Page 1

Use and Care

With Installation Instructions

RECYCLED PAPER

RECYCLABLE

We care about our environment

500A277P046

Page 2

Safety Instructions ................... 3, 4

Installation Instructions

Exhaust.........................................................6, 7

Electric Dryer ...................................................8

Gas Dryer .....................................................8, 9

Reversible Door Instructions .......................5

Care and Cleaning

Dryer Exhaust ...............................................14

Exterior ...........................................................11

Light Bulb Replacement.............................13

Lint Filter ........................................................11

Problem Solver ............................. 15

Operating Instructions, Tips

Automatic Drying ........................................13

Drying Selection Guide .......................12, 13

Electronic Sensor Control..........................13

Extra Care Program..............................10, 12

Knits Drying Tips ..................................11, 12

Lint Filter ........................................................11

Loading ...................................................11, 15

Operating the Dryer ..............10, 11, 12, 13

Permanent Press

Drying Tips .........................................11, 15

Sorting Clothes .....................................11, 12

Special Instructions.....................................12

Timed Drying.........................................12, 13

End Cycle Signal ..........................................10

Read this book carefully.

It is intended to help you operate and

maintain your new dryer properly.

Keep it handy for answers to your

questions.

If you don’t understand something or

need more help, write (include your

phone number)

Consumer Relations Manager

Camco Inc.

1 Factory Lane, Suite 310

Moncton, N.B. E1C 9M3

Consumer Services

Model and Serial Numbers ..........................2

Repair Service .................................................2

Warranty ........................................................16

Save time and money.

Before you request service...

check the Problem Solver section, it

lists causes of minor operating

problems that you can correct

yourself.

If you received a

damaged dryer...

Immediately contact the dealer (or

builder) that sold you the dryer.

Write down the model

and serial numbers.

You’ll find them on a label on the

front of the dryer behind the door.

These numbers are also on the

Consumer Product Ownership

Registration Card that came with

your dryer. Before sending in this

card, please write these numbers

here:

Model Number

WARNING: For your safety the information in this manual must be followed to minimize the

risk of fire or explosion or to prevent property damage, personal injury or death.

– Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Clear the room, building or area of all

occupants.

2

Serial Number

Use these numbers in any

correspondence or service calls

concerning your dryer.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

– Installation and service must be performed

by a qualified installer, service agency, or the

gas supplier.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

Read all instructions before using this appliance

Warning - It is extremely important that you read and adhere to the

following instructions. Failure to do so could cause bodily injuries

and / or property damage due to fire.

• Use this appliance only for its intended purpose

as described in this Use and Care Book.

This dryer must be properly installed

and located in accordance with the

Installation Instructions before it is used.

– Properly ground to conform with Local Codes.

Follow details in Installation Instructions.

– Locate where the temperature is above 50˚F.

(10˚C.) for satisfactory operation of the dryer

control system. Do not install or store the dryer

where it will be exposed to the weather.

– Connect to a properly rated, protected and sized

power supply circuit to avoid electrical overload.

– Exhausting to the outside is STRONGLY

RECOMMENDED to prevent large amounts of

moisture and lint from being blown into the room.

Carefully follow the Exhausting Details in the

Installation Instructions.

Do not repair or replace any part of the

appliance or attempt any servicing

unless specifically recommended in this

Use and Care Book or in published user-repair

instructions that you understand and have the

skills to carry out.

When disconnecting this appliance

pull by the plug rather than the cord

to avoid damage to the cord or junction

of cord and plug. Make sure that the cord

is located so that it will not be stepped on, tripped

over or otherwise subjected to damage or stress.

To Minimize the Possibility of a

Fire Hazard

• Exhaust Duct – See Installation Instructions. Use

only rigid metal or flexible metal 4” diameter

ductwork for exhausting to the outside. USE OF

PLASTIC OR OTHER COMBUSTIBLE

DUCTWORK CAN CAUSE A FIRE. FOIL OR

OTHER EASILY PUNCTURED DUCTWORK

CAN CAUSE A FIRE IF IT COLLAPSES OR

BECOMES OTHERWISE RESTRICTED IN USE

OR DURING INSTALLATION.

• Do not use heat to dry articles containing rubber,

plastic, or similar materials (such as padded bras,

tennis shoes, galoshes, bath mats, rugs, bibs, pillows,

baby pants, plastic bags, etc.) as these materials may

melt or burn. Also, some rubber materials, when

heated, can under certain circumstances produce fire

by spontaneous combustion.

• Do not store items that may burn or melt (such as

clothing, paper material, plastics or plastic

containers, etc.) on top of the dryer during the

operation.

• Garments labeled “Dry Away from Heat” (such

as life jackets containing Kapok or foam) must

not be put in your dryer.

• Do not wash or dry articles that

have been cleaned in, washed in,

soaked in, or spotted with combustible

or explosive substances (such as wax,

paint, gasoline degreasers, dry-

cleaning solvents, kerosene, etc.) which may ignite

or explode. Do not add these substances to the

wash water. Do not use these substances around

your washer and/or dryer during operation.

• Any article on which you have used a cleaning

solvent, or which contains flammable materials (such

as cleaning cloths, mops, towels used in beauty

salons, restaurants or barber shops, etc.) must not be

placed in or near the dryer until all traces of these

flammable liquids or solids and their fumes have

been removed. There are many highly flammable

items used in homes such as: acetone, denatured

alcohol, gasoline, kerosene, some household

cleaners, some spot removers, turpentines, waxes,

wax removers and products containing petroleum

distillates.

(continued on next page)

Important Safety Instructions

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

•Clean the lint filter before each load

to prevent lint accumulation inside

the dryer or in the room.

DO NOT OPERATE THE DRYER

WITHOUT THE LINT FILTER IN

PLACE.

• Keep the area around and underneath your

appliances free from the accumulation of

combustible materials, such as lint, paper, rags,

chemicals, etc.

• Regularly inspect the exhaust duct to be sure it

has not been crushed or otherwise restricted.

• The interior of the dryer cabinet and the exhaust

duct connection inside the dryer should be cleaned

every 2 to 3 years, or more often if needed, by a

qualified service person. (see Care & Cleaning

section)

To Minimize the Possibility of Injury

• Never reach into the dryer while the drum is

moving. Before loading, unloading or adding clothes,

wait until the drum has completely stopped.

• Do not dry fiberglass articles in your dryer. Skin

irritation could result from the remaining glass

particles that may be picked up by clothing during

subsequent dryer uses.

• The laundry process can reduce the

flame retardance of fabrics. To avoid

such a result, the garment manufacturer’s

care instructions should be followed very

carefully.

• Close supervision is necessary if this

appliance is used by or near children.

Do not allow children to play inside,

on, or with this appliance or any

discarded appliance. Dispose of

discarded appliances and shipping or

packing materials properly. Before discarding a

dryer, or removing from service, remove the door

of the dryer compartment.

SAVE THESE

INSTRUCTIONS

• Keep all laundry aids (such as

detergents, bleaches, fabric softeners,

etc.) out of the reach of children,

preferably in a locked cabinet. Observe

all warnings on container labels to avoid

personal injury.

• Keep the floor around your appliances clean and

dry to reduce the possibility of slipping.

• To minimize the possibility of electric shock,

unplug this appliance from the power

supply before attempting any maintenance

or cleaning (except the removal and

cleaning of the lint filter).

• NOTE: Turning the Cycle Selector

knob to an OFF position does NOT

disconnect the appliance from the power

supply.

• Do not tamper with the controls.

• Do not operate this appliance if it is damaged,

malfunctioning, partially disassembled, or has

missing or broken parts, including a damaged

cord or plug.

• Never climb on or stand on the dryer top.

• DO NOT place items exposed to cooking oils in

your dryer. Items contaminated with cooking oils

may contribute to a chemical reaction that could

cause a clothes load to catch fire.

• If yours is a gas dryer, it is equipped with an

automatic electric ignition and does not have a

pilot light. DO NOT ATTEMPT TO LIGHT WITH A

MATCH. Burns may result from having your hand in

the vicinity of the burner when the automatic ignition

may turn on.

Dryer-applied Fabric Softeners or

Anti-static Conditioners

You may wish to soften your laundered fabrics or

reduce the static electricity in them. We recommend

you use either a fabric softener in the wash cycle,

according to the manufacturer’s instructions for those

products, or try a dryer-added product for which the

manufacturer gives written assurance on the package

that their product can be safely used in your dryer.

Service or performance problems caused by the use of

these products are the responsibility of the

manufacturers of those products and are not covered

under the warranty of this appliance.

4

Page 5

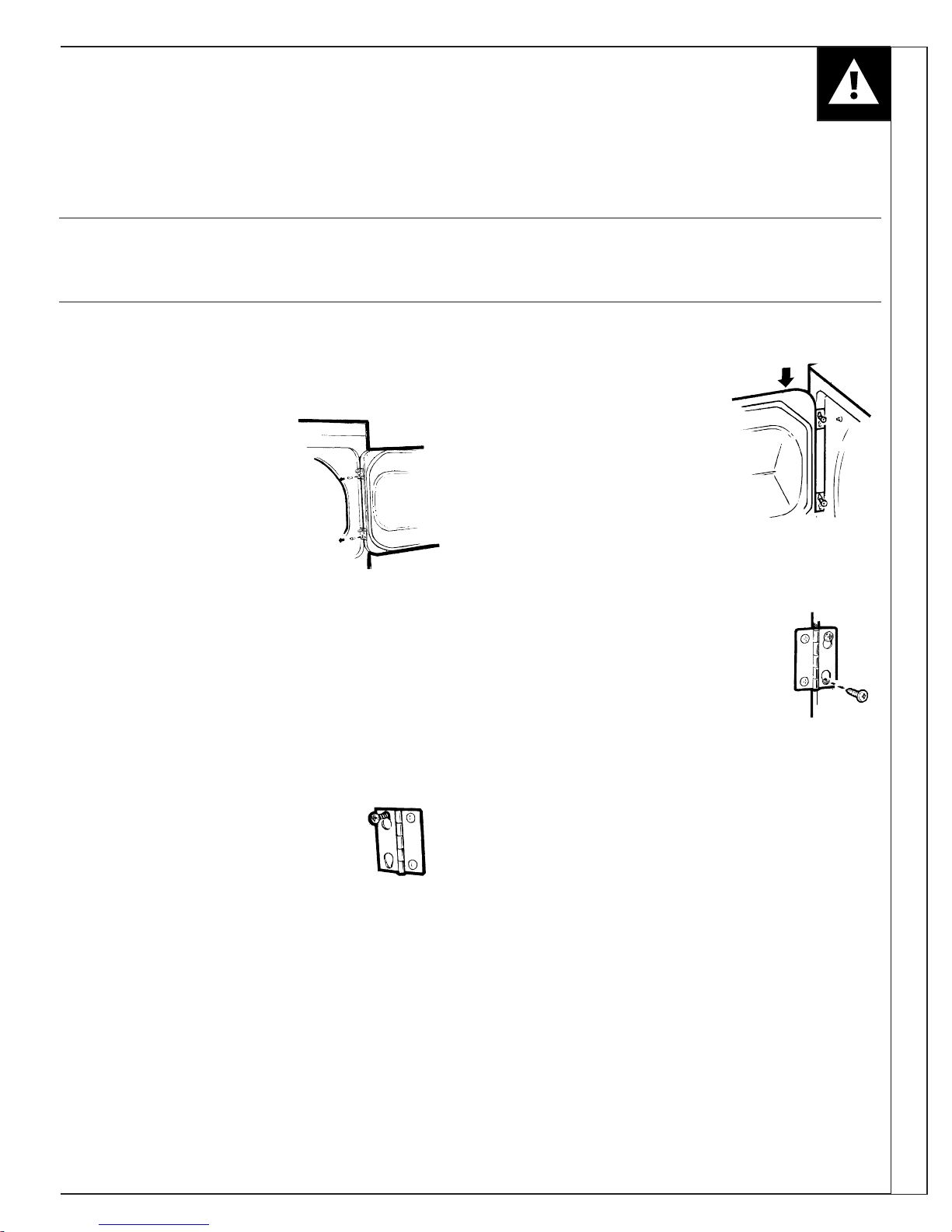

REVERSIBLE DOOR INSTRUCTIONS

These instructions are for changing the hinges from the

right side to the left side.

