fagor 800, 8025, 8030 Installation Manual

CNC 8025 T, TS

New Features (Ref. 0107 in)

ERRORS FOUND IN THE PROGRAMMING MANUAL (REF. 9701)

Page 64. Function G51.

When working in diameters, the "I" value in the table is in diameters and the value to be assigned to parameter

"I" in the G51 function must always be given in radius.

Section 12.4. (Chapter 12 page 133) Nesting levels.

The figure reads M02 ó M30

It should read: M02 or M30

ERRORS FOUND IN THE OPERATING MANUAL (REF. 9701)

Page 46. Last paragraphs.

It should say:

The CNC asks which is the source program number and which is the new program number, after keying each one

of them, press [ENTER].

If the number of the source program does not exist, or there is already a program in memory with the same number

as the new one or if there is not enough when copying the new program , the CNC will issue a message indicating

the cause.

ERRORS FOUNDS IN THE INSTALLATION MANUAL (REF. 9707)

Section 5.4 (chapter 5 page 7) Machine parameters for spindle control:

Parameter P606(3) is missing:

P606(3) Spindle counting direction

It sets the spindle counting direction. If correct, leave it as it is or change it if otherwise.

Possible values: "0" and "1".

MODIFICATIONS TO THE INSTALLATION MANUAL (REF. 9707)

Section 2.3.4 (chapter 2 page 9). Logic Outputs:

In the table, the following output is missing:

Output "C"

Row 1: (pin 3 I/O 1) M strobe

Row 2: (pin 5 I/O 2) output 3, decoded M function

Section 3.3.3 (chapter 3 page 11). P602(4). Another example:

Having a Fagor electronic handwheel (25 lines per turn) set as follows:

P602(1)=0 Millimeters P501=1 Resolution 0.001 mm. P602(4)=0 x4 Multiplication factor

Depending on the position of the MFO switch (Manual Feedrate Override), the selected axis will move:

Position 1 1 x 25 x 4 = 0.100 mm per turn

Position 10 10 x 25 x 4 = 1.000 mm per turn

Position 100 100 x 25 x 4 = 10.000 mm per turn

MODIFICATIONS TO THE LAN MANUAL (REF. 9701)

Section 2.2 (page 3). P616(7)

The first 2 paragraphs change. They should say:

If "P616(7)=0" the 8025 T CNC uses pin 15 of connector I/O1 as the input for the Feed-Hold, Transfer-Inhibit

and M-done signals as described in the Installation manual, chapter 1 section "Inputs of connector I/O 1"

If "P616(7)=1" the CNC behaves as follows:

* The Feed-Hold input will be "taken" .......

- 2 -

Version 7.1 (July 1996)

1. EXPANSION OF THE INTEGRATED PLC RESOURCES

1.1 INPUTS

1.1.1 TYPE OF FEEDRATE (G94/G95)

PLCI input I86 will show at all times the type of feedrate (F) selected a the CNC.

I86 = 0 G94. Feedrate in millimeters (inches) per minute.

I86 = 1 G95. Feedrate in millimeters (inches) per revolution.

1.1.2 TYPE OF CUTTING SPEED (G96/G97)

PLCI input I87 will show at all times the type of cutter speed selected at the CNC.

I87 = 0 G97. Constant tool center speed.

I87 = 1 G96. Constant cutting-edge speed

1.1.3 AXIS BEING HOMED (REFERENCED)

Input I88 indicates whether a home search is taking place and inputs I100, I101, I102, I103 and I104 indicates which

axis is being homed.

I88 Indicates whether any axis is being homed (0=No / 1=Yes)

I100 Indicates whether the X axis is being homed (0=No / 1=Yes)

I101 Indicates whether the 3rd axis is being homed (0=No / 1=Yes)

I102 Indicates whether the Z axis is being homed (0=No / 1=Yes)

I103 Indicates whether the 4th axis is being homed (0=No / 1=Yes)

I104 Indicates whether the C axis is being homed (0=No / 1=Yes)

1.1.4 AXIS MOVING DIRECTION

Inputs I42, I43, I44 and I45 will show, at all times, the moving direction of each axis.

I42 Indicates the moving direction of the X axis (0=Positive / 1=negative)

I43 Indicates the moving direction of the 3rd axis (0=Positive / 1=negative)

I44 Indicates the moving direction of the Z axis (0=Positive / 1=negative)

I45 Indicates the moving direction of the 4th axis (0=Positive / 1=negative)

1.2 OUTPUTS

1.2.1 ENABLING THE CYCLE-START KEY VIA PLCI

With this feature it is possible to set the treatment of the [CYCLE START] of the CNC via PLCI. Machine parameter

"P621(7)" indicates whether this feature is available or not.

P621(7) = 0 This feature is not available.

P621(7) = 1 This feature is available.

When using this feature, the way the CNC handles the [CYCLE START] key depends on the status of PLCI output O25

(CYCLE START ENABLE).

O25 = 0 The CNC ignores both the [CYCLE-START] key and the external [CYCLE-START] signal.

O25 = 1 The CNC takes into account both the [CYCLE-START] key and the external [CYCLE-START]

signal.

1.2.2 TRAVEL LIMITS SET VIA PLCI

With this feature, the travel limits of the axes may be set via PLCI. Machine parameter "P621(7)" indicates whether

this feature is available or not.

P621(7) = 0 This feature is not available.

P621(7) = 1 This feature is available.

To set the travel limits for each axis, use the following outputs:

O52 / O53 Positive / negative X axis limits

O54 / O55 Positive / negative 3rd axis limits

O56 / O57 Positive / negative Z axis limits

O58 / O59 Positive / negative 4th axis limits

When the PLCI activates one of this outputs while the axis is moving in the same direction, the CNC stops the axes and

the spindle and it displays an axis-travel-limit-overrun error.

- 3 -

1.2.3 DENYING ACCESS TO THE EDITOR MODE VIA PLCI

Machine parameter "P621(7)" indicates whether this feature is available or not.

P621(7) = 0 This feature is not available.

P621(7) = 1 This feature is available.

When using this feature, access to the editor mode at the CNC depends on the status of PLCI output O26, as well as

on the current conditions (protected memory, number of the program to be locked).

O26 = 0 Free access to the editor mode (it is protected by current conditions).

O26 = 1 Denied access to the editor mode.

1.2.4 SPINDLE CONTROLLED VIA CNC OR VIA PLCI

From this version on, the spindle analog output may be set either by the CNC or by the PLCI. Machine parameter

"P621(7)" indicates whether this feature is available or not.

P621(7) = 0 This feature is not available

P621(7) = 1 This feature is available

Setting the spindle analog output via PLCI

To do this, use the combination: M1956 - R156.

Register R156 sets the spindle analog output in units of 2.442 mV. (10 / 4095)

R156 = 0000 1111 1111 1111 (R1256=4095) = 10V.

R156 = 0001 1111 1111 1111 = -10V.

R156 = 0000 0000 0000 0001 (R1256=1) = 2.5 mV.

R156 = 0001 0000 0000 0001 = -2.5 mV.

In order for the CNC to assume the value allocated to register R156, one must activate mark M1956 as described

in the PLCI Manual (section 5.5.2. Writing internal CNC variables).

Spindle controlled either by the CNC or by the PLCI

The CNC may have two internal spindle analog outputs, that of the CNC itself and the one set by the PLCI.

Use PLCI output O27 to "tell" the CNC which one of them to output.

O27 = 0 Spindle analog output set by the CNC itself.

O27 = 1 Spindle analog output set by the PLCI (combination: M1956-R156).

1.3 READING INTERNAL CNC VARIABLES

From this version on, the PLCI and the PLC64 have access to more internal CNC information.

With the PLCI, there is no need to activate a mark to access this information. The CNC itself updates this information

at the beginning of each PLCI cycle scan.

With the PLC 64, the corresponding mark must be consulted every time a CNC variable is to be checked.

The CNC information now accessible is:

Real S in rpm (REG119 at the PLCI, M1919 at the PLC64)

Not to be mistaken with R112 which indicates the programmed Spindle speed (S).

It is given in rpm and in hexadecimal format. Example: S 2487 R119= 967

Number of the block in execution (REG120 at the PLCI, M1920 at the PLC64)

It is given in hexadecimal format. Example: N120 R120= 78

Code of the last key pressed (B0-7 REG121 at the PLCI, Not available at the PLC64)

Not to be mistaken with register R118 which also indicates the code corresponding to the last key pressed,

but—

When pressing a key, both registers have the same value; but the data in R121 is only kept there for one cycle

scan whereas R118 keeps its value until another key is pressed.

When pressing the same key several times, (for example: 1111):

R121 will show code "1" four times (once per cycle scan).

R118 will always show the same value, thus not being able to tell whether the "1" key has been pressed once

or more times.

The key codes are listed in the appendix of the PLCI manual.

