Fisher NotchFlo DST CL300, NotchFlo DST CL600, NotchFlo DST CL1500, NotchFlo DST CL2500, NotchFlo DST CL900 Instruction Manual

Instruction Manual

D103211X012

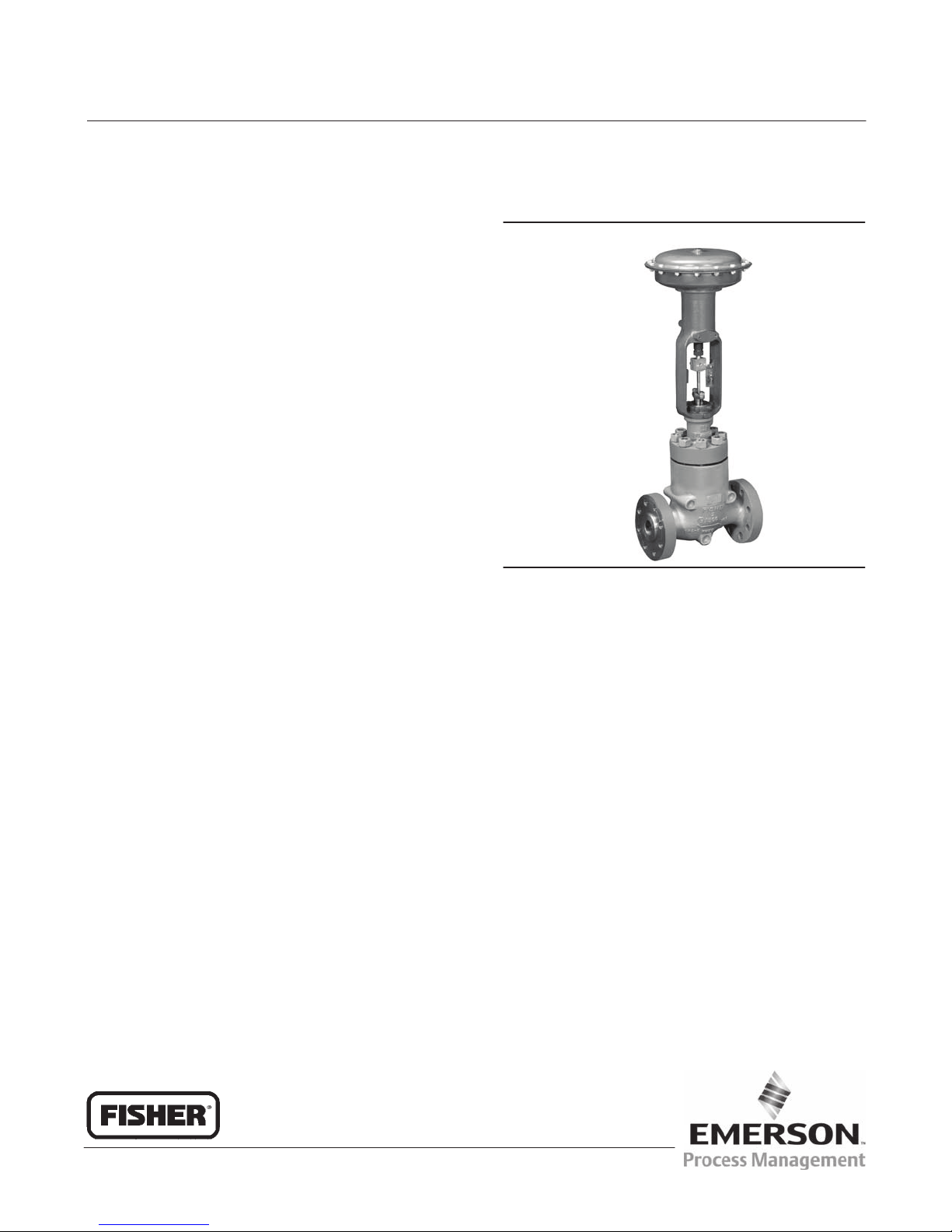

Fisherr NotchFlo™ DST Control Valve

NotchFlo DST Valve

March 2011

Contents

Introduction 1.................................

