Page 1

User’s Guide

www.fetco.com

CBS-3000P Series Coffee Brewers

Contact Information ................................................ 2

Product Description/Features ................................. 2

Technical Data........................................................ 2

Dimensional Drawings & Utilities............................3

Installation............................................................... 4

Pour-Over Models:

f CBS-31P

f CBS-31Pap

Table of Contents

Brewing Specifications........................................ 2

Weights and Capacities ...................................... 2

Electrical Configuration and Brewing Efficiency .2

Operating Procedures ............................................ 5

Service.................................................................... 6

Warranty.............................................................. 6

Adjustments ........................................................ 6

Troubleshooting .................................................. 7

Parts ....................................................................... 8

FETCO® and Driven To Pioneer Innovation™ are trademarks or trade names of Food Equipment Technologies Company.

© 2006 Food Equipment Technologies Company Part # P003 August 2, 2006

Page 2

Contact Information

FETCO®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: sales@fetco.com

techsupport@fetco.com

Product Description/Features

CBS-31P Coffee Brewing System

CBS-31Pap Coffee Brewing System

• Pour-over, requires no plumbing

• Compact design • Iced tea brewing capability

• All stainless steel brewer body construction • Color stainless steel finish

• Electronic temperature control • Custom and export voltage

• “Ready to brew” indicator lamp

• Non clog sprayhead

• Heater protection control

Note: Throughout this manual, all references to the CBS-31 brewer apply to both the “P” and “Pap” versions, unless

otherwise indicated.

Used with 2.5 liter thermal gravity pots

Used with various size airpots*

Optional Features:

