Page 1

TD830

E LECT RO SURGICAL UNIT

Service Manual

698260

E-SM44h

Page 2

Preliminary

Information

Technical data

Read these Instructions before use

Keep this ‘Service Manual’ in a safe convenient place for future reference. Read in conjunction

with the relevant Publications detailed in the preliminary information section.

Safety notes

and alarms

Introduction

Description

Maintenance

Illustrated parts list

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquiries, please quote the

Model and Serial Number of your Electrosurgical Unit which is shown on the Serial Number plate,

the location of which is shown below. Please ensure you include all alpha and numeric digits of

the Serial Number.

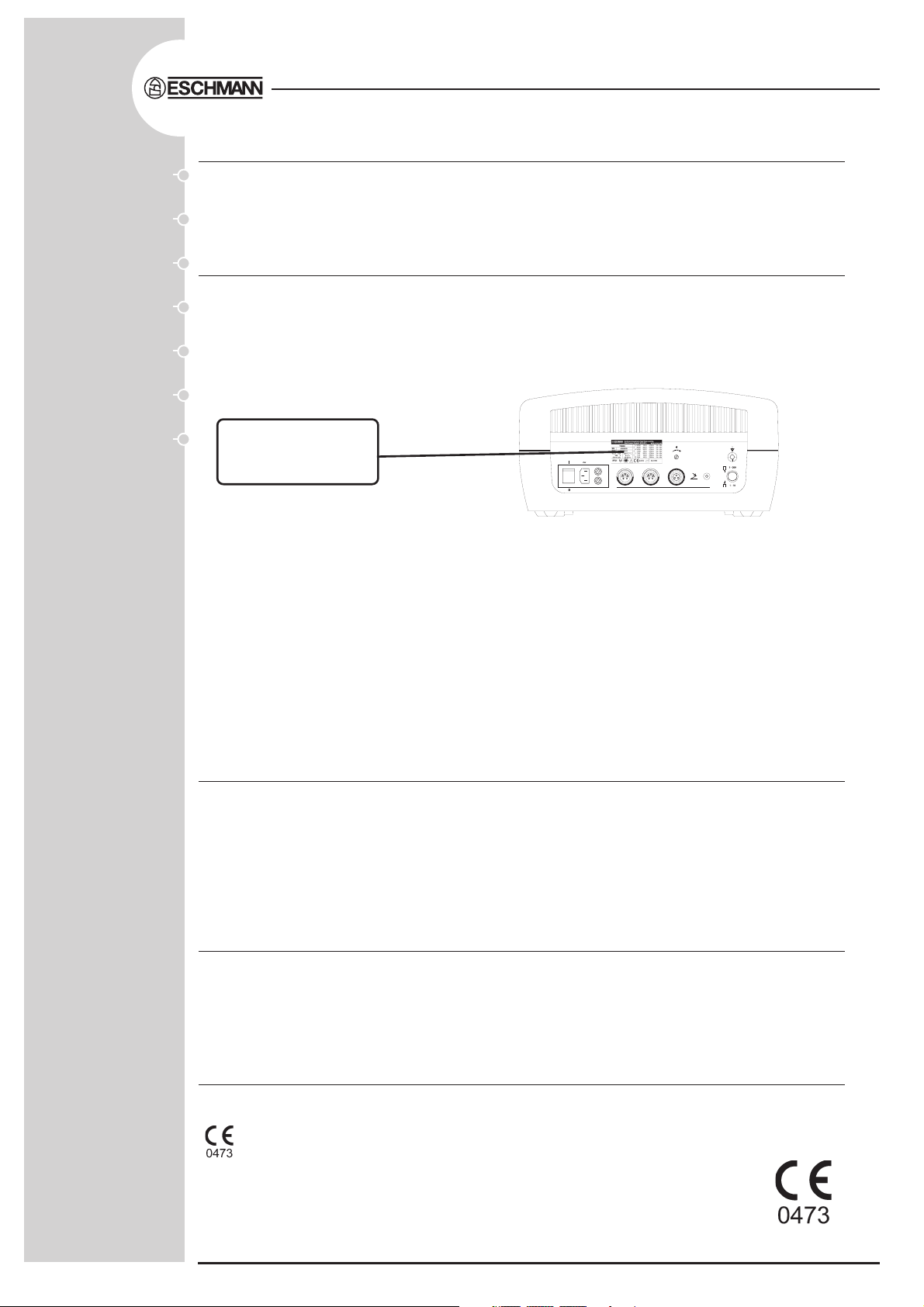

The Serial Number plate

is located here, (view

from rear of unit).

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are trade marks of Eschmann Holdings Limited.

“Eschmann Equipment” is a trading name of Eschmann Holdings Limited.

“TD830” and “Flexoplate” are trade marks of Eschmann Holdings Limited.

Patents : GB2276551, GB2146534, AU673883, ZA94/2173, US5480399,

EP617925, IEE69100 and other Patents Pending.

Copyright © 2008 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

Service Manual

E-SM44h July 2008

Page 3

CONTENTS

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

1.0 PRELIMINARY INFORMATION

Preliminary information . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 TECHNICAL DATA

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Audible indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Visual indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety.. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Duty cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Other symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Button symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Alarm symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environmental conditions . . . . . . . . . . . . . . . . . . . . . . . 8

3.0 SAFETY NOTES & ALARMS

Do’s and Don’ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Alarm circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 INTRODUCTION

General .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating modes / display option.. . . . . . . . . . . . . . . . 11

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Associated Publications . . . . . . . . . . . . . . . . . . . . . . . 11

Equipment certification . . . . . . . . . . . . . . . . . . . . . . . 11

Servicing .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 DESCRIPTION

Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Sub assembly descriptions . . . . . . . . . . . . . . . . . . . . 14

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mains transformer & rectification assy. . . . . . . . . . 15

Main printed circuit board assembly . . . . . . . . . . . 15

Patient interface PCB . . . . . . . . . . . . . . . . . . . 15

Patient interface (plate) PCB . . . . . . . . . . . . . . 16

Tone generator PCB . . . . . . . . . . . . . . . . . . . . 16

PSU PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Bipolar PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Crowbar PCB . . . . . . . . . . . . . . . . . . . . . . . . . 16

PCM DC regulator PCB . . . . . . . . . . . . . . . . . . 17

Monopolar Power Amplifier PCB . . . . . . . . . . . 17

Spray and Monopolar PCB . . . . . . . . . . . . . . . 17

Relay PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Logic and pulse PCB . . . . . . . . . . . . . . . . . . . . 18

Power output graphs . . . . . . . . . . . . . . . . . . . . . . . . . 18

Monopolar cut diagrams . . . . . . . . . . . . . . . . . . . . 19

Monopolar blend diagrams . . . . . . . . . . . . . . . . . . 20

Monopolar specialist cut diagrams . . . . . . . . . . . . 21

Monopolar pinpoint coag diagrams . . . . . . . . . . . . 22

Monopolar spray coag diagrams . . . . . . . . . . . . . . 23

Bipolar macro diagrams . . . . . . . . . . . . . . . . . . . . 24

Bipolar micro diagrams . . . . . . . . . . . . . . . . . . . . . 25

6.0 MAINTENANCE

Routine check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Systems check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning disinfection and care . . . . . . . . . . . . . . . . . . 26

Access for maintenance . . . . . . . . . . . . . . . . . . . . . . 26

Top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Removal and installation . . . . . . . . . . . . . . . . . . . . . . 26

Circuit board removal (except crowbar) . . . . . . . . 26

Crowbar board removal . . . . . . . . . . . . . . . . . . . . 26

Rivet removal/replacement . . . . . . . . . . . . . . . 26

Circuit board replacement . . . . . . . . . . . . . . . . . . . 27

Supply faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuse renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarm remedies . . . . . . . . . . . . . . . . . . . . . . . . 27

Extender board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frequency of calibration . . . . . . . . . . . . . . . . . . . . . . . 28

Performance checks . . . . . . . . . . . . . . . . . . . . . . . . . 28

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Output waveform timings . . . . . . . . . . . . . . . . . 28

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Timing measurements . . . . . . . . . . . . . . . . . . . 28

Monopolar output currents . . . . . . . . . . . . . . . . 29

Specialist cut boost check . . . . . . . . . . . . . . . . . . 29

Monopolar current limit check . . . . . . . . . . . . . . . . 29

Bipolar output current . . . . . . . . . . . . . . . . . . . . . . 29

Active relay function test . . . . . . . . . . . . . . . . . . . . . . 29

Set up overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

System diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.0 ILLUSTRATED PARTS LISTS

Illustrated parts list 1 . . . . . . . . . . . . . . . . . . . . . . . . . 36

Illustrated parts list 2 . . . . . . . . . . . . . . . . . . . . . . . . . 38

Illustrated parts list 3 . . . . . . . . . . . . . . . . . . . . . . . . . 40

Illustrated parts list 4 . . . . . . . . . . . . . . . . . . . . . . . . . 42

ILLUSTRATIONS

Fig. 1 Part identification . . . . . . . . . . . . . . . . . . . . . . . 13

Fig. 2 Using the extender board . . . . . . . . . . . . . . . . 28

Fig. 3 Monopolar mode timing (part 1) . . . . . . . . . . . 31

Fig. 4 Monopolar mode timing (part 2) . . . . . . . . . . . 32

Fig. 5 Biopolar mode timing . . . . . . . . . . . . . . . . . . . . 33

Fig. 6 TD830 System diagram . . . . . . . . . . . . . . . . . . 44

TABLES

Table 1 Mono & Bipolar timings . . . . . . . . . . . . . . . . . 30

Table 2 TD830 set up overview . . . . . . . . . . . . . . . . . 34

E-SM44h P3/44

Page 4

1.0 PRELIMINARY INFORMATION

1.1 This Service Manual should be referred to for details

of the TD830 Electrosurgical Unit, REF 83-256-01,

83-257-02, 83-258-03, 83-259-04, 83-260-05, 83-261-06,

83-262-07, 83-263-08, and 83-264-09 (serial number

A9B0000 or above).

