Page 1

Installation Manual

A.A.R. Combination

Railroad Track / MTS

Scale

Model(s): 12-1492

12-1493

12-1494

12-1495

12-1496

50538

Revision 7 4/12

© 1999-2012 by Fairbanks Scales Inc.

All rights reserved

Page 2

Page 3

04/12 3 50538 Rev. 7

Amendment Record

A. A.R. Railroad

Combination MTS Scale

Model(s): 12-1492,12-1493,12-1494,12-1495

50538

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 9/99

Issue #1 9/99 Software Update.

Issue #2 12/01 Update arrangement/flow.

Issue #3 10/03 Updated Information and Drawings

Revision 4 05/08 Updated Load Cell Assembly image and corresponding parts information;

Added special Load Cell Appendix with parts list

Revision 5 05/08 Updated information and drawings according to notes from Engineering Dept.

Revision 6 03/10 Updates per ECO 626.

Revision 7 04/12 Updated information and drawings according to notes from Engineering Dept.

Page 4

Page 5

Table of Contents

Section 1: General Information

1-A: Introduction & General Description Page 9

1-B: Specifications Page 9

1-C: Rails & Anti-Creep Devices Page 10

1-D: Regulations from the AAR Scale Handbook Page 11

1-E: Foundation Construction & Installation Page 13

1-F: Ground Rods Page 14

1-G: Load Cell Base Plates Page 14

1-H: Check Stands Page 15

1-I: Weighbridge Page 15

1-J: Deck Construction Page 15

1-K: Load Cell Flexure Assembly Page 16

Section 2: Installation

2-A: General Service Policy Page 17

2-B: Pre-Installation checkout Page 17

2-C: Unpacking Page 18

2-D: Safety Page 18

2-E: Recommended Installation Sequence Page 19

2-F: Foundation Inspection Page 20

2-G: Foundation Inspection Check List Page 21

2-H: Base Plate Assemblies Page 22

2-I: Check Stands Page 22

2-J: Weighbridge Steel Page 23

2-K: Weighbridge Hardware Page 24

2-L: Assembling Weighbridge Sections Page 25

2-M: Installing Weighbridge Sections Page 27

2-N: Load Cell Flexure Assembly Page 29

2-O: Adjusting Elevation Page 31

2-P: Leveling Load Cell Flexure Assemblies Page 33

2-Q: Grouting Load Cell Baseplates Page 36

2-R: Checkrods Page 39

2-S: Check Rod Adjustment Page 41

2-T: Deck Forming Page 42

2-U: Junction Boxes Page 47

2-V: Grounding Page 47

Section 3: Service & Maintenance

3-A: Basic Maintenance Page 49

Section 4: Parts list

Parts List Page 50

04/12 5 50538 Rev. 7

Page 6

Table of Contents, Continued

Appendix I: Recommended Tools & Equipment Page 54

Appendix II: Required at Jobsite Page 55

Appendix III: Materials Page 55

Appendix IV: Torque Values Chart Page 56

Appendix V: Tolerances Page 56

Appendix VI: Load Cell Specifications Page 56

Appendix VII: Concrete & Sump Testing Page 57

Appendix VIII: About the AAR, AREMA, & AREA Page 58

Appendix X: Special Product Applications --

Short Load Cell Assembly Page 59

04/12 6 50538 Rev. 7

Page 7

Index of Illustrations:

50538-1 Deck with recessed rail Page 9

50538-2 Anti-Creep Device Page 10

50538-3 Rail Miter Cut Gaps Page 10

50538-4 Ground Rod Locations Page 14, 47

50538-5 Load Cell Flexure Assembly Page 16

50538-3A Foundation Inspection Check list Page 21

50538-6 Base Plate Installation Page 22

50538-7 Weighbridge Steel: Assembled Section Page 23

50538-7A Weighbridge Steel: Component Identification Page 23

50538-7B Weighbridge Hardware Page 24

50538-8 Weighbridge Steel Layout Page 25

50538-9 Weighbridge Steel Assembling Page 25

50538-10 Installing Weighbridge Checkbracket Page 25

50538-11 Installing Stiffener Plate & Top Bearing Plate Assy Page 26

50538-12 Centering Weighbridge Sections Page 27

50538-13 Centering Main Beams Page 28

50538-14A Load Cell Flexure Assembly; Exploded View Page 29

50538-15 Load Cell Flexure Assembly Orientation Page 30

50538-16 Load Cell Flexure Assembly; Centering Page 30

50538-17 Leveling End Section Page 32

50538-18 Leveling Middle Sections Page 32

50538-19A Load Cell Flexure Assembly; Leveling Page 33

50538-20 Load Cell Locations Page 34

50538-21 Base Plate Forming & Grouting Page 37

50538-22 Base Plate Forming & Grouting Page 38

50538-23 Base Plate Forming & Grouting: Sloping Grout Page 38

50538-24 Weighbridge Check Stands Page 39

50538-25A Check Rod Washer Sets Page 39

50538-26 Pier Check Stands Page 40

50538-27 Check Stands: Leveling Page 40

50538-28 Check Rods: Adjusting Page 41

50538-29 Deck with recessed rail Pocket Page 42

50538-30 Deck Forming: Hex Nut Spacers Page 42

50538-31 Deck Forming: Placing and Welding Deck Coping Page 43

50538-32 Deck Forming: Placing and Welding Deck Coping Page 43

50538-33 Deck Forming: 12 Corner Junctures Page 44

50538-34 Deck Forming: Deck Coping at Rails Page 44

50538-35 Deck Forming: Installing Corrugation Page 44

50538-36 Deck Forming: Installing Corrugation Page 45

50538-37 Deck Forming: Installing Rebar Page 45

50538-38 Deck Forming: Installing Bituminous Mastic Page 46

50538-39 Deck Forming: Steel Plates at End of Rail Pockets Page 46

50538-40 Junction Boxes Page 47

50538-41 Grounding Page 47

50538-42 Parts List Page 50

50538-14 Previous Load Cell Revision -- Before 1992 Page 59

04/12 7 50538 Rev. 7

Page 8

Page 9

04/12 9 50538 Rev. 7

A.A.R. Combination Railroad Track / MTS Scale

NOTE: This manual is intended to compliment and be used in conjunction with the Certified

Prints provided by FAIRBANKS SCALES. Installation should be attempted only with the presence and guidance of experienced personnel who are fully familiar with the assembly of these

scales. Please read this Bulletin in its entirety BEFORE setting scale hardware.

SECTION 1-A: Introduction & General Description:

The Fairbanks Model A.A.R.* Combination Railroad Track / Motor Truck Scale is fully electronic in design, and utilizes eight 200,000 lb capacity compression loadcells that are constructed of Stainless Steel and hermetically sealed for protection against moisture. The four

(4) section Scale is pit installed, and is offered in five (5) different standard Models that provide a sectional capacity of 180 Tons, and a total capacity of 360 Tons.

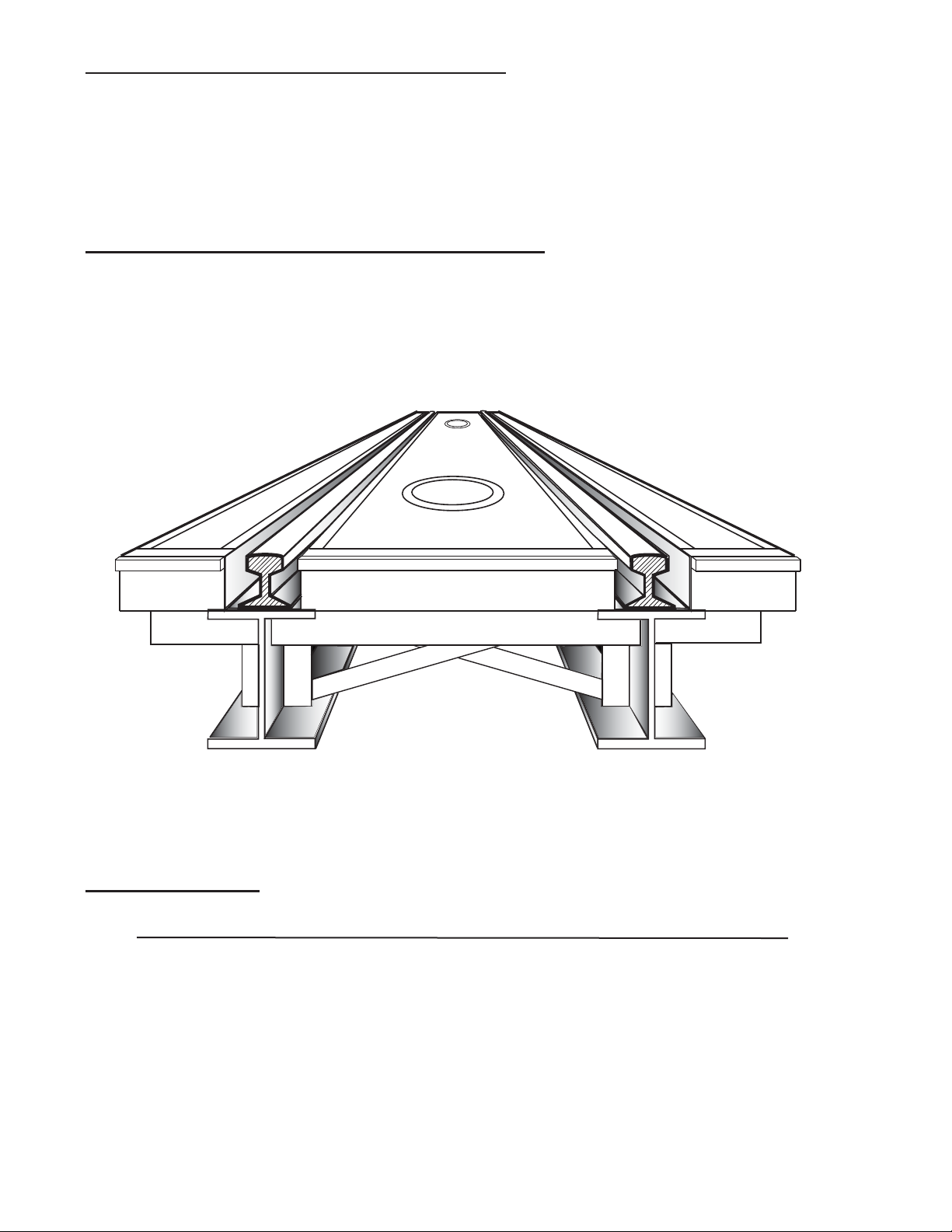

50538-1

The full platform of the scale is arranged to accommodate a railroad car or a motor truck for

weighing. The track rails are installed in a recessed rail pocket below grade, thus presenting

no obstruction to rubber tires. Interface to a Fairbanks 2500 Series Indicator with INTALOGIX technology is standard.

1-B: Specifications:

Product # Description Shipping Weight

145960 (90840**) Model 1492: 60' X 10' Platform 36,500 lb.

