Eschmann RX-500 Service manual

RX500

OPERATION TABLE

Service Manual

698265

T-SM13h

Preliminary Information

Technical Data

Safety Notes

Introduction

Description

Maintenance

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and assistance

during normal office hours. To avoid delays when making enquires, please quote the Model and Serial

Number of your Operation Table which is shown on the Serial Number plate, the location of which is

shown below. Please ensure you include all alpha and numeric digits of the Serial Number .

The Serial Number Plate

is on the inside of the

long trunk section here.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, P eter Road, Lancing, W est Susse x BN15 8TJ , England.

Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 762006.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered tr ade marks of Eschmann Holdings Limited .

“Eschmann Equipment” is a trading name of Eschmann Holdings L imited.

“RX600” is a tr ade mark of Eschmann Holdings L imited.

Patents: GB 2260075 & GB 2242624; F rance 536922 & 450836; US5116032;

Germany P69206378.1 & P69104883.5; Italy 536922 & 450836.

Patents pending in Japan, application n umbers 263630/92 & 97990/91.

Copyright © 2002

All rights reserved. This booklet is protected by cop yright. No part of it may be reproduced, stored in a retriev al

system or transmitted in any form or by any means , electronic, mechanical, photocopying, recording or otherwise

without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company , howe ver, reserves the

right to modify or improve the equipment referred to .

If the CE mark is affixed to the product, it indicates compliance with Council Directive

93/42/EEC of 14 June 1993 concerning medical devices.

T-SM13h October 2002

Service Manual

RX500RX500

RX500

RX500RX500

OPERATION TABLE

READ THESE INSTRUCTIONS BEFORE USE

Keep these Instructions in a saf e convenient place for future ref erence. Read in conjunction

with the relevant Publications detailed in the preliminary information section.

CONTENTS

Section Contents Page

1. PRELIMINARY INFORMATION ..................... 4

2. TECHNICAL DAT A.......................................... 4

3. SAFETY NOTES ............................................ 5

4. INTRODUCTION............................................ 6

General ....................................................... 7

Electrical System ........................................ 7

Main Control Board ................................. 7

Height Opto Board .................................. 7

Tilt Opto Board........................................ 7

Base Distribution Board .......................... 8

Top-Of-Column Distr ibution Board .......... 8

Top-Of-Column Solenoids Board ............ 8

Power Circuits ......................................... 8

Hand Control ........................................... 8

Footswitch ............................................... 8

Ta ble-Base ON/OFF Control ................... 8

Built-in Battery Charger........................... 9

External Batter y Charger ........................ 9

Standby System Connections................. 9

5. DESCRIPTION ............................................. 10

6. MAINTENANCE ........................................... 14

General ..................................................... 14

Cleaning and Storage ............................... 14

General Care and Lubrication................... 14

Gas Springs .......................................... 14

Head, Leg, & Infill Sections................... 14

Head, Leg, & Infill-Locking Mech. ......... 14

Long and Short Tr unk Sections ............. 14

Radiographic Tops................................. 14

Underside of the Table Base ................. 14

Access to Fuses.................................... 15

Hand control.......................................... 15

After Maintenance................................. 15

Functional Checks .................................... 15

General ................................................. 15

Hydraulic System...................................... 18

General ................................................. 18

Topping-Up Reservoir ........................... 18

Adjustments .............................................. 18

Trendelenburg Microswitch ................... 18

Lateral Tilt Opto..................................... 18

Break Microswitch................................. 19

Tilt Switch.............................................. 20

Removal and Installation........................... 20

General ................................................. 20

Remove Table Base Covers .................. 20

Install Table End Base Covers .............. 20

Remove Top-Of-Column Covers ........... 21

Install Top-Of-Column Covers ............... 21

Releasing Telescopic Cover & Upstand 21

Refixing Telescopic Cover & Upstand ... 21

Removing the Telescopic Cover............ 21

Replacing the Telescopic Cover ............ 21

Section Contents Page

Remove Long & Short Trunk Assemblies . 23

Install Long & Short Trunk Assemblies . 23

Remove Break Cylinder ........................ 26

Install Break Cylinder ............................ 26

Remove Lateral Tilt Cylinder................. 27

Install Lateral Tilt Cylinder..................... 27

Remove Trendelenburg Cylinder........... 27

Install Trendelenburg Cylinder............... 28

Remove Height Cylinder ....................... 28

Install Height Cylinder ........................... 28

Gas Spring Replacement...................... 29

Remove Batteries.................................. 29

Install Batteries ..................................... 29

Remove the Base Feet ......................... 29

Install the Base Feet ............................. 30

Infill interlocking mechanism replacement ..............

Push button replacement and adjustment ..............