1.2 Within the text of this manual the term ‘coag’ is used

as a common abbreviation of the term ‘coagulation’.

1.3 The TD830 Electrosurgical Unit requires a mains

electrical supply corresponding to the voltage shown on

the electrical rating plate at the rear of the unit. Only use

the mains supply cable supplied. If the plug supplied prefitted is not suitable it should be replaced with a suitable

plug with protective earthing contact.

1.4 If the plug is a fused type, a 10A fuse must be fitted.

CAUTION

It is most important that fuses of the correct

type, size and rating are installed (see Technical

Data).

CAUTION

Read this ‘Service Manual’ carefully and note

ALL of the warnings, cautions and safety notes

contained within. Keep this ‘Service Manual’

close-to-hand at all times for reference.

1.5 Ensure that the unit ‘mains’ switch (42 of Fig. 12) is

in the ‘O’ position and that the output controls are set to

minimum before connecting to, and switching ‘on’, the mains

supply. A complete systems check must be carried out

before using the Electrosurgery Unit (see the ‘Instructions

for use’).

1.6 Instructions for Use and Service Manuals should

be readily accessible for reference prior to and when

operating, cleaning and servicing the TD830 Electrosurgical

Unit. All manuals are available from Eschmann Equipment,

see inside front cover for address details.

Related Technical Publications:-

Instructions for Use - TD830:

Publication number E-IM54, Part No. 698257

Eschmann accessory ‘Instructions for use’:

Publication number E-IM50, Part No.604802

P4/44 E-SM44h

Page 5

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

2. 0 TECHNICAL DATA

GENERAL

The TD830 Electrosurgical Unit (or Surgical Diathermy

Unit) is classified as ‘HF surgical equipment’

1

- ‘HF surgical equipment’ is defined as, “Medical

electrical equipment including its associated accessories

intended for the performance of surgical operations, such as

the ‘cutting’ 2 or ‘coagulation’ 3 of biological tissue by means of

high frequency (h.f.) currents”.

2

- ‘Cutting’ is defined as, “Resection or dissection of body

tissue caused by the passage of high frequency current of high

current density at the active electrode(s)”.

3

- ‘Coagulation’ is defined as, “Sealing of small blood

vessels or of body tissue caused by the passage of high

frequency current at the active electrode(s)”.

Equipment - High power electrosurgical unit with

monopolar and bipolar outputs

Type - Portable

DIMENSIONS

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39.0 cm

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.0 cm

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.5 cm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 kg

1

Output (bipolar)

Peak

Open

Crest Circuit

Symbol/Function Power factor Voltage

Coagulation

Micro range 17W ±20% Variable 150

Macro range 50W

Power and voltage output data diagrams are shown at the

end of section 5.

+10%

-20%

Variable 230

Monopolar

Carrier frequency - 475kHz nominal, square wave.

Power control - Variable amplitude set by frontpanel

controls. Preset pulse patterns set by mode switches.

Load resistance for maximum output power is 150 ohms

(non-inductive) for cut and pinpoint coag and 200 ohms

(non-inductive) for blend, specialist cut and spray coag.

Test load is 200 ohms (non-inductive) for cut and specialist

cut and 400 ohms (non-inductive) for blend, spray coag

and pinpoint coag.

ELECTRICAL DATA

(Note: Voltage factory set by transformer tapping, according

to model supplied.)

Power Supply . . . . . . . . . . . . . . . . . . 230V a.c., 50-60Hz

or, 240V a.c., 50-60Hz

or, 220V a.c., 50-60Hz

or, 110V a.c., 50-60Hz

Current (max.) . . . . . . . . . 4.4A (230V) or, 4.2A (240V)

or, 4.6A (220V) or, 8.4A (110V)

Fuse rating (240V, 230V, 220V) . . . . . . . . . . . 250V, T5A

Fuse rating (110V) . . . . . . . . . . . . . . . 125V(min.),T10A

Fuse type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 mm

Bipolar

Carrier frequency - 785kHz nominal, square wave.

Power control - Variable pulse group modu-lation set

by front panel control. Amplitude set by micro/macro range

buttons.

Load resistance for maximum output power

- 100 ohms (non-inductive) for Macro

- 50 ohms (non-inductive) for Micro

Output (monopolar)

Output powers are measured to an accuracy of ±20%, with

a maximum power of 400 watts.

Peak

Open

Crest Circuit

Symbol/Function Power factor Voltage

Normal cut 345W(-20%) 1.9 1150

Blend 300W(±20%) 3.0 2200

Specialist cut 345W(-20%) 2.1 1500

Pinpoint coag. 170W(±20%) 5.1 2150

Spray coag. 79W(±20%) 8.7 4000

Power and voltage output data diagrams are shown at the

end of section 5.

Test load - 100 ohms (non-inductive)

E-SM44h P5/44

Page 6

AUDIBLE INDICATORS

SAFETY

Running tones *

Monopolar

Cut, blend or specialist cut 950Hz

Coagulation, pinpoint or spray 800Hz

Bipolar

Micro or macro 730Hz

(* Approximate values, adjustable volume)

Touch button

A ‘bleep’ indicates when any function button is pressed,

the volume is adjustable with running tones above.

Alarm

All modes - alternating two tone preset to maximum volume

(with flashing display).

VISUAL INDICATORS

Green lamp in mains ‘on/off’ switch to indicate power ‘on’

from the rear of the electrosurgical unit.

Digital displays and ‘function selected’ LEDs indicate power

‘on’ from the front of the electrosurgical unit

Three digital displays indicate

and bipolar modes. (Note: These can be set to display the

typical power*

to 10).

(

* typical power

delivered over a range of load resistances. It is less

than the power delivered to the rated load for maximum

power.)

available in watts, or a numerical value up

is an indication of the average power

typical power*

in cut, coag

General

Designed to comply with EN60601-1:1990 Medical

electrical equipment - general requirements for safety and

IEC60601-2-2: 1998 High-frequency surgical equipment particular requirements for safety (3rd edition).

General classification, Class 1, Type CF (Defibrillator proof).

Drip-proof (IPX 1)

Patient leakage (risk) current: always less than 100

microamps to earth (ground) from all patient circuits at 230V

50Hz as required by EN60601-1:1990 for the unit in normal

condition (typically less than 10 microamps).

Battery

This equipment contains a nickel metal hydride battery. In

the event of failure of the display p.c.b. battery, or if the

electrosurgical unit is to be disposed of, it is not necessary

to remove the battery or to return it to Eschmann

Equipment. The battery charge life is six months from a

full charge of 48 hours. The battery charges automatically

when the unit is ‘on’.

Electrode isolation

The plate electrode circuit of this equipment is isolated

from earth at both high and low frequency. The bipolar

output is also fully isolated at both high and low frequency.

Class

Class 1 denotes that the equipment must be earthed via

the protective conductor in the 3-core mains cable

connected to a 3-pin plug.

Power output ‘activated’ LED indicators for:

Cutting modes Yellow lamp

Coag modes Blue lamp

Bipolar mode Blue lamp

Green and bright green function selected LED indicators

above (or below) the relevant touch buttons detailed as

follows:

Monopolar:

Cut, blend, specialist cut (green)

Pinpoint coag (green)

Spray coag (bright green)

Bipolar:

Micro and macro power range (green)

Safety category

This symbol denotes that the equipment is of type

CF, i.e. that it complies with type CF leakage current

requirements. The symbol also denotes that the equipment

will not be damaged by defibrillator discharge and that the

plate electrode need not be removed from the patient if a

defibrillator is used.

Non-ionizing radiation

This symbol warns the user of the possibility of non-

ionizing radiation being emitted by this equipment.

P6/44 E-SM44h

Page 7

Flammable gases

The TD830 equipment is not suitable for use in the

presence of a flammable anaesthetic mixture with air

or with Oxygen or Nitrous Oxide.

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

The symbol on the rear panel serial plate warns the

user to read the accompanying documents, the ‘Instructions

for use’.

Protection

IPX 1 This symbol (drip proof) denotes that the

equipment meets the requirements of IEC529 for

dripping water.

DUTY CYCLE

The duty cycle rating of 10 seconds ‘on’, 30 seconds

‘off’, specified on the serial plate as 10s:40s, indicates

that the equipment can be used at full output power in

any mode for 10 seconds with a 30 seconds rest period.

The unit can remain connected to the mains electrical

supply with the mains switch in the ‘on’ position

continuously. The ‘on’ period at lower power levels can

be extended.