Scope of Manual 1.............................

Description 1.................................

Specifications 3...............................

Installation 4...................................

Maintenance 5.................................

Packing Maintenance 7.........................

Adding Packing Rings 9.....................

Replacing Packing 9........................

Trim Removal 12..............................

Valve Plug Maintenance 12......................

Lapping Seats 13..............................

Trim Replacement 14..........................

Parts Ordering 15...............................

Parts Kits 16...................................

Parts List 16...................................

Introduction

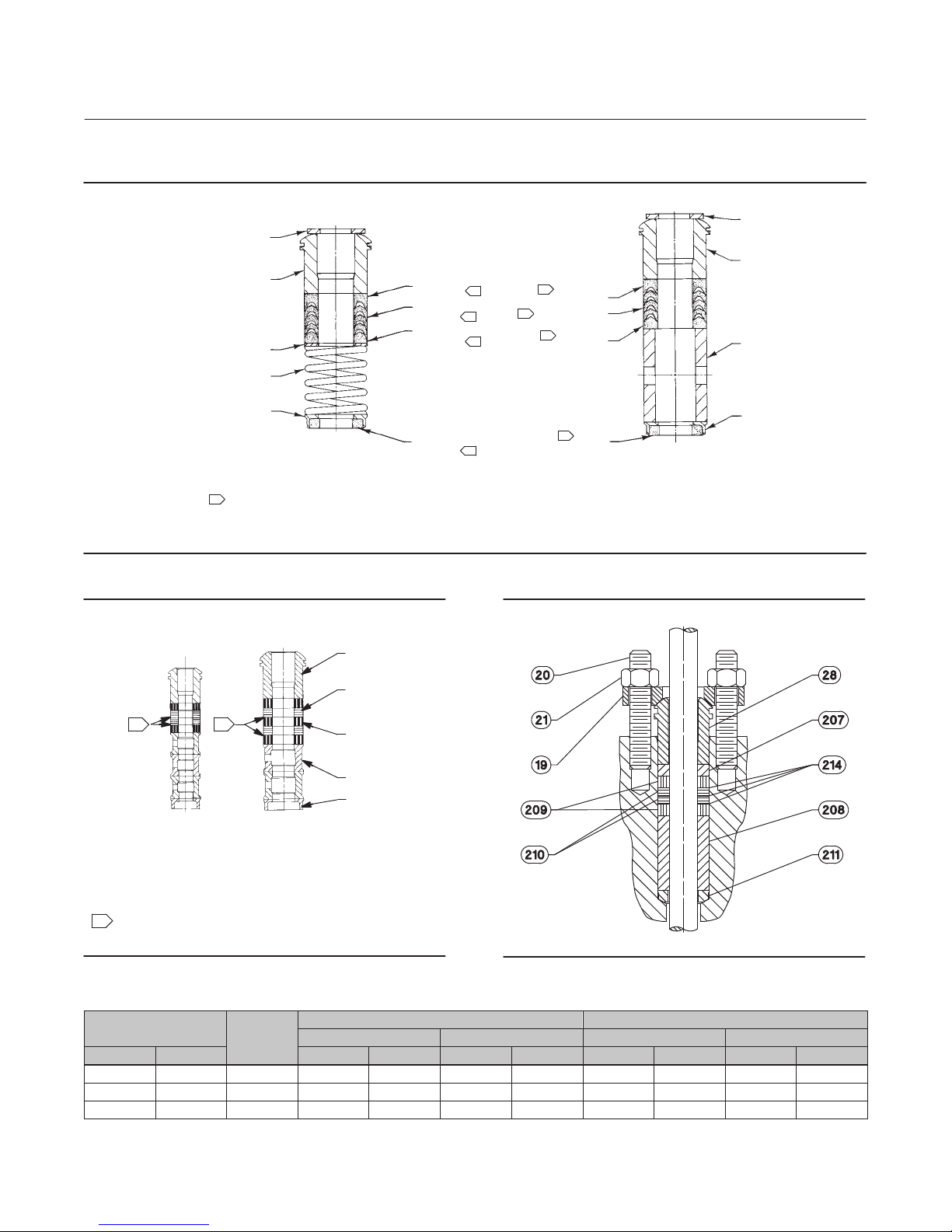

Figure 1. Fisher NotchFlo DST Control Valve

W9050

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for the Fisher NotchFlo DST control

valve. Refer to separate manuals for instructions covering the actuator, positioner, and accessories.

