Page 1

Index

GENERAL SAFETY INSTRUCTIONS FOR INSTALLATION AND MAINTENANCE ....................................... p. 2

TOOLS AND MATERIALS ........................................................................................................................ p. 2

DECLARATION OF CONFORMITY ........................................................................................................ p. 3

WARNINGS FOR THE INSTALLER ............................................................................................................ p. 3

1. DIMENSIONS ..................................................................................................................................... p. 4

2. TECHNICAL SPECIFICATIONS .......................................................................................................... p. 4

3. ANCILLARY ELECTRICAL EQUIPMENT ............................................................................................. p. 4

4. DESCRIPTION ................................................................................................................................... p. 5

5. PRELIMINARY CHECKS ..................................................................................................................... p. 5

6. ASSEMBLY ........................................................................................................................................ p. 6

6.1. Sliding guide ................................................................................................................................... p. 6

ENGLISH

6.2. Rear fitting ...................................................................................................................................... p. 6

6.3. External release (optional) ............................................................................................................ p. 7

7. INSTALLATION ................................................................................................................................... p. 7

7.1. Sliding guide ................................................................................................................................... p. 7

7.2. On-door fitting ................................................................................................................................ p. 8

7.3. Operator ......................................................................................................................................... p. 9

7.4. Releasing the automated system ................................................................................................. p. 9

7.5. External release ............................................................................................................................... p. 9

8. E1000 CONTROL BOARD .................................................................................................................. p. 10

8.1. Technical specifications .......................................................................................................................... p. 10

8.2. E1000 board components ........................................................................................................................ p. 10

8.3. Terminal-boards and connectors ............................................................................................................. p. 10

8.4. DS1 Programming dip-switches ............................................................................................................. p. 10

8.5. Operating logics ...................................................................................................................................... p. 10

9. COURTESY LIGHT .............................................................................................................................. p. 11

10. CONNECTIONS .............................................................................................................................. p. 11

11. PROGRAMMING ............................................................................................................................ p. 12

11.1. Setting the board .................................................................................................................................... p. 12

11.2. Learning (SET UP) ...................................................................................................................................... p. 12

11.3. Pre-flashing ............................................................................................................................................. p. 14

12. MEMORY STORAGE OF RADIO CONTROLS CODING .................................................................. p. 14

12.1. Memory storage of radio controls DS .................................................................................................. p. 14

12.2. Memory storage of radio controls SLH ................................................................................................. p. 14

12.3. Memory storage of radio controls LC (for some markets only) ......................................................... p. 15

12.3.1. Remote memory storage of LC radio controls ................................................................ p. 15

12.4. Radio controls deletion procedure ...................................................................................................... p. 15

13. START-UP ......................................................................................................................................... p. 15

14. PARACHUTE CABLES ...................................................................................................................... p. 16

15. MAINTENANCE .............................................................................................................................. p. 16

16. REPAIRS .......................................................................................................................................... p. 16

17. ACCESSORIES ................................................................................................................................ p. 16

17.1. Central support ....................................................................................................................................... p. 16

17.2. Key-operated release ............................................................................................................................ p. 16

17.3. Safety edge CN60E ................................................................................................................................ p. 16

17.4. Battery KIT ................................................................................................................................................ p. 16

18. TROUBLESHOOTING ....................................................................................................................... p. 17

1

Page 2

GENERAL SAFETY INSTRUCTIONS

FOR INSTALLATION AND MAINTENANCE

For an efficient and safe automated door, correctly observe the installation procedures and instructions for use.

Incorrect installation and use can cause serious damage to persons and property.

Carefully read the whole installation manual before you begin installing.

Do not make any modifications which are not mentioned in this manual.

Do not install the operator for uses other than those indicated.

To fasten, use the supplied accessories or, in any case, fastening systems (screws, expansion plugs, etc.) suitable for the type

of support and for the mechanical stresses exerted by the automated system.

Check if the sectional door conforms to standards EN12604 and EN 12605 (the information can be found in the documentation

accompanying the door itself). For non-EU countries, the above mentioned standards must be observed in addition to the

national standard references to obtain a suitable safety level.

Make sure that the door is correctly balanced, correctly operational, and supplied with mechanical opening stops.

When installing we advise you to:

•obtain the material and tools indicated in the following paragraph “Tools and materials” and keep them near at hand.

•use a stable support for performing operations without a floor support.

•protect your face and hands adequately before making the holes with the drill.

•do not allow children to play near during installation, use and during the automated system release manoeuvre.

•remove any debris and objects which could hamper movement, before powering up the system.

•remove the door’s closing mechanism to ensure the door is closed by the automatism.

•stick on the warning stickers as shown in the instruction.

•install the manual release devices at a height of not over 180cm.

•install the external control devices at a height of not below 150cm, clear of the door movement area, but in a position

enabling visual control of the area.

When you have finished installing we advise you to:

•check if the anti-crushing device is able to detect a 50mm high object on the ground and if a weight of 20 kg applied to the

door, causes the opening movement to stop.

•make sure that no part of the door interferes with public spaces such as pavements and/or roads.

•Use the automated system observing the instructions in the “User’s guide”.

•Fill in, keep and update the maintenance register.

ENGLISH

•The D1000 automated system does not require periodic replacement of parts.

•Every month, run a functional check of the safety devices and of the anti-crushing system: a non-deformable object with

a height of 50 mm laid on the ground, must be correctly detected.

IMPORTANT! DANGER OF CRUSHING.

•If the power cable of operator D1000 is damaged, it must be replaced by qualified personnel, using a new cable of the same

type. Do not use different power cables.

TOOLS AND MATERIALS

Tools you will require to install the D1000 operator:

•a hammer drill with relevant wall and iron bits

•screwdrivers for cross-head and cut-head screws

•two flat wrenches for 13 mm hexagon head screws

Material required for installing the D1000 operator and the relevant accessories (if present):

•cable 2x0,5 mm2 (emitting photocells, pulse generators for opening movement and stop)

•cable 4x0.5 mm2 (receiver photocells)

•cable 2x0.75 mm2 (flashing lamp)

•cable 2 x 1.5 mm2 (power)

Use cables with an adequate degree of insulation.

The electric system must conform to the prescriptions in the chapter entitled “Warnings for the installer”.

The 230 Vac power cable must be laid and connected by a qualified installation technician. Arrange for a 2P 10A 250 V

socket to be installed near the operator.

Lay the cables in the appropriate pipes and do not allow loose cables to come into contact with moving parts of the

automated system and the door.

2

Page 3

CE DECLARATION OF CONFORMITY FOR MACHINES

(DIRECTIVE 98/37/EC)

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: Operator model. D1000 with E1000 unit,

• is built to be integrated into a machine or to be assembled with other machinery to create a machine under

the provisions of Directive 98/37/EC;

• conforms to the essential safety requirements of the other following EEC directives:

73/23/EEC and subsequent amendment 93/68/EEC.

89/336/EEC and subsequent amendment 92/31/EEC and 93/68/EEC

Furthermore, the manufacturer declares that the machinery must not be put into service until the machine into

which it will be integrated or of which it will become a component has been identified and its conformity to the

conditions of Directive 89/392/EEC and subsequent modifications assimilated in Italian National legislation under

ENGLISH

Presidential Decree No. 459 of 24 July 1996 has been declared.

Bologna, 01 January 2006

The Managing Director

A. Bassi

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of the

product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach

of children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be

a source of danger.

6) FAAC declines all liability caused by improper use or use other than

that for which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence

of inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN

12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the

Standards mentioned above must be observed, in addition to national

legal regulations.

9) FAAC is not responsible for failure to observe Good Technique in

the construction of the closing elements to be motorised, or for any

deformation that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the

Standards mentioned above must be observed, in addition to national

legal regulations.

11) Before attempting any job on the system, cut out electrical power .

12) The mains power supply of the automated system must be fitted with

an all-pole switch with contact opening distance of 3mm or greater. Use

of a 6A thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted

upstream of the system.

14) Make sure that the earthing system is perfectly constructed, and connect

metal parts of the means of the closure to it.

15) The safety devices (EN 12978 standard) protect any danger areas

against mechanical movement Risks, such as crushing, dragging, and

shearing.

16) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended

for every system, as well as a warning sign adequately secured to the

frame structure, in addition to the devices mentioned at point “15”.

17) FAAC declines all liability as concerns safety and efficient operation of

the automated system, if system components not produced by FAAC

are used.

18) For maintenance, strictly use original parts by FAAC.

19) Do not in any way modify the components of the automated

system.

20) The installer shall supply all information concerning manual operation

of the system in case of an emergency, and shall hand over to the user

the warnings handbook supplied with the product.

21) Do not allow children or adults to stay near the product while it is

operating.

22) Keep remote controls or other pulse generators away from children, to

prevent the automated system from being activated involuntarily.

23) Transit under the door must occur only when the automated system

has stopped.

24) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

25) Maintenance: check at least every 6 months the efficiency of the

system, particularly the efficiency of the safety devices (including, where

foreseen, the operator thrust force) and of the release devices.

26) Anything not expressly specified in these instructions is not permitted.

3

Page 4

AUTOMATED SYSTEM D1000

These instructions apply to model FAAC D1000.

The D1000 automated systems make it possible to automate

balanced sectional doors of single garages for residential

use.

They consist of an electro-mechanical operator, electronic

control unit and courtesy light built into a single unit. This unit is

fitted to the ceiling and opens the door by means of a transmission

chain or belt.

The system is non-reversing and, therefore, the door locks

mechanically when the motor is not operating and, consequently,

no lock is necessary; two manual releases, one on the inside

and one on the outside (optional) make it possible to move the

door in case of a power cut or fault.

The operator is supplied with an electronic device that detects

the presence of an obstacle that would hinder door movement

- the device prevents crushing or lifting.

This instruction refers to the operator with chain drive, but the

same procedures, regulations and application limits apply also

to the belt driven operator.

The D1000 automated systems were designed and built for

indoor use and to control vehicle access. Do not use them for

any other purpose.

