Page 1

LP-Gas Regulators and Equipment

Application Guide

The industry leader for durability and quality.

Page 2

INTRODUCTION

LP-Gas Regulators and Equipment Application Guide

Welcome

The Emerson LP-Gas Regulator and Equipment Application

Guide is designed to guide you quickly and easily to Fisher®

brand products that solve your particular LP-gas pressure

control and equipment problems. In addition, the Application

Guide provides background information on the principles

of various products and their applications including LP-gas

regulators, relief valves and related equipment. The Education

and Training Section will help you with how-to information

regarding LP-gas pressure regulator use and installation

information. A separate Technical section provides a rich

source of general and specic information to aid you in sizing

various types of pressure regulators for use in applications

other than LP-gas.

Product Sizing Information We highly recommend that

you keep this book in an easily accessible place for quick

reference. If you are an experienced engineer, you will be able

to completely size a product from the information presented

in this book before calling your local sales representative. For

those with a less extensive engineering background, the Quick

Selection Guides found in each application segment will be

especially useful.

Finding What You Want The Quick Reference Guide on

the opposite page allows you to quickly find the Fisher

brand products available for a particular application.

Most users will find this the fastest and most convenient

way to locate a product. A more complete table of contents

is found immediately following the Quick Reference Guide.

In addition, the Index in the back of the book is organized by

product type and the common name, which will easily guide

you through the appropriate section of the book to find a

product description.

Ordering What You Need After selecting a product type or

equipment that ts your needs, contact your local Fisher brand

distributor to place an order. Your local distributor will ensure

that you receive the right product in the shortest possible time.

Other Application Guides

Available

Should your

application

or project

require natural

gas regulators

or regulators for

industrial use, please

request a Natural Gas

Regulators Application

Guide or Industrial

Regulators Application Guide. The Natural Gas Regulators

Application Guide features detailed information covering a

broad range of regulators used for natural gas transmission

and distribution. This includes farm tap, commercial, city gate,

district, and residential applications. The Industrial Regulators

Application Guide contains information covering a broad

range of industrial applications including: Air, Steam, Liquids,

Process Gases, Fuel Gases, Sanitary and Tank Blanketing.

Additional Information Online You can view and

download pressure regulator bulletins, instruction manuals,

product schematics, and many other helpful documents

at emersonprocess.com/regulators/lp. Much of the same

information is also available on the Emerson Process

Management Pressure Regulator CD. Order your copy today at:

www.emersonprocess.com/regulators/lp

United States

1-800-558-5853

Mexico

+52 55 2699040

Outside U.S.

1-972-548-3574

Asia Pacific

+65 6777 8211

Europe

+33 237 3347 28

Page 3

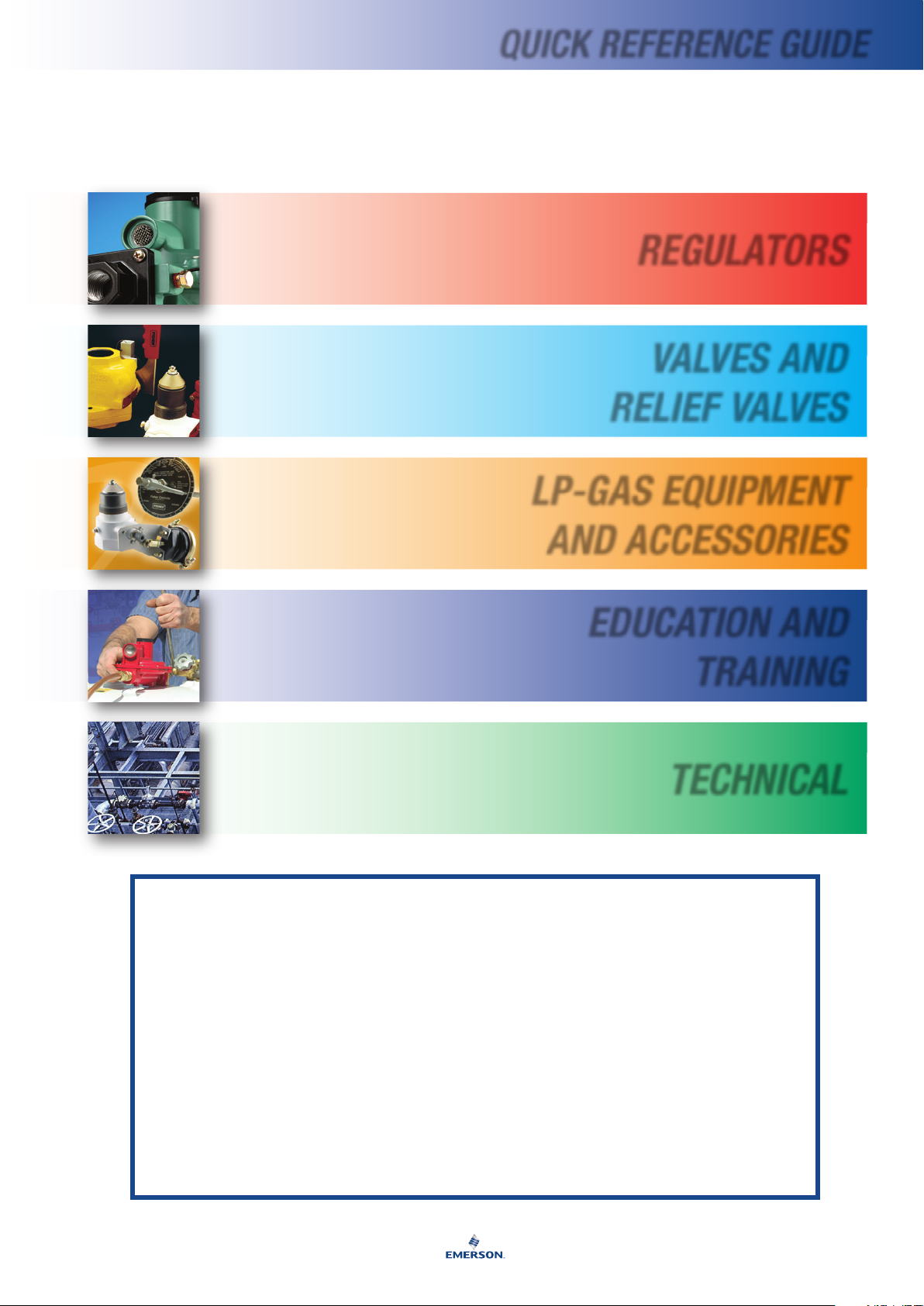

quICk rEfErENCE GuIdE

LP-Gas Regulators and Equipment Application Guide

Commercial/Industrial and High Pressure Regulators

Pressure Reducing Regulators

First Stage, Second Stage, Integral 2-Stage, and 2-PSI Service Regulators

Changeover Manifold Assemblies

Backpressure Regulators/Relief Valves

External/Internal Relief Valves

Backpressure Valves

Internal and Back Check Valves

Emergency Shutoff Valves

Globe and Angle Valves

rEGuLATors

VALVEs ANd

rELIEf VALVEs

Regulator Accessories

Bulk Storage Tank and Valve Accessories

LP-Gas Regulator and Equipment Education Bulletins

Flood Damaged Regulators

Two-Stage Systems

Correct LP-Gas Regulator Installation

Theory

Sizing and Selection

Vacuum

Tips

Reference Data

LP-Gas Regulators and Equipment Application Guide - Edition I

The LP-Gas and Equipment marketing group is

excited to present the first edition of the LP-Gas

Application Guide. This book provides the most

complete resource of Fisher® brand marketing

and engineering information for your LP-Gas and

Equipment needs. It is an excellent quick reference

for the experienced LP-Gas Technician as well as for

those new in the industry.

This edition features Application Maps showing how

LP-Gas regulators fit in various LP-Gas applications.

Quick Selection Guides familiarize users with selection

criteria to find the LP-Gas Equipment best suited for

their application. The Education and Training section,

LP-GAs EquIPmENT

ANd ACCEssorIEs

EduCATIoN ANd

TrAINING

TECHNICAL

Technical section, and Glossary of Terms are great

tools to learn more about regulator and valve theory

and terminology used in the industry. Other features of

the Application Guide are:

• Product Schematics (NEW)

• Engineering Data

• Product Flow and Capacity Curves

• Features and Benefits

• Ordering Guides

We hope the LP-Gas and Equipment Application

Guide proves to be a useful tool for selecting LP-Gas

Equipment to fit your needs. For additional copies

please contact your local LP-Gas Distributor.

i

Page 4

ii

TAbLE of CoNTENTs

R

LP-Gas Regulators and Equipment Application Guide

Introduction...................................................Inside front cover

Table of Contents .................................................................. ii

Emerson Process Management ........................................... iv

The Regulator Division ......................................................... vi

History ................................................................................. viii

rEGuLATors

EduCATIoN ANd

TrAINING

Table of Contents ................................................................. 200

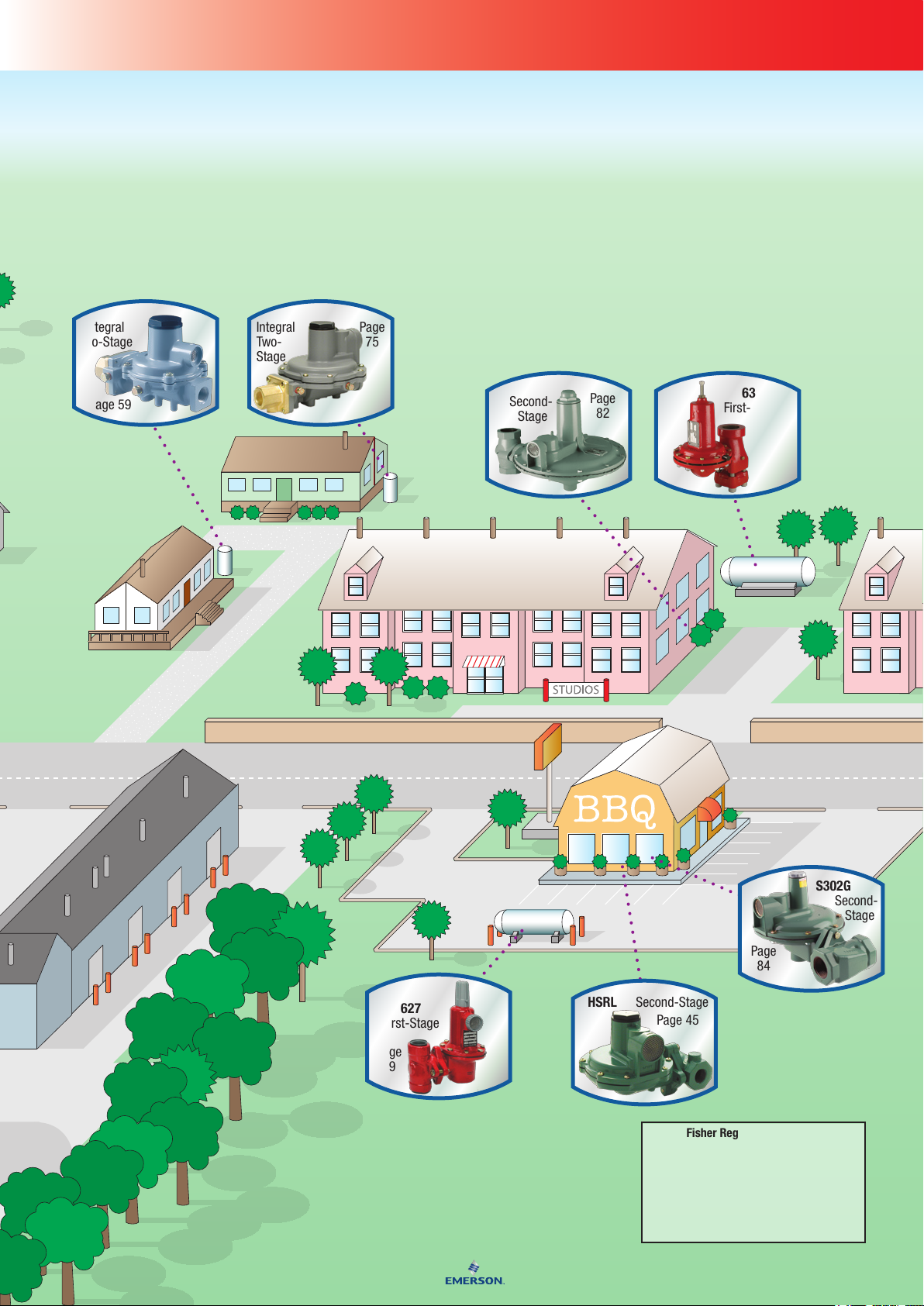

Application Map .................................................................... 2

Quick Selection Guide .......................................................... 4

High Pressure Regulators .................................................. 4

Pressure Reducing Regulators .......................................... 5

Second-Stage Regulators.................................................. 6

Integral Two-Stage Regulators .......................................... 7

Automatic Changeover Manifold ........................................ 8

Automatic Changeover Regulator ...................................... 9

Applications ........................................................................... 10

Products .............................................................................. 11

VALVEs ANd

rELIEf VALVEs

Application Map ............................................................... 88

Quick Selection Guide ....................................................... 95

External/Internal Relief Valves......................................... 95

Internal Valves ............................................................... 96

Emergency Shutoff Valves ................................................ 97

Valves ........................................................................... 98

Applications ...................................................................... 99

Products ........................................................................... 100

LP-GAs EquIPmENT

TECHNICAL

Table of Contents .................................................................. 270

Reference Data ..................................................................... 364

Conversion Tables ................................................................. 364

Glossary of Terms ................................................................. 143

Index ...................................................................................... ix

Notes ...................................................................................... xiii

Certifications/Associations

Where applicable, Fisher products presented in this handbook

are listed by Underwriter’s Laboratories (UL). Use of these

products may provide compliance with standards developed

by the National Fire Protection Association’s Pamphlets 54 and

58. They may also assist in meeting guidelines established by

the Department of Transportation, ASME and other third party

agencies. Contact your Fisher LPG Equipment Distributor for

assistance in determining product applications.

