Page 1

Ferm BV • P.O. Box 134 • 8280 AC Genemuiden • NL • www.ferm.com 0301-09

Art.nr. 125020

CONCEPT 1500

UK

D

NL

F

S

SF

N

DK

R

USERS MANUAL 03

GEBRAUCHSANWEISUNG 07

GEBRUIKSAANWIJZING 12

MODE D’EMPLOI 16

BRUKSANVISNING 21

KÄYTTÖOHJE 25

BRUKSANVISNING 30

BRUGERVEJLEDNING 34

кмдйЗйСлнЗй ий щдлигмДнДсаа 39

UK Subject to change

D Änderungen vorbehalten

NL Wijzigingen voorbehouden

F Sous réserve de modifications

S Ändringar förbehålles

SF Pidätämme oikeuden muutoksiin

N Rett till endringer forbeholdes

DK Ret til ændringer forbeholdes

RäУПО‡МЛfl Ferm ФУТЪУflММУ ТУ‚В¯ВМТЪ‚Ы

ВЪ ‚˚ФЫТН‡ВПЫ ˛ В˛ ФУВ‰ЫНˆЛ˛.

иУБЪУПЫ ‚ ЪВıМЛ˜ВТЛВ ı‡‡НЪВЛТЪЛНЛ

ПУ„ЫЪ ‚МУТЛЪ¸Тfl ·ВБ ФВ‰‚‡ЛЪВО¸МУ„У

Ы‚В‰УПОВМЛfl.

Page 2

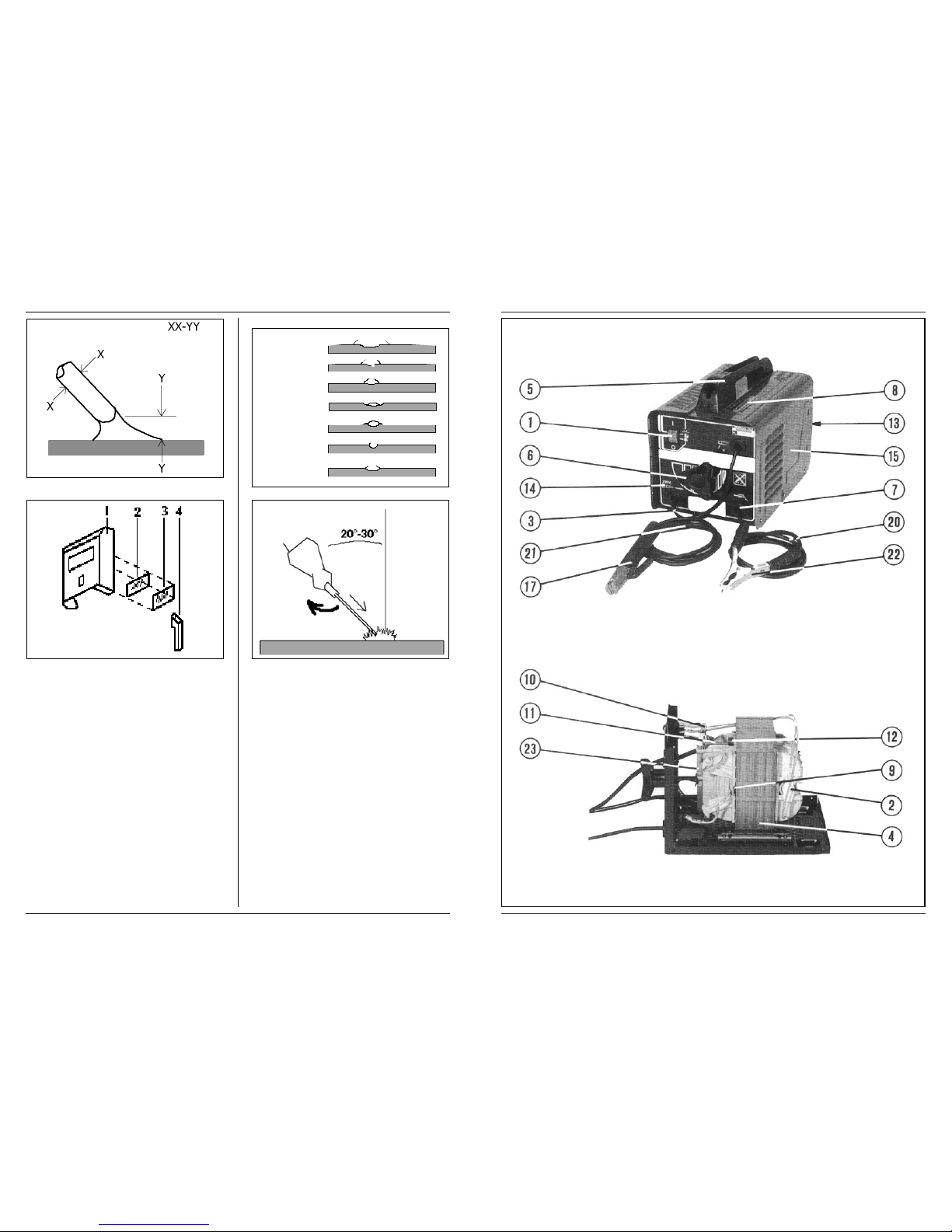

Fig.A

Fig.B

Fig.C

Fig.D

2 Ferm

Ferm 47

EXPLODED VIEW

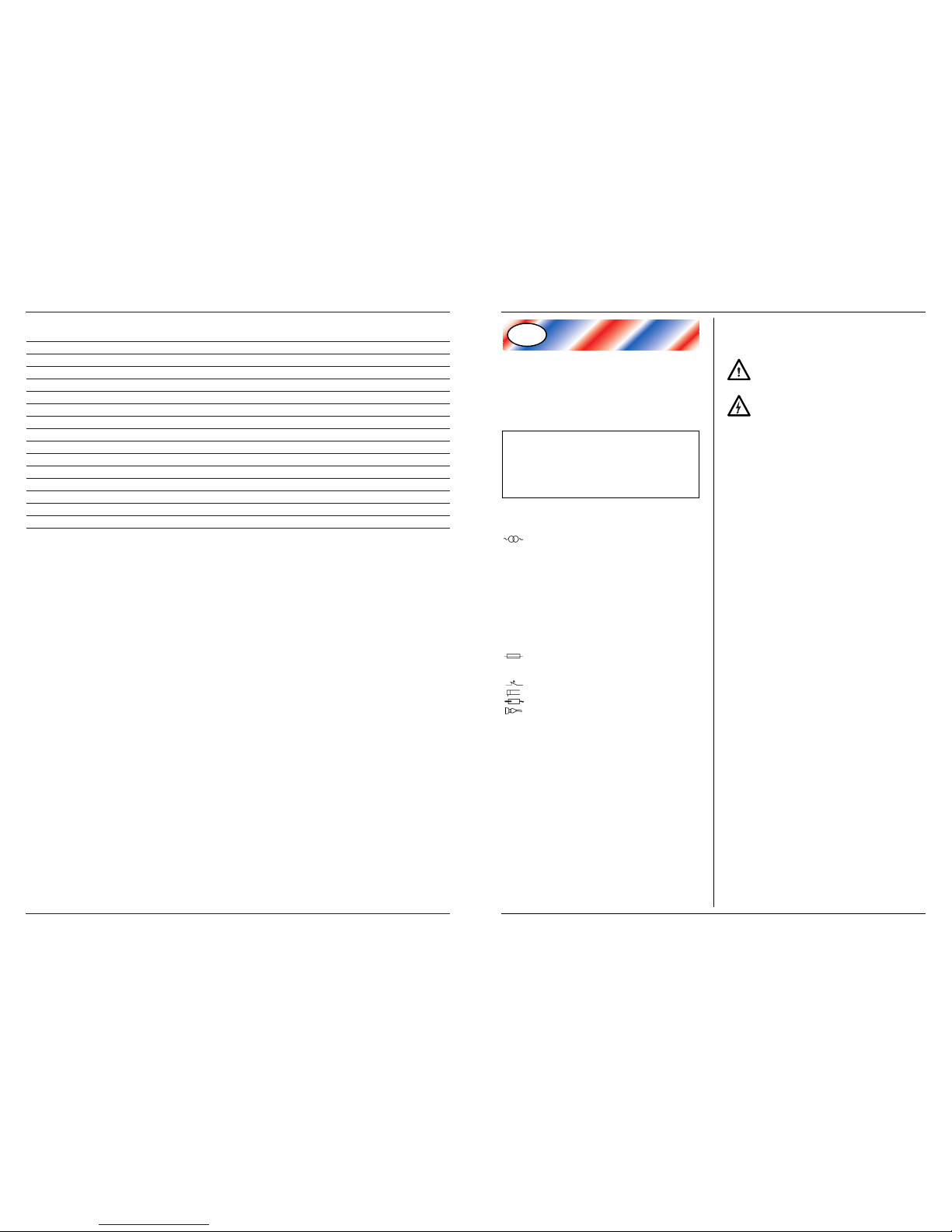

Page 3

46 Ferm

SPARE PARTS LIST CONCEPT 1500

REF NR DESCRIPTION FERM NR

001 SWITCH (5 CONT. POINTS) 100357

002 THERMAL FUSE 100015

005 GRIP 100009

006 HANDWHEEL + ADJUSTMENT SCREW (23CM) 100010

006 HANDWHEEL + ADJUSTMENT SCREW (26CM) 100011

007 PULL RELIEF 101737

010 CURRENT INDICATOR 100003

011 SHUNT 101426

012 SPRING FOR SHUNT 102152

013 BACKPANEL 100008

- SWITCH (4 CONT.POINTS) 100004

- SCALING HAMMER/STEEL WIRE BRUSH 100005

- WELDING GLASS 140500

- WELDING MASK (EXCL. GLASS) 100007

WELDING MACHINE

THE NUMBERS IN THE FOLLOWING TEXT CORRESPOND WITH THE PICTURES AT PAGE 2

TECHNICAL SPECIFICATIONS

DESCRIPTION

EN 50060 Standard relative to welders for limited

use.

Onephase transformer.

P (W) Power in Watts.

Uo (V) No-load voltage in Volt.

f (Hz) Mains frequency in Herz.

I2 (A) Conventional welding current in ampère.

d (mm) Diameter of electrodes in mm.

nc Number of electrodes starting at room

temperature until thermostat intervenes.

nh Number of weldable electrodes after.

thermostat intervenes in first hour.

U1 (V) Mains voltage in Volt.

I1Max (A) Maximum absorbed current. Value in

ampère of use or automatic switch.

Fuse.

IP21 Protection grade covering.

H Class of isolation of transform.

Thermostat.

Collet.

Work collet.

Standardized plug.

ACCESSORIES AND SPARE PARTS

The following is supplied with your welding machine:

• Manual

• Cables

• Work clamp

• Collet clamp

• Protective mask

• Scaling hammer

• Steelbrush.

Spare parts are available through your local Ferm dealer.

When ordering parts, use the numbers listed in the Parts

List. Parts without an number are not available.

SAFETY INSTRUCTIONS

The following symbols are used in these instructions for

use:

Denotes risk of personal injury, loss of life or

damage to the tool in case of non-observance of the

instructions in this manual.

Denotes risk of electric shock.

Carefully read this manual before using the machine.

Make sure that you know how the machine functions and

how to operate it. Maintain the machine in accordance

with the instructions to make sure it functions properly.

Keep this manual and the enclosed documentation with

the machine.

When using electric machines always observe the

safety regulations applicable in your country to

reduce the risk of fire, electric shock and personal

injury. Read the following safety instructions and

also the enclosed safety instructions.

SPECIAL SAFETY RULES

• Arc welding produces sparks and fused metal projectiles and fumes: remove all flammable substances and

materials from work area.

• Provide adequate ventilation of facilities where welding takes place. Arc welding emits fumes which can

be dangerous.

• Do not weld on containers or pipes which hold or

have held flammable liquid or gaseous combustibles

(danger of explosions and/or fires) or on materials

cleaned with chlorinated solvents or on varnished

surface (danger of toxic fumes).

• Make sure connection is correct from welder to supply (mains connection). Any electric shock received

is potentially lethal.

• Avoid stretching the supply cable; unplug before

moving machine.

• Keep welding cables, elektrode holder and work

clamp in good condition; wearing out of isolation and

structural parts carrying current is DANGEROUS

and results in poor welding quality.

• Avoid direct contact with welding circuit. The noload voltage between collet and work clamp can be

dangerous.

• Do not use the machine in damp or wet places and do

not weld in the rain.

• Always protect your eyes with the fitting glasses

(grade DIN 9 - 10) equipped with this machine.

• Use gloves and proper protective clothing which are

dry and not soiled by oil or grease.

• Avoid exposing skin to the ultraviolet rays produced

by the arc. The light radiation produced by the arc can

damage eyesight and cause burns on the skin.

• This welder is automatically protected from thermic

overheating (thermostat automatic re-start). When

the windings reach performance temperature, the

protection cuts off the supply circuit. After a few

minutes cooling the protection will reopen the supply line. The welder is ready for further use.

Mains voltage | 230 V~

Frequency | 50 Hz

Absorbed power max. | 2.5 kVA

Welding current | 40 - 140 A

No load voltage | 45 - 48 V

Usable electrodes | 1.5 - 3.15 mm

Weight | 14.0 kg

UK

English

Ferm 3

Page 4

Ferm 45

• When you’re scaling off the welding slack, protect

yourself from the hot iron by using eyeprotection

and gloves.

• The workpiece can misform during cooling off. Take

care.

IMMEDIATELY SWITCH OFF THE MACHINE

IN CASE OF:

• Malfunction of the mainsplug, -socket or damaged

cables.

• Broken switch.

• Smoke or smell caused by scorched insulation.

MAKE SURE THESE SAFETY RULES ARE NOT

BROKEN, OTHERWISE THE GUARANTEE PROVISIONS WILL BE CANCELLED.

ELECTRICAL SAFETY

Always check that the mains voltage corresponds

to the voltage on the rating plate.

Replacing cables or plugs

Immediately throw away old cables or plugs when they

have been replaced by new ones. It is dangerous to insert

the plug of a loose cable in the wall socket.

Connect to the mains cable a standardized plug of adequate capacity to which the yellow/green conductor of

the cable is to be connected. Set a standardized plug

equipped with fuses or an automatic switch; the correct

terminal is to be grounded to the distribution mains. Use

fuses of 16 Ampère Slow as a minimum.

Immediately throw away old cables or plugs when they

have been replaced by new ones. It is dangerous to insert

the plug of a loose cable in the wall outlet.

Using extension cables

Only use an approved extension cable suitable for the

power input of the machine. The minimum conductor

size is 1.5 mm2. When using a cable reel always unwind

the reel completely.

BEFORE OPERATING THE

MACHINE

EXECUTION OF WELD

Fig.A

After carrying out all electrical connections necessary

both on mains and welding circuits proceed in the following way. Arc welding with an elektric welding machine

is a method in which the warmth is delivered by the arc.

This arc is made between the electrode and the workpiece.

NB: Before carrying out difficult welds do a practise run,

only practice will allow you to obtain a neat and durable

weld.

The temperature of the arc is 4000° Celsius what makes

the electrode and the workpiece melt. As long as the arc

is maintained the electrode will melt and it will supply the

material for the connection.

The distance between the electrode and the workpiece

must be 1.5 - 4 mm, depending on the diameter of the

electrode and the material it is made of. The required

welding current is supplied by the welding machine. The

required capacity of the welding machine depends on the

connections to be made.

