Page 1

para la naturaleza

100% papel reciclado

ist umweltfreundlich

100% Altpapier

450 MPS

450 MPS

pour la nature

papier recyclé 100%

for nature

recycled paper 100%

per la natura

M

R

E

E

T

C

A

Z

I

E

N

D

UNI EN ISO 9001-085

A

C

I

F

A

I

T

C

R

E

A

T

carta riciclata 100%

Page 2

ENGLISH

IMPOR TANT NOTICE FOR THE INSTALLER

GENERAL SAFETY REGULATIONS

1) WARNING! FAAC strongly recommends to follow these instructions literally for the safety of persons. Improper

installation or misuse of the product will cause very serious damages to persons.

2) Packaging material (plastic, polystyrene etc.) is a potential hazard and must be kept out of reach of children.

Read the instructions carefully before installing the product.

3)

4) Keep these instructions for future reference.

5) This product has been designed and manufactured only for the use stated in this manual. Any other use not expressly

set forth will affect the reliability of the product and/or could be source of hazard.

6) FAAC S.p.A. cannot be held responsible for any damage caused by improper use or different from the use for which

the automation system is destined to.

7) Do not use this device in areas subject to explosion: the presence of flammable gas or fumes is a serious hazard.

8) Mechanical constructive elements must comply with UNI8612, CEN pr EN 12604 and CEN pr EN 12605 standards.

Countries outside the EC shall follow the regulations above besides their national normative references in order to

offer the utmost safety.

9) FAAC cannot be held responsible for failure to observe technical standards in the construction of gates and doors,

or for any deformation of the gates which may occur during use.

10) Installation must comply with UNI8612, CEN pr EN 12453 and CEN pr EN 12635.

The degree of safety of the automation must be C+E.

11) Before carrying out any operations, turn off the system’s main switch.

12) An omnipower switch shall be provided for the installation with an opening distance of the contacts of 3 mm or more.

Alternatively, use a 6A thermomagnetic breaker with multi-pole switching.

13) Ensure that there is a differential switch up-line of the electrical system, with a trip threshold of 0.03A.

14) Check that the earthing plant is in perfect condition and connect it to the metallic parts. Also earth the yellow/green

wire of the operator.

15) The automation is fitted with an anti-crush safety system that is a torque control device. In any case, further safety

devices shall be installed.

16) The safety devices (e.g. photocells, safety edges, etc.) protect areas wherethere is a mechanical movement

hazard, e.g. crushing, entrapment and shearing.

17) Each installation must be fitted with at least one flashing light (e.g. FAAC LAMP, MINILAMP etc.) as well as a warning

plate suitably fixed to the gate, besides the safety devices as per point 16. above.

18) FAAC cannot be held responsible regarding safety and correct functioning of the automation in the event that parts

other than FAAC original parts are used.

19) Use only FAAC original spare parts for maintenance operations.

20) Do not carry out any modifications to automation components.

21) The installer must supply all information regarding manual operation of the system in the event of an emergency

and provide the end-user with the leaflet attached to the product.

22) Keep out of persons when the product is in operation.

23) Keep out of reach of children the remote radio controls and any control devices. The automation could be

operated unintentionally.

24) The end-user must avoid any attempt to repair or adjust the automation personally. These operations must be

carried out exclusively by qualified personnel.

25) What is not explicitly stated in these instructions is not permitted.