145966 (90841**) Model 1493 66' X 10' Platform 41,700 lb.

145970 (90842**) Model 1494 70' X 10' Platform 48,700 lb.

145972 (90843**) Model 1495 72' X 10' Platform 49,900 lb.

145980 (99179**) Model 1496 80’ X 10’ Platform 60,900 lb.

* The Association of American Railroads (AAR)

** These Item Numbers are now obsolete, replaced by the Item Numbers to the left.

Page 10

04/12 10 50538 Rev. 7

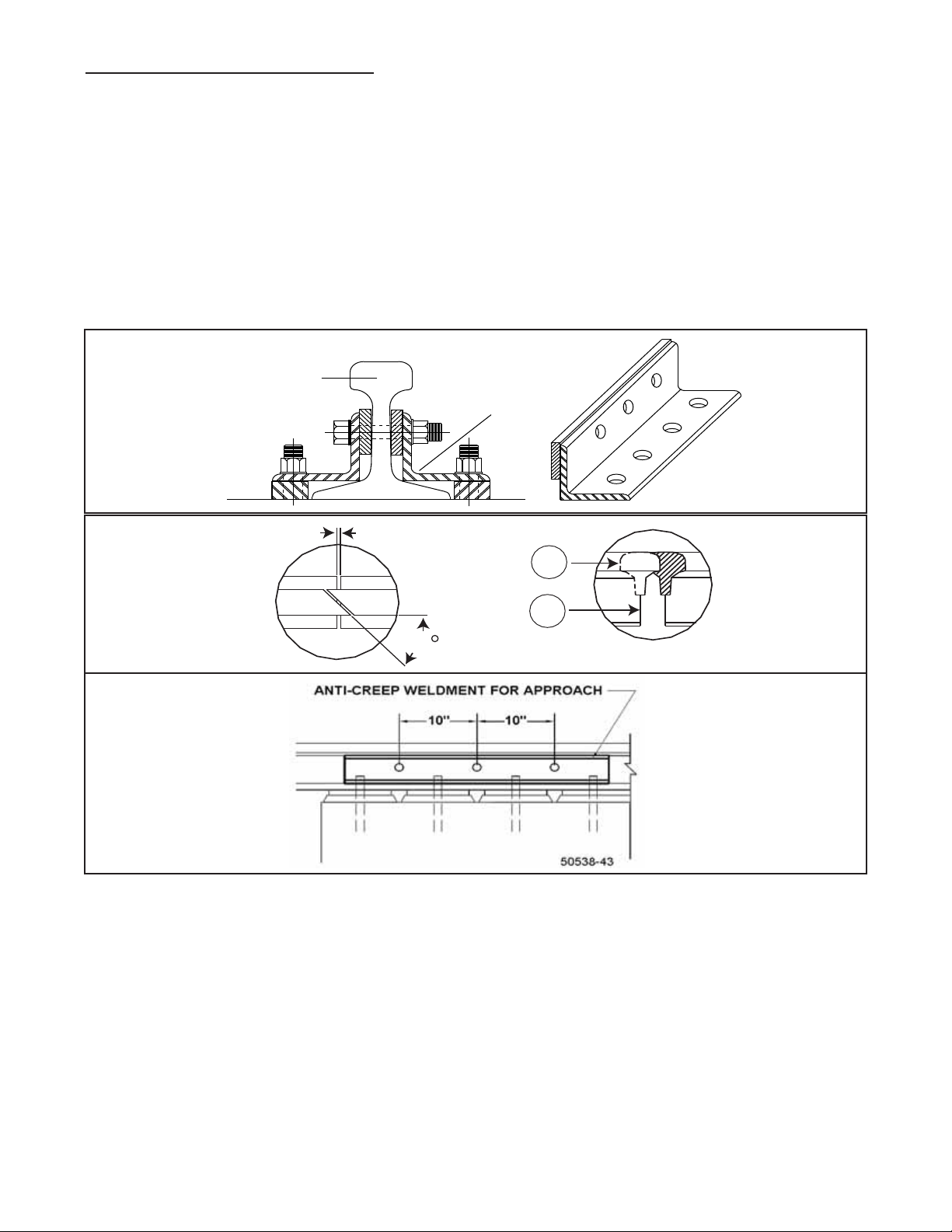

1-C: Rails & Anti-Creep Devices

The Scale is designed to accept a 115 lb. rail with Foster #62 rail clip. The approach rails

and Scale Weigh Rail should be the same weight. The approach anchor bolts, approach rail

plates, rail clips, and anti - creep devices are all optional items. They can be supplied by

Fairbanks Scales when ordered as accessories, otherwise they are not supplied.

Positive means must be provided by others to prevent the creeping of the approach rails and

to maintain a clearance which shall be not less than 1/8 inches or more than 5/8 inches

between the approach rails and the weigh rails. Switch points are highly recommended for

this purpose. A minimum of seventy five (75) feet of tangent track at each approach is

required by the A.A.R.

50538-2

Rail

Weldment

Anti-creep devices are constructed of angle iron with a flat iron weldment to fit to the rail as

shown above, The rail is side drilled through its web and bolted to the anti - creep device,

effectively securing it from any movement.

The AAR Scale Specifications state that the rail on the approach and the weighbridge shall be

properly anchored to prevent creeping of the rails. This is done in order to maintain the proper gap between the approach rail and the weighrail.

Rails should be miter cut at the ends of the weighrails and approach rails to assure a smooth

transfer of wheels in order to reduce impact loading to the scale.

NOTE: It is strongly recommended that any anti-creep device(s) be installed by qualified rail-

road maintenance and repair service personnel.

45

3/8 inch gap

1

2

50538-3

Page 11

04/12 11 50538 Rev. 7

1-D: Regulations:

This Scale is designed and manufactured in accordance with regulations established by

Handbook 44 as adopted by the National Conference of Weights and Measures (NCWM), the

Association of American Railroads (AAR), and the National Institute of Standards and

Technology (NIST). If the Scale is intended to provide weights to the serving railroad for the

purpose of revenue, it shall be installed, repaired, tested, and maintained in accordance with

the Association of American Railroads Scale Handbook, which contains the rules and specifications for the construction and maintenance of track scales for the weighing of railroad vehicles.

Excerpts from the Association of American Railroads Scale Handbook

Location: Scale shall be so located that an adequate foundation and at least 75 feet of

tangent track at each approach to the weighrails can be provided.

Elevation:

In areas with poor drainage, the scale shall be raised to such an elevation that

drainage of the surface water shall be away from it. Means shall be provided to prevent

accumulation of water at the scale site. Solutions for saturated areas with poor drainage shall

be determined by a competent soils engineer.

Drainage:

The pit floor shall be pitched to a common point for drainage and shall be

smooth and free from pockets in which water may stand. If the pit floor is below substrate

water lever, the pit shall be drained from its lowest point into a sump adequately equipped

with automatic means for removal of water as it collects.

Footing or Piers for loadcells:

Concrete footings or piers supporting load cell base plates

shall not be less than 18 inches thick. Their tops shall be above the floor a sufficient distance

to prevent the accumulation of water around or under the base plates.

Pit floor: The floor of the pit may be a mat of concrete approximately as thick as that

required to support the load cell base plates or, if local conditions permit, the thickness may

be reduced to no less than 6 inches.

Ventilation:

All scale pits shall be ventilated to meet the needs of each particular case to

minimize the relative humidity in the pit and to retard corrosion of scale parts and structural

steel.

Entrance to the Scale Pit:

Suitable access to the Scale pit shall be provided. The entrance

shall be closed by a suitable closure fastened to prevent the entry of unauthorized persons.

AAR Scale Handbook

Safety Piers:

Suitable piers, columns, or other supports should be provided to prevent

excessive drop of the girders if there should be a failure of other Scale parts. Clearance

should be maintained at full scale capacity.

Page 12

04/12 12 50538 Rev. 7

Bearing Pressures Under Foundations: The bearing areas of the foundation footings

shall be such that the pressure under the footings will not exceed:

For fine sand and clay .................................. 4,000 lb. per square foot

For coarse sand or hard clay ....................... 6,000 LB per square foot

For boulders or solid rock ........................... 20,000 LB per square foot

If the soil does not have a bearing capacity of at least 4,000 pounds per square foot, and its

bearing capacity cannot be increased by drainage, stabilization, or other means, pile foundations shall be provided. Careful soil exploration, including borings, is always desirable.

Leveling:

Load cell assemblies shall be raised or lowered, as required, by means of leveling screws, shims, or other methods to bring the weighbridge into level traversely and on

grade longitudinally. After leveling the load cell baseplates, to a tolerance of not more than

1/64” per foot, they shall be grouted as required.

Scale House Design:

Except where the indicating elements are mounted in a separate

building, a Scale house large enough to install, observe and service the indicating elements

shall be provided. It should have windows of sufficient size and so located as to give the

weigher an unobstructed view of the Scale deck and approaching cars or trucks.

Where a special scale house is required, a suitable and substantial building shall be provided. To insure proper operation of the indicator and/or recorder, the house shall be equipped

with proper environmental control.

Scale House Location:

The lateral clearance between the Scale house and centerline of

Scale or any track shall not be less than 8 feet, unless otherwise required by law, or the serving railroad.

Indicator - Recorder Shelf: If a shelf is required for mounting the indicator and/or recorder, it

shall be so located as to provide for ease of operation without obscuring the weigher's view

of the Scale deck and approaching cars or trucks. The shelf must not limit ready access to

the instrument for maintenance purposes.

Power Source

The power source of the electronic instrumentation and load cell circuitry

shall conform to the following:

Voltage - 115 v AC +/- 10 v

Frequency - 60 Hz, +/- 0.25 Hz

The power source must be reasonably free from harmonics and electrical transients.

Fusing shall be provided at 15 amp unless otherwise specified by the manufacturer.

The power source shall be a separate circuit back to the distribution transformer.

One side of the 115 v power source shall be at a ground potential.

Power surge protection shall be provided for load cells and instrumentation circuit.

Adequate protection of shielding should be provided to eliminate radio frequency and electromagnetic interference. The scale must satisfy the tolerance requirements when the scale

equipment is subjected to RFI and EMI influences.

Page 13

04/12 13 50538 Rev. 7

Cabling:

All cabling between loadcells, junction boxes, and electronic instrumentation shall conform to

the following:

All cable shields shall be interconnected and carried to a single ground. This should be a separate ground from the power source ground and be provided for the loadcells and instrumentation circuits only. It should be a copper rod which, when possible, is driven to the depth of

the water table.

The connection between the ground rod and the common ground point of the load cell and

instrumentation circuits shall be made with copper wire, or the equivelant, of No. 10 gauge or

larger.

All cable shields in the load cell circuits shall be grounded at one end only.

Homerun cables shall be physically separate from power cables and never run in the same

conduit system.

(NOTE: A 24 inch to 36 inch separation is required by Fairbanks Scales)

All cable connections, junction boxes, etc., in the load cell circuits shall be properly protected

against the effects of moisture.