Remove/Install Hydraulic Components .. 30

Remove/Install Electrical Components... 30

Fault Diagnosis ......................................... 31

Table 1: Fault Diagnosis ........................ 31

Circuit Diagram Index............................ 30

Table 2: Codes for 2-Digit Display ......... 34

FIGURES

1 RX500 Operation Table .................................. 6

2 RX500 Operation Table: Base Details .......... 10

3 RX500 Operation Table: Column/Trunk Detail 12

4 RX500 Operation T ab le: Base

5 RX500 Operation T able: Base

6 Table Tilted for Access .................................. 15

7 Base Detail Table Tilted ................................ 15

8 Main Control Board....................................... 15

9 Hydraulic System - Schematic Diagram....... 16

10 Hydraulic System - Main Components ......... 17

11 Trendelenburg Microswitch ........................... 19

12 Lateral Tilt Opto ............................................ 19

13 Break Microswitch ........................................ 19

14 Tilt Switch ..................................................... 20

15 Cover Retaining Push Riv ets........................ 21

16 Top of Column Hinge Assembly Detail ......... 22

17 Top of Trendelenburg Cylinder...................... 23

18 Break Cylinders ............................................ 24

19 Lateral Tilt Cylinder ....................................... 25

20 Trendelenburg Cylinder ................................ 27

21 Top of Column Detail .................................... 28

22 Bottom of Height Cylinder Detail .................. 28

23 Gas Spring Detail ......................................... 29

24 Base Feet Detail ........................................... 29

25 Infill interlocking mechanism......................... 30

26 Catch mechanism......................................... 30

27 Hand Control Functions................................ 34

28-35Circuit Diagrams*................................. 35-40

(* also see Circuit Diagram Index on page 33)

(short trunk end) ....

(long trunk end) .....

30

30

13

13

T-SM13h 3/40

1. PRELIMINARY INFORMATION

1.1 This Service Manual should be referred to for details of the RX500 Powered Operation Table,

REF 80-600-29 (series) and REF 80-600-61 (series) having Serial Number R5BC8J0000 or above.

Related Technical Publications, available on request from Eschmann Equipment :-

Instructions for Use - T-IM28 - RX500 Powered Operation Table

Illustrated Parts List - T-IPL11- RX500 Powered Operation Table

1.2 Instruction and Service Manuals should be readily accessible for reference prior to and when operating,

cleaning and servicing the Operation Table.

2. TECHNICAL DA TA

DIMENSION

Table with standard table-top (Fig. 1) :

Width including sidebars ............................. 560mm

Sidebars ......................................(31.75 x 6.35)mm

Overall length (with infill section)............... 2000mm

Minimum table height (without mattresses) ....... 700mm

Maximum table height (without mattresses) ....1040mm

SAFETY

The table is built to comply with BS5724 Part 1,

BS5724 Part 2 Section 2.22, IEC601-1,

IEC601-1-2:1993 and BS6859 Part 1. The mattresses

comply with BS2891.

TABLE LOADING

The standard table (Fig. 1) satisfies a static load test

in accordance with the requirements of BS5724

SYMBOLS & SAFETY CLASSIFICATIONS

Caution Refer to the accompanying

documents, the “Instructions for Use”.

or IPX 4 indicates that the equipment will

withstand a moderate quantity of fluid spilled

from above.

Safety Category

Indicates that the equipment is in safety

category BF, i.e. it is manufactured to a

safety standard which agrees with

international regulations for medical electrical

equipment, and provides a high degree of protection

against electric shock. The symbol also indicates that

the equipment will not be damaged by defibrillator

discharge.

Indicates that the equipment is in safety

category B, i.e. it is manufactured to a safety

standard which agrees with international regulations

for medical electrical equipment, and provides a

minimum degree of protection against electric shock.

Class 2 Indicates that the built-in battery

charger is designed to electrical protection Class 2.

MOVEMENTS

Maximum Trendelenburg....................................35°

Maximum Reverse Trendelenburg......................35°

Maximum Lateral Tilt (left and right)...................15°

Maximum Extension......................................... 220°

Maximum Flexion.............................................130°

Head section adjustment ................................ ±45°

Leg section adjustment ......................... (-100+10)°

Note: With the table at minimum height, maximum

Trendelenburg, and maximum head and leg section

movements are reduced due to physical restrictions

(i.e. proximity of floor)..

WEIGHT (nominal)

Ta ble with standard table-top (Fig. 1)............ 300kg

Anaesthetic Proof

Indicates that the parts of the equipment marked

AP are designed for use within a distance of (5

to 25cm) of a part of an enclosed medical gas

system. BS5724 Part 1, 1989 refers.