Tools Needed

Standard #2 Phillips screwdriver

DRYER DOOR

1. Open the door and remove the filler plugs opposite the

hinges.

(A tape-tipped putty knife

or a needle-nosed plier

will help to remove the

plugs. Be careful not to

damage the paint.)

2. With the door completely

open, remove the bottom

screw attaching each hinge

to the dryer front. (Do not

remove the screws located

on the door itself).

If you need to change the hinges from the left side to

the right side, follow these same instructions (merely

reverse all references to the left and right).

6. Rotate the door 180˚.

Insert it on the opposite

door frame by moving the

door IN and DOWN until

the top hinge and the

bottom hinge are resting on

the top screws inserted in

step 3.

7. With the other screws, secure

each hinge at the bottom.

8. Tighten the top screws of each

hinge.

Reversible Door Instructions

3. Insert these screws about half way into the top holes,

for each hinge, on the opposite side (where you

removed the filler plugs).

4. Loosen the remaining top screw

from each hinge on the dryer front,

half way.

5. With one hand holding

the top of the door, and

the other hand holding

the bottom, remove the

door from the dryer

front by lifting it UP

and OUT.

9. Reinsert the plastic plugs on the side from which the

door was removed.

5

Page 6

INSTALLATION INSTRUCTIONS

298mm

(11 3/4")

91mm

(3 1/2")

NOTE: ADD TO

91mm (31/2")

THE DISTANCE

BETWEEN

CABINET BOTTOM

TO FLOOR SURFACE

EXHAUST

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

IMPORTANT: Have your dryer installed properly.

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution, and

carefulness are factors that CANNOT be built into the dryer. These factors MUST BE supplied by the person(s)

installing, maintaining, or operating the dryer.

Failure to install, maintain, and/or operate this machine according to the manufacturer’s instructions may result in

conditions which can produce bodily injury and/or property damage.

This dryer comes ready for rear exhausting (see Fig. 1).

WARNINGS

• DO NOT USE NON METALLIC FLEXIBLE DUCT.

• Never use flexible duct inside the dryer.

• Do not terminate exhaust in a chimney, range hood,

gas vent, floor or attic. The combination of lint and

grease could create a fire hazard or damages.

• Provide an access for inspection and cleaning the

exhaust system at least once a year. (See Care and

Cleaning Section.)

EXHAUST LENGTH

The MAXIMUM ALLOWABLE length of the exhaust

system depends upon the type of duct, number of turns,

the type of exhaust hood (wall cap), and all conditions

noted below. The maximum allowable length for both

rigid and flexible metal duct is shown in the table 1

(next page). More than four 90˚ turns is not

recommended.

EXHAUST SYSTEM CHECK LIST

HOOD or WALL CAP

• Terminate in a manner to prevent back drafts or entry

of birds or other wildlife.

• Termination should present minimal resistance to the

exhaust air flow and should require little or no

maintenance to prevent clogging.

• Wall caps must be installed at least 300 mm (12”)

above ground level or any other obstruction with the

opening pointed down.

• If roof vents or louvered plenums are used, they must

be equivalent to a 100 mm (4”) dampered wall cap in

regard to resistance to air flow, prevention of back

drafts and maintenance required to prevent clogging.

SEPARATION OF TURNS

Separate all turns by at least 1 m (3 ft.) of straight duct,

including distance between last turn and dampered wall

cap. If two turns must be closer than 1 m (3 ft.) deduct

3 m (10 ft.) from the maximum lengths shown in the

table for each occurrence.

TURNS OTHER THAN 90˚

• One turn of 45˚ or less may be ignored.

• Two 45˚ turns should be treated as one 90˚.

• Each turn over 45˚ should be treated as one 90˚.

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male

end of each section of duct must point away from the

dryer.

• Do not assemble the duct work with fasteners that

extend into the duct. They will serve as a collection

point for lint.

• Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

INSULATION

• Duct work which runs through an unheated area or is

near an air conditioning duct, should be insulated to

reduce condensation and lint build up and be sloped

down toward outdoors.

NOTE: Never install screen inside exhaust duct.

CAUTION: THE DRYER MUST EXHAUST TO

THE OUTDOORS.

6

Page 7

INSTALLATION INSTRUCTIONS

EXHAUST

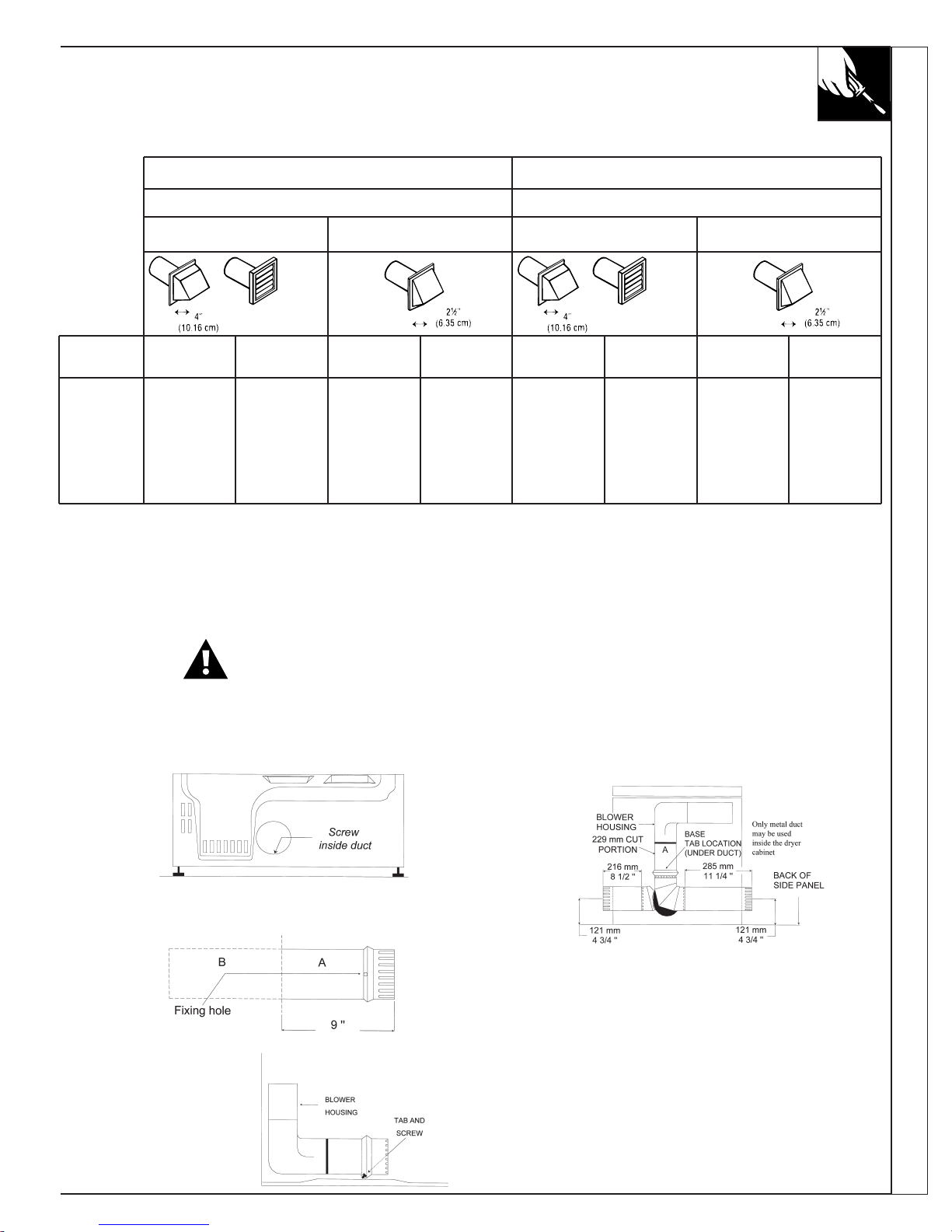

Table 1: RECOMMENDED MAXIMUM LENGTH

ELECTRIC DRYERS GAS DRYERS

Weather Hood Type Weather Hood Type

Recommended

Use only for short

run installations

Recommended

Use only for short

run installations

No. of 90˚

elbows

0

1

2

3

4

* Do not use non metallic flexible duct.

Rigid

27.4 m (90 ft.)

18.3 m (60 ft.)

13.7 m (45 ft.)

10.7 m (35 ft.)

7.6 m (25 ft.)

Metallic

Flexible*

16.8 m (55 ft.)

12.2 m (40 ft.)

9.1 m (30 ft.)

6.1 m (20 ft.)

4.6 m (15 ft.)

Rigid

18.3 m (60 ft.)

13.7 m (45 ft.)

10.7 m ( 35 ft.)

7.6 m (25 ft.)

4.6 m (15 ft.)

13.7 m (45 ft.)

9.1 m (30 ft.)

6.1 m (20 ft.)

4.6 m (15 ft.)

3.0 m (10 ft.)

Metallic

Flexible*

Rigid

13.7 m (45 ft.)

10.7 m (35 ft.)

7.6 m (25 ft.)

4.6 m (15 ft.)

–

Metallic

Flexible*

9.1 m (30 ft.)

6.1 m (20 ft.)

3.0 m (10 ft.)

–

–

Rigid

9.1 m (30 ft.)

6.1 m (20 ft.)

3.0 m (10 ft.)

–

–

Metallic

Flexible*

4.6 m (15 ft.)

3.0 m (10 ft.)

–

–

–

ALTERNATE EXHAUST DIRECTIONS

This dryer comes ready for rear exhausting. If space is limited, use the following instructions to exhaust

directly from the side or bottom of the cabinet.

GAS DRYER CAN NOT BE EXHAUSTED DIRECTLY THROUGH THE RIGHT SIDE OF THE CABINET.

WARNING: Protect your hands and arms when working inside the cabinet.

• Never use flexible duct inside dryer.

• Detach and remove the desired knockout.

• Remove the screw inside the dryer exhaust duct end.

Pull on the duct to remove it. Keep the screw for

later.