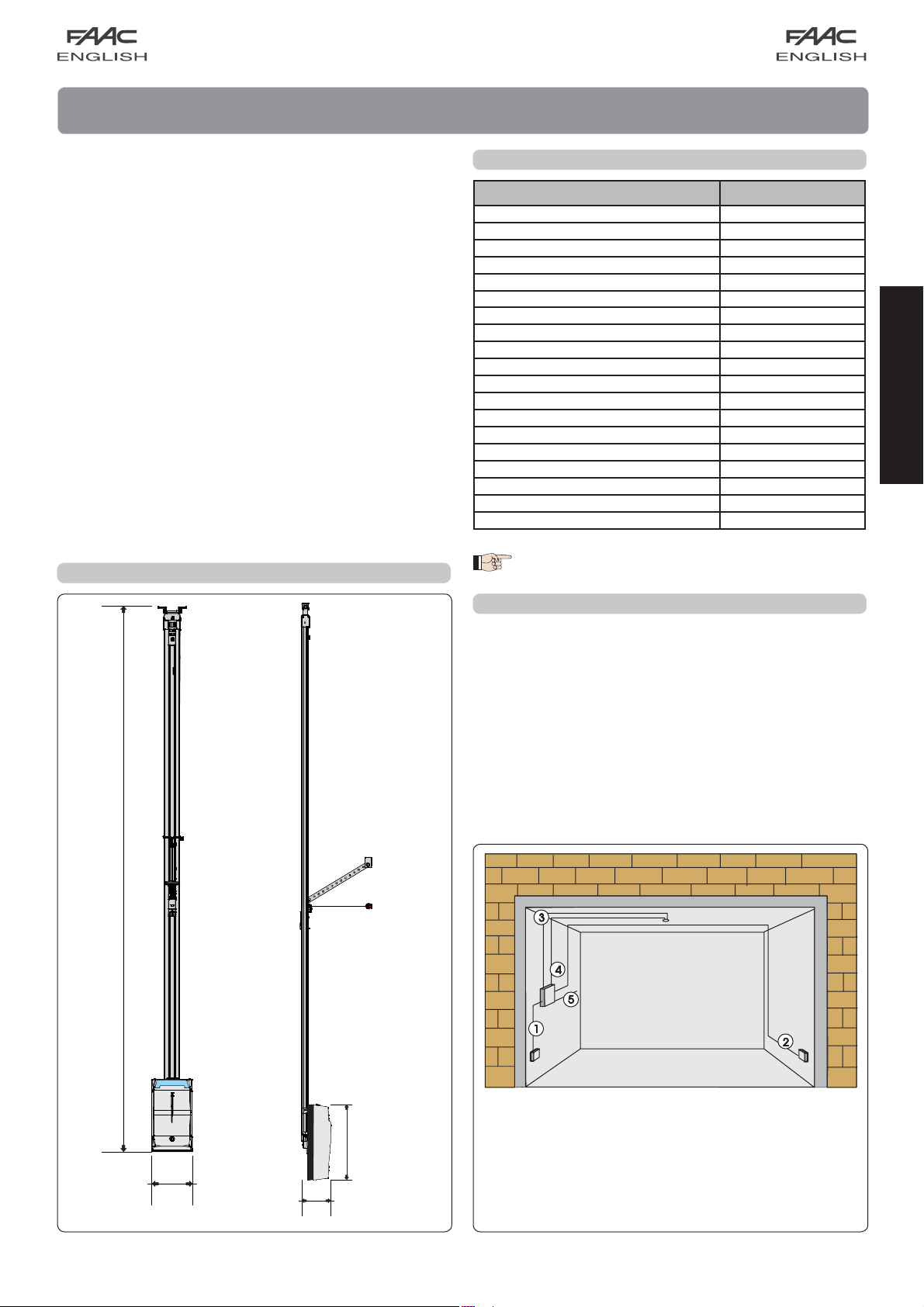

1. DIMENSIONS

Dimensions in mm.

2. TECHNICAL SPECIFICATIONS

Model D1000

Power supply (V ~ / 50 Hz.) 230

Electric motor (Vdc) 24

Maximum absorbed power (W) 350

Thrust force (N) 600/1000

Type of use continuous

Maximum dimensions from ceiling (mm) 35 (Fig. 4)

Courtesy light (V ~/W) 230 / 40 max.

Courtesy light timer (sec) 120

Standard speed with no-load carriage (m/min)

Slow speed with no-load carriage (m/min) 4,5

Carriage deceleration speed (m/min) 1,1

Noise at standard speed (dB(A)) 52

Travel length at deceleration

Intrinsic safety device Category 2

Maximum sectional door width (mm) 5000

Maximum sectional door height (mm) See useful travel

Sliding guide useful travel (mm) 2500 - 3100 - 3800

Protection class For indoor use only (IP20)

Operating ambient temperature (°C) -20 / +55

Varies according to set-up

8,9

The level of noise emission of operator D1000, referred

to the work station, is 52 dB(A).

3. ANCILLARY ELECTRICAL EQUIPMENT

Prepare the electric system in keeping with the instructions in

the chapter entitled “Warnings for the installer”.

When you have finished installing, check if any external pipes

or cables can come into contact with moving parts.

Install the fixed control points at a minimum height of 150 cm,

clear of the door movement area, but in a position enabling

visual control of that area.

ENGLISH

Fig. 1

2168 / 2768 / 3368

200

145

360

Cable 2 x 0.5 mm2 (TX photocell)

Cable 4 x 0.5 mm

2

(RX photocell)

Power pipe (230V)

Low voltage pipe

Cable 2 x 1.5 mm

4

2

(power)

Fig. 2

Page 5

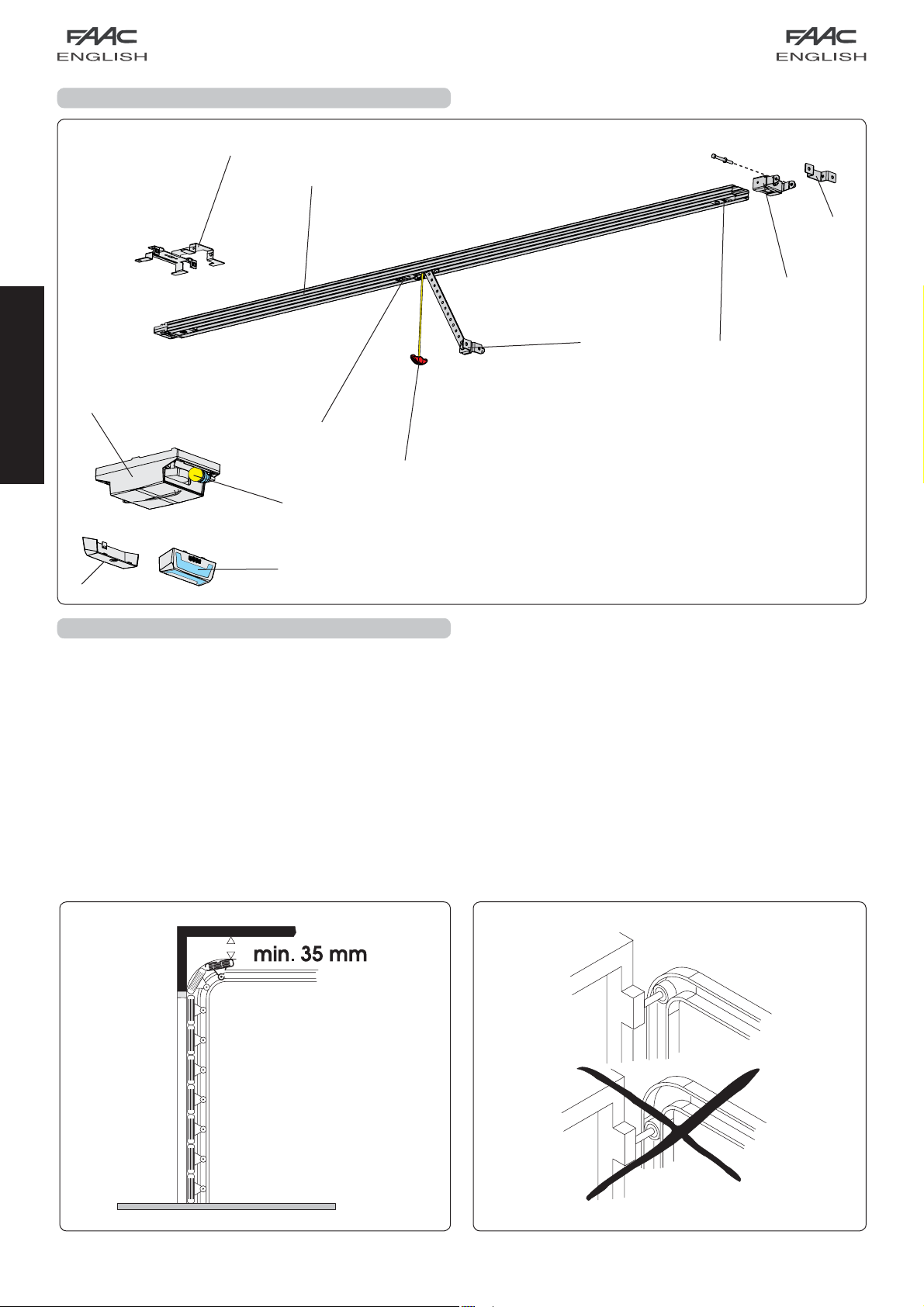

4. DESCRIPTION

ENGLISH

5. PRELIMINARY CHECKS

- The structure of the door must be suitable for fitting automation.

In particular, check that the door dimensions conform to

those indicated in the technical specifications, and that it is

sufficiently sturdy.

- Check if the door conforms to standards EN12604 and

EN12605.

- As it moves, the door must not encroach public areas

dedicated to pedestrian or vehicular transport.

- Check the efficiency of the door bearings and joints.

- Make sure that the door is friction-free. If necessary clean

and lubricate the guides with silicone based products, but do

not use grease, and, in any event, follow the manufacturer’s

instructions.

- Check correct balance and if the opening mechanical stops

Ceiling lamp

Rear door

Courtesy light

Plastic housing for D1000 operator

Rear fitting

Sliding guide

Drive carriage

Release knob

Door fitting bracket

Transmission unit

Front fitting and chain tensioner

Front fitting bracket

have been installed.

- Remove the door’s existing closing mechanism to ensure the

door is closed by the automated system.

- Make sure there is a clearance of at least 35 mm between the

ceiling and the highest sliding point of the door (Fig.4).

- Check if the upper guide roller of the sectional door is in the

horizontal part of the guide while the door is closed (fig. 5).

