Page 1

RX600

OPERATION TABLE

Service Manual

606049

T-SM14g

Page 2

Preliminary Information

Technical Data

Safety Notes

Introduction

Description

Maintenance

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and assistance

during normal office hours. To avoid delays when making enquires, please quote the Model and Serial

Number of your Operation Table which is shown on the Serial Number plate, the location of which is

shown below. Please ensure y ou include all alpha and numeric digits of the Serial Number .

The Serial Number plate can

be found on the inside of the

long trunk section casting

indicated here.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex , BN15 8TJ, England.

T el: +44 (0) 1903 765040. F ax: +44 (0) 1903 762006.

Overseas Customers

Contact your local distributor. In case of doubt contact Esc hmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered tr ade marks of Eschmann Holdings Limit ed.

“Eschmann Equipment” is a trading name of Eschmann Holdings L imited.

“RX600” is a tr ade mark of Eschmann Holdings L imited.

Patents: GB 2260075 & GB 2242624; F rance 536922 & 450836; US5116032;

Germany P69206378.1 & P69104883.5; Italy 536922 & 450836.

Patents pending in Japan, application n umbers 263630/92 & 97990/91.

Copyright © 2002

All rights reserved. This booklet is protected by cop yright. No part of it may be reproduced, stored in a retrie val

system or transmitted in any form or by any means , electronic, mechanical, photocopying, recording or otherwise

without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company , howe ver, reserves the

right to modify or improve the equipment referred to .

If the CE mark is affixed to the product, it indicates compliance with Council Directive

93/42/EEC of 14 June 1993 concerning medical devices.

T-SM14g October 2002

Service Manual

Page 3

RX600RX600

RX600

RX600RX600

OPERATION TABLE

READ THESE INSTRUCTIONS BEFORE USE

Keep these Instructions in a safe con venient place for future reference. Read in conjunction

with the relevant Publications detailed in the preliminary information section.

CONTENTS

Section Contents Page

1. PRELIMINARY INFORMATION.............................. 4

2. TECHNICAL DA TA ................................................. 4

3. SAFETY NOTES ................................................... 5

4. INTRODUCTION .................................................... 6

General .............................................................. 7

Electrical system ............................................... 7

Main control board ......................................... 7

Height opto board........................................... 7

Base distribution board .................................. 8

T op-of-column distribution board..................... 8

T op-of-column solenoids board....................... 8

Tilt opto board................................................ 8

Po wer circuits ................................................ 8

Hand control .................................................. 8

Footswitch ..................................................... 8

T ab le-base on/off control ................................ 9

Built-in battery charger................................... 9

External battery charger................................. 9

Standby system connections......................... 9

T raction beam sto wage detection ................... 9

5 . DESCRIPTION .................................................... 10

6 . MAINTENANCE................................................... 14

General ............................................................ 14

Cleaning and storage ....................................... 14

General care and lubrication............................. 14

Gas springs ................................................. 14

Head, hip & leg sections & sacral extension 1 4

Head and hip locking mechanisms............... 14

Long and short trunk sections...................... 1 4

Radiographic tops ........................................ 15

Underside of the table base ......................... 15

T raction beam attachment............................ 15

Access to fuses ........................................... 18

Hand control ................................................ 18

After maintenance........................................ 18

Functional checks............................................ 18

General ........................................................ 18

Hydraulic system ............................................. 19

General ........................................................ 19

T opping-up hydr aulic reservoir ...................... 19

Adjustments .................................................... 19

T rendelenburg micros witch ........................... 19

Lateral tilt opto ............................................. 19

Break microswitch ....................................... 19

Level tilt switch............................................ 20

Traction beam swiv el joints .......................... 22

Removal and installation .................................. 22

General ........................................................ 22

Remove table base covers .......................... 22

Install table base covers .............................. 22

Remove top-of-column covers ..................... 23

Install top-of-column covers......................... 23

Releasing telescopic cover and upstand ...... 23

Replacing telescopic cover and upstand ...... 23

Removing telescopic cover .......................... 23

Replacing telescopic cover .......................... 23

Remove long and short trunk assembly....... 23

Install long and short trunk assembly .......... 2 4

Section Contents Page

Remove break cylinder ................................ 26

Install break cylinder.................................... 26

Remove lateral tilt cylinder........................... 29

Install lateral tilt cylinder.. ............................ 29

Remove T rendelenburg cylinder.................... 28

Install T rendelenburg cylinder ....................... 30

Remove height cylinder................................ 30

Install height cylinder ................................... 30

Gas spring replacement ............................... 31

Remove batteries......................................... 31

Install batteries ............................................ 31

Remove the base feet.................................. 31

Install the base feet ..................................... 32

Infill interlocking mechanism replacement.... 32

Push button replacement and adjustment .... 32

T raction beam remo val................................. 33

T raction beam replacement .......................... 33

Remove s wiv el joint from short trunk ........... 33

Refit swivel joint to short trunk..................... 33

Traction beam swiv el joint............................ 33

Hydraulic component replacement ............... 34

Electrical component replacement ............... 34

Fault diagnosis................................................. 34

Circuit diagram index ....................................... 37

T able 1 - F ault diagnosis............................................ 35

T able 2 - Codes f or 2-digit displa y.............................. 38

Fig.1 RX600 Pow ered Operation Table ........................ 6

Fig.2 RX600 Operation table - base detail................. 10

Fig.3 RX600 Operation table - column/trunk detail .... 12

Fig.4 RX600 base detail (long trunk end) .................. 13

Fig.5 RX600 base detail (short trunk end) ................. 13

Fig.6 Table tilted for access to underside.................. 14

Fig.7 Underside of table base ................................... 15

Fig.8 Adjustment of beam attachment ...................... 15

Fig.9 Hydraulic system - Schematic diagram............ 1 6

Fig.10Hydraulic system - main components .............. 17

Fig.11Main control board ........................................... 18

Fig.12Trendelenburg microswitch ............................... 18

Fig.13Lateral tilt opto detail........................................ 18

Fig.14Break microswitch ........................................... 20

Fig.15Level tilt switch................................................ 20

Fig.16Swivel joint detail ............................................. 21

Fig.17Cover retaining push rivets .............................. 23

Fig.18Top of T rendelenburg cylinder ........................... 24

Fig.19Top-of-column hinge assembly detail ............... 25

Fig.20Break cylinders................................................ 27

Fig.21Lateral tilt cylinder............................................ 28

Fig.22T rendelenb urg cylinder ..................................... 29

Fig.23Top-of-column detail ......................................... 30

Fig.24Bottom of height cylinder detail........................ 30

Fig.25Gas spring detail.............................................. 31

Fig.26Base feet detail................................................ 31

Fig.27Infill interlocking mechanism............................ 32

Fig.28Catch mechanism............................................ 32

Fig.29Beam attachment ............................................ 33

Fig.30Swivel joint attachment detail .......................... 33

Fig.31Hand control functions ..................................... 38

Fig.32-40 Circuit diagrams (see Index page 37)......39-42

T-SM14g 3/44

Page 4

1. PRELIMINARY INFORMATION

1.1 This Service Manual should be referred to for details of the RX600 Powered Operation Tables,

REF 80-606-59 and REF 80-606-13, Serial Number R6AC9K1001 or above .

Related Technical Publications available on request :-

Instructions for Use - T-IM33 (issue ‘d’ or later) - RX600 P ow ered Operation Table

Illustrated Parts List - T-IPL13 (issue ‘b’ or later) - RX600 Po wered Oper ation Table

1.2 Instruction and Service Manuals should be readily accessible for reference prior to and when operating, cleaning

and servicing the Operation Table. All manuals are availab le from Eschmann Equipment, see inside front cover f or address

details.

2. TECHNICAL DA T A

DIMENSIONS

Table with standard table-top (Fig. 1):

Width including sidebars .............................560mm

Sidebars ......................................(31.75 x 6.35)mm

Overall length (with infill section)............... 1975mm

Minimum table height (without mattresses) .... 700mm

Maximum table height (without mattresses). 1040mm

MOVEMENTS

Maximum Trendelenburg ....................................35°

Maximum Reverse Trendelenburg......................15°

Maximum Lateral Tilt (left and right)...................15°

Maximum Extension......................................... 210°

Maximum Flexion.............................................130°

Head section adjustment ................................ ±45°

Note: With the table at minimum height, maximum

Trendelenburg, and maximum head and leg section

movements are reduced.

WEIGHT (nominal)

Table with standard table-top (Fig. 1) ............ 300kg

SAFETY

The table is built to comply with BS5724 Part 1, BS5724

Part 2 Section 2.22, IEC601-1 and BS6859 Part 1. The

mattresses comply with BS2891.

TABLE LO ADING

The standard table (Fig. 1) satisfies a static load test in

accordance with the requirements of BS5724.

WARNING

The RX600 has been designed for patients up

to 135kg with their centre of gravity (normally

the perineum) over the infill or trunk sections.

Patient positioning and additional loads can

compromise table stability. The perineal

extension may be used to further offset the

patient, however, always ensure loading does

not compromise stability.

To comply with IEC601-1:1988 some accessories have been designed for a maximum

evenly distributed load. For the divided-leg

section this is 15kg per leg section (also see

Publication T-IM49 issue ‘b’ or later) and 10kg

for the detachable ophthalmic head-flap.