Quick Selection Guide ...................................................... 158

Regulator Accessories ................................................. 158

Bulk Storage Tank and Valve Accessories .......................... 160

Products ........................................................................... 165

Page 5

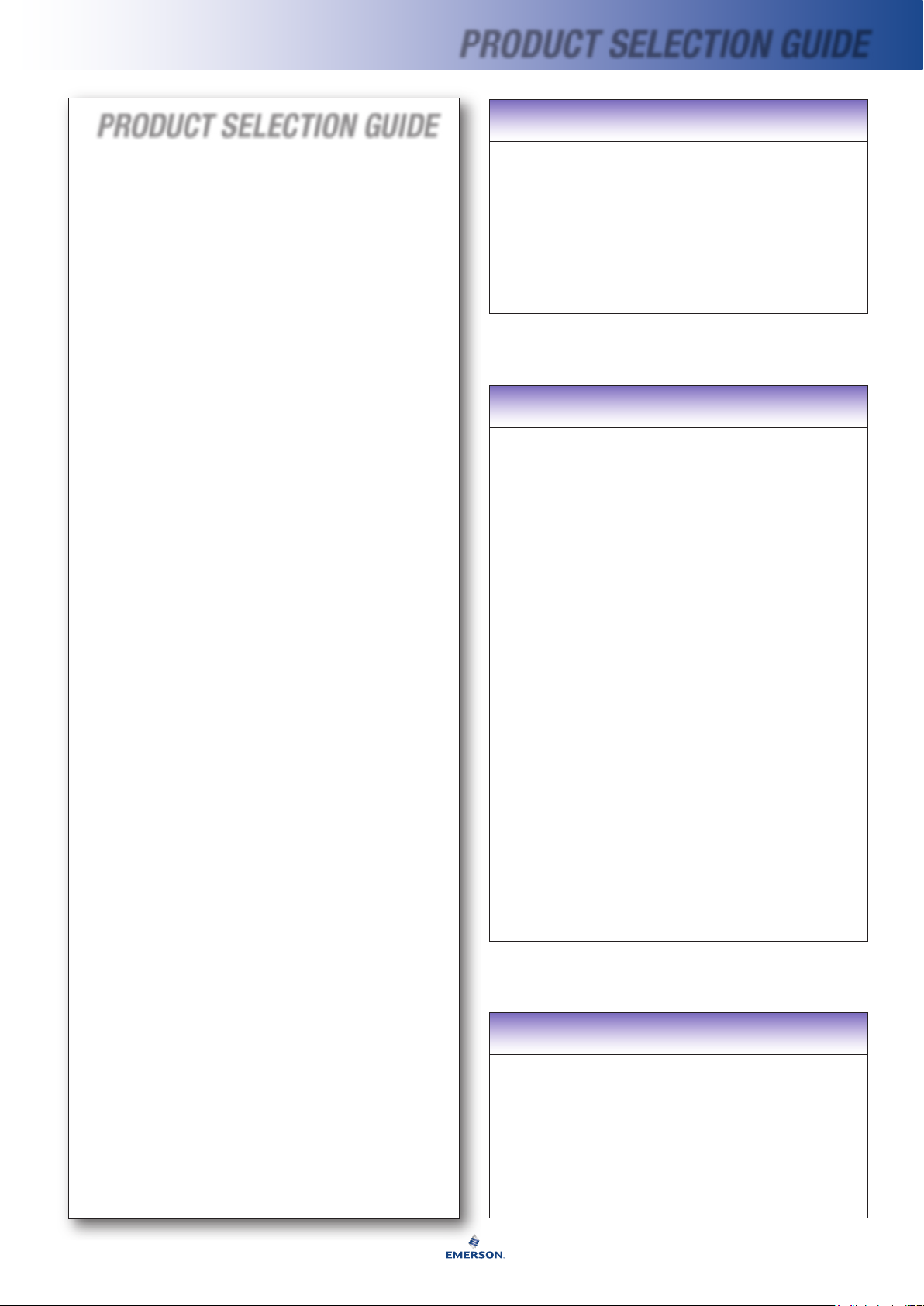

ProduCT sELECTIoN GuIdE

ProduCT sELECTIoN GuIdE

Type Section

50 Series .................................................................................. Accessories

64 Series .....................................................................................Regulators

67C Series ...................................................................................Regulators

98H Series ...................................................................................Regulators

99 Series .....................................................................................Regulators

Type 289H ..................................................................................Regulators

Type 299H ...................................................................................Regulators

627 Series ...................................................................................Regulators

630 Series ...................................................................................Regulators

Type 749B ...................................................................................Regulators

912 Series ...................................................................................Regulators

Type 1301F..................................................................................Regulators

1805 Series .................................................................................Regulators

C402 Series ............................................................ Valves and Relief Valves

C403 and C404 Series ............................................ Valves and Relief Valves

C407-10 Series ...................................................... Valves and Relief Valves

C421 Series ............................................................ Valves and Relief Valves

C427 Series ............................................................ Valves and Relief Valves

D Series .................................................................. Valves and Relief Valves

F Series .................................................................. Valves and Relief Valves

G100 Series ............................................................ Valves and Relief Valves

G200 Series ............................................................ Valves and Relief Valves

H120 Series ........................................................... Valves and Relief Valves

H282, H283, H5112, and H5114 Series ................... Valves and Relief Valves

H500 Series ........................................................... Valves and Relief Valves

H722, H732, and H733 Series ................................. Valves and Relief Valves

Type HSRL ...................................................................................Regulators

J31 Series .................................................................................Accessories

J400 Series ..............................................................................Accessories

J500 Series ..............................................................................Accessories

J700 Series ...............................................................................Accessories

M100 Series .............................................................................. Accessories

M200 Series .............................................................................. Accessories

M300 Series .............................................................................. Accessories

M400 Series .............................................................................. Accessories

Type M450A ..............................................................................Accessories

M500 Series .............................................................................. Accessories

Type M570 ................................................................................Accessories

M600 Series .............................................................................. Accessories

Type M455 ................................................................................Accessories

N100 Series ............................................................ Valves and Relief Valves

N120 Series ........................................................... Valves and Relief Valves

Type N201 .............................................................. Valves and Relief Valves

N300 Series ............................................................ Valves and Relief Valves

N400 Series ............................................................ Valves and Relief Valves

Type N480 and N481 .............................................. Valves and Relief Valves

N550 Series ............................................................ Valves and Relief Valves

N562 Series ............................................................ Valves and Relief Valves

Types P100A, P102A, and P100C ...............................................Accessories

Types P104 and P174 ................................................................Accessories

Type P120B ............................................................................... Accessories

Types P147, P148. and P167 .....................................................Accessories

Types P163, P164, and P164C ................................................... Accessories

Types P206, P297, and P298 .....................................................Accessories

P313 and P340 Series ...............................................................Accessories

Types P314 and P315 ................................................................Accessories

Type P389 .................................................................................Accessories

Types P400, P403, P410, P413, and P414 ..................................Accessories

Type P499 .................................................................................Accessories

Types P500 and P501 ................................................................Accessories

Type P520L................................................................................Accessories

Type P539 .................................................................................Accessories

Types P613, P612, and P639 .....................................................Accessories

Type P614 .................................................................................Accessories

Type P631 .................................................................................Accessories

P650 Series ............................................................................... Accessories

Type R110 ...................................................................................Regulators

Type R122H ...............................................................................Regulators

Type R130 ......................................................................Regulators

R222 Series ....................................................................Regulators

R232 Series ....................................................................Regulators

R600 Series ....................................................................Regulators

Types R622E and R652E .................................................Regulators

R622H Series ..................................................................Regulators

R632 Series ....................................................................Regulators

Type R962 ......................................................................Regulators

S202G Series ..................................................................Regulators

S302G Series ..................................................................Regulators

Y602 Series .................................................................. Accessories

Our Trademarks (TM) & Service Marks ®

®

Big Joe®

Big Joe

Combo Joe®

Combo Joe

easy-e®

easy-e

Emerson

Emerson

Note: The Emerson logo is a trade mark and service mark of Emerson

Electric Co. Trade marks and service marks of Emerson Proc ess

Management, a business division of Emerson Electric Co., are owned by

their respective owners.

®

®

TM

TM

FIELDVUE

Fisher

Snappy Joe®

Whisper Trim®

Other Trademarks (TM) & Service Marks

Aas® is a mark of Asahi Glass Co., Ltd.

Chemraz® is a mark owned by Greene, Tweed & Co.

Dacron® is a mark owned by E.I. du Pont de Nemours and Co.

Delrin® is a mark owned by E.I. du Pont de Nemours and Co.

Durimet® is a mark owned by Duriron Co.

Fluoraz® is a trade name of Greene, Tweed & Co.

HART® is a mark owned by HART Communications Foundation

Hastelloy® C is a mark owned by Haynes International, Inc.

Hydrin® is a mark owned by Zeon Chemicals

Hypalon® is a mark owned by E.I. du Pont de Nemours and Co.

Inconel® is a mark owned by Special Metals Corporation

Intellution® is a mark owned by Intellution, Inc.

Kalrez® is a mark owned by E.I. du Pont de Nemours and Co.

Lustran® is a mark owned by LANXESS Corporation.

Monel® is a mark owned by Special Metals Corporation

Rynite® is a mark owned by E.I. du Pont de Nemours and Co.

Teon® is a mark owned by E.I. du Pont de Nemours and Co.

Thiokol® is a mark owned by Alliant Techsystems Inc.

US DATA® is a mark owned by US DATA Corporation

Valox™/Valox 730™ is a mark owned by General Electric Co.

Viton® is a mark owned by E.I. du Pont de Nemours and Co.

Zytel® is a mark is a mark owned by E.I. du Pont de Nemours and Co.

Note: All other marks mentioned in this publication are the property of their

respective owners.

®

®

®

Contents Notice

The contents of this publication are presented for informational

purposes only, and while every effort has been made to ensure

their accuracy, they are not to be construed as warranties

or guarantees, expressed or implied, regarding the products

or services described herein or their use or applicability.

We reserve the right to modify or improve the designs or

specications of such products at any time without notice.

iii

Page 6

iv

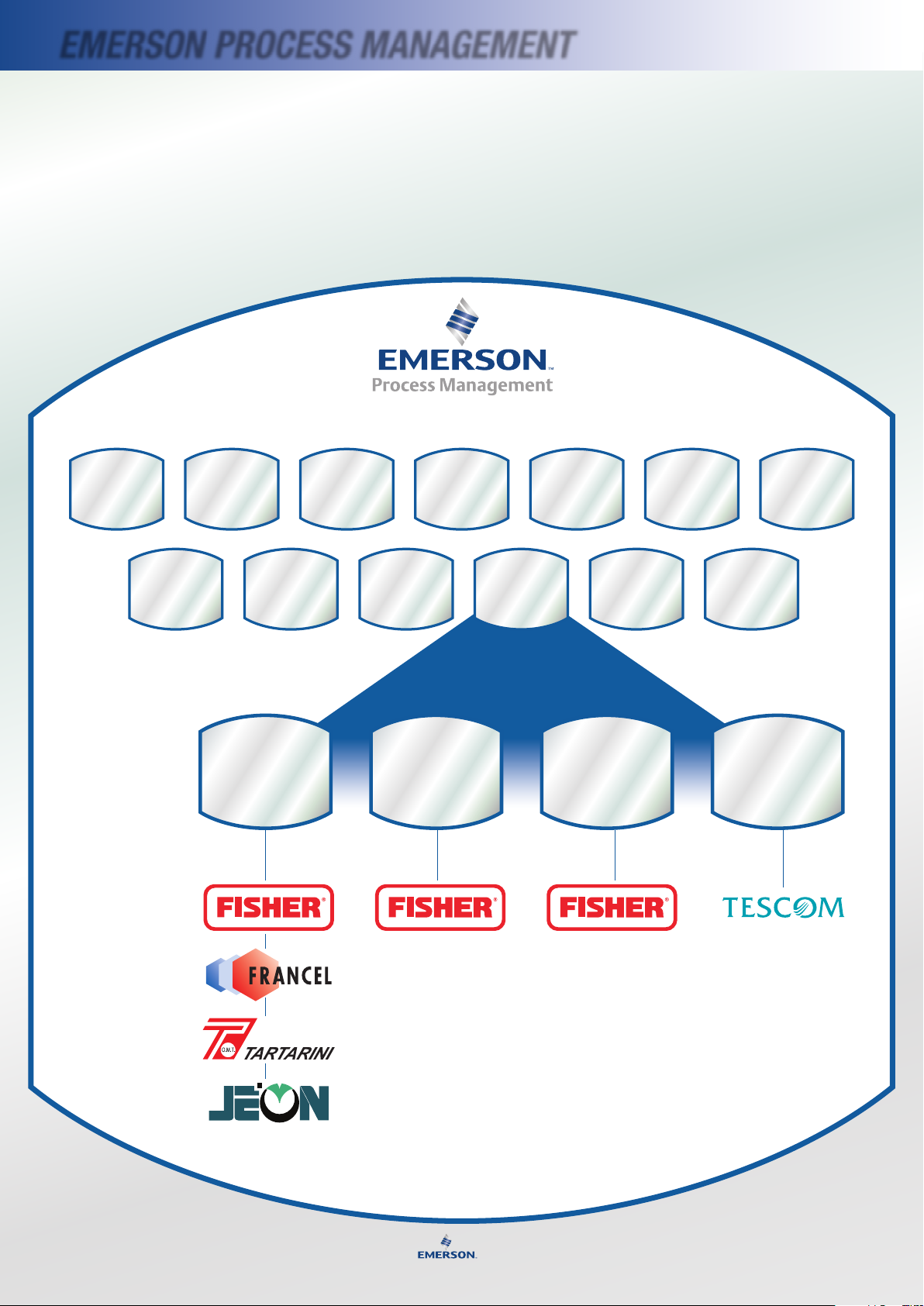

EmErsoN ProCEss mANAGEmENT

Business Units

Natural Gas

Technologies

LP-Gas

Industrial

TESCOM

Our Brands

For more information, visit www.emersonprocess.com/regulators/lp

Micro

Motion

Daniel

Asset

Optimization

Brooks

Instrument

Remote

Automation

Solutions

Process

Systems &

Solutions

Power and

Water

Solutions

Valve

Automation

Fisher

Valves

Regulator

Division

Rosemount

Rosemount

Analytical

The Divisions of Emerson Process Management

Educational

Services

Emerson Process Management

Regulator Division is a part of Emerson

Process Management, a division of Emerson

Electric. Emerson (NYSE:EMR) is a global

company that brings together technology

and engineering providing a wide range of

manufacturing and processing solutions

for industrial, commercial, and consumer

markets.

Emerson’s divisions work together

through the Emerson Brands to deliver

comprehensive customer solutions. The

Emerson divisions are: Process Management,

Network Power, Climate Technologies,

Storage Solutions, Professional Tools, Motor

Technologies, Industrial Automation, and

Appliance Solutions.

Emerson Process Management is

a leading global supplier of products,

services, and solutions that measure,

analyze, control, automate, and improve

process-related operations.

iv

Page 7

brINGING ToGETHEr TECHNoLoGy ANd ENGINEErING

Emerson Process Management offers

best-in-class measurement, analytical,

and control products and innovative

PlantWeb® architecture with a broad array

of engineering, consulting, maintenance,

and project management services.

The Emerson Process Management

organization works closely with the

Emerson process-related divisions. Strategic

acquisitions have enhanced our technology

and industry expertise. From offices, factories,

and service centers around the world, the

Emerson Process Management team now

offers unmatched capabilities to improve

process and asset performance for customers

in the chemical, oil and gas, pulp and paper,

pharmaceutical, food and beverage, power,

water and wastewater, and other process

related industries.

