Fisher & Paykel DE60FA2-96983, DE60FA27AW2-96983 Installation Guide

WARNING- POTENTIAL FIRE AND SHOCK HAZARD

• Use only rigid metal or flexible metal 4" diameter ductwork for exhausting to the outdoors. Never use

plastic or other combustible ductwork.

• This appliance must be properly grounded and installed as described in these instructions.

• Do not install or store appliance in an area where it will be exposed to water/weather.

• The National Fuel Gas Code restricts installations of gas appliances in garages. They must be 18" off

the ground and protected by a barrier from vehicles.

Important

• Exhausting the dryer to the outdoors is strongly

recommended to prevent large amounts of moisture

and lint from being blown into the room.

• Service information and wiring diagram located

in control console.

Installation

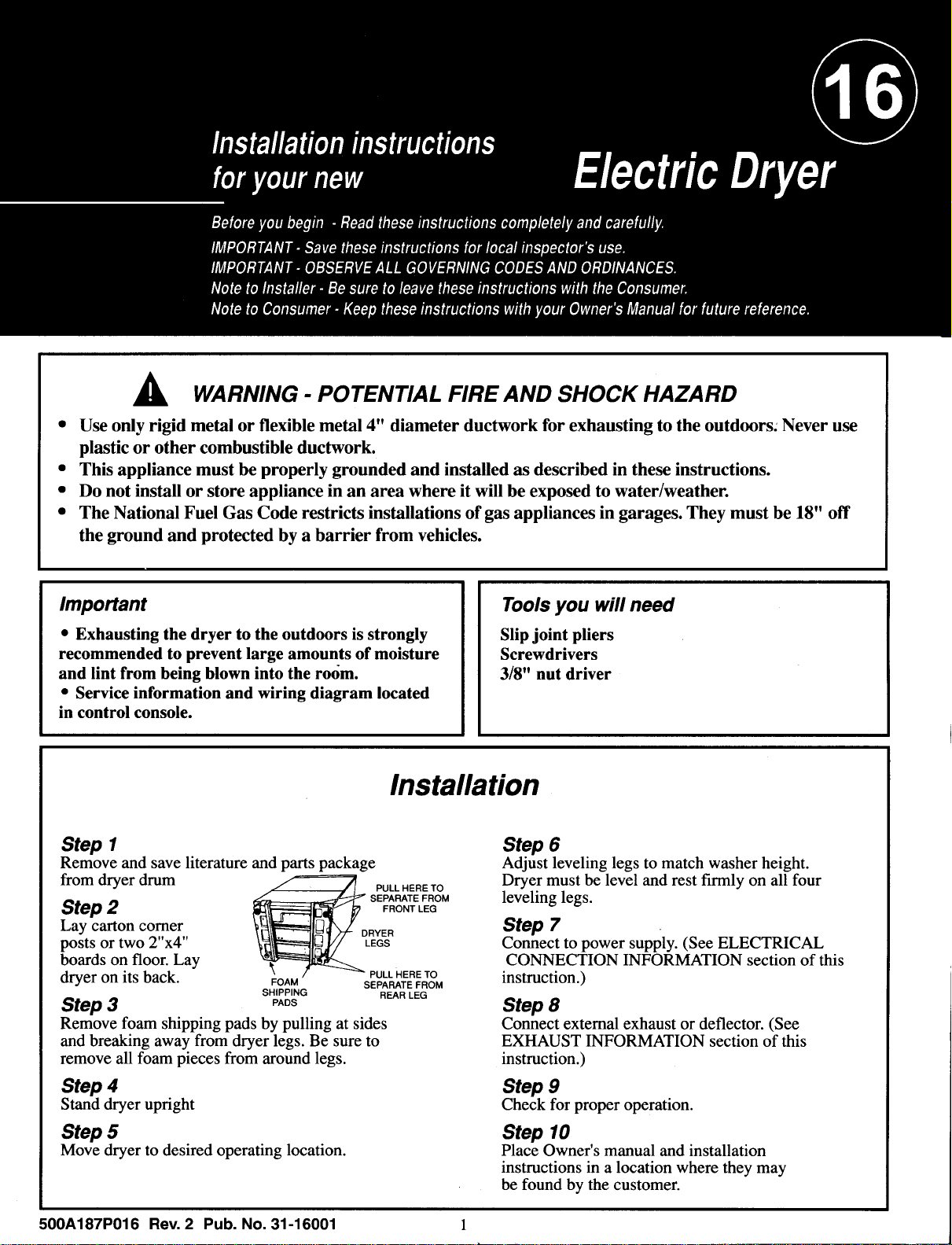

Step 1

Remove and save literature and parts package

from dryer drum PULLHEREro

Step 2 FRONTLEG

Lay carton comer

posts or two 2"x4" LEGS

boards on floor. Lay

dryer on its back. FOAM SEPARATEFROM

SHIPPING REAR LEG

Step 3 PADS

Remove foam shipping pads by pulling at sides

and breaking away from dryer legs. Be sure to

remove all foam pieces from around legs.

