Fagor Automation S. Coop.

Manual code: 14460054

Manual version: 0612

Software version: 4.xx

20i-T / 30i-T

20i-T B / 30i-T B

Installation/Operation Manual

INDEX

1 DRO description ..........................................................................................3

1.1 Front panel ........................................................................................................................ 3

1.2 Turning the unit on and off .............................................................................................. 4

2 DRO operation .............................................................................................5

2.1 Display modes .................................................................................................................. 5

2.2 Incremental, absolute and with respect to Machine Reference Zero .......................... 6

2.2.1 Example .............................................................................................................................. 7

2.3 Machine Reference selection and search ...................................................................... 9

2.3.1 Home search sequence ......................................................................................................9

2.4 Operation with tools ....................................................................................................... 10

2.4.1 Tool Preset ....................................................................................................................... 10

2.4.2 Deleting all tool offsets ..................................................................................................... 10

2.5 Special operations.......................................................................................................... 11

2.5.1 Scaling factor .................................................................................................................... 11

2.5.2 To access the special functions (Hold, taper calculation, calculator) ............................... 11

2.5.3 Coordinate freeze (HOLD). ............................................................................................... 11

2.5.4 Taper (cone) calculation ................................................................................................... 12

2.5.5 Calculator ......................................................................................................................... 13

2.5.5.1 Operating with the calculator. ........................................................................................... 13

2.5.5.2 Recall and Reset modes ..................................................................................................14

3 DRO installation ........................................................................................15

3.1 Installation of the built-in model ................................................................................... 15

3.2 Rear panel ....................................................................................................................... 16

3.3 General technical characteristics ................................................................................. 17

3.4 Connections .................................................................................................................... 17

3.4.1 Connection of the feedback systems ................................................................................ 17

3.5 Easy setup....................................................................................................................... 18

3.5.1 Accessing the "Easy Setup" mode ................................................................................... 18

3.5.2 Operating mode. ............................................................................................................... 18

3.5.3 Power and machine connection ....................................................................................... 19

3.6 Installation parameters .................................................................................................. 19

3.7 Parameters to configure axis position reading and display....................................... 21

4 Appendix ....................................................................................................27

4.1 UL seal............................................................................................................................. 27

4.2 CE seal............................................................................................................................. 27

4.2.1 Declaration of conformity .................................................................................................. 27

4.2.2 Safety conditions .............................................................................................................. 28

4.2.3 Warranty terms ................................................................................................................. 30

4.2.4 Material returning terms .................................................................................................... 30

4.3 Error codes ..................................................................................................................... 31

4.4 Maintenance .................................................................................................................... 32