Fig. 3

Fig. 5Fig. 4

5

Page 6

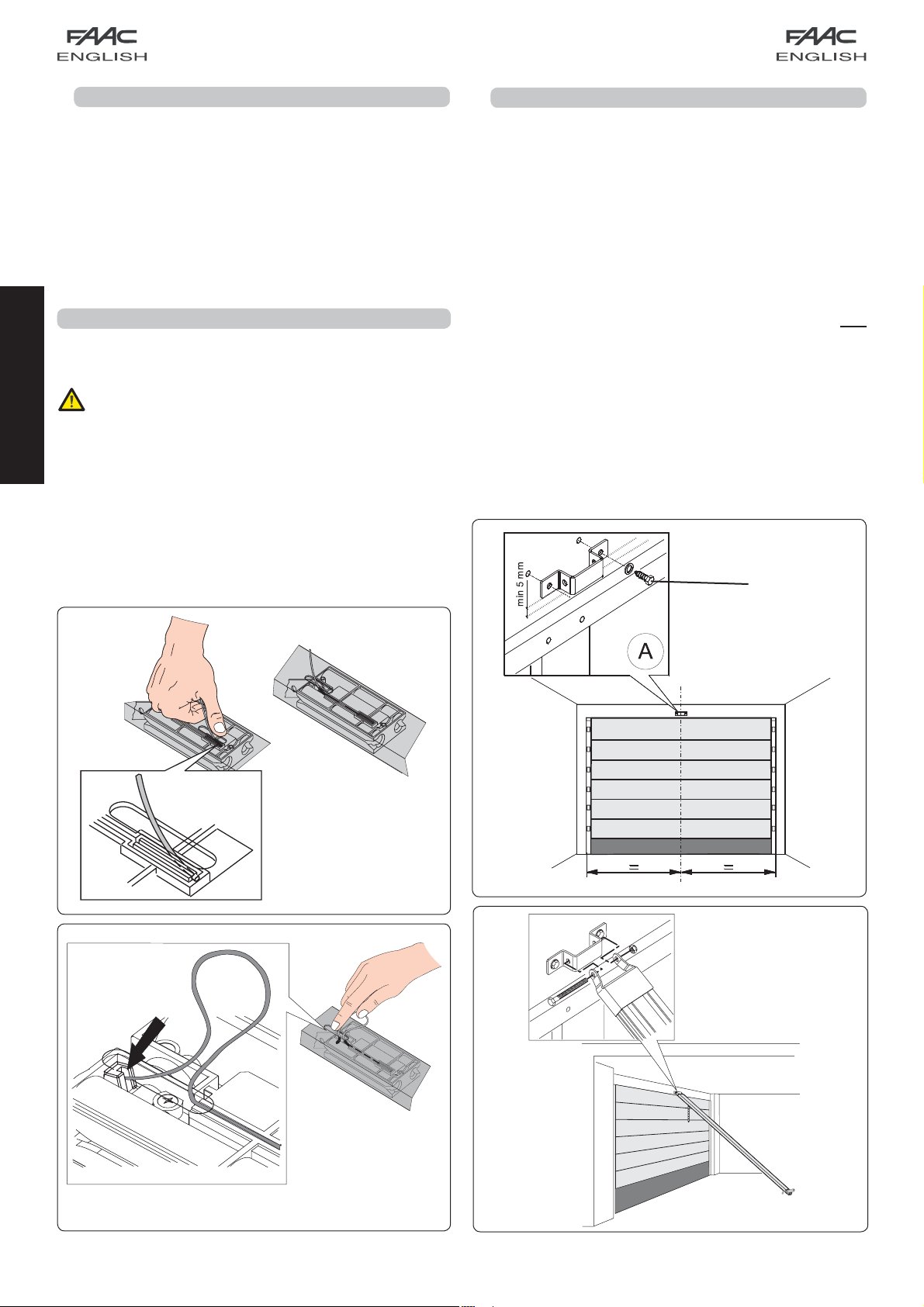

6. ASSEMBLY

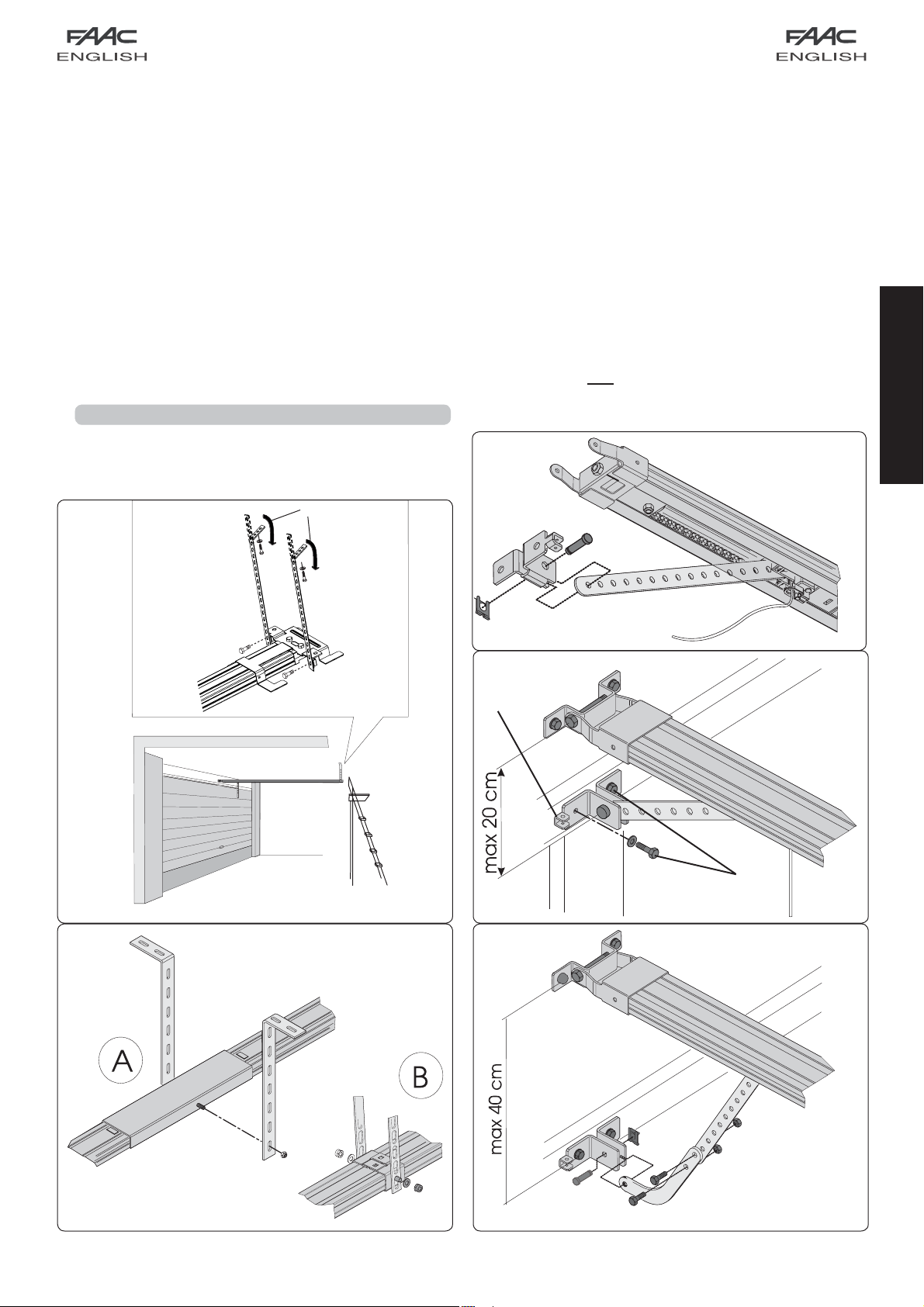

6.1. Sliding guide

If you use a sliding guide in two pieces, you must assemble it,

as explained below. If you have a pre-assembled guide, go

on to paragraph 6.2.

1) Assemble the two pieces of the sliding guide, fitting them

in the central joint (Fig. 6 ref. A) until they come to a stop

against the metal reference reliefs (Fig. 6 ref. B). To facilitate

engaging the sliding guide, we advise you to insert it in the

central joint, compressing it as shown in Fig. 6 ref. C. Do not

use tools which could deform the guide or joint.

2) Slide the transmission unit (Fig.7 ref. A) along the whole sliding

guide, until it is near the front terminal, the one opposite the

drive coupling.

3) Assemble the front fitting (Fig. 7 ref. B) to the transmission unit

(Fig. 7 ref. A).

4) Apply slight tension to the chain, tightening the nut (Fig. 7

ref. C.).

5) Place the sliding guide on the side (Fig. 8).

6) Push the carriage toward the drive clutch unit (Fig.8

ref. C).

7) Adjust the tensioner (fig. 8 ref. A) so that the central zone of

the loop, formed by the top branch of the chain, coincides

with about the mid-point of the sliding guide (Fig. 8 ref. B).

Attention: too much tension can cause damage to the

transmission and drive clutch units.

6.2. Rear fitting

Before securing the sliding guide to the ceiling, assemble the

rear fitting in the seat of the drive clutch unit and fasten the

screws as shown in Fig. 9 ref. .

ENGLISH

Fig. 6

Fig. 7 Fig. 9

Fig. 8

6

Page 7

6.3. External release (optional)

If the external release system has to be installed, the cable

must be placed in its seat before beginning to install.

1) Release the carriage (see par. 7.4 point 3), and take it to

the slot on the top of the sliding guide.

2) Fit the cable terminal on the red seat (Fig. 10).

3) Take the carriage back toward the drive clutch unit until

the through-hole on the carriage coincides with the slot,

and fit the unsheathed cable (Fig. 11).

4) Fully withdraw the cable from the bottom of the

carriage.

5) Wind the cable around itself to prevent it getting in the way

while the sliding guide is being installed.

7. INSTALLATION

- To ensure you work in safe conditions, we advise you

to install the operator while keeping the door fully

closed.

- Use all the specified anchorage points.

- The fastening systems must be suitable for the type of

support and sufficiently tough.

ENGLISH

- Protect your hands and face adequately while drilling

the holes.

- Read this chapter to the full before you begin

installing.

7.1. Sliding guide

When you have finished the preliminary assembly operations,

you can begin installing the sliding guide, as follows:

1) On the architrave, mark a line corresponding to the vertical

mid-point of the door (Fig. 12).

2) On the architrave, mark a horizontal line corresponding to

the maximum height reached by the door during movement

(see Fig. 4).

3) Position the securing bracket of the front fitting, so that the

lower edge is at least 5 mm above the intersection point of

the lines and centred with respect to the vertical line (Fig.

