Page 1

ST80

TROLLEY SYSTEM

Instructions for use

110102

E-IM65c

Page 2

Introduction

Preliminary

information

Read these Instructions before use

Keep these ‘Instructions for use’ in a safe convenient place for future reference during

installation, operation and maintenance procedures.

Safety notes

Installation and

part identification

Instructions

Suction

Instructions

Fibrelight

Technical data

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquires, please quote the

Model and Serial Number of your Suction Unit and the part number of any part referred to.

(NOTE: For location of the Serial Number Plate see below, the alpha parts of the SN are significant).

Serial plate location for basic unit .....................................................inside vertical support

Serial plate location for unit with Fibrelight (only) ...............................back of Fibrelight unit

Serial plate location for unit with Suction ............................................. back of Suction unit

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

T el: +44 (0) 1903 765040. Fax: +44 (0) 1903 762006.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limit ed.

“Eschmann Equipment” is a trading name of Eschmann Holdings Limi ted.

“ST80” is a trade mark of Eschmann Holdings L imited.

Copyright © 2003

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

If the CE mark is affixed to the product, it indicates compliance with Council Directive

93/42/EEC of 14 June 1993 concerning medical devices.

E-IM65c August 2003

Instructions for use

Page 3

ST80

TROLLEY SYSTEM

CONTENTS

INTRODUCTION

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. PRELIMINARY INFORMATION

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Optional Extras . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. SAFETY NOTES

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. INSTALLATION & PART IDENTIFICATION

Unpacking & Assembly . . . . . . . . . . . . . . . . . . . 7

Electrical Connection. . . . . . . . . . . . . . . . . . . . . 7

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . 7

Important Operating Notes . . . . . . . . . . . . . . . . 7

4. INSTRUCTIONS FOR USE - SUCTION

Liner use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Starting the unit . . . . . . . . . . . . . . . . . . . . . . . . . 8

Suction adjustment . . . . . . . . . . . . . . . . . . . . . . 8

Overflow protection . . . . . . . . . . . . . . . . . . . . . . 8

Pump protection . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning & Disinfection . . . . . . . . . . . . . . . . . . . 8

Sterilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Care - daily checks . . . . . . . . . . . . . . . . . . . . . . 9

Fault diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 9

INTRODUCTION

NOTE: These Instructions for Use apply to the following

ST80 Trolley Units :-

REF 83-063-05 Electrosurgical trolley

REF 83-063-05-0002 Trolley plus Fibrelight, 230V

REF 83-063-05-0004 Trolley plus Fibrelight, 1 10V

REF 83-063-05-0005 Trolley plus Suction,

230V , 2 Jars

REF 83-063-05-0006 Trolley plus Suction,

100/120V , 2 Jars

REF 83-063-05-0007 Trolley plus Suction,

230V , 4 Jars

REF 83-063-05-0008 Trolley plus Suction,

100/120V , 4 Jars

REF 83-063-05-0010 Trolley + Fibrelight + Suction,

230V , 2 Jars

REF 83-063-05-0012 Trolley + Fibrelight + Suction,

110V, 2 Jars

REF 83-063-05-0014 Trolley + Fibrelight + Suction,

230V , 4 Jars

REF 83-063-05-0016 Trolley + Fibrelight + Suction,

110V, 4 Jars

with Serial Number S8? B 8 B 0000 or later

(‘?’indicates model variant).

5. INSTRUCTIONS FOR USE - FIBRELIGHT

Attaching light guide . . . . . . . . . . . . . . . . . . . . 10

Using the fibrelight source . . . . . . . . . . . . . . . . 10

Lamp changing . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning and Disinfection . . . . . . . . . . . . . . . . 10

6. TECHNICAL DATA

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FIGURES

Fig.1 ST80 Part identification . . . . . . . . . . . . . . . . 6

Fig.2 ST80 Changing fibrelight lamp . . . . . . . . . . 10

Fig.3 ST80 Fibrelight part identification . . . . . . . . 10

E-IM65c P3/11

Page 4

1. PRELIMINARY INFORMATION

GENERAL

1.1 The ST80 Trolley system is a modular piece of

theatre equipment available in a range of options:

a) Basic trolley.

b) Trolley with fibrelight system.

c) Trolley with suction system.

d) Trolley with both fibrelight and suction systems.

