Page 1

voor de natuur

100% kringlooppapier

para la naturaleza

100% papel reciclado

455D

455D

ist umweltfreundlich

100% Altpapier

pour la nature

papier recyclé 100%

for nature

recycled paper 100%

per la natura

carta riciclata 100%

Page 2

CE DECLARATION OF CONFORMITY

Manufacturer: FAAC S.p.A.

Address: Via Benini, 1 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: 455 D control board,

• conforms to the essential safety requirements of the following directives:

73/23/CEE and subsequent amendment 93/68/CEE.

89/336/CEE and subsequent amendment 92/31/CEE and 93/68/CEE

Additional note:

This product underwent tests in a typical uniform configuration

(all products manufactured by FAAC S.p.A.).

Bologna, 01 May 2005

The Managing Director

A. Bassi

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of

the product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach

of children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be a

source of danger.

6) FAAC declines all liability caused by improper use or use other than that

for which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence

of inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN

12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal

regulations.

9) FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any

deformation that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the Standards

mentioned above must be observed, in addition to national legal

regulations.

11) Before attempting any job on the system, cut out electrical power .

12) The mains power supply of the automated system must be fitted with an

all-pole switch with contact opening distance of 3mm or greater. Use of

a 6A thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted

upstream of the system.

14) Make sure that the earthing system is perfectly constructed, and

connect metal parts of the means of the closure to it.

15) The safety devices (EN 12978 standard) protect any danger areas

against mechanical movement Risks, such as crushing, dragging,

and shearing.

16) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended

for every system, as well as a warning sign adequately secured to the

frame structure, in addition to the devices mentioned at point “15”.

17) FAAC declines all liability as concerns safety and efficient operation

of the automated system, if system components not produced by

FAAC are used.

18) For maintenance, strictly use original parts by FAAC.

19) Do not in any way modify the components of the automated system.

20) The installer shall supply all information concerning manual operation

of the system in case of an emergency, and shall hand over to the user

the warnings handbook supplied with the product.

21) Do not allow children or adults to stay near the product while it is

operating.

22) Keep remote controls or other pulse generators away from children,

to prevent the automated system from being activated involuntarily.

23) Transit is permitted only when the automated system is idle.

24) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

25)

Maintenance: check at least every 6 months the efficiency of the system,

particularly the efficiency of the safety devices (including, where foreseen,

the operator thrust force) and of the release devices.

26) Anything not expressly specified in these instructions is not permitted.

12

Page 3

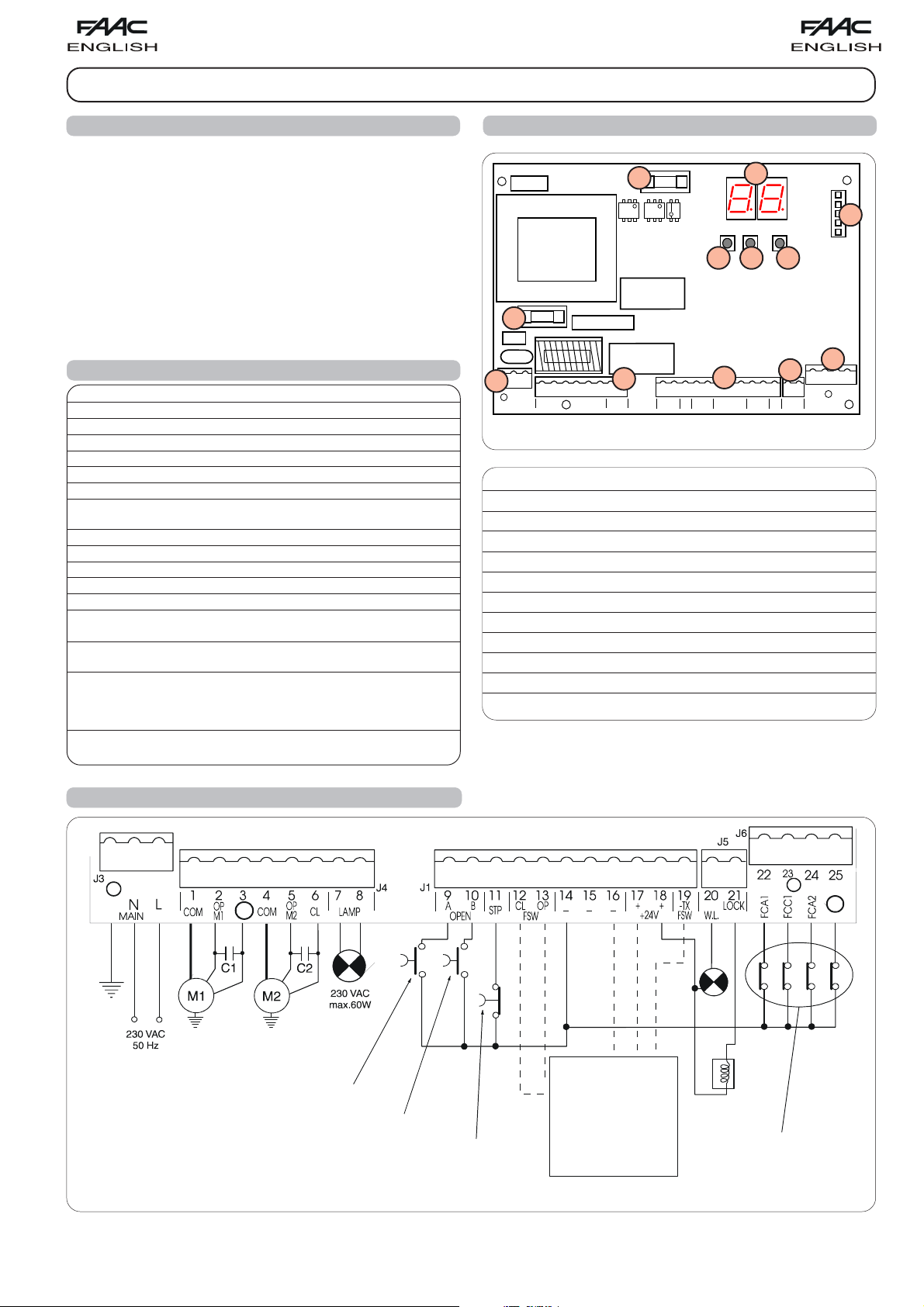

CONTROL BOARD 455 D

1. WARNINGS

3. LAYOUT AND COMPONENTS OF 455 D

Important: Before attempting any work on the control board

(connections, maintenance), always turn off power.