12). Also refer to paragraph 7.2 for correct positioning of the

bracket with respect to the fitting point on the door.

4) Mark the two securing points.

5) Next, drill and install, using the screws (ref. Fig. 12) NOT

supplied.

6) Position the sliding guide on the floor, perpendicular with

respect to the door.

7) Lift guide off the front fitting and assemble the latter with

the securing bracket, using the through screw and nut (Fig.

13).

Fig. 10

Fig. 12

Fig. 11

Fig. 13

7

Page 8

8) Lift the sliding guide until the rear fitting is at the same level

as the front fitting, or until you reach the same inclination as

the door’s horizontal rail. If you are securing directly to the

ceiling, go to point 12.

9) Measure the distance between the ceiling and the

between-axis position of the nuts securing the rear fitting.

10) Bend the supplied brackets according to the measurement

you have taken (measure starting from the centre of the

bracket’s first slot).

11) Fit the brackets on the rear fitting and re-position the sliding

guide (Fig. 14).

12) Mark the on-ceiling securing points of the rear fitting and drill

(taking care to protect the sliding guide). Finish installing the

guide.

13) If using a two-piece guide with central joint (Fig. 15 ref. A) or

the central support for a single rail (Fig. 15 ref. B - optional),

secure to the ceiling, using the brackets and proceed

according to steps 9, 10 and 12 (Fig. 15).

7.2. On-door fitting

1) Assemble the fitting with the carriage rod (Fig. 16).

Position the fitting on the door so that the through-element

of the release cable is facing toward the left side of the door

(ref. Fig. 17).

2) Close the door and take the carriage near to it.

3) Position the fitting on the door, centred with respect to its

mid-point.

4) Make sure that the distance between the between-centres

of the securing holes of the front fitting and the on-door fitting

does not exceed 20 cm (Fig. 17). To ensure correct operation

of the automated system, we advise you to avoid arm

inclinations of over 30° compared to the sliding guide.

If using the curved arm for sectional doors (optional), carry

out the assembly with the straight arm of the carriage as

shown in Fig. 18. To improve efficiency of the anti-crushing

system, we advise you to secure the fitting on the sectional

door as low as possible, without, however, exceeding the

distance of 40 cm from the operator’s front fitting.

5) Mark, drill and secure the fitting to the door, using the screws

(ref. Fig. 17) NOT supplied.

Fig. 16

ENGLISH

Fig. 14

Fig. 17

Fig. 15 Fig. 18

8

Page 9

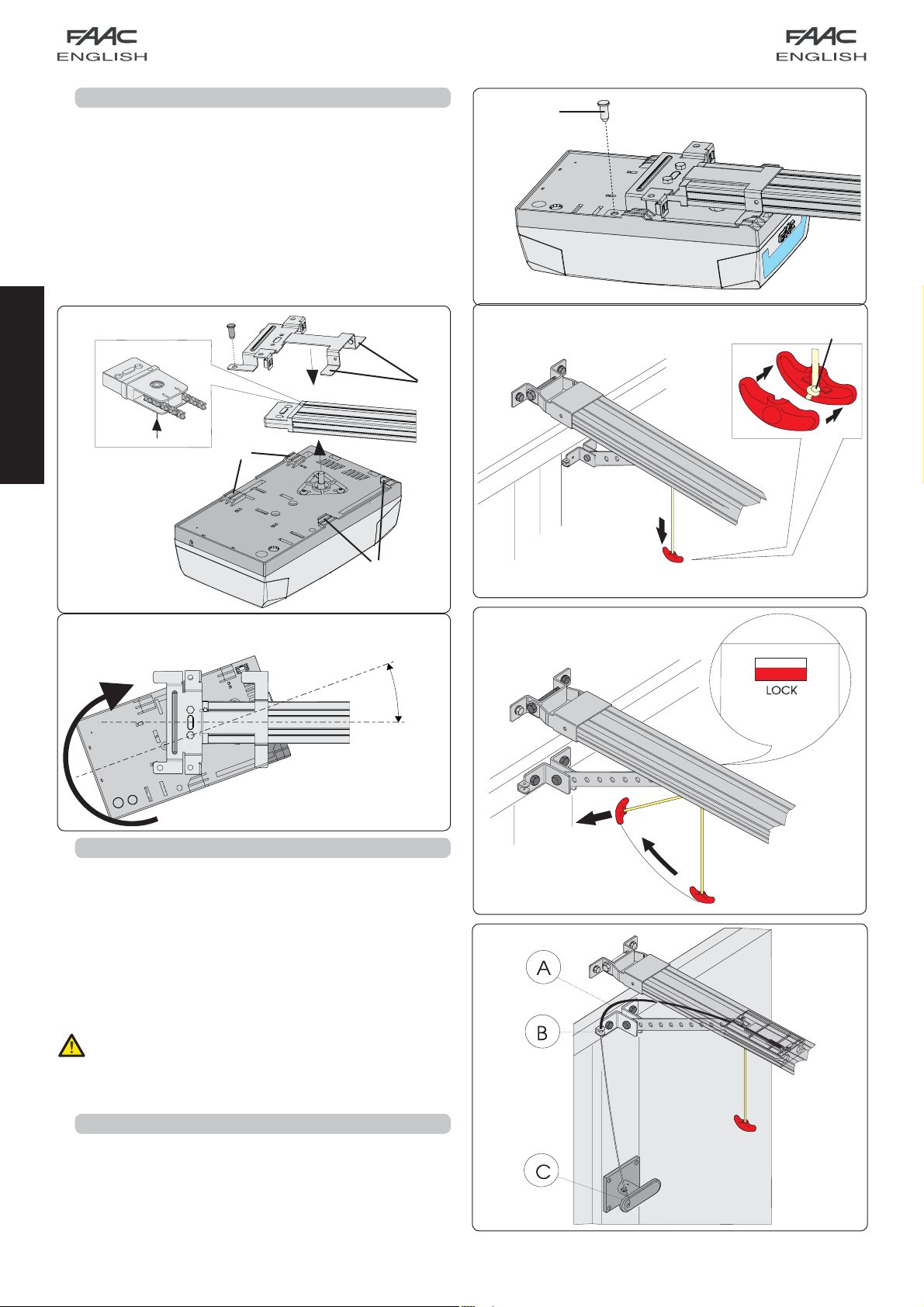

7.3. Operator

When you have assembled the rear fitting to the sliding guide

and finished installing the sliding guide, you can install the

operator:

1) While keeping the operator inclined at 15/20° (Fig. 20), insert

the gearmotor shaft in the coupling on the rear fitting of the

sliding guide and make the fins (Fig. 19 ref. ) near to the

seats at the bottom of the operator base (Fig. 19 ref. ).

2) Turn the operator in the direction of Fig. 20 until you reach

position of Fig. 21, and fit the pin in the hole of the rear fitting

(Fig.21 ref. ).

Fig. 21

ENGLISH

Fig. 19

15°/20°

Fig. 20

7.4. Releasing the automated system

1) Define the height of the release knob, taking into account

that it must not be over 180 cm off the ground, and cut off

the excess section of rope.

2) Make a knot at the end of the rope and assemble the release

handle (Fig. 22).

3) Pull the release handle down and check if the door can be

moved manually (Fig. 22).

4) Pull the release handle horizontally in the direction of the

door (Fig. 23). Check if, when the handle is released, the

LOCK window under the carriage is red. Move the door

manually until you find the carriage’s hook-on point.

Make sure that there are no persons, animals or objects in

the door movement area during the release manoeuvre.

Fig. 22

Fig. 23

7.5. External release

If the automated system has an external release, finish

installing (see par. 6.3):

1) Cut the cable sheath to size (Fig. 24 ref. A).

2) Fit the cable inside the sheath and route it through the eyelet

of the door fitting (Fig. 24 ref. B).

3) Cut the cable to size and assemble it together to the internal

lever of the release handle (Fig. 24 ref. C).

Fig. 24

9

Page 10

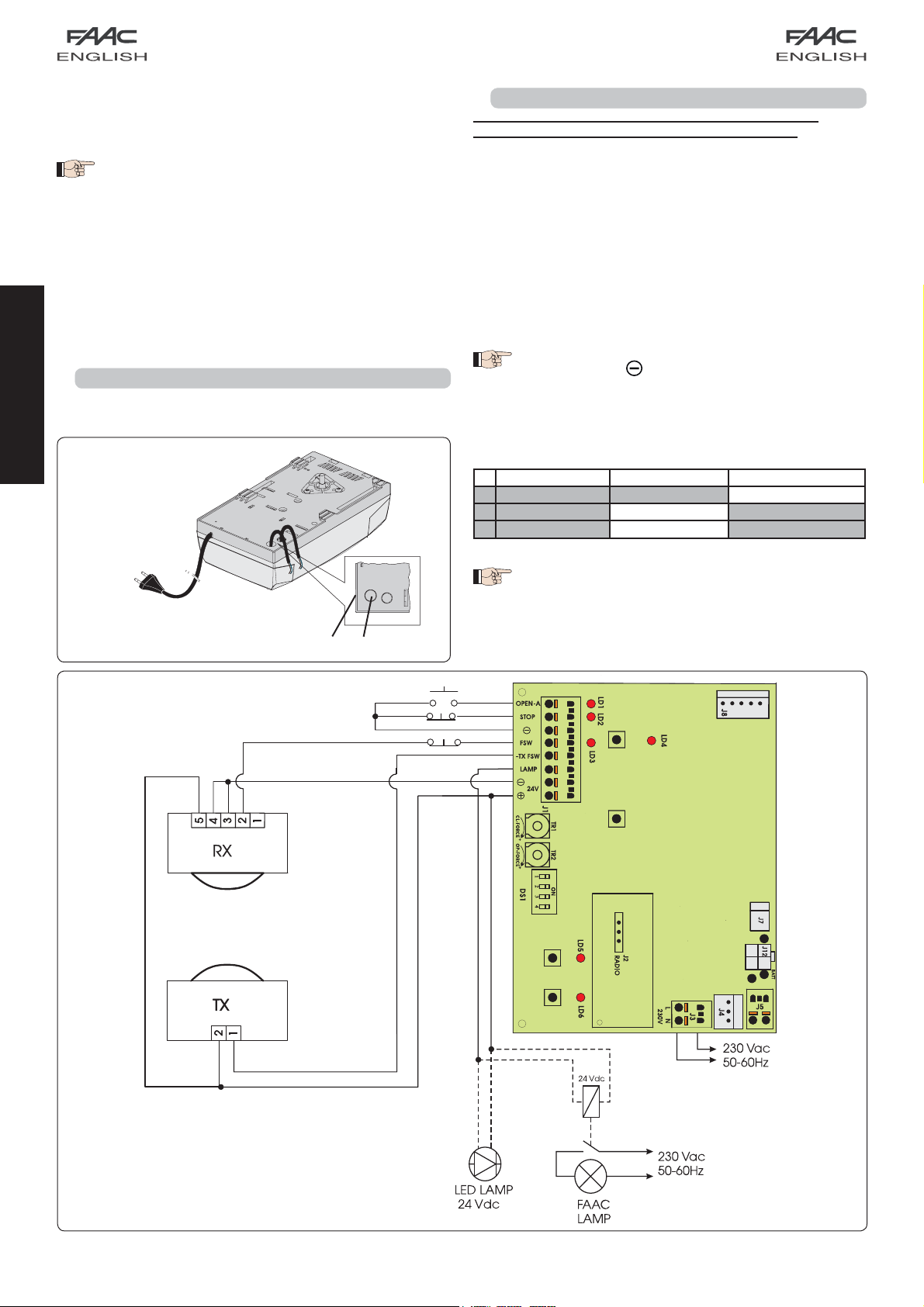

8. E1000 CONTROL BOARD

8.1. Technical specifications

Supply voltage (V ~ / Hz.)

