Eschmann SES2000VAC Service Manual

SES2000 VAC(LS3)

VACUUM AUTOCLAVE

Service Manual

1 10258

ST-SM45g

Introduction

Description

Maintenance

Illustrated

Parts list

Read these Instructions before use

Keep this ‘Service Manual’ in a safe convenient place for future reference. Read in

conjunction with the Publication detailed in Part 1.

This Service Manual applies to the following Autoclaves:-

Note: The ‘E’ in the serial number below is the ‘modification state’ of the autoclave and is used

within this manual to identify availability of spare parts where some items on early models are

no longer available.

SES 2000 V ac (LS3) - Standard, from Serial Number SVE1A0000

without printer - REF 87-050-06

with printer - REF 87-050-14

SES 2000 V ac (LS3) - Long, from Serial Number SLVE1A0000

without printer - REF 87-050-22

with printer - REF 87-050-30

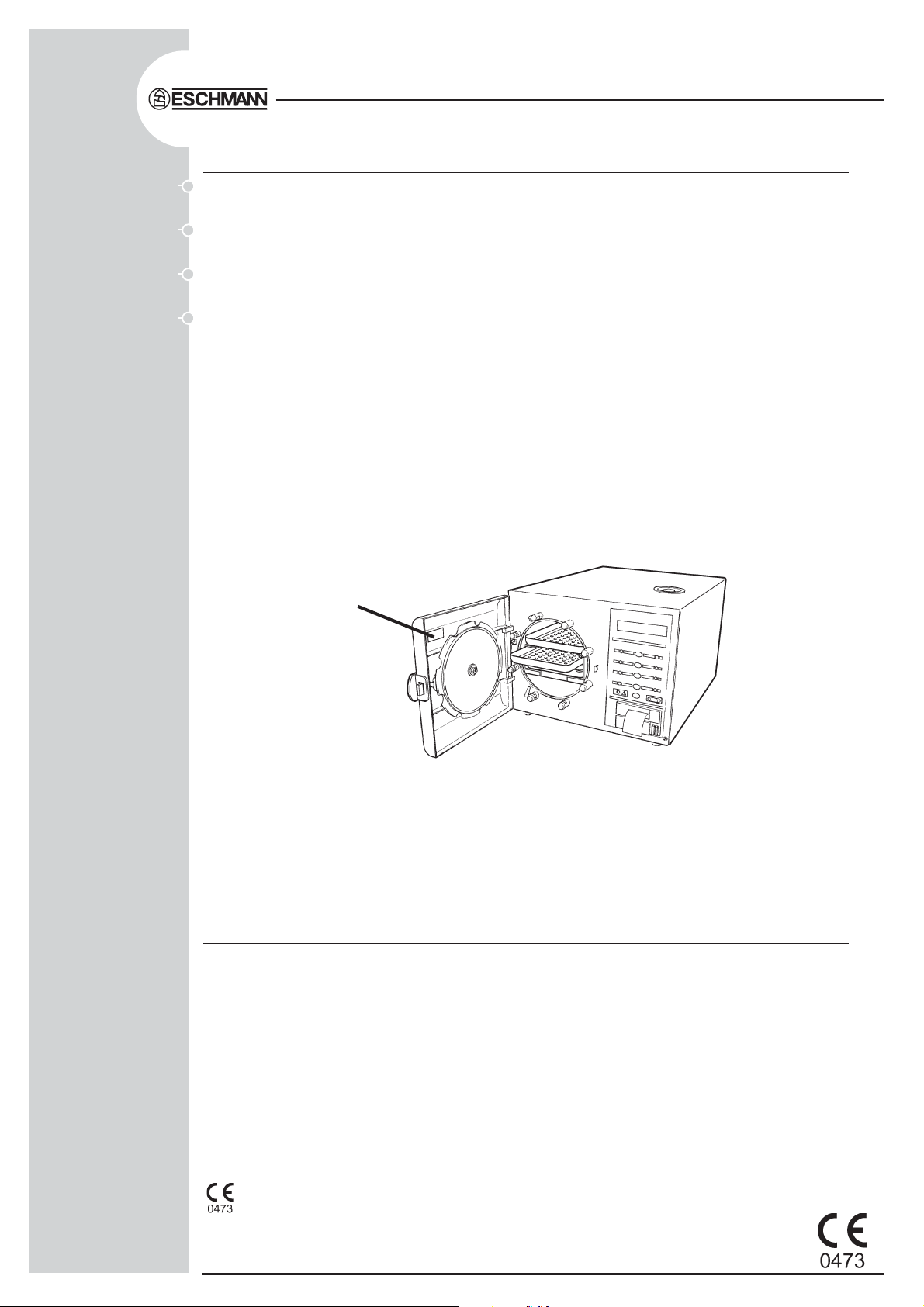

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquiries, please quote the

Model and Serial Number of your Autoclave which is shown on the Serial Number plate, the

location of which is shown below. Please ensure you include all alpha and numeric digits of the

Serial Number.

Serial Number

Plate

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

T el: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN logo is a registered trade mark of Eschmann Holdings Ltd.

“SES200” is a trade mark of Eschmann Holdings Ltd.