DRYER

PULL HERE TO

Tools you will need

Slip joint pliers

Screwdrivers

3/8" nut driver

Step 6

Adjust leveling legs to match washer height.

Dryer must be level and rest firmly on all four

leveling legs.

Step 7

Connect to power supply. (See ELECTRICAL

CONNECTION INFORMATION section of this

instruction.)

Step 8

Connect external exhaust or deflector. (See

EXHAUST INFORMATION section of this

instruction.)

Step 4

Stand dryer upright

Step 5

Move dryer to desired operating location.

500A187P016 Rev. 2 Pub. No. 31-16001 1

Step 9

Check for proper operation.

Step 10

Place Owner's manual and installation

instructions in a location where they may

be found by the customer.

Electrical Connection Information

WARNING: TO REDUCE THE RISK Electrical requirements:

OF FIRE, ELECTRIC SHOCK, OR

PERSONAL INJURY.

• DO NOT USE AN EXTENSION CORD

WITH THIS APPLIANCE.

• THIS APPLIANCE MUST BE PROPERLY

GROUNDED.

Dryer must be electrically grounded in

accordance with local codes and ordinances,

or in the absence of local codes, in accor-

dance with the NATIONAL ELECTRICAL

CODE, ANSI/NFPA NO. 70.

• This dryer must be connected to an

individual branch circuit, protected by the

required time-delay fuses or circuit

breakers. 208V or 240V installation 30 amps.

• If the electric supply does not meet the

above specifications, call a licensed electrician.

Grounding instructions

• This appliance must be connected to a grounded

metal, permanent wiring system, or an equipment-

grounding conductor must be run with the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