3D MoDel PrototyPe AiDs

ProDuct DeveloPMent

lAborAtory tests

siMulAte FielD

conDitions

testing

custoMer

ProDucts

Acoustic testing

oF regulAtor

Designs

v

v

Page 8

vi

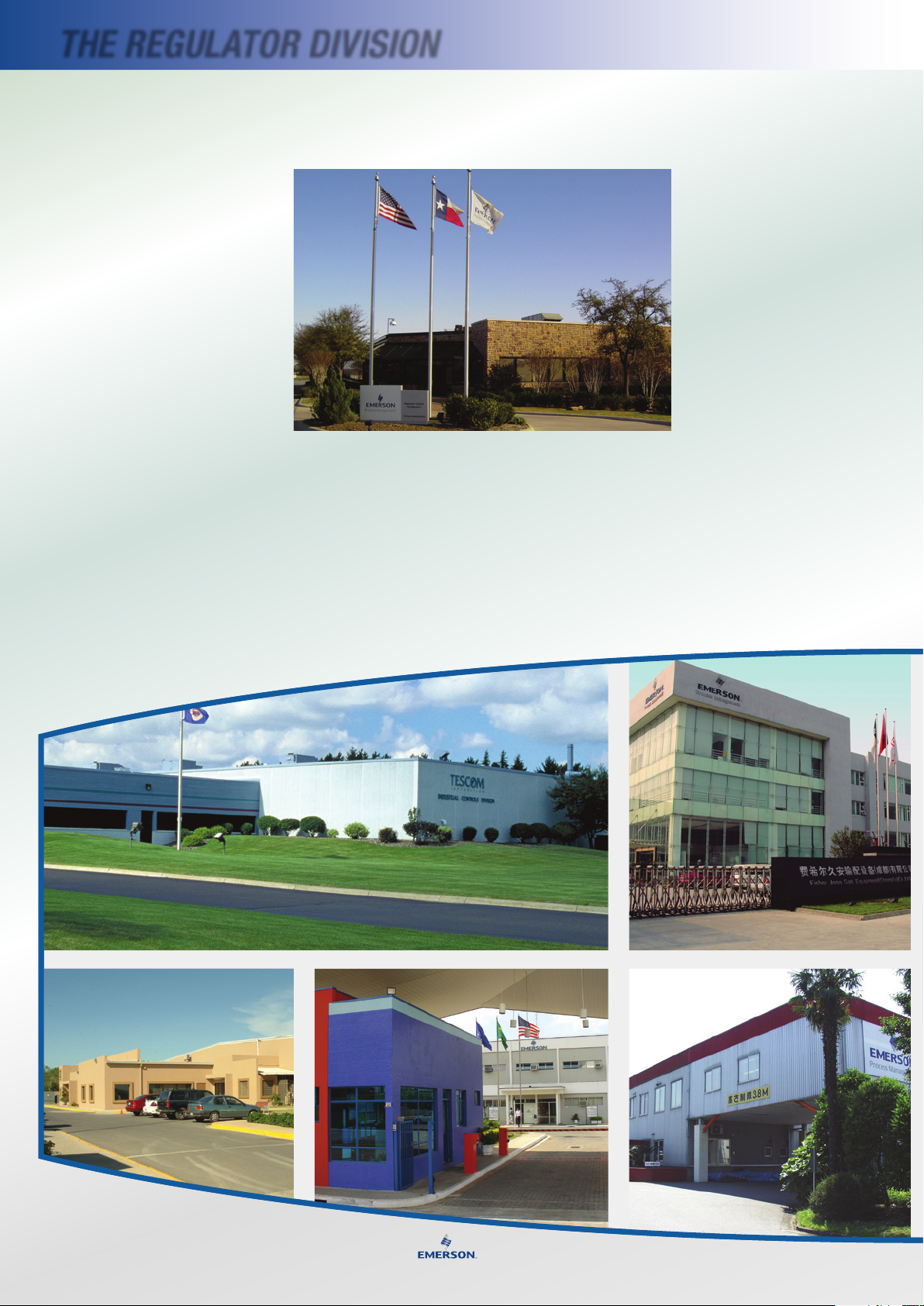

THE rEGuLATor dIVIsIoN

Emerson Process Management Regulator Division, is dedicated to

serving the pressure regulator needs of process industries and natural

gas utilities and LP-gas applications worldwide.

Emerson offers pressure and flow control

solutions in three broad categories –

industrial, LP-gas and natural gas. In this

regard, Emerson offers more pressure

regulator and relief valve solutions than

any other manufacturer in the world.

With over 2,000 local technical experts

to serve you from nearly 200 locations

around the world, our sales and service

network is one of the largest in the

industry.

Whether you need an emergency

replacement regulator or are working

on a long-range growth and expansion plan, there’s a local sales

representative to respond quickly and professionally.

inDustry stAnDArDs For PerForMAnce

Our leading Fisher® brand pressure regulators and relief valves are

marketed throughout the world. Many of our regulators are industry

standards for performance and extended service life.

In recent years several companies and their product brands were added

to the Emerson pressure regulator lineup.

Francel S.A., Gallardon, France, was acquired in 1994 expanding our

distribution capabilities of regulators, relief valves, skids and cabinets

and integral slam shut devices. Fisher and Francel brand regulators are

marketed extensively in France,

and other parts of Europe,

Middle East and Africa.

Tartarini was acquired by

Emerson in the fall of 2001.

Located in Bologna, Italy,

Tartarini manufactures a full

range of regulator and slam

shut products as well as natural

gas measurement and recording

products. Tartarini brand

products extends Fisher’s brand

McKinney, texAs

Jeon, Chengdu, China, (Sichuan Province) joined Emerson in 2004.

Jeon is the leading manufacturer of natural gas regulators and systems

in China. The Jeon brand expands our presence in China’s low-pressure

regulator segment.

Tescom. Acquired in 2005, Tescom designs and manufactures high

pressure and high purity pressure regulators suitable for industrial,

pharmaceutical and semi-conductor applications. Tescom has two

manufacturing locations: Elk River, Minnesota and Selmsdorf,

Germany.

and distribution capability in

Europe and Asia.

elK river, MinnesotA

nuevo lAreDo,

Mexico

vi

chengDu, chinA

sorocAbA, brAzil

toKyo, JAPAn

Page 9

Global Manufacturing

Locations

North America

McKinney, Texas

Elk River, Minnesota

Nuevo Laredo, Mexico

South America

Sorocaba, Brazil

Europe

Gallardon, France

Bologna, Italy

Selmsdorf, Germany

Cluj, Romania

INdusTry CommITmENT

Commitment to Natural Gas, LP-Gas

and Industrial Applications

Emerson’s Regulator Division is committed to advancing

pressure regulator technology for use in natural gas, LP-gas

and industrial applications worldwide.

Our state-of-the-art Technical Center in McKinney, Texas,

is dedicated to new product development and prototype

performance testing under different sets of operating

conditions. As a result, Emerson engineers have a source

of data that is unavailable anywhere else. The R&D staff

is equally capable of simulating conditions at a customer’s

site in order to demonstrate regulator capabilities or solve a

problem.

Dynamic Flow Testing

Asia-Pacific

Shanghai, China

Chengdu, China

Singapore

Tokyo, Japan JV

Chennai, India JV

The lab contains a variety of piping for dynamic

flow testing, including four 2-inch test lines, two

4-inch test lines, and one 8-inch and one 16-inch

test line. Flow rates up to 12 Million SCFH can be

produced with precisely controlled inlet pressures.

Several temperature chambers and hydrostatic test

pumps make it possible to examine how test units

perform under extreme temperatures and pressures.

technicAl center, McKinney, texAs

(Above leFt, Above right)

bolognA, itAly

gAllArDon, FrAnceshAnghAi, chinA

singAPore

selMsDorF, gerMAny

cluJ, roMAniA

vii

vii

Page 10

HIsTory

The Path To Technology Leadership

In 1880 Fisher Controls was founded in

Marshalltown, Iowa, by William Fisher.

Fisher Controls grew steadily over the years,

evolving into an industry leader offering

customers the most complete range of ow

control products in the world.

William Fisher came to America from

England as a boy of 14. As his family

ventured west in the new land, they settled

along the Mississippi in Clinton, Iowa. It

was there, as a mechanic in a small engine

shop for 10 years, that William learned about

steam, the major source of power in the late

1800s. Because of his experience in water

and steam, William, who was 24 at the time,

was invited to Marshalltown to help install

the water works.

The idea of a control device was born in the

engineer ’s mind as a re raged in the city.

Working through the night, William Fisher

hand-throttled the steam-driven pumps to

maintain pressure in the city’s mains. During

that re, he saw a need for a device that would

both control the steam-driven pumps and

maintain them at a constant pressure.

Many months and trials later, William

Fisher was nally satised with one of his

designs and began manufacturing what we

know today as the Fisher Type 1 constant

pressure pump governor. He was granted a

patent in 1884.

One thing remained the same since William

Fisher’s rst Type 1 pump governor: a pledge

to unequalled quality. Today, the brand name

Fisher is synonymous with quality throughout

the world.

Type 1 Pump

Governor 1880

The Fisher Years

1880 Type 1 pump governor is

invented by William Fisher.

1888 The Fisher Governor Company is

incorporated on Dec. 26.

1906 William Fisher dies. His wife,

Martha, becomes president.

1912 Jasper Fisher assumes

presidency; first sales offices

are established.

1937 Serial number 500,000

assigned to a Type 1 pump

governor on Nov. 5.

1938 Jasper Fisher dies.

1940 First Western Union teletype

machine is installed to speed

communication.

1943 One millionth serial number

assigned June 9.

1944 Mrs. J.H. Fisher is elected

president.

1946 Sales department holds first school for

field representatives.

1950 Two-millionth controller made. Fisher

enters licensee agreement with Elliott

Automation to manufacture products for

England and Europe.

1954 Mrs. J.H. Fisher retires; J.W. (Bill) Fisher

is elected president.

1955 New office building opens in

Marshalltown.

1960 Ball valves are added to Fisher’s product

line. Licensing agreement reached to

manufacture in Japan.

1965 Gas regulator department moves to

McKinney, Texas.

1967 Governor Road facility, the most advanced

machine shop of its kind in the world,

begins operation in Marshalltown.

1969 Fisher begins manufacturing electronic

instrumentation. Bill Fisher remains as

Chairman of the Board until 1974.

1970 Our first European facility opens at

Cornwall, England, to manufacture

electronic instrumentation.

1972 The R.A. Engel Technical Center,

Marshalltown, is completed, housing the

world’s most advanced flow test

laboratory.

1975 A new electronics manufacturing

facility is opened in Marshalltown.

1976 Production of our new line of rotary valves

begins in Sherman, Texas. Fisher Brazil

opens its doors.

1979 Fisher Controls Corporation of Delaware

forms a stronger manufacturing, sales,

and service organization.

1980 Fisher celebrates a Century of Control.

1992 ISO 9001 original registration validated,

McKinney, Texas

The Emerson Years

1993 Fisher-Rosemount formed when two

leading process instrumentation suppliers,

Fisher Controls and Rosemount, merge

under ownership of Emerson Electric.

1994 Francel, Gallardon, France, acquired,

expanding manufacturing and distribution

in Europe, Middle East and Africa.

1996 Type 299 pilot-operated regulator

introduced to natural gas market.

1997 The 50th anniversary of the Type 99.

The FloBoss 503 and Regulator Vault

are introduced.

1998 Fisher Regulators FROMEX manufacturing

plant opens in Nuevo Laredo, Mexico.

1999 Revolutionary Type EZR pressure

regulator introduced.

2001 Tartarini, Bologna, Italy, acquired, extending

Fisher’s brand and distribution capability

in Europe and Asia.

2003 Manufacturing capability expanded with

opening of Shanghai Plant.

2003 New, state-of-the-art flow test laboratory

opens in McKinney, Texas.

2004 Introduced digitally controlled odorant

injection system.

2004 Jeon, Chengdu, China, acquired,

expanding Fisher’s presence in China’s

low-pressure regulator market.

2005 125th anniversary observed in all

locations.

2005 EZ Family product lines, EZR, EZH and EZL

pressure regulators expanded.

2005 Customer Center opened to display new

regulator technology and train customers

and sales channel.

2006 Type SR stainless steel Sanitary Regulator

introduced.

2006 Tescom Corporation, Elk River, Minn.,

and Selmsdorf, Germany, manufacturer

of high-pressure, high-purity pressure

regulators, acquired.

2007 Commercial Service Regulators platform

introduced featuring True Monitor™

Protection, Slam Shut, and Secondary

Seat™ Protection options.

2007 Cluj, Romania, manufacturing location

online.

viii

Page 11

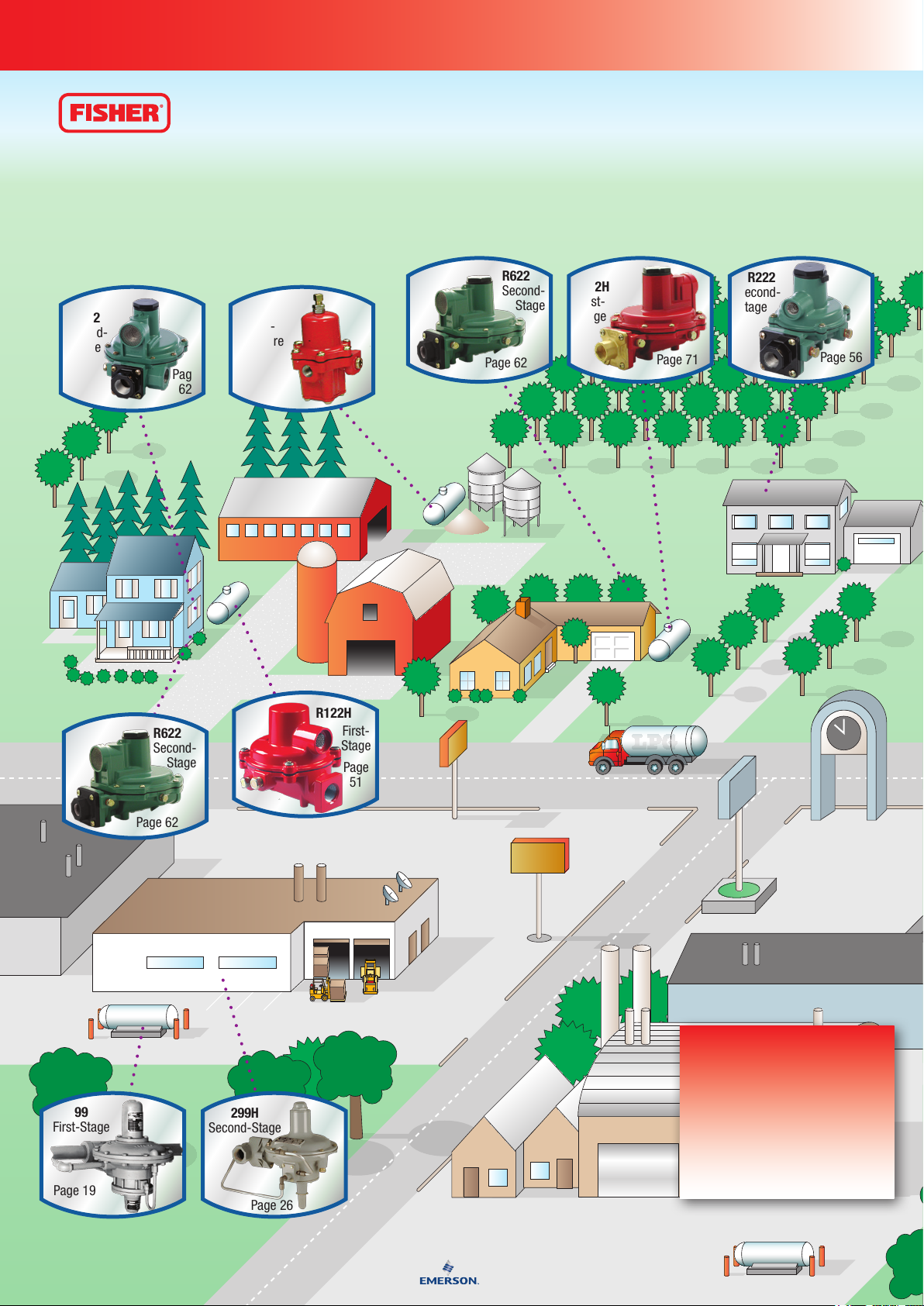

Re g u l a t o R s

LP-Gas regulators compensate for variation in tank pressure to supply

propane at a constant pressure to furnaces, burners, home appliances, farm

taps, commercial businesses, and industrial plants. The regulator must

deliver this pressure despite the intermittent use of the appliances and despite

varying flow demands.

In certain instances codes require two-stage regulation and regulator designs

are available that provide the two-stage reduction in one regulator. Many

regulators provide overpressure protection through an integrated internal

relief valve for overpressure protection, also required by some codes. Other

overpressure protection methods which are available include external relief

valves and monitors.