Technical Data

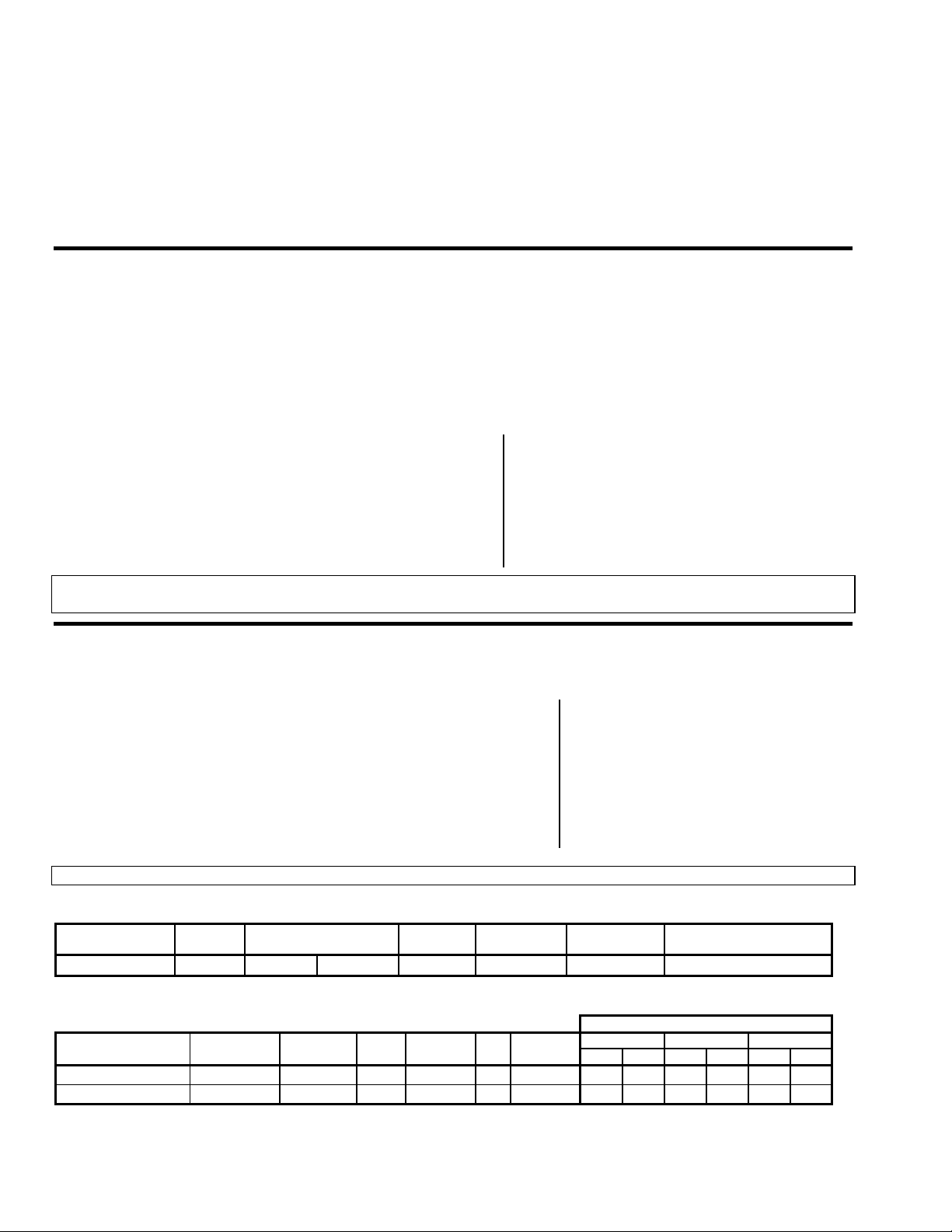

Brewing Specifications

CBS-31P CBS-31Pap

Brew Volume: 2.5 liters 2.2 liters / 3.0 liters Temperature:

Brew Time: 3½ - 4 min 3-3½ min. / 4-4½ min.

(Allow an extra 1-3 minutes for coffee to finish dripping)

Coffee Filters: Plastic Brew Basket: 9¾” X 4½” FETCO # F003

Stainless Steel Brew Basket: 13” X 5” FETCO # F002

*FETCO currently supplies 2.2 and 3.0 liter airpots. Pap brewers can also utilize the other available sizes, 1.9 and 2.5 liters.

Weights and Capacities

Brewer

Model

CBS-31P/Pap 30 lbs. 1.7 gal. 14.2 lbs. 44.2 lbs. 4 lbs. 10.3 lbs. 55 lbs.

Weight

(empty)

Water tank

Capacity & Weight

Weight

(filled)

Dispenser

Weight, ea.

Electrical Configuration and Brewing Efficiency

Brews per Hour (cold or hot water)

Heater Voltage Max. Amp 2.2 lit. (max 13) 2.5 lit. (max 12) 3.0 lit.(max 11)

Model Configuration Connection Phase Wires KW draw cold hot cold hot cold hot

CBS-31P/Pap (-1) 1 X 1300 w 120 1 ph. 2 + grnd 1.3 11.2 5.5 12.8 4.9 11.3 4.1 9.4

CBS-31P/Pap (-2) 1 X 1800 w 120 1 ph. 2 + grnd 1.8 15.3 7.7 13.0 6.8 12.0 5.6 11.0

203°F inside water tank (at sea level)

195°F ± 5° at sprayhead

Dispenser.

Filled, ea.

Total Weight Brewer&

Dispensers, filled

2

Page 3

CBS-31P

Dimensional Drawings & Utilities

CBS-31Pap

3

Page 4

Installation

(For Qualified Service Technicians Only)

Keys Points

Electrical:

•The electronic controls require at least 105 volts. Less than 105 volts will cause erratic behavior from the

brewer.

•The electrical drawing for the brewer is located on the inside of the upper cover.

General:

•Do not adjust the thermostat setting unless absolutely necessary. It is set at the factory for optimum

performance.

Installation Instructions

1. Review the Dimensional Drawings and the Operating Procedures for the unit you are installing. Verify that

the brewer will fit in the space intended for it. Verify that the counter or table will support 55 lbs., the weight

of the brewer and dispensers when filled.

2. The thermostat is pre-set at the factory. There is no need to turn off the heater during the installation

process. The heater is disabled by the liquid level control board until water is sensed. The heating

process will start automatically when the tank has filled with water.

3. When the brewer is in position for use, level the brewer front to back as well as side to side by adjusting the

feet.