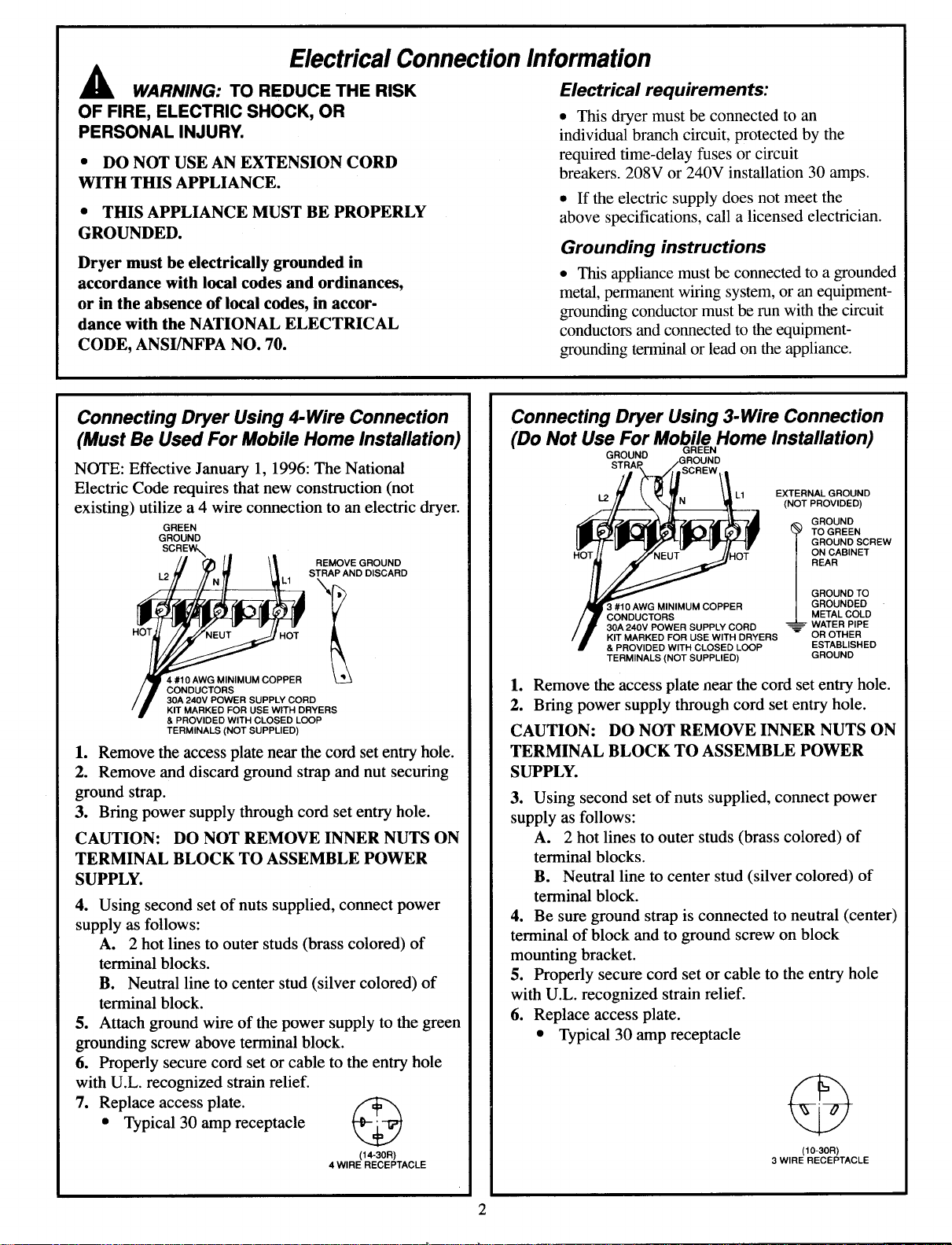

Connecting Dryer Using 4-Wire Connection

(Must Be Used For Mobile Home Installation)

NOTE: Effective January 1, 1996: The National

Electric Code requires that new construction (not

existing) utilize a 4 wire connection to an electric dryer.

GREEN

GROUND

SCREW,,.

_ _1 /I \l REMOVE GROUND

L.2 _'/ 7'/" IPl \| STRAP AND DISCARD

4 #10 AWG MINIMUM COPPER L_J

/ J CONDUCTORS _ _

/ J 30A 240V POWER SUPPLY CORD

' B' KIT MARKED FOR USE WITH DRYERS

& PROVIDED WITH CLOSED LOOP

TERMINALS (NOT SUPPLIED)

1. Remove the access plate near the cord set entry hole.

2. Remove and discard ground strap and nut securing

ground strap.

3. Bring power supply through cord set entry hole.

CAUTION: DO NOT REMOVE INNER NUTS ON

TERMINAL BLOCK TO ASSEMBLE POWER

SUPPLY.

4. Using second set of nuts supplied, connect power

supply as follows:

A. 2 hot lines to outer studs (brass colored) of

terminal blocks.

B. Neutral line to center stud (silver colored) of

terminal block.

5. Attach ground wire of the power supply to the green

grounding screw above terminal block.

6. Properly secure cord set or cable to the entry hole

with U.L. recognized strain relief.

7. Replace access plate.

• Typical 30 amp receptacle

%y

(14-30R)

4 WIRE RECEPTACLE

Connecting Dryer Using 3-Wire Connection

(Do Not Use For Mobile Home Installation)

GROUND GREEN

_N GROUND

III _)11_111 @] [Uil _7 IIF ? TOGREEN

Ip_'/'-[l_'ll_'_ll_'_l_//_lV | GROUND SCREW

I-TOTJ_ - /7"_'NEUT- v JIHoT ! ONCABINET

I i/_-,_'_ / GROUNDTO

AI_I_#10 AWG MINIMUM COPPER | GROUNDED

/ # CONDUCTORS...... _L I kC°P g

/ ll' 30A 240V POWER SUPPLY CORD _ R THER

/ _l' KIT MARKED FOR USE WITH DRYERS O O

f &PROVIDED WITH CLOSED LOOP ESTABLISHED

TERMINALS (NOT SUPPLIED) GROUND

SCREW --

/_L1 EXTERNAL GROUND

(NOT PROVIDED)

_ GROUND

1. Remove the access plate near the cord set entry hole.

2. Bring power supply through cord set entry hole.

CAUTION: DO NOT REMOVE INNER NUTS ON

TERMINAL BLOCK TO ASSEMBLE POWER

SUPPLY.

3. Using second set of nuts supplied, connect power

supply as follows:

A. 2 hot lines to outer studs (brass colored) of

terminal blocks.

B. Neutral line to center stud (silver colored) of

terminal block.

4. Be sure ground strap is connected to neutral (center)

terminal of block and to ground screw on block

mounting bracket.

5. Properly secure cord set or cable to the entry hole

with U.L. recognized strain relief.

6. Replace access plate.

• Typical 30 amp receptacle

(10-30R)

3 WIRE RECEPTACLE

Loading...

Loading...