Page 1

ENGLISH ENGLISH

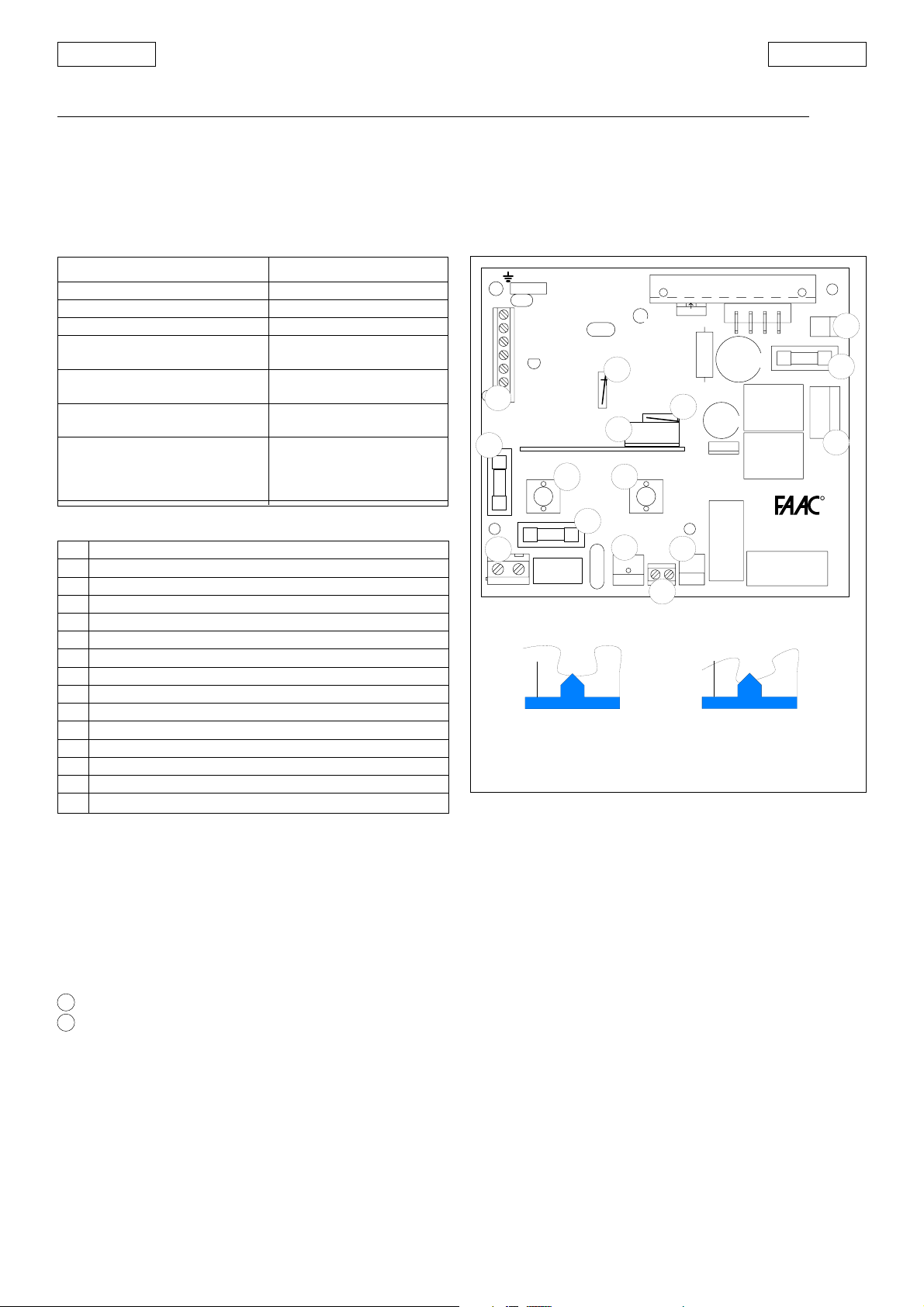

7. CONNECTION OF 565 MPS ELECTRONIC CARD

IMPORTANT: Before attempting any work on the card (connections, programming, maintenance), always turn off power.