All multi - conductor cabling shall be color - coded, or provided with other means of identification of the individual conductors.

1-E: Foundation Construction & Installation

Use only certified prints that are marked for the particular installation, customer, and scale.

All the dimensions indicated on the certified prints must be rigidly and faithfully followed during all phases of construction. There is very little tolerance for misplacements and mistakes.

Pier heights are especially critical as there must be enough space for finishing grout under all

stands (per certified drawings) while rails on the scale weighbridge and approach rail must be

absolutely level.

Placement of foundation bolts is absolutely critical to the successful installation of the scale.

The use of a template or form that matches the design called for can be used. Foundation

bolts must NOT be installed at an angle, too deep, or too shallow. Very close tolerances must

be met on all aspects of pit construction.

Page 14

04/12 14 50538 Rev. 7

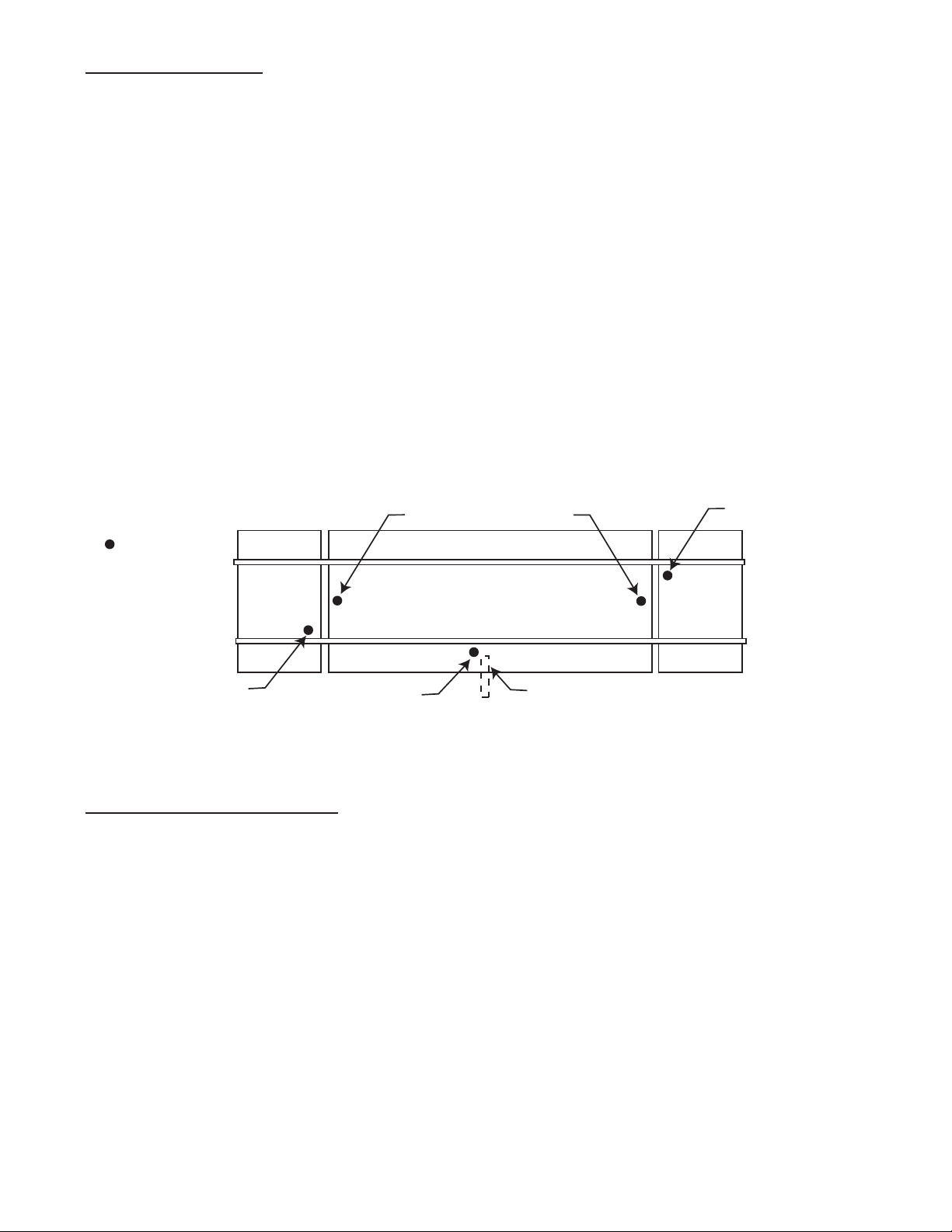

1-F: Ground Rods:

Ground rods are essential in providing protection to the electronic components and loadcells

from both lightning surges and static discharges. Pit ground rods shall be tied to the foundations steel reinforcement rod (rebar) prior to pouring, and shall protrude 4 inches above the

pit floor.

Ground rods for approach rails shall be installed in the approach rail cut-outs and tied to the

rebar assembly. Fairbanks provides the three ground rods located in the pit as part of the

standard foundation kit. The two ground rods in the approach must be provided by others.

There are five (5) rods with the locations specified as below:

One (1) ground rod at each end, in the approach rail-cuts, for approach rail grounding. *

One (1) ground rod at each end, in the pit, for steel weighbridge grounding. *

One (1) ground rod at the pit load cell conduit location for the pit power supply. *

The following drawing shows correct placement of ground rods.

1-G: Load cell Base Plates:

The Load cell base plates are the foundation upon which the scale structure rests, and their

level, accurate position is basic to the entire structure. Base plates must be installed at proper

height and in the same plane. All base plates must be level within 1/64” per foot. All pier bolts

must have enough height to allow vertical adjustment of the base plate's, but not so high as

to interfere or to have insufficient depth into the pier.

* Fairbanks provides the three (3) ground rods located in the pit as part of the standard

foundation kit. The two (2) ground rods in the approach must be provided by others.

Top View of Scale

#2

#4

#5

#3

#1

= Ground Rod

In Pit Floor

In Pit FloorIn Pit Floor

Conduit

In approach rail cutout

Supplied by others

In approach rail cutout

Supplied by others

#4 & #5 Ground Rods Not supplied or Installed by FAIRBANKS

50538-4

Page 15

04/12 15 50538 Rev. 7

1-H: Check Stands:

Check rods allow for vertical movement in order to transfer weight force to the load cells but

they do not allow for lateral or side movement. Checking stands must be level and on the

same plane. All check rods must be level within 1/100” per foot when weighbridge is at correct elevation. Grouting the check stands MUST NOT take place until the load cell base

plates are adjusted to their final height.

1-I: Weighbridge:

The weighbridge supports the loads applied to it, and transfers that weight to the load cells.

Properly installed, this transfer allows the load to be shared by all cells and keeps loading in a

vertical direction. For both safety and expediency, it is recommended to assemble the weighbridge steel in sections outside of the pit, then setting the assembled sections into the pit one

at a time with a suitable capacity crane.

The weighbridge must be square and the main girders must be vertically plumb so that the

bottoms of the main girders are level. Do NOT weld the "X" bracing at the ends of the weighbridge or use impact wrench on steel structure bolts until girders are in place and are plumb.

Main beams must be joined at sections so that the top flanges are level to accommodate the

track rails with full contact support without shimming. Due to steel manufacturing tolerances,

the height of the main beams may be slightly unequal making the bottom flanges uneven. If

shims are required, place between the stiffener plate and the main girder. Full contact shimming is required for stiffener plates. Shims are not supplied with the scale hardware. The

resulting upper stiffener plate and top bearing plate must be level within 1/64” per foot.

1-J: Deck Construction:

The construction of the deck will cover the areas alongside and in-between the main beams

and Rails, and will provide a custom fitted concrete deck for motor truck and vehicle weighing.

All concrete workmanship shall be performed in accordance with the best practice as

described by the American Concrete Institute. The recommended slump is four to six inches

(4" to 6").

Allow concrete to cure thoroughly. Do not use, or subject the deck to any traffic until the concrete has attained its ultimate compressive strength of 3000 psi after 28 days.

The steel supplied for the deck construction is precut at the factory to fit an exact dimension

pit, as indicated on the prints.

Page 16

04/12 16 50538 Rev. 7

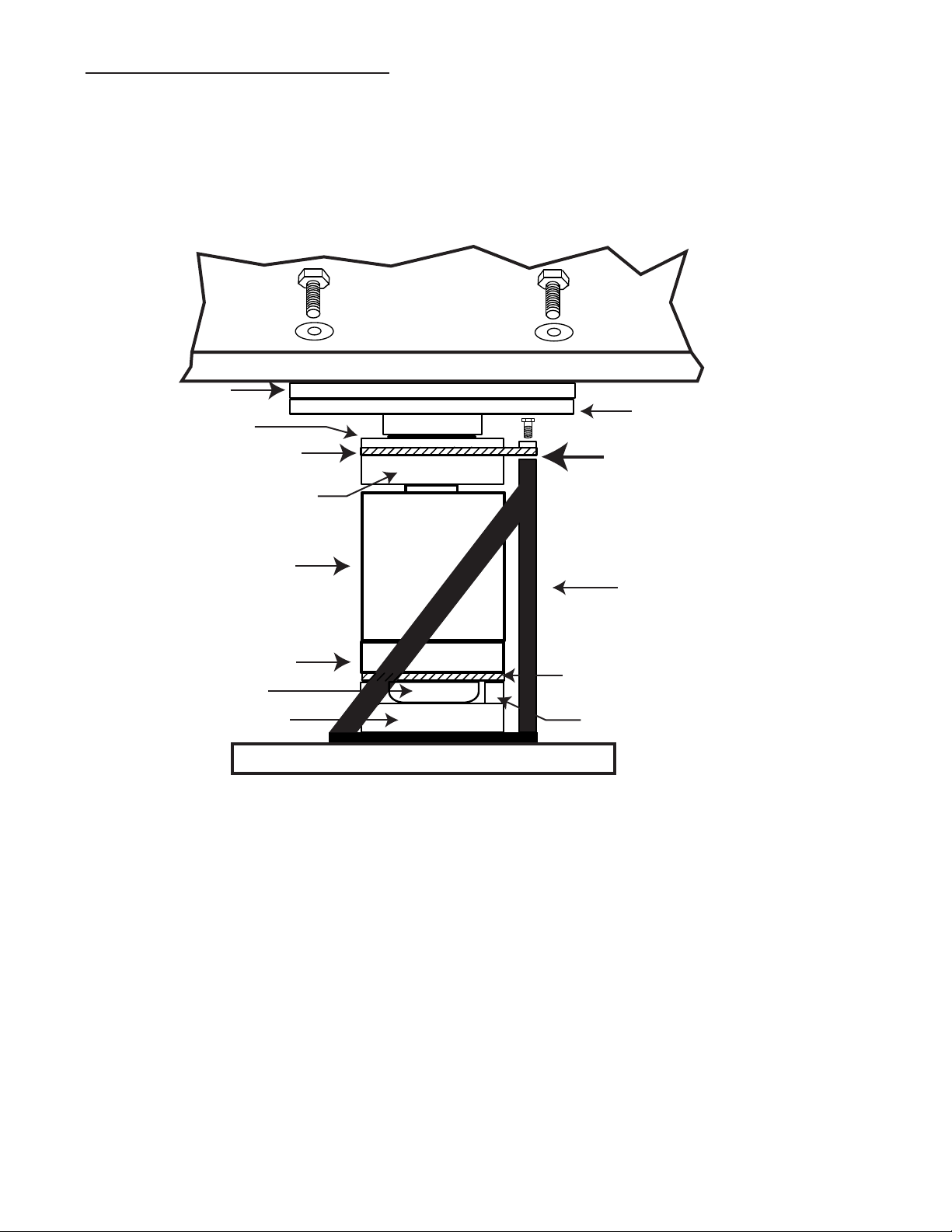

1-K: Load Cell Flexure Assembly:

The Load cell flexure assemblies maintain the load cells in a vertical position. In application,

the design uses a 200,000 lb capacity compression load cell mounted in a support assembly.