- 4 -

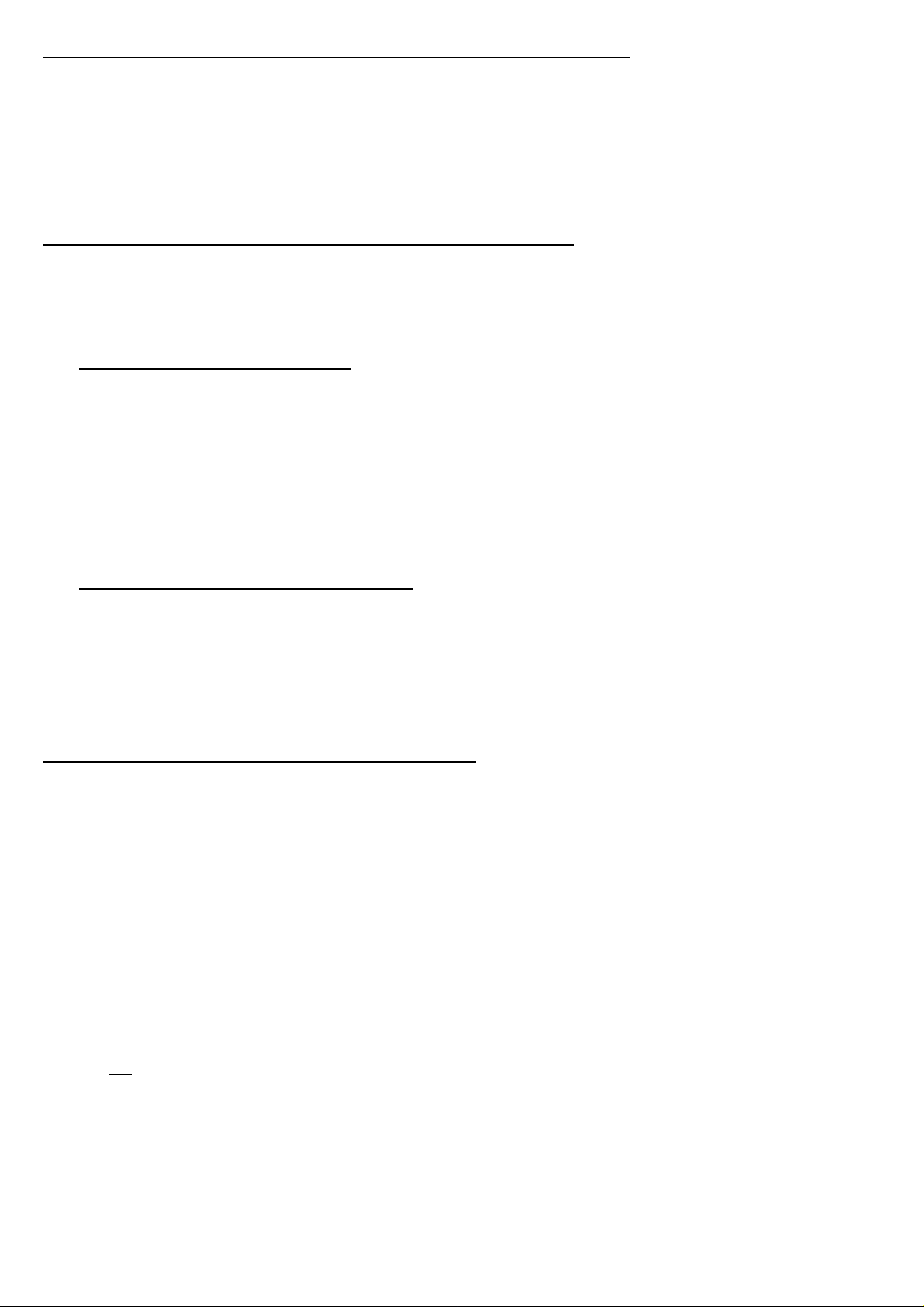

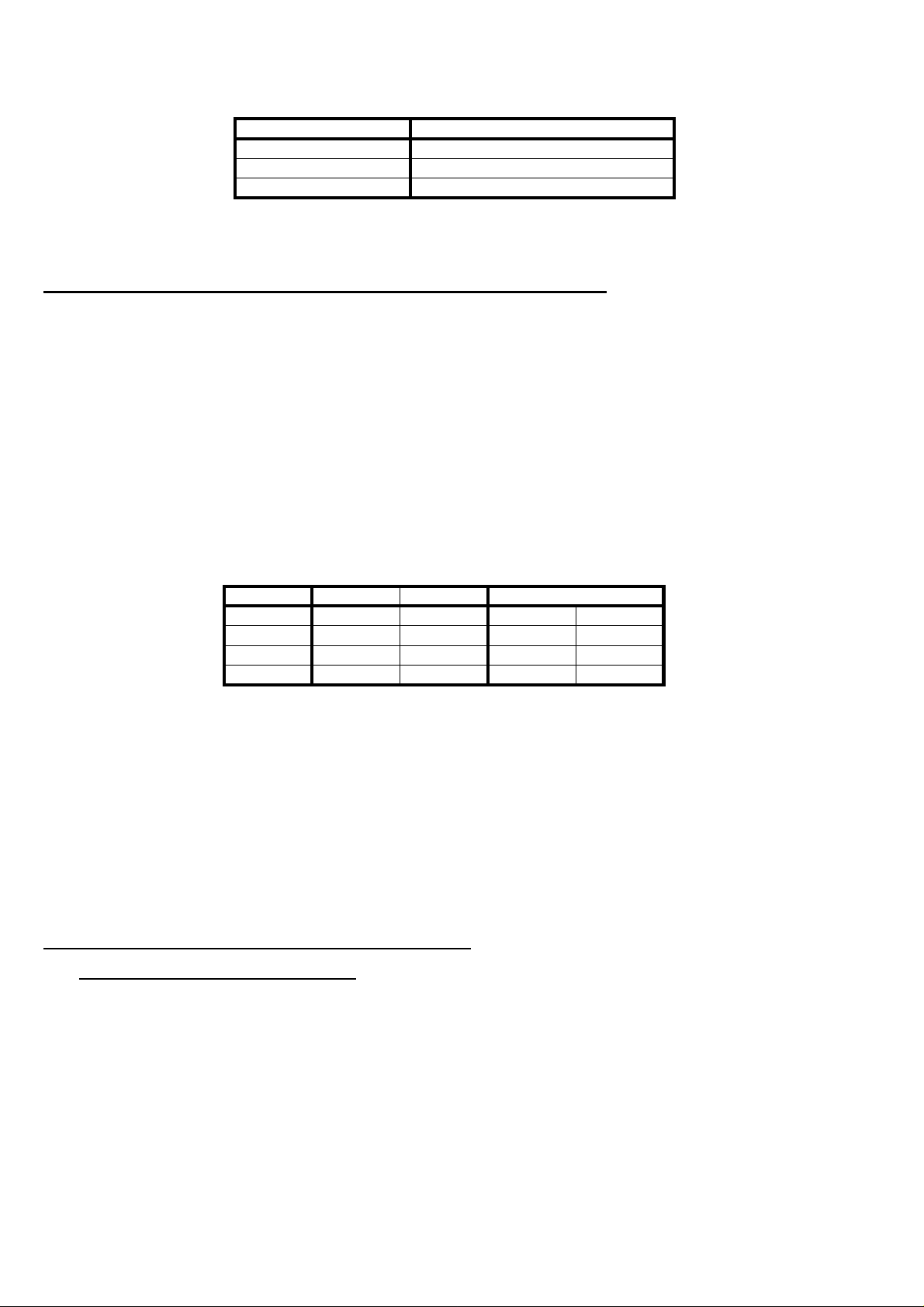

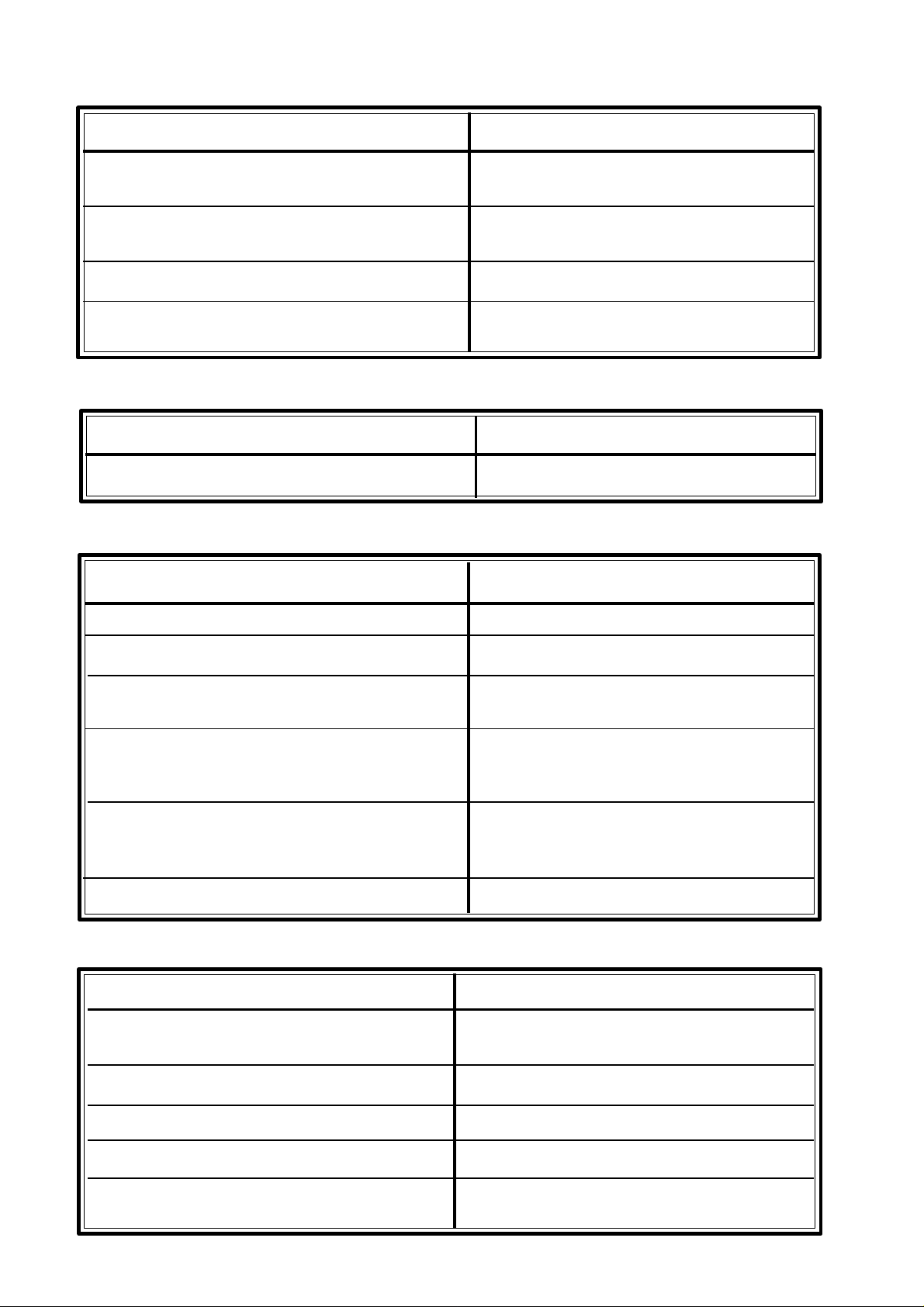

Operating mode selected at the CNC (B8-11 REG121 at the PLCI, Not available at the PLC64)

B8 B9 B10 B11

0 0 0 0 Automatic

0 0 0 1 Single block

0 0 1 0 Play-Back

0 0 1 1 Teach-in

0 1 0 0 Dry-Run

0 1 0 1 JOG

0 1 1 0 Editor

0 1 1 1 Peripherals

1 0 0 0 Tool Table and G functions

1 0 0 1 Special modes

Status of the miscellaneous "M" functions (REG122 at the PLCI, Not available at the PLC64)

The status of each one of these functions is given by a bit and will appear as a "1" when active and "0" when inactive.

B15 B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

M44 M43 M42 M41 M19 M1 M30 M4 M3 M2 M0

2. 4TH AXIS NOW AVAILABLE ON 8025T MODELS

From this version on, this feature is now available on all these models:

CNC-8025T (not available until now) CNC-8025TG CNC-8025TS

CNC-8025TI(not available until now) CNC-8025TGI CNC-8025TSI

3. SPINDLE SPEED DISPLAY UNITS

Until now, the spindle speed was always displayed in rpm. From now on, the display units may be selected by means

of machine parameter "P621(6)".