Indicates that the parts of the equipment

marked APG are designed for use within a

distance of 5cm of a part of an enclosed medical

gas system. BS5724 Part 1,1989 refers.

WARNING

The head section of this operation table is

classified as ‘EQ UIPMENT not suitable f or use in

the presence of a flammable anaesthetic mixture

with air or with Oxygen or Nitrous Oxide’ and is

NOT classified as ‘Category AP Equipment’ or

‘Category APG Equipment’ when it (the head

section) is in its lowest position and the table top

is in full Trendelenburg position.

Inspection

The table must be inspected at regular intervals, and

if necessary , serviced, to ensure that it complies with

all AP and APG requirements relevant to physical

deterioration or breakage of electrical components,

connections and cable insulation.

4/40 T-SM13h

2. TECHNICAL DA TA

MISCELLANEOUS

RX500RX500

RX500

RX500RX500

OPERATION TABLE

Antistatic requirements

The table has an antistatic pathway from the tabletop, through an internal resistor to the castors, which

are held in contact with the floor at all times.

CAUTION

1. T o complete the antistatic pathway , the tabl e

must be used on an electrically conductive, or

on an antistatic floor.

2. Always use purpose-designed Eschmann

mattresses to maintain the antistatic pathway.

Electrical data

System Power

Batteries:

Type....................................... Two sealed lead-acid

Output (each) ......................................... 12V 24Ah

Built-In Battery Charger:

Input ...................................... 200-240Vac 50/60Hz

Output ..............................27.6Vdc (nom) 3A (max)

System Fuses:

Motor....................................... 30A 1.5in. (AGU 30)

Base Control Board: (1)........ F6.3A 250V 20mm

(1)........ T2.5A 250V 20mm

(1)........... T2A 250V 20mm

CAUTION

This equipment contains environmentally

hazardous lead-acid batteries. If the batteries fail,

or if the equipment is to be disposed of, it is

recommended that the batteries are taken to a

disposal site designated for the disposal of leadacid batteries, or that the batteries are collected

by an agent who specialises in the collection of

lead-acid batteries.

Hydraulic Oil

Type.....................Eschmann RX (Part No. 699408)

3. SAFETY NOTES

Attention to the following points will prolong the life and efficiency of the RX500 Powered

Operation Table and will help to avoid the risk of accidents, or damage.

DO:

♦ Keep the Instruction Manual close-to-hand.

♦ Read the instructions carefully before using table.

♦ Check that the head and leg sections are secure,

and put the table base in the braked position

before use.

♦ Disconnect the built-in battery charger from the

power supply and switch tab le off before washing.

♦ Read and follow the instructions f or cleaning, and

for the care of the mattresses.

♦ Use the correct mattresses and accessories.

♦ Remove table accessories and their clamps (in

particular rotary clamps) from sidebars, when

they are not being used.

♦ Ensure that the table is serviced at regular intervals

(every 6 months is the recommended frequency)

by Eschmann personnel only , or accredited agents.

DO NOT:

♦ Lift the table by its table-top.

♦ Push the table over rough surf aces, use a trolley .

♦ Drop the table (or individual sections).

♦ Put heavy weights on the table sections.

♦ Put sharp objects on, or against, mattresses,

pads, or the radiographic table-tops.

♦ Drop heavy objects onto the radiographic tab le-tops.

♦ Spill oil, ether, or other fluids onto the

mattresses or the pads.

♦ Pull the table by any of the table-top sections,

always push it.

♦ Hold or support the leg section by its black

radiographic top, as this is a remov able item and

might come off.

Note: The table cannot be used (under normal

circumstances) with table base standby door open.

WARNING

The RX500 Powered Operation Table has been designed to minimise the possibility of accidental

electrosurgery burns. Contact with any metal surfaces (e.g. table side bars, or other equipment

etc.) can cause burns during electrosurgery and must be avoided.

With the table in (or during transition into) the castor position, the centre of gravity of the patient

(normally the perineum) should lie no more than 200mm away from the centre of the column (i.e. no

more than the length of the short trunk section). Whenever this is not practical the overhanging

weight of the patient and table should be adequately supported (e.g. by at least two able people).

Also see Warnings in Instruction for Use and within the text of this publication.

