Fairbanks 1129 User Manual

Operation/ Maintenance

Dual Platform Counting Scale

WITH OMEGA SERIES COUNTING SCALE

MODEL 1129 SERIES

© 2012 by Fairbanks Scales, Inc.

All rights reserved

51300

Revision 1 08/12

Amendment Record

Dual Platform Counting Scale

With Omega Series Counting Scale

Model 1129 Series

Document 51300

Manufactured by Fairbanks Scales Inc.

821 Locust

Kansas City, Missouri 64106

Created 07/12

Revision 1 08/12 Released Product

08/12 3 51300 Rev. 1

Disclaimer

Every effort has been made to provide complete and accurate information in this manual. However,

although this manual may include a specifically identified warranty notice for the product, Fairbanks

Scales makes no representations or warranties with respect to the contents of this manual, and

reserves the right to make changes to this manual without notice when and as improvements are

made.

Fairbanks Scales shall not be liable for any loss, damage, cost of repairs, incidental or consequential

damages of any kind, whether or not based on express or implied warranty, contract, negligence, or

strict liability arising in connection with the design, development, installation, or use of the scale.

Trademarks

All other product names mentioned herein are used for identification purpose only and may be

trademarks and/or registered trademarks of their respective companies

© Copyright 2012

This document contains proprietary information protected by copyright. All rights are reserved; no part

of this manual may be reproduced, copied, translated or transmitted in any form or by any means

without prior written permission of the manufacturer.

08/12 4 51300 Rev. 1

Table of Contents

SECTION 1: GENERAL INFORMATION .................................................................. 7

1.1. Introduction .............................................................................................................. 7

1.1.1. Standard Applications ....................................................................................................... 7

1.2. Description .............................................................................................................. 8

1.2.1. Omega Series Scales ....................................................................................................... 8

1.2.2. Portable Platform Scale .................................................................................................... 8

1.3. Technical Specifications .......................................................................................... 9

1.3.1. Omega Series Basic Specification ................................................................................... 9

1.3.2. Omega Series Scale specifications .................................................................................. 9

1.3.3. Portable Platform Scale Specifications ........................................................................... 10

1.4. Accessories ........................................................................................................... 10

SECTION 2: CUSTOMER SERVICE INFORMATION .............................................. 11

2.1. General Service Policy .......................................................................................... 11

SECTION 3: INSTALLATION ................................................................................... 13

3.1. Tools Required ...................................................................................................... 13

3.2. Wheel and Pillar Assembly .................................................................................... 13

3.3. Mounting Bracket Kit Assembly ............................................................................. 15

3.4. Installing the instrument ......................................................................................... 17

SECTION 4: USER OPERATIONS .......................................................................... 18

4.1. Introduction ............................................................................................................ 18

4.1.1. General Weighing ........................................................................................................... 18

4.2 Front Panel Display and Key Functions ................................................................. 19

4.2.1. LCD Display Definitions .................................................................................................. 19

4.2.2. Keypad Functions ........................................................................................................... 20

4.3. Basic Operational Functions .................................................................................... 22

4.3.1. Gross, Tare and Net Weight ........................................................................................... 22

4.3.2. Counting by Piece Weight .............................................................................................. 23

4.4. Tare Operations ....................................................................................................... 23

4.4.1. Auto Tare Entry ............................................................................................................... 23

4.4.2. Manual Tare Entry Using The Keypad ........................................................................... 24

4.5. Sampling operation ................................................................................................ 24

4.5.1. Enter Piece Weight By Direct Keypad Input ................................................................... 24

4.5.2. Setup Piece Weight By Sampling (Quick Set) ................................................................ 25

4.5.3. Setup Piece Weight by Sampling (Place Item) ............................................................... 26

4.5.4. Setup Piece Weight By Sampling (Remove Item) .......................................................... 27

4.5.5. Setup Piece Weight by Sampling (Re-sample) .............................................................. 28

4.5.6. Auto Re-sample Operation ............................................................................................. 28

4.6. PLU (Part Look UP) operation ............................................................................... 29

4.6.1. Setting Up PLU Keys 1 thru 9 ......................................................................................... 29

4.6.2. Setting Up PLU Keys 0 thru 999 ..................................................................................... 30

4.6.3. Loading PLU 1 thru 9 ...................................................................................................... 31