P621(6) = 0 In rpm when operating in RPM and in m/min. (ft./min.) when at Constant Surface Speed.

P621(6) = 1 Always in rpm, even when operating at Constant Surface Speed.

4. SINGLE BLOCK TREATMENT

The CNC considers a "Single block" the group of blocks between a G47 and a G48.

After executing function G47, the CNC executes all the following blocks until executing a block containing function

G48 even when in Single Block mode.

If is pressed while executing a "single block" in Automatic or Single-Block mode, the CNC keeps executing

the rest of the blocks until it runs into a G48 and it, then, interrupts program execution.

While function G47 is active, the Manual Feedrate Override switch and the spindle speed override keys will be disabled,

thus the program will be executed at 100% of the programmed F and S values.

Functions G47 and G48 are modal and incompatible with each other.

On power-up, after executing an M02/M30, after an EMERGENCY or a RESET, the CNC assumes G48.

5. TWO ELECTRONIC HANDWHEELS ARE NOW POSSIBLE

From this version on, up 2 electronic handwheels may be used one for the X axis and another one for the Z axis. The

4th axis and the Live Tool will no longer be available. The feedback inputs will be used as follows:

A1 - X axis; A2 - Z axis handwheel; A3 - Z axis; A4 - 3rd axis or "C" axis; A5 - Spindle; A6 - X axis handwheel

The handwheels will be operative when selecting the JOG mode. One of the handwheel positions must also be selected

at the Manual Feedrate Override switch of the operator panel.

The possible positions are: 1, 10 and 100, which indicate the multiplying factor applied to the pulses coming from the

electronic handwheel.

- 5 -

This way and after applying the multiplying factor, one obtains the axis moving units. These units correspond to the

units used for the display format

Example: Handwheel Resolution : 250 lines per turn

MFO Switch position Distance per turn

1 0.250 mm or 0.0250 inch

10 2.500 mm or 0.2500 inch

100 25.000 mm or 2.5000 inches

When attempting to "crank" an axis faster than its maximum feedrate (machine parameters "P110, P310"), the CNC will

limit the actual axis feedrate to that parameter value ignoring the rest of the pulses supplied by the handwheel, thus

preventing a Following Error message from being issued.

5.1 MACHINE PARAMETERS FOR THE HANDWHEELS:

P622(6) = 0 There is no electronic handwheel associated with the Z axis

P622(6) = 1 There is electronic handwheel associated with the Z axis

P609(1) = 0 The electronic handwheel being used is not a FAGOR 100P model.

P609(1) = 1 The electronic handwheel being used is a FAGOR 100P model.

This parameter makes sense when using a single handwheel associated with the X axis. It indicates

whether or not it is a FAGOR 100P with axis selector button.

P500 Counting direction of the X axis handwheel (No / Yes)

P622(5) Counting direction of the Z axis handwheel (0 / 1)

P602(1) Feedback units of the X axis handwheel (0 = millimeters /1 = inches)

P622(3) Feedback units of the Z axis handwheel (0 = millimeters /1 = inches)

P501 Square-wave feedback resolution of the X axis handwheel.

P622(1,2) Square-wave feedback resolution of the Z axis handwheel.

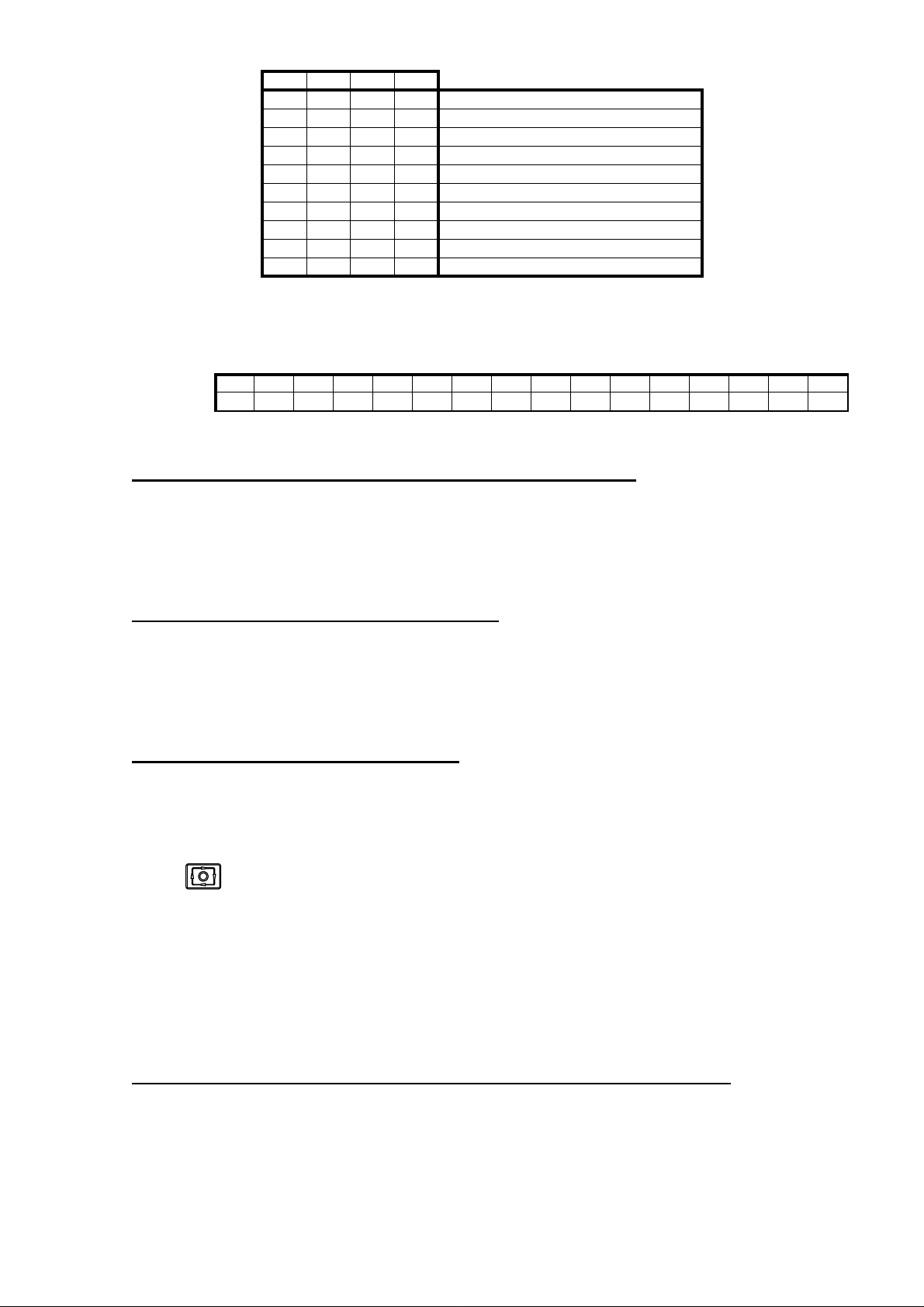

P501 P622(2) P622(1) Resolution

1 0 0 0.001 mm 0.0001"

2 0 1 0.002 mm 0.0002"

5 1 0 0.005 mm 0.0005"

10 1 1 0.010 mm 0.0010"

P602(4) Multiplying factor for X axis handwheel feedback pulses (0= x4 / 1= x2)

P622(4) Multiplying factor for Z axis handwheel feedback pulses (0= x4 / 1= x2)

P621(2) = 0 Handwheel disabled for Manual Feedrate Override (MFO) switch positions other than the

handwheel positions.

P621(2) = 1 When the MFO is at a position other than those for the handwheel , the CNC takes it into account

Example: Having a Fagor electronic handwheel (25 lines per turn) set as follows:

and applies a "x1" multiplying factor.

P602(1)=0 Millimeters; P501=1 Resolution 0.001 mm.; P602(4)=0 x4 Multiplication factor

Depending on the position of the MFO switch (Manual Feedrate Override), the selected axis will move:

Position 1 1 x 25 x 4 = 0.100 mm per turn

Position 10 10 x 25 x 4 = 1.000 mm per turn

Position 100 100 x 25 x 4 = 10.000 mm per turn

5.2 USING ELECTRONIC HANDWHEELS

The machine uses one electronic handwheel

When using a single electronic handwheel, it must be connected to A6.

If the handwheel is a FAGOR 100P type, machine parameter "P609(1)" must be set to "1".

Once the desired handwheel position has been selected at the MFO switch, press one of the JOG keys of the axis

to be jogged. The selected axis appears highlighted.

When using a FAGOR handwheel with an axis selector button, the desired axis can also be selected as follows:

* Press the push-button on the rear of the handwheel. The CNC selects the first axis and it highlights it.

* By pressing the button again, the next axis is selected and so on, rolling over from the last axis to the first one.

* By keeping the button pressed for more than 2 seconds, the CNC de-selects the currently selected axis.

The selected axis will be jogged as the handwheel is turned, reversing directions when reversing the turning direction

of the handwheel.

- 6 -

When trying to move an axis faster than the maximum feedrate allowed (machine parameter "P110, P310"), the CNC

will limit the actual feedrate to that parameter value ignoring the additional pulses, thus, avoiding following error

messages.

The machine uses two electronic handwheels

Each axis will move as its associated handwheel is turned, reversing its direction as the handwheel turning direction

is reversed and according to the selected MFO switch position.

When trying to move an axis faster than the maximum feedrate allowed (machine parameter "P110, P310"), the

CNC will limit the actual feedrate to that parameter value ignoring the additional pulses, thus, avoiding following

error messages.

Version 7.2 (April 1997)

1. SCREEN SAVER

The screen saver function works as follows:

After 5 minutes without pressing a key or without the CNC refreshing the screen, the screen goes blank. Press any

key to restore the display.

Machine parameter "P619(5)" indicates whether this feature is to be used or not.

P619(5) = 0 This feature is not being used.

P619(5) = 1 This feature is being used.

2. JOGGING FEEDRATE

From this version on, machine parameter P812 sets the axis jogging feedrate selected by the CNC when accessing the

JOG mode.

If while in JOG mode, the conditional input (block skip), pin 18 of connector I/O1, the CNC does not allow entering

a new F value. Only the feedrate override (%) may be varied by means of the MFO switch.

