Page 1

Specifications:

Model Number:

Type

Sensing Range

Voltage Supply

Current Drain

Response Time

Light Source

LEDs

Trigger Output

Switching Capacity

Enclosure

Ambient Temperature

Mounting Brackets for Sensor and Reflector

Troubleshooting:

E-931-S45RRQ

Retro-Reflective

0.5' to 45' (0.2 - 14 m)

12-250 VDC or VAC

70mA@12VDC

5ms~100ms (Adjustable)

IR LED

Yellow LED (Alignment), Red LED (trigger)

SPDT Relay output (NO/NC/COM

3A@120VAC / 3A@30VDC

IP 66 Weatherproof

-40~1310F (-200~550C)

Included

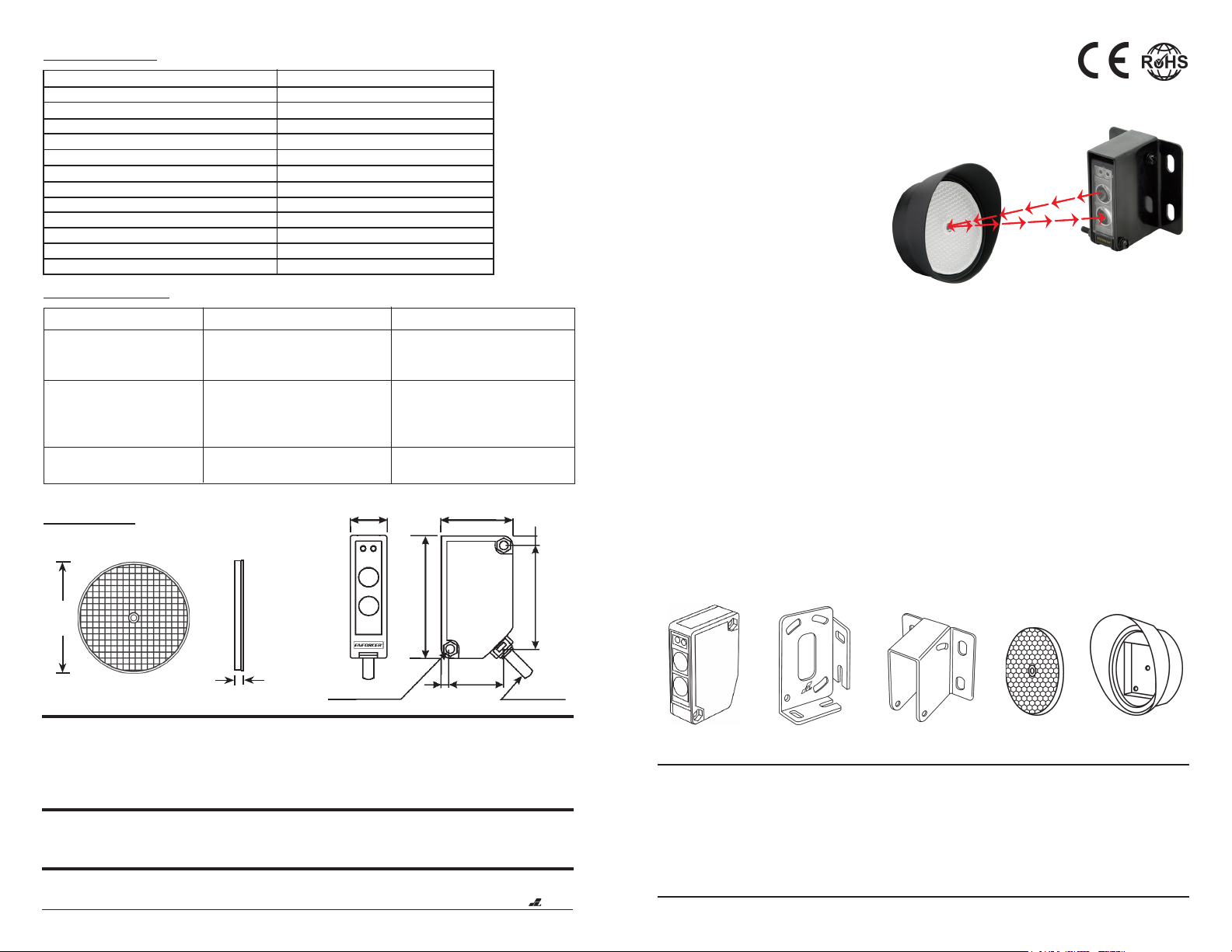

ENFORCER

®

Retro-Reflective

Photoelectric

Beam Sensor

E-931-S45RRQ

Range: 45ft. (14m)

Trouble Remedy(s)

Sensor does not detect the object.