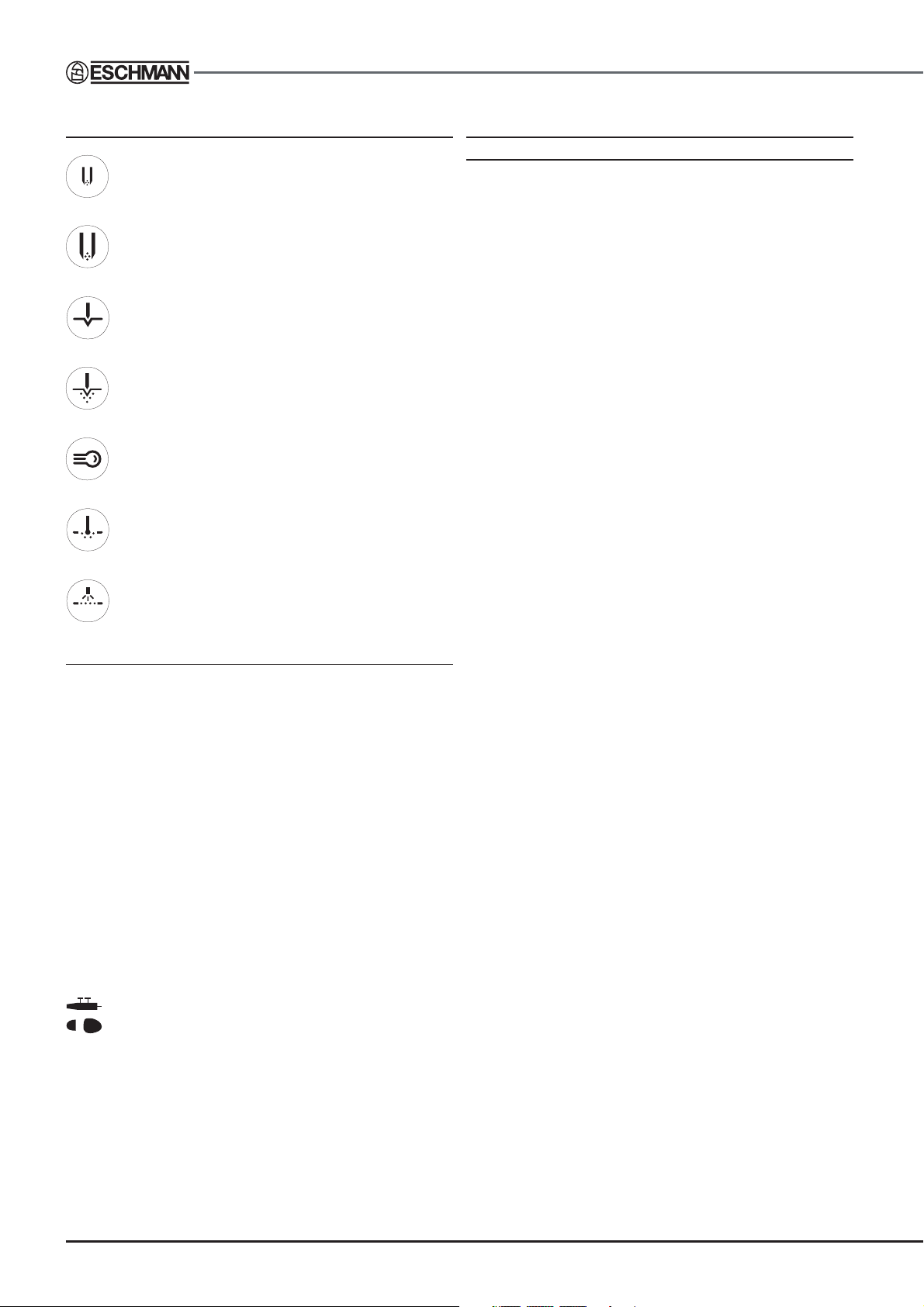

OTHER SYMBOLS

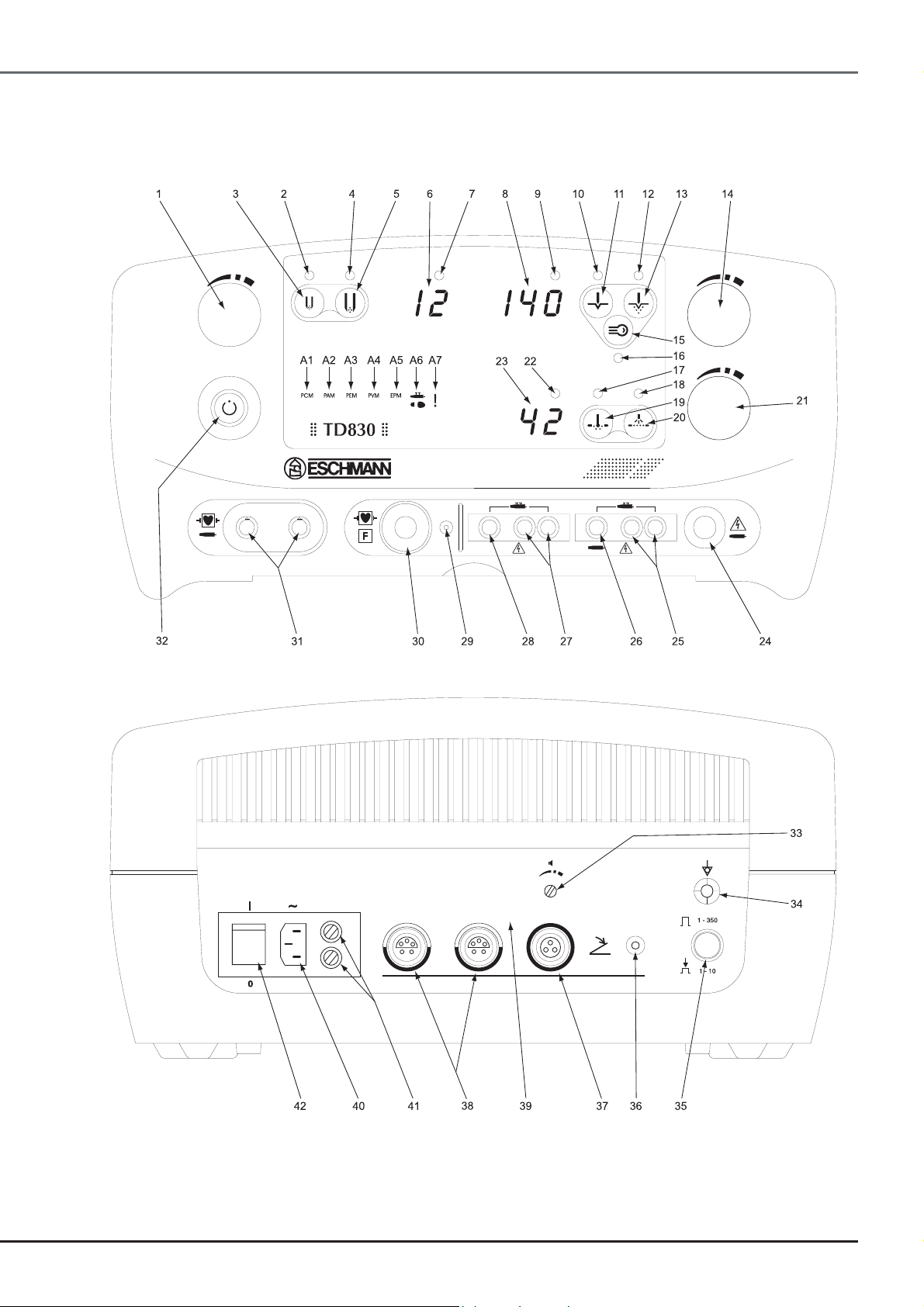

Note: For numbers in brackets refer to Fig. 1.

This symbol above item (33) indicates the running

tone volume control which has a minimum sound level

of 45dBA.

This symbol above items (1, 14, 21 and

33) indicates increasing power output (1, 14 and 21)

and increasing volume (33) for running tone and ‘bleep’

volume.

The symbol above sockets (25, 26, 27 and 28)

denotes connection socket for a two button electrode

handle (fingerswitch type).

The symbol adjacent to sockets (24, 26 and 31)

denotes connection socket for a non-switched active handle

actuated by a footswitch.

This symbol on the monopolar standby selection button

(32) (monopolar ‘on/off’ toggle button) indicates standby

mode for part of the equipment only.

The symbols I and adjacent to the mains ‘on/off’ switch

(42) indicate the ON and OFF positions respectively.

The symbol adjacent to item (34) indicates the

‘equipotentiality’ connection point. (Means for connection

of a potential equalization conductor).

The symbol adjacent to button (35) signifies the button

in the non-pressed (i.e. normal) state. (Digital display on

the front of the electrosurgical unit is a typical power figure,

e.g. 0-200watts for monopolar blend).

This symbol on the rear panel serial plate (39)

and above the mains inlet (40) indicates that the

equipment is for use on alternating current only.

This symbol on the rear panel serial plate

indicates that the mains input fuses, rating and type,

are as shown below the symbol.

The symbol on the front panel denotes that the

plate electrode is isolated from earth at high frequency.

(Note: The plate electrode is also known as the

dispersive, neutral, return, indifferent or patient plate

electrode and is often simply called the ‘pad’).

The symbol on the front panel adjacent to the

active outputs (24 to 28) denotes dangerous voltages.

The symbol adjacent to button (35) signifies the button

in the pressed (i.e. activated) state. (Digital display on the

front of the electrosurgical unit shows a numerical value

up to 10).

The symbol adjacent to sockets (36, 37 and 38)

indicates the connection point for footswitches.

The symbol SN indicates serial number.

The symbol REF indicates catalogue number.

The symbol indicates date of manufacture.

E-SM44h P7/44

Page 8

BUTTON SYMBOLS

ENVIRONMENTAL CONDITIONS

FOR TRANSPORT AND STORAGE

Press to select bipolar - micro range

Press to select bipolar - macro range

Press to select monopolar - cut

Press to select monopolar - blend

Press to select monopolar - specialist cut

Press to select monopolar - pinpoint coag.

Press to select monopolar - spray coag.