3. RAPID TRAVERSE KEY IN JOG MODE

Whenever the conditional input (block skip), pin 18 of connector I/O1, the CNC will ignore the rapid traverse key

Version 7.4 (May 1999)

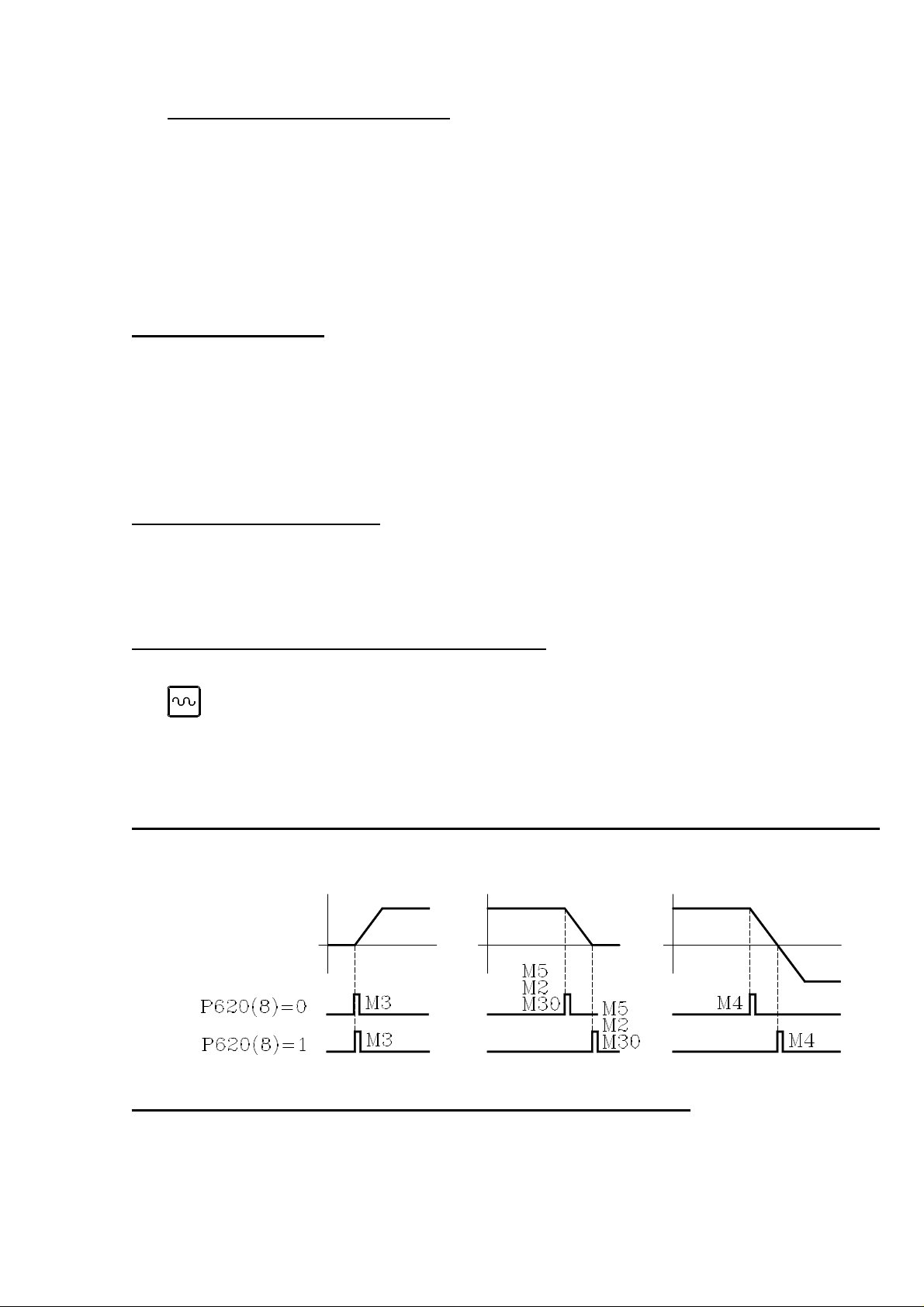

1. NEW MACHINE PARAMETER ASSOCIATED WITH THE M FUNCTIONS

Machine parameter "P620(8)" indicates when the M3, M4, M5 functions are sent out while accelerating or decelerating

the spindle.

2. CANCEL TOOL OFFSET DURING A TOOL CHANGE

From this version on, it is possible to execute a "T.0" type block inside the subroutine associated with the tool to cancel

the tool offset. This lets move to a particular position without the need for cumbersome calculations.

Only the tool offset may be canceled (T.0) or modified (T.xx). The tool cannot be changed (Txx.xx) inside the

subroutine associated with the tool.

- 7 -

3. DIVIDING FACTOR FOR FEEDBACK SIGNALS

Parameters P620(5), P620(6), P613(8) and P613(7) are used together with P602(6), P602(5), P612(5) and P614(5) which

indicate the multiplying factor to be applied to the feedback signals of the X, Z, 3rd and 4th axes respectively.

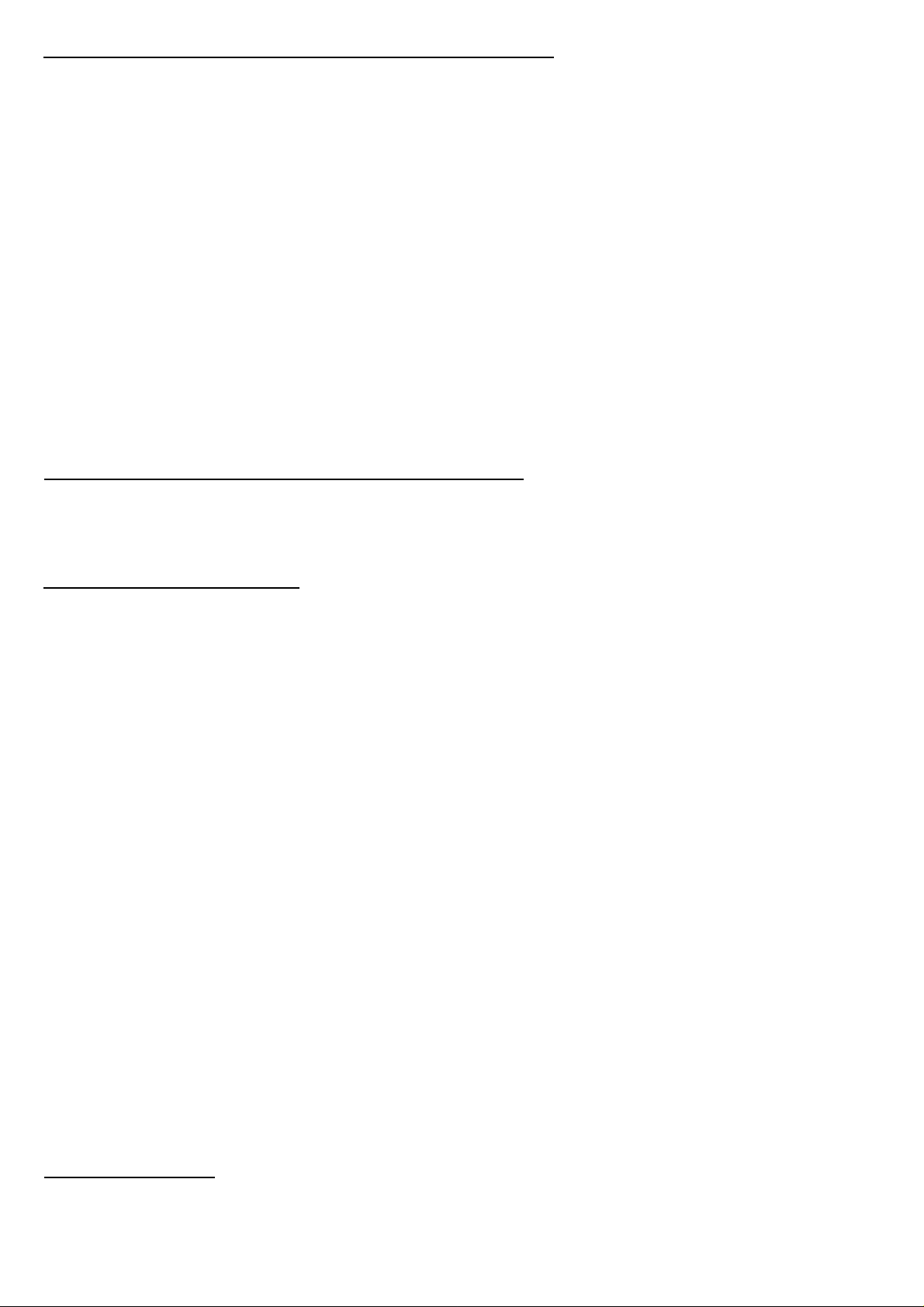

X axis Z axis 3rd axis 4th axis

P602(6) P602(5) P612(5) P614(5)

P620(5) P620(6) P613(8) P613(7)

Indicate whether the feedback signals are divided (=1) or not (=0).

P620(5)=0, P620(6)=0, P613(8)=0 y P613(7)=0 They are not divided

P620(5)=1, P620(6)=1, P613(8)=1 y P613(7)=1 They are divided by two.

Example: We wish to obtain a resolution of 0.01 mm with a squarewave encoders mounted on the X axis with 5mm

pitch ballscrew.

Nr of pulses = ballscrew pitch / (Multiplying factor x Resolution)

With P602(6)=0 & P620(5)=0 x4 multiplying factor Nr of pulses = 125

With P602(6)=1 & P620(5)=0 x2 multiplying factor Nr of pulses = 250

With P602(6)=0 & P620(5)=1 x2 multiplying factor Nr of pulses = 250

With P602(6)=1 & P620(5)=1 x1 multiplying factor Nr of pulses = 500

Version 7.6 (July 2001)

1. G75 AFFECTED BY FEEDRATE OVERRIDE

From this version on, there is a new machine parameter indicating whether G75 is affected by the feedrate override or

not.

P623(1) = 0Not affected. It is always at 100%, like in previous versions.

P623(1) = 1It is affected by the Feedrate override.

2. FEEDBACK FACTOR.

From this version on, there is a new machine parameter to set the resolution of an axis having an encoder and a leadscrew.

P819 Feedback factor for the X axis P820 Feedback factor for the 3rd axis

P821 Feedback factor for the Z axis P822 Feedback factor for the 4th axis

Values between 0 and 65534. The “0” value indicates that this feature is not being used.

Use the following formula to calculate the “Feedback Factor” :

Feedback factor = (Gear Ratio x Leadscrew pitch / Number of Encoder pulses) x 8.192

Examples: Gear Ratio 1 1 2 1

Leadscrew pitch 5000 6000 6000 8000 (microns)

Encoder 2500 2500 2500 2500 (pulses/turn)

Feedback factor 16384 19660.8 39321.6 26214.4

The machine parameters only admit integer values and sometimes the “Feedback Factor” has decimals. In those cases,

assign the integer part to the machine parameter and use the leadscrew compensation table to make up for the decimal

part.

The values to be entered in the table are calculated with the following formula:

Leadscrew position = Leadscrew Error (microns) x Integer of feedback factor / decimals of the feedback factor

For example: Gear ratio = 1 Leadscrew pitch = 6000 Encoder = 2500

Feedback factor = 19660.8 Machine parameter = 19660

For a leadscrew error of 20 microns Leadscrew position = 20 x 19660 / 0.8 = 491520

Going on with the calculation, we come up with the following table.

