OWNER’S/

OPERATOR’S

MANUAL

MODEL NO.’s

UB-645

UB-745

UB-650-T

UB-750-T

UB-850-T

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SINO LEEINGLES, PIDAAYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

CAUTION

THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD

BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE

1. Select an area for assembly that is clean and free of any

debris which might cause persons working on the

assembly to trip.

2. Do not lift heavy parts or assemblies. Use crane, jack,

tackle, fork trucks or other mechanical devices.

3. Preview the assembly instructions in your operator’s

manual before proceeding further.

4. If the assembly instructions call for parts or assemblies to

be blocked up, use only blocking material that is in good

condition and is capable of handling the weight of the

assembly to be blocked. Also insure that the blocking

material is on a clean, dry surface.

5. Never put hands, or any part of body, under blocked up

assemblies if at all possible.

6. After completing assembly, thoroughly inspect the

machine to be sure that all nuts, bolts, hydraulic fittings

or any other fastened assemblies have been thoroughly

tightened.

7. Before operating the machine, thoroughly read the

operation section of your operator’s manual.

8. Before operating, read the maintenance section of your

operator’s manual to be sure that any parts requiring

lubrication, such as gearboxes, are full, to avoid any

possible damage.

9. Before operating equipment – If you have any

questions regarding the proper assembly or

operation, contact your dealer or representative.

