Page 1

®

Model

www.fetco.com

Contact Information ........................................................2

Description & Features ...................................................2

Specifications..................................................................2

Requirements .................................................................2

Weights Capacities and Measurements.........................3

Electrical Configuration and Brewing Efficiency .............3

Installation.......................................................................5

Accessing batch and programming menu screens ........8

NOTICE TO INSTALLER: Please leave this book with the machine.

Table of Contents

User’s Guide

s:

f CBS-2131

f CBS-2132

3 liter and 1 gallon airpot brewers

Operating Instructions...................................................10

Programming- operator access programming..............12

Hot water convenience tap ...........................................17

Adjustable spray pattern ...............................................17

Error Codes...................................................................17

Airpot use instructions and cleaning.............................18

Parts diagrams, bill of materials lists ............................22

Wiring diagrams............................................................33

FETCO®, LUXUS®, EXTRACTOR®, INTERMITTENT BREW, and Driven To Innovation™

are trademarks or trade names of Food Equipment Technologies Company.

© 2012 Food Equipment Technologies Company P114 Version1 October 2012

Page 2

Contact Information

FETCO

®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: sales@fetco.com

techsupport@fetco.com

Description & Features

The CBS-2130 Series coffee brewers feature our universal spray over technology, which works like this:

The following variables are programmed for each batch size:

Brew volume Prewet percent (Percentage of the brew volume)

Brew time Prewet delay (The time between prewetting and the brew cycle.)

Adjustable number of pulses Bypass percent (Percentage of the brew volume)

Three selectable spray patterns

Drip delay (The time between the end of the brew cycle to

empty the brewbasket and end of the brewing cycle.)

Using these variables, the software calculates how much water to use for prewetting, bypass (optional), and

brewing. The total brew time is divided into several cycles. Within these cycles, the software calculates how

long to spray water over the coffee grounds, and how long to pause before the next cycle begins. The optional

bypass valve opens at the beginning of the brew cycle and dispenses the correct amount of water all at once.

Spray pattern into brew basket may be user set for perfect penetration.

Features

Touchscreen Operation Pump circuit calibration on startup

Cascading Spray Dome-no holes to clog in sprayhead Magnetic flux brew basket sensor

Four fully programmable batch sizes per side Dispenser locator under brew basket

Batch sizing Brew at temperature protection

Customizable batch name Brew mechanism is digitally adjustable

Recipe copy Adjustable bypass (with bypass option)

Screen logo customizable by user from SD card Three adjustable spray patterns

SD card firmware program and upgrade installation Totalizing counters for brewer functions

User programs save to and load from SD cards Shipped ready to operate out of the box

Specifications

Requirements

Water Requirements: Inlet Water Temperature: Cold or Hot supply

CBS-2131: 20-75 psig (138-517kPa) 1½gpm/(5.7lpm)

CBS-2132: 20-75 psig (138-517kPa) 1½gpm/(5.7lpm) 13”X5”– standard FETCO # F002

Water inlet fitting is a 1/4 inch male flare. Electrical: See electrical configuration chart.

Brew Volume: Temperature:

Full Batch 3 liter CBS-2132 & CBS-2131—3 liter version

Full Batch 1gal. CBS-2132 & CBS-2131—1 gal. version

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to change by FETCO without notice.

2

Coffee Filter Size:

200°F (93°C) inside water tank (at sea level)

195°F (91°C) ± 5° at sprayhead

Page 3

Weights Capacities and Measurements

Weights and Capacities & Measurements; 3 liter and 1 gallon brewers

Brewer Height Width Depth

CBS-2131

3 liter

CBS-2131

I gallon

CBS-2132

3 liter

CBS-2132

I gallon

21 ⅜”

54.3cm

23 ⅜”

59.4cm

21 ⅜”

54.3cm

23 ⅜”

59.4cm

11 ¾”

30.3cm

11 ¾”

30.3cm

19 ¾”

50.2cm

19 ¾”

50.2cm

20 ⅜”

51.8cm

20 ⅜”

51.8cm

20 ⅜”

51.8cm

20 ⅜”

51.8cm

Empty

Weight

29 lb

13.1kg

29 lb

13.1kg

42.6lb

19.3 kg

42.6lb

19.3 kg

Filled

Weight

50 lb

22.7 kg

50 lb

22.7 kg

87.6 lb

39.7kg

87.6 lb

39.7 kg

Total Weight-

Brewer &

Filled Dispenser

61.2lb

27.8 kg

63lb

28.6 kg

110lb

49.9 kg

114 lb

51.7 kg

Shipping

Weight

36.3 lb

16.5 kg

36.3 lb

16.5 kg

49.4 lb

22.4 kg

49.4 lb

22.4 kg

Shipping Dimensions

22 ¾”x 16 5/8” x 22 7/8”

57.8 x42.3x58.1cm

22 ¾”x 16 5/8” x 22 7/8”

57.8 x42.3x58.1cm

24½” x 22⅞” x 23”

62.2 x 58.1 x 58.4cm

24½” x 22⅞” x 23”

62.2 x 58.1 x 58.4cm

Electrical Configuration and Brewing Efficiency

Electrical Configurations- CBS-2131—3 liter version

Configuration

Code

Heater

Configuration

Bypass

E213103 1 X 1.5 kW NO

E213104 1 X 1.7 kW NO

E213101 1 X 2.3 kW NO

E213105 1 X 2.3 kW NO

E213107 1 X 3.0 kW NO

Voltage

100 - 120

100 - 120

100 - 120

200 - 240

200 - 240

Phase

Wires

1 2+G NEMA 5-15P 1.1 –1.6 10.9 – 13.0 3.9 gal/14.8 lit

1 2+G NEMA 5-15P 1.3 – 1.8 12.3 - 14.7 4.4 gal/16.7 lit

1 2+G NEMA 5-20P 1.7 – 2.4 16.5 - 19.7 5.8 gal/22 lit

1 2+G Cord/No Plug 1.7 – 2.4 8.5 – 10.1 5.8 gal/22 lit

1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

Electrical

Connection

KW

.

Electrical Configurations- CBS-2132—3 liter version

Configuration

Code

Heater

Configuration

Bypass

Voltage

Phase

Wires

E213201 2 X 2.3 kW NO 200-240 1 2+G Terminal Block 3.3 – 4.7 16.5 - 19.7 11.5 gal/43.5 lit

E213202 2 X 3.0 kW NO 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

.

Electrical

Connection

Electrical Configurations- CBS-2131—1 gallon airpot version

Configuration

Code

Heater

Configuration

Bypass

E213102 1 X 2.3 kW NO

E213112 1 X 2.3 kW YES

E213106 1 X 2.3 kW NO

E213116 1 X 2.3 kW YES

E213108 1 X 3.0 kW NO

E213118 1 X 3.0 kW YES

.

Voltage

100 - 120

100 - 120

200 - 240

200 - 240

200 - 240

200 - 240

Phase

Wires

1 2+G NEMA 5-20P 1.7 –2.4 16.5 - 19.7 5.8 gal/22 lit

1 2+G NEMA 5-20P 1.7 – 2.4 16.5 - 19.7 5.8 gal/22 lit

1 2+G Cord/No Plug 1.7 – 2.4 8.5 – 10.1 5.8 gal/22 lit

1 2+G Cord/No Plug 1.7 – 2.4 8.5 – 10.1 5.8 gal/22 lit

1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

1 2+G Cord/No Plug 2.2 – 3.1 10.9 – 13.0 7.7 gal/29.1 lit

Electrical

Connection

Electrical Configurations- CBS-2132—1 gallon airpot version

Configuration

Code

Heater

Configuration

Bypass

Voltage

Phase

Wires

E213203 2 X 3.0 kW NO 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

E213213 2 X 3.0 kW YES 200-240 1 2+G Terminal Block 4.2 – 6.1 21.3—25.5 14.0 gal/53 lit

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to review and change by FETCO without notice

Electrical

Connection

KW

KW

KW

Maximum Amp

Draw

Maximum

Amp Draw

Maximum

Amp Draw

Maximum

Amp Draw

Gallon/Hour

(3 liters per batch)

Gallon/Hour

(3 liters per batch)

Gallon/Hour

(1 gallon per batch)

Gallon/Hour

(1 gallon per batch)