Power supply to accessories (Vdc)

Accessories max. load (mA.)

Operating ambient temperature (°C)

Quick-fit connector

Operating logics

Terminal-board connections

Courtesy light timer (min.)

for receiver boards XF433 /

XF868 and battery module

Automatic / Semiautomatic

Open/Stop/Safety devices/Fail-

safe/Flashing lamp 24 Vdc

8.2. E1000 board components

J1 Low voltage inputs/accessories terminal board

Quick-fit connector for receivers XF433 or XF868

J2

J3 230V power supply input terminal board

J4 Connector for transformer primary winding

J5 Courtesy light terminal-board

J7 Connector for transformer secondary winding

J8 Motor output connector

J12 Battery module connector

OPEN A Radio signal programming push-button

OPEN B Radio signal programming push-button

OPEN OPEN push-button

SETUP SET-UP push-button

DS1 Programming dip-switch

LD1 Signalling LED: OPEN input

LD2 Signalling LED: STOP input

LD3 Signalling LED: FSW input

LD4 Signalling LED: SET UP cycle

LD5 LED signalling memory-storage: radio channel OPEN A

LD6 LED signalling memory-storage: radio channel OPEN B

TR1 Closing force adjustment

TR2 Opening force adjustment

230 / 50

24

200

-20 / +55

2

J1

LD3

LD1

LD2

SET UP

LD4

OPEN

J8

TR1

TR2

DS1

J2

LD5

J7

J12

OPEN BOPEN A

J5

LD6

J3

J4

Fig. 25

Fail Safe

If activated, it enables the photocell operating test before every

movement.

Operating logics

For doors with an irregular movement, it reduces the sensitivity of

the anti-crushing device to prevent unwanted action by it.

ENGLISH

8.3. Terminal-boards and connectors

Description Connected device

OPEN A

STOP

Command device with N.O. contact

(see chap. OPERATING LOGICS)

Device with N.C. contact which stops the

automated system

Negative for OPEN A and STOP devices

FSW

LAMP

-TX FSW

Closing safety device with N.C. contact (see

chap. OPERATING LOGICS)

OPEN COLLECTOR 24 Vdc 100 mA. output for

flashing lamp

Negative for powering safety accessories (FAIL

SAFE function)

Negative for powering accessories

+24 Vdc for powering accessories

8.4. DS1 Programming dip-switches

No. Function OFF ON

1 Fail Safe Enabled

Not enabled

2 Anti-crushing sensitivity Low High

3 Force adjustment Automatic Manual

4 Carriage speed High Low

Manual adjustment of force

If you wish to adjust force manually, before learning, turn ON

switch No. 3 of DS1, and manually adjust the thrust force with TR1

(closure) and TR2 (opening). Maximum available thrust is 1000N.

8.5. Operating logics

Logic A (automatic)

Status Open (pulse) Stop Fsw

CLOSED

OPENING No effect Locks (2) No effect (1)

OPEN IN

PAU S E

CLOSING Reverses motion Locks (2) Reverses motion

LOCKED Closes No effect (2) No effect (1)

Opens and closes

after pause time

Resumes counting of

pause time (1)

No effect (2) No effect

Locks (1)

Resumes counting of

pause time (1)

Logic E (semi-automatic)

Status Open (pulse) Stop Fsw

CLOSED Opens No effect (2) No effect

OPENING Locks Locks (2) No effect (1)

OPEN Closes No effect (2) No effect (1)

CLOSING Reverses motion Locks (2) Reverses motion

LOCKED Closes No effect (2) No effect (1)

10

Page 11

(1) Prevents closing if pulse is maintained.

(2) Prevents closing and/or opening if pulse is

maintained.

During the opening manoeuvre, the

anti-crushing device causes an immediate

stop. During the closing manoeuvre, it opens

the door.

If, during closure, an obstacle is detected more than

three consecutive times, the automated system

considers this distance as the new closing contact point

and goes into closed status. To restore the correct

positions, remove the obstacle and command a new

cycle: at the next closure, the automated system will

advance at low speed until it detects the contact point.

9. COURTESY LIGHT

- The courtesy light stays lighted for 2 minutes after the end of

the manoeuvre (cannot be modified).

ENGLISH

10. CONNECTIONS

IMPORTANT: Before attempting any work on the board

(connections, maintenance), always cut off power.

- To prevent any electric noise whatever, use separate sheaths

for powering the network, signals and accessories.

- The D1000 operator has a cable with a two-pole plug for 230

Vac power supply.

- To connect the external controls, safety devices and signals,

break open the pre-holed element (Fig. 26 ref. ).

- To connect the safety edge (see par. 18.3), break open the

pre-holed element (Fig. 26 ref. ).

- Make the electrical connections, referring to Fig. 27.

If the STOP input is not used, jumper connect the input

to the terminal

If the photocells are not used, connect the FSW

input to terminal -TX FSW.

Inputs status leds:

LD Meaning OFF ON

1 Input status OPEN Not enabled Enabled

2 Input status STOP Enabled Not Enabled

3 Input status FSW

.

Safety devices engaged Safety devices disengaged

Fig. 26

The automated system stopped and at rest is indicated

in bold for each input.

OPEN A

STOP

OTHER SAFETY DEVICES

11

Fig. 27

Page 12

11. PROGRAMMING

11.1. Setting the board

Set the appliance with Dip-Switch DS1 to obtain the operation

you require, referring to chapter 8.4.

If you wish to manually set the thrust force, turn ON

dip-switch 3 of DS1 and adjust potentiometers TR1

(CLOSURE) and TR2 (OPENING) BEFORE EFFECTING THE

LEARNING PROCEDURE. Turn clockwise to increase

thrust, and anti-clockwise to reduce it.

11.2. Learning (SET UP)

During the learning procedure, the obstacle detection device

does not operate. However, the STOP command and the

closing safety devices (FSW) are enabled; if they are triggered,

learning is interrupted and a fault is signalled.

The SETUP cycle is carried out with the plastic housing

installed. Just remove the rear door (Fig. 28).

Grip the rear door with both hands and pull gently

downward. When you have finished the procedure

described in this chapter, put the door back in place.

The learning cycle makes it possible to define the following:

Fig. 28

- the force required to move the door.

- the slow-down points.

- the opening and closing stop points.

- the pause time (in automatic logic).

For heavy doors or for movement problems, learning with a

1000N thrust instead of 600N (Default) is possible.

Learning must be started with the operator locked, irrespective

of the door’s position.

The procedure also determines the operating logic.

The logic tables indicate the behaviour of the automated

system in different conditions, and following commands or

action by the safety devices.

Learning can be automatic or manual. In the latter case, the

opening and closing deceleration points can be determined.

However, in automatic mode, the unit independently determines

the movement parameters.

If the procedure is not correctly concluded (e.g. due to excessive

friction during door movement), the unit signals a fault status

(the SET UP LED flashes slowly). In this case, the procedure must

be repeated after the cause is eliminated.

ENGLISH

AUTOMATIC LEARNING WITH LOGIC “E” (SEMI-AUTOMATIC)

Press the SET UP push-button for one second.

The SET UP LED starts to flash when you release the

push-button.

1) After 8 seconds the operator automatically closes the door

until the stop point is detected.

2) The operator begins the opening movement. Wait until the

stop point is reached, or give an OPEN command in the

position where you wish to stop motion.

3) The operator closes the door.

4) Wait for the door to reach the stop point and for the

operator to stop.

If the learning procedure terminated positively, the SET UP LED

stops flashing and stays lighted for 5 seconds.

RADIO SET UP

OPEN B

OPEN A

Radio signal programming push-button OPEN B.

RADIO SET UP LED signalling that the OPEN B radio signal is stored in the memory.

Radio signal programming push-button OPEN A.

RADIO SET UP LED signalling that the OPEN A radio signal is stored in the memory.

LED signalling the SET UP stage.

LED signalling photocells status.

LED signalling STOP.

LED signalling OPEN A.

OPEN push-button to totally open sectional door.

SET UP push-button for programming operating logics and learning work times.

FSW

SET UP

STOP

OPEN A

Fig. 29

12

Page 13

During these 5 seconds, in order to lighten the load on the

release system, you can send OPEN pulses within a time interval

of 2 seconds from each other, in order to reverse the carriage.

One pulse corresponds to a 5 millimetre travel.

N.B.: The carriage can be seen reversing only during normal

operation of the automated system.

The control unit establishes the deceleration points.

MANUAL LEARNING WITH LOGIC “E” (SEMI-AUTOMATIC)

Press the SET UP push-button for one second. The SET UP LED starts

to flash when you release the push-button. Start the following

procedure within 8 seconds (otherwise the operator will perform

automatic learning):

1) Give the 1st OPEN command: the operator performs a

slowed-down closing manoeuvre until it detects the stop

point and stops.

2) Give the 2nd OPEN command: the operator continues with

an opening movement.

3) Give the 3rd OPEN command in order to define the point

where you wish deceleration to begin.