1.2 The reusable jars supplied with the suction unit are

used with a disposable liner system, as detailed on the

laminated leaflet S-IM08 enclosed with the ST80 Trolley if

a suction unit is fitted.

1.3 The mobile trolley has two breaking castors and a

flat working surface for an electrosurgical unit (optional

extra) or other equipment. It also incorporates removable,

reversible shelving.

1.4 All the information necessary to use the ST80 Trolley

will be found in these Instructions for Use or the Jar and

liner card supplied (if applicable). Because of the modular

nature of this product not all sections of this booklet will

apply. For basic units refer to the relevant parts of the

cleaning and disinfection details section 4.8 - 4.9.

1.5 The following related publications, available from

Eschmann Equipment, also apply to the ST80 Trolley

System.

E-SM52 - Service Manual

S-IM08 - Instructions for Use

(disposable suction liner system)

OPTIONAL EXTRAS

Suction System (see Section 4 for details)

1.6 The vacuum pump is an oil-lubricated electricallydriven pump/motor unit of the rotary vane type, with

replaceable blades. The motor unit is designed to operate

from the mains electrical supply. If required this module

can be added, please contact the Eschmann After Sales

Service Department (see inside front cover).

1.7 The pump/motor unit, its associated pipework and

electrical connections are all contained within a tough,

hygienic plastic case at the base of the ST80. Controls are

mounted on the top of the case and comprise an on/off

power switch, a vacuum control valve and a vacuum gauge.

1.8 A silencer unit in the pump exhaust line ensures

that the pump operates with the minimum of noise, while

the pump inlet is protected by an externally mounted sealed

bacterial or combined hydrophobic/bacterial filter both of

which are disposable.

Fibrelight System (see Section 5 for details)

1.9 The Fibrelight system is a fan-cooled, twin 150 watt

Halogen lamp unit, with both Fibrelight guide adapters and

all controls accessible from the front of the system. Failed

lamps can be easily replaced without the need for any

special tools. If required this module can be added later,

please contact the Eschmann After Sales Service

Department (see inside front cover).

Twin Drip Pole Kit

1.10 The Twin Drip Pole Kit (REF 81-464-03) can be

fitted easily to either, or both sides, of the ST80 Trolley.

The Kit comes complete with all fittings and Instructions

for Use. It provides a conventional style twin drip stand,

taking up less space than an additional free-standing piece

of equipment.

ST80 Trolley System Accessories / Parts List

REF 82-961-68

Filters (pack of 10, bacterial)

REF 82-961-85

Filters (pack of 10, hydrophobic/bacterial)

REF 82-923-61

Jar (with V-mount for disposable liner)

REF 82-923-88

Tapered connector (pack of 10)

REF 82-923-96

Incineration box (pack of 25)

REF 82-929-14

Suction tubing 6.35mm i.d.

REF 82-930-15

Suction tubing (black) 12.7mm i.d.

REF 82-931-12

Suction tubing (clear) 12.7mm i.d.

REF 82-923-57

Disposable liner, standard bore 8.5mm (box of 25)

REF 82-923-69

Disposable liner, wide bore 12.5mm (box of 25)

REF 82-923-65

Disposable liner, Cascade, std. bore 8.5mm (box of 25)

REF 82-929-36

Cascade connecting tube (box of 50)

REF 83-121-41

Fibrelight adaptor, to fit Storz/G.U. guides

REF 83-121-68

Fibrelight adaptor, to fit BS/ACMI guides

REF 81-464-03

ST80 T win drip pole kit

Part No.697603

Fibrelight lamp

P4/11 E-IM65c

Page 5

ST80

TROLLEY SYSTEM

2. SAFETY NOTES

When using the ESCHMANN ST80 TROLLEY

SYSTEM, attention to the following points will

prolong the life of your Trolley System and help

promote safe use.

DO clean all suction equipment and the unit thoroughly

after use.

DO change the disposable filter after each day’s use, or,

IMMEDIATELY if wetted, or, after aspiration of infective

fluids.

DO keep an adequate supply of spare disposable filters

handy.

DO unplug and/or isolate power lead before cleaning

suction unit and when not in use.

DO treat receiver jars carefully, avoiding mechanical or

thermal shock.

DO examine condition of jars and suction tubing regularly,

replacing if worn or damaged.

DO seal disposable liner after use and don’t reopen.

DO use a new liner and a new suction tube for each

patient - don’t risk cross infection.

DO autoclave receiver jar daily.