Yellow LED does not turn on.

Red LED lights when object is

detected, but no output.

Dimensions:

3.23"

(82mm)

NOTICE:

the SECO-LARM policy is one of continual development and improvement. For this reason, SECO-LARM reserves the right

to change specifications without notice. SECO-LARM is also not responsible for misprints or typographical errors.

Copyright © 2011 SECO-LARM U.S.A., Inc. All rights reserved. This material may not be reproduced or copied, in whole

or in part, without the written permission of SECO-LARM.

WARRANTY:

used in normal service for a period of one (1) year from the date of sale to the original customer. Our obligation is

limited to the repair or replacement of any defective part if the unit is returned, transportation pre-paid, to SECO-LARM.

SECO-LARM® U.S.A., Inc.,

Fax: 949-261-7326 Website: www.seco-larm.com E-mail: sales@seco-larm.com

The information and specifications printed in this manual are current at the time of publication. However,

ENFORCER Photobeam Sensors are warranted against defects in material and workmanship while

Possible Origin(s)

••

•

0.81"

••

Change the angle of the sensor or

readjust the sensitivity setting.

••

•

••

Clean the sensor and reflector with a

damp (not wet) cloth.

••

•

••

Adjust the reflector and/or sensor for

proper alignment.

••

•

••

Check cable from sensor to alarm

device. Test sensor.

1.54"

(39mm)

2.48"(63mm)

1.14"

(29mm)

0.20"

(5mm)

MiE931S45RRQ_1110.pmd

Ø 0.24" (6mm)

cable 6.5' (2m)

2" (51mm)

••

•

••

Sensor sensitivity is not properly set.

••

•

••

Object may have a reflective surface

which confuses sensor.

••

•

••

Dirty sensor and/or reflector.

••

•

••

Reflector and/or sensor is misaligned.

••

•

••

No continuity between sensor and

alarm device.

(20.5mm)

0.35" (9mm)

16842 Millikan Avenue, Irvine, CA 92606 Tel: 800-662-0800 / 949-261-2999

2-Ø 0.18" (4.5mm) thru hole

®

PITSW3

INSTALLATION MANUAL

Features: Typical Applications:

••

•

12~250 VAC/VDC.

••

••

•

Weatherproof (IP66) construction for

••

indoor/outdoor usage.

••

•

Pre-wired 6-foot cord.

••

••

•

Bracket and mounting hardware included for

••

both sensor and reflector.

••

•

Adjustable response time and sensing range.

••

••

•

Compact size.

••

Included:

E-931-S45RRQ

Transmitter/Receiver

E-931ACC-BLS1Q

Sensor Mounting Bracket

Sensor Mounting Bracket

Caution:

•

This sensor was not designed to prevent bodily

injury or loss of life.

•

This sensor was not designed for use in

environments where there may be explosive

gasses present.

Note: Products with model numbers that end with "Q" or that have a round green "Q" sticker are RoHS compliant.

•

Safety sensor for garage doors or outdoor gates.

•

Overhead door security sensor.

•

Industrial automation - Detect small objects on

manufacturing line.

•

Entry detection for store fronts.

•

Assist in measuring parking distance.

•

Alarm sensor.

E-931ACC-BLS5Q

•

Use of this sensor in certain security

applications may be regulated by local laws or

codes. SECO-LARM is not responsible for

compliance with such laws or codes.