ENGLISH

4) Give the 4th OPEN command to define the opening stop

point, or wait for the automated system to detect arrival at

the stop point and then stop.

5) Give the 5th OPEN command: the automated system begins

the closing movement.

6) Give the 6th OPEN command in order to define the point

where you wish deceleration to begin.

7) Wait for the door to reach the stop point and for the

operator to stop.

If the learning procedure terminated positively, the SET UP LED

stops flashing and stays lighted for 5 seconds.

During these 5 seconds, in order to lighten the load on the

release system, you can send OPEN pulses within a time interval

of 2 seconds from each other, in order to reverse the carriage.

One pulse corresponds to a 5 millimetre travel.

N.B.: The carriage can be seen reversing only during normal

operation of the automated system.

AUTOMATIC LEARNING WITH LOGIC “A” (AUTOMATIC)

Hold down the SET UP push-button until the SET UP LED goes

on (about 5 seconds). The SET UP LED starts to flash when you

release the push-button.

1) After 4 seconds the operator automatically closes the door

by deceleration until the stop point is detected.

2) The operator moves the door to open. Wait until the stop

point is reached, or give an OPEN command in the position

where you wish to stop motion.

3) The operator closes the door.

4) Wait for the door to reach the stop point and for the

operator to stop.

If the learning procedure terminated positively, the SET UP LED

stops flashing and stays lighted for 5 seconds.

During these 5 seconds, in order to lighten the load on the

release system, you can send OPEN pulses within a time interval

of 2 seconds from each other, in order to reverse the carriage.

One pulse corresponds to a 5 millimetre travel.

N.B.: The carriage can be seen reversing only during normal

operation of the automated system.

The control unit establishes the deceleration points.

Pause time is fixed at 3 minutes.

MANUAL LEARNING WITH LOGIC “A” (AUTOMATIC)

Hold down the SETUP push-button until the SET UP LED goes

on (about 5 seconds). The SET UP LED starts to flash when you

release the push-button. Start the following procedure within

4 seconds (otherwise the operator will perform automatic SET

UP).

1) Give the 1st OPEN command: the operator performs a

deceleration closing manoeuvre until it detects the stop

point.

2) Give the 2nd OPEN command: the operator continues with

an opening movement.

3) Give the 3rd OPEN command in order to define the point

where you wish deceleration to begin.

4) Give the 4th OPEN command to define the opening stop

point, or wait for the automated system to detect arrival at

the stop point. After the stop, the time when the automated

system is left open starts to be counted . This will be the pause

time which will be observed during manual operation (3

minutes maximum).

5) Give the 5th OPEN command: the pause time count is stopped

and the closing movement starts.

6) Give the 6th OPEN command in order to define the point

where you wish deceleration to begin.

7) Wait for the door to reach the stop point and for the

operator to stop.

If the learning procedure terminated positively, the SET UP LED

stops flashing and stays lighted for 5 seconds.

During these 5 seconds, in order to lighten the load on the

release system, you can send OPEN pulses within a time interval

of 2 seconds from each other, in order to reverse the carriage.

One pulse corresponds to a 5 millimetre travel.

N.B.: The carriage can be seen reversing only during normal

operation of the automated system.

LEARNING WITH THRUST FORCE OF 1000N

If learning is not performed correctly due to a heavy door or to

door movement problems, learning with a greater thrust force

(1000N instead of 600N) is possible.

How to start this type of learning:

1) Start the required learning cycle in the normal way.

2) While the automated system is performing the specified

movements, repeat the learning start procedure.

3) The automated system starts the learning cycle again, but

with a greater thrust.

ON GROUND MANUAL SETTING OF STOP CONTACT POINT (at the

learning stage)

During the learning stage, the operator searches for the

on-ground stop point, using the maximum force that can be

supplied (600/1000 N)). To prevent excessive stress, the stop point

can be determined also manually: when the automated system

performs the closing movements, give an OPEN command

when the stop point is reached. If the stop commands at first and

second closing were inconsistent, the automated system signals

the fault status and the learning cycle must be repeated.

During normal operation, the automated system in any case

searches for the stop contact point, but it exercises only the

force necessary to move the door.

The sensitivity of the anti-crushing device depends

on programming (anti-crushing sensitivity, manual

adjustment of force) and on the door’s mechanical

characteristics. When installation and programming

have been completed, always run the checks specified

in the regulations in chapter “WARNINGS FOR THE

INSTALLER” of these instructions.

When the learning cycle has finished, make the automated

system perform a complete cycle, in order to acquire

the correct closing stop point. If, after the end of this

cycle, the automated system opens the door again,

command closure.

13

Page 14

11.3 Pre-flashing

The pre-flashing function can be enabled and disabled

(following an OPEN command, the unit activates the flashing

lamp for 5 seconds before it starts the movement).

Procedure:

1) Press and hold down the SET UP push-button.

2) Press the OPEN push-button too after about 3 seconds. If the

SET UP LED goes ON, pre-flashing was activated, if instead,

it stays OFF, pre-flashing was disabled.

3) Release both push-buttons.12. MEMORY STORAGE OF RADIO

CONTROLS CODING

12. MEMORY STORAGE OF RADIO CONTROLS CODING

The control unit has an integrated 2-channel decoding system

(DS, SLH, LC) named OMNIDEC. This system makes it possible to

memory-store both total opening (OPEN A) and partial opening

(OPEN B) of the automated system - this is made possible by an

additional receiver module (Fig. 30 ref. ) and radio controls

on the same frequency.

RADIO SET UP

OPEN B OPEN A

Fig. 31

4) Within these 5 secs., press the appropriate push-button on

the radio control.

5) The relevant LED lights up on steady beam for 1 second and

then goes OFF, indicating that storage was executed.

6) To add other radio controls, set the same ON - OFF combination

used in point 1).

ENGLISH

Fig. 30

The 3 types of radio codes (DS, LSH, LC) cannot

coexist.

Only one radio code can be used at a time.

To change over from one code to another, you must

delete the existing one (see paragraph on deletion),

and repeat the memory-storage procedure.

12.1. Memory storage of radio controls DS

A maximum of two codes can be stored. One on the

OPEN A channel and one on the OPEN B channel

1) On the DS radio control, select the required ON-OFF combination

for the 12 dip-switches.

2) To respectively memory store total or partial opening, press

the OPEN A or OPEN B push-button for one second (Fig. 31

ref. )

3) The relevant LED (Fig. 31 ref ), begins to flash for 5 sec.

12.2. Memory storage of radio controls SLH

A Maximum of 250 codes can be memory stored, split

between OPEN A and OPEN B.

1) On the SLH radio control, simultaneously press and hold down

push-buttons P1 and P2.

2) The radio control LED begins to flash.

3) Release both push-buttons.

4) To respectively memory store total or partial opening, press

the OPEN A or OPEN B push-button for one second (Fig. 31

ref. ).

5) The relevant LED starts to flash slowly for 5 sec.

6) Within these 5 sec., while the radio control LED is still flashing,

press and hold down the required push-button on the radio

control (the radio control LED lights up on steady beam).

7) The LED on the board lights up on steady beam for 1 second

and then goes OFF, indicating that storage was executed.

8) Release the radio control push-button.

9) Quickly press twice in succession the memory stored radio

control push-button.

The automated system performs one opening operation.

Make sure that the automated system is free of any

obstacle created by persons or things.

10) To add other radio controls, transfer the code of the

memory-stored push-button of the radio control to the

relevant push-button of the radio controls to be added,

observing the following procedure:

- On the memory stored radio control, simultaneously press and

hold down push-buttons P1 and P2.

- The radio control LED begins to flash.

- Release both push-buttons.

- Press and hold down the memory-stored push-button (the radio

control LED lights up on steady beam).

- Approach the radio controls to each other and hold down the

push-button corresponding to the radio control to be added;

then release it after a double flash of the radio control LED

indicating that storage was executed.

14

Page 15

- Quickly press twice in succession the memory stored radio

control push-button.

The automated system performs one opening operation.

Make sure that the automated system is free of any

obstacle created by persons or things.

12.3 Memory storage of radio controls LC (for some markets

only)

A Maximum of 250 codes can be memory stored, split

between OPEN A and OPEN B.

1) Use LC remote controls only with receiver module at 433

MHz.

2) To respectively memory store total or partial opening, press

the OPEN A or OPEN B push-button for one second (Fig. 31

ref. ).

3) The relevant LED starts to flash slowly for 5 sec.

ENGLISH

4) Within these 5 secs., press the appropriate push-button on

the LC remote control.

5) The LED lights up on steady beam for 1 second, indicating

memory storage executed, and then resumes flashing for

another 5 sec., during which another radio control (point 4)

can be memory stored.

6) When the 5 secs. have elapsed, the LED goes OFF indicating

the end of the procedure.

7) To add other radio controls, repeat the operation from point

1).

All codes of radio controls stored as OPEN A and OPEN

B will be deleted.

13. START-UP

After installation, make sure that no part of the door

interferes with public spaces such as pavements and/or

roads.

Fig. 32

12.3.1 Remote memory storage of LC radio controls

Other radio controls can be remotely stored only with the LC

radio controls, i.e. without using the RADIO SETUP

push-buttons, but using a previously stored radio control.

1) Obtain a radio control already stored on one of the 2

channels (OPEN A or OPEN B).

2) Press and simultaneously hold down push-buttons P1 and P2

until the lights of both the LEDs on the board light up.

3) Both LEDs flash slowly for 5 sec.

4) Within 5 sec. press the push-button of the radio control that

had been memory stored to enable learning on the selected

channel (OPEN A or OPEN B).

5) The LED on the board relating to the channel being learned

flashes for 5 sec., within which time the code of another radio

control must be transmitted.

6) The LED lights up on steady beam for 2 seconds, indicating

memory storage executed, and then resumes flashing for 5

sec., during which other radio controls can be memory stored,

as in point 5, and then goes OFF.

12.4. Radio controls deletion procedure

1) To delete ALL the radio control codes, hold down push-button

OPEN A or OPEN B for 10 sec.

2) The LED relating to the pressed push-button flashes for the first

5 sec, and then flashes more quickly for the next 5 sec.

3) Both LEDs light up on steady beam for 2 sec and then go

OFF.

4) Release the pressed push-button when both LEDs light up on

a steady beam.

Fig. 33

Check the status of the unit’s inputs and make sure that all the

safety devices are correctly connected (the relevant LEDs must

be lighted).