• Reconnect and secure the cut portion (A) of the duct

to the blower housing. Make sure that the fixing

hole is aligned with the tab in the base. Use the

reserved screw to secure the duct in place through

the tab on the appliance base.

Installation Instructions

• Cut the duct as shown, 229 mm (9 inches).

Keep portion A.

• Through the rear

opening, locate the

tab in the middle of

the appliance base.

Lift the tab to about

45˚ using a flat

screwdriver.

• Use a standard and ajustable metal elbow and a

metal straight duct to exhaust the dryer through the

knockout choosen. Insert standard elbow and ducts

through rear and side or bottom openings.

• Use only 100 mm (4 inch) diameter rigid metallic

duct.

• Cover the opening at the back with the plate (Kit

WE1M454) available from your Local Service

Provider.

WARNING: Never leave the opening at the back

without the plate.

7

Page 8

INSTALLATION

4 LEVELING

LEGS

SIDE

VIEW

IMPORTANT - OBSERVE ALL GOVERNING CODES

Dryer must be levelled and rest firmly on the floor.

SPECIAL INSTALLATION REQUIREMENTS

ALCOVE OR CLOSET INSTALLATION

• The dryer MUST be exhausted to the outdoor. See

EXHAUST INFORMATION section.

• Minimum clearances between dryer cabinet and

adjacent walls or other surfaces are:

0 mm (0”) either side

76 mm (3”) front and rear

• Minimum vertical space from floor to overhead

cabinets, ceilings, etc. is 132 cm (52”).

NOTE: CONSIDERATION MUST BE GIVEN TO

INSTALLING AND SERVICING THE APPLIANCE.

• Closet door must be louvered or otherwise ventilated

and must contain a minimum of 387 cm

open area equally distributed. If this closet contains

both a washer and a dryer, doors must contain a

minimum of 774 cm

distributed.

• If yours is a gas dryer, the closet should be vented to

the outdoors to prevent gas pocketing in case of a gas

leak in the supply line.

• No other fuel-burning appliance shall be installed in

the same closet with the dryer.

2

(120 in2) of open area equally

2

(60 in2) of

MINIMUM CLEARANCES OTHER THAN

ALCOVE OR CLOSET INSTALLATIONS.

• Minimum clearances to combustible surfaces and for

air opening:

0 clearance both sides and 25 mm (1”) rear.

MOBILE HOME INSTALLATION

• The dryer must be exhausted to the outdoors with the

termination securely fastened to the mobile home

structure. (See EXHAUST INFORMATION section.)

• The exhaust MUST NOT be terminated beneath the

mobile home.

• The exhaust MUST NOT be connected to any other

duct, vent and chimney.

• Provisions must be made for the introduction of

outside air into the dryer room. The free air opening

shall not be less than 160 cm

• The exhaust duct material MUST BE METAL.

• Do not connect the exhaust duct with sheet metal

screws or other fastening devices which extend to the

interior of the duct.

• The dryer must be attached to the floor following

instructions available from the dealer.

• Installation must comply with the current CAN/CSA

Z240 MH series Mobile Home Installation Codes.

NOTE: CONSIDERATION MUST BE GIVEN TO

INSTALLING AND SERVICING THE APPLIANCE.

2

(25 in2).

Adjust all 4 leveling legs to match washer height. Dryer

MUST BE LEVEL and rest firmly on all 4 leveling

legs.

For maximum performance, refer to table for maximum allowable length of exhaust system (Exhaust section).

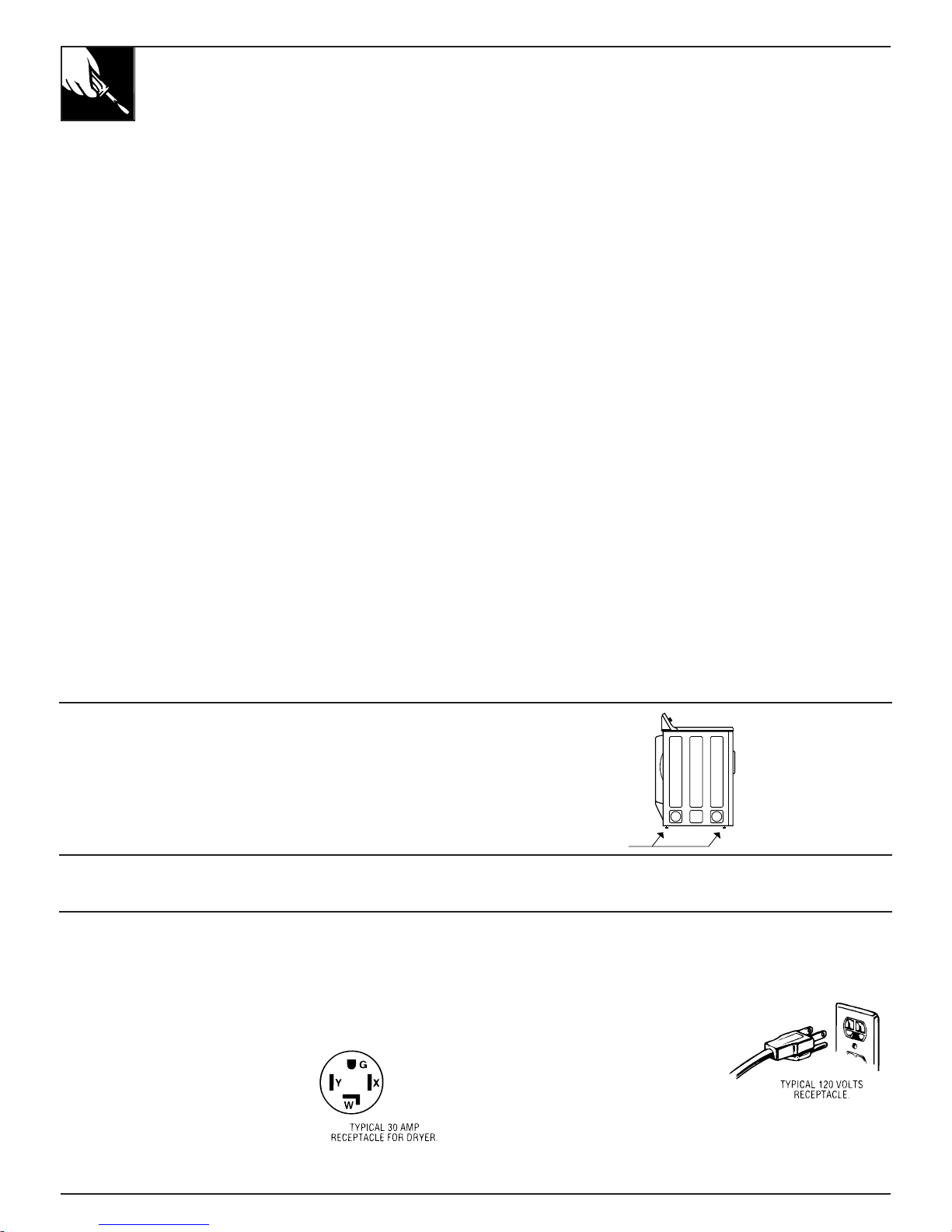

ELECTRICAL POWER SUPPLY

CAUTION: NEVER USE AN EXTENSION CORD WITH THIS APPLIANCE.

Note: If the electrical power supply provided does not meet the specifications listed below, call a licensed electrician.

FOR ELECTRIC DRYERS, POWER SUPPLY...

1. Must be of 120/240 volts or 120/208 volts, 60 Hz

circuit with wall receptacle as

shown beside.

2. Must be protected with 30A

FUSES OR BREAKERS.

3. Must be WELL GROUNDED.

4. Must CONFORM TO LOCAL

CODES.

8

LEVELING THE DRYER

DUCT LENGTH

FOR GAS DRYERS, POWER SUPPLY...

1. Must be of 120 volts, 60 Hz

circuit with wall receptacle as

shown beside.

2. Must be protected with 15 or

20A FUSES OR BREAKER.

3. Must be WELL GROUNDED.

4. Installation must be in accordance

with the current CSA C22.1 Canadian Electrical code

part 1 and/or local codes.

Page 9

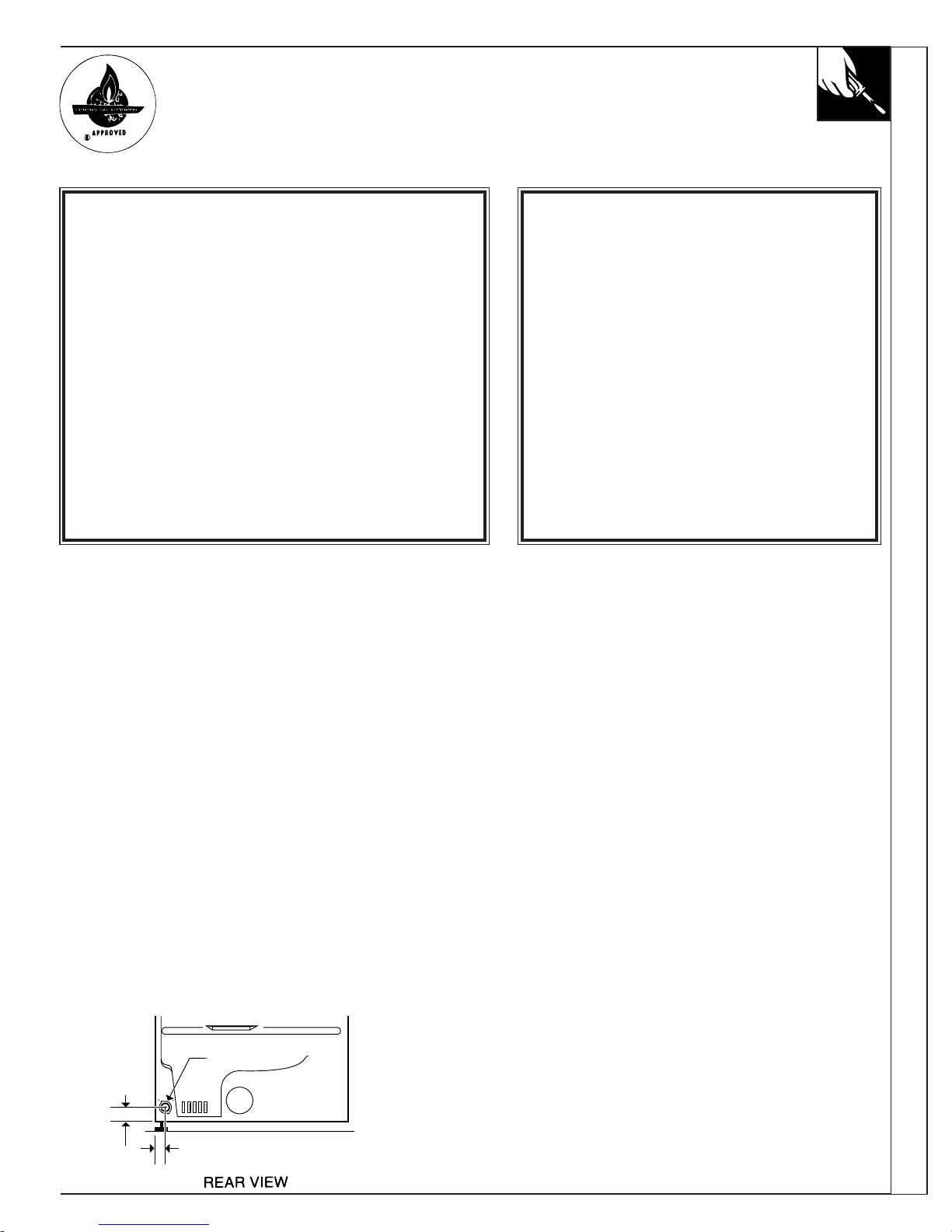

INSTALLATION – GAS DRYER

51mm

(2")

66 mm

(2 5/8")

MALE THREAD GAS SUPPLY

9.52 mm (3/8")

IMPORTANT - OBSERVE ALL GOVERNING CODES

Dryer must be levelled and rest firmly on the floor.