T-SM13h 5/40

4. INTRODUCTION

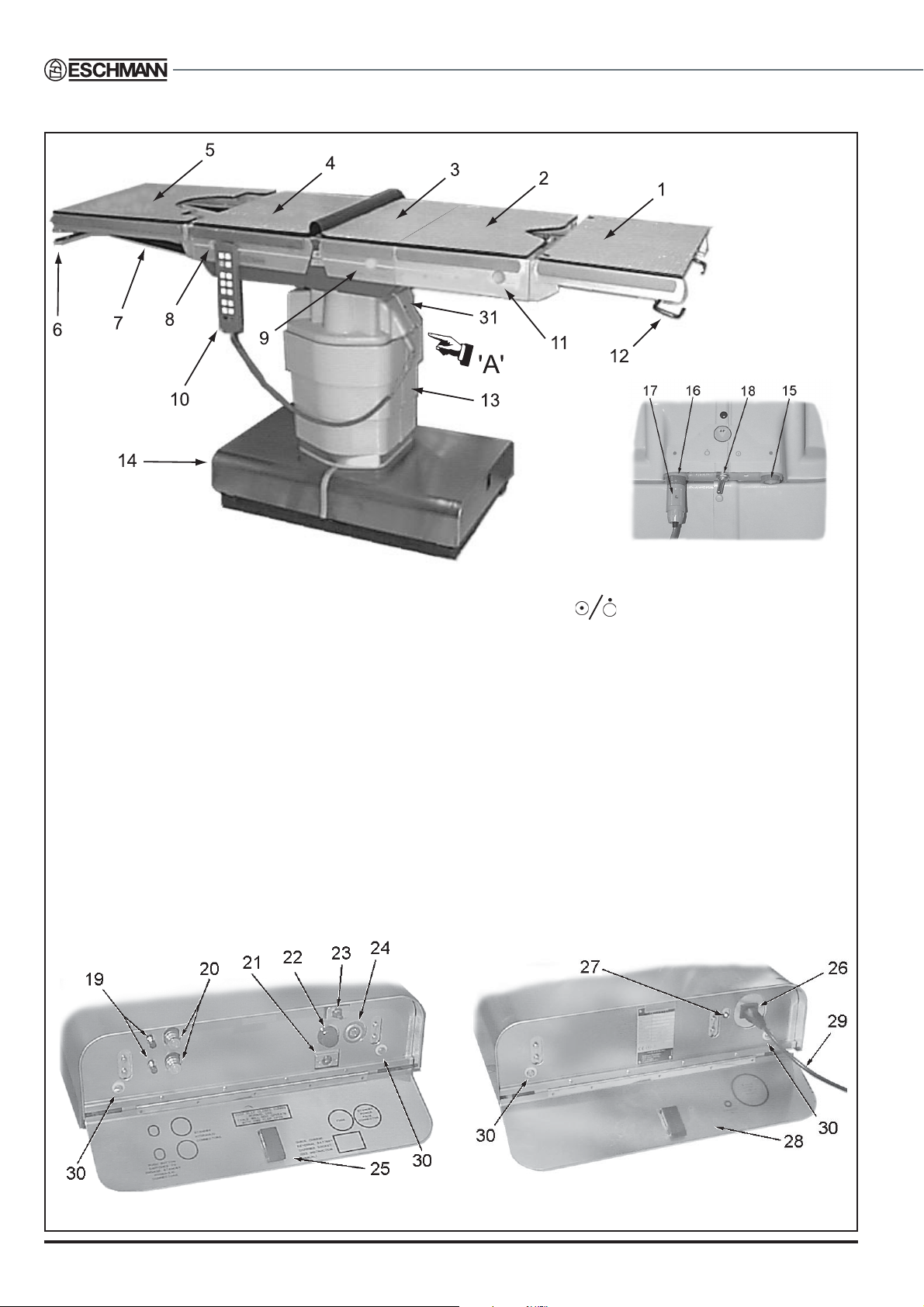

View on ‘A’

1. Head section

2. Infill section

3. Short trunk section

4. Long trunk section

5 Leg section

6. Release bar

7. Gas springs

8. Release button (leg section removal)

9. Release button (Infill section removal)

10. Hand control

11. Release button (head section removal)

12. Release bar

13. Telescopic column

14. Table base

15. Hand control or footswitch socket

16. Hand control or footswitch socket

View on base short trunk end

17. Hand control plug

18. Table

19. Push button switches to engage standby

hydraulic connectors

20. Standby hydraulic connectors

21. Quick-charge external battery charge socket

22. High current 30A fuse

23. Standby door microswitch

24. Standby power pack connector

25. Standby door

26. Built-in battery charger socket

27. Battery charger ‘on’ indicator (green)

28. Battery charger door

29. Removable mains lead

30. Cover retaining screws

31. Top of column covers

View on base long trunk end

(on/off) switch

Fig. 1 RX500 Powered Operation Table

6/40 T-SM13h

4. INTRODUCTION

RX500RX500

RX500

RX500RX500

OPERATION TABLE

GENERAL

4.1 This Service Manual contains a technical

description and maintenance procedures for the

RX500 Pow ered Operation Table.

