149.1

Installation and service must be performed by a qualified or licensed contractor, plumber or gasfitter

qualified or licensed by the state, province, or region where this appliance is being installed.

This dryer must be properly installed and located in accordance with the Installation Instructions

before it is used.

This dryer, when installed, must be electrically grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical Code, ANSI/NFPA70, or the Canadian Electrical

Code, CSAC22.1.

Do not install or store the dryer where it will be exposed to water or exposed to the weather.

Connect to a properly protected, rated and sized power supply circuit to avoid electrical overload.

Do not repair or replace any part of the appliance or attempt any servicing, unless specifically

recommended in the published user repair instructions that you understand and have the skills to

carry out.

To minimize the possibility of electric shock, unplug this dryer from the power supply or disconnect

the dryer at the household distribution panel (by removing the fuse or switching off the circuit

breaker) before attempting any user maintenance or cleaning.

When disconnecting the dryer, pull by the plug rather than the cord or junction of the cord plug, to

avoid damage to the cord or junction of the cord plug.

Make sure the cord is located so that it will not be stepped on, tripped over or otherwise subject to

stress or damage.

Do not tamper with the controls.

Note: Touching the POWER button does NOT disconnect the dryer from the power supply, even

though the lights are out.

Do not operate this dryer if it is damaged, malfunctioning, partially disassembled or has missing

or broken parts, including a damaged cord or plug.

This dryer must be directly connected to an approved fixed electrical outlet. It cannot be plugged

into an extension cord or an adaptor plug.

Do not use the dryer if there is water on the floor near the dryer. Call an Authorized Service Agent

if there is a leak.

Important safety instructions

WARNING!

Fire Hazard

Only dry fabrics that have been washed with water.

Do not use a drying cycle with heat to dry articles containing foam

rubber or similarly textured rubber-like materials. Only dry on the

AIRDRY cycle.

A clothes dryer produces combustible lint and must be exhausted

outdoors. Take care to prevent the accumulation of lint around the

exhaust opening and in the surrounding area.

Do not use fabric softeners or products to eliminate static unless

recommended by the manufacturer of the fabric softener or product.

Failure to follow these instructions can result in death or personal injury.

To reduce the risk of fire in a tumble dryer the following should be observed:

Do not place items in a tumble dryer that have previously been cleaned in, washed in, soaked in,

or spot cleaned with flammable liquids or solids. They give off vapors which are a fire or explosion

hazard. Highly flammable substances commonly used in domestic environments include acetone,

denatured alcohol, gasoline, kerosene, some brands of spot removers and dry cleaning solvents,

turpentine, waxes, wax removers, vegetable oil, fish oil, massage oil, and cooking oil.

Do not place items exposed to cooking oils in your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could cause a load to catch fire.

Do not leave hot oil-affected items in a pile or stack. This can prevent heat from escaping and can

create a fire hazard. Oil-affected items can ignite spontaneously, especially when exposed to heat

sources such as a tumble dryer. The items become warm causing an oxidation reaction in the oil. This

oxidation creates heat. If the heat cannot escape the items can become hot enough to catch fire.

Do not use a drying cycle with heat to dry items containing rubber, foam rubber, plastic or similar

materials (such as padded bras, bath mats, rugs, bibs, baby pants, plastic bags, pillows etc), as these

materials might melt or burn. Some rubber materials when heated can under certain circumstances

produce fire by spontaneous combustion. Only dry on the AIR DRY cycle.

Unless specifically recommended by their manufacturer, do not use fabric softeners or similar

products in a tumble dryer.

Do not store or use gasoline or other flammable gases and liquids near this or any other appliance.

Keep the area around the exhaust opening and adjacent surrounding areas free from the

accumulation of combustible materials such as lint, dust, dirt, paper, rags, chemicals etc.

Do not store any items that may burn or melt (such as paper materials, plastics or plastic containers

etc) next to the dryer.

Clean the lint filter each time you use the dryer, before or after each load.

The dryer must be exhausted to the outside. Carefully follow the exhausting and venting details in

the Installation Instructions.

The interior of the appliance and the exhaust duct should be cleaned periodically by qualified

service personnel.

5

6

Important safety instructions

Safe use of the dryer

Do not allow children to play inside, on, around or with this dryer or any other appliance. Close

supervision is necessary if this dryer is used near children.

Never climb on, climb into, or stand on the dryer top, or drum, or apply weight to the door.

Keep the floor around your dryer clean and dry to reduce the possibility of slipping.

If your dryer is running and you want to unload or add clothes, touch START/PAUSE then open

the dryer door.

Do not reach into the appliance if the drum is moving.

Undergarments that contain metal reinforcements should not be placed directly in the dryer.

Damage to the dryer can result if the metal reinforcements come loose during drying. If you wish

to dry these items use the drying rack supplied with your dryer.

BEFORE THE APPLIANCE IS REMOVED FROM SERVICE OR DISCARDED, REMOVE THE DOOR.

SAVE THESE INSTRUCTIONS

Installation instructions

WARNING! – Risk of fire

Clothes dryer installation must be performed by a qualified installer.

Install the clothes dryer according to the manufacturer’s instructions and local codes.

DO NOT install the clothes dryer with flexible plastic venting materials. If flexible

metal (foil-type) duct is installed, it must be identified by the dryer manufacturer

as suitable for use with clothes dryers and installed in strict accordance with the

instructions found on pages 26 to 38 of these installation instructions. Flexible

venting materials are known to collapse, be easily crushed and trap lint. These

conditions will obstruct dryer airflow and increase the risk of fire.

The dryer must be vented to the outdoors.

Use only rigid metal 4” (102 mm) diameter ductwork inside the dryer cabinet and use

only UL-listed transition ducting between the dryer and the home duct.

Do not install or store this appliance in any location where it could be exposed to

water and/or weather.

To reduce the risk of severe injury or death, follow all installation instructions.

SAVE THESE INSTRUCTIONS

Before you begin

7

Read the important safety instructions on the inside cover and on pages 3 – 6 before you start

installing the dryer.

Check to make sure you have all the tools and parts necessary to correctly install this appliance.

Tools required:

Adjustable wrench 10” (254 mm) × 2 (for gas connection).

Flat-blade screwdriver.

Slip joint pliers.

Pipe wrench 8” (203 mm) (for gas connection).

Phillips screwdriver.

Drill with ⁄” (3 mm) drill bit (for bottom venting only).

Caulking gun and compound (for installing new exhaust vent).

Glasses.

Gloves.

Knife.

Hacksaw.

Spirit level.

8

Installation instructions

Materials:

4”(102mm) diameter rigid metal duct (recommended).

4”(102mm) diameter UL-listed flexible metal duct (if needed).

4”(102mm) diameter metal elbow(s).

Flexible metal gas line connector (for gas connections only).

Duct or spring clamps(2).

Pipe joint compound (pipe dope or tape) for gas pipe connections, resistant to LP Propane,

butane and natural gas (for gas connections only).

Exhaust/vent hood.

Duct tape.

Soap solution for gas leak detection (for gas connections only).

¾”(19mm) strain relief (electric connections only).

Dryer power cord kit (power cord is not supplied with United States models).

Requirement: UL-rated 120/240V, 30 amp with 3 or 4 prongs. Identify the plug type needed from

the existing house receptacle before purchasing. Length of cord must be at least 5 feet (1.5 m) long.

To the installer

Read these instructions completely and carefully.

These instructions must be left with the home owner for future reference.

Correct installation is the responsibility of the installer.

Installation of this appliance must be performed by a qualified installer.

The dryer must be exhausted to the outdoors.

Remove the door from an old dryer before it is removed and discarded.

The wiring diagram and service information can be found in the control console.

The limited warranty does not cover product failure as a result of improper installation.

The dryer must be installed in a location where the temperature is above 50°F (10°C) to ensure

suitable operation of the dryer control system.

UL-listed duct material must be used. Discard existing plastic or metal foil duct and replace with

UL-listed duct material.

Observe all governing codes and ordinances.

Follow the installation instructions carefully.

Important!

Save these instructions for local electrical inspector’s use.

Observe all governing codes and ordinances.

Install the clothes dryer according to the manufacturer’s instructions and local codes.

Installation instructions

Unpacking

To ensure the best performance from the dryer, please follow the instructions below.

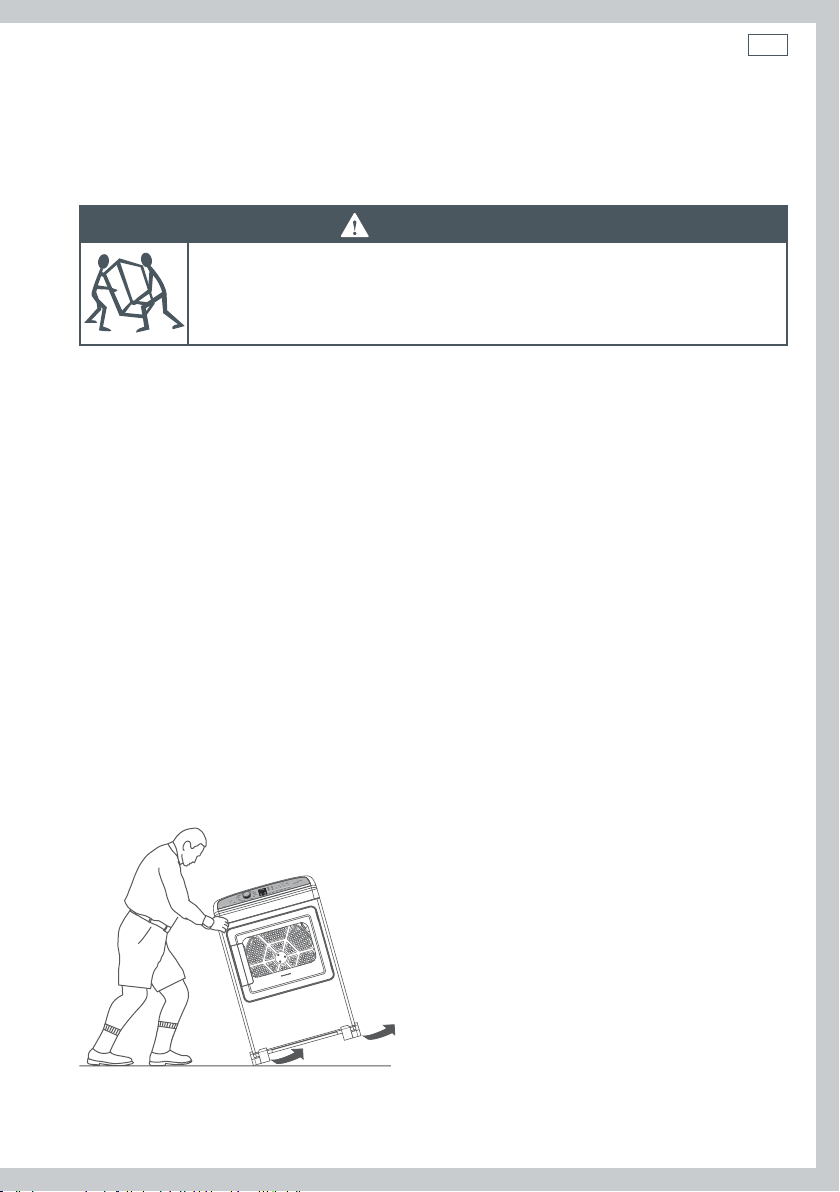

WARNING!

Excess Weight Hazard

Use two or more people to move and install the dryer.

Failure to do so can result in back or other injury.

Important!

Only remove the packaging at the customer’s premises.

This will ensure the appliance arrives in pristine condition and reduces the risk of damage during

transportation to the customer’s home.

1. Remove packaging

Remove all of the outer packaging. Dispose of unwanted packaging thoughtfully.

2. Discard packing material from around dryer feet

Tilt the dryer sideways and remove the foam shipping pads by pulling at the sides and breaking

them away from the dryer feet. Be sure to remove all the foam pieces before continuing with

installation.

9

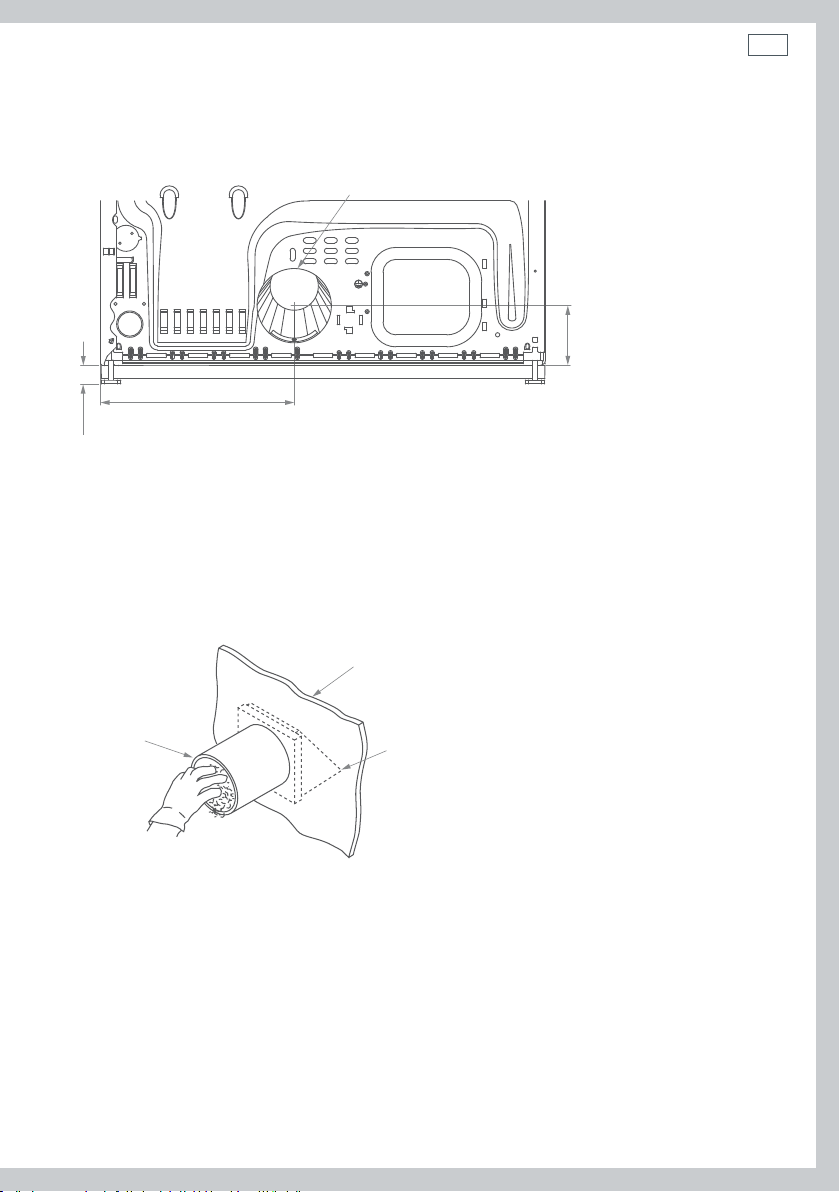

3. Drying rack

Open the door. Remove the tape holding the drying rack in place. Remove the rack and remove

protective tape from ‘legs’ of rack.