The support assembly contains an upper flexure assembly protected by a wear plate, and

weight(s) applied to the scale are transferred to them from the top bearing plate assembly.

Support Assembly

Shims (as required)

Main Girder

Stiffener Plate

Top Bearing Plate Assy

Wear Plate

Lower Bearing Plate

Spacer (4)

Lower Button

Lower Flexure

Load Cell Spacer

Load Cell

Upper Button Bearing Assy

Upper Flexure Assy

Base Plate

50538-5

The flexure assembly isolates any lateral movement of the main girder from the top of the

load cell. This arrangement allows the cell to remain vertical under all loading conditions, and

to minimize the side-load effects of thermal expansion and contraction of the weighbridge.

Page 17

04/12 17 50538 Rev. 7

Section 2: Installation:

2-A: General Service Policy

Prior to installation, it must be verified that the equipment will satisfy the customer's requirements as supplied, and as described in this manual. If the equipment cannot satisfy the application and the application cannot be modified to meet the design parameters of the equipment, the installation should not be attempted.

Overview:

1. These instructions apply to the Scale Platform only; installation procedures for instrumenta-

tion, printers and other peripherals are given in manuals specifically provided for those units.

The instructions include a pre-installation checkout, which must be performed before the

installation.

2. All electronic and mechanical calibrations and or adjustments required to make this equipment perform to accuracy and operational specifications are considered to be part of the

installation, and are included in the installation charge. Only those charges which are incurred

as a result of the equipment's inability to be adjusted or calibrated to performance specifications may be charged to warranty.

3. Absolutely no physical or electrical modifications are to be made to this equipment.

Electrical connections other than those specified may not be performed, and no physical

alterations (mounting holes, etc.) are allowed.

4. The installing technician is responsible to make certain that personnel are fully trained and

familiar with the capabilities and limitations of the equipment before the installation is considered complete.

2-B: Pre-Installation Checklist:

The following points should be checked and discussed with the Area Sales Manager and/or

customer, if necessary, before the technician goes to the site to install the equipment.

1. Has the customer's application been checked to make certain that it is within the capabilities and design parameters of the equipment?

2. If the installation will disrupt the customer's normal operations, is he aware and has he

made arrangements?

3. Is properly-grounded power available at the installation location?

4. Will the equipment operator(s) be available for training?

Page 18

04/12 18 50538 Rev. 7

5. Has the service technician thoroughly reviewed the installation procedures?

6. Has the service technician reviewed the recommended setup with the Area Sales Manager

or Area Service Manager, and identified all necessary variations to satisfy the customer's particular application?

2-C: Unpacking:

1. Check that all components and accessories are on hand, and agree with the customer's

order.

2. Remove all components from their packing material, checking to make certain that all parts

are accounted for and no parts are damaged. Advise the shipper immediately, if damage has

occurred. Order any parts necessary to replace those which have been damaged. Keep the

shipping container and packing material for future use. Check the packing list.

3. Collect all necessary installation manuals and prints, including Certified Prints, for the

Scale being installed.

2-D: Safety:

As is the case with any material handling equipment, certain safety precautions should be

observed during operation:

1. Never load the platform beyond its rated capacity. Refer to the rating on the serial number

plate if in doubt.

2. Ensure that any structure which supports the platform is capable of withstanding the weight

of the platform plus its rated capacity load.

3. Do not load the platform if there is any evidence of damage to the platform or supporting

structure.

4. Use safety chains or other suitable restraining devices if there is any possibility of the load

shifting, falling, or rolling from its position on the load receiver.

5. Do not leave the platform unattended when it is loaded.

Page 19

04/12 19 50538 Rev. 7

2-E: Recommended Installation Sequence:

After pit is completed, follow this sequence:

Measure pit squareness, depth, width, and length against certified prints

Measure cast-in anchors, pier elevation on all piers against certified prints

Dimensions MUST be correct before installing scale hardware

Using packing list, be sure all scale elements/parts have arrived intact and Undamaged

Then install:

Base Plate Assemblies

Check Stands

Wood blocking and cribbing

Weighbridge Steel

Weighbridge Sections

Load Cell Flexure Assembly

Adjusting Elevation

Leveling Load Cell Flexure Assemblies

Grouting Load Cell Baseplates

Checkrods

Grouting Check Stands

Check Rod Adjustment

Deck coping, manholes, deck forming, deck rebar

Grounding

Rail and anti-creep devices

Form and pour concrete deck

When deck is cured, install:

Complete wiring of load cells

Instrumentation and any peripheral equipment

Calibration and testing

Page 20

04/12 20 50538 Rev. 7

2-F: Foundation Inspection

Excerpts from Fairbanks Scales form FF-2267; Foundation Field Check list

A Foundation Inspection should ALWAYS be performed prior to Scale installation, to confirm

the Foundation is constructed correctly and is ready for installation. If possible, this should

be done prior to the scale shipment.

TOOLS REQUIRED:

Certified drawings and site plan. 2' to 4' level

25' & 100' steel tape measures Hammer and concrete nails

Hacksaw laser or builders level if possible

String line (construction string) straight edge for pit foundations

Construction Spray Paint (upside down type, for marking concrete)

Perform the following Foundation checks. It is recommended to keep a copy of the check list

with the job file. ALWAYS familiarize yourself with the CERTIFIED FOUNDATION PRINTS for

the job you are working on as model numbers and their specifications are subject to change.

1: Site Plan and Certified Prints should be thoroughly reviewed to confirm accurate locations

to the scale and all extra items ( scoreboards, lights, poles, etc.) that are included.

2: Check for truck and crane access, overhead wires, fences, green concrete, etc. .

3: Dimensional length and width check; check all 4 sides and record on chart.

4: Diagonal measurements check to verify that the Foundation is square and record on chart.

These measurements should be equal, or within ½ inch. Greater error could result in the

scale not fitting in the Foundation.

5: Check ALL pier heights to make sure they are at the correct elevation and record on chart.

6: Check the pit walls to verify they are straight.

7: Verify Ground Rod locations.

8: Verify conduit locations and pull strings.

9: Verify that drains and sump openings are piped correctly are clear of debris.

10: Check the end coping to ensure they are centerline and that the coping is correct for the

scale being installed (10', 11', 12', width, etc.). Check all coping, side and end, for hollow

areas.

11: Verify location(s) of any and all required embeds

Record all measurements and observations. Physically mark any discrepancies with the

marking paint. Do not proceed with Installation until corrections have been made.

Page 21

04/12 21 50538 Rev. 7

2-G: Foundation Inspection Check list

Length & Width Check

Diagonal Measurements

Check

A

B

Pier Height Check

Pier

Pier

Side View

Strings

1

2

3

4

5

6

7

8

9

10

1:

2:

3:

4:

Measurement A to A=________

Measurement B to B=________B

A

B

A

B

A

A = Coping length

B = 1/2 of the coping length, or Centerline

C = Distance from Centerline to load cell Center lines

C

L

Loadcell Center Line

Loadcell Center Line

C

C

C

C

C

L

= Concrete Nails

= Centerline of Scale

50538-3A

Page 22

04/12 22 50538 Rev. 7

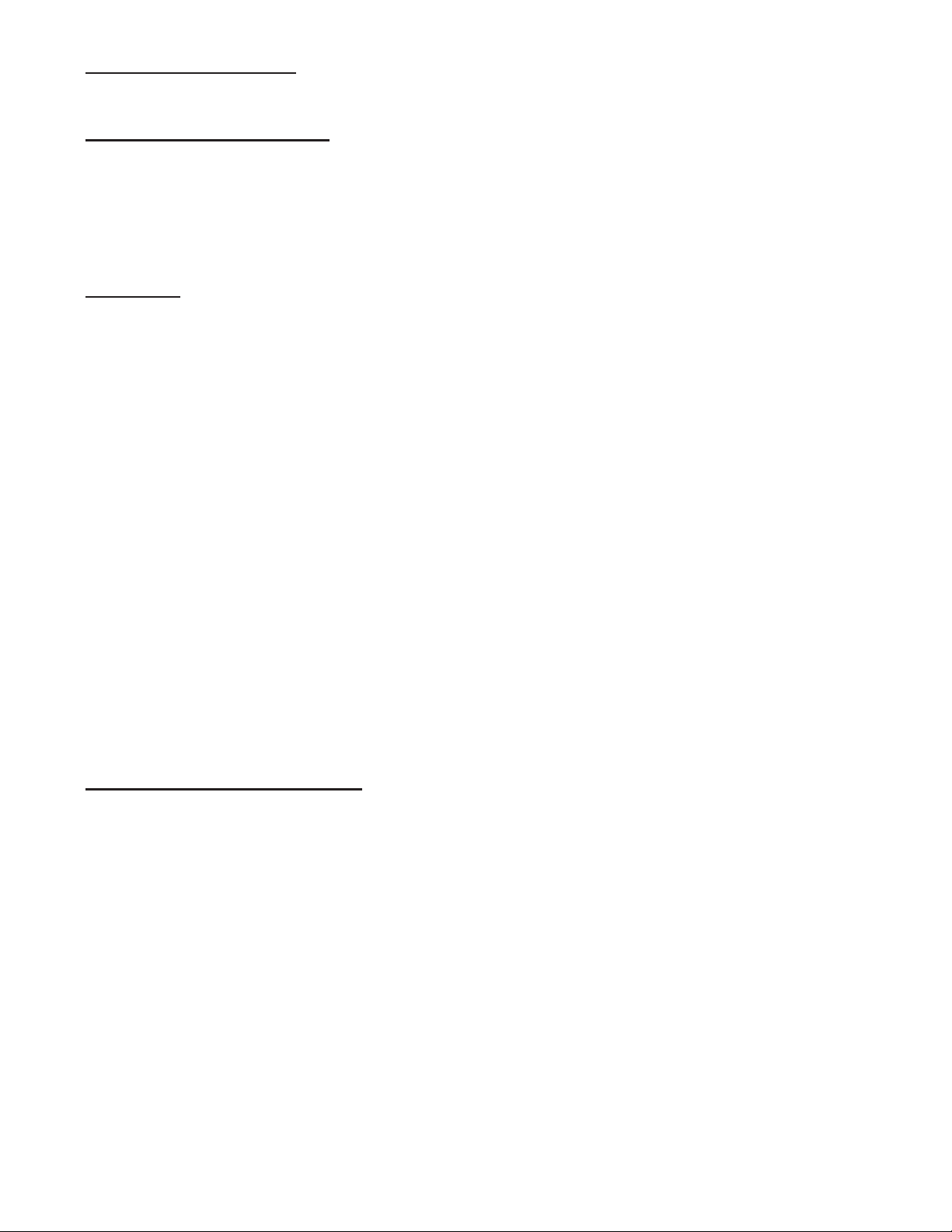

2-H: Base plate assemblies:

Caution: Base plates weigh approximately 245 lb.each. Work Safely.