Run a few complete cycles to check if the automated system

and the accessories connected to it are operating correctly,

addressing special care to the safety devices and the

anti-crushing device of the operator. Check if the automated

system is able to detect an obstacle with a height of 50mm laid

on the ground.

Apply the stickers indicating the release manoeuvre near the

automated system. Apply the danger signal sticker (Fig. 32), so

that it is clearly visible, near to the door or near to the control

device.

Hand the customer the page entitled “User’s guide”, and

describe how the system works, and the operator release and

locking operations indicated in the guide.

This operation is NOT reversible.

15

Page 16

14. PARACHUTE CABLES

Connect the parachute cables to the rear door and to the

ceiling lamp to prevent accidental falls (Fig. 33).

15. MAINTENANCE

Run a functional check of the system at least every 6 months,

with special attention to the efficiency of the safety and release

devices.

Once a month: check the efficiency of the anti-crushing device

and also check if it is able to detect a 50mm high obstacle laid

on the ground.

16. REPAIRS

For repairs, contact FAAC’s authorised Repair Centres.17.1.

Central support

The central support (Fig. 34) provides a central securing point

also for the single-piece sliding guide.

17. ACCESSORIES

17.1. Central support

The central support (Fig. 34) provides a central securing point

also for the single-piece sliding guide.

17.3. Safety edge CN60E

The use of the safety edge with conductive element, is

facilitated because the control unit (Fig. 36 ref ) can be

housed on board the operator.

Procedure:

- Grip the rear door with one hand.

- Pull gently, separating it from the plastic housing.

- Grip the ceiling light with one hand.

- Pull gently, separating it from the plastic housing.

- Unscrew the 4 screws in the 4 corners of the plastic housing.

- Separate it from the base.

- House the control unit as shown in Fig. 36.

- First hook on the two fastening clips on the coupling on the

base.

- Then press lightly until you can hear the hooking snap sound.

- For the connections, refer to the specific instructions for the

CN60E safety edge, and Fig. 27 of these instructions.

ENGLISH

Fig. 34

17.2. Key-operated release

The external release can be installed with the lever system

(Fig. 35 ref. A) or the key system (Fig. 35 ref. B). See instructions

in par. 6.3 and par. 7.5.

Fig. 36

17.4. Battery kit

The buffer battery kit will activate the automated system in

the event of a power cut. The batteries are housed inside the

operator (Fig. 37 ref. ) fastened by a supplied screw.

To install, consult the specific instructions.

The batteries come into operation when a power cut

occurs.

After installing the batteries, connect the male

connector to the J12 female connector on the E1000

control board.

Fig. 35

Fig. 37

16

Page 17

Trouble Possible causes Solution

When the learning procedure is started,

the SET UP LED flashes but the automated

system does not perform any

manoeuvre

The automated system does not

perform any movement

The automated system opens the door

but does not close it

Learning is not finished correctly and the

SET UP LED flashes to signal a fault

The automated system frequently

ENGLISH

reverses motion during the opening

and/or closing manoeuvre

It is difficult to release the automated

system while the door is closed

18. TROUBLESHOOTING

The STOP and FSW safety devices are

enabled also during the learning stage.

Non-connection or wrong connection

prevents the operator from working

STOP command enabled

The Fail-Safe function is enabled, but the

NC contact of the devices connected

to the FSW input does not open during

test by the unit before the manoeuvre

is started

FSW safety devices engaged

-The automated system detects that

the door movement is too difficult.

- If you are using manual adjustment of

force, the set thrust could be insufficient.

Too much mechanical load on the release

system with the door closed

Check the LEDs’ status following the

instructions of the “Inputs status LEDs”.

Check the connections shown in fig. 27

Check the balance of the door and

make sure that it moves without too much

friction. Move the door manually, using

the rod fitting on the door, and check

if the movement is smooth and does

not require too much traction or thrust.

Execute a new learning cycle. If necessary,

vary the thrust force (if using manual

adjustment) or start learning with a maximum thrust of 1000N.

Run a new learning cycle and,

when over, lighten the closing thrust,

commanding the carriage to withdraw

as described in paragraph 11.2.

The SET UP LED flashes to signal a fault

status

The learning cycle did not finish

positively.

DS1’s switch No. 3 (automatic/manual

adjustment of force) was shifted and a

new learning cycle was not executed.

Run a new learning cycle

17

Page 18

USER’s GUIDE D1000

Read the instructions carefully before using the product and store them for future use.

GENERAL SAFETY REGULATIONS

If correctly installed and used, the D1000 automated system will ensure a high degree of safety.

Some simple rules on behaviour can prevent accidental trouble:

- Do not, under any circumstances, stand under the door.

- Do not allow persons, animals or things to stay near the automated systems, especially while they are

operating.

- Transit must occur while the door is fully open and with the automated system stopped. Keep the door

under control during the entire movement and prevent other people accessing the area involved.

- Keep remote-controls, or other pulse generators that could open the door, well away from children.

- IMPORTANT! DANGER OF CRUSHING.

- Once a month: check if the anti-crushing system is able to detect the presence of a 50 mm high obstacle laid on the

ground.

- Do not allow children to play with the automated system.

- Do not willingly obstruct door movement.

- Prevent any branches or shrubs from interfering with door movement.

- Keep the indicator-lights efficient and easy to see.

- In the event of malfunctions, release the door to allow access and wait for qualified technical personnel to do the necessary

work.

- When you have set manual operation mode, cut power to the system before restoring normal operation.

- Do not in any way modify the components of the automated system.

- Do not attempt any kind of repair or direct action whatever and contact qualified FAAC personnel only.

- At least every six months: arrange a check by qualified personnel of the automated system and the safety devices.

DESCRIPTION

The D1000 automated system is ideal to automate balanced sectional doors of single garages for residential use.

The automated systems consist of an electro-mechanical operator, electronic control unit and courtesy light built into a single unit.

The system is non-reversing and, therefore, the door locks mechanically when the motor is not operating and, consequently, no lock is necessary;

a manual release makes it possible to move the door in case of a power cut or fault.

The automated system has an electronic obstacle detection system. If an obstacle is detected during the closing manoeuvre, the automated

system fully re-opens the door. If the automated system operates in automatic logic, the door re-closes

after the pause time, otherwise, a new pulse has to be given to command closure. If an obstacle is

detected during the opening manoeuvre, this will stop motion (e.g. thus preventing things and people

from being lifted). To restore normal operation, give a new opening pulse.

If, during closure, an obstacle is detected in the same position more than three consecutive times, the

automated system considers this distance as the new closing contact point and goes into closed status.

To restore the correct positions, remove the obstacle and command a new cycle: at the next closure,

the automated system will advance at low speed until it detects the closing contact point.

The door is normally closed; when the control unit receives an opening command by radio control,

or from another type of pulse generator (Fig. 1), it activates the electric motor which, by means of a

transmission chain or belt, pulls the door open to allow access.

- If the automatic mode was set, the door closes automatically after pause time has elapsed. An

opening pulse given during the opening stage has no effect.

- If the semi-automatic mode was set, a second pulse must be sent to close the leaf again.

- An opening pulse supplied during opening, stops movement. An opening pulse given during re-closing,

always causes movement to be reversed.

- A stop pulse (if specified) always stops movement.

For details of door activity during the different logics, consult the installation engineer.

Accessories (photocells) may be present in automated systems, that prevent the door from closing when

there is an obstacle in the area they control.

Emergency manual opening is possible by using the release system.

The indicator-light (if supplied) indicates the current door movement.

The courtesy light is activated when the motor starts and continues for about 2 minutes after it turns off.

If the courtesy light flashes, this means that automated system is in shut-down status due to a fault, and

qualified personnel must be called in to repair.

MANUAL OPERATION

The D1000 operator is equipped with an emergency release system activated from the inside – however,

a lock can be fitted on request, for activating the release from the outside too.

If the door has to be moved manually due to a power cut or fault of the automated system, use the

release device as follows:

- Turn off electric power to the system.

- Release the operator, by pulling the release handle downward (Fig. 2 ref. A).

Attention: make sure that there are no persons, animals or objects in the door movement area during

the release manoeuvre.

RESTORING AUTOMATIC OPERATION MODE

- Relock the automated system by pulling the handle horizontally (Fig. 2 ref. B) and make sure that, when

you release it, the “LOCK” window under the carriage is red, to confirm correct resetting.

- Move the door until you find the hook-on point.

- Power up the system.

MAINTENANCE

The D1000 automated system does not require any periodic replacement of parts.

COURTESY LIGHT REPLACEMENT

To replace the lamp, grip the ceiling light with one hand and pull downward, as shown in Fig. 3.

Unscrew the lamp (type E27 - 230 Vac - max 40 W) and re-position the ceiling light.

- Do not attempt to activate the door by hand unless you have released it.

RELEASE

RE-LOCK

Fig.1

Fig.2

Fig.3

Page 19

Technician

Customer 2Technician

Customer 3Technician

Customer 4Technician

Customer 5Technician

Customer 6Technician

Customer 7Technician

Customer 8Technician

Customer 9Technician

Customer 10Technician

Customer

Date Job description Signatures

No.

1

MAINTENANCE REGISTER

REGISTRO DI MANUTENZIONE

System data

System configuration

Installer

Customer

Start-up

Serial No.

Type of system

Installation date

PART MODEL SERIAL NUMBER

Operator

Safety device 1

Safety device 2

Control device 1

Pair of photocells 1

Control device 2

Pair of photocells 2

Radio control

Flashing lamp

Indication of residual risks and of foreseeable improper use

Page 20

D1000

D1000

Page 21

Page 22

GUIDA UTENTE D1000

Leggere attentamente le istruzioni prima di utilizzare il prodotto e conservarle per eventuali necessità

future.

NORME GENERALI DI SICUREZZA

L’automazione

curezza.

Alcune semplici norme di comportamento possono evitare inoltre inconvenienti accidentali:

- Non sostare assolutamente sotto alla porta.

- Non permettere a persone, animali o cose di sostare nelle vicinanze delle automazioni specialmente

durante il funzionamento.

- Il transito deve avvenire a porta totalmente aperta e con automazione ferma.Tenere sotto controllo la

porta per tutto il movimento ed impedire l’avvicinamento di altre persone all’area interessata.

- Tenere fuori dalla portata dei bambini radiocomandi o qualsiasi altro datore di impulso che possa

azionare la porta.

- In caso di malfunzionamenti, sbloccare la porta per consentire l’accesso ed attendere l’intervento tecnico di personale qualificato.