Leadscrew position Leadscrew error

P0 = -1966.000 P1 = -0.080

P2 = -1474.500 P3 = -0.060

P4 = -983.000 P5 = -0.040

P6 = -491.500 P7 = -0.020

P8 = 0 P9 = 0

P10 = 491.500 P11 = 0.020

P12 = 983.000 P13 = 0.040

P14 = 1472.500 P15 = 0.060

P16 = 1966.000 P17 = 0.080

3. NEW MODEL

From this version on, the new model TLI is now available.

It offers the same features as the TGI model and it is sold together with the motors and ACS drives..

FAGOR 8025/8030 CNC

Models: T, TG, TS

INSTALLATION MANUAL

Ref. 9707 (in)

ABOUT THE INFORMATION IN THIS MANUAL

This manual is addressed to the machine manufacturer.

It includes the necessary information for new users as well as advanced subjects for

those who are already familiar with the 8025 CNC.

It may not be necessary to read this whole manual. Consult the list of "New Features

and Modifications" and the appendix related to the machine parameters. Practically

all of them are cross referenced indicating the chapter and section of the manual

where they are described.

This manual explains all the functions of the 8025 CNC family. Consult the

Comparison Table for the models in order to find the specific ones offered by your

CNC.

To install the CNC onto your machine, we suggest that you consult the appendix

regarding the enclosures required to mount the CNC as well as chapter 1 (CNC

configuration) which indicates the CNC dimensions and details the pin-out of its

connectors.

If your CNC has an integrated PLC (PLCI), the I/O pin-out is different. Therefore,

the PLCI manual must also be consulted.

Chapter 2 (Power and Machine Interface) shows how to connect the CNC to A.C.

power (Mains) and to the electrical cabinet.

To adapt the CNC to the machine, set the CNC machine parameters. Consult chapters

3, 4 and 5 as well as the appendix concerning machine parameters.

There are 2 appendices; one where the parameters are ordered by subject and the

other one where the parameters are in numerical order.

Both appendices offer cross references indicating the section of the manual describing

each parameter.

When explaining each parameter in detail, chapters 3, 4 and 5, they sometimes refer

to chapter 6 (Concepts) where some of them are dealt with in further detail indicating

how to perform various adjustments of the CNC-machine interface.

Once all machine parameters are set, we suggest that you write their settings down

on the charts provided for this purpose in the appendix on "Machine Parameter Setting

Chart".

There is also an appendix on error codes which indicates some of the probable reasons

which could cause each one of them.

Also, if you wish this CNC to communicate with other FAGOR products, you must

use the Fagor Local Area Network (LAN). To do that, refer to the manual on FAGOR

LAN.

Notes

: The information described in this manual may be subject to variations due

to technical modifications.

FAGOR AUTOMATION, S. Coop. Ltda. reserves the right to modify the

contents of this manual without prior notice.

INDEX

Section Page

Comparison Table for lathe model 8025 CNCs ........................................................ix

New features and modifications ...............................................................................xiii

INTRODUCTION

Declaration of Conformity ........................................................................................3

Safety Conditions ...................................................................................................... 4

Warranty Terms ........................................................................................................7

Material Returning Terms .........................................................................................8

Additional Remarks .................................................................................................. 9

Fagor Documentation for the 800T CNC .................................................................11

Manual Contents ....................................................................................................... 12

Chapter 1 CONFIGURATION OF THE CNC

1.1 8025 CNC ..................................................................................................................1

1.2 Dimensions and installation of the 8025 CNC ........................................................ 2

1.2 8030 CNC ..................................................................................................................3

1.2.1 Central Unit of the 8030 CNC .................................................................................4

1.2.1.1 Keyboard connector ..................................................................................................6

1.2.1.2 Video connector ........................................................................................................8

1.2.2 Monitor/Keyboard of the 8030 CNC........................................................................9

1.2.2.1 Dimensions of the monitor/keyboard .......................................................................9

1.2.2.2 Elements of the monitor/keyboard ...........................................................................10

1.2.2.3 Connector and and monitor/keyboard interface .......................................................11

1.2.3 Operator Panel of the 8030 CNC .............................................................................12

1.3 Connectors and 8025/8030 interface ........................................................................13

1.3.1 Connectors A1, A2, A3, A4 .....................................................................................15

1.3.1.1 Dip-switches for connectors A1, A2, A3, A4 ..........................................................17

1.3.2 Connector A5 ............................................................................................................18

1.3.2.1 Dip-switches for connector A5 .................................................................................19

1.3.3 Connector A6 ............................................................................................................20

1.3.4 RS232C connector .....................................................................................................21

1.3.5 RS485 connector .......................................................................................................24

1.3.5.1 Recommended cable for the RS485 .........................................................................24

1.3.6 Connector I/O 1 .........................................................................................................25

1.3.6.1 Inputs of connector I/O 1 .........................................................................................26

1.3.6.2 Outputs of connector I/O 1 .......................................................................................29

1.3.7 Connector I/O 2 .........................................................................................................31

1.3.7.1 Outputs of connector I/O 2 .......................................................................................32

Section

Chapter 2 POWER AND MACHINE INTERFACE

2.1 Power interface .........................................................................................................1

2.1.1 Internal power supply................................................................................................1

2.2 Machine interface ......................................................................................................2

2.2.1 General considerations ..............................................................................................2

2.2.2 Digital outputs ...........................................................................................................4

2.2.3 Digital inputs .............................................................................................................4

2.2.4 Analog outputs...........................................................................................................5

2.2.5 Feedback inputs .........................................................................................................5

2.3 Set-up.........................................................................................................................6

2.3.1 General considerations ..............................................................................................6

2.3.2 Precautions.................................................................................................................6

2.3.3 Connection.................................................................................................................7

2.3.4 System input/output test ............................................................................................8

2.4 Emergency input/output connection ......................................................................... 10

Chapter 3 MACHINE PARAMETERS

3.1 Introduction ...............................................................................................................1

3.2 Operation with parameter tables................................................................................3

3.3 General machine parameters .....................................................................................4

3.3.1 Machine parameters related to axes configuration....................................................5

3.3.2 Input/output parameters.............................................................................................7

3.3.3 Handwheel parameters...............................................................................................10

3.3.4 Touch probe parameters ............................................................................................12

3.3.5 Tool parameters .........................................................................................................13

3.3.6 Parameters related to the emergency subroutine.......................................................15

3.3.7 Machine parameters for the RS232C serial line .......................................................16

3.3.8 Display related parameters ........................................................................................18

3.3.9 Jog-mode related parameters .....................................................................................19

3.3.10 Operating-mode related parameters...........................................................................21

Page

Chapter 4 MACHINE PARAMETERS FOR THE AXES

4.1 Parameters related to axis resolution.........................................................................2

4.2 Parameters for axis analog outputs ...........................................................................5

4.3 Parameters for the travel limits of the axes ..............................................................6

4.4 Machine parameters for the leadscrews ....................................................................7

4.4.1 Leadscrew backlash ...................................................................................................7

4.4.2 Leadscrew error .........................................................................................................8

4.5 Machine parameters for axis feedrates ...................................................................... 11

4.6 Machine parameters for axis control ......................................................................... 13

4.7 Machine parameters for machine reference zero ......................................................15

4.8 Parameters for acc/dec of the axes ............................................................................ 18

4.8.1 Linear acc./dec...........................................................................................................18

4.8.2 Bell-shaped acc./dec. .................................................................................................19

4.8.3 Feed-forward gain .....................................................................................................20

4.9 Parameters for the live or synchronized tool ............................................................ 21

4.10 Special machine parameters ......................................................................................23

Section Page

Chapter 5 SPINDLE MACHINE PARAMETERS

5.1 Machine parameters for spindle speed range change ..............................................2

5.2 Machine parameters for analog spindle speed output .............................................4

5.3 Machine parameters for spindle speed output in BCD ............................................5

5.4 Machine parameters for spindle control ...................................................................7

5.4.1 Parameters related to spindle orientation (M19) .....................................................9

Chapter 6 CONCEPTS

6.1 Axes and coordinate systems ....................................................................................1

6.1.1 Nomenclature and selection of the axes ..................................................................1

6.2 Feedback systems ......................................................................................................2

6.2.1 Counting frequency limits ........................................................................................3

6.3 Axis resolution ..........................................................................................................4

6.4 Adjustment of the axes .............................................................................................13

6.4.1 Adjustment of the drift (offset) and maximum feedrate (G00)...............................14

6.4.2 Gain adjustment ........................................................................................................16

6.4.3 Proportional gain adjustment ....................................................................................17

6.4.3.1 Calculation of K1, K2 and gain break-point ............................................................19

6.4.4 Feed-Forward gain adjustment .................................................................................21

6.4.4.1 Calculation of feed-forward gain .............................................................................21

6.4.5 Leadscrew error compensation .................................................................................22

6.5 Reference systems.....................................................................................................25

6.5.1 Reference points........................................................................................................25

6.5.2 Machine reference (home) search .............................................................................26

6.5.3 Adjustment on systems without coded Io ................................................................27

6.5.3.1 Machine reference point (Home) adjustment ...........................................................27

6.5.3.2 Considerations ...........................................................................................................28

6.5.4 Adjustment on axis with coded Io............................................................................29

6.5.4.1 Scale offset adjustment .............................................................................................29

6.5.4.2 Considerations ...........................................................................................................30

6.5.5 Software travel limits for the axes ...........................................................................31

6.6 Auxiliary functions M, S, T ..................................................................................... 32

6.6.1 Decoded M function table ........................................................................................33

6.6.2 M, S, T function transfer ..........................................................................................35

6.6.3 M, S, T function transfer using the M-done signal .................................................36

6.7 Spindle.......................................................................................................................38

6.8 Spindle speed range change ......................................................................................41

6.9 Spindle control ..........................................................................................................43

6.10 Tools ..........................................................................................................................44

6.11 Live/synchronized tool ..............................................................................................45

6.11.1 Live tool ....................................................................................................................45

6.11.2 Synchronized tool ..................................................................................................... 46

6.11.2.1 Application examples for the synchronized tool .....................................................47

6.12 "C" axis .....................................................................................................................48

6.12.1 Adjustment of the "C" axis .......................................................................................48

Section Page

APPENDICES

A Technical characteristics of the CNC...................................................................... 2

B Enclosures................................................................................................................. 5

C Recommended Probe connection diagrams.............................................................. 6

D CNC inputs and outputs ........................................................................................... 7

E 2-digit BCD coded "S" output conversion table ..................................................... 8

F Machine parameter summary chart .......................................................................... 9

G Sequential machine parameter list........................................................................... 14