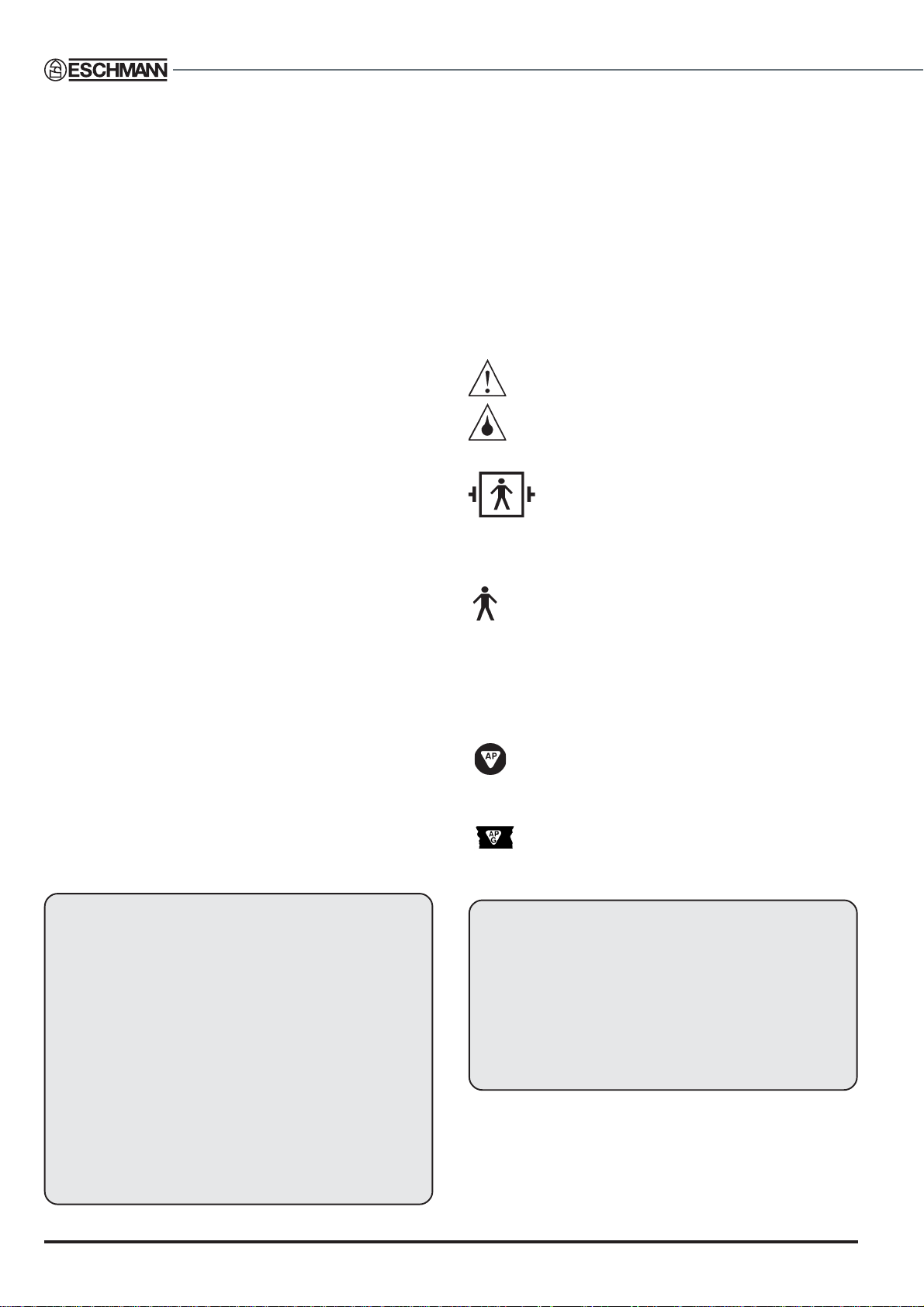

SYMBOLS & SAFETY CLASSIFICATIONS

Caution Refer to the accompanying documents,

the “Instructions for Use”.

or IPX 4 indicates that the equipment will withstand

a moderate quantity of fluid spilled from above.

Safety category

Indicates that the equipment is in safety category

BF , i.e. it is manufactured to a saf ety standard which

agrees with international regulations for medical

electrical equipment, and provides a high degree of protection

against electric shock. The symbol also indicates that the

equipment will not be damaged by defibrillator discharge.

Indicates that the equipment is in safety category B, i.e. it

is manufactured to a safety standard which agrees with

international regulations for medical electrical equipment, and

provides a minimum degree of protection against electric shock.

Class 2 Indicates that the built-in battery charger is

designed to electrical protection Class 2.

Anaesthetic proof

Indicates that the parts of the equipment marked

AP are designed for use within a distance of 5-25cm

of a part of an enclosed medical gas system. BS5724

Part 1, 1989 refers.

Indicates that the parts of the equipment marked APG

are designed for use within a distance of 5cm of a

part of an enclosed medical gas system. BS5724 Part 1,1989

refers.

WARNING

The head section of this operation table is

classified as ‘EQUIPMENT not suitab le f or use in

the presence of a flammable anaesthetic mixture

with air or with Oxygen or Nitrous Oxide’ and is

NOT classified as ‘Category AP Equipment’ or

‘Category APG Equipment’ when it (the head

section) is in its lowest position and the table top

is in full Trendelenburg position.

Inspection

The table must be inspected at regular intervals, and if

necessary , serviced, to ensure that it complies with all AP

and APG requirements relevant to physical deterioration

or breakage of electrical components, connections and

cable insulation.

4/44 T-SM14g

Page 5

2. TECHNICAL DATA

RX600RX600

RX600

RX600RX600

OPERATION TABLE

Antistatic requirements

The table has an antistatic pathway from the table-top,

through an internal resistor, to the castors, which are held

in contact with the floor at all times.

CAUTION

1. To complete the antistatic pathway, the

table must be used on an electrically

conductive, or on an antistatic floor.

2. Always use purpose-designed Eschmann

mattresses to maintain the antistatic pathway.

Electrical data

System power

Batteries:

Type........................................Two sealed lead-acid

Output (each) ......................................... 12V 24Ah

Built-in battery charger:

Input ...................... 100-120 / 200-240Vac 50/60Hz

Output ..............................27.6Vdc (nom) 3A (max)

System fuses:

Motor....................................... 30A 1.5in. (AGU 30)

Base Control Board: (1)........ F6.3A 250V 20mm

(1)........ T2.5A 250V 20mm

(1)........... T2A 250V 20mm

CAUTION

This equipment contains environmentally

hazardous lead-acid batteries. If the batteries

fail, or if the equipment is to be disposed of, it

is recommended that the batteries are taken

to a disposal site designated for the disposal

of lead-acid batteries, or that the batteries are

collected by an agent who specialises in the

collection of lead-acid batteries.

Hydraulic oil

Type.....................Eschmann RX (Part No. 699408)

3. SAFETY NOTES

Attention to the following points will prolong the life and efficiency of the RX600 Powered

Operation Table and will help to avoid the risk of accidents, or damage.

DO:

? Keep the Instruction for Use close-to-hand.

? Read the instructions carefully before using table .

? Check that the head and leg sections are secure, and

put the table base in the braked position bef ore use.

? Disconnect the built-in battery charger from the

power supply before w ashing the table .

? Read and follow the instructions for cleaning, and

for the care of the mattresses.

? Use the correct mattresses and accessories.

? Remove table accessories and their clamps (in

particular rotary clamps) from sidebars, when they

are not being used.

? Ensure that the table and accessories are serviced

at regular intervals (every 6 months is the

recommended frequency) by Eschmann personnel

only , or accredited agents.

? Store the table as detailed in this manual.

DO NOT:

? Lift the table by its table-top.

? Push the table over rough surfaces, use a trolle y.

? Drop the table (or individual sections).

? Put heavy weights on the table sections.

? Put sharp objects on, or against, mattresses, pads,

or the radiographic table-tops.

? Drop heavy objects onto the radiographic table-tops.

? Spill oil, ether, or other fluids onto the mattresses

or the pads.

? Pull the table by any of the table-top sections,

always push it.

? Hold or support the leg section by its black

radiographic top, as this is a removable item and

might come off.

Note: The table cannot be used (under normal

circumstances) with table base stand-by door open.

WARNING

The RX600 Powered Operation Table has been designed to minimise the possibility of accidental

electrosurgery burns. Contact with any metal surfaces (e.g. table side bars, or other equipment

etc.) can cause burns during electrosurgery and must be avoided.

With the table in (or during transition into) the castor position, the centre of gravity of the patient

(normally the perineum) should lie no more than 200mm away from the centre of the column (i.e. no

more than the length of the short trunk section). Whenever this is not practical the overhanging

weight of the patient and table should be adequately supported (e.g. by at least two able people).

Also see Warnings in the Instruction for Use and within the text of this publication.

T-SM14g 5/44

Page 6

4. INTRODUCTION

View on ‘A’

1. Head section

2. Long trunk section

3. Short trunk section

4. Perineal post

5. Hip section

6. Sacral extension

7. Pre-traction leg section

8. Traction beam s wivel joints

9. Column cover

10. Table base cov ers

11. T raction beams

12. Hand control

15 Hand control/Footcontroller sock et

16 Hand control/Footcontroller sock et

17 Hand control plug

1 8 Tab le ‘on/off’ switch ( = on, = off)

19 Standby hydraulic pow er-pack pushb uttons

20 Standby hydraulic po wer-pac k connectors

21 External battery charger socket

22 High current 30A Fuse

23 Door microswitch

24 External power-pack connector

25 Standby door

26 Internal battery charger socket

27 Internal battery charger 'on' indicator

28 Internal battery charger door

29 Removable mains lead

30 Cover retaining screws

31 Top of column cov ers

View on base long trunk end View on base short trunk end

Fig. 1 RX600 Powered Operation Table

6/44 T-SM14g

Page 7

4. INTRODUCTION

RX600RX600

RX600

RX600RX600

OPERATION TABLE

GENERAL

4.1 This Service Manual contains a technical

description and maintenance procedures for the RX600

Po wered Operation Table as shown in Fig. 1.

4.2 The table is a battery powered, mobile,

orthopaedic, and trauma table with two integral articulated

telescopic traction beams, which stow under the table-top

when not in use. The beams are e xtended for use, and are

used in conjunction with traction accessories. The tabletop comprises pre-traction leg supports, and head, hip, long

and short trunk sections.

4.3 The table can be used as a general purpose fivesection Operation Table, by fitting optional infill sections,

and an optional leg section, in place of the pre-traction leg

supports. The table design allows a full range of orthopaedic

and trauma surgical procedures to be carried out, including

pin and plate femur and tibia nailing, and arm traction.

4.4 The table is operated by electrical/electronic

circuits, which control the position of hydraulic cylinders

(via electro-hydraulic v alves) in response to signals from a

touch-button hand control, or from an optional foots witch.

The hand control and the footswitch both plug into

connectors at the top of the table column.

4.5 Power is provided by two 12V sealed lead-acid

batteries in the table base. The 12V batteries are connected

in series to give an output voltage of 24V. Trickle charging

for the batteries is provided by an inbuilt battery charger,

provision is also made for connection of an e xternal battery

charger for quick battery charging. Connection of the inbuilt

battery charger to the mains electrical supply is via a

removable cab le which plugs into the tab le base .