DO keep ‘sharps’ away from liners.

DO read these ‘Instructions for Use’ carefully and keep in

an accessible place.

WARNING

Operators of this unit should be aware of the

potential risks of ‘Cross Contamination’ and

‘Biological Contamination’ whilst using this

equipment. The correct procedures for the handling

of potentially contaminated components (e.g. Jar,

Tubing, Filters) and liquids should be followed

rigidly during Use, Cleaning and Maintenance.

Always change filters regularly and if they become

wetted or contaminated. All users should be familiar

with the procedures for dealing with, and disposing

of, potentially contaminated components and

liquids. Suction equipment should only be used by

persons who have received adequate instructions

in its use.

The contents of the liner and accessories should

be disposed of safely and carefully, taking into

account any National, Local or Hospital procedures,

covering the disposal of potentially contaminated

liquid, or solid, waste.

The maintenance procedures described in these

‘Instructions for Use’ should be made the

responsibility of the engineer in charge of services

in the hospital. If maintenance is neglected, suction

performance could be found inadequate in an

emergency situation. It is also recommended that if

placed on stand-by for emergency duty the unit is

tested by switching on, at regular intervals.

DON’T start unit without removing transit bolt and filling

pump with oil.

DON’T use substitute disposable filters (see available

spares list on page 4).

DON’T continue to use unit, without attention, if vacuum

reading or suction rate is too low.

DON’T obstruct or cover ventilation holes in unit cabinet.

DON’T use the electrical power lead or suction tubing as

a tow rope, use the unit’s handle.

DON’T leave part filled liners in the system overnight -

always incinerate.

DON’T overfill suction liners - change when three quarters

full.

DON’T use phenols or solvent based disinfectants to

clean receiver jar, use Savlon, Hibitane or similar

(also see leaflet S-IM08 supplied with the unit).

DON’T touch inside surface of fibrelight lamp reflector or

the quartz bulb.