Ambient temperature range:

-30°C to +50°C

Relative humidity range:

30-90% RH non-condensing

Atmospheric pressure range:

1060hPa down to 690hPa

ALARM SYMBOLS

PCM - Indicates the ‘Plate continuity monitor’ alarm has

been activated.

PAM - Indicates the ‘Plate attachment monitor’ alarm

has been activated.

PEM - Indicates the ‘Patient earth monitor’ alarm has

been activated.

PVM - Indicates the ‘Plate voltage monitor’ alarm has

been activated.

EPM - Indicates the ‘Excess power monitor’ alarm has

been activated.

- Indicates the ‘Multiple activation’ alarm has been

activated.

! - Indicates an internal fault has been detected (see section

5, Alarm conditions, in the ‘Instructions for Use’, for details).

P8/44 E-SM44h

Page 9

3.0 SAFETY NOTES & ALARMS

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

Attention to the following points is necessary

in order to reduce the risk of accidental burns

during the use of this electrosurgical unit. Other

safety notes and warnings are also given within

the text of this manual and these should be

noted before using this electrosurgical unit.

DO:

♦ Use only Eschmann accessories, in particular active

and plate electrodes and cables which should

preferably be no more than 3 metres in length. All

Eschmann accessories are rated above the

corresponding maximum peak output voltage of this

electrosurgical unit (see graphs in section 5). For

reference Eschmann accessories can be used safely

at the following h.f. peak voltages:

Bipolar active - 400 V peak

Monopolar active - 4000 V peak

Monopolar plate electrode - 2250 V peak

♦ Use bipolar techniques in preference to monopolar,

whenever possible. For surgical procedures on parts

of the body having a relatively small cross-sectional

area, the use of bipolar techniques may be desirable

to avoid unwanted coagulation.

♦ Seek approved qualified advice (e.g. cardiology

department) before using this electrosurgical unit on

patients with implanted pacemakers or other active

implants to avoid interference or damage to the implant.

Monitor such patients carefully.

♦ Set power output controls to the minimum setting

before use and select the minimum power setting to

achieve the desired effect.

♦ Check all cables and accessories routinely before

use. In particular, electrode cables and endoscopically

used accessories for possible damage to the insulation.

♦ Ensure the entire area of the plate electrode is reliably

attached to the patient’s body and as close to the

operating field as possible.

♦ Store temporarily unused active electrodes such that

they are isolated from the patient [e.g. use a quiver

(REF 83-186-38) to hold active accessories when not

in use].

DO NOT:

♦ Do not use uninsulated forceps, monopolar or bipolar.

♦ Do not place monitoring electrodes close to the

operating site. When high frequency surgical

equipment (i.e. electrosurgical equip-ment) and

physiological monitoring equip-ment are used

simultaneously on the same patient, any monitoring

electrodes should be placed as far as possible from

the surgical electrodes. Needle monitoring electrodes

are not recommended. In all cases, monitoring

systems incorporating high frequency current limiting

devices are recommended.

♦ Do not allow active cables to drape across or contact

the patient's body or contact the cables or leads of

other equipment.

♦ Do not use flammable anaesthetics, flammable

solvents or oxidizing gases such as nitrous oxide

(N2O) or oxygen if the surgical procedure is carried

out in the region of the thorax or head, unless these

agents are sucked away.

♦ Do not allow the patient's body to touch conductive

objects. The patient should not come into contact with

metal parts which are earthed or which have an

appreciable capacitance to earth, e.g. operation table,

supports, etc. The use of antistatic sheeting is

recommended for this purpose.

♦ Do not use hook type active cables (with or without

adapters designed for use with hook type cables) use

4 mm or 8 mm plug type active cables.

♦ Do not reuse disposable plate electrodes.

♦ Do not rely solely on surgical gloves to provide

insulation.

♦ Do not allow ‘skin-to-skin’ contact (e.g. between the

arms and body of the patient), this can be avoided, for

example by the insertion of adequate dry gauze.

E-SM44h P9/44

Page 10

Attention to the following points will prolong

the life and efficiency of your

electrosurgical unit and will help to avoid the

risk of accidents, or damage:

DO:

♦ Switch off and disconnect from the mains electrical

supply prior to cleaning the equipment and when it is

not in use.

♦ Grasp the connector(s) not the cable when connecting

and disconnecting cables and leads from the

equipment.

♦ Contact the hospital electronics engineer or Eschmann

After Sales Service Department if the equipment fails

to function after checking.

♦ Ensure the equipment is serviced regularly (at least

every six months). Contact Eschmann After Sales

Service Department for details.

DO NOT:

♦ Use a faulty unit as failure could result in an unintended

increase of output power.

♦ Service this equipment unless you are suitably qualified

to do so.

Alarm Circuits

3.1 The unit has several alarm circuits as detailed in

the following sections.

Plate Continuity Monitor (PCM).

3.2 Ensures that the unit cannot be used in the

monopolar mode with an electrically defective plate

electrode or cable. It does not monitor the contact between

the plate electrode and the patient’s body. It is reset

automatically when a satisfactory plate electrode and cable

are connected to the unit.

Patient Earth Monitor (PEM).

3.5 The PEM circuit detects a low impedance path

between the patient and earth. It also reduces the chances

of secondary contact electrosurgical burns. The circuit

detects earth contact paths while the plate electrode is

attached to the patient and the unit, when a monopolar

fingerswitch or footswitch is pressed, but before the

monopolar output is activated. If such an earth path is

present, the alarm will operate until the path has been

removed and the unit reset by reactivating a pressed

monopolar footswitch or fingerswitch.

Plate Voltage Monitor (PVM).

3.6 Is designed to prevent dangerous electrosurgical

voltages appearing on the patient’s body. Such voltages

could occur because of insulation faults in the active circuit

or because the active electrode is in contact with an earthed

object and could cause burns at points of contact between

the patient and conductive objects. This alarm will operate

when monopolar output power is ‘on’ and the fingerswitch

or footswitch is operated. This monitor will not detect a poor

contact between the plate electrode and the patient. Note:

Under specific electrical conditions, with the plate electrode

completely detached from the patient, the PVM could

alarm.

Multiple Activation Alarm.

3.7 Operates if more than one fingerswitch or footswitch

is pressed at the same time in a given user section (i.e.

monopolar USER 1 or USER 2 or bipolar). It will

automatically be reset when ALL activations have been

released. This alarm will also operate if a footswitch or

fingerswitch is being activated when the unit is switched

‘on’. (Note: This could indicate a damaged accessory locked

in the ‘on’ position).

Internal error alarm

3.8 Operates if an internal fault arises such as power

being detected when not enabled by a footswitch or

fingerswitch.

Plate Attachment Monitor (PAM).

3.3 Ensures that the unit cannot be used in the

monopolar mode if a divided plate electrode is attached to

the patient’s body incorrectly. Applies only when a divided

plate electrode is used and will not operate if monopolar is

switched ‘off’ by the monopolar standby selection button.

Excess Power Monitor (EPM).

3.4 The unit monitors its output power in monopolar and

bipolar modes, compares this with the maximum allowed

power under single fault conditions and alarms, disabling

output, if the delivered power exceeds the allowed value

by more than a certain margin.

P10/44 E-SM44h

Page 11

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

4.0 INTRODUCTION

GENERAL

Note: For numbers in brackets refer to Fig. 1.

4.1 The TD830 electrosurgical unit provides two outputs

both for high power monopolar cut and coag (on a first

come first served basis), together with a separate output

for bipolar coag. Bipolar coag output is available

simultaneously with either monopolar output. The unit

incorporates touch button controls, seven segment LED

(light emitting diode) displays and LED visual indicators.

4.2 The digital displays can show two scale modes, one

shows the

shows a numerical value up to 10 (the latter is only

displayed whilst digital display range selection toggle

button (35) is held pressed).

Note: The power delivered depends on the resistance

between the active electrode and the plate electrode (or

between the tips of bipolar forceps) at the time the power

is applied. This resistance can vary widely and many times

per second during the application of h.f. output.

4.3 The unit incorporates several alarm code indicators

as detailed in the Technical Data section. Innovative safety

features include a divided plate electrode monitoring

system called the Plate Attachment Monitor (PAM) as well

as the standard Eschmann Plate Voltage Monitor (PVM),

Patient Earth Monitor (PEM) , and Plate Continuity Monitor

(PCM). An Excess Power Monitor (EPM) and a Multiple

activation alarm are also included. A high frequency

leakage control circuit is included in the monopolar mode.

4.4 Within this manual the terms USER 1 and USER 2 are

used to distinguish between the two monopolar outputs.

The bipolar output is fully independent of the monopolar

output and can be considered as USER 3.

OPERATING MODES / DISPLAY OPTION

Monopolar mode

4.5 The monopolar operating mode offers a choice of

fingerswitch or footswitch control of ‘cut’ or ‘coagulation’

outputs for USER 1. Fingerswitch operation utilises the

Eschmann two-button fingerswitch whilst footswitch control

requires the use of an active electrode handle in conjunction

with one of a range of electrical footswitches.

Bipolar mode

4.6 Bipolar coag is an efficient method of effecting

haemostasis, and closure of vessels such as Fallopian tubes.

It is extremely safe to use, as the main current path is

between the tips of the bipolar forceps and the tissue held

between them is directly in view of the surgeon at all times.

4.7 A plate electrode is not required and safety is

increased even further as two power range outputs are

available allowing precise setting of the power output.

4.8 The bipolar mode of operation offers a choice of

footswitch, electrical or pneumatic.

typical

power available in watts the second

Monopolar standby mode

4.9 The unit can be switched into monopolar standby mode,

in which only bipolar power is available, using monopolar standby

selection button (32). This button is a toggle switch, each press

of the button will turn monopolar mode ‘on’ (if ‘off ’) or ‘off ’ (if ‘on’).