Dryer must be exhausted to the outdoors.

FOR YOUR SAFETY

What to do if you smell gas

• Do not try to light appliance.

• Do not touch any electrical switch ; do not use

any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you can not reach your gas supplier, call fire

department.

• Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

Installation Instructions

GAS CONNECTION INFORMATION

Installation must conform with local Gas Codes and

with CAN/CGA-B149, Natural Gas Installation Code.

Some local codes restrict installation of gas appliances

in garages. They must be 45 cm (18”) off the ground

and protected by a barrier from vehicules.

GAS BURNER ORIFICE

This gas dryer is equipped with a Valve & Burner

Assembly for use ONLY WITH ONE TYPE OF GAS.

Using the appropriate kit, your local service

organization can convert this dryer for use with the

alternate fuel.

Use kit WE25M35 to convert from Natural Gas to LP

Gases (Propane).

Use kit WE25M36 to convert from LP Gases to Natural

Gas.

WARNING: CONVERSION SHALL BE CARRIED

OUT IN ACCORDANCE WITH THE

REQUIREMENTS OF THE PROVINCIAL

AUTHORITIES HAVING JURISDICTION AND/OR

ACCORDANCE WITH THE REQUIREMENTS OF

THE CAN/CGA B149.1 AND B149.2

INSTALLATION CODE.

GAS SUPPLY

• Supply line is to be 12.7 mm (1/2 in) rigid pipe.

(9.53 mm (3/8 in) copper tubing may be used if the

dryer is operated on propane gas) and equipped with

an accessible shutoff within 6 feet (2 m) from, and in

the same room with the dryer. Increase pipe size for

runs longer than 20 feet (7 m).

• During pressure test:

– When test pressure is in excess of 1/2 PSIG

(3.45kPa), disconnect dryer and its individual

shutoff valve from gas supply line prior to test.

– When test pressure is equal to or less than 1/2 PSIG

(3.45kPa), close the dryer shutoff valve prior to test.

• A 3.18 mm (1/8 in) National Pipe Taper thread

plugged tapping, accessible for test gauge connection,

must be installed immediately upstream of the gas

supply connection to the dryer. Contact your local gas

utility should you have questions on the installation of

the plugged tapping.

• Pipe dope must be resistant to the action of propane

and applied sparingly to all male threads.

• If local codes permit, it is recommended the dryer be

connected to the gas supply with approved semi-rigid

metal tubing or listed connectors.

LEAK TEST

Check all connections for leaks with soapy solution or

equivalent. Leak test solutions must not contain ammonia

which could cause damage to brass fittings or pipe.

CAUTION: NEVER USE AN OPEN FLAME TO

TEST FOR GAS LEAKS.

9

Page 10

OPERATING YOUR DRYER

WARNING – To reduce the risk of fire, electric shock, or injury to persons

when using your appliance read the IMPORTANT SAFETY INSTRUCTIONS

before operating this appliance.

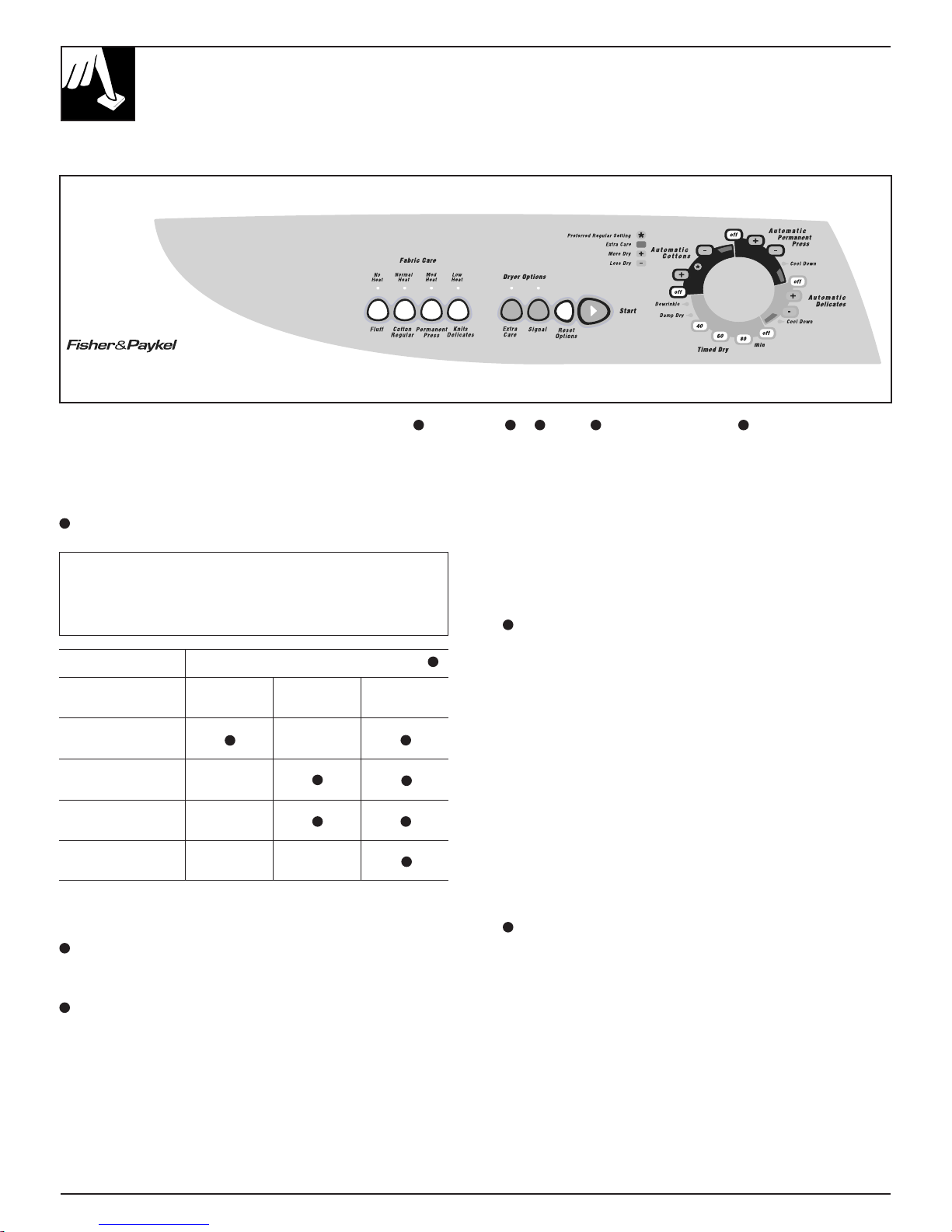

Features and appearances may vary

1

Drying Selections. Select the proper heat on the Fabric

Care selector for your load.

NOTE: Drying times will vary according to the type of

heat used (Electric, Natural gas or LP gas), size of load,

types of fabrics, wetness of clothes, and condition of

exhaust ducts.

Should be used with cycles indicated

Drying Automatic Automatic

Selections Cottons Perm. Press Timed

Cottons

High Heat

Perm. Press

Medium Heat

Knits/Delicates

Low Heat

Fluff

No Heat*

*Fluff-No Heat option can be used with an automatic cycle, but for best

performance it is recommended to be used with a timed cycle.

2

Cycle Selector. Turn the Cycle Selector to the desired

cycle setting. The selector may be turned in either

direction.

3

Press Guard Cycle. (Available on some models.)

The Press Guard cycle operates only with the

Automatic Permanent Press and Automatic Cottons

cycles. Turn the Press Guard knob to SET or press the

pad to select, and turn the Cycle Selector Dial to the

desired amount of heated drying time.

51 3 4 2

To minimize the wrinkle setting in clothes, the Press

Guard cycle provides from15 to 20 minutes of no-heat

tumbling after the clothes are dry.

Used the End Cycle Signal to remind you to remove

the dried laundry.

4

End Cycle Signal. (Available on some models.)

Set End Cycle Signal, if desired. This signal operates

with any cycle on some models. The control can be set

anywhere between OFF and LOUD, depending on the

desired sound level. The signal will start to sound just

before the end of the cycle to remind you to remove the

clothes. To stop the signal while sounding, turn the

signal control to OFF or advance the Cycle Selector to

OFF.

This signal should always be used when drying

polyester knits or permanent press items which should

be removed as soon as the dryer stops to help prevent

setting of wrinkles.

If the signal is on and you choose the Press Guard

cycle, you will hear the signal sound on and off

throughout the cycle. This reminds you that the clothes

are dry.

5

Start. Turn the Start knob or press the Push to Start

button to start the dryer. (Opening the door during

operation stops the dryer. To restart, close the door and

follow above directions.)

10

Page 11

OPERATING YOUR DRYER

Polyester Knits & Permanent Press Drying Tips

•DO NOT OVERLOAD-

Garments being dried or

dewrinkled should tumble

freely.

•REMOVE CLOTHES

PROMPTLY-

To help prevent wrinkling,

remove clothes from the dryer

promptly at the end of the

drying cycles.

•PLACE ON HANGERS-

Permanent press and polyester

knit garments look best if

placed on hangers after drying.

HOW TO LOAD THE CLOTHES

Don’t overload your dryer. Crowded

loads don’t dry efficiently and clothes

may be unnecessarily wrinkled. Loads

should look like this:

HOW TO SORT CLOTHES

As a general rule, sort clothes by surface texture, fabric, colour and weight, as you would for your washer.

Operating Instructions/Care and Cleaning

Dryer Exterior

Wipe off any spills or washing

compounds. Wipe or dust with a

damp cloth. Try not to strike the

surface with sharp objects.

Lint filter

Before every

dryer use, clean the

lint filter. Put your

moistened fingers at

one side of the filter

and wipe in a sideways

motion all the way

across to the other side.

CARE AND CLEANING

Dryer control panel and finishes

may be damaged by some laundry

pre-treatment soil and stain

remover products if such products

are sprayed on or have direct

contact with the dryer.

CARE AND CLEANING

To keep your dryer

operating at peak

performance.

periodically, remove

the lint filter and

insert the suction hose

from your vacuum

cleaner into the

opening.

Apply these pre-treatment products

away from the dryer. The fabric

may then be washed and dried

normally. Damage to your dryer

caused by pre-treatment products is

not covered by your warranty.