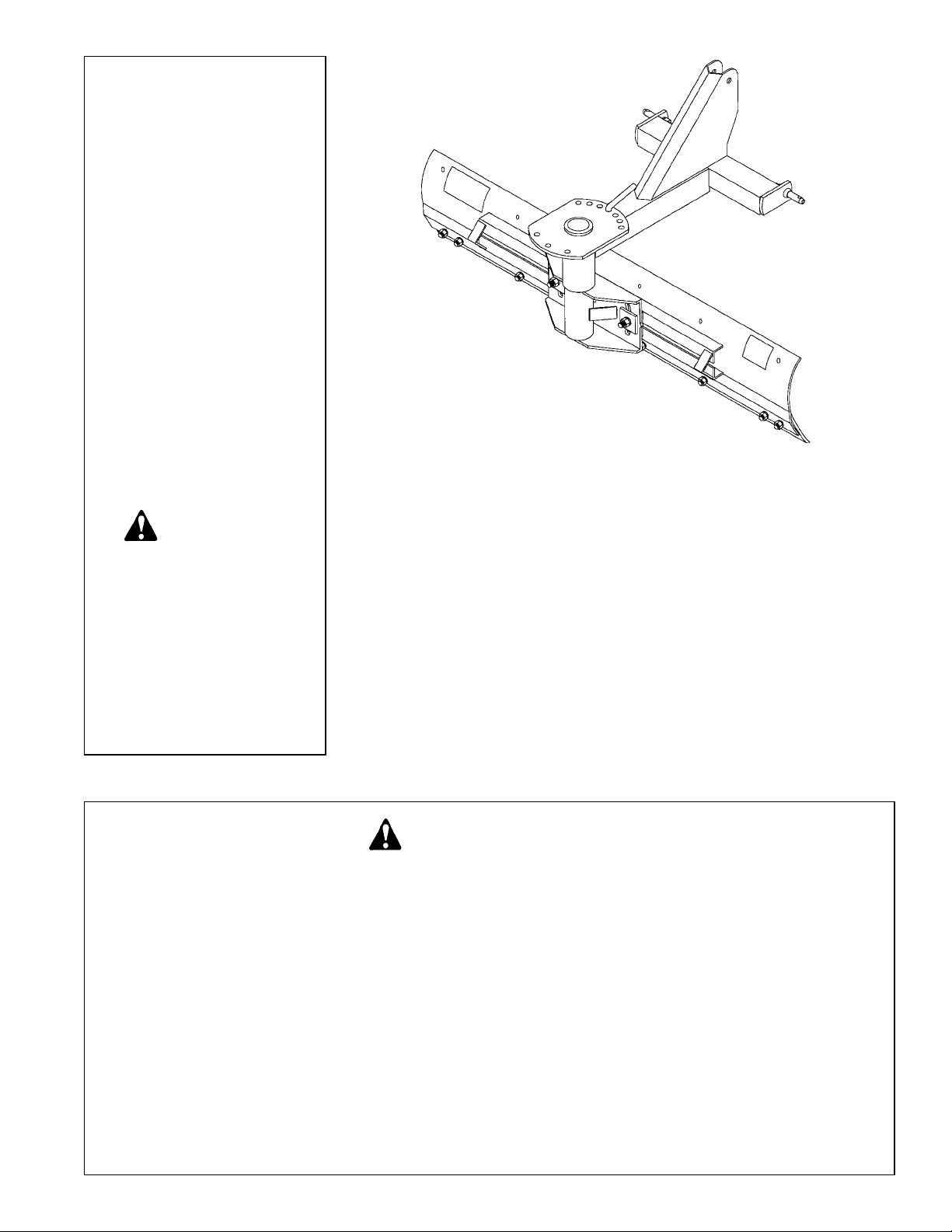

3 PT. REAR

MOUNTED BLADE

For Cat. I 3 Pt. Hitch Tractors

Up To 50 H.P.

Safety Instructions Assembly & Mounting

Tractor Preparation Maintenance

Operating Instructions Repair Parts

TABLE

OF

CONTENTS

SINO LEEINGLES, PIDA AYUDA A

AIGUIEN QUE SI LO LEA PARA QUE

LE TRADUZCA LAS MEDIDAS DE

SEGURIDAD.

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

STATEMENT

OF POLICY

SAFETY SIGNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PREPARATION INSTRUCTIONS . . . . . . . . . . . . . . . . . 5

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 6

OWNER MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 7

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . 8 - 9

PARTS DRAWING/LIST . . . . . . . . . . . . . . . . . . . . . . . . 10 - 13

It is the policy of Farm Star

to improve its products

where it is possible and practical

to do so. Farm Star

reserves the right to make

changes or improvements in

design and construction at any

time, without incurring the obligation to make these changes on

previously manufactured units.

TO THE OWNER:

Read this manual before using your 3 pt. Rear Blade. This manual is provided to give you the necessary

operating and maintenance instructions for keeping your Loader Fork in top operating condition. Please read this

manual thoroughly. Understand what each control is for and how to use it. Observe all safety signs on the

machine and noted throughout the manual for safe operation of implement. Keep this manual handy for ready

reference.

Like all mechanical products, it will require cleaning and upkeep.

Use only genuine Fa rm Star service parts. Substitute parts will void the warranty and may not meet stan-

dards required for safe and satisfactory operation. Record the model and serial number of your Rear Blade here:

Model:________________________________________ Serial Number:_______________________________

RETAIL CUSTOMER’S RESPONSIBILITY

It is the Retail Customer and/or Operator’s responsibility to read the Operator’s Manual, to operate, lubricate, maintain, and store the product in accordance with all instructions and safety procedures. Failure

of the operator to read the Operator’s Manual is a misuse of this equipment.

It is the Retail Customer and/or Operator’s responsibility to inspect the product and to have any part(s)

repaired or replaced when continued operation would cause damage or excessive wear to other parts or

cause a safety hazard.

It is the Retail Customer’s responsibility to deliver the product to the authorized Farm Star Dealer, from

whom he purchased it, for service or replacement of defective parts which are covered by warranty.

Repairs to be submitted for warranty consideration must be made within forty-five (45) days of failure.

It is the Retail Customer’s responsibility for any cost incurred by the Dealer for traveling to or hauling

of the product for the purpose of performing a warranty obligation or inspection.

1

2

T o the Owner/Operator/Dealer

All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this

implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

BEFORE YOU START!!

Read the safety messages on the implement and shown in your manual.

Observe the rules of safety and common sense!

THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT

SAFETY WARNING MESSAGES. CAREFULL YREAD EACH

WARNING MESSAGE THAT FOLLOWS. FAILURE TO

UNDERSTAND AND OBEY A SAFETY WARNING, OR

RECOGNIZE A SAFETY HAZARD, COULD RESULT IN AN

INJURY OR DEATH TO YOU OR OTHERS AROUND YOU.

THE OPERATOR IS ULTIMATELY RESPONSIBLE FOR THE

SAFETY OF HIMSELF, AS WELL AS OTHERS, IN THE

OPERATING AREA OF THE TRACTOR AND ATTACHED

EQUIPMENT.

IMPORTANT SAFETY INFORMATION!

Working with unfamiliar equipment can lead to careless injuries. Read this manual, and the manual for your tractor,

before assembly or operating, to acquaint yourself with the machines. It is the implement owner’s responsibility, if this

machine is used by any person other than yourself, is loaned or rented, to make certain that the operator, prior to

operating:

1. Reads and understands the operator’s manuals.

2. Is instructed in safe and proper use.

The use of this equipment is subject to certain hazards which cannot be protected against by mechanical

means or product design. All operators of this equipment must read and understand this entire manual, paying

particular attention to safety and operating instructions, prior to using. If there is something in this manual you

do not understand, ask your supervisor, or your dealer, to explain it to you.