4. Accessories

Remove the accessories from inside the dryer.

Fig.2 Unpacking your dryer correctly

10

Installation instructions

Location requirements

WARNING!

Explosion Hazard

Keep flammable materials and vapors, such as gasoline, away from

thedryer.

Place dryer at least 18” (460 mm) above the floor for a garage installation.

Failure to do so can result in death, explosion, fire, or burns.

The dryer must be installed or stored in an area which is not exposed to water or weather.

It is extremely important that the dryer is installed in a well ventilated location. This dryer must

exhaust air outdoors. Do not install the dryer in any room or closet which does not permit the

free flow of replacement air. The free area of any opening for the introduction of outside air shall

not be less than twice the area of the dryer exhaust outlet.

The area in which the dryer is located must be kept clear and free from combustible materials,

gasoline and other flammable vapors and liquids. A dryer produces combustible lint so the area

around the dryer must be cleaned regularly to keep it free of lint.

Make sure dryer is in a suitable location for installation.

Consider installing the dryer before the washing machine in a side by side installation, this will

allow better access to electrical and exhaust connections.

Installation instructions

Minimum clearance required other than alcove or closet installation

Allow sufficient room behind the dryer for the exhaust. The air intake is at the rear of the dryer.

Ensure that there is a sufficient air passage on each side of the dryer for intake air.

The minimum clearance to combustible surfaces and for air openings are: 1” (25 mm) clearance

both sides, 2” (51 mm) clearance at the front, and 1” (25 mm) clearance at the rear, or 5” (127mm)

clearance if the dryer exhaust duct is at the rear. Consideration must also be given to provide

adequate clearance for proper operation and service.

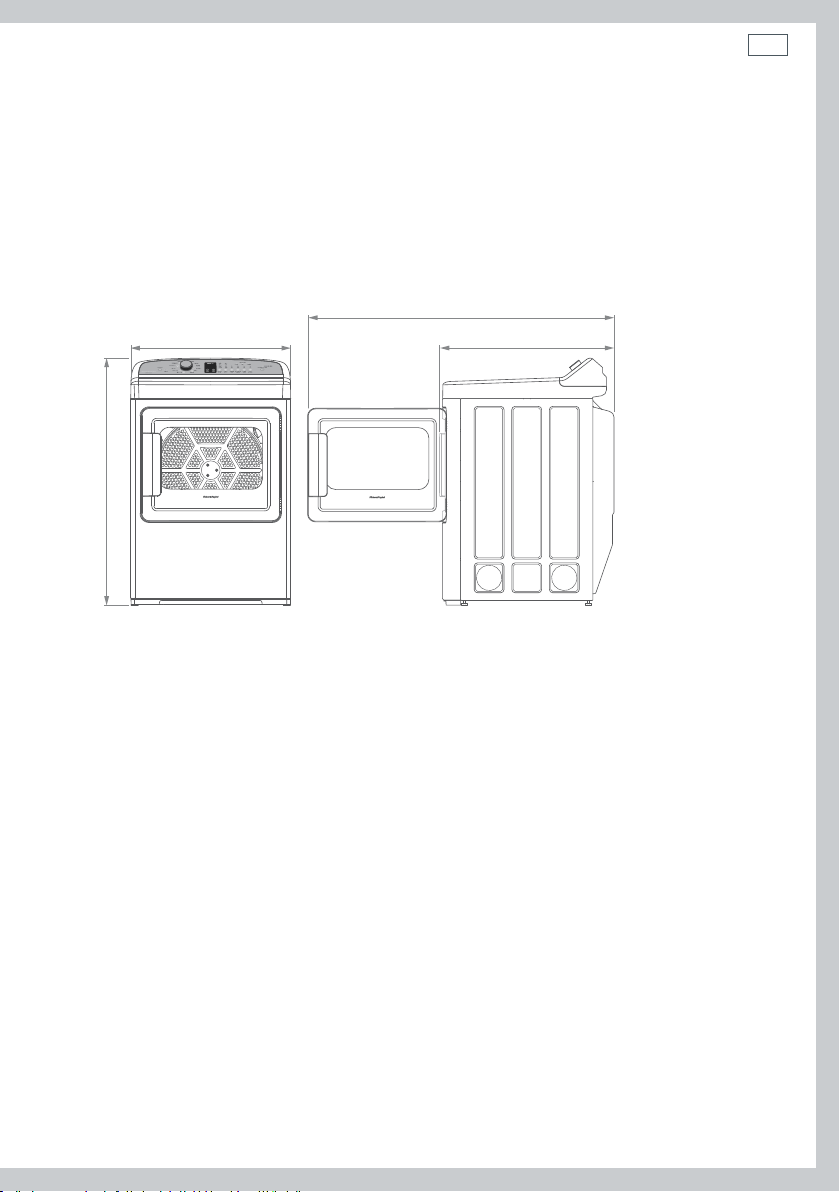

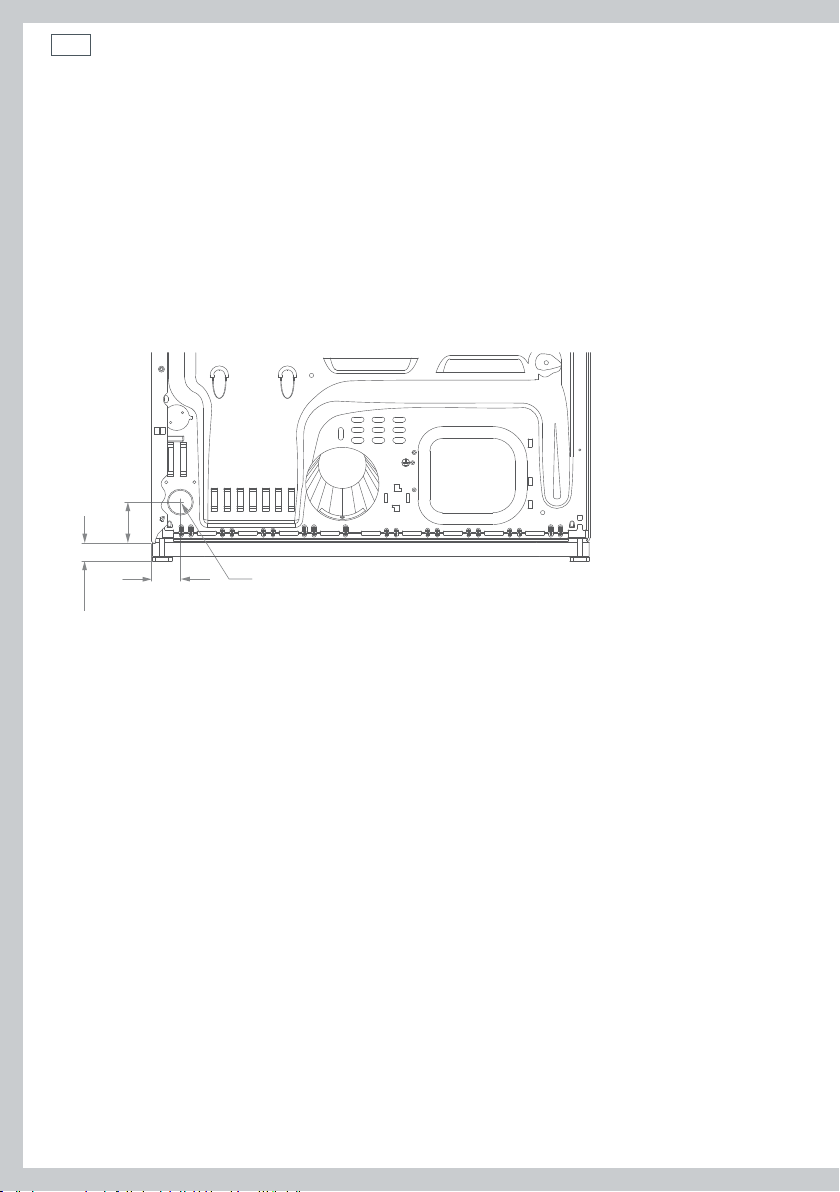

52 ½” (1332 mm)

27” (683 mm)

41 ½” (1051 mm)*

* Excludes adjustable foot height

29 ½” (743 mm)

11

Fig.3 AeroCare dimensions

12

Installation instructions

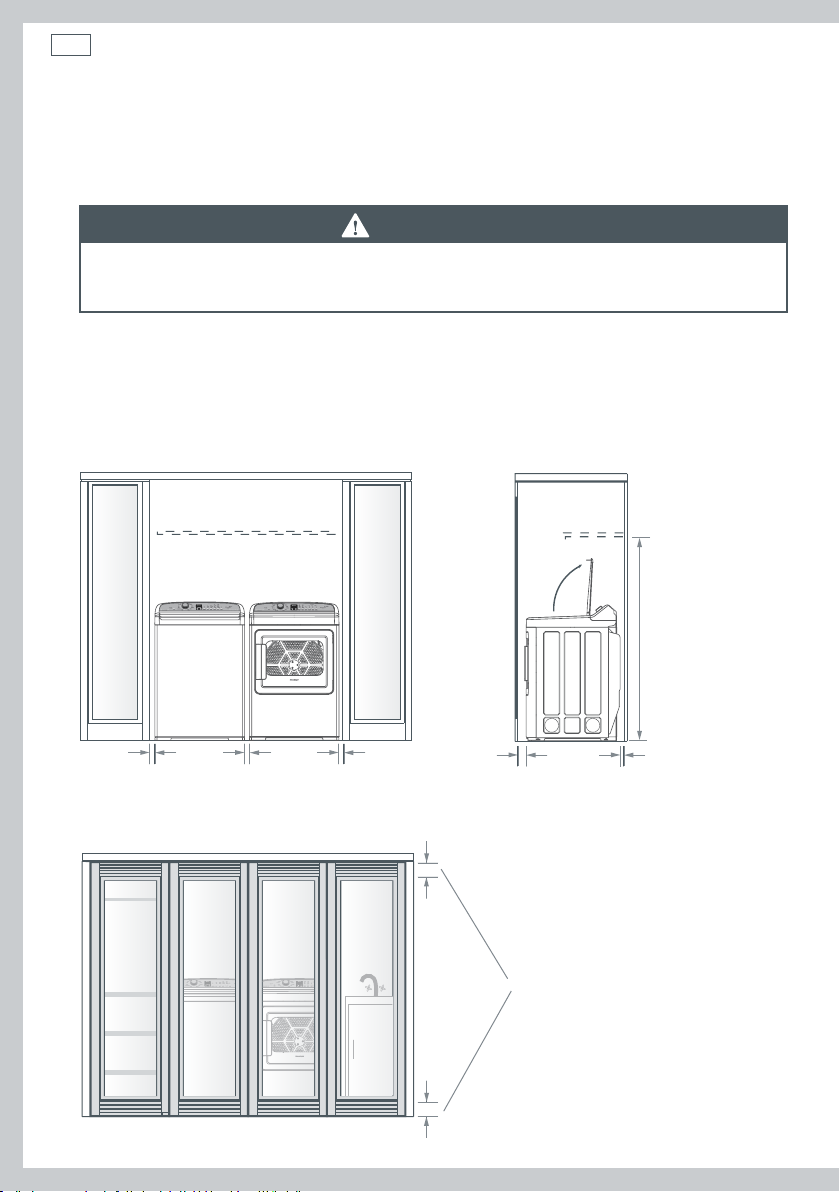

Requirements for alcove or closet installation

Your dryer is approved for installation in an alcove or closet (as specified on the dryer back).

WARNING!

When installing a dryer in a closet alcove it MUST be exhausted to the outdoors. No

other fuel burning appliance can be installed in the same closet or alcove.

The total ventilation area must be a minimum of 60 sq. in. (387 cm2) of open area equally

distributed. If the closet contains both a washer and a dryer, doors must contain a minimum of

120 sq. in. (774 cm

louvered door with the minimum air opening is acceptable). Minimum installation clearances are

required but more clearance is recommended.

2

) of open area equally distributed. The openings must never be obstructed (a

minimum clearance

required

56 ⁄” (1430 mm)

1” (25 mm) 1” (25 mm) 1” (25 mm) min 1” (25 mm)

min 2” (50 mm)

(rear of product to wall)

Fig.4 Minimum clearances

total ventilation area

120 in.sq (774 cm)

Fig.5 Minimum ventilation

Installation instructions

Requirements for alcove or closet installation continued

The closet should be vented to the outdoors to prevent gas pocketing in case of a gas leak in the

supply line.

No other fuel-burning appliance shall be installed in the same closet with the dryer (gas models

only).

Note: when the exhaust duct is located at the rear of the dryer, minimum clearance required

from the wall is 5” (127 mm).

Bathroom or bedroom installation

The dryer MUST be vented to the outdoors. See “Exhausting the dryer” (page 26).

Mobile or manufactured home installation

Installation is required to comply with the Manufactured Home Construction & Safety Standard,

title 24CFR, part 3280. If or when such standard is not applicable, installation must comply with

the American National Standard for Mobile Home, ANSI/NFPA No. 501.

The dryer MUST be vented to the outdoors with the termination securely fastened to the mobile

home structure.

Exhaust ducts MUST be securely fastened to a non-combustible portion of the mobile home

structure.

The exhaust MUST NOT be terminated beneath a mobile or manufactured home.

The exhaust duct material MUST BE METAL.

The exhaust duct MUST NOT be connected to any other duct, vent, or chimney, or be vented into

a wall, ceiling or concealed space of a building.

Do not use sheet metal screws or other fastening devices which extend into the interior of the

exhaust vent.

13

In addition to the above, for gas dryer models:

Kit 14-D346-33 MUST be used to attach the dryer securely to the structure.

Provide an opening with a free area of at least 25 sq. in. (161 cm2) for introduction of outside air

into the dryer room.

Residential garage installation

Dryers installed in residential garages must be elevated 18” (460 mm) above the floor.

The installation must conform with local codes or, in the absence of local codes, with the

National Electrical Code, NFPANO.70 (for electric dryers) or National Fuel Gas Code,

ANSIZ223.1/NFPA54 (for gas dryers) in the United States; and the Canadian Electrical Code

CSAC22.1 (for electric dryers) or Natural Gas and Propane Installation Code, CSAB149.1 (for gas

dryers), in Canada.

14

Installation instructions

Connecting a gas dryer (skip for electric dryer)

Refer to page 7 for tools required.

Note: installation and service of this dryer must be performed by a qualified installer, service

agency or the gas supplier.

Gas supply and installation requirements

In the Commonwealth of Massachusetts:

Installation of the dryer must be completed by a plumber or gas fitter licensed by the state.

When using ball-type gas shut-off valves, the t-handle type shall be used.

If using a flexible gas connector, this must not exceed a length of 3 feet in total.

WARNING!

Explosion Hazard

Installations must be performed by a qualified or licensed contractor,

plumber, or gasfitter qualified or licensed by the state, province, or

region where this appliance is being installed.

Use a new AGA or CSA approved gas supply line.

Install a shut-off valve in an accessible place.

