T20

OPERATION TABLES

Series

Instructions for use

113158

T-IM114b

Read these Instructions before use

Keep these ‘Instructions for use’ in a safe convenient place for future reference.

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquiries, please quote the

Model and Serial Number of your Operation Table which is shown on the Serial Number Plate

located on the table base (or the trunk section for the T20-m). Please ensure you include all

alpha and numeric digits of the Serial Number.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are trade marks of Eschmann Holdings Limited.

“T20-a”, “T20-m” and “T20-s” are trade marks of Eschmann Holdings Limited.

“Eschmann Equipment” is a trading name of Eschmann Holdings Limited.

Patents : Worldwide Patents Pending.

Copyright © 2006 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

Instructions for use

T-IM114b April 2006

T20

Series

OPERATION TABLE

The T20 Series of operation table

T20-a

The T20-a table is a

powered operating

table suitable for a full range of general and specialist surgical

procedures. This operating table has an X-ray translucent traversing

tabletop with a built-in X-ray cassette tunnel and is capable of

supporting a maximum patient weight of 300kg (mobile 135kg). The

slimline column is offset relative to top and base for ease of C-arm

access. The T20-a table features a corded handset

controlling Trendelenburg, reverse Trendelenburg,

lateral tilt, flexion/extension (including 90º chair

position) traverse and height. The handset also

provides a battery level indication. Ergonomically

designed foot pedals are located at the head and leg end of the table base to provide braked, castor and 360°

mobility. The batteries in the table base are mains rechargeable with a standby battery in case of emergency.

Covers to the top and base are purple and made of a special scratch resistant, hard-wearing and easy to clean

seamless acrylic capped ABS. The mattress is moulded and antistatic with no seams.

T20-s

The T20-s table is a

powered operating

table suitable for a full range of general surgical procedures. This operating

table has an X-ray translucent traversing tabletop with a built-in X-ray

cassette tunnel and is capable of supporting a maximum patient weight of

300kg (mobile 135kg). The slimline column is offset relative to top and base

for ease of C-arm access. The T20-s table features a

corded handset controlling Trendelenburg, reverse

Trendelenburg, lateral tilt, flexion/extension (including

90° chair position) traverse and height. The handset

also provides a battery level indication. Ergonomically

designed foot pedals are located at the head and leg end

of the table to accommodate different operating theatre layouts providing braked, castor and 360° mobility. The

batteries in the table base are mains rechargeable with a standby battery in case of emergency. Covers to the top

and base are ocean blue and made of a special scratch resistant, hard-wearing and easy to clean seamless

acrylic capped ABS. The mattress is moulded and antistatic with no seams.

T20-m

The T20-m table is a

powered operating table

(maximum patient weight of 300kg or 200kg mobile) featuring all the

functions of the T20-a table with a mobile base that is supported by

four 125mm castors to enhance manoeuvrability and usability of the

operating table. The T20-m table is suitable for theatre environments

that require the functionality of a trolley system whilst maintaining the

performance of a table for a full range of surgical

procedures. The ergonomically designed single foot

pedal is located at the head end of the table and

has three positions to enable the table to be static

(braked), rotated 360° or moved in a straight line.

Covers to the top and base are purple and made of

a special scratch resistant, hard wearing and easy to clean seamless

acrylic capped ABS. The mattress is moulded and antistatic with no seams.