E-931ACC-RC1Q

Round Reflector

E-931ACC-HR1Q

Reflector Hood for

Round/Square Reflector

Page 2

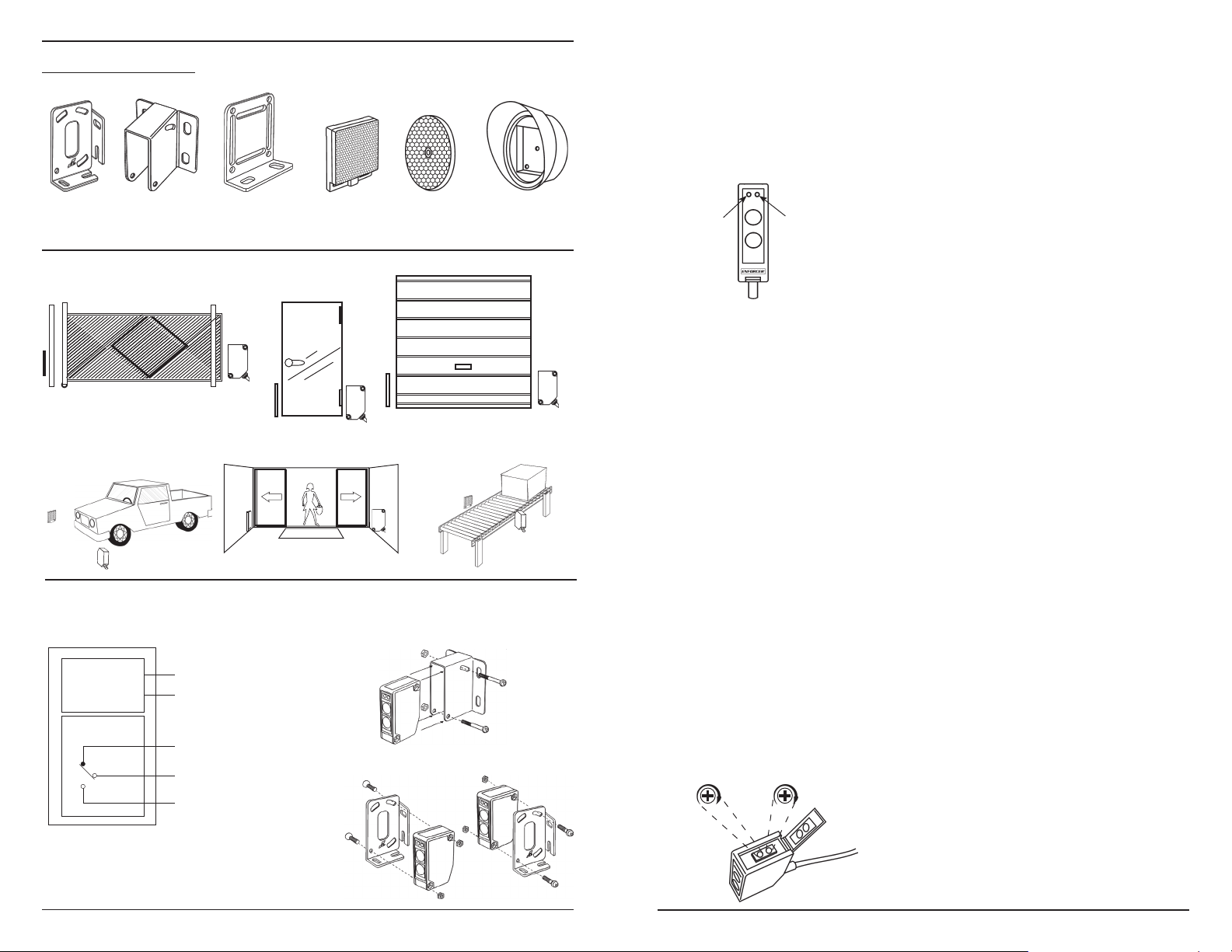

Optional Accessories:

E-931ACC-BLS1Q

Sensor Mounting

Bracket

E-931ACC-BLS5Q

Sensor Mounting

Bracket

E-931ACC-BLR1Q

Square Reflector

Mounting Bracket

E-931ACC-R1Q

Square Reflector

53 x 63 mm

E-931ACC-RC1Q

Round Reflector

82 x 9 mm

Sample Installations:

Gate

Gate

Gate

Gate

Gate

Main

entrance

¤¤¤¤¤¤¤¤¤¤¤

¤¤¤¤¤¤¤¤¤¤¤

Vehicle detection Factory assembly line

¤¤¤¤¤¤¤¤

¤¤¤¤¤¤¤¤

¤¤¤¤¤¤¤¤¤¤¤¤¤¤¤¤

Wiring:

Connection (5 wires)

Brown

Multi-voltage

circuit

12-250VAC or VDC

polarity not important

Blue

]

door

¤¤¤¤¤

Store front door

W

m

c

o

e

e

l

¤¤¤¤¤¤¤¤¤¤

¤¤¤¤¤

¤¤¤¤¤¤¤¤¤¤¤¤¤¤¤¤

Mounting the Sensor:

a. For E-931ACC-BLS5Q bracket

Relay Output

Gray (N.C.)