11

Page 12

SUGGESTED FABRIC

AND DRYING SELECTIONS

Cycle Suggested For Clothes Load/Fabrics such as: Drying Selection

Automatic Cottons

Automatic Permanent Press

• Cottons and linens

• Permanent press fabrics with cotton

High

Medium

• Down-filled garments, if machine washing and

drying is recommended

• Synthetics

Automatic Permanent Press

with Extra Care (Automatic

Delicates if available)

Timed

• Silks and wools

• Rayon and acetate

• Pillows*

Low

Medium or Low

• Blankets**

Cotton

Synthetics or Down

• Extra large items***

Cottons/Reg Heat

Medium or Low

Medium Heat

The terms High, Medium and Low Heat are those usually found on fabric care labels.

For best results, follow your fabric care labels.

MAY BE

DRIED IN A

TUMBLE

DRYER AT

MEDIUM TO

REGULAR

(green) (yellow) (green) (green) (yellow)

SETTING.

MAY BE

DRIED IN A

TUMBLE

DRYER AT

LOW

SETTING.

SHOULD BE

HUNG TO

DRY.

SHOULD BE

HUNG

SOAKING

WET TO

DRIP DRY.

SHOULD BE

DRIED ON A

FLAT

SURFACE.

*Pillows

**Blankets

***Extra Large Items-

Queen or King size

sheets; Blankets or

Spreads; Mattress

Covers/Pads;

Snowsuits.

12

Check ticking for holes or weak seams where feathers or filling could escape. DRY ONLY ONE

PILLOW AT A TIME. Set dryer for maximum time. Stop dryer occasionally and shake pillow to

redistribute filling for more even drying. Check pillow at end of drying time – if not completely dry,

return pillow to dryer and reset for more drying time. Feather pillows dry very slowly and must be

dried completely to prevent mildew. DO NOT tumble dry pillows containing kapok.

Add 2 or 4 dry towels to the blanket in the dryer. Set timer for 20-25 minutes. DO NOT set control

for more than 25 minutes. DRY ONLY ONE BLANKET AT A TIME. Remove blanket at the end of

the cycle and block the blanket back to its original shape. Allow to dry thoroughly before storing.

First setting – 20 minutes; check and redistribute load. Then set timer for 15 minutes; check load

again. Reset timer at 5 minute intervals, checking after each 5 minutes to make sure that the articles

do not fill the dryer drum; many large items, when wet, have ample room in the dryer, but as they

dry and fluff up, they may not have room to tumble. CAUTION: If large items do not have room to

tumble, the air flow may be blocked, which could result in scorching your valuable items. NOTE:

Mattress cover/pads should be dried alone.

Page 13

HOW TO OPERATE YOUR DRYER

The Difference Between Automatic and Timed Drying

Automatic Drying (Electronic)

(on some models)

When using the Automatic Cycles,

the Electronic Sensor Control

system continually senses the

moisture in the tumbling clothes,

determines when they are dried to

your pre-selected setting, and

terminates the cycle automatically.

The Cycle Selector will not

advance until clothes have reached

a certain degree of dryness.

Automatic Drying

When using the Automatic Cycles,

the Automatic Dry Control system

continually senses the temperature

of the air in the dryer drum. Wet

laundry keeps this air cool. When

laundry is dry enough (and the

drum air warms enough) the heat

turns off. When the air cools, the

heat turns back on. This off and on

cycling may happen a number of

times (depending on the fabric,

load size and Cycle Selector

setting). The Cycle Selector

advances (when the heat is off)

until it automatically turns off the

dryer.

Drying Selections Guide for the Automatic Cycles

DRY / SEC

Auto

Cottons

Cotons

DRY / SEC

DRY / SEC

Auto Per

& Knits

DRY / SEC

COOL DOW

REFROIDIS

Auto

Cottons

Cotons

DRY / SEC

DRY / SEC

DRY / SEC

Auto Per

& Knits

DRY / SEC

COOL DOW

REFROIDIS

Timed Drying

When using the Timed Cycles, you

select the number of minutes you

wish the dryer to run and it turns

off at the end of this time period.

DRY / SEC

Auto

Cottons

Cotons

DRY / SEC

DRY / SEC

Auto Per

& Knits

DRY / SEC

COOL DOW

REFROIDIS

How to Operate Your Dryer/Drying Selections/Accessories

As a general guideline...

Set near the midway position

• For most normal loads.

Accessories

•DRYING RACK (available on

some models)

A handy door rack is provided for

drying solid articles such as

stuffed toys and washable running

shoes without tumbling. This rack

is easy to install, just hook on the

bottom of the front opening.

The drying rack must be used

with a timed cycle.

Note:When rack is used

make sure there are

no loose articles in

the drum.

Set toward Less Dry

•For light-weight fabric loads

•If you desire to remove less

moisture

•For very small loads

• DRUM LAMP

(available on some

models)

BEFORE

REPLACING LIGHT

BULB, BE SURE TO

UNPLUG THE

DRYER POWER

CORD. Simply reach

above loading

opening from inside

drum. Remove bulb

and replace with the

same type and rating

bulb.

Set toward More Dry

•For loads that include heavyweight fabrics.

• If you desire to remove more

moisture.

13

Page 14

MAXIMIZE YOUR DRYER EFFICIENCY

BY KEEPING THE EXHAUST DUCT CLEAN.

1. Disconnect the plug from the wall socket

or turn off the circuit breaker to cut the

electrical supply to the dryer.

2. Disconnect duct from dryer.

3. Clean exhaust duct from end where dryer is

connected to the exhaust hood using:

• the hose attachment of your vacuum cleaner:

• a dust rag attached to a pole (for straight stretches)

or to a drain cleaning wire (for less accessible

turns).

4. Inspect exhaust hood. To minimize resistance to the

exhaust air flow:

• flap must move freely (you may check with a

mirror);

• flap should be fully open when dryer is on;

• ensure that no wildlife (birds, insects,...) have

nested inside the duct.

CLEANING LINT FROM YOUR DRYER

Combustible lint may collect on the inside of the dryer cabinet. CLEAN EVERY 2 TO 3 YEARS OR

MORE OFTEN DEPENDING ON USAGE. Cleaning should be done by a qualified service person.

ALWAYS VERIFY PROPER OPERATION AFTER SERVICING

14

Page 15

QUESTIONS?

USE THIS PROBLEM SOLVER

PROBLEM POSSIBLE CAUSE

DRYER WON’T START • Dryer unplugged. Make sure power cord is plugged in.

• No power to dryer. Check fuses and circuit breakers to make sure dryer is getting

current. Most electric dryers use two.

• Controls improperly set. Make sure controls are set and that the Start button is

pressed or turned. Opening the door during operation stops the dryer. To restart,

close the door and push the Start button.

CLOTHES TAKE TOO • Controls improperly set. Check all controls to make sure they are correctly set for

LONG TO DRY the load you want to dry. See the How to Operate Your Dryer section.

• Clogged lint filter. Clean filter before every load. Periodically remove lint filter

and clean area under it with vacuum cleaner. See the Care and Cleaning section.

• Improper ducting. Make sure dryer is ducted in accordance with the Installation

Instructions.

• Obstruction in exhaust ducting. Make sure ducting is clean and free of

obstruction; make sure damper in outside wall cap operates easily. If flexible

ducting is used, be sure it is not kinked and is properly installed according to the

Installation Instructions.

• Blown fuses or tripped circuit breakers. Check household fuses or circuit

breakers. Most electric dryers use two. It is possible for one to be blown or

tripped and the dryer still tumble without heat.

• Improper sorting. Do not mix heavy, hard-to-dry items with lightweight articles.

• Too many items in dryer. Dry only one washer load at a time. Do not combine

loads.

• Too few items in dryer. If drying only one article, add two more similar articles,

even if dry, to ensure proper tumbling.

SHRINKAGE • Some fabrics will shrink whether machine washed and tumble dried or washed

by hand and drip dried; others may be safely washed but will shrink in a dryer.

Follow Garment Manufacturers’Care Labels exactly. If in doubt, do not machine

wash or tumble dry.

WRINKLING • Leaving clothes in dryer after tumbling stops. Remove clothes promptly and

hang them immediately.

• Improper loads. Avoid laundering heavy Permanent Press items, such as work

clothes, with lighter Permanent Press items, such as shirts or blouses. Do not

wash or dry Permanent Press with regular laundry.

• Failure to use fabric softener. Proper use of fabric softener will minimize

wrinkling.

TO REMOVE WRINKLES Try one or more of these suggestions

• Retumble on Perma Press setting.

• Rerinse and dry on Perma Press setting.

• If unsuccessful, retumble on high heat for 10 - 12 minutes and hang immediately

• Iron carefully

• Send to dry cleaners for pressing

• Some wrinkles may remain which cannot be removed.*

* NOTE: If you follow good laundry procedures and Permanent Press clothes still

come out wrinkled, the finish may not be good quality. Also, in permanent press

synthetic/cotton blends, the cotton portion of the fabric can eventually wear

away leaving only the synthetic. Since it’s the cotton portion which is treated for

Permanent Press, a loss or decrease of Permanent Press performance will result.

“Easy Care” fabrics may eventually lose their finish and wrinkle even with

proper care.

Questions? Use This Problem Solver

IF DRYER STILL DOES NOT OPERATE, call for Service, GIVE THE MODEL AND SERIAL NUMBERS AND

DESCRIBE THE SYMPTOMS OF THE DRYER.

15

Page 16

YOUR AUTOMATIC CLOTHES DRYER

WARRANTY

Save proof of original purchase date such as your sales slip or copy of the check

cashed to establish warranty period.

WHAT IS COVERED BY THE WARRANTY

FULL TWO-YEAR WARRANTY

For two years from the date of original purchase, we will provide, free of charge, parts

and service labor in your home to repair or replace any part of the dryer that fails

because of a manufacturing defect.

This warranty is extended to the original purchaser and any succeeding owner for

products purchased for ordinary home use in Canada.

All warranty will be provided by a Fisher & Paykel Authorized Service Agent during

normal working hours. Should your appliance need service, during the warranty period or

beyond:

in Canada call DIRECT 1 877 744 7400

WHAT IS NOT COVERED BY THE WARRANTY

- Service trips to your home to teach you how to use the product.

Read your USE & CARE book. If you then have any questions about operating the

product, please contact your dealer or

in Canada call DIRECT 1 877 744 7400

- Improper installation.

If you have an installation problem, contact your dealer or installer. You care

responsible for providing adequate electrical, exhausting and other connection

facilities.

- Replacement of house fuses or resetting of circuit breaker.

- Failure of the product if it is misused, or used for other than the intended purpose or

used commercially.

- Damage to product caused by accident, fire, floods or Acts of God.

- Correction of unauthorized repairs.

- Normal recommended maintenance as set out in the products USE & CARE book.

WARRANTOR IS NOT RESPONSIBLE FOR CONSEQUENTIAL DAMAGES

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusion may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from

state to state. To know what your legal rights are in your state, consult your local or

state consumer affairs office or your state’s Attorney General.

Warrantor: Fisher & Paykel Appliances Inc.