E-IM65c P5/11

Page 6

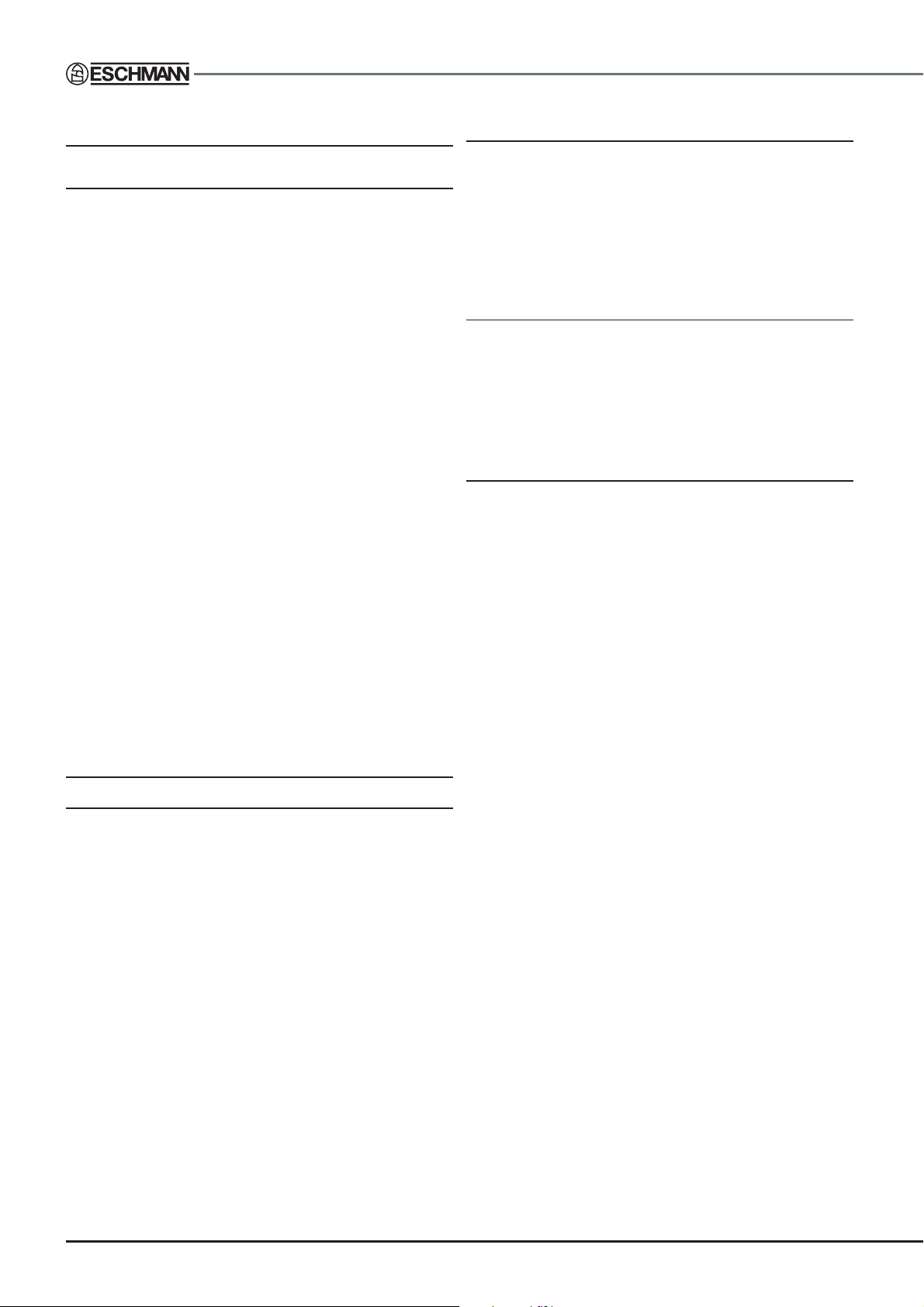

1. Trolley top

2. Fibrelight controls and indicators.

3. Fibrelight case

4. Fibrelight lamp plate

5. Vacuum gauge

6. Vacuum power switch

7. Vacuum control valve

8. Receiver jar mounting bracket

9. Pump case

10. Receiver jar with liner

11. Castor

12. Foot assembly

13. Cable cleat

14. Front moulding

15. Disposable filter (either type)

16. Shelving (reversible if basic unit only)

17. Side frame

18. Handrail

19. Connecting tubing

20. Suction electrical rating plate

21. Suction system fuses

22. Pump exhaust outlet

23. Mains supply cable

24. Fibrelight system fuses

25. Fibrelight electrical supply socket

26. Air intake for fibrelight fan

27. Fibrelight electrical rating plate

Fig. 1 ST80 Trolley - parts identification

P6/11 E-IM65c

Page 7

ST80

TROLLEY SYSTEM

3. INSTALLATION AND

PART IDENTIFICATION

Unpacking and assembly

3.1 Proceed carefully as follows:

i) Remove muff (UK market) or open carton

(Overseas market).

ii) Remove loosely packed items and documents

and carefully remove the ST80 unit from the

carton.

iii) If Trolley has a suction system fitted, remove

motor transit screw (painted red) from base of

pump case and discard screw.

Note: The vacuum pump is supplied charged with oil and

ready for use. Recharging instructions are included in the

Service Manual.

3.2 The suction collection system (if fitted) is provided

with two or four 1600ml receiver jars (working capacity).

Remove any loose items from within the jars.

3.3 If required, clean and sterilize jars before use as

described in leaflet S-IM08 supplied with the unit, where

preferred methods are detailed.

3.4 Fit disposable liners in the jars and place the jars in

the mounting brackets (item 8, Fig. 1) at the front of unit.

(Also see 1.2).

3.5 Then insert either the hydrophobic/bacterial filter,

or the bacterial type filter (item 15, Fig. 1) into the rubber

mount on the front moulding as shown in Fig. 1. (Note:

Filters will only fit one way round).

3.6 Connect the connector on the connecting tubing

(item 19, Fig. 1) to the filter. Ensure that the tapered

connector on the free end of the tubing is pushed firmly

into the socket in the disposable liner.

Electrical connection

3.7 Connect a three-pin fused plug, if not already fitted

to the mains supply cable. If the plug is removed a new

plug should be fitted (with a 5A fuse) as follows:

Brown . . . . . . . . . . . . . . . . . . . . . . . Live

Blue . . . . . . . . . . . . . . . . . . . . . . . Neutral

Green/Yellow . . . . . . . . . . . . . . . . . Earth

Dispose of the removed plug safely having first removed

its fuse.

3.8 The mains supply must agree with the information

on the electrical rating plate at the rear of the unit. In the

UK a 5A fuse must always be fitted in the plug if the fuse is

replaced.