T-IM114b P3/62

CONTENTS

1.0 PRELIMINARY INFORMATION ..............6

1.1 General 6

1.2 About this manual.......................................... 6

1.3 Table description ........................................... 7

2.0 TABLE PARTS AND SYMBOLS ............. 8

2.1 Part identification ........................................... 8

2.2 Symbols and graphics ................................... 8

2.2.1 Symbols general ...................................... 8

2.2.2 Handset button symbols ........................... 9

2.2.3 Handset graphics ..................................... 9

2.2.4 Standby control panel button symbols ...... 9

3.0 INSTALLATION ...................................13

3.1 General ..................................................... 13

3.2 Lifting the operation table ............................ 14

3.3 Technical ..................................................... 14

4.0 SAFETY NOTES & CAUTIONS ............ 15

4.1 Warnings ..................................................... 15

4.2 Do’s and Don’ts ........................................... 16

4.3 Daily ‘Before use’ test.................................. 16

4.4 Accessories................................................. 16

4.5 Manual handling .......................................... 17

5.0 OPERATING THE TABLE ................... 18

5.1 Operating the table base ............................. 18

5.1.1 T20-a and T20-s base ............................ 18

5.1.1.1 ‘Wheel’ orientation (from ‘braked’) 18

5.1.1.2 ‘Castor’ orientation (from ‘wheel’) . 18

5.1.1.3 ‘Castor’ orientation (from ‘braked’) 19

5.1.1.4 ‘Braked’ orientation ...................... 19

5.1.2 T20-m table base .................................. 20

5.1.2.1 Foot pedal operation .................... 20

5.1.2.2 ‘Braked’ ........................................ 20

5.1.2.3 ‘Castor’ mode ............................... 20

5.1.2.4 ‘Wheel’ mode ............................... 22

5.1.3 Moving table with a patient ..................... 22

5.2 Using the removable sections. .................... 23

5.2.1 Re-aligning a section’s pins .................... 23

5.2.2 Attaching a removable section ............... 23

5.2.3 Removing a tabletop section .................. 24

5.2.4 Removable section adjustment .............. 24

5.2.5 Changing sections during a procedure ... 25

5.2.6 Attaching/Removing mattresses ............. 25

5.3 Powered and electrical functions. ................ 25

5.3.1 Batteries and mains................................ 25

5.3.1.1 Battery charging introduction........ 25

5.3.1.2 Battery charging ........................... 26

5.3.1.3 Battery changing .......................... 26

5.3.1.4 Standby batteries ......................... 26

5.3.2 Powered motions ................................... 27

5.3.2.1 General ........................................ 27

5.3.2.2 Tabletop motions.......................... 28

5.3.3 Using the handset .................................. 28

5.3.3.1 General ........................................ 28

5.3.3.2 Handset button functions.............. 29

5.3.4 Using the standby control panel ............. 31

5.3.5 Fuse replacement .................................. 31

6.0 PATIENT POSITIONING .....................32

6.1 General ..................................................... 32

6.2 Treatment of the obese patient .................... 32

6.3 Radiographic procedures ............................ 32

6.4 Table positions and safe loading ................. 32

7.0 ACCESSORIES ................................... 42

8.0 AFTER USE, CLEANING & CARE ...... 44

8.1 After use procedures ................................... 44

8.2 Cleaning ..................................................... 44

8.2.1 Operation table and accessories ............ 44

8.2.2 Mattresses and pads .............................. 44

8.3 Disinfection .................................................. 45

8.3.1 Disinfection procedure............................ 45

8.3.2 Table, accessories mattresses and pads 45

8.4 Care ..................................................... 45

8.5 Storing the operation table (long term) ........ 46

8.6 Maintenance ................................................ 46

8.6.1 General .................................................. 46

8.6.2 Fault diagnosis ....................................... 46

8.6.3 Environmental considerations ................ 46

8.6.4 Technical Lifetime .................................. 46

9.0 TECHNICAL DATA .............................. 50

9.1 Weights ..................................................... 50

9.2 Dimensions ................................................. 50

9.3 Movements.................................................. 50

9.4 Table loading ............................................... 50

9.5 Electrical ..................................................... 50

9.5.1 Antistatic requirements ........................... 50

9.5.2 Batteries ................................................. 50

9.5.3 Internal battery charger .......................... 50

9.5.4 Fuses ..................................................... 52

9.5.5 Duty cycle .............................................. 52

9.6 Classification and symbology ...................... 52

9.7 Use with other equipment ............................ 52

9.7.1 Electrosurgical equipment (h.f.) .............. 52

9.7.2 Defibrillation equipment .......................... 52

9.7.3 RF communications equipment .............. 52

9.8 Standards compliance ................................. 52

9.9 Environmental conditions ............................ 52

9.9.1 Operating environment ........................... 52

9.9.2 Transport & storage environment ........... 52

9.10 Alarms ..................................................... 52

9.10.1 Visual ................................................ 52

9.10.2 Audible .............................................. 53

9.11 Electromagnetic compatibility (EMC) ........... 53

9.11.1 Interference considerations ............... 53

9.11.2 Interference from other equipment .... 53

9.11.3 Interference with other equipment ..... 53

9.11.4 RF communications equipment ......... 53

9.11.5 Accessories....................................... 53

9.11.6 Installation ......................................... 53

9.11.7 EMC tables ....................................... 53

P4/62 T-IM114b

T20

Series

OPERATION TABLE

FIGURES AND APPENDICES

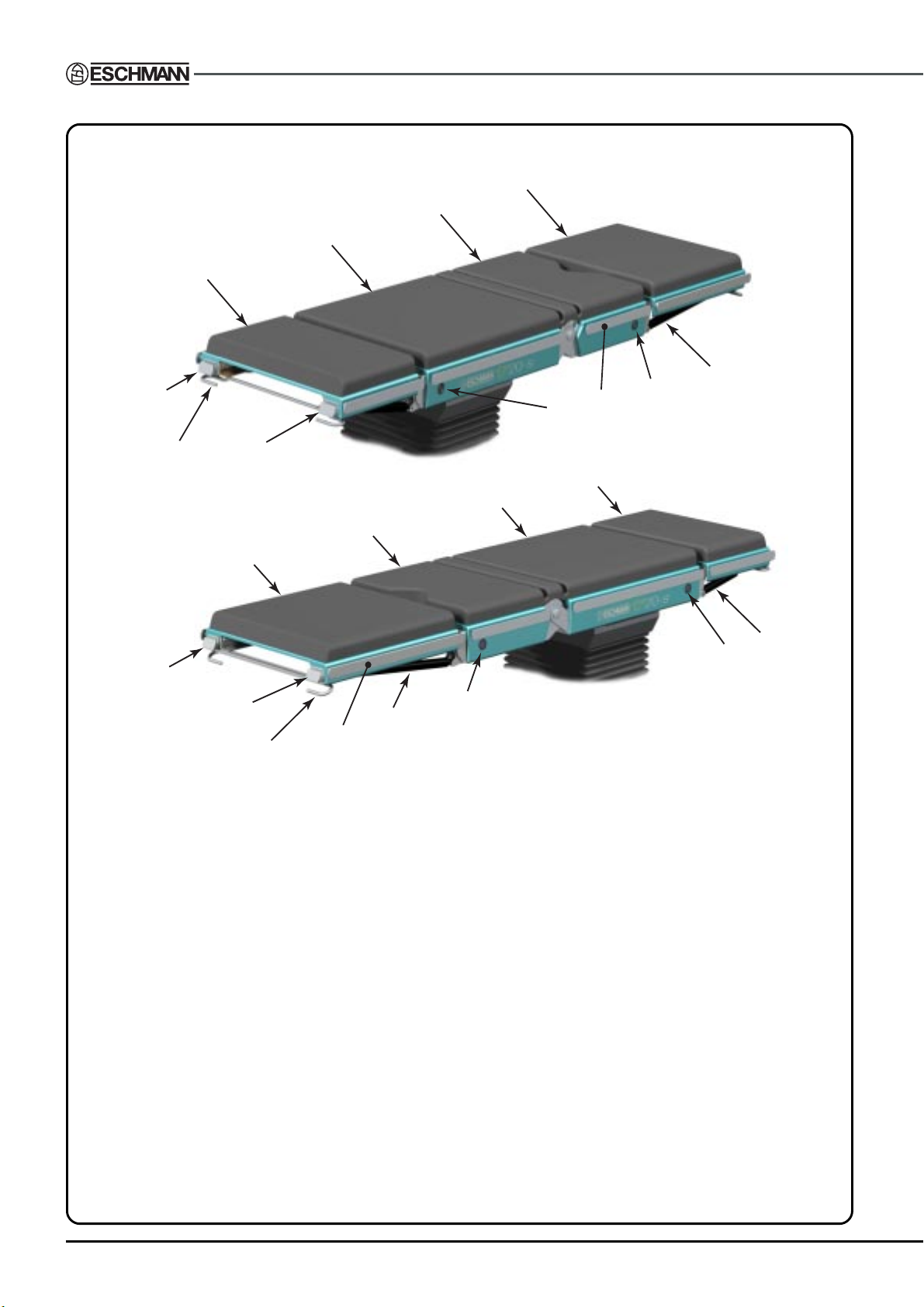

Fig. 2.1 Identification of the main parts of the T20 Series table top. ................................................... 10

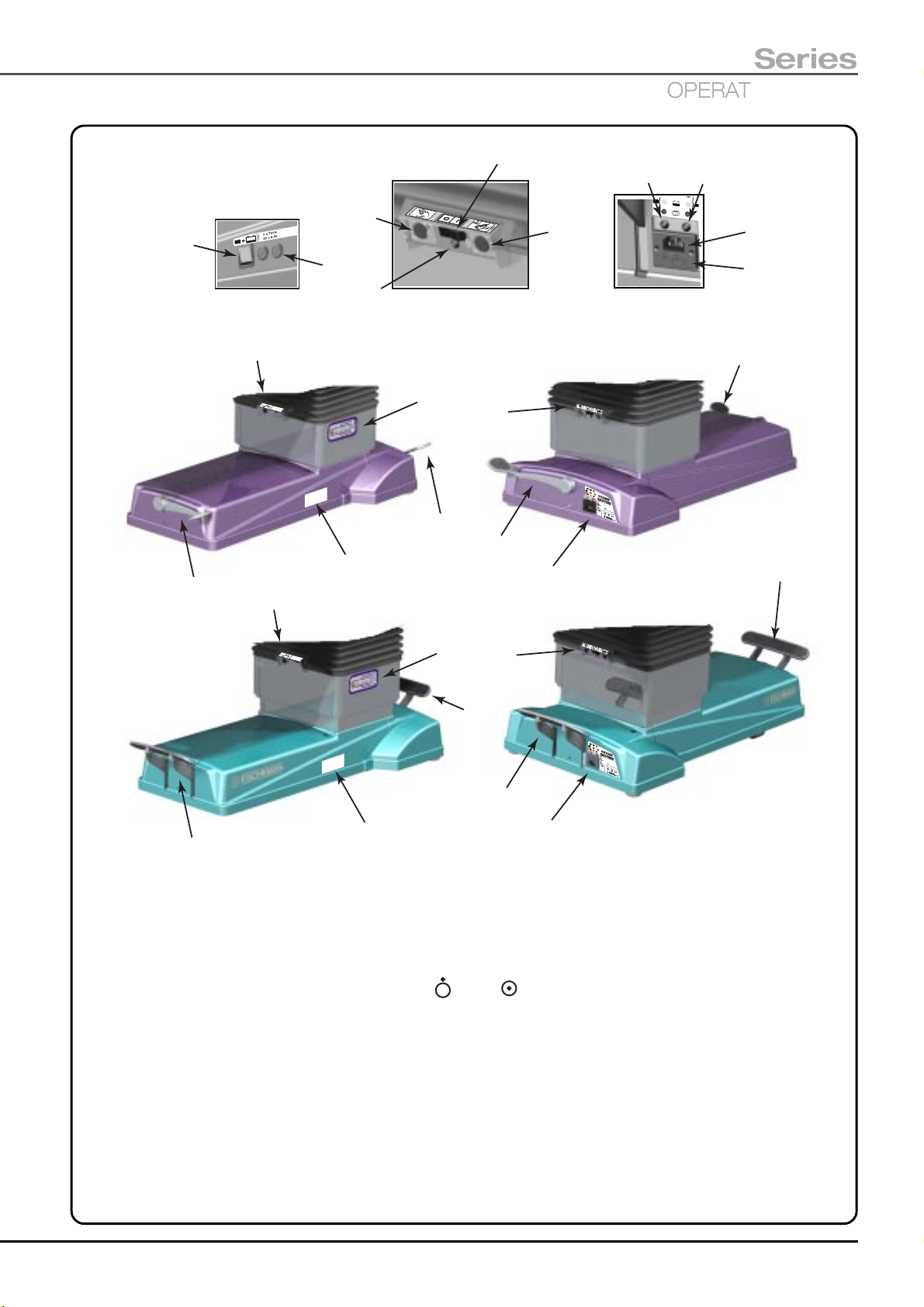

Fig. 2.2 Identification of the main parts of the T20-a and T20-s table base and column. ...................11

Fig. 2.3 Identification of the main parts of the T20-m table base and column. ...................................12

Fig. 3.1 Lifting the T20 Series operation table ....................................................................................12

Fig. 5.1a Lowering a T20-a foot pedal ..................................................................................................19

Fig. 5.1b Lowering a T20-s foot pedal ..................................................................................................19

Fig. 5.2a Raising a T20-a foot pedal.....................................................................................................19

Fig. 5.2b Raising a T20-s foot pedal .....................................................................................................19

Fig. 5.3 T20-a and T20-s foot pedal quick reference guide ................................................................20

Fig. 5.4 Operating the T20-m base.....................................................................................................21

Fig. 5.5 Alternative table position for moving table with a patient .......................................................22

Fig. 5.6 Section pin alignment ............................................................................................................23

Fig. 5.7 Aligning section pre-attachment ............................................................................................23

Fig. 5.8 Removing a table section ......................................................................................................24

Fig. 5.9 Adjusting a head or leg section..............................................................................................24

Fig. 5.10 Handset and charging indicators ...........................................................................................26

Fig. 5.11 Controller sockets and release buttons .................................................................................28

Fig. 5.12 Handset button functions and serial labels ............................................................................30

Fig. 5.13 Standby control panel ............................................................................................................31

Fig. 6.1 Approximate patient weight distributions ............................................................................... 32

Fig. 6.2 Patient positioning for radiographic procedures ....................................................................33

Fig. 6.3 Maximum patient weight v table position graphs

(head and leg section in normal positions). ...........................................................................34

Fig. 6.4 Maximum patient weight v table position graphs

(head and leg section reversed). ...........................................................................................35

Fig. 6.5 Patient in various ‘Supine’ positions ......................................................................................36

Fig. 6.6 Patient in various ‘Prone’ positions ........................................................................................ 37

Fig. 6.7 Patient in various ‘Lawn chair’ & ‘Trendelenburg’ positions...................................................38

Fig. 6.8 Patient in various ‘Chair’ positions ......................................................................................... 39

Fig. 6.9 Patient in various ‘Proctology’ positions ................................................................................40

Fig. 6.10 Patient in ‘Lithotomy’, ‘Prone Laminectomy’ and ‘Lateral Nephrectomy’ ...............................41

Fig. 9.1 Major dimensions and movements ........................................................................................51

APPENDIX 1 .......................................................................................................................................... 58

APPENDIX 2 .......................................................................................................................................... 59

APPENDIX 3 .......................................................................................................................................... 60

APPENDIX 4 .......................................................................................................................................... 61

T-IM114b P5/62

1.0 PRELIMINARY INFORMATION

1.1.5 Ensure the table has been correctly installed

before starting to use it, see section 3.0.

WARNING

Read this preliminary information carefully and

note ALL of the warnings, cautions and safety

notes contained within these ‘Instructions for

use’ before using this Operation Table. Keep

these ‘Instructions for use’ close-to-hand at all

times for reference.

1.1 General

1.1.1 T20 Series operation tables are classified as

battery powered, mobile, general purpose, four section

operation tables. Their intended function is to support and

position a patient, in conjunction with their associated

accessories, during general surgical operations and

procedures in an operating theatre. Their intended

application is for use by medically qualified personnel,

trained in the use of the T20 Series powered operating

tables, during surgical operations and procedures in

accordance with these instructions.

1.1.2 These ‘Instructions for Use’ should be referred to

for details of the following T20 Series Powered Operation

Tables, see the table’s Serial Number Plate for the actual

table Serial Number and REF No.:

T20-a Catalogue (REF) number prefixed T20

Serial Numbers (SN) prefixed T2AC*...... or above.

T20-s Catalogue (REF) number prefixed T20

Serial Numbers (SN) prefixed T2SB*...... or above.

T20-m Catalogue (REF) number prefixed T2M

Serial Numbers (SN) prefixed T2MA*...... or above.

* The last digit of the SN prefix is the design modification

state, this may increase during the build life of the tables.

NOTE: Some models have ‘Denyer’, ‘USA’, or ‘Euro (Kifa)’

accessory side rails, standard Eschmann accessories

that locate onto these may not fit, please check with

Eschmann Equipment before purchasing accessories.