Patents : Patents Pending plus - Pat. US5090033 and Pat. GB2238407

Copyright © 2004 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

Service manual

ST-SM45g January 2005

SES 2000 Vac (LS3) AUTOCLAVE

CONTENTS

Page

Contents .. .. .. .. .. .. .. .. 3

T echnical data .. .. .. .. .. .. .. 4

PART 1 INTRODUCTION

General .. .. .. .. .. .. .. .. 6

Associated publications .. .. .. .. .. 6

Servicing .. .. .. .. .. .. .. .. 6

PART 2 DESCRIPTION

General .. .. .. .. .. .. .. .. 7

Operating features .. .. .. .. .. .. 7

Operation cycle .. .. .. .. .. .. .. 9

Display messages .. .. .. .. .. .. 1 1

Error indication .. .. .. .. .. .. .. 11

General.. .. .. .. .. .. .. .. 11

Overheating .. .. .. .. .. .. .. 12

PART 3 MAINTENANCE

Fuses .. .. .. .. .. .. .. .. 17

Fault diagnosis .. .. .. .. .. .. .. 17

Parts replacement and adjustment .. .. .. 23

Autoclave cover .. .. .. .. .. .. 23

Reservoir assembly .. .. .. .. .. 23

Transformer .. .. .. .. .. .. .. 23

Control board .. .. .. .. .. .. 24

Pressure door lock .. .. .. .. .. 24

Steam bleed solenoid valve .. .. .. .. 24

Door interlock microswitch .. .. .. .. 24

Solenoid door lock.. .. .. .. .. .. 25

T emperature sensors .. .. .. .. .. 25

Solenoid valves

V acuum, steam bleed, water discharge .. 25

Air-Inlet Solenoid Valve Assembly .. .. 25

Water-Fill Solenoid Valve Assembly .. .. 26

Heating element .. .. .. .. .. .. 26

Door seal .. .. .. .. .. .. .. 26

V acuum pump .. .. .. .. .. .. 26

Condenser .. .. .. .. .. .. .. 27

Cooling Fans.. .. .. .. .. .. .. 27

Bacterial air filter .. .. .. .. .. .. 27

Discharge line filter .. .. .. .. .. 27

Pressure transducer .. .. .. .. .. 27

Solid-state relay board .. .. .. .. .. 27

EMC board .. .. .. .. .. .. .. 28

Printer .. .. .. .. .. .. .. .. 28

Safety V alve .. .. .. .. .. .. .. 28

Band heater Temp. Sensor .. .. .. .. 28

Power switch .. .. .. .. .. .. 28

Float switch .. .. .. .. .. .. .. 28

Cooling ducts .. .. .. .. .. .. 28

Band heater .. .. .. .. .. .. .. 28

Chamber water level sensor .. .. .. .. 28

Manual reset cut-out .. .. .. .. .. 29

Reservoir water filter .. .. .. .. .. 29

V acuum pump maintenance .. .. .. .. 29

Page

Display board .. .. .. .. .. .. .. 30

Special operating modes .. .. .. .. .. 30

Engineering mode.. .. .. .. .. .. 30

Machine Set-up mode .. .. .. .. .. 30

Set-up procedure .. .. .. .. .. .. 30

Setting the autoclave serial number .. 31

Setting the cycles in use.. .. .. .. 32

Setting the display language .. .. .. 32

Setting date and time .. .. .. .. 32

Setting cycle counter .. .. .. .. 32

Errors and error clearing .. .. .. .. .. 32

Leak test procedure .. .. .. .. .. .. 33

Autoclave Calibration .. .. .. .. .. .. 33

General.. .. .. .. .. .. .. .. 33

Calibration procedure .. .. .. .. .. 33

Pressure relief valve test .. .. .. .. 35

Band heater calibration .. .. .. .. .. 36

Functional test .. .. .. .. .. .. 36

PART 4 ILLUSTRATED PARTS LISTS

Illustrated parts list 1: General spares .. .. 41

Illustrated parts list 2: Pipes and valves .. .. 44

Illustrated parts list 3: Heater

and process controls .. .. .. 46

ILLUSTRATIONS

Fig.1 SES 2000 V ac (LS3) autoclave .. .. .. 6

Fig.2.1a Autoclave door handle .. .. .. .. 10

Fig.2.1b Autoclave control panel.. .. .. .. 10

Fig.2.2 Autoclave: general arrangement .. .. 13

Fig.2.3 Autoclave: pipes and valves .. .. .. 14

Fig.2.4 Autoclave: heater and process controls .. 15

Fig.2.5 Sterilizing system schematic diagram .. 16

Fig.3.1 Door interlock microswitch .. .. .. 37

Fig.3.2 Discharge line filter.. .. .. .. .. 37

Fig.3.3 Control panel and switch identities .. .. 37

Fig.3.4 Control board adjustments .. .. .. 37

Fig.3.5 System circuit diagram .. .. .. .. 38

Fig.3.6 Piston vacuum pump .. .. .. .. 40

Fig.3.7 Replacement kit for piston pump .. .. 40

TABLE

Error code table .. .. .. .. .. .. .. 12

Fault Diagnosis table .. .. .. .. .. .. 17

APPENDIX A

Autoclave printer .. .. .. .. .. .. 50

Fig.A1-Fig.A4 Autoclave printer .. .. .. .. 51

APPENDIX B

PCA 424138 and Relay Assembly 112507

modification November 2004 .. .. .. .. 52

APPENDIX C

New fittings for EMC board .. .. .. .. 53

ST-SM45g Page 3 of 53

SES 2000 Vac (LS3) AUTOCLAVE

TECHNICAL DATA

(Standard Version)

Electrical Data

Supply 230V ac at 50/60Hz

Nominal Loading @ 230V - 2kW (8.7A)

Fuses Chassis

F10A, 250V, (x2)

Part No. 380003

Relay board

F5A, 250V (x1)

T2A, 250V (x1, was x 2 see Parts List 3)

T3.15A, 250V (x1)

Safety standards

EN61010-1:1993

EN61010-2-041:1996

Sterilizing Data (for software version 4.xx or later)

Sterilizing time

At 134/137°C 3 mins 15 sec.

At 121/124°C 15 mins

Typical overall cycle 134°C Unwrapped:

time (D indicates 20 minutes

drying included) 134°C Unwrapped:

35 minutes (D)

134°C Wrapped:

53 minutes (D)

134°C Porous:

63 minutes (D)

121°C Unwrapped:

28 minutes

121°C Unwrapped:

42 minutes (D)

121°C Wrapped:

62 minutes (D)

121°C Porous:

70 minutes (D)

Note: Overall cycle times may vary depending on

machine and loading conditions.

Dimensions

Autoclave Width 460mm

Length 650mm*

Height 360mm

* Feet spaced to fit 600mm worktop

Chamber Diameter 200mm

Length 348mm (max)

Porous Load Width 156mm (max)

basket Length 280mm

Height 93mm

Trays Width 183mm

Length 282.6mm

Height l7mm

Tray Loading 1.5 kg per tray

Chamber capacity 10.6 litres

Weight (approx.)

Net 45.7kg

Shipping 50.0kg

Symbols

For use with alternating current

Caution Hot Surface

Caution refer to

accompanying documents

"Porous load + Dry" cycle

"Wrapped + Dry" cycle

Nominal Operating pressures:

134°C cycle - 3.14 bar abs

121°C cycle - 2.11 bar abs

Water reservoir

capacity 3.5 litres

Page 4 of 53 ST-SM45g

"Unwrapped+Dry" cycle

"Unwrapped" cycle

SES 2000 Vac (LS3) AUTOCLAVE

TECHNICAL DATA

(Long Version)

Electrical Data

Supply 230V ac at 50/60Hz

Nominal Loading @ 230V - 2.75kW (12A)

Fuses Chassis

15A, 250V, (x2)

Part No. 301871

Relay board

F5A, 250V (x1)

T2A, 250V (x1, was x 2 see Parts List 3)

T3.15A, 250V (x1)

Safety standards

EN61010-1:1993

EN61010-2-041:1996

Sterilizing Data

Sterilizing time

At 134/137°C 3 mins 15 sec.

At 121/124°C 15 mins

Typical overall cycle 134°C Unwrapped:

time (D indicates 15 minutes

drying included) 134°C Unwrapped:

31 minutes (D)

134°C Wrapped:

46 minutes (D)

134°C Porous:

56 minutes (D)

121°C Unwrapped:

26 minutes

121°C Unwrapped:

41 minutes (D)

121°C Wrapped:

57 minutes (D)

121°C Porous:

67 minutes (D)

Note: Overall cycle times may vary depending on

machine and loading conditions.

Dimensions

Autoclave Width 460mm

Length 650mm*

Height 360mm

* Feet spaced to fit 600mm worktop

Chamber Diameter 200mm

Length 500mm (max)

Porous Load Width 156mm (max)

basket Length 450mm

Height 80mm

Trays Width 180mm

Length 450mm

Height 23mm

Tray Loading 3.5 kg per tray

Chamber capacity 15.6 litres

Weight (approx.)

Net 52kg

Shipping 58kg

Symbols

For use with alternating current

Caution Hot Surface

Caution refer to

accompanying documents

"Porous load + Dry" cycle

"Wrapped + Dry" cycle

Nominal Operating pressures:

134°C cycle - 3.14 bar abs

121°C cycle - 2.11 bar abs

Water reservoir

capacity 3.5 litres

ST-SM45g Page 5 of 53

"Unwrapped+Dry" cycle

"Unwrapped" cycle

SES 2000 Vac (LS3) AUTOCLAVE

PART 1 INTRODUCTION

Part 1

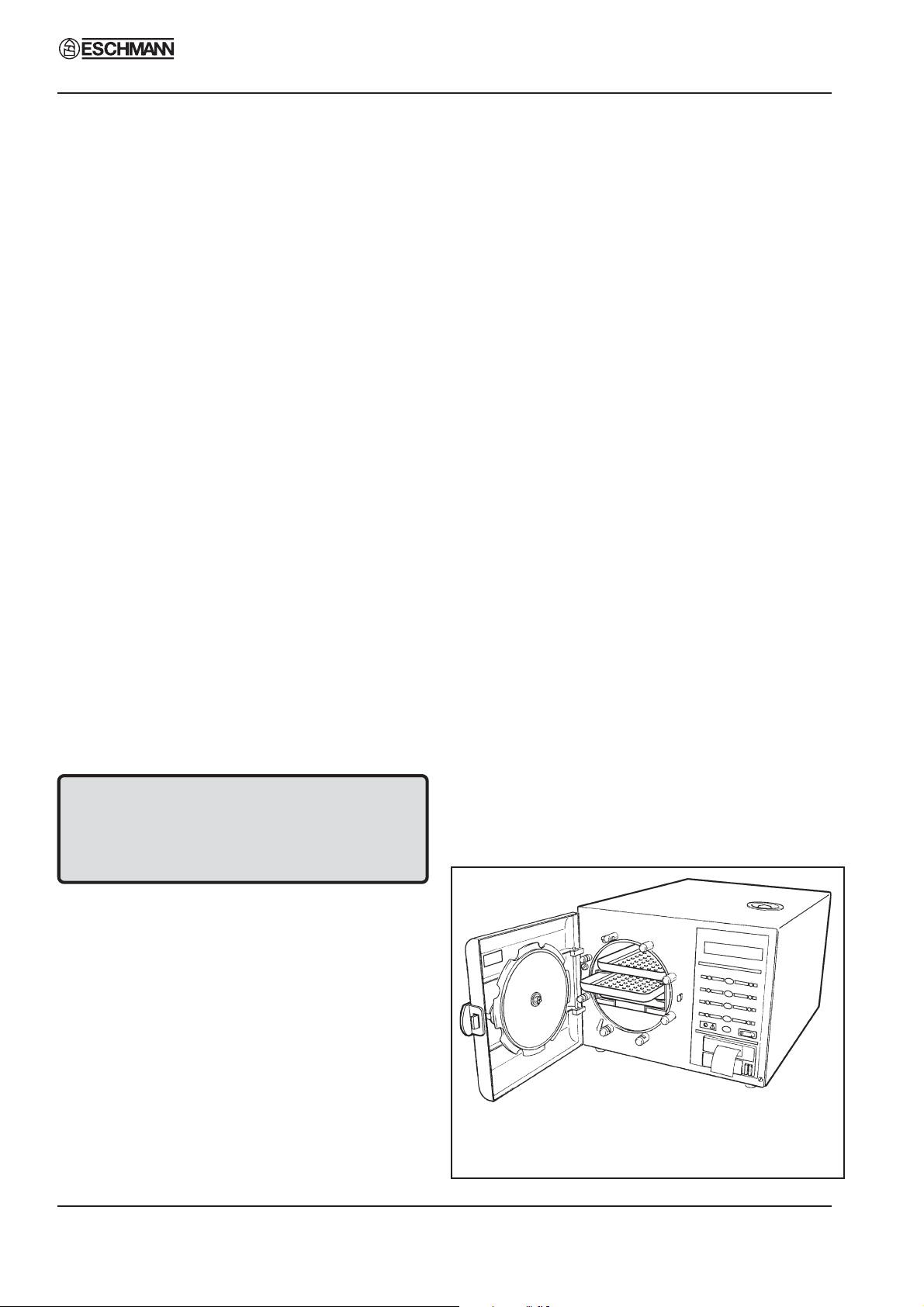

GENERAL (Fig. 1)

1 This Manual contains descriptive, maintenance

and spare parts information for the SES 2000 V ac (LS3)

autoclave units only .