4.6.4. Loading PLU 0 thru 999 .................................................................................................. 31

4.6.5. Modifying a PLU ............................................................................................................. 32

08/12 5 51300 Rev. 1

Table of Cont ents

SECTION 4: USER OPERATIONS .......................................................................... 18

4.7. More operations ..................................................................................................... 33

4.7.1. Accumulation .................................................................................................................. 33

4.7.2. Recall .............................................................................................................................. 34

4.7.3 Alarm Function ................................................................................................................ 37

4.8. “B Scale” Selection ................................................................................................ 39

SECTION 5: SERVICE AND MAINTENANCE ......................................................... 40

5.1. Basic Cleaning ...................................................................................................... 40

5.2. Troubleshooting ..................................................................................................... 40

5.2.1. Error Code List ................................................................................................................ 40

5.2.2. Solutions ......................................................................................................................... 41

SECTION 6: PARTS ................................................................................................. 42

6.1. Platform and Pillar Assembly Parts List ................................................................. 42

6.2. Platform & Pillar Assembly Diag ram ...................................................................... 43

6.3. Acc 380 Mounting Bracket Parts ............................................................................ 44

6.4. Omega Series Parts List ........................................................................................ 45

6.5. Parts Diagram ....................................................................................................... 46

APPENDIX I: REMOTE PLATFORM WIRING ......................................................... 47

APPENDIX II: RS232C CONNECTION:DB9 (MALE) .............................................. 48

08/12 6 51300 Rev. 1

6 lbs.

15 lbs.

30 lbs.

60 lbs.

100 lbs.

Section 1: General Information

1.1. INTRODUCTION

The 1129 Series Dual Platform Counting Sc al e is available in five (5)

standard models. The difference between these models is the capacity of the local

scale.

The Omega Series Counting Scale is available in five model sizes. This allows

the user to weigh and count their products based on the smallest size of the parts

being weighed.

–

–

–

–

–

The Remote Platform has a capacity of one thousand pounds (1,000 lbs.).

– It is used for weighing larger products, both in capacity and dimensionally.

The Omega Counting Scale is assembled in the same manner for all models.

It is constructed with a mechanical cast iron lever system and base, metal pillar,

Acc 380 Omega Bracket Adapter, and an Omega Counting Scale.

1.1.1. STANDARD APPLICATIONS

Material handling Warehousing Parts distribution

Inventory management Auditing Bag filling

08/12 7 51300 Rev. 1

Section 1: General Information

1.2. DESCRIPTION

1.2.1. Omega Series Scales

The self-contained, local weighing platform and instrument, O m e ga Counting

Scale

platform, perfect for al most any counting scale appli cati on .

Standard units include the following features.

is designed in a rugged ABS plastic enclosure with a stainless steel weighing

– The 9.64” x 13.97” weighing platform can easily accommodate most parts

counting needs.

• Lead-Acid Rechargeable

Battery

S erial Port 1 is dedicated to a Printer, Computer or a Remote Display.

Serial Port 2 is dedicated to Barcode Readers.

• Programmable PLU

(Parts Look Up)

• Dual RS232C Serial

Ports

1.2.2. Portable Platform Scale

The Portable Platform Scale is a remote platform used for bulk w eig hi ng and

counting.

This platform is selected using the front panel of the Omega series Counting

Scale.

The 17.75” x 23.5” weighing platform provides a large space to weigh and

count bulk items up to one thousand pounds (1000 lbs.)

08/12 8 51300 Rev. 1

Section 1: General Information

TEMPERATURE

(0℃

HUMIDITY

1.3. TECHNICAL SPECIFICATIONS

1.3.1. Omega Series Basic Specification

DIGITAL DISPLAY

PLATTER SIZE

DIMENSIONS

NET WEIGHT (KG)

OPERATING

RELATIVE

POWER

INTERFACE

LCD, height 0.6 in (14.5 mm)

6/7/7(Weight / Piece Weight / Total Pieces)

9.64” x 13.97” (245 x 355 mm )

(15.24” x 14.37” x 4.61” (387 x 365 x 117 mm)

8.16 lbs. (3.7 kg)

◌ ۫

32

˚F to +104˚F

Less than 85%

117VAC 50/60Hz +/- 10%

– 9V / 500mA, AC adapter;