Parts identification

3.10 Refer to Fig. 1 to gain knowledge of the names for

various parts of the ST80 Trolley.

3.11 The suction collection system utilises a disposable

liner system, leaflet (S-IM08) supplied with the unit explains

how to use them.

3.12 The front two castors of the trolley incorporate a

foot operated brake. To apply the brake press the bottom

of the lever until it locks in the down position with a click. T o

release the break apply pressure to the top of the lever

until it releases.

Brake Lever

Important operating notes

3.13 The following notes should be followed when

operating the ST80 suction system :

i. This suction unit is not intended for field and

transport use.

ii. The suction pump must be removed and

serviced if liquid or solid matter has been drawn

into it.

iii. It is recommended that this suction unit is used

only on a horizontal floor or surface.

iv. This suction system incorporates an overfill

device (float valve) which will operate and stop

suction in an ‘overfill’ situation. See leaflet

(S-IM08) supplied with the unit for more details

and information on disposal.

v. The recommended suction tubing is sterile

tubing for surgical suction of 6.35mm (1/4 inch)

inner diameter (see parts list on page 4). The

method of connection to the liner is described

in the leaflet (S-IM08).

WARNING

The ST80 high vacuum suction unit should not be

used for continuous drainage of body cavities.

Nevertheless it should be noted that the pump is

rated for continuous operation. A new disposable

liner and a new suction tube, must be used for each

patient.

3.9 Suction and fibrelight functions can be used

independently by selecting the appropriate switches.

E-IM65c P7/11

Page 8

4. INSTRUCTIONS FOR USE SUCTION SYSTEM

Liner use

4.1 The ST80 suction system uses a jar and disposable

liner system. The leaflet (S-IM08) supplied with the unit

explains how to use them.

NOTE: Graduations are approximate; suitable volume

measuring equipment should be used if accurate

assessment is required (e.g. the CMV see S-IM08).

Starting the unit

4.2 Connect unit to mains electrical supply and if supply

socket is controlled by a switch, ensure it is switched ‘ON’.

4.3 Ensure installation stages 3.3 to 3.8 have been

followed then start the vacuum pump by turning the mains

switch (item 6, Fig. 1) to ‘l’. Adjust the Vacuum to the

required level as detailed in section 4.4.

Note: Before using the suction unit for the first time, the

suction performance can be checked quickly by switching

on the unit and placing a finger over the end of the

connecting tube (item 19, Fig. 1). The vacuum gauge

reading should move quickly to approximately 620 mm Hg

(atmosphere at 760 mm Hg) with vacuum control valve

turned to maximum setting.

Suction adjustment

Inlet connection

Clear top

Outlet

connection

environmental protection from contaminated suction pump

exhaust. Should the hydrophobic filter become wetted it

will prevent fluid passing into the pump but still allow suction

to continue. Only when the filter upper chamber is full of

fluid, will suction cease. The second filter, the bacterial type

shown below, provides improved protection against

Outlet

connection

bacteria and other airborne pathogens from the pump

exhaust. In the event of becoming wetted this filter will not

prevent body fluids contaminating the pump. Also see

WARNING on page 5.

Blue base

Inlet connection

Clear top

and Base

4.4 T o set the required vacuum on this suction unit switch

the mains switch ‘ON’ (mains switch to ‘1’), place a finger

over the nozzle (patient inlet) of the liner to which the

"patient" tubing connects, then turn the vacuum control

valve (item 7, Fig. 1) clockwise or anticlockwise to increase

or decrease the suction until the desired vacuum is

indicated on the vacuum gauge.

4.5 When applying suction to the patient it may be

desirable to increase or decrease the suction rate. This is

achieved by turning the vacuum control valve clockwise to

increase or counter-clockwise to decrease suction.

Overflow protection

4.6 Aspiration should be stopped when level of fluid

reaches approximately the 3/4 full mark, but in the event

of accidental overfilling the float valve will close shutting

off vacuum to the liner .

Pump protection

4.7 The sealed disposable filter, of either type, must be

changed after each day’s use or immediately if wetted or

after aspiration of infective fluids. The hydrophobic/bacterial

filter shown provides total environmental protection pump

protection from body fluids together with improved

WARNING

Do not use substitutes for the specified sealed

disposable filters see parts list on page 4.

Cleaning & disinfection

WARNING

Disconnect equipment from the mains electrical

supply prior to cleaning and disinfection.