THIS SYMBOL MEANS

– A TTENTION!

– BECOME ALERT!

– YOUR SAFETY IS INVOLVED!

UNDERSTAND SIGNAL WORDS

Note the use of the signal words DANGER, WARNING

and CAUTION with the safety messages. The

appropriate signal word for each has been selected

using the following guidelines:

DANGER: Indicates an imminently hazardous situation

that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme

situations typically for machine components which, for

functional purposes, cannot be guarded.

If you have questions not answered in this manual or require additional copies or the manual is damaged, please

contact your dealer or the manufacturer directly.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death

or serious injury, and includes hazards that are

exposed when guards are removed. It may also

be used to alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

SAFETY INSTRUCTIONS (continued)

All equipment is potentially hazardous. There is no substitute for a cautious, safe-minded operator who

recognizes potential hazards and follows reasonable safety practices.

When the use of hand tools is required to perform any part of assembly, installation, adjustment, maintaining,

repairing, removal, or moving the implement, be sure the tools used are designed and recommended by the

tool manufacturer for that specific task.

Personal protection equipment including safety glasses, safety shoes, and gloves are recommended during

assembly, installation, operation, adjustment, maintaining, repairing, removal, or moving the rear blade.

Always use two people to handle heavy, unwieldy components during assembly, installation, removal, or

moving the rear blade.

Never place any part of your body where it would be in danger if movement should occur during assembly,

installation, operation, maintaining, repairing, removal, or moving the implement.

Never place yourself between the tractor and implement while implement is in operation.

Do not work under a raised implement unless it is securely blocked or held in position. Do not depend on the

tractor hydraulic system to hold the implement in place.

A heavy load can cause instability of the tractor. Use extreme care during travel. Slow down on turns and

watch out for bumps. The tractor may need front counter-weights to counter-balance the weight of the

implement.

Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating this

equipment. Consult your doctor about operating this machine while taking prescription medications.

Do not allow others to ride on the tractor with an operator. Riders are subject to injury such as being struck by

foreign objects or being thrown off. Riders obstruct the operator’s view resulting in unsafe operation. Never

allow anyone to ride on the implement!

Before you operate the rear blade, check over all pins, bolts and connections to be sure all are securely in

place. Replace any damaged or worn parts immediately.

Do not allow anyone who is not familiar with the safety rules and operation instructions to use this rear blade.

Never allow children to operate or be around equipment.

Use stabilizer bars, adjustable sway chains, or sway blocks on your tractor lift arms to keep the rear blade from

swinging side to side. Adjust as tightly as practical for best performance.

3

4

SAFETY INSTRUCTIONS (continued)

SAFETY SIGNS

This SAFETY SIGN is

located on the frame of

your rear blade.

Obey ALL Safety

Warnings.

NOTE:

If Safety Sign is missing

or damaged, replace

immediately.

Keep alert and watch the front as well as the rear when working with the implement.

When maneuvering close to buildings or passing through narrow areas, be sure to allow sufficient clearance

for the implement.

Do not operate close to ditches or creeks. Slow down when operating over rough ground.

Always be sure the implement is in the fully raised position when in transport.

When adjusting the angle of the moldboard assembly, be sure that your feet are never under the rear blade.

Use extreme caution when backfilling deep holes or trenches.

Be careful to avoid catching the rear blade on stumps or other immovable objects.

Use care when working on slopes.

Avoid excessive speed during operation.

Make adjustments only when the implement is attached to the tractor.

When using the rear blade in a reverse position, use extra care. Do not ram rear blade into piles of dirt.

Tractor lift arms and the rear blade are not built to take high impact loads in this position. Ramming backwards

can also dislodge operator from seat and/or tractor controls, resulting in possible serious injury or death.

Always ease the tractor into the load. It may be necessary to reposition and take less “bite” on the material to

move it safely.

Watch for and avoid hidden obstructions, i.e., buried pipes, rocks, concrete piers, uneven concrete slabs,

stumps, etc., when operating.

INSTRUCTIONS

TRACTOR REQUIREMENTS

AND PREPA R ATION

The UB Series Rear Blades will fit most Category I

tractors equipped with a standard 3-point hitch. These

blades are designed for use on tractors up to 50

horsepower. For use on larger tractors, extra care is

required and it is strongly suggested that purchasing a

heavier rear blade be considered.