H Machine parameter setting chart .............................................................................. 20

I Decoded "M" function setting chart ......................................................................... 22

J Leadscrew error compensation setting chart ........................................................... 23

K Maintenance ............................................................................................................. 24

ERROR CODES

COMPARISON TABLE

FOR

LATHE MODEL

FAGOR 8025/8030 CNCs

TECHNICAL DESCRIPTION

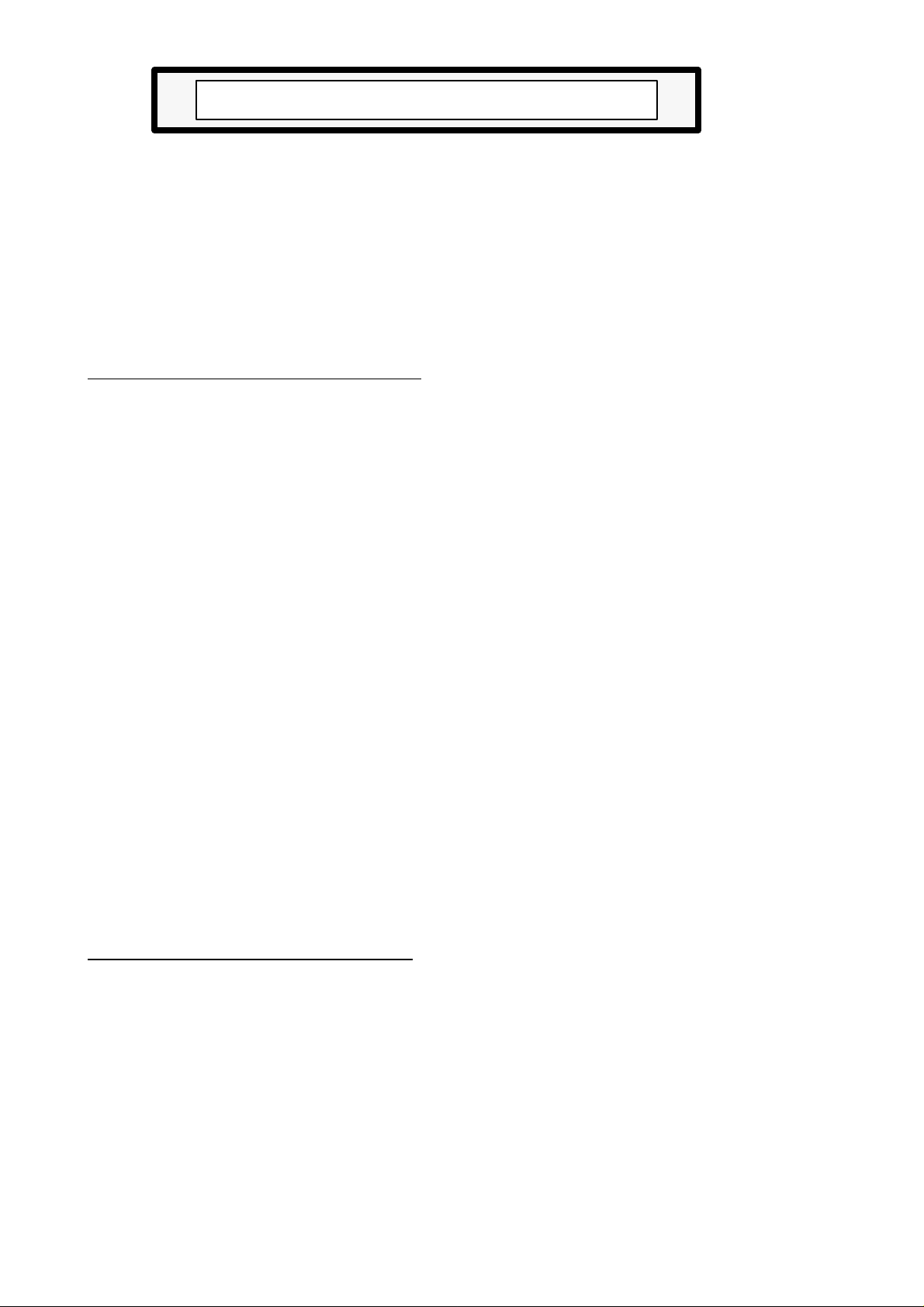

T TG TS

INPUTS/OUTPUTS

Feedback inputs. ............................................................................................. 6 6 6

Probe input .................................................................................................. x x x

Square-wave feedback signal multiplying factor, x2/x4 ................................... x x x

Sine-wave feedback signal multiplying factor, x2/x4/10/x20........................... x x x

Maximum counting resolution 0.001mm/0.001°/0.0001inch........................... x x x

Analog outputs (±10V) for axis servo drives .................................................... 4 4 4

Spindle analog output (±10V) ......................................................................... 1 1 1

Live tool .................................................................................................. 1 1 1

AXIS CONTROL

Axes involved in linear interpolations ............................................................. 3 3 3

Axes involved in circular interpolations .......................................................... 2 2 2

Electronic threading ........................................................................................ x x x

Spindle control ................................................................................................ x x x

Software travel limits....................................................................................... x x x

Spindle orientation .......................................................................................... x x x

PROGRAMMING

Part Zero preset by user.................................................................................... x x x

Absolute/incremental programming................................................................. x x x

Programming in cartesian coordinates.............................................................. x x x

Programming in polar coordinates ................................................................... x x x

Programming by angle and cartesian coordinate .............................................. x x x

Linear axes ................................................................................ 4 4 4

Rotary axes................................................................................ 2 2 2

Spindle encoder ......................................................................... 1 1 1

Electronic handwheel ................................................................ 1 1 1

Third axis as "C" axis ................................................................. x

Synchronized tool ...................................................................... x

COMPENSATION

Tool radius compensation ............................................................................... x x x

Tool length compensation............................................................................... x x x

Leadscrew backlash compensation .................................................................. x x x

Leadscrew error compensation......................................................................... x x x

DISPLAY

CNC text in Spanish, English, French, German and Italian ............................... x x x

Display of execution time................................................................................ x x x

Piece counter .................................................................................................. x x x

Graphic movement display and part simulation ............................................... x x

Tool tip position display ................................................................................. x x x

Geometric programming aide........................................................................... x x x

COMMUNICATION WITH OTHER DEVICES

Communication via RS232C........................................................................... x x x

Communication via DNC ................................................................................ x x x

Communication via RS485 (FAGOR LAN)...................................................... x x x

ISO program loading from peripherals.............................................................. x x x

OTHERS

Parametric programming.................................................................................. x x x

Model digitizing ............................................................................................. x

Possibility of an integrated PLC ...................................................................... x x x

PREPARATORY FUNCTIONS

T TG TS

AXES AND COORDINATES SYSTEMS

Part measuring units. Millimeters or inches (G70,G71)..................................... x x x

Absolute/incremental programming (G90,G91)................................................ x x x

Independent axis (G65) ................................................................................... x x x

REFERENCE SYSTEMS

Machine reference (home) search (G74) ........................................................... x x x

Coordinate preset (G92)................................................................................... x x x

Zero offsets (G53...G59)................................................................................... x x x

Polar origin offset (G93) .................................................................................. x x x

Store current part zero (G31) ............................................................................ x x x

Recover stored part zero (G32)......................................................................... x x x

PREPARATORY FUNCTIONS

Feedrate F .................................................................................................. x x x

Feedrate in mm/min. or inches/min. (G94)........................................................ x x x

feedrate in mm/revolution or inches/revolution (G95)...................................... x x x

Programmable feed-rate override (G49)............................................................ x x x

Spindle speed (S)............................................................................................. x x x

Spindle speed in rpm (G97) ............................................................................. x x x

Constant Surface Speed (G96) ......................................................................... x x x

S value limit when working at constant surface speed (G92)............................ x x x

Tool and tool offset selection (T) ..................................................................... x x x

Activate "C" axis in degrees (G14) ................................................................... x

Main plane C-Z (G15) ..................................................................................... x

Main plane C-X (G16) ..................................................................................... x

AUXILIARY FUNCTIONS

Program stop (M00)......................................................................................... x x x

Conditional program stop (M01) ..................................................................... x x x

End of program (M02) ..................................................................................... x x x

End of program with return to first block (M30) ............................................... x x x

Clockwise spindle start (M03) ......................................................................... x x x

Counter-clockwise spindle start (M04) ............................................................ x x x

Spindle stop (M05).......................................................................................... x x x

Spindle orientation (M19) ............................................................................... x x x

Spindle speed range change (M41, M42, M43, M44)....................................... x x x

Tool change with M06 .................................................................................... x x x

Live tool (M45 S) ............................................................................................ x x x

Synchronized tool (M45 K) ............................................................................. x

PATH CONTROL

Rapid traverse (G00)........................................................................................ x x x

Linear interpolation (G01)............................................................................... x x x

Circular interpolation (G02,G03) ..................................................................... x x x

Circular interpolation with absolute center coordinates (G06).......................... x x x

Circular path tangent to previous path (G08) ................................................... x x x

Arc defined by three points (G09) .................................................................... x x x

Tangential entry (G37) .................................................................................... x x x

Tangential exit (G38) ...................................................................................... x x x

Controlled radius blend (G36) ......................................................................... x x x

Chamfer (G39)................................................................................................. x x x

Electronic threading (G33) .............................................................................. x x x

ADDITIONAL PREPARATORY FUNCTIONS

Dwell (G04 K) ................................................................................................. x x x

Round and square corner (G05, G07) ............................................................... x x x

Scaling factor (G72)......................................................................................... x x x

Single block treatment (G47, G48)................................................................... x x x

User error display (G30)................................................................................... x x x

Automatic block generation (G76)................................................................... x

Communication with FAGOR Local Area Network (G52)................................. x x x

T TG TS

COMPENSATION

Tool radius compensation (G40,G41,G42) ....................................................... x x x

Loading of tool dimensions into internal tool table (G50, G51) ....................... x x x

CANNED CYCLES

Pattern repeat (G66)......................................................................................... x x x

Roughing along X (G68) ................................................................................. x x x

Roughing along Z (G69) ................................................................................. x x x

Straight section turning (G81) ......................................................................... x x x

Straight section facing (G82) ........................................................................... x x x

Deep hole drilling (G83).................................................................................. x x x

Circular section turning (G84) ......................................................................... x x x

Circular section facing (G85)........................................................................... x x x

Longitudinal threadcutting (G86).................................................................... x x x

Face threadcutting (G87) ................................................................................. x x x

Grooving along X (G88) .................................................................................. x x x

Grooving along Z (G89) .................................................................................. x x x

PROBING

Probing (G75).................................................................................................. x x x

Tool calibration canned cycle (G75N0) ........................................................... x

Probe calibration canned cycle (G75N1).......................................................... x

Part measuring canned cycle along X (G75N2) ................................................ x