Do not install, operate, or maintain NotchFlo DST valves without being fully trained and qualified in valve, actuator,

and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important

to carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If

you have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

Description

The NotchFlo DST globe (figure 1) and angle valves have metal seats, cage guiding, quick change trim, and

push‐down‐to‐close valve plug action. All available valve sizes and pressure ratings use balanced valve plugs with the

exception of CL900 and CL1500 (NPS 1 and 1‐1/2 valves) which use an unbalanced valve plug. To provide a seal

between the cage and a balanced valve plug, the balanced valve plugs use a pressure‐assisted spring‐loaded seal ring.

A properly sized NotchFlo DST valve with 3‐, 4‐, or 6‐stage dirty service anti‐cavitation trim (figure 2) offers excellent

control of high pressure drop liquids with entrained solids, while avoiding the damaging effects of cavitation and

erosive solids.

www.Fisher.com

NotchFlo DST Valve

March 2011

Table 1. Specifications

Instruction Manual

D103211X012

Available Valves

CL600 3‐Stage: Level C only

CL900 and CL1500 v NPS 4, 4‐Stage: Levels A, B, and

(1)

C

CL1500 w NPS 6, 4‐Stage: Level C only

CL2500 6‐Stage: Level C only

End Connection Styles and Ratings

(2)

Also see table 2

Shutoff Classification

Class V: [5x10

(0.0005 mL/min/psid/in) of water at service pressure

drop] per ANSI/FCI 70‐2 and IEC 60534‐4

Flow Characteristic

Linear

Flanged: Consistent with CL600, 900, 1500, and 2500

per ASME B16.34

Socket Welding: Consistent with CL600, 900, and

Flow Direction

Flow up

1500 per ASME B16.34

Buttwelding: Consistent with CL600, 900, 1500, and

2500 per ASME B16.34

1. Levels A, B, and C provide for varied pressure drops and capacity.

2. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

Approximate Weights

See table 2

Figure 2. Fisher NotchFlo DST Trim

12m3

/sec/bar/mm of port diameter

W8538-1

NotchFlo DST control valves utilize a high resistance, multi‐stage, axial flow path (or passage) where fluid flow is

parallel to the axis of the plug and cage.

Pressure reduction occurs throughout the length of the plug; thus individual stages aren't exposed to the full pressure

differential. Therefore, trim life is enhanced.

NotchFlo DST trim utilizes a series of notched flow restrictions and expansions to control the pressure drop of the

fluid. The amount of pressure drop per stage is controlled to prevent cavitation problems and minimize erosion issues.

Flow passage configuration provided by the multi‐stage plug and cage design make the NotchFlo DST valves

well‐suited for applications involving fluids with entrained particles. This is a potentially serious problem for other

anti‐cavitation valve designs which are subject to clogged flow passages.

Design of the trim allows for high rangeability.

2

Instruction Manual

D103211X012

Specifications

Specifications for NotchFlo DST valves are shown in table 1.