THE ELECTRODE

The electrode consists of an iron core with cover. This

cover consists partly of irondust. While welding the

cover will melt and it will vapor. This way a gas surrounds

the welding area protecting the melted iron from oxygen

in the air. Some parts of the cover will floot on the melted

iron (it is of less weight than the iron) and it will protect

the iron while cooling off. After cooling this cover can be

removed easily by a scaling hammer or steelbrush. Make

sure the cover of the electrode is not incapsulated by the

iron. This would make an unreliable connection.

Treat the electrodes with caution. The cover can be

damaged and this will make the welding very diffi-

cult. Make sure the electrodes are stored cool and dry.

Choice of the electrode

To make a good connection it is important to choose the

right electrode. Also the position in which you have to

make the connection, for example above your head, is

important while choosing the electrode. A normal elektrode can do most ordinary welding jobs.

Electrodes are available in three types:

1. Fast solidification

The cover consists of a lot organic material, which

give a good gasprotection. It can be used in all kinds of

positions, specially for vertical, downgoing connections.

2. Medium solidification

The cover consists of a lot organic material. Good

welding in all positions except vertical, downgoing

connections. They are useful for vertical, upgoing

connections.

4 Ferm

Page 5

3. Slow solidification

The cover is thicker than the other two types and

consists less organic material. Thick compact slack.

The meltingbath is very thin liquid. Connections

most of the time in horizontal direction. For welding

aluminium and stainless steel special electrode are

available. Ask for advice from your local Ferm-dealer.

PERFORMANCE

The performance of this welder may be expressed by the

number of electrodes : nc and nh.

nc: Refers to the number of electrodes which may be

welded when the welder commences at room temperature until the thermostat intervenes.

nh: Refers to the AVERAGE VALUE of the number of

electrodes which may be welded between re-start and

intervention of thermostat, in the first hour of use.

WELDINGCURRENT

By turning the wheel clockwise the current is increased.

By turning the wheel counter-clockwise the current is

decreased. The value of the current (I2) may be read on

the graduated scale on the upper panel and corresponds

to the voltage of the arc (U2) according to the equation

U2(V)=18 + 0,04 x I2 (EN 50060). When you’re using

long extension cables, the current is reduced considerably. The required current also depends on the size of the

workpiece. Small workpieces require a smaller current.

Workpiece Electrode core Welding

thickness Ø (mm2) current (A)

2 - 3 2 4 5 - 6 5

4 - 5 2,5 70 - 95

6 - 7 3,25 90 - 130

8 - 12 4 130 - 160

Tab.1

OPERATING THE MACHINE

COLLET CABLE

This has a special clamp on the terminal to attach to the

exposed part of the electrode.

WORK CABLE

This must be directly connected to the workpiece or the

work bench.

Make sure contact to workpiece is adequate by

avoiding varnished surfaces and/or non-metallic

materials.

PROTECTIVE MASK

Fig.B

This must ALWAYS be used during welding and protects

the eyes from the light radiation produced by the arc.

The mask alows observation of the welding being carried

out.

1. Mask

2. Glass

3. Filter

4. Handgrip

Assemble the welding glass and the cover glass,

before you begin to weld.

Never look directly into the arc without the use of a protective

mask.

SCALING HAMMER

With this hammer the slack of the welded connection

can be removed. Do not hit too hard, otherwise the connection will be damaged. Always use safety glasses.

STEELBRUSH

With this steelbrush you can remove rust before attaching the work cable to the workpiece or to remove the

slack after welding.

CHARACTERISTICS OF THE WELD SEAM

Fig.C

1. Advancement too low

2. Excessive advancement

3. Arc too short

4. Arc too long

5. Current too low

6. Current too high

7. Current correct

Ferm 544 Ferm

Page 6

нЦпзауЦлдйЦ

йЕлгмЬаЗДзаЦ

иЛ У·ТОЫКЛ‚‡МЛЛ Л ˜ЛТЪНВ ‡ФФ‡‡Ъ‡

Ы·В‰ЛЪВТ¸ ‚ ЪУП, ˜ЪУ УМ У·ВТЪУ˜ВМ

(¯ЪВФТВО¸М‡fl ‚ЛОН‡ ‚˚МЫЪ‡ ЛБ УБВЪНЛ).

аБ‰ВОЛfl ЩЛП˚ Ferm ТНУМТЪЫЛУ‚‡М˚ Ъ‡НЛП

У·‡БУП, ˜ЪУ·˚ ‡·УЪ‡Ъ¸ ·ВБ ФУ·ОВП Л ФЛ

ПЛМЛП‡О¸МУП ЪВıМЛ˜ВТНУП У·ТОЫКЛ‚‡МЛЛ М‡

ФУЪflКВМЛЛ ФУ‰УОКЛЪВО¸МУ„У ‚ВПВМЛ.

кВ„ЫОflМ˚И ЫıУ‰ Л ˜ЛТЪН‡, ‡ Ъ‡НКВ ЪВıМЛ˜ВТНЛ

„‡ПУЪМУВ У·‡˘ВМЛВ Т ‚‡¯ЛП ‡ФФ‡‡ЪУП

ФУ‰ОВ‚‡˛Ъ ТУН В„У ТОЫК·˚.

уЛТЪН‡

ЗУ ЛБ·ВК‡МЛВ ФВ„‚‡ ˝ОВНЪУПУЪУ‡ ‡ФФ‡‡Ъ‡ В„У

‚ВМЪЛОflˆЛУММ˚В УЪ‚ВТЪЛfl ‰УОКМ˚ ТУ‰ВК‡Ъ¸Тfl ‚

˜ЛТЪУЪВ. зВУ·ıУ‰ЛПУ В„ЫОflМУ ˜ЛТЪЛЪ¸ НУФЫТ

‡ФФ‡‡Ъ‡ Т ЛТФУО¸БУ‚‡МЛВП Пfl„НУИ Т‡ОЩВЪНЛ ЛБ

ЪН‡МЛ, КВО‡ЪВО¸МУ, ФУТОВ Н‡К‰У„У ЛТФУО¸БУ‚‡МЛfl.

тОЛˆВ‚˚В ‚ВМЪЛОflˆЛУММ˚В Ф‡Б˚ ‰УОКМ˚ ·˚Ъ¸

Т‚У·У‰М˚ УЪ Б‡„flБМВМЛИ Л Ф˚ОЛ.

зВФУО‡‰НЛ

З ТОЫ˜‡В ‚УБМЛН¯Лı МВФУО‡‰УН, М‡ФЛПВ, ЛБ-Б‡

ЛБМУТ‡ ‰ВЪ‡ОЛ, У·‡˘‡ИЪВТ¸ Н З‡¯ВПЫ ПВТЪМУПЫ

‰ЛОВЫ ЩЛП˚ Ferm. з‡ У‰МУИ ЛБ ФУТОВ‰МЛı ТЪ‡МЛˆ

ЫНУ‚У‰ТЪ‚‡ ФЛ‚В‰ВМ‡ ТıВП‡ ‡ФФ‡‡Ъ‡ ‚

‡БУ·‡ММУП ‚Л‰В, „‰В ФУН‡Б‡М˚ ‰ВЪ‡ОЛ, НУЪУ˚В

ПУКМУ Б‡Н‡Б‡Ъ¸ ‚Б‡ПВМ МВЛТФ‡‚М˚ı.

бДфанД йдкмЬДыфЦв лкЦСх

уЪУ·˚ ФВ‰УЪ‚‡ЪЛЪ¸ ‚УБМЛНМУ‚ВМЛВ ФУ‚ВК‰ВМЛИ

‚У ‚ВПfl Ъ‡МТФУЪЛУ‚НЛ, ЛБ‰ВОЛВ ФУТЪ‡‚ОflВЪТfl ‚

ФУ˜МУИ ЫФ‡НУ‚НВ. мФ‡НУ‚Н‡ ТУТЪУЛЪ ‚ УТМУ‚МУП ЛБ

П‡ЪВЛ‡ОУ‚, ФЛ„У‰М˚ı ‰Оfl ‚ЪУЛ˜МУИ ФВВ‡·УЪНЛ.

иУ˝ЪУПЫ ЛТФУО¸БЫИЪВ ‚УБПУКМУТЪ¸ ‰Оfl Т‰‡˜Л

ЫФ‡НУ‚НЛ ‚ ФЫМНЪ˚ ‚ЪУЛ˜МУИ ФВВ‡·УЪНЛ. ЦТОЛ ‚‡П

·УО¸¯В МВ МЫКВМ УЪТОЫКЛ‚¯ЛИ ТЪ‡˚И ‡ФФ‡‡Ъ, ЪУ

‰УТЪ‡‚¸ЪВ В„У ‚‡¯ВПЫ ПВТЪМУПЫ ‰ЛОВЫ ЩЛП˚ Ferm.

н‡П ФУБ‡·УЪflЪТfl У· ˝НУОУ„Л˜ВТНЛ ˜ЛТЪУИ В„У

ФВВ‡·УЪНВ.

ЙДкДзнаь

Й‡‡МЪЛИМ˚В ЫТОУ‚Лfl ФЛ‚У‰flЪТfl М‡ ТФВˆЛ‡О¸МУП

„‡‡МЪЛИМУП Ъ‡ОУМВ, НУЪУ˚И ФЛО‡„‡ВЪТfl УЪ‰ВО¸МУ.

иУ‰ М‡¯Ы ЛТНО˛˜ЛЪВО¸МЫ˛ УЪ‚ВЪТЪ‚ВММУТЪ¸

Û‰ÓÒÚÓ‚ÂflÂÏ, ˜ÚÓ ‰‡ÌÌÓ ËÁ‰ÂÎËÂ

Û‰Ó‚ÎÂÚ‚ÓflÂÚ ÒÎÂ‰Û˛˘ËÏ

Òڇ̉‡Ú‡Ï Ë ÌÓχÚË‚Ì˚Ï

‰УНЫПВМЪ‡П Цл:

EN50060 + ‰УФУОМВМЛВ,

EN50199 + ‰УФУОМВМЛВ

EN60974-1 + ‰УФУОМВМЛВ,

Òӄ·ÒÌÓ ÒÎÂ‰Û˛˘ËÏ Ô‰ÔËÒ‡ÌËflÏ:

LDV 73/23 EEC + ‰УФУОМВМЛВ

EMC 89/336 + ‰УФУОМВМЛВ

20.09.2002

ЙЦзЦейвСЦз,

зЛ‰ВО‡М‰˚

Ç. ä‡ÏÔıÓÙ

éÚ‰ÂÎ ÍÓÌÚÓÎfl ͇˜ÂÒÚ‚‡

CE

ı

ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ ВЕЛИКОБРИТАНИЯ

(R)

Ferm 43

WELDING

Fig.D

• Insert the exposed part of the electrode into the collet and connect the work clamp to the welding piece

taking care that electric contact is good.

• Turn on welder and regulate welding current in function of the electrode in use.

• Holding the mask IN FRONT OF FACE stroke the

electrode point on the workpiece as if striking a

match. This is the most correct method for striking

the arc.

Don’t hit the electrode on the workpiece, which will

damage the stick electrode and make arc strike-up

difficult.

• Immediately after arc strike up try to maintain a distance from the workpiece which is equivalent to the

diameter of the electrode used. Maintain this distance as constantly as possible during the weld,

remember that the inclination of the electrode to the

advancement must be 20° - 30°.

Always use pliers to remove consumed electrodes

or to move welded pieces.

MALFUNCTION

Below we have listed a number of possible causes and

corresponding solutions in case the machine does not

function as it should:

When the welding machine doesn’t function,

check the following

• The thermal fuse is disconnected.

• The fuse is defect (mains).

• The work cable is not connected with the workpiece.

• The collet or work cable or the mains supply is damaged.

MAINTENANCE

Make sure that the machine is not live when carrying out maintenance work on the motor.

The Ferm machines have been designed to operate over

a long period of time with a minimum of maintenance.

Continuous satisfactory operation depends upon proper machine care and regular cleaning.

Cleaning

Keep the ventilation slots of the machine clean to prevent overheating.

Regularly clean the machine housing with a soft cloth,

preferably after each use. Keep the ventilation slots free

from dust and dirt.

Faults

Should a fault occur, e.g. after wear of a part, please contact your local Ferm dealer.

In the back of this manual you find an exploded view

showing the parts that can be ordered.

ENVIRONMENT

In order to prevent the machine from damage during

transport, it is delivered in a sturdy packaging. Most of

the packaging materials can be recycled. Take these

materials to the appropriate recycling locations.

Take your unwanted machines to your local Fermdealer. Here they will be disposed of in an environmentally safe way.

6 Ferm

Page 7

GUARANTEE

The guarantee conditions can be found on the separately

enclosed guarantee card.

We declare under our sole responsibility that this

product is in conformity with the following

standards or standardized documents

EN50060 + Amdt,

EN50199 + Amdt

EN60974-1 + Amdt,

in accordance with the regulations:

LDV 73/23 EEC + Amdt

EMC 89/336 + Amdt

from 20-09-2002

GENEMUIDEN NL

W. Kamphof

Quality department

SCHWEIßGERÄT

DIE NUMMERN IM NACHFOLGENDEN TEXT

KORRESPONDIEREN MIT DER ABBILDUNGEN

AUF SEITE 2

TECHNICAL SPECIFICATIONS

BESCHREIBUNG VON SYMBOLE

EN 50060 Schweißnorm für limitierte Nutzung.

Einphasentrafo.

Uo (V) Leerspannung in Volt.

f(Hz) Netzfrequenz in Herz.

I2(A) Secundair- oder Schweißstrom in

Ampère.

d(mm) Schweißelektrodendurchmeßer in mm.

nc Schweißelektrodennummer vom kalten

Zustand bis zum ersten Einsetzen des

Thermostats.

nh Elektrodennummer nach dem ersten

Einsetzen des Thermostats in der ersten

Benützungsstunde.

U1(V) Netzspannung in Volt

I1(A) Maximaler Aufnahmestrom in Ampère

Sicherung

IP21 Schutzgrad der Schutzhüle

H Isolierungsklasse des Trafos

Thermostat

Elektrodenhalter

Erdungsklemme

Normstecker

ZUBEHÖR UND ERSATZTEILE

Bei das Schweißgerät wird als Standard mitgeliefert:

• Gebrauchsanweisung

• Kabel

• Erdungsklemme

• Elektrodenhalter

• Schutzmaske

• Pickhammer

• Stahlbürste

Über Ihren Ferm-Händler können Sie Ersatzteile nachbestellen, die in Vorrat gehalten werden. Beim Bestellen

der Ersatzteile sollten Sie die Nummern benutzen, die in

der Unterteil-Liste aufgeführt sind.

Netzanschluß | 230 V~

Frequenz | 50 Hz

Max. Leistungsaufnahme | 2.5 kVA

Schweißstrom | 40 - 140 A

Leerlaufspannung | 45 - 48 V

Elektrodenstärke | 1.5 - 3.15 mm

Gewicht | 14.0 kg

Deutsch

D

CE

ı

DECLARATION OF CONFORMITY

(UK)

Ferm 7

щдлигмДнДсаь ДииДкДнД

дДЕЦгъ щгЦднкйСйСЦкЬДнЦгь

аПВВЪ ТФВˆЛ‡О¸М˚И Б‡КЛП М‡ НОВППВ ‰Оfl НВФОВМЛfl

У„УОfiММУИ ˜‡ТЪЛ ˝ОВНЪУ‰‡.