This button (32) can be considered as an ‘on/off’ switch for

monopolar, the advantage being that if only bipolar outputs are

required and monopolar standby mode is selected, no plate

electrode needs to be connected to the unit. (If monopolar

standby mode is not selected for ‘bipolar use only’ and a patient

plate electrode is not connected to the unit the PAM alarm or

PCM alarm will activate). The unit is in monopolar standby mode

when only the digital display for bipolar can be seen illuminated.

Digital display options

4.10 The digital displays normally show the

available in watts. The digital displays can also show a

numerical value up to 10 (maximum). To display the power

setting as a numerical value up to 10 press and hold the

digital display range selection button (35). The display will

revert to the normal setting (and display the

available in watts) when the button is released.

(

* typical power

delivered over a range of load resistances. It is less than

the power delivered to the rated load for maximum power.)

is an indication of the average power

typical power*

typical power*

ACCESSORIES

4.11 The equipment is designed to be used with the

Eschmann range of active, plate and bipolar cables. The front

panel is colour coded, PALE BLUE for bipolar, YELLOW for

monopolar cut, blend and specialist cut, and BLUE for monopolar

coag. For a list of all accessories see the ‘Instructions for use’.

ASSOCIATED PUBLICATIONS

4.12 This manual contains service and maintenance

instructions for user servicable parts (PCBs are deemed

to be none user serviceable) and an illustrated parts list.

For detailed user instructions refer to the TD830

Instructions for Use, E-IM44 (part number 698257).

EQUIPMENT CERTIFICATION

4.13 The electrosurgical unit fully complies with the major

international safety standards (see Technical Data).

(Note: Tested at 230V).

CAUTION

This electrosurgical unit is to be operated

by medically qualified personnel only.

SERVICING

4.14 It is recommended that electrosurgical safety checks

and routine servicing are carried out at regular intervals

(every six months) and only by Eschmann trained

personnel or Eschmann trained hospital engineers,

otherwise the warranty could be infringed.

4.15 Read the information given in this manual carefully

before using, cleaning, sterilizing, or servicing the

electrosurgical unit.

E-SM44h P11/44

Page 12

1 Power output control, BIPOLAR

2 MICRO BIPOLAR selected, indicator (green LED)

3 Touch button, MICRO BIPOLAR

4 MACRO BIPOLAR selected, indicator (green LED)

5 Touch button, MACRO BIPOLAR

6 BIPOLAR digital power display (green seven segment LEDs)

7 BIPOLAR, power activated indicator (blue LED)

8 MONOPOLAR CUT digital power display (green seven segment LEDs)

9 MONOPOLAR CUT, power activated indicator (yellow LED)

10 MONOPOLAR (normal cut) selected, indicator (green LED)

11 Touch button MONOPOLAR (normal cut)

12 MONOPOLAR (blend) selected, indicator (green LED)

13 Touch button MONOPOLAR (blend)

14 Power output control, MONOPOLAR (cut)

15 Touch button MONOPOLAR (specialist cut)

16 MONOPOLAR (specialist cut) selected, indicator (green LED)

17 MONOPOLAR COAGULATION (pinpoint) selected, indicator (green LED)

18 MONOPOLAR COAGULATION (spray) selected, indicator (bright green LED)

19 Touch button MONOPOLAR COAGULATION (pinpoint)

20 Touch button MONOPOLAR COAGULATION (spray)

21 Power output control MONOPOLAR COAGULATION

22 MONOPOLAR COAGULATION, power activated indicator (blue LED)

23 MONOPOLAR COAGULATION digital power display (green seven segment LEDs)

24 8mm active electrode socket USER 1 only (footswitch activation only) - red

25 Fingerswitch sockets (for use with active electrode socket 26) - black

26 4mm active electrode socket USER 1 (footswitch or fingerswitch activation) - red

27 Fingerswitch sockets (for use with active electrode socket 28) - black

28 4mm active electrode socket USER 2 (fingerswitch activation only ) - red

29 ‘S’ (scope) connector socket (for use with flexible endoscopes)

30 Plate electrode connector socket - black

31 Bipolar output socket - white

32 Monopolar standby selection button (monopolar ‘on/off’ toggle button)

33 Running tone volume control

34 Potential equalization point (see Technical Data section)

35 Digital display range selection button (display in watts if not held pressed)

36 Bipolar pneumatic (white) footswitch socket

37 Bipolar electric (white) footswitch socket

38 Sockets for monopolar footswitches (blue, yellow or combination blue and yellow)

39 Serial number plate

40 Mains cable connection socket

41 Mains fuses (see technical data)

42 Mains power on/off control (with internal green lamp)

A1 - PCM alarm activated LED A5 - EPM alarm activated LED

A2 - PAM alarm activated LED A6 - MULTIPLE ACTIVATION alarm LED

A3 - PEM alarm activated LED A7 - Internal error alarm activated LED

A4 - PVM alarm activated LED

All alarms are accompanied by an audible two tone warning and the activated digital displays will flash (i.e. if in

monopolar standby mode, only the bipolar digital display will flash).

Key to Figure 1

P12/44 E-SM44h

Page 13

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

Figure 1 - Part identification

E-SM44h P13/44

Page 14

5.0 DESCRIPTION

CONSTRUCTION (See Fig. 6)

5.1 The TD830 Electrosurgical unit is made of four

principle electronic sub assemblies as listed below :

♦ Front panel

♦ Rear panel

♦ Mains transformer and rectification assembly

♦ Main printed circuit board assembly

5.2 The front panel includes the display and control

board, operator controls, finger switch inputs and the RF

outputs.

5.3 The rear panel includes the foot switch interface,

mains input switch and lamp, display control switch and

the tone volume control.

5.4 The mains transformer and rectification assembly,

fitted inside on the right hand side (when viewed from the

front) on a metal base plate, provides mains isolation and

voltage conversion, protection and a 180V d.c. rectified

power feed to the RF power section.

5.5 The main printed circuit board assembly, positioned

within the unit on the left hand side (when viewed from the

front) fitted on a metal base plate, controls and supplies all

the RF outputs.

SUB ASSEMBLY DESCRIPTIONS

(see Fig.6)

Front panel

5.6 The front panel assembly comprises a main display

and control board (see 5.7) with its buttons, LEDs and three

7 segment displays (Bipolar, Monopolar Cut and Monopolar

Coag). There are three Potentiometer controls for setting

RF power levels (Bipolar, Monopolar Cut and Monopolar

Coag), a Bovie sensing microswitch and pivot assembly.

The panel also includes the connectors and cabling for

the four RF outputs (Plate, Bipolar, Mono1, Mono 2 and

Bovie). There are two current sense toroids, the larger for

leakage sensing and the smaller for output current sensing.

5.7 The main display and control board performs the

following functions:-

i Uses the front panel control knobs to set the

maximum allowable power for each mode.

ii Allows mode selection (IC4) and display (IC8)

through 8 front panel buttons and associated LEDs

(Bipolar Macro or Micro; Specialist Cut, Normal Cut

or Blend; Pinpoint Coag. or Spray Coag. and

Standby).

iii Provides the controls for all RF outputs through a

64-way ribbon cable (J6).

iv Provides alarm control and logic (IC6) and

illuminates an LED to indicate the type of Alarm.

v Provides three digital 7 segment displays (IC13, IC1,

IC5) for power levels of Bipolar, Cut and Coag.

vi Provides all logic for foot and finger switch controls

(IC12, IC11).

vii Provides Battery back up of the last mode selection

before switching off (BATT1, IC2,IC4).

viii Uses the Bovie sense microswitch to enable the RF

routing to the Bovi RF output for Mono user 1.

ix Provides CMOS (IC9, IC10) and open collector

drives (IC7) for the main printed circuit board

assembly.

x Provides control signals as follows:

SPEC BLEND

CUT SPRAY

CUTMODE COAGMODE

MONENABLE BIPENABLE

BIP_LOW MONORELAY1_SEL

PEM_RELAY MONORELAY2_SEL

MONORELAYBOVI_SEL

xi Provides Tone Generator controls as follows:

BLEEP_TONE CUT_TONE

COAG_TONE BIPOLAR_TONE

ALARM_TONE

xii Receives Foot and Finger switch signals as follows:

FINGERCUT_1 FINGERCOAG_1

FINGERCUT_2 FINGERCOAG_2

FOOTCUT_1 FOOTCOAG_1

FOOTAIR_BIP FOOTELEC_BIP

xiii Receives alarm signals as follows:

PVM PAM

PCM PEM

MONOPWRDET BIP_EXCESS

MONO_EXCESS

ALARM SQUARE (from Tone generator).

5.8 The one set up potentiometer (VR1) is factory set

at manufacture and does not need resetting during the life

of the product.

Rear panel (see Fig. 6)

5.9 The rear panel provides connection to the mains

a.c. supply via an IEC inlet (which includes fuses, switch

and integral green lamp), also fitted to the rear panel are:

i A volume control potentiometer.

ii A range switch.

iii Two Monopolar footswitch circular multi-pin

connectors

iv An electrical Bipolar footswitch connector.

v A pneumatic Bipolar footswitch connector.

vi The Rating and Serial Number plate.

P14/44 E-SM44h

Page 15

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

vii A 15 way interconnect cable (from the footswitches,

range switch, volume control and the Mother board

of the main PCB Assembly).

viii Mains interconnect to the Mains Transformer

Assembly.

ix Safety earth strap for the rear panel.

