Page 1

PN: 52413:B ECN 07-494

Addressable Fire Alarm Control Panel

MS-9050UD

IMPORTANT! The SLC Manual Document #51309 must be referenced in addition to this

manual when installing or servicing the Fire Alarm Control Panel.

Document #52413

8/29/07 Revision:

B

Page 2

Fire Alarm System Limitations

While a fire alarm system may lower insurance

rates, it is not a substitute for fire insurance!

An automatic fire alarm system–typically made up of

smoke detectors, heat detectors, manual pull stations,

audible warning devices, and a fire alarm control panel with

remote notification capability–can provide early warning of a

developing fire. Such a system, however, does not assure

protection against property damage or loss of life resulting

from a fire.

The Manufacturer recommends that smoke and/or heat

detectors be located throughout a protected premise following the recommendations of the current edition of the

National Fire Protection Association Standard 72 (NFPA 72),

manufacturer's recommendations, State and local codes,

and the recommendations contained in the Guides for

Proper Use of System Smoke Detectors, which are made

available at no charge to all installing dealers. These documents can be found at http:/www.systemsensor.com/html/

applicat.html. A study by the Federal Emergency Management Agency (an agency of the United States government)

indicated that smoke detectors may not go off in as many as

35% of all fires. While fire alarm

systems are designed to provide early warning against fire,

they do not guarantee warning or protection against fire. A

fire alarm system may not provide timely or adequate

warning, or simply may not function, for a variety of reasons:

Smoke detectors may not sense fire where smoke cannot

reach the detectors such as in chimneys, in or behind walls,

on roofs, or on the other side of closed doors. Smoke

detectors also may not sense a fire on another level or floor

of a building. A second-floor detector, for example, may not

sense a first-floor or basement fire.

Particles of combustion or "smoke" from a developing fire

may not reach the sensing chambers of smoke detectors

because:

• Barriers such as closed or partially closed doors, walls, or

chimneys may inhibit particle or smoke flow.

• Smoke particles may become "cold," stratify, and not

reach the ceiling or upper walls where detectors are

located.

• Smoke particles may be blown away from detectors by air

outlets.

• Smoke particles may be drawn into air returns before

reaching the detector.

The amount of "smoke" present may be insufficient to alarm

smoke detectors. Smoke detectors are designed to alarm

at various levels of smoke density. If such density levels are

not created by a developing fire at the location of detectors,

the detectors will not go into alarm.

Smoke detectors, even when working properly, have sensing limitations. Detectors that have photoelectronic sensing

chambers tend to detect smoldering fires better than flaming fires, which have little visible smoke. Detectors that have

ionizing-type sensing chambers tend to detect fast-flaming

fires better than smoldering fires. Because fires develop in

different ways and are often unpredictable in their growth,

neither type of detector is necessarily best and a given type

of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate

warning of fires caused by arson, children playing with

matches (especially in bedrooms), smoking in bed, and

violent explosions (caused by escaping gas, improper stor-

age of flammable materials, etc.).

Heat detectors do not sense particles of combustion and

alarm only when heat on their sensors increases at a

predetermined rate or reaches a predetermined level.

Rate-of-rise heat detectors may be subject to reduced

sensitivity over time. For this reason, the rate-of-rise

feature of each detector should be tested at least once

per year by a qualified fire protection specialist. Heat

detectors are designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the

same room as the control panel and in rooms used by

the system for the connection of alarm transmission

wiring, communications, signaling, and/or power. If

detectors are not so located, a developing fire may

damage the alarm system, crippling its ability to report

a fire.

Audible warning devices such as bells may not alert

people if these devices are located on the other side of

closed or partly open doors or are located on another

floor of a building. Any warning device may fail to alert

people with a disability or those who have recently consumed drugs, alcohol or medication. Please note that:

• Strobes can, under certain circumstances, cause

seizures in people with conditions such as epilepsy.

• Studies have shown that certain people, even when

they hear a fire alarm signal, do not respond or comprehend the meaning of the signal. It is the property

owner's responsibility to conduct fire drills and other

training exercise to make people aware of fire alarm

signals and instruct them on the proper reaction to

alarm signals.

• In rare instances, the sounding of a warning device

can cause temporary or permanent hearing loss.

A fire alarm system will not operate without any

electrical power. If AC power fails, the system will

operate from standby batteries only for a specified time

and only if the batteries have been properly maintained

and replaced regularly.

Equipment used in the system may not be technically

compatible with the control. It is essential to use only

equipment listed for service with your control panel.

Telephone lines needed to transmit alarm signals from

a premise to a central monitoring station may be out of

service or temporarily disabled. For added protection

against telephone line failure, backup radio transmission systems are recommended.

The most common cause of fire alarm malfunction is

inadequate maintenance. To keep the entire fire alarm

system in excellent working order, ongoing maintenance

is required per the manufacturer's recommendations,

and UL and NFPA standards. At a minimum, the requirements of NFPA 72 shall be followed. Environments with

large amounts of dust, dirt or high air velocity require

more frequent maintenance. A maintenance agreement

should be arranged through the local manufacturer's

representative. Maintenance should be scheduled

monthly or as required by National and/or local fire codes

and should be performed by authorized professional fire

alarm installers only. Adequate written records of all

inspections should be kept.

PrecauLarge.PMD 02/26/2007

Page 3

Installation Precautions

Adherence to the following will aid in problem-free

installation with long-term reliability:

WARNING - Several different sources of power can be

connected to the fire alarm control panel. Disconnect all

sources of power before servicing. Control unit and associated equipment may be damaged by removing and/or

inserting cards, modules, or interconnecting cables while

the unit is energized. Do not attempt to install, service, or

operate this unit until this manual is read and understood.

CAUTION - System Reacceptance Test after Software

Changes. To ensure proper system operation, this product

must be tested in accordance with NFPA 72 after any

programming operation or change in site-specific software.

Reacceptance testing is required after any change,

addition or deletion of system components, or after any

modification, repair or adjustment to system hardware or

wiring.

All components, circuits, system operations, or software

functions known to be affected by a change must be 100%

tested. In addition, to ensure that other operations are not

inadvertently affected, at least 10% of initiating devices that

are not directly affected by the change, up to a maximum of

50 devices, must also be tested and proper system

operation verified.

This system meets NFPA requirements for indoor dry

operation at 0-49° C/32-120° F

93 ±2% RH (non-condensing) at 32 ±2° C/90 ±3° F.

However, the useful life of the system's standby batteries

and the electronic components may be adversely affected

by extreme temperature ranges and humidity. Therefore, it

is recommended that this system and all peripherals be

installed in an environment with a nominal room temperature of 15-27° C/60-80° F.

Verify that wire sizes are adequate for all initiating and

indicating device loops. Refer to manual Specifications

section for maximum allowable I.R. drop from the specified

device voltage.

and at a relative humidity of

Like all solid state electronic devices, this system may

operate erratically or can be damaged when subjected to

lightning-induced transients. Although no system is

completely immune from lightning transients and

interferences, proper grounding will reduce susceptibility.

Overhead or outside aerial wiring is not recommended, due

to an increased susceptibility to nearby lightning strikes.

Consult with the Technical Services Department if any

problems are anticipated or encountered.

Disconnect AC power and batteries prior to removing or

inserting circuit boards. Failure to do so can damage

circuits.

Remove all electronic assemblies prior to any drilling,

filing, reaming, or punching of the enclosure. When

possible, make all cable entries from the sides or rear.

Before making modifications, verify that they will not

interfere with battery, transformer, and printed circuit board

location.

Do not tighten screw terminals more than 9 in-lbs.

Over-tightening may damage threads, resulting in reduced

terminal contact pressure and difficulty with screw terminal

removal.

This system contains static-sensitive components.

Always ground yourself with a proper wrist strap before

handling any circuits so that static charges are removed

from the body. Use static-suppressive packaging to

protect electronic assemblies removed from the unit.

Follow the instructions in the installation, operating, and

programming manuals. These instructions must be

followed to avoid damage to the control panel and

associated equipment. FACP operation and reliability

depend upon proper installation by authorized personnel.

FCC Warning

WARNING: This equipment generates, uses, and can

radiate radio frequency energy and if not installed and

used in accordance with the instruction manual, may

cause interference to radio communications. It has

been tested and found to comply with the limits for class

A computing device pursuant to Subpart B of Part 15 of

FCC Rules, which is designed to provide reasonable

protection against such interference when operated in a

commercial environment. Operation of this equipment

in a residential area is likely to cause interference, in

which case the user will be required to correct the

interference at their own expense.

PrecauLarge.PMD 02/26/2007

Canadian Requirements

This digital apparatus does not exceed the Class A

limits for radiation noise emissions from digital

apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits

radioelectriques depassant les limites applicables aux

appareils numeriques de la classe A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par

le ministere des Communications du Canada.

Page 4

Table of Contents

Table of Content s

SECTION 1: Product Description .........................................................................................................................12

1.1: Features and Options...................................................................................................................................12

1.2: Specifications ..............................................................................................................................................13

1.2.1: Current Availability...........................................................................................................................14

1.3: Controls and Indicators........................................................................................... .....................................14

1.4: Circuits ........................................................................................................................................................15

1.5: Digital Alarm Communicator/Transmitter..................................................................................................16

1.6: Components.................................................................................................................................................17

1.6.1: Intelligent Addressable Detectors: Newer Series..............................................................................17

1.6.2: Intelligent Addressable Modules: Newer Series............................................................. ..................17

1.6.3: 300 Series Intelligent Addressable Devices......................................................................................17

1.6.4: Device Accessories ...........................................................................................................................17

1.7: Optional Modules........................................................................................................................................18

1.8: Accessories..................................................................................................................................................18

1.8.1: PK-CD Programming Utility ............................................................................................................18

1.8.2: Dress Panel........................................................................................................................................18

1.8.3: Trim Ring..........................................................................................................................................18

1.9: ANN-BUS Devices .....................................................................................................................................19

1.9.1: ANN-BUS Wiring.............................................................................................................................19

1.9.1.1 Calculating Wiring Distance for ANN-BUS Modules ............................................................ 19

1.9.1.2 Wiring Configuration ..............................................................................................................21

1.9.1.3 Powering ANN-BUS Devices from Auxiliary Power Supply ................................................22

1.9.2: ANN-BUS Device Addressing..........................................................................................................22

1.9.3: ANN-80 Remote Fire Annunciator...................................................................................................23

1.9.3.1 Specifications ....................................................................................... ...................................23

1.9.3.2 Installation ................................................................................. ..............................................23

1.9.3.3 Mounting .......................................................................................................... .......................23

1.9.3.4 Opening/Closing Annunciator .......................................................................................... ......23

1.9.3.5 Wiring ANN-80 to FACP ................................................................................... ....................24

1.9.4: ANN-S/PG Serial/Parallel Interface Module....................................................................................26

1.9.4.1 Specifications ....................................................................................... ...................................26

1.9.4.2 PRN 6 Printer Installation .......................................................................................................26

1.9.4.2.1 Connecting PRN 6 Printer ....................................................................................................27

1.9.4.2.2 Setting Printer Options .........................................................................................................27

1.9.5: ANN-I/O LED Driver Module..........................................................................................................28

1.9.5.1 ANN-I/O Board Layout ................................................................................ ..........................28

1.9.5.2 Specifications ....................................................................................... ...................................28

1.9.5.3 ANN-I/O Connection to FACP ...............................................................................................29

1.9.5.4 ANN-I/O Module LED Wiring ...............................................................................................30

1.9.6: ANN-LED Annunciator Module.......................................................................................................31

1.9.6.1 ANN-LED Board Layout ........................................................................................................31

1.9.6.2 Specifications ....................................................................................... ...................................31

1.9.6.3 ANN-LED Connection to FACP ............................................................................................32

1.9.7: ANN-RLY Relay Module..................................................................................................................33

1.9.7.1 ANN-RLY Board Layout ........................................................................................................33

1.9.7.2 Specifications ....................................................................................... ...................................33