Page 12

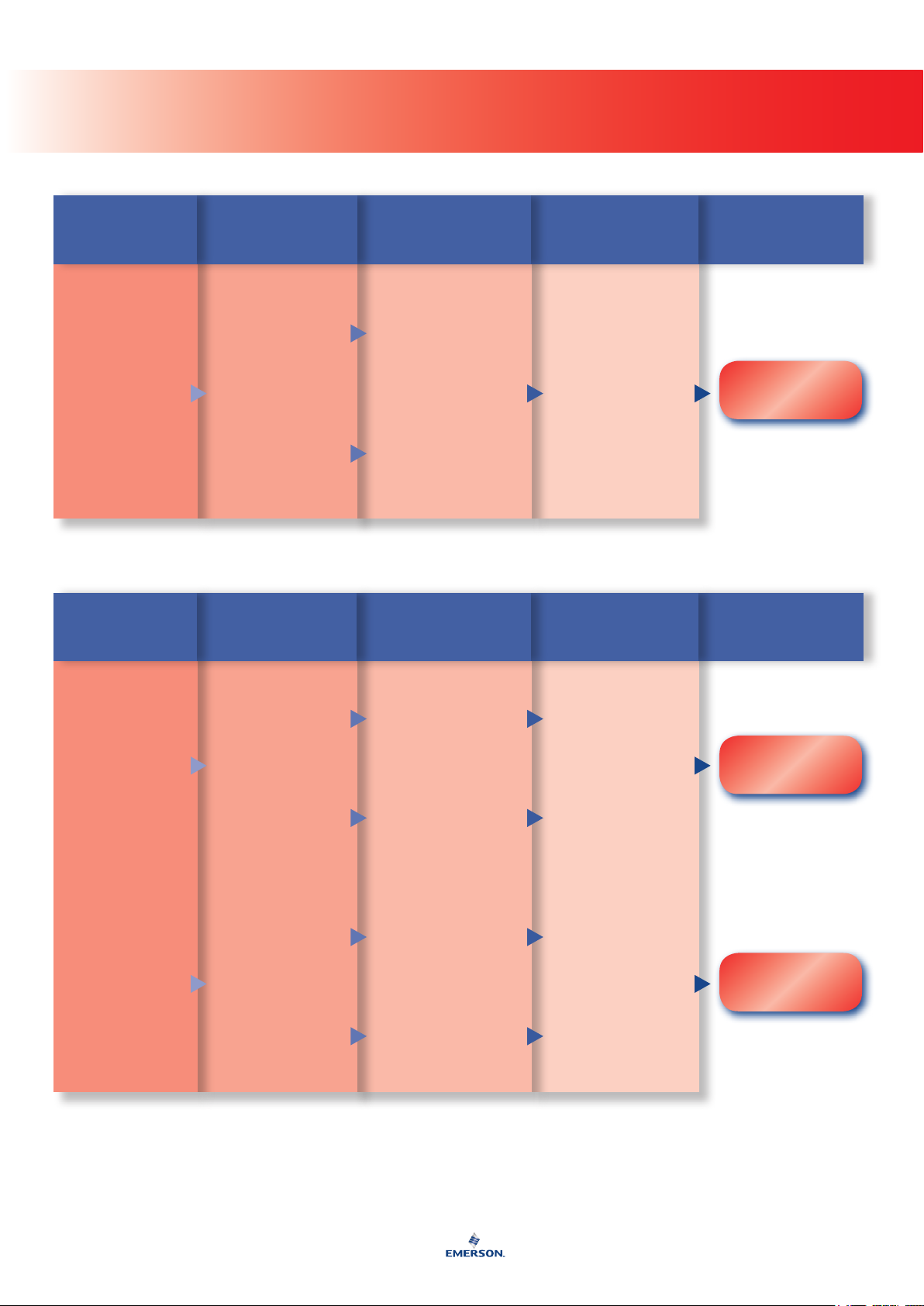

R642

Second-

Stage

First-

Stage

99

First-Stage

299H

Second-Stage

R622

Second-

Stage

R622

Second-

Stage

R222

Second-

Stage

R622H

First-

Stage

67CW

High-

Pressure

Page

14

Page

62

Page

51

Page 19

Page 26

Page 62

Page 62

Page 71

Page 56

R122H

Application: Regulators

Introduction

The regulator truly is the heart of an LPGas installation. It must compensate for

variations in tank pressure from 8 to 250 psig

(0,55 to 17,2 bar) and deliver a constant outlet

pressure of LP-Gas typically at 11-inches wc

(27,4 mbar) to consuming appliances. The

Features*

• Corrosion-Resistantand

Wear-ResistantMaterials

• StainlessSteelInletScreen

• LargeDrip-LipVent

• HighCapacityRelief

• EasyInstallation

• ImprovedRegulation

• Built-inGaugeTaps

*Features Vary By Model.

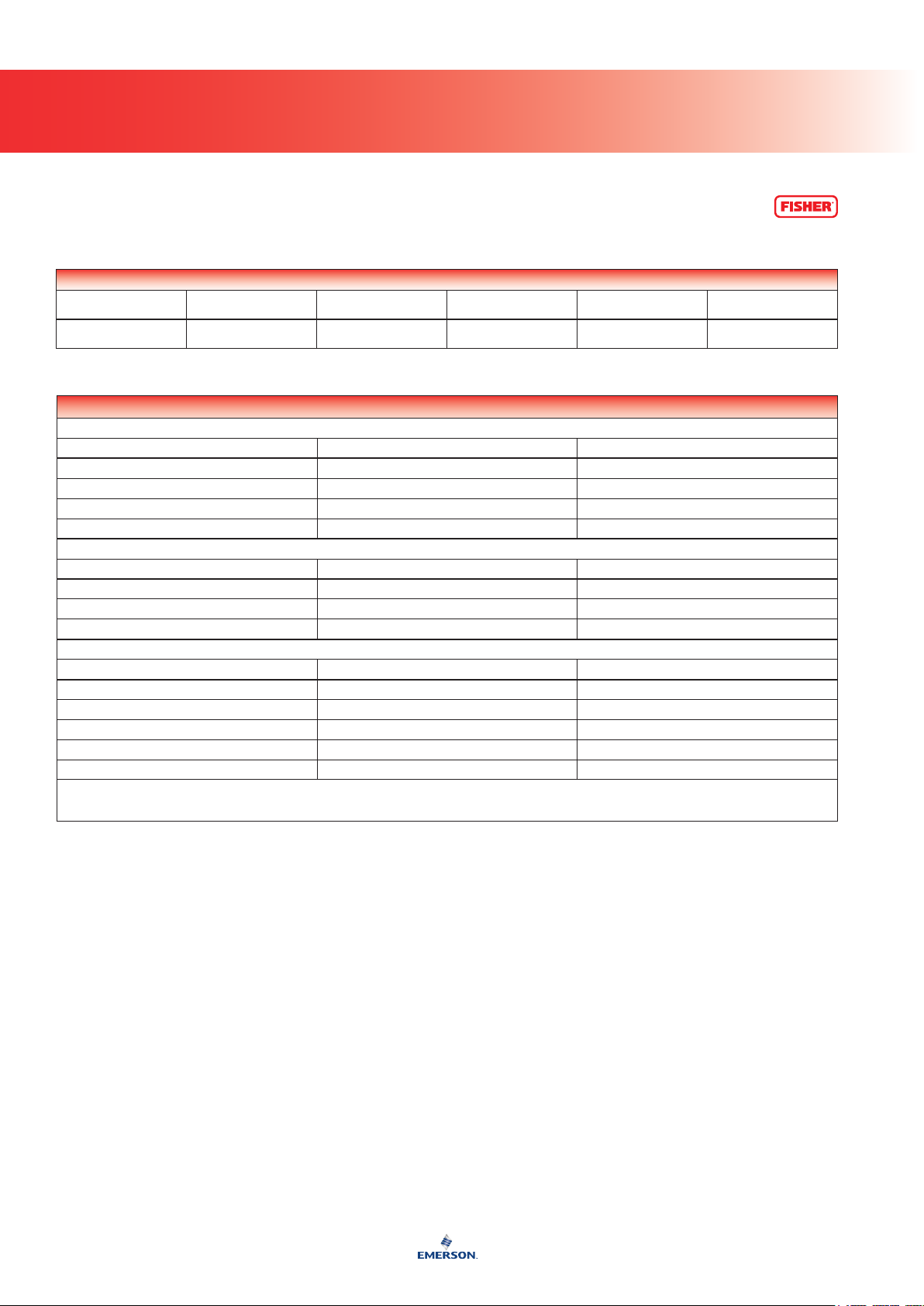

Page 13

S202G

Second-

Stage

Second-Stage

627

First-Stage

630

First-Stage

R632

R232

Page

75

Page 59

Page

82

Page

31

Page

29

Page 45

Page

84

Integral

Two-

Stage

HSRL

S302G

Integral

Two-Stage

Second-

Stage

Re g u l a t o R s ap p l i c a t i o n Ma p

regulator must deliver this pressure despite

the intermittent use of the appliances.

In propane service, NFPA 58 requires TwoStage regulation on all fixed piping systems

that serve 1/2 psig (34,5 mbar) appliance

systems (normally operated at 11-inches wc

(27,4 mbar pressure). Two-Stage regulation

produces a nearly constant pressure to the

appliance and can result in a more efficient

LP-Gas operation for the dealer resulting

in less maintenance and fewer installation

call-backs.

With properly selected regulators, the

internal relief valve provides 2 psig (0,14 bar)

overpressure protection as required by

NFPA 58.

Emerson Process Management is a leading

international supplier of cost-effective

products, services, and solutions used in the

propane industry. Around the world, Fisher®

brand LP-Gas Equipment Distributors offer

quality products as well as applications

engineering, education programs and after

sales service. For any of the products

described in this handbook, contact your

local LP-Gas Equipment Distributor.

Fisher Regulator Color Code

First-Stage ........................... Red

Second-Stage ......................Palm Green

2-PSI Service .......................White*

Integral Two-Stage ...............Gray

Pounds to Pounds ................Red

Industrial .............................Black or Gray

*R622E and R652E are green with white closing caps

Page 14

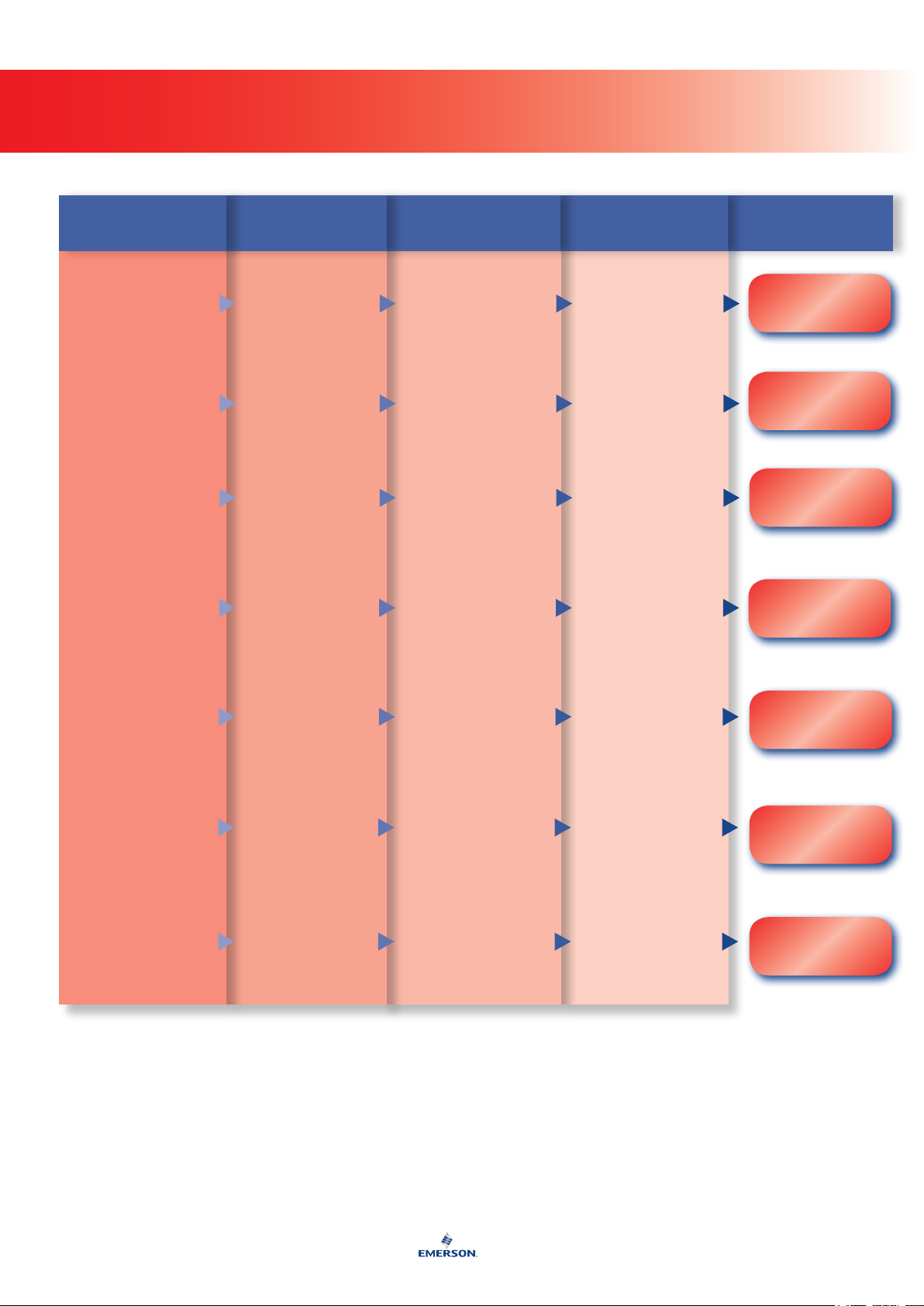

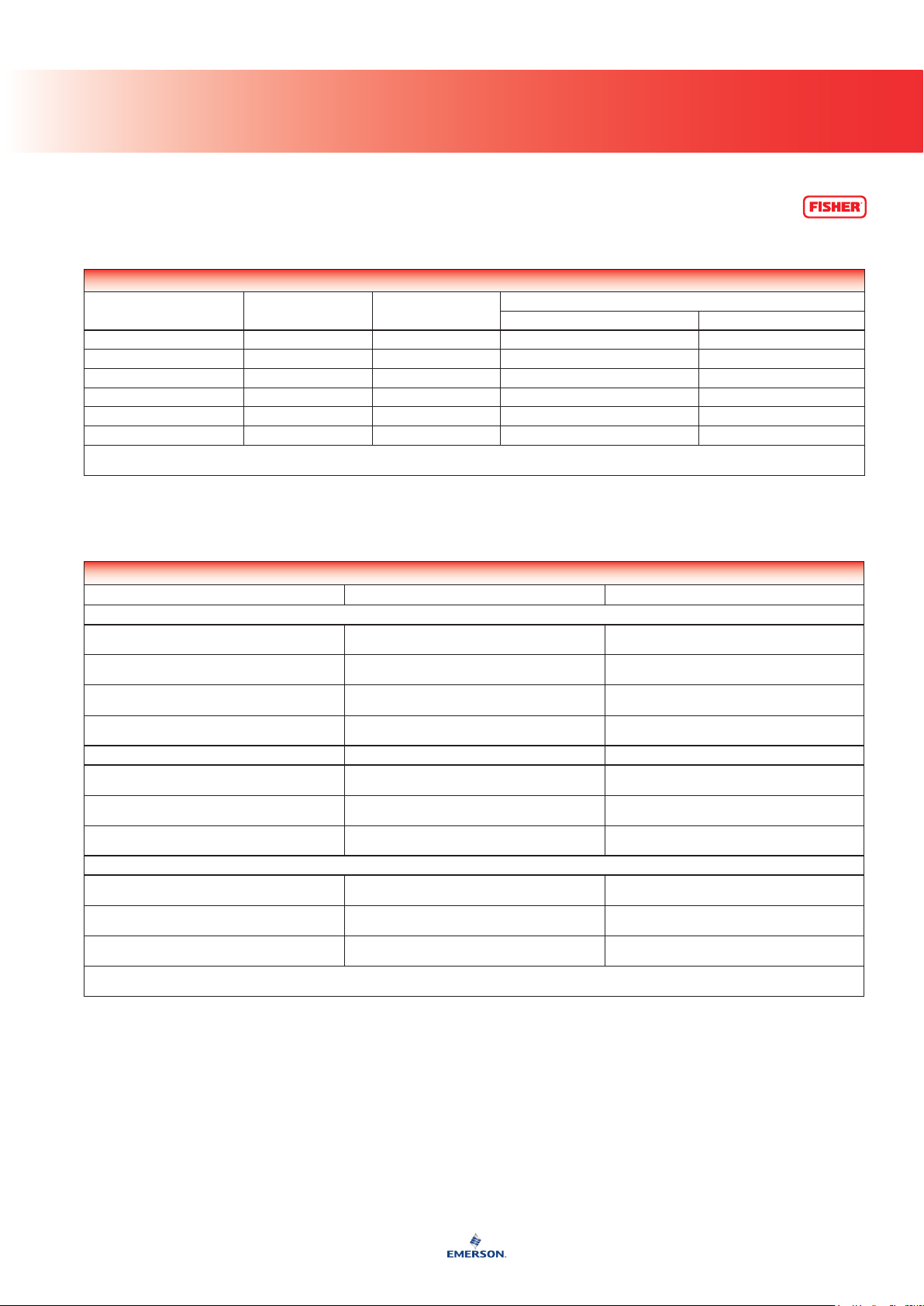

4

Re g u l a t o R s Qu i c k se l e c t i o n gu i d e

COMMERCIAL/

INDUSTRIAL

HIGH PRESSURE

REGULATORS

MAXIMUM INLET

PRESSURE

250 psig

(17,2 bar)

250 psig

(17,2 bar)

300 psig

(20,7 bar)

250 psig

(17,2 bar)

250 psig

(17,2 bar)

OUTLET

PRESSURE RANGE

3 to 100 psig

(0,21 to 6,9 bar)

3 to 135 psig

(0,21 to 9,3 bar)

0.25 to 100 psig

(0,02 to 6,9 bar)

5 to 20 psig

(0,35 to 1,4 bar)

8 to 20 psig

(0,55 to 1,4 bar)

CAPACITY*

(1)

5 200 000 BTU/hr

(58,5 SCMH)

1 200 000 BTU/hr

(13,5 SCMH)

74 300 000 BTU/hr

(836 SCMH)

10 700 000 BTU/hr

(120 SCMH)

14 000 000 BTU/hr

(158 SCMH)

TYPE

NUMBER

64 Series

Page 11

67C Series

Page 14

99 Series

Page 19

627 Series

Page 29

630 Series

3-inches w.c.