Observe points 10, 11, 12, 13 and14 of the GENERAL SAFETY RULES.

Observing the indications in fig.2, install the raceways and make the electrical connections from the 565 MPS electronic appliance

to the selected accessories (fig. 28).

Always separate power cables from control and safety cables (push-button receiver, photocells, etc.). To prevent any electric noise

whatever, use separate sheaths.

TECHNICAL SPECIFICATIONS

Power supply voltage 230V ac 50Hz

Power supply for accessories 24Vdc

Accessories max. load 200 mA

Ambient temperature -20°/+55°C

Fuses transf./motor primary

winding

Quick-fit connector for decoding cards and

RPreceivers

Function logics Automatic/Semi-

automatic

Terminal board connections Open/Stop/Safety

devices/Failsafe/

Flashlight

F3

J1

P1

LK2

LK1

J2

P2

J7

F2

J8

R

565 MPS CARD COMPONENTS

F1 Fuse for transf. primary winding, 1A

F2 Motor fuse, 10A

F3 Fuse for 0,5A accessories output

J1 Low voltage terminal board for inputs /accessories

J2 Rapid connector for decoding/RP receivers cards

J3 230V power supply input terminal board

J4 Connector for transformer primary winding

J5 Courtesy light connector

J6 Flashlight output terminal board

J7 Connector for transformer secondary winding

J8 Motor output connector

P1 Open push-button

P2 Set-up push-button

LK1 Enable/disable fail-safe

LK2 Varies sensitivity of reversing device

DESCRIPTION

TERMINAL BOARD J1 (low voltage)

OPEN=Open Command (N.O.)

Any device (push-button, detector,…) which, by closing a contact, supplies an opening (or closing) pulse to the door.

To install several Open devices, connect N.O. contacts in parallel.

STOP=Stop command (N.C.)

Any device (e.g. a push-button) which, by opening a contact, stops door movement.

To install several stop devices, connect the N.C. contacts in series.

N.B.: if stop devices are not used, jumper connect STOP to the inputs common contact.

=input/negative accessories supply common contact.

-

=Accessories supply positive pole (24V dc 200mA max)

+

J3

fail-safe enabled fail-safe disabledLK1=

reversing sensitivity

LK2=

150N (~15Kg)

F1

J4

565 MPS

J5

J6

reversing sensitivity

300N (~30Kg)

Fig.27

FSW= Closing safety-devices contact (N.C.)

Safety devices are all devices (photocells, sensitive edges,…) with N.C. contact, which, if there is an obstacle in the area they

protect, operate to reverse door closing movement.

If the safety devices are activated when the door is locked or open, they prevent it from closing.

To install several safety devices, connect the N.C. contacts in series.

N.B.: if safety devices are not connected, jumper connect FSW to the inputs common contact.

-FSW TX= Terminal for connection of the negative pole (-) of the photocells transmitter (TX).

CONNECTOR J2 (low voltage)

Connector J2 is used for rapid connection of MINIDEC, DECODER, and RP RECEIVER cards.

Insert and remove the cards after cutting power.