4.6 All table top trunk movements are electrically

controlled using either the hand control or, as an optional

accessory, the footswitch which is used by the surgeon

during cer tain procedures for height and Trendelenburg

control.

4.7 The main operation table sections are:

? Base.

? Central column.

? Head section.

? Long and Short trunk sections.

? Hip section.

? Sacral extension.

? Pre traction leg section.

? Traction accessories.

NOTE: Instruction and Service manuals should he readily

accessible for reference prior to, and when operating,

cleaning and servicing the table.

ELECTRICAL SYSTEM

NOTE: Electrical/electronic circuit diagrams are provided

at the end of this Manual in section 6.

Main control board

4.8 The main control board receives signals from the

hand control via an RS485 serial communication link. The

board also receives signals from the foots witch, table-base

cover s witches, levelling micros witches, level tilt s witch, opto

board, standby unit socket, door s witch, traction beam opto

sensors and table base on/off controls.

4.9 Outputs from the main control board pass to the

hand control via an RS485 serial communication link, to

the hydraulic solenoids via the top-of-column distributor and

solenoid boards, and to the base distributor board and FETRelay board for motor on/off control and motor direction

control. The main control board is supplied with 24V d.c.

from the batteries and generates its own 12V d.c. and 5V

d.c. supplies .

4.10 The principal functional areas of the main control

board are:

? Input buffering (pull-up and pull-down resistors and

capacitors).

? The microcontroller, which uses software to

implement table control functions.

? Output buffering (current drivers and le v el shifters).

? Motor direction drive and on/off control.

Height opto board

4.11 The height opto board is fitted at the base of the

column in a fixed position relative to the baseplate. It

responds to a metal reflector plate which moves up and

down with the column chassis and hence with the table

top. When the reflector mo ves in front of the three reflective

opto sensors (only two are used) electrical signals are

generated to signal to the main control board that the table

is at or above ‘minimum height’, or in the ‘castor’ position.

4.12 When the reflector plate is in front of reflective opto

coupler 01 and at the correct distance from it, a signal is

produced which passes via J1 on the opto board and the

10-way ribbon cable to J22 on the main control board.

4.13 When the reflector plate is in front of both reflective

opto couplers 01 and 03 signals from both pass to the main

control board which stops the table movement at the correct

position.

T-SM14g 7/44

Page 8

4. INTRODUCTION

Base distribution board

4.14 This board receives signals from the main control

board for the height (e xtend) solenoid, the height (contract)

solenoid, the pump-isolate (forward) solenoid and the

pump-isolate (reverse) solenoid.

4.15 The board also passes signals to the main control

board from the cover micros witches.

4.16 Any inductive overswings from the solenoids are

blocked by diodes Dl to D4. PL7 on the base distribution

board is connected via a 14-way ribbon cab le to J4 on the

main control board.

Top-of-column distribution board

4.17 This board connects to J2 on the main control

board via a 34-way retractable ribbon cable which

terminates on PL1 of this board. It distributes signals to

10-way hand control/f ootswitch sock ets PL2 and PL3, and

to:

? the level tilt s witch via PL7

? the Trend level position microswitch via PL5

? the lateral tilt opto board via PL4

? the break level position micros witch via PL6

? top-of-column solenoids board via PL8

? the on/off switch via PL9

? proximity sensors on long trunk via J10/11/12.

Top-of-column solenoids board

4.18 This board receives signals on J7 via a 10-way

ribbon cable from J8 on the top-of-column distributor board

to drive the top-of-column solenoids via cage clamp

connectors J1 to J6. It also blocks inductive overswings

from solenoids using diodes D1 to D6.

Tilt opto board

4.19 The tilt opto board is fitted at the top of the column

in a fixed position relativ e to the yoke. It responds to a metal

plate which moves with the y oke and hence with the tab le

top. When the reflector mo v es in front of the opto sensors

electrical signals are generated to signal the main control

board that the table is lev el.

4.20 When the reflector plate moves in front of the

opto sensor, a logic signal 0 is produced which passes

via J1 on the opto board to the top of column

distribution board and then via a 10-way ribbon cable

to J2-4 on the main control board.

4.21 When the reflector plate is not in front of the

opto sensor, a logic signal 1 is produced which is

passed to the main control board as above.

Power circuits

4.22 The power source for the table is two 12V, 24Ah

sealed lead acid batteries connected in series. A 30A inline, high current fuse protects the batteries, motor, FET

relay board and interconnections.

4.23 Current from the batteries passes via the reversing

relay , where it is s witched by the FET’ s, and then passes to

the pump motor and returns to the batteries. The 24V d.c.

supply is also routed to the hydraulic solenoids and the

main control board.

Hand control

4.24 The RX600 hand control communicates with the

main control board via an RS485 serial communication link.

The hand control contains a microcontroller which receives

inputs from the hand control buttons and generates outputs

which go to the hand control LED’s and the hand control

audible warning device. The microcontroller uses software

to implement hand control, control functions.

4.25 The hand-control incorporates a 2-digit display that

indicates a code if a problem should occur. Such prob lems

could be the result of the user pushing a button in the wrong

sequence or at the wrong time or of a system failure (see

T able 1 - F ault Diagnosis, T ab le 2 - Codes for 2-Digit display

and Fig. 31)

Footswitch (optional accessory)

4.26 The footswitch plugs into either of the two 10-w a y

sockets used by the hand control. It uses the same +5V

d.c. and 0V pins, b ut the signal lines are different from those

of the hand control. The footswitch does not use a serial

communication link.

4.27 There are four functions on the foots witch:

? Height up.

? Height down.

? Trendelenburg.

? Reverse T rendelenb urg.

4.28 Each of these four functions is associated with two

microswitches mounted inside the body of the foots witch,

one normally open and the other normally closed. The

normally open microswitch for each function is connected

on one side to the +5V d.c. line and on the other side to a

common ‘alarm’ line. The normally closed microswitch for

each function is connected on one side to the 0V line and

on the other side to an individual input line on the main

control board. If , for any function of the foots witch, e.g. height

up, the normally open microswitch operates and the

normally closed microswitch does not, or vice versa, the

main control board will recognise a fault and freeze the

table. The lik elihood of two microswitches failing at the same

time is very remote.

8/44 T-SM14g

Page 9

4. INTRODUCTION

RX600RX600

RX600

RX600RX600

OPERATION TABLE

Table base ON/OFF control

4.29 The table is switched ‘on’ and ‘off’ by selecting

and respectiv ely . When switched ‘on’, 24V d.c. is switched

directly to the main control board. When it is switched ‘off’

the main control board is isolated from the 24V d.c. supply.

T o isolate the system the 30Amp fuse should be remo ved.

Built-in battery charger

4.30 This is a internal low current output ‘trickle’ charger,

which replenishes an average day’s table use of the

batteries with an overnight charge.

4.31 The mains input comes via the mains lead, which

should be fitted with a fused plug. The output of the charger

is regulated to provide 27.6V d.c. to the batteries for float

charging. This voltage will fall when the batteries are not

completely charged and hence are drawing a significant

current. The charger has short-circuit and thermal

protection. There is an output from the board which supplies

current to the batteries, an output to the ‘trickle’ charger

indicator LED and an input from the external charger.

Current from either the internal or the external charger is

routed to the batteries via the ‘trickle’ charger board.

External battery charger (optional accessory)

4.32 The external battery charger plugs into the external

battery charger socket in the table base and supplies

current via the ‘trickle’ charger board to fast-charge the

batteries.

Standby system connections

4.33 An RX Standby Unit (optional accessory) which

provides standby hydr aulic and electrical services, can be

connected to the RX600 table via hydraulic connectors and

an electrical socket behind a door on the table base.

4.34 Next to the hydraulic connectors are two pushbuttons which release stored hydraulic pressure when the

standby hydraulic connections are first made . This is done

by energizing the pump forward and re verse solenoids with

power from the standby unit.

4.35 To connect the standby unit to the table it is

necessary to open the base door. This operates a

microswitch which disconnects the main control board

solenoid control circuits from the solenoids so that they

can be controlled by the standby unit, also the pump motor

is hydraulically isolated from the hydraulic solenoids. The

electrical signals from the standby socket pass to J1 on

the main control board (15-way D-connector).

Traction beam stowage detection

4.36 Proximity sensors fitted in the underside of the long

trunk section detect the traction beams when they are in

their stowed position. The sensors signal the tab le control

system to stop the table top being driven down onto the

stowed traction beams.