4. Plug the power cord into a proper receptacle

5. Turn the power switch to the “on” position.

• The “ready” light will go on briefly, then go off.

• The heaters will be disabled by the L.L.C. board until water is sensed by the water level probe.

6. Fill the water tank as follows:

• Remove the pour-over tank cover.

• Place a container under the brew basket.

• Slowly pour approximately 1½ gallons of water into the top of the brewer. This will almost completely

fill the brewer’s main tank.

• Pour additional water into the top until water begins flowing out of the brew basket into the container.

• The brewer’s tank is now completely full and the water will begin heating.

• Due to the expansion of the water as the temperature rises, water will drip from the brew basket during

the heating process. Therefore, the brew basket and container should be kept in place until the water

has reached operating temperature.

The brewer will be ready for operation as soon as the ready light comes on to indicate that the water tank is

up to brewing temperature. The time required to reach brewing temperature will vary according to the electrical

configuration and the temperature of the cold water.

Depending on the cost of electricity in your area, very little savings may be had by turning the brewer off

between shifts. The water tank is well insulated and may actually use less electricity to keep the tank hot, than reheating the tank from a cold condition. Leaving the brewer in the on position will also avoid delays at the beginning

of shifts for the brewer to reach operating temperature.

7. Review the entire operating procedures with whomever will be using the brewer. Pay particular attention to

the following areas.

• Don't remove the brew basket until it has stopped dripping.

• Make sure the dispenser is empty before brewing into it.

• Show how to close and/or secure the dispensers for transporting.

4

Page 5

Operating Procedures

1. Turn the power switch

• The power switch will illuminate to indicate that the brewer has power.

• When the ready light

time required to gain full operating temperature will vary depending on the electrical configuration that

was ordered, and the temperature of the cold water.

2. Prepare the brew basket

• Place a paper filter in each basket to be used. Pour the appropriate amount of pre-measured, ground

coffee into the filter. The amount of coffee used will depend on your personal tastes and the

recommendation of your roaster.

• Slide the brew basket back into the rails on the brewer.

3. Prepare the dispenser.

• Ensure that the dispenser is empty. If you are using an

airpot, open the cover and remove the pump stem

before brewing.

• Place the dispenser in position under the brew basket.

4. Remove the tank cover

amount of water into the top of the brewer.

• It is normal for the ready light to go out after the start of

the brew cycle.

• The electrical configuration and the electrical power

connected to the brewer will determine how long before

the ready light comes back on for the next brew.

5. You now have a dispenser of freshly brewed coffee, ready to serve, that will taste fresh and stay hot.

ONLY a non-heated dispenser can do that.

• If you are using an airpot, insert the pump stem before closing the cover.

CAUTION:

Do not remove the brew basket immediately after the brew cycle has finished. Wait until

dripping from the bottom of the brew basket has stopped. Carefully remove the brew basket

while inspecting the inside of the basket for hot coffee that has not finished draining.

(A) to the on position

(B) illuminates, the brewer is fully up to brewing temperature. The amount of

(C).

(D), and pour the appropriate

Gravity pot

Airpot

D

Legend:

Power switch

A-

Ready light

BC-Brew basket

D-Pour-over tank cover

B

POWER

READY

A

C

5

Page 6

Service

Warranty

All FETCO brewers come with a limited warranty. All warranty service must be authorized by calling FETCO

Technical Support at (800) 338-2699.

Adjustments

Thermostat Adjustment:

For equipment manufactured before April 1, 2004

The brewer’s water tank temperature is factory set at 205°F (slightly lower for high altitudes, to prevent boiling).

This setting will deliver water at 195°F ± 5° to the coffee grounds.

Measure the temperature by holding a thermometer in the stream of water flowing out of the brew basket, 1/3 of

the way through the brew cycle. The temperature should be 195°F ± 5°.

If an adjustment is necessary:

• Turn the power switch off.

• Remove the four screws on the upper cover. The upper water tank is attached to the cover.

• Lift the cover and tank just enough to reach the thermostat, which

is located on the right side, under the tank.