1.9.7.3 Mounting/Installation .......................................... ..................................................... ............... 33

1.9.7.4 ANN-RLY Connection to FACP ............................................................................................34

1.10: Getting Started...........................................................................................................................................34

1.11: Telephone Requirements and Warnings....................................................................................................35

1.11.1: Telephone Circuitry.........................................................................................................................35

1.11.2: Digital Communicator.....................................................................................................................35

1.11.3: Telephone Company Rights and Warnings .....................................................................................36

1.11.4: For Canadian Applications..............................................................................................................37

SECTION 2: Installation ........................................................................................................................................38

4

MS-9050UD P/N: 52413:B 8/29/07

Page 5

Table of Contents

2.1: Mounting Backbox............................................... ...................................................... ................................. 38

2.2: Mounting Chassis/Transformer/Main Circuit Board...................................................................................39

2.3: Power...........................................................................................................................................................42

2.3.1: AC Power and Earth Ground Connection.........................................................................................42

2.3.2: Battery Power....................................................................................................................................42

2.4: Relays.............................................................................................................. ............................................43

2.5: Notification Appliance Circuits ..................................................................................................................43

2.5.1: Configuring NACs........................................................................................... .................................44

2.6: UL Power-limited Wiring Requirements....................................................................................................45

2.7: Digital Communicator.................................................................................................................................46

2.8: Optional Modules/Accessories Installation.................................................................................................47

2.8.1: 4XTMF Transmitter Module Installation..........................................................................................47

SECTION 3: Programming ..................................................................................................... ..............................50

3.1: Programming Data Entry ............................................................................................................................50

3.2: User Programming ............................ ..................................................... .....................................................51

3.3: Initial Power-up...................................................................................... .....................................................52

3.4: Programming Screens Description..............................................................................................................52

3.5: Programming and Passwords ......................................................................................................................52

3.6: Master Programming Level............................................................ .............................................................54

3.6.1: Autoprogram......................................... ..................................................... .......................................55

3.6.2: Point Program........................................................................................ ............................................56

3.6.2.1 Detector Programming ............................................................................................................56

3.6.2.1.1 Add Detector ........................................................................................................................56

3.6.2.1.2 Delete Detector ....................................................................................................................57

3.6.2.1.3 Edit Detector ........................................................................................................................57

3.6.2.2 Module Programming .............................................................................................................66

3.6.2.2.1 Add Module .........................................................................................................................66

3.6.2.2.2 Delete Module ......................................................................................................................67

3.6.2.2.3 Edit Module Screen for Monitor Module ............................................................................67

3.6.2.2.4 Edit Module Screen for Control Modules ............................................................................76

3.6.3: Zone Setup ........................................................................................................................................83

3.6.3.1 Enable ......................................................................................................................................83

3.6.3.2 Disable ....................................................................................................................................84

3.6.3.3 Zone 17, 18 and 19 ..................................................................................................................84

3.6.3.4 Zones Installed ........................................................................................................................85

3.6.3.5 Zones Enabled .........................................................................................................................85

3.6.3.6 Zones Disabled ........................................................................................................................85

3.6.3.7 Zone Type ...............................................................................................................................85

3.6.3.8 Zones Available ......................................................................................................................87

3.6.4: Loop Setup...................................... ...................................................... ............................................87

3.6.4.1 Style ........................................................................................................................................87

3.6.4.2 Loop Protocol .........................................................................................................

.................87

3.6.5: System Setup................................ ...................................................... ...............................................88

3.6.5.1 Trouble Reminder ...................................................................................................................89

3.6.5.2 Banner .....................................................................................................................................89

3.6.5.3 Time-Date ...............................................................................................................................90

3.6.5.3.1 Time .....................................................................................................................................90

3.6.5.3.2 Date ......................................................................................................................................91

3.6.5.3.3 Clock Format ........................................................................................................................91

3.6.5.3.4 Daylight Savings Time .........................................................................................................91

3.6.5.4 Timers .....................................................................................................................................92

3.6.5.4.1 PAS (Positive Alarm Sequence) Delay ................................................................................92

3.6.5.4.2 Pre-signal Delay ...................................................................................................................93

3.6.5.4.3 Waterflow Delay ..................................................................................................................93

3.6.5.4.4 AC Loss Delay .....................................................................................................................94

MS-9050UD P/N: 52413:B 8/29/07 5

Page 6

Table of Contents

3.6.5.5 NAC (Notification Appliance Circuit) ....................................................................................94

3.6.5.5.1 Enabled ....................................................................................................... ..........................95

3.6.5.5.2 Type ........................................................................................ ..............................................96

3.6.5.5.3 Silenceable ...........................................................................................................................96

3.6.5.5.4 Auto Silence .........................................................................................................................97

3.6.5.5.5 Coding (only for NACs not programmed as Sync Strobe Type) .........................................97

3.6.5.5.6 Zone ........................................................................................ ..............................................99

3.6.5.5.7 Silence Inhibited ......................................................................................... ..........................99

3.6.5.5.8 Sync Type ..................................... ........................................................................................99

3.6.5.6 Relays .............................................................................................. ........................................100

3.6.5.7 Canadian Option ............................................................................................ ..........................101

3.6.5.8 Waterflow Silenceable ............................................................................................................101

3.6.6: Verify Loop .......................................................................................................................................101

3.6.7: History...............................................................................................................................................102

3.6.7.1 View Events ........................................................................................................ ....................102

3.6.7.2 Erase History ........................................................................................... ................................102

3.6.8: Walktest.............................................................................................................................................103

3.6.9: Option Modules................................................................................................................................104

3.6.9.1 ANN-BUS ........................................................................................................... ....................104

3.6.9.1.1 ANN-BUS Enabled ............................................................................................ ..................104

3.6.9.1.2 Modules Installed .................................................. ...............................................................105

3.6.9.1.3 Auto-Configure .................................................................................................. .................. 115

3.6.9.1.4 ANN-S/PG (Print) Options Screen ......................................................................................115

3.6.9.1.5 ANN-80 Options Screen ......................................................................................................116

3.6.9.2 Onboard DACT ............................................................................................. ..........................117

3.6.9.2.1 Onboard DACT Enable ........................................................................................................117

3.6.9.2.2 Primary Phone ............................................................................................... .......................117

3.6.9.2.3 Secondary Phone ................................................................................................ ..................118

3.6.9.2.4 Service Terminal ........................................................................................ ..........................118

3.6.9.2.5 Central Station ......................................................................................................................121

3.6.9.2.6 Trouble Call Limit (Dialer Runaway Prevention) ...............................................................122

3.6.9.2.7 Manual Dial Mode ...............................................................................................................134

3.6.10: Password Change ............................................................................................................................135

3.6.11: Clear Program..................................................................................................................................136

3.6.12: Program Check................................................................................................................................137

3.7: Maintenance Programming Level ...............................................................................................................139

3.7.1: Disable Point.....................................................................................................................................140

3.7.2: History...............................................................................................................................................141

3.7.3: Program Check..................................................................................................................................142

3.7.4: Walktest.............................................................................................................................................143

3.7.5: System...............................................................................................................................................143

3.7.6: Zone Setup.........................................................................................................................................145

SECTION 4: Operating Instructions ....................................................................................................................147

4.1: Panel Control Buttons..................................................................................................................................147

4.1.1: Acknowledge/Step.............................................................................................................................147

4.1.2: Alarm Silence....................................................................................................................................147

4.1.3: Drill/Hold 2 Sec ................................................................................................................................147

4.1.4: Reset..................................................................................................................................................147

4.2: Status Indicators and LEDs.........................................................................................................................148

4.3: Normal Operation........................................................................................................................................149

4.4: Trouble Operation........................................................................................................................................149

4.5: Alarm Operation..........................................................................................................................................151

4.6: Supervisory Operation.................................................................................................................................152

4.7: Process Monitor Operation..........................................................................................................................153

4.8: Hazard/Tornado Condition Operation .........................................................................................................153

6

MS-9050UD P/N: 52413:B 8/29/07

Page 7

Table of Contents

4.9: Medical Alert Condition Operation.............................................................................................................153

4.10: NAC Operation .........................................................................................................................................153

4.11: Programmed Zone Operation....................................................................................................................154

4.12: Disable/Enable Operation .........................................................................................................................154

4.13: Waterflow Circuits Operation ...................................................................................................................154

4.14: Detector Functions ....................................................................................................................................154

4.15: Time Functions: Real-Time Clock ............................................................................................................154

4.16: Synchronized NAC Operation ..................................................................................................................155

4.17: Coded Operation .......................................................................................................................................155

4.18: Presignal....................................................................................................................................................155

4.19: Positive Alarm Sequence ..........................................................................................................................156

4.20: Special System Timers..............................................................................................................................157

4.20.1: Silence Inhibit Timer.......................................................................................................................157

4.20.2: Autosilence Timer............................ ..................................................... ..........................................157

4.20.3: Trouble Reminder ....................................................................................................... ....................157

4.20.4: Waterflow Retard Timer..................................................................................................................157

4.20.5: Alarm Verification (None or One Minute)......................................................................................158

4.21: Walktest.....................................................................................................................................................158

4.22: Read Status................................................................................................................................................159

4.22.1: System Point ....................................... ............................................................................................160

4.22.2: Zones.......................................... ...................................................... ...............................................161

4.22.3: Power............................ ...................................................... .............................................................162

4.22.4: Trouble Reminder ....................................................................................................... ....................163

4.22.5: Timers............. ...................................................... ...........................................................................163

4.22.6: NAC ................................................................................................................................................164

4.22.7: Relays.............................. ...................................................... ..........................................................164

4.22.8: Program Check................................................................................................................................165

4.22.9: History......................................................................................................... ....................................165

4.22.10: ANN-BUS.....................................................................................................................................166

4.22.11: Phone Line.....................................................................................................................................167

4.22.12: Central Station...............................................................................................................................167

4.22.13: Service Terminal ...........................................................................................................................168

4.22.14: Print...............................................................................................................................................169

4.22.15: Time-Date......................................................................................................................................171

SECTION 5: Central Station Communications ..................................................................................................172

5.1: Transmittal Priorities.................................... ..................................................... ..........................................175

SECTION 6: Local/Remote Site Upload/Download ............................................................................................177

6.1: Remote Download.................................. ...................................................... ...............................................177

6.2: Transferring a Program........................... .....................................................................................................178

6.3: Security Features.........................................................................................................................................179

SECTION 7: Power Supply Calculations .............................................................................................................180

7.1: Overview..................................... ...................................................... ..........................................................180

7.2: Calculating the AC Branch Circuit .............................................................................................................180

7.3: Calculating the System Current Draw............................................................. ............................................181

7.3.1: Overview............................................... ..................................................... .......................................181

7.3.2: How to Use Table 7.3 on page 182 to Calculate System Current Draw ...........................................181

7.4: Calculating the Battery Size..............................................................................................