T-SM14g 9/44

Page 10

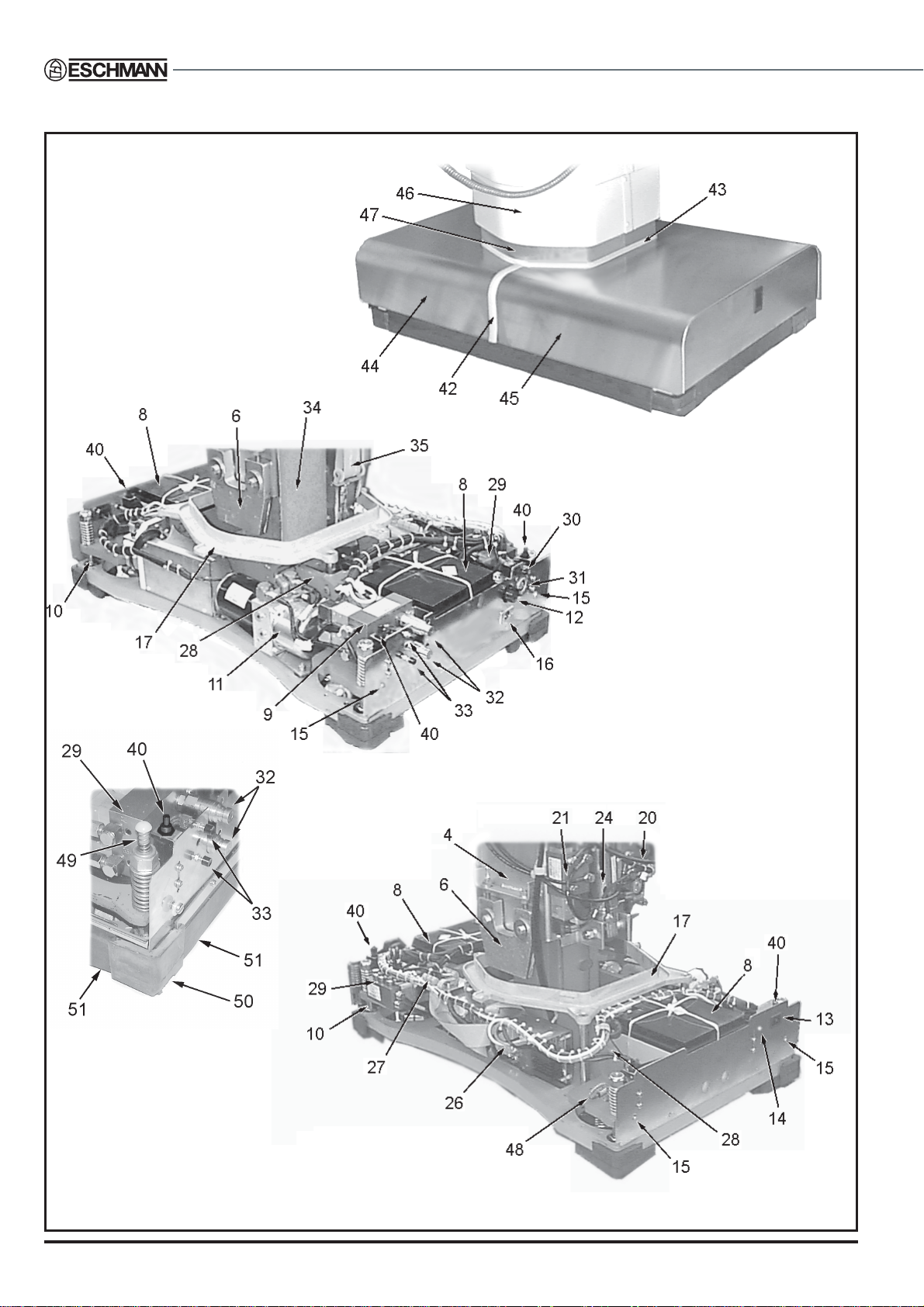

5. DESCRIPTION

For greater detail of

the table base ends also

refer to Fig. 4 and 5

Fig. 2 RX600 Operation Table : Base details, covers on and off

10/44 T-SM14g

Page 11

5. DESCRIPTION

Key to Figs 2 and 3

RX600RX600

RX600

RX600RX600

OPERATION TABLE

1. Long trunk assembly

2. Short trunk assembly

3. Lateral tilt cylinder

4. Wrap around

5. Trunk assembly plastic covers

6. Wedge

7. Outer column

8. Battery

9. Manifold block No 1

10. Castor plate guide pillar

11. Hydraulic power unit

12. High current fuse, 30A

13. Mains socket

14. Battery charging LED (green)

15. Cover retaining screw location

16. External battery charger socket

17. Drip gutter

18. Opto reflector plate

19. Inner column

20. Manifold block No 4

21. Manifold block No 3

22. Upper bezel

23. Hand control and cable

24. Trendelenb urg cylinder

25. Break cylinders

26. Main control PCB

27. Base distribution PCB

28. Castor frame assembly

29. Manifold block No 2

30. Door microswitch

31. Standby power pack connector

32. Standby hydraulic connectors

33. Push buttons to engage standby

hydraulic connectors

34. Hydraulic reservoir

35. Ribbon cable reel assembly

36. T op-of-column distribution PCB

37. Hinge

38. Lateral tilt opto board

39. Yoke

40. Cover microswitch

41. T able ‘on/off’ switch

42 Base seal

43. Column seal

44. Short trunk base cover

45. Long trunk base cover

46. T elescopic column co ver

47. Column upstand

48. Antistatic discharge path resistor

49. Base cover spring support

50. Base foot

51. Base skirt

52. T raction arm selector knob

53. T raction handle

54. Swivel joint, knuckle

55. T raction arm

56. Hip section

57. Swivel joint locking knob

T-SM14g 11/44

Page 12

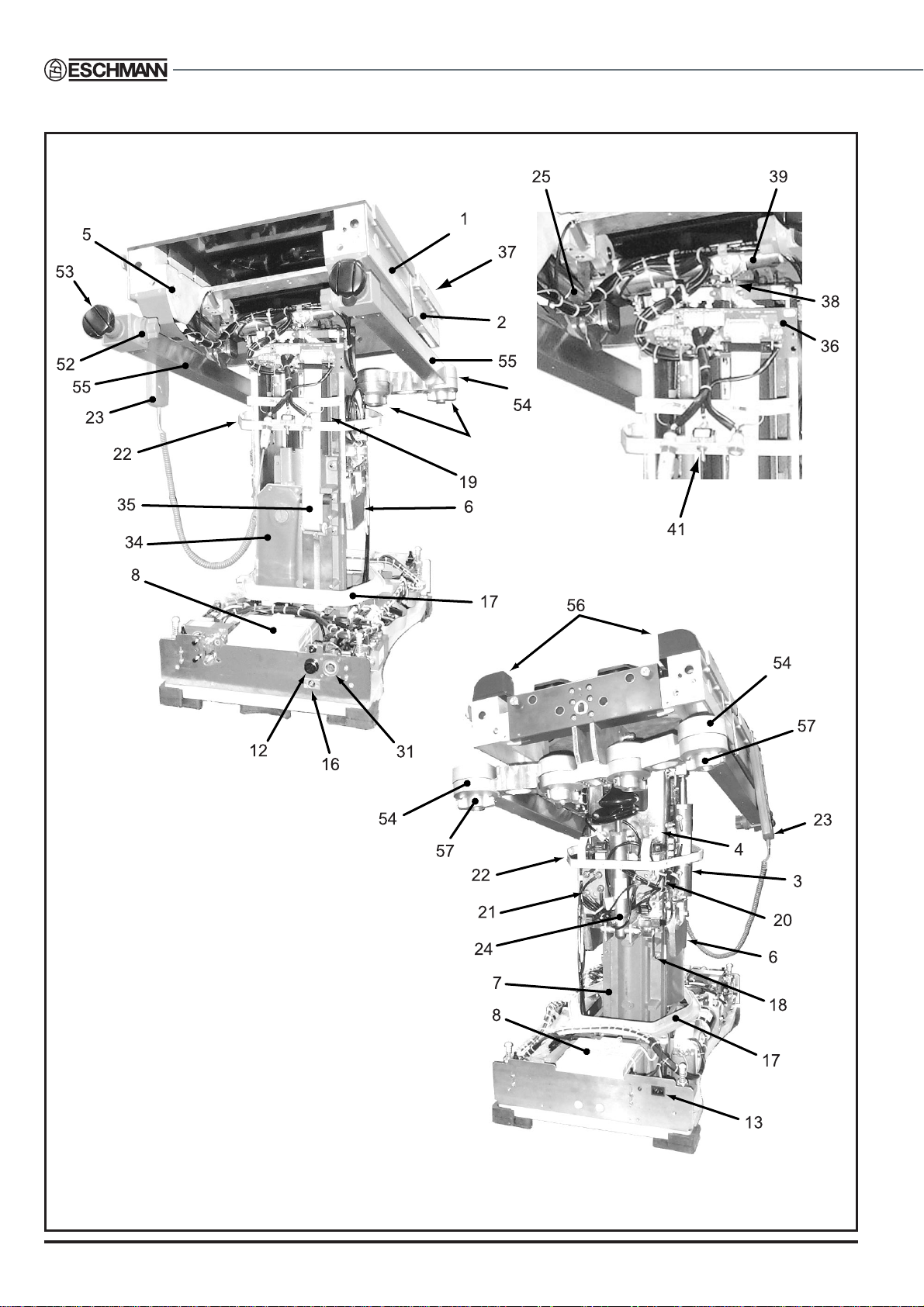

5. DESCRIPTION

Fig. 3 RX600 Operation Table : Column and trunk section detail

12/44 T-SM14g

Page 13

5. DESCRIPTION

RX600RX600

RX600

RX600RX600

OPERATION TABLE

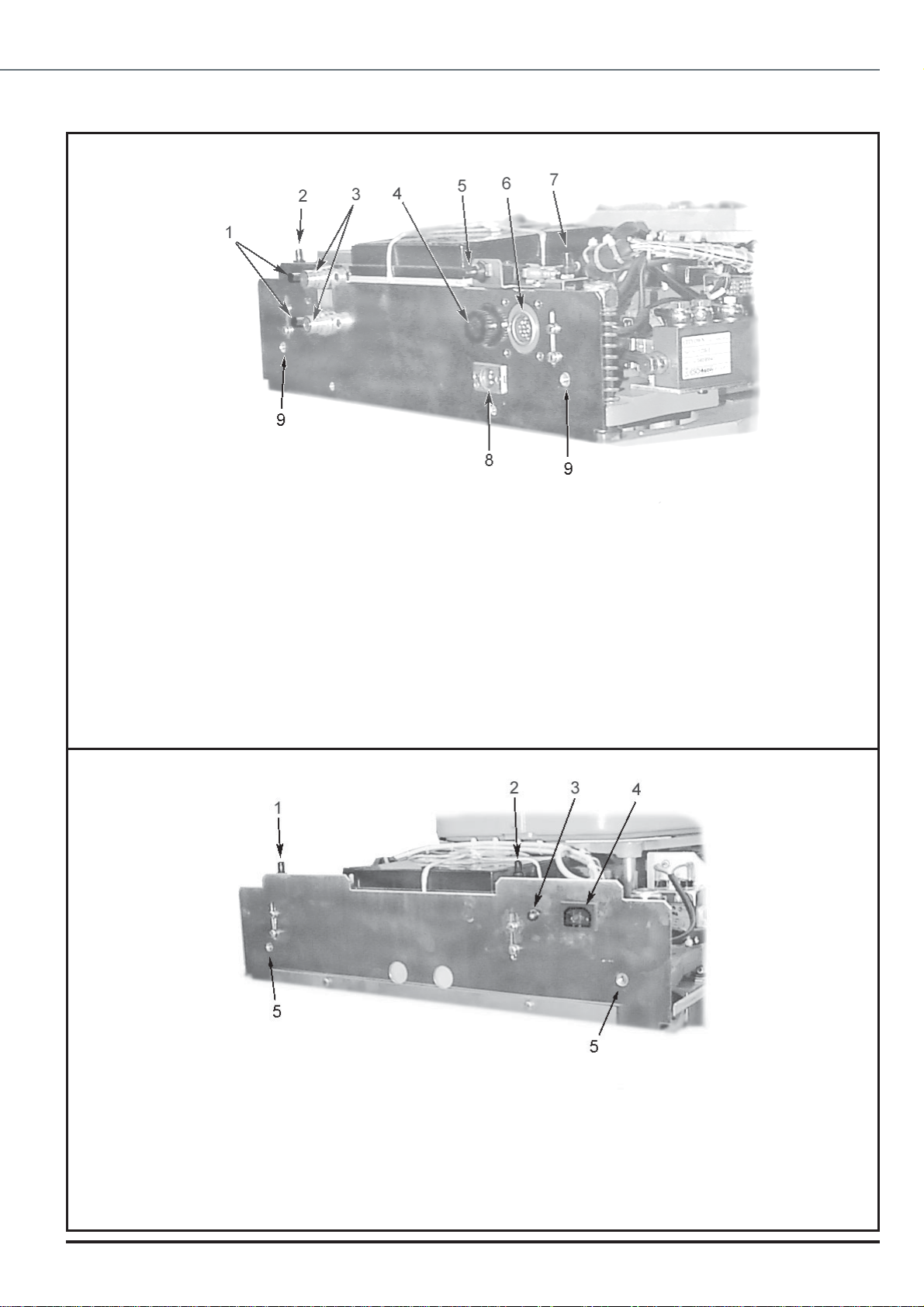

1 Standby hydraulic push buttons

2 Base cover microswitch

3 Standby hydraulic connectors

4 High current (30A) fuse

5 Door Microswitch

6 Standby power pack connector

7 Base cover microswitch

8 External batter y charger socket

9 Fixing for cover retaining screw

Fig. 4 RX600 Operation Table base detail (long trunk end)

1 Base cover microswitch

2 Base cover microswitch

3 Mains charging LED

4 Mains connection socket

5 Fixing for cover retaining screw

Fig. 5 RX600 Operation Table base detail (short trunk end)

T-SM14g 13/44

Page 14

6. MAINTENANCE

GENERAL

6.1 Maintenance of the RX600 Powered Operation

Table falls into the following categories:

Cleaning and storage. Adjustments.

General care and lubrication. Remov al and Installation.

Functional checks. Fault diagnosis.

Hydraulic system.

CLEANING AND STORAGE

WARNING

Always switch off table at table ‘ON/OFF’

switch (item 18, Fig. 1) prior to cleaning.

6.2 For cleaning and storage instructions refer to

RX600 Powered Operation Table Instruction for Use

(Publication No . T-IM33 issue ‘d’ or later).

6.3 For cleaning and storage instructions of the tab le

accessories refer to the Accessory Instructions for Use

(Publication No. T-IM56).

Note: If the tab le is to be stored for any length of time the

head and leg sections should be fully lowered. This is

necessary to ensure that the gas spring seals and pistons

are kept fully lubricated.

alternative leg section, examine the release handle

for signs of damage.

iii Check the guide pin retaining screw for tightness.

iv On the head and alternative leg section, check the

hinge and gas spring pivots for security (grub screws

or starlock washers, whichever fitted), particularly

the main hinge pivot pin. (Note that the grub screw