9

Page 3

ENGLISH

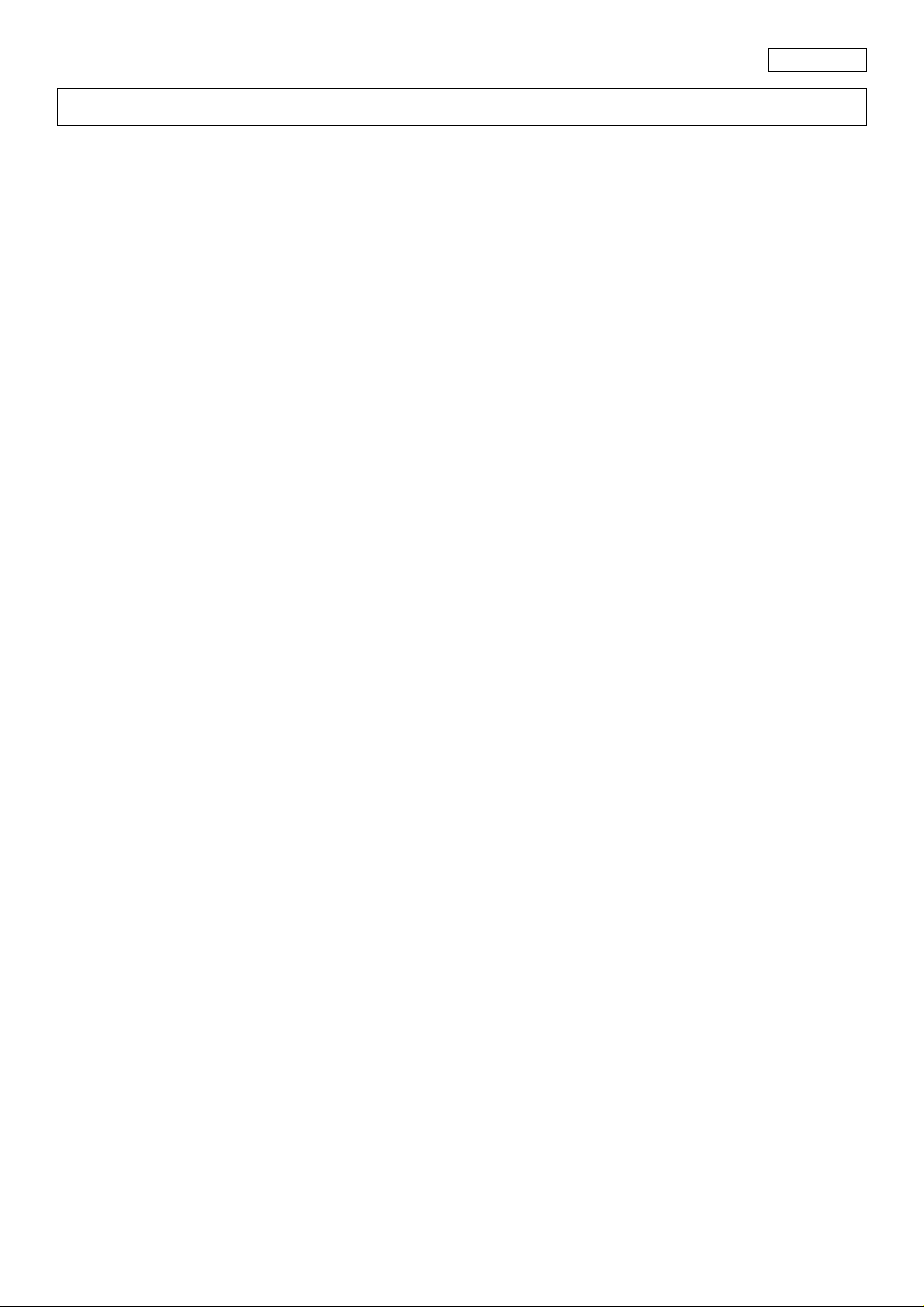

DESCRIPTION AND TECHNICAL SPECIFICATIONS

LAYOUT AND ELECTRICAL WIRING

Table 1: 450 MPS Control unit technical specifications

Power supply 230 V(+6%-10%) - 50 Hz

Absorbed power 10 W

Max. motor load 800 W

Max. accessories load 0,5 A

Max. electric lock load 12 VA

Temperature range -20 °C +55 °C

Fuses N. 4 (see fig.1)

Operations logics Automatic / Semi-automatic / Safety / Dead-man

Automatic timer/ button / Step-by-step semi-automatic

Opening/closing time Adjustable by trimmer (from 0-120 s)

Pause time Adjustable by trimmer (from 0-240 s)

Closing leaf delay time Adjustable by trimmer (from 0 -28 s)

Opening leaf delay time 2.5 s (Can be disabled through bridge)

Thrust force Adjustable by trimmer

Terminal block inputs Open/Open single leaf/Stop/Opening safeties/Closing

Terminal block outputs Flashing light - motors - 24 Vdc accessories power

Quick connector Decoding cards - RP 433 SL/DS

Microswitch programmable functions Operating logics - Reversing stroke for

J1

supply - 24 Vdc warning light power supply -

J2

safeties/ mains power +earth

12 Vac electric lock power supply

electric lock - Closing safeties logics

F1

J3

F4

F2

l

F3

OPENING

e

LEAF DELAY

DISABLE

i

DL4

DL5

J2 J3J1

NL

a b c

j

m

k

f

FAILSAFE

ON-OFF

DL2

DL3

g

d

h

n

o

DL1

Fig. 1

1

2

N

230 V

3

L

50 Hz

4

6

5

OP COM CL CL COM OP

LAMP MOTOR 1 MOTOR 2

BLU

M1

C1

98

7

10

BLU

M2

C2

11

N.B.: The capacitors are provided with the operators.

Caution: Before touching the electronic unit (connections,

programming, maintenance) always switch off the power

supply.

a J1 terminal block (fig. 2)

: Earth connection

N. : power supply 230 V~ ( Neutre )

L. : power supply 230 V~ ( Phase)

N.B.: For correct operation the card must be connected to the

system’s earth. Install a suitable differential magneto-thermal

circuit-breaker upstream of the system.

b J2 terminal block (fig. 2)

LAMP.: flashing light output ( 230 V ~)

MOTOR 1 Open /Common/ Close: Motor 1 connection

Can be used in one-leaf application.

(

leaf closing delay)

MOTOR 2 Close /Common/ Open: Motor 2 connection

Not to be used in one-leaf application.