- Install, upstream of the system, a differential thermal breaker

with adequate tripping threshold.

- Connect the earth cable to the appropriate terminal on the J3

connector of the equipment (see fig.2).

- Always separate power cables from control and safety cables

(push-button, receiver, photocells, etc.). To avoid any electric

noise, use separate sheaths or a shielded cable (with earthed

shield).

F1

2. TECHNICAL SPECIFICATIONS

Power supply 230 V~ ( +6% -10%) - 50 Hz

Absorbed power 10 W

J3

J3

PE N

MAIN

Motor max. load 800 W

Accessories max. load 0,5 A

Electric lock max. load 15 VA

Operating ambient temperature -20 °C +55 °C

Protection fuses 2 (see fig. 1)

Function logics Semi-automatic / Automatic / Safety devices / "Stepped" semi-automatic

/ "Stepped" automatic / "Stepped" Safety devices / Semi-automatic B / Dead-man C

Opening/closing time Programmable (from 0 to 120 s)

Pause time Programmable (from 0 to 4 min.)

Closing leaf delay Programmable (from 0 to 4 min.)

Opening leaf delay 2 s (can be excluded)

Thrust force Adjustable on 50 levels for each motor

Terminal board inputs Open / Open free leaf / Stop / Limit-switch

Opening safety devices / Closing safety devices / Power supply + Earth

Terminal board outputs Flashing lamp - Motors - 24 Vdc accessories power

supply- 24 Vdc indicator-light - Fail safe - 12 Vac electric lock power supply

Programmable functions Logic - Pause time - Thrust Force - Torque at initial thrust

Opening and closing leaf delay - Reversing stroke - Over-pushing stroke - indicatorlight - Pre-flashing - Electric lock - Fail safe - Safety devices logic - Assistance request

DL SIGNALLING AND PROGRAMMING DISPLAY

J1 LOW VOLTAGE TERMINAL BOARD

J2 CONNECTOR FOR DECODER/MINIDEC/RP RECEIVER

J3 230 VAC POWER SUPPLY TERMINAL BOARD

J4 MOTORS AND FLASHING LAMP CONNECTION TERMINAL BOARD

J5 INDICATOR-LIGHT AND ELECTRIC LOCK TERMINAL BOARD

J6 LIMIT-SWITCH AND GATECODER TERMINAL BOARD

F1 MOTORS AND TRANSFORMER PRIMARY WINDING FUSE (F 5A)

F2 LOW VOLTAGE AND ACCESSORIES FUSE (T 800mA)

F "F" PROGRAMMING PUSH-BUTTON

– "–" PROGRAMMING PUSH-BUTTON

+ "+" PROGRAMMING PUSH-BUTTON

- Detection time of obstacle or contact point

Learning function

Simple

or

complete

work time learning, with or without

Limit-switch and/or Gatecoder.

F1

12 45678

L

COM

OP

OP

COM

M2

M1

F2

F2

J4

J1

J4

9 10111213141516171819

AB

CL

CL

LAMP

OPEN

STP

FSW

OP

OP_A

STOP

OP_B

J1

---

FSWCL

+

DL

FCA2

–

–+

++

+24V

FCC1

FCC2

F

J2

J2

F

J6

J6

J5

J5

222324 25

20 21

-TX

LOCK

FCA1

FCC2

FCC1

FSW

W.L.

FCA2

FCA1

FSWOP

Fig. 1

4. ELECTRIC CONNECTIONS

PE

BLUE

NB.: Capacitors are supplied with the operators.

BLUE

TOTALLY OPEN

OPEN LEAF 1

STOP

For connection of

the photocells

and safety

devices, see

paragraph 4.1

(page 14).

24 Vdc

3 W

12 V ac

FCC2

LIMIT-SWITCH

Fig. 2

13

Page 4

1

2

5

4

3

1

2

RX CL TX CL

1

2

5

4

3

1

2

RX OP/CL

TX OP/CL

9 10111213141516171819

OPEN

A

B

STP

CL

OP

FSW

--+24V

++

-TX

FSW

20 21

W.L.