2 The autoclave is a portable, electrically operated

steam unit designed for sterilizing wrapped, unwrapped

or porous loads. A drying phase is included in the porous

and wrapped cycles, which is optional for an unwrapped

cycle.

3 Wrapped loads must be packed single-wrapped

in L.M.G. SMITH BROTHERS “VIEW-PACK SELF

SEAL” pouches, and sterilized using the special pouch

rack accessory . The autoclave will also take cassettes

using a cassette carrier. A wire basket is provided for

sterilizing porous loads.

4 The autoclave operates automatically at the touch

of a single programme selector touch button, and has

eight sterilization programmes.

5 The autoclave is available with short or long

chambers and with or without an integral printer for

recording details of the sterilizing cycle. Details of the

printer are given in Appendix A page 50.

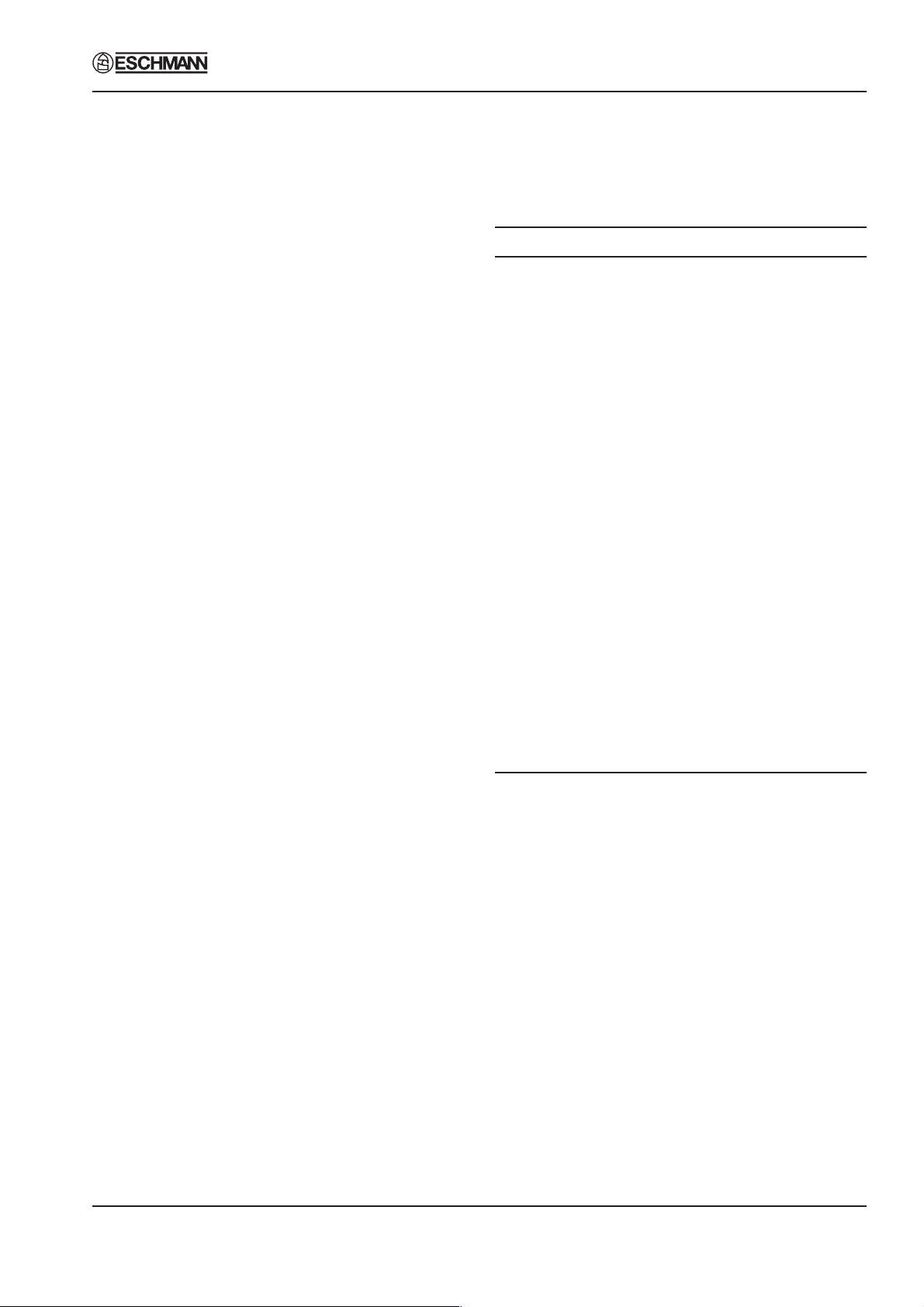

ASSOCIATED PUBLICATIONS

6 Separate installation and user instructions are

given in the SES 2000 V ac (LS3) autoclave ‘Instructions

for Use’, ST-IM62.

SERVICING

Note: When sterilizing lubricated dental handpieces,

the reservoir water should be changed every week to

prevent contamination of the door seal, and other rubber

components, used in the pressure system.

9 Eschmann recommend filling the reservoir with

‘Sterile Water for Irrigation’. This is low in dissolved solids

and has a low microbial count. In the U.K. the Department

of Health recommend that ‘Sterile Water for Irrigation’ is

used in bench-top Autoclaves (NHS Estates document

HTM2031).

If ‘Sterile Water for Irrigation’ is not being used then

Eschmann strongly recommend the use of either distilled

water, deionized water, purified water or water treated

by the reverse osmosis process. These types of water

are low in dissolved solids and can help reduce the

effects of tap water detailed below.

DO NOT USE TAP WATER, this is high in dissolved

solids and can deposit lime scale, block filters and cause

damage to the pressure vessel.

Eschmann also recommend that the reservoir is drained,

allowed to dry and is refilled on a weekly basis, with the

type of water detailed in ‘a’ (or ‘b’) above. At every service

interval the reservoir must be removed, be thoroughly

cleaned and dried, and then refilled. This will reduce

the build-up of contaminants in the water that may cause

blocked filters and/or damage to the pressure vessel.

Y our local Health Authority may suggest that you change

the reservoir water more frequently. Eschmann advise

you to follow your local Health Authority’s

recommendations (also see PART 3, MAINTENANCE

para. 5 to 7).

WARNING

When replacing parts during maintenance

procedures ONLY use parts supplied by

Eschmann Equipment or the safety of the

autoclave may be affected.

7 Ensure that routine servicing is carried out at

regular intervals by either Eschmann trained personnel

or suitably trained engineers only , otherwise the warranty

could be infringed.

8 Keep the Instructions for Use and this Service

Manual readily accessible for reference purposes prior

to and during operation, cleaning and servicing of the

autoclave.

CAUTION

In common with other systems containing static

water reservoirs, water used in this unit can become

contaminated over a period of time, or following an

aborted cycle, and should be treated as a potential

risk of infection.

Page 6 of 53 ST-SM45g

Fig. 1 SES 2000 Vac (LS3) autoclave

SES 2000 Vac (LS3) AUTOCLAVE Part 2

PART 2 DESCRIPTION

GENERAL (Fig. 1.1)

1 The autoclave is a portable steam unit heated by

electric elements. For sterilization of porous loads, a

vacuum is created in the chamber. The unit is supplied

to suit the mains electrical supply shown in TECHNICAL

DATA (pages 4 and 5).

2 The autoclave is electronically controlled and has

eight sterilizing programmes:

❑ 134°C Porous load with drying

❑ 134°C Wrapped load with drying

❑ 134°C Unwrapped load with drying

❑ 134°C Unwrapped load

❑ 121°C Porous load with drying

❑ 121°C Wrapped load with drying

❑ 121°C Unwrapped load with drying

❑ 121°C Unwrapped load

For typical sterilization cycle times, refer to TECHNICAL

DATA.

3 The required sterilizing programme is selected and

started by pressing the appropriate programme button on

the front panel of the unit, following which, the sterilizing/

drying cycle proceeds automatically until complete. The

printer (if fitted) will start automatically when the programme

button is pressed.

4 Indication of cycle status or error codes during a

cycle are provided by a digital display and printer (if fitted).