N.B. To check the operation of the equipment at the test

bench, a load must be connected on the MOTOR 1 input.

c J3 terminal block: low voltage (fig. 2) used to connect all

accessories (see table 2).

12

13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

+ —

OP — CL NC —

30 Vcc FSW STOP

B — A — + —

OPEN

STOP

IND.

OPEN

TOT.

FSWTX W.LIGHT LOCK

FSW TX

+ —

24 Vdc

3 W

For the safety and fail-safe devices, see the “Safety devices” section.

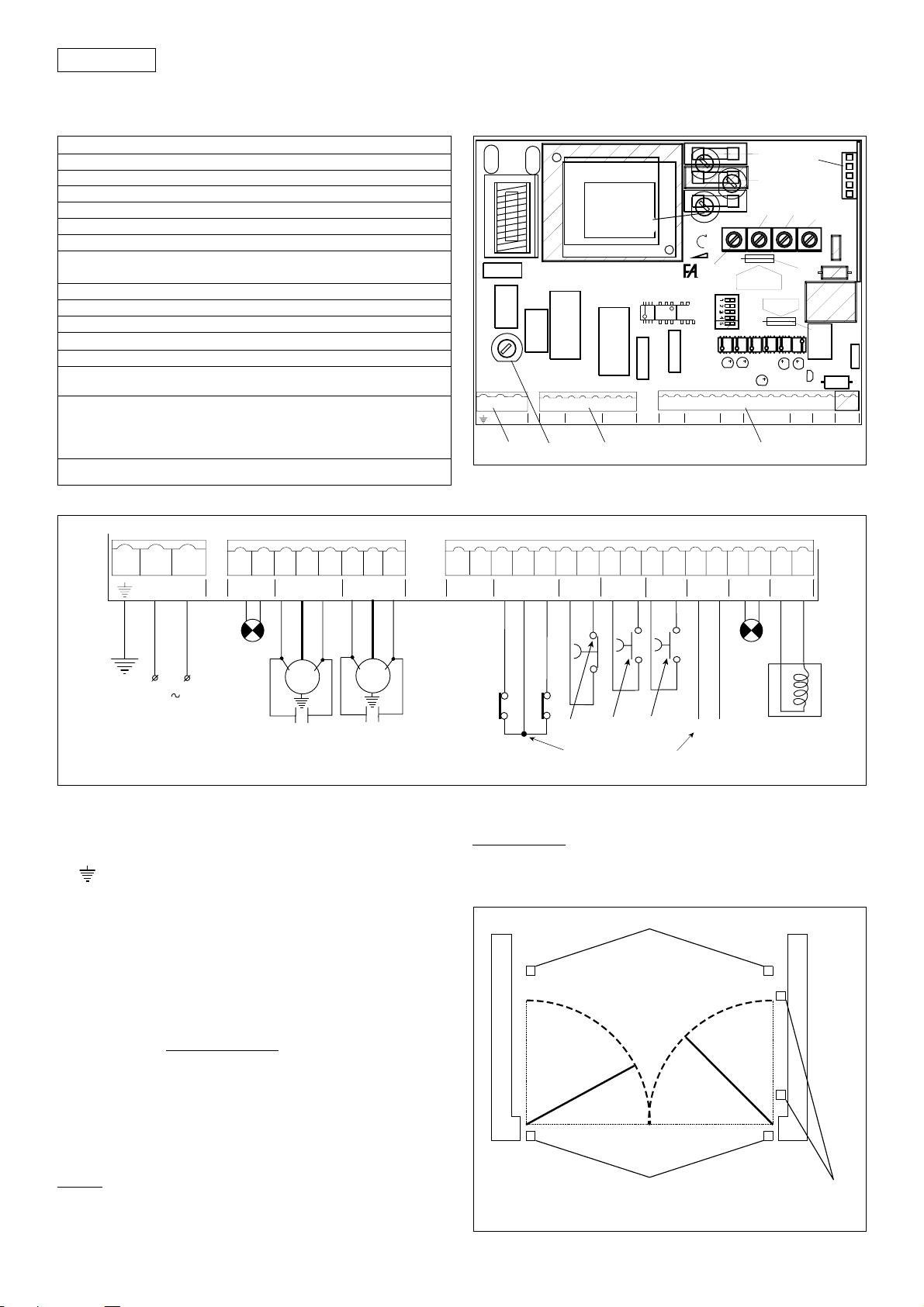

Fig. 2

Warning: the max. accessory load is 500 mA. To calculate

absorption values, refer to table 2.

Safety devices

These are all devices (photocells, safety edges, magnetic

coils, etc.) with an N.C. (normally closed) contact which

activate if an obstacle obstructs the area protected by the

Opening, closing or opening/closing photocells

A

A

A

B

B

30 Vdc

– accessories power supply negative

+ accessories power supply positive (+ 30 Vdc)

10

Closing photocells

Opening

photocells

Fig. 3

Page 4

ENGLISH

1

2

5

4

3

1

2

RX CL TX CL

1

2

5

4

3

1

2

RX OPTX OP

14

15

2423

16

12

13

30Vcc

OP — CL

FSW

+ —

FSWTX

+ —

safety devices and stop the movement of the gate leaves

(fig. 3).