150 psig

(10,3 bar)

6000 psig

(414 bar)

*See capacity tables in the following sections for expanded rating information.

1. Based on inlet pressure 20 psig (1,4 bar) greater than outlet with 20% droop, unless otherwise noted.

2. Based on 2000 psig (138 bar) inlet pressure setting.

3. Types 912-101 and -104 rating at 30 (2,1 bar) psig inlet.

to 5 psig

(7 mbar to 0,34 bar)

10 to 75 psig

(0,69 to 5,2 bar)

320 000 BTU/hr

(3,60 SCMH)

(3)

3 800 000 BTU/hr

(43,0 SCMH)

(2)

Page 31

912 Series

Page 36

Type 1301F

Page 39

Page 15

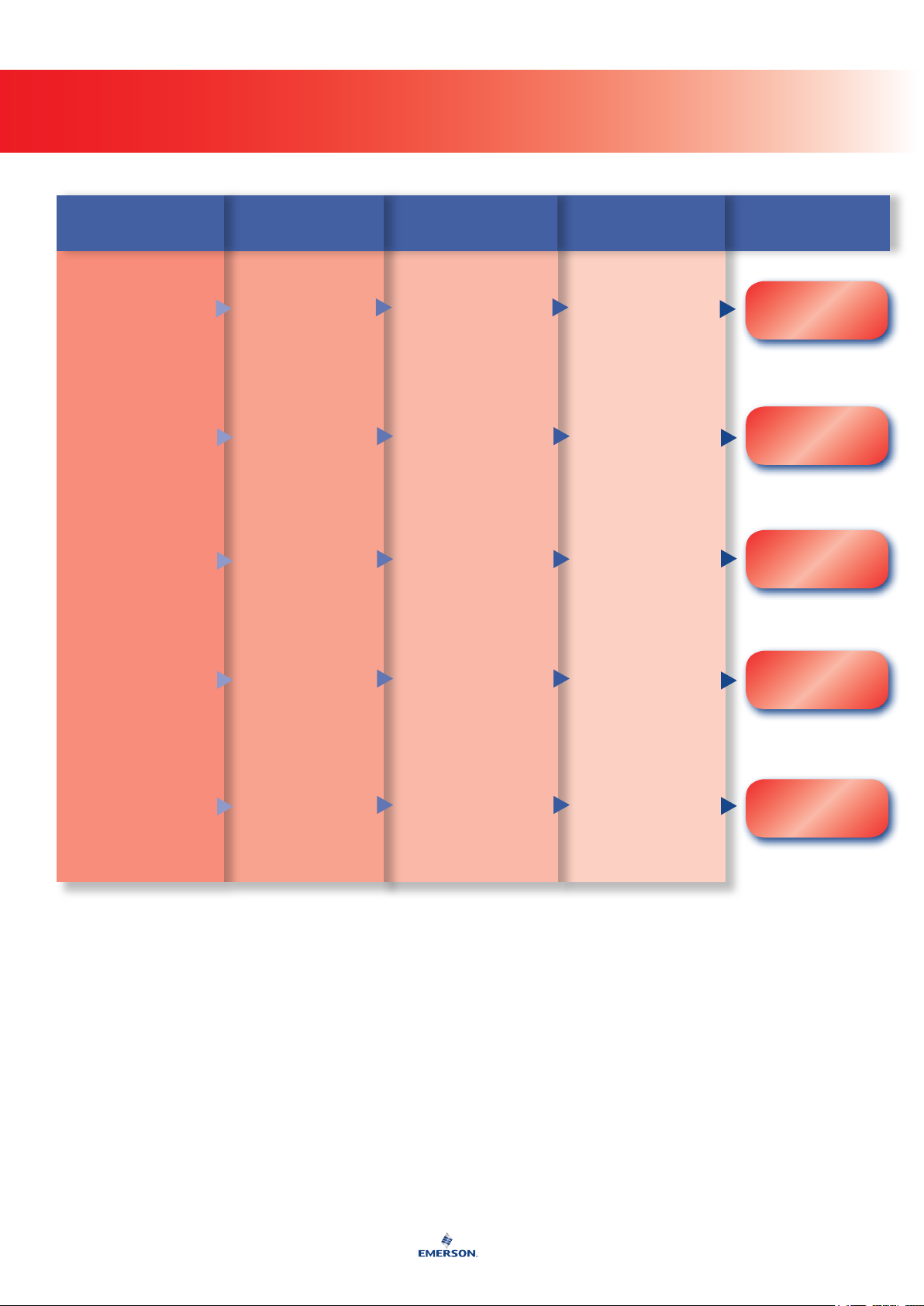

5

Re g u l a t o R s Qu i c k se l e c t i o n gu i d e

COMMERCIAL/

INDUSTRIAL

LOW PRESSURE

REGULATORS

MAXIMUM INLET

PRESSURE

150 psig

(10,3 bar)

150 psig

(10,3 bar)

25 psig

(1,7 bar)

15 psig

(1,03 bar)

OUTLET

PRESSURE RANGE

0.25 to 15 psig

(0,02 to 1,0 bar)

7-inches w.c.

to 16 psig

(17 mbar to 1,1 bar)

9 to 18-inches w.c.

(22 to 45 mbar)

6 to 14-inches w.c.

(15 to 35 mbar)

CAPACITY*

(1)

63 250 000 BTU/hr

(712 SCMH)

38 000 000 BTU/hr

(428 SCMH)

21 600 000 BTU/hr

(243 SCMH)

(3)

5 500 000 BTU/hr

(62,0 SCMH)

(3)

TYPE

NUMBER

99 Series

Page 19

299H Series

Page 26

S202G Series

Page 82

S302G Series

Page 84

MAXIMUM INLET

PRESSURE

OUTLET PRESSURE

SETTING/STANDARD

SETPOINTS

10 psig (0,69 bar)

250 psig

(17,2 bar)

FIRST-STAGE

+/- 1 psig (0,07 bar)

nominal outlet setting

(non-adjustable)

REGULATORS

5 or 10 psig

250 psig

(17,2 bar)

*See capacity tables in the following sections for expanded rating information.

1. Based on inlet pressure 20 psig (1,4 bar) greater than outlet with 20% droop, unless otherwise noted.

2. Based on 30 psig (2,1 bar) inlet pressure and 20% droop.

3. Based on 10 psig (0,69 bar) inlet pressure setting and 2-inches w.c. (5 mbar) droop.

(0,34 or 0,69 bar)

standard setpoints

CAPACITY*

(2)

1 100 000 BTU/hr

(12,4 SCMH)

2 400 000 BTU/hr

(27,0 SCMH)

TYPE

NUMBER

Type R122H

Page 51

R622H Series

Page 71

Page 16

6

Re g u l a t o R s Qu i c k se l e c t i o n gu i d e

SECOND-STAGE

REGULATORS

MAXIMUM INLET

PRESSURE

10 psig

(0,69 bar)

10 psig

(0,69 bar)

10 psig

(0,69 bar)

STANDARD

SETPOINT

9 to 13-inches w.c.

(22 to 32 mbar)

11-inches w.c.

(27 mbar)

11-inches w.c.

(27 mbar)

CAPACITY*

(1)

2 600 000 BTU/hr

(29,3 SCMH)

650 000 BTU/hr

(7,3 SCMH)

1 400 000 BTU/hr

(15,8 SCMH)

TYPE

NUMBER

Type HSRL

Page 45

R222 Series

Page 56

R622 Series

Page 62

10 psig

11-inches w.c.

(0,69 bar)

10 psig

11-inches w.c.

(0,69 bar)

*See capacity tables in the following sections for expanded rating information.

1. Based on 10 psig (0,69 bar) inlet pressure setting.

(27 mbar)

(27 mbar)

920 000 BTU/hr

(10,4 SCMH)

1 080 000 BTU/hr

(12,2 SCMH)

R642 Series

Page 62

R652 Series

Page 62

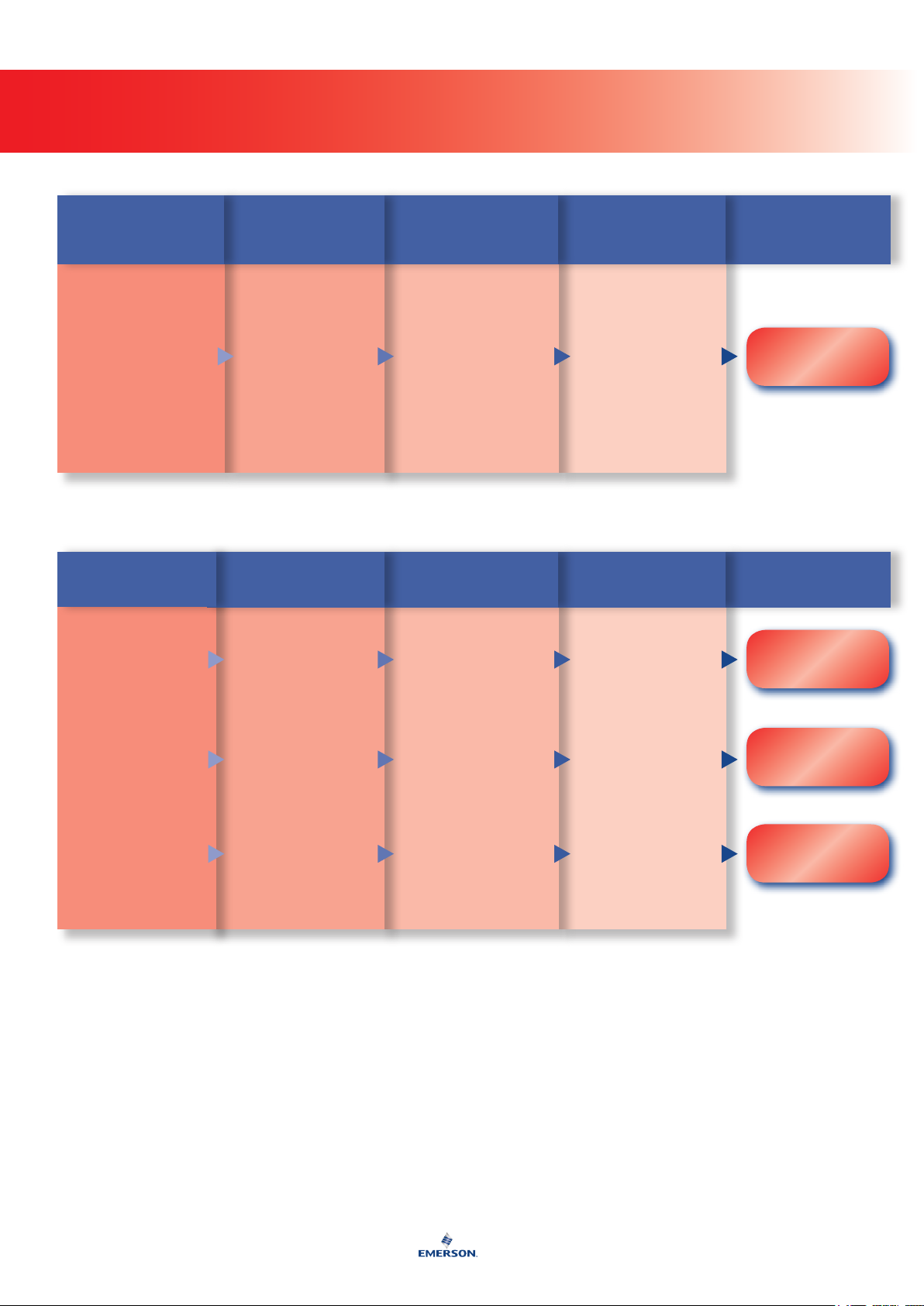

Page 17

7

Re g u l a t o R s Qu i c k se l e c t i o n gu i d e

INTEGRAL

TWO-STAGE

REGULATORS

MAXIMUM INLET

PRESSURE

250 psig

(17,2 bar)

250 psig

(17,2 bar)

STANDARD

SETPOINT

First-Stage:

Approximately

10 psig (0,69 bar)

(non-adjustable)

Second-Stage:

11-inches w.c.

(27 mbar)

First-Stage:

Approximately

10 psig (0,69 bar)

(non-adjustable)

Second-Stage:

11-inches w.c.

(27 mbar)

CAPACITY*

(1)

450 000 BTU/hr

(5,1 SCMH)

(1)

850 000 BTU/hr

(9,6 SCMH)

(1)

TYPE

NUMBER

R232 Series

Page 59

R632 Series

Page 75

MAXIMUM INLET

PRESSURE

STANDARD

SETPOINT

10 psig

(0,69 bar)

(0,14 bar)

2-PSI SERVICE

REGULATORS

10 psig

(0,69 bar)

*See capacity tables in the following sections for expanded rating information.

2. Based on 30 psig (2,1 bar) inlet pressure setting.

(0,14 bar)

2 psi

2 psi

CAPACITY*

(2)

1 680 000 BTU/hr

(18,9 SCMH)

1 500 000 BTU/hr

(16,9 SCMH)

TYPE

NUMBER

R622E Series

Page 67

Type R652E

Page 67

Page 18

8

Re g u l a t o R s Qu i c k se l e c t i o n gu i d e

AUTOMATIC

CHANGEOVER

MANIFOLD

MAXIMUM INLET

PRESSURE

250 psig

(17,2 bar)

MAXIMUM WORKING

PRESSURE

300 psig

(20,7 bar)

OUTLET PRESSURE

SETTING

15 psig (1,0 bar)

from the supply

cylinder and

7 psig (0,48 bar)

from the

reserve cylinder

RELIEF PRESSURE

RANGE

25 to 140 psig

(1,7 to 9,7 bar)

CAPACITY*

500 000 BTU/hr

(5,6 SCMH)

RELIEF

CAPACITY*

93.1GPM

(352 l/min)

Propane

TYPE

NUMBER

Type R110

Page 49

TYPE

NUMBER

98H Series

Page 17

BACKPRESSURE

REGULATORS/

25 psig

(1,7 bar)

0.5 to 2.25 psig

(0,03 to 0,16 bar)

RELIEF VALVES

150 psig

(10,3 bar)

*See capacity tables in the following sections for expanded rating information.

