Page 1

Autoclave Testing

Much emphasis is placed on the importance

of autoclave testing. This is because routine

performance tests are the most reliable way

of ensuring an autoclave is functioning

correctly.

The requirements for autoclave testing are

identified in a number of documents

published by the Medicines and Healthcare

Products Regulatory Agency (MHRA), along

with Healthcare Technical Memoranda

(HTM) 2010. Not all establishments,

however, are required to follow this regime.

If you are in doubt or need guidance on

which guidelines you should follow please

refer to your local Infection Control Nurse,

their details will be available from the

Primary Care Trust for your area.

All autoclave testing is periodic. Simple

tests are performed on a daily basis, whilst

more sophisticated tests are conducted on a

quarterly, half yearly or annual basis.

Responsibility for testing will be shared

between the ‘User’ and a designated ‘Test

Person’ (TP). The definition of these two

individuals may be found on Autoclave

Advice Sheet 7. All testing should be

preceded by a safety check to ensure the

autoclave is both safe for use and for

testing.

All test results should be recorded and

retained in accordance with your local

Primary Care Trust protocols.

Daily Tests

These are performed by the ‘User’ and

consist of the following:

Automatic Control Test (ACT)

It is recommended this is carried out at the

start of the day or before the autoclave is

used for the first time that day.

Some autoclaves may require a warm up

cycle prior to performing daily tests. Please

check your autoclave’s Instructions for Use

Number 5

to establish if a warm up cycle is

required. ‘Little Sister’ and ‘SES’

autoclaves do not require a warm up

cycle.

To perform the test the autoclave should

be empty and the most frequently used

cycle selected (e.g. 134°C, unwrapped

without drying), or a test cycle if the

autoclave is programmed with this

feature. If the unit has a printer installed,

the print out of the test cycle should be

retained and recorded in a daily logbook

for that autoclave.