Check the tractor’s 3-point hydraulic lift system. It

should operate up and down smoothly and hold its

position when set. Refer to your tractor owner’s manual

or dealer for any adjustments necessary to put the 3point hydraulic lift system in good working order. (I&T

shop manuals will list most specifications and adjustment

instructions – available from most farm equipment

dealers.)

Tractor should be equipped with stabilizer bars,

adjustable sway chains, or sway blocks to keep the

implement from swinging side to side.

Smaller size tractors may need front counter weights to

counter-balance the weight of the implement.

It is recommended that the tractor be equipped with a

Rollover Protection System (ROPS) and a seat belt that

is used.

CAUTION!

Be sure your tractor is in good condition and

properly equipped with counter weights. Read all the

safety precautions and make sure all tractor

operators are familiar with the safety rules of tractor

operation.

UB-645 BLADE

(6 ft. Moldboard mounting instruction.)

1. Remove the two center plow bolts from the moldboard

assembly.

2. Position the moldboard assembly in front of the spindle assembly and place the two center plow bolts

through the moldboard assembly and into the corresponding holes in the lower moldboard bracket on the

spindle assembly.

3. Place the two 1/2” x 11/2” hex head bolts provided

through the two center holes at the top of the

moldboard assembly into the corresponding holes on

the upper moldboard bracket on the spindle assembly .

(NOTE: The moldboard assembly may be positioned

in the center, 12” to the right, or 12” to the left, according to the setting desired.)

4. Tighten all bolts securely.

UB-745 BLADE

(7 ft. Moldboard mounting instruction.)

1. Remove the three center plow bolts from the moldboard assembly.

2. Position the moldboard assembly in front of the spindle assembly and place the three center plow bolts

through the moldboard assembly and into the corresponding holes in the lower moldboard bracket on the

spindle assembly.

3. Place the two 1/2” x 11/2” hex head bolts provided

through the two center holes at the top of the moldboard

assembly and into the corresponding holes on the

upper moldboard bracket on the spindle assembly.

(NOTE: The moldboard assembly may be positioned

in the center, 12” to the right, or 12” to the left, according to the setting desired.)

4. Tighten all bolts securely.

ASSEMBLY AND MOUNTING

It is suggested that you mount the main frame on the 3point hitch of your tractor before assembling the blade as

follows:

1. Lower the 3-point hitch on your tractor to facilitate

mounting of the main frame of the blade to the tractor.

2. Insert the lift arm pins on the main frame into the ball

sockets in the lift arms of the tractor 3-point hitch. Pin

in place with linch pins (not furnished).

3. Attach the mast of the main frame to the tractor by

installing the tractor center (or top) link with a top link

pin (not furnished). Pin in place with a linch pin (not

furnished).

The main frame of the blade is now installed on the

tractor. You are ready to proceed with assembling the

moldboard and cutting edge assembly to the main frame

as follows:

UB-650-T, UB-750-T, AND UB-850-T BLADES

(6 ft., 7 ft., & 8 ft. Moldboard mounting instructions.)

1. Place the two tilt adjustment bolts into the moldboard

brackets (one on each end).

2. Position the moldboard against the spindle mounting

bracket, with the two tilt adjustment bolts extending

through the radial slots in the spindle mounting bracket.

3. Place the tie plates over the tilt adjustment bolts.

4. Tighten all bolts securely.

5. In order to tilt the moldboard simply loosen the nuts

on the tilt adjustment bolts and pivot to the desired

angle, then retighten the nuts.

NOTE:Always use the tractor anti-sway bars, blocks, or

chains to prevent blade side-sway. This is a must when

using the blade in a reverse position.

Your Rear Mounted Blade is now assembled and

mounted on your tractor. It is ready to go to work for you.

5

6

INSTRUCTIONS (continued)

When using the rear blade in a reverse position use

extra care - DO NOT RAM REAR BLADE into dirt

piles! Tractor lift arms and the rear blade are not

built to take high impact loads in this position. RAMMING backwards can also dislodge operator from

seat and/or tractor controls, resulting in possible

serious injury or death.

CAUTION!

Watch for and avoid hidden obstructions, i.e.,

buried pipes, rocks, concrete piers, or uneven slabs

of concrete, when operating, or blade damage may

occur. This is especially true when removing snow.

CAUTION!

O PE R ATION

Check for ditches, stumps, holes, or other obstacles

that could upset tractor or damage blade. Always turn off

tractor engine, set parking brake, lower blade to ground

before dismounting tractor.

Attaching the blade to the tractor increases the overall

length of the working unit. Allow additional clearance for

the blade to swing when turning.