20

Page 2

ENGLISH ENGLISH

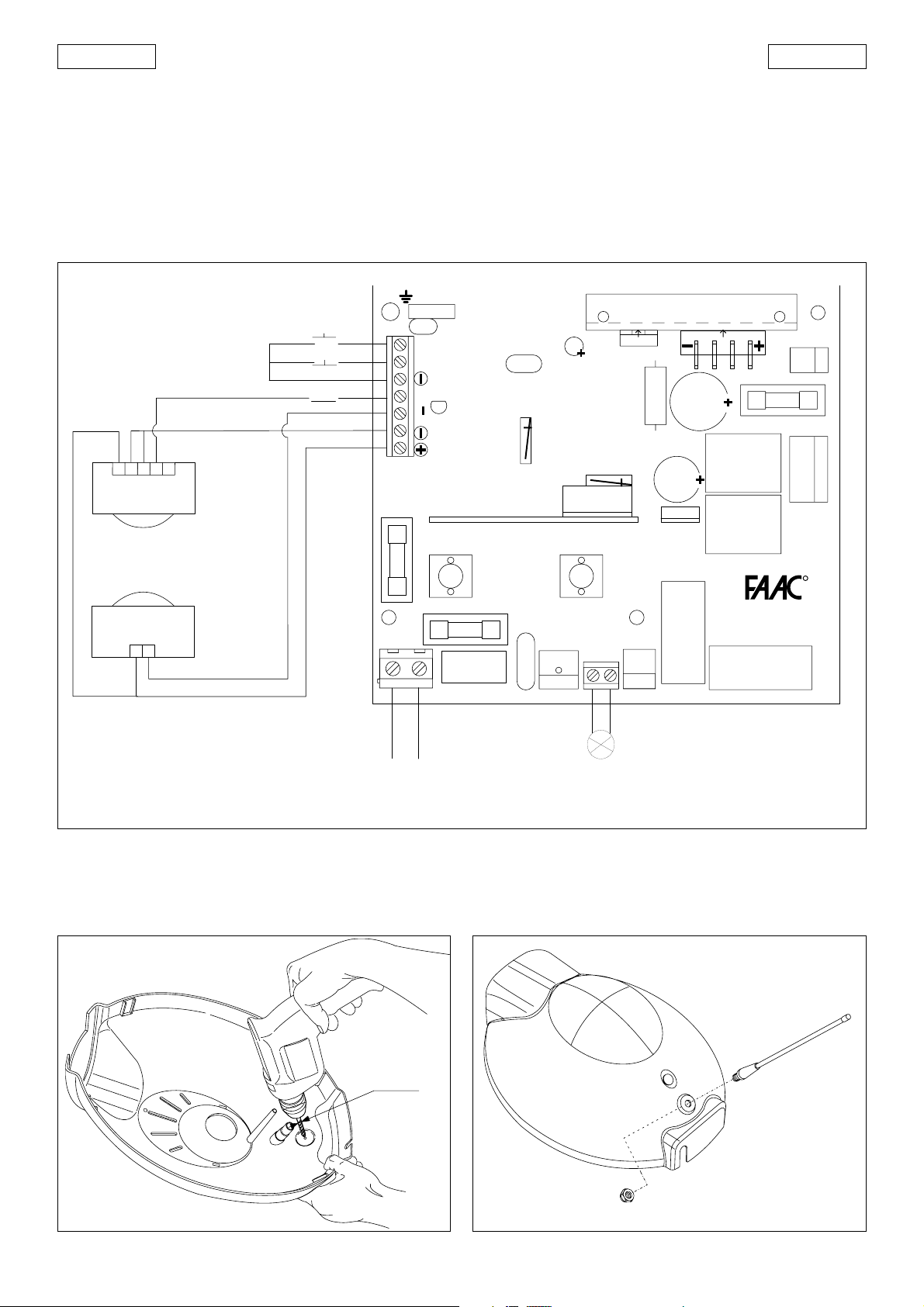

TERMINAL BOARD J3 (high voltage)

Terminal board for power supply of 230V ~50Hz (F=phase N= neutral)

Connect the system’s earth wire to the dedicated terminal (see ID sticker – fig.31 ref.A).

TERMINAL BOARD J6 (high voltage)

230V~ Terminal board for connection of flashlight.

LK1 JUMPER (enable/disable fail-safe)

The 565 MPS card has another safety device – the FAIL-SAFE – which, prior to any activation, controls if the N.C. contact on the

photocell receiver (fig.27) is operating efficiently.

JUMPER LK2 (150N/300N)

Serves to vary the sensitivity of the reversing device (fig. 27).