for the main hinge pivot pin is underneath the

radiographic top.)

v Check the side bars for security.

vi Examine the guide pin locking button on the hip , and

pre-traction leg support sections, and the release

latch on the Sacral extension for damage. Apply a

smear of light machine oil to all moving parts.

vii On the infill section, examine the guide pin locking

button devices for damage and ensure that the

mechanism, which prevents removal of the infill

section before any attached section has been

removed, functions correctly (ref er to section 6.49).

Apply a smear of light machine oil to all moving parts.

GENERAL CARE AND LUBRICATION

6.4 Once a week proceed as follo ws:

Gas Springs

WARNING

The gas springs are filled with high pressure

gas. Do not attempt to open them.

CAUTION

Gas springs MUST NOT be

additionally lubricated.

6.5 The gas spring supports for the head section are

sealed units which require no routine maintenance.

Malfunction of a gas spring makes it impossible to lock the

head section in position. Seepage of fluid indicates a f ailing

unit.

6.6 If a gas spring is faulty, the complete unit must be

renewed, gas springs are non-repairable items (see section

6.44).

Head, hip, pre-traction leg support and

alternative leg sections, and sacral extension

6.7 Service the head, hip, and pre-traction leg support

sections, and sacral extension as f ollo ws:

i Apply a smear of light machine oil to the guide pins

and pivot pins on the head, hip, and pre-tr action leg

sections, and the Sacral extension.

ii Examine all sections, and the sacral extension for

signs of damage, particularly for scoring or bending

of the attachment guide pins. On the head and

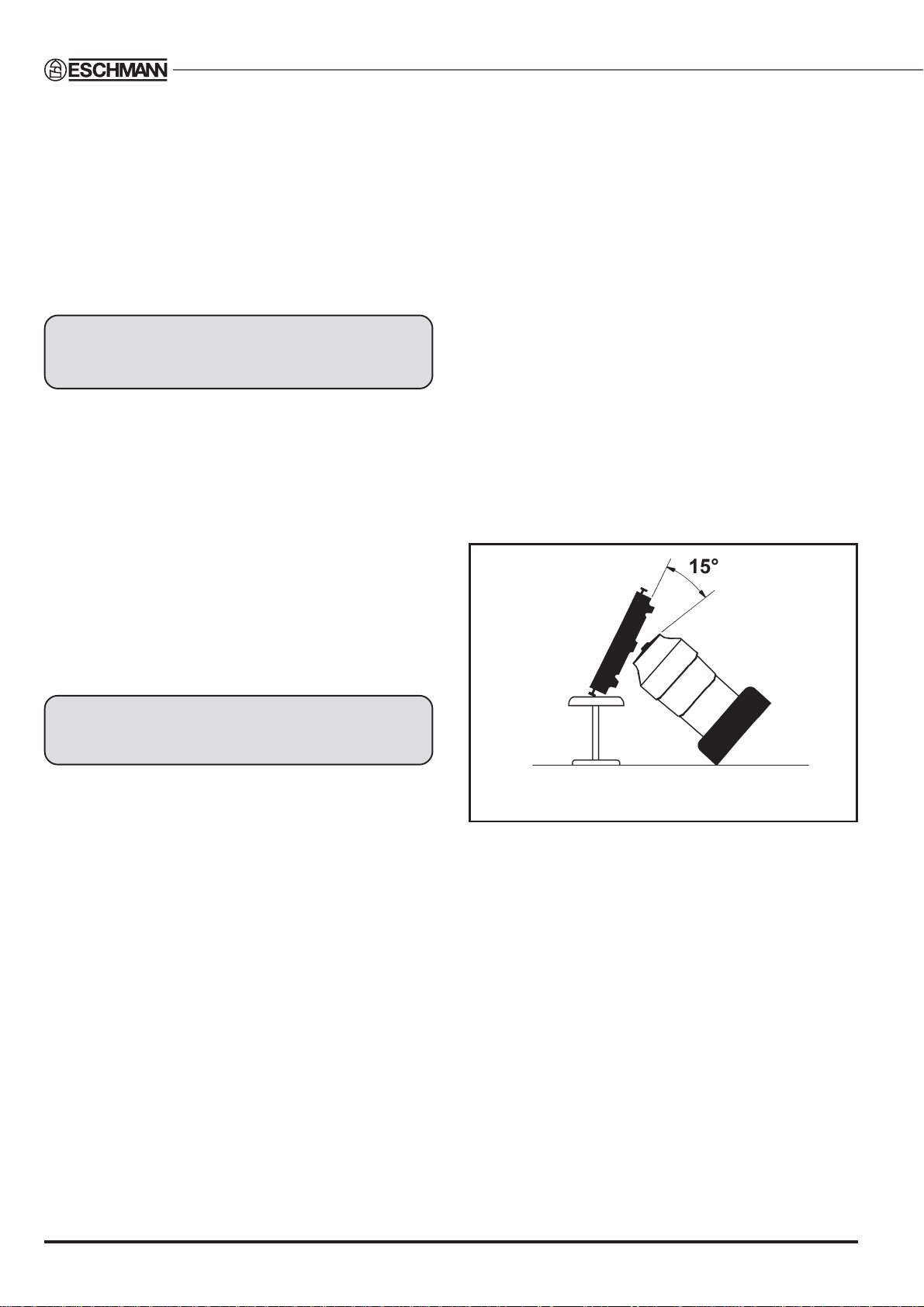

Fig. 6 Table tilted for access to underside

Head and hip sections, locking mechanisms

6.8 Remove the head, hip and sacral extension

sections from the table and clean out any collected fluff or

other debris from guide pin sockets in the ends of the trunk

sections, in the sacral extension attachment and location

holes in the crossbeam. Spra y a little aerosol lubricant into

each socket and attachment hole. Check the operation of

the locking mechanisms when re-attaching the sections

(for adjustment refer to section 6.50).

Long and short trunk sections

6.9 Ser vice the long, and short trunk sections as

follows:

i Apply a smear of light machine oil to the pivot pins

on the long and short trunk sections.

ii Examine the guide pin button locking devices for

damage (for adjustment refer to section 6.50). Apply

a smear of light machine oil to all moving parts.

14/44 T-SM14g

Page 15

6. MAINTENANCE

Radiographic tops

6.10 Examine the radiographic tops for cracks, chips

and scoring. Significant damage will necessitate

replacement of the damaged section. Make sure that the

radiographic tops are securely attached (not applicable to

the optional leg section).

Underside of the table base

6.11 To maintain the underside of the table base, it is

necessary to tilt the table onto its side as follows:

i If necessary , remove head, and pre-tr action leg and

support sections or the leg and infill section

accessories.

ii Using the hand control, raise the table to its maximum

height and make sure that the long and short trunk

sections are level.

iii Using the hand control, set the table top to the

maximum lateral tilt position corresponding to the

direction in which the table is to be tilted (see Fig.6).

iv Place an anaesthetist’s stool, or a similar strong

support, along one side of the table (see Fig.6). With

two people standing on the same side of the table

as the support (one at each end), tilt the table over

and gently lower it onto the support, making sure

that it rests on the side bars of the long and short

trunk sections.