• Turn the adjustment stem slightly counter-clockwise to increase

the temperature, and clockwise to decrease the temperature.

• Place the tank and cover in their normal positions and turn the

power switch on.

• If you decreased the temperature setting, place a container

under the brew basket and pour water into the top of the brewer

until the “ready” light goes out

• Wait for the “ready” light to come on, and measure the temperature again.

Repeat until the desired temperature is obtained.

Effective December, 2004:

A new digital thermostat and temperature probe were introduced as a direct replacement for the old style

thermostat and probe.

During normal operation, the digital readout displays the last two digits of the actual water temperature. When the

adjustment tool is turned, the readout begins flashing to indicate the set point, not the actual temperature. After the

tool is released, the readout stops flashing and displays the actual temperature again.

A red LED lights when the power to the thermostat is on. A yellow LED lights when the thermostat is calling for

heat.

To adjust, turn the adjustment tool. If no adjustment tool is present, a small flat-head screwdriver may be used. The

display will flash, indicating that the display is showing the set point, not the actual temperature.

The dots below the numbers indicate the temp range.

0 dots – less than 100° F

1 dot – between 100° and 200° F

2 dots – over 200° F

Thermostat

Examples:

7 5

8 7

= 75°F

= 187°F

0 3

= 203°F

6

Page 7

Troubleshooting

Brewing Problem Possible Cause Solution

Short brew levels

High brew levels

Dispenser not empty -Empty the dispenser completely and try again

Brew basket or filter overflows

Grounds not saturated

Water Softener in use -Obtain water from a non-softened source.

Weak Coffee

Too many filter papers -Make sure only one paper is used

Low brew temperature

Spray head / brew basket drips

Coffee tastes too strong

Short brew levels -See “Short brew levels”, above.

Incorrect amount of water poured

in top of brewer.

Incorrect amount of water poured

into top of brewer.

-Call FETCO Service Dept. to discuss. (800) 338-2699

Half batch used incorrectly -Use smaller brew basket

Degassing - extremely fresh

coffee

Improper dose -Measure and confirm correct dose

(Temperature inside the water

tank should be set to 203° F.)

Condensation around the

sprayhead area

Condensation from water tank

dripping through dispense tube

Incorrect dosage -Measure and confirm the correct amount of coffee

Temperature Problem (brewer only) Possible Cause Solution

Brew water is cold / not hot enough,

ready light is OFF.

Water tank is not full.

Defective liquid level control

Bad heating element.

Brew water is cold / not hot enough,

ready light is ON.

Slow to recover temperature

(Ready light takes a long time to come

back on after brewing.)

Boiling and Steams

No power to brewer. -Make sure power switch is on

(If the brewer has not been used

for an extended period, the

water level may drop below the

probe tip, disabling the

thermostat.)

board.

(No power to thermostat).

Bad Thermostat

(The thermostat believes that it is

at set temperature)

Low brew temperature

(Temperature inside the water

tank should be set to 203° F.)

Hot water tank limed up -Remove access cover to the hot water tank and inspect

Thermostat set too high for

altitude (Denver etc.)

Defective thermostat -Replace the thermostat and or thermal probe. It’s not

Dispenser Problem Possible Cause Solution

Coffee not hot enough

Using 1/2 batch on regular basis -Encourage full batch use except at end of day or shift.

Parts related problems

Attempting to hold coffee too

long.

-Contact dispenser manufacturer:

Use correct amount of water for the size of the dispenser

being used.

Use correct amount of water for the size of the dispenser

being used.

-Call FETCO Service Dept. to discuss.

(800) 338-2699

-Adjust thermostat so the water stream measured at the

bottom of the brew basket, 1/3 of the way through the

brew cycle, equals 195 degrees + or - 5 degrees

-Wipe sprayhead area after brewing; place an empty

container under brew cone when not in use.

-Insert an empty brew basket and server under brew

heads when not in use

required

-Make sure brewer is plugged in.

-Check the wall circuit breaker / reset

-Refill the tank by pouring water into the top of the

brewer until it begins flowing out of the sprayhead.