The 450 MPS card has an additional FAIL-SAFE device which

serves to check that the N.C. contact on the photocell

receiver is working efficiently before any operation (Can

be disabled through bridge Fig. 1 ref.15) .

N.B.: If the Opening safety devices are engaged when the

gate is closed, they prevent the leaves from opening.

If the Closing safety devices are engaged when the gate

is open, they prevent the leaves from closing.

OP. - Opening safety device contact (N.C.): in the A-S-E-EP-AD

logics, during the opening phase the safety devices stop

the movement of the gate leaves; when they are

disengaged the opening movement recommences. They

do not engage during closure.

In the B, C and B/C logics, they interrupt movement during

the opening cycle. They do not engage during the closing

cycle.

N.B.: If opening safety devices are not connected, jumper

inputs OP and FSW TX (Fig. 4).

Application examples

The following are the commonly used connection arrangements (enable fail -safe):

No safety device connected One pneumatic edge connected as closing safety device and

15

14

OP — CL

FSW

16

+ —

FSWTX

2423

The purpose of the opening safety devices is to safeguard

the zone behind the gate leaves (A, fig. 3).

CL. - Closing safety device contact (N.C.): in the A-S-E-EP-AD

logics, during the closing phase the safety devices reverse

the direction of movement of the gate leaves, or they stop

the movement of the leaves then reverse direction when

they are disengaged (see microswitch SW4 settings). They

do not engage during the opening cycle.

In B, C and B/C logics, they interrupt movement during the

closing cycle. They do not engage during the opening

cycle.

N.B.: If closing safety devices are not connected, jumper

inputs OP and FSWTX (fig. 4).

The purpose of the closing safety devices is to safeguard

the zone in which the leaves move during the closing cycle

(B, fig. 3).

If the Fail-Safe function is not used, see cabling at page 4

for connections of photocells.

one connected as opening safety device

15

14

OP — CL

FSW

16

+ —

FSWTX

2423

1 pair of closing photocells connected 1 pair of opening photocells connected

15

16

14

13

12

+ —

OP — CL

30Vcc

FSW

1

2

3

4

5

RX TX

1 pair of opening photocells and 1 pair of closing

photocells connected

15

16

14

13

12

+ —

30Vcc

OP — CL

FSW

1

2

3

4

5

RX CL TX CL

+ —

FSWTX

1

2

+ —

FSWTX

1

2

2423

Fig. 4

2423

12

+ —

30Vcc

Fig. 6

13

15

16

14

OP — CL

FSW

1

2

3

4

5

RX TX

+ —

FSWTX

1

2

2423

Fig. 5

Fig. 7

1 pair of closing photocells and 1 pair of opening/closing

photocells connected

1

2

Important: for further information on the operation of the safety devices, see table 3.

1

2

3

4

5

RX OPTX OP

Fig. 8

Fig. 9

11

Page 5

ENGLISH

Application examples

The following are the commonly used connection arrangements (disable fail -safe)

No safety device connected

15

16

14

OP — CL

FSW

+ —

FSWTX

1 pair of closing photocells connected

15

16

14

13

12

+ —

30Vcc

OP — CL

FSW

1

2

3

4

5

RX TX

+ —

FSWTX

1

2

2423

2423

Fig. 4/A

Fig. 6/A

One pneumatic edge connected as closing safety device and

one connected as opening safety device

15

14

OP — CL

FSW

16

+ —

FSWTX

2423

Fig. 5/A

1 pair of opening photocells connected

12

+ —

30Vcc

13

15

16

14

OP — CL

FSW

1

2

3

4

5

RX TX

+ —

FSWTX

1

2

2423

Fig. 7/A

Two pair of closure photocells connected

15

16

14

13

12

+ —

30Vcc

OP — CL

FSW

1

2

3

4

5

1

2

RX TX

TX

1

2

RX

+ —

FSWTX

5

4

3

2

1

1 pair of closing photocells and 1 pair of opening/closing

photocells connected

2423

12

+ —

30Vcc

13

15

14

OP — CL

FSW

1

2

3

4

5

16

RX TX

1

2

TX

Fig. 8/A

RX

+ —

FSWTX

1

2

5

4

3

2

1

2423

Fig. 9/A

12

Page 6

ENGLISH

STOP

– Common ( - )

N.C. - STOP contact: all devices (such as pushbuttons)

which by opening a contact stop gate movement.

To install several safety stop devices, connect the N.C.

contacts in series.

N.B. If the STOP devices are not connected, jumper STOP

and - inputs.

B - SINGLE LEAF OPENING (N.O.): all devices (e.g. pushbutton)

which, by closing a contact activates opening and/or

closing of the leaf driven by motor 1.