3

Page 4

CBS-2131

3 liter

Dimensions & Utility Connections—Rough-in drawings

CBS-2132

3 liter

CBS-2131

1 gallon

Rough-in CBS-2131—Single station 3 liter airpot version

Rough-in CBS-2132—Twin station 3 liter airpot version

NEMA PLUG CONFIGURATION

G

W

NEMA 5-15P NEMA 5-20P

G

CBS-2132

1 gallon

Rough-in CBS-2131—Single station 1 gallon airpot version

Rough-in CBS-2132—Twin station 1 gallon airpot version

4

Page 5

g

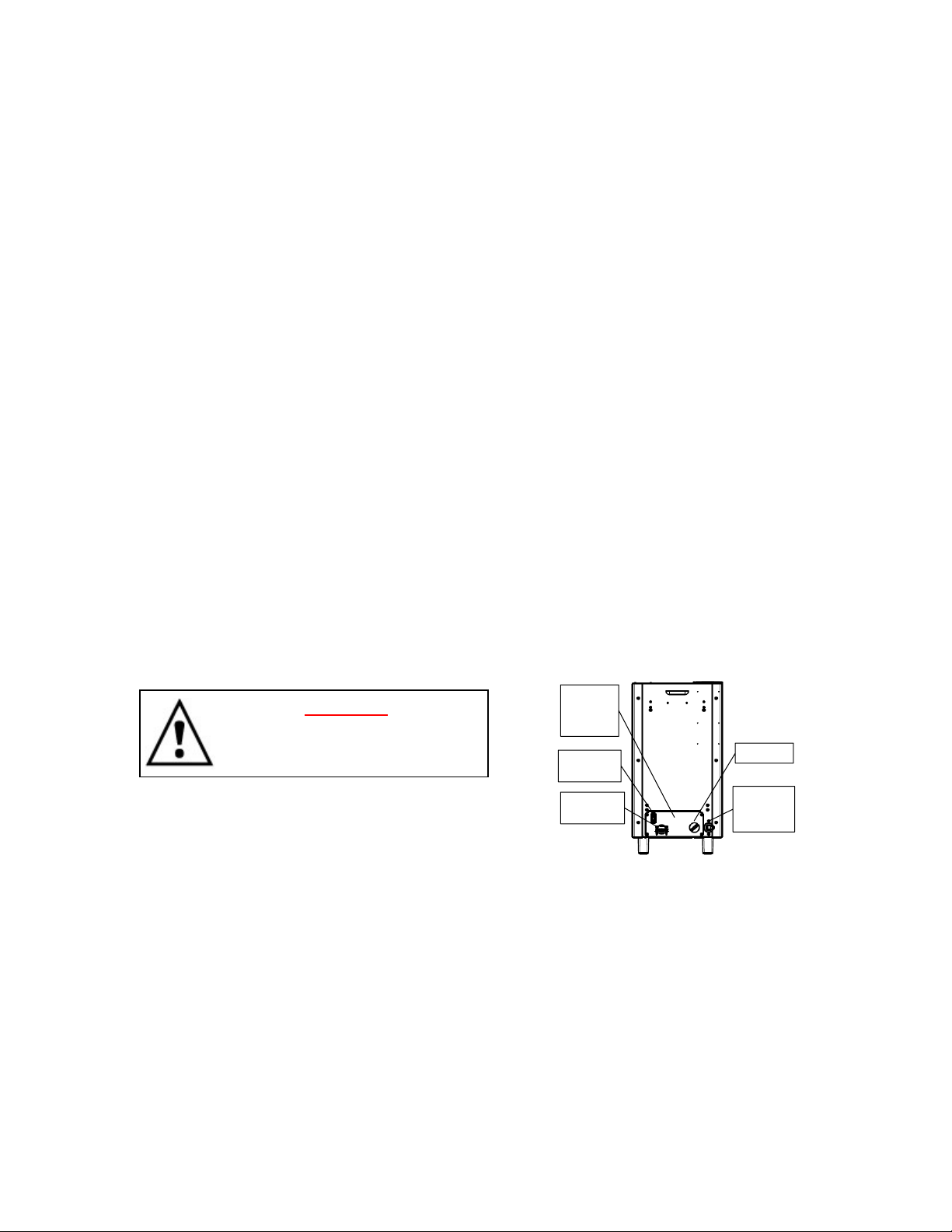

Installation

(For Qualified Service Technicians Only)

Guide to A Successful Installation

If not installed correctly by qualified personnel, the brewer will not operate properly and damage may result.

Damages resulting from improper installation are not covered by the warranty, and will void the warranty.

Here are the key points to consider before installation:

Electrical:

All FETCO brewers require an electrical ground wire. Installation without grounding is dangerous.

Verify voltages, polarity, circuits, and circuit breaker access before attaching equipment.

The electrical diagram is located in the Users Guide and online at www.fetco.com.

The installation must comply with applicable federal, state, and local codes having jurisdiction at your

location. Check with your local inspectors to determine what codes will apply.

Plumbing:

All installations must comply with applicable federal, state, or local plumbing codes.

An inline water filter is highly recommended. It should be installed after a water shutoff valve and in a

position to facilitate filter replacement.

The water line and newly installed filter cartage must be flushed thoroughly prior to connecting it to the

brewer to prevent debris from contaminating the machine.

Verify that the water line will provide a flow rate of at least 1½gpm/ (5.7lpm) per minute and water

pressure is between 20-75 psig (138-517kPa) before making any connections.

Install a backflow prevention device if required. Many municipalities require a recognized backflow

preventer. Usable on all hot beverage and cold beverage equipment is a WATTS® SD-2 or SD-3.

These spring loaded double check valve models are accepted by most zoning authorities.

The check valve should be as close to the water supply inlet of the beverage equipment as possible.

General:

Utilize only qualified beverage equipment service technicians for installation.

A Service Company Directory is available at www.fetco.com.

Leveling legs, if installed, are to be

adjusted for leveling the brewer only.

Do not use for height adjustment, or extend

them hi

WARNING

her than necessary.

Installation Instructions

Brewer Setup

1. Review the dimensions for the unit and verify that it will fit properly in the space intended for it. Verify that

the counter or table will support the total weight of the brewer and dispensers when filled (specifics-page

3).

2. Place the brewer on the counter or stand.

3. When the brewer is in position, level it front to back as well as side to side by adjusting the legs.

4. For 200-240 volt units: remove the lower utility slide out at the back of the equipment to access the

electrical connections. The utility slide must remain close to the unit, Note: it cannot be detached

completely.

5

Utility slide

on back

of brewer

Power

Switch

Electrical

Connection

Tank Drain

Water

Supply

Connection

Page 6

L2

Water Connection

1. Water inlet is a ¼ inch male flare fitting.

2. The brewer can be connected to a cold or hot water line. Cold water is preferred for best coffee flavor, but

hot water will allow for faster recovery times. High temperature water should not exceed 160°F/71°C.

3. Install a water shut off valve near the brewer to facilitate service. An in-line water filter should be used, it

should be installed after the water shut off valve and in a position to facilitate filter replacement.

4. Flush the water supply line and filter before connecting it to the brewer.

5. Verify that the water line will provide at least 1½gpm/(5.7lpm) per minute for the CBS-2131& CBS-2132 and

also that the water pressure is between 20-75 psig (138-517kPa).before connecting it to the brewer.

Electrical Connection – US & Canada

1. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

brewer’s serial number label. Install an electrical ground wire.

2. The temperature and water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The heaters are disabled by the control board until the tank is full of water.

The heating process will start automatically when the tank has filled.

3. Most CBS-2131 equipment is factory equipped with a 120 V cord and plug. Some CBS-2131 and all CBS2132 have a terminal block for connecting the incoming power wires. Consult local codes to determine if a

cord and plug can be installed on factory supplied terminal block equipment, or if the unit must be hard

wired.

4. Plug in unit if the equipment has an attached cord & plug, or, wire into circuit for terminal block units. Note

that the plug is NEMA 5-15P or NEMA 5-20P (domestic).

5. A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near

the brewer, and its location and markings known to the operators.

6. The body of the brewer must be grounded to a suitable building ground. A ground lug is provided in the

brewer next to the power terminal block. Use 10 gauge copper wire for grounding.

7. Electrical connections must be secured in-place within the unit to meet national and local

standards.

Warning : To prevent

electrical shock, this

unit must be prope rly

grounded.

Electrical Configurations Terminal Block Diagram – US & Canada

WARNING—DANGER

Do not plug-in or electrically

energize this equipment, or attempt

operation without all covers in place

and all screws fastened

.

CBS-2131

120 volt models

Factory Configuration:

Attached cord 120 VAC, 3 wires

GROUND

LUG

L1 L2

N

Factory Configuration:

Terminal block for professional installation

(some)CBS-2131 and (all)CBS-2132

208-240 volt models

GROUND LUG

L1

N

L2 - NOT USED

For 120 volt

GROUND WIRE

!MUST BE INSTALLED!

CORD WITH

NEMA 5-15P or 5-20P

or without PLUG

120V 120V

GROUND WIRE

!MUST BE INSTALLED!

N

NOT USED

208-240V

NEW FETCO CONFIGURATIION METHOD!

6

Page 7

Final Setup

Final Setup

1. Turn on incoming water supply line and carefully inspect both inside and

outside of the brewer for leaks in all fittings and tubes

2. Turn on power.

3. Press the brewer’s main power switch (located on the lower right of the

back of the equipment)

4. Pre-check will display: "DC voltage calibration for pumps is

running…Please wait…Calibration is successfully done”. (15 seconds)

5. The water tank will begin filling. FETCO Home Screen #1 will read

“FILLING”.

6. When the water level rises and is sensed by the probe at the top of the

tank the heaters will activate

7. Heaters are automatically disabled until the tank is full.

8. While the water is heating Screen #2 “HEATING” will display and the

actual water temperature will be displayed.

9. After the water has reached the set temperature Screen #3 will display

“READY”

10. Review the Operating Instructions. Brew one full batch (water only) on

each side to confirm proper fill levels. The brewer is factory set with water

only (no coffee) to dispense the correct amount of water. If the actual

volume is slightly different from the programmed volume, fine tuning the

brewer may be necessary. See Calibrate Pumps in the OUTPUT section

in the PROGRAMMING section.