RX600RX600

RX600

RX600RX600

OPERATION TABLE

6.12 With the table in the tilted position, proceed as

follows (see Fig.7):

i Examine the five base feet for damage or e xcessive

wear. If necessary , replace the appropriate base feet

as described in sections 6.47 and 6.48.

ii Clean each castor assembly making sure that they

are free of dust and debris. Lubricate the bearings

of each castor and the directional wheel with a light

machine oil.

iii On completion, return the table to the upright

position.

Traction beam attachment

6.13 Routine maintenance of the beam attachment

consists of checking for secure attachment of the beam as

follows:

i Remove the two locking socket set scre ws (items 1,

Fig.8) from the underside of the beam.

ii Two socket dog point set screws under the two

locking socket set scre ws remo v ed in (i) above can

now be checked and tightened.

iii Replace and tighten the two locking socket set

screws removed in (i) abov e .

iv Check and tighten the slotted countersunk screw

(item 2, Fig. 8).

1 Castor assembly

2 Table base plate

3 Height cylinder pivot clamp blocks

4 Height cylinder

5 Base feet

Fig. 8 Adjustment of beam attachment

Fig. 7 Underside of table base

T-SM14g 15/44

Page 16

Fig. 9 Hydraulic system - Schematic diagram

16/44 T-SM14g

Page 17

6. MAINTENANCE

1 Manifold 1

2 Hydraulic connections

3 Pow er unit

4 Feed from reservoir

5 Pow er unit electrical lead

6 Base distribution board

7 Base control board

8 Manifold 2

9 T rendelenburg cylinder

10 Tilt cylinder

11 Manifold 4

12 Manifold 3

RX600RX600

RX600

RX600RX600

OPERATION TABLE

Note: Hydraulic cylinder rams are

retracted when the table top is positioned

as follows, b ut care must be taken when

moving the table into this position to av oid

damage, sections will be very close to

the floor :

Minimum height and onto castors.

Maximum extension achievable at the

minimum height set above.

Maximum tilt achiev able with table at the

minimum height and extension set abov e

(tilt table such that the right hand side is

lowered when viewed from short trunk

end of table).

For break cylinders see Fig.18

and for height cylinder see Fig.22.

The lateral tilt cylinder is also

shown in greater detail in Fig.19.

Fig. 10 Hydraulic system - main components

T-SM14g 17/44

Page 18

6. MAINTENANCE

Access to fuses

6.14 The high current 30A mains fuse is fitted in the

table base standby panel (item 4, Fig. 4). The three other

fuses for the operation table are fitted on the main PCB

(item 3, Fig.11) in the base of the table. To get to them

remove the base cov ers as described in section 6.26. The

installation of the base covers is described in section 6.27.

1 Programmed microcontroller

2 Beeper

3 Fuses

Fig. 11 Main control board

Hand control

1 Break cylinder

2 Microswitch adjusting screws

3 T rendelenburg micros witch

4Yoke

5 Pivot pin

6 Pivot pin set screw

7 Tilt cylinder ram lock nut

8 Tilt cylinder ram

6.15 The factory sealed hand control requires no

maintenance. If a fault is suspected in the hand control first

test all table functions using a hand control known to be

fault free. If a fault is confirmed with the hand control the

complete assembly (including lead and plug) should be

replaced (see Fig.31 for details of hand control function).

After maintenance

6.16 After maintenance on the operation table, alw ays

check all functions (section 6.17) and lower the tab le fully.

FUNCTIONAL CHECKS

General

6.17 The following functional chec ks should be carried

out after maintenance of the operation table, or after

rectification of any faults:

i Refer to Manual T-IM33 issue ‘d’ or later , and chec k

the state of batteries using the hand control, codes

01 and 02 should not be displayed. If they are the

table batteries need recharging.

ii Using the hand control, check that all table

movements agree with the Technical Data.

iii Using the foot control unit (optional accessory),

check that the table movements are correct for

T rendelenburg, Re verse T rendelenburg, and Height.

iv Use hand control to check operation of the ‘auto le vel’

function.

Fig. 12 Trendelenburg microswitch

1Yoke

2 Adjusting screws

3 Lateral tilt opto board

4 Lateral tilt opto flag

5 Top of column distribution board

Fig. 13 Lateral tilt opto detail

18/44 T-SM14g

Page 19

HYDRAULIC SYSTEM

6. MAINTENANCE

ADJUSTMENTS

RX600RX600

RX600

RX600RX600

OPERATION TABLE

CAUTION

Scrupulous cleanliness is essential to prevent

contamination of the fluid in the hydraulic

system.

Notes:

1 Use only Eschmann RX hydraulic oil, Part

No.699408, which is obtainable from Eschmann

Equipment or their accredited agents. Replace cap

on oil container after use.

2 When replacing hydraulic components all Banjo

fittings must be tightened to a torque setting between

19 and 21 Nm.

3 The hydraulic system schematic diagram is shown

in Fig. 9 with the main components illustrated in Fig.

10. Individual cylinders are also shown in the

‘Removal and Installation’ section later in the manual.

General

6.18 If the table cannot be placed into the castor position

using the hand control, it may be necessary to manually

raise the table base. To raise the table base, proceed as

follows:

i Remove table base covers , see section 6.26

ii Locate the jacking nut at each corner of the table

base (see Fig.26, item 1) and wind the nuts down

evenly to raise the tab le base .

Topping-up the hydraulic reservoir

6.19 Top-up the hydr aulic reservoir as follo ws:

i Set table to an appropriate height and remove base

covers as described in section 6.26.

ii Release the central column cover and remove the

upstand as described in section 6.30.

iii Retract all cylinder rams before filling reservoir so

that the true oil level can be established (see Note in

Fig. 10). Overfilling could damage the reservoir .

iv Remove the filler cap from the hydraulic reservoir

and fill the reservoir with Eschmann RX hydraulic oil

until oil level is 13 mm below the filler hole of the

reservoir.

v Refit the filler cap on reservoir .

vi Refit the central column cover and upstand as

described in section 6.31.

vii Refit the base covers as described in section 6.27.

Trendelenburg (Trend) microswitch

6.20 T o check and adjust the T rendelenburg micros witch

(item 3, Fig. 12) proceed as f ollo ws:

i Ensure the table is on a level surface .

ii Using the hand control, move the table top to the

maximum T rendelenburg position.

iii On the hand control, press the ‘auto level’ b utton and

wait until the table top stops when lev el.

iv Using an inclinometer (on section radiopaque top

not the mattress), check the angle of the short trunk

section in the horizontal plane.

v If the angle is more than one degree out in either

direction adjust the Trendelenburg microswitch as

necessary, by releasing the adjusting screws

(item 2, Fig.12) and moving the microswitch in the

appropriate direction, retighten the adjusting screws.

vi Repeat steps ‘ii-v’ until the short trunk section stops

level.

Lateral tilt opto

6.21 T o check and adjust the lateral tilt opto flag (item 4,

Fig.13) proceed as follows:

i Ensure the table is on a level surface .

ii Using the hand control, tilt the table top to the

maximum lateral tilt position (left or right).

iii On the hand control, press the ‘auto level’ b utton and

wait until the table top stops when lev el.

iv Using an inclinometer (on section radiopaque top

not the mattress), check the angle of the table top in

the lateral plane.

v If the angle is more than one degree out in either

direction adjust the flag (item 4, Fig.13) for the lateral

tilt opto by releasing the adjusting screws (item 2,

Fig.13) and moving the flag in the appropriate

direction, retighten adjusting screws.

vi Repeat steps ‘ii-v’ until the table stops le v el.

Break microswitch

6.22 T o chec k and adjust the break microswitch (item 1,

Fig. 14) proceed as follows:

i Ensure the table is on a level floor .

ii On the hand control, press the break (extension)

button and move the tab le top to the maximum break

(extension) position.

iii On the hand control, press the ‘auto level’ b utton and

wait until the table top stops when lev el.

T-SM14g 19/44

Page 20

1 Break microswitch

2 Long trunk assembly

3 Short trunk assembly

4 Adjusting screws

5 Tilt cylinder ram

6 Break cylinder ram

6. MAINTENANCE

iii On the hand control, press patient right orientation

button (button 2, Fig.31).

iv On the hand control, press the Trendelenburg button

(button 3, Fig.31) and move the table top to the

maximum reverse Trendelenburg position.

v Using an inclinometer (on the radiopaque top not

the mattress of the short trunk section), check the

angle of the table top. The angle should be 35

degrees.

Fig. 14 Break microswitch

iv Using an inclinometer (on section radiopaque top

not the mattress), check that the short trunk section

is level, if it is not adjust the Trendelenburg

microswitch as detailed in section 6.20.

v Using an inclinometer (on section radiopaque top

not the mattress), check the angle of the long trunk

section.

vi If the angle is more than one degree out in either

direction adjust the break microswitch by releasing

the adjusting screws (items 4, Fig.14) and moving

the microswitch in the appropriate direction, retighten

the adjusting screws.

vii Repeat steps ‘ii-vi’ until the long trunk section stops

level.

Level tilt switch

6.23 To adjust the level tilt switch (item 4, Fig.15)

proceed as follows:

i Ensure the table is on a level floor.

ii On the hand control, press the ‘auto le vel’ button and

wait until the table top stops when level (check the

long and short truck sections are level in both

directions and adjust if required as detailed in

sections 6.20 to 6.22).

1 Push button

2 Short trunk assembly

3 Adjusting screws

4 Level tilt s witch

Fig. 15 Level tilt switch

vi On the hand control, press the break (extension)

button (button 5, Fig.31) and check f or movement of

the long trunk section of the table top. If movement

occurs, adjust the level tilt switch by releasing the

adjusting screws (item 3, Fig.15) and moving the

level tilt switch in the appropriate direction to stop

any mov ement of the long trunk section with the table

top in the reverse Trendelenburg position.

vii After adjusting the level tilt s witch repeat actions (iv)

(v) and (vi) until there is no movement of the long

trunk section in the maximum T rendelenb urg position.

20/44 T-SM14g

Page 21

6. MAINTENANCE

RX600RX600

RX600

RX600RX600

OPERATION TABLE

Fig. 16 Swivel joint detail

T-SM14g 21/44

Page 22

6. MAINTENANCE

Traction beam swivel joints

CAUTION

Never force a locking knob as this may cause

damage, if it is too tight it needs to be adjusted.