– Common ( - )

A - TWO-LEAF OPENING (N.O.): all devices (pushbuttons ,

photocells, detectors, etc.) which assures opening/closing

of both leaves by closing a contact.

To install several control devices, connect the N.O. contacts

in parallel.

FSWTX

+ – Photocell transmitter power supply (FailSafe)

To use the Fail-Safe function, power supplies to the photocell

transmitters must be connected.

W.LIGHT

+– Warning lamp power supply 24 Vdc 3 W max.

For correct operation of the system,

power (see table 2).

LOCK

12 Vac electric lock power supply.

do not exceed stated

d J4 quick connector for decoder SL/DS - MINIDEC SL/DS - RP

433 SL/DS cards (figs. 10-11-12-13)

e TORQUE trimmer: thrust adjusting trimmer (anti-crushing

safety system).

f PAUSE trimmer: pause time adjusting trimmer (A/S/AD

logics).

Pause time is adjustable from 0 to 240 seconds.

g OP/CL trimmer: Opening/Closing time adjusting trimmer

Time is adjustable from 0 to 120 seconds.

h LEAF DELAY trimmer: closing leaf delay adjusting trimmer.

Leaf delay time is adjustable from 0 to 28 seconds.

N.B.:

1) If the opening/closing time is less than the set delay

time, the delayed leaf closes at the end of the closing

time.

2) In one-leaf application, set the leaf delay time to

minimum

i Programming microswitches

j Fuse F1 5x20 5 A/250 V rapid (motor power supply)

k Fuse F2 5x20 800 mA/250 V delayed (accessories power

supply)

l Fuse F3 5x20 1.6 A/250 V delayed (electric power supply)

m Fuse F4 5x20 250 mA/250 V delayed (transformer power

supply)

n Bridge to enable/disable the Fail-Safe (Fig. 14).

o Bridge to enable/disable the wing opening

delay(Fig. 14).

Table 2 - Current drawn by accessories

ACCESSORY CURRENT DRAWN

PLUS 40 SL 30 mA

PLUS 433 E 20 mA

MINIDEC SL / DS 6 mA

DECODER SL / DS 20 mA / 55 mA

RP 433 SL / DS 12 mA / 6 mA

DIGICARD 15 mA

METAL DIGIKEY 15 mA

FOTOSWITCH 90 mA

DETECTOR F4 / PS6 50 mA

PHOTOBEAM 50 mA

WARNING LIGHT 150 mA

PLUS

433 E

450 MPS

DECODER

MINIDEC

SL/DS

Fig. 10

N.B. Use a dedicated decoder for other accessory types.

SL

Fig. 11

Fig. 12

13

Fig. 13

Page 7

ENGLISH

4) Switch on the power.

5) Send an OPEN signal to input A (fig. 2) and check that the

If the gate closes, invert the motor wires on the control unit

(brown and black wires).

FAIL-SAFE

LEAF DELAY

Disable

Enable

DisableEnable

Fig. 14

Opening/closing times are set by the OP/CL trimmer on the

control unit (fig. 1 - ref.7).

To reduce operation time, adjust the trimmer anticlockwise

To increase operation time, adjust the trimmer clockwise.

Maximum operation time is 120 seconds.

For 90° opening the approximate opening/closing time is 18

1. PROGRAMMING THE MICROSWITCHES

Automation programming is carried out by the microswitches

(fig. 1 - ref. 9) as shown in the diagram below.

Fig. 15

12345

seconds.

For optimal system efficiency set the opening/closing time so

that the electric motor remains activated for a few seconds

after the leaf has reached the mechanical travel stop.

In the case of overlapping leaves, it is possible to delay closing

of the leaf driven by motor M1 (see fig. 2) to ensure correct

closure of the gate.

Set the delay by the LEAF DELAY trimmer on the 450 MPS control

SW2

OPERATING LOGICS

A

S

E

EP

B

C

B/C

AD

SW1

OFF

ON

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

ON

OFF

1.1. OPERATION LOGICS

SW3

OFF

OFF

OFF

OFF

ON

ON

ON

ONON

REVERSING STROKE FOR

ELECTRIC LOCK

NOT ACTIVATED

ACTIVATED

SAFETIES ON CLOSING

INVERTS MOVEMENT

IMMEDIATELY

STOPS AND INVERTS

MOVEMENT ON

DISENGAGEMENT

SW5

OFF

ON

SW4

OFF

ON

unit (fig. 1 - ref. 8).

To reduce delay time, adjust the trimmer anticlockwise.

To increase delay time, adjust the trimmer clockwise.

Maximum delay time is 28 seconds. If the operation time is

shorter, the delay time is reduced automatically.

When A or S logics are selected, the leaf momentary stop time

can be set using the PAUSE trimmer (fig. 1 ref. 6).

Turn the trimmer clockwise to increase the time.

Turn the trimmer anticlockwise to reduce the time.