1.1.3 The T20 Series operation tables and accessories

must only be used as detailed within these ‘Instructions

for use’. Failure to do so could result in injury to patients or

users, or damage to the operation table and accessories.

Always ensure that all warnings and cautions detailed

within these ‘Instructions for use’, are strictly complied with.

Appendix 1 is provided for Hospitals that wish to keep a

log of those people trained in the safe use of this table.

Eschmann Equipment offers full training in the safe use of

these tables, please contact our After Sales Service

Department for details.

1.1.4 ‘Instructions for use’ and ‘Service manuals’ (see

section 3.3.9) as applicable should be readily accessible

for reference prior to and when operating, cleaning and

servicing the operation table. All manuals are available from

Eschmann Equipment, see inside front cover for address.

1.1.6 All servicing and maintenance procedures should

be carried out by engineers who have been trained by

Eschmann. Training, a Service, or a Service Contract can

be arranged through our After Sales Service Department

(see inside front cover for contact details). Do not remove

the table covers at any time (danger of accessible mains

voltage), this should only be carried out during maintenance

procedures. Ensure that the operation table is regularly

serviced and checked for safety at least every six months.

1.2 About this manual

1.2.1 Within the text of these ‘Instructions for use’ the

following terminology is used:

i)

Left and right

the side of the table when viewed from the long trunk

end (i.e. the head end with the table in its normal

configuration, head section fitted to the long trunk

as shown in Fig. 2.1). This is also the patient’s ‘left’

and ‘right’ when lying on the tabletop in a supine

position, with their head on the head section and

with the table in its normal configuration.

ii)

Auto-level

the automatic sequence of movements to return the

table to a preprogrammed position by pressing and

holding a single handset button. This does not affect

the head or leg sections, or any other manually

operated, or powered accessory, fitted to the table.

iii)

LEDs.

This abbreviation is used when referring to

the various indicator lights on the table or handset

which are light emitting diodes (LEDs).

iv)

Cranially and Caudally.

section moves away from column) and ‘caudally’ (leg

section moves away from column) are used to

describe tabletop movement (table in the normal

orientation). Normal table orientation is with the head

section in the long trunk, normal patient orientation is

with the patient’s head on the head section.

1.2.2 These ‘Instructions for use’ have been split into

specific sections for ease of finding information (see the

main headings in ‘Contents’). Where applicable and within

each section, adequate cross references to other sections

are made to eliminate the need to duplicate information.

1.2.3 Section 5 (Operation) details how to use the T20

Series of tables and operate their controls correctly. It is

strongly recommended that the user has read and is

familiar with sections 1, 2 and 4 before passing onto

section 5 and starting to use this operation table.

1.2.4 Within this manual the sections in bold type

headed ‘WARNING’ give guidance on possible actions that

could lead to injury of the patient, or theatre staff, and

potential damage to the operation table. Sections headed

‘CAUTION’ give guidance on possible actions that could

lead to damage of this operation table which could then

lead to injury of the patient, or theatre staff.

. The terms ‘left’ and ‘right’ refer to

. The term ‘auto-level’ is used to describe

The term ‘cranially’ (head

P6/62 T-IM114b

T20

Series

OPERATION TABLE

1.3 Table description

1.3.1 The T20 Series of four section operation tables

have been designed to provide facilities for General

Surgery, including Minimal Access procedures, Urology

and Gynaecology, Thoracic, Ophthalmic and ENT,

Neurosurgery, Plastic and Maxillo-Facial surgery, and nontraction Orthopaedic Surgery, they allow for intra-operative

radiography using a C-arm image intensifier. They are not

suitable for Orthopaedic procedures requiring traction.

1.3.2 Careful design has minimised traps for potential

contamination stopping fluid entering the table during

normal use, cleaning and disinfection procedures. They

are stable, rigid in use and the robust construction provides

protection from patient trolley or C-arm knocks whilst still

providing easy access for servicing.

1.3.3 Tabletop movements (i.e. Trendelenburg, height,

tilt, break and traverse) are electrically powered and

incorporate ‘soft start and stop’ motions for patient comfort

and safety. The pedestal base is foot operated and the

standard head and leg sections are hand operated (see

sections 5.1 and 5.2 respectively).

1.3.4 The T20 Series of table are easy to operate,

theatre staff can quickly learn how to use them correctly

and safely. Tabletop control is provided by a corded

handset, or an optional footswitch (for Trendelenburg and

height control only) or an optional infrared handset. Hand

controls override footswitch control at all times and if a

corded handset is plugged into the table this will take

precedence over the infrared handset.

1.3.5 Power for all powered table movements is

provided by internal rechargeable batteries. There are two

battery sets, main batteries and standby batteries. These

are recharged by an internal battery charger which requires

connection to mains voltage using the mains cord supplied.

Note: If the main table batteries fail or become critically

low (i.e. warning indicators were ignored and batteries have

not been recharged) the table cannot be powered directly

from the mains. However by depressing and holding the

standby battery switch, powered table movements can

again be achieved (using power from standby batteries).

1.3.6 In emergencies (e.g. handset failure or a critically

low battery) a standby control panel on the column can be

used to control the table (however this MUST be limited to

emergency use ONLY, certain safety features are overridden when this panel is used, see section 4.6.5). It may

be required to press the standby battery switch if the main

battery charge level is too low.

1.3.7 The bases on T20-a and T20-s tables are fitted

with enclosed multidirectional castors, that can be engaged

at any table height, making it easy to move on most theatre

floors. They have two foot pedals providing either castor,

wheel or braked orientations. The T20-m table is provided

with four large castors that can be adjusted by a single

foot pedal to provide wheel and castor modes and a braked

position (see section 5.1).

1.3.8 Visual indicators have been restricted to essential

functions and information only (e.g. table switched ‘on’ see

section 5.3.2.2, battery level indication and battery charging

state see section 5.3.1). Audible signals are only used to

signal that the table has been switched ‘on’ for a long time

without operation and that it should be switched ‘off’ see

section 8.1, a ‘beep’ is also provided when switching ‘on’

(the audible inactivity ‘beep’ can be configured ‘off’ during

a service if required).

1.3.9 Tabletops have a lightweight X-ray translucent

surface (designed to reduce shadows on images) and an

X-ray cassette tunnel with the facility for an X-ray cassette

(430mm x 340mm) to be placed at any point beneath the

full length of the patient’s body, see section 6.3. The

standard side rails allow placement of clamps and most

standard accessories. Simple button operated catches

release the head and leg sections when required.

1.3.10 The tabletop can be adjusted into the following

patient positions:

♦ Supine with C-arm access to patient from nipple

region to feet

♦ Supine with C-arm access to patient from groin to

head

♦ Supine Extension with C-arm access to break area

(Cholecystectomy-type procedure)

♦ Supine Flexion (‘Lawn chair’ position)

♦ Lateral

♦ Lateral Extension with C-arm access to break

(Nephrectomy position)

♦ Supine Lithotomy with C-arm access to whole of

the Urinary tract

♦ Supine Lithotomy with or without Trendelenburg

♦ Prone with or without extension at waist or hips (with

C-arm access)

♦ 90° Chair position with patient’s knees at the same

level as the heart, offset to the head end.

1.3.11 For additional information see section 6.0 for

patient positioning notes, section 6.2 for the obese patient,

6.3 for radiographic procedures and 6.4 for illustrations

and details of safe loading.

1.3.12 Castor covers (spats) are supplied as an optional

item with the T20-m table. These can be fitted by an

Eschmann Engineer at any time, please contact the After

Sales Service Department.

T-IM114b P7/62

2.0 TABLE PARTS AND SYMBOLS

2.1 Part identification

2.1.1 Fig. 2.1 shows the table top in its normal

configuration and identifies the major parts of the table

top.

2.1.2 Fig. 2.2 identifies the various parts of the T20-a

and T20-s table base and column.

SN This symbol indicates the unit serial number is

as indicated adjacent to the symbol.

REF This symbol indicates the catalogue number is

as indicated adjacent to the symbol.

This symbol indicates that the date of manufacture is as indicated adjacent to the symbol.

This symbol indicates the connection point for

a footswitch.

2.1.3 Fig. 2.3 identifies the various parts of the T20-m

base.

2.2 Symbols and graphics

To enable an easy reference to all the symbols and graphics

used on the T20 Series of tables (and within these

‘Instructions for use’) the following grouped sections show

all the symbols and graphics used.