If further help is needed concerning this warranty write:

Fisher & Paykel Appliance Inc., 27 Hubble, Irvine California, CA 92618-9858

16

Page 17

SÉCHEUSE

Guide d’utilisation

et d’entretien

et directives d’installation

PAPIER RECYCLÉ

RECYCLABLE

Notre environnement nous tient à coeur.

500A277P046

Page 18

Mesures de sécurité................ 3, 4

Directives d’installation

Directives d’inversion de la porte...............5

Évacuation...................................................6, 7

Sécheuse électrique ......................................8

Sécheuse à gaz ..........................................8, 9

Entretien et nettoyage

Évacuation de la sécheuse ........................14

Extérieur.........................................................11

Filtre à charpie ..............................................11

Remplacement de l’ampoule ...................13

Guide de dépannage............... 15

Fonctionnement et conseils

Avertisseur ....................................................10

Chargement...........................................11, 15

Conseils pour le séchage

• Des apprêts permanents................11, 15

• Des tricots ..........................................11, 12

Directives spéciales.....................................12

Filtre à charpie ..............................................11

Fonctionnement ....................10, 11, 12, 13

Guide de séchage automatique .......12, 13

Programme Soins + .............................10, 12

Programmes suggérés...............................12

Réglage des programmes..................10, 12

Séchage automatique ................................13

Séchage électronique par capteur..........13

Séchage minuté....................................12, 13

Tri des vêtements ........................................12

Lisez attentivement le

présent guide

Il a été conçu pour vous aider à faire

fonctionner et entretenir

convenablement votre nouvelle

sécheuse.

Gardez-le à la portée de la main pour y

trouver les réponses à vos questions.

Si vous desirez de plus amples

renseignements ou avez besoin d’aide,

écrivez (en indiquant votre numéro de

téléphone) à l’adresse suivante :

Directeur, Relations avec les

consommateurs

Camco Inc.

1, Factory Lane, bureau 310

Moncton (Nouveau-Brunswick)

E1C 9M3

Services à la clientèle

Garantie..........................................................16

Numéros de modèle et de série .................2

Réparations......................................................2

Économisez du temps et

de l’argent

Avant d’appeler un réparateur,

consultez le Guide de dépannage. Vous

y trouverez les causes de problèmes de

fonctionnement mineurs que vous

pouvez corriger vous-même.

Si la sécheuse que vous

avez reçue est

endommagée...

Communiquez immédiatement avec le

marchand (ou l’entrepreneur) qui vous

a vendu l’appareil.

Transcrivez les numéros

de modèle et de série

Ils sont inscrits sur une plaque située à

l’avant de la sécheuse, derrière la porte.

Ces numéros figurent également sur la

carte d’enregistrement qui accompagne

votre sécheuse. Avant de nous

retourner cette carte, veuillez inscrire

ces numéros ci-dessous :

Numéro de modèle

Numéro de série

Mentionnez ces numéros dans toute

correspondance ou appel de service

concernant votre sécheuse.

MISE EN GARDE : Pour votre sécurité, veuillez suivre à la lettre les directives données dans le présent

manuel afin de réduire au minimum les risques d’incendie ou d’explosion, ou de prévenir tout dommage,

blessure ou décès.

– Ne rangez pas ou n’utilisez pas d’essence ou

autres liquides ou vapeurs inflammables à

proximité de votre sécheuse ou de tout autre

électroménager.

– SI VOUS REMARQUEZ UNE ODEUR

DE GAZ

• Ne faites fonctionner aucun appareil électrique.

• N’actionnez aucun interrupteur électrique;

n’utilisez aucun téléphone dans votre édifice.

• Faites sortir tous les occupants de la pièce ou

de l’édifice, ou faites évacuer les environs.

2

• Communiquez immédiatement avec votre

fournisseur de gaz en utilisant le téléphone d’un

voisin. Suivez les directives qu’il vous donnera.

• Si vous ne pouvez rejoindre votre fournisseur de

gaz, appelez les pompiers.

– L’installation et les réparations doivent être

effectuées par un installateur qualifié, une

entreprise de réparation ou le fournisseur de gaz.

Page 19

MESURES DE SÉCURITÉ IMPORTANTES

Veuillez lire toutes les directives avant d’utiliser l’appareil.

Mise en garde - Il est extrêmement important de lire et de suivre les

directives ci-dessous, afin d’éviter les blessures ou les dommages

matériels que pourrait causer un incendie.

• N’utilisez cet appareil que pour l’usage auquel il est

destiné, comme expliqué dans le présent Guide

d’utilisation et d’entretien.

Avant d’utiliser votre sécheuse, assurez-vous

qu’elle a été adéquatement installée,

conformément aux Directives d’installation.

– L’appareil doit être adéquatement mis à la terre,

conformément à tous les codes locaux. Pour plus de

détails, consultez les Directives d’installation.

– Pour un fonctionnement satisfaisant du système de

commande de la sécheuse, installez l’appareil dans

un endroit où la température est supérieure à 50 ˚F

(10 ˚C). Installez ou entreposez la sécheuse dans un

endroit où elle ne sera pas exposée aux intempéries.

– Branchez l’appareil à un circuit protégé de capacité

appropriée afin d’éviter toute surcharge électrique.

– Il est FORTEMENT RECOMMANDÉ d’évacuer

l’air de la sécheuse vers l’extérieur afin de prévenir

l’accumulation d’une quantité importante d’humidité et

de charpie dans la pièce. Veuillez suivre à la lettre les

mesures d’évacuation indiquées dans les Directives

d’installation.

Ne réparez ou ne remplacez aucune pièce

de cet appareil, ou ne tentez pas de le faire,

à moins que cela ne soit spécifiquement

recommandé dans le présent Guide

d’utilisation et d’entretien ou indiqué dans les

directives de réparation que vous comprenez et que

vous êtes en mesure de suivre.

Lorsque vous débranchez l’appareil, tirez

sur la fiche et non pas sur le cordon, afin

d’éviter d’endommager le cordon ou le

raccord entre le cordon et la fiche. Installez

le cordon de sorte que personne ne trébuche

dessus ou qu’il ne soit pas exposé à des dommages ou

soumis à des contraintes.

Pour réduire les risques d’incendie

• Conduit d’évacuation – Voir les Directives

d’installation. N’utilisez qu’un conduit métallique

rigide ou souple de 4 po de diamètre pour

l’évacuation de l’air vers l’extérieur.

L’UTILISATION D’UN CONDUIT DE PLASTIQUE

OU FABRIQUÉ AVEC TOUT AUTRE MATÉRIAU

COMBUSTIBLE PEUT CAUSER UN INCENDIE.

LORSQU’UN CONDUIT EN MÉTAL SOUPLE OU

AUTRE S’AFFAISSE OU DEVIENT OBSTRUÉ AU

COURS DE L’UTILISATION OU DE

L’INSTALLATION, IL PEUT ÉGALEMENT CAUSER

UN INCENDIE.

• Ne faites pas sécher à la chaleur des articles

contenant du caoutchouc, du plastique ou autres

matériaux similaires (comme des soutiens-gorge

préformés, des chaussures de tennis, des caoutchoucs,

des tapis de bain, des carpettes, des bavoirs, des oreillers,

des culottes de bébé, des sacs de plastique, etc.) car ces

matériaux peuvent fondre ou brûler. De plus, dans

certaines circonstances, certains matériaux de

caoutchouc peuvent causer un incendie par combustion

spontanée lorsqu’ils sont chauffés.

• Ne rangez pas des articles qui peuvent fondre ou brûler

(comme des vêtements, du papier, des articles ou des

contenants de plastique, etc.) sur le dessus de la sécheuse

pendant qu’elle fonctionne.

• Les vêtements portant la mention «Faire sécher loin

de la chaleur» (comme les gilets de sauvetage

contenant du kapok) ne doivent pas être séchés dans

votre sécheuse.

• Ne lavez pas ou ne faites pas sécher des

articles qui ont été lavés avec les produits

combustibles ou explosifs, ou qui ont été

trempés dans ces produits ou qui en sont

tachés (comme de la cire, de la peinture,

de l’essence, des dégraissants, des solvants pour le

nettoyage à sec, du kérosène, etc.) car ils risquent de

s’enflammer ou d’exploser. Ne versez pas ces

substances dans l’eau de la laveuse. N’utilisez pas ces

substances à proximité de votre laveuse ou de votre

sécheuse pendant qu’elles fonctionnent.

• Ne placez pas dans la sécheuse ou n’utilisez pas à

proximité de celle-ci tout article ayant été utilisé avec un

solvant dégraissant ou imbibé d’une substance

inflammable (comme des chiffons de nettoyage, des

vadrouilles, des serviettes utilisées dans les salons de

beauté, les restaurants ou les salons de coiffure, etc.), à

moins qu’il ait été débarrassé de toute trace et toute

vapeur de substance inflammable. On utilise à la maison

de nombreux produits inflammables comme l’acétone,

l’alcool dénaturé, l’essence, le kérosène, certains

produits nettoyants ménagers, certains détachants, la

térébenthine, la cire, les décapants pour la cire et les

produits contenant du distillat de pétrole.

(suite à la page suivante)

Mesures de sécurité importantes

3

Page 20

MESURES DE SÉCURITÉ IMPORTANTES

• Avant chaque séchage, nettoyez le

filtre à charpie afin de prévenir

l’accumulation de charpie à l’intérieur

de la sécheuse ou dans la pièce.

NE FAITES PAS FONCTIONNER LA

SÉCHEUSE SANS LE FILTRE À

CHARPIE.

• Ne laissez pas s’accumuler autour et au-dessous de

vos électroménagers des matériaux combustibles,

comme de la charpie, du papier, des chiffons, des

produits chimiques, etc.

• Inspectez régulièrement le conduit d’évacuation pour

vous assurer qu’il n’a pas été écrasé ou qu’il n’est pas

obstrué de quelque façon que ce soit.

• L’intérieur de l’appareil et le raccord du conduit

d’évacuation à l’intérieur de la sécheuse doivent être

nettoyés tous les 2 ou 3 ans, ou plus souvent si

nécessaire, par un réparateur qualifié. Voir la section

«Entretien et nettoyage».

Pour réduire les risques de blessures

• Ne vous penchez jamais dans la sécheuse pendant que

le tambour tourne. Avant de charger ou de décharger la

sécheuse ou d’y ajouter des vêtements, attendez que le

tambour se soit complètement arrêté.

• Ne faites pas sécher d’articles en fibre de verre dans

votre sécheuse. Des particules pourraient demeurer dans

la sécheuse et être recueillies par les vêtements lors d’un

séchage subséquent, ce qui risque de causer des irritations

cutanées.

• La lessive peut atténuer les propriétés

ignifugeantes des tissus. Pour éviter cette

situation, suivez à la lettre les directives

données par le fabricant du vêtement.

• Il faut exercer une étroite surveillance

lorsque vous faites fonctionner cet

appareil en présence d’enfants. Ne les

laissez pas jouer avec l’appareil ni

monter dessus, ou s’introduire à

l’intérieur d’un vieil appareil qui ne sert

plus. Jetez de la façon appropriée les vieux

électroménagers ainsi que le matériel d’emballage.

Avant de jeter ou d’entreposer une sécheuse, enlevez

toujours la porte.