..........................183

7.4.1: NFPA Battery Requirements................................................ .............................................................183

7.4.2: Selecting and Locating Batteries.......................................................................................................183

APPENDIX A: Software Zones ............................................................................................................................184

A.1: Correlations ...............................................................................................................................................184

APPENDIX B: Default Programming .................................................................................................................189

APPENDIX C: NFPA Standard-Specific Requirements ...................................................................................190

MS-9050UD P/N: 52413:B 8/29/07 7

Page 8

Table of Contents

C.1: Central Station/Remote Station Transmitter:

Connection to FACP Dry Contacts ...........................................................................................................194

C.2: MBT-1 Municipal Box Trip - Silenceable .................................................................................................195

APPENDIX D: FACP with Keltron .....................................................................................................................196

APPENDIX E: Wire Requirements .................................................................................. ...................................197

APPENDIX F: HVAC Control ........................................................................................ .....................................198

F.1: Control Module Operation .........................................................................................................................198

F.1.1: HVAC SHUTDN .............................................................................................................................198

F.2: Monitor Module Operation ........................................................................................................................198

F.2.1: HVAC RESTART ............................................................................................................................198

F.2.2: HVAC OVRRIDE ............................................................................................................................199

APPENDIX G: Ademco Contact ID Format

Event Code Descriptions ...............................................................................................................200

G.1: Transmission Format Between DACT and Receiver ................................................................................200

G.2: Ademco Contact ID Typical Printout ........................................................................................................200

8

MS-9050UD P/N: 52413:B 8/29/07

Page 9

It is imperative that the installer understand the requirements of the Authority Having Jurisdiction

(AHJ) and be familiar with the standards set forth by the following regulatory agencies:

• Underwriters Laboratories Standards

• NFPA 72 National Fire Alarm Code

• CAN/ULC - S527-99 Standard for Control Units for Fire Alarm Systems

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

NFPA 72 National Fire Alarm Code

NFPA 70 National Electrical Code

Underwriters Laboratories Documents:

UL 38 Manually Actuated Signaling Boxes

UL 217 Smoke Detectors, Single and Multiple Station

UL 228 Door Closers–Holders for Fire Protective Signaling Systems

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 268A Smoke Detectors for Duct Applications

UL 346 Waterflow Indicators for Fire Protective Signaling Systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1610 Central Station Burglar Alarm Units

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for Hearing Impaired

UL 2017 General-Purpose Signaling Devices and System

CAN/ULC - S524-01 Standard for Installation of Fire Alarm Systems

Other:

EIA-232E Serial Interface Standard

EIA-485 Serial Interface Standard

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction (LAHJ)

Fire-Lite Documents:

Fire-Lite Device Compatibility Document #15384

SLC Wiring Manual Document #51309

This product has been certified to comply with the requirements in the Standard for Control Units and Accessories for Fire

Alarm Systems, UL 864, 9th Edition. Operation of this product with products not tested for UL 864, 9th Edition has not

been evaluated. Such operation requires the approval of the local Authority Having Jurisdiction (AHJ).

MS-9050UD PN 52413:B 8/29/07 9

Page 10

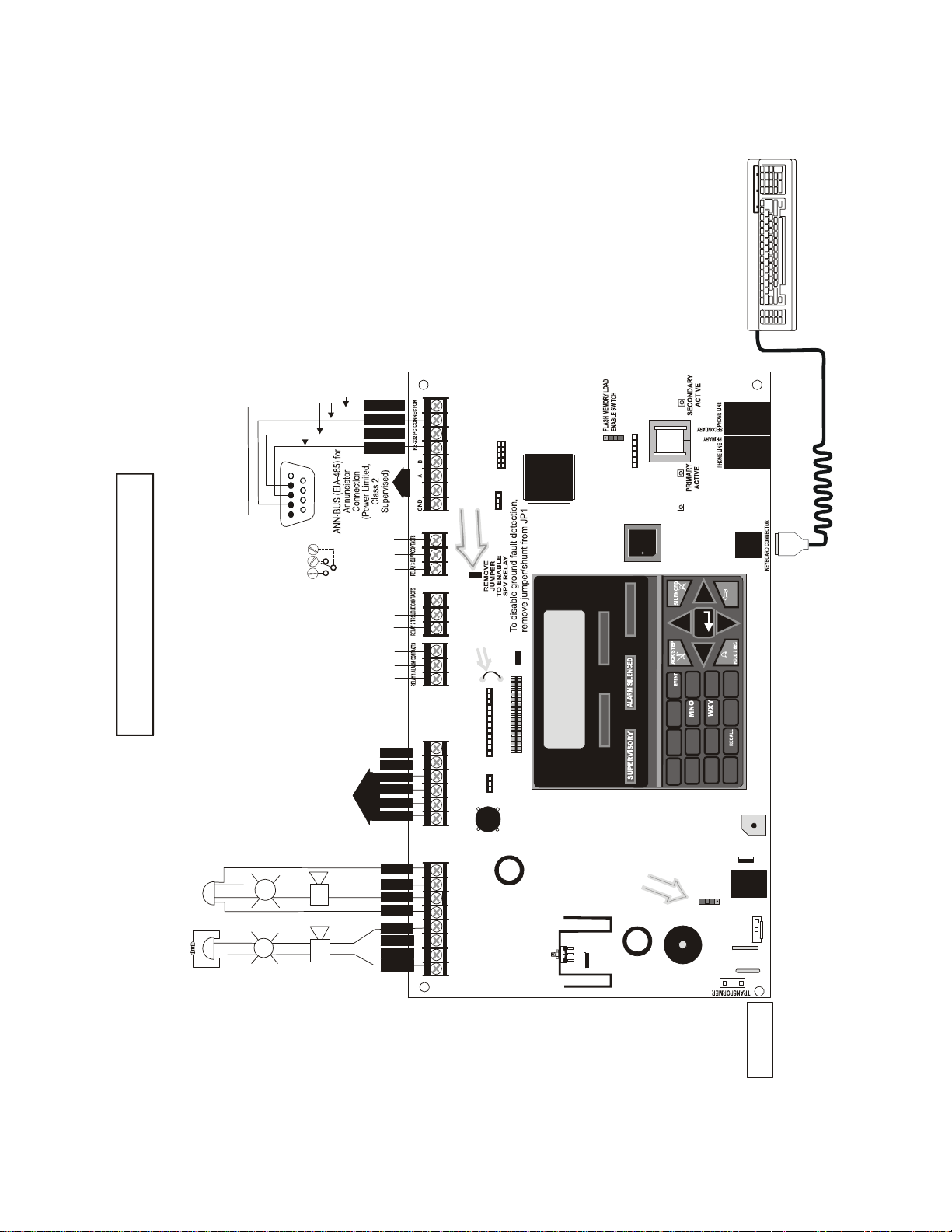

9050udlayo90.cdr

Black

Red

Green

EIA-232 to

personal computer

2 Programmable Relays &

White

(Nonsupervised,

Upload/Download Utility.

personal computer with FACP

Power-limited (Class 2) Circuit)

50 foot maximum within same room.

1 Fixed Trouble Relay

Nonsupervised Contact Ratings:

2.0 amps @ 30 VDC (resistive)

0.5 amps @ 30 VAC (resistive)

Conta c ts shown below in normal

9 8 7 6

DB9F

5 4 3 2 1

NC NO C

A Fail Safe Trouble

relay switches to the

NO position du r i n g

trouble co nd itions and

conditi on (AC power with no al ar m ,

trouble or supervisory activity).

under loss of all power.

(* )Factory default relay programming

N

G

DTR

X

M

R

C

Supervisory*

Alarm* Trouble

8

D

7

6

T

5

V

RCV XMT DTR GND

PWR

ANN-BUS

C

NC

NO NC C

NONC

NO

NC NO C

NC

CC

NO NC C

NO

J5

J4

Remove this jumper to enable

Supervisory relay wh en

4XTMF module is installed

TB7 TB3

JP2

TB6

Cut JP28 to

supervise

4XTMF

JP1

JP28

TB5

J11

SW1

TROUBLE

FIRE ALARM

Basic System Connections

6

BA

AB

5

A

SHIELD

4

A

-

3

B

-

SLC

+

2

1

B

SLC Loop

Manual for detailed

Refer to the SLC Wiring

Supervised Ci rcuit)

for Style 4, 6 and 7.

addressable devices

information on wiring

(Power- Limit ed, Clas s 2

+

B+ A+ B- A-

4XTMF

TB2

LCD DISPLAY

J9

J3

J8

AC POWER

KISSOFF

ALARM

ST

1

DEF

3

ABC

2

1

LED1

LED2

LED3

CLEAR

6

JKL

5

GHI

4

ENTER

DRILL

ESC

MODE

_/.

#

89

QZ_

PRS TUV

7

PH2

DACT Phone

Line Jacks

(nonpower-limited,

supervised)

PH1

J6

RESET

PS2 Keyboard Interface

0

*

B

-

78

A

+

NAC #2

+

Special Application Power

NAC #1

+

+

+

+

-

A

+

NAC2

56

B

+

4

B

-

A

-

23

A

+

NAC1

1

B

+

B+ B- B-B+A+ A- A+ A-

-

TB1

Charger Enable/Disable

Switch (shown in charger

enable position)

SW27

+

_

J1

BATTERY

Battery

24 VDC, nonpowe r - l im it e d,

supervised, 18 Amp Hour max.

J2

Notification Appliance Circuits

ELR 4.7K, ½W

2.5 amps m a x. per circuit . Tota l available current 2.5 amps.

Connector

Supervised

NAC #2 Shown Style Z (Class A) (Power-Limit ed, Class 2, Su pervised)

NAC #1 Shown Style Y (Class B) (Power-Limited, Class 2, Supervised)

For specific UL wiring

information, refer to "UL

Power-limited Wiring

Requirements" on page 45

Transformer

CAUTION!

HIGH VOLTAGE

Nonpower-limited,

10 MS-9050UD PN 52413:B 8/29/07

Page 11

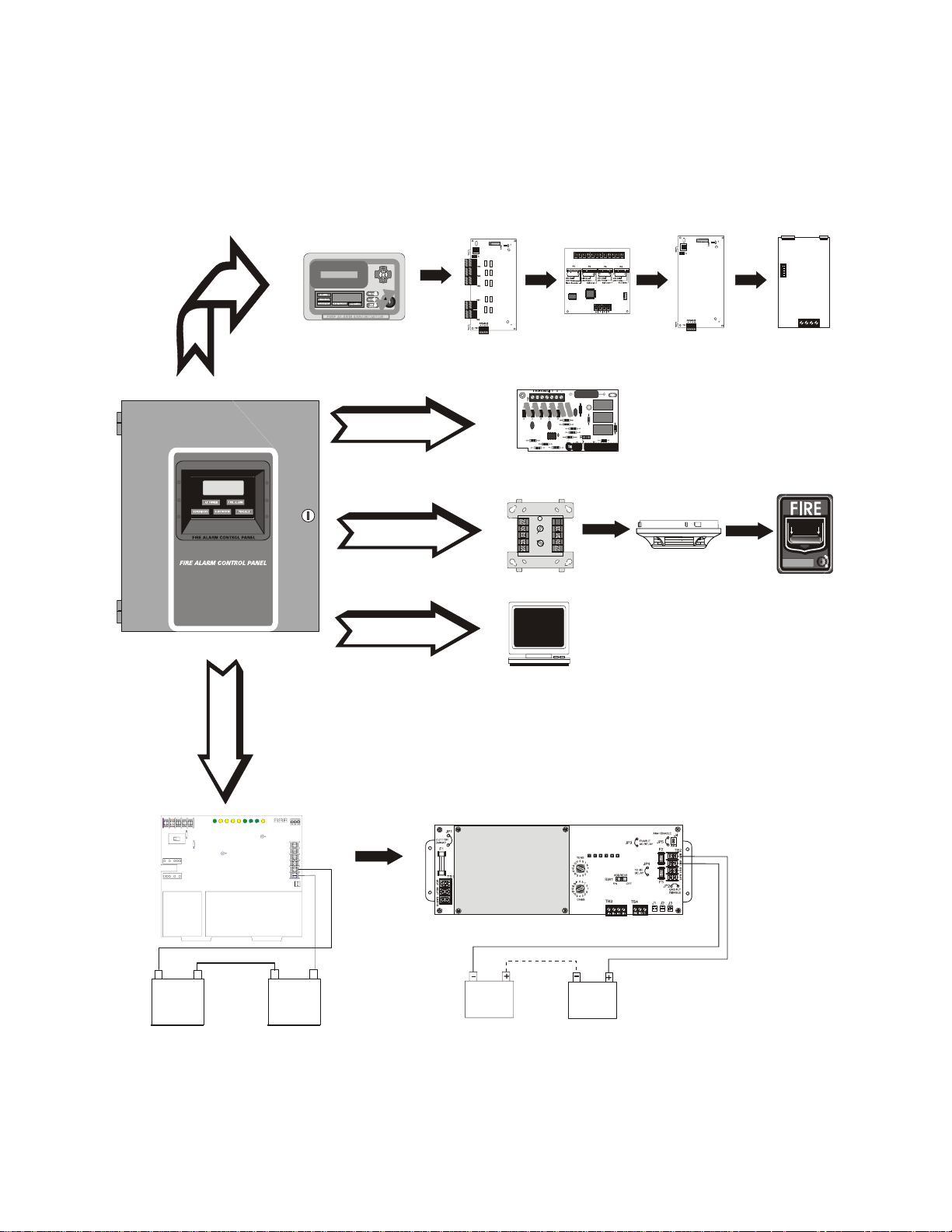

Peripheral Devices

ANN-BUS

ANN-80

Text Annunciator

Doc. #52749

SLC Loop

ANN-I/O

LED Driver

Doc. #151416

ANN-RLY

10 Form-C Relay Card

Doc. #53033

4XTMF

Municipal Box Transmitter

Addressable Devices and SLC Wiring

ANN-S/PG

Printer Driver

Doc. #151417

ANN-(R)LED

LED Display

Doc. #53032

Doc. #51309

Battery Connector

CHG-120F Charger

Doc. #50888

RS-232

Local PC

9050UDperi.cdr

CHG-75 Charger

Doc. #51315

MS-9050UD PN 52413:B 8/29/07 11

Page 12

Product Description Features and Options

SECTION 1 Product Description

The MS-9050UDis a combination FACP (Fire Alarm Control Panel) and DACT (Digital Alarm