(2/32) - Installation/Operation - 20i-T / 30i-T - V0612

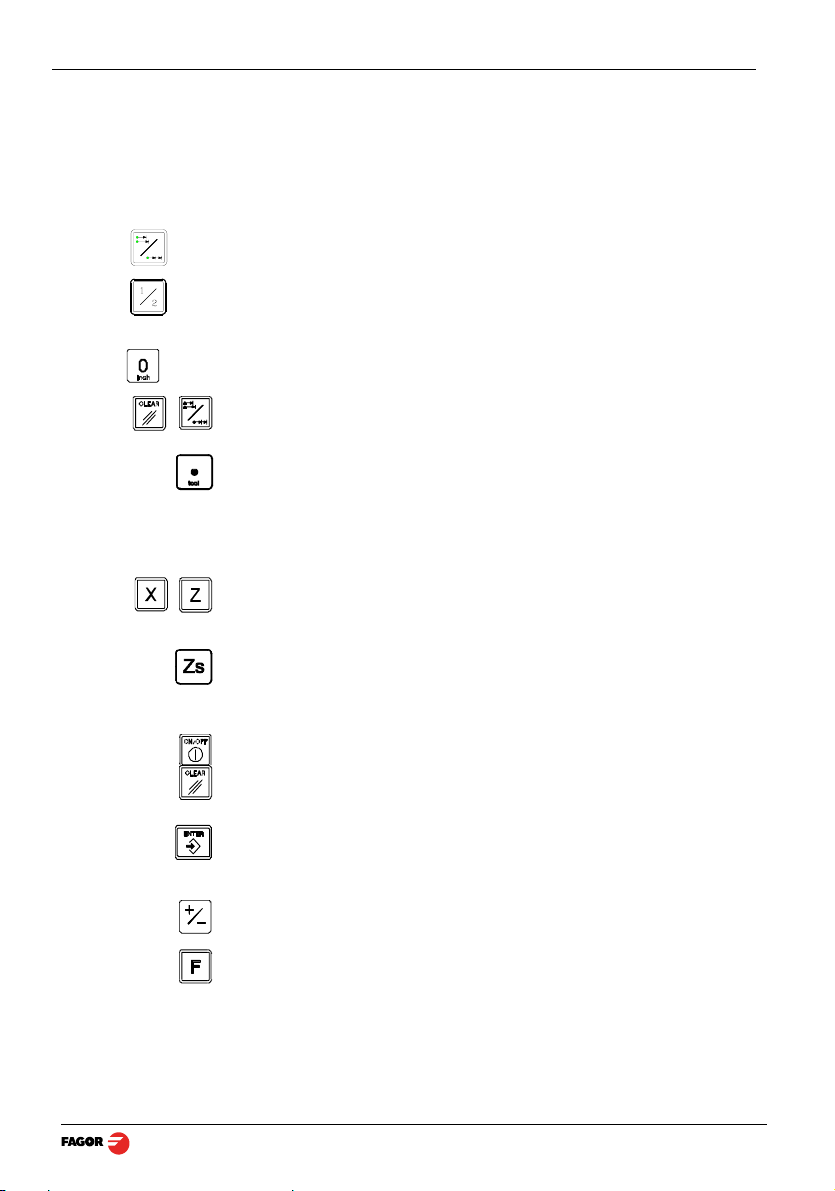

1.1 Front panel

Each axis display has eight 14.1mm high LEDs and another one for the minus

sign (-).

Description of LED's and keys:

ABS It stays on when operating in absolute mode and off when in incremental

mode. To access it or quit it, press this key.

Φ It stays on when operating in diameter mode. In this mode, the DRO displays

twice the actual axis movement. To access it or quit it, use this key if allowed

by installation parameter PAR04.

INCH It stays on when working in inches and off when doing it in millimeters. To

access it or quit it, press this key.

To get into and out of home search mode.

Selection of the current tool.

There are 20 tools that may be set for the part when using absolute

coordinates. The possible reference points (datum points) are from 0 to 19.

The 20i-T model shows the active reference on the display at all times,

whereas the 30i-T model only shows it when it is selected, after pressing the

reference key.

To select the axis or preset it with a certain value.

To zero the axis when the "quick zeroing" mode has been activated (see

PAR11 in the installation manual).

Only at the 30i-T. Key to select whether the 2nd display corresponds to "Z

"Z

" or to the "Z1+Z2" combination respectively. Every time this key is

2

pressed, the rightmost digit of the 3rd display rotates from "1" to "2" and off

respectively.

To turn the display off while keeping track of the axes position at all times.

To cancel or abort an operation already initiated.

1 DRO description

1

",

To validate a preset value or another operation.

Beginning of preset when the "quick zeroing" mode has been activated (see

PAR11 in the installation manual).

To change the sign of the entered value or change from fine to coarse

resolution and vice versa.

To access the special functions (Hold, taper calculation)

V0612 - 20i-T / 30i-T - Installation/Operation - DRO description - (3/32)

1.2 Turning the unit on and off

It turns on automatically when applying voltage or after pressing the on/off

key.

It shows Fagor dro or the corresponding error code. See the error table and

PAR11 for more options.

Turns the DRO on or off.

Precautions

Before disconnecting this unit from mains, press this key so it saves the

current position.

If the unit is turned off or there is a power outage, the DRO will try to save the

current position. If it does not have enough time to safe all the data, it will

display ERROR 2 when turned back on.

(4/32) - DRO description - Installation/Operation - 20i-T / 30i-T - V0612

2 DRO operation

2.1 Display modes

MM / INCH conversion

To display the position of the axes either in millimeters or inches by pressing

this key depending on whether the INCH led is off or on respectively.

Fine / coarse resolution

To turn off the last decimal digit (coarse resolution) for cases in which fine

resolution is excessive, simply by pressing this key.

Number of decimals

This keystroke sequence accesses parameter PAR53. The first digit

corresponds to the number of decimals to be displayed in mm and the second

digit in inches.

Radius / Diameter

When these models are used for measuring radii or diameters, one can

display twice the real displacement of the axis (diameter) by pressing this key.

The Φled will turn on or off to indicate the double or actual reading

respectively.

Notes: - This works in this way if bit 2 of installation parameter PAR04

Z axis as a single axis or combination of both (Z1 and Z2). Only at the 30i-T:

Axis feedrate. Only at the 30i-T:

(radius/diameter) of the axis has been preset as “1” (commutated).