Built-in 6V Rechargeable Battery

– 15-20 hours continuous

– 7-10 hours continuous with an external platform

– 14-16 hours recharge time

RS-232C, Serial 1 and Serial 2

to +40℃)

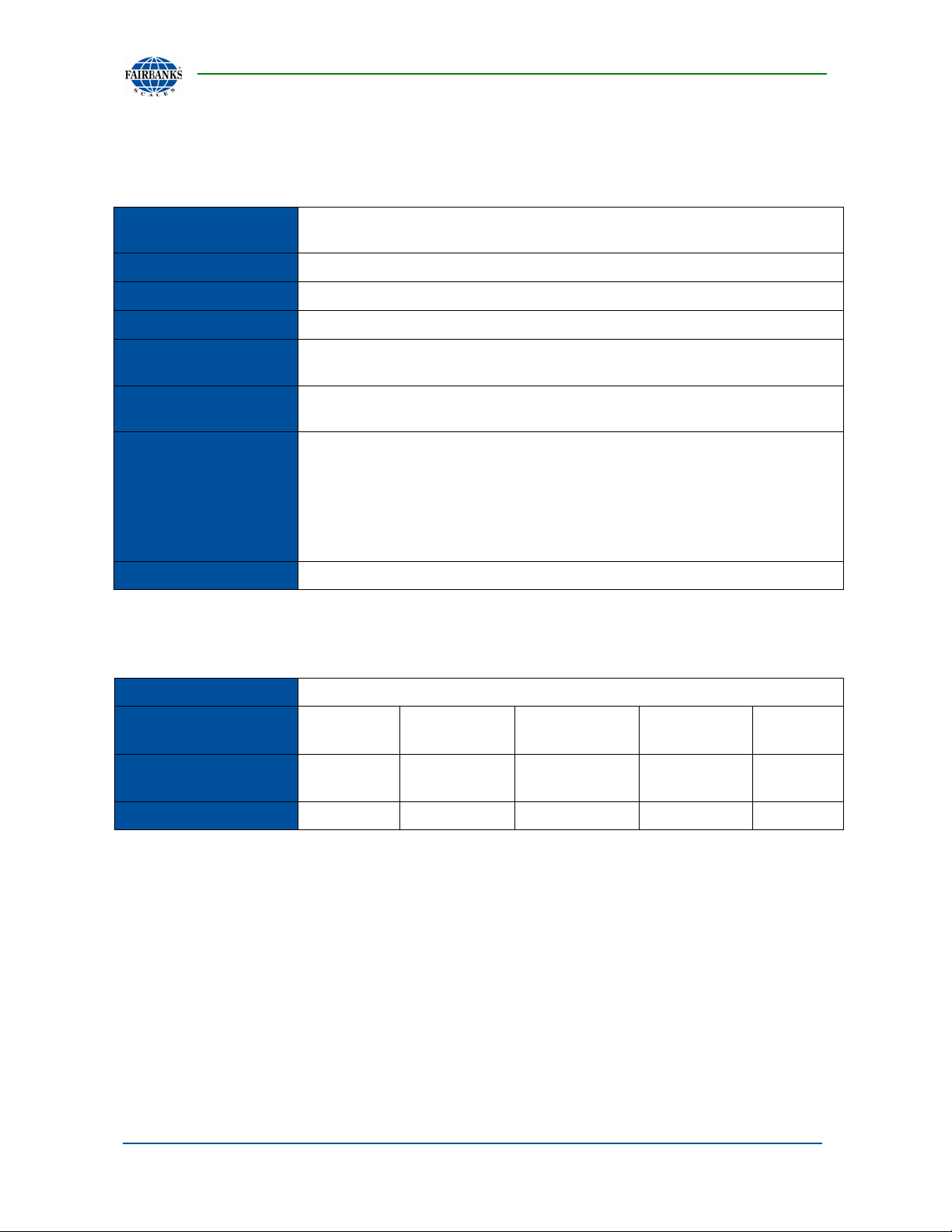

1.3.2. Omega Series Scale specifications

MODEL

MAX . CAPAC ITY

DISPLAYED

DIVISIONS

ACCURACY

Omega Counting Scales

6 lb /

3 kg

0.0002 lb /

0.1 g

1/30000 1/30000 1/30000 1/30000 1/50000

15 lb /

6 kg

0.0005 lb /

0.2 g

30 lb /

15 kg

0.001 lb /

0.5 g

60 lb /

30 kg

0.002 lb /

1 g

100 lb /

50 kg

0.002 lb /

1 g

08/12 9 51300 Rev. 1