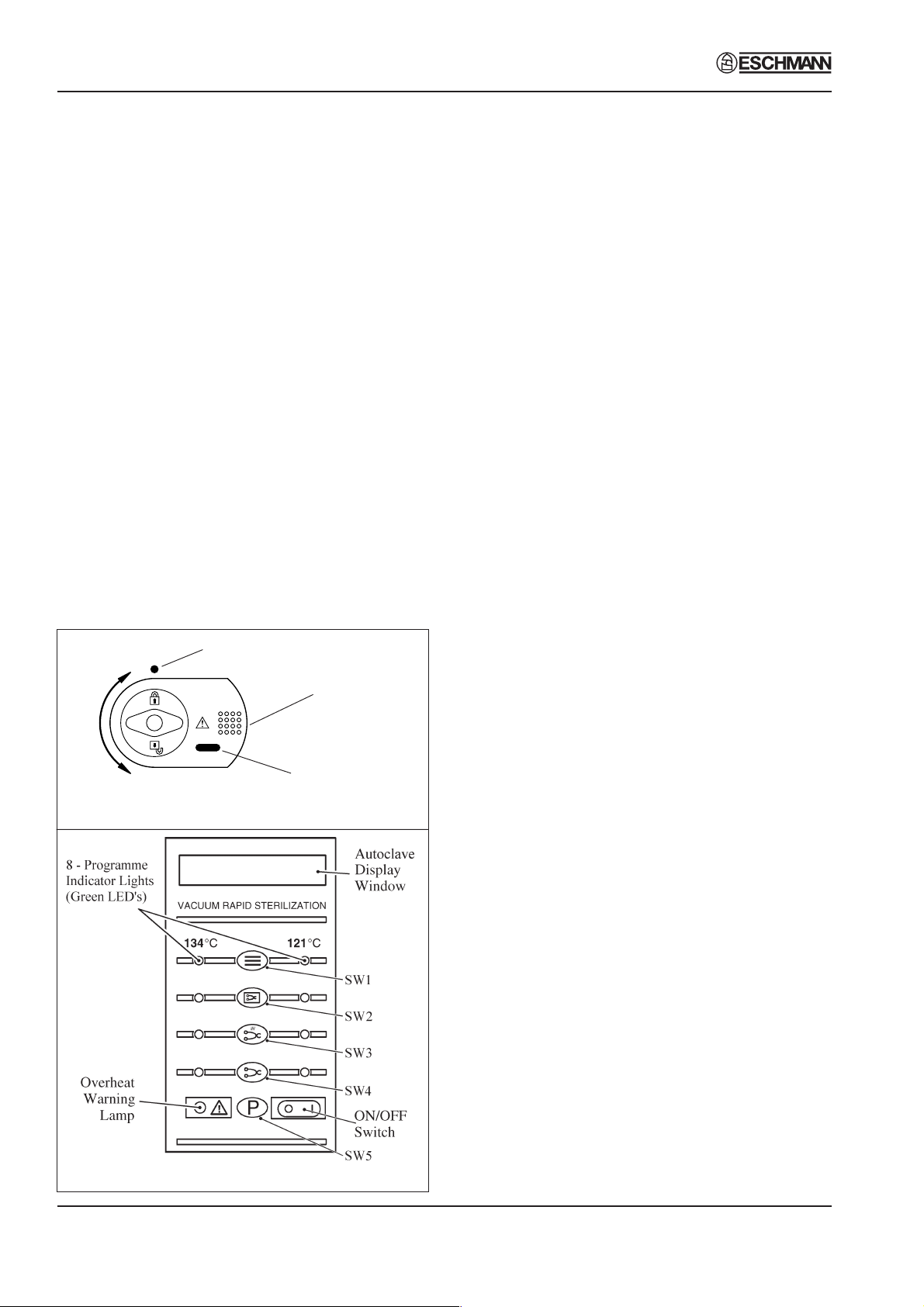

OPERATING FEATURES (Figs. 2.1, 2.2, 2.3 & 2.4)

5 The following equipment, designed for control or

protection, is incorporated in the autoclave:

❑ Process Display Window (Fig. 2.2, item 1). The

digital display indicates the temperature and pressure

inside the chamber. It also provides simple messages

for the user which indicate the stages through the

cycle, and also error conditions, should any occur.

❑ Four Programme Selector Buttons (Fig. 2.1b, SW1

to SW4). These are used to select and start

particular cycles. They can also be used to put the

autoclave in the ‘Engineering’ mode as described

later.

❑ Green Light Emitting Diodes (LED’s) (Fig. 2.1b).

There are eight LED’s which flash primarily to

indicate the cycles available for selection that can

be started and, when this has been done, to indicate

the particular cycle which is in progress.

❑ Power On/Off Switch (Fig. 2.1b). This switch

controls the mains power supply to the autoclave.

❑ Overheat Warning Lamp (Fig. 2.1b). Illumination of

this lamp indicates that one of the two protective

overheat cut-outs has operated.

❑ Door Latching Handle (Fig. 2.2, item 3). This handle

operates the door mechanism to secure the door in

the locked position against the chamber face.

❑ Door Safety Latch (Fig. 2.2, item 5). Engages a

safety catch to ensure that the door does not fly

open should there be residual pressure in the chamber

when the door latching handle is operated. It can

also be used to keep the door slightly ajar when the

autoclave is not in use.

❑ Door Interlock Microswitch (Fig. 2.4, item 4). This

is used to signal the controller that the door is

properly closed. It is operated by a simple, adjustable

mechanism and should operate just as the door is

fully closed.

❑ Pressure Door Lock (Fig. 2.3, item 14). This is a

safety device designed to ensure that the door

cannot be opened if the internal chamber pressure

exceeds approximately 0.2 bar (3.0 lbf/in2). The

device comprises a spring-loaded plunger driven by

the chamber pressure via a rubber diaphragm.

❑ Chamber Pressure Safety Indicator (Fig. 2.1a).

Fitted adjacent to the door latching handle (Fig.2.2

item 3) and operated by the pressure door lock

(Fig.2.3 item 14), it indicates that the chamber is

pressurised (red) and it is unsafe to open the door,

or unpressurised (green) and it is safe to open the

door.

❑ Solenoid Door Lock (Fig. 2.4, item 12). The

solenoid door lock prevents the door being opened

by the operator once the cycle has started. The lock

holds the door closed until the sterilizing cycle is

complete. It will also keep the door closed under all

fault conditions. As absence of power is also a

‘fault’ the unit power switch must be set to ‘on’ in

order to open the door.

Note: It is necessary to override the electrical door

lock to clear an error code. This is done by setting

the power switch to ‘off’, then, after a few seconds,

setting it back to ‘on’ again while pressing and

holding the ‘P’ selector (SW5) on the front panel (Fig

2.1b).

❑ Water Reservoir (Fig. 2.2, item 16). This is used to

hold distilled or deionized water or water treated by

reverse osmosis which is admitted into the chamber

via the water fill valve. The water reservoir also

receives hot water and steam vapour discharged

from the chamber towards the end of the cycle, via

the discharge valve. The vacuum pump (Fig. 2.3,

item 7) also discharges into the water reservoir.

ST-SM45g Page 7 of 53

Part 2 SES 2000 Vac (LS3) AUTOCLAVE

PART 2 DESCRIPTION

❑ Water Filter. The water filter is fitted on the end of

the water fill pipe in the water reservoir, and filters

the water entering the chamber.

❑ Reservoir Float Switch (Fig. 2.3, item 11). The water

reservoir is fitted with a float switch which will stop

the cycle being started if there is insufficient water

in the reservoir to complete a chamber fill. ‘Fill

Reservoir’ will be displayed should this occur.

❑ Heating Element (Fig. 2.4, item 1). The heating

element consists of a single immersion element

inside the chamber. The heating element is controlled

by a solid state relay and protected from overheating

by a manual reset thermostat. Refer to TECHNICAL

DATA for heater element loading.

❑ Solid-State Relay Board (Fig. 2.4, item 14). See

Appendix B. There are a number of key functions

provided by the relay board:

w Solid state relays (SSR) control the mains

supply to the water heater element (10A), band

heater (10A) and vacuum pump (2A).

w SSR status LEDs, give an indication of drive

status (On/Off).

w Mechanical relay provides additional safety

for heater and pump circuits.

w Fuses for protecting the 20V a.c. supply (3.15A),

condenser fan (2A) and vacuum pump (5A)

see 'Parts List 3'.

w Two voltage regulators.

w Autoclave bleeper.

w Connections for mains loom, signal loom,

temperature and pressure sensors, solenoid

valves, and transformer.

w Interface for front panel, control board, and

printer.

❑ Manual Reset Overheat Cutout (Fig. 2.4, item 21).

The manual reset overheat cutout is fitted at the rear

of the unit and is connected in series with the power

supply switch, band heater overheat cutout,

mechanical and SS relay and heater element. The

manual reset overheat cutout is operated by a fluidfilled capsule clamped to the heating element,

providing protection if the temperature of the heater

surface exceeds 250°C. It will remake electrically if

the reset button at the rear of the cabinet is pressed,

after giving the heater element time to cool.

❑ Band Heater Overheat Cutout (Fig. 2.4, item 24).

The band heater cutout is fitted on the band heater

and is connected in series with the power supply

switch, Manual Reset Overheat Cutout, mechanical

and SS relay and Band Heater. It contains a bimetallic disc thermostat which operates if the

temperature of the heater surface exceeds 250°C.