Never lubricate the 4mm ball bearings, ball

retaining ring, riser , or the locking rings, as this

will impair function.

6.24 The traction beam swivel joints should lock in

position when the locking knob is turned about 1/2 turn

clockwise. If they do not, adjust each one as follo ws:

i Refer to Fig.16 and remove the bottom “heyco” plug

and unlock the locking knob .

ii If the locking knob can be locked throughout the

whole movement range without resistance, tighten

the M10 self locking nut until some resistance to

locking becomes evident.

iii Find the tightest position to lock the knuckle being

adjusted, by rotating it through its complete range of

movement and checking at each 10° position by

turning the locking knob to the locked position and

back again. With the knob in this position slacken

the M10 self locking nut and then adjust (tighten) to

3.4N-m (30lb-in). Do not o v er tighten.

iv Check the locking function, it should not be difficult at

any position. Check for any free lateral mov ement with

the link beam in its ‘park ed’ position and the e xtending

beam swung 180° out from its ‘parked’ position. When

locked, the total maximum lateral mo vement of each

beam assembly , should not e xceed 46mm at the end

of the retracted beam. If adjustment is still not

satisfactory it may be necessary to change some or

all of the ‘loose’ parts within the swiv el joint. Guidance

on this procedure is given in section 6.55.

v Refit the heyco plug when adjustment is completed.

REMOVAL AND INST ALLATION

General

6.25 All equipment in the base of the operation table is

accessible after the base cov ers have been remo ved (see

section 6.26). T o get to equipment located around the centr al

column it is necessary to remove the top-of-column covers

(see section 6.28) and release the central column cover

(see section 6.30).

Remove table base covers

6.26 T o remov e the table base covers proceed as f ollows:

i Open doors at the ends of the table base, see Fig.

1.

ii At the short trunk end of the table base:

(a) Remove two screws (item 30, Fig.1) and

shouldered washers and pull the short trunk end

base cover (item 45, Fig. 2) from the base.

iv At the long trunk end of the table base:

(a) Remove the two black button covers from the

standby hydraulic push buttons (item 1, Fig.5) by

gently pulling them off.

(b) Remove two screws (item 30, Fig.1) and

shouldered washers and pull the long trunk end base

cover (item 44, Fig. 2) from the base.

v Remove the two base seals (item 42, Fig. 2). The

column seal (item 43, Fig. 2) can remain in place on

the upstand unless access is required to the lower

column (see section 6.30).

Note: When the hinged cover at the long trunk end of the

table is opened, or when the base cover is removed, a

microswitch operates to isolate the electrical supply to the

table. To operate the table with this cover removed, the

microswitch must be taped in the operated position.

Install table base covers

Note: Before replacing covers check that all cables and

hydraulic pipes are secured and that they cannot be

pinched, chaffed or cut by any mo ving parts.

6.27 T o install table end base covers proceed as f ollows

referring as required to Fig.1 and 2 :

i Check that all tools and discarded equipment have

been removed from inside table base bef ore installing

base covers.

ii To install the long trunk end base cover:

(a) Press the two springs at the long trunk end of

the base and locate the long trunk base cover in the

slide rails along the sides of the base.

(b) Push the end cover fully home and secure with

two screws and shouldered washers , finally replace

the two push button cov ers .

iii To install the short trunk end base cover proceed as

follows ref erring as required to Fig.1 and 2 :

(a) Press two springs at the short trunk end of the

base and locate the end cover in the slide rails along

the sides of the base.

(b) Push the end cover onto the base until it is

approximately 3 to 4 mm from the long trunk end

base cover .

(c) Push two base seals into position between the

end base covers, and push the short trunk end base

cover fully into position. Secure the short trunk base

cover using two scre ws and shouldered washers .

(d) If removed, replace the column seal onto the

upstand, it may be necessary to leave the seal to

contract after initial assembly before butting the

edges together, do not stretch the seal or trim length.

(e) Test cover pressure micros witches.

22/44 T-SM14g

Page 23

6. MAINTENANCE

RX600RX600

RX600

RX600RX600

OPERATION TABLE

Remove top-of-column covers

6.28 To remov e the two top-of-column covers (item 31,

Fig.1) proceed as follows:

i Using the hand control or foot switch control unit set

the table to full height and full flexion position.

ii Switch the table ‘off’, unplug hand control and remove

the main 30 Amp fuse from the table base (item 22,

Fig.1).

ii Remove the f our screws and w ashers on the top of

the covers and the two push rivets (see Fig.17) at

the bottom edge of the covers.

iii Release the two top-of-column covers taking care

when removing the covers to ensure that the gaiter

for the Trendelenburg cylinder is not damaged.

Install top-of-column covers

Note: Before replacing covers check that all cables and

hydraulic pipes are secured and that they cannot be

pinched, chaffed or cut by an y moving parts.

6.29 Installation of the top-of-column covers is the

reverse of the remov al procedure described in section 6.28.

When installing the top-of-column covers make sure that

the gaiter for the Trendelenburg cylinder is correctly

installed.

Releasing the telescopic cover and upstand

6.30 T o release the telescopic cover and upstand (items

46 and 47, Fig.2) proceed as follows:

i Remove the top-of-column covers as described in

section 6.28.

ii Remove all the push rivets (see Fig. 17) holding the

telescopic cover to the top bezel to enable the co ver

to be lowered.

iii Flex upstand to release cover from its lower edge .

iv Remove the 4 slotted screws and the base seal (item

42, Fig.2) from the lower edge of the upstand and

remove the upstand (if access to the lower column

is required).

Replacing the telescopic cover and upstand

Note: Before refitting covers and upstand check that all

cables and hydraulic pipes are secured and that the y cannot

be pinched, chaffed or cut by any moving parts and that

the ribbon cable mechanisms are working correctly.

.

6.31 Refit telescopic cover and upstand (if remov ed for

access to lower column) by the re verse of section 6.30 but

note that it may be necessary to leave the base seal to

contract after initial assembly to the upstand to allow the

edges to butt together (do not trim length to fit).

Removing the telescopic cover

6.32 To remove the telescopic cover (items 46, Fig.2)

proceed as follows:

i Remove the top-of-column covers as described in

To remove riv ets :

a) Pull up plunger head (see 2 above) taking

care not to damage rivet head.

b) Pull rivet out of cover section (see 1 above).

To replace rivets :

a) Align holes in cover sections (see 1 abo v e).

b) Place rivet into hole so that the shoulder of

the rivet shaft is flush with the outer cover

face (see 2 abov e).

c) Press rivet plunger head until flush with

cover surf ace (see 3 abo v e).

Fig. 17 Cover retaining push rivets

section 6.28.

ii Remove all the push rivets (see Fig. 17) holding the

telescopic cover to the top bezel. Then remove the

rivets in each pair of telescopic cover section (top

pair first then middle and lower) and remove the

telescopic cover . Remove the upstand if required as

detailed in section 6.30.

Replacing the telescopic cover

Note: Before refitting covers check that all cables and

hydraulic pipes are secured and that they cannot be

pinched, chaffed or cut by any moving parts and that the

ribbon cable mechanisms are working correctly.

.

6.33 Refit the telescopic covers (and upstand if

removed) in pairs in the correct sequence so they work

correctly by the rev erse of section 6.32.

Remove long and short trunk assemblies

6.34 To remove the long and short tr unk assemblies

proceed as follows:

i Remove the head section, leg supports, hip sections

sacral extension and perineal post, or , head, leg and

T-SM14g 23/44

Page 24

6. MAINTENANCE

infill section whichever is applicable (i.e. all removable

sections fitted to the table). Remove the tractions

beams (see section 6.51) and the swivel joint

assembly from the short trunk section (see section

6.53).

ii Remove the top-of-column covers as described in

section 6.28.

iii Remov e the black tops, side bars, aluminium co vers,

plastic covers and hinge covers from the long and

short trunk assemblies.

iv Disconnect the hydraulic hoses (item 3 and 5, Fig.20)

from the two break cylinders (item 7, Fig.20) and

blank off the hydraulic connections and cylinders .

v Remove two screws (item 3, Fig.15), shakeproof

washers and plain washers which secure the level

tilt switch (item 4, Fig.15) to the short trunk assembly

and remove the le v el tilt s witch.

vi Remove the lateral tilt opto flag (item 4, Fig.13) to

prevent damage by removing the two adjusting

screws (item 2, Fig.13).

vii Remove the two screws (item 2, Fig.12) , shak eproof

washers and plain washers which secure the

T rendelenb urg microswitch (item 3, Fig.12) to the tilt

hanger (item 12, Fig.19) and remove the

Trendelenburg microswitch and microswitch plate

(item 13 and 14, Fig.19).

viii Remove the two screws (item 4, Fig.14), shakeproof

washers and plain washers which secure the ‘break’

microswitch (item 1, Fig.14) to the short trunk and

remove the ‘break’ microswitch.

ix Remove the ty-wrap straps which secure the

hydraulic hoses and the electrical wires to the yoke

and move the hydraulic hoses and electrical wires

clear of the yoke. Note routing and attachment of

hoses and wires.

WARNING

The long and short trunk assemblies are

heavy , tw o people are needed to lift them. The

next stages will enable the table top

assemblies to move freely in Trendelenburg

and then tilt positions and will need to be

firmly supported until they have been removed

and placed aside.

x Remove the two dome headed nuts (item 1, Fig.18)

and plain washers from the Trendelenburg cylinder

pivot pin on the underside of the short trunk

assembly . Remov e the pivot pin (item 4, Fig.18) and

disconnect the Trendelenburg cylinder ram from the

short trunk assembly. Collect the two spacers (item

5, Fig.18) which are fitted on the pivot pin.

Fig. 18 Top of Trendelenburg cylinder

xi Remove the grub screw (item 5, Fig.21) which retains

the pivot pin for the later al tilt cylinder (item 1, Fig.21).

Remove the piv ot pin (item 6, Fig.21) and disconnect

the clevis (item 10, Fig.21) on the lateral tilt cylinder

ram from the tilt hanger (item 12, Fig.19 and item 7,

Fig.21), take care not to misplace the bush inside

the tilt hanger.

xii See note Fig. 19. Remove the hexagon headed bolt

(item 1, Fig.19), and shakeproof washer (item 2,

Fig.19).

xiii See note Fig. 19. The pivot pin (item 7, Fig.19) together

with washer (item 10, Fig.19) which attaches the yoke

(item 4, Fig.19) of the long trunk assembly to the hinge,

can now be removed if the full weight of the Long and

Short trunk assemblies are suppor ted. Remove the

long and short trunk assemblies and lay them aside

upside down taking care to protect the radiopaque

surfaces. Remove the Yoke pivot bush (item 11, Fig.19)

and Sel-Lok pin (item 5, Fig.19) if required from the

yoke and inner column respectively.