11. Re-attach the covers after one final inspection for leaks. Look closely in

the top of the brewer section at the dispense fittings during this

inspection.

Features of your FETCO Brewer

Touch-screen for brewer operation

Brew basket sensor (not accessible)

SD card interface port (Load & Save)

Hot Water Faucet

FETCO Home Screen #1 “FILLING”

FETCO Home Screen #2 “HEATING”

FETCO Home Screen #3 “READY

Locator removable for service access

Locator for airpot dispenser

(Two for CBS-2132)

Main power switch

Slide out back panel for service access

7

Page 8

p

Accessing batch and programming menu screens

Accessing batch and programming menu screens

DC voltage calibration for pumps is running

Please wait…

Calibration is successfully done.

Batch selection and brew operation menu screens

Å Tap FETCO HOME SCREEN to enter batch selection screen.

Hold down batch selector pennant to begin brew.

FETCO home screen

Programming menu screens

ÅFirst message on touchscreen display at powerup. This shows

only at “POWER ON”, when ON/OFF. The software is analyzing

and correcting any variations as a quality control feature.

Å FETCO home screen will display on completion

Tap left or right side batchesÆ

Operation screens

Touchscreen

MAIN POWER SWITCH

Located to lower right

side of back

anel

FETCO home screen

DC voltage calibration for pumps is running

Please wait…

Calibration is successfully done.

ÅFirst message on touchscreen display at powerup. This shows

only at “POWER ON”, when ON/OFF. The software is analyzing

and correcting any variations as a quality control feature.

Å FETCO home screen will display on completion

From power “OFF”ÆTurn main power switch to “ON”

Touch screen will illuminate, and pump voltage calibration will display

When Complete: FETCO HOME SCREEN will display

Immediately touch and hold finger to enter programming

In 5-8 seconds “PROGRAMMING” screen will appearÆ

8

Page 9

Operator Training

Review the operating procedures with whoever will be using the brewer.

Pay particular attention to the following areas:

1. Always pre-heat the dispensers before the first use of each day by filling them half way with hot water, and

letting them stand for at least 5 minutes.

2. Don't remove the brew basket from a coffee brewer until it has stopped dripping.

3. Make sure the dispenser is empty before brewing into it.

4. Show how to attach covers, close, and or secure the dispensers for transporting.

5. Show the location and operation of the water shut off valve as well as the circuit breaker for the brewer.

6. Steam from the tank will form condensation in the vent tubes. This condensation will drip into and then out of

the brew baskets. Up to 1/4 cup/118cc discharging overnight is possible. Place an appropriate container

under each brew basket when not in use.

7. We recommend leaving the power to the brewer on overnight. The water tank is well insulated and very little

electricity is used to keep the tank hot. Leaving the brewer in the “ON” position will also avoid delays at the

beginning of shifts for the brewer to reach operating temperature.

Cleaning & Maintenance

After Each Brew:

1. Dispose of grounds and rinse brew basket.

2. Never strike a brewbasket or hit it against a hard surface.

This will damage the brew cone, and may damage the brewbasket support rails

3. Rinse dispensers before reuse.

Every Day:

1. Wash brew basket with hot sudsy water.

2. Pull CSD from the spray head, it is magnetically attached. Use gloves or a heavy towel. Æ

Wash off any film and reattach. Use vinegar if limescale filming is present.

3. Clean dispensers with hot suds water and a brush, rinse and air dry.

4. Use only a soft cloth and hot suds on the outside to avoid scratches. Never use abrasives

which will scratch surface.

Weekly

1. Use a commercial coffee dispenser cleaner such as URNEX™, TABZ™, DIP-IT™ or Squeak 'n Clean™.

2. Carefully Follow the instructions supplied with the cleaning product

3. Never use spray cleaners, solvent, solvent based cleaner or petroleum based polish anywhere on dispensers

Safety notes

1. Professional installation is required. This appliance is manufactured for commercial use only.

2. Operation requirements and maintenance for commercial cooking appliances differ from household appliances.

3. Operators must be trained for this equipment and must understand the use, maintenance and hazards.

4. Do not attempt to move hot beverage equipment once it is filled. Drain equipment before moving.

5. CBS-2130 series coffee brewers prepare up to 3 liters/1 gallon of coffee or tea in a single batch using very hot

water. For safety, the brew basket is locked and may be serviced 5.5 minutes after starting the brew. The

factory set brew (default) time is 5.5 minutes with the brew basket locked for safety from start of brew.

! Æ Never attempt to defeat or override a brew basket locking feature.

Warning

1. Turn off power before any cleaning procedure, including wiping the exterior for appearance reasons.

2. Dry the exterior, especially the face panel, before turning on power.

3. Do not apply any type of spray cleaner on the face panel of this equipment.

4. Never use solvent or solvent-based cleaner or petroleum based polish anywhere on this equipment.

5. Dry the face of the touch pad before turning on power

6. Do not electrically energize this equipment or attempt operation without all covers in place and all screws fastened.

7. Unplug machine before disassembly or servicing.

9

Page 10

Operating Instructions

ÆQuick brewer setup NOTES

Install plumbing and electrical utilities.

Turn rear power switch “ON”.

Brewer hot water tank will fill in 4-8 minutes.

Heater(s) activate when tank is full

Initial heating will be 15-30 minutes

Tank displays “ ▪ READY” when filled & 200°F/93°C is reached

Brewer is ready to brew when “▪ READY” is displayed

-See Installation Section in this guide

-Located on back, lower right side

-Ready screen will display ”▪FILLING”

-Ready screen will display ”▪HEATING”

-Place dispenser under brewbasket(s)

to collect any overflow and condensate

-Best results if brewer remains “ON”

Brewing

ÆTo brew a single 3 liter coffee batch, using default recipe NOTES

FETCO CBS-2130 series equipment is factory calibrated and preloaded with recipes and is ready to brew.

Place 13”X5” paper filter in brew basket

Add 3-8 ounces (85 – 227 g) of ground coffee

Insert loaded brewbasket into brewer rails

Have empty dispenser under brewbasket

Tap “▪ READY” screen to enter the batch selection menu

-FETCO Product # F002 or any 13”X5”

-Weights given are only suggested

-Brewbasket(s) must be in place

-Use the convenient locator guide

-A long duration “TAP” with fingertip

Touch a top batch key for “REGULAR 1”

Brewer will brew and display the icon for the function step it is in

On dual side brewer, touch other side to access batches for brewing

Batch will complete brewing in 5 ½ minutes

Touch the “Ready” screen

anywhere briefly to activate

(CBS-2131)

(CBS-2132)

Touch and hold finger on

selection pennant for about two

seconds to start brew

CBS-2132 selection

for brewing on right,

left or both sides.

Touch batch pennant

to access menu

-Touch batch pennant with fingertip

-Icon may be toggled for information

-Right to left side switching by touch

-Brew time: 4 minutes+1½ min. drip out

10

Page 11

Brewing-shown by touchscreen

Brewer screens displayed for brewing NOTES

CBS-2131 CBS-2132

“READY SCREEN”

Tap screen to display

menus

Unit displays four

preprogrammed batch

buttons per side. CBS-

2132 has right and left

ÅCBS-2131

CBS-2132 Æ

Select and hold one button

for 2 seconds

Brew started

(in prewet)

ÅCBS-2131

CBS-2132 Æ

Note: there are three “BREW AT

TEMPERATURE DEFINITONS”. The “Brew

at temperature default routine is shown below.

Brew basket sensor

enabled.

Unit is brewable only when

brebasket is in place.

(option may be disabled by

user)

Brew at tempertaure

enabled: brew will start

when tank temperature

reaches he set point

Both sides of CBS-2132

brewing simaltanously.

Brewing

ÅCBS-2131

CBS-2132 Æ

Brewing

ÅCBS-2131

CBS-2132 Æ

Brew completed

(in drip delay)

ÅCBS-2131

CBS-2132 Æ

Both sides of CBS-2132

brewing simaltanously.

Both sides of CBS-2132

brewing simaltanously.

Left side completing drip

delay

CBS-2132 right side

completing drip delay, left

side ready for next brew

11

Page 12

-The FETCO CBS-2130 brewers have four brew batch menus per side.

They are preprogrammed with basic settings that will operate the equipment as purchased.

There are two batches each marked “Regular” and two marked “Decaf”

-Most operators prefer a full batch and half batch setting for regular and decaf or specialty coffees. These will need

to be programmed by the operator

-Settings are adjustable and the names can be changed. -Batch 1 & 4 cannot be disabled.

Menu screen displayed

(FETCO “HOME” screen)

Programming- operator access programming

Accessing

Programming

Turn unit “OFF”

After 10 second delay:

Pre-check will display: "DC

voltage calibration for pumps is

running…Please wait…Calibration

is successfully done”.

Turn unit “ON”

“HOME" Screen on left will

appear

Å

Immediately place finger on

screen and “HOLD”

Screen on right will appear

Æ

Menu screen displayed

<

<

PROGRAM

Batch 1 Left

EXIT

<< >>

T

ÅTop line is programming

>

category

>

Å Second line displays

items for programming

Right and left hand arrows

will scroll to the screens that

display “Program, General,

Inputs, Outputs and Other”.