LOCK

-

+

-

+

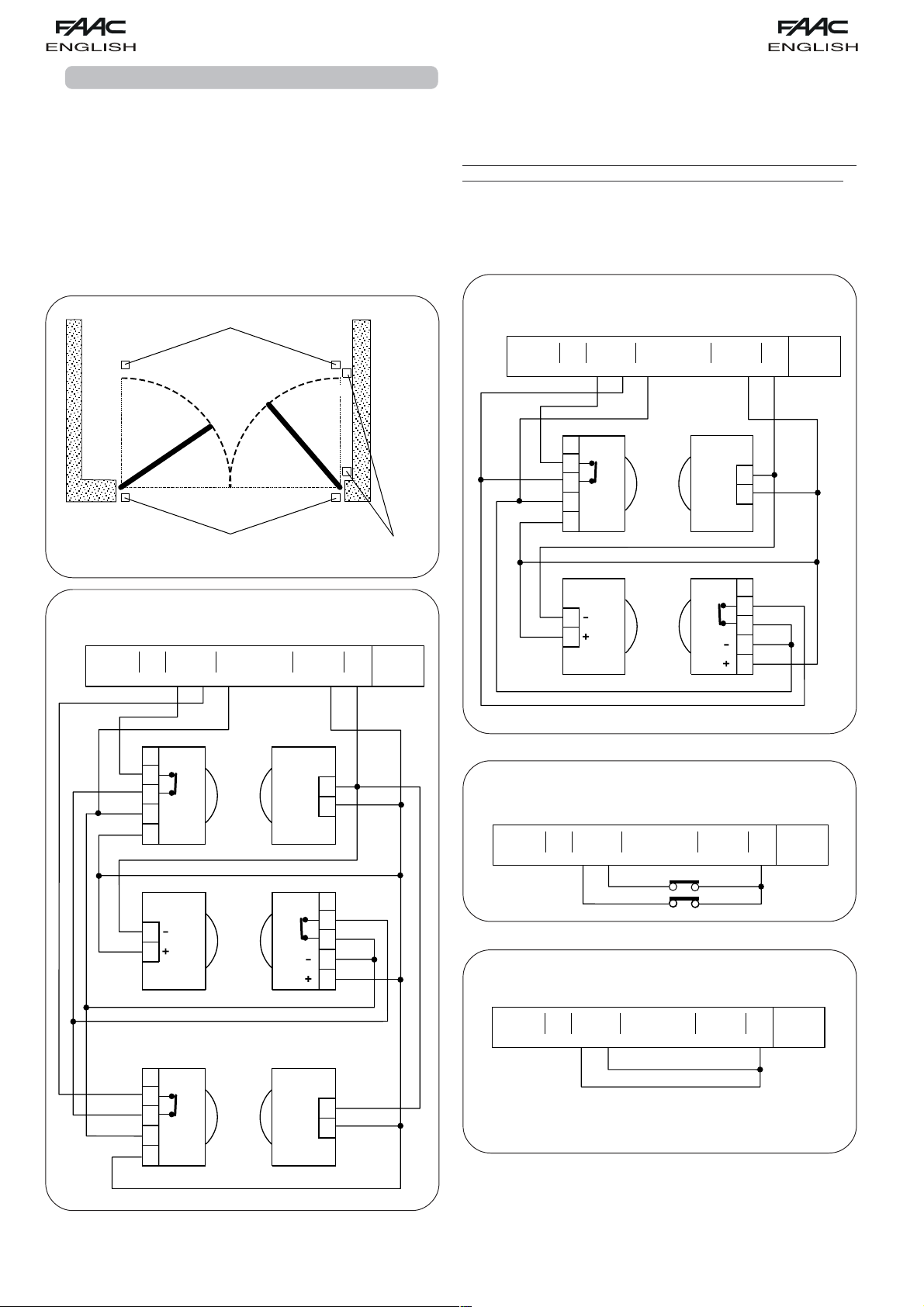

4.1. CONNECTION OF PHOTOCELLS AND SAFETY DEVICES

Before connecting the photocells (or other devices) we advise

you to select the type of operation according to the movement

area they have to protect (see fig.3):

Opening safety devices:

they operate only during the gate

opening movement and, therefore, they are suitable

for protecting the area between the opening leaves

and fixed obstacles (walls, etc) against the risk of

impact and crushing.

Closing safety devices:

they operate only during the gate

closing movement and, therefore, they are suitable

for protecting the closing area against the risk of

impact.

Opening/closing safety devices

Opening/closing safety devices:

they operate during the gate

opening and closing movements and, therefore, they

are suitable for the opening and closing areas against

the risk of impact.

FAAC recommends use of the lay-out in fig. 4 (in the event of

fixed obstacles at opening) or in fig. 5 (no fixed obstacles).

N.B. If two or more devices have the same function (opening

or closing), they should be connected to each other in series

(see fig. 12). N.C. contacts must be used.

Connection of a pair of closing photocells and a pair of

opening/closing photocells (recommended lay-out)

Closing safety devices

Fig. 3

Connection of a pair of closing photocells, a pair of

opening photocells and a pair of opening/closing

photocells (recommended lay-out)

9 10111213141516171819

A

OPEN

B

STP

CL

FSW

OP

---

RX CL TX CL

1

2

3

4

-

+

5

1

2

TX OP/CL

Fig. 4

RX OP TX OP

1

2

3

4

-

+

5

++

+24V

-

+

RX OP/CL

-

+

Opening

safety devices

20 21

-TX

FSW

W.L.

1

2

1

2

3

4

5

1

2

LOCK

14

Fig. 5

Connection of a closing safety device and an opening

9 10111213141516171819

B

A

OPEN

STP

CL

FSW

OP

safety device

---

++

+24V

-TX

FSW

20 21

LOCK

W.L.

Fig. 6

Connection of no safety device

9 10111213141516171819

B

A

OPEN

STP

CL

FSW

OP

---

++

+24V

-TX

FSW

20 21

LOCK

W.L.

Fig. 7

Page 5

1

2

5

4

3

1

2

RX CL1

TX CL1

1

2

5

4

3

1

2

RX CL2

TX CL2

9 10111213141516171819

OPEN

A

B

STP

CL

OP

FSW

--+24V

++

-TX

FSW

20 21

W.L.

LOCK

-

+

-

+

Connection of 1 pair of opening photocells

9 10111213141516171819

B

A

OPEN

STP

CL

FSW

OP

---

++

+24V

-TX

FSW

20 21

LOCK

W.L.

Connection of two pairs of closing photocells

RX

1

2

3

4

-

+

5

TX

Fig. 8

Connection of 1 pair of closing photocells

9 10111213141516171819

B

A

OPEN

STP

CL

FSW

OP

---

RX

1

2

3

4

-

+

5

++

+24V

TX

Fig. 9

1

-

2

+

20 21

LOCK

-TX

FSW

W.L.

Fig. 11

1

-

+

2

Connection of 2 N.C. contacts in series

(e.g. Photocells, Stop)

Connection of a pair of opening photocells and a pair of

closing photocells

9 10111213141516 171819

B

A

OPEN

STP

CL

FSW

OP

---

RX OP

1

2

3

4

-

+

5

TX CL

Fig. 10

1

-

+

2

++

+24V

TX OP

-

+

RX CL

-

+

1

2

4

1

2

3

5

-TX

FSW

20 21

LOCK

W.L.

Fig. 12

Connection of 2 N.O. contacts in parallel

(e.g. Open A, Open B)

Fig. 13

4.2. TERMINAL BOARD J3 - POWER SUPPLY (FIG. 2)

PE: Earth connection

N:230 V~ power supply ( Neutral )

L:230 V~ power supply ( Line )

NB.: For correct operation, the board must be connected to

the earth conductor in the system. Install an adequate

differential thermal breaker upstream of the system.

4.3. TERMINAL BOARD J4 - MOTORS AND FLASHING LAMP

(FIG. 2)

M1 : COM / OP / CL: Connection to Motor 1

Can be used in the single-leaf application

M2 : COM / OP / CL: Connection to Motor 2

Cannot be used in the single-leaf application

LAMP : Flashing lamp output ( 230 V ~)

15

Page 6

MINIDEC

SL / DS / SLH

PLUS

433 / 868

455 D

4.4. TERMINAL BOARD J1 - ACCESSORIES (FIG. 2)

OPEN A - "Total Opening" command (N.O.): any pulse

generator (push-button, detector, etc.) which, by closing

a contact, commands opening and/or closing of both

gate leaves.

To install several full opening pulse generators, connect

the N.O. contacts in parallel.

OPEN B - "Partial Opening" command (N.O.) / Closing: any

pulse generator (push-button, detector, etc.) which,

by closing a contact, commands opening and/or

closing of the leaf driven by motor M1.

In the B and C

logics, it always commands closing of both leaves.