5 to 125 psig

(0,34 to 8,6 bar)

11 000 SCFH

(312 SCMH)

Propane

2840 SCFH

(80,4 SCMH)

Propane

289H Series

Page 23

1805 Series

Page 41

Page 19

9

Re g u l a t o R s Qu i c k se l e c t i o n gu i d e

AUTOMATIC

CHANGEOVER

REGULATOR

MAXIMUM INLET

PRESSURE

250 psig

(17,2 bar)

MAXIMUM INLET

PRESSURE

SELECTION

INFORMATION

First Stage

Regulator

Type R110

Second Stage

Regulator

R622 Series

STANDARD OUTLET

SETTING

CAPACITY*

600 000 BTU/hr

(6,8 SCMH)

CAPACITY*

TYPE

NUMBER

Type R962

Page 79

TYPE

NUMBER

CHANGEOVER

MANIFOLD

ASSEMBLIES

250 psig

(17,2 bar)

250 psig

(17,2 bar)

Supply:

15 psig (1,0 bar)

Reserve:

5 psig (0,34 bar)

Supply:

45 psig (3,1 bar)

Reserve:

30 psig (2,1 bar)

1 575 000 BTU/hr

(17,7 SCMH)

1 500 000 BTU/hr

(16,9 SCMH)

Type 749B

Page 33

Type R130

Page 54

*See capacity tables in the following sections for expanded rating information.

Page 20

Re g u l a t o R s ap p l i c a t i o n s

OVERVIEW

Emerson Process Management’s Fisher®

brand provides the most complete line of

regulators in the industry today. Pressure

reducing regulators supply LP-gas at

a constant pressure for commercial

applications such as furnaces and boilers

in industrial facilities to farm taps and

jurisdictional systems. These facilities

and systems provide several million BTU

per hour to small domestic and appliance

applications. Fisher brand regulators

are designed to the highest standards for

safe and accurate gas delivery, regardless

of variations in supply pressure. This

Application Guide briefly explains the types

of regulators available for these regulators.

Your local LP-Gas Distributor can assist

you in selecting the proper regulators and

accessories for your system.

COMMERCIAL/INDUSTRIAL HIGH- AND

LOW-PRESSURE REGULATORS

Commercial or industrial regulators are

often higher-volume devices that reduce

tank pressures of 250 psig (1,7 bar) to

pressures as low as 11-inches w.c. (water

column) (27 mbar). Flows can be as low

as 1 000 000 BTU/hr or as high as

100 000 000 BTU/hr.

FIRST-STAGE REGULATORS

A two-stage pressure-reducing regulator

system uses two regulators to cut the

supply pressure from the storage tank to

the appliance. The first-stage regulator

supplies a nearly constant inlet pressure

around 8 to 10 psig (0,55 to 0,69 bar) to

a second-stage regulator. This relative

constant pressure allows appliances to work

efficiently. To comply with requirements,

such as NFPA 58, a two-stage system is

used. The second-stage unit does not

have to compensate for widely varying

inlet pressures. The first-stage regulator

is often at the tank and the second stage at

the building or equipment being supplied.

Second-stage pressure can be adjusted as

desired. The first stage must be capable of

higher inlet pressures.

TWO-PSI REGULATORS

A two-psi pressure regulator is used as an

intermediate regulator after the first-stage

regulator. These regulators are designed for

2 psig (0,14 bar) LP-gas regulator systems.

These regulators feature a combination relief

valve and large vent that provide over pressure

protection and exceed UL requirements.

SECOND-STAGE REGULATORS

A two-stage pressure-reducing regulator

system uses two regulators to cut the

supply pressure from the storage tank to the

appliance. The two-stage system supplies

a nearly constant outlet pressure to the

appliance allowing the appliance to work

efficiently. To comply with requirements,

such as NFPA 58, a two-stage system is

used. The first-stage regulator is often at

the tank and the second stage at the building

or equipment being supplied. Second-stage

pressure can be adjusted as desired. The

second-stage regulator reduces the pressure

from a first-stage unit to 11-inches w.c.

(27 mbar) in domestic installations. Vents

are normally screened.

INTEGRAL TWO-STAGE REGULATORS

Integral two-stage regulators combine both

stages into one compact unit and are often

used for installations where piping distance

between the building being served and the tank

is short. Integral two-stage regulators provide

all the advantages of two-stage regulation.

FIVE REASONS TO USE A

TWO-STAGE SETUP

1. Ifrequiredforcompliancewithcode

requirementssuchasNFPA58.

2. Fewertroublecalls

With a two-stage system, you can expect

fewer customer trouble calls due to regulator

freeze-ups from too much water in the gas. A

two-stage regulator reduces these possibilities

in two ways: First, a larger orifice can be

used, making it more difficult for ice to

build-up and block the orifice. Second,

more heat can be transferred through the

walls of two regulators than one.

3. Smallerpipeortubing

Due to the higher pressure between the

first and second-stage units, smaller pipe or

tubing can be used in a two-stage system.

These savings can make a two-stage system

more economical to install than a singlestage system.

4. Constantappliancepressure

With a two-stage system, a first-stage

regulator supplies a nearly constant inlet

pressure of 8 to 10 psig (0,55 bar to 0,69 bar)

to a second-stage regulator. This means that

the second-stage regulator does not have to

attempt to compensate for widely varying

inlet pressures. With more uniform pressure,

appliances work better, and customers are

less likely to experience problems that result

in service calls.

5. Keepdownstreampressurebelow

2psig(0,14bar)

Second-stage and Integral two-stage

regulators have internal pressure relief

valves, which limit the outlet pressure

to 2 psig (0,14 bar) when the seat disc is

removed and the inlet pressure is 10 psig

(0,69 bar) or less as specified in UL 144,

STANDARD for LP-GAS REGULATORS.

WHEN TO USE A TWO-STAGE SETUP

Emerson Process Management recommends

Fisher brand two-stage systems whenever

the following conditions exist:

1. Compliancewithregulationcodes.

2. Thereisapossibilityofmoisturein

theLP-gas.

3. Widefluctuationsingasdemandexist.

4. Winterandsummertemperatures

varygreatly.steamheader.

10

Page 21

64 Series High Pressure Regulators

Re g u l a t o R s

Introduction

The 64 Series adjustable high-pressure

regulators offer a wide range of available

pressure ranges. High-pressure regulators

usually reduce tank pressure to an

intermediate pressure for use by another

regulator. They may be used as highpressure regulators on distribution systems

when used in conjunction with rst-stage

downstream regulators.

When equipped with an internal relief valve

(64SR Series), the regulator may be used as a

nal-stage regulator on high-pressure systems.

It may also be used as a rst-stage regulator

when set at 10 psig (0,69 bar) or less.

The 64KB Series has a special

Polytetrauoroethylene (PTFE) diaphragm

protector that makes it suitable for anhydrous

ammonia (NH3) service. The 1/4-inch FNPT

tapped and plugged side outlet can be used

to install a pressure gauge or a hydrostatic

relief valve.

Body Size and End Connection Style

End:1/2-inch threaded NPT

SideOutlet: 1/4-inch threaded NPT

Spring Case Vent

1/4-inch threaded NPT with screen

Temperature Capabilities

-20° to 150°F (-29° to 66°C)

Maximum Inlet Pressure

250 psig (17,2 bar)

Maximum Emergency Outlet Pressure

The value of 220 psig (15,2 bar) is designated

strictly for emergency outlet pressure and not for

maximum outlet (operating) pressure. This should

be incorporated to distinguish safety pressures from

operating pressures.

Outlet Pressure Ranges

3 to 100 psig (207 mbar to 6,9 bar)

in four ranges

See Table 1

Flow Coefficient

Wide-OpenCg: 35.6

Additional Technical Data

For more technical information,

contact your local LP-Gas

Equipment Distributor or log on to:

www.emersonprocess.com/regulators/lp

P1027

Figure 1. 64 Series High Pressure Regulator

Features

• Versatility

• BodySideConnection

• EasyMaintenance

• ULListed

Table 1. Outlet Pressure Ranges

OUTLET PRESSURE RANGE,

PSIG (bar)

3 to 15 (207 mbar to 1,0 bar) 1D892327022 Red

5 to 35

(0,3 to 2,4)

30 to 60

(2,1 to 4,1)

35 to 100

(2,4 to 6,9)

SPRING PART

NUMBER

1D665927022

1D745527142

1E543627142

SPRING

COLOR

Blue

Green

Yellow

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

M1020

Figure 2. Operational Schematic

11

Page 22

64 Series High Pressure Regulators

12

Re g u l a t o R s

Table 2. Construction Materials

BODY

Die-cast

aluminum

REGULATOR

SPRING

Steel

SPRING CASE

Die-cast

aluminum

Table 3. Capacities

Outlet Pressure Setting Spring Range Capacity in BTU/hr (SCMH) of Propane

10 psig (0,69 bar) 3 to 15 psig (0,21 to 1,0 bar) 2 625 000 (29,6)

20 psig (1,4 bar) 5 to 35 psig (0,34 to 2,4 bar) 3 600 000 (40,5)

40 psig (2,8 bar) 30 to 60 psig (2,1 to 4,1 bar) 4 150 000 (46,7)

50 psig (3,4 bar) 35 to 100 psig (2,4 to 6,9 bar) 5 250 000 (59,1)

Outlet Pressure Setting Spring Range Capacity in BTU/hr (SCMH) of Propane

10 psig (0,69 bar) 3 to 15 psig (0,21 to 1,0 bar) 2 625 000 (29,6)

15 psig (1,0 bar) 5 to 20 psig (0,34 to 1,4 bar) 3 000 000 (33,8)

20 psig (1,4 bar) 5 to 35 psig (0,34 to 2,4 bar) 3 600 000 (40,5)

Outlet Pressure Setting Spring Range Capacity in SCFH (SCMH) of Ammonia

10 psig (0,69 bar) 3 to 15 psig (0,21 to 1,0 bar) 1650 (46,7)

15 psig (1,0 bar) 5 to 20 psig (0,34 to 1,4 bar) 2050 (58,0)

20 psig (1,4 bar) 5 to 35 psig (0,34 to 2,4 bar) 2250 (63,7)

40 psig (2,8 bar) 30 to 60 psig (2,1 to 4,1 bar) 2600 (73,6)

50 psig (3,4 bar) 35 to 100 psig (2,4 to 6,9 bar) 3300 (93,4)

1. Based on inlet pressure 20 psig (1,4 bar) greater than outlet with 20% droop.

2. Capacity based on 20 psig (1,4 bar) above setpoint and 20% droop.

3. Metric conversion is based on 2516 BTU/ft3 of gas at 60°F (16°C).

64 SERIES

64SR SERIES

64KB SERIES

STEM GUIDE AND

DISK HOLDER

Stainless steel Nitrile (NBR) Stainless steel

DIAPHRAGM VALVE STEM

(1)(3)

(1)(3)

(2)

Page 23

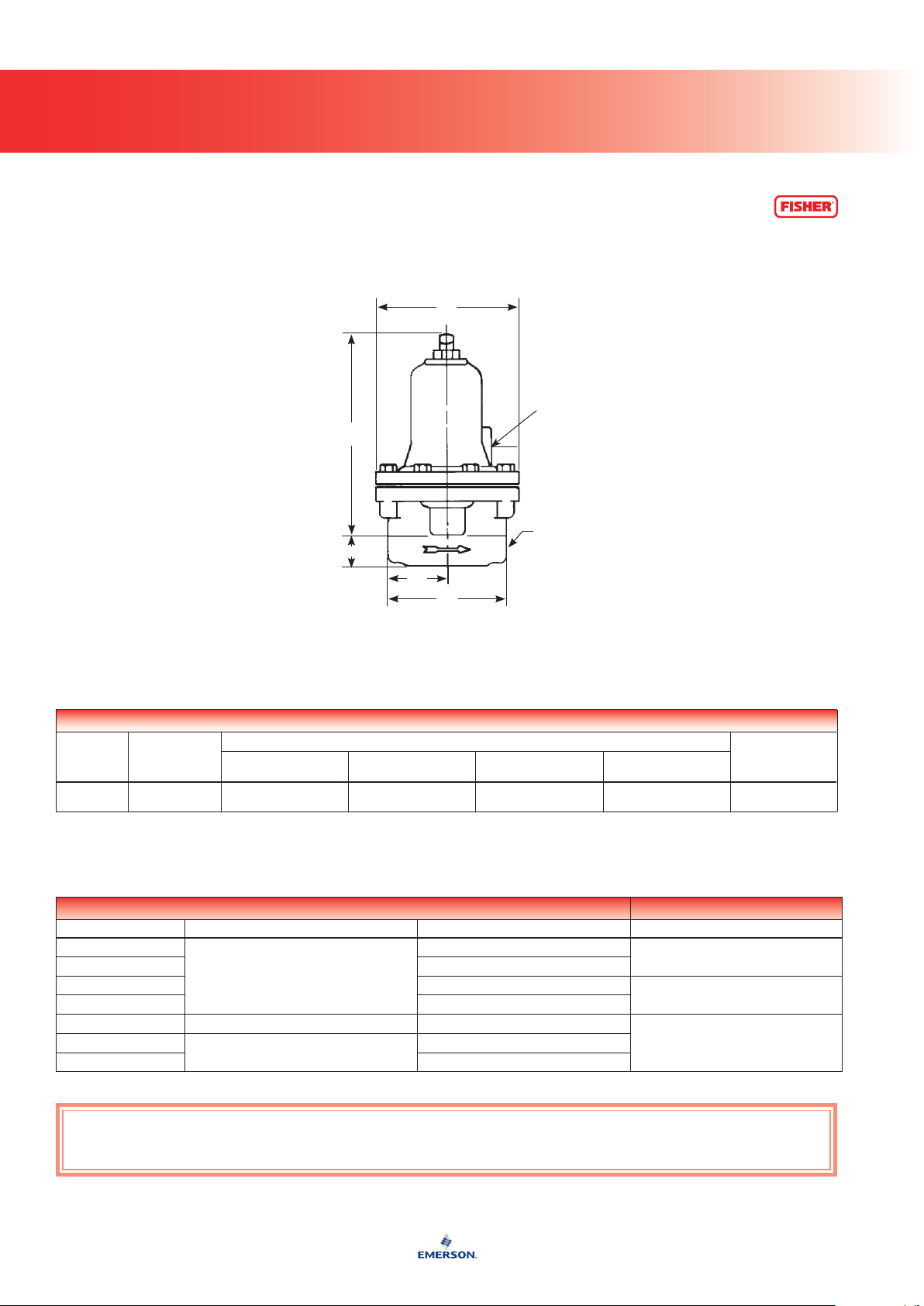

64 Series High Pressure Regulators

13

Re g u l a t o R s

1/4-INCH NPT

SCREENED VENT

B

A

(MAXIMUM)

1/2-INCH NPT

1/4-INCH NPT SIDE OUTLET

A0813_1

C

D

Figure 3. Dimensions

Table 4. Dimensions and Approximate Weight

DIMENSIONS, INCHES (mm)

A B C D

8.25 (209) 4.12 (105) 2.75 (69,9) 1.56 (39,6) 2.25 (1,02)

Ordering Guide

Ordering Information

TYPE NUMBER DESCRIPTION

64-33

64-35 20 (1,38) 5 to 35 (0,35 to 2,41)

64-36 40 (2,76) 30 to 60 (2,07 to 4,14)

64-222 50 (3,45) 35 to 100 (2,41 to 6,90)

64SR-21

64SR-22 15 (1,03) 5 to 20 (0,35 to 1,38)

64SR-23 20 (1,38) 5 to 35 (0,35 to 2,41)

64SR-122 10 (0,69) 5 to 20 (0,35 to 1,38)

64KB-33

64KB-34 15 (1,03) 5 to 20 (0,35 to 1,38)

64KB-35 20 (1,38) 5 to 35 (0,35 to 2,41)

64KB-36 40 (2,76) 30 to 60 (2,07 to 4,14)

64KB-222 50 (3,45) 35 to 100 (2,41 to 6,90)

Basic Regulator

With Internal Relief Valve

With Special Diaphragm Protector

OUTLET PRESSURE SETTING,

PSIG (bar)

10 (0,69) 3 to 15 (0,21 to 1,03)

10 (0,69) 3 to 15 (0,21 to 1,03)

10 (0,69) 3 to 15 (0,21 to 1,03)

OUTLET ADJUSTMENT RANGE,

PSIG (bar)

APPROXIMATE WEIGHT,

POUNDS (kg)

INLET AND OUTLET

CONNECTIONS, INCHES

1/2 FNPT

To order, refer to the Ordering Information table above and specify the type number that satises your requirement.