Down arrow enters the

individual programming items

shown below

Accessing

Programming menu

screens

Programming-category screens: Menu Tree

Programming category screens

To enter: Turn unit “OFF”, After 10 second delay, turn unit “ON”, (Home Screen will appear),

Immediately place finger on screen and “HOLD” PROGRAM

Use right/left and down arrows to travel through programming. “EXIT” saves settings

Screen (first below) will appear.

Programming Category

PROGRAM

Items for Programming Items for Programming Items for Programming

Batch 1 LEFT*

Batch 2 Left**

Batch 3 Left **

Batch 4 Left **

Batch 1 RIGHT*

Batch 2 Right **

Batch 3 Right **

Batch 4 Right **

Batch Copy

Programming Category Programming Category Programming Category

GENERAL

Tank Temp

Brew At Temp

Unit of Meas.

Volume

ECO Mode

Logo Timeout

Brew B.Sensor

INPUTS OUTPUTS

Display Inputs Left Pump

Calib Touch Scr L.Bypass Pump* Display Errors

12

Programming Category

Items for

Programming

Right Pump

R.Bypass Pump* Copy Program

Fill Valve

Heater

Screen

*

Bypass option is only on

1 gallon airpot version

Items for Programming

OTHER

Error Codes

Reset Errors

From SD to B

From B to SD

Upload Logo

Res to Factory

Firmware

Page 13

Menu Features: Batch Parameters

PROGRAM Programming Items Factory set Default Programming Range Notes

Batch 1 LEFT*

• Batch Summary

• Batch Name

• Batch Volume

• Brew Time

• Spray Pattern

• Nr Of Pulses

• Prewet Perc.

• Prewet Delay

Batch 2 Left**

• Bypass Perc.

• Drip Delay

**Batch 2-4—Right and Batch2-4—Left may be individually selected-or-entirely deleted

• Batch ON/OFF

• Batch Summary

• Batch Name

Batch 3 Left **

Batch 4 Left **

Batch 1 Right *

Batch 2 Right **

Batch 3 Right **

Batch 4 Right **

Batch Copy

Copy?

*Batch 1&4 cannot be disabled. (CBS-2132); *Batch 1 cannot be disabled. (CBS-2131) **Batch can be disabled, and removed from display

• Batch Volume

• Brew Time

• Spray Pattern

• Nr Of Pulses

• Prewet Perc.

• Prewet Delay

• Bypass Perc.

• Drip Delay

(See Batch 2-Left)

(See Batch 2-Left)

(See Batch 1-Left)

(See Batch 2-Left)

(See Batch 2-Left)

(See Batch 2-Left)

Copy From Batch L1 L1-L4;R1-R4

Copy To Batch L1 L1-L4;R1-R4

Display Summary

Regular 1(-16)

3.05 liter

[ 1.0-4.7]

4:00 mm:ss

Wide

8

0%

0:00 mm:ss

0%

1:30 mm:ss

ON

Choose from list:

Regular1

3.03 liter

|_________

0.94 4.73

4:00 mm:ss

[]___________|

|_____

2:00 10:00

[]______________|

|__

Wide Middle Narrow

[]___________|

|_____

1 30

[]_______________|

|_

0 15

1:30 mm:ss

[]________________|

|

0:00 1:00

[]_______________|

|_

0 40

1:30 mm:ss

[]___________|

|_____

0:30 5:00

|_________

0.94 4.73

[]________|

Wide

8

0 %

0 %

ON

[]________|

(Regular 1-16)

-OR- Write: any name

Bypass option is only on 1

gallon airpot version

Display Summary

Regular 1

3.03 liter

[ 0.94-4.73]

4:00 mm:ss

Wide

8

0%

0:00 mm:ss

0%

1:30 mm:ss

Regular 1-16;Write own name

ON

[]______________|

|___

ON OFF

4:00 mm:ss

[]___________|

|_____

2:00 10:00

Wide Middle Narrow

0:00 1:00

0:

Wide

[]______________|

|__

8

[]___________|

|_____

1 10

|_

[]________________|

|

|_

0 %

[]_______________|

0 15

0:00 mm:ss

0 %

[]_______________|

0 40

1:30 mm:ss

[]_________|

|_____

30 5:00

Bypass option is only on 1

gallon airpot version

L1ÆL2?

(example)

|_______________

YES NO

NO

[]__|

13

Page 14

g(°F)

GENERAL

Tank Temp.

Brew at Temp.

Units of Meas.

Logo Timeout

Brew B. Sensor

Programming

Items

200°F

“OFF” allows

brewing at any

temperature.

• Temperature

• Volume

1:00 mm:ss

Factory set

Default

AUTO

°F

Liters

Programming Range

|______________[]___|

180 207

|____________[]___|

OFF ON AUTO

|___[]____________|

|_____________[]__|

|_[]_______________|

0:00 5:00

NORMAL

NORMAL OVERRIDE

(display)

200 °F

AUTO

°F

°F °C

Liters

Gallons Liters

1:00 mm:ss

NORMAL

|__[]____________|

Notes

Correction for high

altitude below

SEE NOTE BELOW!

INPUTS

Display Inputs

Cal. Touch Scr

Chart to correct for boiling point for altitude

in tank water temperature.

Altitude (ft.)

0 200 212.0

500 200 211.1

1000 200 210.2

2000 200 208.4

2500 200 207.5

3000 200 206.6

3500 197 205.7

4000 195 204.8

4500 194 203.9

5000 194 203.0

5500 193 202.0

6000 192 201.1

6500 191 200.2

7000 190 199.3

7500 188 198.3

8000 187 197.4

Suggested

Settin

Programming

Items

• Input

Summery

Boiling

point (° F)

Factory set

Default

Calibrate

Programming Range

(display)

Brew Basket Sensor

High Liquid Level probe

High Tank Temperature Probe

Lower Tank Temperature Probe

SD Card Recognized

USB Drive Recognized

________________[]____

YES NO

Calibrate

USB is for factory

Follow directions on

the touch screen

BREW AT TEMPERATURE DEFINITONS

BREW AT TEMP: AUTO

(DEFAULT: FACTORY PROGRAMMED INTO BREWER)

This allows the “BREW START” to active. If the hot water

tank is at the selected temperature—the brew will start.

If the temperature is too low, the brewer will wait until the

proper temperature is reached. A screen (example to the

right) will display showing a thermometer icon and the tank

temperature.

IMPORTANT: ALWAYS have dispenser(s) under the brew

baskets when in the BREW AT TEMP mode.

BREW AT TEMP: ON USER SELECTABLE

“BREW START” Batch Section Buttons will not be

accessible until tank temperature is at set point.

The “BREW START” screens with the Batch Section

Buttons become accessible when hot water tank is at the

selected temperature. The screen at right displays when

the “BREW AT TEMP” is selected.

BREW AT TEMP: OFF USER SELECTABLE

Allows brewing at any temperature above 179°F/82°C. (Not recommended)

.

14

Notes

setup only

If Yes

:

Page 15

OTHER

Error Codes

Copy

Program

Upload Logo

Res to

Factory

Counters

Firmware

Programming

Items

• Display Errors (Codes)

• Reset Errors

• From SD to B.

• From B to SD

Factory set

Default

(Reset)

SDÆ Brewer

BrewerÆ SD

Upload Logo

Reset to default

• Display

Counters

-OR-

• Reset

Counters

• Reset

Counters

• Firmware

Version

-Software type

• Update

Firmware

Counters

Display Total

Counters

Reset All

Counters

Firmware Version

UPDATE

Programming Range

(display)

1:

2:

3:

|_______________[]____|

|________________[]____

|________________[]____|

|________________[]____|

|________________[]____|

Left Brews

Left Brew activated

Left Brew [liters]

Left Bypass Activated

Left Bypass [liters]

Right Brews

Right Brew activated

Right Brew [liters]

Right Bypass Activated

Right Bypass [liters]

Fill valve Activated

Fill Valve [liters]

Heater Activated

Heater “on” time

Touch To Return

|________________[]____|

|________________[]____|

Reset

YES NO

SDÆ Brewer

YES NO

BrewerÆ SD

YES NO

UPLOAD LOGO

Are you sure

YES NO

Reset to Default

Are you sure

YES NO

All Counters

Reset All Counters

Are you sure

YES NO

SW ver. 1.0.2A

HW ver

BL ver.1.0.1

QP ver. 4.5.01

UPDATE

YES NO

Notes

Chart is below

!!Errors must be

corrected and cleared!!

Setup upload

------------------------------------------------------------------------

Please insert SD card with

------------------------------------------------------------------------

Please insert SD card with

sufficient space

Please insert SD

card with logo file!

overwrites all user

setup, incl. user logo.

0

0

0

0

0

0

Resetting will

0

restart counter

0

from zero

0

0

0

0

0

0

Displays firmware

------------------------------------------------------------------------

Please insert SD card with

----

the setup data!

Setup download

----

(≥2GB)

Completely

version

Firmware upload

----

the firmware file!