To install several partial opening pulse generators,

connect the N.O. contacts in parallel.

STP - STOP contact (N.C.): any device (e.g. a push-button)

which, by opening a contact, is able to stop gate

movement.

To install several STOP devices, connect the N.C.

contacts in series.

NB.: If STOP devices are not connected, jumper connect

the STP terminals and -.

CL FSW - Closing safety devices contact (N.C.): The purpose

of the closing safety devices is to protect the leaf

movement area during closing. During closing, in the E-

A-S-EP-AP-SP logics, the safety devices reverse the

movement of the gate leaves, or stop and reverse the

movement when they are released (see advanced

programming in Chapter 5.2.). During the closing cycle

in logics B and C, they interrupt movement.

They never

operate during the opening cycle. If the closing safety

devices operate when the gate is open, they prevent

the leaf closing movement.

NB.: If no closing safety devices are connected, jumper

connect terminals CL and -TX FSW (fig. 7).

OP FSW - Opening safety devices contact (N.C.): The purpose

of the opening safety devices is to protect the leaf

movement area during opening. During opening,in the

E-A-S-EP-AP-SP

movement of the gate leaves

in logics B and C, they interrupt movement.

logics,

the safety devices reverse the

. During the opening cycle

They never

operate during the closing cycle.

If the opening safety devices operate when the gate is

closed, they prevent the leaf opening movement.

NB.: If no opening safety devices are connected, jumper

connect inputs OP and -TX FSW (fig. 7).

– - Negative for power supply to accessories

4.6. CONNECTOR J2 - RAPID CONNECTION TO MINIDEC,

DECODER AND RP

This is used for rapid connection of Minidec, Decoder and RP

receivers (see fig. 14, 15, 16 and 17). Connect the accessory,

with the components side facing the inside of the card. Insert

and remove after cutting power.

Fig. 14

PLUS

433 / 868

455 D

DECODER

SL / SLH

Fig. 15

PLUS

DIGIKEY

DIGICARD

433 / 868

N.B.:

accessories (Plus 433 or 868,

Digicard, Digikey) in parallel

Never put two

on the same decoder, but

use a decoder for every

accessory.

+ - 24 Vdc - Positive for power supply to accessories

Important: Accessories max. load is 500 mA. To

calculate absorption values, refer to the instructions

for individual accessories.

-TX FSW - Negative for power supply to photocell

transmitters.

If you use this terminal for connecting the negative for

supplying power to the photocell transmitters, you

may, if necessary, also use the FAIL SAFE function (see

advanced programming in Chapter 5.2.).

If this function is enabled, the equipment checks

operation of the photocells before every opening or

closing cycle.

4.5. TERMINAL BOARD J5 - INDICATOR-LIGHT AND ELECTRIC

LOCK (FIG.2)

W.L. - Power supply to indicator-light

Connect a 24 Vdc - 3 W max. indicator-light, if

necessary, between this terminal and the +24V supply.

To avoid compromising correct operation of the system,

do not exceed the indicated power.

LOCK - Power supply to electric lock

If necessary, connect a 12 V ac electric lock between

this terminal and the +24V supply.

455 D

Fig. 16

RP 433 DS / SL

RP 868 DS / SLH

455 D

Fig. 17

16

Page 7

4.7. TERMINAL BOARD J6 - LIMIT-SWITCHES AND/OR

GATECODER (FIG.2)

These inputs are designed for connection of opening and

closing limit-switches which, according to type of programming

- can command either leaf stop or start of deceleration.

Unconnected limit-switches must be jumper connected (if no

limit-switch is connected, there is no need to make jumpers).

Gatecoders can also be used to detect the leaf's angular

position and to thus obtain deceleration and stop positions

independent of work time.

Limit-switches and Gatecoders can also be used in combination

to stop movement before the mechanical stop limit is reached.

To wire, see fig. 18, 19 and 20.

FCA1 - Leaf 1 opening limit-switch

FCC1 - Leaf 1 closing limit-switch

FCA2 - Leaf 2 opening limit-switch

FCC2 - Leaf 2 closing limit-switch

Fig. 18

14 15 16 17 18 19

---

++

+24V

-TX

FSW

J5

20 21

LOCK

W.L.

J6

23

22

FCA1

24 25

FCC1

FCA2

FCC2

Fig. 19

FCC2

RED

BLACK

RED

BLACK

WHITE

WHITE

Fig. 20

5. PROGRAMMING

To program operation of the automated system, you have to

access the "

Programming is split into two parts:

5.1. BASIC PROGRAMMING

To access BASIC PROGRAMMING, press key F:

•if you press it (and hold it down), the display shows the name

of the first function.

•if you release the key, the display shows the value of the

function that can be modified with keys + and -.

•if you press F again (and hold it down), the display shows the

name of the next function, etc.

•when you reach the last function, press F to exit the program,

and the display resumes showing the status of the inputs.

The following table shows the sequence of functions accessible

in BASIC PROGRAMMING:

BASIC PROGRAMMING

PROGRAMMING

" mode.

BASIC

and

ADVANCED

F

.

!

Display Function Default

FUNCTION LOGICS (see tab. 3/a - h):

= Semi-automatic

= Automatic

= "Safety" Automatic

= "Stepped" Semi-automatic

= "Stepped" Automatic

= "Safety Stepped" Automatic

= "B" Semi-automatic

= Dead-man

PAUSE TIME:

This has effect only if the automatic logic

was selected. Adjustable from

sec. in one-second steps.

Subsequently, display changes to

minutes and tens of seconds (separated

by a point) and time is adjusted in 10second steps, up to the maximum value

of

minutes.

E.g. if the display shows

is 2 min. and 50 sec.

LEAF 1 FORCE :

Adjusts thrust of Motor 1.

= maximum force (hydraulic)

LEAF 2 FORCE :

Adjusts thrust of Motor 2.

= minimum force

= maximum force (hydraulic)

= minimum force

*

*

to

, pause time

FCC2

RED

BLACK

RED

BLACK

N.B.:Maximum configurations are shown on the drawings.

All intermediate configurations are allowed, using only

some elements (only 1 Gatecoder, only 1 limit-switch, 2

Gatecoders and 2 limit-switches etc.).In this case, the

unused inputs must be jumpered to earth

WHITE

WHITE

LEAF 1 CLOSING DELAY:

Delays closing start of leaf 1 with respect to

leaf 2. Adjustable from

(see Pause Time).