Then, contact or visit your local LP-Gas Equipment Distributor for availability.

Page 24

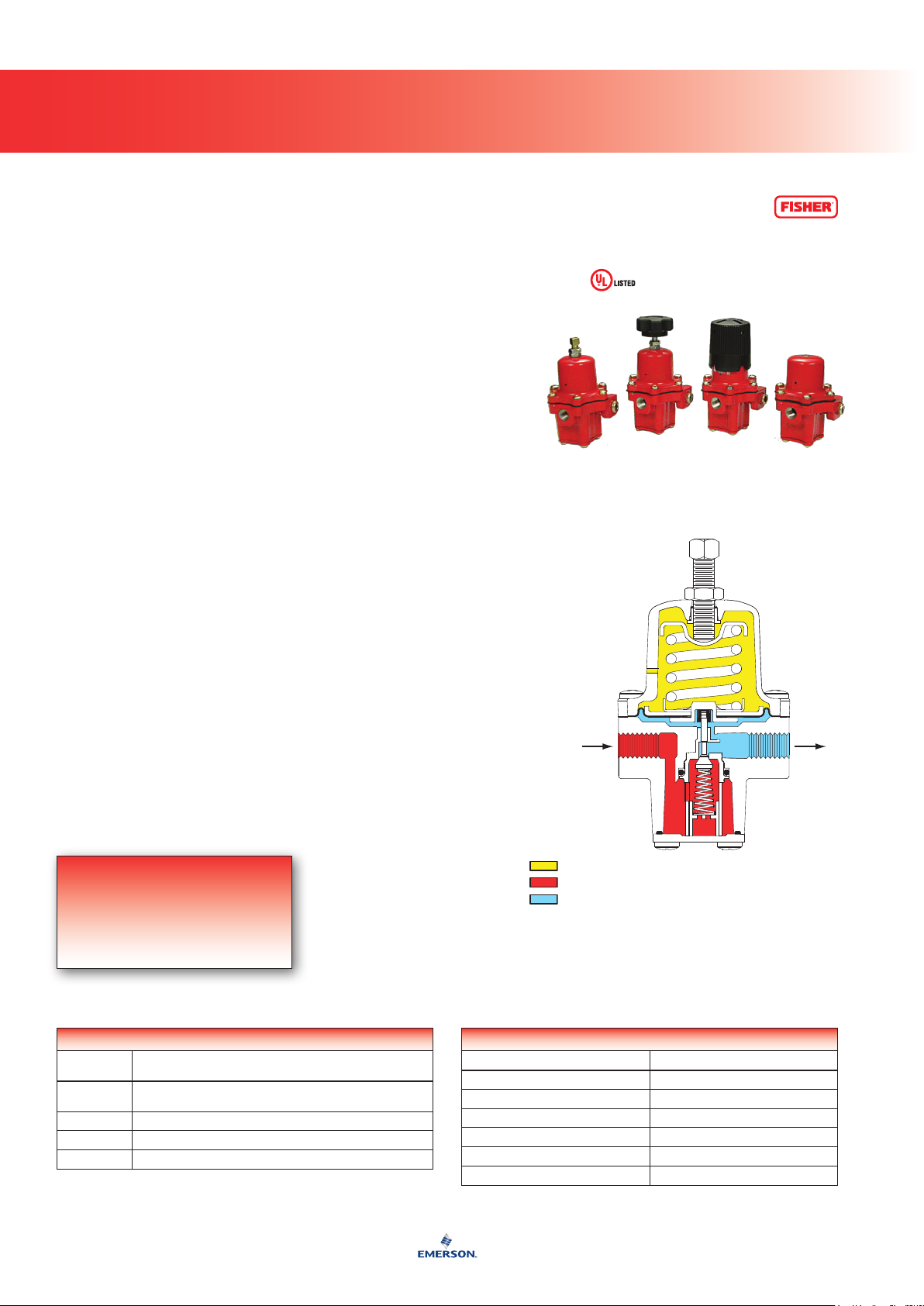

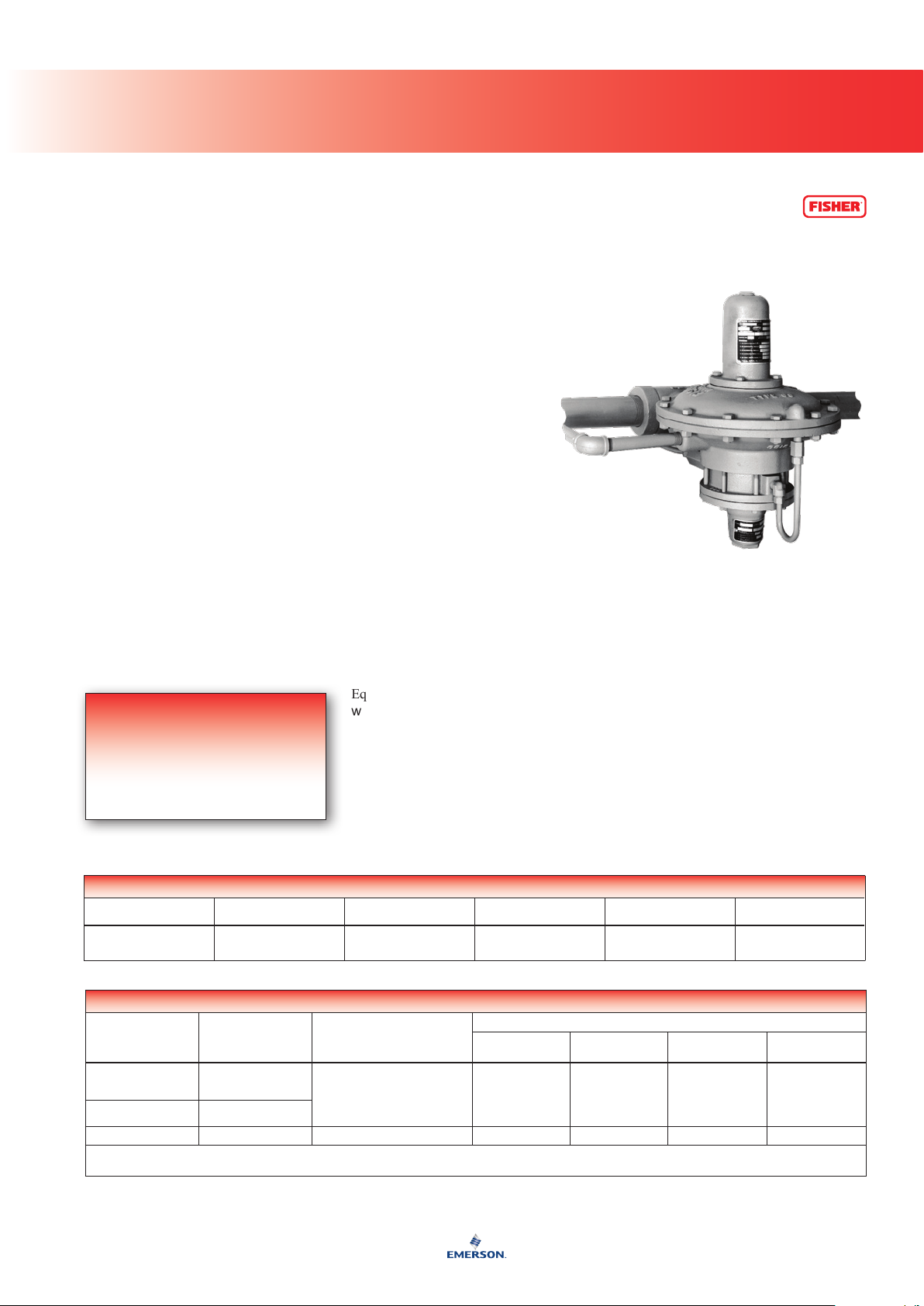

67C Series High Pressure Regulators

14

Re g u l a t o R s

Introduction

The 67C Series is a Underwriters

Laboratories (UL) listed high-pressure

regulators that meets a variety of

applications in liquid or vapor service.

The compact body design makes the

67C Series particularly useful in

installations with space limitations.

The basic 67C Series regulators come

equipped with a wrench or handwheel

adjustment (67CW or 67CH Series). The

highly accurate 67CD Series eliminates

the need for a pressure gauge on portable

applications by using calibrated scales on

the spring case, allowing visual adjustment

of outlet pressure. The non-adjustable

67CN Series provides a tamper-resistant

spring case and one of three xed setpoints:

10, 15, or 20 psi (0,69; 1,0; or 1,4 bar).

The 67C Series carries a UL listing as a

high pressure, non-relief regulator. This

series contains brass materials that are not

compatible with anhydrous ammonia service.

Body Size and End Connection Style

1/4-inch FNPT

Side Outlet Connection Style (Plugged)

1/4-inch threaded NPT; pressure gauge

(J500 Series) can be installed

Maximum Inlet Pressure (Body Rating)

250 psig (17,2 bar)

Maximum Emergency Outlet Pressure

50 psig (3,4 bar) over outlet pressure

Pressure Registration

Internal

Spring Case Vent Location

Aligned with inlet, other position optional

Flow Coefficient

Wide-OpenCgforReliefSizing: 11.7

Temperature Capabilities

-20° to 180°F (-29° to 82°C)

Approximate Weights

Type67CW: 0.7 pound (0,32 kg)

Type67CH: 1 pound (0,45 kg)

Type67CD: 0.8 pound (0,36 kg)

Type67CN: 1.1 pound (0,50 kg)

Option

• Outlet Pressure Gauge

Additional Technical Data

For more technical information,

contact your local LP-Gas

Equipment Distributor or log on to:

www.emersonprocess.com/regulators/lp

Figure 1. 67C Series Regulators

Features

• Compact

• HighStability

• ULListed

• DurablePowderPaintCoating

Table 1. Available Congurations

TYPE

NUMBER

67CW

67CH Basic regulator with handwheel adjustments.

67CD Basic regulator with dial cap adjustments.

67CN Basic regulator, factory set with no eld adjustments.

Basic regulator with wrench adjustment and 4 spring ranges from

DESCRIPTION

3 to 135 psig (0,2 to 9,3 bar) no relief.

ATMOSPHERIC PRESSURE

INLET PRESSURE

OUTLET PRESSURE

W8442

Figure 2. Operational Schematic

Table 2. Construction Materials

PART NAME MATERIAL

Body Aluminum

Valve Stem Brass

Spring Music wire

Valve Plug Nitrile (NBR)

O-Ring and Soft Seats Nitrile (NBR)

Diaphragm Nitrile (NBR) / Nylon (PA)

Page 25

67C Series High Pressure Regulators

15

Re g u l a t o R s

Table 3. Spring Ranges and Factory Setpoints

SPRING RANGE,

3 to 20 (0,2 to 1,4) Green Stripe GE07809T012 15 (1,0) N/A

5 to 35 (0,3 to 2,4) Silver T14059T0012 20 (1,4) 10, 15, or 20 psi (0,69; 1,0; or 20 bar)

20 to 50 (1,4 to 3,4) Blue Stripe T14058T0012 40 (2,8) Type 67CD only N/A

30 to 60 (2,1 to 4,1) Blue Stripe T14058T0012 40 (2,8) Types 67CW and 67CH only N/A

35 to 100 (2,4 to 6,9) Red Stripe T14060T0012 50 (3,4) Type 67CD only N/A

35 to 135 (2,4 to 9,3) Red Stripe T14060T0012 50 (3,4) Types 67CW and 67CH only N/A

1. All springs can be backed off to 0 psig (0 bar) except Type 67CN. However, for the highest capacity and most control, use the lowest spring that can be adjusted to the

required setpoint.

PSIG (bar)

(1)

SPRING COLOR CODE SPRING PART NUMBER

Types 67CW, 67CD, and 67CH Type 67CN

TYPE AND FACTORY SETPOINT, PSIG (bar)

Table 4. Capacities

OUTLET PRESSURE SETTING, SPRING RANGE INLET PRESSURE CAPACITIES IN BTU/hr (SCMH) PROPANE

Type 67CW or 67CH

15 psig (1,0 bar) setting

3 to 20 psig (0,2 to 1,4 bar)

20 psig (1,4 bar) setting

5 to 35 psig (0,3 to 2,4 bar)

40 psig (2,8 bar) setting

30 to 60 psig ( 2,1 to 4,1 bar)

50 psig (3,4 bar) setting

35 to 135 psig (2,4 to 9,3 bar)

15 psig (1,0 bar) setting

5 to 20 psig (0,3 to 1,4 bar)

40 psig (2,8 bar) setting

20 to 50 psig (1,4 to 3,4 bar)

50 psig (3,4 bar) setting

35 to 100 psig (2,4 to 6,9 bar)

10 psig (0,7 bar)

Non-adjustable

15 psig (1,0 bar)

Non-adjustable

20 psig (1,4 bar)

Non-adjustable

1. Capacities are based on inlet pressure 20 psig (1,4 bar) greater than outlet with 20% droop.

2. Metric conversion is based on 2516 BTU/ft3 of gas at 60°F (16°C).

35 psig (2,4 bar) 675 000 (7,60)

40 psig (2,8 bar) 750 000 (8,44)

60 psig (4,1 bar) 1 200 000 (13,5)

70 psig (4,8 bar) 1 000 000 (11,3)

Type 67CD

35 psig (2,4 bar) 675 000 (7,60)

60 psig (4,1 bar) 1 200 000 (13,5)

70 psig (4,8 bar) 1 000 000 (11,3)

Type 67CN

30 psig (2,1 bar) 400 000 (4,50)

35 psig (2,4 bar) 600 000 (6,75)

40 psig (2,8 bar) 750 000 (8,44)

(1)(2)

Page 26

Re g u l a t o R s

IN

OUT

IN

OUT

IN

OUT

67C Series High Pressure Regulators

3.95

(100)

1.51

(38)

2.56

(65)

5.50

(140)

2.92

(74)

1.46

(37)

67CD SERIES WITH

OPTIONAL GAUGE

OPTIONAL

GAUGE

SIDE OUTLET

1/4-INCH NPT

4.01

(102)

1.51

(38)

2.56

(65)

67CH SERIES WITH

OPTIONAL GAUGE

2.92

(74)

1.46

(37)

5.50

(140)

3.24

(82)

OPTIONAL

GAUGE

SIDE OUTLET

1/4-INCH NPT

Figure 3. Dimensions

1.51

(38)

2.56

(65)

67CW SERIES WITH

OPTIONAL GAUGE

2.92

(74)

1.46

(37)

5.50

(140)

OPTIONAL

GAUGE

SIDE OUTLET

1/4-INCH NPT

0.50

(12,7)

67CN SERIES

2.29

(58)

1.51

(38)

INCHES

(mm)

Ordering Guide

Ordering Information

ADJUSTMENT STYLE

AND TYPE NUMBER

Wrench Handwheel - - - - - - - -

67CW-683 67CH-751 15 (1,0) 3 to 20 (0,2 to 1,4)

67CW-684 67CH-743 20 (1,4) 3 to 35 (0,2 to 2,4)

67CW-685 67CH-742 40 (2,8) 30 to 60 (2,1 to 4,1)

67CW-701 67CH-741 50 (3,4) 50 to 135 (3,4 to 9,3)

Dial Cap - - - - - - - -

67CD-100 15 (1,0) 5 to 20 (0,3 to 1,4)

67CD-102 40 (2,8) 20 to 50 (1,4 to 3,4)

67CD-103 50 (3,4) 40 to 100 (2,8 to 6,9)

Non-Adjustable - - - - - - - -

67CN-106 10 (0,7)

67CN-105 20 (1,4)

To order, refer to the Ordering Information table above and specify the type number that satises your requirement.