CONSERVEZ

CES DIRECTIVES

• Gardez tous les produits de lessive

(comme les détersifs, les javellisants, les

assouplissants, etc.) hors de la portée

des enfants, de préférence dans une

armoire verrouillée. Observez toutes les

mises en garde sur les emballages afin

d’éviter les accidents.

• Gardez le sol propre et sec à proximité de vos

électroménagers pour ne pas glisser.

• Pour réduire les risques de chocs

électriques, débranchez toujours

l’appareil avant de le réparer ou de le

nettoyer (sauf pour enlever et nettoyer le filtre

à charpie).

• REMARQUE : Le fait de placer le

sélecteur de programme à OFF ne coupe

PAS l’alimentation électrique de l’appareil.

• Ne trafiquez pas les commandes de l’appareil.

• Ne faites pas fonctionner l’appareil s’il est

endommagé, défectueux, partiellement démonté, ou si

des pièces sont manquantes ou défectueuses, ou si le

cordon d’alimentation ou la fiche sont endommagés.

• Ne montez jamais sur le dessus de la sécheuse.

• Ne placez PAS dans votre sécheuse des articles

imbibés d’huile de cuisson. Les articles contaminés par

de l’huile de cuisson peuvent provoquer une réaction

chimique et les vêtements pourraient prendre feu.

• Si votre sécheuse fonctionne à gaz, elle est pourvue

d’un système d’allumage électrique automatique et ne

possède pas de veilleuse. N’ESSAYEZ PAS DE

L’ALLUMER AVEC UNE ALLUMETTE. Vous risquez

de vous brûler si vous approchez votre main du brûleur et

que le dispositif d’allumage automatique s’allume.

Assouplissants textiles pour la sécheuse ou

produits antistatiques

Il est possible que vous désiriez assouplir votre lessive ou

réduire le collement électrostatique. Nous vous

recommandons d’utiliser un assouplissant liquide au cours

du programme de lavage, conformément aux directives du

fabricant de ce type de produit, ou de faire l’essai d’un

assouplissant textile pour la sécheuse, pour lequel le

fabricant certifie sur l’emballage que son produit peut être

utilisé en toute sécurité dans la sécheuse.

La responsabilité des problèmes de rendement ou de

fonctionnement, qui ne sont pas couverts par la garantie de

cet appareil et qui sont attribuables à l’utilisation de ces

produits, relève du fabricant de ces produits.

4

Page 21

DIRECTIVES D’INVERSION DE LA PORTE

Les directives qui suivent permettent de transférer du côté

gauche les charnières situées du côté droit.

Outils nécessaires

Tournevis Phillips standard n˚ 2

PORTE DE LA SÉCHEUSE

1. Ouvrez la porte et enlevez les capuchons situés du côté

opposé des charnières.

(Pour enlever les capuchons,

utilisez un couteau à mastic

dont l’extrémité de la lame est

recouverte de ruban gommé ou

des pinces à becs pointus. Faites

attention de ne pas égratigner

la peinture.)

2. Ouvrez complètement la porte,

puis enlevez la vis inférieure qui

fixe chacune des charnières au

panneau avant de la sécheuse.

(N’enlevez pas les vis qui se

trouvent sur la porte.)

Si vous désirez retransférer les charnières du côté droit,

suivez les mêmes directives (en remplaçant simplement le

mot «gauche» par le mot «droit» et vice versa).

6. Faites pivoter la porte sur

elle-même à 180˚.

Installez-la du côté opposé

du panneau avant en

l’ABAISSANT jusqu’à ce

que la charnière supérieure

et la charnière inférieure

reposent sur les vis

supérieures installées à

e

étape.

la 3

7. À l’aide des autres vis,

fixez la partie inférieure de

chacune des charnières.

8. Serrez les vis supérieures

de chacune des charnières.

Directives d’inversion de la porte

3. Revissez ces vis à moitié dans les trous supérieurs

de chaque charnière, du côté opposé de la porte

(aux endroits où vous avez enlevé les capuchons).

4. Dévissez à moitié la dernière vis

de chacune des charnières sur le

panneau avant de la sécheuse.

5. D’une main, saisissez le dessus de

la porte et de l’autre, tenez la partie

inférieure de la porte. Dégagez

ensuite la porte du panneau avant

de la sécheuse en la SOULEVANT

et la TIRANT vers vous.

9. Réinstallez les capuchons de plastique du côté où se

trouvaient les vis de charnière que vous avez

enlevées.

5

Page 22

298mm

(11 3/4")

91mm

(3 1/2")

NOTE : AJOUTER AUX

91mm (3 1/2")

LA DISTANCE

ENTRE LE FOND DU

CABINET ET LA SURFACE

DU PLANCHER

DIRECTIVES D’INSTALLATION

ÉVACUATION

L’installation et les réparations doivent être confiées à un installateur qualifié, à une entreprise de réparation ou

au fournisseur de gaz.

IMPORTANT : Faites installer correctement votre sécheuse.

REMARQUE : Les MISES EN GARDE et les directives IMPORTANTES données dans le présent manuel ne couvrent

pas toutes les conditions et situations possibles qui peuvent survenir. Il est bien évident que les personnes qui installent,

entretiennent ou font fonctionner la sécheuse DOIVENT faire preuve de jugement, d’attention et de prudence.

Si cet électroménager n’est pas installé, entretenu ou utilisé conformément aux directives du fabricant, il peut se produire

des conditions pouvant occasionner des blessures ou des dommages matériels.

Cette sécheuse a été préparée en vue d’une évacuation par

l’arrière (voir la fig. 1).

MISES EN GARDE

• N’UTILISEZ PAS UN CONDUIT FLEXIBLE NON

MÉTALLIQUE.

• N’utilisez jamais un conduit flexible à l’intérieur de la

sécheuse.

• Ne faites pas évacuer l’air de la sécheuse dans une

cheminée, une hotte de cuisinière, un évent à gaz, un

plancher ou un grenier. Le mélange de charpie et

d’humidité pourrait constituer un risque d’incendie ou

causer des dommages.

• Prévoyez un accès pour l’inspection et le nettoyage du

système d’évacuation au moins une fois par année. (Voir

la section « Entretien et nettoyage ».)

LONGUEUR DU CONDUIT D’ÉVACUATION

La longueur MAXIMALE PERMISE du système

d’évacuation dépend du type de conduit, du nombre de

coudes, du type d’évent mural, ainsi que des conditions

indiquées ci-dessous.

La longueur maximale permise des conduits rigides et des

conduits métalliques flexibles est indiquée dans le tableau

à la page suivante. Il est déconseillé d’installer plus de

quatre coudes de 90˚.

VÉRIFICATION DU SYSTÈME D’ÉVACUATIONÉVENT MURAL

• Installez l’évent de façon à empêcher le retour d’air ou

l’entrée d’oiseaux ou d’autres animaux.

• L’évent doit offrir le moins de résistance possible à

l’évacuation de l’air et n’exiger que peu ou pas

d’entretien.

• L’évent doit être installé à au moins 300 mm (12 po) audessus du sol ou de tout obstacle, et son ouverture doit

être dirigée vers le bas.

• Si vous utilisez un évent de toiture ou à persiennes,

celui-ci doit avoir des caractéristiques équivalentes à

celles d’un évent mural de 100 mm (4 po) en ce qui

concerne la résistance à l’évacuation de l’air, le retour

d’air et l’entretien.

LONGUEUR DE CONDUIT ENTRE LES COUDES

Prévoyez entre chacun des coudes une longueur de

conduit droit d’au moins 1 m (3 pi), y compris entre le

dernier coude et l’évent mural. Chaque fois que deux

coudes sont espacés d’une longueur inférieure à 1 m

(3 pi), réduisez de 3 m (10 pi) la longueur maximale de

conduit indiquée dans le tableau.

6

AUTRES TYPES DE COUDES

• Un coude de 45˚ ou moins : ne pas tenir compte

• Deux coudes de 45˚ ou moins : suivre les indications

données pour un coude de 90˚.

• Chaque coude de plus de 45˚ : suivre les indications

données pour un coude de 90˚.

SCELLEMENT DES JOINTS

• Tous les joints doivent être étanches pour éviter les

fuites d’air. L’extrémité mâle de chaque section de

conduit doit être orientée en sens contraire par rapport à

la sécheuse.

• N’assemblez pas les sections de conduit avec des vis qui

dépassent à l’intérieur du conduit. Celles-ci risquent de

créer des points d’accumulation de charpie.

• Assurez l’étanchéité à l’air et à l’humidité des conduits

en recouvrant les joints de ruban gommé pour conduit.

ISOLATION

• Les conduits qui traversent une zone non chauffée ou

qui se trouvent à proximité d’un conduit de

climatisation doivent être isolés afin de réduire la

condensation et l’accumulation de charpie, et doivent

avoir une pente descendante vers l’extérieur.

REMARQUE : N’installez jamais de grille à l’intérieur

du conduit d’évacuation.

ATTENTION : L’AIR DE LA SÉCHEUSE DOIT

ÊTRE ÉVACUÉ À L’EXTÉRIEUR.

ARRIÈRE DE LA SÉCHEUSE

FIG. 1

Page 23

DIRECTIVES D’INSTALLATION

ÉVACUATION

Tableau 1: LONGUEUR MAXIMALE RECOMMANDÉE

SÉCHEUSES ÉLECTRIQUES SÉCHEUSES À GAZ

Type d’évent mural Type d’évent mural

Recommandé

Pour les conduits d’évacuation

courts seulement

Recommandé

Pour les conduits d’évacuation

courts seulement

21⁄2 po

(6,35 cm)

Métallique

flexible*

4,6 m (15 pi)

3,0 m (10 pi)

–

–

–

bre

N

de

coudes de 90˚

0

1

2

3

4

4 po

(10,16 cm)

Rigide

27,4 m (90 pi)

18,3 m (60 pi)

13,7 m (45 pi)

10,7 m (35 pi)

7,6 m (25 pi)

Métallique

flexible*

16,8 m (55 pi)

12,2 m (40 pi)

9,1 m (30 pi)

6,1 m (20 pi)

4,6 m (15 pi)

Rigide

18,3 m (60 pi)

13,7 m (45 pi)

10,7 m ( 35 pi)

7,6 m (25 pi)

4,6 m (15 pi)

21⁄2 po

(6,35 cm)

Métallique

flexible*

13,7 m (45 pi)

9,1 m (30 pi)

6,1 m (20 pi)

4,6 m (15 pi)

3,0 m (10 pi)

4 po

(10,16 cm)

Rigide

13,7 m (45 pi)

10,7 m (35 pi)

7,6 m (25 pi)

4,6 m (15 pi)

–

Métallique

flexible*

9,1 m (30 pi)

6,1 m (20 pi)

3,0 m (10 pi)

–

–

Rigide

9,1 m (30 pi)

6,1 m (20 pi)

3,0 m (10 pi)

–

–

* N’utilisez pas de conduit flexible non métallique

AUTRES POSSIBILITÉS D’ÉVACUATION

Cette sécheuse est prête pour évacuer l’air à l’arrière du cabinet. Si votre espace est restraint, utilisez les instructions

suivantes pour évacuer l’air de la sécheuse directement du côté ou du dessous du cabinet.