4.2 The RX500 Pow ered Operation Table is a fully

mobile table with a five section top comprising short

and long trunk sections, an interchangeable infill

section and head and leg sections.

4.3 The table enables a full range of surgical and

radiographic procedures to be done including: general,

urological, gynaecological, cardiothoracic, ophthalmic,

ENT and neurosurgical. Certain procedures require

the addition of specific accessories, information about

which is availab le on request.

4.4 The RX500 Powered Operation Table is an

electro-hydraulically operated, battery powered unit,

remotely operated from a touch-button hand control, or

a footswitch, both plug into the top of the table column

4.5 Power is provided by tw o 12V sealed lead-acid

batteries in the table base. The 12V batteries are

connected in series to give an output voltage of 24V.

T rickle charging for the batteries is pro vided by an inbuilt

battery charger, provision is also made for connection

of an external battery charger for quick battery charging.

4.6 All table top trunk movements are electrically

controlled using either the hand control or, as an

optional accessory the four function foots witch (height

and Trendelenburg only) which is used by the surgeon

during certain procedures.

4.7 The operation table has these main sections:

G Base.

G Central column.

G Long trunk.

G Short trunk.

G Interchangeable head, leg and infill sections.

NOTE: Instr uction and Service manuals should be

readily accessible for reference prior to, and when

operating, cleaning, and servicing the table.

ELECTRICAL SYSTEM

NOTE: Electrical/electronic circuit diagrams are

provided at the end of this Manual in section 6 (see

index page 33).

Main Control Board

4.8 The main control board receives signals from

the hand control via an RS485 serial communication

link. The board also receives signals from the

footswitch, base cover switches, levelling

microswitches, tilt switch, opto boards, standby unit

socket, door switch and table on/off controls.

4.9 Outputs from the main control board pass

to the hand control via an RS485 serial

communication link, to the hydraulic solenoids via the

top-of-column distribution and solenoid boards, and

to the base distribution board, motor on/off control

and motor direction control. The main control board

is supplied with 24V d.c. from the batteries and

generates its own 12V d.c. and 5V d.c. supplies.

4.10 The principal functional areas of the main

control board are:

- Input buffering (pull-up and pull-down resistors

and capacitors).

- The microcontroller, which uses software to

implement table control functions.

- Output buffering (current drivers and le vel shifters).

- Motor direction dr ive and on/off control.

Height Opto Board

4.11 The height opto board is fitted at the base of

the column in a fixed position relative to the baseplate .

It responds to a metal reflector plate which moves up

and down with the column chassis and hence with

the table top. When the reflector mo ves in front of the

three reflective opto sensors (only two are used)

electrical signals are generated to signal to the main

control board that the table is at or above ‘minimum

height’, or in the ‘castor’ position.

4.12 When the reflector plate is in front of reflective

opto coupler 01 and at the correct distance from it, a

signal is produced which passes via J1 on the opto

board and the 10-way ribbon cable to J22 on the main

control board.

4.13 When the reflector plate is in front of both

reflective opto couplers 01 and 03 signals from both

pass to the main control board which stops the table

movement at the correct position.

Tilt Opto Board

4.14 The tilt opto board is fitted at the top of the

column in a fixed position relative to the y oke. It responds

to a metal plate which moves with the yok e and hence

with the table top. When the reflector moves in front of

the opto sensors electrical signals are generated to

signal the main control board that the table is lev el.

4.15 When the reflector plate moves in front of the

opto sensor, a logic signal 0 is produced which passes

via J1 on the opto board to the top of column

distribution board and then via a 10-way ribbon cable

to J2-4 on the main control board.

4.16 When the reflector plate is not in front of the

opto sensor, a logic signal 1 is produced which is

passed to the main control board as above.

T-SM13h 7/40

4. INTRODUCTION

Base Distribution Board

4.17 This board receives signals from the main

control board for the height (extend) solenoid, the

height (contract) solenoid, the pump-isolate (forw ard)

solenoid and the pump-isolate (reverse) solenoid.

4.18 The board also passes signals to the main

control board from the cover microswitches .

4.19 Any inductive ov erswings from the solenoids

are blocked by diodes Dl to D4. PL7 on the base

distribution board is connected via a 14-way ribbon

cable to J4 on the main control board.

Top-of-Column Distribution Board

4.20 This board connects to J2 on the main control

board via a 34-way retractable ribbon cable which

terminates on PL1 of this board. It distributes signals

to 10-way hand control/footswitch sockets PL2 and

PL3, and to:

G the tilt switch via PL7

G the Trendelenburg level position microswitch

via PL5

G the lateral tilt opto board via PL4

G the break level position microswitch via PL6

G top-of-column solenoids board via PL8

G table ON/OFF switch via PL9

Top-of-Column Solenoids Board

4.21 This board receives signals on J7 via a 10way ribbon cable from J8 on the top-of-column

distribution board to drive the top-of-column solenoids

via cage clamp connectors J1 to J6. It also blocks

inductive overs wings from solenoids using diodes D1

to D6.