дДЕЦгъ «еДллх»

СУОКВМ ·˚Ъ¸ МВФУТВ‰ТЪ‚ВММУ ФЛНВФОВМ Н

ЛБ‰ВОЛ˛ ЛОЛ ЪУНУФУ‚У‰fl˘ВПЫ ‡·У˜ВПЫ ТЪУОЫ.

м·В‰ЛЪВТ¸, ˜ЪУ Н‡·ВО¸ «П‡ТТ˚» М‡‰ВКМУ

ТУВ‰ЛМfiМ Т ЛБ‰ВОЛВП Л ЪУ˜Н‡ ТУВ‰ЛМВМЛfl МВ

ФУН˚Ъ‡ ЛБУОЛЫ˛˘ЛП П‡ЪВЛ‡ОУП, М‡ФЛПВ, О‡НУП.

бДфанзДь еДлдД

êËÒ.B

б‡˘ЛЪМ‡fl П‡ТН‡ ‰УОКМ‡ У·flБ‡ЪВО¸МУ ЗлЦЙСД

ЛТФУО¸БУ‚‡Ъ¸Тfl ФЛ Т‚‡НВ. йМ‡ Б‡˘Л˘‡ВЪ „О‡Б‡ УЪ

Т‚ВЪУ‚У„У ЛБОЫ˜ВМЛfl ‰Ы„Л. е‡ТН‡ ФУБ‚УОflВЪ

М‡·О˛‰‡Ъ¸ Б‡ ‚˚ФУОМВМЛВП ФУˆВТТ‡ Т‚‡НЛ.

1. å‡Ò͇

2. лЪВНОУ

3. л‚ВЪУЩЛО¸Ъ

4. êÛÍÓflÚ͇

иВВ‰ М‡˜‡ОУП Т‚‡НЛ МЫКМУ ТУ·‡Ъ¸

Т‚‡У˜МУВ ТЪВНОУ Л ФУНУ‚МУВ ТЪВНОУ.

д‡ЪВ„УЛ˜ВТНЛ Б‡ФВ˘‡ВЪТfl ТПУЪВЪ¸ ФflПУ М‡

Т‚‡У˜МЫ˛ ‰Ы„Ы ·ВБ Б‡˘ЛЪМУИ П‡ТНЛ!

ейгйнйд Сгь йдДгазх

л ФУПУ˘¸˛ ˝ЪУ„У ПУОУЪН‡ Ы‰‡ОflВЪТfl ¯О‡Н ТУ

Т‚‡МУ„У ТУВ‰ЛМВМЛfl. зВ ТОВ‰ЫВЪ Ы‰‡flЪ¸ ПУОУЪНУП

ТОЛ¯НУП ТЛО¸МУ. щЪУ ПУКВЪ ФЛ‚ВТЪЛ Н

ФУ‚ВК‰ВМЛ˛ ¯‚‡. иЛ ˝ЪУП ‚ТВ„‰‡ ЛТФУО¸БЫИЪВ

Б‡˘ЛЪМ˚В У˜НЛ.

икйЗйгйузДь фЦндД

л ФУПУ˘¸˛ ˘ВЪНЛ ЛБ ТЪ‡О¸МУИ ФУ‚УОУНЛ ПУКВЪ

Ы‰‡ОflЪ¸Тfl К‡‚˜ЛМ‡ ФВВ‰ НВФОВМЛВП Н‡·ВОfl Н

Т‚‡У˜МУИ ‰ВЪ‡ОЛ ЛОЛ КВ Ы‰‡ОflЪ¸Тfl ¯О‡Н ФУТОВ

Т‚‡НЛ.

пДкДднЦкалнада лЗДкзхп тЗйЗ

êËÒ.C

1лОЛ¯НУП ПВ‰ОВММУВ ‚В‰ВМЛВ

2 лОЛ¯НУП ·˚ТЪУВ ‚В‰ВМЛВ

3й˜ВМ¸ НУУЪН‡fl ‰Ы„‡

4 й˜ВМ¸ ‰ОЛММ‡fl ‰Ы„‡

5 лОЛ¯НУП П‡О˚И ЪУН

6 лОЛ¯НУП ·УО¸¯УИ ЪУН

7 йФЪЛП‡О¸М˚И ЪУН

лЗДкдД

êËÒ.D

• ЗТЪ‡‚¸ЪВ У„УОfiММЫ˛ ˜‡ТЪ¸ ˝ОВНЪУ‰‡ ‚

˝ОВНЪУ‰У‰ВК‡ЪВО¸ Л ФЛТУВ‰ЛМЛЪВ Б‡КЛП

Н‡·ВОfl «П‡ТТ˚» Н Т‚‡Л‚‡ВПУИ ‰ВЪ‡ОЛ,

Ы·В‰Л‚¯ЛТ¸ ‚ М‡ОЛ˜ЛЛ ıУУ¯В„У ˝ОВНЪЛ˜ВТНУ„У

НУМЪ‡НЪ‡.

• ЗНО˛˜ЛЪВ Т‚‡У˜М˚И ‡ФФ‡‡Ъ Л УЪВ„ЫОЛЫИЪВ

Т‚‡У˜М˚И ЪУН ‚ ТУУЪ‚ВЪТЪ‚ЛЛ Т ЪЛФУП

ФЛПВМflВП˚ı ˝ОВНЪУ‰У‚.

• СВК‡ П‡ТНЫ иЦкЦС гасйе, ОВ„НУ ФУ‚В‰ЛЪВ

НУМˆУП ˝ОВНЪУ‰‡ ФУ ЛБ‰ВОЛ˛, Н‡Н ·Ы‰ЪУ ‚˚

Б‡КЛ„‡ВЪВ ТФЛ˜НЫ. щЪУ Т‡П˚И Ф‡‚ЛО¸М˚И ТФУТУ·

Б‡КЛ„‡МЛfl ‰Ы„Л.

зВ Ы‰‡flИЪВ ТЛО¸МУ ˝ОВНЪУ‰УП ФУ ЛБ‰ВОЛ˛.

щЪУ ПУКВЪ ФЛ‚ВТЪЛ Н ФУ‚ВК‰ВМЛ˛

˝ÎÂÍÚÓ‰‡ Ë Á‡ÚÛ‰ÌËÚ Á‡ÊË„‡ÌË ‰Û„Ë.

• л‡БЫ ФУТОВ Б‡КЛ„‡МЛfl ‰Ы„Л ФУТЪ‡‡ИЪВТ¸

‚˚‰ВКЛ‚‡Ъ¸ ‡ТТЪУflМЛВ УЪ ЛБ‰ВОЛfl, ‡‚МУВ

‰Л‡ПВЪЫ ФЛПВМflВПУ„У ˝ОВНЪУ‰‡.

З˚‰ВКЛ‚‡ИЪВ ˝ЪУ ‡ТТЪУflМЛВ ФЛ Т‚‡НВ ФУ

‚УБПУКМУТЪЛ ‚Тfi ‚ВПfl ФУТЪУflММ˚П. иУПМЛЪВ У

ЪУП, ˜ЪУ М‡НОУМ ˝ОВНЪУ‰‡ ФУ УЪМУ¯ВМЛ˛ Н

М‡Ф‡‚ОВМЛ˛ В„У ‰‚ЛКВМЛfl ‰УОКВМ ТУТЪ‡‚ОflЪ¸

20° - 30°.

ЗТВ„‰‡ ЛТФУО¸БИЪВ ТФВˆЛ‡О¸М˚В ˘ЛФˆ˚ ‰Оfl

Ы‰‡ОВМЛfl УЪ‡·УЪ‡ММУ„У ˝ОВНЪУ‰‡ ЛОЛ

ÔÂÂÏ¢ÂÌËfl Ò‚‡ÂÌÌ˚ı ‰ÂÚ‡ÎÂÈ.

ЗйбейЬзхЦ зЦийгДСда а

еЦнйСх ап млнкДзЦзаь

зЛКВ ФЛ‚У‰ЛЪТfl fl‰ МВЛТФ‡‚МУТЪВИ, Лı

‚УБПУКМ˚В ФЛ˜ЛМ˚ Л ПВЪУ‰˚ ЫТЪ‡МВМЛfl:

ÖÒÎË Ò‚‡Ó˜Ì˚È ‡ÔÔ‡‡Ú Ì ‡·ÓÚ‡ÂÚ,

Ôӂ¸Ú ÒÎÂ‰Û˛˘ÂÂ:

• л‡·УЪ‡О ЪВПУФВ‰Уı‡МЛЪВО¸;

• иВВ„УВО ФО‡‚НЛИ ТВЪВ‚УИ ФВ‰Уı‡МЛЪВО¸;

• 䇷Âθ «Ï‡ÒÒ˚» Ì ÔËÒÓ‰ËÌÂÌ Í Ò‡ÏÓÏÛ

ËÁ‰ÂÎ˲;

• иУ‚ВК‰ВМЛВ Н‡·ВОfl ‰ВК‡ЪВОfl ˝ОВНЪУ‰‡,

Н‡·ВОfl «П‡ТТ˚» ЛОЛ ‚ ОЛМЛЛ ФУ‰‡˜Л ФЛЪ‡МЛfl.

42 Ferm

Page 8

SICHERHEITSVORSCHRIFTEN

In dieser Betriebsanleitung erscheinen folgende Piktogramme:

Verweist auf Verletzungsgefahr, Gefahr für Leben

und mögliche Beschädigung der Maschine, falls die

Anweisungen in dieser Betriebsanleitung nicht befolgt werden.

Deutet das Vorhandensein elektrischer Spannung

an.

Lesen Sie diese Betriebsanleitung aufmerksam, bevor Sie

die Maschine in Betrieb nehmen. Machen Sie sich vertraut mit der Funktionsweise und der Bedienung. Warten

Sie die Maschine entsprechend den Anweisungen, damit

sie immer einwandfrei funktioniert. Die Betriebsanleitung und die dazugehörende Dokumentation müssen in

der Nähe der Maschine aufbewahrt werden.

Bei der Verwendung von elektrischen Maschinen

sollten Sie immer die einschlägigen nationalen

Sicherheitsvorschriften befolgen um das Risiko auf

Feuer, elektrische Schläge und persönliche Verletzung zu reduzieren. Lesen Sie die nachstehenden

Sicherheitsvorschriften sowie die beigefügten

Sicherheitsanweisungen.

Diese Anweisungen sollten an einem sicheren Ort

aufbewahrt bleiben.

SPEZIELLE SICHERHEITSVORSCHRIFTEN

• Bogenschweißen erzeugt Funken, geschmolzene

Metallteile und Rauch, achten Sie darauf das keine

brandbare Gegenstände sich in der Nähe des

Arbeitsplatzes befinden.

• Überzeugen Sie sich, daß ausreichend Luftzufuhr zur

Verfügung steht.

• Schweißen Sie nicht auf Behältern. Gefäßen oder

Rohren, die brennbare Flußigkeiten oder Gase enthalten haben (Gefahr von Emission toxischer Gase).

• Vergewissen Sie sich daß das Gerät richtig an das

Netzkabel angeschloßen ist. Jeder Elektroschock

kann möglicherweise tödlich sein.

• Vermeiden sie jede Spannung des Netzkabels. Stec-

ken Sie das Gerät aus, bevor Sie es andernorts aufstellen wollen.

• Achten Sie auf den Zustand der Schweißkabel der

Elektrodenzange sowie der Erdungsklemmen.

Abnützungen an der Isolierung und an den stromführende Teilen können eine gefährliche Situation hervorrufen und die Qualität der Schweißarbeit mindern.

• Vermeiden Sie jeden direkten Kontakt mit dem Sch-

weißkreislauf; die Leerspannung die zwischen Elektrodenzange und Erdungsklemme auftritt kann

gefährlich sein.

• Verwenden Sie das Gerät nicht in feuchter oder

naßer Umgebung oder in Regen.

• Schützen sie die Augen mit dafür bestimmten Schutz-

brillen, die Sie auf der beigelegten Maske befestigen.

• Verwenden Sie Handschuhe und trockene Schutz-

kleidung, die frei von Öl und Fett ist.

• Wenn Sie die Schweißraupe mit einen Pickhammer

entfernen, benützen Sie in jeden Fall eine Schutzbrille

und Handschuhe gegen die heiße Stücke.

• Um die Haut nicht der ultravioletten Strahlung des

Bogens auszusetzen müssen Sie Schutzkleidung

benützen.

• Dieses Gerät ist gegen Thermischer Überladung

durch eine automatische Schutzeinrichtung (Thermostat mit automatischer Wiederaufnahme)

geschützt. Die Schutzvorrichtung unterbricht den

Stromkreis. Nach einigen Minuten der Abkühlung

wird das Gerät wieder aktiviert. Das Gerät ist für

weiter Arbeiten bereit.

• Das Werkstuck kann sich Verformen während das

abkühlen. Achten Sie darauf.

DAS GERÄT SOFORT AUSSCHALTEN BEI:

• Störung im Netzstecker, dem Netzkabel oder

Schnurbeschädigung.

• Defekter Schalter.

• Rauch oder Gestank verschmorter Isolation.

NICHT ERFOLGEN DER SICHERHEITSVORSCHRIFTEN HAT EINSCHRENKUNG DER

GARANTIEBEDINGUNGEN ZUFOLGE!

ELEKTRISCHE SICHERHEIT

Überprüfen Sie immer, ob Ihre Netzspannung der

des Typenschilds entspricht.

Austauschen von Kabeln oder Steckern

Entsorgen Sie alte Kabel oder Stecker, unmittelbar nachdem Sie durch neue ersetzt sind. Das Anschließen eines

Steckers eines losen Kabels an eine Steckdose ist gefährlich.

Daß Gerät muß von zwei Leitern gespeist werden und

mit einem dritten Leiter der ausschließlich für die Erdung

(PE) zuständig ist versehen sein. Dieser Leiter ist

gelb/grün. Suchen Sie sich eine Netzsteckdose die mit

einer Sicherung oder einem automatischen Unterbrecher abgesichert ist. Das vorgesehene Erdungsende muß

mit dem Erdungsnetz des Stromnetzes verbunden werden.

Benützen Sie Sicherungen von minimal 16 Ampère Langsam

Verwendung von Verlängerungskabeln

Benutzen Sie nur ein genehmigtes Verlängerungskabel,

das der Maschinenleistung entspricht. Die Ader müssen

einen Mindestquerschnitt von 1,5 mm

2

haben. Befindet

das Kabel sich auf einem Haspel. muß es völlig abgerollt

werden.

8 Ferm

иЦкЦС зДуДгйе

щлдигмДнДсаа

ЗхийгзЦзаЦ лЗДкда

êËÒ.A

иУТОВ ‚˚ФУОМВМЛfl ‚ТВı ˝ОВНЪЛ˜ВТНЛı

ФУ‰ТУВ‰ЛМВМЛИ ТВЪЛ Л Т‚‡У˜МУ„У НУМЪЫ‡

ФУЛБ‚У‰ЛЪВ Т‚‡НЫ ТОВ‰Ы˛˘ЛП У·‡БУП. СЫ„У‚‡fl

˝ОВНЪУТ‚‡Н‡ Т ФУПУ˘¸˛ ˝ОВНЪУТ‚‡У˜МУ„У

‡ФФ‡‡Ъ‡ - ˝ЪУ ПВЪУ‰ Т‚‡НЛ, ФЛ НУЪУУП

ЛТЪУ˜МЛНУП ЪВФО‡ fl‚ОflВЪТfl ‰Ы„‡. щЪ‡ ‰Ы„‡ ‚УБМЛН‡ВЪ

ПВК‰Ы ˝ОВНЪУ‰УП Л Т‚‡Л‚‡ВПУИ ‰ВЪ‡О¸˛.