ERROR CODES

Error code 50: Shorted temperature probe

Error code 51: Open temperature probe

Error code 100: Initial Fill Error. Initial fill time was more than 4 minutes after power up.

Error code 101: Error on refill

Error code 102: Unwanted fill; possible leak

Error code 103: Liquid level probe fault

Error code 201: Heater open, high limit thermostat, or Solid State Relay (SSR) fault

15

Page 16

OUTPUTS

Left Pump

’’ ’’ ’’ ’’

L.Bypass Pump*

’’ ’’ ’’ ’’

Right Pump

’’ ’’ ’’ ’’

R.Bypass Pump*

’’ ’’ ’’ ’’

Fill Valve

Heater

Screen

Programming

Items

• Left Pump Test (Press to test)

• L. Pump Calib

• Left BP Pump

Test

• L. BP Pump

Calib

• Right Pump Test (Press to test)

• R. Pump Calib

• Right BP Pump

Test

• R. BP Pump

Calib

• Fill Valve Test (Press to test)

• Heater Test (Press to test)

• Screen Contrast Contrast

• S. Brightness

Factory set

Default

Calibrate

*Flow Rate

(Press to test)

Calibrate

*Flow Rate

Calibrate

*Flow Rate

(Press to test)

Calibrate

*Flow Rate

Brightness

*Bypass option is only on 1 gallon airpot version

*How to calculate flow rate

Measured Æ

Set Point Æ

If flow rate setting is 0.49

Then new flow rate is

0.49 X 0.96=0.47

By entering the new flow rate number

into the brewer, the software will

correct the discrepancy in the pump.

2.90

———

3.00

Programming Range

(display)

TEST

Press To Test

|_________[]________|

0.39 0.59

Press To Test

|_________[]________|

0.39 0.59

Press To Test

|_________[]________|

0.39 0.59

Press To Test

|_________[]________|

0.39 0.59

Press To Test

Press To Test

|____________[]____|

|____________[]____|

=

0.96

0.49

TEST

0.49

TEST

0.49

TEST

0.49

TEST

TEST

8

1 10

8

1 10

Notes

Runs pump to verify

flow. Have container

under brewbasket!

Factory or service use

for flow rate

Runs pump to verify

flow. Have container

under brewbasket!

Factory or service use

for flow rate

Runs pump to verify

flow. Have container

under brewbasket!

Factory or service use

for flow rate

Runs pump to verify

flow. Have container

under brewbasket!

Factory or service use

for flow rate

Operates fill valve.

Have container under

both brewbaskets!

Energizes Heater(s)

Use for servicing.

16

Page 17

Hot water convenience tap

1. The CBS-2130 coffee brewers include a hot water convenience tap for single cup beverage purposes.

2. Single use delivery volume should not exceed maximum 16fl.oz/473cc.

3. Water dispensed from this faucet is very hot, up to 205°F/96°C

Adjustable spray pattern

This FETCO equipment features digitally adjustable spray patterns for perfect penetration

FETCO CBS-2131 and CBS-2132 coffee brewers feature digitally adjustable spray patterns for perfect penetration.

All batches can be set for wide, middle or narrow spray patterns of the hot brew water that showers the coffee bed

in the brewbasket. The turbulence created by the spray pattern combined with variable pulses is infinitely

adjustable for desired flavor extraction of individual roasts and grinds of any coffee variety.

The default setting for all batches is WIDE. The brewer software calculates and corrects to achieve proper volume

based on the flow rate changes of the spray pattern.

Error Codes

Code Description Possible Cause Corrective Action

050 Shorted temperature probe Probe failure. Replace probe.

051 Open temperature probe.

Initial Fill Error. Initial fill

100

time was more than 4

minutes after power up.

Error on refill

101

Tank did not refill within 3

minutes.

102 Unwanted fill;

103 Liquid level probe fault

Heater open, high limit

201

thermostat, or Solid State

Relay (SSR) fault

INSERT

Bad probe

connection, or

probe failure.

Water supply flow

rate is too low.

Water supply flow

rate is too low.

Possible leak in

tank, fitting, or

valve.

Probe fouled or

shorts

SSR, High Limit,

or heating

element failure.

Brewbasket must

be in place

Check all connections.

Replace probe if necessary.

Watch for short potting

during brew cycle.

Investigate cause of low flow

rate. (Clogged water filter...)

Watch for short potting

during brew cycle.

Investigate cause of low flow

rate. (Clogged water filter…)

Check inside of machine for

leaks.

Clean, check all

connections. Replace probe

if necessary.

Check and replace heating

elements if necessary.

Insert brewbasket

BREW

BASKET

CLEAR FAULT, make

repairs as required

Below is the only way to

clear error codes

1) Enter

“PROGRAMMING”

2)Scroll left to “OTHER”

3)Scroll down to

“ERROR CODES”

4)Scroll down to “Display

Errors”

5)Scroll left to “Reset

Errors”

6)Scroll down to “Reset”

7)Follow directions

shown on screen.

Toggling ON/OFF switch

will not

Error codes must be

cleared!

How to Clear

Error Codes

clear error codes.

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to review and change by FETCO without notice

17

Page 18

Airpot use instructions and cleaning

Dispenser Diagram

D041 (3 liter) and

®

D063 (1 gallon) Airpot

DESCRIPTION : Dispenser Diagram

The FETCO D041 (3 liter) and D063 (1 gallon) airpots are lever type, air pressure evacuated

beverage dispenser featuring double-wall, vacuum insulated construction.

The hermetically sealed vacuum double-wall construction provides excellent heat or cold

retention, while the stainless steel outer and inner liners provide robust durability.

PARTS :

Locking Tab

Lever

Bellow Cap

Bellow

Bellow Cap Plate

Spout Tube

Drip-Through

Down Tube

Lip Release Button

18

Page 19

Dispenser Operation Instructions

D041 (3 liter) and

®

D063 (1 gallon) Airpot

To Fill :

Set brewer to dispense the

1

proper amount into the

airpot :

3 liters (FETCO D041)

-or-

1gallon (FETCO D063)

To Dispense:

After the brew cycle is

1

completed:

Remove the airpot from

under the brewbasket and

close the lid.

Squeeze the Lid Release

2

Buttons to release the lid.

Swing the lid completely

backwards

Lift the handle up until the

2

Lever Lock drops into

position, and engages the

pump mechanism.

Place the airpot under the

3

brewer against the airpot

dispenser Locator (if

featured).

Align the center of the

airpot Drip-Through with

the outlet of the

brewbasket.

Push the lever downwards

3

multiple times to dispense

the desired amount

19

Page 20

4

Dispenser Cleaning & Maintenance

D041 (3 liter) and

®

D063 (1 gallon) Airpot

To Clean :

Squeeze the Lid Release

1

Buttons to release the lid.

Press the Lid Detach Button

that will completely detach

the lid.

Remove the Lid Cover.

Remove the Drip-Through

2

Detach the Down-Tube

and the Spout-Tube.

Clean with warm water,

detergent and a brush.

Proprietary airpot cleaners

may also be used.

Carefully remove the

3

bellows Cap.

Handling the parts gently,

clean the Bellows,

Bellows Cap, and Bellow

Cap Plate with warm

water, and non-abrasive

mild detergent.

Clean the interior of the tank

with warm water, detergent

and a brush. Proprietary

airpot cleaners may also be

used

.

Do not put the airpot into

an automatic dishwasher.

Do not allow solutions

containing chlorine to

remain in tank.

Clean the exterior of the

5

with warm water, non-

unit

abrasive mild detergent.

Do not submerge the unit

in water

6

C4H9OCH2CH2OH

Do not use petroleum

based or organic cleaners

on food equipment.

Never use cleaners or

polishes formulated with

the solvent diethylene

glycol butyl ether(DGBE)

on any equipment.

20

Page 21

FETCO® CBS-2130

COFFEE BREWING SYSTEM

Complete Commercial Parts Listing

For CBS-2131 and CBS-2132 Model Range

Includes types for the 3 liter and 1 gallon airpot dispensers

NEW September, 2012

Please see our website-www.fetco.com for the most up to date listings and additional parts and service information

Designs, materials, specifications, physical dimensions, firmware and software protocol for equipment or replacement parts are subject to change without notice.