Your rear blade can be used for all types of blade

work, including casting, side ditching, leveling, terracing,

grading, bulldozing, and snow removal.

1. CASTING: The blade should be angled horizontally –

only enough to allow the material to slide along it

easily . The vertical angle (tilt) of the blade must be set

to suit conditions. This is controlled by the lift arm

leveling assembly (turnbuckle) on the tractor 3-point

hitch.

2. SIDE DITCHING: The horizontal angle should be at

its sharpest. This is obtained by removing the shift pin

and turning the moldboard so that the last hole in the

circle plate is in line with the shift pin hole, then

replace the shift pin. It is suggested that the blade be

set in an offset position and then use the shorter

blade side to be the cutting side. This reduces the

load movement on the end of the blade.

The vertical angle of the blade (tilt) is adjusted by

means of the adjustable turnbuckles on the tractor 3point hitch. For the sharpest angle, lengthen the

center link on the tractor as far as possible. Also,

lower the adjustable leveling turnbuckle as far as

possible.

3. LEVELING: The blade should be straight across, i.e.,

90˚ to the line of travel of the tractor, in other words 0˚

horizontal angle.

There should be 0˚ vertical angle, i.e., the lift arms

on the tractor 3-point hitch should be parallel to the

ground.

The cutting pitch of the blade should be the opposite of that used in side ditching and casting, with the

cutting edge behind the top edge of the moldboard.

This adjustment is made with tractor center link.

4. TERRACING: Use a combination of ditching, casting,

and leveling. The first cut is into the hillside in the

ditching position. Continue until the terrace is at

proper depth, then switch to the casting position until

the terrace width is established. It may be necessary

to use the leveling position to complete the job.

5. BULLDOZING: When bulldozing, the blade is in

reverse position. Depending on the job, the casting,

side ditching, or leveling position may be used. Snow

removal can also be done with the blade in this

position (blade in reverse, cutting edge away from

tractor).

(NOTE: Most blades are damaged in this position –

use extra care – DO NOT RAM blade into snow or

dirt piles!)

6. GRADING: Grading is a combination of casting, side

ditching, and leveling. Snow removal can also be

done with the blade in this position (cutting edge

toward the tractor).

These suggestions are generalities; best results will be

obtained after some experience.

NOTE: Do not load either end of the blade heavily. Try

to balance the load on both ends of the blade.

GENERAL SAFETY

The designed and tested safety of this machine

depends on it being operated within the limitations as

explained in this manual. Be familiar with and follow all

safety rules in the manual, on the blade and on the

tractor.

The safe operation of this machine is the responsibility

of the owner / operator. The operator should be familiar

with the blade and tractor and all safety practices before

starting operation. Read the safety rules.

Never let anyone stand between the rear of the tractor

and the rear blade while the tractor is backing up to connect to the blade. Always stand to the side until tractor

has come to a complete stop and the brakes set or the

tractor shift placed in “PARK”.

OWNER SERVICE

TRANSPORTING

Pay particular close attention to the Safety Messages

regarding transport. Avoid unnecessary injuries and

equipment damage by exercising cautious, conscientious travel procedures.

Attaching the blade to the tractor increases the overall

length of the working unit. Allow additional clearance for

the blade to swing when turning.

Raise the blade as high as possible for transporting.

Always transport blade with blade centered on tractor.

Never attempt road travel with blade offset into the traffic

lane.

MAINTENANCE

W ARNING!

▲ Lower blade to ground or block securely, turn trac-

tor engine off, remove key and set brakes or place

shift lever in “Park” position.

▲ Before working underneath, raise 3-pt. hitch to

highest position and block blade securely.

Hydraulic system leakdown and failure of

mechanical or hydraulic system can cause equipment to drop.

STORING SAFELY

• Never store equipment with fuel in the tank inside a

building where fumes may reach an open flame or

spark. Allow engine to cool before storing in an

enclosure.

• Always store blade in a clean, dry location away from

children or livestock.

• Storage location should be level and solid to make

hitching and unhitching easy.

OPTIONS

The optional skid shoes provide cutting height adjustment to reduce the chance of blade or surface damage

during snow removal. This option is very helpful when

plowing gravel or loose stone driveways.

OPTIONAL

MODEL SK-6 SKID SHOE INSTALLATION

Attach the skid shoe mounting bracket to the 2nd and

3rd cutting edge holes from each end of the moldboard.

Insert the skid shoe in the mounting bracket and secure

with the 1/2” – 13NC x 11/2” long square head set screw

and jam nut. Be sure the skid shoes are turned so the

adjustment holes match the point of the set screw. See

parts illustration.