Power Circuits

4.22 The power source for the table are two 12V,

24Ah sealed lead acid batteries connected in series.

A 30A in-line, high current fuse protects the batteries,

motor, FET’ s , rela y and interconnections. The fuse is

fitted on a panel in the table base.

4.23 Current from the batteries passes via the

reversing rela y , where it is s witched by the FET’ s, and

then passes to the pump motor and returns to the

batteries. The 24V d.c. supply is also routed to the

hydraulic solenoids and the main control board.

Hand control

4.24 The RX500 hand control communicates with

the main control board via an RS485 serial

communication link. The hand control contains a

microcontroller which receives inputs from the hand

control buttons and generates outputs which go to

the hand control LED’s and the hand control audib le

warning device. The microcontroller uses software to

implement hand control, control functions.

4.25 The hand-control incorporates a 2-digit display

that indicates a code if a problem should occur. Such

problems could be the result of the user pushing a

button in the wrong sequence or at the wrong time or

of a system failure (see Table 1 - Fault Diagnosis,

Ta ble 2 - Codes for 2-Digit display and Fig. 27)

Footswitch (Optional Accessory)

4.26 The footswitch plugs into either of the two 10way sockets used by the hand control. It uses the

same +5V d.c. and 0V pins, but the signal lines are

different from those of the hand control. The f ootswitch

does not use a serial communication link.

4.27 There are four functions on the footswitch:

G Height up

G Height down

G Trendelenburg

G Reverse Trendelenburg.

4.28 Each of these f our functions is associated with

two microswitches mounted inside the body of the

footswitch, one normally open and the other normally

closed. The normally open microswitch for each

function is connected on one side to the +5V d.c. line

and on the other side to a common ‘alarm’ line. The

normally closed microswitch for each function is

connected on one side to the 0V line and on the other

side to an individual input line on the main control

board. If , for any function of the f ootswitch, e .g. height

up, the normally open microswitch operates and the

normally closed microswitch does not, or vice versa,

the main control board will recognise a fault and freeze

the table. The likelihood of two microswitches failing

at the same time is very remote.

Table Base ON/OFF Control

4.29 An ‘on/off’ toggle switch, fitted on the top of

the table column, switches 24V d.c. on the main

control board. To isolate the system the 30Amp fuse

should be removed.

8/40 T-SM13h

4. INTRODUCTION

RX500RX500

RX500

RX500RX500

OPERATION TABLE

Built-in Battery Charger

4.30 This is a low current output ‘trickle’ charger

which replenishes an average day’s table use of the

batteries with an overnight charge.

4.31 The mains input comes via the mains lead,

which should be fitted with a fused plug. The output

of the charger is regulated to provide 27.6V d.c. to

the batteries for float charging. This voltage will fall

when the batteries are not completely charged and

hence are drawing a significant current. The charger

has short-circuit and thermal protection. There is an

output from the board which supplies current to the

batteries, an output to the ‘trickle’ charger indicator

LED and an input from the external charger. Current

from either the internal or the external charger is

routed to the batteries via the ‘trickle’ charger board.

External Battery Charger (Optional Accessory)

4.32 The external battery charger plugs into the

external battery charger socket in the table base and

supplies current via the ‘trickle’ charger board to the

batteries.

Standby System Connections

4.33 An RX Standby Unit (optional accessory)

which provides standby hydraulic and electrical

services, can be connected to the RX500 table via

hydraulic connectors and an electrical socket behind

the door on the table base (short trunk section end).

4.34 Next t o the h ydraulic connectors are two pushbuttons which release stored hydraulic pressure when

the standby hydraulic connections are made. This is

done by energizing the pump forward and reverse

solenoids with power from the standby unit.

4.35 To connect the standby unit to the table it is

necessary to open the base door. This operates a

microswitch which disconnects the main control board

solenoid control circuits from the solenoids so that

they can be controlled by the standby unit, also the

pump motor is hydraulically isolated from the hydr aulic

solenoids. The electrical signals from the standby

socket pass to J1 on the main control board (15-wa y

D-connector).