-With power on, and water tank full, disconnect the

green wire connected to the water level probe.

Touching this wire to the tank should cause the relay

on the control board to click. If not, replace the board.

-Check amperage draw on heater wires. 0 amps = bad

heater.

-Replace the thermostat and or thermal probe. It’s not

possible to trouble shoot the probe.

-Adjust thermostat so the water stream measured at the

bottom of the brew basket, 1/3 of the way through the

brew cycle, equals 195 degrees + or - 5 degrees

for lime. Remove the brewer for shop de-liming if build

up is thick.

-Reduce temperature setting to 3 degrees below boiling

at your altitude

possible to trouble shoot the probe.

-Review discard times

Explore the need for smaller dispensers

Zojirushi - (800) 733-6270

Techni-Brew - (800) 545-4077

7

Page 8

CBS-31P

Parts

ITEM QTY PART NO. DESCRIPTION

1 1 72006 KNOB, WATER INLET COVER

2 1 01180 WATER INLET LID

3 1 82041 CHAIN, #10, ROUND BEAD

4 1 01160 COVER TOP

5a 1 23174 LID, UPPER TANK

5b 1 23200 BODY, UPPER TANK

6 1

6 1

7 1 31036 FITTING, COMPR., MALE CONNECT.,1/4 TUBE OD. X 1/4 MPT

8 1 83064 WASHER, .812" OD X .563"ID, FLAT

10 2 31117 LOCKNUT, 1/4 STRAIGHT PIPE THREAD

11 1 12030 WATER LEVEL PROBE FITTING

12 1 21069 BREW HOUSING

53015 thermostat temp probe 14" (use with K045 digital thermostat or 53012 thermostat)

102198 Digital temp probe assy., 14” (use with K045 digital thermostat only)

8

Page 9

13 1 31101 FITTING, BARB, 90 ELBOW, 1/2 HOSE ID X 3/8 MPT

14 2 31118 LOCKNUT, 3/8 STRAIGHT PIPE THREAD

15 1 21038 HOUSING, ELECTRODE

16 1 002034 WELDMENT, WATER LEVEL PROBE

17 1 102047 TANK COVER ASSY

18 1 25094 VENT,SILICONE TUBE,

19 1 32047 TUBE, FITTING, TANK

20 1 32045 TUBE, FITTING, BREW

21 1 25095 TUBE, SILICONE

22 1 03098 BRACKET, SPRAY HEAD HOLDING

23 1 83065 WASHER, 1.0"OD X .412"ID, FLAT

24 1 24036 O'RING, .562" OD X .375" ID

25 1 21061 FLOW DISC, DISENSE

26 1 23104 SPRAY CUTTER, CLEAR, 6 + 1 HOLE

27 1 24010 O'RING SPRAY CUTTER

35 1 52023 TERMINAL BLOCK

36 2 82054 #6-32 X .625 S.S., PHIL, MS.

37 1 01152 BACK COVER

38 1 401044 WIRING DIAGRAM

39 1 22048 INSULATION

40 1 03076 BRACKET, THERMOSTAT

41 1 K045 DIGITAL THERMOSTAT, 100-120VAC

41 1 K046 DIGITAL THERMOSTAT, 200-240VAC (EXPORT ONLY)

42 1 108055 Liquid Level Control Brd. 100-120VAC, digital

42 1 108056 Liquid Level Control Brd. 200-240VAC, digital (EXPORT ONLY)

43 1 107006 1300W, 120VAC HEATER KIT

43 1 107007 1800W, 120VAC HEATER KIT

43 1 107001 2300W, 240VAC HEATER KIT (EXPORT ONLY)

44 1 004008 TANK WELDMENT

45 1 31116 1/8 LOCKNUT SPT

46 1 83041 .812 X .412 FLAT WASHER

47 1 31076 FITTING BARB, 1/8 MPT X 5/16

48 1 25024 TUBE, SILICONE, DRAIN

49 1 102032 CORD, 120VAC, 15AMPS W/5-15P NEMA PLUG ASSY.