The maximum pause time is 240 sec.

There are seven operating logics available:

A: “AUTOMATIC ” E : “SEMI-AUTOMATIC”

S : “SAFETY” EP : “SEMI-AUTOMATIC STEP-BY-STEP”

B : “DEAD-MAN BUTTON” C : “DEAD-MAN BUTTON”

B/C : “DEAD-MAN BUTTON” AD :“AUTOMATIC TIMER”

Operation of the different logics is described in tables 3/a-b-c-d-e-f-g-h.

1.2. REVERSING STROKE FOR ELECTRIC LOCK

This function is to be activated only if the electric lock is

installed.

1.3. SAFETIES ON CLOSING

This function serves to select the operating mode for the closing

safeties:

- OFF: immediate reverse of movement during gate closure

- ON: movement is stopped during closing and reversed on

opening when the safety is disengaged.

The 450 MPS control unit has been designed for use on both

electromechanical and hydraulic operators.

When the 450 MPS card is used on electromechanical operators,

the torque control device must be set by turning the TORQUE

trimmer (fig. 1 ref. 5).

To reduce torque, adjust the trimmer anticlockwise.

To increase torque, adjust the trimmer clockwise.

In any event, FAAC advises not to exceed a torque of 15 Kg

measured on the outer edge of the leaf.

To ensure precise torque adjustment use a linear dynamometer.

When the 450 MPS card is used on hydraulic operators, the

torque control device must be set to the maximum value by

turning the TORQUE trimmer clockwise.

This device is already present inside the operator hydraulic

circuit (BY-PASS valves).

2. START-UP

1) Program the 450 MPS electronic control unit according to

specific requirements as shown in fig. 14.

2) Check led status as shown in table.

LED functions

LEDS ON OFF

DL 1 (OPEN INPUT A) Command active Command not active

DL 2 (OPEN INPUT B) Command active Command not active

DL 3 (STOP) Command not active Command active

DL 4 (FTSW OPEN) Safeties disengaged Safeties engaged

DL 5 (FTSW CLOSE) Safeties disengaged Safeties engaged

N.B.: the bold text indicates led status with gate idle.

2.1. DIRECTION OF ROTATION

1) Switch off the power.

2) Manually move the gate to halfway.

3) Lock the operators.

leaf opens.

2.2. OPERATION TIME ADJUSTMENT

2.3. CLOSING LEAF DELAY ADJUSTMENT

2.4. SETTING PAUSE TIME

2.5. ANTI-CRUSHING SYSTEM ADJUSTMENT

14

Page 8

ENGLISH

on

W.L.

OPENING/CLOSING SAFETIESCLOSING SAFETIESOPENING SAFETIES

on

flashing light

continues to open

No effect (OPEN inhibited)

Stops opening and, when disengaged,

Stops closing and, when disengaged, opens

No effect off

No effect

Freezes pause until disengagement (*1) (OPEN inhibited)

See paragraph 1.3

on

on

W.L.

No effect (OPEN inhibited)

OPENING/CLOSING SAFETIESCLOSING SAFETIESOPENING SAFETIES

No effect (OPEN inhibited)

No effect off

Freezes pause until disengagement (*1) (OPEN inhibited)

on

on

flashing light

continues to open

Stops opening and, when disengaged,

Stops closing and, when disengaged, opens

No effect (OPEN inhibited)

No effect

on

W.L.

No effect (OPEN inhibited)

OPENING/CLOSING SAFETIESCLOSING SAFETIESOPENING SAFETIES

No effect (OPEN inhibited)

No effect off

on

flashing light

Stops opening and, when disengaged,

Stops closing and, when disengaged, opens

No effect

See paragraph 1.3

on

continues to open

on

W.L.

No effect (OPEN inhibited)

OPENING/CLOSING SAFETIESCLOSING SAFETIESOPENING SAFETIES

No effect (OPEN inhibited)

No effect off

on

flashing light

continues to open

Stops opening and, when disengaged,

Stops closing and, when disengaged, opensSee paragraph 1.3

No effect

on

No effect (OPEN inhibited)

PULSES

No effect

No effect (OPEN inhibited)

Stops opening and, when disengaged, closes

No effect (OPEN inhibited)

STOP

Stops

OPEN-B

after pause time

Recloses leaf immediately

Opens single leaf and re-closes

No effect

OPEN-A

Opens leaves and

recloses after pause time

Reopens leaves immediately Reopens leaf immediately

Recloses leaves immediately

No effect

PULSES

No effect

No effect (OPEN inhibited)

STOP

No effect (OPEN inhibited)

OPEN-B

Opens single leaf and

recloses after pause time

Recloses leaf immediately

Closes the leaf/leaves

OPEN-A

Opens leaves and

recloses after pause time

Recloses leaves immediately

No effect

No effect (OPEN inhibited) See paragraph 1.3

Stops opening and, when disengaged, closes

Stops

No effect (OPEN inhibited)