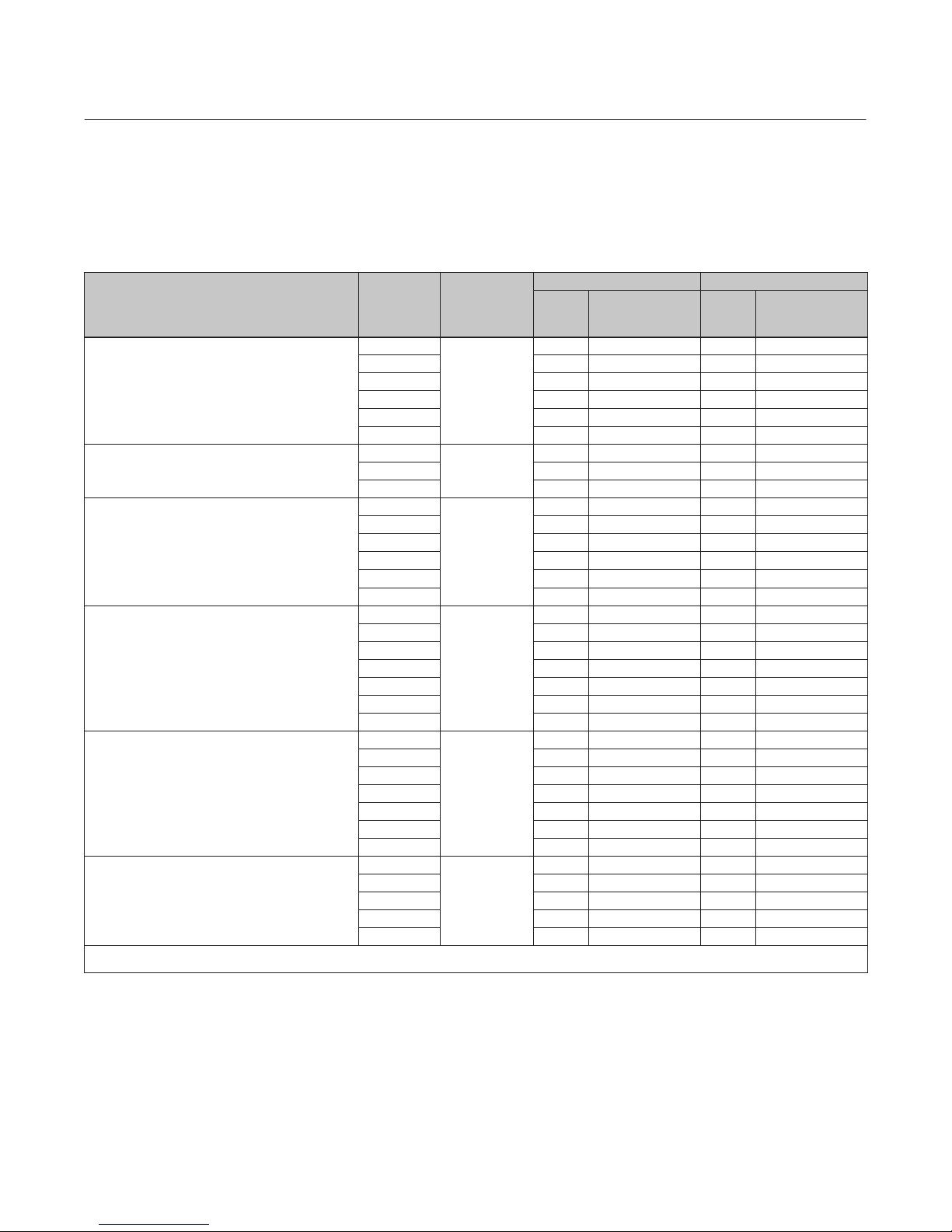

Table 2. Approximate Weights (Valve and Bonnet Assemblies)

VALVE DESIGN

3-Stage Globe Valves

4-Stage Globe Valves

3-Stage Angle Valves

4-Stage Angle Valves

4-Stage Cast Angle Valves

6-Stage Angle Valves

1. SWE available on NPS 1, 1-1/2, and 2 only.

2. Screwed end available on NPS 1 and 2 CL600 only.

VALVE SIZE,

NPS

1

2 40 30 90 70

3 70 50 155 110

4 120 80 265 175

6 275 230 610 510

8 510 445 1130 980

2

3 185 140 405 310

4 340 280 750 620

1

2 42 - - - 93 - - 3 86 - - - 190 - - 4 140 - - - 315 - - 6 300 - - - 660 - - 8 605 - - - 1340 - - 1