èËϘ‡ÌËÂ: иВВ‰ Т‚‡НУИ ТОУКМ˚ı ¯‚У‚

‚˚ФУОМЛЪВ ФУ·МЫ˛ Т‚‡НЫ. нУО¸НУ Ф‡НЪЛН‡

ФУБ‚УОЛЪ ‚‡П ФУОЫ˜‡Ъ¸ ‡ННЫ‡ЪМ˚В Л ФУ˜М˚В ¯‚˚.

нВПФВ‡ЪЫ‡ ‰Ы„Л ТУТЪ‡‚ОflВЪ 4000° л Л ФЛ‚У‰ЛЪ Н

‡ТФО‡‚ОВМЛ˛ ˝ОВНЪУ‰‡ Л Т‚‡Л‚‡ВПУИ ‰ВЪ‡ОЛ. ЦТОЛ

‰Ы„‡ ФУ‰‰ВКЛ‚‡ВЪТfl, ˝ОВНЪУ‰ ФО‡‚ЛЪТfl Л ‰‡ВЪ

П‡ЪВЛ‡О ‰Оfl ТУВ‰ЛМВМЛfl.

к‡ТТЪУflМЛВ ПВК‰Ы ˝ОВНЪУ‰УП Л ‰ВЪ‡О¸˛ ‰УОКМУ

·˚Ъ¸ УЪ 1,5 ‰У 4,0 ПП ‚ Б‡‚ЛТЛПУТЪЛ УЪ ‰Л‡ПВЪ‡ Л

П‡ЪВЛ‡О‡ ˝ОВНЪУ‰‡. зВУ·ıУ‰ЛП˚И Т‚‡У˜М˚И ЪУН

ФУ‰‡ВЪТfl Т‚‡У˜М˚П ‡ФФ‡‡ЪУП. зВУ·ıУ‰ЛП‡fl

ПУ˘МУТЪ¸ Т‚‡У˜МУ„У ‡ФФ‡‡Ъ‡ Б‡‚ЛТЛЪ УЪ

‚˚ФУОМflВП˚ı ТУВ‰ЛМВМЛИ.

щгЦднкйСх

щОВНЪУ‰ ТУТЪУЛЪ ЛБ ПВЪ‡ООЛ˜ВТНУ„У ТЪВКМfl Л

ФУН˚ЪЛfl. иУН˚ЪЛВ ˜‡ТЪЛ˜МУ ТУТЪУЛЪ ЛБ

ПВЪ‡ООЛ˜ВТНУИ Ф˚ОЛ. иЛ Т‚‡НВ ФУН˚ЪЛВ ФО‡‚ЛЪТfl

Л ЛТФ‡flВЪТfl. й·‡БЫ˛˘ЛИТfl „‡Б УНЫК‡ВЪ БУМЫ

Т‚‡НЛ, Б‡˘Л˘‡fl ‡ТФО‡‚ОВММ˚И ПВЪ‡ОО УЪ НЛТОУУ‰‡

‚УБ‰Ыı‡. у‡ТЪ¸ НУПФУМВМЪУ‚ ФУН˚ЪЛfl ˝ОВНЪУ‰‡

ФО‡‚‡˛Ъ М‡ ФУ‚ВıМУТЪЛ ‡ТФО‡‚ОВММУ„У ПВЪ‡ОО‡

(УМЛ ОВ„˜В В„У) Л Б‡˘Л˘‡˛Ъ ПВЪ‡ОО ‚ ФУˆВТТВ

УıО‡К‰ВМЛfl. иУТОВ УıО‡К‰ВМЛfl ˝ЪУЪ ¯О‡Н ОВ„НУ

Ы‰‡ОflВЪТfl ПУОУЪНУП ЛОЛ ФУ‚УОУ˜МУИ ˘ВЪНУИ. зВ

‰УФЫТН‡ИЪВ ФУФ‡‰‡МЛfl ˜‡ТЪЛ˜ВН ФУН˚ЪЛfl ˝ОВНЪУ‰‡

‚ ПВЪ‡ОО ¯‚‡. щЪУ ЫıЫ‰¯‡ВЪ М‡‰ВКМУТЪ¸ ТУВ‰ЛМВМЛfl.

é·‡˘‡ÈÚÂÒ¸ Ò ˝ÎÂÍÚÓ‰‡ÏË ÓÒÚÓÓÊÌÓ.

иУН˚ЪЛВ ˝ОВНЪУ‰‡ ПУКВЪ ·˚Ъ¸ ОВ„НУ

ФУ‚ВК‰ВМУ, ˜ЪУ ˜ВБ‚˚˜‡ИМУ Б‡ЪЫ‰МЛЪ Т‚‡НЫ.

п‡МЛЪВ ˝ОВНЪУ‰˚ ‚ ТЫıУП ФУıО‡‰МУП ПВТЪВ.

Ç˚·Ó ˝ÎÂÍÚÓ‰Ó‚

СОfl Н‡˜ВТЪ‚‡ ТУВ‰ЛМВМЛfl ‚‡КВМ Ф‡‚ЛО¸М˚И ФУ‰·У

˝ОВНЪУ‰У‚. иЛ ‚˚·УВ ˝ОВНЪУ‰У‚ ЛПВВЪ БМ‡˜ВМЛВ

ФУОУКВМЛВ ¯‚‡, М‡ФЛПВ, ‚ВıМВВ. й·˚˜М˚В

˝ОВНЪУ‰˚ У·ВТФВ˜Л‚‡˛Ъ ‚˚ФУОМВМЛВ ·УО¸¯ЛМТЪ‚‡

Т‚‡У˜М˚ı ‡·УЪ.

ëÛ˘ÂÒÚ‚Û˛Ú ÚË ÚËÔ‡ ˝ÎÂÍÚÓ‰Ó‚:

1. Å˚ÒÚÓ„Ó Á‡Ú‚‰‚‡ÌËfl

иУН˚ЪЛВ ‚НО˛˜‡ВЪ ·УО¸¯УИ ФУˆВМЪ

У„‡МЛ˜ВТНУ„У П‡ЪВЛ‡О‡, ˜ЪУ У·ВТФВ˜Л‚‡ВЪ

ıУУ¯Ы˛ „‡БУ‚Ы˛ Б‡˘ЛЪЫ. еУ„ЫЪ ФЛПВМflЪ¸Тfl

‰Оfl ‚ТВı ‚Л‰У‚ ФУОУКВМЛИ, УТУ·ВММУ ‰Оfl

‚ВЪЛН‡О¸М˚ı, Л‰Ы˘Лı ‚МЛБ ТУВ‰ЛМВМЛИ.

2. ë‰ÌÂ„Ó Á‡Ú‚‰‚‡ÌËfl

иУН˚ЪЛВ ‚НО˛˜‡ВЪ ·УО¸¯УИ ФУˆВМЪ

У„‡МЛ˜ВТНУ„У П‡ЪВЛ‡О‡. пУУ¯‡fl

Т‚‡Л‚‡ВПУТЪ¸ ФЛ ‚ТВı ФУОУКВМЛflı ¯‚‡, Б‡

ЛТНО˛˜ВМЛВП ‚ВЪЛН‡О¸М˚ı, М‡Ф‡‚ОВММ˚ı ‚МЛБ

ТУВ‰ЛМВМЛИ. щОВНЪУ‰˚ ˝ЩЩВНЪЛ‚М˚ ‰Оfl

‚ВЪЛН‡О¸М˚ı, М‡Ф‡‚ОВММ˚ı ‚‚Вı ТУВ‰ЛМВМЛИ.

3. еВ‰ОВММУ„У Б‡Ъ‚‰‚‡МЛfl

иУН˚ЪЛВ ЪУО˘В, ˜ВП ФВ‰˚‰Ы˘ЛВ ‰‚‡, Л

ТУ‰ВКЛЪ ПВМ¸¯В У„‡МЛ˜ВТНУ„У П‡ЪВЛ‡О‡.

С‡ВЪ ЪУОТЪ˚И ТОУИ ФОУЪМУ„У ¯О‡Н‡. З‡ММУ˜Н‡

‡ТФО‡‚ОВММУ„У ПВЪ‡ОО‡ ЛПВВЪ У˜ВМ¸ МВ·УО¸¯Ы˛

„ОЫ·ЛМЫ. иВЛПЫ˘ВТЪ‚ВММУ ‰Оfl „УЛБУМЪ‡О¸М˚ı

ТУВ‰ЛМВМЛИ.

СОfl Т‚‡НЛ ‡О˛ПЛМЛfl Л МВК‡‚В˛˘ВИ ТЪ‡ОЛ

ТЫ˘ВТЪ‚Ы˛Ъ ТФВˆЛ‡О¸М˚В ˝ОВНЪУ‰˚.

иУНУМТЫО¸ЪЛЫИЪВТ¸ Ы ПВТЪМУ„У ‰ЛОВ‡ Ferm.

кДЕйуаЦ ийдДбДнЦга

ꇷӘË ÔÓ͇Á‡ÚÂÎË ‰‡ÌÌÓ„Ó Ò‚‡Ó˜ÌÓ„Ó ‡ÔÔ‡‡Ú‡

ÏÓ„ÛÚ ·˚Ú¸ ‚˚‡ÊÂÌ˚ ˜ÂÂÁ ÍÓ΢ÂÒÚ‚Ó ˝ÎÂÍÚÓ‰Ó‚:

nc Ë nh.

nc: НУОЛ˜ВТЪ‚У ˝ОВНЪУ‰У‚, НУЪУУВ ПУКВЪ ·˚Ъ¸

ЛТФУО¸БУ‚‡МУ Т ПУПВМЪ‡, НУ„‰‡ ‡ФФ‡‡Ъ ЛПВВЪ

НУПМ‡ЪМЫ˛ ЪВПФВ‡ЪЫЫ ‰У ПУПВМЪ‡ ‚НО˛˜ВМЛfl

ЪВПУТЪ‡Ъ‡.

nh: лкЦСзЦЦ бзДуЦзаЦ НУОЛ˜ВТЪ‚‡ ˝ОВНЪУ‰У‚,

НУЪУУВ ПУКВЪ ·˚Ъ¸ ЛТ‡ТıУ‰У‚‡МУ ПВК‰Ы

ФУ‚ЪУМ˚П ФЫТНУП Л ‚НО˛˜ВМЛВП ЪВПУТЪ‡Ъ‡ ‚

ЪВ˜ВМЛВ ФВ‚У„У ˜‡Т‡ ‡·УЪ˚.

лЗДкйузхв нйд

нУН ФУ‚˚¯‡ВЪТfl ФЛ ФУ‚УУЪВ В„ЫОflЪУ‡ ФУ

˜‡ТУ‚УИ ТЪВОНВ. нУН ЫПВМ¸¯‡ВЪТfl ФЛ ФУ‚УУЪВ

В„ЫОflЪУ‡ ФУЪЛ‚ ˜‡ТУ‚УИ ТЪВОНЛ. бМ‡˜ВМЛВ ТЛО˚

ЪУН‡ (I2) ПУКМУ Т˜ЛЪ‡Ъ¸ Т „‡‰ЫЛУ‚‡ММУИ ¯Н‡О˚ М‡

‚ВıМВИ Ф‡МВОЛ. йМУ ТУУЪ‚ВЪТЪ‚ЫВЪ М‡ФflКВМЛ˛

‰Ы„Л (U2) ТУ„О‡ТМУ Ы‡‚МВМЛ˛ U2(V)=18 + 0,04 x I2

(EN 50060). иЛ ЛТФУО¸БУ‚‡МЛЛ ˜ВБПВМУ ‰ОЛММУ„У

Ы‰ОЛМЛЪВО¸МУ„У Н‡·ВОfl ЪУН ТЫ˘ВТЪ‚ВММУ ТМЛК‡ВЪТfl.

нВ·ЫВП˚И ЪУН Ъ‡НКВ Б‡‚ЛТЛЪ УЪ ЩЛБЛ˜ВТНУ„У

‡БПВ‡ ЛБ‰ВОЛfl. зВ·УО¸¯ЛВ ‰ВЪ‡ОЛ ЪВ·Ы˛Ъ

ПВМ¸¯В„У ЪУН‡.

íÓ΢Ë̇ ëÚÂÊÂ̸ 낇ӘÌ˚È

˝ÎÂÍÚÓ‰‡

‰ÂÚ‡ÎË Ò˜ÂÌË (ÏÏ2) ÚÓÍ (A)

2-3 2 45-65

4-5 2,5 70-95

6-7 3,25 90-130

8-12 4 130-160

퇷Îˈ‡ 1

Ferm 41

Page 9

VOR INBETRIEBNAHME

SCHWEIßEN

Fig.A

Nachdem Sie alle elekrischen Anschluße für die Strom

versorgung sowie für den Schweißkreislauf vergenommen haben, können sie folgendermaßen vorgehen. Lichtbogenschweißen ist einer Methode wobei die Wärme

entwickeld wird im Lichtbogen. Der Lichtbogen befindet

Sich zwischen der Elektrode und das Schweißstück.

NB: Vor heiklen Schweißarbeiten sollten Sie vorher

üben, denn nur durch Übung erhalten Sie schöne und

dauerhafte Resultate.

Die Temperatur der Lichtbogen beträgt 4000° Celsius.

Mit dieser Hitze schmeltzt der Elektrode und das Schweißstück. Während der Lichtbogen da ist, schmeltzt

der Elektrode und liefert das Material für der Verbindung. Der abstand zwischen Elektrode und Schweißstück muß 1,5 - 4 mm betragen, anbhängig der Dikke

des Elektrodes und das zu Schweißen Materiales. Die

benötigte Schweißstrom ist erzeugt von des Schweißgerätes. Die benötigte Kapazität des Schweißgerätes ist

abhängig von der zu machen Verbindung.

DER ELEKTRODE

Der Elektrode enthält einen Kern aus Eisen mit einen

Bedeckung. Dieser Bedeckung enthält Eisenstaub. Während das Schweißen schmeltzt die Bedeckung und sie

wird verdampfen. Auf dieser entsteht ein Gas um das

Schmeltzbad herum das das Bad beschützt gegen Sauerstoff aus der Luft. Einige Teile werden auf das Schmeltzbad treiben (die Teile sind nicht so schwer wie das Eisen)

und werden die Verbindung schützen während das

Erstarren der Verbindung. Wenn die Verbindung

abgekühlt ist können die Reste der Bedeckung entfernt

werden mit einen Pickhammer und Stahlbürste.

Achten Sie darauf das keine Teile der Bedeckung eingekapselt werden beim Schweißen. Das wird eine schlechte Verbindung geben.

Fassen Sie die Elektroden mit vorsicht an. Die

Abdeckung der Elektroden kan schnell beschädigt

werden und das Schweißen schwerig machen. Heben Sie die

Elektroden in einen Trockenen und Kühleb Stelle auf.

Wahl der elektrode

Damit Sie eine gute Verbindung machen können müssen

Sie die richtige Elektrode wähelen. Auch der Position in

den Sie die Verbindung machen müssen ist entscheidend.