TIME LEARNING (see Chapter 6.3.):

Enables the selection between "simple"

(automatic) learning and "complete"

(manual choice of deceleration and stop

points) learning.

Simple learning:

to minutes

+

앓앓

앓

1 s.

앓앓

!

+

>

Complete learning:

3 s.

!

Exit from programming and return to

display of inputs status.

NB.:

*

if you are using hydraulic operators, set force to maximum

level.

17

Page 8

5.2. ADVANCED PROGRAMMING

To access ADVANCED PROGRAMMING, press key F and, as

you hold it down, press key

•if you release key + , the display indicates the name of the first

function.

•if you release key F too, the display shows the value of the

function that can be modified with keys + and -.

•if you press key F (and hold it down), the display shows the

name of the next function, and if you release it, the value

that can be modified with keys + and - is shown.

•when you reach the last function, press F to exit the program,

and the display resumes showing the status of the inputs.

The following table shows the sequence of functions accessible

in ADVANCED PROGRAMMING:

ADVANCED PROGRAMMING

Display Function Default

MAXIMUM TORQUE AT INITIAL THRUST :

The motors operate at maximum torque

(ignoring the torque setting) at start of

movement. Useful for heavy leaves.

= Active = Disabled

LAST STROKE AT CLOSING:

The motors are activated at full speed

for 1 s to facilitate locking of the electric

lock.

= Active = Disabled

REVERSING STROKE:

Before opening, while the gate is closed,

the motors thrust to close for 2 s thus

facilitating release of the electric lock.

= Active = Disabled

+:

F

!

+

+

!

Display Function Default

INDICATOR-LIGHT:

If

is selected, the output functions as a

standard indicator-light (lighted at

opening and pause, flashing at closing,

and off when gate closed). Different

figures correspond to the extra time

compared to normal work time (opening

or closing) when the output can be used

- via a relay - to power a courtesy light.

Time can be adjusted from to s in

1 s steps, and from

10 s steps.

= Standard indicator-light

to = Timed output

from

CLOSING PHOTOCELLS REVERSE AT

RELEASE:

Enable this function if you want the

closing photocells to stop movement

and reverse it at release. Default setting

is immediate reverse.

= Active = Disabled

A.D.M.A.P. function:

If this function is enabled, the safety

devices operate in compliance with

French standard NFP 25/362.

= Active = Disabled

ASSISTANCE REQUEST (combined with

next function):

If activated, at the end of countdown

(settable with the next function i.e. "Cycle

programming") it effects 8 s of preflashing at every Open pulse (job

request). Can be useful for setting

scheduled maintenance jobs.

= Active = Disabled

to min. in

LEAF 2 OPENING DELAY (2 s):

Enables delayed start (at opening) of leaf 2,

avoiding interference between leaves.

= Active = Disabled

FAIL SAFE:

If this function is activated, it enables a

function test of the photocells before

any gate movement. If the test fails

(photocells not serviceable), the gate

does not start the movement.

= Active = Disabled

PRE-FLASHING (5 s):

Activates the flashing lamp for 5 s before

start of movement.

= Active = Disabled

ELECTRIC LOCK ON LEAF 2:

For using the electric lock on leaf 2 instead

of on leaf 1.

= Active = Disabled

NB.:

modification of programming parameters comes into effect immediately, whereas definitive memory storage occurs only when

you exit programming and return to gate status viewing. If the equipment is powered down before return to status viewing, all

modifications will be lost.

To restore the default settings of the programming press the three buttons +, -, F simultaneously and keep them pressed for 5

seconds.

18

CYCLE PROGRAMMING:

For setting countdown of system

operation cycles. Settable (in thousands)

from

displayed value is updated as cycles

proceed.

This function can be used to check use

of the board or to exploit the "Assistance

request".

ANTI-CRUSHING SENSITIVITY:

When operating with the gatecoder, it

controls anti-crushing sensitivity.

EXTRA WORK TIME:

When operating without a gatecoder

and limit-switch, if reversing occurs, and

if the leaf does not reach its end contact

point, you can activate this function to

increase work time.

Exit from programming and return to

display of inputs status.

to thousand cycles.The

= Low = High.

= Active = Disabled

Page 9

6. START-UP

6.1. LED CHECK

The board has a two-digit display. If out of the

"PROGRAMMING" mode, this display is used to indicate status

of inputs. Fig. 16 shows how the segments (we'll call these

LEDs from now on) of the display exactly correspond to the

inputs.

Fig. 21

The table below shows the status of the LEDs in relation to to

the status of the inputs.

Note the following:

LED

LIGHTED

= closed contact

LED

OFF

= open contact

Check the state of the LEDs as per Table.

Operation of the status signalling LEDs

LEDs LIGHTED OFF

OP_A Command activated Comando inattivo

OP_B Command activated Comando inattivo

STOP Command inactive Command activated

FSWCL Safety devices disengaged Safety devices engaged

FSWOP Safety devices disengaged Safety devices engaged

FCA1 (if used) Limit-switch free Limit-switch engaged

FCC1 (if used) Limit-switch free Limit-switch engaged

FCC2 (if used) Limit-switch free Limit-switch engaged

FCA2 (if used) Limit-switch free Limit-switch engaged

NB.:

The status of the LEDs while the gate is closed at rest are shown in bold.

6.2. ROTATION DIRECTION AND FORCE CHECK

1) Program the functions of the 455 D control board according

to need, as shown in Chapter 5.

2) Cut power to the electronic control equipment.

3) Release the operators and manually move the gate to the

mid-point of the opening angle.

4) Re-lock the operators.

5) Restore power.

6) Send and opening command on the OPEN A input (fig.2)

and check if the gate leaves are being commanded to

open.

N.B.: If the first OPEN A pulse commands a closing, cut power

and change over the phases of the electric motor (brown

and black wires) on the 455 D terminal board.

7) Check power setting of the motors and, if necessary,

modify it (see Chapter 5.1).

N.B.:If using hydraulic operators, force should be programmed to

maximum level (50)

8) Stop leaf movement with a STOP command.

9) Release the operators, close the leaves and re-lock the

operators.

6.3. LEARNING OF OPERATING TIMES

WARNING:

during the learning procedure, the safety devices are disabled!

Therefore any transit must be avoided in the leaf movement

area when this operation is carried out.

Make sure the travel limit mechanical stops are present.

Opening/closing time is established by a learning procedure

which varies slightly according to whether you are using limitswitches and/or Gatecoders.