Only use a gas shut-off valve approved for use within the state, province,

or region where this appliance is being installed.

Securely tighten all gas connections.

If connecting to LP Gas, have a qualified person make sure gas pressure

does not exceed 13” (330 mm) water column.

Failure to follow these instructions can result in death, explosion, or fire.

Installation instructions

WARNING!

To Reduce the Risk of Fire, Electrical Shock and Personal Injury:

Before connecting the dryer turn off circuit breaker(s) or remove the dryer’s circuit

fuses at its electrical box. Ensure the power cord is unplugged from the wall socket.

Ensure the gas shut off valve in the supply line is OFF.

Use only new ducting materials. Remove and discard old flexible gas connector and

duct material.

Gas type

This gas dryer is equipped with a valve and burner assembly for use only with natural gas. Your

local service organization can convert this dryer for use with propane (LP) gas, using conversion

kit WC254C1258A001.

Important!

All conversions must be completed by correctly trained and qualified personnel, in accordance

with all local codes and ordinances.

Pressure testing

The dryer must be disconnected from the gas supply piping system during any pressure testing

of the system at a pressure greater than 0.5psi (3.5kPa).

The dryer must be isolated from the gas supply piping system by closing the equipment shut-off

valve during any pressure testing of the gas supply piping of test pressure equal to or less than

0.5psi (3.5kPa).

15

Gas supply

A ⁄” National Pipe Taper (NPT) plugged tapping must be installed immediately upstream of the

gas supply connection to the dryer. This must be accessible for test gauge connection. Please

contact your local gas utility if you have questions regarding the installation of the plugged

tapping.

The gas supply line is to be ½” (12.7 mm) rigid pipe. The line must be equipped with an

accessible shut-off which is within 6 feet (1.8 m) of the dryer AND in the same room as the

appliance.

Pipe thread compound appropriate for Natural or Propane (LP) gas must be used.

New flexible metal gas line connector should be used to connect the dryer and gas supply.

16

Installation instructions

Elevation adjustment

The input ratings of gas operated clothes dryers are based on their operation at sea level, and

need not be adjusted for operation at or below 2000 ft. (610 m) elevation. For operation at

elevations above 2000feet (610m), input ratings should be reduced at a rate of four percent per

1000feet (305m) elevation above sea level.

Installation must conform to all local codes and ordinances. In the absence of local codes and/or

ordinances, installation shall conform to the National Fuel Gas Code, ANSIZ223.1/NFPA54, or the

Natural Gas and Propane Installation Code, CSAB149.1.

Gas supply connection

2 ½” (64 mm)

1 ¾” (45 mm)

Note: add to vertical dimension the

distance between cabinet bottom to floor

⁄” NPT Male thread gas supply

Fig.6 Gas connection at rear of dryer

Installation instructions

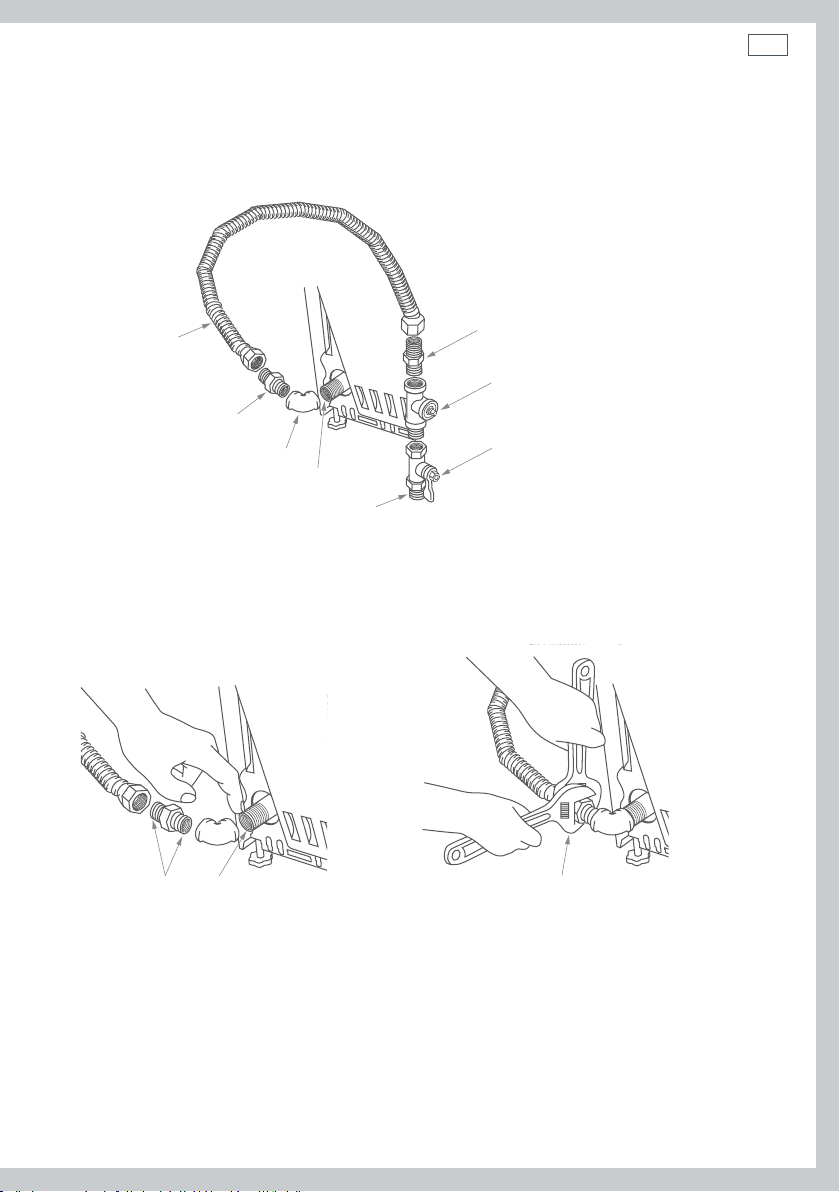

Connecting the dryer to the gas supply

Gas connection parts

Ensure you have the following parts before installing the dryer.

Adapter

New metal flexible

gas line connector

⁄” NPT pipe plug for

checking gas inlet pressure

17

Adapter

Elbow

⁄” NPT

Pipe size at least ½” (12.7 mm)

Shutoff valve

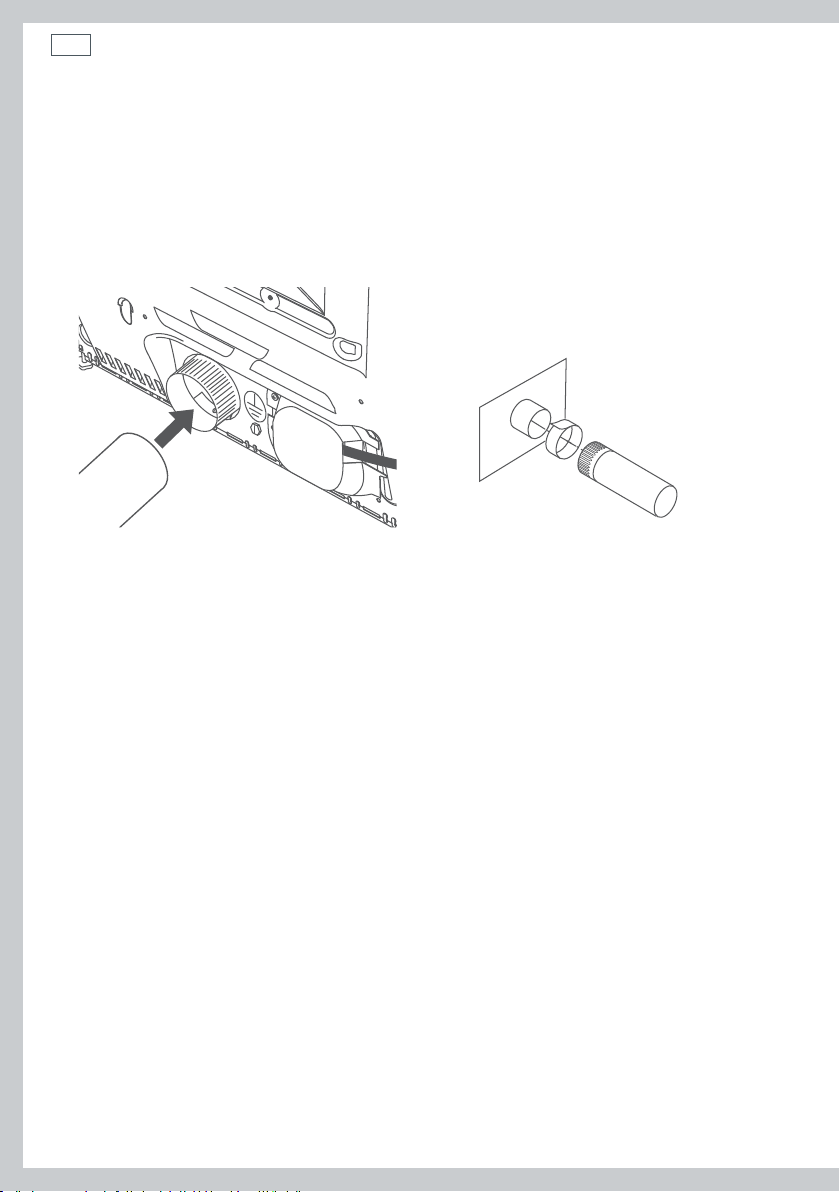

Fig.7 Parts required for gas connection

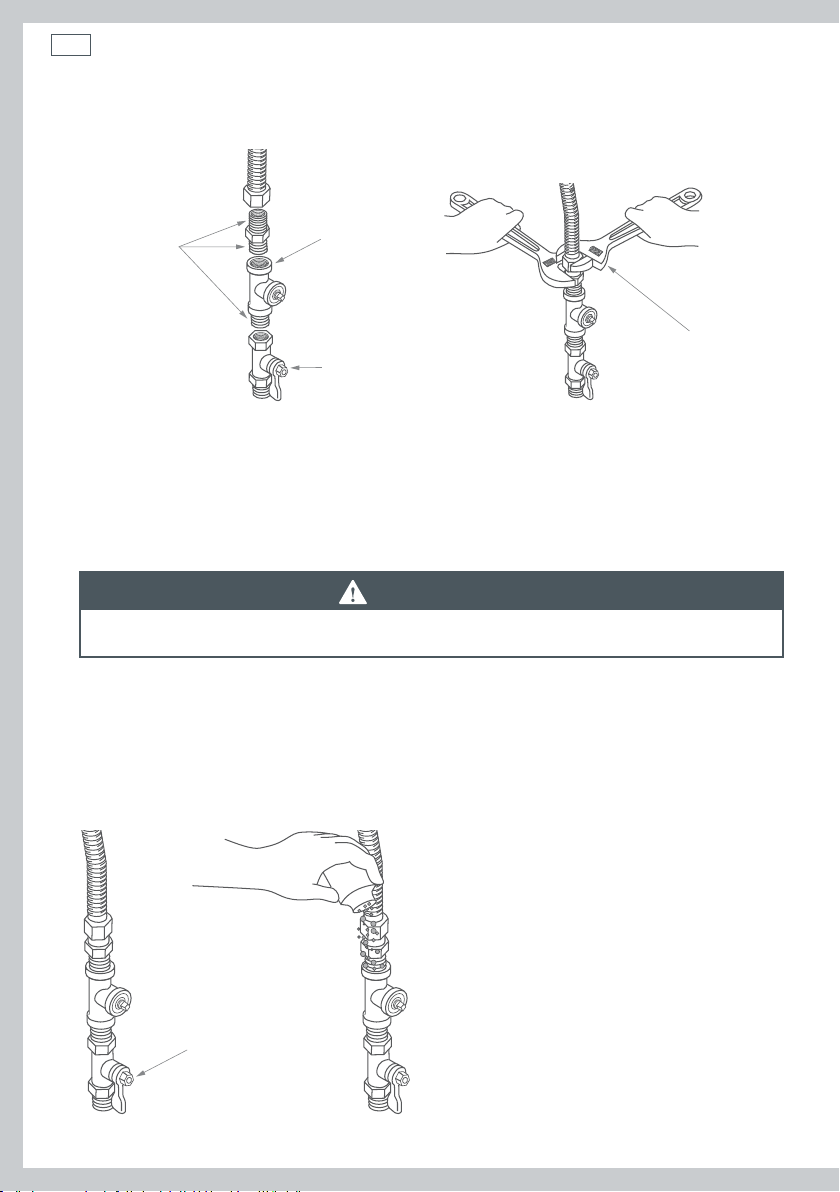

Connecting to dryer

Install a female ⁄” NPT elbow at the gas inlet end of the dryer.

Attach a ⁄” flare union adapter to the female NPT elbow.

Apply pipe compound to the adapter

and dryer gas inlet threads

Fig.8 Attaching elbow and adapter

Using two adjustable wrenches tighten

the flexible gas line connection

Fig.9 Tighten connections

Important!

Securely hold on to the end of the dryer gas inlet with a pipe wrench to help prevent twisting

the inlet.

18

Installation instructions

Connecting to supply

Apply pipe

compound to

all male threads

Fig.10 Connecting supply

Plugged

Tapping

Shutoff valve

Using two adjustable

wrenches tighten all

connections

Fig.11 Tightening supply connections

Important!

Do not over tighten the connections.

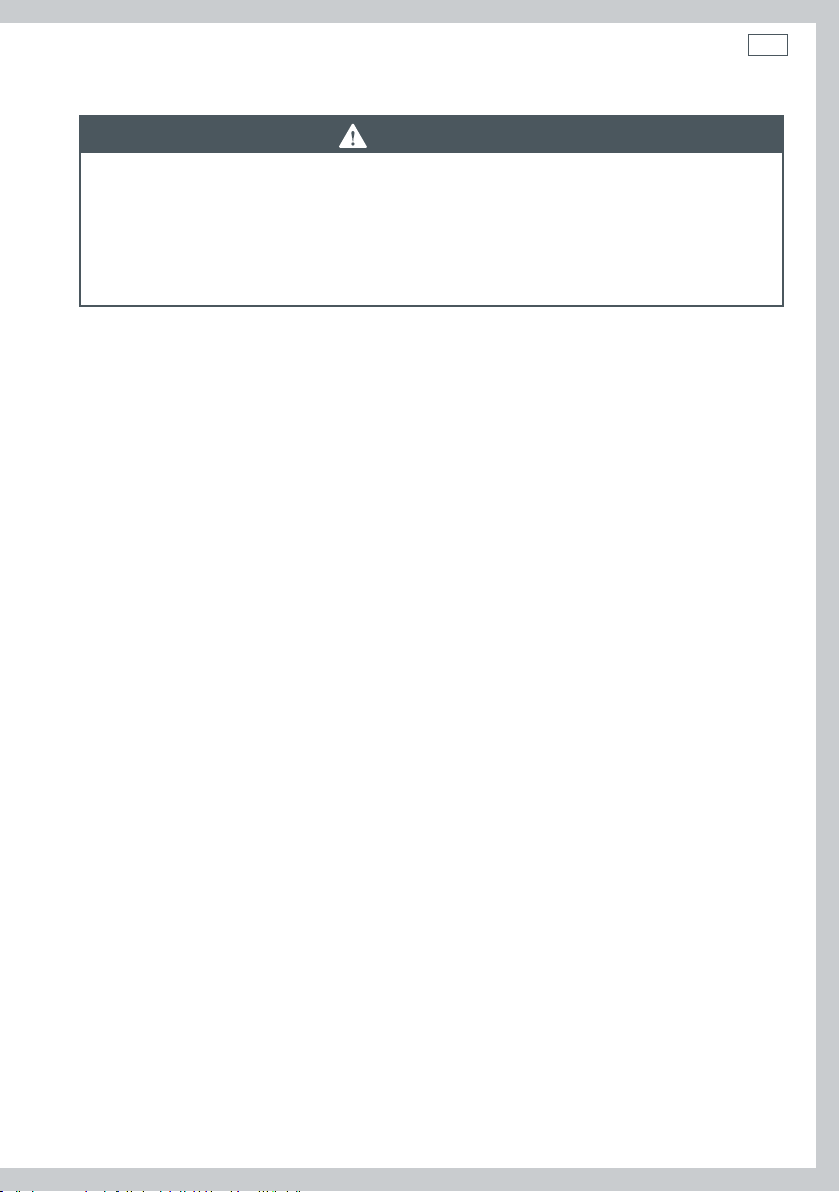

Test for gas leaks

WARNING!