Ein Universeller Elektrode kan die meisten Verbindungen machen.

Elektroden sind in drei typen erhältlich:

1. Schnell Erstarrend

Die Bedeckung der Elektrode besitzt eine mänge Organisches Material, das erzeugt eine gute Gasbeschützung. Er kann in viele Stellen benützt werden, auch in

Vertikaler, nach unten bewegenden Schweißvorgang.

2. Mittelmäßig Erstarrend

Die Bedeckung der Elektrode besitzt eine mänge Organisches Material. Gute Verbindungen können in viele

Positionen gemacht werden aber nicht in Vertikaler

richtung nach unten Schweißend. Er ist brauchbar für

Vertikaler, nach oben gehende Schweißvorgang.

3. Langsam Erstarrend

Die Bedeckung ist dünner als bei der anderen zwei

Typen und erhält weniger Organisches Material. Das

Schweißbad ist ganz dün flüssig. Die Verbindungen

können Horizontal gemacht werden.

DIE LEISTUNG

Die Leistungen dieses Schweißgerätes werden durch die

Elektrodenbezugsnummern nc und nh ausgedruckt.

nc: Sind Elektrodenbezugsnummern, bei denen bis zum

ersten Einzetzen des Thermostats bei Raumtemperatur

geschweißt wird.

nh: Ist der Mittelwert der Elektrodenbezugsnummern,

bei denen vom der ersten Arbeitsstunde geschweißt

werden kann.

SCHWEIßSTROM

Durch das drehen des Rades kann der Schweißstrom

eingestelt werden. Nach rechts drehen erhöht die Strom

und nach Links drehen verringert die Strom. Der Stromwert I2 laßt sich auf einer Skala am oberen Teil des Gerätes ablesen, Er hängt von der bogenspannung (U2) gemäß

der Formel U2(V)=18+0,04xI2 (EN 50060).

Wenn Sie lange Verlängerungskabel benützen, wird der

Strom bedeutend abnehmen. Die benötigte Schweißstrom ist auch abhängig von die größe des Schweißstückes. Kleine Schweißstücke benötigen kleinere

Schweißstrome (Siehe Tab.1).

Schweißstück Elektroden Kern Schweiß

Strom

Dicke Ø (mm2) (A)

2-3 2 45-65

4-5 2,5 70-95

6-7 3,25 90-130

8-12 4 130-160

Tab.1

Ferm 9

• иУ‰‰ВКЛ‚‡ИЪВ Т‚‡У˜М˚В Н‡·ВОЛ, ‰ВК‡ЪВО¸

˝ОВНЪУ‰У‚ Л Б‡КЛП ‰ВЪ‡ОЛ ‚ ЛТФ‡‚МУП

ТУТЪУflМЛЛ; ЛБМУТ ЛБУОflˆЛЛ Л ЪУНУМВТЫ˘Лı

˝ОВПВМЪУ‚ НУМТЪЫНˆЛЛ йиДлЦз Л ФЛ‚У‰ЛЪ Н

МЛБНУПЫ Н‡˜ВТЪ‚Ы Т‚‡НЛ.

• аТНО˛˜‡ИЪВ МВФУТВ‰ТЪ‚ВММ˚И НУМЪ‡НЪ ТУ

Т‚‡У˜М˚П НУМЪЫУП. пУОУТЪУВ М‡ФflКВМЛВ

ПВК‰Ы ˝ОВНЪУ‰У‰ВК‡ЪВОВП Л Б‡КЛПУП ЛБ‰ВОЛfl

ПУКВЪ ·˚Ъ¸ УФ‡ТМ˚П.

• зВ ˝НТФОЫ‡ЪЛЫИЪВ ‡ФФ‡‡Ъ ‚У ‚О‡КМ˚ı ЛОЛ Т˚˚ı

ПВТЪ‡ı Л МВ ФУЛБ‚У‰ЛЪВ Т‚‡НЫ ФУ‰ ‰УК‰ВП.

• ЗТВ„‰‡ Б‡˘Л˘‡ИЪВ „О‡Б‡ ФОУЪМУ ФЛОВ„‡˛˘ЛПЛ

У˜Н‡ПЛ (ЪЛФ DIN 9 - 10), ‚ıУ‰fl˘ЛПЛ ‚ НУПФОВНЪ

ФУТЪ‡‚НЛ ‡ФФ‡‡Ъ‡.

• аТФУО¸БЫИЪВ ТЫıЛВ Л МВ ЛТФ‡˜Н‡ММ˚В ‚ П‡ТОВ ЛОЛ

ТП‡БНВ ФВ˜‡ЪНЛ Л Б‡˘ЛЪМЫ˛ ТФВˆУ‰ВК‰Ы.

• зВ ‰УФЫТН‡ИЪВ ‚УБ‰ВИТЪ‚Лfl М‡ НУКЫ

ЫО¸Ъ‡ЩЛУОВЪУ‚У„У ЛБОЫ˜ВМЛfl ‰Ы„Л. л‚ВЪУ‚УВ

ЛБОЫ˜ВМЛВ ‰Ы„Л ПУКВЪ ФУ‚В‰ЛЪ¸ БВМЛВ Л

‚˚Б‚‡Ъ¸ УКУ„Л НУКЛ.

• С‡ММ˚И Т‚‡У˜М˚И ‡ФФ‡‡Ъ ‡‚ЪУП‡ЪЛ˜ВТНЛ

Б‡˘Л˘ВМ УЪ ФВ„‚‡ (‡‚ЪУП‡ЪЛ˜ВТНЛИ

ФВВБ‡ФЫТН ЪВПУТЪ‡ЪУП). дУ„‰‡ У·ПУЪНЛ

‰УТЪЛ„МЫЪ ‡·У˜ВИ ЪВПФВ‡ЪЫ˚, Б‡˘ЛЪ‡

УЪНО˛˜‡ВЪ ‡ФФ‡‡Ъ УЪ ТВЪЛ. уВВБ МВТНУО¸НУ

ПЛМЫЪ УıО‡К‰ВМЛfl Б‡˘ЛЪ‡ ‚УТТЪ‡М‡‚ОЛ‚‡ВЪ

ФУ‰НО˛˜ВМЛВ Н ТВЪЛ. л‚‡У˜М˚И ‡ФФ‡‡Ъ „УЪУ‚ Н

‰‡О¸МВИ¯ВИ ‡·УЪВ.

• иЛ Ы‰‡ОВМЛЛ УН‡ОЛМ˚ Б‡˘Л˘‡ИЪВ ТВ·fl УЪ

„Уfl˜В„У ПВЪ‡ОО‡, ЛТФУО¸БЫfl У˜НЛ Л ФВ˜‡ЪНЛ.

• СВЪ‡О¸ ФЛ УıО‡К‰ВМЛЛ ПУКВЪ

‰ВЩУПЛУ‚‡Ъ¸Тfl. иЛМЛП‡ИЪВ

ТУУЪ‚ВЪТЪ‚Ы˛˘ЛВ ПВ˚.

зЦбДеЦСганЦгъзй ЗхдгыуанЦ

ДииДкДн З лгмуДЦ:

• зВЛТФ‡‚МУТЪЛ ¯ЪВФТВО¸МУИ ‚ЛОНЛ, УБВЪНЛ ЛОЛ

ФУ‚ВК‰ВМЛfl Н‡·ВОВИ.

• зВЛТФ‡‚МУТЪЛ ‚˚НО˛˜‡ЪВОfl.

• й·М‡ЫКВМЛfl ‰˚П‡ ЛОЛ Б‡Ф‡ı‡ „УВОУИ ЛБУОflˆЛЛ.

З лгмуДЦ зЦлйЕгыСЦзаь зДлнйьфап

икДЗаг нЦпзада ЕЦбйиДлзйлна

ЙДкДзнаь ДззмгакмЦнль.

икДЗагД ий щгЦднкйЕЦбйиДлзйлна

í·ÛÂÚÒfl ‚Ò„‰‡ ÔÓ‚ÂflÚ¸,

ТУУЪ‚ВЪТЪ‚ЫВЪ ОЛ З‡¯В ТВЪВ‚УВ

М‡ФflКВМЛВ БМ‡˜ВМЛ˛, ЫН‡Б‡ММУПЫ М‡ Б‡‚У‰ТНУИ

Ъ‡·ОЛ˜НВ П‡¯ЛМ˚.

á‡ÏÂ̇ ÒÂÚ‚˚ı ¯ÌÛÓ‚ Ë ‚ËÎÓÍ

аБ·‡‚ОflИЪВТ¸ УЪ ТЪ‡˚ı ¯МЫУ‚ Л ¯ЪВНВМ˚ı ‚ЛОУН

Т‡БЫ КВ ФУТОВ Лı Б‡ПВМ˚ М‡ МУ‚˚В. лОЫ˜‡ИМУВ

‚НО˛˜ВМЛВ ‚ ТВЪВ‚Ы˛ УБВЪНЫ ‚ЛОНЛ

МВФУ‰НО˛˜ВММУ„У Т ‰Ы„У„У НУМˆ‡ ¯МЫ‡ УФ‡ТМУ.

д ТВЪВ‚УПЫ ¯МЫЫ ТОВ‰ЫВЪ ФЛТУВ‰ЛМЛЪ¸

ТЪ‡М‰‡ЪМЫ˛ ¯ЪВФТВО¸МЫ˛ ‚ЛОНЫ ‰УТЪ‡ЪУ˜МУИ

ПУ˘МУТЪЛ, Н НУЪУУИ ФУ‰НО˛˜‡ВЪТfl КВОЪУ-БВОВМ˚И

ФУ‚У‰МЛН ¯МЫ‡. н‡НЫ˛ ТЪ‡М‰‡ЪМЫ˛ ‚ЛОНЫ

ЪВ·ЫВЪТfl УТМ‡ТЪЛЪ¸ ФО‡‚НЛП ФВ‰Уı‡МЛЪВОВП ЛОЛ

‡‚ЪУП‡ЪЛ˜ВТНЛП ФВ˚‚‡ЪВОВП. зЫКМ˚И НУМЪ‡НЪ

ТОВ‰ЫВЪ Б‡БВПОЛЪ¸ М‡ ‡ТФВ‰ВОЛЪВО¸МЫ˛ ТВЪ¸.

аТФУО¸БУ‚‡Ъ¸ ВНУПВМ‰ЫВЪТfl ФВ‰Уı‡МЛЪВОЛ

ПУ˘МУТЪ¸˛ ПЛМЛПЫП М‡ 16 ‡ПФВ Т Б‡‰ВКНУИ

Т‡·‡Ъ˚‚‡МЛfl.

аТФУО¸БУ‚‡МЛВ Ы‰ОЛМЛЪВО¸МУ„У Н‡·ВОfl

аТФУО¸БЫИЪВ ЪУО¸НУ ‡БВ¯ВММ˚И Ы‰ОЛМЛЪВО¸М˚И

Н‡·ВО¸, НУЪУ˚И ТУУЪ‚ВЪТЪ‚ЫВЪ ПУ˘МУТЪЛ П‡¯ЛМ˚.

ЬЛО˚ ‰УОКМ˚ ЛПВЪ¸ ПЛМЛП‡О¸МУВ ФУФВВ˜МУВ

ТВ˜ВМЛВ 1,5 ПП2.

ЦТОЛ Н‡·ВО¸ М‡ıУ‰ЛЪТfl М‡ Н‡ЪЫ¯НВ, УМ ‰УОКВМ ·˚Ъ¸

ФУОМУТЪ¸˛ ‡БПУЪ‡М.

40 Ferm

Page 10

INBETRIEBNAHME

ELEKTRODENHALTERKABEL

Dieses Kabel besitzt am Ende eine Spezialklemme, die

zum Zusammenziehen des Teiles, der durch die Elektrode verdeckt ist, dient.

ERDUNGSKABEL

Das Erdungskabel wird direkt am Schweißstück oder an

der Unterlage auf der das Gerät abgestellt ist, befestigt.

Sorgen Sie dafür daß ein direkter Kontakt mit den

Schweißstück besteht. Meiden Sie daher lackierte

Oberflachen und/oder Nichtmetalle.

SCHUTZMASKE

Fig.B

Sie schützt die Augen vor der vom Bogen ausgehenden

Lichtstrahlung und erlaubt dennoch genau Beobachtung

der Schweißarbeit, die man gerade verrichtet.

1. Maske

2. Glas

3. Filter

4. Handgriff

Montieren Sie das Maskeglas und das Spritzen-

glas, bevor Sie mit schweißen anfangen.

Die Schutzmaske muß während des Schweißens immer verwendet.

PICKHAMMER

Mit dieser Hammer können Sie Schweißraupe entfernen.

Schlagen Sie nicht zu hard damit die Verbindung nicht

beschädigt wird.

STAHLBÜRSTE

Mit dieser Bürste können Sie Corrosion von das zu Schweißen Material entfernen damit es ein guten Elektrischen Kontakt machen wird, oder zum entfernen von

Schweißraupe.

QUERSCHNITTE DER SCHWEIßSPUREN

Fig.C

1. Zu langsames Arbeiten

2. Zu schnelles Arbeiten

3. Zu kurzer Bogen

4. Zu langer Bogen

5. Zu geringer Strom

6. Zu viel Strom

7. Richtig

SCHWEIßVORGANG

Fig.D

• Führen Sie den unbedeckten Teil der Elektrode in die

elektrodenzange ein und verbinden Sie der Erdungsklemme mit das Schweißstück. Achten Sie dabei

darauf, daß ein guter elektrischer Kontakt besteht.

• Schalten Sie das Gerät ein und stellen Sie den Sch-

weißstrom, je nach Elektrode, die man verwenden

will, ein.

• Halten Sie die Maske vor das Gesicht und reiben Sie

die Elektrodenspitze auf dem Schweißstück so, daß

eine Bewegung wie beim Anzünden eines Streichholzes ausführen. Dies ist die beste Methode, um den

Bogen zu zünden.

Benutzen Sie immer eine Zange um verbrauchte

Elektroden zu entfernen oder um eben gesch-

weißte Stücke zu bewegen.

• Sobald sich der Bogen entzündet hat, versuchen Sie

eine Distanz zum Werkstuck einzuhalten, die dem

verwendeten Elektrodendurchmeßer entspricht.

Der Abstand sollte möglichst konstant bleiben, während Sie schweißen. Die Elektrodenneigung in

Arbeitsrichtung sollte 20° bis 30° betragen.

Tupfen Sie nicht mit der Elektrode auf des

Werkstück, es könnte dadurch ein Schaden auftre-

ten und die Zündung des Bogens erschweren.

STÖRUNGEN

Im fall das die Maschine nicht gut funktioniert, geben wir

jetzt einige mögliche ursachen un lösungen.

Wenn das Schweißgerät nicht functioniert,

kontrolieren Sie folgendes

• Den Thermischen Sicherung ist ausgeschaltet.

• Den Sicherung ist Defekt (der Netzspannung).

• Die Erdungsklemmen hat kein guten Elektrische

Kontakt mit das Schweißstück.

• Der Elektrodenhalterkabel, der Erdungskabel oder

der Netzkabel ist beschädigt.