5.10 The two Monopolar footswitch circular multi-pin

connectors are wired together so that either of two

footswitches can enable RF power.

5.11 The range switch selects either normal power levels

or a 0–10 range when pressed (see the ‘Instructions for

Use’ supplied with the unit).

Mains transformer & rectification assembly

(see Fig.6)

5.12 The mains transformer and rectification assembly

comprises a 50/60Hz mains transformer with several

secondaries providing the following:

i 50 V a.c. (Bipolar low/Micro) and 75V a.c. (Bipolar

high/Macro) for the Bipolar Output.

ii 15 V a.c. (rms) for the +15V output supply from the

PSU board.

iii 15V a.c. (rms) for the -15V output supply from the

PSU board.

iv 5V a.c. (rms) for the +5V output supply from the

PSU board.

5.13 The above a.c. supplies are connected to the

motherboard at SK12 through a 9-way cable and connector

from the Transformer PCB. They are short circuit protected

by thermistors, which recover when an overload is

removed.

5.14 Another secondary provides the feed for a rectifier

whose output from the PCB is through a 2-wire (P1)

connection to a large reservoir capacitor fitted near the

transformer. This provides a 180V d.c. power feed to the

Monopolar outputs which are supplied from the capacitor

to the mother board at SK13. This secondary is protected

by an internal over temperature sensor. Fitted to the

discharge resistor is a capacitor so that energy is drained

away to make the capacitor safe when the mains power is

switched off.

5.15 The mains input voltage is factory selected by links

on the input connector P10.

Main printed circuit board assembly (see Fig. 6)

5.16 The main printed circuit board assembly comprises

a motherboard assembly (Part No 715205) which supports

the other boards that make up the main printed circuit board

assembly. The motherboard provides the inter-board

connections and power feeds to the other boards of this

assembly and is positioned horizontally under them. The

other boards are listed below and are detailed in their own

sections:

♦ Patient Interface (Active) PCB

♦ Patient Interface (Plate) PCB

♦ Tone Generator PCB

♦ PSU PCB

♦ Bipolar PCB

♦ Crowbar PCB

♦ PCM DC regulator PCB

♦ Monopolar Power Amplifier PCB

comprising the:

♦ Spray and Monopolar PCB

which includes the:

♦ Relay PCB

♦ Logic and pulse PCB

5.17 The motherboard receives power from the mains

transformer (SK12), 180V d.c. power (SK13), control from

the front panel (SK2) and the rear panel (SK14) and current

(SK3) and leakage sensor (SK4) feedback. The rear panel

footswitch circuitry has an isolated supply (IC3) and

interface (IC’s 1 and 2) providing 250V AC isolation.

5.18 Capacitors are fitted to the motherboard (C1-2, C47, C10, C13-14, C15 A-I) to protect against RF interference.

Patient Interface (Active) PCB (Part No 715201)

5.19 This board is fitted in the front slot nearest the display

board (SK3 of the Mother board). It receives a single

Monopolar Active RF power feed on PL4-2.

5.20 It also receives control signals (MONORELAY_1,

MONORELAY_2, MONORELAY_BOVI) and returns finger

switch signals (FINGERCOAG_1, FINGERCUT_1,

FINGERCOAG_2 and FINGERCUT_2) to the display

board through the motherboard and the 64-way ribbon

connector.

5.21 The Monopolar RF feed is routed by HV RF relays

to one of three outputs: Mono1 (connector PL1 through

Relay RL3), Mono2 (PL2, RL1) or Bovi (PL3, RL2). This is

done under control from the display board (signal names

MONORELAY_1, MONORELAY_2, MONORELAY_BOVI).

5.22 In addition to the RF power output feed to Monopolar

1 there are two finger switch control lines which allow

activation of Cut or Coag RF power (PL1-2, PL1-1). These

lines are supplied with a sensing drive signal (IC1, TR1,

L1) through a transformer (TX10) and return to two optoisolators (O11, O12). When a fingerswitch is pressed that

line causes current to flow through the opto-isolator and

activate the control signal from the PIA active board to the

display board (signal names FINGERCOAG_1,

FINGERCUT_1).

5.23 The same applies to Monopolar 2 (PL2-3, 4). (Optoisolators O13, O14, signal names FINGERCOAG_2 and

FINGERCUT_2).

5.24 Fingerswitch signals (FINGERCUT/COAG_1,_2)

are returned to the Display board through the motherboard

and the 64-way ribbon connector.

E-SM44h P15/44

Page 16

Patient Interface (Plate) PCB (Part No 715203)

5.25 This board is fitted in the second slot from the front

(SK4 of the Mother board). It receives a single Monopolar

Plate RF power feed on PL2-4. This is then fed into two

plate outputs via HV RF capacitors C1 and C6 (PL2 -2,3).

These go to the front panel Plate RF output along with a

third plate wire (PL2 -1) which becomes shorted to PL2-2

when a plate connector is fitted.

5.26 It also receives a control signal (PEM_RELAY) and

returns alarm signals (PEM, PCM, PAM, PVM) to the

display board through the motherboard and the 64-way

interconnecting ribbon cable.

5.27 When a plate connector is fitted terminals PL2-1 and

PL2-2 are shorted together. This turns on an Oscillator

(TR1, TR2, TX3) which is detected by IC4B and RV5 and

supplies a PCM ‘OK’ signal (low) to the display board.

Conversely if the plate connector is not fitted a PCM alarm

(high) is sent to the Display board. If the plate is not fitted

correctly to the patient PL2-3 is isolated from PL2-2 at the

oscillator frequency. This is sensed (IC4A, RV4) and sends

a PAM (plate attached alarm) to the display board which

gives the alarm.

5.28 The plate voltage is monitored through PL2-1, C10,

C13, R 10-14. This voltage is then sensed (IC3, RV2, D15,

C44) and, if high, sends a PVM (high) signal to the display

board.

5.29 A sample of the impedance between the plate and

earth (at the units mains inlet) is carried out during a 2040msec sample just before supplying any RF output power.

This is achieved using relay RL1, Oscillator IC1F, TR6, L2,

C16 and TX2. If the PEM impedance is below 200W as

sensed by IC2, RV3, D14 and R32 an alarm is sent to the

Display board (signal name PEM). Oscillator TR5, TX4,

C18 provides the means to supply an isolated DC rail on

the secondary of TX4 ,D3, D4.

Tone Generator PCB (Part No 715273)

5.33 The volume of Cut, Coag, and Bipolar tones and

the ‘bleep’ are controllable by the potentiometer on the rear

panel. This is fed through the motherboard to the Tone

Generator.

PSU PCB (Part No 732061)

5.34 This board is fitted in the fourth slot from the front

(SK6 of the Mother board). It receives AC power from the

Mains transformer through SK12 and SK6 on the

motherboard and provides +15V (SK6 A-C2), +5V (SK6

A-C4) and –15V (SK6 A-C6) for all the other boards in the

unit. These rails are fed through the Mother board.

Note: The +15V regulator on this board does get hot.

Bipolar PCB (Part No 715222)

5.35 This board is fitted in the fifth slot from the front (SK7

of the Mother board). It receives AC power from the mains

transformer through SK12 and SK7 on the motherboard

and provides a Bipolar RF output on PL1 which is

connected to the front panel through a 2 wire RF cable.

5.36 It receives control signals (BIP_EN, BIP_LOW) from

the display board through the motherboard and the 64way ribbon cable. It also receives a power level control

(BIPC-, BIPC+) and excess power threshold (BIP_LEVEL)

from the front panel Bipolar control knob.

5.37 The Bipolar control knob is composed of two ganged

potentiometers one of which (BIPC 100KΩ) provides power

control and is routed through the display board 64-way

ribbon cable and motherboard to the bipolar board. The

other (BIP_LEVEL) is buffered on the display board and

fed to the Bipolar through the 64-way ribbon cable and

motherboard.

5.38 The Bipolar board has a Push Pull RF output driver

(IC6, TR7, TR8) which feeds RF power through a

transformer (TR6). The transformer provides isolation and

voltage step up. Control of power is achieved by controlling

the output duty cycle (IC5, IC8).

5.30 This board is fitted in the third slot from the front

(SK5 of the Mother board). It receives control signals

(CUTTONE, COAGTONE, BIPTONE, BLEEP, ALARM)

from and returns ALARM SQUARE to the display board

through the motherboard and 64-way connector.

5.31 The Tone Generator has a speaker (LS1) which

gives the following tones when activated:

♦ 950Hz for Monopolar Cut.

♦ 800Hz for Monopolar Coag

♦ 730Hz for Bipolar

Note: If both Bipolar and Monopolar modes are active it is

the first tone which is retained until it is released.

5.32 When a button is pressed a ‘bleep’ is given and when

an alarm is given a loud two-tone sound is provided. Cut,

Coag and Bipolar Tones are provided by IC1 and fed

through IC2 and speaker driver IC4. Alarm and two tone

control is provided by IC3 and IC6.

5.39 IC10 provides the fundamental oscillator, which also

limits the on time of each FET driver and through IC9, forces

the drive for FET’s TR7 and TR8 to be asynchronous.

5.40 The Transformer primary voltage (IC3C,

VOLTAGE_A/B) is combined with the output current (TR5,

CURRENT+/-) to provide the output power level (IC1, R3,

C10). This is then compared (IC2B) with the front panel

displayed power level (BIP_LEVEL , IC3A,B) and if the

output power exceeds a tolerance from the displayed power

level (VR3,4) an alarm signal (IC7, PL3-24, BIP_EXCESS)

is sent to the display board and the RF power is immediately

removed (IC8B, IC8A).