White (COM)

b. For E-931ACC-BLS1Q bracket

Black (N.O.)

Note:

1. Can be connected to AC or DC voltage.

2. Maximum cable extension length is 325 feet (100m).

Garage

door

E-931ACC-HR1Q

Reflector Hood for

Round/Square Reflector

¤¤¤¤¤¤¤¤

¤¤¤¤¤¤¤¤

Installation and Adjustment:

LED Functions:

• Red LED -- When ON, it indicates the sensor is triggered.

• Yellow LED -- When ON, it indicates that the sensor is

properly aligned with the reflector, and the sensor is not

triggered.

Fig. 1

Yellow LED Red LED

Sensing Range Adjustment Functions:

The Sensing Range adjustment knob sets how powerful the

infrared signal emitted by the sensor is.

• Min. Setting -- The infrared power signal emitted by the

¤¤¤¤¤¤¤¤¤¤

sensor is at its minimum or weakest.

• Max. Setting -- The infrared power signal emitted by the

sensor is at its maximum or strongest.

The objective of this function is to set the appropriate power of

the infrared signal corresponding to the distance between the

sensor and the reflector of a particular application.

The factory default setting is set at "Max.".

Note: If the infrared signal is too strong, the sensor may not

trigger. If the infrared signal is too weak, the sensor

may be susceptible to false alarms.

Response Time Adjustment Functions:

The Response Time adjustment knob sets how long the beam

can be interrupted before triggering.

• Min. Setting -- The interrupt time is set at 5ms (high

sensitivity) and is suitable for detecting fast moving

objects, but is more susceptible to false alarms.

• Max. Setting -- The interrupt time is set at 100ms (low

sensitivity) and will reduce false alarms, but fast moving

objects may not trigger the sensor.

The objective of this function is to set the appropriate interrupt

time of the sensor corresponding to the sensitivity required of

a particular application.

The factory default setting is set at "5ms".

Fig. 2

Sensing

Range

Min Max

Response

5ms

Time

100ms

Installation:

1. Mount the reflector and the sensor so they face each other.

2. Connect power to the sensor. Typically the red LED will turn

ON indicating that the sensor and reflector are not yet

properly aligned. If the yellow LED is ON (red LED OFF), it

indicates that the sensor and reflector are aligned (although

it still may be necessary to slightly adjust the alignment).

3. Turn the sensing range knob to Max.

4. To find the correct alignment, slowly adjust the angles of the

sensor (and/or reflector) up, down, left or right.

Note: Correct alignment is reached when the red LED turns

OFF and the yellow LED turns ON.

Note: If both LEDs are OFF, the sensor is at the edge of sensing

the signal, and may not work properly.

Adjusting the Sensing Range and Response Time:

After the sensor and the reflector have been properly installed,

the next step is to adjust the approriate setting for the sensing

range and response time. Open the top cover of the sensor as

shown in Fig. 2.

Adjusting the Sensing Range :

Starting from the Max. position, slowly turn the knob counterclockwise until the red LED turns ON. This position represents

the weakest point of the infrared signal for this particular

application. The setting of the sensing range must be a little

higher than this point, so turn the knob clockwise to have a

little distance from the weakest point. The ideal setting is

midpoint between the weakest point and Max.

Note: When turning the knob counter-clockwise from the Max.

position, if the weak point is near the Max. position then

the knob should be set at the Max. position.

Adjusting the Response Time :

Adjust the knob according to the requirements of each

application, this may require an interruption test to achieve the

ideal result. For example, to avoid false alarms from falling

leaves and passing birds, adjust the knob to a level wherein the

sensor will not trigger from these interruptions.

Note: After the sensing range and response time have been

adjusted, make sure to close the top cover securely to

prevent water from entering the sensor.

Testing:

1. Power up the sensor. The yellow LED should be ON; the red

LED should be OFF.

2. Pass the object to be detected between the sensor and

reflector. The red LED should turn ON and the yellow LED

should turn OFF. This indicates that the object has been

detected.

Note: If a shiny object, such as a chrome-plated item or

something with reflective tape, is within close proximity of

the path of the IR beam the sensor may not be able to

detect the passing object. In this case it may be necessary

to turn the sensitivity knob counter-clockwise until the

desired sensitivity setting is obtained.

2

3

Loading...

Loading...