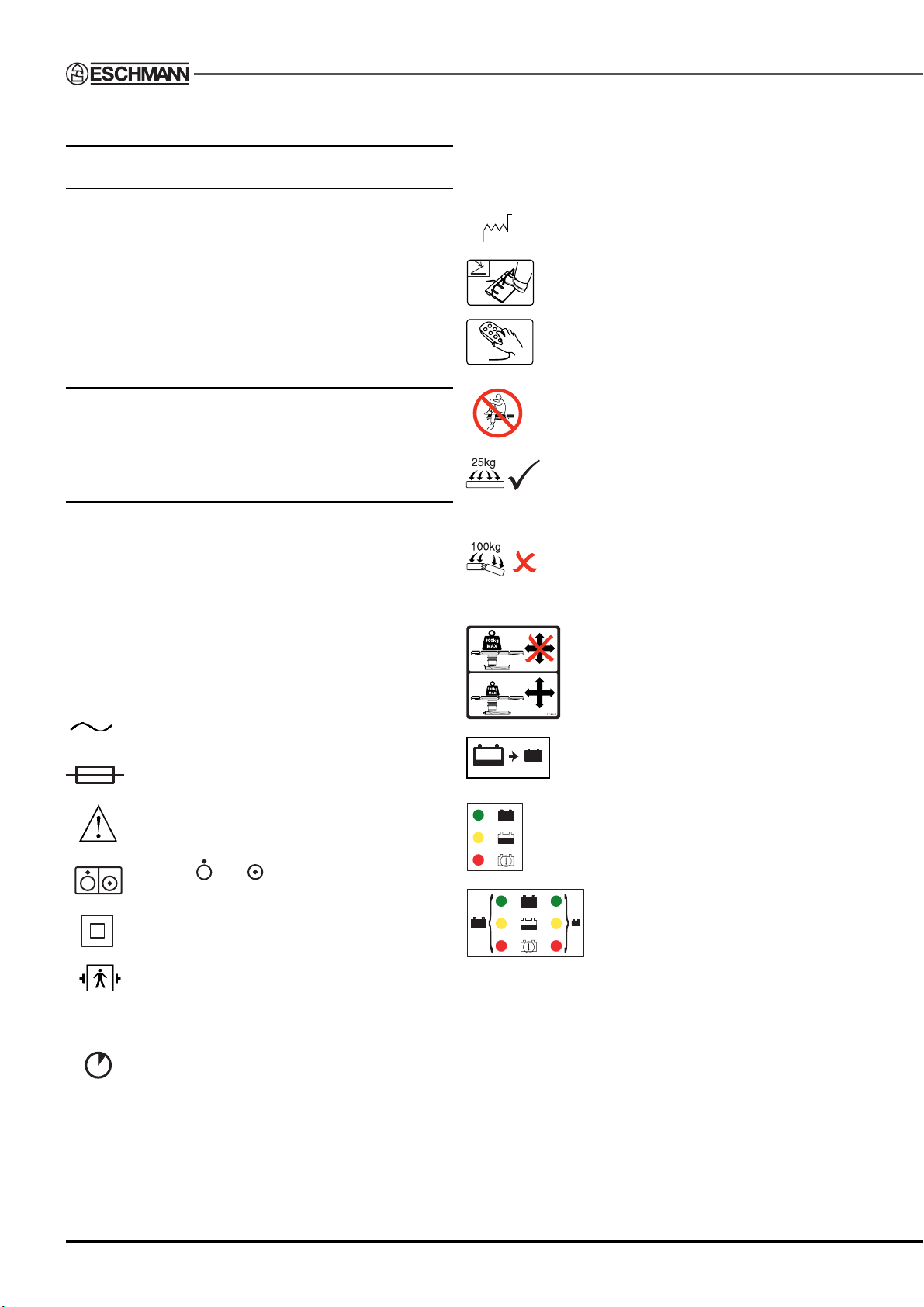

2.2.1 Symbols general

The following symbols are shown on various parts of the

table, handset or Serial Number Plate.

IPX 4 This symbol (splash proof) denotes that the

equipment (the table) meets the requirements of IEC529

for protection from splashing water.

IPX 6 This symbol (protection against heavy seas) denotes

that the equipment (the handset) meets the requirements

of IEC529 in that water from heavy seas or water projected

from powerful jets shall not enter in harmful quantities.

This symbol indicates that the equipment is for

use on alternating current.

This symbol indicates that fuses adjacent to the

symbol have a rating and type as detailed.

This symbol warns the user to read the accompanying documents, these ‘Instructions for use’.

Symbols and near the main table ‘on/off’

switch, indicate ‘OFF’ and ‘ON’ respectively.

With the mains cord attached the equipment has

‘Class II’ protection against electric shock.

The patient leakage current, with mains voltage

on the applied parts, meets the requirement for

type BF medical electrical equipment and are

defibrillator proof.

This symbol indicates the connection point for

the corded handset.

This symbol indicates that the table section

to which it is applied (e.g. head section, under

the mattress) should not be used as a seat.

This symbol indicates the ‘Safe working load’

of the section to which it is applied can safely

support an evenly distributed load to the value

indicated, in this example 25kg.

This symbol indicates the ‘Minimum breaking

load’ of the section to which it is applied. An

evenly distributed load (in this example 100kg

or greater) may break the section.

This symbol on the table base indicates the

table should not be loaded above 300kg,

nor moved with a load above 135kg for the

T20-a and T20-s tables, or 200kg for the

T20-m table.

This symbol is used to identify the standby

113150-01

battery switch.

This graphic (T20-m table only) adjacent to the

mains socket, identifies the relationship between

the colour of the mains ‘on’ LED and the battery

charge state, see section 5.3.1.

This graphic (T20-a and T20-s tables

only) adjacent to the mains socket,

identifies the relationship between the

colour of the mains ‘on’ LED and the

battery charge state for the main and

standby batteries, see section 5.3.1.

This symbol is used to indicate the table’s duty

cycle which is the ratio of the operating time to

the sum of the operating time and the ensuing

interval.

P8/62 T-IM114b

T20

Series

OPERATION TABLE

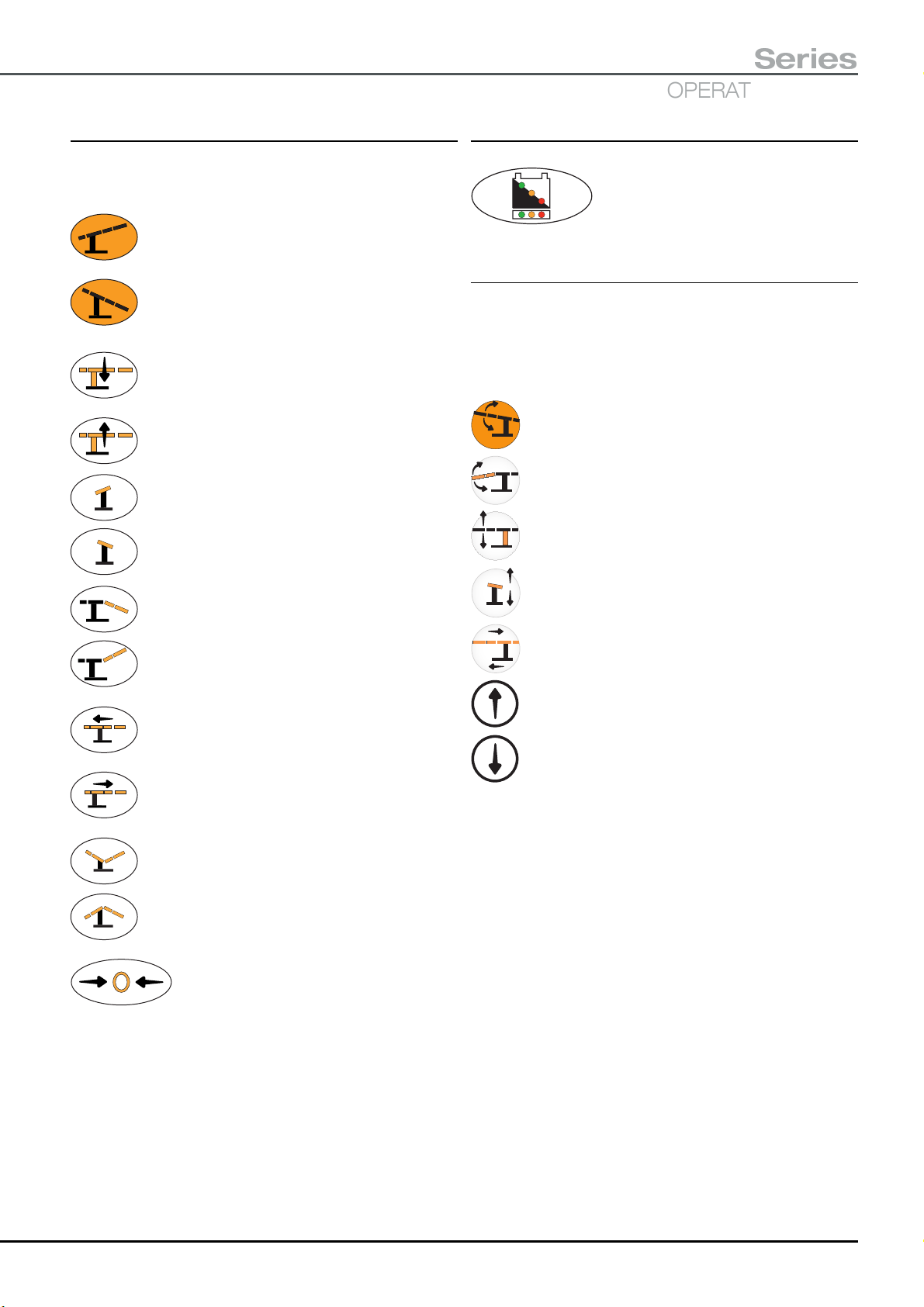

2.2.2 Handset button symbols

The following symbols are shown on the handset buttons

to indicate their function. Use of the handset is fully detailed

in section 5.3.3 of this manual.

Trendelenburg - Press to rotate tabletop in the

Trendelenburg (head down) direction.

Reverse Trendelenburg - Press to rotate

tabletop in the Reverse Trendelenburg (head

up) direction.

Height down - Press to move tabletop down.

Height up - Press to move tabletop up.

Tilt - Press to tilt tabletop down on the left (when

viewed from the long trunk end)

Tilt - Press to tilt tabletop down on the right

(when viewed from the long trunk end)

2.2.3 Handset graphics

This graphic is shown on the corded

handset to indicate the battery charge

level for both the main and standby

batteries, see section 5.3.1.

2.2.4 Standby control panel button symbols

The following symbols are shown on the standby control

panel buttons, indicating the function they select. The

arrows (upper or lower) indicate the direction the selected

function will move, if the corresponding direction button

(i.e. upper or lower) is pressed, see section 5.3.4.

Button selects Trendelenburg function.

Button selects Break function.

Button selects Height function.

Break down - Press to move the break down

(i.e. short trunk moves down w.r.t. long trunk)

Break up - Press to move the break up

(i.e. short trunk moves up w.r.t. long trunk)

Traverse Cranially (towards the head) - Press

to move the tabletop Cranially (i.e. tabletop

moves in the long trunk direction).

Traverse Caudally (towards the feet) - Press

to move the tabletop Caudally (i.e. tabletop

moves in the short trunk direction).

Flexion - Press to move tabletop into Flexion.

Extension - Press to move table into Extension.

Return to Level - Press to return tabletop

to a preset level position.

Button selects Tilt function.

Button selects Traverse function.

Direction button - Press button to obtain movement

indicated by upper arrow of function button.

Direction button - Press button to obtain movement

indicated by lower arrow of function button.

T-IM114b P9/62

View from Head end

2

1

9

3

4

8

7

5

6

10

9

1

2

3

4

9

9

6

5

12

1 Head section

2 Long trunk section

3 Short trunk section

4 Leg section

5 Leg section gas spring

6 Short trunk section release button

7 Accessory side rail (can also be used to stow handset*)

8 Long trunk section release button

9 Head or leg section end block (use to stow UK/EURO handset)

10 Head section release bar

11 Head section gas spring

12 Leg section release bar

7

View from Leg end

11

8

* Clip on handset must match side rail type, see accessory section 4.8

Fig. 2.1 Identification of the main parts of the T20 Series table top.