10 Ferm

лЗДкйузхв ДииДкДн

икаЗйСаехЦ СДгЦЦ З нЦдлнЦ саокх

лййнЗЦнлнЗмын калмздДе зД

лнкДзасЦ 2

нЦпзауЦлдаЦ пДкДднЦкалнада

йиалДзаЦ абСЦгаь

EN 50060 ëڇ̉‡Ú ‰Îfl Ò‚‡Ó˜Ì˚ı ‡ÔÔ‡‡ÚÓ‚

У„‡МЛ˜ВММУ„У ФЛПВМВМЛfl.

й‰МУЩ‡БМ˚И Ъ‡МТЩУП‡ЪУ.

P (W) åÓ˘ÌÓÒÚ¸ ‚ ‚‡ÚÚ‡ı.

Uo (V) з‡ФflКВМЛВ ·ВБ М‡„ЫБНЛ ‚ ‚УО¸Ъ‡ı.

f (Hz) ó‡ÒÚÓÚ‡ ÒÂÚÂ‚Ó„Ó ÚÓ͇ ‚ „ˆ‡ı.

I2 (A) é·˚˜Ì˚È Ò‚‡Ó˜Ì˚È ÚÓÍ ‚ ‡ÏÔ‡ı.

d (mm) ÑˇÏÂÚ ˝ÎÂÍÚÓ‰Ó‚ ‚ ÏÏ.

nc äÓ΢ÂÒÚ‚Ó ˝ÎÂÍÚÓ‰Ó‚, ̇˜Ë̇fl Ò

НУПМ‡ЪМУИ ЪВПФВ‡ЪЫ˚, ‰У

‚ПВ¯‡ЪВО¸ТЪ‚‡ ЪВПУТЪ‡Ъ‡.

nh дУОЛ˜ВТЪ‚У ˝ОВНЪУ‰У‚ ФУТОВ

‚ϯ‡ÚÂθÒÚ‚‡ ÚÂÏÓÒÚ‡Ú‡ ‚ Ô‚˚È ˜‡Ò

‡·ÓÚ˚.

U1 (V) з‡ФflКВМЛВ ТВЪЛ ‚ ‚УО¸Ъ‡ı.

I1Max (A) å‡ÍÒËχθÌ˚È ÔÓÚ·ÎflÂÏ˚È ÚÓÍ.

бМ‡˜ВМЛВ ‚ ‡ПФВ‡ı ФУЪВ·ОflВПУ„У

ЪУН‡ ЛОЛ МУПЛМ‡О ФВ‰Уı‡МЛЪВОfl

‡‚ЪУП‡Ъ‡.

иВ‰Уı‡МЛЪВО¸.

IP21 ä·ÒÒ Á‡˘ËÚ˚.

H ä·ÒÒ ËÁÓÎflˆËË Ú‡ÌÒÙÓχÚÓ‡.

íÂÏÓÒÚ‡Ú.

ÑÂʇÚÂθ ˝ÎÂÍÚÓ‰‡.

á‡ÊËÏ ËÁ‰ÂÎËfl.

ëڇ̉‡Ú̇fl ‚ËÎ͇.

иказДСгЦЬзйлна а бДиДлзхЦ

уДлна

С‡ММ˚И Т‚‡У˜М˚И ‡ФФ‡‡Ъ ФУТЪ‡‚ОflВЪТfl ‚ПВТЪВ ТУ

ТОВ‰Ы˛˘ЛПЛ ФЛМ‡‰ОВКМУТЪflПЛ:

• кЫНУ‚У‰ТЪ‚У ФУ ˝НТФОЫ‡Ъ‡ˆЛЛ

• 䇷ÂÎË

• á‡ÊËÏ ËÁ‰ÂÎËfl

• á‡ÊËÏ ‰ÂʇÚÂÎfl ˝ÎÂÍÚÓ‰‡

• ᇢËÚ̇fl χÒ͇

• еУОУЪУН ‰Оfl УН‡ОЛМ˚

• èÓ‚ÓÎӘ̇fl ˘ÂÚ͇

б‡Ф‡ТМ˚В ˜‡ТЪЛ ФУТЪ‡‚Оfl˛ЪТfl ‚‡¯ЛП ПВТЪМ˚П

‰ЛОВУП Ferm. иЛ Б‡Н‡БВ Б‡Ф‡ТМ˚ı ˜‡ТЪВИ

ЫН‡Б˚‚‡ИЪВ МУПВ‡, ФЛ‚В‰ВММ˚В ‚ ФВВ˜МВ. СВЪ‡ОЛ,

Ы НУЪУ˚ı МУПВ УЪТЫЪТЪ‚ЫВЪ, МВ ФУТЪ‡‚Оfl˛ЪТfl.

азлнкмдсаа ий

ЕЦбйиДлзйлна

З М‡ТЪУfl˘ВП ЫНУ‚У‰ТЪ‚В ЛТФУО¸БУ‚‡М˚ ТОВ‰Ы˛˘ЛВ

ТЛП‚УО˚:

кЛТН Ъ‡‚ПЛУ‚‡МЛfl, УФ‡ТМУТЪ¸ ‰Оfl КЛБМЛ

ЛОЛ ‚УБПУКМУТЪ¸ ФУ˜Л П‡¯ЛМ˚ ‚ ТОЫ˜‡В

ÌÂÒӷβ‰ÂÌËfl Ô˂‰ÂÌÌ˚ı ‚ ÛÍÓ‚Ó‰ÒÚ‚Â ËÌÒÚÛ͈ËÈ.

йФ‡ТМУТЪ¸ ФУ‡КВМЛfl ˝ОВНЪЛ˜ВТНЛП

ЪУНУП.

иВВ‰ М‡˜‡ОУП ˝НТФОЫ‡Ъ‡ˆЛЛ ЛБ‰ВОЛfl ‚МЛП‡ЪВО¸МУ

УБМ‡НУП¸ЪВТ¸ Т ‰‡ММ˚П ЫНУ‚У‰ТЪ‚УП. м·В‰ЛЪВТ¸ ‚

ЪУП, ˜ЪУ ‚‡П ЛБ‚ВТЪВМ ФЛМˆЛФ В„У ‡·УЪ˚ Л flТМ˚

Ф‡‚ЛО‡ В„У ФЛПВМВМЛfl. З ˆВОflı У·ВТФВ˜ВМЛfl

МУП‡О¸МУ„У ЩЫМНˆЛУМЛУ‚‡МЛfl ‡ФФ‡‡Ъ‡

МВУ·ıУ‰ЛПУ ТУ·О˛‰‡Ъ¸ ЛМТЪЫНˆЛЛ ФУ ЫıУ‰Ы Л

ЪВıУ·ТОЫКЛ‚‡МЛ˛. С‡ММУВ ЫНУ‚У‰ТЪ‚У Л

ФЛО‡„‡ВПЫ˛ ‰УНЫПВМЪ‡ˆЛ˛ ТОВ‰ЫВЪ ı‡МЛЪ¸ ‚ПВТЪВ

Т ‡ФФ‡‡ЪУП.

З ˆВОflı ТМЛКВМЛfl УФ‡ТМУТЪЛ ‚УБМЛНМУ‚ВМЛfl

ФУК‡‡, ФУ‡КВМЛfl ˝ОВНЪЛ˜ВТНЛП ЪУНУП Л

Ъ‡‚ПЛУ‚‡МЛfl УФВ‡ЪУ‡ МВУ·ıУ‰ЛПУ

Ъ˘‡ЪВО¸МУ ТУ·О˛‰‡Ъ¸ ‰ВИТЪ‚Ы˛˘ЛВ ‚ ‚‡¯ВИ

ТЪ‡МВ УТМУ‚М˚В Ф‡‚ЛО‡ ЪВıМЛНЛ ·ВБУФ‡ТМУТЪЛ

ФЛ ФУО¸БУ‚‡МЛЛ ˝ОВНЪУЛМТЪЫПВМЪУП Л

У·УЫ‰У‚‡МЛВП. иУОМУТЪ¸˛ ФУ˜ЛЪ‡ИЪВ ‰‡ММУВ

ЫНУ‚У‰ТЪ‚У Л УЪ‰ВО¸МУ ФЛО‡„‡ВП˚В

ЛМТЪЫНˆЛЛ, ФВК‰В ˜ВП ФЛТЪЫФ‡Ъ¸ Н ‡·УЪВ Т

‰‡ММ˚П ‡ФФ‡‡ЪУП.

лиЦсаДгъзхЦ икДЗагД нЦпзада

ЕЦбйиДлзйлна

• иЛ ‰Ы„У‚УИ Т‚‡НВ ‚УБМЛН‡˛Ъ ЛТН˚,

‡Б·˚Б„Л‚‡МЛВ Н‡ФВО¸ ‡ТФО‡‚ОВММУ„У ПВЪ‡ОО‡ Л

‰˚П. З Т‚flБЛ Т ˝ЪЛП ЛБ ‡·У˜ВИ БУМ˚ ‰УОКМ˚ ·˚Ъ¸

Ы‰‡ОВМ˚ ‚ТВ „У˛˜ЛВ ‚В˘ВТЪ‚‡ Л П‡ЪВЛ‡О˚.

•Ç ÔÓÏ¢ÂÌËflı, „‰Â ÔÓËÁ‚Ó‰ËÚÒfl Ò‚‡Í‡, ‰ÓÎÊ̇

·˚Ъ¸ У·ВТФВ˜ВМ‡ ‰УТЪ‡ЪУ˜М‡fl ‚ВМЪЛОflˆЛfl. иЛ

‰Ы„У‚УИ Т‚‡НВ У·‡БЫВЪТfl ‰˚П, ФВ‰ТЪ‡‚Оfl˛˘ЛИ

УФ‡ТМУТЪ¸.

• зВ ФУЛБ‚У‰ЛЪВ Т‚‡НЫ М‡ ВПНУТЪflı ЛОЛ

ЪЫ·УФУ‚У‰‡ı, ‚ НУЪУ˚ı М‡ıУ‰flЪТfl (ЛОЛ

М‡ıУ‰ЛОЛТ¸) ‚УТФО‡ПВМfl˛˘‡flТfl КЛ‰НУТЪ¸ ЛОЛ

„‡Б (ТЫ˘ВТЪ‚ЫВЪ УФ‡ТМУТЪ¸ ‚Б˚‚‡ Л/ЛОЛ ФУК‡‡)

ЛОЛ М‡ П‡ЪВЛ‡О‡ı, У·‡·УЪ‡ММ˚ı

ıОУЛУ‚‡ММ˚ПЛ ‡ТЪ‚УЛЪВОflПЛ ЛОЛ ФУН˚Ъ˚ı

О‡НУП (УФ‡ТМУТЪ¸ ‚УБМЛНМУ‚ВМЛfl ЪУНТЛ˜М˚ı

ЛТФ‡ВМЛИ).

• м·В‰ЛЪВТ¸ ‚ Ф‡‚ЛО¸МУТЪЛ ФУ‰НО˛˜ВМЛfl

Т‚‡У˜МУ„У ‡ФФ‡‡Ъ‡ Н ˝ОВНЪУФЛЪ‡МЛ˛.

иУ‡КВМЛВ ˝ОВНЪУЪУНУП УФ‡ТМУ ‰Оfl КЛБМЛ.

• зВ ‰УФЫТН‡ИЪВ ‡ТЪfl„Л‚‡МЛfl ¯МЫ‡ ФЛЪ‡МЛfl.

иВВ‰ ФВВПВ˘ВМЛВП П‡¯ЛМ˚ ‚˚М¸ЪВ

¯ЪВФТВО¸МЫ˛ ‚ЛОНЫ ЛБ УБВЪНЛ.

з‡ФflКВМЛВ ФЛЪ‡МЛfl

|

230 Ç~

ó‡ÒÚÓÚ‡ ÚÓ͇

|

50 Ɉ

èÓÚ·ÎflÂχfl ÏÓ˘ÌÓÒÚ¸, χÍÒ.|2,5 ÍÇÚ

íÓÍ Ò‚‡ÍË

|

40 - 140 A

з‡ФflКВМЛВ ·ВБ М‡„ЫБНЛ

|

45 - 48 Ç

ê‡ÁÏ ˝ÎÂÍÚÓ‰Ó‚

|

1,5-3,15 ÏÏ

å‡ÒÒ‡

|

14 Í„

R

Russian

Ferm 39

Page 11

WARTUNG

Bei der Ausführung von Wartungsarbeiten muss

der Netzstecker gezogen sein.

Die Maschinen von Ferm sind entworfen, um während

einer langen Zeit problemlos und mit minimaler Wartung zu funktionieren. Sie Verlängern die Lebensdauer,

indem Sie die Maschine regelmäßig reinigen und fachgerecht behandeln.

Reinigen

Reinigen Sie das Maschinengehäuse regelmäßig mit

einem weichen Tuch, vorzugsweise nach jedem Einsatz.

Halten Sie die Lüfterschlitze frei von Staub und Schmutz

Entfernen Sie hartnäckigen Schmutz mit einem weichen

Tuch, angefeuchtet mit Seifenwasser. Verwenden Sie

keine Lösungsmittel wie Benzin, Alkohol, Ammonia,

usw. Derartige Stoffe beschädigen die Kunststoffteile.

Störungen

Wenden Sie sich in Störungsfällen, z.B. durch Verschleiß

eines Teils, an Ihren örtlichen Ferm-Vertragshändler.

Am Ende dieser Betriebsanleitung finden Sie eine Zeichnung der erhältlichen Ersatzteile.

UMWELT

Um Transportschäden zu verhinderen, wird die

Maschine in einer soliden Verpackung geliefert. Die Verpackung besteht weitgehend aus verwertbarem Material. Benutzen Sie also die Möglichkeit zum Recyclen der

Verpackung.

Bringen Sie bei Ersatz die alten Maschinen zu Ihren örtlichen Ferm-Vertagshändler. Er wird sich um eine

umweltfreundliche Verarbeitung ïhrer alten Maschine

bemühen.

GARANTIE

Lesen Sie die Garantiebedingungen auf der separat beigefügten Garantiekarte.

Wir erklären in alleiniger Verantwortung, daß

dieses Produkt mit den folgende Normen oder

normativen Dokumenten übereinstimmt:

EN50060 + Amdt,

EN50199 + Amdt

EN60974-1 + Amdt,

gemaß den Bestimmungen der Richtlinien:

LDV 73/23 EEC + Amdt

EMC 89/336 + Amdt

ab 20-09-2002

GENEMUIDEN NL

W. Kamphof

Quality department

CE

ı

KONFORMITÄTSERKLÄRUNG

(D)

Ferm 11

VEDLIGEHOLDELSE

Vær opmærksom på, at stikket er taget ud af stikkontakten, før du begynder at foretage vedligehol-

delse på svejseapparatet.

Ferms maskiner er konstrueret til at kunne fungere problemfrit i lang tid og med et minimum af vedligeholdelse.

Ved regelmæssigt at gøre maskinen rent og behandle den

på den rigtige måde bidrager du til, at den får en lang

levetid.

Rengøring

Gør med regelmæssige mellemrum maskinen/kabinettet

rent med en blød klud, helst hver gang den har været i

brug. Sørg for, at ventilationssprækkerne er fri for støv

og smuds.

Til særlig hårdnakket smuds bruges en blød klud fugtet i

sæbevand. Brug ikke opløsningsmidler som benzin, sprit,

ammoniak osv. Disse stoffer beskadiger plasticdelene.

Fejl

Hvis der opstår en fejl f.eks. på grund af slitage på en maskindel, kontakt da din lokale Ferm-forhandler

Sidst i denne brugsanvisning ses en tegning af de enkelte

dele med de dele, der kan efterbestilles.