The cutout will remake electrically if the reset button

is pressed when the heater has cooled.

❑ Fuses. The unit has five fuses:

w Two fuses (Fig. 2.4, item 2) on the rear panel

of the cabinet rated as shown in TECHNICAL

DATA, which are connected in the ‘mains

supply’ to the unit.

w Three more fuses are fitted on the solid-state

relay board (see TECHNICAL DATA).

❑ Transformer (Fig. 2.4, item 17). The transformer

converts the incoming mains voltage to 24V a.c. It

is rated at 50VA.

❑ Water Fill Solenoid Valve (Fig. 2.3, item 4). The

water fill valve controls the water fill sequence. It is

electrically operated from the 24V d.c. supply

generated and signalled from the SSR board.

❑ Water Discharge Solenoid Valve (Fig. 2.3, item 3).

The water discharge valve is used at the end of the

sterilizing cycle to allow water and steam vapour

from the chamber to pass back into the reservoir.

The valve is electrically operated from a 24V d.c.

supply generated and signalled from the SSR board.

❑ Discharge Line Filter (Fig. 2.3, item 12). Prevents

debris from the chamber entering and fouling the

water discharge valve.

❑ Steam Bleed Solenoid Valve (Fig. 2.3, item 2). The

steam bleed solenoid valve operates in conjunction

with the steam bleed valve.

❑ Steam Bleed Valve (Fig. 2.3, item 15). The steam

bleed valve is connected in series with the steam

bleed solenoid valve to bleed steam from the chamber

during the 121°C cycles. It contains a ball and

spring which allows air displaced by the steam

generated in the chamber to pass into the reservoir.

Once steam starts to pass, the ball then lifts and

seals. A small ‘bleed’ remains, however, and it is

quite normal for small quantities of steam to escape

into the reservoir throughout the cycle.

❑ Safety Valve (Fig. 2.3, item 16). The safety valve

is fitted on the chamber tee-piece at the rear of the

chamber, and is factory set to release pressure from

within the chamber. It is a primary safety device and

must not be readjusted.

❑ Air In Solenoid Valve (Fig. 2.3, item 5). The air inlet

valve controls the admission of bacteriologically

filtered air to the chamber during the drying phase.

A non-return valve prevents flow from the chamber

to the bacterial filter to keep it dry.

❑ Vacuum Solenoid Valve (Fig. 2.3, item 1). When

open, this valve allows the vacuum pump to suck air

and steam from the chamber.

Page 8 of 53 ST-SM45g

SES 2000 Vac (LS3) AUTOCLAVE Part 2

PART 2 DESCRIPTION

❑ Vacuum Pump (Fig. 2.3, item 7). The vacuum pump

is a two stage diaphragm pump used to suck air and

steam from the chamber. Some models were fitted

with a piston pump (see Fig. 3.6) which is no longer

available, in case of fault, replace it with the current

diaphragm pump.

❑ Condenser (Fig. 2.3, item 6). The condenser pre-

cools air and steam from the chamber before it

enters the vacuum pump.

❑ Bacterial Filter (Fig. 2.3, item 10). The bacterial filter

filters the air entering the chamber.

❑ Chamber Temperature Sensors (Fig. 2.4, item 16).

These are used to sense the chamber temperature

and are fitted at the rear of the chamber. One sensor

controls the temperature within the chamber and the

other controls the displayed and the printed

temperatures.

❑ Band Heater Temperature Sensor (Fig. 2.4, item

15). The band heater temperature sensor is used to

control the band temperature during the drying

phase.

❑ Thermocouple Entry Port (Fig. 2.4, item 23). This is

used to insert a thermocouple into the chamber to

allow the operating temperature to be measured

and, if necessary, adjusted.

❑ Pressure Test Port (Fig. 2.4, item 22). The pressure

test port is used to insert a pressure measuring

probe to monitor the chamber pressure.

❑ Control Board (Fig. 2.4, item 19). The control board

interfaces with the relay board and front panel board

to control every aspect of management of the

autoclave. The main features are:

w Two microcontrollers (U1 and U12 Idents. on PCB)

which receive information from the front panel and

all the sensors (temperature (3 off), pressure, door

interlock, chamber water level, reservoir level). If

any errors are detected they are shown on the

display, and printed (if a printer is fitted) as error

codes (see Part 2, para. 28 and 29).

w Message memory (U13) in four variants

covering all the main languages spoken by

Eschmann customers.

w Trimmer potentiometers for calibration of the

band heater and temperature/pressure

channels.

w Engineering switch for set-up and calibration

modes (see special operating modes page 30).

w Outputs from the control board control the

heaters, pump, and solenoid valves via the

relay board interface.

❑ Front Panel Board (Fig. 2.4, item 13). This board

incorporates the vacuum fluorescent display,

programme select and cancel switches, and

programme indicator LEDs. It interfaces with the

control and relay boards via a 10-way ribbon

connector.

❑ Pressure Transducer (Fig. 2.4, item 7). The pressure

transducer monitors the pressure in the chamber

and generates chamber pressure signals for cycle

monitoring, control, and display.

❑ Printer (Fig. 2.2, item 21). The printer, if fitted, starts

automatically when a cycle button is selected and

will print out a hardcopy of the sterilization cycle.

Details of the printer are given in Appendix A to this

Manual.

❑ Fans (Fig. 2.4, items 10 and 11). Two fans are fitted

in the autoclave. One fan provides cooling for the

condenser and the PCB compartment (via a bleed

conduit). The other fan draws air over the chamber

for rapid cooling between cycles.

❑ Band Heater (Fig. 2.4, item 18). The band heater

heats the chamber during the drying cycle.

❑ EMC Board (Fig. 2.4, item 5). The EMC board

provides electro-magnetic compatibility protection

for the autoclave.

OPERATION CYCLE

6 A detailed knowledge of the operation of the autoclave

is not necessary to be able to repair it effectively;

however, a basic understanding of the various processes

of autoclave operation which occur during a cycle is given

in the following paragraphs.

CAUTION

Ensure that the Autoclave is switched off before

filling the reservoir. DO NOT USE TAP WATER.

Note: When filling the reservoir, consult the 'Instructions

for Use' which provides information on the types of water

that should be used.

7 Power is switched on by selecting the power switch

(O-I) to I (Fig. 2.1b). If the chamber door is open there now

follows a single audible tone accompanied by the display

'SES Vacuum LS3+cycle count+version of software',

which then changes to 'CLOSE THE DOOR'.

8 If the door is closed, when power is switched on, the

display will show 'SES Vacuum LS3+cycle count+version

of software', which then changes to 'OPEN THE DOOR'.

9 After the work trays have been put in the chamber

and the door closed, a programme can be selected and

initiated by pressing one of the programme selector

buttons (Fig. 2.1b). If the autoclave has a printer it will

automatically start when the programme selector button

is pressed.

ST-SM45g Page 9 of 53

Part 2 SES 2000 Vac (LS3) AUTOCLAVE

PART 2 DESCRIPTION

10 When the door is closed, with the power switched on,

this is sensed by the control board via the door interlock

switch. If any attempt is made to open the door once the

cycle has begun, the display 'ERROR 2' will appear and

an audible signal will sound. Under these circumstances

it is necessary to switch the autoclave off, wait 5 seconds,

reset the error (see Part 3, para. 54) and restart the cycle.

11 The autoclave operates automatically at the touch of

a single programme selector touch button ( Fig. 2.1b), and

has eight programmes:

❑ 134°C Porous load with drying (SW1)

❑ 134°C Wrapped load with drying (SW2)

❑ 134°C Unwrapped load with drying (SW3)

❑ 134°C Unwrapped load (SW4)

❑ 121°C Porous load with drying (SW1)

❑ 121°C Wrapped load with drying (SW2)

❑ 121°C Unwrapped load with drying (SW3)

❑ 121°C Unwrapped load (SW4)

12 Each programme selector button on the control panel

(Fig. 2.1b) will select either the 134°C or 121°C cycles.

The programme indicator lights, at each side of the

programme selector buttons, will change to indicate a

change of selection between 134°C and 121°C each time

Door lock position

Locked

indicator

Safety catch

behind door plate

the appropriate selector button is pressed. In addition,

the display will show the appropriate programme

description to confirm the programme that has been

selected. Once the programme and the temperature

range has been selected, the sterilization cycle will start

automatically, after a delay of approximately four seconds.

13 The printer, if fitted, will start printing and, as the

cycle progresses, various display messages will appear

in the display window to indicate the programme status.

Note: If a programme is started in error, it can be cancelled

by pressing the 'P' selector button (SW5), provided that the

cycle has not reached the water fill stage.

14 When a cycle is selected (SW1- SW4 pressed),

'CYCLE STARTED' will be displayed, quickly followed by

'VACUUM ON', indicating that the vacuum pump has

started, and the vacuum solenoid valve has opened to

evacuate the air from the chamber.

15 When the pressure in the chamber has decreased to

the required value for the programme selected, the water

fill valve will open and 'FILLING' will be displayed, indicating

that water is being sucked from the reservoir and into the

chamber.