Part measuring canned cycle along Z (G75N3)................................................. x

Part measuring canned cycle with tool compensation along X (G75N4) ........... x

Part measuring canned cycle with tool compensation along Z (G75N5)............ x

SUBROUTINES

Number of standard subroutines....................................................................... 99 99 99

Definition of a standard subroutine (G22) ........................................................ x x x

Call to a standard subroutine (G20) ................................................................. x x x

Number of parametric subroutines ................................................................... 99 99 99

Definition of a parametric subroutine (G23) ..................................................... x x x

Call to a parametric subroutine (G21) .............................................................. x x x

End of standard or parametric subroutine (G24) ............................................... x x x

JUMP OR CALL FUNCTIONS

Unconditional jump/call (G25)........................................................................ x x x

Jump or call if zero (G26)................................................................................. x x x

Jump or call if not zero (G27)........................................................................... x x x

Jump or call if smaller (G28) ............................................................................ x x x

Jump or call if greater (G29)............................................................................. x x x

NEW FEATURES

AND

MODIFICATIONS

Date: March 1991 Software Version: 2.1 and newer

FEATURE MODIFIED MANUAL & SECTION

The home searching direction is set by machine Installation Manual Section 4.7

parameter P618(5,6,7,8)

The 2nd home searching feedrate is set by Installation Manual Section 4.7

machine parameter P807...P810

New resolution values 1, 2, 5 and 10 for sine-wave Installation Manual Section 4.1

feedback signals P619(1,2,3,4)

Access to PLCI registers from the CNC Programming Manual G52

Date: June 1991 Software Version: 3.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

New function: F36. It takes the value of the Programming Manual Chapter 13

selected tool number

G68 and G69 canned cycles modified. if P9=0 Programming Manual Chapter 13

it runs another final roughing pass

Date: September 1991 Software Version: 3.2 and newer

FEATURE MODIFIED MANUAL AND SECTION

Subroutine associated with the T function Installation Manual Section 3.3.5

G68 and G69 canned cycles modified. Programming Manual Chapter 13

P9 can now have a negative value

Date: March 1992 Software Version: 4.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

Bell-shaped ACC./DEC. Installation Manual Section 4.8

It is now possible to enter the sign of the Installation Manual Section 4.4

leadscrew backlash for each axis P620(1,2,3,4)

Independent axis movement execution Programming Manual G65

It is now possible to work at Constant Surface Installation Manual Section 3.3.9

Speed in JOG mode P619(8)

Date: July 1992 Software Version: 4.2 and newer

FEATURE MODIFIED MANUAL AND SECTION

Synchronisation with independent axis P621(4) Installation Manual Section 3.3.10

Date: July 1993 Software Version: 5.1 and newer

FEATURE MODIFIED MANUAL AND SECTION

Linear & Bell-shaped acc./dec. ramp combination Installation Manual Section 4.8

Spindle acc/dec control. P811 Installation Manual Section 5.

The subroutine associated with the tool Installation Manual Section 3.3.5

is executed before the T function. P617(2)

G68 and G69 cycles modified. If P10 <> 0, Programming Manual Chapter 13

it runs a final roughing pass before the

finishing pass

When having only one spindle range, if G96 is Programming Manual Chapter 6

executed without any range being selected, the

CNC will automatically select it.

8030 CNC with VGA Monitor Installation Manual Chapter 1

Date: March1995 Software Version: 5.3 and newer

FEATURE MODIFIED MANUAL AND SECTION

Management of semi-absolute feedback devices Installation Manual Sections 4.7 & 6.5.

(with coded Io)

Spindle inhibit by PLC Installation Manual Section 3.3.10

Handwheel managed by PLC Installation Manual Section 3.3.3

Simulation of the "rapid JOG" key from PLC PLCI Manual

Initialization of machine parameters in case of

memory loss.

Atention:

INTRODUCTION

Before starting up the CNC, carefully read the instructions of Chapter

2 in the Installation Manual.

The CNC must not be powered-on until verifying that the machine

complies with the "89/392/CEE" Directive.

Introduction - 1

DECLARATION OF CONFORMITY

Manufacturer: Fagor Automation, S. Coop.

Barrio de San Andrés s/n, C.P. 20500, Mondragón -Guipúzcoa- (ESPAÑA)

We hereby declare, under our responsibility that the product:

Fagor 8025 T CNC

meets the following directives:

SAFETY:

EN 60204-1 Machine safety. Electrical equipment of the machines.

ELECTROMAGNETIC COMPATIBILITY:

EN 50081-2 Emission

EN 55011 Radiated. Class A, Group 1.

EN 55011 Conducted. Class A, Group 1.

EN 61000-3-2 Current Harmonics

EN 61000-3-3 Voltage fluctuations and flickers

EN 50082-2 Immunity

EN 61000-4-2 Electrostatic Discharges.

EN 61000-4-3 Radiofrequency Radiated Electromagnetic Fields.

EN 61000-4-4 Bursts and fast transients.

EN 61000-4-5 Conducted high voltage pulses in mains (Surges)

EN 61000-4-6 Conducted disturbance induced by radio frequency fields.

EN 61000-4-8 Magnetic fields at mains frequency

EN 61000-4-11 Voltage fluctuations and Outages.

ENV 50204 Fields generated by digital radio-telephones

As instructed by the European Community Directives: on Low Voltage 73/23/CEE, on

Machine Safety 89/392/EEC, 89/336/EEC on Electromagnetic Compatibility and its

upgrades.

In Mondragón, on October 1st, 2001

Introduction - 3

SAFETY CONDITIONS

Read the following safety measures in order to prevent damage to personnel, to

this product and to those products connected to it.

This unit must only be repaired by personnel authorized by Fagor Automation.

Fagor Automation shall not be held responsible for any physical or material

damage derived from the violation of these basic safety regulations.

Precautions against personal damage

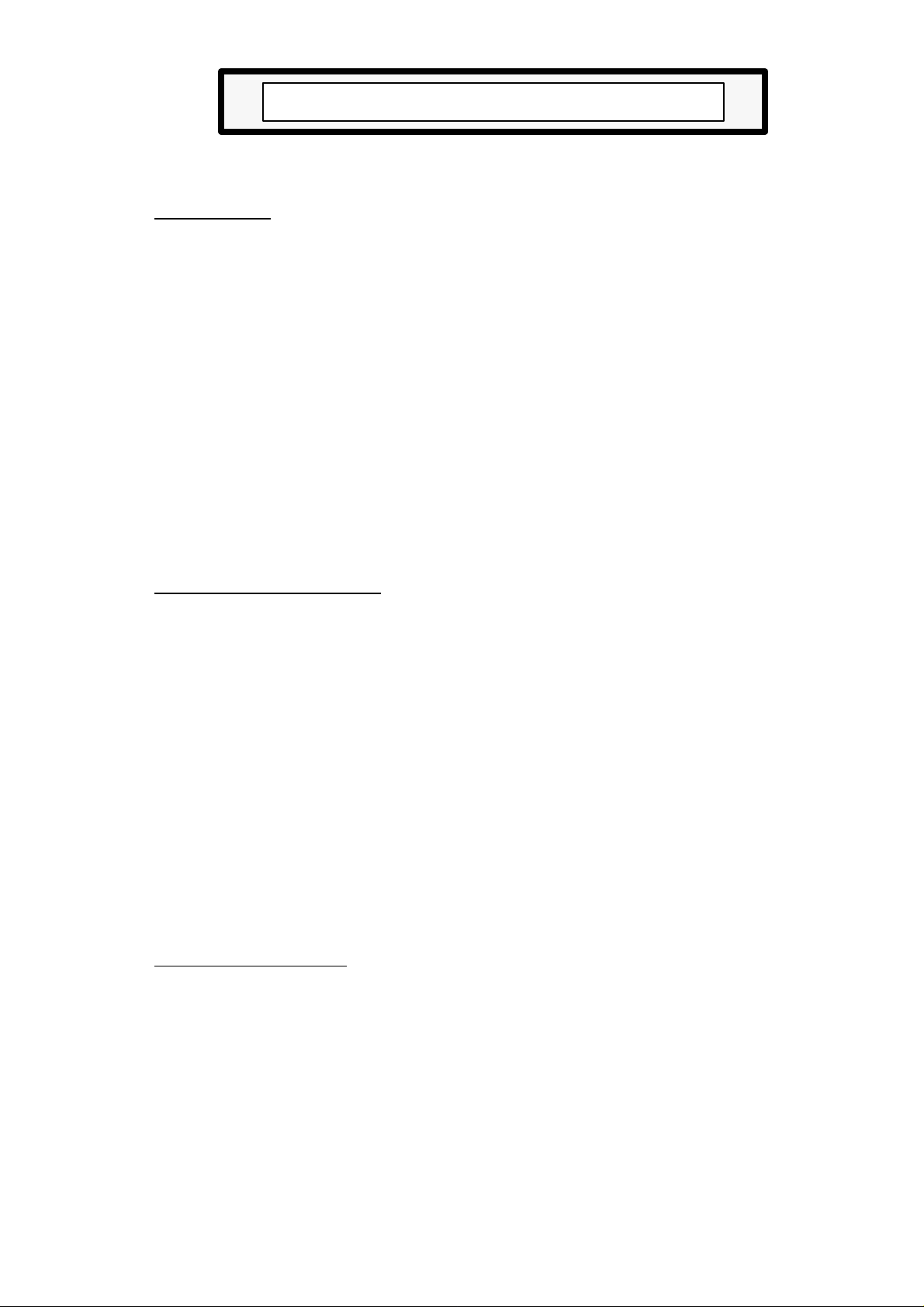

Module interconnection

Use the cables supplied with the unit.

Use proper Mains AC power cables

To avoid risks, use only the Mains AC cables recommended for this unit.

Avoid electrical overloads

In order to avoid electrical discharges and fire hazards, do not apply electrical voltage

outside the range selected on the rear panel of the Central Unit.

Ground connection

In order to avoid electrical discharges, connect the ground terminals of all the

modules to the main ground terminal. Before connecting the inputs and outputs of this

unit, make sure that all the grounding connections are properly made.

Before powering the unit up, make sure that it is connected to ground

In order to avoid electrical discharges, make sure that all the grounding connections

are properly made.

Do not work in humid environments

In order to avoid electrical discharges, always work under 90% of relative humidity

(non-condensing) and 45º C (113º F).

Do not work in explosive environments

In order to avoid risks, damage, do not work in explosive environments.

Precautions against product damage

Working environment

This unit is ready to be used in Industrial Environments complying with the directives

and regulations effective in the European Community

Fagor Automation shall not be held responsible for any damage suffered or caused

when installed in other environments (residential or homes).

Install the unit in the right place

Introduction - 4

It is recommended, whenever possible, to instal the CNC away from coolants,

chemical product, blows, etc. that could damage it.