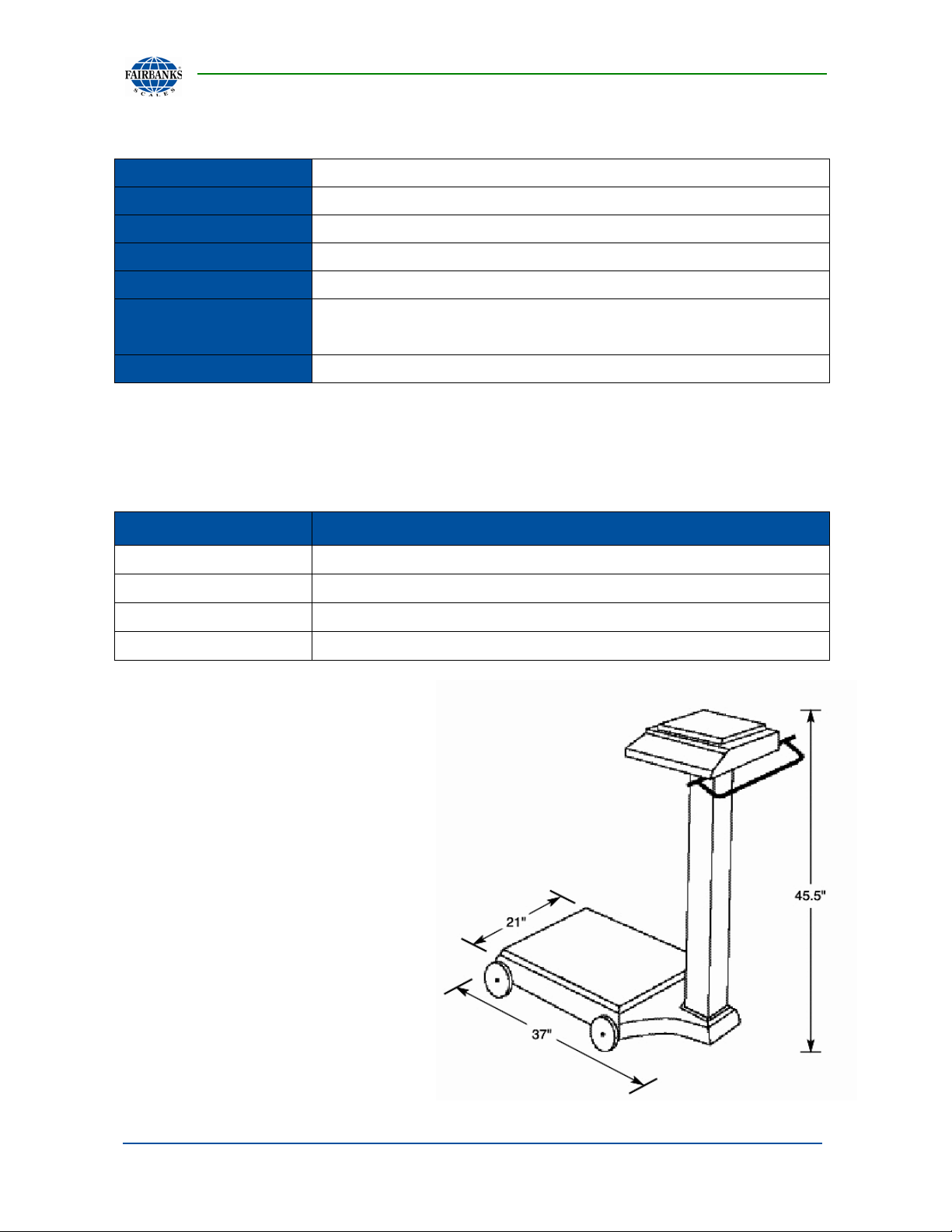

Section 1: General Information

MODEL

MAXIMUM CAPACITY

DIVISION SIZE (D)

PLATFORM SIZE

OVERALL LENGTH

WEIGHT

1.3.3. Portable Platform Scale Specifications

Portable Platform Scale

1000 lbs/ 454 kgs

0.5 lbs/ 0.2 kgs

17.75” x 23.5”

37”

CONSTRUCTION

1.4. ACCESSORIES

PRODUCT NO. DESCRIPTION

31701

31789

24482

20483

Base/ Platform/ Wheels: Cast Iron

Column: Fabricated Steel

168 lbs/ 76 kgs

Bar code scanner (Symbol) with hands-free stand

Dust cover (Qty. 5)

2844 series label printer

2844 printer cable (required when a 24482 printer is ordered.)