5.41 Current limit is provided by IC3D, TR2 and set by

VR2.

Crowbar PCB (Part No 732059)

5.42 This board is fitted in SK8 between the Bipolar board

in SK7 and the PCM board in SK9. It is a small board

P16/44 E-SM44h

Page 17

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

secured near the Mother board. It provides over voltage

protection for the Monopolar inverter d.c. power feed.

5.43 In normal operation the 180V d.c. is supplied by the

transformer assembly and reservoir capacitor and fed

through SK13 on the Mother board and on to SK8-1,2 on

the Crowbar at which point it is passed through a safety

fuse (5A FF) and on to the PCM board back through SK84,5.

5.44 If the PCM board fails such that it places too many

volts (140V) into the inverter, the Crowbar circuit detects

this and turns on a high power transistor to load the 180V

power feed to the PCM. This diverts current away from the

failed PCM board until the fuse on the Crowbar board blows

and isolates the 180V source.

5.45 The 5A fuse also protects against FET failures within

the output inverter or any other form of short circuit within

the PCM, which loads the High Voltage power rail.

PCM (Power control Mono) DC regulator PCB

(Part No 715272).

5.46 This board is fitted in the second slot from the back

(SK9 of the motherboard). It provides a regulated d.c.

supply to the Monopolar RF inverter.

5.47 180V d.c. power is provided from the Crowbar

protection circuit through the motherboard.

5.48 Control signals (MON_ENABLE, CUT_MODE,

COAG_MODE, SPRAY, CUT, BLEND, SPEC_CUT) are

received from the display board along with the power level

(0-15V control from the front panel Cut or Coag control

knobs).

5.49 A Mono-power-detect signal is returned to the

display board (D5, R10, R11) through the motherboard

(SK9 A22) and the 64-way ribbon cable. This is a Logic

level, which is high when the output of the regulator is above

5V (i.e. on). If this signal is high when power was not

requested the display board and tone generator give an

internal fault (!) alarm.

5.50 This board uses a step down, pulse width modulated

voltage regulator to provide a variable output voltage of 5–

120V from the 180V supply. Switching FET’s (TR3, TR4)

are driven by IC1 from IC8 and controlled by IC7 to force

the output voltage (A30, C30) to be proportional (R9, R16,

R30) to the dc control level on IC7 pin 2. Output power is

proportional to the square of the output RF voltage and so

it is important to provide a regulated output proportional to

the square root of the front panel setting to have a linear

relationship between control setting and final output power.

5.51 The control level on IC7 pin 2 is derived from the

front panel Coag or Cut control knob. This is sent by the

display board according to whether a Cut or Coag switch

has been activated and passed to the PCM board through

the 64-way ribbon cable connector and motherboard.

according to the mode of operation of the unit (Spray/Blend/

Cut etc.). When using Specialist cut mode an initial power

boost (10%) (R22, IC3, IC6B) is provided for a period of

about 300msec (C17 ,VR1).

5.53 The input current to the PCM board is monitored

(R1A-E) and sensed (TR1) to limit (IC2A, IC3A) the input

current drawn by the PCM card to less than 8Amps in case

of a fault on the regulator or on the subsequent RF inverter.

5.54 An output fuse (5A FF) is also used to protect the

output stage of the PCM card.

Monopolar Power Amplifier PCB

(Part No 715275)

5.56 This assembly is made up of three boards and fitted

into the slot nearest the rear panel (motherboard SK11)

the three boards are:

Spray and Monopolar PCB

Relay PCB

Logic and Pulse PCB

These boards detailed in the following sections are not

available as separate, individual boards.

Spray and Monopolar PCB

5.57 The Spray and Monopolar board is a large board

and carries two other circuit boards, the relay PCB and

the Logic and Pulse PCB. Its function is to take the

regulated 5–120V d.c. supply (PL2) and turn this into a

high frequency high voltage RF source.

5.58 The pulsed RF output for Cut, Blend, Pinpoint and

Specialist Cut is provided by switching (TR14, 16, 18, 19)

the supply, alternately through an RF output transformer

(T1).

5.59 The high voltage low duty cycle Spray output is

provided by releasing (TR4-11) energy, stored in an

inductor (L1) through the output transformer (T1) and

resonating capacitors (C8A-E).

5.60 The regulated d.c. is fed to this board from the PCM

regulator board through the motherboard (SK9, SK10) and

a 2 wire interconnecting cable to PL2.

5.61 The controls are received through SK11 and passed

to the Logic and Pulse board (SK3). Drive waveforms for

the switching FET’s (TR14 etc.) are provided by the Logic

and pulse board, buffered and amplified (IC9, 10, 15, 16

and IC14 for Spray) on the spray and monopolar board.

5.62 The RF Output current is sensed by a toroid (MTG

24-27) and fed back to the logic and pulse board for current

limiting and control (SK6).

Relay PCB

5.63 The Relay board is a small board holding 3 relays

(RLA-C) mounted on the Spray and Monopolar board.

5.52 This control/power level is received by the PCM

board (A12), scaled (R18, R19), buffered and square rooted

(IC4A), and further scaled (R21, R24-R28, IC2, IC3)

5.64 Relay ‘A’ passes the energy pulse from the Spray

circuit to the output transformer in Spray mode only. In all

other modes this relay is off and isolated.

E-SM44h P17/44

Page 18

5.65 Relays ‘B’ and ‘C’ pass the push pull power drive

from the switching FET’s to the output transformer in all

modes accept Spray.

5.66 These relays are special high voltage devices.

Logic and Pulse PCB

5.67 The Logic and pulse board assembly is fitted with

surface mounted components and is mounted on the spray

and monopolar board assembly. This board provides all

the control and interfacing for the Monopolar output. It has

the RF oscillators (IC8, IC9) for Cut modes and Pinpoint

and the RF oscillator (IC11) for Spray.

5.68 It receives control signals (CUT, SPEC, BLEND,

CUTMODE, COAGMODE, MONENABLE) from the

Display board and sends an excess power alarm signal

back to the display (via the Monopolar Power Amplifier

Assembly and Motherboard and 64-way ribbon cable). All

inverter pulse drive waveforms (PL4 -15, 16, 19, 20) for

the Spray and Monopolar board are supplied by this board.

5.69 It receives Voltage feedback (IC24B, TP33) from the

Primary of the Monopolar output transformer and current

feedback (IC 24A, TP25) from the Current Sense coil which

is fitted near the front panel. These two feedbacks are used

to measure the output power of the unit (IC18) which is

compared (IC5B) with the front panel setting (PL4-21,

IC12B, TP19).

POWER OUTPUT GRAPHS

5.75 The power output graphs (shown on the following

pages) have been optimized to provide effective cutting

and coagulation over the wide range of tissue impedances

that may be encountered. The low impedance region of

the profiles, below the normal operating range, is controlled

by a current limiting circuit designed to protect the

equipment and accessories connected to it. All

measurements are made at 20°C (68°F).

5.70 If the output power exceeds the set power level by

an excessive margin an alarm is given (PL4-22, IC12C)

and RF power is removed (IC22A, IC21B, C) by stopping

the RF inverter clocks.

5.71 This board also receives (PL4-10, 11, IC23, IC13B,

IC14A) the leakage current feedback from the Leakage

sensor near the front panel. This leakage current is

compared (IC14D) with a 75mA target level set up by VR20.

If the leakage current exceeds the 75mA threshold, the

output power will be reduced (IC19A, IC16A, IC15B, IC19D,

IC22A) to limit it to 75mA.

5.72 This board also delays the control of leakage current

to allow full power at the beginning of a cut. Leakage control

is disabled when the Monopolar output is loaded by less

than a set point, see table 2.

5.73 The load is measured (VR21, IC24C, IC14C, IC15A,

IC2, IC16B) for Spray Coag by monitoring the decay rate

of the output power after an energy pulse (IC17A). The

load measurement for all other modes is achieved by

comparing (IC14B) the output voltage (TP33) and the

output current (R112, VR22) to see if their ratio is above or

below the set point. If above, then leakage control is in

operation. If not, then leakage control is disabled.

5.74 The Relay board controls are also supplied by the

logic and pulse board (TR1, TR2, PL4, 17-18).

P18/44 E-SM44h

Page 19

MONOPOLAR CUT DIAGRAMS

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

E-SM44h P19/44

Page 20

MONOPOLAR BLEND DIAGRAMS

P20/44 E-SM44h

Page 21

ELECTROSURGICAL UNIT

MONOPOLAR SPECIALIST CUT DIAGRAMS

TD830TD830

TD830

TD830TD830

E-SM44h P21/44

Page 22

MONOPOLAR PINPOINT COAG DIAGRAMS

P22/44 E-SM44h

Page 23

ELECTROSURGICAL UNIT

MONOPOLAR SPRAY COAG DIAGRAMS

TD830TD830

TD830

TD830TD830

E-SM44h P23/44

Page 24

BIPOLAR MACRO DIAGRAMS

P24/44 E-SM44h

Page 25

BIPOLAR MICRO DIAGRAMS

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

E-SM44h P25/44

Page 26

6.0 MAINTENANCE

ROUTINE CHECK

6.1 Routine checking should be limited to external

checks of the unit, and must include all accessories and

cables. Routine checks detailed in the ‘Instructions for use’

(see Section 1, Related Technical Publications’) must be

carried out each time the unit is used.

SYSTEMS CHECK

6.2 The systems check detailed in the ‘Instructions for

use’ should be carried out before the unit is used for the

first time and after every service or maintenance procedure.