NEVER use an open flame to test for gas leaks.

Turn on the gas (open the gas shut off valve).

All connections should be checked for leaks with a soapy, or equivalent solution. Apply a soap

(or equivalent) solution to the connection points. If leaks are found, close the shut-off valve,

re-tighten the joint, then repeat the test.

Note: Do not use a solution that contains ammonia. This may cause damage to the brass fittings.

Open gas valve

Fig.12 Testing for gas leaks

Installation instructions

WARNING!

Fire and Poisoning Hazard

Gas leaks cannot always be detected by the sense of smell.

Use of an approved UL or CSA gas detector is recommended.

If a gas leak is detected follow the “What to do if you smell gas” instructions, stated on

the inside font cover of this user guide.

19

20

Installation instructions

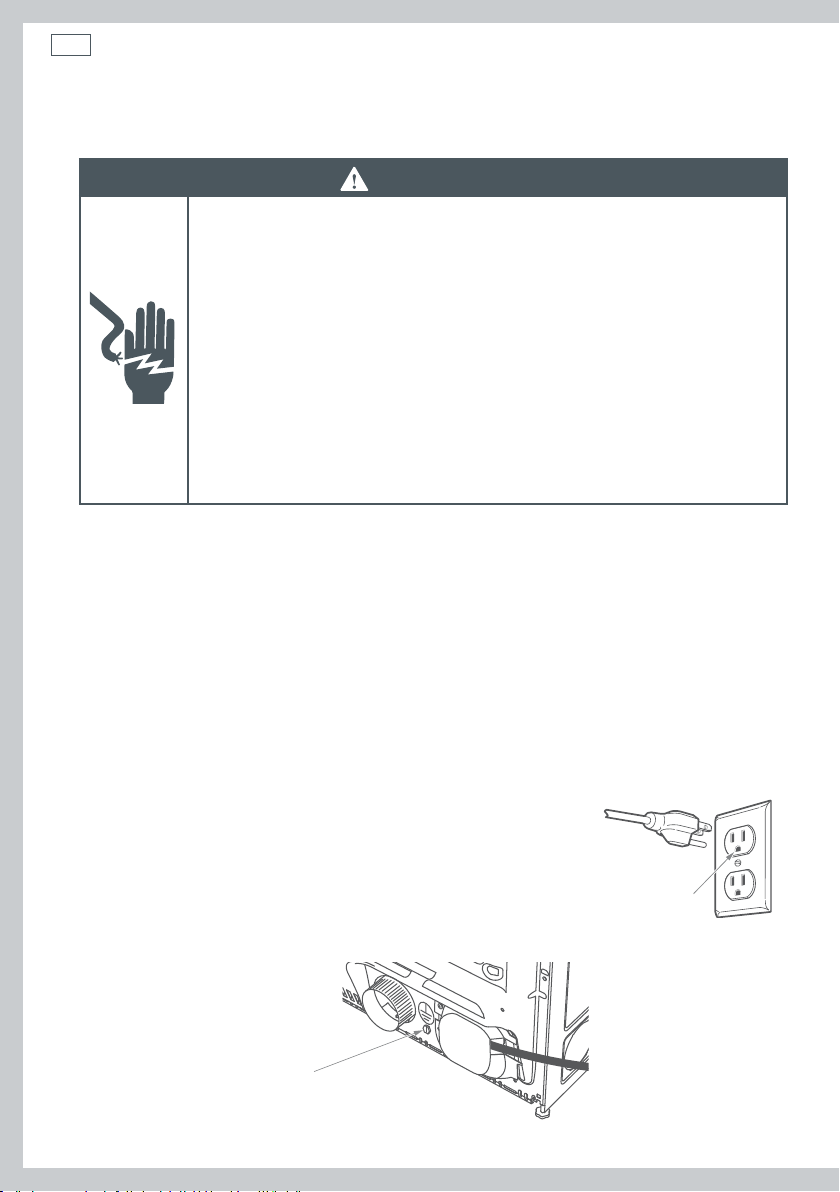

Electrical connection information for gas dryers

WARNING!

Electrical Shock Hazard

Make sure appliance is wired or plugged into a grounded outlet.

Improper connection of the equipment-grounding conductor can result in

a risk of electric shock. Check with a qualified electrician or service person

if you are in doubt as to whether the appliance is properly grounded.

Do not modify the plug if it will not fit the outlet.

Have the proper outlet installed by a qualified electrician.

Do not use an adaptor.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire or

electricalshock.

The appliance must be electrically grounded in accordance with all local codes and ordinances.

In the absence of local codes, the dryer must be electrically grounded in accordance with the

National Electrical Code, ANSI/NFPANO.70, or the Canadian Electrical Code, CSAC22.1.

Electrical requirements for gas dryers

The power supply must be 120V, 60Hz, and connected to a properly grounded branch circuit,

which is protected by a 15 or 20 amp circuit breaker, or a time-delay fuse.

If the electrical supply provided does not meet specifications outlined above, the installation of

an approved outlet by a licensed electrician is recommended.

Important!

The dryer is supplied with a three-prong (grounding) plug for your

protection against electric shock. The plug should be plugged

directly into a correctly grounded three prong power socket.

DONOT cut or remove the grounding terminal from this plug.

Ensure proper ground exists before use.

If local codes permit, an external

ground wire (not provided), which

meets local codes, may be added by

attaching to the green ground screw

on the rear of the dryer, and to a

grounded metal cold water pipe or

other established ground.

Fig.13 Grounding screw

Ensure proper

ground exists

before use

Installation instructions

Connecting an electric dryer (skip for gas dryers) – in the United States only

Refer to page 7 for tools required.

Electrical requirements (electric models only)

WARNING!

To reduce the risk of fire, electrical shock & personal injury:

The appliance must be correctly grounded electrically, in accordance with all local

codes and ordinances. In the absence of these, the appliance shall be grounded in

accordance with the National Electrical Code ANSI/NFPA No. 70.

Before connecting the dryer, turn off the circuit breaker(s) or remove the dryer’s circuit

fuses at its electrical box. Ensure the power cord is unplugged from the wall outlet.

DO NOT leave the cover off the terminal block.

Never use an extension cord or adapter plug with the dryer.

Use only new ducting materials. Remove and discard old duct material.

WARNING!

Electric Shock Hazard

Use a new UL/CSA-listed 30-ampere power cord.

Use a UL-listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center terminal.

On all four wire installations remove the grounding link and connect the

ground wire to the green ground connecting screw.

Connect remaining two supply wires to remaining two terminals.

Securely tighten all electrical connections.

Failure to do so can result in death, fire, or electrical shock.

21

Note: the wiring diagram is located in the control console.

The dryer must be plugged into or connected to an individual branch circuit, protected by the

correct time delay fuses or circuit breakers. The power supply must be a 3- or 4-wire, single

phase, 120/240 V, 60 Hz, 30 amp circuit.

22

Installation instructions

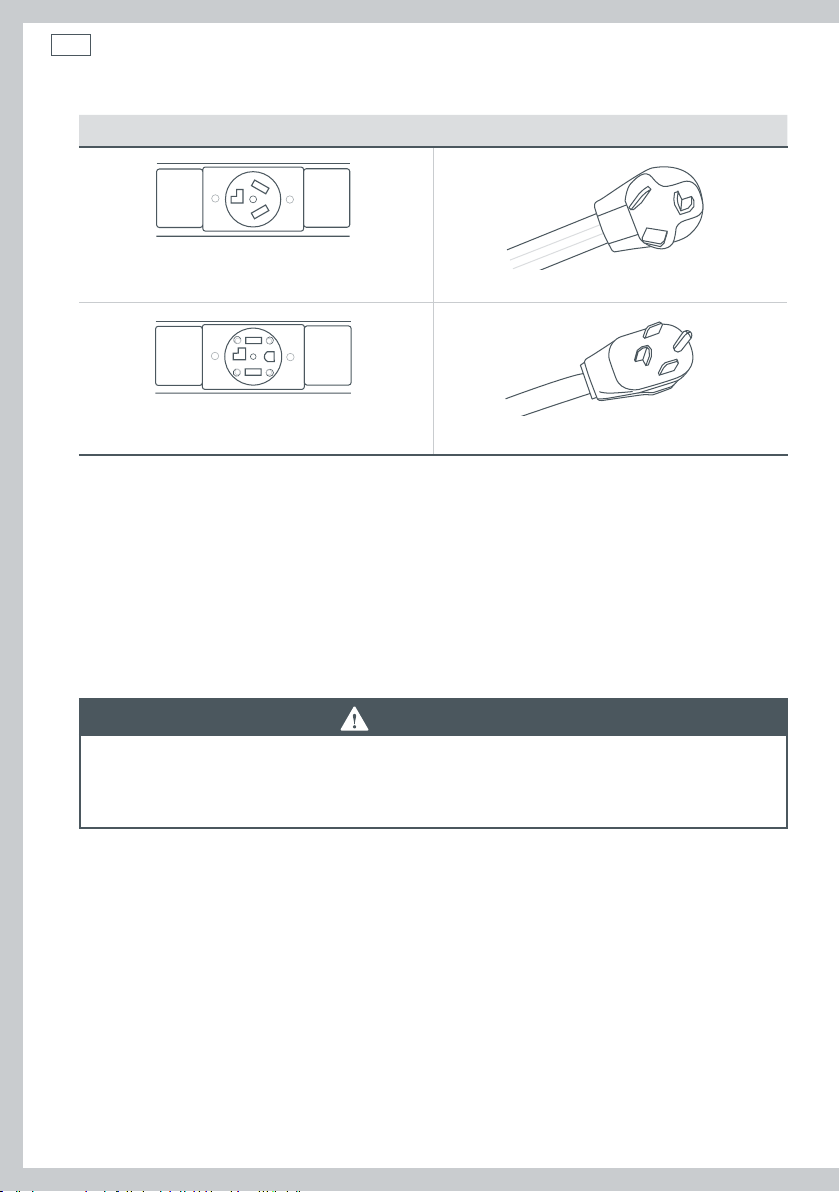

If your outlet looks like this Choose this power supply cord

3-wire

(NEMA type 10-30R) (See 3-wire connection)

4-wire

(NEMA type 14-30R) (See 4-wire connection)

If a power cord is used, this must be plugged into a 30 amp socket only.

The power cord is NOT supplied with electric model dryers in the United States.

Contact a licensed electrician if the electricity supply does not meet the required specifications.

Grounding instructions

This dryer MUST be connected to a grounded metal, permanent wiring system. Alternatively, an

equipment grounding conductor must be run with the circuit conductors and connected to the

equipment grounding terminal on the dryer.

WARNING!

Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service representative if you are in

doubt as to whether the appliance is properly grounded.

Installation instructions

Connecting the dryer using 4-wire connection (must be used for mobile home installation)

Note: the National Electrical Code requires that new constructions use a 4-wire connection to

an electric dryer (effective as of January 1, 1996). Where local codes do not permit grounding

through the neutral, a 4-wire cord must also be used.

Important!

New constructions must NOT use a 3-wire connection.

23

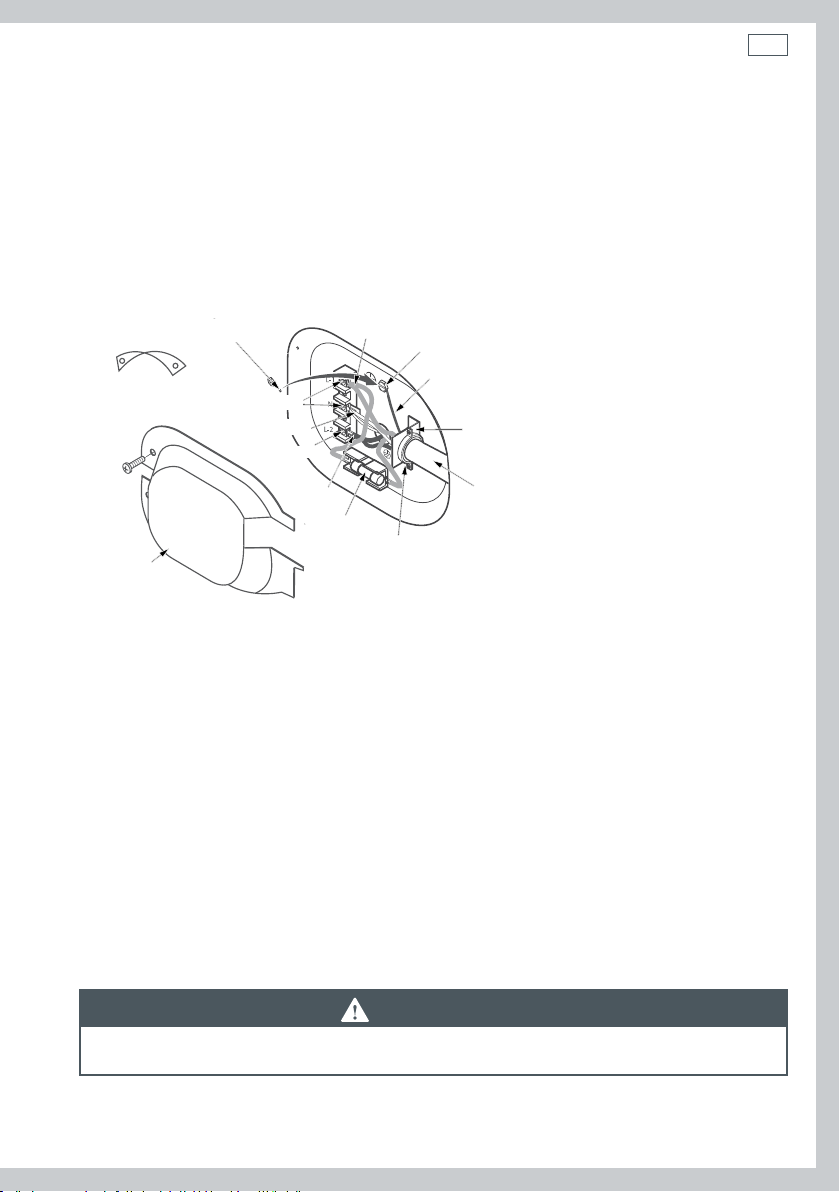

Remove ground strap and discard.