16 When the cycle has started, the door cannot be

opened due to the electric door lock and vacuum force on

the door.

Unlocked

Fig. 2.1a Autoclave door handle

Fig. 2.1b Autoclave control panel

Chamber pressure

indicator

1 7 When the correct quantity of water has entered the

chamber, the water fill valve closes together with the

vacuum valve. The heater, controlled by the control

board, will switch on, and the pressure in the chamber will

increase. This phase is indicated by 'PULSING' being

shown on the display.

1 8 The heater is controlled by a system which ensures

that the operating temperature is reached with minimal

overshoot. Initially, the heater will be 'on' continuously

and the measured temperature will be displayed. Note,

however, that the system does not register temperatures

below 92°C.

19 Temperatures are displayed with a resolution of

0.1°C, using signal averaging to ensure a stable, accurate

display.

20 Control of the cycle is fully automatic with temperature

information being monitored by temperature sensors.

Timing is controlled by the control board and cycle times

cannot be adjusted. By comparing measured values with

known time/temperature relationships, the control board

is able to detect faults such as lack of water at the fill

stage, or loss of water and steam during the process, and

Page 10 of 53 ST-SM45g

SES 2000 Vac (LS3) AUTOCLAVE Part 2

PART 2 DESCRIPTION

it will indicate such problems by displaying errors codes

such as 'ERROR 3' or 'ERROR 4' respectively, which will

be accompanied by an audible warning signal (see Error

Code Table page 12).

21 The autoclave operates at temperatures slightly

above the usual recommended minimums. The operating

temperature for the 121°C cycle is set to 122°C, and the

134°C cycle is set for 135°C.

22 As the cycle enters the sterilization phase, the

display shows 'STERILIZING'. At the end of the sterilizing

phase the heater is turned off and the discharge valve is

opened to discharge water and steam from the chamber.

This phase is indicated by 'CONDENSING' being shown

on the display.

23 Once the controller detects that chamber temperature

and pressure have fallen to a safe level, the display

'CYCLE COMPLETE' will be shown to indicate that the

cycle is complete. When the chamber door is opened the

display will show 'CLOSE THE DOOR'.

Note: If the autoclave has a printer, the printout will

include the following details:

❑ Autoclave type and serial number.

❑ Date and time of sterilization cycle.

❑ Counter indication (five digits with leading zeros).

❑ Sterilization cycle type, e.g. 134°C without drying.

❑ Sterilization cycle time, temperature, and pressure.

❑ Sterilization cycle ended message.

Operating information relating to the printer is given in

Appendix A to this Manual.

24 The overall time for the cycle is not fixed and

depends on many factors such as the supply voltage, the

load, and the ambient temperature. However, the control

board will ensure a satisfactory sterilization cycle even

when these factors vary over wide ranges.

25 If a cycle employing a drying phase is selected,

operation to the end of the sterilizing phase is as described

previously. After discharge of steam and water back into

the reservoir, however, the display 'DRYING' will be

indicated, together with the time remaining to the end of

the cycle. During the drying phase, operation of the

autoclave will alternate between vacuum pulses and

filtered air inlet pulses to achieve optimum drying.

2 6 The length of the drying phase will vary according to

the programme selected, and the chamber band heater

will operate to promote drying. At the end of the drying

phase, the display 'CYCLE COMPLETE' will appear

indicating that the door can be opened.

DISPLAY MESSAGES

2 7 Throughout a selected cycle the following symbols

may appear on the digital display:

Display Meaning

OPEN THE DOOR Door was closed when the

autoclave was switched 'on'.

PLEASE WAIT* The autoclave is measuring

atmospheric pressure

CLOSE THE DOOR The door is open and the cycle

cannot start.

READY FOR USE Waiting programme selection.

CYCLE STARTED Programme selected and cycle

started.

VACUUM ON Chamber air/steam discharge

in progress.

FILLING Water entering chamberprior to

steriliszation

PULSING Pre-sterilization steam

treatment.

STERILIZING Sterilization in progress.

CONDENSING Discharging water and steam

from chamber.

DRYING Load being dried (time remaining

to the end of cycle will also be

shown).

CYCLE COMPLETE Cycle completed successfully.

* Only applicable to software version 5.2 or above (as

shown briefly on display when autoclave first switched on).

ERROR INDICATION

General

2 8 If an error occurs during the cycle, an error code will

be displayed (see the Error Code Table on page 12).

29 If an error occurs during a cycle, the control board will

cancel the cycle (see Fault Diagnosis, and Errors and

Error Clearing in Part 3).

Note: These error codes will generally require investigation

by an Eschmann trained engineer. If an error occurs

during the cycle, the printer (if fitted) will print out the date

and time, the message 'CYCLE FAILED' and the appropriate

error code. Information relating to the printer, if fitted, is

given in Appendix A to this Manual.

ST-SM45g Page 11 of 53

Part 2 SES 2000 Vac (LS3) AUTOCLAVE

PART 2 DESCRIPTION

ERROR CODE TABLE

Display Meaning / Cause

POWER FAILURE Temporary failure in the

(Error 1 not shown) mains supply to the unit.

Error 2 Faulty or incorrectly adjusted

door switch, or door not fully

closed at start of cycle.

Error 3 Water failed to enter chamber

from reservoir.

Error 4 Water level in chamber has

dropped during run-up to

sterilizing cycle.

Error 5 Heater element not working

during run-up to sterilizing phase.

Error 6 Control channel low temperature.

Error 7 Control channel high

temperature.

Error 8 Display channel low

temperature.

Overheating

30 In the unlikely event of overheating, the red overheat

warning lamp (see Fig. 2.1b and Fig. 2.4 item 8 ) at the

front of the autoclave will illuminate. If this happens, first

allow 10 to 15 minutes to elapse for the autoclave to cool,

then check the water level in the reservoir and top-up if

required. When the water level is correct, press the

'PRESS TO RESET' button at the rear of the cabinet (Fig.

2.4 item 21) and restart the cycle as normal. If the fault

persists, switch off the autoclave and call an Eschmann

Trained Engineer.

Error 9 Display channel high

temperature.

Error 10 Insufficient first vacuum pulse.

Error 11 Insufficient second vacuum

pulse.

Error 12 No steam pulse.

Error 13 (i) Before filling takes place

= Air Detector test failure

(ii) At beginning of sterilization =

Steam quality error.

Error 14 Insufficient drying vacuum.

Error 15 Sensor system failure.

Error 16 Clock speed error during

sterilizing phase.

Error 17 Band heater not achieving

setpoint temperature during

drying phase.

FILL RESERVOIR Water level in reservoir has

dropped below 'MIN' mark.