In addition the systems check should involve verification

of the performance of the unit relative to the information

under Performance Checks (sections 6.27 through to 6.34).

This should be done at least every six months. Also see

the section ‘Short circuit test’.

CLEANING DISINFECTION AND CARE

6.3 Consult the ‘Instructions for use’ for cleaning

disinfection and care instructions.

ACCESS FOR MAINTENANCE

Front panel

6.6 To release the front panel first remove the top cover

(see 6.5) and then the two screws at the bottom rear edge

of the front panel moulding (see 18 parts list 4) and finally

remove the two screws from inside the unit (see 15 parts

list 4) that hold the front cover to the base moulding. To

finally release the front panel unplug all cables from the

internal electronics noting their locations.

Rear panel

6.7 To remove the rear panel in the easiest manner use

the sequence that follows:-

i Release the two brackets (5, parts list 1) holding

the power amplifier board (1, parts list 4) in place.

ii Release the two leads plugged into the top of the

power amplifier board and carefully remove the

power amplifier board from the unit by releasing it

from its mother board connection.

iii Unplug the lead from the back panel where it plugs

into the transformer socket and release the earth

connection from the back panel to the chassis plate.

iii Release the rear panel connection to the mother

board and then lift the rear panel up and out of its

location in the base moulding.

WARNING

When the equipment cover is removed

potentially dangerous voltages are exposed.

CAUTION

Before removing a board, disconnect plug from

socket P1 on mains transformer board (see

22, parts list 1) and wait for five minutes to allow

mains storage capacitor (12, parts list 1) to

discharge.

CAUTION

This equipment contains ‘static sensitive

devices’, during maintenance appropriate

handling precautions should be followed at all

times.

6.4 Before gaining access inside the unit switch off the

mains supply and remove the mains lead.

Top cover

6.5 To remove the top cover turn the unit over and

remove the two cover retaining screws located in the base

recesses near the two rear feet. Carefully turn the unit back

onto its feet and lift the rear of the top cover up and then

backwards releasing it from the front panel. To replace the

cover reverse this procedure.

To replace the rear panel reverse the above sequence and

check all leads have been connected.

REMOVAL AND INSTALLATION

Circuit board removal (except crowbar)

6.8 To remove any circuit board remove the top cover

as detailed in section 6.5. The large power amplifier board

is removed as detailed in 6.7 parts i and ii, all other boards

(except the crowbar board, see section 6.9) can be

removed from the mother board after removing both PCB

clamps (4, parts list 1) fitted to the top of the PCB card

guides (1, parts list 3).

Crowbar board removal

6.9 The crowbar board, situated between the Power

control (monopolar) board and the Bipolar board, can only

be removed after first removing both of these boards from

the unit. Once access has been made to the crowbar board

the retaining rivet through the bracket and crowbar board

should be removed (not the rivet through the bracket and

the mother board) see the ‘Rivet removal/replacement’

section that follows. Finally remove the crowbar board from

the mother board.

Rivet removal/replacement (crowbar board)

6.10 To remove the rivet pull up the plunger head (see 2

below) taking care not to damage rivet head, pull rivet out

from bracket (see 1 below). To replace the rivet align the

holes in board and bracket (see 1 below), place rivet into

P26/44 E-SM44h

Page 27

TD830TD830

TD830

TD830TD830

ELECTROSURGICAL UNIT

hole so that the shoulder of the rivet shaft is flush with the

outer cover face (see 2 below), press rivet plunger head

until flush with cover surface (see 3 below).

Circuit board replacement

6.11 All boards incorporate anti-confusion plug and

socket connections, otherwise replacing boards is selfevident, but ensure that any disconnected cables are

correctly connected. When replacing the crowbar board

ensure the rivet is replaced as detailed in section 6.10.

Ensure all PCB clips and clamps are replaced after

installation

SUPPLY FAULTS

6.12 When the unit is switched ‘on’, the green ‘mains’ pilot

lamp in the switch should come ‘on’. If no pilot lamps come

‘on’ check the mains fuses on the rear panel (Fig. 1 item

41). If fuses are satisfactory, check fuse in mains supply

plug and if this is satisfactory, check that electrical supply

is available.

Fuse Renewal (Fig. 1 item 41)

6.13 To fit a new fuse:

iEnsure unit is disconnected from mains electrical supply.

ii Remove fuse retainer and fuse.

iii Fit new fuse of correct type and rating (see unit back

panel).

If the fuse repeatedly fails, either when the unit is switched

‘on’ or during use, call Eschmann Equipment After Sales

Service Department (see inside front cover) or the hospital

engineer.

Alarm remedies

6.16 If the PCM circuit has been activated:

(i) Check plate electrode is connected to unit.

(ii) Check plate electrode and cable for condition, if

faulty, substitute new plate electrode and/or cable.

This procedure should normally be carried out before

plate electrode is attached to patient.

6.17 If the PAM circuit has been activated:

(i) If a divided plate cable and divided plate electrode

are being used check that the divided plate electrode

is making good contact with the patient’s body.

(ii) Check plate electrode and cable for condition, if

faulty, substitute new plate electrode and/or cable.

This procedure should normally be carried out before

plate electrode is attached to patient.

6.18 If the PEM circuit has been activated:

(i) Check for accidental direct contact between patient

and an earthed object, (drip stand or conductive part

of operation table).

(ii) If applicable disconnect suspect ECG electrodes.

Note: An activated PEM alarm will be reset by

removing the earth path and reactivating a monopolar

footswitch or fingerswitch.

6.19 If the circuit has been activated:

(i) The alarm will operate if the bipolar pneumatic

footswitch and the bipolar electrical footswitch are

pressed simultaneously. The alarm will also sound

if both the cut and coag footswitches, or if one of the

two footswitches and a fingerswitch button are

pressed simultaneously for USER 1, or if both

fingerswitch buttons are pressed for USER 1 or

USER 2. The circuit will automatically reset when

ALL activations stop from ALL switches. This is an

important safety feature and applies to any

combination of footswitch and fingerswitch.

FAULT FINDING

6.14 If the equipment malfunctions, first check

accessories and cables by substitution before doing further

checks.

6.20 If the EPM circuit has been activated:

(i) Because the EPM alarm cannot be reset by the

User, if unit EPM alarm activates as soon as output

is activated, Eschmann Equipment should be

contacted.

Alarms

6.15 All alarm conditions are indicated by an audible twotone alarm and an error indication on the front panel. The

alarm symbols are detailed in the Technical data section

with additional information in the ‘Safety notes and alarms’

section of the ‘Instructions for use’. The ‘Instructions for

use’ also provide details of alarm conditions, identification

and remedies but for ease of reference the remedies are

repeated below:

6.21 If the PVM circuit has been activated:

(i) If unit PVM alarm activates check for accidental

direct contact between the active electrode and an

earthed object.

(ii) Check that the plate electrode is correctly attached

to the patient’s body.

Note: An activated PVM alarm will automatically be reset

by releasing a depressed footswitch or fingerswitch.

If none of the above remedies stop the alarm activated, or

the (!) alarm is activated contact Eschmann Equipment

and do not use the unit.

E-SM44h P27/44

Page 28

EXTENDER BOARD (Fig. 2)

PERFORMANCE CHECKS

WARNING

When the extender board is used in the

monopolar power control position, high

voltages are exposed and extreme care must

be taken.

6.22 To facilitate testing and servicing of boards on the

mother board, Eschmann have produced a special-to-type

extender board (Part No. 711367). The board has separate

pins located below the 96-way socket, allowing easy

connection of measuring equipment.

Fig. 2 Using the extender board

General

6.26 Unless otherwise stated, errors found in the output

waveforms and the current readings measured will indicate

a fault in the unit and will probably need the attendance of

a service engineer.

Output Waveform Timings

6.27 The following equipment will be needed:

♦ Oscilloscope with timebase resolution to at least 10

nanoseconds.

♦ Current probe or inductive pick-up loop attached to

the oscilloscope.

♦ Eschmann ETS3 test set.

Note: The Eschmann ETS3 test set should be used for

routine power output checking. When set for monopolar

power output, the test load is 200 or 400 ohms and the

power output can be read directly from the outer scale of

the appropriate meter. This value can be compared with

the value derived from the relevant monopolar power graph

and should be within the limits required by EN60601-1:1990

and IEC60601-2-2:1998. For bipolar power measurement

the test load is 100 ohms.

Instructions for use, and connections are given in the test

set lid.

6.23 Three LEDs on the board indicate healthy logic

supply rails. The left hand LED indicates

-15Vd.c. and just comes ‘on’ at -14Vd.c. The centre LED

indicates +15Vd.c. and just comes ‘on’ at +14Vd.c., while

the right hand LED indicates +5Vd.c., and just comes ‘on’

at +4Vd.c.

6.24 When it is necessary to test a board, disconnect

plug from socket P1 on mains transformer board (see 22,

parts list 1) and wait for five minutes to allow capacitor (12,

parts list 1) to discharge. Disconnect/remove the board

from the mother board and replace it with the extender

board. Plug the removed board into the top of the extender

board as shown in Fig. 2. Where applicable, any

disconnected cables should be reconnected to the board

being serviced.

Note: If testing PCM pcb (item 2, parts list 4), the plug

must be reconnected to socket P1 on the mains transformer

board. (Running tones and lamps will not be enabled with

P1 disconnected).

FREQUENCY OF CALIBRATION

6.25 Calibration need only involve verification of the

performance of the unit relative to the information under

Performance Checks (sections 6.25 through 6.33). This

should be carried out at least every six months.

Do not use test sets ETS1 or ETS2 as they are not designed

for use on the TD830 Electrosurgical unit.