1-1/2 55 45 120 95

2 95 95 210 210

3 185 - - - 405 - - 4 285 - - - 625 - - 6 560 - - - 1230 - - -

8 1260 - - - 2770 - - -

1

1-1/2 43 35 95 77

2 75 57 165 126

3 148 118 326 260

4 243 200 536 441

6 523 443 1153 977

8 1062 920 2342 2029

1

2 180 170 405 375

3 500 473 1110 1043

4 465 433 1025 955

6 1060 1030 2330 2271

PRESSURE

RATING

CL600

CL900 and

CL1500

CL600

CL900 and

CL1500

CL900 and

CL1500

CL2500

NotchFlo DST Valve

KILOGRAMS POUNDS

Socket Weld

Flanged

20 15 45 35

95 85 210 185

20 - - - 44 - - -

50 40 110 90

40 32 88 71

64 67 140 148

Butt Weld,

Screwed

(1)

,

Flanged

(2)

Socket Weld

March 2011

Butt Weld,

(2)

Screwed

(1)

,

3

NotchFlo DST Valve

March 2011

Instruction Manual

D103211X012

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or property damage caused by sudden release of pressure may result if the valve assembly is installed where

service conditions could exceed the limits given in table 1 or on the appropriate nameplates. To avoid such injury or

damage, provide a relief valve for over‐pressure protection as required by government or accepted industry codes and good

engineering practices.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

WARNING

Some bonnet flanges have a tapped hole that was used to handle the bonnet during manufacture. Since this tapped hole

was not designed or intended to support the weight of the valve/bonnet assembly, do not use this tapped hole to lift the

valve assembly or personal injury may result from the assembly falling.

CAUTION

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop, and controlled fluid conditions. Since some body/trim material combinations are limited in their pressure

drop and temperature ranges, do not apply any other conditions to the valve without first checking with your Emerson

Process Management sales office.

1. Before installing the valve, inspect it to ensure that the valve body cavity is free of foreign material.

2. Clean out all pipelines to remove scale, welding slag, and other foreign materials before installing the valve.

3. Flow through the valve must be in the direction indicated by the flow arrow, which is cast on or attached to the

valve body.

4. Use accepted piping practices when installing the valve in the pipeline. For flanged valve bodies, use a suitable

gasket between the body and pipeline flanges.

5. Install a three‐valve bypass around the valve if continuous operation is required during maintenance.

6. If the actuator and valve body are shipped separately, refer to the actuator mounting procedure in the appropriate

actuator instruction manual.

4

Instruction Manual

D103211X012

NotchFlo DST Valve

March 2011

7. If the valve body was shipped without packing installed in the packing box, install the packing before putting the

valve body into service. Refer to instructions given in the Packing Maintenance procedure.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened prior to shipment; however, the packing

might require some readjustment to meet specific service conditions. Check with your process or safety engineer for any

additional measures that must be taken to protect against process media.

Maintenance

Refer to figure 7 through 12.

Valve parts are subject to normal wear and must be inspected and replaced as necessary. Inspection and maintenance

frequency depends on the severity of service conditions. This section includes instructions for packing maintenance

and trim maintenance. All maintenance operations may be performed with the valve in the line.

WARNING

Avoid personal injury or damage to property from sudden release of pressure or uncontrolled process fluid. Before starting

disassembly:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the power actuator loading pressure and relieve any actuator spring precompression.

D Use lock‐out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

5

NotchFlo DST Valve

March 2011

Figure 3. PTFE V‐Ring Packing Arrangements for Plain and Extension Bonnets

UPPER WIPER

(KEY 27)

PACKING

12A7837‐A

B1429‐5

FOLLOWER

(KEY 28)

WASHER

(KEY 25)

SPRING

(KEY 24)

PACKING BOX

RING (KEY 26)

FOR 316 SST

METAL PACKING BOX PARTS

NOTE:

1

AND LOWER WIPER ARE PART OF PACKING SET (KEY 22).