This unit complies with the European directives on electromagnetic compatibility.

Nevertheless, it is recommended to keep it away from sources of electromagnetic

disturbance such as.

- Powerful loads connected to the same AC power line as this equipment.

- Nearby portable transmitters (Radio-telephones, Ham radio transmitters).

- Nearby radio / TC transmitters.

- Nearby arc welding machines

- Nearby High Voltage power lines

- Etc.

Enclosures

The manufacturer is responsible of assuring that the enclosure involving the equipment

meets all the currently effective directives of the European Community.

Avoid disturbances coming from the machine tool

The machine-tool must have all the interference generating elements (relay coils,

contactors, motors, etc.) uncoupled.

Use the proper power supply

Use an external regulated 24 Vdc power supply for the inputs and outputs.

Grounding of the power supply

The zero volt point of the external power supply must be connected to the main ground

point of the machine.

Analog inputs and outputs connection

It is recommended to connect them using shielded cables and connecting their shields

(mesh) to the corresponding pin (See chapter 2).

Ambient conditions

The working temperature must be between +5° C and +45° C (41ºF and 113º F)

The storage temperature must be between -25° C and 70° C. (-13º F and 158º F)

Monitor enclosure

Assure that the Monitor is installed at the distances indicated in chapter 1 from the

walls of the enclosure.

Use a DC fan to improve enclosure ventilation.

Main AC Power Switch

This switch must be easy to access and at a distance between 0.7 m (27.5 inches) and

1.7 m (5.6 ft) off the floor.

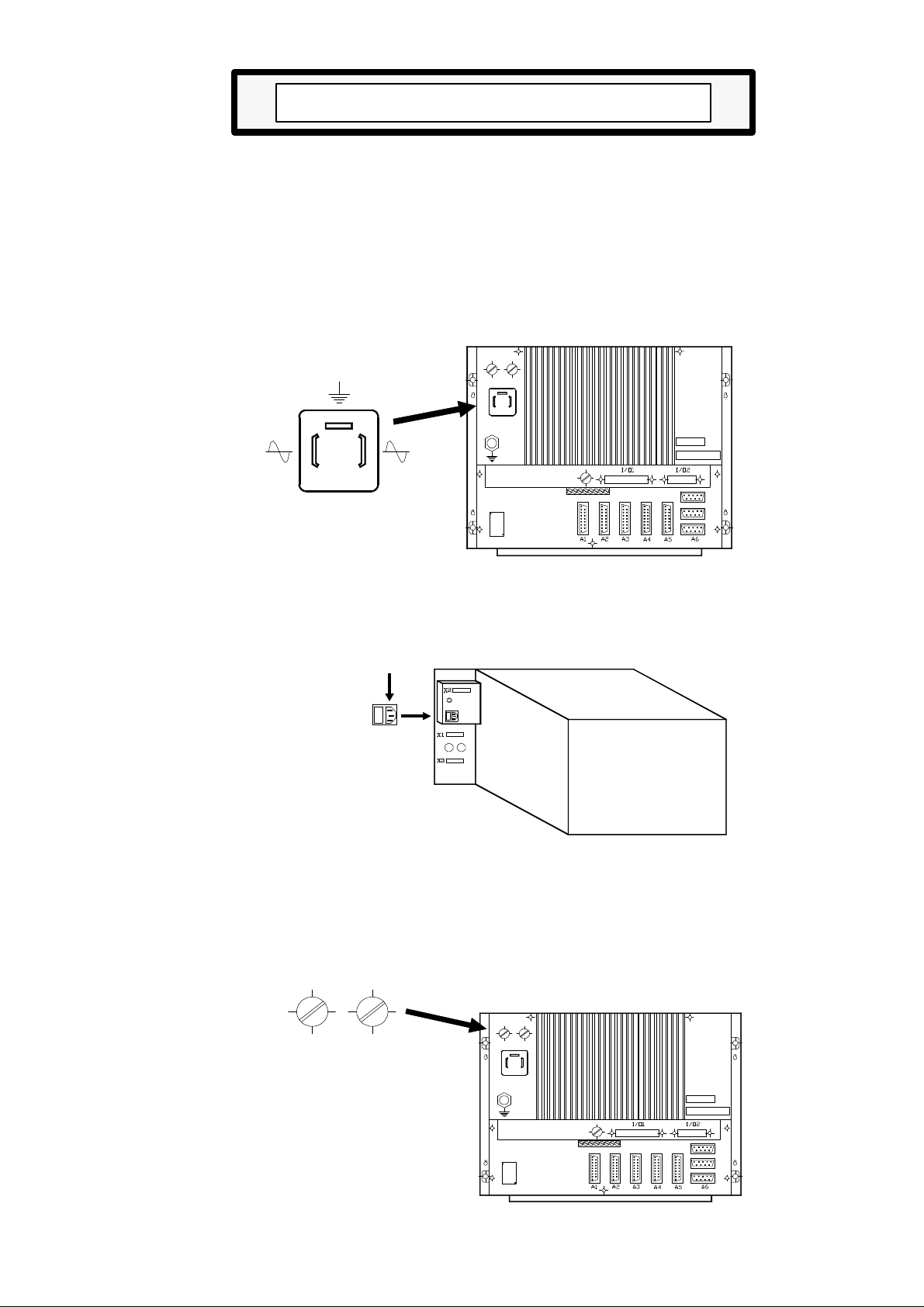

Protections of the unit itself

It carries two fast fuses of 3.15 Amp./ 250V. to protect the mains AC input.

All the digital inputs and outputs have galvanic isolation via optocouplers between

the CNC circuitry and the outside.

They are protected by an external fast fuse (F) of 3.15 Amp./ 250V. against over

voltage and reverse connection of the power supply.

The type of fuse depends on the type of monitor. See the identification label of the

unit.

Introduction - 5

Precautions during repair

Do not manipulate the inside of the unit

Only personnel authorized by Fagor Automation may manipulate the

inside of this unit.

Do not manipulate the connectors with the unit connected to AC

power.

Before manipulating the connectors (inputs/outputs, feedback, etc.)

make sure that the unit is not connected to AC power.

Safety symbols

Symbols which may appear on the manual

WARNING. symbol

It has an associated text indicating those actions or operations may hurt

people or damage products.

Symbols that may be carried on the product

WARNING. symbol

It has an associated text indicating those actions or operations may hurt

people or damage products.

"Electrical Shock" symbol

It indicates that point may be under electrical voltage

"Ground Protection" symbol

It indicates that point must be connected to the main ground point of the

machine as protection for people and units.

Introduction - 6

WARRANTY

All products manufactured or marketed by Fagor Automation has a warranty period

of 12 months from the day they are shipped out of our warehouses.

The mentioned warranty covers repair material and labor costs, at FAGOR facilities,

incurred in the repair of the products.

Within the warranty period, Fagor will repair or replace the products verified as being

defective.

FAGOR is committed to repairing or replacing its products from the time when the

first such product was launched up to 8 years after such product has disappeared from

the product catalog.

It is entirely up to FAGOR to determine whether a repair is to be considered under

warranty.

WARRANTY TERMS

EXCLUDING CLAUSES

The repair will take place at our facilities. Therefore, all shipping expenses as well

as travelling expenses incurred by technical personnel are NOT under warranty even

when the unit is under warranty.

This warranty will be applied so long as the equipment has been installed according

to the instructions, it has not been mistreated or damaged by accident or negligence

and has been manipulated by personnel authorized by FAGOR.

If once the service call or repair has been completed, the cause of the failure is not to

be blamed the FAGOR product, the customer must cover all generated expenses

according to current fees.

No other implicit or explicit warranty is covered and FAGOR AUTOMATION shall

not be held responsible, under any circumstances, of the damage which could be

originated.

SERVICE CONTRACTS

Service and Maintenance Contracts are available for the customer within the

warranty period as well as outside of it.

Introduction - 7

MATERIAL RETURNING TERMS

When returning the CNC, pack it in its original package and with its original packaging

material. If not available, pack it as follows:

1.- Get a cardboard box whose three inside dimensions are at least 15 cm (6 inches) larger

than those of the unit. The cardboard being used to make the box must have a

resistance of 170 Kg (375 lb.).

2.- When sending it to a Fagor Automation office for repair, attach a label indicating the

owner of the unit, person to contact, type of unit, serial number, symptom and a brief

description of the problem.

3.- Wrap the unit in a polyethylene roll or similar material to protect it.

When sending the monitor, especially protect the CRT glass.

4.- Pad the unit inside the cardboard box with poly-utherane foam on all sides.

5.- Seal the cardboard box with packing tape or industrial staples.

Introduction - 8

ADDITIONAL REMARKS

* Mount the CNC away from coolants, chemical products, blows, etc. which could

damage it.

* Before turning the unit on, verify that the ground connections have been properly

made. See Section 2.2 of this manual.

* To prevent electrical shock at the Central Unit, use the proper mains AC connector at

the Power Supply Module. Use 3-wire power cables (one for ground connection)

* To prevent electrical shock at the Monitor, use the proper mains AC connector at the

Power Supply Module. Use 3-wire power cables (one for ground connection)

* Before turning the unit on, verify that the external AC line fuse, of each unit, is the right

one.

Central Unit

Must be 2 fast fuses (F) of 3.15 Amp./ 250V.

Introduction - 9

Monitor

Depends on the type of monitor. See identification label of the unit itself.

* In case of a malfunction or failure, disconnect it and call the technical service. Do not

manipulate inside the unit.

Introduction - 10

FAGOR DOCUMENTATION

FOR THE 8025/30 T CNC

8025 T CNC OEM Manual Is directed to the machine builder or person in charge of installing and starting

up the CNC.

It contains 2 manuals:

Installation Manual describing how to isntall and set-up the CNC.

LAN Manual describing how to instal the CNC in the Local

Sometimes, it may contain an additional manual describing New Software

Features recently implemented.

8025 T CNC USER Manual Is directed to the end user or CNC operator.

It contains 2 manuals:

Operating Manual describing how to operate the CNC.

Programming Manual describing how to program the CNC.

Sometimes, it may contain an additional manual describing New Software

Features recently implemented.

DNC 25/30 Software Manual Is directed to people using the optional DNC communications software.

Area Network.

DNC 25/30 Protocol Manual Is directed to people wishing to design their own DNC communications

software to communicate with the 800 without using the DNC25/30 software..

PLCI Manual To be used when the CNC has an integrated PLC.

Is directed to the machine builder or person in charge of installing and starting

up the PLCI.

DNC-PLC Manual Is directed to people using the optional communications software: DNC-PLC.

FLOPPY DISK Manual Is directed to people using the Fagor Floppy Disk Unit and it shows how to use

it.

Introduction - 11

Loading...

Loading...