▲ Keep all persons away from operator control area

while performing adjustments, service or maintenance.

▲ Do not run engine indoors – exhaust gases

contain carbon monoxide, an odorless and deadly

poison.

Inspect the blade for loose, damaged or worn parts and

adjust or replace if needed.

Repaint parts where paint is worn or scratched to

prevent rust.

Check all bolts and nuts to be sure they are tight.

At the end of the working season or when the blade will

not be used for a long period, it is good practice to clean

off any dirt that may have accumulated on the blade and

any of the moving parts.

Check the shift pin for excessive wear and replace if

necessary.

Always store blade in a clean, dry location away from

children or livestock.

Optional end plates provide a “boxed” blade for grading. This is helpful when spreading dirt or loose stone or

just leveling an area. It keeps the material from sliding off

the end of the blade.

OPTIONAL

MODEL EP-38 END PLATE INSTALLATION

The end plates mount to the inside of the blade using

the end cutting edge hole and the hole in the moldboard

directly above it. Replace the cutting edge bolt with the

longer 5/8” – 11NC x 2” long carriage bolt provided. On

earlier models it may be necessary to match drill the

upper 11/16” Dia. hole in the moldboard. Install the upper

5

/8” – 11NC carriage bolt. See parts illustration.

OBEY ALL

SAFETY WARNINGS!

7

8

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY

Blade will not penetrate

soil.

1. Cutting edge dull.

2. Blade set too straight.

3. Soil too hard.

Replace cutting edge.

Increase 3 pt. hitch toplink length.

Loosen soil with scarifiers or disk.

Wait for rain.

Moldboard digging in

too much.

1. Blade pitch excessive.

2. Soft ground.

Adjust toplink (shorten).

Install skid shoes.

Wait for dryer soil.

3 Pt. hitch frame bent.

1. Hitting hidden objects in backfill

position or ramming backwards at

high speed into hard piles.

2. Using too large of tractor.

Use slow speed when in unknown

conditions.

Always backfill or push backwards

at slow speed.

Preferably use tractor of recommended horsepower.

Slow down and use extra care.

Unable to hold level

grade.

1. Tractor draft control lifting blade.

2. Soil too hard.

Set tractor draft control.

Use scarifiers.

Bent moldboard.

1. Small curve is normal from welding.

2. Hitting hidden objects in backfill

position or ramming backwards at

high speed into hard piles of soil,

snow, or ice.

3. Using too large of tractor or one that

is heavily weighted and has four

wheel drive.

Can be removed, but will not effect

blade operation.

Use slow speed when in unknown

conditions.

Always backfill or push backwards

at slow speed.

Preferably use tractor of recommended horsepower.

Slow down and use extra care.

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE POSSIBLE REMEDY

Only one end of blade

moldboard cutting or

“working.”

Blade moves side to

side.

Front of tractor moves

sideways when blade is

angled.

1. Moldboard not level. Adjust tractor 3 pt. linkage to level

lift arms.

1. Anti-sway bars, blocks, or chains

missing.

2. Anti-sway chains loose.

1. Too much material being handled.

2. Tractor too light.

Install anti-sway bars, blocks or

chains.

Adjust chains.

Reduce material load.

Add front weights.

Use larger size tractor.

Angle shift pin breaks

or bends.

Blade catches

cracks/joints in hard

surface driveways.

Blade plows most loose

stone/gravel into grass

at side of driveway.

1. Hitting solid objects.

2. Ramming blade into “solid” snow/ice

or dirt piles.

3. Using too large tractor.

Drive carefully and check work

area.

Stop dangerous practice.

Use proper size tractor for blade

rating.

PLOWING SNOW PROBLEMS:

1. Need optional skid shoes. Add skid shoes.

1. Skid shoes not adjusted properly. Adjust skid shoes so cutting edge

clears.