To display the Z axis position, one or two feedback devices may be used. One

for the cross slide (Z

When using two feedback devices, the "Z" axis display may show the position

of Z1, that of Z2 or the result from combining (adding) the positions of both

axes.

The rightmost digit of the third display shows a "1", a "2" or is off to indicate

that the Z axis display (2nd one) corresponds to "Z

combination of "Z

key. It also shows the text "tool" followed by the number of the active tool

corresponding to the XZ coordinates shown on the other displays.

The third axis (Zs) display shows the feedrate of the fastest moving axis in

m/min or feet/min depending on the status of the "inch" LED. To activate or

cancel this option, see PAR11 in the installation manual.

)and the other one for the carriage (Z2).

1

", "Z2" or to the

" respectively. This selection rotates by pressing this

1+Z2

1

V0612 - 20i-T / 30i-T - Installation/Operation - DRO operation - (5/32)

2.2 Incremental, absolute and with respect to Machine Reference Zero

This DRO shows the current position of two or three axes (20i-T / 30i-T).

Coordinate means the distance from one point or position with respect with

another chosen as reference.

These DRO's can show the position of the axes in incremental or absolute

mode.

•In Home mode, it displays the distance from the current position of the axis

to the home point chosen in the feedback system.

Press this sequence to access the Home mode (only to search home).

(ABS) •In Absolute (ABS), when the ABS led is on , it displays the distance from

the present position of the axis to part zero (D).

(I) •In Incremental, when the ABS and "home" LEDs are off the distance from

the present position of the axis to the previous position is displayed.

Toggles between the ABS and incremental modes.

It could occur that the installation parameter PAR11(1) has been set to “0” for

this key to independently affect each axis so that one axis can display its

position in incremental mode while the other does this in absolute. In this

case, to change the display mode, press one of these two sequences.

(6/32) - DRO operation - Installation/Operation - 20i-T / 30i-T - V0612

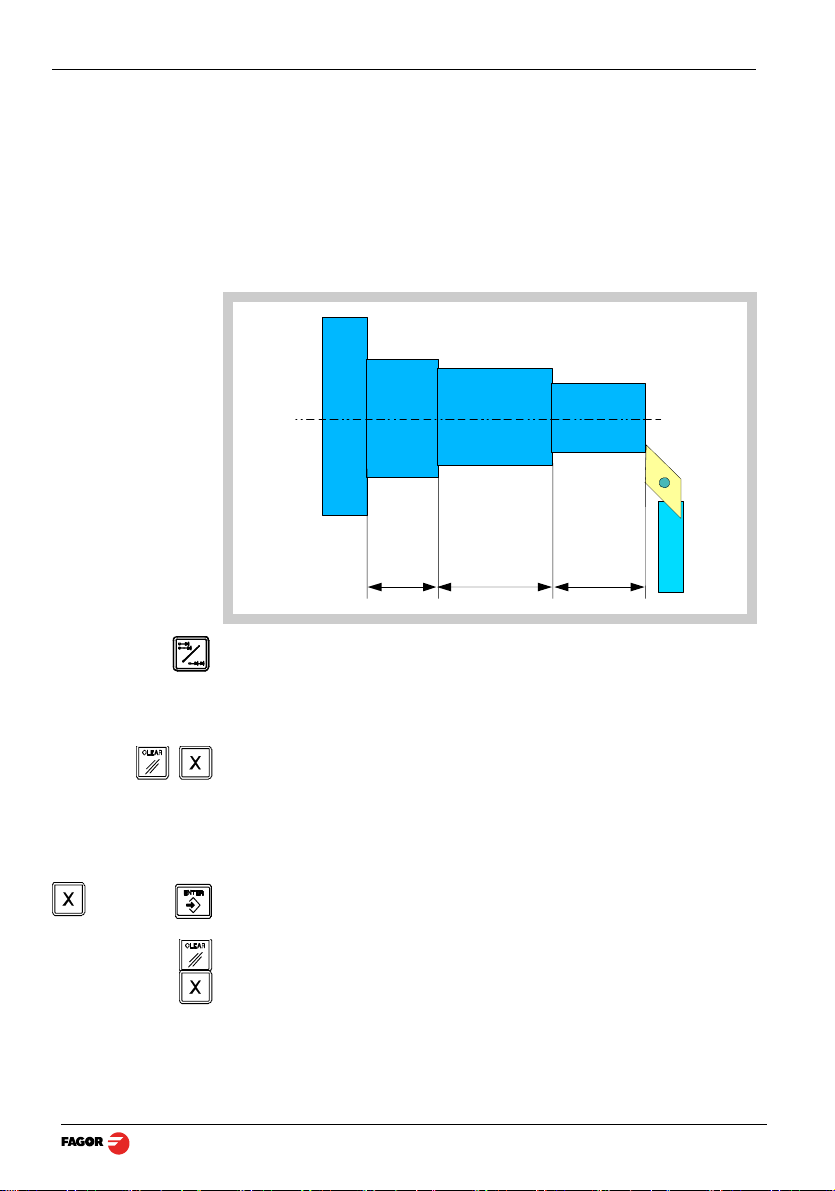

2.2.1 Example

In incremental

mode:

Using the lower figure, let us imagine we wish to make a part in which three

holes have to be drilled with the coordinates stated. It is clear that the

blueprint will only reflect the incremental coordinates (I) or the absolute ones

(ABS) referring to the part zero (point "0" in the figure) although the DRO also

shows them with respect to home (Io).

After referencing the axes, as was described in the previous section, we can

make this part in incremental or absolute mode according to whether we

chose a type of dimensions (I) or (ABS) of the blue-print.

[22.600

[22.600]

[0.000]

15.000

-Press this key until the ABS LED is turned off.

-Move the axis up to the face of the part to set it as part zero.

At this point, one can proceed in two ways:

-Preset the axis with a zero value by pressing this keystroke sequence:

-Move the axis towards the first position until the DRO reads: 22.600.

or...

-Preset the axis with a value of 22.600 by pressing this keystroke sequence.

In case of a mistake, press this key to cancel it and leave it as it was.

Pressing this key displays the previous preset value.

- Move the axis towards the first position until the DRO reads: 0.000.

This last method turns out to be more practical as after selecting the

destination coordinate one only has to remember to move the axis until the

DRO reads zero.

V0612 - 20i-T / 30i-T - Installation/Operation - DRO operation - (7/32)

22.60025.000

[25.000]

[0.000]

Note:

ABS

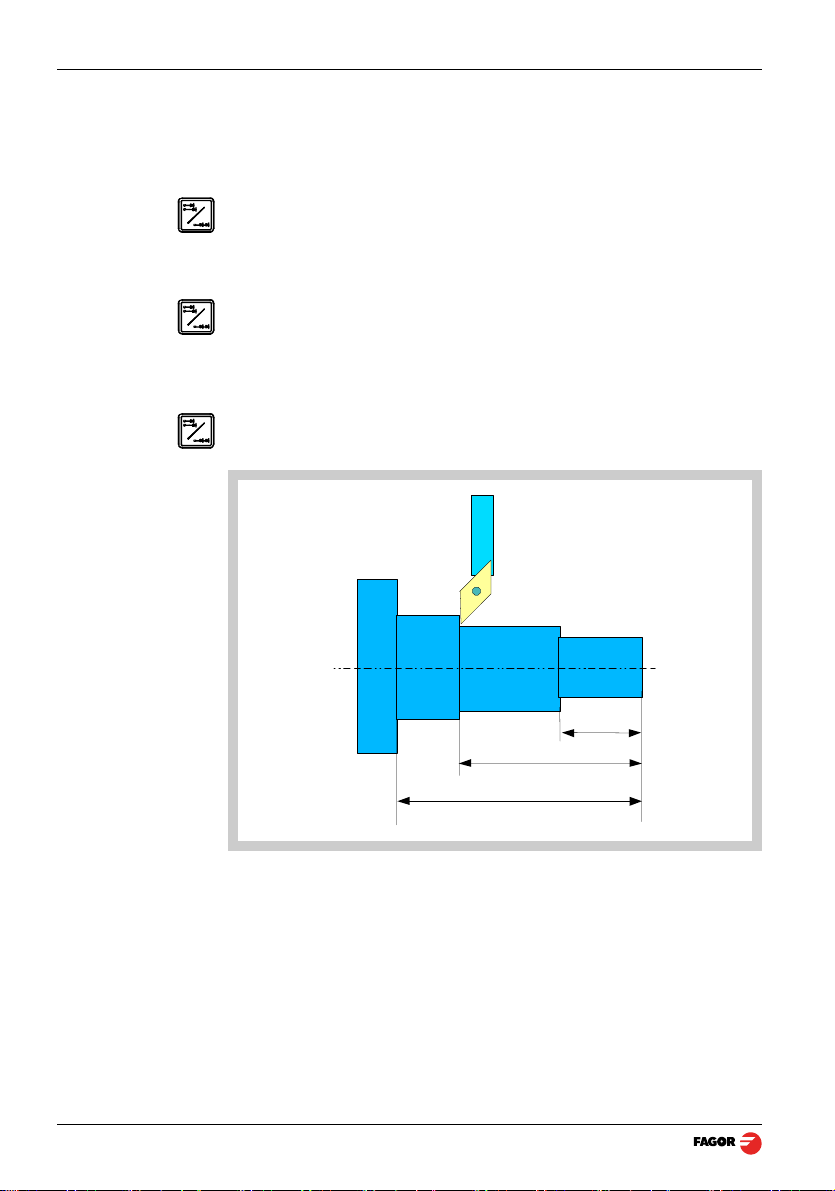

In absolute mode:

ABS

ABS

- Once this turning operation has concluded, one can go to the next position,

after having preset the next coordinate (25.000), by moving the axis until the

display reads 0.000.

- And so on until all the turning operations are concluded.

By pressing this key until the ABS LED lights up, the DRO will show the real

position of the axis with respect to part zero "0"

-Press this key until the ABS LED is turned on.

-To preset part zero:

-Place the axis exactly over “0” and press:

At any time, by pressing this key, the DRO will display the present position

with respect with the previous zero (ABS led on).

(8/32) - DRO operation - Installation/Operation - 20i-T / 30i-T - V0612

22.600

47.600

63.600

2.3 Machine Reference selection and search

Although it is not absolutely necessary, it is recommended to use the

reference marks (Io) of the feedback system in order to set a machine zero

point.

This allows the user to reference the machine axes and restore the work

coordinates after having turned the dro off, moved the machine while the dro

was off, for safety or for any other reason.

Fagor linear encoders have reference marks every 50 mm all along its length.

In order to use these marks properly, choose an area on the axis, for example

in the middle of the measuring length or at one end. Approach this area and

carry out the home search. Once the reference mark has been found, mark

this area with a marker or sticker in order to carry out the home search in the

same area in later occasions and make sure that you are using the same

machine zero point (home).

Fagor also offers encoders with distance-coded reference marks every 20, 40

or 100 mm. When using these distance-coded reference marks, there is no

need to move to the 0 position to find the references, simply move a distance

equal to the gap between marks (20, 40 or 100 mm depending on the linear

encoder)

When using an absolute encoder, there is no need to search for the reference

marks (home).

The dro stores in its internal memory work coordinates such as machine zero,

absolute and incremental.

2.3.1 Home search sequence

For encoders with regular reference marks, move the axis to the home area.

Access or exit the home search mode.

The axis displays blink showing " r " if the axis has not been homed or

" r on" if it has been homed.

Select the axis to be referenced (homed)

The selected axis blinks until a reference mark is detected. The reference

signal presets the axis display automatically with the value of PAR10, 0.000

mm by default.

If the encoder does not have a reference mark, move the axis to the desired

position and press this key.

V0612 - 20i-T / 30i-T - Installation/Operation - DRO operation - (9/32)

2.4 Operation with tools

2.4.1 Tool Preset

Up to 20 tools may be preset on this DRO model (from "tool 0" to "tool 19").

The unit stores in its internal memory the relative offsets of all the tools with

respect to that of "T0".

Therefore, if "T0" has been preset in ABS mode (on X and Z) and, then, the

rest of the tools, it will suffice to just preset "T0" again (on Z) to make a new

part. The DRO will then automatically recalculate all the offsets of the rest of

the tools without having to preset them for each part.

To preset a tool, just follow this procedure:

ABS

Notes: The presets done with any tool in incremental mode change the part zero for

- Place a part of known diameter in the chuck in absolute mode (ABS led on).

- Move the tool to be preset until it touches the part.

- Press this key. The 3rd display shows the word "tool" followed by the

number of the active tool.

- Enter the tool number.

- Press [ENTER] to validate this operation or [C] to cancel it.

- Preset the part diameter.

These tool presets are kept in memory even when the unit is powered off up

to a maximum of 10 years.

all the tools.

If a tool offset has been preset in Z

the same mode (Z

The tool offsets are referred to the machine zero found at the time. When

turning the DRO on, it is necessary to find the same reference mark.

The calculator function can also be used to preset an axis with the result of

the calculation. See section 2.5.5 Calculator.

, Z2 or Zs) when using it to machine the part.

1

, Z2 or Zs mode, that tool must be used in

1

2.4.2 Deleting all tool offsets

To delete the offsets of ALL the tools. Press this keystroke sequence: It will

show the text: "Delete?",

Press [ENTER] to validate the operation or [C] to cancel it.

(10/32) - DRO operation - Installation/Operation - 20i-T / 30i-T - V0612

Loading...

Loading...