Install long and short trunk assemblies

Note: Before proceeding read the Caution and notes that

precede section 6.18 and the W ARNING in section 6.34.

6.35 To install the long and short trunk assemblies

proceed as follows:

Note: Apply Rocol white grease (Part No.110477) to all pivot

pins prior to assembly.

i Apply Rocol white grease (Part No.110477) to the

Yoke pivot bush (item 11, Fig.19) and install into the

inner column.

ii Using at least two people, carefully lift and correctly

position the long and short trunk assemblies onto

the inner column hinge (item 9, Fig.19) and replace

the pivot pin, washer and Sel-Lok pin (items 5,7 and

10, Fig.19). Hold in place with he xagon headed bolt

and shakeproof washer (items 1 and 3, Fig.19).

24/44 T-SM14g

Page 25

6. MAINTENANCE

RX600RX600

RX600

RX600RX600

OPERATION TABLE

1 Yoke pivot bolt

2 Spring washer

4Yoke

5 Sel-Lok pin

6 Tilt opto flag

7 Yoke pivot

8 Tilt opto board

9 Top of column

casting

10 Washer

11 Yoke pivot bush

12 Tilt hanger

13 Microswitch plate

14 Microswitch

15 Microswitch

adjusting screws

16 Top of column

distribution board

17 Hinge plate

18 Height cylinder

locking screws

1 9 Column assy .

inner

NOTE: Re vised ne w y oke assembly (preferred): New ‘Thrust washer’ (item 10, Part number 110905)

either side of item 19. Thrust washers orientation is important, position black face of both tow ards head

of pivot bolt. Use new ‘Washer’ (item 2, Part number 110904) and modified bush (no shoulder), with

‘Loctite 270’ (Part number 110906) on screw thread of item 1.

Fig. 19 Top of column hinge assembl y detail

T-SM14g 25/44

Page 26

6. MAINTENANCE

iii Attach the eye-end of the Trendelenburg cylinder to

the pivot plates on the cross member of the short

trunk assembly as follows (ref er to Fig.18 and Fig.21

as required) :

(a) Position the eye-end of the Trendelenburg

cylinder between the pivot plates on the cross

member.

(b) Install pivot pin through one pivot plate on cross

member and install one spacer on pivot pin.

(c) Push pivot pin through the spacer and eye-end

and install remaining spacer on the pivot pin.

(d) Push the pivot pin through the second spacer

and the second pivot plate.

(e) Secure the pivot pin equally between the pivot

plates using the two dome nuts and plain washers.

iv Position the cle vis on the tilt cylinder ram around the

tilt hanger and install the pivot pin taking care not to

dislodge the bush in the tilt hanger . Secure the piv ot

pin in the lugs of the clevis with pivot pin g rub screw.

v Route the hydraulic hoses and electrical wires over

the yoke in the same positions noted in the remov al

procedure.

vi Remove the blanks from the break cylinder h ydraulic

hoses and connect the hydraulic hoses to each break

cylinder.

vii Install the ‘break’ microswitch on the short trunk

assembly, ensur ing that two spacers are installed

behind the bracket, and secure with two screws,

shakeproof washers and plain washers.

viii Install the Trendelenburg microswitch on the tilt

hanger with the microswitch plate and secure with

two screws, shak eproof washers and plain washers.

ix Install the lateral tilt opto flag onto the hinge pivot

pin and secure with two screws, shakeproof w ashers

and plain washers.

x Install the level tilt switch on the inside web of the

short trunk section, ensur ing wires for the switch

faces toward the end of the short trunk. Secure the

level tilt s witch with two screws , shakeproof washers

and plain washers.

xi Use ty-wrap straps to secure the hydraulic hoses

and the electrical wires.

xii Top up the hydr aulic system reservoir as described

in section 6.19.

xiii Check and adjust the Trendelenburg and break

microswitches, lateral tilt opto and le vel tilt s witch as

described in sections 6.22-6.23.

xiv Carry out a full functional check of the operation table

as described in section 6.17.

xv Install plastic covers on the hinge pivot points and

install the plastic covers, aluminium outer covers,

black tops and side bars on the long and short trunk

assemblies. Make sure that the plastic covers and

the aluminium outer covers do not protrude above

the top face of the long and short trunk castings and

that they do not restrict push button movement.

xvi Install top-of-column covers as described in

section 6.29.

xvii Replace the s wivel joint assemb ly to the short trunk

assembly (see section 6.54) and then attach the

traction beams (see section 6.52).

Remove break cylinder

Note: Before proceeding read the Caution and notes that

precede section 6.18.

6.36 To remove a break cylinder proceed as f ollo ws:

i At the applicable side of the long trunk assembly,

remove the side bar, aluminium outer cover, inner

plastic cover and the hinge cov er.

ii Disconnect the three hydraulic hoses (item 4, Fig.20)

from the applicable break cylinder (item 7, Fig.20)

and blank off the hydraulic connections and cylinder

(items 3 and 5, Fig.20).

iii At the short trunk end of the break cylinder, remove

the grub screw which secures the pivot pin (item 2,

Fig.20) and remove the piv ot pin.

iv At the long trunk end of the break cylinder, remov e

the grub screw which secures the pivot pin (item 6,

Fig.20) and remove the piv ot pin.

v Remove break cylinder from long trunk assembly.

Install break cylinder

6.37 To install a break cylinder proceed as follows

(referring as required to Fig.20) :

i Position the break cylinder in the long trunk assembly

with the cylinder eye-end positioned at the long trunk

end.

ii Apply Rocol white grease (Part No.110477) to the

pivot pin for the long trunk end and install the pivot

pin in the long trunk and the break cylinder eye-end.

Secure the pivot pin to the long trunk with a grub

screw.

iii Apply Rocol white grease (Part No.110477) to the

pivot pin for the short trunk end and install the pivot

pin in the short trunk and the break cylinder piston

eye-end. Secure the piv ot pin to the short trunk with

a grub screw .

26/44 T-SM14g

Page 27

6. MAINTENANCE

RX600RX600

RX600

RX600RX600

OPERATION TABLE

1 Short trunk assembly

2 Short trunk pivot pin

3 Hydraulic connection

4 Hydraulic hoses

5 Hydraulic connection

6 Long trunk pivot pin

7 Break cylinder

8 Long trunk assembly

9 Break microswitch

Fig. 20 Break cylinders

T-SM14g 27/44

Page 28

6. MAINTENANCE

1 Tilt cylinder

2 Hydraulic connection

3 Top of column solenoid board

4 Clevis nut

5 Pivot pin grub screw

6 Pivot pin

7 Tilt hanger

8 Microswitch adjusting screws

9 Break microswitch

10 Clevis

11 ‘R’ clip

12 Washer

13 Pivot pin

Fig. 21 Lateral tilt cylinder (upper bezel omitted for clarity)

28/44 T-SM14g

Page 29

6. MAINTENANCE

iv Remove the blanks from the three hydraulic hoses

for the break cylinder and connect the hydraulic

hoses to the break cylinder.

v T op up the h ydr aulic system reservoir as described

in section 6.19.

vi Carry Out a functional check of the operation table

as described in section 6.17.

vii Install the hinge cover, inner plastic cov er, aluminium

outer cover, and side bar on the applicable side of

the long trunk assembly. Make sure that the inner

plastic cover and the outer aluminium cover do not

protrude above the top face of the long trunk casting

and that they do not restrict push button movement.

Remove lateral tilt cylinder

Note: Before proceeding read the Caution and notes that

precede section 6.18.

6.38 To remove lateral tilt cylinder (item 1, Fig.21)

proceed as follows:

i Remove the top-of-column covers as described in

section 6.26, and release the telescopic column

cover as described in section 6.28.

ii Disconnect the two hydraulic hoses (item 2, Fig.21)

from the lateral tilt cylinder (item 1, Fig.21) and blank

off the hydraulic connections.

iii Remove the grub screw (item 5, Fig.21) which retains

the lateral tilt cylinder pivot pin (item 6, Fig.21) and

remove the pivot pin. Disconnect the lateral tilt

cylinder from the tilt hanger assembly (take care not

to loose the bush in the tilt hanger).

iv At the column chassis, remove the ‘R’-clip (item 11,

Fig.21) from each end of the pivot pin (item 13,

Fig.21). Remov e the washers (item 12, Fig.21) and

remove the pivot pin.

v Remove the lateral tilt cylinder and remove cle vis if

refitting a new cylinder by releasing nut (item 4,

Fig.21) and unscrewing clevis (item 10, Fig.21).

Install lateral tilt cylinder

6.39 Installation of the lateral tilt cylinder is the rev erse

of the removal procedure, ho wever , note the following points

on installation and refer to Fig.21 as required :

i Apply Rocol white grease (Part No.110477) to the

pivot pins prior to installation.

ii On completion, top-up the hydraulic system reservoir

as described in section 6.19, and carry out a

functional test of the operation table as described in

section 6.17.

RX600RX600

RX600

RX600RX600

OPERATION TABLE

1 T rendelenburg cylinder bellows

2 T rendelenburg cylinder

3 Hydraulic connection

4 Pivot pin nut

5 Spacers

6 Pivot pin

Fig. 22 Trendelenburg cylinder

Remove T rendelenburg cylinder

Note: Before proceeding read the Caution and notes that

precede section 6.18.

6.40 To remove the Trendelenburg cylinder (item 2,

Fig.22) proceed as follows:

i Remove the top-of-column covers as described in

section 6.28, and release the central column

telescopic cover as described in section 6.30.

ii Disconnect the two hydraulic hoses from the

Trendelenburg cylinder and blank off the hydraulic

connections and cylinder (only one connection

shown, item 3 Fig.22, the second one is underneath

the bellows, item 1 Fig.22).

iii At the short trunk assembly, remove the two dome

headed nuts (item 1, Fig.18) and plain washers (item

6, Fig.18) from the Trendelenburg cylinder pivot pin

T-SM14g 29/44