PULSES

No effect

No effect (OPEN inhibited)

No effect (OPEN inhibited)

STOP

Stops

OPEN-B

Opens single leaf

Recloses leaf immediately

Closes the leaf/leaves

Reopens leaves immediately Reopens leaf immediately

Recloses leaves immediately

OPEN-A

Reopens leaf immediately

Opens leaves

Recloses leaves immediately Recloses leaf immediately

Reopens leaves immediately

No effect No effect (OPEN inhibited)

Stops opening and, when disengaged, closes

PULSES

STOP

No effect

Stops opening and, when disengaged, closes

No effect (OPEN inhibited)

Stops

OPEN-B

Stops

Closes the leaf/leaves No effect (OPEN inhibited)

Recloses leaf/leaves immediately

OPEN-A

Opens leaves Opens single leaf

Stops

Stops

No effect (if the gate must open, inhibits OPEN) No effect (if gate must close, inhibits OPEN)

No effect (OPEN inhibited)

Inverts the direction

GATE STATUS

LOGICS "A"

Table 3/a

CLOSING

CLOSED

OPEN on PAUSE

STOPPED

OPENING

GATE STATUS

LOGICS "S"

Table 3/b

CLOSED

CLOSING

OPEN on PAUSE

STOPPED

OPENING

Table 3/c

15

CLOSED

GATE STATUS

LOGICS "E"

OPEN

CLOSING

STOPPED

OPENING

GATE STATUS

LOGICS "EP"

Table 3/d

OPEN

CLOSED

OPENING

CLOSING

STOPPED

Page 9

ENGLISH

on

off

W.L.

on

No effect

No effect

(OPEN A/B inhibited)

(OPEN A/B inhibited)

flashing light

Interrupts operation

(OPEN-A/B inhibited)

on

No effect

Interrupts operation

(OPEN-A/B inhibited)

OPENING/CLOSING SAFETIES

No effect

No effect

(OPEN-B inhibited)

(OPEN-B inhibited)

CLOSING SAFETIESOPENING SAFETIES

Interrupts operation

(OPEN-B inhibited)

No effect

No effect

off

W.L.

No effect

(OPEN A/B inhibited)

(OPEN A/B inhibited)

OPENING/CLOSING SAFETIES

(OPEN-B inhibited)

No effect

(OPEN-B inhibited)

CLOSING SAFETIESOPENING SAFETIES

on

No effect

(OPEN A/B inhibited)

No effect

(OPEN-B inhibited)

on

flashing light

Interrupts operation

Interrupts operation

(OPEN-A/B inhibited)

(OPEN-A/B inhibited)

No effect

(OPEN-B inhibited)

Interrupts operation

on

No effect

(OPEN A/B inhibited)

W.L.

No effect

OPENING/CLOSING SAFETIES

No effect

(OPEN-B inhibited)

CLOSING SAFETIES

Interrupts operation

on

off

flashing light

No effect

(OPEN A/B inhibited)

(OPEN A/B inhibited)

(OPEN-B inhibited)

Interrupts operation

(OPEN-A/B inhibited)

(OPEN-B inhibited)

Interrupts operation

(OPEN-B inhibited)

Interrupts operation

on

Interrupts operation

(OPEN-A/B inhibited)

W.L.

No effect (OPEN inhibited)

OPENING/CLOSING SAFETIESCLOSING SAFETIESOPENING SAFETIES

No effect

No effect off

on

on

flashing light

Stops closing and, when disengaged, opens

Freezes pause until disengagement (*1) (OPEN inhibited)

See paragraph 1.3

on

continues to open

Stops opening and, when disengaged,

No effect (OPEN inhibited)

No effect

PULSES

STOP

No effect

No effect

(OPEN-A inhibited)

No effect

(OPEN A/B inhibited)

OPEN-B

Closes the leaf/leaves

OPEN-A

Opens the leaf/leaves

No effect

(OPEN-A inhibited)

Stops

No effect

(OPEN A/B inhibited)

No effect

Closes the leaf/leaves

No effect

Opens the leaf/leaves

No effect

(OPEN-A inhibited)

(OPEN-A inhibited)

Interrupts operation

No effect

(OPEN A/B inhibited)

No effect

Closes leaves or 1 leaf

No effect

Opens leaves or 1 leaf

No effect

No effect

No effect

(OPEN-A inhibited)

(OPEN-A inhibited)

No effect

(OPEN-A inhibited)

(OPEN-A inhibited)

Interrupts operation

HOLD-TO-RUN CONTROLS

OPENING PULSE/HOLD TO RUN CONTROL

STOP

No effect

(OPEN A/B inhibited)

OPEN-B

Closes the leaf/leaves

OPEN-A

Opens the leaf/leaves

Stops

No effect

(OPEN A/B inhibited)

No effect

Closes the leaf/leaves

No effect

Opens the leaf/leaves

No effect

(OPEN A/B inhibited)