2 REQ'D FOR DOUBLE ARRANGEMENTS, EXCEPT LOWER WIPER.

MALE ADAPTOR, PACKING RING, FEMALE ADAPTOR,

FEMALE

ADAPTOR

PACKING

RING

MALE

ADAPTOR

LOWER

WIPER

1

1

1

1

SINGLE ARRANGEMENTS

FEMALE

1

ADAPTOR

1

PACKING RING

MALE

1

ADAPTOR

1

LOWER

WIPER

Instruction Manual

D103211X012

UPPER WIPER

(KEY 27)

PACKING

FOLLOWER (KEY 28)

SPACER (KEY 24)

PACKING BOX

RING (KEY 26)

FOR ALL OTHER METAL PACKING

BOX PART MATERIALS

Figure 4. Detail of Graphite Ribbon/Filament Packing

for Plain and Extension Bonnets

1

13A9775‐B

12.7 mm

(1/2 INCH)

STEM

1

13A9776‐B

19.1 & 25.4 mm

(3/4 & 1 INCH)

STEM

PACKING

FOLLOWER

(KEY 28)

GRAPHITE

RIBBON

PACKING RING

(KEY 23)

GRAPHITE

FILAMENT

PACKING RING

(KEY 23)

LANTERN

RING (KEY 24)

PACKING BOX

RING (KEY 26)

Figure 5. Detail of Graphite ULF Packing for Plain

Bonnets

SINGLE ARRANGEMENTS

NOTE:

1

0.102 mm (0.004 INCH) THICK SACRIFICIAL ZINC WASHERS;

USE ONLY ONE BELOW EACH GRAPHITE RIBBON RING.