08/12 10 51300 Rev. 1

Absolutely NO physical, electrical or program modifications other

Section 2: Customer Service Information

2.1. GENERAL SERVICE POLICY

It is the customer/operator's responsibility to ensure the equipment provided by

Fairbanks is operated within the parameters of the equipment's specifications and

protected from accidental or malicious damage.

WARNING!

than selection of standard options and accessories can be made

by customers to this equipment

Repairs are performed by Fairbanks Scales Service Technicians

and Authorized Distri butor Personnel ONLY!

Failure to comply with this poli c y voids al l im pli e d a nd/or written

warranties.

The equipment consists of printed circuit assemblies which must be handled

using ESD handling procedures, and must be replaced as units.

Replacement of individual components is strictly not allowed.

Using electric arc welding can severely damage scale components, such as

digital weight indicators, junction boxes, power supplies, and load cells.

08/12 11 51300 Rev. 1

Section 2: Customer Service Information

All load cells, load cell cables and interconnecting cables used to connect all scale

IMPORTANT INST ALLATION NOTIC E

components shall be locate d a minimum of t hirty-six (36”) inches

distance away

current carrying conductors.

This includes digital weight indicators, junction boxes, and power supplies.

This includes any peripheral devices, such as printers, remote displays, and

auxiliary data entry devices.

Also included is the scale components themselves, such as 120 volt AC, 240

volt AC, 480 volt AC and electric supply of higher voltage wiring runs and

stations, AC power transformers, overhead or buried cables, electric

distribution panels, electric motors, florescent and high intensity lighting

which utilize ballast assemblies, electric heating equipment, traffic light

wiring and power, and relay boxes.

All scale components, including digital weight indicators and peripheral devices are

not designed to operate on internal combustion engine driven electric generators and

other similar equipment.

from all single and multiple phase high energy circuits and electric

NOTE: For more information, please contact a Fairbanks Ser vice

Representative.