4.8 The following routine should be carried out

immediately after each period of use:

i. The disposable filters must be changed after

each day's use, or IMMEDIATELY if wetted, or

after aspiration of infective fluids.

ii. All components likely to be in contact with

aspirated body fluids should be thoroughly

cleaned and sterilized after use, or whenever it

is suspected that infective fluids have been in

contact with the unit.

iii. The outside of the unit should be washed with

hot (55°C) neutral (pH7) detergent solution

(diluted in accordance with the manufacturers

instructions) rinsed with clean water, and wiped

dry.

P8/11 E-IM65c

Page 9

ST80

TROLLEY SYSTEM

v. Phenol based disinfectants and solvent based

liquids should not be used for cleaning receiver

jars, use aqueous based liquids at all times.

4.9 The following disinfection procedure is used by

Eschmann Equipment, and its use is recommended if no

other approved procedures are available.

i Remove all jars and filters etc. and sterilize or

dispose of separately as required.

ii Wash down all surfaces and crevices with hot

(55°C) neutral (pH7) detergent solution (diluted

in accordance with the manufacturers

instructions) to remove all visible contamination.

Use a small brush to clean areas of limited

access.

iii W ash down with hot (55°C) water.

iv Dry all surfaces with absorbent paper.

v Wash down all surfaces and crevices with a 70%

solution of industrial methylated spirit and water.

vi Allow to dry by evaporation.

vii Dispose of all cleaning material and solutions in

accordance with authorized disposal

procedures.

WARNING

Do not allow Hypochlorite solutions to come

into contact with any metal components.

Sterilization of jars

4.10 See leaflet S-IM08 supplied with the unit.

Care - Daily checks

4.11 T o ensure the ST80 Suction Unit operates ef ficiently

in an emergency, the following checks should be carried

out on a daily basis:

i. Check jar for cracks or chips, renew if damaged.

ii. Check suction performance as detailed in the

‘note’ after section 4.3.

Note: Disposable filters, suction tubing, jars and liners

are relatively inexpensive items, and a stock of spares

should always be readily available (see parts list on page 4).

F AUL T DIAGNOSIS

4.12 The following table lists possible causes of faults that can be rectified by the user. Rectification of other faults

can only be carried out by trained personnel in conjunction with the relevant Service Manual.

Fault Possible Cause Remedy

1. Total loss of (a) Disconnection in suction line (a) Reconnect

suction (b) Overflow protection operated (b) Switch to new liner

(c) Disposable filter completely (c) Replace filter immediately

blocked

2. Partial loss of (a) Split or damaged liner (a) Replace liner

suction (b) Leakage in suction line (b) Check/remake suction

connections/renew tubing

(c) Disposable filter wetted (c) Replace filter immediately

or fouled

3. Vacuum gauge (a) Loss of vacuum (a) See (1) and (2) above

no indication

4. No power (a ) Fuse in ‘mains’ plug faulty (a ) Check/replace fuse (5Amp)

(b ) Mains supply failure (b ) Check ‘mains’ supply

5. On switching pump off (a) Leakage in suction tubing or (a) Tighten or renew faulty items

with inlet blocked, connections

immediate vacuum loss

Note: A thermal overload switch, which is self-resetting, is incorporated to protect the motor in the event of

pump seizure or excessive running temperatures. Should the overload switch operate to stop the motor it is

essential to disconnect the electrical supply to the unit before attempting any form of maintenance. In the case of

faults which cannot be resolved, please contact the Eschmann After Sales Service Department (see inside front

cover for contact information).

E-IM65c P9/11

Page 10

Attaching Light Guide (Fig. 3)

5.1 Screw appropriate adapter(s) into lamp plate (item

12 Fig.3) sockets and connect flexible light guide to adapter.

(See parts list page 4 for adapters available from Eschmann

Equipment)

Using Fibrelight Source (Fig. 3)

5.2 Connect fibrelight assembly to mains electrical

supply and if supply socket is controlled by a switch, ensure

that it is switched ‘on’. The amber stand-by indicator (item

7) will illuminate.

5.3 Press lamp ‘on’ touch button (item 6), lamp ‘on’

indicator (item 5) will illuminate green.

5.4 Press lamp selector button (item 1) or (item 3),

corresponding stand-by lamp indicator (item 2) or (item 4)

will illuminate amber.

5.5 Press button (item 11) to increase or button (item

10) to decrease brightness.