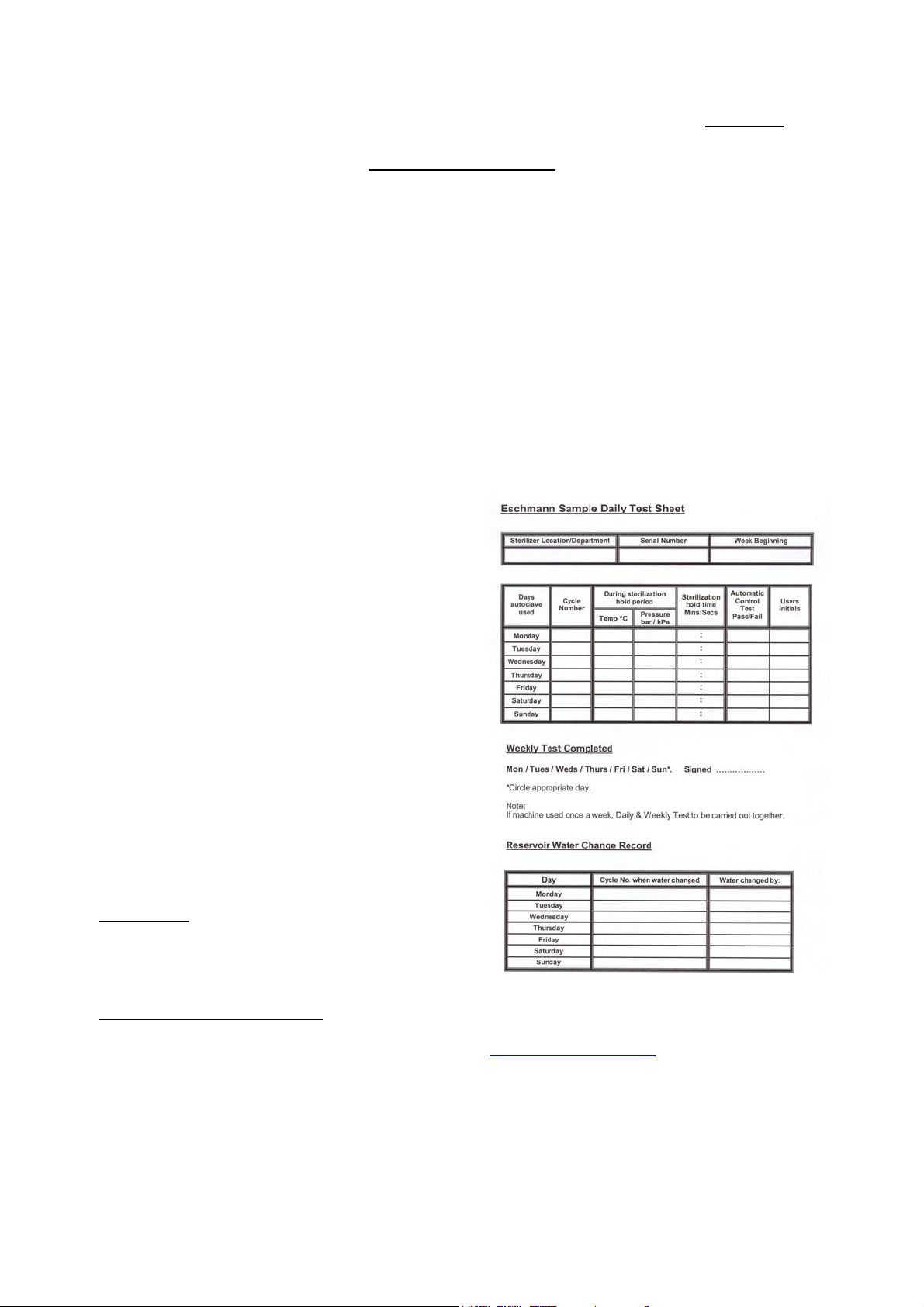

A sample logbook may be downloaded

from the Eschmann website.

www.eschmann.co.uk

Page 2

If the autoclave does not have a printer, the

following information must be observed and

recorded manually.

• Cycle Time

• Sterilization ‘hold time’ (i.e. the

length of time temperature is held at

either 134°C or 121°C during the

cycle)

• Temperature

• Pressure

Manual recording of test results can be time

consuming. The use of a printer is highly

recommended, as it provides the dual

benefits of saving time and is assured of

accurately recording the test results.

In addition to these tests, users of vacuum

autoclaves should perform a daily steam

penetration test. The purpose of the steam

penetration test is to ensure sufficient steam

is produced in order to penetrate complex

loads (e.g. multi-wrapped items or

materials). The most frequently used test

method is a ‘Bowie & Dick’ Type. It is

possible with some autoclaves to conduct

both the steam penetration test and the

automatic control test on the same cycle,

please refer to the instructions for use

supplied with the autoclave.

Note: Only use the steam penetration

test designed for use with the autoclave

you are using – Steam penetration test

packs are not universal and use of the

incorrect one may provide inaccurate

and misleading results.

Weekly Tests

Weekly tests may be performed by the

‘User’ provided adequate training has been

conducted and agreed by the Authorised

Person otherwise testing must be performed

by the Test Person.

The weekly test consists of the following

safety checks:

• Examine the door seal for signs

of deterioration and leaks.

• Check the security and

performance of the door safety

devices.

• Air leakage test (automatic)

This test is intended to check that air will

not leak into the sterilizer during periods

of vacuum, at a rate greater than

specified by the manufacturer. Most

autoclaves should be fitted with

automatic leak detection function test,

and this should indicated within the

Instructions for Use.

Quarterly & Annual Testing

Should only be performed by a qualified

Test Person (TP). The Test Person (TP)

may be a suitably qualified service

engineer, and tests may be performed as

part of a service agreement. Any service

agreement should clearly identify

whether this routine testing is included as

part of the contact and whether the

person performing the test is sufficiently

qualified.

SES Little Sister Benchtop Autoclave

Advice Sheets

No 1 The Decontamination Cycle

No 2 Pre-sterilization Cleaning & Disinfection

No 3 Selecting A New Autoclave

No 4 Best Practice in Use of Benchtop Autoclaves

No 5 Autoclave Testing

No 6 Health Technical Memoranda

No 7 Frequently used terms

For copies of the above please contact

Eschmann Customer Service Tel: 01903 753322

The Eschmann name & logo are registered trade marks of Eschmann Holdings Ltd.

“Little Sister” is a trade mark of Eschmann Holdings Ltd. PS 261 Dec 2004

Loading...

Loading...