- Una volta predisposto il funzionamento manuale, prima di ripristinare il funzionamento normale, togliere alimentazione elettrica all’impianto.

- Non eseguire alcuna modifica sui componenti facenti parte il sistema di automazione.

- Astenersi da qualsiasi tentativo di riparazione o d’intervento diretto e rivolgersi solo a personale qualificato FAAC.

- Far verificare almeno semestralmente l’efficienza dell’automazione, dei dispositivi di sicurezza da personale qualificato.

DESCRIZIONE

L’ automazione

Le automazioni sono costituite da un operatore elettromeccanico, un‘apparecchiatura elettronica di controllo, una lampada di cortesia e un

carter di protezione integrati in un unico monoblocco.

Il sistema irreversibile garantisce il blocco meccanico della porta quando il motore non è in funzione e quindi non occorre installare alcuna serratura; uno sblocco manuale rende manovrabile la porta in caso di black-out o disservizio.

L’automazione è dotata di un sistema elettronico per il rilevamento di ostacolo. Se viene rilevato un ostacolo durante la manovra di chiusura, l’automazione riapre completamente la porta. Se l’automazione

funziona in logica automatica, la porta si richiuderà dopo il tempo di pausa, in caso contrario occorrerà

dare un nuovo impulso per comandare la chiusura. Durante la manovra di apertura, la rilevazione di

un ostacolo causa l’arresto del moto (ciò ad evitare sollevamento di cose o persone). Per ripristinare il

normale funzionamento occorre dare un nuovo impulso di apertura.

Se viene rilevato un ostacolo in chiusura nella stessa posizione per tre volte consecutive, l’automazione

assume tale quota come nuova battuta di chiusura e si pone in stato di chiuso. Per ripristinare le corrette

posizioni, rimuovere l’ostacolo e comandare un nuovo ciclo: alla successiva chiusura l’automazione

avanzerà a velocità rallentata fino ad individuare la battuta.

La porta normalmente si trova chiusa; quando la centralina elettronica riceve un comando di apertura

tramite il radiocomando, o qualsiasi altro datore di impulso (Fig. 1), aziona il motore elettrico che tramite

trasmissione a catena od a cinghia trascina il portone in posizione di apertura e consente l’accesso.

- Se è stato impostato il funzionamento automatico, la porta si richiude da sola dopo il tempo pausa.

Un impulso di apertura dato durante la fase di apertura non ha nessun effetto.

- Se è stato impostato il funzionamento semiautomatico, è necessario inviare un secondo impulso per

ottenere la richiusura.

- Un impulso di apertura dato durante la fase di apertura provoca l’ arresto del movimento. Un impulso

di apertura dato durante la fase di richiusura provoca sempre l’inversione del movimento.

- Un impulso di stop (se previsto) arresta sempre il movimento.

Per il dettagliato comportamento della porta nelle diverse logiche fare riferimento al Tecnico installatore.

Nelle automazioni possono essere presenti accessori (fotocellule) che impediscono la richiusura della

porta quando un ostacolo si trova nella zona da essi controllata.

L’apertura manuale d’emergenza è possibile intervenendo sull’apposito sistema di sblocco.

La segnalazione luminosa (se prevista) indica il movimento in atto della porta.

La luce di cortesia si attiva alla partenza del motore e permane per un tempo di circa 2 minuti dal suo

spegnimento. Se la lampada di cortesia lampeggia, l’automazione è in stato di blocco per anomalia

ed occorre richiedere l’intervento di personale qualificato per la riparazione.

FUNZIONAMENTO MANUALE

L’ operatore

a richiesta, applicare una serratura che permetta l’azionamento dello sblocco anche dall’esterno.

Nel caso sia necessario azionare la porta a causa di mancanza di alimentazione elettrica o disservizio

dell’automazione è necessario agire sul dispositivo di sblocco come segue:

- Togliere l’alimentazione elettrica all’impianto.

- Sbloccare l’operatore tirando verso il basso la maniglia di sblocco (Fig. 2 rif. A).

Attenzione: evitare che persone, animali od oggetti si trovino nella zona di movimento della porta durante la manovra di sblocco.

RIPRISTINO DEL FUNZIONAMENTO AUTOMATICO

- Ribloccare l’automazione tirando orizzontalmente la maniglia (Fig. 2 rif. B) ed accertarsi che, al rilascio,

la finestrella “LOCK” posta sotto al carrello sia di colore rosso, a conferma del corretto riarmo.

- Muovere la porta fino a ritrovare il punto di aggancio.

- Alimentare nuovamente l’impianto.

MANUTENZIONE

L’automazione

SOSTITUZIONE LAMPADA DI CORTESIA

Per la sostituzione della lampada, afferrare con una mano la plafoniera e tirare verso il basso, come

indicato in Fig. 3.

Svitare la lampada (tipo E27 - 230 Vac - max 40 W) e riposizionare la plafoniera.

D1000, se correttamente installata ed utilizzata, garantisce un elevato grado di si-

- ATTENZIONE! PERICOLO DI SCHIACCIAMENTO.

- Controllare mensilmente che il sistema antischiacciamento sia in grado di rilevare la presenza di un ostacolo alto

50 mm posto a terra.

- Non permettere a bambini di giocare con l’automazione.

- Non contrastare volontariamente il movimento della porta.

- Evitare che rami o arbusti possano interferire col movimento della porta.

- Mantenere efficienti e ben visibili i sistemi di segnalazione luminosa.

- Non tentare di azionare manualmente la porta se non dopo averla sbloccata.

D1000 è ideale per automatizzare porte sezionali bilanciate di garages singoli residenziali.

D1000 è dotato di un sistema di sblocco di emergenza azionabile dall’interno; è possibile,

D1000 non richiede alcuna sostituzione periodica di parti.

Fig.1

SBLOCCARE

RIBLOCCARE

Fig.2

Fig.3

Page 23

Tecnico

Cliente2Tecnico

Cliente3Tecnico

Cliente4Tecnico

Cliente5Tecnico

Cliente6Tecnico

Cliente7Tecnico

Cliente8Tecnico

Cliente9Tecnico

Cliente10Tecnico

Cliente

Nr Data Descrizione intervento Firme

1

REGISTRO DI MANUTENZIONE

Dati impianto

Configurazione impianto

Cliente

Installatore

Tipo impianto

Matricola

Attivazione

Data installazione

Operatore

COMPONENTE MODELLO MATRICOLA

Coppia fotocellule 1

Dispositivo di sicurezza 1

Dispositivo di sicurezza 2

Lampeggiante

Radiocomando

Coppia fotocellule 2

Dispositivo di comando 1

Dispositivo di comando 2

Indicazione dei rischi residui e dell’uso improprio prevedibile

Page 24

USER’s GUIDE D1000

Read the instructions carefully before using the product and store them for future use.

GENERAL SAFETY REGULATIONS

If correctly installed and used, the D1000 automated system will ensure a high degree of safety.

Some simple rules on behaviour can prevent accidental trouble:

- Do not, under any circumstances, stand under the door.

- Do not allow persons, animals or things to stay near the automated systems, especially while they are

operating.

- Transit must occur while the door is fully open and with the automated system stopped. Keep the door

under control during the entire movement and prevent other people accessing the area involved.

- Keep remote-controls, or other pulse generators that could open the door, well away from children.

- IMPORTANT! DANGER OF CRUSHING.

- Once a month: check if the anti-crushing system is able to detect the presence of a 50 mm high obstacle laid on the

ground.

- Do not allow children to play with the automated system.

- Do not willingly obstruct door movement.

- Prevent any branches or shrubs from interfering with door movement.

- Keep the indicator-lights efficient and easy to see.

- In the event of malfunctions, release the door to allow access and wait for qualified technical personnel to do the necessary

work.

- When you have set manual operation mode, cut power to the system before restoring normal operation.

- Do not in any way modify the components of the automated system.

- Do not attempt any kind of repair or direct action whatever and contact qualified FAAC personnel only.

- At least every six months: arrange a check by qualified personnel of the automated system and the safety devices.

DESCRIPTION

The D1000 automated system is ideal to automate balanced sectional doors of single garages for residential use.

The automated systems consist of an electro-mechanical operator, electronic control unit and courtesy light built into a single unit.

The system is non-reversing and, therefore, the door locks mechanically when the motor is not operating and, consequently, no lock is necessary;

a manual release makes it possible to move the door in case of a power cut or fault.

The automated system has an electronic obstacle detection system. If an obstacle is detected during the closing manoeuvre, the automated

system fully re-opens the door. If the automated system operates in automatic logic, the door re-closes

after the pause time, otherwise, a new pulse has to be given to command closure. If an obstacle is

detected during the opening manoeuvre, this will stop motion (e.g. thus preventing things and people

from being lifted). To restore normal operation, give a new opening pulse.

If, during closure, an obstacle is detected in the same position more than three consecutive times, the

automated system considers this distance as the new closing contact point and goes into closed status.

To restore the correct positions, remove the obstacle and command a new cycle: at the next closure,

the automated system will advance at low speed until it detects the closing contact point.

The door is normally closed; when the control unit receives an opening command by radio control,

or from another type of pulse generator (Fig. 1), it activates the electric motor which, by means of a

transmission chain or belt, pulls the door open to allow access.

- If the automatic mode was set, the door closes automatically after pause time has elapsed. An

opening pulse given during the opening stage has no effect.

- If the semi-automatic mode was set, a second pulse must be sent to close the leaf again.

- An opening pulse supplied during opening, stops movement. An opening pulse given during re-closing,

always causes movement to be reversed.

- A stop pulse (if specified) always stops movement.

For details of door activity during the different logics, consult the installation engineer.

Accessories (photocells) may be present in automated systems, that prevent the door from closing when

there is an obstacle in the area they control.

Emergency manual opening is possible by using the release system.

The indicator-light (if supplied) indicates the current door movement.

The courtesy light is activated when the motor starts and continues for about 2 minutes after it turns off.

If the courtesy light flashes, this means that automated system is in shut-down status due to a fault, and

qualified personnel must be called in to repair.

MANUAL OPERATION

The D1000 operator is equipped with an emergency release system activated from the inside – however,

a lock can be fitted on request, for activating the release from the outside too.

If the door has to be moved manually due to a power cut or fault of the automated system, use the

release device as follows:

- Turn off electric power to the system.

- Release the operator, by pulling the release handle downward (Fig. 2 ref. A).