5.6 In the event of lamp failure, press button (item 1) or

(item 3) and reposition light guide to other adapter.

v Hold new lamp (see parts list page 4) by

connector pins and/or rim of reflector and with

the key (item 3) as shown. Then locate lamp in

lamp holder (item 4), ensuring connector pins

are aligned with sockets, and push lamp firmly

into position.

vi Raise fibrelight chassis and secure in closed

position.

vii Connect equipment to mains electrical supply.

viii T est both lamps as detailed in 5.3 to 5.5.

Cleaning & disinfection

5.8 See the relevant parts of 4.8-4.9

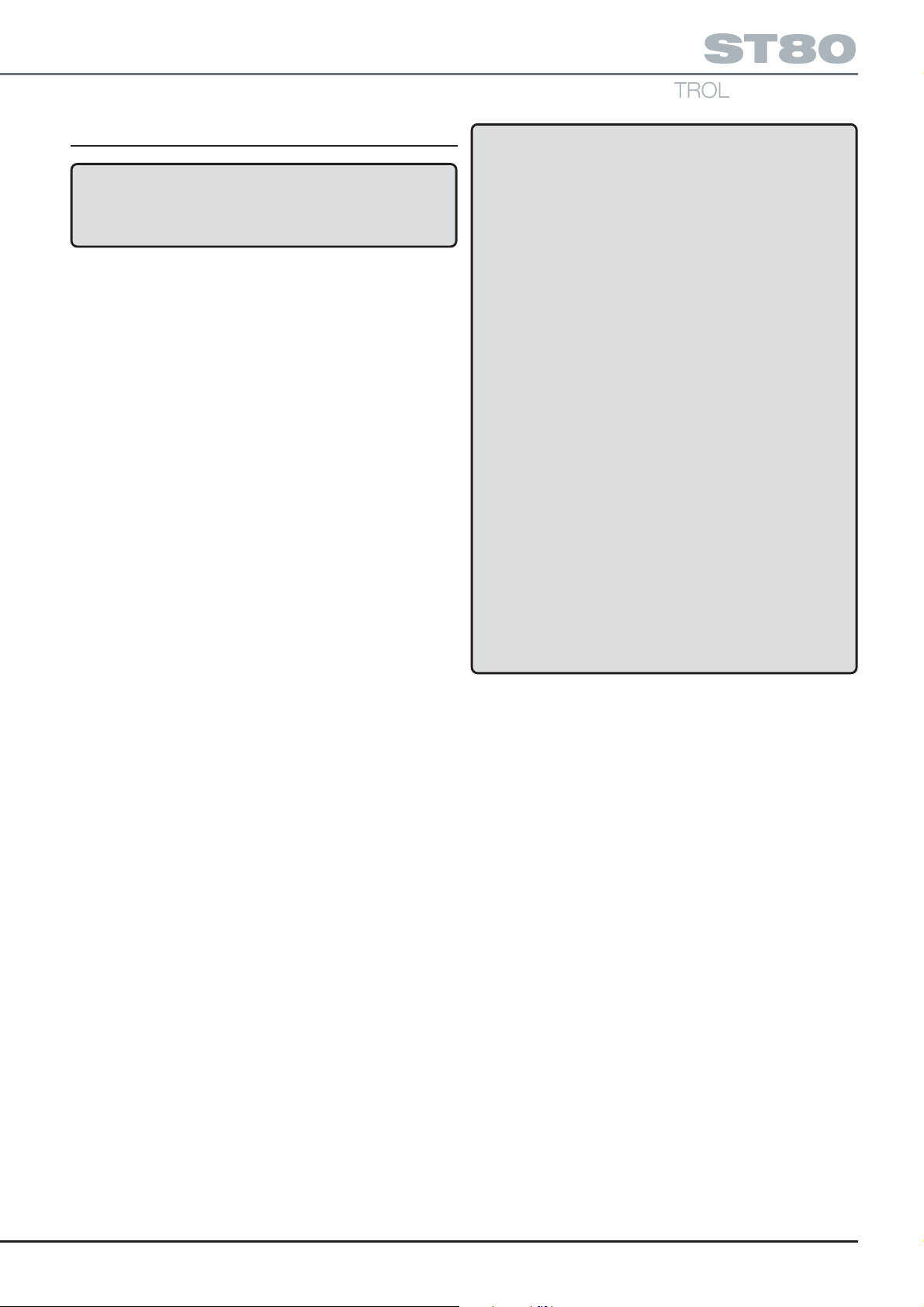

Lamp changing (Fig. 2)

5.7 T o change a lamp proceed as follows:

i Disconnect equipment from the mains electrical

supply.

ii If necessary, allow lamp(s) to cool.

iii Release flap catch (item 1) and supporting

fibrelight chassis (item 2), hinge chassis

carefully downwards.

iv Raise ejector lever (item 5) to remove the failed

lamp.