Then, contact or viisit your local LP-Gas Equipment Distributor for availability.

OUTLET PRESSURE SETTING,

PSIG (bar)

SPRING RANGE,

PSIG (bar)

Non-Adjustable67CN-104 15 (1,0)

BODY AND END

CONNECTION SIZE

1/4-inch FNPT

16

Page 27

98H Series Backpressure Regulators/Relief Valves

A6925

Type 98H

COMP

Type 98H

A6925

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE/LOADING PRESSURE

January 2007

Type 98H

COM P

Re g u l a t o R s

Introduction

The 98H Series, liquid service valves are

direct-operated relief valves for use on relief

and backpressure applications involving

large LP-Gas pumping systems and

vaporizers. Internal pressure registration

eliminates the need for a control line.

Body Sizes and End Connection Style

1/2, 3/4, and 1-inch FNPT

Pressure Registration

Internal

Flow Capacities

See Table 3

Features

• Versatility

• Compact,RuggedDesign

• InternalRegistration

Maximum Relief (Inlet) Pressure

300 psig (20,7 bar)

Relief Pressure Ranges

See Table 2

Temperature Capabilities

-20° to 150°F (-29° to 66°C)

Additional Technical Data

For more technical information,

contact your local LP-Gas

Equipment Distributor or log on to:

www.emersonprocess.com/regulators/lp

W6155

Figure 1. Type 98H Backpressure/Relief Valve

BODY SIZE,

INCH FNPT

TYPE NUMBER

Table 1. Construction Materials

PART NAME MATERIAL

Body, Spring case Cast iron

Orice, O-ring retainer, Valve plug,

Valve plug guide, Pusher post

Diaphragm retaining washer 316 Stainless steel

Diaphragm Neoprene

O-ring seat Nitrile (NBR)

416 Stainless steel

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

A6925

Figure 2. Operational Schematic

Table 2. Relief Pressure Ranges

1/2

3/4 or 1

RELIEF PRESSURE RANGES,

PSIG (bar)

25 to 75 (1,7 to 5,2) 1D7455T0012 Green Stripe 0.234 (5,94) 2.0 (50,8)

70 to 140 (4,8 to 9,7) 1E395727192 Black Stripe 0.281 (7,14) 1.94 (49,3)

25 to 75 (1,7 to 5,2) 1E399027142 Black 0.343 (8,71) 4.00 (102)

70 to 140 (4,8 to 9,7) 1E399127162 Red 0.406 (10,3) 4.00 (102)

PART NUMBER COLOR CODE

WIRE DIAMETER,

INCHES (mm)

FREE LENGTH,

INCHES (mm)

Table 3. Capacities

PROPANE RELIEF CAPACITY IN GALLONS PER MINUTE (l/min)

RELIEF PRESSURE

SETTING, PSIG (bar)

98H-13 50 (3,4) 25 to 75 (1,7 to 5,2) 10.5 (39,7) 15.4 (58,3) 21.7 (82,1) 25.9 (98,0) 30.8 (117)

98H-14 100 (6,9) 70 to 140 (4,8 to 9,7) 8.4 (31,8) 15.4 (58,3) 27.3 (103) 32.9 (125) 39.2 (148)

98H-22 100 (6,9) 70 to 140 (4,8 to 9,7) 30.8 (117) 49 (185) 67.9 (257) 79.8 (302) 93.1 (352)

98H-30 100 (6,9) 70 to 140 (4,8 to 9,7) 30.8 (117) 49 (185) 67.9 (257) 79.8 (302) 93.1 (352)

RELIEF PRESSURE

RANGE, PSIG (bar)

5 Psig

(0,34 bar)

AT FOLLOWING PRESSURE BUILD-UP OVER RELIEF SETTING

10 Psig

(0,69 bar)

20 Psig

(1,4 bar)

30 Psig

(2,1 bar)

50 Psig

(3,4 bar)

17

Page 28

Re g u l a t o R s

98H Series Backpressure Regulators/Relief Valves

D

1/4-INCH NPT

C

NPT

B

A/2

A

B2557

Figure 3. Dimensions

Table 4. Dimensions and Approximate Weights

TYPE

NUMBER

98H

BODY SIZE,

INCHES

1/2

3/4 or 1

A B

4.25 (108)

5.00 (127)

DIMENSIONS, INCHES (mm)

0.88 (22)

1.25 (32)

C

(Maximum)

7.19 (183)

9.69 (246)

D

4.25 (108)

6.06 (154)

Ordering Guide

Ordering Information

TYPE NUMBER BODY SIZE AND END CONNECTION STYLE RELIEF PRESSURE RANGE, PSIG (bar) DIAPHRAGM MATERIAL

98H-13

98H-14 70 to 140 (4,8 to 9,7)

98H-17 25 to 75 (1,7 to 5,2)

98H-18 70 to 140 (4,8 to 9,7)

98H-22 3/4-inch FNPT 70 to 140 (4,8 to 9,7)

98H-31 130 to 200 (9,0 to 13,8)

1/2-inch FNPT

1-inch FNPT

25 to 75 (1,7 to 5,2)

70 to 140 (4,8 to 9,7)

Neoprene (CR)

302 Stainless steel

Neoprene (CR)98H-30

APPROXIMATE

WEIGHTS,

POUNDS (kg)

7 (3,18)

16 (7,26)

18

To order, refer to the Ordering Information table above and specify the type number that satises your requirement.

Then, contact or visit your local LP-Gas Equipment Distributor for availability.

Page 29

99 Series Commercial/Industrial Regulators

Re g u l a t o R s

Introduction

The 99 Series commercial/industrial

regulator is a pilot-operated unit that keeps

outlet pressure constant despite varying

ow rates and inlet pressures. It can

be used for either low or high-pressure

applications while maintaining accuracy.

Ease of maintenance is only one of the

many features of the 99 Series. The

actuator diaphragm and pilot respond

simultaneously to control nal positioning

of the main valve, permitting full main

valve travel and higher capacity capabilities.

Body Size and End Connection Style

2-inch threaded NPT

Maximum Inlet Pressures

See Table 3

Features

• Versatility

• BodySideConnection

• EasyMaintenance

• HighCapacityPressureControl

• RuggedConstruction

Maximum Outlet (Casing) Pressure

100 psig (6,9 bar)

Outlet Pressure Ranges

See Table 2

Maximum Actuator Pressures

Operating: 100 psig (6,9 bar)

Emergency: 110 psig (7,6 bar)

Orifice Size

7/8 or 1-1/8-inch (22,2 or 28,6 mm)

Temperature Capabilities

-20° to 180°F (-29° to 82°C)

Pressure Registration

External

Approximate Weight

115 pounds (52 kg)

Additional Technical Data

For more technical information,

contact your local LP-Gas

Equipment Distributor or log on to:

www.emersonprocess.com/regulators/lp

W2676

Figure 1. 99 Series Commercial/Industrial Regulator

Table 1. Construction Materials

BODY

Cast iron Cast iron

SPRING CASE AND

DIAPHRAGM CASE

DIAPHRAGMS AND MAIN

VALVE SEAT DISK

Nitrile (NBR), Neoprene,

and Nylon

MAIN VALVE TRIM PILOT TRIM TUBING AND FITTINGS

Brass

Steel, Stainless steel,

Cast iron, Aluminum, Zinc,

or Brass

Table 2. Outlet Pressure Ranges

PILOT TYPE

(1)

61LD

(2)

61LE

61HP 600 (41) 35 to 100 (2,4 to 6,9) 1D387227022 Blue 0.200 (0,51) 1.69 (4,3)

1. Type 61LD construction has narrower proportional band than does the standard Type 61L Pilot.

2. Type 61LE construction has broader proportional band than does the standard Type 61L Pilot.

MAXIMUM PILOT

SUPPLY PRESSURE,

PSIG (bar)

160 (11,0)

400 (27,6)

OUTLET (CONTROL)

PRESSURE RANGES,

PSIG (bar)

0.25 to 2

(17 to 138 mbar)

1 to 5

(69 mbar to 0,3 bar)

2 to 10

(138 mbar to 0,7 bar)

5 to 15

(0,3 to 1,0)

10 to 20

(0,7 to 1,4)

Part Number Color Code

1B886327022

1J857827022

1B886427022

1J857927142

1B886527022

PILOT CONTROL SPRING

Wire Diameter,

Inches (cm)

Red

Yellow

Blue

Brown

Green

0.109

0.142

0.172

0.187

0.363

(0,28)

(0,36)

(0,44)

(0,48)

(0,92)

Copper and Brass

Free Length,

Inches (cm)

2.75

(7,0)

2.75

(7,0)

2.87

(7,3)

2.87

(7,3)

3.12

(7,9)

19

Page 30

99 Series Commercial/Industrial Regulators

20

Re g u l a t o R s

Type 99

INWLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

A6469

Figure 2. Operational Schematic

Table 3. Selected Capacities

PILOT TYPE TYPE NUMBER SPRING RANGE, PSIG (bar)

99-501P 0.25 to 2 (0,02 to 0,14)

Low Pressure

High Pressure

1. Capacity based on inlet pressure 20 psig (1,4 bar) greater than outlet pressure and 20% droop.

2. Metric conversion is based on 2516 BTU/ft3 of gas at 60°F (16°C).

99-502P 1 to 5 (0,07 to 0,34) 50 600 000 (570)

99-503P 2 to 10 (0,14 to 0,69) 61 650 000 (694)

99-504P 5 to 15 (0,34 to 1,0) 63 250 000 (712)

99-510P 0.25 to 2 (0,02 to 0,14)

99-511P 1 to 5 (0,07 to 0,34) 33 206 000 (374)

99-512P 5 to 15 (0,34 to 1,0) 37 950 000 (427)

99-513P 2 to 10 (0,14 to 0,69) 36 368 000 (409)

99-515P 10 to 20 (0,69 to 1,4) 41 112 000 (463)

99-903P 10 to 65 (0,69 to 4,5) 44 275 000 (498)

99-502PH 1 to 5 (0,07 to 0,34)

99-503PH 2 to 10 (0,14 to 0,69) 61 668 000 (694)

99-504PH 5 to 15 (0,34 to 1,0) 63 250 000 (712)

99-505PH 10 to 20 (0,69 to 1,4) 67 993 000 (765)

99-901PH 10 to 65 (0,69 to 4,5) 74 318 000 (837)

ORIFICE SIZE,

INCHES (mm)

1-1/8 (29) 150 (10,3)

7/8 (22) 250 (17,2)

1-1/8 (29) 300 (20,7)

MAXIMUM INLET

PRESSURE,

(1)(2)

PSIG (bar)

CAPACITIES IN PROPANE,

BTU/hr (SCMH)

49 000 000 (552)

29 400 000 (331)

50 600 000 (570)

Page 31

99 Series Commercial/Industrial Regulators

21

Re g u l a t o R s

9.75

(248)

15.25

(387)

MAXIMUM

6.12

(155)

1.44 (37)

RAINPROOF VENT

1/4-INCH NPT

19.25

(489)

13.12

(333)

21.12

(536)

5.25

(133)

Figure 3. Dimensions

1/2-INCH NPT ALTERNATIVE

PLUGGED CONTROL

CONNECTION

10.4

(264)

1/2-INCH NPT

CONTROL CONNECTION

3.03

(77)

6.06

(154)

12.25

(311)

INCHES

(mm)

Regulator Tip

All regulators should be installed and used in accordance with federal, state, and local codes and regulations.

Page 32

Re g u l a t o R s

99 Series Commercial/Industrial Regulators

Ordering Guide

Ordering Information

TYPE NUMBER

99-501P

99-501PM Monitor Regulator

99-502P Regulator

99-502PM Monitor Regulator

99-502PH Regulator

99-502PHM Monitor Regulator

99-502PHO Regulator

99-502PHOM Monitor Regulator

99-503P Regulator

99-503PM Monitor Regulator

99-503PH Regulator

99-503PHM Monitor Regulator

99-503PHO Regulator

99-503PHOM Monitor Regulator

99-504P Regulator

99-504PM Monitor Regulator

99-504PH Regulator

99-504PHM Monitor Regulator

99-504PHO Regulator

99-504PHOM Monitor Regulator

99-505P Regulator

99-505PM Monitor Regulator

99-505PH Regulator

99-505PHM Monitor Regulator

99-505PHO Regulator

99-505PHOM Monitor Regulator

99-510P Regulator

99-510PM Monitor Regulator

99-511P Regulator

99-511PM Monitor Regulator

99-512P Regulator

99-512PM Monitor Regulator

99-513P Regulator

99-513PM Monitor Regulator

99-515P Regulator

99-515PM Monitor Regulator

99-901P Regulator

99-901PM Monitor Regulator

99-901PH Regulator

99-901PHM Monitor Regulator

99-901PHO Regulator

99-901PHOM Monitor Regulator

99-903P Regulator

99-903PM Monitor Regulator

99-924 Regulator

99-924PM Monitor Regulator

99-926 Regulator

99-926PM Monitor Regulator

99-926PH Regulator

99-926PHM Monitor Regulator

99-926PHO Regulator

99-926PHOM Monitor Regulator

Note: Contact your local LP-Gas Equipment Distributor for information on use of the 99 Series in monitor regulator applications.

END CONNECTION

SIZES AND STYLE

2-inch FNPT

APPLICATION SPRING RANGE, PSIG (bar)

Regulator

0.25 to 2 (17 mbar to 0,1 bar)

1 to 5 (69 mbar to 0,3 bar)

2 to 10 (138 mbar to 0,7 bar)

5 to 15 (0,3 to 1,0)

10 to 20 (0,7 to 1,4)

0.25 to 2 (17 mbar to 0,1 bar)

1 to 5 (69 mbar to 0,3 bar)

2 to 10 (138 mbar to 0,7 bar)

5 to 15 (0,3 to 1,0)

10 to 20 (0,7 to 1,4)

35 to 100 (2,4 to 6,9)

ORIFICE SIZE,

INCHES (mm)

1-1/8 (28,6)

7/8 (22,2)

1-1/8 (28,6)

7/8 (22,2)

1-1/8 (28,6)

MAXIMUM INLET

PRESSURE, PSIG (bar)

150 (10,3)

300 (20,7)

250 (17,2)

150 (10,3)

300 (20,7)

250 (17,2)

150 (10,3)

300 (20,7)

250 (17,2)

150 (10,3)

300 (20,7)

250 (17,2)

150 (10,3)

300 (20,7)

250 (17,2)

150 (10,3)

300 (20,7)

250 (17,2)

22

To order, refer to the Ordering Information table above and specify the type number that satises your requirement.

Then, contact or visit your local LP-Gas Equipment Distributor for availability.

Page 33

Type 289H Backpressure Regulator/Relief Valve

Re g u l a t o R s

Introduction

Available for settings between 0.5 to

2.25 psig (34 to 155 mbar), the 289 Series

relief valve is a throttling relief valve used