L’AIR DES SÉCHEUSES À GAZ NE PEUT ÊTRE ÉVACUÉ DIRECTEMENT DU CÔTÉ DROIT DU CABINET.

MISE EN GARDE: Protégez vos mains et vos bras lorsque vous travaillez à l’intérieur du cabinet.

• N’utilisez jamais un conduit flexible à l’intérieur de la

sécheuse.

• Enfoncez et retirez la débouchure au fond de l’appareil

ou du côté choisi.

• Enlevez la vis à l’intérieur et à l’extrémité du conduit

d’évacuation. Gardez la vis pour plus tard.

Vis à

l’intérieur

du conduit

• Réinstallez le conduit (section A) sur le boîtier de

ventilateur. Assurez-vous que le trou de fixation se

trouve vis-à-vis la languette dans la base de l’appareil.

Fixez le conduit en place en le vissant dans la languette.

Utiliser seulement des tuyaux

metaliques à l’intérieur du

285 mm

(11 1/4 ")

cabinet de la sécheuse

ARRIERE DU

PANNEAU LATERAL

BOITIER

VENTILATEUR

PORTION COUPEE

DE 229 mm

216 mm

(8 1/2 ")

LOCALISATION DE LA

LANGUETTE (SOUS

A

CONDUIT EVACUATION)

Directives d’installation

• Comme illustré, racourcissez le conduit à 229 mm (9

po). Gardez section la A.

B

Trou de fixation

A

229 mm

(9 ")

•À travers l’ouverture

arrière, localisez la

languette située dans la

BOITIER

VENTILATEUR

base, au milieu de

l’appareil et relevez la à

environ 45˚ à l’aide

d’un tournevis plat.

LANGUETTE

ET VIS

121 mm

(4 3/4 ")

121 mm

(4 3/4 ")

• Pour faire évacuer l’air de la sécheuse par l’orifice choisi,

utilisez un coude de métal standard réglable ainsi qu’une

longueur de conduit droit en métal. Introduire les pièces

dans le cabinet à travers les ouvertures arrière, du

dessous ou de côté.

• Utilisez seulement un conduit en métal rigide de 100

mm (4 po) de diamètre.

• Couvrez l’ouverture à l’arrière à l’aide de la plaque (Kit

WE1M454) disponible chez votre fournisseur de service

local.

MISE EN GARDE: Ne laissez jamais l’ouverture de

l’arrière sans la plaque.

7

Page 24

INSTALLATION

QUATRE

PATTES DE

NIVELLEMENT

VUE

LATÉRALE

IMPORTANT - SE CONFORMER À TOUS LES CODES EN VIGUEUR

La sécheuse doit être de niveau et stable sur le plancher.

EXIGENCES D’INSTALLATION SPÉCIALES

INSTALLATION DANS UNE ALCÔVE OU UN PLACARD

• L’air de la sécheuse DOIT être évacué à l’extérieur. Voir la

section « ÉVACUATION ».

• Les dégagements minimums entre la sécheuse et les murs

adjacents ou autres surfaces sont les suivants :

0 mm (0 po) de chaque côté

76 mm (3 po) à l’avant et à l’arrière

• Le dégagement vertical minimum entre le plancher et les

armoires, le plafond, etc., doit être de 132 cm (52 po).

REMARQUE : PRÉVOYEZ SUFFISAMMENT

D’ESPACE POUR L’INSTALLATION ET LA

RÉPARATION DE L’APPAREIL.

• Les portes du placard doivent être pourvues de persiennes

ou autre dispositif d’aération équivalant à une ouverture

d’au moins

une sécheuse et une laveuse sont installées dans l’armoire,

les portes doivent être pourvues d’un dispositif d’aération

équivalant à une ouverture de 774 cm

de façon égale.

• Dans le cas d’une sécheuse à gaz, le placard doit être

pourvu d’un conduit d’aération vers l’extérieur afin

d’empêcher l’accumulation de gaz en cas de fuite de la

conduite d’alimentation en gaz.

• Aucun autre appareil de combustion ne doit être installé

dans le même placard que la sécheuse.

387 cm2(60 po2) répartie de façon égale. Si

2

(120 po2) répartie

DÉGAGEMENTS MINIMUMS POUR LES AUTRES

TYPES D’INSTALLATION

• Dégagements minimums par rapports aux surfaces

combustibles et de l’admission d’air :

- 0 mm de chaque côté et 25 mm (1 po) à l’arrière.

INSTALLATION DANS UNE MAISON MOBILE

• L’air de la sécheuse doit être évacué à l’extérieur et le

conduit doit être raccordé à un évent solidement fixé à la

structure de la maison. (Voir la section « ÉVACUATION »).

• L’évent NE DOIT PAS être installé sous la maison mobile.

• Le conduit d’évacuation ne doit pas être raccordé à un

autre conduit, évent ou cheminé.

• Il faut prévoir dans la salle de séchage l’admission d’air en

provenance de l’extérieur. L’ouverture de la prise d’air doit

avoir une superficie d’au moins 160 cm

• Le conduit d’évacuation DOIT ÊTRE EN MÉTAL.

• N’assembler pas le conduit d’évacuation avec des vis ou

autre mécanisme d’attache qui dépassent à l’intérieur du

conduit.

• La sécheuse doit être fixée au sol, conformément aux

directives fournies par le marchand.

• L’installation doit être conforme aux Codes d’installation

dans les maisons mobiles CAN/CSA série Z240 MH.

REMARQUE : IL FAUT PRÉVOIR SUFFISAMMENT

D’ESPACE POUR L’INSTALLATION ET LA

RÉPARATION DE L’APPAREIL.

2

(25 po2).

MISE DE NIVEAU DE LA SÉCHEUSE

Réglez les quatre pieds de nivellement pour que l’appareil

soit à la même hauteur que la laveuse. La sécheuse doit

être DE NIVEAU et reposer solidement sur ses quatre

pieds de nivellement.

LONGUEUR DU CONDUIT D’ÉVACUATION

Pour un rendement optimum, consultez le tableau pour connaître la longueur maximale suggérée pour le conduit d’évacuation

(à la section « Évacuation »).

ATTENTION : N’UTILISEZ PAS DE RALLONGE ÉLECTRIQUE AVEC CET ÉLECTROMÉNAGER.

REMARQUE : Si le circuit électrique n’est pas conforme aux exigences ci-dessous, appelez un électricien compétent.

POUR UNE SÉCHEUSE ÉLECTRIQUE,

LE CIRCUIT ÉLECTRIQUE DOIT :

1. Être de 120/240 volts ou 120/208 volts, de 60 Hz, doté

d’une prise murale comme celle

illustrée ci-contre.

2. Être protégé par un

DISJONCTEUR OU DES

FUSIBLES DE 30 A.

3. ÊTRE CONVENABLEMENT

MIS À LA TERRE.

4. ÊTRE CONFORME À TOUS LES CODES LOCAUX.

8

ÉLECTRICITÉ

PRISE TYPIQUE DE 30 A

POUR SÉCHEUSE

POUR UNE SÉCHEUSE À GAZ,

LE CIRCUIT ÉLECTRIQUE DOIT :

1. Être de 120 volts, de 60 Hz, pouvu d’une prise murale

comme celle illustrée ci-contre.

2. Être protégé par un

DISJONCTEUR OU DES

FUSIBLES DE 15 A OU DE 20 A.

3. ÊTRE CONVENABLEMENT MIS

À LA TERRE.

4. L’installation doit être conforme à

la norme C22.1 de l’ACNOR, à la Partie 1 du

Code canadien de l’électricité ou aux codes locaux en

vigueur.

PRISE TYPIQUE

DE 120 VOLTS

Page 25

INSTALLATION – SÉCHEUSE À GAZ

51mm

(2")

66 mm

(2 5/8")

ALIMENTATION EN GAZ À FILETAGE MÂLE

9.52 mm (3/8")

VUE ARRIÈRE

IMPORTANT - SE CONFORMER À TOUS LES CODES EN VIGUEUR

La sécheuse doit être de niveau et stable sur le plancher.

L’air de la sécheuse doit être évacué à l’extérieur.

POUR VOTRE SÉCURITÉ

Si vous remarquez une odeur de gaz :

• Ne faites fonctionner aucun appareil électrique

• N’actionnez aucun interrupteur électrique; n’utilisez aucun

téléphone dans votre édifice

• Faites sortir tous les occupants de la pièce ou de l’édifice,

ou faites évacuer les environs.

• Communiquez immédiatement avec votre fournisseur de

gaz en utilisant le téléphone d’un voisin. Suivez les directives

qu’il vous donnera.

• Si vous ne pouvez rejoindre votre fournisseur de gaz,

appelez les pompiers.

• L’installation et les réparations doivent être effectuées par

un installateur qualifié, une entreprise de réparation ou le

fournisseur de gaz.

RACCORDEMENT À LA CONDUITE DE GAZ

L’installation doit être conforme aux codes locaux et avec

le code CAN/CGA-B149, Code d’Installation au Gaz

Naturel.

Certains codes locaux restreignent l’installation des

appareils au gaz dans les garages. Ils doivent être 45 cm

(18 po) au dessus du sol et protégé des véhicules par une

barrière.

INJECTEUR DU BRÛLEUR

Cette sécheuse à gaz est pourvue d’une électrovanne et

d’un brûleur pour utilisation avec un seul type de gaz. En

utilisant la trousse appropriée, votre centre de service local

peut convertir votre sécheuse pour un fonctionnement avec

un autre type de combustible.

Utilisez la trousse WE25M35 pour passer du gaz naturel

au propane.

Utilisez la trousse WE25M36 pour passer du propane au

gaz naturel.

MISE EN GARDE : LES CONVERSIONS DOIVENT

ÊTRE EFFECTUÉES CONFORMÉMENT AUX

EXIGENCES STIPULÉES PAR LES AUTORITÉS

PROVINCIALES COMPÉTENTES OU

CONFORMÉMENT AUX EXIGENCES DES CODES

D’INSTALLATION CAN/CGA B.149.1 ET B.149.2

POUR VOTRE SÉCURITÉ

Ne rangez pas ou n’utilisez pas d’essence ou

autres liquides ou vapeurs inflammables à

proximité de cet appareil ou de tout autre

électroménager.

ALIMENTATION EN GAZ

• La conduite d’alimentation en gaz doit être constituée

d’un tuyau rigide de 12,7 mm (1/2 po) (on peut utiliser

un tuyau de cuivre de 9,53 mm (3/8 po) si la sécheuse

fonctionne au gaz propane) doté d’un robinet accessible

à moins de 6 pieds (2 m) de la sécheuse et se trouvant

dans la même pièce que celle-ci. Augmentez le diamètre

si la longueur de la conduite est supérieure à 20 pi (7 m).

• Durant l’essai de pression :

– Lorsque la pression d’essai est supérieure à 1/2 lb/po

(3,45 kPa), débranchez la sécheuse et le robinet de la

conduite de gaz avant d’effectuer l’essai.

– Lorsque la pression est inférieure ou égale à 1/2 lb/po

(3,45 kPa), fermez le robinet de la conduite de la

sécheuse avant d’effectuer l’essai.