49 1 102033 CORD, 120VAC, 20AMP W/5-20P NEMA PLUG ASSY

49 1 102035 CORD, 16AMP W/EUROPEAN PLUG ASSY

49 1 102050 CORD 15AMP W/AUSTRALIAN PLUG ASSY

49 1 102049 CORD, 15AMP W/BRITISH PLUG ASSY

50 1 86012 BUSHING, HEYCO STRAIN RELIEF

51 1 31086 VALVE, DRAIN

52 1 31087 FITTING, DRAIN VALVE CONNECT

53 1 58064 LAMP "READY" INDICATOR GREEN, 120VAC

54 1 58063 SWITCH, POWER ROCKET, RED, 240VAC

55 1 46009 LABEL, INFO. SET CBS-30'S

56 6 84002 NUT, HEX #8-32 S.S., MS

57 2 82049 SCREW, ROUND HD, PHIL, MS.#6-32 X 1/4

58 1 25011 TUBE,SILICONE,

60 1 23036 BREW BASKET,BROWN PLASTIC (9-3/4 X 4-1/2 FILTER)

60 1 23035 BREW BASKET, BLACK PLASTIC (9-3/4 X 4-1/2 FILTER) TEA

61 1 86038 CLAMP, HEYCO HOSE

62 1 25004 TUBE, 1/4OD X 1/8ID TEMP.PROBE COVER

63 1 84006 NUT, CAP, #8-32

67 5 83026 WASHER, #8 INTER. TOOTH LOCK

69 3 84001 NUT, #6-32, MS, S.S.

70 2 84002 NUT HEX, #8-32 S.S. MS.

71 3 83011 WASHER, #6, INTERN. TOOTH LOCK

72 10 82053 SCREW,S.S. #6-32 X 1/2, TRUSS HD,PHIL MS

73 4 73007 LEG, 2.5" HIGH, ADJUSTABLE

74 1 83063 WASHER,FLAT, .536 X .875 X .060TH

75 1 24002 TANK COVER GASKET

76 1 09010 BASKET, WIRE, 13 X 5, GOURMET

77 1 101098 ASSY, BREW BASKET, 13 X 5 (OPTIONAL)

78 1 102072 HANDLE ASSY WITH SCREWS & INSERTS

79 2 82042 FITTING, BEAD CHAIN

80 1 102046 WATER POUR OVER LID COVER ASSY

81 4 73002 LEG, 4.0" ADJUSTABLE, FLANGED FOOT

9

Page 10

CBS-31Pap

ITEM QTY PART NO. DESCRIPTION

1 1 72006 KNOB, WATER INLET COVER

2 1 01180 WATER INLET LID

4 1 01160 COVER TOP

5 1 23047 UPPER TANK

6 1

6 1

7 1 31036 FITTING, COMPR., MALE CONNECT.,1/4 TUBE OD. X 1/4 MPT

8 1 83064 WASHER, .812" OD X .563"ID, FLAT

10 2 31117 LOCKNUT, 1/4 STRAIGHT PIPE THREAD

11 1 12030 WATER LEVEL PROBE FITTING

12 1 21069 BREW HOUSING

13 1 31101 FITTING, BARB, 90 ELBOW, 1/2 HOSE ID X 3/8 MPT

14 2 31118 LOCKNUT, 3/8 STRAIGHT PIPE THREAD

15 1 21038 HOUSING, ELECTRODE

16 1 002034 WELDMENT, WATER LEVEL PROBE

17 1 102047 TANK COVER ASSY

53015 thermostat temp probe 14" (use with K045 digital thermostat or 53012 thermostat)