1: Clean the top of the piers thoroughly, and ensure they are free of any oil or grease

deposits. Clean the threads of all base plate pier bolts with a wire brush, using a thread file

to restore any damaged threads. Lightly grease the threads, and ensure the threads are

clean and in good condition by running a threaded nut down and up the full threads of the

bolt. Remove all nuts from the pier bolts.

2: Place several short lengths of wooden 2 X 4's or 4 X 4's in the center of the pier bolts,

and place the base plate onto the wooden blocking on the pier, guiding the 4 pier bolts into

the 4 corner holes of the baseplate.

Base Plate

Pier bolts

Leveling

Screws

1/4" Flat steel

Concrete Pier

50538-6

3: Insert greased leveling screws into the provided tapped holes in the base plates, and

place a cut piece of 1/4" Flat Steel under each leveling screw. Adjust each screw to raise the

base plate off of the blocking and to approximately level the base plate. Remove the blocking

from underneath the base plate. Place flat washers and nuts on the pier bolts loosely.

2-I: Check Stands:

1: Clean the top of the piers thoroughly, and ensure they are free of any oil or grease

deposits. Clean the threads of all check stand pier bolts with a wire brush, using a thread

file to restore any damaged threads. Lightly grease the threads, and ensure the threads are

clean and in good condition by running a threaded nut down and up the full threads of the

bolt. Remove all nuts from the pier bolts.

2: Place several short lengths of wooden 2 X 4's in the center of the pier bolts, and place the

check stand onto the wooden blocking on the pier, guiding the pier bolts into the holes of the

check stand.

3: Insert greased leveling screws into the provided tapped holes in the check stands, and

place a cut piece of 1/4" Flat Steel under each leveling screw. Adjust each 5/8-11 X 4" screw

to raise the base plate off of the blocking and to approximately level the check stand.

Remove the blocking from underneath the check stand. Place flat washers and nuts on the

pier bolts loosely.

Page 23

04/12 23 50538 Rev. 7

2-J: Weighbridge Steel:

Caution: Individual Steel beams can weigh as much as 5,500 lb. each. Work Safely.

Assembling in Sections:

It is recommended to assemble the weighbridge in 3 sections near the pit, with each section

located near its intended installation location. The means to safely move and position the

various steel beams will be required to facilitate the assembling of the weighbridge.

50538-7

Main Beam

Crossmember

Outrigger

Diagonal Cross Bracing

A suitable capacity hydraulic crane, and personnel familiar with safe and effective rigging

methods using flexible non-metalic rigging of suitable capacity is recommended to handle and

position the beams.

The Diagonal Cross Bracing is not installed until the Weighbridge is in the pit, and has been

made plumb, is squared up and has been leveled.

Loadcell Top

Bearing Plate

Weighbridge

Check Bracket

Stiffener

Connecting

Web Splice

Plates

Plates

Upper

Crossmember

Lower

Crossmember

Plate

50538-7A

Page 24

04/12 24 50538 Rev. 7

2-K: Weighbridge Hardware

1

5

2

3

4

1

4

Loadcell Top

Bearing Plate

Weighbridge

Check Bracket

50538-7B

1: Part # 54532; 3/4-10 X 3" Hex Bolt. Qty 32 required to connect the load Cell Top Bearing

Plate Assy's to Main Beam bottom flange. Their final Torque value is 150 foot pounds.

Note: The Load Cell Top Bearing Plate Assy mounting holes are tapped 3/4-10.

2: Part # 54229; 3/4-10 X 3 1/2" Hex Bolt A325 with Nut. Qty 16 required to connect the

mid section connecting plates to the bottom of the Main Beams. These bolts are installed to

the connecting plates end, outside holes only. Their final Torque value is 250 foot pounds.

3: Part # 54199; 3/4-10 X 2 1/4" Hex Bolt with Nut. Qty 36 required to connect the lower

cross members to the Main Beams. Their final Torque value is 250 foot pounds.

4: Part # 54217; 3/4-10 X 3" Hex Bolt A325 with Nut. Total Qty 232 required. Their final

Torque value is 250 foot pounds.

Qty 168 required to connect Crossmembers and Outriggers to the Main Beams.

Qty 64 required to connect the Web Splice Plates to the Main Beams at the Mid Sections.

5: Part # 54402; 1" X 3 1/2" Hex Bolt A325 with Nut. Qty 32 required to connect the Check

Brackets to the bottom of the Main Beams. Their final Torque value is 640 foot pounds.

Not Pictured:

Part # Description Qty Used On:

54342 1 1/2-6 Hex Nut 64 Check Rods

58617 1 ½ Spherical Washer Set 32 Check Rods

55766 3/4" X 1 1/4" Bar, J Box 5 Junction Boxes

Page 25

04/12 25 50538 Rev. 7

2-L: Assembling Weighbridge Sections

1: Identify each main beam pair per the certified prints, and select the appropriate end sec-

tion beams as the first to begin assembling. Place one main beam onto blocking, ensuring it

is supported and stable. Place the second main beam onto blocking, in parallel with the first

main beam, and close enough together to enable the middle crossmembers to be placed into

position

Crossmembers

Outriggers

Orientation

50538-8

temporarily by laying them down onto the bottom flanges of the main beams and in-between

them. Note the correct orientation of these crossmembers as indicated by the certified prints.

Place the outriggers near their intended installation location, and the mounting hardware.

Main Beams

Crossmembers

Outriggers

Orientation

50538-9

2: Starting at one end of the section, install the first crossmember into position, along with

both outriggers, leaving the bolts loose. Install the next crossmember, with its outriggers, and

proceed in order to the other end of the section. A chain come-along (with suitable capacity)

at the opposite end of the main beams can be used to slowly draw the main I-beams together

as the crossmembers and outriggers are being installed. When all crossmembers and outriggers have been installed in this manner, tighten all bolts. Do not tighten to their final torque

value at this time.

3: Locate the Weighbridge Checking Bracket locations on the lower flanges of the main

beams, and per the Certified Prints. Raise that area higher and support it with blocking, the

bracket will require a minimum of fifteen (15) inches of clearance. Install and tighten the

weighbridge checking bracket.

50538-10

Page 26

04/12 26 50538 Rev. 7

4: Install the stiffener plate and the top bearing plate assemblies. The mounting bolts will

install into the Top Bearing Plates threaded holes. Do not tighten to their final torque value at

this time. Do not perform any welding to the end sections at this time.

Stiffener Plate

Top Bearing Plate Assy

Hex Bolts

Flat W ashers

Main beam

50538-11

5: In similar manner, assemble the center section (s), and the other end section.

Page 27

04/12 27 50538 Rev. 7

2-M: Installing Weighbridge Sections

Caution: Weighbridge Sections can weigh as much as 17,000 lb. each. Work Safely.

1: Place wooden blocking and cribbing material suitable for supporting and jacking the

weighbridge steel into position near each pier and base plate. Each section will require four

points of support, therefore arrange the placement of these supports accordingly. It is recommended to set blocking to support the weighbridge against the pit wall, and 1 to 2 inches

higher (than the certified prints indicate its final elevation should be) at this time. If Safety

Piers have been installed, they can be utilized in lieu of blocks provided they are thoroughly

and completely cured.

2: With a crane and rigging (4 leg drop) of suitable capacity, install an end section into the

pit, and onto the supports. Set up a mason line to check and ensure that the centers of the

main beams are centered on the rail cutouts in the concrete approaches for the entire section.

Plumb bob

Mason line

50538-12

3: Ensure the distance from the approach pit wall is correct to ensure equal clearance at

both ends.

Page 28

04/12 28 50538 Rev. 7

50538-13

ABOVE: Check weighbridge steel for squareness by suspending a plumb bob at the

juncture of the previously established "centering" line, and at the juncture of the middle web

of the main beams. Measure and observe the distance between the plumb bob line and the

web, it should be the same at the top and bottom.

4: When end section has been centered, install the middle section, and connect the sections

together as indicated on the certified drawings. The top flange of the joined main beams

must be level and on the same plane to fully support the track rail without shimming. When

this is completed, and all plates and bolts have been installed, tighten all bolts to their final

torque value.

5: Install the other end section in the same manner, checking to ensure that the centers of

the main beams are centered on the rail cutouts in the concrete approaches for the entire

scale.

Ensure the top flanges of the main beams are level, install all plates and bolts, and tighten all

bolts to their final torque value.

NOTE: Do not weld in the Cross Bracing until the bridge is leveled and the dead load is balanced. See Step 9 on page 35.

Page 29

04/12 29 50538 Rev. 7

2-N: Load Cell Flexure Assembly:

Page 30

04/12 30 50538 Rev. 7

End

Center

50538-15

Referring to the detail above, note that the "open" side of the assemblies at end sections face

the center of the scale; middle sections have assemblies installed with the "open" side facing

the end of the scale.

TIP: For Analog Instrumentation, measure the bridge resistance of each load cell, and pair

the closest matches for installation in each section.

Lower Assembly:

1: Ensure the base plate is clean and free from any dirt and debris. Place the support

assembly into position, correctly orienting it in the appropriate direction and approximately

centered on the base plate.

2: Apply grease and install the two 5/8-18 x 1¼” socket-set screws (headless) in the holes at

the bottom plate of the support assembly to serve as locating pins for the lower bearing plate.

3: Place the lower bearing plate in position with the two holes engaging the locating pins.

4: Place the lower button's threaded stud through the center hole of the bottom flexure. Apply

grease to the threads. Place the stainless steel spacer (4” diameter, 1/8” thick) over the stud

so that it rests on top of the flexure plate.

5: With the load cell supported on its side, place the lower button/flexure/spacer against the

base of the load cell with the center hole aligned. Then screw the lower button/flexure/spacer

into the cell until all threads are very snug. Turn the lower button with large pliers, being careful not to bend or damage the lower flexure in any way.

6: Position the four spacers at the corners of the lower bearing plate concentric with the

tapped ½" holes.

7: Carefully lift the load cell assembly upright, and place it into the support assembly with the

load cell wiring junction facing the open side of the support assembly.