CAUTION

Do not touch inside surface of new lamp reflector

or the quartz bulb as this will impair efficiency and

shorten lamp life. Hold new lamp reflector as shown

in Fig. 2.

1. Flap catch

2. Chassis

3. Key

4. Lamp holders

5. Lamp ejector lever

6. Lamp

Fig. 2 ST80 Changing fibrelight lamp

1. Lamp selector touch button

2. Stand-by lamp indicator (amber)

3. Lamp selector touch button

4. Stand-by lamp indicator (amber)

5. Lamp ‘on’ indicator (green)

6. Lamp ‘on’ touch button

7. Stand-by indicator (amber)

8. Lamp ‘off’ touch button

9. Brightness display (red)

10. Decrease brightness touch button

11. Increase brightness touch button

12. Fibrelight lamp plate

Fig. 3 ST80 Fibrelight - Parts identification

P10/11 E-IM65c

Page 11

TROLLEY SYSTEM

6. TECHNICAL DAT A

General

Equipment Type: Mobile trolley system, of modular construction.

Overall dimensions (approx.): Height, 880 mm Width, 590 mm Depth, 615 mm

Weight (approx): T rolley, 26kg Trolley + Suction, 45kg T rolley + Suction + F’light, 54kg

Suction system

Either: Connection to Hospital piped vacuum, or,

Internal Pump:

Type: High vacuum, high flow, oil lubricated rotary vane type, mains operated.

Oil charge: 25ml (approx.) Oil type: Eschmann ‘Universal’, High Vacuum Oil

Performance: Maximum airflow rate, 35 litre/min Nominal vacuum, 620 mm Hg (80kPa)

Electric motor: T otally enclosed, fan cooled, Power consumption 60W

Duty cycle, Continuous Mains input: 230V a.c. 50/60 Hz, or 1 10V a.c. 50/60 Hz

Fuses: (2 off) for 230V supply, T2A anti-surge 20mm to IEC127

(2 off) for 100/120V supply, T5A anti-surge 20mm to IEC127

Filters: Sealed disposable combined hydrophobic/bacterial type designed to provide

100% pump protection against aqueous fluids, or, Sealed disposable bacterial type

ST80

Fibrelight system

Type: High intensity fan cooled light source for fibrelight endoscopic instruments.

Mains input: 230V a.c. 50/60Hz

Output: Continuously variable Duty: Continuous Power consumption: 150W

Fuses: (2 off) for 230V supply, T1.6A anti-surge 20mm to IEC127

(2 off) for 100/120V supply, T3.15A anti-surge 20mm to IEC127

Lamps: Prefocused 150 watt Quartz Halogen type, (2 off - selectable)

Safety

Standards : EN 60601-1:1990+A1:1993+A2:1995, ISO 10079-1:1991,

BS 5724:Part 1:1979, IEC 601-1:1977

Classification : Class 1. Type BF Drip proof

Electromagnetic compatibility : IEC 601-1-2:1993

Class

Class 1 denotes that the equipment must be earthed via the protective conductor

in the 3-core mains cable connected to a 3-pin plug.

Explanation of symbols

The symbol (drip proof) indicates that the equipment will withstand

a moderate quantity of water spilled from above the unit.

The symbol denotes that the equipment is in the category type BF, i.e. that it is manufactured to a safety standard

commensurate with international regulations for medical electrical equipment incorporating floating patient applied

parts.

The symbol indicates that the equipment isfor use on alternating current only.

The symbol indicates that vacuum is increased by clockwise rotation of this control.

For SINGLE USE ONL Y

E-IM65c P11/11

Page 12

Page 13

Page 14

Eschmann Equipment, Peter Road, Lancing, West Sussex, BN15 8TJ, England.

T el: +44 (0) 1903 753322. Fax: +44 (0) 1903 766793. www.eschmann.co.uk

Loading...

Loading...