08/12 12 51300 Rev. 1

Section 3: Installation

3.1. TOOLS REQUIRED

#1 or Small Slotted Screwdriver

#2 Phillips Screwdriver

10" Adjustable Wrench

Pliers

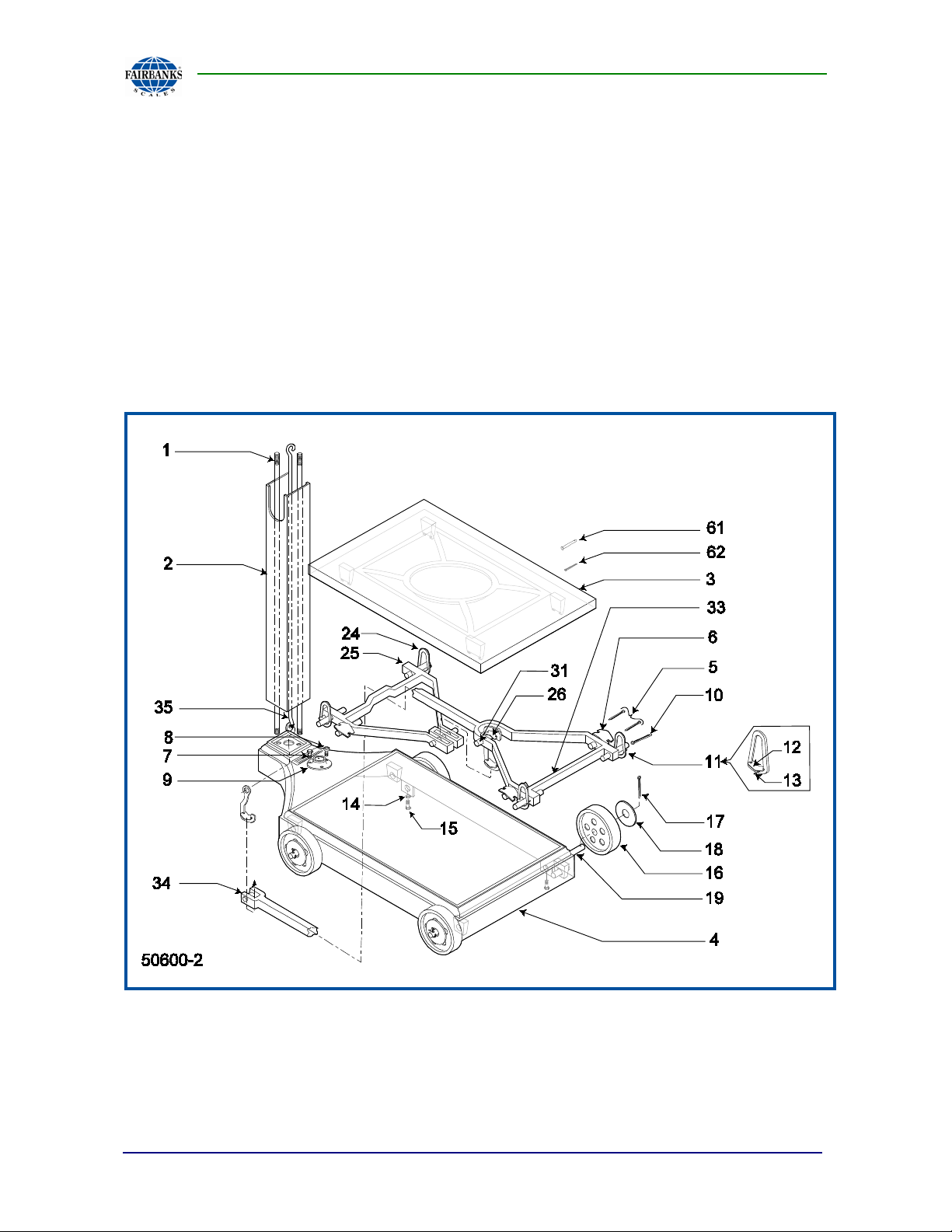

3.2. WHEEL AND PILLAR ASSEMBLY

6. Set the Scale Base Assembly (#4) sideways on the floor.

7. Insert a Cotter Pin (

(#19).

8. Place a Flat Washer (#18) and a Wheel (#16) onto the open end of the axle.

9. Insert the axle's other end through both holes in the base.

10. Place the Second Wheel (#16) onto the axle.

11. Place a Flat Washer (#18) over the axle, and then insert a cotter pin (#17)

through the axle’s small hole.

12. Repeat steps 2-6 for the second axle.

13. With the Scale Base Assembly (#4) in an upside-down position, center the axles

in the base.

14. Insert the Locking Screws (#15) into the tapped holes in the bottom of the base,

tightening the axle into place with the screws.

– Directly under the axle holes.

15. Secure the Lock Nuts (#14).

#17) through the small hole in one end of the First Axle

NOTE: See the diagram on the following page to identify parts in these assembly

instructions.

08/12 13 51300 Rev. 1

Section 3: Assembly

3.2. WHEEL & PILLAR ASSEMBLY, CONTINUED

16. With the Scale Base Assembly (#4) in an upright position Screw the two (2)

Pillar Rods (#1) into the two (2) tapped ho les of the base.

17. Place the Pillar (#2) over the pillar rods.

– The cutouts face to the left and right of the platform

18. Insert the Steelyard Rod (#35) down through the pillar.

– The bent hook is on top, and the loose swivel hook is on the bottom.