8: Apply grease and install four ½"-13 x 1½" screws and lock washers through the lower flexure and pipe spacers, and turn them into the corner holes of the lower bearing plate.

Page 31

04/12 31 50538 Rev. 7

Upper Assembly:

1: Place the upper button bearing assembly to the underside of the upper flexure assembly.

With the wear plate correctly orientated as to its corner countersunk holes, apply grease and

install the four ¼-20 x ½” flat-head screws through the wear plate, flexure assembly, and into

the bearing assembly.

2: Position the flexure and bearing assembly on the top of the load cell with the three holes

at the edge of the flexure facing the three holes in the mounting block at the upper rear of the

support assembly.

3: Position the mounting block bar, and loosely install three ½-13 x 1-1/4” hex bolts and lock

washers to hold the flexure assembly and bar into position. Apply grease to the bolt threads.

2-O: Adjusting Elevation:

1: With all load cell support assemblies installed, assembled, and placed upon the load cell

base plates as described in the preceding pages, prepare to carefully lower the weighbridge

onto each load cell support assembly one at a time with a hydraulic jack of sufficient capacity.

Starting with an end section, lower the weighbridge onto the load cell support assemblies at

that section one at a time.

Support Assembly

Main Girder

Top Bearing Plate Assy

Base Plate

Wear Plate

C

Hex Bolts & Lock W ashers

50538-16A

Ensure that the top bearing plate centers on the wear plate at each flexure, moving the

entire assembled load cell support assembly on the base plate as required to accomplish this

centering. Ensure the hex bolts that connect the top flexure plate to the support assembly

stand are inserted but not completely tightened before lowering the weighbridge onto the load

cell support assembly. Continue until the weighbridge is completely supported by the loadcells.

DO NOT REMOVE THE SUPPORTING BLOCKING AND CRIBBING AT THIS TIME.

LEAVE THEM IN PLACE CLOSE TO THE MAIN BEAMS TO SERVE AS A SAFETY PIER.

Page 32

04/12 32 50538 Rev. 7

Main Beam

Level Approach

Main Beam

Pit coping

Deck coping

50538-17

2: For the end sections, the elevation reference is the end wall (approach) pit coping. Place

and clamp deck coping across the main beams at an end section facing the pit wall coping.

Adjust the load cell base plate leveling screws of both base plates in the end section to level

the approach as shown above. Ensure both base plates are also level to within 1/64” per

foot.

3: Proceed to the next section, which is a middle section. Ensure the hex bolts that connect

the top flexure plate to the support assembly stand are inserted but not completely tightened.

Ensure that the top bearing plate centers on the wear plate at each flexure, moving the entire

load cell support assembly on the base plate as required to accomplish this centering. Lower

the weighbridge onto the load cell support assemblies.

4: For the middle sections, the elevation reference is both the absolute level of the main

beams with respect to the end sections, and the equal loading of the loadcells that support

the middle of the scale. Adjust the load cell base plate leveling screws to level the main

beams. Alternately, a transit can be used to compare and maintain elevation, and a tightly

stretched mason line. Ensure both base plates are also level to within 1/64” per foot.

Main Beams

Maintain same elevation

LEVEL

LEVEL

50538-18

5: Repeat these steps for the remaining sections of the scale.

Page 33

04/12 33 50538 Rev. 7

2-P: Leveling Load Cell Flexure Assemblies:

ener Plate

Top Bearing Plate

Upper

Flexure

Base Plate

LEVEL

Main Beam

LEVEL

Upper

Flexure

Base Plate

Top Bearing Plate

LEVEL

LEVEL

Load

Cell

Load

Cell

A

B

50538-19A

1: Starting at one end section, lift the main beam slightly from one load cell at a time and

loosen the three screws that secure the flexure to the support assembly block, and note any

space between the flexure and the block. Use a precision level across the flexure and add or

remove shims between the flexure and the block to get best possible level on the flexure and

insure there are no spaces or gaps (see "A" above). Tighten the three screws to torque specifications.

2: Check that the top bearing plate assembly is level and at right angles to the main beam

web. If adjustment is necessary, install shims only between the main beam's lower flange

and the stiffener plate ( see "B" above). Shims must extend the full length of the bearing

surface.

3: Check that the load cell is vertical and that the top bearing plate is centered on the flexure

wear plate. Adjust if necessary. Ensure the base plates, load cell, upper flexure plate, and

top bearing plate assembly are level to within 1/64” per foot.

4: Continue for each load cell flexure assembly.

5: Providing a suitable power supply to connect to the loadcells, measure and record the

mV/V output from each load cell in the scale. The resulting readings will indicate the current

weight distribution of the scale's deadload among the eight (8) points of support. The outputs

will be greater for number's 3, 4, 5, and 6 because there is physically more deadload weight

upon them.

Page 34

04/12 34 50538 Rev. 7

Top View of Scale

Loadcell's

Conduit

1

2

3

4

5

6

7

8

50538-20

This final base plate elevation adjustment should be made to match the mV/V outputs of the

load cells to assure correct distribution of the scale's deadload among the eight (8) points of

support. Adjust the base plate leveling screws (equally) to match loadcells 3, 4, 5, and 6.

Then adjust to match loadcells 1, 2, 7, and 8. When this has been completed, ensure each

load cell base plate is level to within 1/64” per foot.

NOTE: The load cell numbering sequence shown is designed for interfacing Fairbanks INTALOGIX technology instrumentation.

6:

Perform a final check to all:

• Load cell base plates are level to within 1/64” per foot.

• All Cell assemblies are centered on base plates, & All Load cells are vertical and plumb

• Top bearing plate centers on the wear plate at each flexure

• Top bearing plate assembly and stiffener plates are level to 1/64” per foot and at right

angles to the main beam web(s).

• Upper flexures are level to 1/64” per foot with weight and without weight, and shimmed

properly

• Top flanges of the main beams are absolutely level and on the same plane as the end sections.

• There is correct distribution of the scale's deadload among the eight (8) points of support.

• All assembly hardware is secure

Page 35

04/12 35 50538 Rev. 7

7: Insulate and separate each load cell's wiring from adjoining wires and from the steel with

insulated electrical tape. Be certain load cell cables are isolated from contact with steel and

not attached to any junction boxes.

Be certain load cell cables are isolated from contact with steel and not attached to

junction boxes. Welding ground should be kept as close to the electrode (welding rod)

end as is practical.

DO NOT PERMIT ELECTRIC ARC CURRENT TO CONDUCT THROUGH A LOAD CELL(S)

8: Weld the support stands to the load cell base plates per certified drawings. Welding

ground must be on the same physical side of each load cell as the electrode (welding rod)

end.

9: Install and weld all section "X" bracing per the certified prints.

10: All structural steel shall have one shop prime coat. Areas around field welded connec-

tions shall be painted. Immediately following the connecting of the members, the heads, nuts,

and washers of all permanent bolts, all field welds after removal of residual flux, all abrasions

of the shop prime coat, and all field erection marks shall be thoroughly covered with one coat

of primer.

Page 36

04/12 36 50538 Rev. 7

2-Q: Grouting Load Cell Baseplates:

Grout becomes the base which supports the entire structure. Grout MUST be fully supporting

the stands and plates with NO gaps or spaces. A good method is to build the forms slightly

bigger than the stand to permit the pouring and the rising of the grout mixture.

The pier should be thoroughly saturated with clean water for a minimum of 4 hours. This will

both prevent the dry pier concrete from absorbing water from the mix as it is poured, and

greatly enhance the ability for the grout mix to bond with the pier.

1. Grout selection:

Grout shall be precision, packaged dry, non-metallic, hydraulic, non-shrink, and non-gaseous.

Grout shall meet or exceed ASTM C-1107 and Corps of Engineers CRD-C621.

Grout shall be bleed free and attain a minimum

of 8000 psi compressive strength in 28 days

at flowable consistency.

Grout MUST be mixed to a flowable consistency as specified by the grout manufacturer.

Do not permit any loads upon the scale until the grout has reached the compressive strength

of 8000 psi per the grout manufacturers instruction.

2. Surface preparation:

• Surfaces to be grouted shall be prepared in accordance with the manufacturers instructions.

• Surfaces to be grouted shall be free of loose debris, grease, oil and other contaminant’s.

• Contaminant’s shall be removed using caustic soda or other approved concrete cleaners.

• All surfaces shall be flushed with clean water.

• Prior to pouring, all surfaces should be saturated with clean water for a minimum of 4 hours.

Page 37

04/12 37 50538 Rev. 7

1.0" Min.

3"

Min.

Grout

3"

Min.

Concrete Pier

Forms

(Typ.)

Forms

(Typ.)

50538-21

3. Forming:

• Forming must be completed and installed before starting to pour grout.

• Forms shall be slightly larger (six to seven inches) than the dimension of the load cell base

plate or checking stand.

• Forms shall be of sufficient strength, anchored properly, and sealed. Seal with caulk and

use a form release agent on forms if required. Leave access for pouring grout in a convenient

place.

4. Mixing and Pouring:

• Mix grout per the manufacturers instructions until a very smooth, pourable mix is obtained.

Be sure you mix enough quantity for the form you are filling.

• If necessary, use a large funnel or cone to direct mix into form and under stands.

• Pour the grout mix from one end until it fully reaches the other side and rises to fill the form

completely. By using this method, there will be no gaps or air pockets. Vibrators are not

recommended due to the danger of disturbing the placement of the load cell base plate(s).

Ensure the grout mixture totally fills all voids.

Page 38

04/12 38 50538 Rev. 7

50538-22

TIP: Forms can sometimes be easily made and secured to the pier as shown above. Be

careful not to tighten the pier nuts too tightly on the wooden forms. DO NOT DISTURB THE

LOAD CELL BASE PLATE'S LEVEL, ELEVATION, OR LOCATION IN ANYWAY !!!

Base

Grout

Concrete Pier

Trim grout at an angle

for the entire loadcell

baseplate

50538-23

• The A.A.R. requires that if grout extends beyond the base plate, it must be sloped away

from the base plates and stands so that water will not pool and saturate the metal, thereby

rusting it. The form may be larger than the base or stand by about 3" on all sides.

*When grout is firm but can still be shaped, remove the forms and angle all four sides of the

grout and away from the base plate or stand.

• The grout should be cured according to the manufacturer’s recommendations on the package. For any unusual conditions, call the manufacturer for guidance.

• When the grout is fully cured, remove base plate leveling screws completely and discard,

then fill the empty holes with silicon caulking. Tighten all load cell base plate pier bolt nuts.

Page 39

04/12 39 50538 Rev. 7

2-R: Check Rods:

1: Check rods allow for vertical movement in order to transfer weight force to the load cells

but they do not allow for lateral or side movement. Prepare the check rods, special convex /

concave washer sets, and hardware for installation. Clean the threads with a wire brush,

using a thread file to restore any damaged threads. Lightly grease the threads, and ensure

the threads are clean and in good condition by running a threaded nut up and down the full

threads of the checkrods.