6.3.1. LEARNING OF NORMAL TIMES

Normal learning (i.e. without limit-switches and Gatecoders)

can be done in two different ways:

- SIMPLE LEARNING (without deceleration):

Check if the leaves are closed, enter "

BASIC PROGRAMMING

",

select the TIME LEARNING function and press the + push-button

for 1 second: the display begins flashing and the leaves begin

the opening movement.

As soon as the leaves reach the opening contact point, give

an OPEN A pulse (with the key operated push-button or with

the radio control) to stop the movement: the leaves stop and

the display stops flashing.

Press push-button F to exit and save the programming.

The procedure has ended and the gate is ready to operate.

- COMPLETE LEARNING (with deceleration):

Check if the leaves are closed, enter "

BASIC PROGRAMMING

",

select the TIME LEARNING function and press the + push-button

for more than 3 seconds: the display begins flashing and leaf

1 begins the opening movement. The following functions can

be commanded by the OPEN A pulses (by key push-button or

radio control):

1° OPEN - Deceleration at opening of leaf 1

2° OPEN - Leaf 1 stops at opening and leaf 2 begins its

opening movement

3° OPEN - Deceleration at opening of leaf 2

4° OPEN - Leaf 2 stops at opening and immediately begins

its closing movement

5° OPEN - Deceleration at closing of leaf 2

6° OPEN - Leaf 2 stops at closing and leaf 1 begins its

closing movement

7° OPEN - Deceleration at closing of leaf 1

8° OPEN - Leaf 1 stops at closing

The display stops flashing: press push-button F to exit and save

the programming.

The procedure has finished and the gate is ready to operate.

Notes: •If you wish to eliminate deceleration in certain

stages, wait for the leaf to reach its stop-limit and

supply 2 consecutive Open pulses (by 1 second).

•If only one leaf is present, the entire sequence must

nevertheless be effected. When the leaf has finished

opening, supply 5 Open pulses until the leaf begins

to close, and then resume normal operation.

6.3.2. LEARNING WITH LIMIT-SWITCHES

Learning with limit-switches can be done in two different ways:

- SIMPLE LEARNING (without deceleration):

Check if the leaves are closed, enter "

BASIC PROGRAMMING

",

select the TIME LEARNING function and press the + push-button

for 1 second: the display begins flashing and the leaves begin

the opening movement.

The motors stop automatically when the opening limit-switches

are reached, but an OPEN A pulse must be given (by radio

control or key push-button) to end the cycle.

The display stops flashing: press push-button F to exit and save

the programming.

The procedure has finished and the gate is ready to operate.

- COMPLETE LEARNING (with deceleration):

Check if the leaves are closed, enter "BASIC PROGRAMMING",

select the TIME LEARNING function and press the + push-button

for more than 3 seconds: the display begins flashing and leaf

1 begins the opening movement.

19

Page 10

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto, lasciando

inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza

impegnarsi ad aggiornare la presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti

tecnici o per qualsiasi altra esigenza di carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the right, whilst

leaving the main features of the equipments unaltered, to undertake any modifications it holds necessary for either

technical or commercial reasons, at any time and without revising the present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le droit

d’apporter à tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant les caractéristiques

essentielles, sans devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält sich das Recht

vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne Verbindlichkeiten in Bezug auf

die Neufassung der vorliegenden Anleitungen, technisch bzw. konstruktiv/kommerziell bedingte Verbesserungen

vorzunehmen.

voor de natuur

100% kringlooppapier

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se reserva el

derecho, dejando inmutadas las características esenciales de los aparatos, de aportar, en cualquier momento

y sin comprometerse a poner al día la presente publicación, todas las modificaciones que considere oportunas

para el perfeccionamiento técnico o para cualquier otro tipo de exigencia de carácter constructivo o comercial.

De beschrijvingen in deze handleiding zijn niet bindend. FAAC behoudt zich het recht voor op elk willekeurig

moment de veranderingen aan te brengen die het bedrijf nuttig acht met het oog op technische verbeteringen

of alle mogelijke andere productie- of commerciële eisen, waarbij de fundamentele eigenschappen van de

apparaat gehandhaafd blijven, zonder zich daardoor te verplichten deze publicatie bij te werken.

FAAC per la natura

• La presente istruzione è realizzata al 100% in carta riciclata.

• Non disperdete nell'ambiente gli imballaggi dei componenti dell'automazione bensì selezionate

i vari materiali (es. cartone, polistirolo) secondo prescrizioni locali per lo smaltimento rifiuti e le

norme vigenti.

FAAC for the environment

• The present manual is produced in 100% recycled paper

• Respect the environment. Dispose of each type of product packaging material (card, polystyrene)

in accordance with the provisions for waste disposal as specified in the country of installation.

FAAC écologique

• La présente notice a été réalisée 100% avec du papier recyclé.

• Ne pas jeter dans la nature les emballages des composants de l’automatisme, mais sélectionner

les différents matériaux (ex.: carton, polystyrène) selon la législation locale pour l’élimination des

déchets et les normes en vigueur.

FAAC der Umwelt zuliebe

• Vorliegende Anleitungen sind auf 100% Altpapier gedruckt.

• Verpackungsstoffe der Antriebskomponenten (z.B. Pappe, Styropor) nach den einschlägigen

Normen der Abfallwirtschaft sortenrein sammeln.

FAAC por la naturaleza.

• El presente manual de instrucciones se ha realizado, al 100%, en papel reciclado.

• Los materiales utilizados para el embalaje de las distintas partes del sistema automático (cartón,

poliestireno) no deben tirarse al medio ambiente, sino seleccionarse conforme a las prescripciones

locales y las normas vigentes para el desecho de residuos sólidos.

FAAC voor de natuur

• Deze gebruiksaanwijzing is gedrukt op 100% kringlooppapier.

• Laat de verpakkingen van de componenten van het automatische systeem niet in het milieu

achter, maar scheidt de verschillende materialen (b.v. karton, polystyreen) volgens de plaatselijke

voorschriften op de afvalverwerkingen en de geldende normen.

para la naturaleza

100% papel reciclado

ist umweltfreundlich

100% Altpapier

pour la nature

papier recyclé 100%

FAAC S.p.A.