21

Page 22

Parts diagrams, bill of materials lists

22

Page 23

Drawing 1101.00128.00 CBS-2131ASSEMBLY, 1gallon NO BYPASS, 2.3kW/120VAC

Ref# Qty Part number Description

1 1 1111.00030.00 WELDMENT BODY, CBS-2131

2 2 1024.00049.00 EDGE PROTECTOR, 7.00"LG, CBS-2130

3 3 1086.00004.00 BUSHING, SNAP, 1" MOUNTING HOLE

4 1 1024.00017.00 O'RING, 3.739" ID X 0.070" CS, 70 DURO, BUNA "N", FDA

5 1 1102.00183.00 SPRAY HOUSING ASSEMBLY, CBS-2130

6 4 1083.00010.00 WASHER, #10 SCREW W/NEOPRENE-BONDED SEAL

7 8 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

8 1 1102.00113.00 SWITCH, REED, ASSEMBLY

9 4 1029.00006.00 #4-40 NYLON FINGER NUT

10 1 1071.00010.00 FAUCET HPSC-BR-8 REGULAR HANDLE

11 1 1031.00003.00 FITTING, BARB 3/8'ID x 1/4" FPT

12 1 1057.00043.00 SOLENOID VALVE, SINGLE, 180 DEG, 24VDC

13 1

14 2 1083.00005.00 WASHER, M4 18-8 INTERNAL TOOTH LOCKWASHER

15 2 1082.00010.00 SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

16 1 1102.00164.00 ADAPTER ASSY, 3/4" BSP X 1/4 SAE FLARE

17 1 1104.00043.00 TANK ASSY, 2300W/120VAC, CBS-2131, GROMMETS

18 1 1112.00163.00 WELDMENT TANK LOCK BRACKET, CBS-2100

19 4 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

20 2 1082.00023.00 SCREW, #8-32 X 3/8 TRUSS HD PHIL., MACHINE

21 1 1102.00187.00 PUMP BRACKET AND HOLDER ASSEMBLY

22 9 1086.00003.00 UNICLAMP, 15.9 HOSE OD CLAMP

23 1 1025.00063.00 TUBE, 5/8'OD X 3/8"ID X 8.50"LG

24 1 1102.00181.00 ASSEMBLY BACK PANEL, CBS-2130

25 11 1082.00017.00 SCREW, # 6-32 X 1/2" TRUSS HD PHIL., MACHINE

26 1 1023.00147.00 PLUG, TANK SERVICE DRAIN FOR 18GA AND UP BODY

27 1 1024.00040.00 CARD PLUG, HWD-2100

28 1 1102.00190.00 ASSEMBLY FRONT PANEL, CBS-2100

29 4 1082.00058.00 SCREW, # 8-32 X 5/8, FLAT HD, PH, 18-8 SS

30 1 1102.00182.00 ASSEMBLY, LOCATOR CBS-2130

31 1 1082.00065.00 SCREW #8-32 X 1 1/2", FLAT HD PH, 18-8 SS

32 1 1023.00159.00 CORNER INSERT

33 1 1112.00168.00 WELDMENT, TOP COVER, CBS-2131

34 1 1402.00034.00 HARNESS, HIGH AMP, CBS-2131

35 1 1402.00035.00 HARNESS, LOW AMP, CBS-2131

36 1 B012280B1 BB ASSY, 13"X5", .280" DIA. HOLE, BLK HNDL

37 1 1024.00052.00 CONNECTOR, BREW PUMP

38 1 1086.00002.00 CLAMP, HOSE, SIZE "G" NYLON

39 1 1055.00001.00 PUMP, HOT LIQUID

40 1 1025.00012.00 TUBE, 5/16'OD X 3/16"ID X 11.00"LG

41 1 1025.00061.00 TUBE, 9/16'OD X 5/16"ID X 2.75"LG

42 1 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

43 1 1025.00058.00 TUBE, 9/16'OD X 5/16"ID X 25.00"LG

44 1 1025.00060.00 TUBE, 9/16'OD X 5/16"ID X 3.25"LG

45 1 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

46 1 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

47 1 1025.00006.00 TUBE, VENT SUPPORT, 5/16" OD X 3/16" ID X 1/2" LG

48 1 1025.00064.00 TUBE, 1/2 OD X 1/4 ID X 9.00 LG

49 1 1013.00073.00 TUBE, 5/16" OD, 1" LONG

50 1 1046.00006.00 LABEL, WARNING, "HOT WATER FAUCET"

51 1 1044.00004.00 LABEL, DANGER, HIGH VOLTAGE

52 1 1046.00003.00 LABEL, CSD WARNING, 1.5" X 5.0"

53 4 1023.00163.00 LEG BODY, CBS-2130

54 4 1083.00021.00 WASHER, 1/4" SCREW SIZE, SPRING LOCK

55 4 1112.00158.00 WELDMENT, LEG ROD, CBS-2130

56 4 1021.00017.00 LEG INSERT THREADED, CBS-2130

23

Page 24

24

Page 25

Drawing 1101.00127.00 CBS-2131ASSEMBLY, 3 Liter NO BYPASS , 2.3kW/120VAC

Ref# QTY PART NO DESCRIPTION

1 1 1111.00030.00 WELDMENT BODY, CBS-2131

2 2 1024.00049.00 EDGE PROTECTOR, 7.00"LG, CBS-2130

3 3 1086.00004.00 BUSHING, SNAP, 1" MOUNTING HOLE

4 1 1024.00017.00 O'RING, 3.739" ID X 0.070" CS, 70 DURO, BUNA

5 1 1102.00183.00 SPRAY HOUSING ASSEMBLY, CBS-2130

6 4 1083.00010.00 WASHER, #8 SCREW SIZE W/NEOPRENE- BONDED SEAL

7 8 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

8 1 1102.00113.00 SWITCH, REED, ASSEMBLY

9 4 1029.00006.00 #4-40 NYLON FINGER NUT

10 1 1071.00010.00 FAUCET HPSC-BR-8 REGULAR HANDLE

11 1 1031.00003.00 FITTING, BARB 3/8'ID x 1/4" FPT

12 1 1057.00043.00 SOLENOID VALVE, SINGLE, 180 DEG, 24VDC

13 1

14 2 1083.00005.00 WASHER, M4 18-8 INTERNAL TOOTH LOCKWASHER

15 2 1082.00010.00 SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

16 1 1102.00164.00 ADAPTER ASSY, 3/4" BSP X 1/4 SAE FLARE

17 1 1104.00043.00 TANK ASSY, 2300W/120VAC, CBS-2131, GROMMETS

18 1 1112.00163.00 WELDMENT TANK LOCK BRACKET, CBS-2100

19 4 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

20 2 1082.00023.00 SCREW, #8-32 X 3/8 TRUSS HD PHIL., MACHINE

21 1 1102.00187.00 PUMP BRACKET AND HOLDER ASSEMBLY

22 9 1086.00003.00 UNICLAMP, 15.9 HOSE OD CLAMP

23 1 1025.00063.00 TUBE, 5/8'OD X 3/8"ID X 8.50"LG

24 1 1102.00181.00 ASSEMBLY BACK PANEL, CBS-2130

25 11 1082.00017.00 SCREW, # 6-32 X 1/2" TRUSS HD PHIL., MACHINE

26 1 1023.00147.00 PLUG, TANK SERVICE DRAIN FOR 18GA AND UP BODY

27 1 1024.00040.00 CARD PLUG, HWD-2100

28 1 1102.00190.00 ASSEMBLY FRONT PANEL, CBS-2100

29 4 1082.00058.00 SCREW, # 8-32 X 5/8, FLAT HD, PH, 18-8 SS

30 1 1102.00182.00 ASSEMBLY, LOCATOR CBS-2130

31 1 1082.00065.00 SCREW #8-32 X 1 1/2", FLAT HD PH, 18-8 SS

32 1 1023.00159.00 CORNER INSERT

33 1 1112.00168.00 WELDMENT, TOP COVER, CBS-2131

34 1 1402.00034.00 HARNESS, HIGH AMP, CBS-2131

35 1 1402.00035.00 HARNESS, LOW AMP, CBS-2131

36 1 B012280B1 BB ASSY, 13"X5", .280" DIA. HOLE, BLK HNDL

37 4 1073.00008.00 FOOT, CBS-2130

38 4 1082.00066.00 SCREW 1/4-20 X 1/2", SOCKED HD CUP

39 1 1024.00052.00 CONNECTOR, BREW PUMP

40 1 1086.00002.00 CLAMP, HOSE, SIZE "G" NYLON

41 1 1055.00001.00 PUMP, HOT LIQUID

42 1 1025.00012.00 TUBE, 5/16'OD X 3/16"ID X 11.00"LG

43 1 1025.00061.00 TUBE, 9/16'OD X 5/16"ID X 2.75"LG

44 1 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

45 1 1025.00058.00 TUBE, 9/16'OD X 5/16"ID X 25.00"LG

46 1 1025.00060.00 TUBE, 9/16'OD X 5/16"ID X 3.25"LG

47 1 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

48 1 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

49 1 1025.00006.00 TUBE, VENT SUPPORT, 5/16" OD X 3/16" ID X 1/

50 1 1025.00064.00 TUBE, 1/2 OD X 1/4 ID X 9.00 LG

51 1 1013.00073.00 TUBE, 5/16" OD, 1" LONG

52 1 1046.00006.00 LABEL, WARNING, "HOT WATER FAUCET"

53 1 1044.00004.00 LABEL, DANGER, HIGH VOLTAGE

54 1 1046.00003.00 LABEL, CSD WARNING, 1.5" X 5.0"