P10/62 T-IM114b

5

T20

OPERATION TABLE

7

8

Series

T20

T20-a

T20-s

3

1

2

4

Detail A Detail CDetail B

3

12

A

10

3

11

12

B

11

B

C

6

9

13

10

10

11

11

A

C

10

1 Standby battery switch

2 Battery fuses

3 Connection socket for Eschmann handset (ONLY)

4 Table ‘On’ LED (green). Bright or Dim see section 5.3.1)

5 Main table ‘On/Off’ switch (

6 Connection socket for Eschmann footswitch (ONLY)

7 Mains ‘on’ and Main Battery charging state LED. Red, Amber or Green.

8 Mains ‘on’ and Standby Battery charging state LED. Red, Amber or Green.

9 Connection socket for mains (ONLY use Eschmann mains cord supplied)

10 Castor foot pedal

11 Wheel foot pedal

12 Standby control panel

13 Mains fuses

= Off, = On)

Fig. 2.2 Identification of the main parts of the T20-a and T20-s table base and column.

T-IM114b P11/62

3

1

4

2

1 Standby battery switch

2 Mains ‘on’ and Battery charging state LED. Red, Amber or Green.

3 Connection socket for mains (ONLY use Eschmann mains cord supplied)

4 Foot pedal

5 Mains fuses

Note: Castor covers (spats) are supplied as an optional item (see section 1.3.12)

The following items on the column are identical to the T20-a table:

Connection socket for Eschmann handset (ONLY) - see item 3, Fig. 2.2

Connection socket for Eschmann footswitch (ONLY) - see item 6, Fig. 2.2

Standby control panel - see item 12, Fig. 2.2

Main table ‘On/Off’ switch - see item 5, Fig. 2.2

Table ‘On’ LED (green) - see item 4, Fig. 2.2

Fig. 2.3 Identification of the main parts of the T20-m table base and column.

5

Use webbing straps of minimum width 100mm

and a minimum breaking load of 1000kg.

Position adequate padding in the areas indicated

(on both sides) to avoid damaging the table covers.

T20-a & T20-s Position straps inside,

but as close as possible to the castors.

T20-m Position straps

inside castors as indicated.

Fig. 3.1 Lifting the T20 Series operation table

P12/62 T-IM114b

T20

Series

OPERATION TABLE

3.0 INSTALLATION

3.1 General

3.1.1 In the U.K. the table is delivered un-crated with

the head and leg section fitted. The mattress set is boxed

individually and placed on the trunk sections. The handset,

mains cord and literature are supplied loose. Any

accessories ordered with the table will be packed

individually. Some of the following unpacking and assembly

information is not therefore applicable to U.K. customers.

For overseas markets the table is usually packed in a

container with the head and leg section fitted, together with

a boxed mattress set a mains cord and the literature. The

handset is packed within the container in an antistatic bag.

Other accessories are usually packed separately, but some

may be included in the main case and should be unpacked

and stored separately during the table installation.

3.1.2 When delivered packaged, carefully remove the

T20 operation table (having first removed any accessories

and packing restraints from within the container) from the

packing case as follows:-

i Remove the walls of the case leaving the table on

the base still in the braked position as packed.

Remove any chocks from the pallet base to enable

later table movement (iv below).

ii Position the ramp provided (in the packing case)

adjacent to the base of the case.

iii Follow the instruction provided in section 5.1 of this

manual and place the table base into the ‘Wheel’

orientation or mode.

iv With at least two people to support the table’s weight,

push it (do not pull it) off of the pallet base and down

the ramp.

v Note that the table should not be wheeled over rough

ground, always use a trolley until a smooth floor area

has been reached.

vi Should it be necessary to lift the operation table refer

to section 3.2 where suitable lifting points and

methods are detailed.

3.1.3 Unpack the mattress set and fit a mattress to

each tabletop section as detailed in section 5.2.6.

3.1.4 Any packaging materials should be recycled or

disposed of in accordance with current legislation.

3.1.5 The T20 Series of table are powered by internal

rechargeable batteries which are connected and charged

before delivery (see disposal note in section 8.6.3). The

tables also have standby batteries. An internal mains

powered battery charger is incorporated in the table’s base,

to charge both the main batteries and the standby batteries.

CAUTION

It is most important that fuses of the correct

type, size and rating are installed (see Technical

Data, section 9.5.4).

3.1.6 The T20 Series of table require a mains electrical

supply corresponding to the voltage shown on the Serial

Number Plate located on the table base. Only use the

Eschmann mains supply cord provided with the table. If

the plug supplied fitted to the cord is not suitable it should

be replaced with a suitable plug wired as below. If the plug

is a fused type, a 10A fuse must be fitted. The mains supply

cord must always be wired as follows:

Brown internal cord to LIVE

Blue internal cord to NEUTRAL

Green internal cord to Earth

(Note: The T20-a, T20-s and T20-m tables are

Class II, Type BF, there is no EARTH connection

through to the table)

3.1.7 The table batteries should be recharged (see

section 5.3.1) and the table operated through the cycle of

movements detailed below to check and ensure correct

function, before the tables are first used.

Full Trendelenburg / reverse Trendelenburg

Maximum to minimum height

Maximum tilt, left and right

Maximum traverse, caudally and cranially

Maximum to minimum break

CAUTION

To complete and maintain the antistatic

pathway the table must be used on an

electrically conductive or antistatic floor and

with mattresses supplied by Eschmann

Equipment.

3.1.8 The table has an antistatic pathway from the

tabletop, through an internal resistor, to the castors. To

complete the antistatic pathway, the table must be used

on an electrically conductive, or on an antistatic floor (also

see the warning in section 6.1).

3.1.9 As with all medical electrical equipment care

should be taken with regard to electromagnetic

compatibility (EMC) during installation. These instructions

are written in line with the latest international standards

(EN 60601-1-2:2001) and are designed to minimise the

risk of electromagnetic compatibility issues. The T20 Series

of table should be installed and put into service in

accordance with the EMC information provided in the

Technical Data section of these ‘Instructions for Use’

(Section 9.11).

3.1.10 The table should be cleaned and disinfected prior

to its first use as detailed in section 8.2 and 8.3 and then

commissioned in accordance with any local procedures

applicable to new equipment, this should include staff

training. Eschmann supply a range of wall charts with the

table, additional training aids and on-site training can be

arranged, contact Eschmann for more information.

T-IM114b P13/62

3.2 Lifting the operation table

WARNING

The table is heavy and at least four strong

people are required to lift it. Ensure that

adequate precautions are taken (e.g. wear

protective shoes, use the correct straps).

3.2.1 The T20 Series of table should only be lifted as

a last resort. Ideally it should be placed on a trolley directly

from the delivery vehicle, or moved on the base of the

delivery packing case (overseas only) and then rolled down

the ramp provided.

3.2.2 If required the T20 table should only be lifted by

placing suitable webbing straps underneath the table base

in the positions indicated in Fig. 3.1 (having placed the

T20-a and T20-s tables into their ‘castor’ orientation to

increase ground clearance) and observing the notes that

follow. The table should only be lifted the minimum amount

required and not carried. Lift the table sufficiently high to

allow a fully decked pallet to be slid underneath. The table

should be placed into its ‘braked’ orientation whilst on the

pallet. Transport the table on the pallet using a forklift truck

or similar equipment ensuring the table is strapped securely

to the pallet.

3.2.3 Extreme care should be taken to pad the straps

where they pass the base covers and the table top sections

to avoid damage. Take special care not to cause damage

to the lower edge of the base covers.

3.2.4 Before lifting remove all tabletop sections,

accessories and mattresses, to minimise the weight to

approx. 248kg (T20-a and T20-s tables) or 196kg (T20-m

table). Place the table top into a level plane in both

directions (i.e. tilt and Trendelenburg) and traverse the top

so the long trunk is central to the column as shown in

Fig. 3.1. Lower the short trunk and then the table top to

their maximum limits.

3.2.5 When lowering the table after the lift take care

not trap feet under the tables base. Inspect the table for

any signs of damage and check all functions prior to placing

the table back into service.

3.3 Technical

3.3.1 The following sections are provided for the user

to note prior to using a T20 Series of operation table.

3.3.2 The T20 Series of table meets the requirements

of international standards (see section 9.8) and conforms

dimensionally to meet most requirements, for the full table

technical specification details refer to the Technical Data,

section 9.0.

3.3.3 The table should only be used on an antistatic

floor and is classified as type ‘BF’ (i.e. the table has isolation

from earth equivalent to that of type ‘BF’ equipment when

the mains cord is attached).

3.3.4 The antistatic properties of the table depend upon

the use of the recommended mattresses (i.e. Eschmann

antistatic mattresses ONLY) also see section 3.1.8.

3.3.5 Only Eschmann accessories listed in this manual

should be used on the table and in accordance with the

‘User Handbook’ supplied with the accessory. Accessories

available from Eschmann are listed in section 7.0. Other

accessories, especially those that could compromise table

stability, must not be used. Use of other equipment with

T20 tables should only be considered after evaluating the

safety of the patient and personnel. For accessories that

fit onto the side rail ensure that they are compatible with

the side rail fitted to the table. These tables can be supplied

with standard UK, Euro USA or Denyer style side rails,

see section 1.1.2

3.3.6 Provision of a diagnostic port within the table

enables access for reprogramming the tables software,

down-loading of fault information and service functions.

Use of this port MUST be limited to trained service

personnel only, and should only be used in accordance

with the correct Eschmann manuals (see 3.3.9 below).

3.3.7 The table has four fuses (two on the T20-m) that

the user has access to in the event of failure. The position

of these are shown in Fig. 2.2 and 2.3 and are replaced as

detailed in section 5.3.5.

3.3.8 Eschmann can provide customers with manuals

(see 3.3.9 below), for use by them in maintaining their own

equipment. These manuals contain schematic diagrams,

component part lists, descriptions and calibration

instructions which will assist the customer’s Eschmann

trained personnel to service the equipment or replace parts

(which should only be obtained from Eschmann).

3.3.9 The following manuals are applicable to the T20

Series of operation table and their accessories (the part

number is in brackets following the manual reference) they

are available to order, see inside front cover for contact

details:-

T-SM52 (113175) - Service manual

T-IPL40 (113177) - Illustrated parts list

T-IM94 (111012) - Application software manual

T-IM56 (698907) - General accessory leaflet

Note: Some accessories are provided with their

own ‘User/Service Handbooks’.