Page 12 of 53 ST-SM45g

SES 2000 Vac (LS3) AUTOCLAVE Part 2

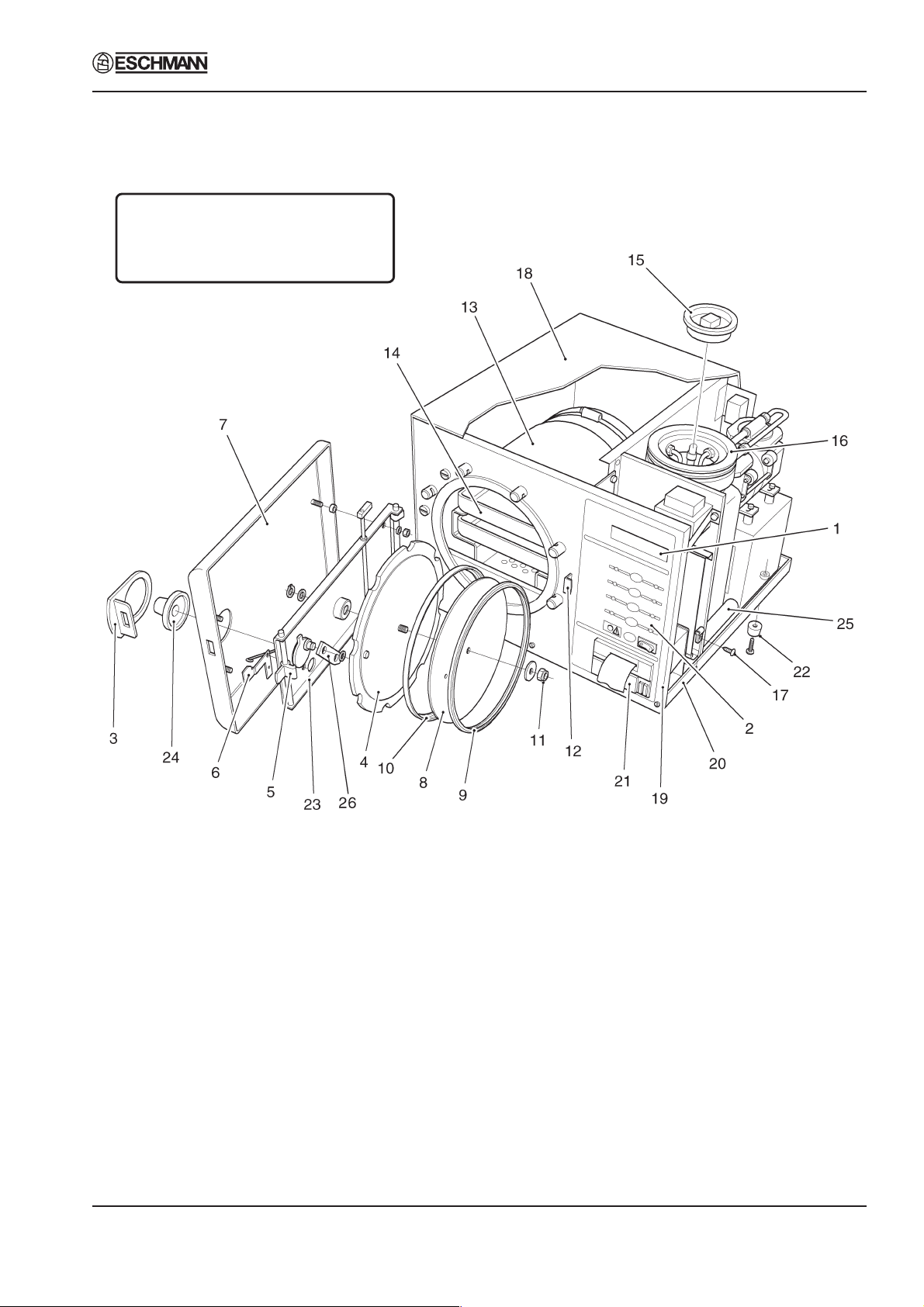

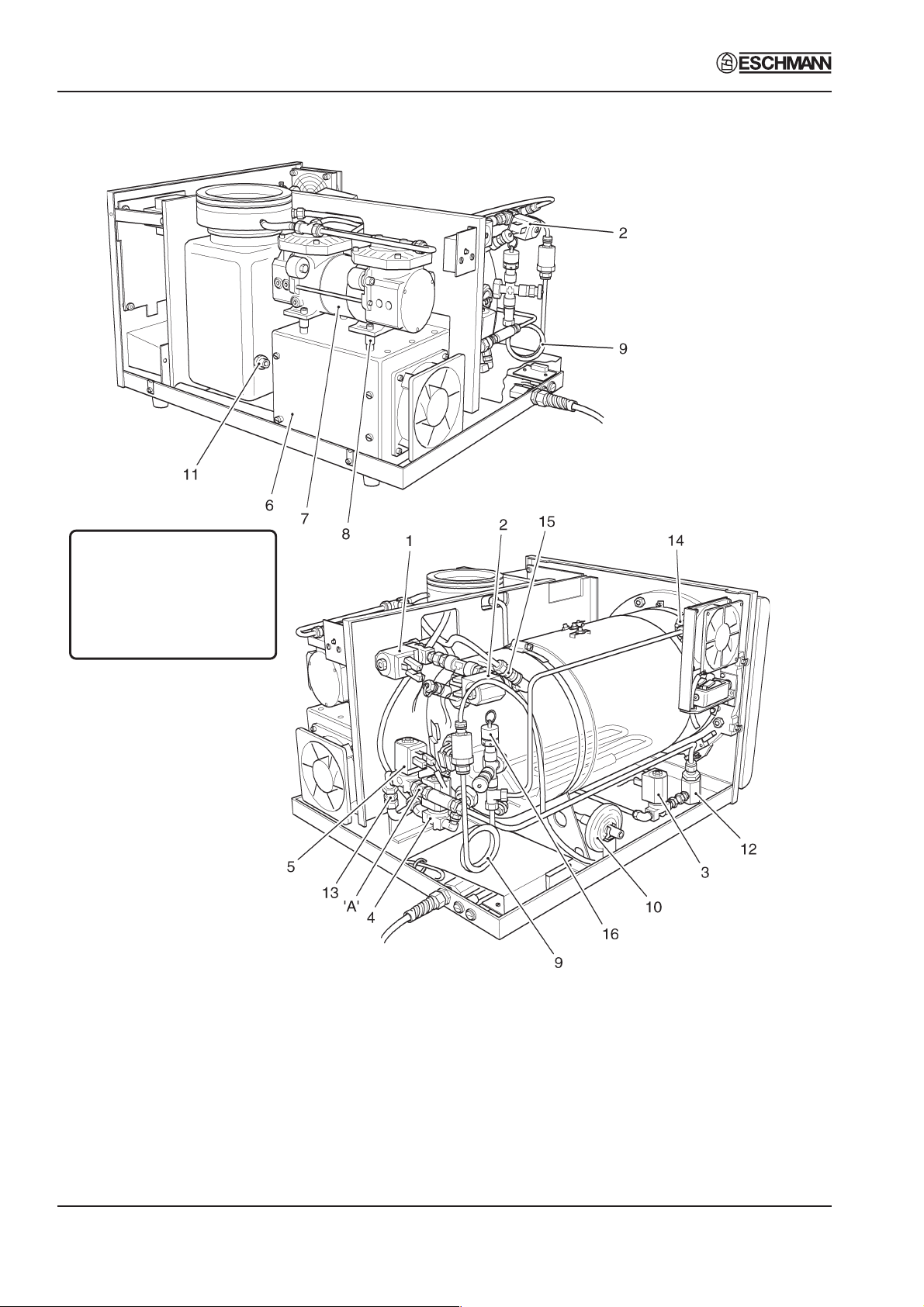

Note: Some autoclaves will have a

different pump to that shown. See

maintenance section and parts list for

pump replacement details.

PART 2 DESCRIPTION

1 Process display window 10 Seal retaining rim 19 Front panel

2 Control panel 11 Aerotight nut 20 Chassis

3 Door latching handle 12 Door safety catch 2 1 Printer

4 Pressure door 13 Pressure chamber assembly 22 Foot

5 Door latch 1 4 Work tray 2 3 Door beam

6 Pressure safety indicator 1 5 Reservoir lid 2 4 Door knob

7 Door cover 16 Reservoir 25 PCB cooling conduit

8 Seal retaining disc 1 7 Cover screw 2 6 Link

9 Door seal 18 Unit cover

Fig. 2.2 Autoclave: General Arrangement

ST-SM45g Page 13 of 53

Part 2 SES 2000 Vac (LS3) AUTOCLAVE

PART 2 DESCRIPTION

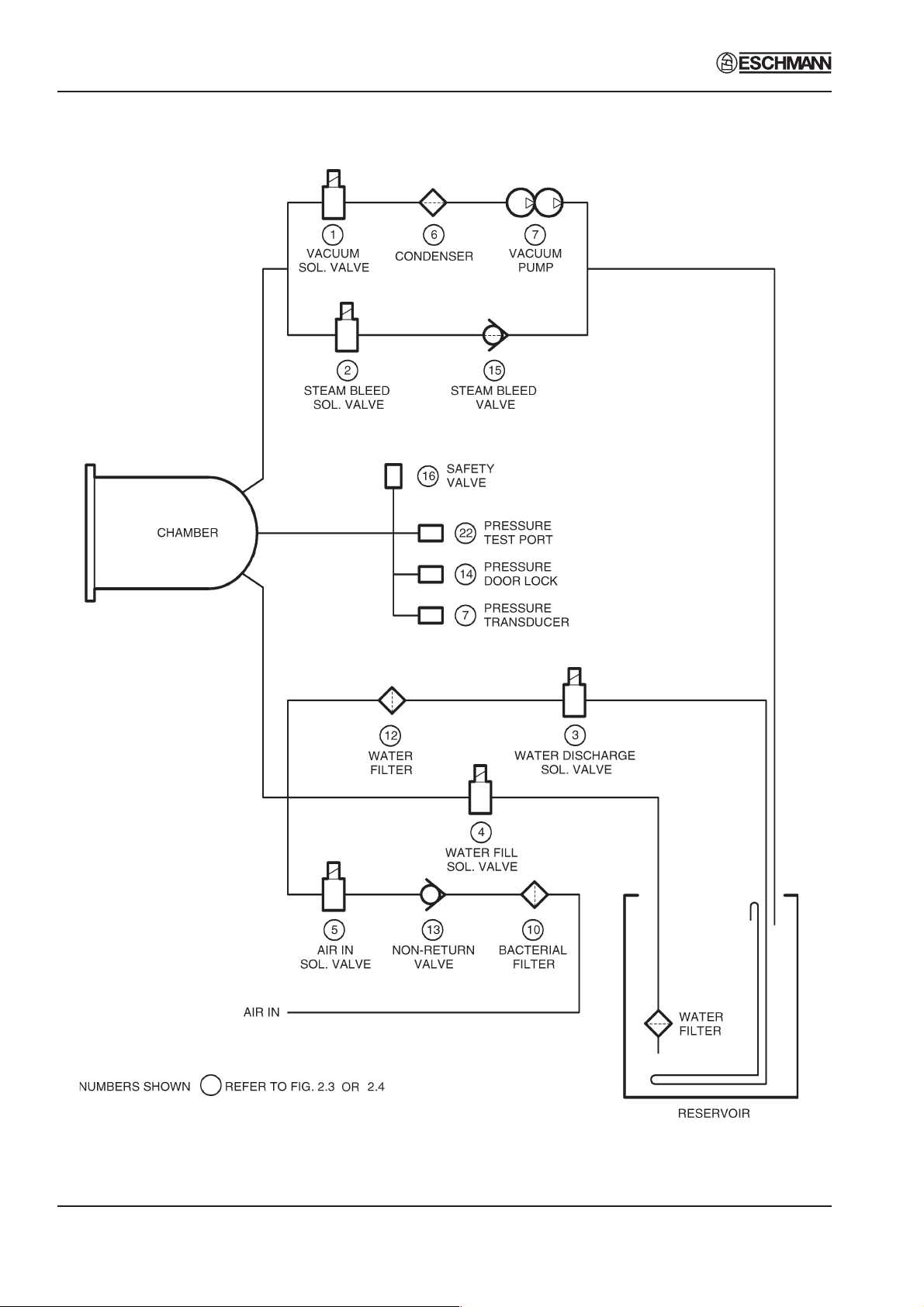

Note: Some autoclaves will

have a different pump to

that shown. See

maintenance section and

parts list for pump

replacement details.