25

Page 26

Drawing 1104.00043.00 TANK ASSY, 2300W/120VAC, CBS-2131, GROMMETS

Ref# QTY PART NO DESCRIPTION

1 1 1114.00066.00 WELDMENT TANK CBS-2131, GROMMET DESIGN

2 4 1024.00050.00 GROMMET, SILICONE, 11.4mm ID

3 1 1024.00051.00 GROMMET, SILICONE, BLANK

4 2 1024.00053.00 GROMMET, SILICONE, LL & TEMP. PROBES

5 1 1003.00005.00 BRACKET, ONE SHOT THERMOSTAT

6 1 1053.00003.00

7 2 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

8 2 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

9 1 1003.00140.00 ALUMINUM BRACKET FOR SSR

10 1 1052.00014.00 ASSEMBLY RELAY, SOLID STATE, 25A/230V

11 2 1081.00042.00 STANDOFF, 6-32 x1.25 LG.,1/4 HEX WIDTH

12 1 1107.00021.00 HEATER ASSEMBLY, IMMERSION 1500W/120VAC

12 1 1107.00022.00 HEATER ASSEMBLY, IMMERSION 1700W/120VAC

12 1 1107.00019.00

12 1 1107.00020.00

12 1 1107.00018.00 HEATER ASSEMBLY, IMMERSION 3000W/240VAC

13 1 1112.00002.00 PROBE WELDMENT, WATER LEVEL 2.25" LG

14 1 1102.00161.00 PROBE ASSEMBLY, TEMP. AND LLC, HWD-2100

15 1 1024.00007.00 O-RING, DASH #344, TANK COVER

16 1 1102.00007.00 TANK COVER ASSEMBLY

17 1 1023.00167.00 FITTING, BREW, GROMMET DESIGN

18 1 1023.00168.00 FITTING, HOT WATER, GROMMET DESIGN

19 1 1023.00166.00 FITTING, COLD WATER INLET, GROMMET DESIGN

20 1 1022.00056.00 TANK INSULATION, CBS-2131e, GROMMET DESIGN

THERMOSTAT, SINGLE SHOT, 240V/40A

HEATER ASSEMBLY, IMMERSION 2300W/120VAC

HEATER ASSEMBLY, IMMERSION 2300W/240VAC

26

Page 27

27

Page 28

Drawing 1101.00132.00 CBS-2132-3 Liter NO BYPASS 2 X 3kW/240VAC

Ref# QTY PART NO DESCRIPTION

1 1

2 2

3 6

4 2

5 2

6 8

7 12

8 2

9 6

10 1

11 1

12 1

13 1

14 2

15 2

16 1

17 1

18 1

19 4

20 2

21 1

22 2

23 2

24 10

25 2

26 1

27 1

28 1

29 1

30 1

31 1

32 11

33 1

34 1

35 1

36 4

37 2

38 2

39 2

40 1

41 1

42 1

43 2

44 2

45 1

46 1

47 2

48 2

49 2

50 3

51 3

1111.00029.00

1024.00049.00

1086.00004.00

1024.00017.00

1102.00183.00

1083.00010.00

1084.00006.00

1102.00113.00

1029.00006.00

1071.00010.00

1031.00003.00

1057.00043.00

1083.00005.00

1082.00010.00

1102.00164.00

1104.00044.00

1112.00163.00

1083.00011.00

1082.00023.00

1102.00187.00

1024.00052.00

1055.00001.00

1086.00003.00

1025.00012.00

1029.00002.00

1025.00060.00

1025.00061.00

1025.00058.00

1025.00063.00

1102.00181.00

1082.00017.00

1023.00147.00

1024.00040.00

1102.00190.00

1082.00058.00

1102.00182.00

1082.00065.00

1023.00159.00

1112.00167.00

1402.00032.00

1402.00033.00

B012280B1

1086.00002.00

1083.00009.00

1084.00010.00

1025.00006.00

1025.00064.00

1013.00073.00

1073.00008.00

1082.00066.00

WELDMENT BODY, CBS-2132

EDGE PROTECTOR, 7.00"LG, CBS-2130

BUSHING, SNAP, 1" MOUNTING HOLE

O'RING, 3.739" ID X 0.070" CS, 70 DURO, BUNA

SPRAY HOUSING ASSEMBLY, CBS-2130

WASHER, #8 SCREW SIZE W/NEOPRENE- BONDED SEAL

NUT, 8-32 18-8 HEX MACHINE SCREW

SWITCH, REED, ASSEMBLY

#4-40 NYLON FINGER NUT

FAUCET HPSC-BR-8 REGULAR HANDLE

FITTING, BARB 3/8'ID x 1/4" FPT

SOLENOID VALVE, SINGLE, 180 DEG, 24VDC

WASHER, M4 18-8 INTERNAL TOOTH LOCKWASHER

SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

ADAPTER ASSY, 3/4" BSP X 1/4 SAE FLARE

TANK ASSY, 2 X 3000W/240VAC, CBS-2132, GROMMETS

WELDMENT TANK LOCK BRACKET, CBS-2100

WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

SCREW, #8-32 X 3/8 TRUSS HD PHIL., MACHINE

PUMP BRACKET AND HOLDER ASSEMBLY

CONNECTOR, BREW PUMP

PUMP, HOT LIQUID

UNICLAMP, 15.9 HOSE OD CLAMP

TUBE, 5/16'OD X 3/16"ID X 11.00"LG

FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

TUBE, 9/16'OD X 5/16"ID X 3.25"LG

TUBE, 9/16'OD X 5/16"ID X 2.75"LG

TUBE, 9/16'OD X 5/16"ID X 25.00"LG

TUBE, 5/8'OD X 3/8"ID X 8.50"LG

ASSEMBLY BACK PANEL, CBS-2130

SCREW, # 6-32 X 1/2" TRUSS HD PHIL., MACHINE

PLUG, TANK SERVICE DRAIN FOR 18GA AND UP BODY

CARD PLUG, HWD-2100

ASSEMBLY FRONT PANEL, CBS-2100

SCREW, # 8-32 X 5/8, FLAT HD, PH, 18-8 SS

ASSEMBLY, LOCATOR CBS-2130

SCREW #8-32 X 1 1/2", FLAT HD PH, 18-8 SS

CORNER INSERT

WELDMENT, TOP COVER, CBS-2132

HARNESS, HIGH AMP, CBS-2132

HARNESS, LOW AMP, CBS-2132

BB ASSY, 13"X5", .280" DIA. HOLE, BLK HNDL

CLAMP, HOSE, SIZE "G" NYLON

WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

TUBE, VENT SUPPORT, 5/16" OD X 3/16" ID X 1/

TUBE, 1/2 OD X 1/4 ID X 9.00 LG

TUBE, 5/16" OD, 1" LONG

FOOT, CBS-2130

SCREW 1/4-20 X 1/2", SOCKED HD CUP

28

Page 29

29

Page 30

1101.00131.00 CBS-2132, 2 X 3kW/240VAC, 1gal BYPASS

Ref# Qty

1 1 1111.00029.00 WELDMENT BODY, CBS-2132

2 2 1024.00049.00 EDGE PROTECTOR, 7.00"LG, CBS-2130

3 6 1086.00004.00 BUSHING, SNAP, 1" MOUNTING HOLE

4 2 1024.00017.00 O'RING, 3.739" ID X 0.070" CS, 70 DURO, BUNA

5 2 1102.00183.00 SPRAY HOUSING ASSEMBLY, CBS-2130