Weighbridge

Check Stand

Pier

Check Stand

50538-24

Ensure the check stands are parallel, and squarely face each other by measuring as shown

above.

50538-25A

1 1/2" Sperical W asher Set

Part # 58617

1 1/2-6 Hex Nut

Part # 54342

1 1/2-6 Hex Nut

Part # 54342

Install two nuts and one washer set to each end of the check rod. Lightly grease the special

washer set. Arrange and install the Special Convex - Concave washers as shown.

Page 40

04/12 40 50538 Rev. 7

5/8-11 Tapped Hole

for Leveling Screw

TOP VIEW

5/8-11 Tapped Hole

for Leveling Screw

TOP VIEW

1 3/8" Hole

1 5/8" Hole

1 3/8" Hole

1 5/8" Hole

50538-26

LEVEL

CHECKROD

50538-27

2: Install the check rod into position, and place the rest of the hardware onto both ends, leaving the hardware loose.

All check rods must be level within 1/100" per foot when weighbridge is at correct elevation.

Raise or lower the Pier Checking stand with its leveling screws until this is achieved.

Page 41

04/12 41 50538 Rev. 7

2-S: Check Rod Adjustment:

NOTE: See Section 2-Q for complete assembly descriptions of Grouting Check Stands,

Grout Selection, Surface Preparation, Forming, and Mixing and Pouring.

NO LATERAL

MOVEMENT

*NOTE

50538-28

All checkrod threads and Spherical washer sets shall be greased.

* NOTE: All checkrods shall be adjusted so there is no lateral movement at all, while the

checkrod can be rotated to ensure the scale is not being subjected to any side forces or influence from them. Lock the double nuts together tightly.

Page 42

04/12 42 50538 Rev. 7

2-T: Deck Forming:

1

2

3

4

50538-29

Above: 1: Deck Coping 2: Manhole access 3: Poured concrete 4: Rail pocket

Deck forming will prepare a custom fitted deck that provides correct clearance while conforming to the pit walls and rails. The construction of the deck provides several custom "pans" to

contain the reinforcement rods, manholes, and to support the poured redi-mix concrete until it

cures.

Weld

Deck

Coping

Rock

Guard

Hex

Nut

50538-30 Rev. 2

Weld

1: To maintain a 5/8" spacing between the scale deck and the pit wall, machine screw nuts

are welded to the outer face of the channel iron below the rock guard at each end, and at sixteen 16 inch intervals, more if required. Use 5/8 inch nuts, which measure 1.0 inch across

the flats.

Page 43

04/12 43 50538 Rev. 7

Main

Beam

2 X 4

Weld

LEVEL

Outrigger

Pit

Coping

50538-31 Rev. 2

Nut

2: The deck channel is then placed into position. A 2 X 4 can be used as shown to help

force and position the deck channel against the pit wall. Ensure the deck channel is level

with the pit coping, then weld the nut to the pit coping as shown.

LEVEL

Outrigger

LEVEL

Weld

Maintain

Clearence

Shim here with

plate steel if req.

\

3: Pit coping irregularities may cause gaps between the deck coping and outriggers. Shim

as needed with steel plate. Maintain proper spacing as shown, and weld the deck coping to

the outrigger, including any steel plate shims as applicable. Continue until all pit wall deck

coping has been installed.

Page 44

04/12 44 50538 Rev. 7

Weld

50538-34 Rev. 2

4: Layout the deck coping on the main beams beside each rail as shown. Position the deck

coping to provide rail clearances per the certified prints. Ensure they are straight. Clamp and

weld the deck coping as shown. Welds should be one (1) inch long, and at sixteen (16) inch

intervals more if required.

Top View of Scale

Rail Pocket

Rail Pocket

50538-33

5: At the twelve (12) corner junctures of the deck coping, and at all other points, ensure there

are no gaps or openings through which redi-mix concrete can leak. Cut and weld steel plate

to cover any gaps or openings as necessary.

Corrugated Sheet Metal Deck Forming

50538-35 Rev. 2

6: Corrugated steel sheets are used for deck forming, and can be purchased in a variety of

different configurations, thickness, and dimensions. It is recommended to use steel galvanized sheets, 22 to 24 gauge, and 9/16 inches high. Cut the corrugation to fit tightly at the

bottom flanges of the deck coping, and overlap the adjoining sheets by three (3) feet.

Ensure all corrugation is resting on the lower flanges of the deck coping. If required, fasten

the corrugation where needed to secure it into position.

Page 45

04/12 45 50538 Rev. 7

Weld additional support between crossmembers as needed

50538-36 Rev. 2

7: Additional supports are required (between the crossmembers and outriggers) to prevent

the corrugation from collapsing when the redi-mix concrete is poured and floated. This support can be provided by welding flat steel plate or reinforcement rod as shown.

8: Install the manholes exactly as noted in the certified prints. Ensure they are placed in

their correct positions on the corrugation, and are supported properly. Fill a large plastic bag

with loose dry dirt or sand and place it in each manhole ring (this will keep the redi-mix concrete out of the ring). Place the covers onto both manhole assemblies.

50538-37 Rev. 2

9: Install, block, and tie the rebar per the certified prints. Ensure the rebar is lifted from the

corrugation to provide the specified concrete cover, per the certified prints.

10: Pour, float, edge, and broom finish the concrete mix.

All concrete workmanship shall be performed in accordance with the best practice as

described by the American Concrete Institute.

Allow concrete to cure thoroughly. Do not use, or subject the deck to any traffic until the concrete has attained its ultimate compressive strength of 3000 psi after 28 days.

NOTE: The installation and finishing of poured concrete is best left to trained, experienced,

and well equipped personnel.

Page 46

04/12 46 50538 Rev. 7

Fill the Rail Pockets with Mastic or Cold Patch

50538-38 Rev. 2

11: After the concrete has cured and the rail is installed, fill the rail pockets continuously with

bituminous mastic or asphalt, except at the ends of the scale where clearance must be maintained between the approach and scale rail, and between the pit coping and scale deck coping.

50538-39

6 1/2"

1 1/4"

6.0"

4 1/2"

3/4"

6" X 1/4" Plate 6 1/2" Long

8 ea. Required

Shaping and welding steel plate to the end of the Rail pockets as shown above will provide a

dam for the mastic at the ends of the rail pockets.

12: After the deck has cured, remove all welded coping spacer nuts. Open manholes and

provide access by cutting the corrugation.

Page 47

04/12 47 50538 Rev. 7

2-U: Junction Box(s)

The A.A.R. Combination Railroad Track / MTS Scale is shipped for installation to a 2500

Series Instrument. As part of that installation, there may be five (5) junction boxes to be

installed in the pit. To provide mounting for these junction boxes, locate the following part that

is shipped with the scale.

Part #

QTY Description

55766 5 Bar, Junction Box; 3/4" X 1 1/4" (2 holes tapped 3/8-16).

The Junction Box bars can be welded to cross member at each load cell section. Place the

Junction Box bars in a servicable location.

1: Clean #1, #2, and #3 ground rod end(s) with abrasive to assure a good electrical connection. Keep all ground straps untwisted, clear of standing water, with a drip loop, and as short

as possible. Secure the strap to the ground rods with the provided clamp and coat with

grease. Cover the connections to protect from condensation.

2-V: Grounding:

Top View of Scale

#2

#4

#5

#3

#1

= Ground Rod

In Pit Floor

In Pit FloorIn Pit Floor

Conduit

In approach rail cutout

Supplied by others

In approach rail cutout

Supplied by others

50538-4 Rev. 2

50538-41

Ground Rod

= Clamp

= Terminal

Pit Power Supply

Isolated Ground

Junction

Box Plate

T

C

C C

T

T

T

T

C

Page 48

04/12 48 50538 Rev. 7

2: Connections to the weighbridge are installed by drilling a hole in the welded flange (stiffener). Scrape / sand enough paint / coating away to make a good electrical connection and

secure with the provided hardware.

3: Connect the strap to the weighbridge steel using the provided set screw terminals and

coat with grease AFTER the connection has been made.

4: Ground rod #3 should be located near the interface conduit. It is used to connect to the

isolated ground of the Pit Power Supply (PPS) Acc 2001-1 only.

5: The Junction Box Plate MUST be connected to the weighbridge with a ground braid, or a

conductor of not less than 10 AWG.

Page 49

04/12 49 50538 Rev. 7

Section 3: Service & Maintenance

3-A: Basic Maintenance:

Inspect the Scale and its understructure on a regular basis to ensure:

1: The approach rails and Scale rails remain securely in position and are properly aligned

and fastened in place.

2: The space between the deck edge, pit coping, and rails is clear and free of material which

could jam the deck and cause inaccurate weights.

3: The Scale Pit and understructure is clean and dry. Keep the pit and the understructure of

the Scale as clean and as dry as possible. Any moisture problems should be addressed

immediately to prevent steel deterioration. Structural steel should be wire brushed and painted as soon as rust appears.

4: All Load Cell Support Assy's are clean and free of debris. Top Bearing Plate Assy's are

centered on wear plate. Upper Flexure is clean and undamaged. All bolts are tight. Lower

Flexure is clean and undamaged. Inspect Lower Button Closely and carefully for any surface

cracks or other visible damage.

5: Drains for the pit are clear and unblocked. Any installed automatic sump pump and discharge piping shall be in good working condition.

6: The Check rods and spherical washer sets are in good condition, greased, and adjusted

properly.

7: All junction box wire gland nuts are securely tightened, and that nylon plugs are in place in

any unused gland fittings.

8: Secure the Junction Box Covers onto the unit using their latches.

9: All excess cable is neatly coiled and tied up out of any possible accumulations of standing

water.

10: All cable entry and exiting points are finished with a drip loop.

11: All ground rod connections are clean, tight, and greased to protect against corrosion.

Page 50

04/12 50 50538 Rev. 7

Section 4: Parts List

Page 51

04/12 51 50538 Rev. 7

-Section 4: Parts List, Continued

FE AAR Track Scales

Load Cell Assembly Parts and Hardware

Part No. Part Description

Qty.

(per cell)

Location Notes

Parts

61155

Int Sect, Upper Bearing Plate

(8 holes)

1

Shown in diagram.