Communicator/Transmitter) all on one circuit board. This compact, cost effective, intelligent

addressable control panel has an extensive list of powerful features. The combination of Fire-Lite’s

newer series devices and legacy 300 Series devices, along with the MS-9050UD FACP, offer the

latest in fire protection technology. The power supply and all electronics are contained on a single

circuit board housed in a metal cabinet, providing a complete fire control system for most

applications. Available accessories include local and remote upload/download software, remote

annunciators and reverse polarity/city box transmitter.

The integral DACT transmits system status (alarms, troubles, AC loss, etc.) to a Central Station via

the public switched telephone network. It also allows remote programming or interrogation of the

control panel using the PK-CD Upload/Download utility via the public switched telephone

network. Any personal computer with Windows

speed of 2400 baud or faster and Upload/Download software kit PK-CD, may serve as a Service

T erminal. This allows download of the entire program or upload of the entire program, history file,

walktest data and current status.

Inventory

When the MS-9050UD shipment is received, check to make certain that all parts have been

included in the shipment. The MS-9050UD shipment should consis t of one of each of the

following:

™

XP or newer, and compatible modem with a

main circu it board with display

chassis with transformer

backbox wit h doo r

plastic bag containing screws, cables, key, etc.

manual

1.1 Features and Options

• Built-in DACT (Digital Alarm Communicator/Transmitter) with remote upload/download

• Single addressable SLC loop which meets NFPA Style 4, 6 and 7 requirements

• 50 addressable device capacity (any combination of addressable detectors and addressable

control/relay/monitor modules totalling 50)

• 20 software zones

• Two onboard NACs (Notification Appli ance Circ ui ts) which can be configured as Style Y

(Class B) or Style Z (Class A) circuits

• 2.5 amps total power for NACs

• 2.7 amps total system power (includes battery charger)

• Two programmable relays and one fixed trouble relay

• Built-in Programmer

• Telephone Line Active LEDs

• Communication Confirmation (Kissoff) LED

• Touchtone/Rotary di aling

• EIA-232 PC interface for local upload/download

• 80-character LCD display (backlit)

12 MS-9050UD PN 52413:B 8/29/07

Page 13

Specifications Product Description

• Real-time clock/calendar with daylight savings time control

• History file with 500 event capacity

• Advanced fire technology features:

Automatic drift compensation

Maintenance alert

Detector sensitivity test capability (NFPA 72 compliant)

Automa tic devi ce type-code veri fication

Point trouble identification

• Waterflow selection per module point

• Alarm verification selection per detector point

• Walktest, silent or audible

• PAS (Positive Alarm Sequence) per addressable detector and Pre-signal per point (NFPA 72

compliant)

• Silence inhibit timer option per NAC

• Autosilence timer option per NAC

• Continuous, March Time, Temporal or California code for main circuit board NACs with

two-stage capability

• Selectable strobe synchronization per NAC

• Remote Acknowledge, Alarm Silence, Reset and Drill via addressable modules or remote

annunciator

• Auto-program (learn mode) reduces installation time. Reports two devices set to the same

address

• Password and key-protected nonvolatile memory

• User programmable password

• Fully programmable from local keypad or optional keyboard

• SLC operates up to 10,000 ft. (3,000 m) with twisted, unshield ed fire wire

• Compatible with Fire-Lite’ addressable devices (refer to SLC Wiring Manual)

• Compatible with legacy Fire-Lite 300 Series addressable devices (refer to SLC Wiring

Manual)

• Optional 4XTMF module (conventional reverse polarity/city box transmitter)

• Optional ANN-I/O LED Driver module

• Optional ANN-S/PG printer interface module

• Optional ANN-80 remote LCD annunciator

• Optional ANN-LED Annunciator Module annunciates alarm, trouble and supervisory

• Optional ANN-RLED Annunciator Module annunciates alarms only

• Optional ANN-RLY Form-C Relay Module

• Optional Dress Panels (DP-51050)

1.2 Specifications

Refer to Illustration on page 10 for terminal locations and connections.

AC Power - Transformer Connection

MS-9050UD: 120 VAC, 60 Hz, 3.0 amps

Wire size: minimum 14 AWG (2.00 mm

Nonpower-limited, supervised

Battery (Lead Acid Only) - J1

Maximum Charging Circuit: Normal Flat Charge - 27.6 VDC @ 1.2 amp

Maximum Battery Charger Capacity: 18 Amp Hour, (FACP cabinet holds maximum of two 18

Amp Hour batteries)

Minimum Battery: 7 Amp Hour

Nonpower-limited, supervised

MS-9050UD PN 52413:B 8/29/07 13

2

) with 600 V insulation

Page 14

Product Description Controls and Indicators

SLC Communication Loop - TB2

24 VDC nominal, 27.6 VDC maximum

Maximum length is 10,000 ft. (3,000 m) total twisted, unshielded fire wire

Maximum loop current is 400 mA (short circuit) or 100 mA (normal)

Maximum loop resistance is 40 ohms

Supervised and power-limited circuit

Refer to SLC Loop manual for wiring information

Notification Appliance Circuits - TB1

Terminal Block provides connections fo r two NACs, Style Y (Class B) or

Style Z (Class A)

Special Application power

Power-limited, supervised circuitry

Maximum voltage drop in wiring: 2.0 VDC

Nominal operating voltage: 24 VDC

Current-limit: fuseless, electronic, power-limited circuitry

Maximum signaling current per circuit: 2.5 amps

End-of-Line Resistor: 4.7 kΩ, ½ watt (P/N 71252 UL listed) for Style Y (Class B) NAC

Refer to Fire-Lite Device Compatibility Document for listed compatible devices

Two Programmable Relays and One Fixed Trouble Relay - TB5, TB6 & TB7

Contact rating: 2.0 amps @ 30 VDC (resistive), 0.5 amps @ 30 VAC (resistive)

Form-C relays, nonpower-limited, nonsupervised

Refer to Figure 2.5 on page 43 for information on power-limited relay circuit wiring

EIA-232 - TB3

EIA-232 PC applications connections: Terminal 5 (Receive), 6 (Transmit),

7 (DTR), 8 (Ground)

Power-limited, supervised

ANN-BUS (EIA-485) - TB3

Annunciator connector: Terminal 1 (Ground), 2 (Power), 3 (A), 4 (B)

Nominal Operating Voltage: 24 VDC

Maximum Current (Terminals 1 & 2): 500 mA

Power-limited, supervised

1.2.1 Current Availability

The Notification Appliance Circuits can provide 2.5 amps maximum per circuit. Total available

current for the FACP is 2.7 amps.

1.3 Controls and Indicators

LCD Display

The FACP uses an 80-character

(4 lines X 20 characters) high viewing angle

LCD display. The display includes a long life

LED backlight that remains illuminated. If AC

power is lost and the system is not in alarm, the

LED backlight will turn off to conserve batteries.

LED Indicators

LED indicators are provided to annunciate the following conditions:

• AC Power (green)

• Fire Alarm (red)

• Supervisory (yellow)

• Trouble (yellow)

• Alarm Silenced signals (yellow)

SYSTEM ALL NORMAL

10:00A 092105

14 MS-9050UD PN 52413:B 8/29/07

Page 15

Circuits Product Description

Key Panel

Mounted on the main circuit board, the key panel includes a window for the LCD display and LED

indicators as listed above. The key panel, which is visible with the cabinet door closed, has 25

keys, including a 16 key alpha-numeric pad similar to a telephone keypad.

Function keys:

• Acknowledge/Step

• Alarm Silenced

• Drill (Manual Evacuate)

• Reset (lamp test)

Service/program keys:

• Keys labeled 1 to 9

• * key

• # key

• 0 (recall) key

• 1st Event key

• Clear key

• Escape key

• Mode key

• Four cursor keys (up, down, left and right)

• Enter key

Local Piezo Sounder

A piezo sounder provides separate and distinct pulse rates for alarm, trouble and supervisory

conditions.

Figure 1.1 Membrane/Display Panel

9050udkypd.cdr

1.4 Circuits

Reference

Manual

SLC Communication Loop

One SLC loop is provided on the FACP main circuit board. The SLC loop, configurable for NFPA

Style 4, 6 or 7, provides communication to addressable detectors, monitor (initiating device) and

control (output device) modules. Refer to the SLC Wiring manual for information on wiring

devices.

Output Circuits

The following output circuits are available on the FACP:

• Charger

24 VDC Battery Charger (up to 18 AH batteries)

• NAC (Notification Appliance Circuits)

Two NACs configurable for Style Y (Class B) or Style Z (Class A), are provided with various

programmable features.

MS-9050UD PN 52413:B 8/29/07 15

Page 16

Product Description Digital Alarm Communicator/Transmitter

Relays

One fixed and two fully programmable Form-C dry contact relays are provided. The fixed fail-safe

relay monitors system trouble and the two programmable relays are factory default programmed for

system alarm and system supervisory. Contacts are rated 2.0 amps @ 30 VDC (resistive) and 0.5

amps @ 30 VAC (resistive). The programmable relays can be programmed for the following

operations:

• fire alarm

• silenceable alarm

• trouble

• supervisory

• supervisory auto-resettable

• DACT communication failure

• process monitor

• process monitor auto-resettable

• hazard alert

• medical alert

•AC loss

1.5 Digital Alarm Communicator/Transmitter

T wo modular phone jacks allow easy connection to telephone lines. Modular jacks are labeled PH1

for Primary Phone Line and PH2 for Secondary Phone Line. Two telephone line active red LEDs

are provided as well as a green Kissoff LED. The integral digital communicator provides the

following functions:

• Line Seizure: takes control of the phone lines disconnecting any premises phones

• Off/On Hook: performs on and off-hook status to the phone lines

• Dialing the Central Station(s) number: default is Touch-Tone

®

, programmable to rotary

• For tone burst or touchtone type formats: discern proper Ack and Kissoff tone(s). The

frequency and time duration of the tone(s) varies with the transmission format. The control

panel will adjust accordingly.

• Communicate in the following formats:

12 Tone Burst types: 20 pps

(3+1, 4+1, 4+2, 3+1 Exp., 4+1 Exp., 4+2 Exp.)