Via Benini, 1

40069 Zola Predosa (BO) - ITALIA

Tel.: 051/61724 - Fax: 051/758518

www.faacgroup.com

Timbro del Rivenditore:/Distributor’s Stamp:/Timbre de l’Agent:/ Fachhändlerstempel:/Sello del Revendedor:/Stempel van de dealer:

for nature

recycled paper 100%

per la natura

carta riciclata 100%

732452 - Rev. B

Page 11

The leaves automatically decelerate when they reach the limitswitches, and therefore, it is sufficient to inform the equipment

that the stop limits have been reached by means of OPEN A

pulses (by radio control or key push-button):

FCA1 - Deceleration at opening of leaf 1

1° OPEN - Leaf 1 stops at opening and leaf 2 begins its

opening movement

FCA2 - Deceleration at opening of leaf 2

2° OPEN - Leaf 2 stops at opening and immediately begins

its closing movement

FCC2 - Deceleration at closing of leaf 2

3° OPEN - Leaf 2 stops at closing and leaf 1 begins its

closing movement

FCC1 - Deceleration at closing of leaf 1

4° OPEN - Leaf 1 stops at closing

The display stops flashing: press push-button F to exit and save

the programming.

The procedure has finished and the gate is ready to operate

Notes: •If you wish to eliminate deceleration in some stages,

you must supply an Open pulse within 1 second of

reaching the limit-switch.

•If some limit-switches are not installed, start the

corresponding deceleration by supplying an Open

pulse (which replaces the limit-switch).

•If only one leaf is present, the entire sequence must

nevertheless be effected. When the leaf has finished

opening, supply 5 Open pulses until the leaf begins

to close, and then resume normal operation.

6.3.3. LEARNING TIMES WITH GATECODER

Learning with the Gatecoder can be done in two different

ways:

- SIMPLE LEARNING (with deceleration):

Check if the leaves are closed, enter "

select the TIME LEARNING function and press the + push-button

for 1 second: the display begins flashing and the leaves begin

the opening movement.

The movement stops automatically when the opening stop

limit is reached and the display stops flashing.

Press push-button F to exit and save the programming.

The procedure has ended and the gate is ready to operate,

using fixed deceleration.

BASIC PROGRAMMING

",

- COMPLETE LEARNING (with deceleration):

Check if the leaves are closed, enter "

select the TIME LEARNING function and press the + push-button

for more than 3 seconds: the display begins flashing and leaf

1 begins the opening movement. The following functions can

be commanded by the OPEN A pulses (by radio control or

key push-button):

1° OPEN - Leaf 1 Decelerates at opening (it stops

automatically on reaching the stop limit)

2° OPEN - Leaf 2 opening movement begins

3° OPEN - Leaf 2 Decelerates at opening (it stops

automatically on reaching the stop limit)

4° OPEN - Leaf 2 closing movement begins

5° OPEN - Leaf 2 decelerates at closing (it stops

automatically on reaching the stop limit)

6° OPEN - Leaf 1 closing movement begins

7° OPEN - Leaf 1 Decelerates at closing (it stops

automatically on reaching the stop limit)

8° OPEN- End of learning

The display stops flashing: press push-button F to exit and save

the programming.

The procedure has finished and the gate is ready to operate.

BASIC PROGRAMMING

",

Notes: •The deceleration pulse should be supplied a little

earlier with respect to the stop limit to prevent the

leaf reaching it at full speed (it would be taken for

an obstacle).

•If only one leaf is present, the entire sequence must

nevertheless be effected. When the leaf has finished

opening, supply 5 Open pulses until the leaf begins

to close, and then resume normal operation.

6.3.4. LEARNING TIMES WITH GATECODER + LIMIT-SWITCH

Learning with Gatecoder + Limit-switch can be done in two

different ways:

- SIMPLE LEARNING (without deceleration):

Check if the leaves are closed, and then access

PROGRAMMING”

push-button + for 1 second: the display starts to flash and the

leaves begin the opening movement.

The motors stop automatically when the opening limit-switches

are reached, and the display stops flashing. Press push-button

F to exit and save the programming.

The procedure has finished and the gate is ready to operate.

The Gatecoder is used solely as an obstacle sensor.

, select the TIME LEARNING function and press

“BASIC

- COMPLETE LEARNING (with deceleration):

Check if the leaves are closed, and then access

PROGRAMMING”

push-button + for more than 3 seconds: the display starts to

flash and the leaf 1 begins the opening movement. The leaves

automatically slow down on reaching the limit-switches, and

you can command the following functions with the OPEN A

pulses (from a radio control or from a key operated pushbutton):

FCA1 - Deceleration at opening of leaf 1 (stops

1st OPEN- Opening movement of leaf 2 begins

FCA2 - Deceleration at opening of leaf 2 (stops

2nd OPEN- Closing movement of leaf 2 begins

FCC2 - Deceleration at closing of leaf 2 (stops

3rd OPEN-Closing movement of leaf 1 begins

FCC1 - Deceleration at closing of leaf 1 (stops

4th OPEN- End of learning

The display stops flashing: press push-button F to exit and save

the programming.

The procedure has finished and the gate is ready for normal

operation.

, select the TIME LEARNING function and press

automatically when it reaches the end contact

point)

automatically when it reaches the end contact

point)

automatically when it reaches the end contact

point)

automatically when it reaches the end contact

point)

“BASIC

Note: •If some limit-switches are not installed, start the

corresponding deceleration by supplying an Open

pulse (which replaces the limit-switch).

•If only one leaf is present, the entire sequence must

nevertheless be effected. When the leaf has finished

opening, supply 5 Open pulses until the leaf begins

to close, and then resume normal operation.

7. AUTOMATED SYSTEM TEST

When you have finished programming, check if the system is

operating correctly.

Most important of all, check if the force is adequately adjusted

and if the safety devices are operating correctly.