Keep green ground screw

Screws (2)

Neutral (white)

Cover

Fig.14 4-wire connections

1

Turn off the circuit breaker(s) (30 amp) or remove the dryer’s circuit fuse at the electrical box.

2

Ensure the dryer cord is unplugged from the wall outlet.

3

Locate and remove the power cord cover at the lower rear of the dryer.

4

Remove and discard the ground strap. Retain the green ground screw for later relocation (Step 7).

5

Install a ¾” (19 mm) UL-recognized strain relief to the entry hole for the power cord. Move the

Screw

Hot wire

Hot wire

Relocate green ground screw here

Green or yellow wire

Strain relief bracket

120/240V 30 amp power supply cord kit (min

length: 5 feet (1.5 m) marked for use with

dryers & provided with closed loop or spade

Fuse

⁄” (19 mm), UL recognized strain relief

terminals with upturned ends (not supplied).

power cord through the strain relief.

6

Connect the power cord according to the following:

a

Connect the two hot lines to the outer screws of the terminal block (labelled L1 and L2).

b

Connect the neutral (white) line to the center of the terminal block (labelled N).

7

Use the green ground screw to attach the ground wire of the power cord (ie relocate the green

ground screw to the hole above strain relief bracket).

8

Tighten all three terminal block screws completely.

9

Correctly secure the power cord to the strain relief.

10

Replace the power cord cover.

WARNING!

NEVER leave the power cord cover off the terminal block.

24

Installation instructions

Connecting the dryer using 3-wire connection

Important!

DO NOT use in Canada.

DO NOT use for Mobile home installations, on new constructions, or on recreational vehicles.

NOT for use in areas where local codes prohibit grounding through the neutral conduction.

If required by local codes, install an external ground (not provided) to grounded metal,

a cold water pipe or other established ground as determined by a qualified electrician.

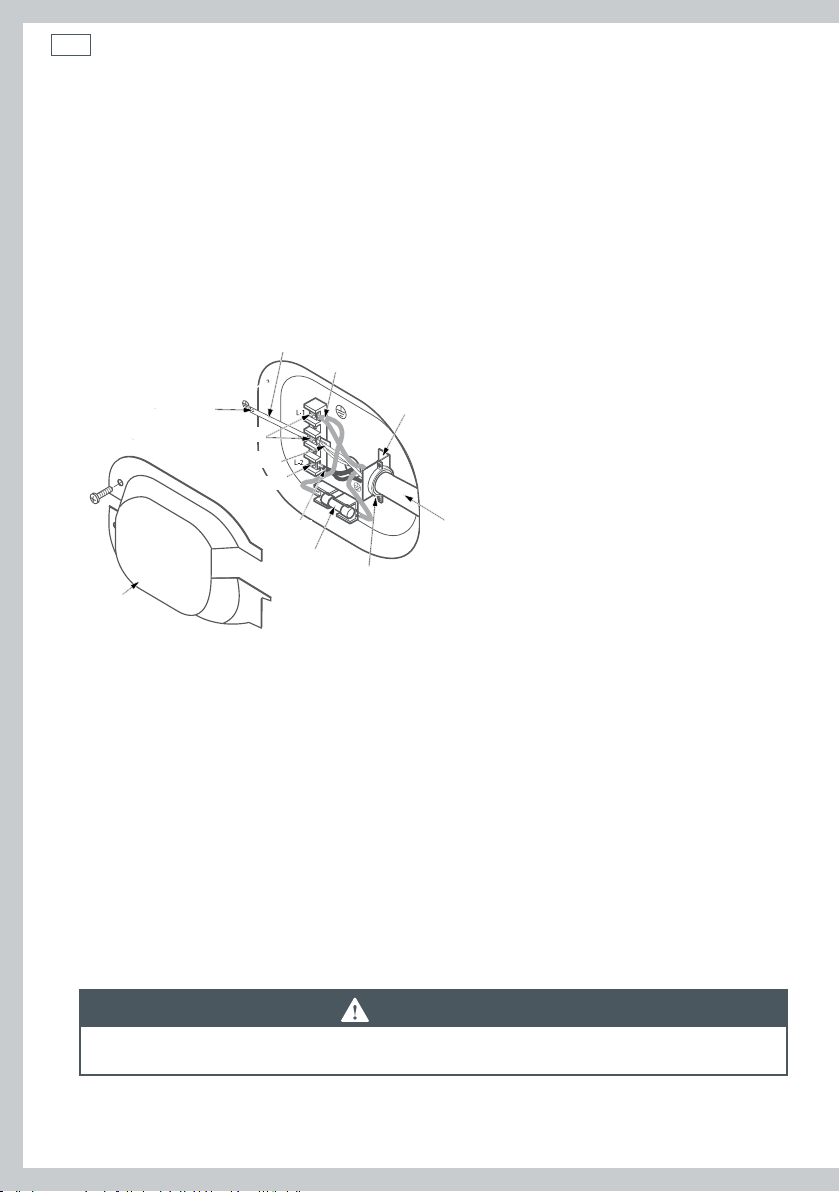

Ground strap

Hot wire

Green ground screw

Screws (2)

Neutral (white)

Screw

Hot wire

Fuse

Cover

Fig.15 3-wire connections

1

Turn off the circuit breaker(s) (30 amp) or remove the dryer’s circuit fuse at the electrical box.

2

Ensure the dryer cord is unplugged from the wall outlet.

3

Locate and remove the power cord cover at the lower rear of the dryer.

4

Install a ¾” (19 mm) UL-recognized strain relief to the entry hole for the power cord. Move the

Strain relief bracket

120/240V 30 amp power supply cord kit (min

length 4 feet (1.5 m)) marked for use with

dryers and provided with closed loop or spade

terminals with upturned ends (not supplied)

⁄” (19 mm), UL recognized strain relief

power cord through the strain relief.

5

Connect the power cord according to the following:

a

Connect the two hot lines to the outer screws of the terminal block (labelled L1 and L2).

b

Connect the neutral (white) line to the center of the terminal block (labelled N).

6

Ensure the ground strap is connected to neutral (center) terminal of block, and to the green

ground screw on located on the cabinet rear.

7

Tighten all three terminal block screws completely.

8

Correctly secure the power cord to the strain relief.

9

Replace the power cord cover.

WARNING!

NEVER leave the power cord cover off the terminal block.

Installation instructions

Connecting an electric dryer (skip for gas dryers) – in Canada only

Electrical requirements (electric models only)

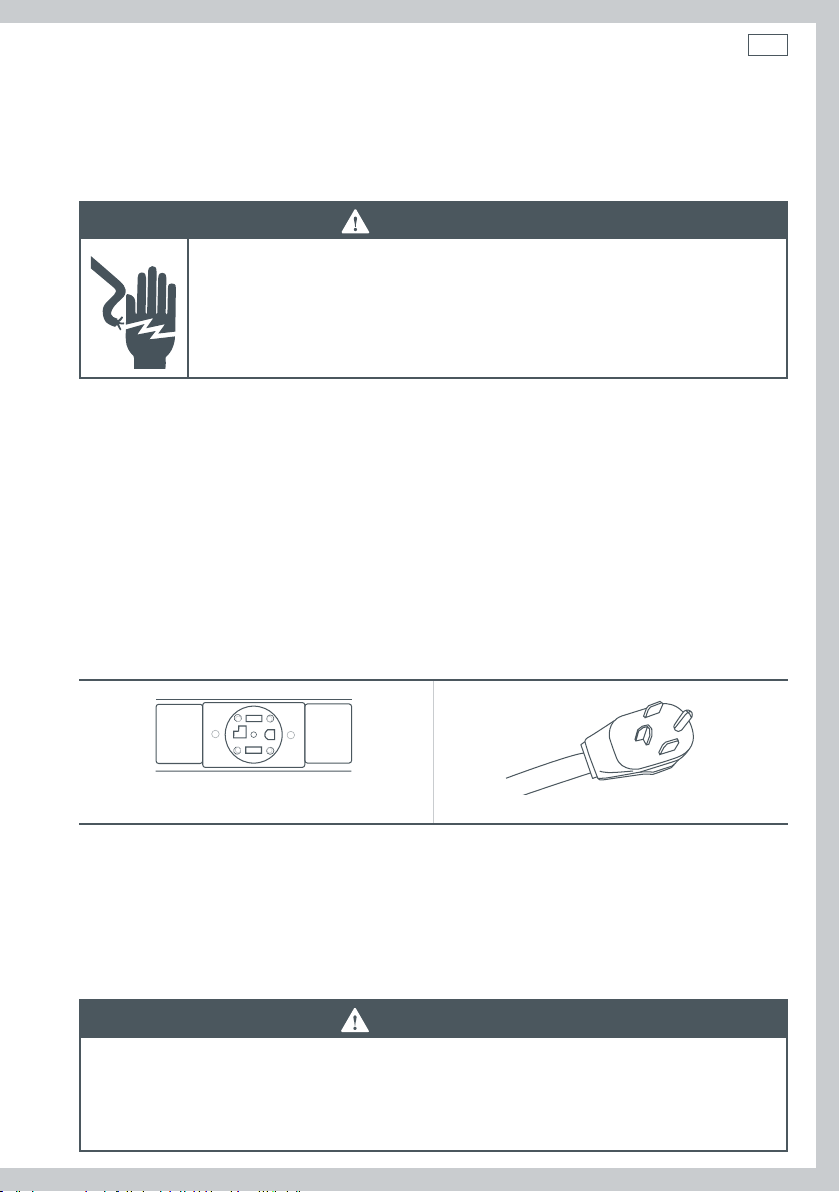

WARNING!

Electric Shock Hazard

Plug appliance into grounded 4 prong outlet.

Failure to do so can result in death or electric shock.

Note: the wiring diagram is located in the control console.

It is your responsibility to:

Contact a qualified electrical installer.

Ensure the electrical connection is adequate and conforms with Canadian Electrical Code, C22.1

and all local code requirements.

Plug the dryer into, or connect the dryer to an individual branch circuit, which is protected by

the correct time delay fuses or circuit breakers. The power supply must be a 4-wire, single phase,

120/240 V, 60Hz, 30 amp circuit.

This dryer is supplied with a CSA approved power cord (5 feet (1.52 m) in length, intended for

plugging into a 14-30R wall outlet. Ensure the outlet is within reach of the dryer’s final location.

25

4-wire

(NEMA type 14-30R)

A replacement power cord is available, if required. Use of part number 248C1014G001 (240 V

cord set) is recommended. Contact Fisher & Paykel Customer Care (refer to page 84).

Grounding instructions

This dryer MUST be connected to a grounded metal, permanent wiring system.

WARNING!

Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. Check with a qualified electrician or service representative if you are

in doubt as to whether the appliance is properly grounded. Do not modify the plug

provided with the dryer.

26

Installation instructions

Exhausting the dryer

Refer to page 7 for tools required.

WARNING!

Fire Hazard

The dryer must be vented to the outdoors.

Use rigid or thick wall flexible metal exhaust duct only.

Do not use a plastic exhaust duct.

Do not use a metal foil exhaust duct.

Failure to follow these instructions can result in death or fire.

This dryer must be vented to the outdoors. This will prevent the build up of lint and moisture in

the room in which it is located and reduce the risk of fire.

Use only 4” (102 mm) rigid metal ducting material for the home exhaust duct.

Use only 4” (102 mm) rigid metal or UL-listed flexible metal (semi-rigid or foil-type) duct material

to connect the appliance to the home exhaust duct. The ducting must be installed according to

the instructions found in the section “Connecting the dryer to the house vent” (page 29).

The dryer must not under any circumstances be exhausted into a chimney, a wall, a ceiling, gas

vent, crawl space, attic, under an enclosed floor, or into any concealed space of a building.

Never vent the dryer into a common duct with an exhaust system originating from a kitchen. The

combination of grease and lint creates a potential fire hazard.

Ducting must be kept as short in length and as straight as possible. Ducts can accumulate lint

and create a potential fire hazard. Do not exceed the maximum exhaust duct lengths stated later

in these installation instructions (page 33).

Never install a screen in or over the dryers exhaust duct. The screen will cause lint to accumulate,

creating a potential fire hazard.

Use duct tape to secure joints in the ducting. Do not use screws as these will extend into the

duct system, accumulate lint and create a potential fire hazard.

Never obstruct incoming or exhausted air.

Ensure access is provided for inspection and cleaning of the exhaust. This is particularly

important at turns and joints. The exhaust system shall be inspected and cleaned annually.

The dryer is set up for rear exhausting. If space available for installation is limited, the dryer can

be vented directly from the sides or bottom of the cabinet. Refer to pages 35 to 38.

Installation instructions

Dimensions

Exhaust outlet location

Exhaust outlet

3 ½” (89 mm)

11 ¾” (298 mm)

Note: add to vertical dimension the

distance between cabinet bottom to floor

Before you start

If required, remove and discard of all existing plastic or metal foil duct. Replace this with

UL-listed duct material.

Check for and remove any lint from the vent opening in the wall.

Ensure the exhaust hood damper moves freely.

Fig.16 Exhaust outlet dimensions

27

Internal duct

opening

Wall

Check that exhaust

hood damper opens

and closes freely

Fig.17 House vent opening

28

Installation instructions

Exhaust system setup

Hood or wall cap

Ensure the exhaust duct ends with a vent hood

with a swing out damper to prevent back drafts

12” min.

(305 mm)

and entry of wildlife.

Ensure there is minimal resistance to the exhaust

airflow. The structure should also require little or

no maintenance to prevent clogging.

Never place a screen in or over the duct.

The vent hood should have at least 12”(305 mm)

clearance between the bottom of the hood and

the ground or other obstruction.

The hood or wall cap should point downward.

Fig.18 Exhaust hood installation

12” min.

(305 mm)

Separation of turns

Separate all turns by at least 4 feet (1.2 m) of straight ducting (including the distance between

the last turn and the wall cap) to ensure the best performance of the dryer.

Turns other than 90°

One turn of 45° or less may be ignored.

Two 45° turns are to be considered equal to one 90° turn.

Each turn greater than 45° should be considered as equal to one 90° turn.

Important!

Choose a route that will provide the straightest and most direct path to the outdoors. Plan the

installation to use the fewest number of elbows and turns as possible.

When using elbows (rigid duct) or making turns (thick wall flexible metal duct), allow as much

room as possible. Bend thick wall flexible metal duct gradually to avoid kinking, and avoid

90°turns using this material.