102198 Digital temp probe assy., 14” (use with K045 digital thermostat only)

10

Page 11

18 1 25094 VENT, SILICONE, TUBE

19 1 32047 TUBE, FITTING, TANK

20 1 32045 TUBE, FITTING, BREW

21 1 25095 TUBE, SILICONE

22 1 03098 BRACKET, SPRAY HEAD HOLDING

23 1 83065 WASHER, 1.0"OD X .412"ID, FLAT

24 1 24036 O'RING, .562" OD X .375" ID

25 1 21061 FLOW DISC, DISPENSE

26 1 23104 SPRAY CUTTER, CLEAR, 6 + 1 HOLE

27 1 24010 O'RING SPRAY CUTTER

29 2 01490 LEG CHANNEL

30 4 83027 WASHER, 1/4" SCREW SIZE, INTERNAL TOOTH LOCK

31 4 82073 SCREW, SOCKED HD, CAP, 1/4-20 X 1/2LG

32 4 73016 LEG, 1.0" HIGH

34 1 83041 WASHER, .812"OD X .412"ID FLAT

35 1 52023 TERMINAL BLOCK

36 2 82054 #6-32 X .625 S.S, PHIL, MS.

37 1 01152 BACK COVER

38 1 401044 WIRING DIAGRAM

39 1 22048 INSULATION

40 1 03076 THERMOSTAT BRACKET

41 1 K045 DIGITAL THERMOSTAT, 100-120VAC

41 1 K046 DIGITAL THERMOSTAT, 200-240VAC (EXPORT ONLY)

42 1 108055 Liquid Level Control Brd. 100-120VAC, digital

42 1 108056 Liquid Level Control Brd. 200-240VAC, digital (EXPORT ONLY)

43 1 107006 1300W, 120VAC HEATER KIT

43 1 107001 2300W,240VAC HEATER KIT (EXPORT ONLY)

43 1 107007 1800W 120VAC HEATER KIT

44 1 004008 TANK WELDMENT

45 1 31116 1/8 LOCKNUT SPT

47 1 31076 FITTING, BARB, 1/8 MPT X 5/16

48 1 25024 TUBE SILICONE, DRAIN

49 1 102033 CORD, 120VAC, 20AMP W/5-20P NEMA PLUG ASSY

49 1 102035 CORD, 16AMP W/EUROPEAN PLUG ASSY

49 1 102050 CORD 15AMP W/AUSTRALIAN PLUG ASSY

49 1 102049 CORD, 15AMP W/BRITISH PLUG ASSY

49 1 102032 CORD, 120VAC, 15AMPS W/5-15P NEMA PLUG ASSY.

50 1 86012 BUSHING, HEYCO STRAIN RELIEF

51 1 31086 VALVE,DRAIN

52 1 31087 FITTING, DRAIN VALVE CONNECT

53 1 58064 LAMP "READY" INDICATOR GREEN, 120VAC

54 1 58063 SWITCH, POWER ROCKET, RED 240VAC

55 1 46009 LABEL, INFO. SET CBS-30'S

56 6 84002 NUT, HEX, #8-32 S.S, MS

57 2 82049 SCREW,ROUND HD, PHIL, MS. #6-32 X 1/4

58 1 25011 TUBE, SILICONE

60 1 23035 BREW BASKET,BLACK, PLASTIC (9-3/4 X 4-1/2 FILTER) TEA

60 1 23036 BREW BASKET, BROWN, PLASTIC (9-3/4 X 4-1/2 FILTER)

61 1 86038 CLAMP, HEYCO HOSE

62 1 25004 TUBE1/4 OD 1/8 ID TEMP. PROBE COVER

63 1 84006 NUT, CAP, #8-32

66 1 82041 CHAIN, #10 ROUND BEAD

67 1 82042 FITTING, BEAD CHAIN

68 7 83026 WASHER, #8 INTER. TOOTH

69 1 83063 WASHER,FLAT, .536 X .875 X .060TH

70 3 84001 NUT, #6-32, S.S.

71 3 83011 WASHER, #6, INTERN. TOOTH

72 10 82053 SCREW,S.S. #6-32 X 1/2, TRUSS HD, PHIL, MS.

73 1 09010 BASKET, WIRE, 13 X 5, GOURMET

74 1 101098 ASSY, BREW BASKET, 13 X 5 (OPTION)

75 1 102072 HANDLE ASSY WITH SCREWS & INSERTS

76 1 102046 WATER POUR OVER INLET LID ASSY

77 1 24002 COVER GASKET

11

Page 12

Loading...

Loading...