3 Touchtone Types

4+1 Ademco Express

4+2 Ademco Express

Ademco Contact ID

16 MS-9050UD PN 52413:B 8/29/07

Page 17

Components Product Description

1.6 Components

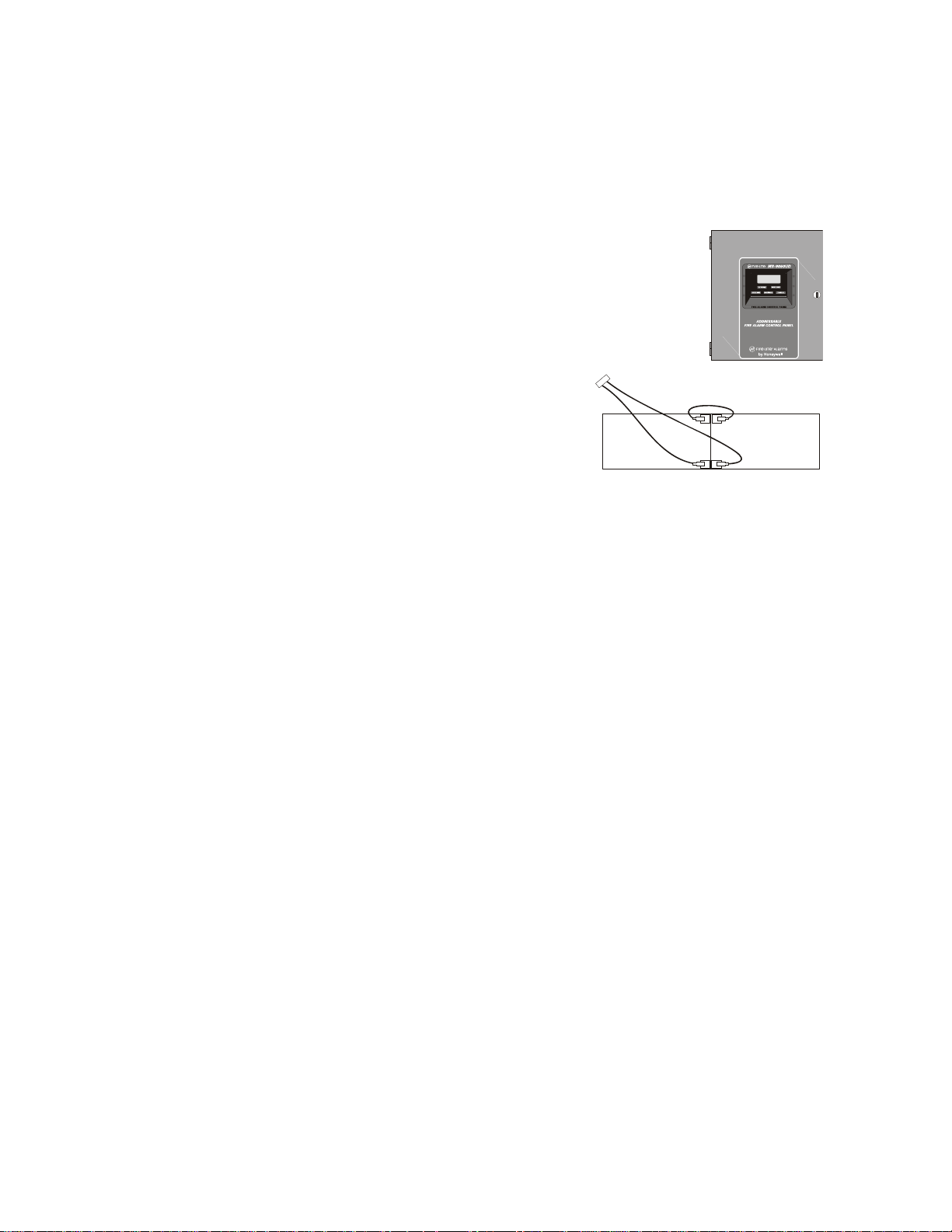

Main Circuit Board

The main circuit board contains the system’s CPU, power supply, other primary components and

wiring interface connectors. The 4XTMF option module plugs in and is mounted to the main

circuit board. The circuit board is delivered mounted to a chassis in the MS-9050UD backbox

See Page

(refer to circuit board illustration on page 10).

Cabinet

The MS-9050UD backbox provides space for two batteries (up to 18 Amp

Hour). Ample knockouts are provided for system wiring. Also available is

an optional dress panel, which mounts to the inside of the cabinet (required

by ULC for Canadian installations). The dress panel must be installed to

meet FM requirements.

MS_9050UD.cdr

Reference

Manual

Batteries

The MS-9050UD cabinet provides space for two

batteries (up to 18 Amp Hour). Batteries must be

ordered separately.

Battery Cable P/N 75203

-

+

+

-

9200batt.cdr

1.6.1 Intelligent Addressable

Detectors: Newer Series

Intelligent, addressable detectors provide information to the control panel on an SLC Signaling

Line Circuit (refer to the SLC Wiring Manual for detailed information on addressable devices,

device installation, wiring and operation). This allows the control panel to continually process the

information to determine the status (alarm, trouble, maintenance or normal) of each detector . Each

detector responds to an SLC address that is set in the detector head using built-in rotary decimal

switches. Note that a blinking LED on an intelligent detector indicates communication between the

detector and the control panel. Refer to the Fire-Lite Device Compatibility Document for a list of

approved conventional detectors.

1.6.2 Intelligent Addressable Modules: Newer Series

The newer series of Control Modules and Monitor Modules provide an interface between the

control panel and conventional notification and initiating devices. Each module can be set to

respond to an address with built-in rotary switches. A blinking LED on a monitor module indicates

communication between the module and the control panel. These devices can also be used when

installed on older systems. Refer to the SLC Wiring Manual for information on addressable

devices. Refer to the Fire-Lite Device Compatibility Document for a list of approved conventional

notification and initiating devices.

1.6.3 300 Series Intelligent Addressable Devices

Fire-Lite’s 300 Series Intelligent Addressable Devices are fully compatible with the MS-9050UD

FACP. Refer to the SLC Wiring Manual for device information.

1.6.4 Device Accessories

End-of-Line Resistor Assembly

Refer to the SLC Wiring Manual for device information. The 47 kΩ End-of-Line Resistor

assembly (P/N: R-47K) is used to supervise the MMF-300, MDF-300, MMF-301 and CMF-300

module circuits. The 3.9 kΩ End-of-Line Resistor assembly is used to supervise the MMF-302

module circuit. The End-of-Line resistors are included with each module.

MS-9050UD PN 52413:B 8/29/07 17

Page 18

Product Description Optional Modules

Power Supervision Relay

The UL listed End-of-Line power supervision relay is used to supervise the power to 4-wire smoke

detectors and notification appliances.

N-ELR Mounting Plate

The N-ELR is a single End-of-Line resistor plate which is required for use in Canada. An ELR,

which is supplied with each module and fire alarm control panel, is mounted to the ELR plate.

Resistors mounted to the N-ELR plate can be used for the supervision of a monitor and control

module circuit.

1.7 Optional Modules

The MS-9050UD main circuit board includes option module connectors for the followin g mo dule:

4XTMF Transmitter Module

The 4XTMF provides a supervised output for local energy municipal box transmitter, alarm and

trouble reverse polarity. It includes a disable switch and disable trouble LED. A jumper on the

module is used to select an option which allows the reverse polarity circuit to open with a system

trouble condition if no alarm condition exists. The module plugs into connectors J8 and J9 which

are located near the top center of the main circuit board. When the 4XTMF module is installed,

Jumper JP28, on the main circuit board, must be cut to allow supervision of the module.

1.8 Accessories

1.8.1 PK-CD Programming Utility

The PK-CD Programming Utility can be used to locally or remotely program an MS-9050UD

directly from most IBM compatible personal computers (PC), running Windows

MS-9050UD program files can also be created and stored on the PC and then downloaded to the

control panel. The PK-CD Kit includes the MS-9050UD Windows-based Programming Utility

software on CD-ROM with on-line help file. A serial cable (P/N: PRT/PK-CABLE), which must

be purchased separately, is required for local connection of the PC to the RS-232 (PC/Printer)

terminals at TB3 of the MS-9050UD main circuit board. Remote programming requires that the

PC have a 2400 baud (or faster) modem.

Important: Remote modification of FACP programming requires that the panel be enabled for

remote download (refer to "Remote Download" on page 177). Remote interrogation of panel

programming, history logs, detector status, etc., is possible without enabling the remote download

option.

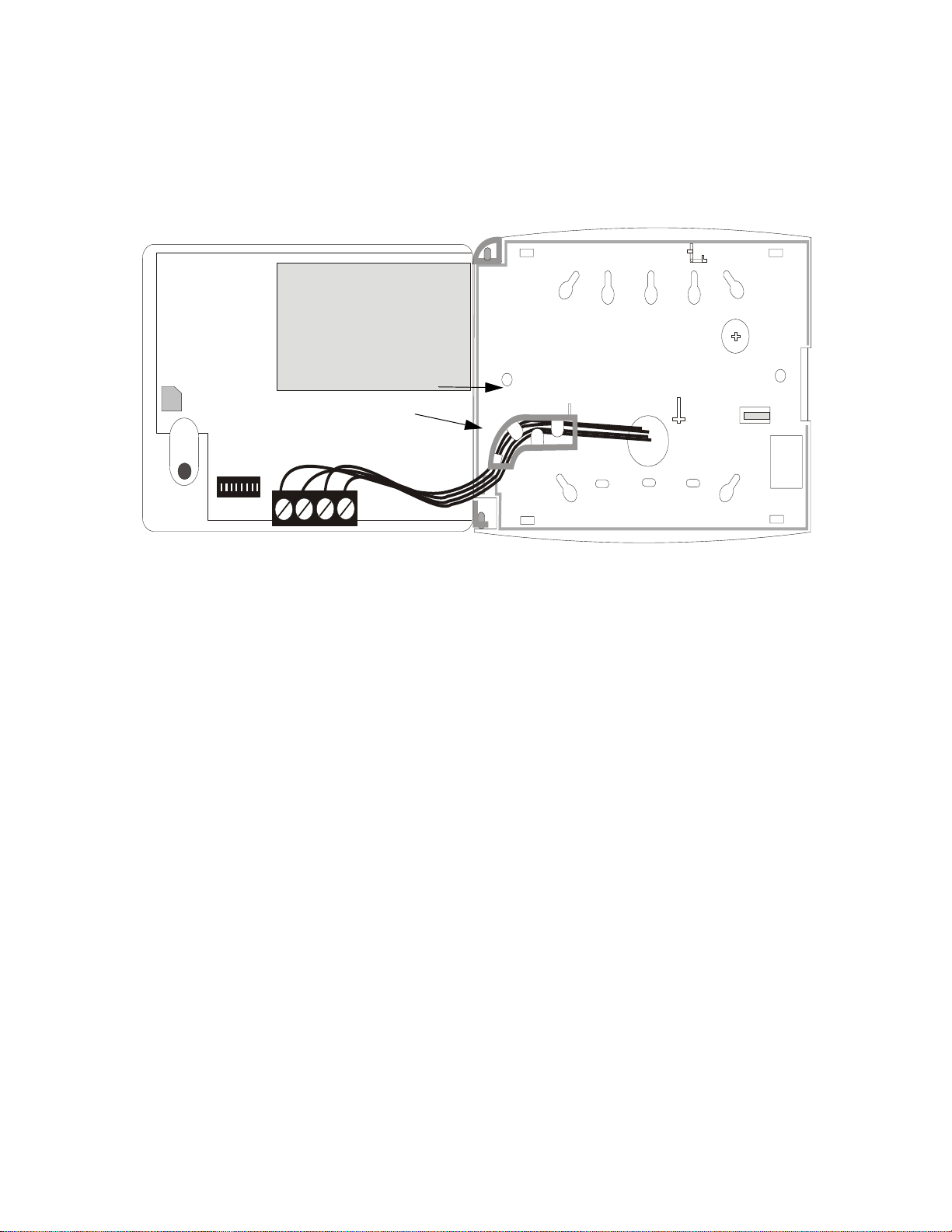

1.8.2 Dress Panel

An optional dress panel (DP-51050) is available for the MS-9050UD (required by ULC for

Canadian installations). The dress panel restricts access to the system wiring while allowing access

to the key panel. The dress panel must be installed to meet FM requirements.

1.8.3 Trim Ring

™ XP (or newer).

An optional Trim Ring (TR-CE) is available for semi-flush mounting of the FACP backbox.