61293

End Sect. Upper Bearing Plate

(4 holes)

1

"

58652

Top Bearing Plate (w/ Teflon Pad)

1

"

12125

Wear Plate

1

"

58650

Upper Flexure Assy Clamp Bar

1

"

12126

0.05" Upper Flex Assy Shim

2

"

12127

0.025" Upper Flex Assy Shim

2

"

12122

Upper Flexure Assy

1

"

58782

LC Upper Bearing Plate

1

"

81352

Revere CSP-B10-200K-15RP

1

"

145865

Cell Spacer (4" Dia., 1/8" Thick, SS)

1

"

12128

Lower Flexure Plate

1

"

58663

Pipe Spacers

4

"

58664

Load Cell Button

1

"

58670

LC Bottom Bearing Plate

1

"

58661

LC Stand

1

"

58671

Grout Plate

1

"

59600

Leveling pads (1/4" X 2" X 2")

3

"

Hardware

54428

3/4"-16 x 1 1/4" Set Screw

(Ref. #135FSS)

2

LC stand as locating studs for bott bearing plate

54380

5/8"-18 x 1 1/4" Headless Socket

Screw

2

LC stand as locating studs for bott bearing plate

54367

1/2"-13 x 1 1/4" Hex Bolt

3

Clamp bar for upper flex assy

54370

1/2"-13 x 1 1/2" Hex Bolt

4

Thru lower flex assy, pipe spacer, to bott bearing plate

54769

1/2" Spring Lock Washer

3

For bolts used at clamp bar

145866

LC Assy Box

1

For LC Assembly with spacer changes

145875

LC Hdwr Box

1

Hdwr purchase box for 145866

145905

ST Hdwr Box

1

Hdwr box for weighbridge steel

145915

Kit, Rail Hdwr

1

Scale, approach, and anticreep hdwr for 12-1492 thru

12-1496

145916

Kit, Rail Hdwr

1

Scale, approach, and anticreep hdwr for 12-1492 thru

12-1496

145917

Kit, Purch

1

Purchase box for 145916

54223

1/4"-20 x 1/2" Flathead Screw

4

Thru wear plate, upper flex assy, into LC upper bearing

plate

54591

3/4"-10 x 6" Hex Bolt

3

Leveling screws, thru grout plate to leveling pad

54532

3/4"-10 X 3" Hex Bolt

32

Thru girder flange and upper bearing plate, into top bearing plate

54229 3/4"-10 X 3 1/2" A325 Hex Bolt w/ Nut 16

Thru girder flange and outside holes of int sect. upper

bearing plate

Page 52

10/03 52 50538 Issue #3

FE AAR Track Scales, Continued

Weighbride Assembly Parts and Hardware

Part

No. Part Description Qty and Location Notes

Parts

61037 Girder Conn. Plate, 1/2" x 8" x 2', 16 Holes 2 per interior section beam splices (one each side of web)

61295 Dam Plate 2 per open trough to dam mastic.

61153 Angle Brace, L3" x 3" x 1/2", 5' Lg. Field weld angle cross braces, two per section

61154 Brace Weld Plate, 1/2" x 8" x 8" Weld plat for brace, one per section.

55766 J-Box Mounting Bar One per section, plus one per PPS

Hd

54217

3/4"-10 x 3", A325 Hex Bolt w/ Nut

6 each end of 12" cross channel, plus 16 for each pair of girder

connection plates

54199 3/4"-10 x 2 1/4" Hex Bolt w/ Nut 6 per 10" cross channel, 3 each end

Checking Assembly Parts and Hardware

Part

No.

Part Description Qty and Location Notes

Parts

61195 1 1/2" Check Rod,Threaded Ends, 68" Lg. 1 per section for lat. checking, plus 4 total for long. checking

145609 Long. Check Bracket, Fnd. Mount, 8 Holes 2 per scale total

145620 Lat. Check Bracket, Fnd. Mount, 4 Holes 1 per section for lat. checking

145615 Check Bracket, Beam Mount, 4 Holes 1 per section for lat. checking, plus 4 total for long. checking

Hd

54402 1" X 3 1/2" A325 Hex Bolt w/ Nut

4 per beam mount check bracket, thru girder flange and base of

bracket

59239 5/8"-11 X 6" Hex Bolt, Full Thread 3 per fnd. mounted long. check bracket (no leveling pads required)

54342 1 1/2"-6 Hex Nut 8 per check rod, one each side of each check bracket

54897 1 1/2"-6 Hex Jam Nut 5 per check rod, one each side of each check bracket

58617 1 1/2" Spherical Washer 6 per check rod, one each side of each check bracket

Page 53

10/03 53 50538 Issue #3

Grounding Kit Components

60811 ¾" X 8' Ground Rod, Copper Plated,

65061 1/2-1, Ground Clamp

11296 Braid Shield, 5/8" ID - #8 AWG

58618 Ground Rod Cap, PVC

54569 1/4-20 X 1 ½" Hex Cap Screw

54757 1/4" Spring Lock Washer

54368 1/4-20 Hex Nut

66942 Connector Clamp

66978 I Beam Clamp

54054 1/4-20 x 1/2” Cap Screw

50584 Manual Grounding Kit

Items below are replaced components from the previous Grounding Kit.

65061 Clamp, Ground Rod

79386 5/16-18 X 1 ½" Hex Cap Screw

54760 5/16" Spring Lock Washer

54224 5/16-18 Hex Nut

79385 Set Screw, Ground Braid Clamp

Page 54

04/12 54 50538 Rev. 7

Appendix I: Recommended Tools & Equipment:

QTY DESCRIPTION

2 EA MASON LINE

1 EA 25 FOOT TAPE MEASURE

1 EA 100 FOOT TAPE MEASURE

1 EA TRANSIT

1 EA PRECISION LEVEL (Starrette Model 98 Mechanics Level, 6 inch long model)

1 EA. TORQUE WRENCH OF SUITABLE CAPACITY

1 EA THREAD FILE; STANDARD THREAD SIZES OF 10, 8, 7, 6.

1 EA ELECTRIC DRILL / VARIABLE / 1/2" CHUCK SIZE

1 EA 1 1/4" & 1 1/2" WOOD DRILL BIT

1 EA WOOD HAND SAW

1 EA CARPENTERS CLAW HAMMER

4 EA 5 GALLON BUCKETS, WITH HANDLE

2 EA LARGE & SMALL TROWEL S

2 EA 1 1/4" STRUCTURAL WRENCH WITH OFFSET HEAD

(TO FIT 3/4-10 X 3 1/2" LONG A325 BOLTS)

1 EA 3/4" SOCKET SET

1 EA 1/2" OR 3/4" ELECTRIC IMPACT WRENCH

1 EA 1 1/4" HARDENED DEEP 6 POINT IMPACT SOCKETS

2 EA 24" ADJUSTABLE WRENCH (2 7/16" MAX. OPENING)

6 EA 6" HEAVY DUTY C-CLAMP, SUITABLE FOR WELDING

2 EA 8" HEAVY DUTY C-CLAMP, SUITABLE FOR WELDING

1 EA STEEL CARPENTERS SQUARE

1 EA HEAVY DUTY RIGHT ANGLE ELECTRIC GRINDER

WITH 7" DEPRESSED CENTER STONE.

1 EA AC/DC 200 AMP ARC WELDER / IF GASOLINE DRIVEN, INCLUDE A GAS

CAN. BOTH WIRE LEADS MUST BE LONG ENOUGH TO REACH EVERY

AREA OF THE SCALE

1 EA OXYGEN / ACETYLENE CUTTING TORCH SET

2 EA 36" CROW BAR / GOOSENECK BAR

2 EA 24" CROW BAR / GOOSENECK BAR

1 EA SHORT HANDLED 4 LB SLEDGE HAMMER

1 EA LONG HANDLED 5 LB SLEDGE HAMMER

1 EA ADJUSTABLE SQUARE

1 EA 2 FOOT LEVEL, GENERAL PURPOSE

2 EA 20 TON CAPACITY JACKS

1 EA HAND TRUCK

2 EA WIRE BRUSHES

1 EA 5 LB. GREASE

6 EA CANS OF SPRAY PAINT, COLOR = RED OXIDE PRIMER

Page 55

04/12 55 50538 Rev. 7

Appendix II: Required at the Jobsite:

117 VAC Electric Power (Extension cords as needed)

Water

Suitable crane(s)

Rigging (I.E. Straps, 4 leg drops, etc.)

NOTE: The weight capacity of all lifting and rigging equipment must be suitable for their

intended use.

Appendix III: Materials:

Grout shall be precision, packaged dry, non-metallic, hydraulic, non-shrink, and non-gaseous.

Grout shall meet or exceed ASTM C-1107 and Corps of Engineers CRD-C621.

Grout shall be bleed free and attain a minimum

of 8000 psi compressive strength in 28 days

at flowable consistency.

Grout MUST be mixed to a flowable consistency as specified by the grout manufacturer.

Quantity required will vary according to pier heights. Projected amount is 3 bags per load

cell base plate, and 2 bags per checking stand at 40lb per bag.

NOTE: Pier heights other that those indicated on the certified prints will affect the quantity

required.

Wood for forming base plates and checking stands. Select unfinished pine, 1 1/2" to 2” wide

X 12 feet long. Project quantity is one stick per base plate, and one stick per check stand.

Drywall screws suitable for constructing and securing wood forms.

50 lbs of welding rod, 1/8" X 14" rods, AC/DC, all purpose, Type 7014.

Wood blocking and cribbing material, suitable for supporting the weighbridge, and the 20 ton

jacks. Sufficient quantity to provide a safe, stable support from the pit floor to the bottom of

the main I-beams. Shipping weights for these scales range from 36,500 lbs to 50,000 lbs.

Materials and equipment for mixing the grout and water to a suitable consistency, and delivering it to each base plate and checking stand.

Grease: NLGI #2, Water resistant, Anti-wear Grease such as CRC Super White.

Page 56

04/12 56 50538 Rev. 7

Appendix IV: Torque Values Chart

All Values are Pounds (LB).

SIZE GRADE 2 GRADE 2 GRADE 5 GRADE 5 GRADE 8 GRADE 8

LUBED DRY LUBED DRY LUBED DRY

1/4-20 49 in 65 in 75 in 100 in 107 in 143 in

5/16-18 101 in 134 in 157 in 210 in 220 in 305 in

3/8-16 15 FT 20 FT 23 FT 31 FT 32.5 FT 44 FT

7/16-14 24 FT 30 FT 37 FT 50 FT 53 FT 70 FT

1/2-13 36.5 FT 49 FT 57 FT 75 FT 80 FT 107 FT

9/16-12 53 FT 70 FT 82 FT 109 FT 115 FT 154 FT

5/8-11 73 FT 97 FT 113 FT 151 FT 159 FT 211 FT

3/4-10 129 FT 173 FT 200 FT 266 FT 282 FT 376 FT

7/8-9 125 FT 166 FT 321 FT 430 FT 454 FT 606 FT

1-8 187.5 FT 250 FT 482.5 FT 640 FT 680 FT 900 FT

Appendix V: Tolerances:

Load Cell Base Plates, level within 1/64”" per Foot

Upper bearing Plates, level within 1/64”" per Foot

Check Stands, level within 1/64”" per Foot

Check Rods, level within 1/100" per Foot

Appendix VI: Load Cell Specifications:

Capacity: 200,000 LB.

Height: 7 1/4" Inches High.

Input Resistance: 450.50 Ohm

Output Resistance: 482.64 Ohm

Isolation Resistance: >=5000 Meg Ohm (measured with 50 volts DC)

Calibration: 2.0 mV/V

Cable Length: 15 ft.

Wiring: Excitation (+) = Green