No effect

Closes leaves or 1 leaf

No effect

Opens leaves or 1 leaf

No effect

(OPEN-A inhibited)

OPENING SAFETIES

STOP

No effect

(OPEN A/B inhibited)

OPEN-B

Closes the leaf/leaves

OPEN-A

Opens the leaf/leaves

No effect

No effect

(OPEN-A inhibited)

No effect

(OPEN A/B inhibited)

No effect

Closes the leaf/leaves

No effect

Opens the leaf/leaves

PULSES

(OPEN-A inhibited)

Interrupts operation

Stops

No effect

No effect

No effect

No effect (OPEN inhibited)

No effect (OPEN inhibited)

STOP

OPEN-B

OPEN-A

pause time

after pause time

Opens single leaf and re-closes

It controls the re-counting of the

pause time

Opens leaves and

recloses after pause time

It controls the re-counting of the

No effect

Stops opening and, when disengaged, closes

Stops

No effect (OPEN inhibited)

Closes the leaf/leaves

If held, it remains in pause (timer function).

Reopens leaves immediately Reopens leaf immediately

GATE STATUS

LOGICS "B"

Table 3/e

CLOSED

OPEN

CLOSING

OPENING

STOPPED

Table 3/f

CLOSED

GATE STATUS

LOGICS "B/C"

OPEN

CLOSING

OPENING

16

STOPPED

Table 3/g

CLOSED

GATE STATUS

LOGICS "C"

OPEN

CLOSING

OPENING

GATE STATUS

LOGICS "AD"

Table 3/h

CLOSED

OPEN on PAUSE

STOPPED

CLOSING

OPENING

(*1) If residual pause time is less than 5 seconds on safety disengagement, the gate closes after 5 seconds.

N.B.: Effects of other active impulse inputs are shown in brackets

Page 10

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto,

lasciando inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque

momento e senza impegnarsi ad aggiornare la presente pubblicazione, le modifiche che essa ritiene

convenienti per miglioramenti tecnici o per qualsiasi altra esigenza di carattere costruttivo o

commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the

right, whilst leaving the main features of the equipments unaltered, to undertake any modifications

it holds necessary for either technical or commercial reasons, at any time and without revising the

present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le

droit d’apporter à tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant

les caractéristiques essentielles, sans devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält

sich das Recht vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne

Verbindlichkeiten in Bezug auf die Neufassung der vorliegenden Anleitungen, technisch bzw.

konstruktiv/kommerziell bedingte Verbesserungen vorzunehmen.

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se

reserva el derecho, dejando inmutadas las características esenciales de los aparatos, de aportar, en

cualquier momento y sin comprometerse a poner al día la presente publicación, todas las

modificaciones que considere oportunas para el perfeccionamiento técnico o para cualquier otro

tipo de exigencia de carácter constructivo o comercial.

para la naturaleza

100% papel reciclado

ist umweltfreundlich

100% Altpapier

FAAC per la natura

• La presente istruzione è realizzata al 100% in carta riciclata.

• Non disperdete nell'ambiente gli imballaggi dei componenti dell'automazione bensì selezionate

i vari materiali (es. cartone, polistirolo) secondo prescrizioni locali per lo smaltimento rifiuti e le

norme vigenti.

FAAC for the environment

• The present manual is produced in 100% recycled paper

• Respect the environment. Dispose of each type of product packaging material (card, polystyrene)

in accordance with the provisions for waste disposal as specified in the country of installation.

FAAC der Umwelt zuliebe

• Vorliegende Anleitungen sind auf 100% Altpapier gedruckt.

• Verpackungsstoffe der Antriebskomponenten (z.B. Pappe, Styropor) nach den einschlägigen

Normen der Abfallwirtschaft sortenrein sammeln.

FAAC écologique

• La présente notice a été réalisée 100% avec du papier recyclé.

• Ne pas jeter dans la nature les emballages des composants de l’automatisme, mais sélectionner

les différents matériaux (ex.: carton, polystyrène) selon la législation locale pour l’élimination des

déchets et les normes en vigueur.

FAAC por la naturaleza.

• El presente manual de instrucciones se ha realizado, al 100%, en papel reciclado.

• Los materiales utilizados para el embalaje de las distintas partes del sistema automático (cartón,

poliestireno) no deben tirarse al medio ambiente, sino seleccionarse conforme a las prescripciones

locales y las normas vigentes para el desecho de residuos sólidos.

FAAC S.p.A.

Via Benini, 1

40069 Zola Predosa (BO) - ITALIA

Tel.: 051/6172411 - Tlx.: 521087

Fax: 051/758518

pour la nature

papier recyclé 100%

for nature

recycled paper 100%

Timbro del Rivenditore:/Distributor’s Stamp:/Timbre de l’Agent:/ Fachhändlerstempel:/Sello del Revendedor:

per la natura

732260 - Rev. D - 11000 - 697 - M

carta riciclata 100%

Loading...

Loading...