9

10

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346601 3 Pt. Mount Frame 1

2 590108 Lift Pin Assembly (AK-578) 2

3 350030 Adjustment Pin 1

4 2500003 Full Hex Nut 1/2” – 13NC 2

5 2502002 Spring Lockwasher 1/2”2

6 2500013 Full Hex Nut 5/8” – 11NC 8

7 2502007 Spring Lockwasher 5/8”8

8 2503045 No. 3 Plow Head Bolt 5/8” – 11NC x 11/2”6

9 2503179 No. 3 Plow Head Bolt 5/8” – 11NC x 2” 2

10 350405 6 Ft. Cutting Edge 1

11 346612 6 Ft. Moldboard 1

12 2503004 Hex Head Bolt 1/2” – 13NC x 11/2”2

13 101033 Decal – Caution, Safe Operating Practices 1

14 101052 Decal – Warranty Notice 1

UB-645 BLADE

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346601 3 Pt. Mount Frame 1

2 590108 Lift Pin Assembly (AK-578) 2

3 350030 Adjustment Pin 1

4 2500003 Full Hex Nut 1/2” – 13NC 2

5 2502002 Spring Lockwasher 1/2”2

6 2500013 Full Hex Nut 5/8” – 11NC 9

7 2502007 Spring Lockwasher 5/8”9

8 2503045 No. 3 Plow Head Bolt 5/8” – 11NC x 11/2”6

9 2503179 No. 3 Plow Head Bolt 5/8” – 11NC x 2” 3

N/S 350029 7 Ft. Cutting Edge 1

N/S 346701 7 Ft. Moldboard 1

12 2503004 Hex Head Bolt 1/2” – 13NC x 11/2”2

13 101033 Decal – Caution, Safe Operating Practices 1

14 101053 Decal – Warranty Notice 1

UB-745 BLADE

MODEL NO.

UB-645

SHOWN

MODEL NO.

UB-650-T

SHOWN

UB-650-T

UTILITY BLADE

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346801 Mount Frame 1

2 346807 Moldboard Assembly 1

3 350405 Cutting Edge 1

4 2503045 Plow Bolt 5/8” – 11NC x 11/2”8

5 2502007 Lockwasher 5/8”8

6 2500013 Nut 5/8” – 11NC Full Hex 8

7 346810 Tilt Adjustment Bolt 2

8 346812 Tie Plate 2

9 2502001 Lockwasher 3/4”2

10 2500002 Nut 3/4” – 10NC Full Hex 2

11 590108 Lift Pin (AK-578) 2

12 350030 Adjustment Pin 1

13 101033 Decal – Caution, Safe Operating Practices 1

14 101054 Decal – Warranty Notice 1

11

12

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346801 Mount Frame 1

N/S 346901 Moldboard Assembly 1

N/S 350029 Cutting Edge 1

4 2503045 Plow Bolt 5/8” – 11NC x 11/2”9

5 2502007 Lockwasher 5/8”9

6 2500013 Nut 5/8” – 11NC Full Hex 9

7 346810 Tilt Adjustment Bolt 2

8 346812 Tie Plate 2

9 2502001 Lockwasher 3/4”2

10 2500002 Nut 3/4” – 10NC Full Hex 2

11 590108 Lift Pin (AK-578) 2

12 350030 Adjustment Pin 1

13 101033 Decal – Caution, Safe Operating Practices 1

14 101055 Decal – Warranty Notice 1

UB-750-T

UTILITY BLADE

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346801 Mount Frame 1

N/S 347001 Moldboard Assembly 1

N/S 350105 Cutting Edge 1

4 2503045 Plow Bolt 5/8” – 11NC x 11/2”10

5 2502007 Lockwasher 5/8”10

6 2500013 Nut 5/8” – 11NC Full Hex 10

7 346810 Tilt Adjustment Bolt 2

8 346812 Tie Plate 2

9 2502001 Lockwasher 3/4”2

10 2500002 Nut 3/4” – 10NC Full Hex 2

11 590108 Lift Pin (AK-578) 2

12 350030 Adjustment Pin 1

13 101033 Decal – Caution, Safe Operating Practices 1

14 101142 Decal – Warranty Notice 1

UB-850-T

UTILITY BLADE

SK-6 (OPTIONAL)

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346632 Skid Shoe Weldment 2

2 346635 Mount Weldment 2

3 2503203 Set Screw 1/2” – 13NC x 11/2” Sq. Head 2

4 2500058 Nut 1/2” – 13NC Hex Jam 2

5 2504068 Cotter Pin 1/4” x 13/4”2

N/S 2503179 No. 3 Plow Head Bolt 5/8” – 11NC x 2” 4

EP-38 (OPTIONAL)

REF. PART NO.

NO. NO. DESCRIPTION REQ.

1 346621 End Plate 2

2 2503136 Bolt 5/8” – 11NC x 2” Carriage Head Grade 5 4

3 2502007 Washer 5/8” Springlock 4

4 2500013 Nut 5/8” – 11NC Full Hex 4

13

14

LIMITED WARRANTY

Farm Star warrants its implements, parts and accessories to be free from defects in materials and workmanship for a period of six (6) months from date of purchase for non-commercial, state, and municipalities’. Use

ninety (90) days for commercial use from date of retail sale.