6 8 1083.00010.00 WASHER, #10 SCREW W/NEOPRENE-BONDED SEAL

7 12 1084.00006.00 NUT, 8-32 18-8 HEX MACHINE SCREW

8 2 1102.00113.00 SWITCH, REED, ASSEMBLY

9 6 1029.00006.00 #4-40 NYLON FINGER NUT

10 1 1071.00010.00 FAUCET HPSC-BR-8 REGULAR HANDLE

11 1 1031.00003.00 FITTING, BARB 3/8'ID x 1/4" FPT

12 1 1057.00043.00 SOLENOID VALVE, SINGLE, 180 DEG, 24VDC

13 1

14 2 1083.00005.00 WASHER, M4 18-8 INTERNAL TOOTH LOCKWASHER

15 2 1082.00010.00 SCREW, M4x10 ZINC PLATED PAN PHILLIPS MACHINE

16 1 1102.00164.00 ADAPTER ASSY, 3/4" BSP X 1/4 SAE FLARE

17 1 1104.00044.00 TANK ASSY, 2 X 3000W/240VAC, CBS-2132, GROMMETS

18 1 1112.00163.00 WELDMENT TANK LOCK BRACKET, CBS-2100

19 4 1083.00011.00 WASHER, #8 SCREW SIZE, INTERNAL TOOTH LOCK

20 2 1082.00023.00 SCREW, #8-32 X 3/8 TRUSS HD PHIL., MACHINE

21 1 1102.00187.00 PUMP BRACKET AND HOLDER ASSEMBLY

22 2 1024.00048.00 Y-CONNECTOR

23 4 1055.00001.00 PUMP, HOT LIQUID

24 12 1086.00003.00 UNICLAMP, 15.9 HOSE OD CLAMP

25 4 1025.00012.00 TUBE, 5/16'OD X 3/16"ID X 11.00"LG

26 1 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON

27 1 1025.00060.00 TUBE, 9/16'OD X 5/16"ID X 3.25"LG

28 1 1025.00061.00 TUBE, 9/16'OD X 5/16"ID X 2.75"LG

29 1 1025.00058.00 TUBE, 9/16'OD X 5/16"ID X 25.00"LG

30 1 1025.00063.00 TUBE, 5/8'OD X 3/8"ID X 8.50"LG

31 1 1102.00181.00 ASSEMBLY BACK PANEL, CBS-2130

32 11 1082.00017.00 SCREW, # 6-32 X 1/2" TRUSS HD PHIL., MACHINE

33 1 1023.00147.00 PLUG, TANK SERVICE DRAIN FOR 18GA AND UP BODY

34 1 1024.00040.00 CARD PLUG, HWD-2100

35 1 1102.00190.00 ASSEMBLY FRONT PANEL, CBS-2100

36 4 1082.00058.00 SCREW, # 8-32 X 5/8, FLAT HD, PH, 18-8 SS

37 2 1102.00182.00 ASSEMBLY, LOCATOR CBS-2130

38 2 1082.00065.00 SCREW #8-32 X 1 1/2", FLAT HD PH, 18-8 SS

39 2 1023.00159.00 CORNER INSERT

40 1 1112.00167.00 WELDMENT, TOP COVER, CBS-2132

41 3 1023.00163.00 LEG BODY, CBS-2130

42 3 1083.00021.00 WASHER, 1/4" SCREW SIZE, SPRING LOCK

43 3 1112.00158.00 WELDMENT, LEG ROD, CBS-2130

44 3 1021.00017.00 LEG INSERT THREADED, CBS-2130

45 1 1402.00032.00 HARNESS, HIGH AMP, CBS-2132

46 1 1402.00033.00 HARNESS, LOW AMP, CBS-2132

47 2 B012280B1 BB ASSY, 13"X5", .280" DIA. HOLE, BLK HNDL

48 2 1086.00002.00 CLAMP, HOSE, SIZE "G" NYLON

49 1 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

50 1 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

51 2 1025.00006.00 TUBE, VENT SUPPORT, 5/16" OD X 3/16" ID X 1/

52 2 1025.00064.00 TUBE, 1/2 OD X 1/4 ID X 9.00 LG

53 2 1013.00073.00 TUBE, 5/16" OD, 1" LONG

30

Page 31

TANK ASSY, 2 X 3000W/240VAC, CBS-2132, GROMMETS

REF# QTY PART NO DESCRIPTION

1 1 1114.00062.00 WELDMENT TANK CBS-2132e, GROMMET DESIGN

2 2 1024.00053.00 GROMMET, SILICONE, LL & TEMP. PROBES

3 6 1024.00050.00 GROMMET, SILICONE, 11.4mm ID

4 1 1024.00051.00 GROMMET, SILICONE, BLANK

5 2 1107.00018.00 HEATER ASSEMBLY, IMMERSION 3000W/240VAC

6 1 1003.00005.00 BRACKET, ONE SHOT THERMOSTAT

7 1 1053.00003.00 THERMOSTAT, SINGLE SHOT, 240V/40A

8 2 1083.00009.00 WASHER, #6 SCREW , INTL TOOTH LOCKWASHER

9 2 1084.00010.00 NUT, HEX, #6-32, UNDERSIZED, ZINC PLATED

10 2 1003.00140.00 ALUMINUM BRACKET FOR SSR

11 2 1052.00016.00 ASSEMBLY RELAY, SOLID STATE, 50A/600VAC

12 4 1081.00042.00 STANDOFF, 6-32 x1.25 LG.,1/4 HEX WIDTH

13 1 1112.00002.00 PROBE WELDMENT, WATER LEVEL 2.25" LG

14 1 1102.00161.00 PROBE ASSEMBLY, TEMP. AND LLC, HWD-2100

15 1 1024.00007.00 O-RING, DASH #344, TANK COVER

16 1 1102.00007.00 TANK COVER ASSEMBLY

17 2 1023.00167.00 FITTING, BREW, GROMMET DESIGN

18 1 1023.00168.00 FITTING, HOT WATER, GROMMET DESIGN

19 1 1023.00166.00 FITTING, COLD WATER INLET, GROMMET DESIGN

20 1 1022.00057.00 TANK INSULATION, CBS-2132e, GROMMET DESIGN

21 6 1065.00006.00 CONNECTOR, TAB, .250", FASTON

22 1 1044.00004.00 LABEL, DANGER, HIGH VOLTAGE

31

Page 32

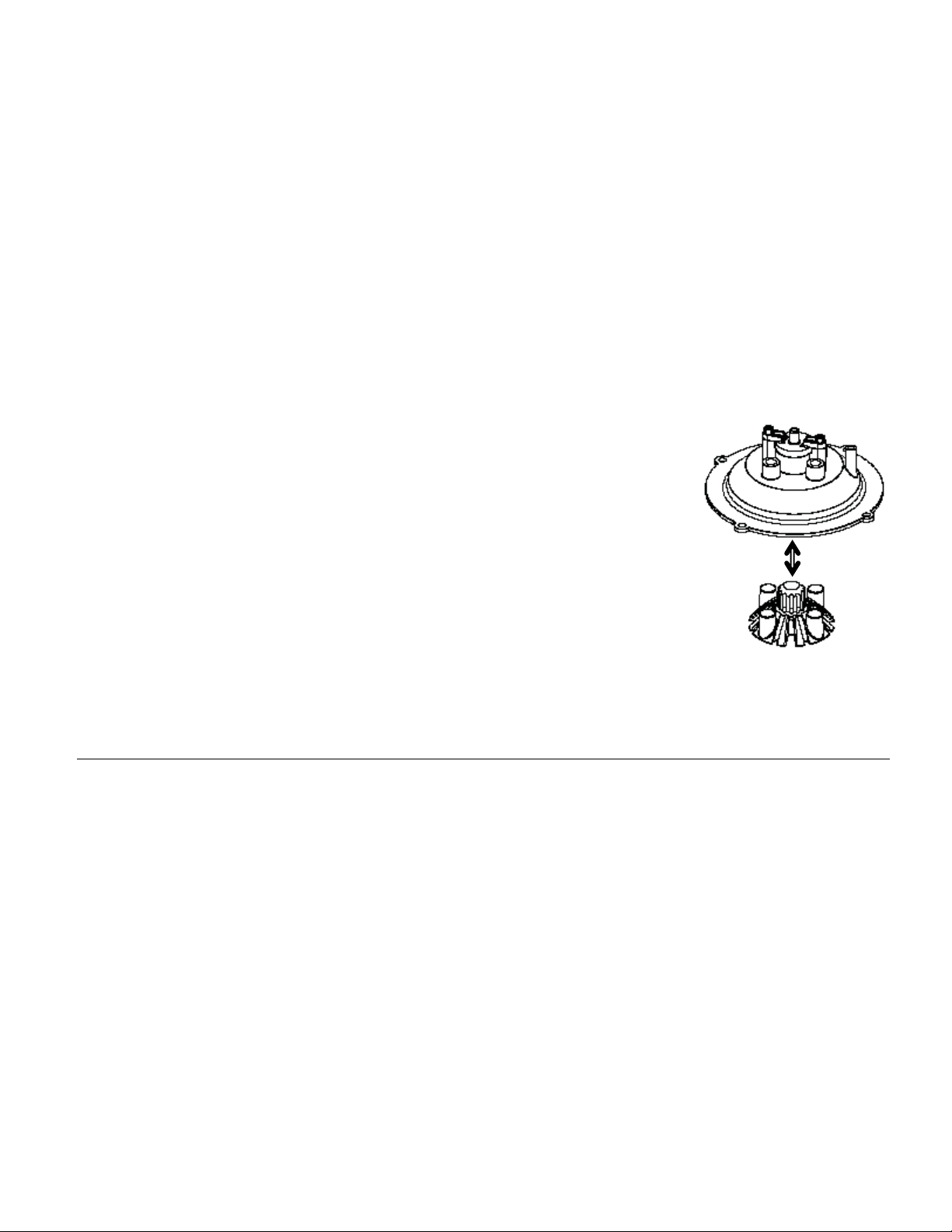

1102.00183.00 PCSD Pump Spray Housing Assembly

Parts

Ref. QTY PART NO DESCRIPTION

1 1 1102.00020.00

2 1 1024.00045.00

3 1 1023.00164.00

4 2 1082.00068.00

5 1 1102.00019.00

SPRAY HOUSING ASSY&

MAGNETS, CSD DESIGN

O-RING, 5/8 X 13/16, 3/32

SPRAY HOUSING ADAPTER

SCREW, M3.9x13, CHEESE PH.,

T/FORM

CASCADE SPRAY DOME

ASSEMBLY

Complete CBS-2130 Spray Housing Assembly

-Part number 1102.00183.00

CBS-2100 Series Brew Basket Assembly, 13” X 5”, Part # B012280B1 (SQUARE)

Ref# Qty Part Number Description

1 1 1112.00073.00 BB WLDMNT, 13"X5", W/ Ø.280 HOLE

2 1 1102.00064.00 HANDLE W/MAGNET ASSEMBLY, BLACK RUBBER

3 1 1082.00040.00 SCREW, 1/4-20 X .5, FL HD, PH., W/NYLON

4 1 1009.00006.00 BASKET, WIRE, 13" X 5", CBS-2040'S

5 1 1046.00025.00 LABEL, BREW BASKET WARNING

Never strike or hit a

brewbasket against

any hard surface

32

Page 33

Page 34

Loading...

Loading...