'A' - Stud coupling nut

1 Vacuum valve 9 Transducer coil

2 Steam bleed solenoid valve 10 Bacterial air filter

3 Water discharge valve 11 Reservoir float switch

4 Water fill valve 1 2 Discharge line filter

5 Air in valve 13 Non-return valve

6 Condenser 1 4 Pressure door lock

7 Vacuum pump 15 Steam bleed valve

8 Pump foot 16 Safety valve

Fig. 2.3 Autoclave: Pipes and Valves

Page 14 of 53 ST-SM45g

SES 2000 Vac (LS3) AUTOCLAVE Part 2

PART 2 DESCRIPTION

Note: Some autoclaves will have a

different pump to that shown. See

maintenance section and parts list for

pump replacement details.

1 Heating element 9 ON/OFF (O/I) switch 1 7 Transformer

2 Mains fuses 1 0 Enclosure fan 18 Band heater

3 Mains cable 1 1 Condenser fan 19 Control board

4 Microswitch 12 Solenoid door lock 2 0 Printer

5 EMC board 13 Front panel board 21 Manual reset overheat cut-out

6 Choke 14 Solid-state relay board* 22 Pressure test port

7 Pressure transducer 15 Band heater temperature sensor 23 Thermocouple entry port

8 Overheat warning lamp 16 Chamber temperature sensors 2 4 Band heater overheat cut-out

2 5 Bulb (for Manual Reset 21)

* see Appendix B

Fig. 2.4 Autoclave: Heater and Process Controls

ST-SM45g Page 15 of 53

Part 2 SES 2000 Vac (LS3) AUTOCLAVE

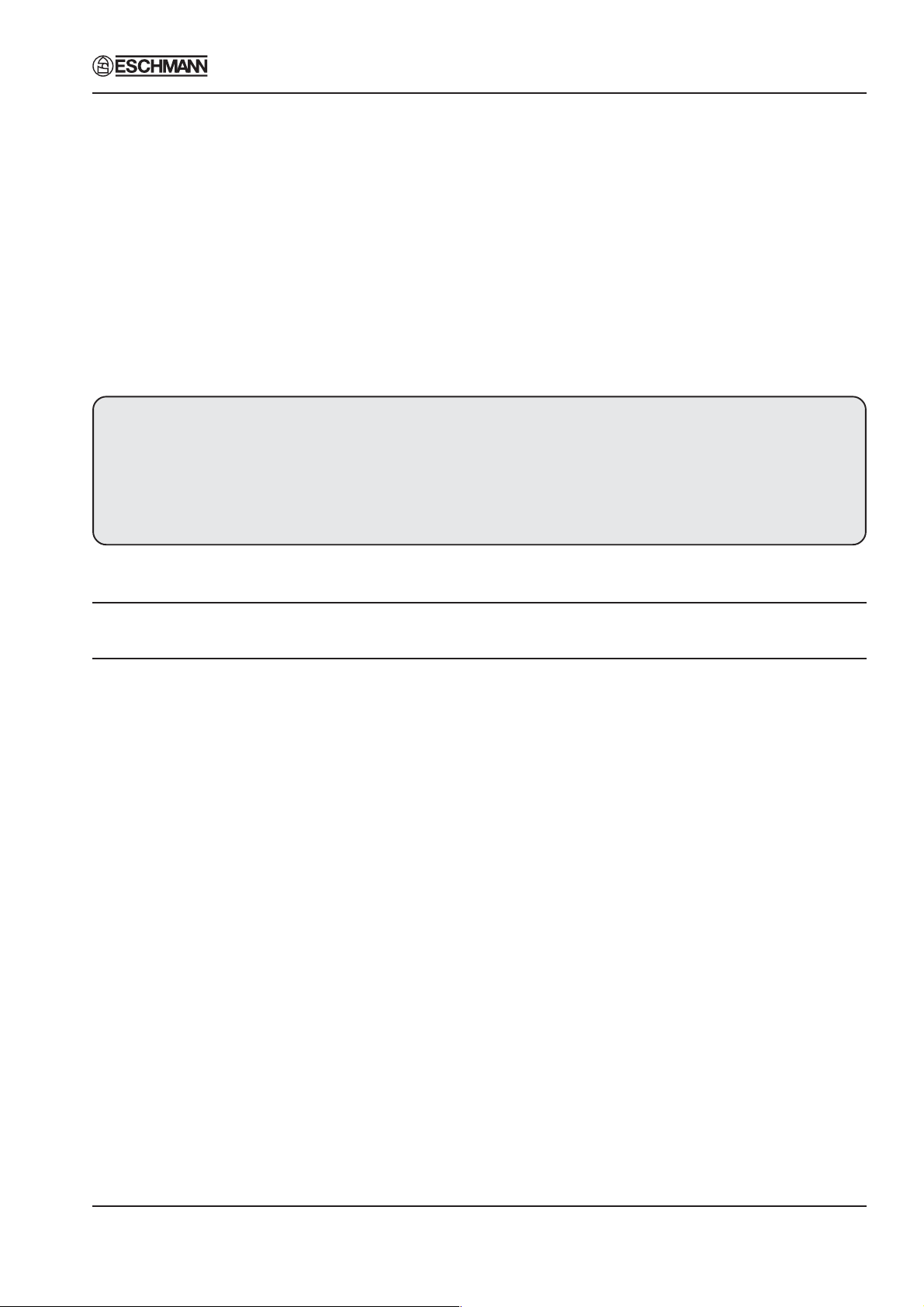

PART 2 DESCRIPTION

Fig. 2.5 Sterilizing System Schematic Diagram

Page 16 of 53 ST-SM45g

SES 2000 Vac (LS3) AUTOCLAVE Part 3

PART 3 MAINTENANCE

FUSES (Fig. 2.4 )

1 The autoclave is protected by five fuses. Two mains supply fuses are fitted on the rear cover of the autoclave

(Fig. 2.4 item 2). Three more fuses are fitted to the solid state relay board (Fig. 2.4. item 14). All fuse ratings are given

in the TECHNICAL DATA section.

FAULT DIAGNOSIS

2 A number of typical faults which could occur, their possible causes and how to remedy them are listed below. For

maintenance procedures refer to Parts Replacement and Adjustment.

Note: Cross references in the ‘Remedy’ column (e.g. para.10) refer to paragraphs in the Parts Replacement and

Adjustment section that follow later in Part 3.

WARNINGS

Switch-off and disconnect mains power supply before removing the autoclave cover, or doing

maintenance procedures. During certain procedures mains voltage may have to be present with the

cover removed and extreme care should be taken to avoid contact with mains voltage.

Check that chamber is at atmospheric pressure before opening the door.

Should the door be opened beware of possible very hot water or steam escaping from the chamber.

Fault Diagnosis Table

Fault Possible Cause Remedy

(1 ) Nothing happens when power (a) Mains supply failure. (a ) Check mains supply, also

switched on (No display). plug and supply cable

for loose connections

or breaks.

(b ) Main fuses blown (b) Replace fuse(s)*.

(rear panel).

(c) Faulty power switch. (c) Replace power switch

(para 31).

(d ) Solid-state relay board ( d) Replace fuse*.

fuse blown or loose.

(e ) Transformer failed. (e ) Check transformer secondary

voltage (20V a.c. rms).

Replace transformer if

output is zero (para 8).

(f) Short circuit on (f) Check sensor, fill valve, vent

24V circuit. valve etc. for short circuit

Replace where necessary.

(g ) Short circuit on solid-state ( g ) Check SSR board is correctly

relay board. fitted in bottom guide,

with correct clearance from

dividing panel. Also see

Appendix B

*Note: Blown fuses can indicate further problems. Always investigate the reason for any fuse blowing,

but bear in mind that fuses can ‘age’ and blow for no other reason.

Continued

ST-SM45g Page 17 of 53

Loading...

Loading...