T-SM13h 9/40

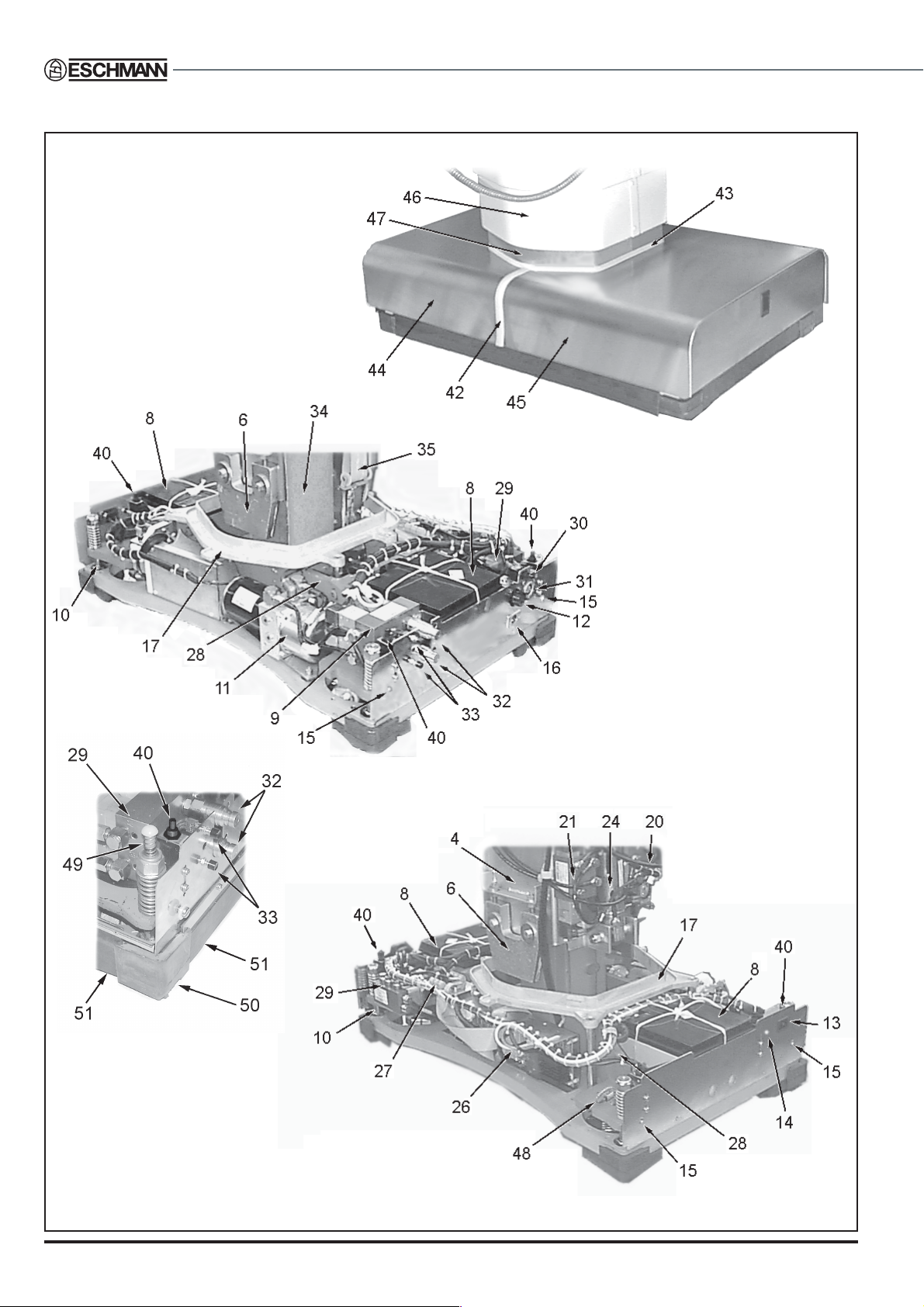

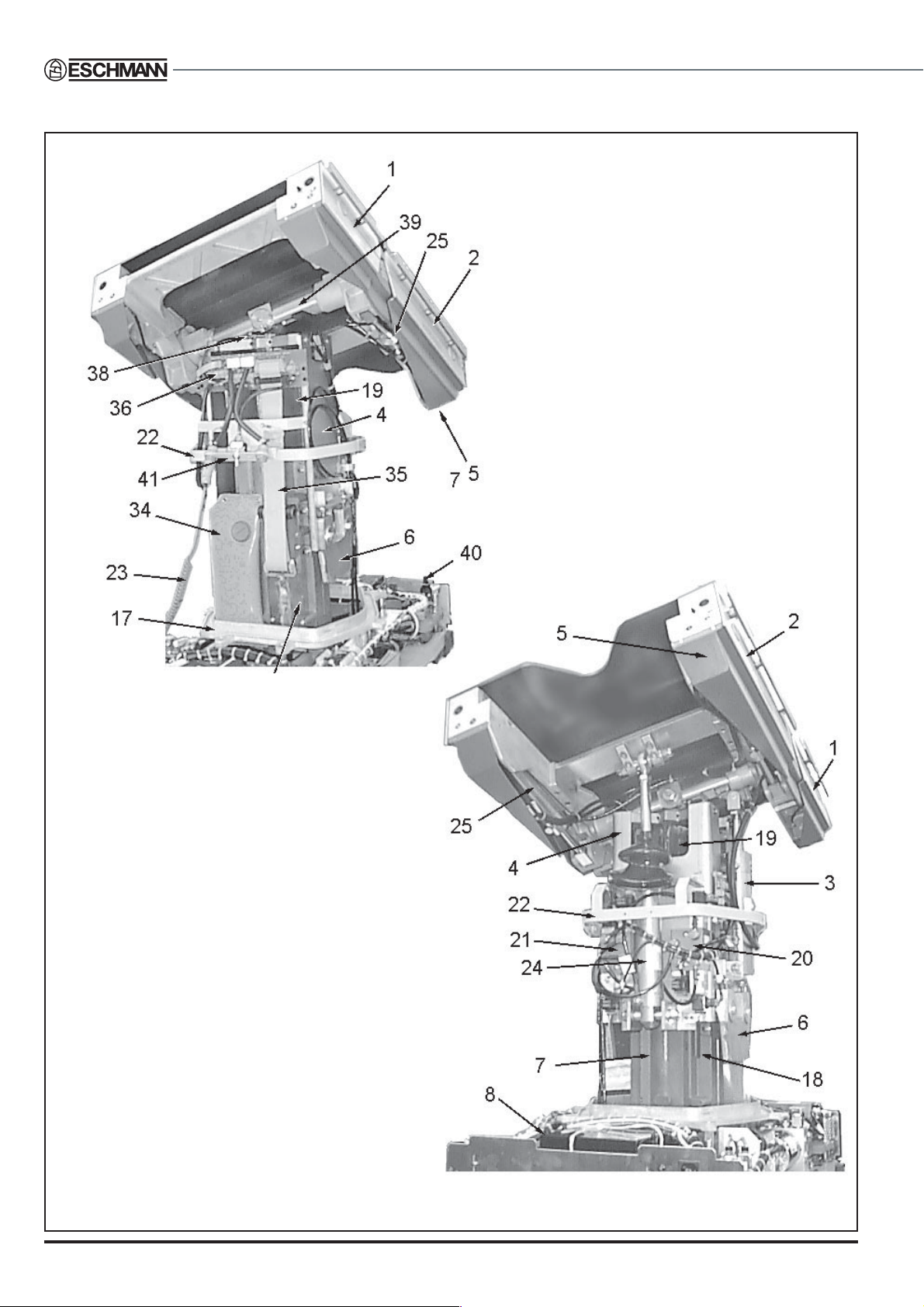

5. DESCRIPTION

For greater detail of

the table base ends also

refer to Fig. 4 and 5

Fig. 2 RX500 Operation Table : Base details, covers on and off

10/40 T-SM13h

5. DESCRIPTION

Key to Figs 2 and 3

RX500RX500

RX500

RX500RX500

OPERATION TABLE

1. Short trunk assembly

2. Long trunk assembly

3. Lateral tilt cylinder

4. Wrap around

5. Tr unk assembly plastic covers

6. Wedge

7. Outer column

8. Battery

9. Manifold block No 1

10. Castor plate guide pillar

11. Hydraulic power unit

12. High current fuse, 30A

13. Mains socket

14. Battery charging LED (green)

15. Cover retaining screw location

16. External batter y charger socket

17. Drip gutter

27. Base distribution PCB

28. Castor frame assembly

29. Manifold block No 2

30. Door microswitch

31. Standby power pack connector

32. Standby hydraulic connectors

33. Push buttons to engage standby

hydraulic connectors

34. Hydraulic reservoir

35. Ribbon cable reel assembly

36. Top-of-column distribution PCB

37. Hinge

38. Lateral tilt opto board

39. Yoke

40. Cover microswitch

41. Table ‘on/off’ switch

42 Base seal

18. Opto reflector plate

19. Inner column

20. Manifold block No 4

21. Manifold block No 3

22. Upper bezel

23. Cable from hand control

24. Trendelenburg cylinder

25. Break cylinders

26. Main control PCB

43. Column seal

44. Long trunk base cover

45. Short trunk base cover

46. Telescopic column cover

47. Column upstand

48. Antistatic discharge path resistor

49. Base cover spring support

50. Base foot

51. Base skirt

T-SM13h 11/40

5. DESCRIPTION

Fig. 3 RX500 Operation Table : Column and trunk section detail

12/40 T-SM13h

Loading...

Loading...