20

Page 12

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)delbasidNEPO(

tceffeoN

tceffeoN

otsesrever,esaelerno,dnaskcoL

nepo

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

)delbasidNEPO(

tceffeoN

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

)1(emitesuapsdaoleR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

otsesrever,esaelerno,dnaskcoL

)delbasidNEPO(

gninepo

nepo

)delbasidNEPO(

tceffeoN

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

"5retfasesolc,esaelernO

)2("2rofesolcotsesreveR

)delbasidNEPO(

)delbasidNEPO

tceffeoN

seunitnoc,esaelerno,dnaskcoL

otsesrever,esaelerno,dnaskcoL

)delbasidNEPO(

gninepo

nepo

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

)delbasidNEPO(tceffeoN

seunitnoc,esaelerno,dnaskcoL

otsesrever,esaelerno,dnaskcoL

gninepo

nepo

)3()1(emitesuapsdaoleR

.2.5hpargarapees

)delbasidNEPO(

)3(tceffeoN

tceffeoN

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

,degagnesecivedytefaSgnisolChtiw(faelehtsesolC

)3(yletaidemmifaelehtsesolc-eR

yletaidemmifaelehtsnepo-eR

)3()eslupdn2ehttasnepo

)3(noitarepospotS esolcotsesreveRtceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

sesolcdnafaelelgnissnepO

)1(emitesuapretfa

.2.5hpargarapees

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

)1(yletaidemmifaelehtsnepo-eR

)3()1(emitesuapsdaoleR

)3(faelehtsesolC

)3()1(tceffeoN esolcotsesreveRtceffeoN

NEPO("5retfasesolc,esaelernO

.2.5hpargarapees

)3()delbasid

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

tceffeoN

)delbasidNEPO(

tceffeoN

sesolcdnafaelelgnissnepO

emitesuapretfa

)3(yletaidemmifaelehtsesolc-eR

)NEPOsevas(

tceffeoN

tceffeoN

)NEPOsevas(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

)3(yletaidemmifaelehtsesolc-eR esolcotsesreveR

yletaidemmifaelehtsnepo-eR

)3(faelehtsesolC

)3()delbasidNEPO(tceffeoN )delbasidNEPO(tceffeoN

tceffeoN )delbasidNEPO(tceffeoN

ANEPO.gnpo.trapnofi(tceffeoN

)delbasid

)delbasidNEPO(

tceffeoN

noitarepo

spotS

)3(yletaidemmifaelehtsesolc-eR

noitarepospotS )NEPOsevas(tceffeoN.2.5hpargarapees

)NEPOselbasidti,esolctsumtifi(

tceffeoN

)NEPOselbasidti,nepotsumtifi(

tceffeoN

)delbasidNEPO(

tceffeoN

)3(noitceridesrevernitnemevomstratseR

)potSaretfasesolcsyawla(

)3(noitarepospotS esolcotsesreveRtceffeoN

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"E"cigoL SESLUP

Tab. 3/a

sesolcdnafaelehtsnepO

)1(emitesuapretfati

faelehtsnepOfaelelgnissnepO

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

GNINEPO

DESOLC

GNISOLC

NEPO

DEKCOL

"A"cigoL SESLUP

Tab. 3/b

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

Tab. 3/c

sesolcdnafaelehtsnepO

emitesuapretfati

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"S"cigoL SESLUP

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

faelehtsnepOfaelelgnissnepO

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"PE"cigoL SESLUP

DESOLC

NEPO

GNINEPO

GNISOLC

DEKCOL

Tab. 3/d

21

Page 13

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

emitesuapsdaoleR

)delbasidNEPO(

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

tceffeoN

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

emitesuapsdaoleR

)delbasidNEPO(

nepo

)3(emitesuapsdaoleR

.2.5hpargarapees

)delbasidNEPO(

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

tceffeoN

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

"5retfasesolc,esaelernO

)delbasidNEPO(

nepo

NEPO("5retfasesolc,esaelernO

.2.5hpargarapees

)3()delbasid

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

)delbasidNEPO

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidBNEPO(

tceffeoN

)delbasidB-NEPO(

)delbasidBNEPO(

noitarepospotS

tceffeoN

tceffeoN

)ANEPOsevas(

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidB/ANEPO(

tceffeoN

)delbasidB/A-NEPO(

noitarepospotS

)delbasidBNEPO(

tceffeoN

tceffeoN )2("2rofesolcotsesreveR

)delbasidA-NEPO(

)delbasidA-NEPO(

noitarepospotS

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidB/A-NEPO(

)delbasidBNEPO(

noitarepospotS

tceffeoN

)delbasidBNEPO(

)delbasidB-NEPO(

noitarepospotS

tceffeoN

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

tceffeoN )2("2rofesolcotsesreveR

)delbasidANEPO(

)delbasidA-NEPO(

noitarepospotS

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

sesolcdnafaelelgnissnepO

emitesuapretfa

yletaidemmifaelehtsnepo-eR

)3(noitarepospotS

sesolcdnafaelehtsnepO

emitesuapretfati

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"PA"cigoL SESLUP

ESUAPnoNEPO

DESOLC

,degagnesecivedytefaSgnisolChtiw(faelehtsesolC

)3()eslupdn2ehttasnepo

)3(noitarepospotS esolcotsesreveRtceffeoN

GNINEPO

GNISOLC

DEKCOL

sesolcdnafaelelgnissnepO

emitesuapretfa

sesolcdnafaelehtsnepO

emitesuapretfati

SUTATSETAGA-NEPOB-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

"PS"cigoL SESLUP

DESOLC

noitarepo

spotS

yletaidemmifaelehtsnepo-eR

)3(noitarepospotS

ESUAPnoNEPO

GNISOLC

)delbasidNEPO(

tceffeoN

)3(noitarepospotS esolcotsesreveR

)3(faelehtsesolC

GNINEPO

DEKCOL

"B"cigoL SESLUP

NEPO(tceffeoN

)delbasidB

faelehtsnepOtceffeoN

SUTATSETAG)gninepo(A-NEPO)gnisolc(B-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

DESOLC

nepootsesreveRtceffeoN

tceffeoNfaelehtsesolC

GNISOLC

NEPO

)delbasidB/ANEPO(

tceffeoN

noitarepo

spotS

faelehtsnepOfaelehtsesolC

tceffeoNtceffeoN

SUTATSETAG)gninepo(A-NEPO)gnisolc(B-NEPOPOTSSECIVEDYTEFASGNINEPOSECIVEDYTEFASGNISOLCECIVEDYTEFASLC/POECIVEDYTEFASEGDE

GNINEPO

DEKCOL

"C"cigoLNWODDLEHSYAWLASLORTNOC SESLUP

)delbasidB/A-NEPO(

noitarepospotS

tceffeoN

)delbasidA-NEPO(

faelehtsesolC

tceffeoN

)delbasidB-NEPO(

faelehtsnepO

DESOLC

noitarepospotS/

tceffeoN

/noitarepospotS

GNINEPO

GNISOLC

NEPO

Tab. 3/e

Tab. 3/f

22

Tab. 3/g

Tab. 3/h

(1) If maintained, it prolongs the pause until disabled by the command (timer function) (3) During the partial opening cycle, an OPEN A pulse causes total opening.

(2) If a new pulse occurs within 2 seconds after reversing, it immediately stops operation. NB.: Effects on other active pulse inputs in brackets.

Loading...

Loading...