39B9286‐A

SINGLE ARRANGEMENTS

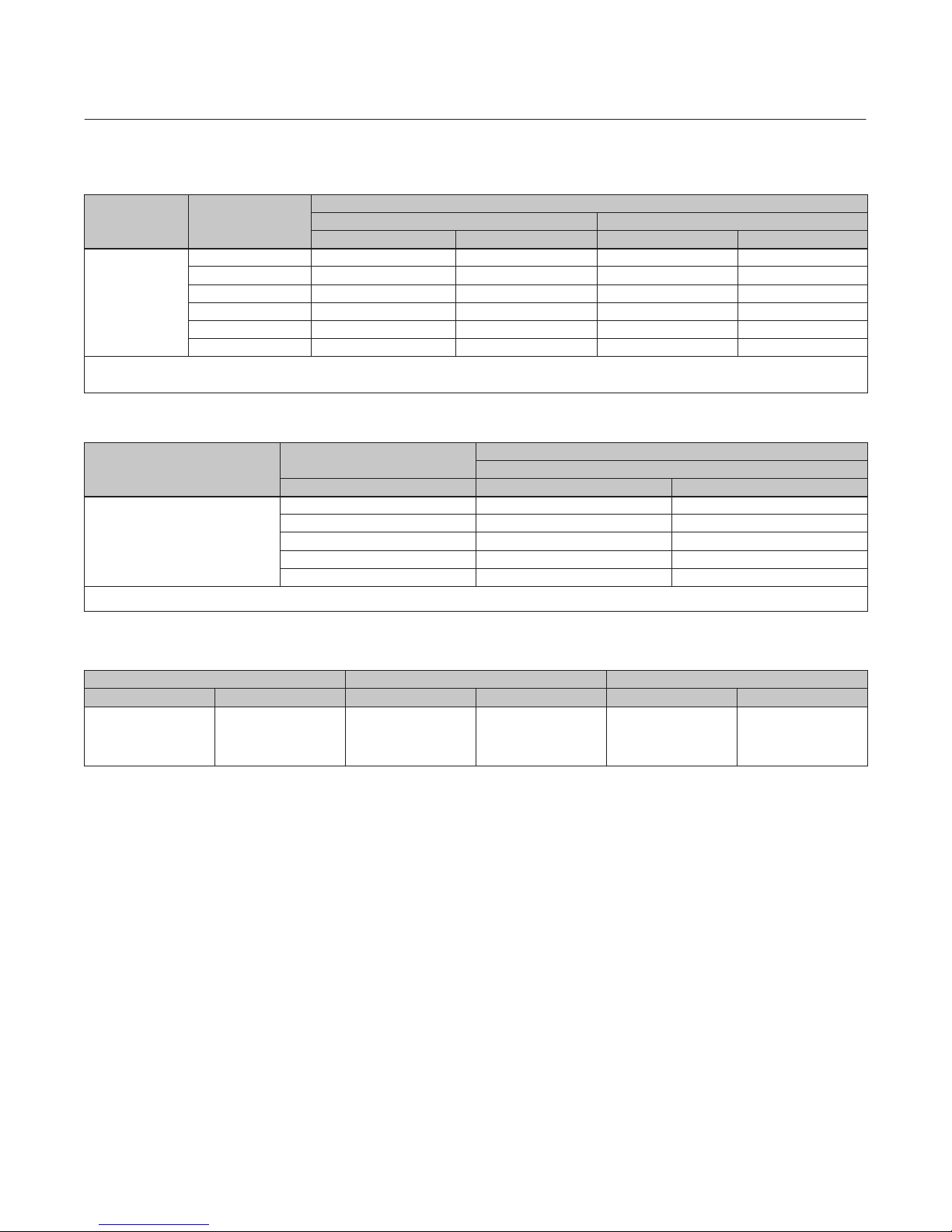

Table 3. CL600 Recommended Torque for Packing Flange Nuts (non live‐loaded)

VALVE STEM DIAMETER

mm Inches NSm LbfSin NSm LbfSin NSm LbfSin NSm LbfSin

PRESSURE

RATING

Minimum Torque Maximum Torque Minimum Torque Maximum Torque

12.7 1/2 CL600 9 81 14 122 4 39 7 58

19.1 3/4 CL600 21 182 31 274 10 87 15 131

25.4 1 CL600 35 310 53 466 17 149 25 223

GRAPHITE TYPE PACKING PTFE TYPE PACKING

6

Instruction Manual

D103211X012

NotchFlo DST Valve

March 2011

Table 4. CL900, 1500, and 2500 Recommended Torque for Packing Flange Nuts (non live‐loaded)

VALVE STEM

DIAMETER

mm Inches Min Max Min Max

12.7 1/2

19.1 3/4

25.4 1

31.8 1‐1/4 CL1500 68 102 50 75

PRESSURE RATING

CL900 12 18 9 13

CL1500 15 22 11 16

CL900 27 41 20 30

CL1500 34 50 25 37

CL900 42 62 31 46

CL1500 52 77 38 57

CL2500 61 91 45 67

NSm lbfSft

TORQUE

CAUTION

The NotchFlo DST valve uses spiral‐wound gaskets which are crushed to provide their seal. A spiral‐wound gasket should

never be reused. Whenever a gasket seal is disturbed by removing or shifting gasketed parts, a new gasket must be

installed upon reassembly. This is necessary to ensure a good gasket seal, since the used gasket will not seal properly.

The spiral‐wound gaskets are of special design. Failure to use genuine Fisher replacement parts may result in valve damage

and/or failure.

Packing Maintenance

Key numbers refer to figure 3 for PTFE V‐ring packing and to figure 4 and 5 for graphite ribbon/filament and graphite

ULF packing, unless otherwise indicated.

WARNING

To avoid personal injury or equipment damage resulting from packing leakage, inspect the valve plug stem and packing box

wall for nicks or scratches while performing the following procedures.

Use care to avoid damaging these surfaces.

For spring‐loaded single PTFE V‐ring packing, the spring (key 24) maintains a sealing force on the packing. If leakage is

noted around the packing follower (key 28), check to be sure the shoulder on the packing follower is touching the

bonnet. If the shoulder is not touching the bonnet, tighten the packing flange nuts (key 21, figure 7 through 12) until

the shoulder is against the bonnet. If leakage cannot be stopped in this manner, proceed to the Replacing Packing

procedure.