3.3.10 Appendix 1 provides a log that can be used to

record those people trained in the safe use of this operation

table. It is suggested that this is used to ensure that ALL

personnel using this table, are aware of all the warnings

and cautions contained within these ‘Instructions for use’.

3.3.11 The T20 Series of table and their accessories,

as listed in these ‘Instructions for use’, do not contain

‘Latex’.

P14/62 T-IM114b

T20

Series

OPERATION TABLE

4.0 SAFETY NOTES & CAUTIONS

4.1 Warnings

The warnings and cautions that follow must be followed,

they are repeated as applicable within the text of these

‘Instructions for use’ to emphasise their importance. Ensure

you are familiar with them before using the table.

WARNINGS

The T20 Series of table have been designed to

minimise the possibility of accidental

electrosurgery burns. Contact with any metal

surfaces (e.g. table side rail, or other equipment

etc.) can cause burns during electrosurgery

and must be avoided.

The T20 tables are not rated as AP or APG and

should not therefore be used in the presence

of explosive gases.

The T20 tables have been designed for patients

weighing up to 300kg (47 stone) with their centre

of gravity (normally the umbilicus) positioned

close to the column on the trunk sections.

However patient positioning and additional

loads from accessories can compromise table

stability and strength. Ensure that loading does

not compromise table stability or damage the

table (see graphs in section 6.4).

To comply with BS EN 60601-1:1990 some

accessories have been designed for a

maximum evenly distributed load, see the ‘User

Handbook’ supplied with each accessory.

With the table in (or during transition into) the

‘castor’ or ‘wheel’ orientation, the centre of

gravity of the patient (normally the umbilicus)

should lie no more than 200mm away from the

centre of the column. Whenever this is not

practical the table should be adequately

supported (e.g. by at least two able people).

The head and leg sections are designed to

support and position the corresponding part

of the patient’s weight only. Damage leading to

failure of the section may be caused if

excessive weight is applied. Take care when

handling these sections to avoid strain and

ensure no body parts or objects are trapped

when replacing or adjusting them.

Only use Eschmann accessories and sections

that are compatible with this table. When parts

are replaced during maintenance procedures,

ensure that ONLY parts supplied by, or from,

Eschmann Equipment are used. Alternatives,

although similar, may affect the safety of the

table. Eschmann cannot be held responsible

for service, modification or adjustments to the

equipment, when performed by other than

Eschmann accredited personnel.

Where given, descriptions and illustrations of

patient operating positions, and positioning

procedures, are for guidance only. It is the

responsibility of the operating surgeon to make

sure that the positions, and the positioning

procedures are appropriate for the operation

to be performed, and the safety of the patient.

(See section 6.0).

During any table positioning procedure care

should be taken to ensure the patient’s safety.

In particular during Trendelenburg and tilt

movements the patient should be supported

to ensure they remain secure on the tabletop.

The patient’s weight should be supported

whenever the sections are adjusted or removed

from the table during repositioning.

During ANY movement of the table or tabletop,

ensure that no part of either patient or hospital

staff, or object (e.g. drapes, infusion tubing,

diathermy connections, ECG cords etc.) can

become trapped between any moving and/or

stationary equipment, or in a pinch point,

causing injury or damage to equipment.

Particular table movements that should be

operated with care are reducing the height and

Trendelenburg, which can cause trapping

situations. Always ensure adequate slack is

available in drapes and tubing for the movement

required (e.g. maximum Trendelenburg).

When moving the table (e.g. in or out of theatre)

with a patient (maximum weight 135kg for T20-a

and T20-s, or 200kg for T20-m, see section 5.1)

always ensure that the patient‘s limbs are

secure on the tabletop to prevent crushing or

trapping them against another object, always

use cot sides (available as an accessory).

Always keep the patient under observation (e.g.

check respiratory and circulatory system and

for the possibility of pressure sores etc.) and

correctly positioned whilst on the table.

Ensure that electrical equipment connected to

the communication port (available during

maintenance procedures only) complies with

appropriate electrical safety standards. Note

that standards compliance of this product may

be affected if noncompliant equipment is

attached to the communication port.

T-IM114b P15/62

CAUTIONS

Do not place either heavy accessories, or, long

accessories that could impose high torques,

to the side rails, as this may lead to damage of

the rails.

♦ Ensure that only the Eschmann mains cord supplied

with the table is used to connect the table to the mains.

♦ Ensure that only Eschmann supplied parts are used

during part replacement.

DO NOT:

Do not exceed the duty cycle for any table

motor drive as detailed in the technical data

section 9.5.5.

Moving the table over soft floors (e.g. carpet

or ‘cushion’ flooring) will increase resistance

to movement compared to normal hospital

‘hard’ flooring and care should be taken.

4.2 Do’s and Don’ts

Attention to the following points will prolong the life and

efficiency of the T20 Series of table and will help to avoid

the risk of accidents, or damage. Other safety notes and

warnings are also given within the text of this manual and

these should be noted during use of the table.

DO:

♦ Keep these ‘Instructions for use’ close-to-hand.

♦ Read these ‘Instructions for use’ carefully before

adjusting, moving or using the table.

♦ Use the table on an antistatic floor to prevent

inadvertent static buildup.

♦ Use only the correct Eschmann mattresses and

accessories that are compatible with the T20 Series

of table as detailed in these instructions.

♦ Check that handset cables and standby controls are

not damaged before use.

♦ Check that the table and its accessories are not worn

or damaged, or are in any way not suitable for the

intended purpose, before use.

♦ Check that all the sections (e.g. head and leg) and

accessories are secure, and put the table base in the

‘braked’ position before use.

♦ Ensure that all cables are not stretched leading to

disconnection or damage during movement or

readjustment of the operation table or patient.

♦ Remove table accessories and their clamps (in

particular rotary clamps) from side rails, when they

are not being used.

♦ Read and follow the instructions for cleaning, and for

the care of the table and mattresses.

♦ Switch ‘off’ and disconnect from the mains electrical

supply prior to cleaning and/or disinfecting the table

and when it is not being recharged.

♦ Ensure that the table and accessories are serviced at

regular intervals (every six months is the

recommended frequency) only by Eschmann trained

personnel, or by accredited agents.

♦ Do not lift the table by its tabletop.

♦ Do not move the table with a patient without cot sides

in place on either side of the tabletop.

♦ Do not push the table over rough surfaces, use a

trolley.

♦ Do not drop the table (or individual sections).

♦ Do not put heavy weights on the table sections,

observe the maximum advised loading.

♦ Do not put sharp objects on, or against, mattresses,

pads, or the radiographic tabletop.

♦ Do not place any objects on the base covers

♦ Do not drop heavy objects onto the radiographic

tabletop or base covers.

♦ Do not spill oil, ether, or other fluids onto the mattresses

or the pads.

♦ Do not pull the table by any of the tabletop sections,

or accessories, always push it.

♦ Do not service this equipment unless you have been

trained by Eschmann.

4.3 Daily ‘Before use’ test

It is recommended that a ‘Daily test’ is carried out before

using the table every day. First check that the batteries

are charged if they are not charge them (see section 5.3.1.1

and 5.3.1.2) and ensure that a suitable practice is put in

place so they are charged at the end of every shift in future.

Then check the table responds to the following movements

from the handset (each movement only needs to be brief,

one or two seconds each):

Trendelenburg / reverse Trendelenburg

Height Up / Down

Tilt Left / Right

Traverse Caudally / Cranially

Break Up /Down

Then check at least two of the above plus Trendelenburg

using the Standby control panel.

4.4 Accessories

The accessories available from Eschmann for the T20

Series of table are listed in section 7.0. Use of other

equipment with the T20 tables should only be considered

after evaluating the safety of the patient and personnel.

Inadvertent use of incorrect accessories could damage the

table and lead to injury. Always ensure that the information

in the ‘Instruction’ or ‘User Handbook’ supplied with the

accessory are complied with and follow all the safety notes

P16/62 T-IM114b

contained within them during use. For accessories that fit

onto the side rails ensure that they are compatible with the

side rails fitted to these tables. These tables can be supplied

with standard UK, USA or Denyer style side rails.

4.5 Manual handling

WARNING

Ensure care is taken when moving adjusting

or lifting any part of the table or patient. Note

the guidelines provided.

4.5.1 During adjustment or changing the configuration

of the T20 series of operation tables, there are occasions

when the user should be aware of the safe practises to be

employed during manual handling or adjustment of parts

of the table. For information, the weights of the heaviest

sections and accessories commonly used are listed in

Appendix 4. Appendix 4 also contains other information

on manual handling. When lifting, carrying or fitting these

components it is recommended that care is taken and that

two or more people are employed when required.

T20

Series

OPERATION TABLE

4.5.2 These ‘Instructions for use’ advise supporting the

weight of the patient during adjustment of any section,

obviously this requires the intervention of several

personnel, some supporting the patient’s limbs and others

adjusting the table sections.

4.5.3 When moving the table note that extra effort is

required to start the table moving, take care not to strain

limbs or back. The table should not be moved when heavily

loaded note the warnings and cautions provided. It is good

practice to use two or more people when moving a table.

T-IM114b P17/62

5.0 OPERATING THE TABLE

manual operations achieved by using one or both of the

foot pedals on the table base.

This section has been split into sections as follows:

5.1 Moving/operating the table base.

5.2 Using the removable sections.

5.3 Using the table’s powered/electrical functions.

5.1 Operating the table base

WARNING

Always push the table (do not pull it) at a

suitable height ensuring that it is stable at all

times, take care not to collide with personnel

or equipment. Maximum stability will be at

minimum height. Ensure that the patient is

adequately supported and restrained

(especially limbs) using cot sides as

appropriate (also see section 5.1.3). Ensure that

all connections via cord or tube, to the patient

or table, have either been disconnected, or are

only attached to equipment that will move with

the table to avoid inadvertent disconnection.

When changing from ‘castor’ or ‘wheel’ orientation, to ‘braked’, ensure that no objects (e.g.

cords, tubing etc.) can become trapped beneath

the table base and floor (T20-a and T20-s tables

only). Do not move the table with a patient

weighing more than 135kg (T20-a and T20-s

tables) or 200kg (T20-m table) and ensure

stability is maintained.

If table is difficult to move check for objects

under castors and that castors are maintained

and kept clean and free from foreign objects

(also see section 1.3.12).