SPECIAL WARRANTY PROVISION

Warranty shall only apply to defects in material and workmanship. In no case shall the manufacturer be liable

to the purchaser for the bending or breakage of any part of the blade by abuse or misuse, such as striking

hidden objects, grubbing stumps, or using tractors larger than the blades maximum horsepower rating whether

intentional or unintentional.

DISCLAIMER OF IMPLIED WARRANTIES & CONSEQUENTIAL DAMAGES

Farm Star’s obligation under this warranty, to the extent allowed by law, is in lieu of all warranties, implied or

expressed, including implied warranties of merchantability and fitness for a particular purpose and any liability

for incidental and consequential damages with respect to the sale or use of the items warranted. Such

incidental and consequential damages shall include but not be limited to: transportation charges other than

normal freight charges; cost of installation other than cost approved by Farm Star; duty; taxes; charges for

normal service or adjustments; loss of crops or any other loss of income; rental of substitute equipment,

expenses due to loss, damage, detention or delay in the delivery of equipment or parts resulting from acts

beyond the control of Farm Star.

THIS WARRANTY SHALL NOT APPLY:

1. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident.

2. If parts not made or supplied by Farm Star have been used in connection with the unit, if, in sole

judgement of Farm Star such use affects its performance, stability, or reliability.

3. If the unit has been altered or repaired outside of an authorized Farm Star dealership in a manner which,

in the sole judgement of Farm Star affects its performance, stability or reliability.

4. To expendable or wear items such as skid shoes, cutting edges, and other items that in the company’s sole

judgement is a wear item.

NO EMPLOYEE OR REPRESENTATIVE OF FARM STAR IS AUTHORIZED TO CHANGE THIS

WARRANTY IN ANY WAY OR GRANT ANY OTHER WARRANTY UNLESS SUCH CHANGE IS MADE IN

WRITING AND SIGNED BY FARM STAR’S SERVICE MANAGER, POST OFFICE BOX 100, LITCHFIELD,

ILLINOIS 62056-0100.

SAFETY PRECAUTIONS

MOST ACCIDENTS OCCUR BECAUSE OF NEGLECT OR CARELESSNESS.

AVOID NEEDLESS ACCIDENTS BY FOLLOWING ALL OF THE SAFETY PRECAUTIONS LISTED BELOW.

• Machinery should be operated only by those who are

responsible and are authorized to do so.

• Stop the engine, lower all equipment, lock the brakes,

and remove the ignition key before dismounting from the

tractor.

• Never stand between tractor and implement while tractor

is being backed to hitch.

• Loose fitting clothing should not be worn, to avoid catch-

ing on various parts.

• Detach implement in area where children normally do not

play.

• When performing adjustments or maintenance on an

implement, first lower it to the ground or block it securely

at a workable height.

• Only a qualified operator should be permitted on tractor

when in operation; no riders allowed.

• Make certain everyone is in the clear before starting

tractor or raising or lowering equipment.

• Operate the tractor and implement only while seated in

the driver’s seat.

•

Reduce speed when transporting mounted implements

to avoid bouncing and momentary loss of steering

control.

• A heavy load can cause instability of the tractor. Use

extreme care during road travel. Slow down on turns and

watch out for bumps. Tractor may need front counterweights to counter-balance the weight of the implement.

• Reduce speed on hillsides or curves so there is no

danger of tipping.

• Avoid driving too close to the edge of ditches or creeks.

• Do not transport implement on public roads without

reflectors and slow moving vehicle emblem in daylight

and with approved warning lights at night and other

periods of poor visibility.

• Due to the width of some implements, use extra caution

on highways, farm roads, and when approaching gates.

• Always be sure the implement is in the proper position for

transport.

• Keep alert and watch the front as well as the rear when

working with the implement.

OWNER’S/

OPERATOR’S

MANUAL

MODEL NO.’s

UB-645

UB-745

UB-650-T

UB-750-T

UB-850-T

3 PT. REAR MOUNTED BLADE

For Cat. I 3 Pt. Hitch Tractors

up to 50 H.P.

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE

FOLLOWING INFORMATION:

1. PART NUMBER

2. PART DESCRIPTION

3. MODEL NUMBER

4. NAME OF ITEM

MAKE EVERY DAY

A HOLIDAY

FROM ACCIDENTS!

JANUARY 2002

FS-RB002-OG

FARM STAR

P.O. BOX 100 LITCHFIELD, IL 62056-0100 (217) 324-5973

WEB: http:// www.farmstar.com E-MAIL: sales@farmstar.com

Loading...

Loading...