Table 5. Torque for Body‐to‐Bonnet Bolting Using Anti‐Seize Lubricant for CL600 Fisher NotchFlo DST Valves

VALVE

RATING

CL600

1. Determined from laboratory tests.

2. SA193‐B8M annealed.

3. SA193‐B8M strain hardened.

4. For other materials, contact your Emerson Process Management sales office for torques.

VALVE SIZE, NPS

1 122 90 61 45

2 91 67 43 32

3 163 120 84 62

4 258 190 149 110

6 740 550 ‐ ‐ ‐ ‐ ‐ ‐

8 550 405 ‐ ‐ ‐ ‐ ‐ ‐

SA193‐B7, SA193‐B8M Class 2

NSm LbfSft NSm LbfSft

BOLT TORQUES

(3)

(1, 4)

SA193‐B8M Class 1

(2)

7

NotchFlo DST Valve

March 2011

Instruction Manual

D103211X012

Table 6. Torque for Body‐to‐Bonnet Bolting Using Anti‐Seize Lubricant for CL900 and CL1500, Fisher NotchFlo DST

Valves

VALVE

RATING

CL900 & 1500

1. Determined from laboratory tests.

2. SA193‐B8M annealed.

3. SA193‐B8M strain hardened.

VALVE SIZE,

1 or 1‐1/2 258 190 149 110

BOLT TORQUES

NPS

2 373 275 237 175

3 712 525 509 375

4 942 695 705 520

6 2800 2070 ‐ ‐ ‐ ‐ ‐ ‐

8 2800 2070 ‐ ‐ ‐ ‐ ‐ ‐

SA193‐B7, SA193‐B8M Class 2

NSm LbfSft NSm LbfSft

(3)

(1)

SA193‐B8M Class 1

(2)

Table 7. Torque for Body‐to‐Bonnet Bolting Using Anti‐Seize Lubricant for CL2500 Fisher NotchFlo DST Valves

(1)

(2)

VALVE RATING

CL2500

1. Determined from laboratory tests.

2. SA193‐B8M strain hardened.

VALVE SIZE

NPS NSm lbfSft

1 390 290

2 740 550

3 2240 1650

4 2800 2070

6 2800 2070

BOLT TORQUES

SA193‐B7, SA193‐B8M Class 2

Table 8. Valve Stem Connection Torque and Hole Size for Pin

VALVE STEM DIAMETER TORQUE, MINIMUM TO MAXIMUM HOLE SIZE

mm Inches NSm LbfSft mm Inch

12.7

19.1

25.4

31.8

1/2

3/4

1

1‐1/4

81‐115

237‐339

420‐481

827‐908

60‐85

175‐250

310‐355

610‐670

3.20 ‐ 3.25

4.80 ‐ 4.88

6.38 ‐ 6.45

6.38 ‐ 6.45

0.126 ‐ 0.128

0.189 ‐ 0.192

0.251 ‐ 0.254

0.251 ‐ 0.254

If there is undesirable packing leakage with other than spring‐loaded PTFE V‐ring packing, first try to limit the leakage

and establish a stem seal by tightening the packing flange nuts (key 21, figure 7 through 12) to at least the minimum

recommended torque in table 3 or 4. However, do not exceed the maximum recommended torque in table 3 or 4. or

excessive friction may result. If leakage continues, replace the packing by following the numbered steps presented in

the Replacing Packing procedure.

If the packing is relatively new and tight on the valve plug stem, and if tightening the packing flange nuts does not

stop the leakage, it is possible that the stem is worn or nicked so that a seal cannot be made. The surface finish of a

new stem is critical for making a good packing seal. If the leakage comes from the outside diameter of the packing, it

is possible that the leakage is caused by nicks or scratches around the packing box wall. While replacing the packing

according to the Replacing Packing procedure, inspect the valve plug stem and packing box wall for nicks or scratches.

8

Loading...

Loading...