18 MS-9050UD PN 52413:B 8/29/07

Page 19

ANN-BUS Devices Product Description

1.9 ANN-BUS Devices

WARNING! Disconnect all sources of power (AC and DC) before installing or removing any

modules or wiring.

A variety of optional devices can be connected to the FACP ANN-BUS communication circuit.

Compatible devices include:

• ANN-80 LCD Annunciator

• ANN-S/PG Serial/Parallel Printer Interface Module

• ANN-I/O LED Driver Module

• ANN-LED Annunciator Module (alarm, trouble, supervisory LEDs)

• ANN-RLED Annunciator Module (red alarm LEDs only)

• ANN-RLY Relay Module

1.9.1 ANN-BUS Wiring

This section contains information on calculating ANN-BUS wire distances and the types of wiring

configurations (Class B).

1.9.1.1 Calculating Wiring Distance for ANN-BUS Modules

The following instructions will guide the installer in determining the type of wire and the

maximum wiring distance that can be used with FACP ANN-BUS accessory modules.

To calculate the wire gauge that must be used to connect ANN-BUS modules to the FACP, it is

necessary to calculate the total worst case current draw for all modules on a single 4-conductor

bus. The total worst case current draw is calculated by adding the individual worst case

currents for each module. The individual worst case values are shown in the following table:

Model Number Worst Case Current Draw

ANN-80 LCD Annunciator 0.040 amps

ANN-S/PG Serial/Parallel Printer Interface Module 0.040 amps

ANN-I/O LED Driver Module 0.200 amps

ANN-RLY Relay Module 0.075 amps

ANN-(R)LED Annunciator Module 0.068 amps

Note: Total worst case current draw on a single ANN-BUS cannot exceed 0.5 amp. If current

draw exceeds 0.5 amps, refer to "Powering ANN-BUS Devices fr om Auxiliary Power Supply"

on page 22.

MS-9050UD PN 52413:B 8/29/07 19

Page 20

Product Description ANN-BUS Devices

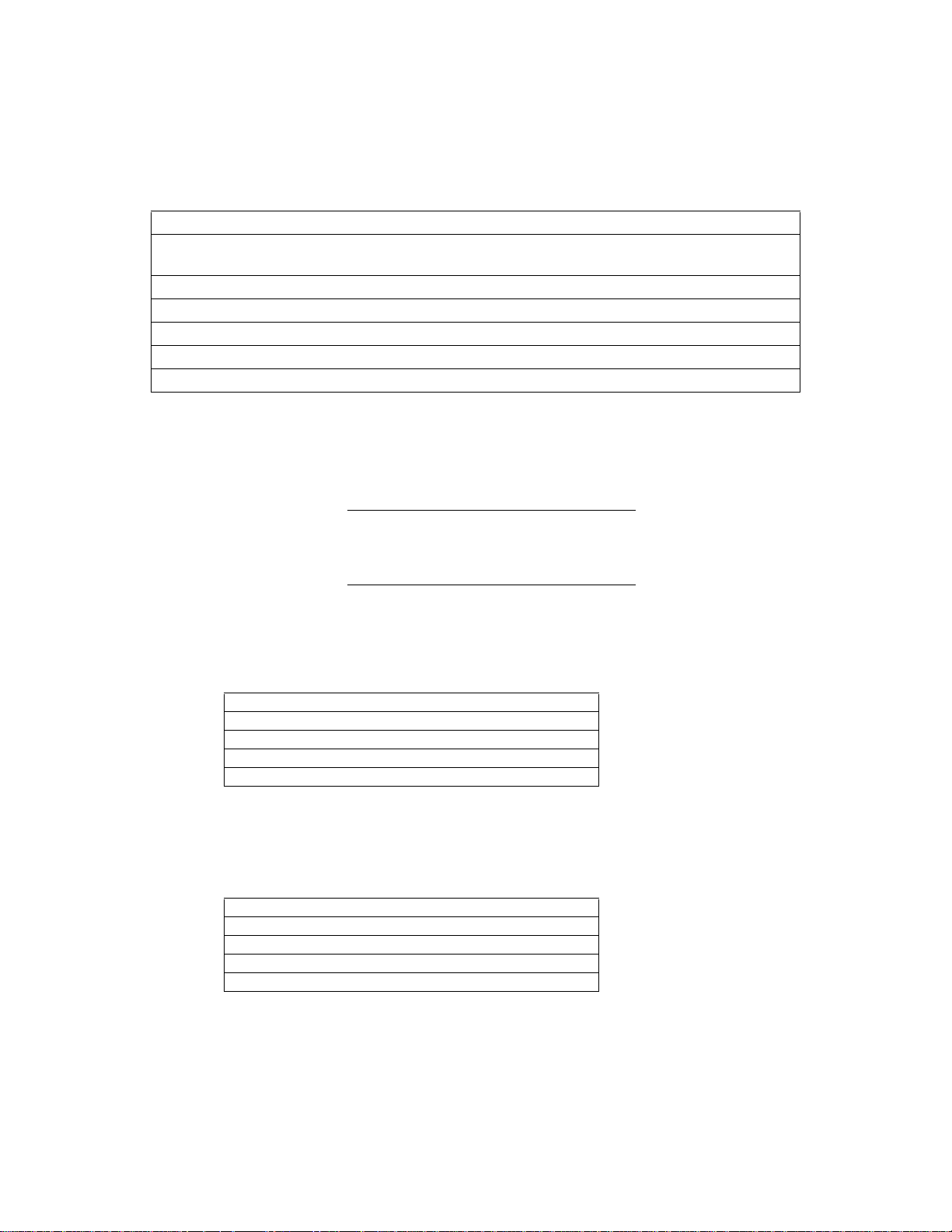

After calculating the total worst case current draw, Table 1.1 specifies the maximum distance

the modules can be located from the FACP on a single wire run. The table ensures 6.0 volts of

line drop maximum. In general, the wire length is limited by resistance, but for heavier wi re

gauges, capacitance is the limiting factor. These cases are marked in the chart with an asterisk

(*). Maximum length can never be more than 6,000 feet (1,800 m), regardless of gauge used.

The formula used to generate this chart is shown in the note below.

Wiring Distance: ANN-BUS Modules to FACP

Total Worst Case

Current Draw (amps)

0.100 1,852 ft. 4,688 ft. * 6,000 ft. *6,000 ft.

0.200 926 ft. 2,344 ft. 3,731 ft. 5,906 ft.

0.300 617 ft. 1,563 ft. 2,488 ft. 3,937 ft.

0.400 463 ft. 1,172 ft. 1,866 ft. 2,953 ft.

0.500 370 ft. 938 ft. 1,493 ft. 2,362 ft.

22 Gauge 18 Gauge 16 Gauge 14 Gauge

Table 1.1 Wiring Distances

Note: The following formulas were used to generate the wire distance chart:

6.0 Volts

Maximum Resistance (Ohms) = Total Worst Case Current Draw (amps)

Maximum Wire Length (feet) = Maximum Resistance (Ohms) *500

(6,000 feet maximum) Rpu

where: Rpu = Ohms per 1,000 feet for various Wire Gauges (see table below)

Wire Gauge Ohms per 1,000 feet (Rpu)

22 16.2

18 6.4

16 4.02

14 2.54

Exception: When using the ANN-RLY module, the installer must ensure that the maximum

24VDC power line drop does not exceed 0.3 volts. This results in the following wiring

limitations:

Wire Gauge Maximum Wire Length

18 312 feet

16 497 feet

14 787 feet

12 1,250 feet

20 MS-9050UD PN 52413:B 8/29/07

Page 21

ANN-BUS Devices Product Description

Wiring Distance Calculation Example:

Suppose a system is configured with the following ANN-BUS modules:

• 3 ANN-80 Remote Fire Annunciators

• 1 ANN-S/PG Serial/Parallel Printer Interface Module

• 1 ANN-I/O LED Driver Module

The total worst case current is calculated as follows:

ANN-80 Current Draw = 3 X 0.040 amps = 0.120 amps

ANN-S/PG Current Draw = 1 X.0.040 amps = 0.040 amps

ANN-I/O Current Draw = 1 X.0.200 amps = 0.200 amps

Total Worst Case Current Draw = 0.360 amps

Using this value and referring to the Wiring Distance Table 1.1 on page 20, it can be found that

the available options are:

463 feet maximum using 22 Gauge wire

1,172 feet maximu m using 18 Gauge wire

1,866 feet maximu m using 16 Gauge wire

2,953 feet maximu m using 14 Gauge wire

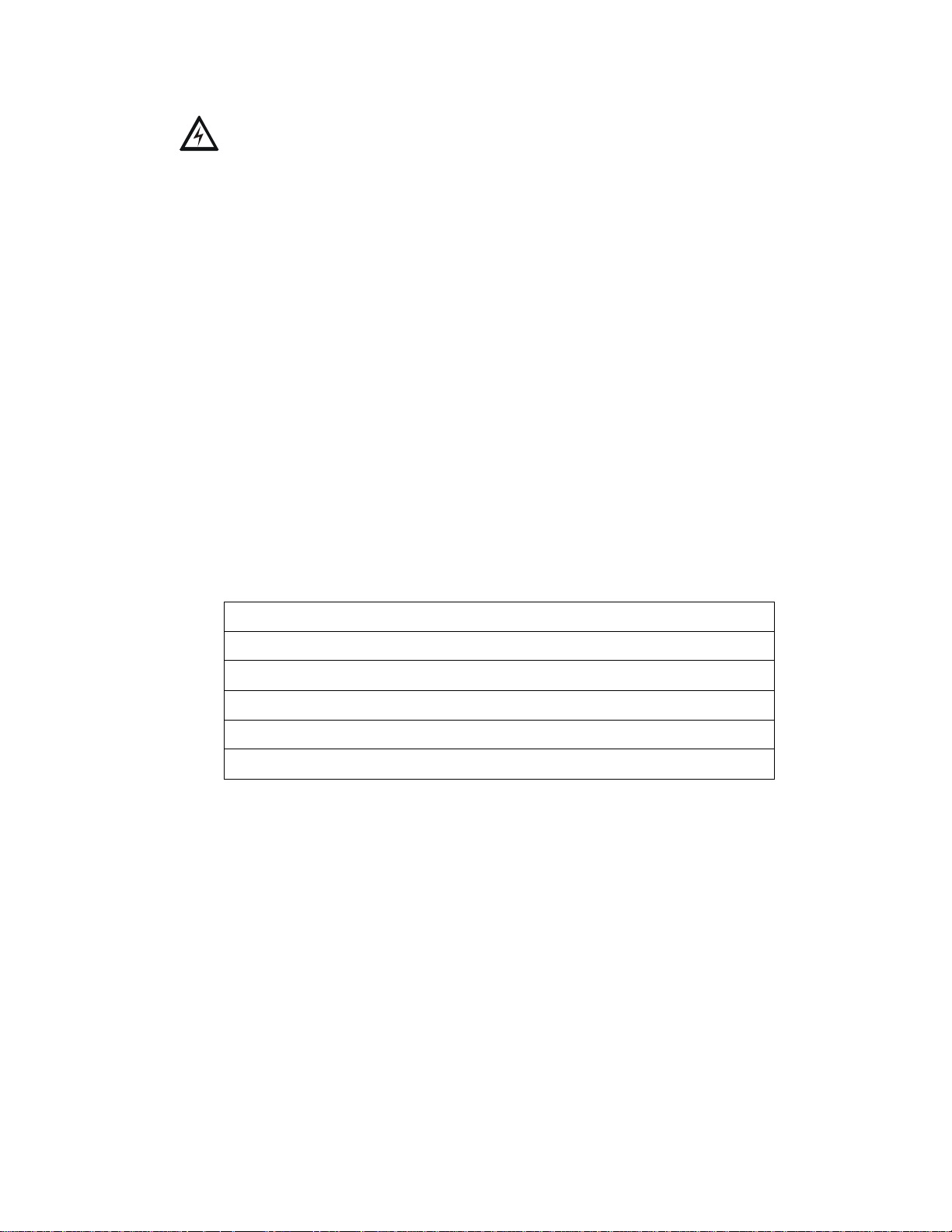

1.9.1.2 Wiring Configuration

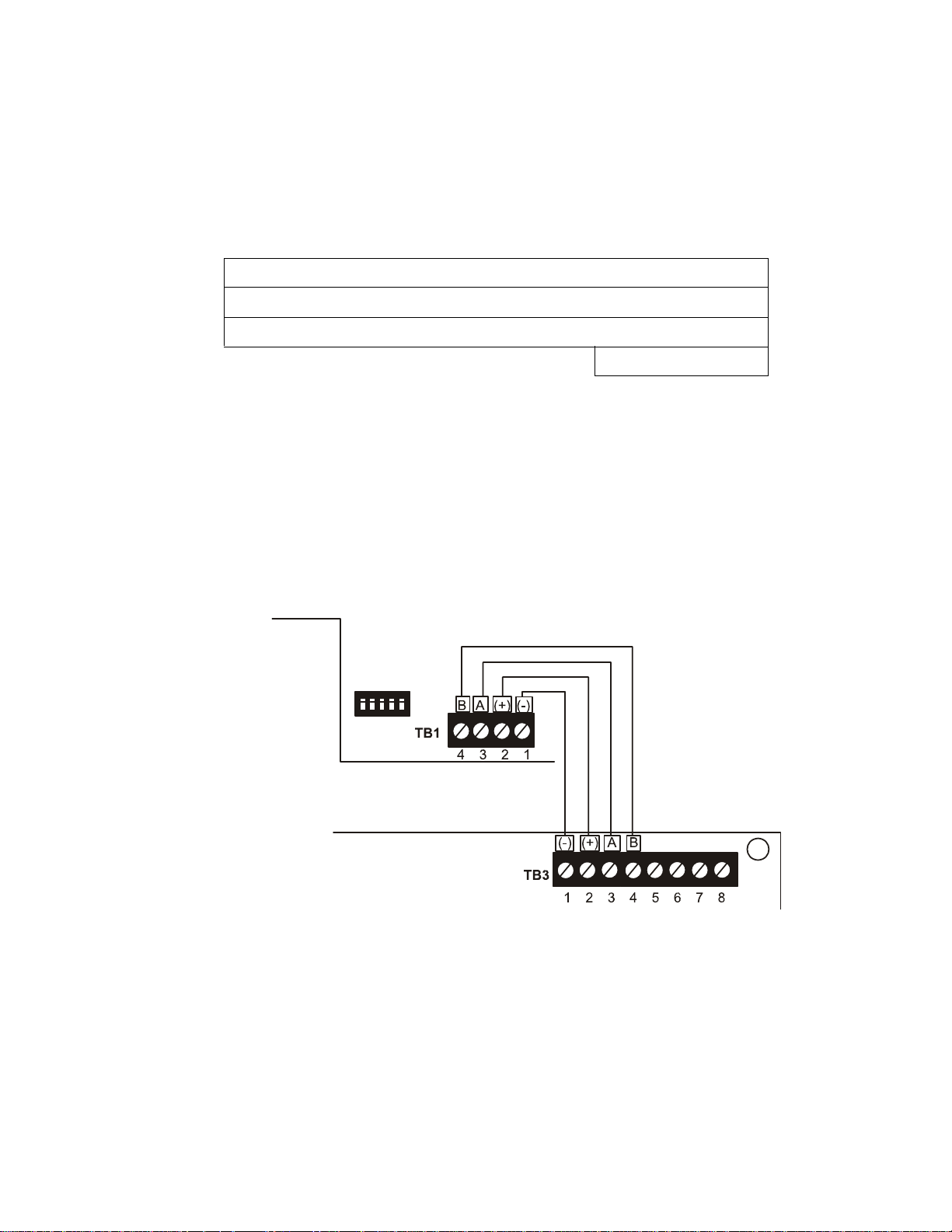

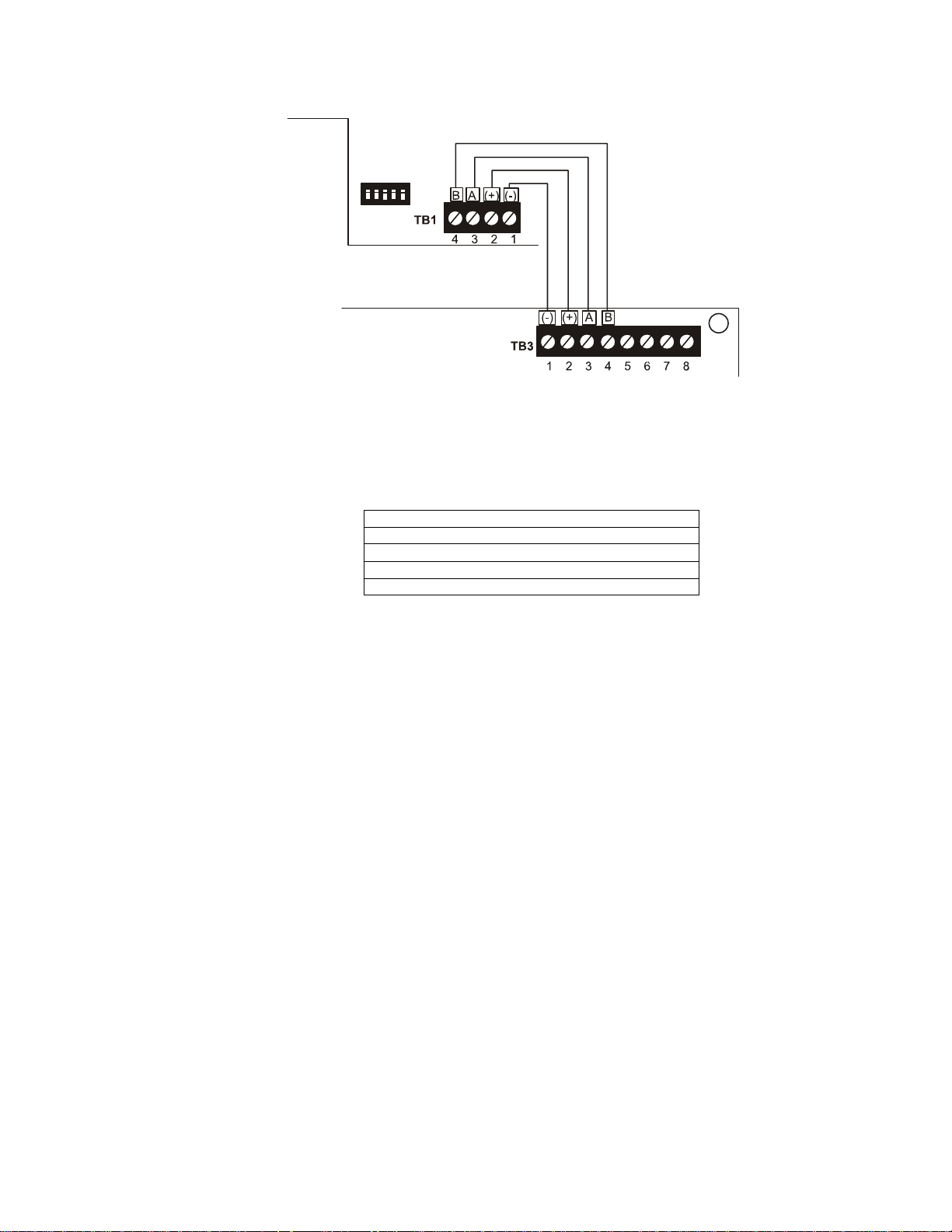

Figure 1.2 illustrates the wiring between the FACP and ANN-BUS devices.