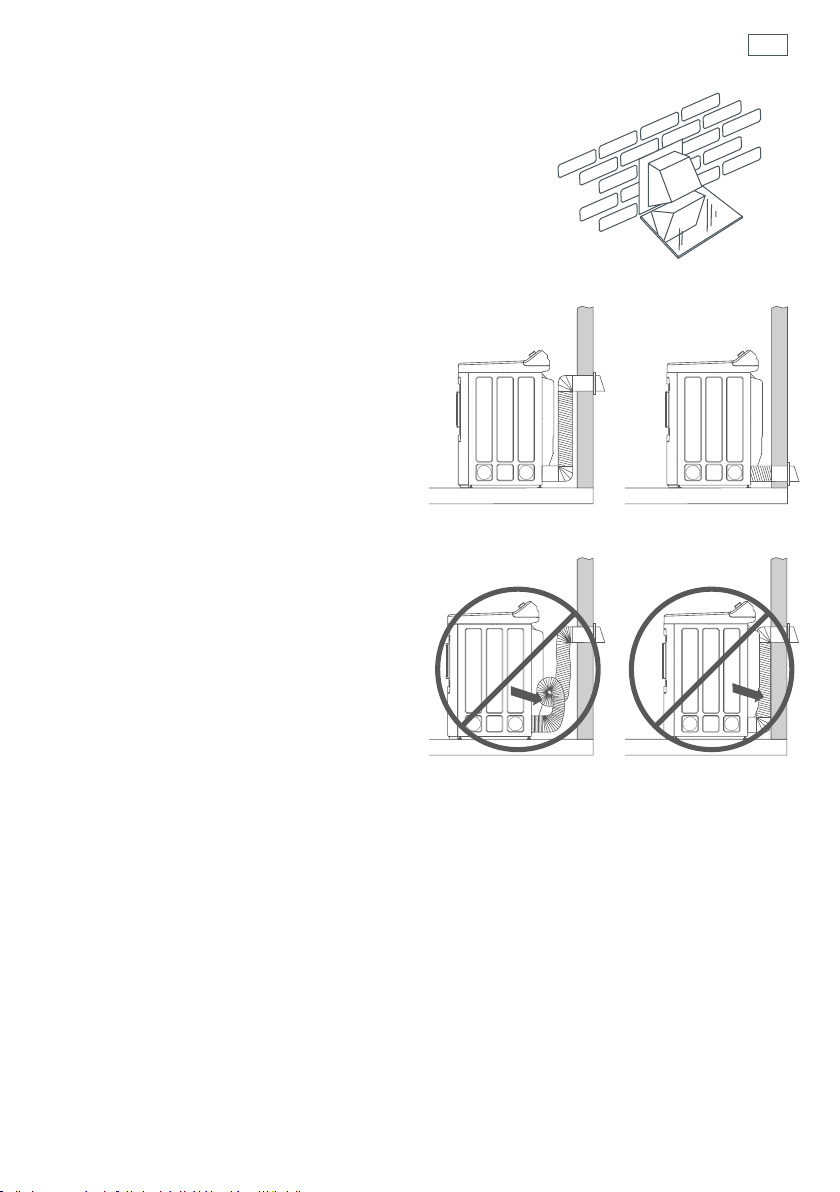

Recommended Acceptable

Fig.19 Duct configurations

Installation instructions

Sealing of joints

All joints must be tightly sealed to avoid leaks.

The male end of each section of duct must be installed away from the dryer.

Do not use screws or fasteners that extend into the duct to secure the joint as lint will

accumulate around these, creating a potential fire hazard.

Joints should be made air- and moisture-tight by securing the overlapped joints with duct tape,

or aluminum tape.

Horizontal duct runs should slope down towards the outdoors ¼” (6 mm) per foot.

Insulation

Ducting that is directed through an unheated area or is near air conditioning should be insulated

in order to reduce condensation and lint build-up.

Connecting the dryer to the house vent

Rigid metal duct

The use of a rigid metal ducting is recommended for best drying performance.

The risk of crushing and kinking of the duct is reduced when using this duct material.

UL-listed flexible metal (semi-rigid) transition duct

If rigid metal duct is not appropriate, a UL-approved flexible metal (semi-rigid) duct material can

be used (kit WC572D559P006).

Do not install flexible metal duct in walls, ceilings, floors or other enclosed spaces.

Flexible metal duct should not exceed 8 feet (2.4 m) in total.

Installing elbows at both the dryer and the wall is highly recommended. An elbow allows the

dryer to be positioned close to the wall without kinking and/or crushing the transition duct, and

maximizes the performance of the dryer.

Do not rest the ducting on sharp materials and objects.

29

30

Installation instructions

UL-listed flexible metal (foil-type) transition duct

Connecting the dryer to the house vent using flexible metal (foil-type) duct maybe required in

some installations. A UL-listed flexible metal (foil-type) duct can ONLY be used where:

rigid metal or flexible metal (semi-rigid) ducting cannot be used, AND

a 4” (102 mm) diameter can be maintained throughout the entire length of the transition duct.

Only flexible metal (foil-type) ducts that comply with the requirements of the “Outline for

Clothes Dryer Transition Duct Subject UL2158A”, shall be used in the United States and Canada.

Do not install flexible metal duct in walls, ceilings, floors or other enclosed spaces.

Flexible metal duct shall not exceed 8 feet (2.4 m) in total.

Do not rest the ducting on sharp materials and objects.

To ensure the best performance of flexible metal (semi-rigid and foil type) transition duct:

1

Slide one end of the duct over the exhaust outlet pipe at the back of the dryer.

2

Secure the duct to the pipe with a clamp.

3

Move the dryer to its final position.

4

Extend the duct to its full length. Allow 2” (51 mm) of duct to overlap the house exhaust

outlet pipe. Cut off and remove the unwanted duct. Keep the duct as straight as possible for

maximum airflow.

5

Secure the duct to the house exhaust outlet pipe with a clamp.

For transition venting (dryer to wall):

DO:

Installation instructions

Elbows

31

DO cut duct as short as possible

and install straight into wall

Fig.20 Correct venting installation

DO NOT:

DO NOT bend or collapse ducting

Use elbows if turns are necessary

DO use elbows when turns

are necessary

DO NOT use excessive exhaust length

Cut duct as short as possible

DO NOT crush duct against the wall DO NOT set dryer on duct

Fig.21 Dangerous venting installation set ups

32

Installation instructions

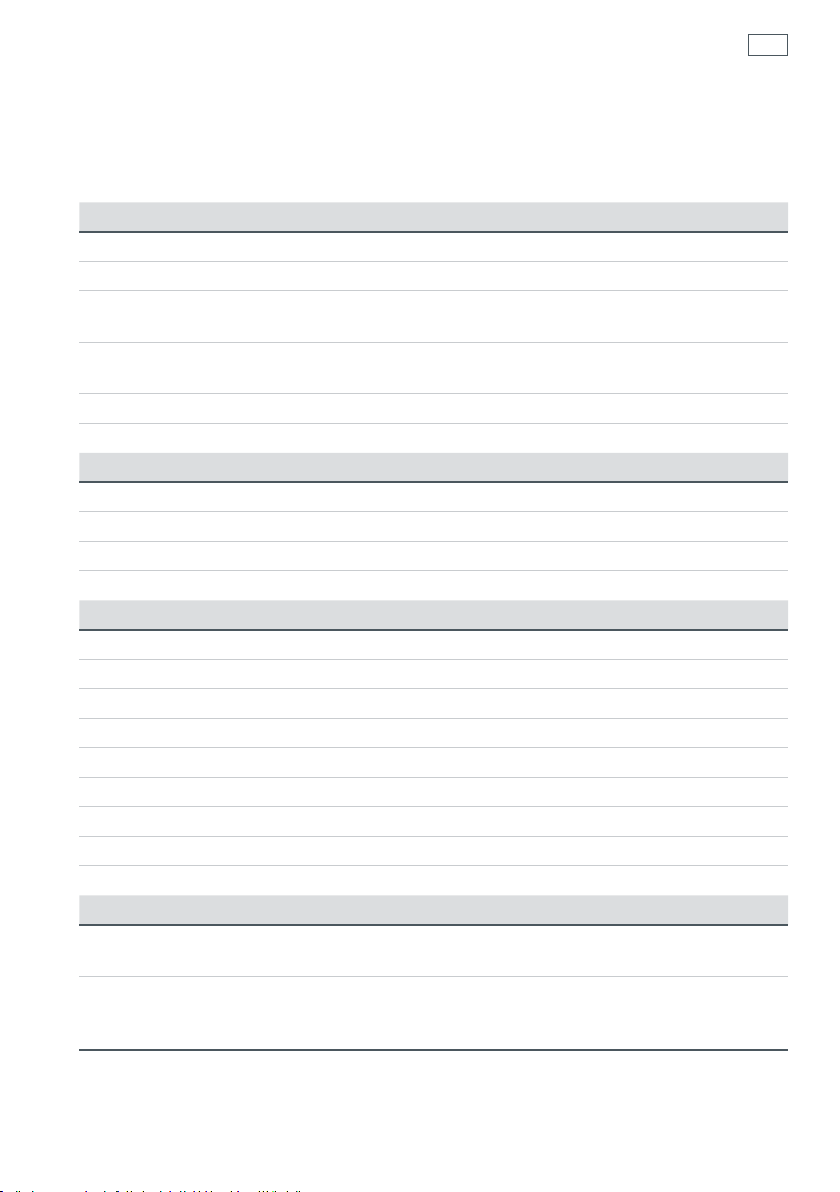

Exhaust Length

Maximum length of exhaust duct

The maximum length of the exhaust duct system depends upon:

The type of ducts used (rigid or thick-walled flexible metal).

The number of elbows or bends used.

The type of exhaust hood (wall cap).

1

Refer to the exhaust duct length chart (page 33) that matches your hood type to determine

the maximum duct lengths you can use. DO NOT use duct lengths longer than specified in the

exhaust duct length charts.

Using exhaust duct systems longer than is specified will:

Accumulate lint creating a potential fire hazard.

Shorten the life of the dryer.

Reduce the performance, resulting in longer drying times and an increased energy usage.

2

Determine the number of elbows/bends you will need.

3

In the column listing the type of metal duct you are using (rigid or flexible metal), find the

maximum length of metal duct on the same line as the number of elbows/bends to be used

(refer to page 33).

Important!

Use 4” (102 mm) metal duct only.

Do not use duct that is longer than that specified in the table on page 33.

Flexible metal duct shall not exceed 8 feet (2.4 m) in total.

The correct exhaust installation is YOUR RESPONSIBILITY.

Problems due to incorrect installation are not covered by the limited warranty.

WARNING!

Incorrect installation of the exhaust duct may result in poor dryer performance and

increase the risk of fire.

Installation instructions

Preferred 4” (102 mm) Hoods

33

4” Dia (102 mm)

4” (102 mm)

When you have a 4” (102 mm) Hood

Maximum length of 4” (102 mm) diameter metal duct.

Number of 90˚

elbows/bends

0 90 ft 27.4 m 8 ft 2.4 m

1 60 ft 18.3 m 8 ft 2.4 m

2 45 ft 13.7 m 8 ft 2.4 m

3 35 ft 10.7 m 8 ft 2.4 m

4 25 ft 7.6 m 8 ft 2.4 m

Rigid metal

4” Dia (102 mm)

Flexible metal

(fully extended)

Acceptable 2 ½” (64 mm) Hood (for short length installations)

4” Dia (102 mm)

2 ½” (64 mm)

When you have a 2 ½” (64 mm) Hood

Maximum length of 4” (102 mm) diameter metal duct.

Number of 90˚

elbows/bends

0 60 ft 18.3 m 8 ft 2.4 m

1 45 ft 13.7 m 8 ft 2.4 m

2 35 ft 10.7 m 8 ft 2.4 m

3 25 ft 7.6 m 8 ft 2.4 m

4 15 ft 4.6 m 8 ft 2.4 m

Rigid

Flexible Metal

(fully extended)

34

Installation instructions

Standard rear exhaust

We strongly recommend the use of rigid metal exhaust duct. We recommend you install your dryer

first, before installing your washer. This will allow you easier access for connecting the exhaust.

Place the end of the exhaust duct on the outlet at the rear of the dryer. Secure with duct tape or

a hosed clamp. For a straight installation, connect the dryer exhaust directly to the wall. Use duct

tape to secure the join.

Wall side

Duct

Dryer side

Fig.22 Attaching the metal duct to the dryer outlet

Fig.23 Securing the duct join with duct tape

Installation instructions

Dryer exhaust to right, left or bottom of cabinet

WARNING!

Before performing this exhaust installation, be sure to disconnect the dryer from its

electrical supply. Protect your hands and arms from sharp edges when working inside

the cabinet. Be sure to wear gloves.

Important!

Dryer exhaust to right of cabinet (electric models only).

Dryer exhaust to left of cabinet (gas and electric models).

Detach and remove the bottom, right or left side knockout (the opening for alternate ducting),

as preferred for the direction of ducting. Tape around the knockout and exhaust opening to

provide protection from sharp edges during installation. Remove the screw inside the dryer

exhaust duct and slide the duct out of the dryer. Keep the screw. Cut the duct as shown in

Figure24. Retain portion A of the duct.

Right (electric

models only)

Fixing hole

35

Remove screw

and save

Bottom (gas

and electric

models)

Left (gas and

electric models)

Remove desired

knockout (one only)

Fig.24 Removing and

shortening the duct

9” (230 mm)

Tab location

Through the rear opening, find the tab located in the middle of the dryer base. Using a flat blade

screwdriver, lift the tab to approximately 45°.

Bend tab

up 45°

Fig.25 Lifting the tab

36

Installation instructions

Adding shortened duct section

Connect portion “A” of the original length of duct to the blower housing, ensuring the shortened

duct is aligned with the tab in the base. Use the screw saved previously to secure the duct in

place through the tab on the dryer base.

Fixing

hole

Portion “A”

Side exhaust

Fig.26 Installing shortened duct section

Installation instructions

Adding ducting for exhaust to the right or left side of the cabinet

Assemble a 4” (102 mm) elbow with a 4” (102 mm) length of duct. Secure the joint with duct tape.

Insert the elbow end of the duct assembly carefully through the side opening, and connect this

end to the internal duct of the dryer (inside).

WARNING!

Be sure not to pull or damage the electrical wires inside the dryer when inserting the duct.

Internal duct joints must be secured with tape, otherwise they may separate and cause

a safety hazard.

Exhaust can be added

to the left (gas or electric

models) or right side (electric

models only)

Duct tape

Fig.27 Left and right exhausting

Use duct tape (as shown in Figure 28) to secure the joint between the dryer internal duct and the

elbow, and also the joint between the elbow and the side duct.

37

Duct tape

Fig.28 Securing joints correctly with duct tape

Cover the original duct opening at the back with a plate (kit WE1M454), available from Fisher &

Paykel, refer to page 84).

Fig.29 Cover plate

38

Installation instructions

Adding elbow for exhaust through bottom of cabinet

Insert the elbow section of the duct through the rear opening and connect it to the dryer

internal duct.

Secure the joint between the internal duct and elbow with duct tape, as shown in Figure28

(page37).

Fig.30 Exhaust elbow

Complete the exhaust system by connecting the required standard metal elbows and ducts.