The table should always be left in the ‘braked’ orientation

with both pedals in their raised positions. Do not leave the

table with the wheel pedal up and the castor pedal down.

When familiar with sections 5.1.1.1 - 5.1.1.2, use Fig. 5.3

as a quick reference guide for pedal operation.

5.1.1.1 ‘Wheel’ orientation (from ‘braked’)

T20-a wheel pedal operation is easily achieved if the pedal

is pressed down with the right foot whilst steadying yourself

with hands on the tabletop. Stand on the side of the table

on which the footpad is located. T20-s wheel pedal operation

is easily achieved if you steady yourself with your hands

on the tabletop, note that you can stand on either side of

the table to operate the pedal. For either type of pedal use

a steady ‘press’ rather than a ‘rapid depression’ of the pedal,

this provides easier identification of the ‘click’ and avoids

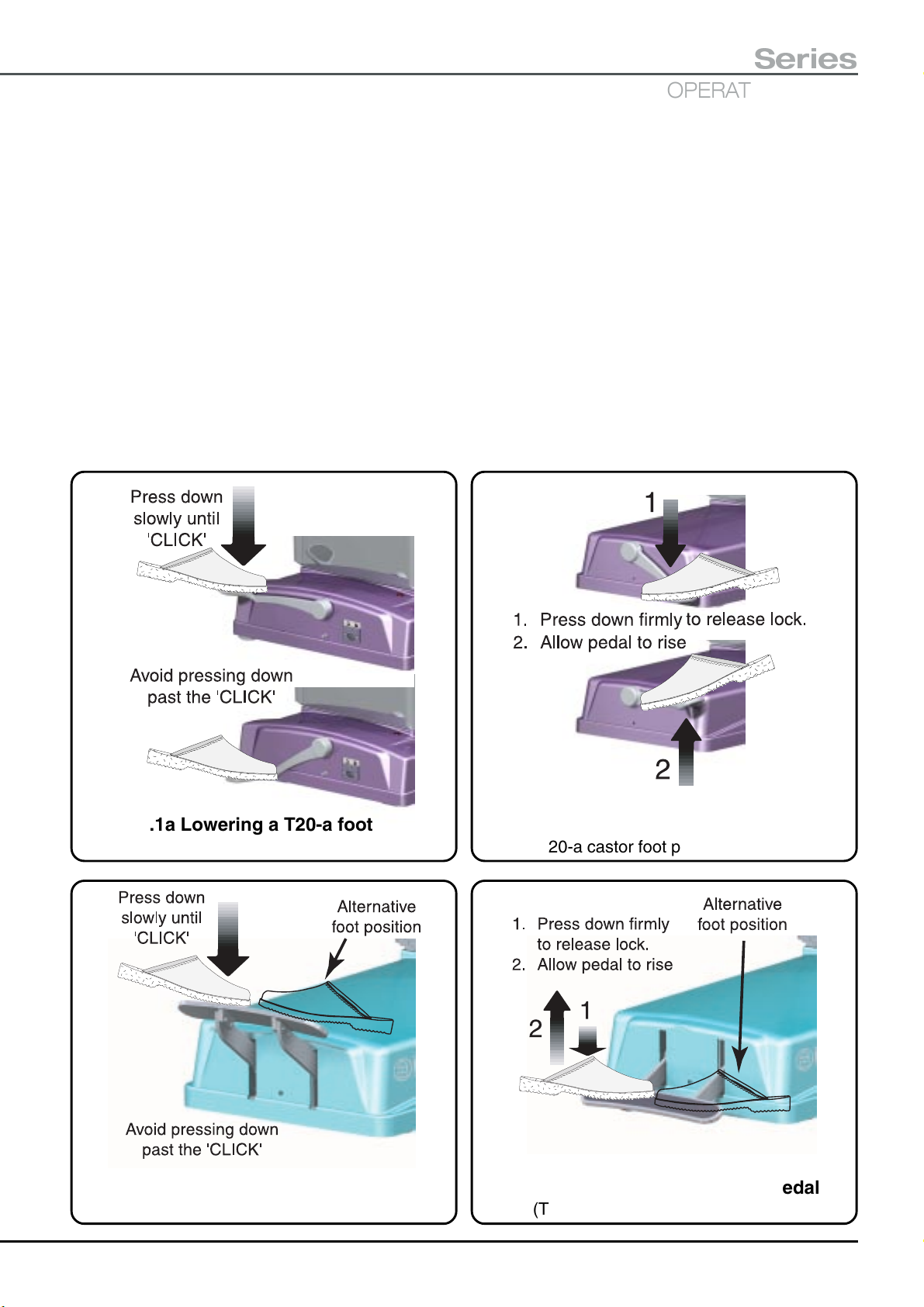

pressing the pedal passed its locking position.

To place the table into the ‘Wheel’ orientation from the

‘braked’ orientation, press the wheel pedal (item 11, Fig. 2.2)

down steadily until you hear an audible ‘click’ (action

indicated in Fig. 5.1a or 5.1b). This ‘click’ indicates that the

pedal has locked in the down position. Do not continue to

press the pedal after the ‘click’ as this will release the internal

catch and the pedal will not lock down. If this does happen

the pedal must be allowed to rise fully (this resets the internal

catch) before pressing it down again.

When placed into the ‘Wheel’ orientation the table base is

supported on two wheels at the short trunk end and two

castors at the long trunk end. To move the table in ‘wheel’

orientation always push it (do not pull it) from the long trunk

end, moving the end nearest to you, left or right, to steer the

table in the required direction. The table is in ‘wheel’

orientation when the wheel pedal is in the lowered position

and castor pedal is in the raised position.

5.1.1.2 ‘Castor’ orientation (from ‘wheel’)

The table base has three formats, the T20-a and T20-s

tables (basically similar, differentiated by the design of the

foot pedal) see section 5.1.1 and the T20-m table which

has a single foot pedal, see section 5.1.2.

5.1.1 T20-a and T20-s table base

The T20-a and T20-s tables can be moved easily on builtin castors and wheels. Normally the table rests on brake

pads at the long trunk end and wheels at the short trunk

end, these provide a secure and static location on the

operating theatre floor. Lower the table to a suitable height

to achieve a stable position before moving the table.

To move the T20-a and T20-s tables they are placed onto

their wheels and castors in two ways, providing both a

‘castor’ orientation and a ‘wheel’ orientation. The latter

enables easy movement of the table in a straight line (down

a corridor for example). Moving the table into either of these

orientations does not require battery power, they are

T20-a castor pedal operation is easily achieved if the pedal

is pressed with the left foot whilst steadying yourself with

hands on the tabletop. Stand on the side of the table on

which the footpad is located. T20-s castor pedal operation

is easily achieved if you steady yourself with your hands

on the tabletop, note that you can stand on either side of

the table to operate the pedal. For either type of pedal use

a steady ‘press’ rather than a ‘rapid depression’ of the pedal,

this provides easier identification of the ‘click’ and avoids

pressing the pedal passed its locking position.

To place the table into the ‘castor’ orientation from the ‘wheel’

orientation, press the castor pedal (item 10, Fig. 2.2) down

steadily until you hear an audible ‘click’ (action indicated in

Fig. 5.1a and 5.1b). This ‘click’ indicates that the pedal has

locked in the down position. Do not continue to press the

pedal after the ‘click’ as this will release the internal catch

and the pedal will not lock down. If this does happen the

pedal must be allowed to rise fully (this resets the internal

catch) before pressing it down again.

P18/62 T-IM114b

T20

Series

OPERATION TABLE

When placed into the ‘castor’ orientation the table base is

supported on four castors, two at each end of the table.

This orientation enables the table to be moved in any

direction including sideways and swivelling within its own

length. To move the table always push it in the required

direction, never pull it. The table is in ‘castor’ orientation when

both pedals are in their lowered positions.

5.1.1.3 ‘Castor’ orientation (from ‘braked’)

To place the table into ‘castor’ orientation from the ‘braked’

orientation follow 5.1.1.1 to place the table into ‘wheel’

orientation and then follow 5.1.1.2 to complete the move

into the ‘castor’ orientation.

Note: It is not critical that sections 5.1.1.1 and 5.1.1.2 are

carried out in this sequence the reverse is equally suitable

and correct.

5.1.1.4 ‘Braked’ orientation

To place the table into the ‘braked’ orientation move the pedals

(items 10 and 11, Fig. 2.2) into their raised position. If either

pedal is in the lowered position raise them, in any sequence.

For the T20-a table stand on the standby control panel side of

the table and use the foot advised in 5.1.1.1 or 5.1.1.2 as

appropriate. For the T20-s table you can stand on either

side of the table. Steady yourself with your hands on the

tabletop and press the pedal ‘firmly down’ see Fig. 5.2a

and 5.2b, this disengages the internal locking catch.

Release pressure on the pedal and allow it to rise. The

table will gently lower onto its brake pads and wheels, the

motion is softened and braked by an internal damper.

The table is in ‘braked’ orientation when both pedals are in

their raised positions.