MILJØ

For at forhindre beskadigelser under transport leveres

maskinen i en robust emballage. Denne emballage er så

vidt muligt fremstillet af materiale, der kan genbruges.

Benyt derfor muligheden for at genbruge emballagen.

Bring gamle maskiner, der skal udskiftes, til din lokale

Ferm-forhandler. Her vil maskinen blive forarbejdet

miljøvenligt.

GARANTI

Læs om garantibetingelserne på det separat vedlagte

garantikort.

Vi erklærer herved, at dette produkt

opfylder følgende standarder eller normative

dokumenter

EN50060 + Amdt

EN50199 + Amdt

EN60974-1 + Amdt

I overensstemmelse med bestemmelserne i direktiverne

LDV 73/23 EØF + Amdt

EMC 89/336 + Amdt

fra 20-09-2002

GENEMUIDEN NL

W. Kamphof

Quality department

CE

ı

KONFORMITETSERKLÆRING

(DK)

38 Ferm

Page 12

IBRUGTAGNING

ELEKTRODEHOLDEREN

Elektroden klemmes fast heri. Elektrodeholderen er ved

et kabel forbundet med svejseapparatet.

JORDKLEMMEN

Jordklemmen kan klemmes direkte på det arbejdsstykke,

der skal svejses, eller på et stålbord, som det arbejdsstykke, der skal svejses, ligger på.

Læg aldrig elektrodeholderen eller jordklemmen på

varme arbejdsstykker eller arbejdsstykker af metal.

SVEJSESKÆRMEN

Fig.B

Svejseskærmen tjener til at beskytte øjnene mod de farlige stråler, der slipper ud under svejsningen. Kig aldrig

ind i svejseflammen med åbne øjne.

1. Maske

2. Dækglas

3. Svejseglas

4. Håndtag

SLAGGEHAMMEREN

Med slaggehammeren fjernes slaggen efter svejsningen.

Bank roligt mod slaggen, hvorefter denne hurtigt kommer løs. Slår man for hårdt, kommer der gruber i svejsningen, som misdanner svejsesømmen. Bær beskyttelsesbriller til dette arbejde.

STÅLBØRSTE

Stålbørsten bruges til at gøre arbejdsstykkerne rustfrie

med før svejsningen, eller til at fjerne de sidste slaggerester med efter svejsningen.

KENDETEGN FOR SVEJSESØMMEN

Fig.C

1. For langsom bevægelse

2. For lille svejsebue

3. For lav svejsestrøm

4. For hurtig bevægelse

5. For stor svejsebue

6. For høj svejsestrøm

7. RIGTIG

SVEJSNING

Fig.D

• Anbring den del af elektroden, der er uden kappe, i

elektrodeholderen og forbind jordklemmen med

arbejdsstykket, sådan at den elektriske kontakt er

god.

• Tænd for svejseapparatet og reguler svejsestrømmen i forhold til den anvendte elektrode og arbejdsstykkets størrelse.

• Hold svejseskærmen foran ansigtet og stryg elektrode-spidsen over arbejdsstykket, som om du tænder en tændstik. Dette er den bedste måde at starte

svejsebuen på.

Monter svejseglasset og dækglasset, før du begynder at svejse.

• Prøv så snart svejsebuen starter at holde samme

afstand mellem elektrodespidsen og arbejdsstykket.

Hold hele tiden denne afstand lig med elektrodens

diameter. Bevar denne afstand så konstant som

muligt under svejsningen. Hold vinklen mellem elektroder og arbejdsstykke mellem 20° og 30°.

Slå ikke elektroden mod arbejdsstykket. Dette vil

beskadige elektroden og gøre det vanskeligt at

starte svejsebuen.

Sørg for, at elektrodeholderen og jordklemmen

altid er fri for rust, så de kan blive ved med at holde

en god elektrisk kontakt.

FEJL

For de tilfælde, hvor maskinen ikke fungerer, som den

skal, angives i det følgende en række mulige årsager og de

dertil hørende løsninger.

Hvis din svejsetransformator ikke fungerer, kan

dette have én af følgende årsager:

• Termisk sikring slået fra.

• Smeltesikring defekt (i målerskabet).

• Jordklemmen har ikke en god forbindelse med det

arbejdsstykke der skal svejses.

• Brud på tilførselsledning eller stikkontakt (brug en

stikkontakt med beskyttelsesleder).

Ferm 37

LASAPPARAAT

DE NUMMERS IN DE NU VOLGENDE TEKST VERWIJZEN NAAR DE AFBEELDINGEN OP PAGINA 2

TECHNISCHE SPECIFICATIES

PRODUKTBESCHRIJVING

EN 50060 Norm voor lasapparaten met beperkt

gebruik.

Eén-fase transformator.

P (W) Opgenomen vermogen in Watt.

f (Hz) Netfrequentie in Herz.

I2 (A) Secundaire- of lasstroom in Ampère.

d (mm) Elektrodendiameter.

nc Aantal te verlassen elektroden vanaf

starten tot uitschakelen van de

thermostaat.

nh Aantal te verlassen elektroden nadat

de thermostaat inschakeld in het

eerste uur.

U (V) Netspanning in Volt.

I1max (A) Maximale primaire- of opgenomen

stroom in Ampère.

Zekering.

IP21 Beschermingsklasse. Dicht voor

voorwerpen tot12 mm en tegen

loodrecht vallend druipwater.

H Isolatieklasse.

Thermostaat.

Elektrodehouder.

Massaklem.

Standaard netstekker.

DE VOLGENDE ACCESSOIRES WORDEN

STANDAARD BIJ DE ELEKTRISCHE LASTAFO GELEVERD

• Gebruiksaanwijzing

• Laskabels

• Aardklem

• Elektrodenhouder

• Laskap

• Bikhamer

• Roestborstel

Via uw Ferm-dealer zijn onderdelen na te bestellen die

op voorraad worden gehouden. Bij het bestellen van

onderdelen kunt u de nummers gebruiken die in de spare

parts list vermeld staan.

VEILIGHEIDSVOORSCHRIFTEN

In deze gebruiksaanwijzing worden de volgende pictogrammen gebruikt:

Duidt op mogelijk lichamelijk letsel, levensgevaar

of kans op beschadiging van de machine indien de

instructies in deze gebruiksaanwijzing worden genegeerd.

Geeft elektrische spanning aan.

Lees deze gebruiksaanwijzing aandachtig door voor u de

machine in gebruik neemt. Zorg dat u kennis heeft van de

werking van de machine en op de hoogte bent van de

bediening. Onderhoud de machine volgens de instructies opdat deze altijd goed functioneert. Bewaar deze

gebruiksaanwijzing en de bijgevoegde documentatie bij

de machine.

Neem bij het gebruik van elektrische machines altijd

de plaatselijk geldende veiligheidsvoorschriften in

acht in verband met brandgevaar, gevaar voor elektrische schokken en lichamelijk letsel. Lees behalve

onderstaande instructies ook de veiligheidsvoorschriften in het apart bijgevoegde veiligheidskatern

door.

Bewaar de instructies zorgvuldig!

SPECIALE VEILIGHEIDSVOORSCHRIFGEN

• Tijdens het lassen komen vonken en hete metalen

vrij. Denk om brandgevaar, verwijder alle brandbare

voorwerpen uit de werkomgeving.

• Zorg voor goede ventilatie van de werkomgeving. Bij

het lassen komen gassen vrij die een gevaar zijn voor

uw gezondheid.

• Las niet op containers of buizen die brandbare vloeistoffen of gassen bevatten of hebben bevat (gevaar

voor brand of explosies).

Las ook niet op materialen die zijn schoongemaakt

met lichtontvlambare vloeistoffen of op geverfde

oppervlakken (kans op vrijkomende gevaarlijke gassen).

• Let erop dat de verbinding van lasapparaat en lichtnet

in orde zijn. Elke kans op een elektrische schok kan

levenbedreigend zijn.

• Draag zorg voor goede verbindingen, zowel voor

elektrodenhouder als voor de massaklem.

• Voorkom het kapottrekken van de elektrische

kabels. Maak ze eerst los voordat u het lasapparaat

verplaatst.

• Vermijd contact met het elektrisch geleidende deel

van het lasapparaat, de elektrodehouder en de massaklem.

• Werk niet in een vochtige of natte omgeving en las

niet in de regen.

• Bescherm altijd uw ogen met de bijgeleverde laskap.

• Gebruik handschoenen en beschermende kleding

die droog zijn en niet bedrenkt zijn met olie of vuil.

• De af te bikken slak is soms gloeiend heet en kan

lelijke oogverwondingen veroorzaken tijdens het

verwijderen. Draag altijd een veiligheidsbril en handschoenen.

Spanning | 230 V~

Frequentie | 50 Hz

Max. vermogen | 2.5 kVA

Lasvermogen | 40 - 140 A

Ontsteekspanning | 45 - 48 A

Elektrodendikte | 1.5 - 3.15 mm

Gewicht | 14.0 kg

Nederlands

NL

12 Ferm

Page 13

• Tijdens het lassen kan de ultra-violette straling uw

huid verbranden. Zorg dus voor de juiste beschermende kleding.

• Uw transformator is beveiligd tegen overbelasting.

Dus wordt de transformator bij overbelasting automatisch uitgeschakeld. Na voldoende te zijn afgekoeld schakelt de transformator zich automatisch

weer in.

• Tijdens het lassen en afkoelen kan uw werkstuk door

spanningen vervormen. Houd daar rekening mee.

HET APPARAAT ONMIDDELIJK UITZETTEN

BIJ:

• Storing in de netstekker, netsnoer of snoerbeschadiging.

• Defecte schakelaar.

• Rook of stank van verschroeide isolatie.

BIJ HET NIET IN ACHT NEMEN VAN DEZE BASISVOORSCHRIFTEN VERVALT DE GARANTIE.

ELEKTRISCHE VEILIGHEID

Controleer altijd of uw netspanning overeenkomt

met de waarde op het typeplaatje van de machine.

Bij vervanging van snoeren of stekkers

Gooi oude snoeren of stekkers direct weg zodra ze door

nieuwe exemplaren zijn vervangen. Het is gevaarlijk om

de stekker van een los snoer in het stopcontact te steken.

Het apparaat is voorzien van een drie-aderige aansluitkabel. Monteerhieraan een lichtnet-stekker met randaarde. Uw installateur zal echter een goede verbinding

tot stand kunnen brengen.

Gebruik voor alle lasapparaten op 230 Volt minimaal 16

Ampère Traag zekeringen

Bij gebruik van verlengsnoeren

Gebruik uitsluitend een goedgekeurd verlengsnoer, dat

geschikt is voor het vermogen van de machine. De aders

moeten een doorsnede hebben van minimaal 1,5 mm2.

Wanneer het verlengsnoer op een haspel zit, rol het

snoer dan helemaal af.

VOOR INGEBRUIKNAME

WAT IS ELEKTRISCH LASSEN

Fig.A

Elektrisch vlamboog lassen is een smeltlasmethode,

waarbij de benodigde warmte geleverd wordt door een

elektrische vlamboog.

Deze vlamboog wordt gevormd tussen de elektrode en

het werkstuk

NB: Voordat u moeilijke werkstukken gaat lassen kunt u

beter eerst oefenen op een proefstukje.

De temperatuur van de vlamboog bedraagt ca. 4000°

Celsius, waardoor het einde van de elektrode en het

werkstuk tot smelten worden gebracht. Zolang de vlamboog in stand wordt gehouden, zal de elektrode wegsmelten en het benodigde toevoermateriaal leveren

voor de te verbinden delen. De afstand tussen de elektrode en het werkstuk moet zo kort mogelijk zijn (ca. 1,5

- 4 mm) afhankelijk van de diameter en soort elektrode.

De benodigde stroom voor het lassen wordt geleverd

door een lasapparaat. De benodigde kapaciteit van het

lasapparaat is afhankelijk van het te verrichten werk.

Zorg dat de elektroden goed droog zijn, vochtige elektroden geven problemen. Wanneer de elektrode tijdens

het lassen aan het werkstuk kleeft, is uw stroomsterkteinstelling te laag.

DE ELEKTRODE

De elektrode bestaat uit een ijzeren kern met daaromheen de bekleding. De bekleding bestaat ook voor een

deel uit ijzerpoeder. Tijdens het lassen smelt de elektrode af. Een gedeelte van de bekleding verdampt. De

hierdoor gevormde gasmantel beschermt het vloeibare

staal tegen indringen van zuurstof en stikstof uit de lucht.

Een gedeelte van de bekleding drijft op het smeltbad (het

is lichter dan staal) en beschermt ook dan de afkoelende

las. Na afkoeling bevindt deze bekleding zich als een

vaste, doch gemakkelijk te verwijderen slak op de lasrups. Het is van groot belang te zorgen dat de slak niet

tussen het staal komt (z.g. slakinsluiting geeft slechte

hechtingen).

Behandel de elektroden voorzichtig, zodat de

bekleding niet kapot gaat. Dit bemoeilijkt n.l. het

lassen. Zorg dat de elektroden goed droog zijn, dus vochtvrij

bewaren.

Elektrodenkeuze

Om een goede en sterke lasverbinding te maken is het

van groot belang de juiste elektrode te gebruiken voor

een bepaald te lassen materiaal. Ook de stand waarin

gelast moet worden b.v. boven het hoofd, is belangrijk

voor de te gebruiken elektrode. Een universeel elektrode zal in veel gevallen geschikt zijn voor uw karweitjes.

Elektroden zijn te verdelen in drie types:

1. Snelstollend

De bekleding bevat veel organische stoffen, die een

beschermende gasomhulling geven. Goed lasbaar in

alle standen, speciaal voor vertikaal neergaand lassen.

Ferm 13

FØR IBRUGTAGNING

HVAD ER ELEKTRISK SVEJSNING?

Fig.A

Elektrisk lysbuesvejsning er en metode til smeltesvejsning, hvortil den nødvendige varme leveres af en elektrisk lysbue.

Denne lysbue dannes mellem elektroden og arbejdsstykket

NB: Før du begynder at svejse på vanskelige arbejdsstykker, er det bedst først at foretage en prøve på et prøvestykke.

Lysbuens temperatur er ca. 4000° Celsius, hvilket får

elektrode-spidsen og arbejdsstykket til at smelte. Så

længe lysbuen vedligeholdes, vil elektroden smelte væk

og levere det nødvendige tilførselsmateriale til de dele,

der skal forbindes. Afstanden mellem elektroden og

arbejdsstykket skal være så kort som muligt (ca. 1,5 - 4

mm) og afhænger af elektrodens diameter og art. Den

nødvendige strøm til svejsningen leveres af et svejseapparat. Hvilken kapacitet der er nødvendig for svejseapparatet afhænger af, hvilket arbejde der skal udføres. Sørg

for, at elektroderne er godt tørre, fugtige elektroder

giver problemer. Når elektroden klæber til arbejdsstykket, mens der svejses, er din strømstyrkeindstilling for

lav.

ELEKTRODEN

Elektroden består af en kerne af jern med en beklædning

udenom. Beklædningen består også delvis af jernpulver.

Under svejsningen smelter elektroden ned. En del af

beklædningen fordamper. Den gaskappe, der opstår herved, beskytter det flydende stål mod ilt og kvælstof fra

luften.