Cover the original duct opening at the back with a plate (kit WE1M454, available from Fisher &

Paykel (refer to page 84). Refer to Figure 29 (page 37).

Move the dryer into its final position.

WARNING!

The rear duct opening must be covered with a plate. The dryer must not be operated

without the plate in place.

Installation instructions

39

Water connection (for selected models with Steam cycles)

Supply requirements

The hot and cold faucets MUST be installed no further than 42” (1070 mm) from the washer’s

inlet supply. Faucets need to be ¾” (19 mm) so the inlet hoses can be connected correctly.

Inlet water pressure required: Min. 10 psi (70 kPa) to Max. 120 psi (827 kPa). Consult your Water

Department for information about the pressure supplied to your home.

Note: if your domestic water supply is hard, we recommend using a water softener to help

reduce the build up of lime scale within the steam generator. Over time, a build up of lime scale

may block up the water system, causing reduced performance and the possible need for part

repair or replacement.

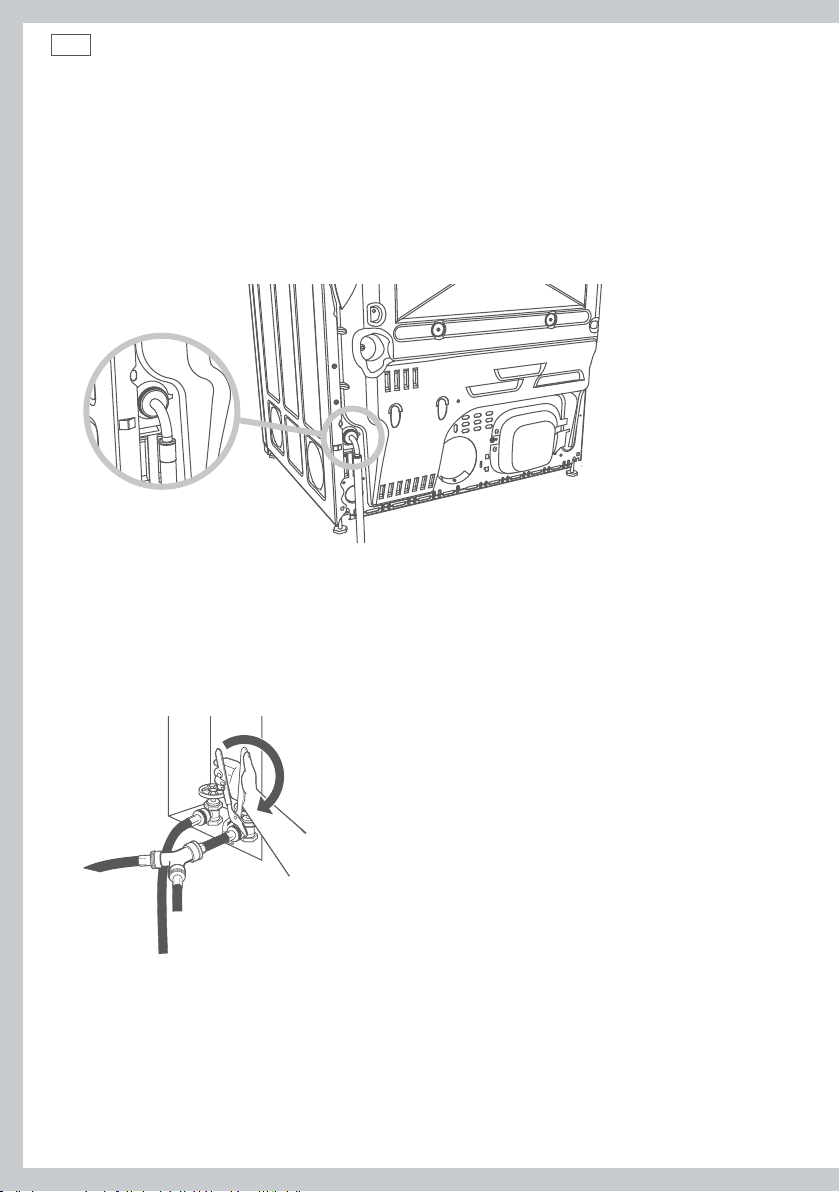

Water supply connection

For the Steam cycles to work correctly, the dryer must be connected to the cold water supply. A

“Y” connector can be used so that the washer (which also requires a cold water supply) and dryer

can be connected to the cold supply at the same faucet.

Important!

Use the new inlet hoses provided with your dryer. Never reuse old hoses or rubber washers.

Inlet hose replacement

We recommend the inlet hoses are changed every 5 years. Hoses should also be checked from

time to time and replaced if any wear, cuts, bulges, kinks or leaks are found. WARNING!: Failure to

do so may result in a flood and damage to property.

To connect the dryer

Parts required:

Flat rubber washers(4).

Filter washer.

“Y” connector.

Short inlet hose.

Long inlet hose.

1

Ensure the cold faucet is turned off. Disconnect

the cold inlet hose from the end of the faucet.

2

Insert the filter washer into the female coupling

of the short inlet hose and connect it to the

cold faucet.

3

Insert a flat washer into the female coupling of

the “Y” connector and fit the connector to the

male coupling of the short inlet hose.

Long inlet hose

“Y” connector

Flat rubber

washer(s)

Filter washer

Filter washer

Short inlet hose

Fig.31 “Y” Connector

40

Installation instructions

4

Check that the washer inlet hose (which has been removed from the faucet) has a flat washer or

filter washer fitted. If not insert a flat washer and connect the hose to one of the male couplings

on the “Y” connector.

5

Take the long inlet hose and insert a flat washer into the straight female coupling and connect it

to the other male coupling on the “Y” connector.

6

Insert a flat rubber washer into the other female connector and couple the hose to the inlet

valve on the rear of the dryer.

Fig.32 Attaching the inlet hose to the dryer

7

Check that all connections are firmly hand tight, then using a pair of pliers tighten each coupling

another two-thirds of a turn.

Important!

Ensure you DO NOT OVERTIGHTEN the connections. Overtightening may result in damage to the

couplings.

Fig.33 Tightening the connections

8

Check immediately for any leaks from the “Y” connector, hose couplings and/or the faucet. Check

again for leaks after 24 hours.

Installation instructions

Reversing the door

Tools required:

Standard #2 Phillips screwdriver.

Tape-tipped putty knife.

Needle-nosed pliers.

1

Remove the plug from the power outlet.

2

Open the door and remove the blanking plugs opposite the hinges. Retain the blanking plugs

for Step 4.

3

With the door completely open, remove the bottom screw from each hinge on the dryer face.

Insert these screws about half way into the top holes, for each hinge, on the opposite side

(where you removed the plastic plugs). Apply firm pressure to get the screw started in untapped

holes.

41

Fig.34 Removing the door

4

Loosen the top screw from each hinge on the dryer face to half way. With one hand holding

the top of the door and the other hand holding the bottom, remove the door from the dryer by

lifting it up and out. Remove the two remaining screws and retain for later use. Fit the blanking

plugs removed in Step 2.

42

Installation instructions

5

To invert the direction of the door panel, lay the door face down on a safe, protected surface and

remove the four screws from the hinges.

Fig.35 Removing screws from the hinges

6

Separate the door panel from the inside of the door by removing the six screws, as shown in

Figure 36.

Fig.36 Separating door panel from inside of door

Important!

Remove only the six screws as shown.

7

Lift and rotate the door panel 180º then reinsert the inside of the door in the panel. Replace the

six screws removed in Step 6.

Fig.37 Rotating door panel, then replacing screws

Installation instructions

8

Reattach the hinges on the opposite side to the door handle, using the same four screws on the

hinge retained from removing the hinges in Step 5.

Fig.38 Fixing hinges to opposite side

Important!

Check the position of the hinge as shown in Figure 38.

9

To change the direction of the door strikes, unscrew both the cover plate and the strike plate

(the strike plate being the plate with the metal part protruding). Reinstall one plate in place of

the other.

43

Fig.39 Exchanging cover plate and strike plate location

10

Install the door on the opposite side of the opening by moving the door in and down until the

top hinge and bottom hinge are resting on the two screws inserted in Step 3. With the two

screws retained in Step 4, secure each hinge at the bottom.

Fig.40 Installing the door in the reverse position

11

Tighten the two top screws of each hinge.

44

Installation instructions

Leveling the dryer

Position the dryer near the final location. Adjust the four leveling legs (wind up or down) at the

corners as needed, to ensure the dryer matches the height of the washer and is level from side to

side and front to back. The dryer must rest firmly on all four legs, and not rock in any direction.

1

Move the dryer to its final location.

2

To ensure the dryer is correctly level from side-to-side, place a spirit level on the top center of

the machine. If level, the air bubble will sit between the two lines.

3

To check whether the dryer is correctly level from front-to-back, open the door to the 90°

position, place the spirit level on the top edge of the door and check the bubble sits between

the two lines.

4

If the dryer is not level in any direction, adjust the height of the appropriate leg(s) until the dryer

is correctly level.

Level side-to-side

Level front-to-back

4 leveling feet

Fig.41 Leveling the machine

Installation instructions

Installation checklist

1. Packaging

Have all of the packaging materials been removed, and disposed of responsibly? Remove the

accessories from the drum.

2. Parts

Check that all parts have been installed.

3. Tools

Check all tools are present.

4. Grounding

Important!

Make sure the dryer is correctly grounded before operating.

45

This appliance must be grounded. In the event of malfunction

or breakdown, grounding will reduce the risk of electric shock

by providing a path of least resistance for electric current.

This appliance is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must be

plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Fig.42 Ensure outlet is grounded

correctly before use

Ensure proper

ground exists

before use

5. Installation

Please ensure:

No plastic or non-UL listed flexible metal foil material has been used for the exhaust ducting.

Exhaust material used is either rigid ducting or thick wall flexible metal ducting.

All joints in the ducting are secured with duct tape, as described in the instructions. Screws or

other fastening devices which extend into the inside of the duct should not be used.

Ducting system is clean and is correctly and securely connected to the dryer.

The ducting system is not being crushed or kinked when the dryer is in its final position.

The faucets are turned on. Check for leaks around the connections (at the Y connector, hoses

and faucets).

The dryer is correctly level and does not rock in any direction.

The inside of the drum is wiped out with a damp cloth to remove any residue remaining from

manufacture or installation, before use.

46

Installation instructions

Additionally for electric dryer models only, check:

Dryer is plugged or directly wired into an approved fitting, and is properly grounded.

Dryer starts, heats, cools and shuts off.

Customer has been shown how to use the dryer.

Additionally for gas dryer models only, check:

Dryer is plugged into an approved fitting, and is properly grounded.

All fittings in the gas line have been tested for leaks.

Exhaust temperature increases, to confirm ignition has occurred.

– If ignition does not occur initially, it may be due to air in the gas line or low voltage power supply.

– The gas regulator valve may fail to open if the power supply falls below 105 Volts.

– If the gas fails to flow or does not ignite, the dryer will automatically switch off.

Customer has been shown how to use the dryer.

6. Turning the dryer on

To turn the dryer on, simply touch the POWER button.

Note: if the dryer has been exposed to temperatures below freezing for

an extended period of time, allow it to warm up before touching POWER.

Otherwise, the display will not come on.

If the dryer will not start, check that:

The START/PAUSE button has been pressed firmly.

The dryer is plugged in and the power is turned on. Could the household supply be at fault?

The household fuse is intact and that the circuit breaker has not been tripped.

The dryer door is completely closed.

Note: some models of dryer have a drum reversal feature to reduce clothes tangle. Throughout

the drying cycle the motor will run for 4 minutes, then stop and run in the opposite direction for

40 seconds before reversing again.

The dryer may emit an odor when it is first used. This is due to the new heating element, and is

normal. The odor will diminish with the use of the dryer.

Important!

Please read the user guide in its entirety and familiarize yourself with the correct use and care of

the dryer.

Installation instructions

Servicing

Important!

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation after servicing/installation.

For service and other information, refer to the “How to get service” section in the back of this

book (refer to page 84).

Drum light replacement

Before replacing the light bulb, be sure to unplug the

dryer power cord or disconnect the dryer at the household

distribution panel by removing the fuse or switching off

the circuit breaker. Reach inside, above the dryer opening

inside the drum. Remove the bulb and replace with the

same size bulb.

Fig.43 Drum light

47

48

The first time you turn your dryer on

Remove the protective tape from the control panel.

WARNING!

Electric Shock Hazard

To reduce the risk of fire, electric shock, or injury to persons, read and

follow the IMPORTANT SAFETY INSTRUCTIONS outlined in this User

Guide before operating this appliance, pages 3 – 6.

Failure to do so can result in death, electric shock, fire or injury to

persons.

Features

Perfect with the Fisher & Paykel AquaSmart™ washer

The dryer combined with the AquaSmart™ washer’s superior spin performance and quick cycle

times will cut laundry turn around time, reducing the time you spend doing laundry.

Superior clothes care

Superior clothes care is accomplished by an efficient high airflow fan and careful heat control.

Your AeroCare dryer provides the right heat for temperature-sensitive delicate garments while

still efficiently drying more robust regular and denim loads.

Reverse action tumbling (selected models only)

You can select to have the drum rotate in the reverse direction regularly, so your clothes dry

more evenly and roping and tangling of garments is minimized.

Autosensing

AeroCare’s internal computer measures the moisture content of the load using metal sensing

bars and together with a temperature sensor determines when the clothes have reached the

selected dryness level.

Steam cycles (selected models only)

Two cycles, AEROSTEAM and AEROSTEAM PLUS use pulses of steam to de-wrinkle items and/or

freshen your garments from unpleasant odors or after prolonged storage.

Stainless steel drum

AeroCare’s stainless steel drum is not only more hygienic, it’s also more resilient and is easier to

keep looking good.

The first time you turn your dryer on

Wrinkle Free

Use WRINKLE FREE to minimize wrinkling and creasing in your garments. After the clothes are

dried, they will be tumbled periodically in cool air. WRINKLE FREE will continue for 24 hours or

until the dryer is stopped by pressing POWER, or opening the door.

WRINKLE FREE can be selected if you are using one of the automatic cycles (excluding the

ENERGY SAVER cycle), and on the TIME DRY cycle.

Drum light

A convenient light located inside the dryer helps make unloading easier. The light switches on

automatically when the door is opened.

For drum light replacement, please refer to page 47.

Drying rack

The drying rack can be used for drying articles such as soft toys,

pillows, washable sweaters and shoes, ie items that are too

delicate or maybe damaged by tumbling. Place (hook) the rack

over the lint filter so that it extends back into the drum.

Note: the drying rack should be used with the RACK DRY or

TIMEDRY cycles only. Also, the drying rack should not be used

when there are other items in the dryer as this may cause

damage to the garments.

Fig.44 Drying rack

49

50

Getting started quickly

Ensure the lint filter has been cleaned before each drying cycle. Check the lint filter has been

replaced correctly in its housing before using your dryer.

Sort and load items into the dryer drum. Ensure that no items are caught in the way of the door,

then close the door. Check the door is fully closed before starting the dryer.

Important!