RX

TX

•

OPEN

•

•

•

•

•

STOP

•

OTHER SAFETY DEVICES

•

•

21345

J1

OPEN

STOP

FSW

FSW

TX

RP - DECODER

P1

OPEN

LK2

J2

LK1

FAIL SAFE

P2

SETUP

J7

C3

J8

R

565 MPS

1

2

J3

230V ac 50Hz

J4

PRIM.TF. LIGHT

FAAC LAMP

J6

J5

Fig.28

8. ANTENNA INSTALLATION (OPTIONAL)

8.1 If you are using an RP receiver, and wish to increase its range, you can use an external 433 MHZ antenna (antenna connection

instructions are on the rear of the RP receiver blister-pack).

8.2 Pick up the housing and, using an appropriate bit, drill from the inside outward in the guided area (fig. 29).

8.3 Turn the housing toward the front, fit the antenna and secure it from the inside with a suitable nut (fig. 30).

Ø10

Fig 30Fig.29

21

Page 3

ENGLISH ENGLISH

9. CONNECTIONS

9.1 Connect the power cable, as shown in figure 31, securing it with a clamp in the indicated area.

A

Fig.31

A

Fig.32

10. PROGRAMMING

To access the programming push-button, dismantle the courtesy light ceiling fixture, unscrewing the appropriate screw.

Slide the ceiling fixture in the direction shown by the arrow (fig.34).

SET-UP CYCLE

During this procedure, the obstacle detection and Fail-safe

device are NOT operating.

The set-up cycle defines:

- anti-crushing safety levels during opening and closing

- deceleration points

- door complete opening and closing point

- pause time

This procedure can be carried out at any time, with the operator

in any position, by means of the set-up push-button (see different

set-up modes).

Set-up occurs with a max. force of 800N. If the force is not sufficient

to complete the learning, it can be increased to 1200N by

activating, during the 800N cycle, a second set-up procedure

(by pressing the set-up push-button again as indicated in the

different modes).

Two function logics are available on this appliance:

AUTOMATIC (TABLE 1)

SEMI-AUTOMATIC (TABLE 2)

Fig.33

9.2 Fit the screw in the appropriate seat and tighten with washer

and nut (fig.31 ref.A).

9.3 Position the earth eyelet on the screw, add a washer and

tighten wit the nut (fig. 32 ref.A).

9.4 If you are using tube sleeves to secure the cables, make a slot

as shown in figure 32.

9.5 Screw the lamp in the appropriate lamp-holder.

9.6 Secure the operator housing using appropriate screws (fig.33).

A

Fig.34

22

Page 4

ENGLISH ENGLISH

AUTOMATIC SET-UP

The set-up procedure is executed automatically just with a pulse.

MANUAL SET-UP

This procedure enables you to select the deceleration points, the

fully open point, and pause time.

AUTOMATIC SET-UP WITH LOGIC “E” (SEMI-AUTOMATIC)

Press and release the SET-UP push-button to select the logic.

After 8 seconds the operator effects a closing operation until a

stop is detected.

The operator now opens the door, and the opening movement

finishes when the mechanical stop is recognised.

The door is immediately closed.

The electronic appliance establishes the deceleration points.

If the SETUP procedure was successful, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals

travel of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the automated system is operating normally.

MANUAL SET-UP WITH LOGIC “E” (SEMI-AUTOMATIC)

Press and release the SET-UP push-button to select the logic.Carry

out the following procedure within 8 seconds after pressing the

SETUP push-button, otherwise the oprator will execute automatic SETUP.

1st OPEN: the operator effects a closing operation until a stop is

detected.

2nd OPEN: the operator continues with an opening movement.

3rd OPEN: defines the point at which start of deceleration is

required.

4th OPEN: defines the end of the opening** movement.

5th OPEN: starts closing movement.

6th OPEN: defines the point at which start of deceleration is

required.

Allow the operator to reach the stop.

If the SETUP procedure was successful, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals

travel of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the automated system is operating normally.

AUTOMATIC SET-UP WITH LOGIC “A” (AUTOMATIC)

Hold down the SET-UP push-button to select the logic until the

courtesy light goes on (about 5 seconds).