En del af beklædningen driver oven på smeltebadet (den

er lettere end stål) og beskytter også da den svejsning,

der er ved at køle af. Efter afkølingen ligger denne

beklædning på svejsesømmen som en fast slagge, som

dog er nem af fjerne. Det er meget vigtigt at sørge for, at

slaggen ikke kommer ind i stålet (en såkaldt slaggeindeslutning giver dårlige klæbninger).

Behandl elektroderne forsigtigt, så beklædningen

ikke går i stykker. Dette gør nemlig svejsningen

vanskelig. Sørg for, at elektroderne er godt tørre, de skal altså

opbevares fugtfrit.

Elektrodevalg

For at skabe en stærk svejseforbindelse er det meget vigtigt at bruge den rigtige elektrode til et bestemt materiale, der skal svejses. Også den stilling, som der skal svejses i, f.eks. over hovedet, er vigtig for, hvilken elektrode

der skal bruges. En universel elektrode vil i mange

tilfælde være egnet til dine småopgaver.

Elektroder kan inddeles i tre typer:

1. Koldtsvejsende

Beklædningen indeholder mange organiske stoffer,

der giver en beskyttende gasindkapsling. Godt svejsbar i alle stillinger, specielt til lodret nedadgående

svejsning.

2. Medium størknende

Beklædningen indeholder mange organiske stoffer.

Godt svejsbar i alle stilligner, undtagen lodret

nedadgående svejsning. Specielt til lodret

opadgående svejsning.

3. Langsomt størknende

Tykkere beklædt end de foregående 2 typer, indeholder færre organiske stoffer, tæt kompakt slagge.

Smeltepladen er yderst tyndtflydende. Selv om den

er svejsbar i alle stillinger anvendes den hovedsagelig

til vandret svejsning, især stående vinkelsvejsning. Til

svejsning af rustfrit stål og støbejern findes der særlige elektroder i handelen. Spørg før svejsningen om

disse materialer hos din forhandler, som gerne rådgiver dig.

PRÆSTATION

Svejseapparatets præstation kan udtrykkes i antal elektroder nc og nh.

nc: Antal elektroder, der skal svejses ned, fra start til termostaten slår fra.

nh: Antal elektroder, der skal svejses ned, i den første

time efter, at termostaten er tændt.

STRØMSTYRKE

Ved at dreje håndhjulet til højre øger man strømstyrken.

Når man drejer håndhjulet til venstre, reducerer man

strømstyrken, hvilket kan aflæses på skalaen på apparatet. Denne værdi (I2) svarer til spændingen (U2) efter

formlen: U2(V)=18+0,04xI2 (EN 50060).

Hvis der bruges lange forlængerledninger, vil der være et

betydeligt strømtab. Apparatet skal således indstilles

højere. Også når der bruges ekstra lange eller ekstra

tynde svejsekabler, vil der være spændingstab. Hvis

arbejdsstykkerne har små mål, bliver de hurtigt varme. I

dette tilfælde sættes strømstyrken lavere.

Arbejdsstykke Elektrodekerne Svejs-

estrøm

Tykkelse Ø (mm2) (A)

2-3 2 45-65

4-5 2,5 70-95

6-7 3,25 90-130

8-12 4 130-160

Tab.1

36 Ferm

Page 14

SIKKERHEDSFORSKRIFTER

I denne brugsanvisning er følgende piktogrammer

anvendt:

Påpeger muligheden for legemsbeskadigelse, livsfare eller risiko for beskadigelse af maskinen, hvis

anvisningerne i denne brugsanvisning ignoreres.

Angiver, at der er elektrisk spænding.

Læs denne brugsanvisning omhyggeligt igennem, før du

tager maskinen i brug. Sørg for at have kendskab til, hvordan maskinen fungerer, og for at være orienteret om,

hvordan den skal betjenes. Vedligehold maskinen efter

anvisningerne, så den altid fungerer rigtigt. Opbevar

denne brugsanvisning og den vedlagte dokumentation

sammen med maskinen.

Overhold altid de lokalt gældende sikkerhedsforskrifter for brugen af elektriske maskiner af hensyn til

brandfare, fare for elektriske stød og legemsbeskadigelse. Læs foruden nedenstående anvisninger også

sikkerhedsforskrifterne i det sikkerhedsark, der er

vedlagt separat.

Opbevar anvisningerne omhyggeligt!

SÆRLIGE SIKKERHEDSFORSKRIFTER

• Under svejsningen er der udslip af gnister og varme

metaller. Tænk på brandfaren, fjern alle brændbare

genstande fra arbejdsomgivelserne.

• Sørg for en god ventilation af arbejdsomgivelserne.

Under svejsning er der udslip af luftarter, som udgør

en fare for dit helbred.

• Svejs ikke på beholdere eller rør, der indeholder eller

har indeholdt brændbare væsker eller luftarter

(risiko for brand eller eksplosioner).

Svejs heller ikke på materialer, der er renset med

letantændelige væsker, eller på malede flader (risiko

for udslip af farlige luftarter).

• Kontroller, at forbindelsen mellem svejseapparatet

og lysnettet er i orden. Enhver risiko for et elektrisk

stød kan være livstruende.

• Sørg for, at der er gode forbindelser, både til elektrodeholderen og til jordklemmen.

• Undgå, at de elektriske kabler kan trækkes i stykker.

Kablerne skal løsnes, før du flytter svejseapparatet.

• Undgå at berøre den elektrisk ledende del af svejseapparatet, elektrodeholderen og jordklemmen.

• Arbejd ikke i fugtige eller våde omgivelser og svejs

ikke i regn.

• Beskyt altid øjnene med den svejseskærm, der er

leveret sammen med apparatet.

• Brug handsker og beskyttende påklædning, som er

tør og ikke gennemvædet af olie eller smuds.

• Den slagge, der skal bankes af, er somme tider glohed

og kan forårsage alvorlige øjenbeskadigelser, når den

fjernes. Brug altid beskyttelsesbriller og handsker.

• Under svejsningen kan de ultraviolette stråler give

hudforbrændinger. Sørg derfor for at bære den rigtige beskyttende påklædning.

• Din transformator er sikret mod overbelastning.

Transformatoren slår således automatisk fra ved

overbelastning. Når den er tilstrækkeligt afkølet,

tænder den automatisk igen.

• Under svejsningen og afkølingen kan dit arbejdsstykke blive misdannet på grund af spændinger. Tag

højde for dette.

APPARATET SKAL STRAKS SLUKKES I

TILFÆLDE AF:

• Fejl i netstikkontakten, netledningen eller ledningsbeskadigelse.

• Defekt afbryder.

• Røg eller stank fra sveden isolering.

HVIS DISSE BASISFORSKRIFTER IKKE OVERHOLDES, BORTFALDER GARANTIEN.

ELEKTRISK SIKKERHED

Kontroller altid, at netspændingen svarer til den

værdi, der er angivet på maskinens typeskilt.

Ved udskiftning af ledninger eller stik

Smid straks gamle ledninger eller stik væk, når de er blevet erstattet af nye eksemplarer. Det er farligt at sætte

stikket til en løs ledning i stikkontakten.

Apparatet er forsynet med et tre-året tilslutningskabel.

Monter et lysnet-stik med beskyttelsesleder på dette

kabel. Din installatør vil imidlertid kunne lave en god forbindelse.

Til alle svejseapparater på 230 volt skal der bruges langsomme sikringer på mindst 16 ampere.

Ved brug af forlængerledninger

Brug udelukkende en godkendt forlængerledning, som

er egnet til maskinens effekt. Årerne skal have et gennemsnit på mindst 1,5 mm

2

. Hvis forlængerledningen sid-

der på en tromle, rulles ledningen helt af.

Ferm 35

2. Middelmatig stollend

De bekleding bevat veel organische stoffen. Goed lasbaar in alle standen, behalve vertikaal neergaand lassen. Speciaal voor vertikaal opgaand lassen.

3. Traag stollend

Dikker bekleed dan voorgaande 2 types, bevat minder organische stoffen, dichte kompakte slak. Het

smeltblad is uiterst dun vloeibaar. Hoewel lasbaar in

alle standen hoofdzakelijk toegepast voor horizontaal lassen, vooral staande hoeklassen. Voor het lassen van roestvrije staalsoorten en gietijzer zijn aparte

elektroden in de handel. Raadpleeg voor het lassen

van deze materialen eerst uw handelaar, deze zal u

graag advies geven.

PRESTATIE

De prestatie van het lasapparaat kan uitgedrukt worden

in het aantal elektroden nc en nh.

nc: Aantal te verlassen elektroden vanaf starten tot uitschakelen van de thermostaat.

nh: Aantal te verlassen elektroden nadat de thermostaat

inschakeld in het eerste uur.

STROOMSTERKTE

Door het handwiel naar rechts te draaien verhoogt men

de stroomsterkte. Door het handwiel naar links te

draaien verlaagt men de stroomsterkte, wat af te lezen is

op de schaalverdeling op het apparaat. Deze waarde (I2)

correspondeert met de spanning (U2) volgens de formule: U2(V)=18+0,04xI2 (EN 50060).

Worden lange verlengsnoeren gebruikt, dan zal er een

aanmerkelijk stroomverlies optreden. Dus ook dan het

apparaat hoger instellen. Ook bij het gebruik van extra

lange of extra dunne laskabel treedt spanningsverlies op.

Als de werkstukken kleine afmetingen hebben, zullen ze

vlug heet zijn. In dit geval de stroomsterkte lager instellen.

Werkstuk Elektrode kern Lasstroom

dikte Ø (mm2) (A)

2-3 2 45-65

4-5 2,5 70-95

6-7 3,25 90-130

8-12 4 130-160

Tab.1

INGEBRUIKNAME

DE ELEKTRODENHOUDER

Hierin wordt de elektrodegeklemd. De elektrodenhouder is met een kabel verbonden met het lasapparaat.

DE MASSAKLEM

De massaklem kan rechtstreeks aan het te lassen werkstuk geklemd worden of aan een stalen tafel waarop het

te lassen werkstuk ligt.

Leg de elektrodenhouder of massaklem nooit op hete of

metalen werkstukken.

DE LASKAP

Fig.B

De laskap dient ervoor om de ogen te beschermen tegen

de gevaarlijke stralingen die tijdens het lassen vrijkomen.

Kijk nooit met open ogen in de lasvlam.

1. Masker

2. Spatglas

3. Lasglas

4. Handgreep

DE BIKHAMER

Met de bikhamer wordt na het lassen de slak verwijderd.

Tik rustig tegen de slak waardoor deze spoedig loslaat.

Slaat men te hard, dan komen er putjes in de las die de lasrups vervormen. Draag hierbij een veiligheidsbril.

DE STAALBORSTEL

De staalborstel dient om voor het lassen de werkstukken roestvrij te maken, of om na het lassen de laatste

slakrestjes te verwijderen.

KENMERKEN VAN DE LASRUPS

Fig.C

1. Te langzame beweging

2. Te kleine lasboog

3. Te lage lasstroom

4. Te snelle beweging

5. Te grote lasboog

6. Te hoge lasstroom

7. GOED

LASSEN

Fig.D

• Plaats het deel van de elektrode zonder mantel in de

elektrodehouder en verbind de massaklem met het

werkstuk op zo’n manier dat het elektrisch kontakt

goed is.

• Zet het lasapparaat aan en regel de lasstroom naar

gelang de gebruikte elektrode en de grote van het

werkstuk.

• Houd de laskap voor uw gezicht en strijk de elektrode-punt over het werkstuk alsof u een lucifer aansteekt. Dit is de beste manier om de lasboog te starten.

Monteer het lasglas en spatglas, alvorens met het

lassen te beginnen.

14 Ferm

Page 15

• Probeer onmiddelijk nadat de lasboog start de

afstand tussen elektrodepunt en werkstuk gelijk te houden. Deze afstand gelijk houden aan de diameter van de

elektrode. Bewaar deze afstand zo constant mogelijk tijdens het lassen. Houd de hoek tussen elektroden en

werkstuk tussen 20° en 30°.

Sla de elektrode niet tegen het werkstuk. Dit zal de

elektrode beschadigen en het starten van de las-

boog bemoeilijken.

Zorg dat de elektrodenhouder en aardklem corrosievrij blijven zodat ze een goed elektrisch kontakt

kunnen blijven maken;

STORINGEN

In het geval de machine niet naar behoren functioneert,

geven wij onderstaand een aantal mogelijke oorzaken en

de bijbehorende oplossingen.

Wanneer uw Lastrafo niet functioneert, kan dit

een van de volgende redenen hebben

• Thermische beveiliging uitgeschakeld.

• Smeltzekering defekt (in de meterkast).

• Aardklem heeft geen goede verbinding met het te lassen werkstuk.

• Breuk in voedingssnoer of stopkontakt (randaarde

stopkontakt gebruiken).

ONDERHOUD

Let erop dat de stekker uit het stopcontact neemt,

voordat u met onderhoud aan het lasapparaat

gaat beginnen.

De machines van Ferm zijn ontworpen om gedurende

lange tijd probleemloos te functioneren met een minimum aan onderhoud. Door de machine regelmatig te

reinigen en op de juiste wijze te behandelen, draagt u bij

aan een hoge levensduur van uw machine.

Reinigen

Reinig de machine-behuizing regel matig met een zachte

doek, bij voorkeur iedere keer na gebruik. Zorg dat de

ventilatiesleuven vrij van stof en vuil zijn.

Gebruik bij hardnekkig vuil een zachte doek bevochtigd

met zeepwater. Gebruik geen oplosmiddelen als benzine, alcohol, ammonia, etc. Dergelijke stoffen beschadigen de kunststof onderdelen.

Storingen

Indien zich een storing voordoet als gevolg van bijvoorbeeld slijtage van een onderdeel, neem dan contact op

met uw plaatselijke Ferm-dealer.

Achterin deze gebruiksaanwijzing vindt u een onderdelentekening met de na te bestellen onderdelen.

MILIEU

Om transportbeschadiging te voorkomen, wordt de

machine in een stevige verpakking geleverd. De verpakking is zo veel mogelijk gemaakt van recyclebaar materiaal. Maak daarom gebruik van de mogelijkheid om de verpakking te recyclen.

Breng oude machines wanneer u ze vervangt naar uw

plaatselijke Ferm-dealer. Daar zal de machine op milieuvriendelijke wijze worden verwerkt.

Ferm 15

GARANTI

Garantibetingelsene er beskrevet på garantikortet, som

leveres separat.

Vi erklærer at dette produktet tilfredsstiller følgende

harmoniserte standarder eller standarder

EN50060 + Amdt

EN50199 + Amdt

EN60974-1 + Amdt

og er i samsvar med følgende direktiver

Lavspenningsdirektivet 73/23/EØF + Amdt

EMC-direktivet 89/336/EØF + Amdt

fra 20-09-2002

GENEMUIDEN NL

W. Kamphof

Quality department

SVEJSEAPPARAT

NUMRENE I DEN FØLGENDE TEKST HENVISER

TIL ILLUSTRATIONERNE PÅ SIDE 2

TEKNISKE SPECIFIKATIONER

PRODUKTBESKRIVELSE

EN 50060 Standard for svejseapparater med

begrænset anvendelse.

Én-fase transformator.

P (W) Optaget effekt i watt.

f (Hz) Netfrekvens i herz.

I2 (A) Sekundær strøm eller svejsestrøm i

ampere.

d (mm) Elektrodediameter.

nc Antal elektroder der skal svejses ned, fra