ANN-BUS and power wiring are

supervised and power-limited

ANN-BUS Device

MS-9050UD

Figure 1.2 FACP wiring to ANN-BUS Device

MS-9050UD PN 52413:B 8/29/07 21

Page 22

Product Description ANN-BUS Devices

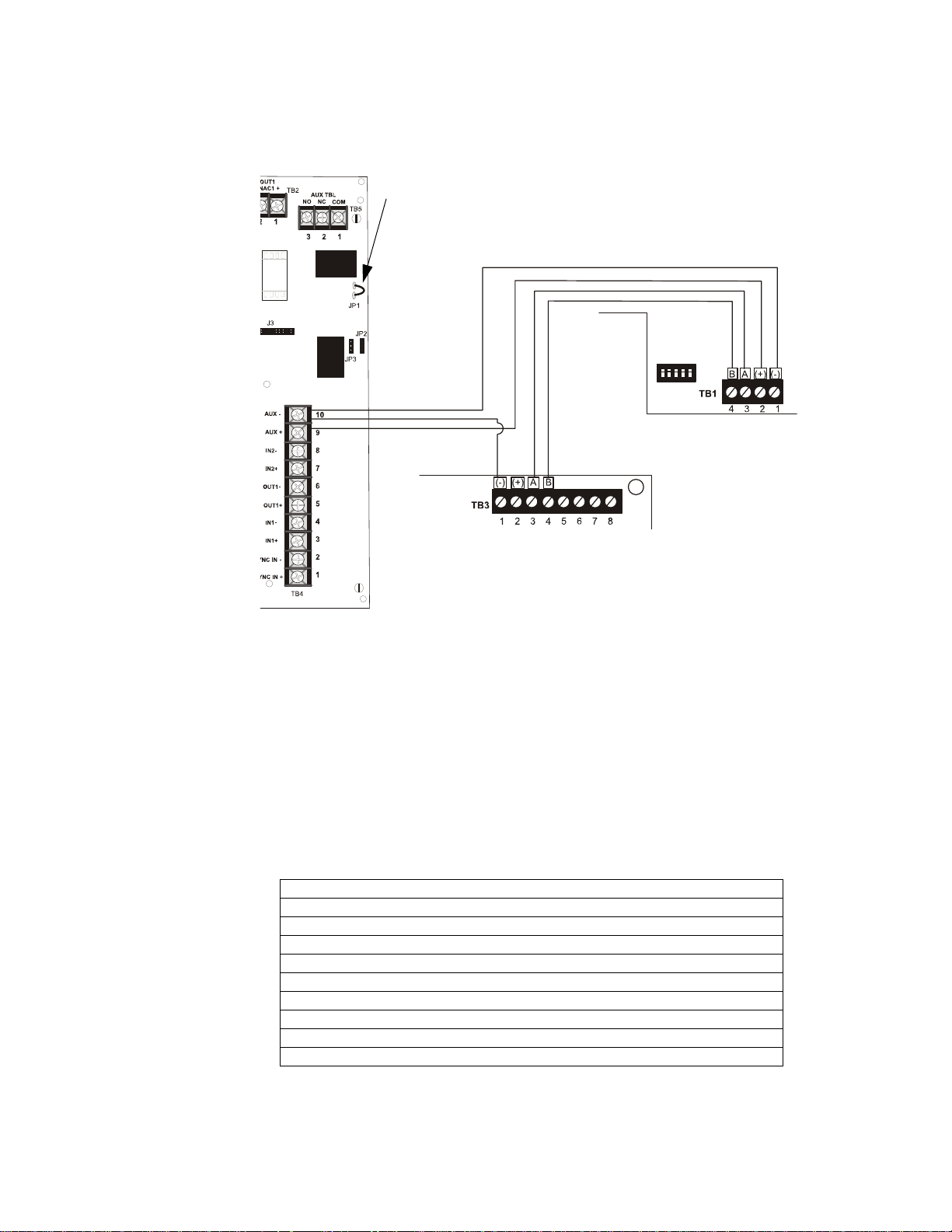

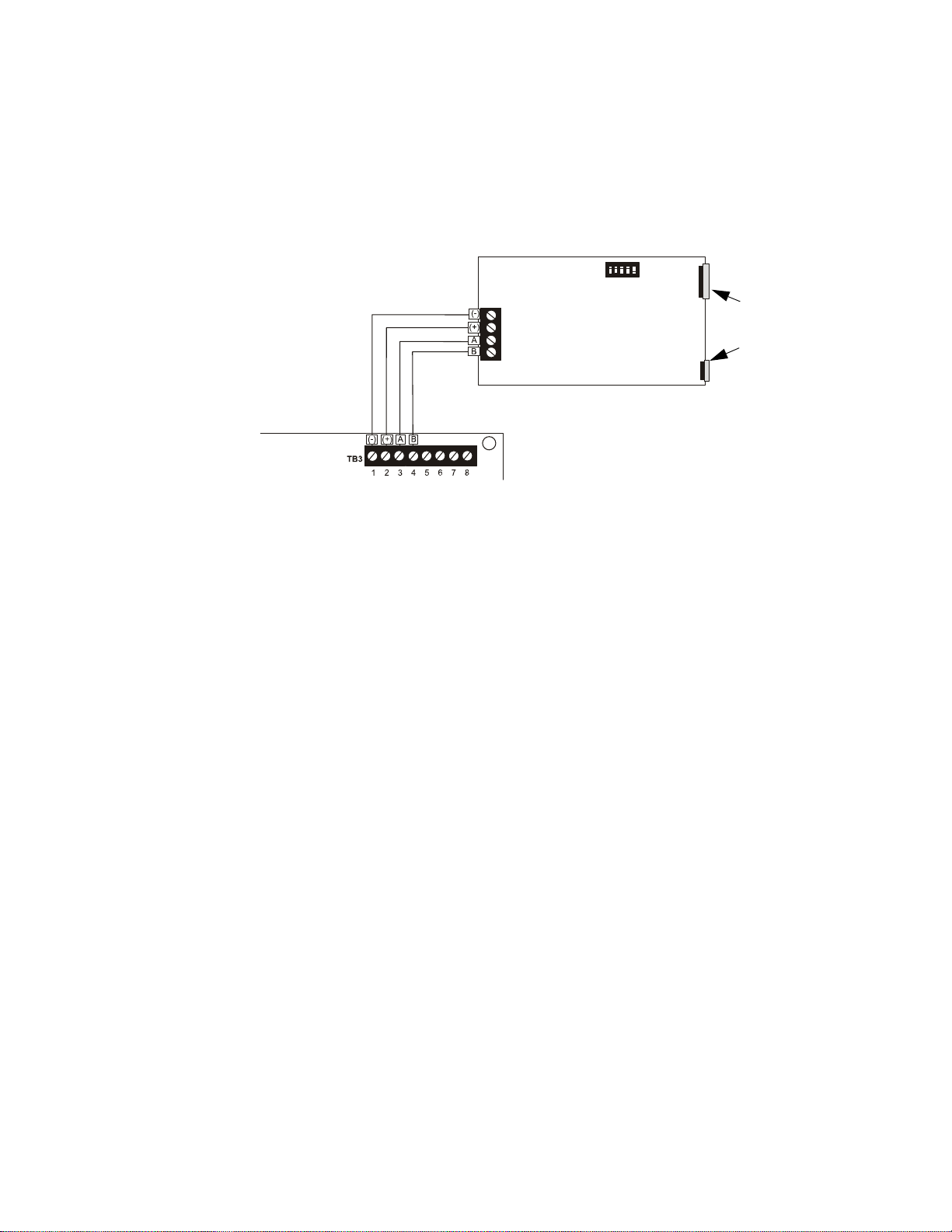

1.9.1.3 Powering ANN-BUS Devices from Auxiliary Power Supply

Figure 1.3 illustrates the powering of ANN-BUS devices from an auxiliary power supply such

as the FCPS-24FS6/8, when the maximum number of ANN-BUS devices exceeds the ANNBUS power requirements.

Cut Ground Fault Detection jumper JP1 (FACP monitors for ground faults)

ANN-BUS and power wiring are

supervised and power-limited

-24 VDC

+24 VDC

ANN-BUS

ANN-80

MS-9050UD

FCPS-24FS6/8

Figure 1.3 Powering ANN-BUS Devices from FCPS-24FS6/8

1.9.2 ANN-BUS Device Addressing

Each ANN-BUS device requires a unique address (ID Number) in order to communicate with the

F ACP. A 5-position DIP switch on each device is used to set this address. The address set for these

devices must also be programmed at the FACP for the specific device (refer to the programming

section titled "ANN-BUS" on page 104).

A maximum of 8 devices can be connected to the FACP ANN-BUS communication circuit. Device

addresses do not need to be sequential and can be set to any number between 01 and 08. Note that

00 is not a valid address. The following table shows the DIP switch setting for each address.

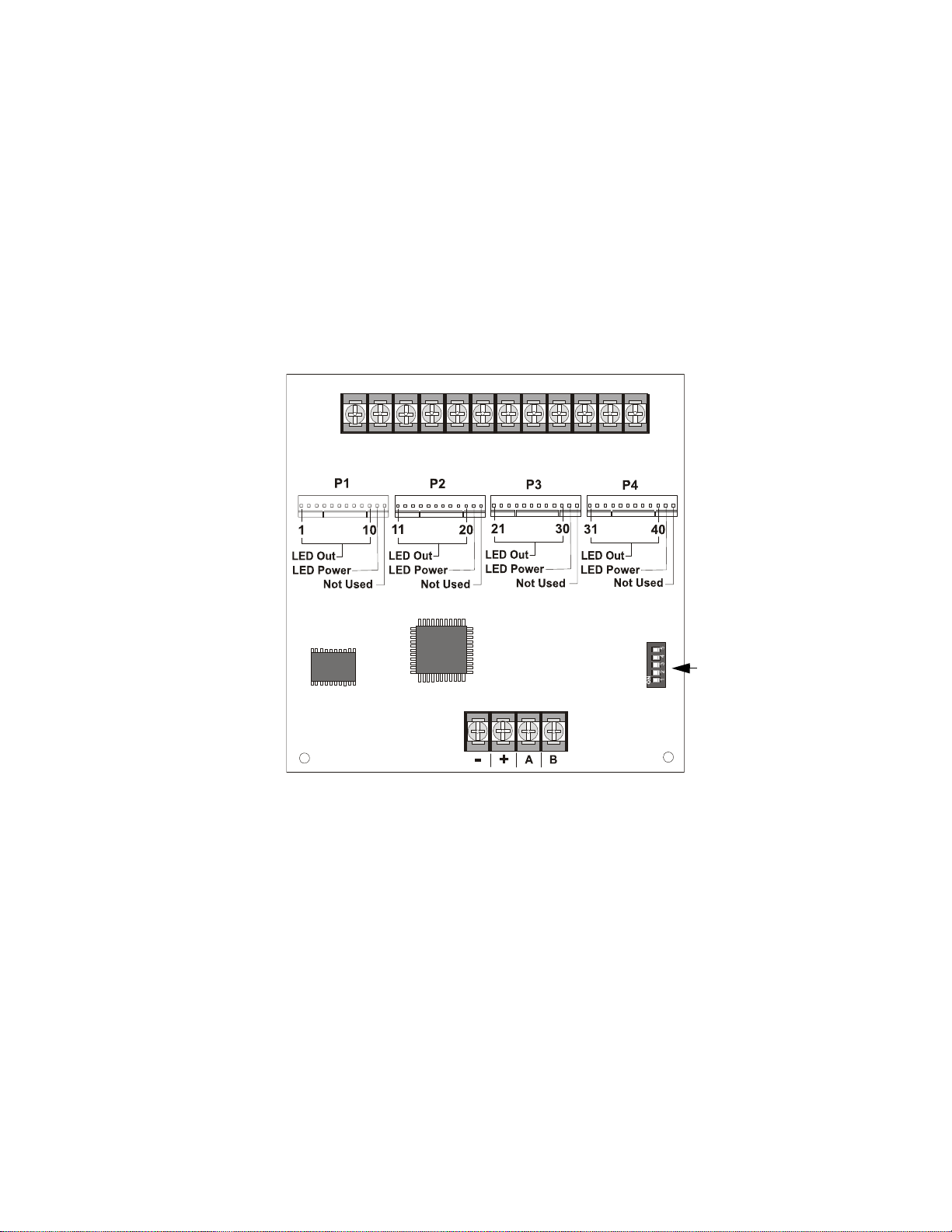

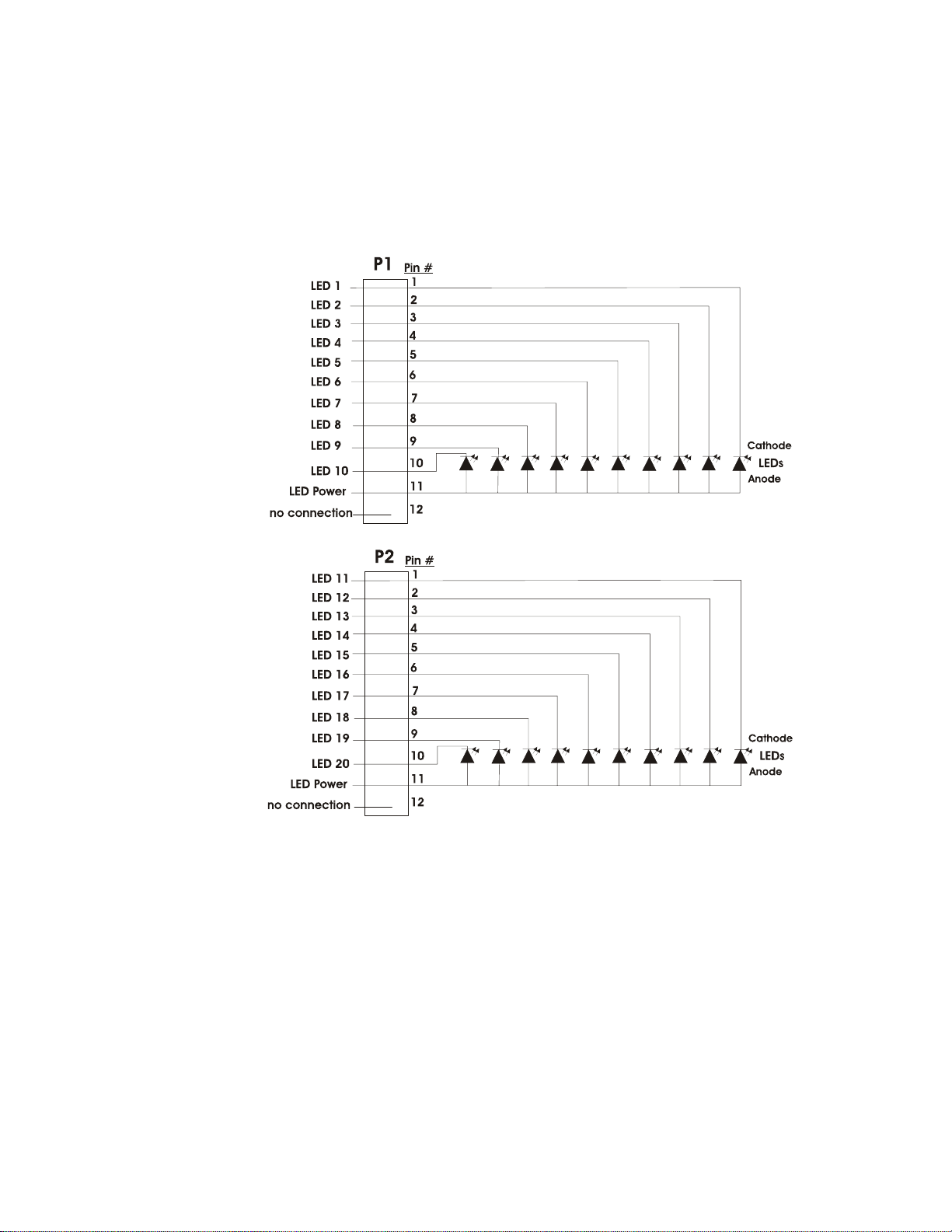

Address Switch 5 Switch 4 Switch 3 Switch 2 Switch 1