Ensure there is plenty of room for the garments to tumble freely while drying – do not overload

your dryer. Load in terms of the space clothes take up when dry rather than when they are wet.

1

Press POWER to activate your dryer.

2

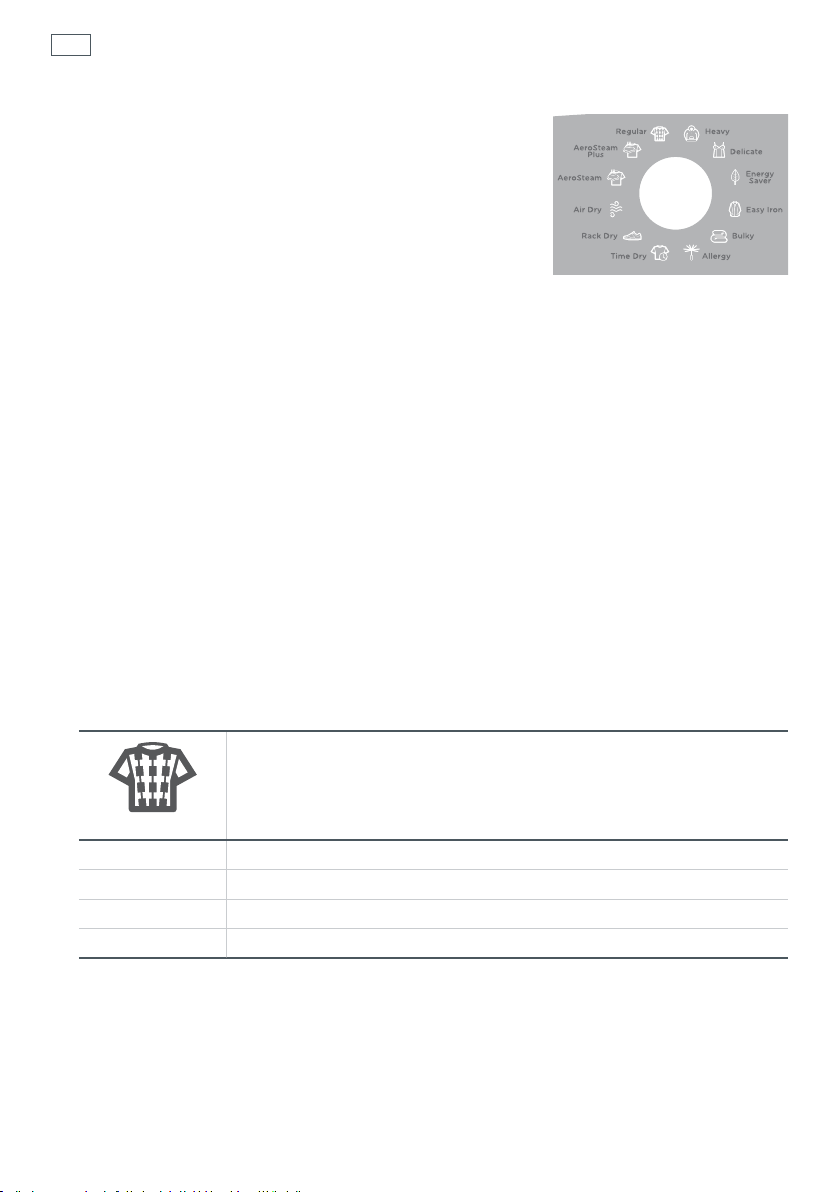

Your dryer will default to the REGULAR cycle. Select your desired drying cycle by turning the

SmartTouch™ Control Dial.

3

Select your preferred drying options (if you wish to select different options from the default options

programmed for the cycle) using the SmartTouch™ buttons on the right hand side of the panel.

4

Touch the START/PAUSE button to start the drying cycle.

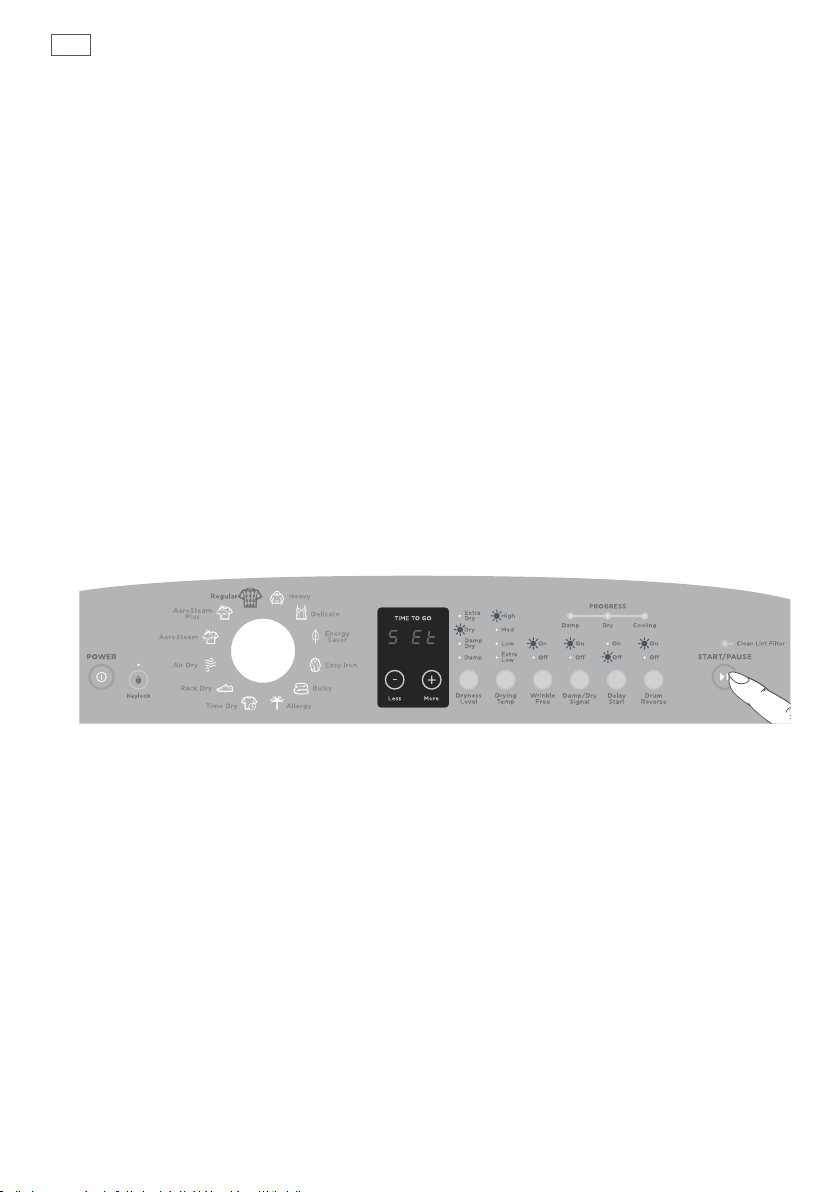

Fig.45 AeroCare control panel (models may vary)

Note: the control panel may differ depending on what model of dryer you have.

21

Getting started quickly

If you make an invalid selection the dryer will beep to alert you.

When the cycle finishes, your dryer will beep to alert you and then turn off automatically. If the

WRINKLE FREE option has been selected the machine will rotate the drum periodically after the

end of the cycle, blowing cool air into the drum to help minimize wrinkling of the clothes.

If you wish to stop your dryer at any point during a cycle simply touch START/PAUSE to pause the

cycle, then open the door. To restart the dryer, close the door and touch START/PAUSE to resume

the cycle.

If you wish to cancel a cycle or select a different option once a drying cycle has started, touch

the START/PAUSE button then select the new cycle or option. Touch START/PAUSE to restart the

dryer with the new settings.

Important!

If you wish to stop the dryer before the cycle has finished you MUST remove the clothes

IMMEDIATELY and spread them out to cool. DO NOT leave the clothes in the dryer or bunched

up in a clothes basket, these must be spread out in order for the heat to dissipate. There is a risk

of spontaneous combustion. Take extreme care when removing items as the drum and the load

items may be extremely hot.

51

43

Important!

Failure to follow the advice in this guide may result in damage to your garments and your

expectations of drying performance may not be met.

Note: selected drying cycles and options may not be available depending on your model of dryer.

52

AeroCare controls

SmartTouch™ Control Dial

The SmartTouch™ Control Dial provides easy and efficient drying cycle selection. As you rotate

the dial, the icon of the drying cycle selected will be illuminated, along with the default settings

for that cycle on the right side of the control panel.

SmartTouch™ buttons

The smooth, easy clean buttons enable simple selection of options with lights clearly showing

the selections you are making.

Digital display screen

The digital display screen provides feedback on how long the drying cycle has to go. If you have

programmed a DELAY START, the time remaining until the cycle will start will be displayed here,

along with any messages to help you with the overall running of your dryer (eg user warnings).

Time to go

Your AeroCare dryer displays approximately how many minutes the cycle has remaining, so

that you can tell at a glance when your drying will be finished. Please be aware that a number

of factors influence the overall cycle time, eg the fabric type, load size, the wetness of the load,

environmental conditions, etc. If the dryer display screen shows a dashed line tracing around the

outside of the screen, this indicates the dryer is sensing the moisture in the load. The updated

time remaining will soon appear on the screen.

Progress lights

The progress lights indicate what part of the cycle the dryer is currently up to (DAMP, DRY, or

COOLING). The light for the current part of the cycle flashes, to let you know at a glance how dry

your load is.

AeroCare controls

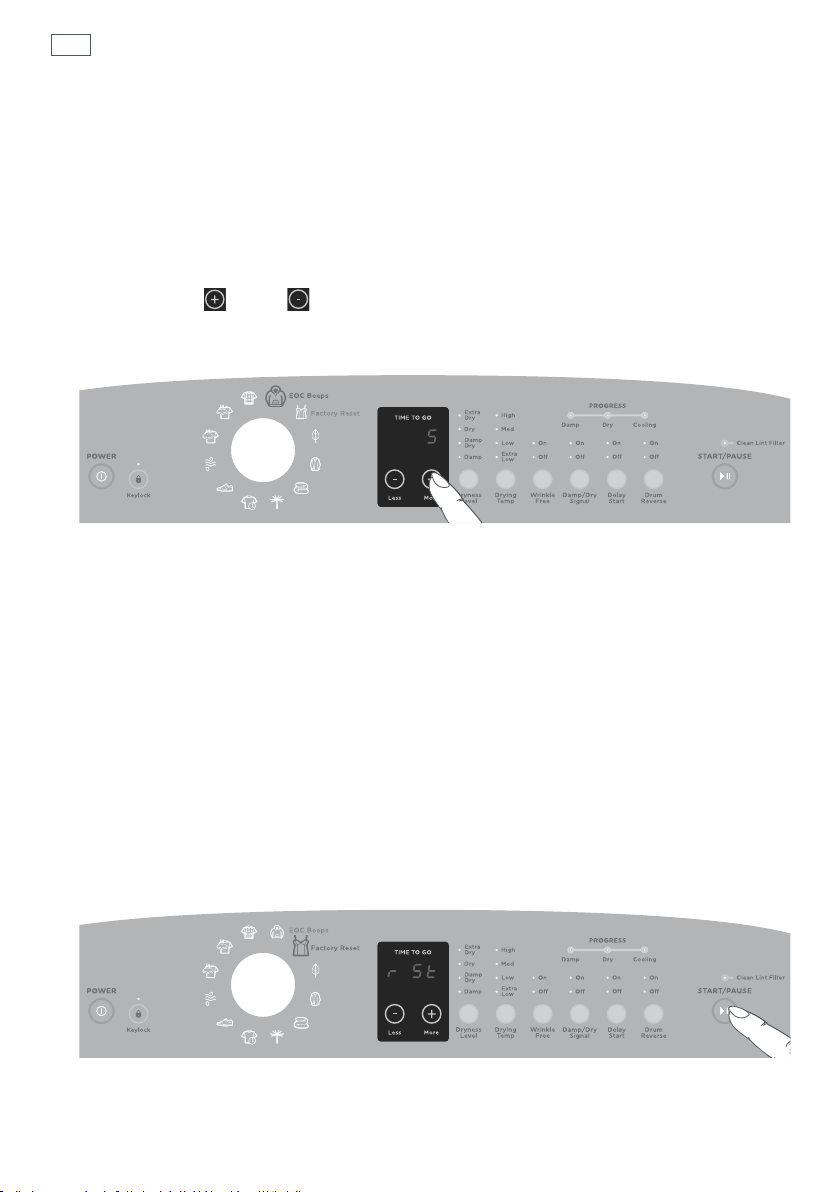

Keylock

Keylock can be used to deactivate the buttons on your AeroCare dryer when it is in use. This

will avoid accidental button touches from items left on top of the dryer (eg washing baskets,

clothing) as well as touches from any little fingers.

To turn Keylock ON or OFF:

Touch and hold the KEYLOCK button for two seconds.

Note: when activated, the light above the KEYLOCK button is illuminated.

If Keylock is activated:

To turn your dryer on, touch and hold the POWER button for two seconds. This will activate the

control panel. Keylock will remain activated but let you select your drying cycle options and start

the cycle.

To PAUSE your dryer at any time during the cycle, touch and hold the START/PAUSE button for

two seconds.

To STOP your dryer and power off, simply touch the POWER button.

53

54

Sorting and loading

When preparing your load there are some important things to consider:

Sorting

Check the fabric care labels on the inside of garments to determine whether the item is suitable

for tumble drying.

It is best that you sort your garments into loads of similar items, and loads that take similar times

to dry, before placing them in the dryer. Heavier items (eg towels, t-shirts and sheets) are best

dried separately from lightweight items (eg synthetics and shirts). This prevents the possibility of

some garments becoming over-dried whilst others are still damp. It will also help to extend the

life of your clothing and linen.

Drying your clothes as soon as you remove them from the washer will reduce the chance of

wrinkles occurring and the chance of dye transfer from colored items to white items.

We recommend that articles of clothing with screen-printing are turned inside out to minimize

damage to the print. Garments with hooks or zippers should be fastened and where possible

turned inside out.

Use the drying rack to dry garments and items that could be damaged by tumbling or you do

not wish to tumble, eg woolen garments, shoes, toys.

Before you load

Check pockets for items that could damage your clothes or get caught in the dryer.

Close zippers, hooks and eyes, and other fastenings (ie fasten the openings of comforter covers),

and remove loose bra wires. These may damage both your dryer and your clothes.

Check the lint filter is clean.

To reduce wrinkling

Shake clothes out and load individually to help items dry evenly.

Launder “permanent press” garments separately, eg business shirts.

Allow enough room in the dryer for clothes to tumble freely.

Use the WRINKLE FREE option.

Hang garments as soon as the dryer cycle is complete to reduce the need for ironing.

Loading

Garments need to be loaded correctly to minimize creasing and wrinkling, and to ensure the

load is dried evenly. Ensure there is plenty of room for the garments to tumble freely while

drying. Load in terms of the space the garments take up when dry, rather than when they are wet.

The general rule is that one wash load equals one dryer load. Do not overload your dryer, as it

may damage your dryer and clothes.