After 8 seconds the operator effects a closing operation until a

stop is detected.

The operator now opens the door, and the opening movement

finishes when the mechanical stop is recognised.*

The door is immediately closed.

The electronic appliance establishes the deceleration points,

and pause time is fixed at 3 minutes.

If the SETUP procedure was successful, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals

travel of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the automated system is operating normally.

MANUAL SET-UP WITH LOGIC “A” (AUTOMATIC)

Hold down the SET-UP push-button to select the logic until the

courtesy light goes on (about 5 seconds).Carry out the following

procedure within 8 seconds after pressing the SETUP push-button,

otherwise the oprator will execute automatic SETUP.

st

OPEN: the operator effects a closing operation until a stop is

1

detected.

2nd OPEN: the operator continues with an opening movement.

3rd OPEN: defines the point at which start of deceleration is

required.

4th OPEN: defines the end of the opening movement and starts

the pause time count** (3 minutes max.).

5th OPEN: interrupts the pause time count and starts the closing

movement.

6th OPEN: defines the point at which start of deceleration is

required.

Allow the operator to reach the stop.

If the SETUP procedure was successful, the courtesy lamp stays

lighted for 5 seconds. During this time, in order to reduce the load

on the release system, open pulses can be sent within 2 seconds

of each other to reverse the release carriage. A pulse equals travel

of 5 millimetres.

N.B.: the carriage can be seen to reverse only when the automated system is operating normally.

* Otherwise, an OPEN pulse may replace the stop.

** Otherwise, the stop can be used during opening.

IMPORTANT: At set-up, if the operator does not effect any movement when the OPEN push-button (see fig.34 ref. A) is pressed,

check that the housing is in correct position.

FUNCTION LOGICS

Table 1 AUTOMATIC Logic

OVERHEAD

DOOR

CLOSED

OPEN FOR

PAUSE

CLOSING

OPENING

LOCKED

Opens and

closes after the

pause time

Restarts pause

time count*

Reverses motion

No effect

Closes

STOPOPEN SAFETY DEVICES

No effect**

Locks *

Locks **

Locks **

No effect**

No effect

Restarts pause

time count*

Reverses motion

No effect *

No effect *

Table 2 SEMI-AUTOMATIC Logic

OVERHEAD

DOOR

CLOSED

OPEN

CLOSING

OPENING

LOCKED

Open

Closes

Reverses motion

Locks

Closes

STOPOPEN SAFETY DEVICES

No effect**

No effect**

Locks **

Locks **

No effect**

No effect

No effect *

Reverses motion

No effect *

No effect *

* Prevents closing if pulse is maintained

* Prevents closing and/or opening if pulse is maintained

23

Page 5

ENGLISH ENGLISH

When installation has been completed, check the efficiency

of the automated system and safety devices, and then

apply the “danger” warning sticker (fig.35) on the panel of

the up-and-over door to make it easy to see.

Apply the sticker, which indicates the release device of the

automated system (fig.35).

11. OPTIONAL ACCESSORIES

• If you are using the card for the CN60-E Sensitive Edge, a

compartment is provided for it inside the operator housing in the

position shown in figure 36.

• Floating batteries installation procedure: fit them on the operator with the appropriate bracket, and secure them with screw

and nut in the position shown in figure 37.

ATTENTION! If replacing batteries, cut out electrical power

before attempting any operation.

WARNING

Fig.35

RELEASE

DEBLOQUER

ENTRIEGELN

DESBLOQUEAR

SBLOCCARE

RE-LOCK

BLOQUER A NOUVEAU

WIEDER BLOKIEREN

BLOQUEAR DE NUEVO

RIBLOCCARE

LOCK

• Two external release systems can be fitted:

- with handle (fig.38 ref.A)

- with wrench (fig.38 ref.B)

• Counterbalanced doors can be automated by using the accessory shown in fig. 39 (GDA 3000).

Fig.37Fig.36

B

A

Fig.39Fig.38

24

Loading...

Loading...