08/12 14 51300 Rev. 1

Section 3: Assembly

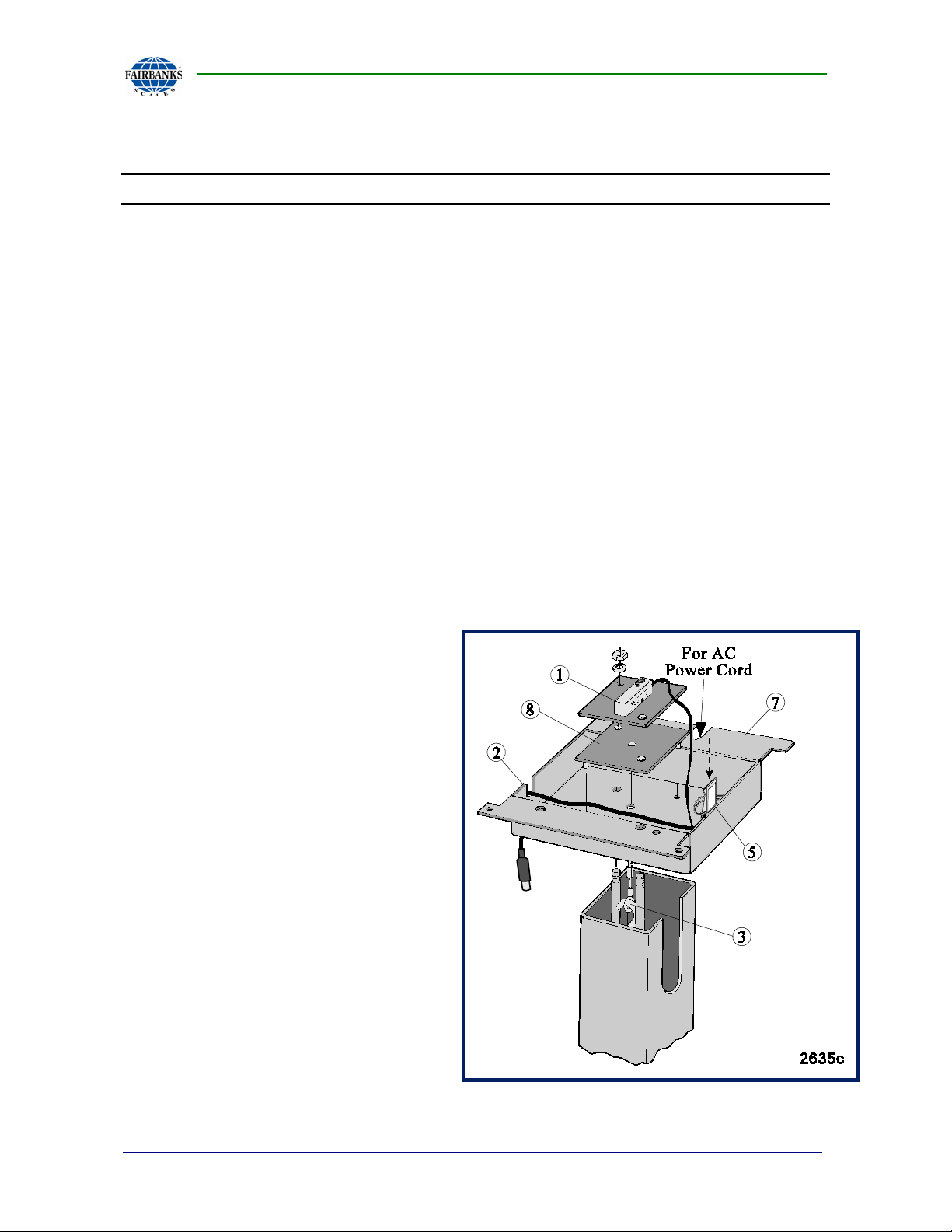

3.3. MOUNTING BRACKET KIT ASSEMBLY

NOTE: The MOUNTING BRACKET KIT ASSEMBLY is partially assembled.

1. With the portable platfor m rig ht-side-up, place the Bracket (#7) on top of the

pillar.

– The two (2) pillar rods must pass through the two (2) holes in the Bracket

(#7).

– The scale display may face any direction on the platform.

2. Place the Stiffener Plate (#8) on the pillar rod, inside the bracket.

3. From the parts envelope, remove the Cable Assembly (#2) which connects the

load cell to the platform.

4. Turn the Jam Nut onto the Linkage Assembly all the way to the bottom of the

threads.

5. Insert the threaded end of the Cable Assembly (#2) into the hole in the bottom of

the Load Cell Assembly (#1).

6. Turn the L inkage Assembly until the top of the threads can be seen in the Load

Cell opening.

7. With a quarter inch (¼”) wrench,

gently tighten the Jam Nut against

the Load Cell.

8. Place the Load Cell Assembly

(#1) on top of the pillar bolts, with

the load cell cable exiting in the

direction to easily connect the cable

to the counting scale.

08/12 15 51300 Rev. 1

Loading...

Loading...