Fig. 5.1a Lowering a T20-a foot pedal

(T20-a wheel foot pedal illustrated)

Fig. 5.2a Raising a T20-a foot pedal

(T20-a castor foot pedal illustrated)

Fig. 5.1b Lowering a T20-s foot pedal

(T20-s castor foot pedal illustrated)

Fig. 5.2b Raising a T20-s foot pedal

(T20-s castor foot pedal illustrated)

T-IM114b P19/62

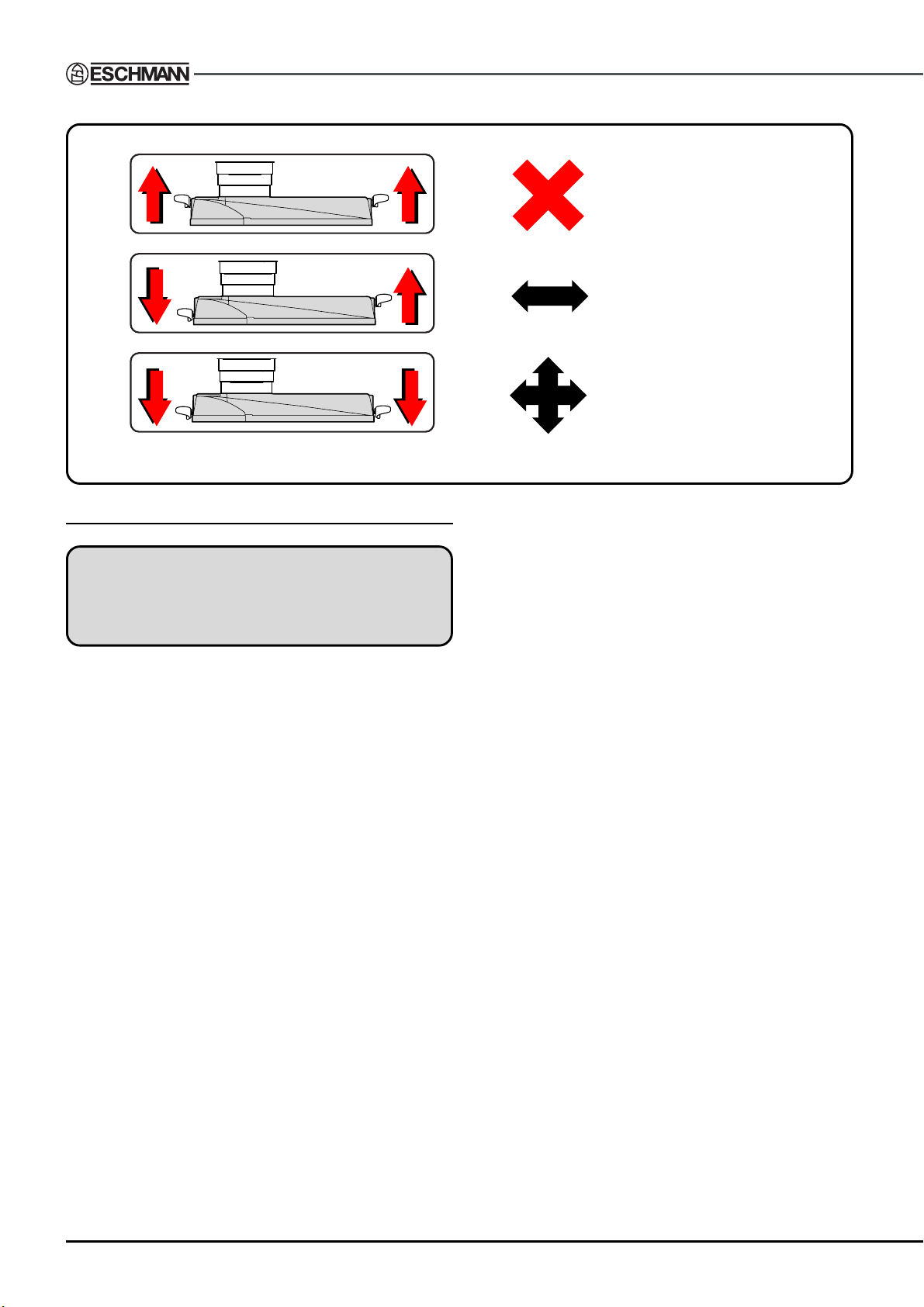

=

BRAKED

TABLE WILL NOT MOVE

Fig. 5.3 T20-a and T20-s foot pedal quick reference guide

5.1.2 T20-m table base

WARNING

Before using the table, position the castors

under the base covers to help protect them

from any falling contamination.

The T20-m table base has been provided with four large

castors. The table rests on these castors at all times

providing either a secure and static location on the

operating theatre floor (‘braked’), or two modes for easy

movement (‘castor’ and ‘wheel’ modes). Adjust the table

to a suitable height to achieve a stable position before

moving the table.

The T20-m table should always be left ‘braked’ with the

foot pedal in its lowest position. When familiar with sections

5.1.2.1 to 5.1.2.4, refer to the label on the table base as a

quick reference guide to pedal operation (label is illustrated

in Fig. 5.4).

To move the table it is placed into its ‘castor’ mode or ‘wheel’

mode. The latter enables easy movement of the table in a

straight line (down a corridor for example). The ‘castor’

mode provides full free wheeling mobility with 360° rotation

and movement sideways.

Adjusting the table into either of these modes does not

require battery power, they are manual operations achieved

by using the single foot pedal on the table base (see item 4,

Fig. 2.3).

5.1.2.1 Foot pedal operation

Foot pedal operation is easily achieved when the pedal is

operated with either foot whilst steadying yourself with your

hands on the tabletop. Stand on either side of the table or

the pedal end, which ever is the most suitable and easy.

=

PUSH IN A STRAIGHT LINE

CASTOR

WHEEL

=

Do not operate the pedal from the end of the table when a

long table section (e.g. a leg section) has been fitted to the

long trunk end, this may require unnecessary stretching

by the operator to reach the pedal. Operate the pedal from

the side of the table.

Use a steady motion rather than a ‘rapid’ movement of the

foot pedal, this provides easy identification of the ‘snap’

into any of its three positions.

5.1.2.2 ‘Braked’

To place the table into the ‘braked’ orientation press the

foot pedal (item 4, Fig. 2.3) down to its lowest position.

Operate the pedal as detailed in section 5.1.2.1. and press

the foot pedal down until it snaps into its lowest position.

The pedal can be moved from its highest ‘wheel’ position

through its central ‘castor’ position and into the ‘braked’

position in one easy movement.

The table is ‘braked’ when the foot pedal is in its lowest

position.

5.1.2.3 ‘Castor’ mode

To place the table into the ‘castor’ mode, move the foot

pedal (item 4, Fig. 2.3) into its central position. Operate

the pedal as detailed in section 5.1.2.1 and move the foot

pedal until it snaps into its central position.

The pedal is moved up from its lowest ‘braked’ position by

lifting the pedal up with the top of the foot, or down from its

raised ‘wheel’ position by pressing the pedal down with the

ball of the foot, until the pedal snaps into the central ‘castor’

position.

The table is in ‘castor’ mode when the foot pedal is in its

central position.

Note: When the table has been moved to the required

location always leave the table ‘braked’.

PUSH IN ANY DIRECTION

P20/62 T-IM114b

Press pedal down fully with the castors

in any position to brake all four castors

(see WARNING in section 5.1.2).

Lift pedal up, or press pedal down,

into the central position to enable the

table to be 'castored'. All four castors

will swivel allowing full table mobility.

Select 'castor' mode' (pedal in the central position) and

push the table until the short trunk end castors are correctly

aligned as indicated. Lift the pedal up fully into the 'wheel'

position (to stop the short trunk end castors swivelling).

This will enable the table to be 'wheeled' in a straight line.

Push and steer the table from the pedal (head) end.

A

B

Detail of the required short trunk end castor postion, which should be obtained, before

lifting the foot pedal into its top position to place the table base into the 'wheel' mode.

Note:

In position A the castor leads its mount, in position B the castor trails its mount.

WHEEL

CASTOR

BRAKE

See A above

See B above

113136-01

T20

Series

OPERATION TABLE

Illustration of the table’s base ‘quick

reference guide’ label. Note the

booklet symbol that indicates

reference to these instructions

should be observed.

Fig. 5.4 Operating the T20-m table base

T-IM114b P21/62

5.1.2.4 ‘Wheel’ mode

WARNING

Do not push the table in the ‘wheel’ mode until

you are sure the castors have moved into their

correct orientation for the ‘wheel’ mode, as

detailed in the second stage below and Fig. 5.4.

If the table is pushed with the castors locked out

of position this will cause undue wear leading to

failure of the short trunk end castors.

Placing the table into the ‘wheel’ mode is a four stage

procedure which will ensure that the short trunk end

castors are locked in position correctly.

First, if the table is ‘braked’ move the foot pedal (item 4,

Fig. 2.3) into its ‘castor’ position as detailed in section

5.1.2.3.

Second, push the table forwards from the long trunk end

until both the short trunk end castors have swivelled into

the position ‘B’ shown in Fig. 5.4. They do not need to be

exactly in line, but they should not be as shown in ‘A’ Fig. 5.4

(i.e. leading their mounts).

Third, lift the pedal up with the top of the foot, as detailed

in section 5.1.2.1, until the pedal snaps into its highest

‘wheel’ position.

Fourth and finally, continue to push the table in a straight

line, the short trunk end castors will lock automatically in

line with the table base. This enables the table to be moved

easily down a corridor, being steered from the long trunk

end.

The table is in ‘wheel’ mode when the foot pedal is in its

highest position and the short trunk end castors have locked

in-line with the table base.

Note: When the table has been moved to the required

location adjust the table into ‘castor’ mode to enable full

mobility and positioning and then leave the table ‘braked’

(press the pedal fully down).

5.1.3 Moving table with a patient

The normal table position when moving it with a patient is

level in both directions (i.e. tilt and Trendelenburg) and

with the patient in the supine or lateral recovery position.

Fig. 5.5 shows an alternative position that can be used,

the notes in Fig. 5.5 also apply when moving the table with

the patient in the supine or lateral recovery position.

Notes:

Always use cot sides.

Lower table to a suitable height.

Ensure patient limbs are secure.

Check patient weight and position complies with Fig. 6.3 and Fig. 6.4.

Always push table from the head end (do not pull).

Position also applies to T20-a and T20-s tables (T20-m table illustrated).

Fig. 5.5 Alternative table position for moving table with a patient

P22/62 T-IM114b

T20

Series

OPERATION TABLE

5.2 Using the removable sections.

WARNING

Ensure that nothing becomes trapped

(e.g. fingers, tubing, cords) when attaching

tabletop sections. When removing a section be

prepared to support the full weight of the

section when the guide pins disengage. Always

carry the section holding the side rails. Never

hold or pick up the section using the black

gas support struts and take care not to operate

the release handle accidentally. Do not operate

the release handle when the section is removed

from the table. For users of small stature, when

handling larger sections (e.g. the leg section)

two people should work together to avoid strain

injuries. Also to minimise weight for all users

remove mattresses before fitting or removing

a section. Users of earlier Eschmann tables

(e.g. MR and RX Series) should note that T20

guide pins are shorter and disengage earlier.

Always ensure that the sections have been

correctly and securely fitted before use and

only use the correct Eschmann sections.

To attach the section to a table after re-aligning the pins

insert the pins into the tabletop for 90% of their length,

actuate the release handle and adjust the section until

horizontal and then push the section fully home until the

locking catches engage (also see section 5.2.2).

During long term storage of a section it should be positioned

with the pins up, this ensures continued lubrication of the

gas spring seals (e.g. attached to the table and fully

lowered). If stored separately from the table take care not

to actuate the release handle during storage since this will