Page 1

LS5

VACUUM & NON-VACUUM AUTOCLAVES

Instructions for use

1 10151

ST-IM61e

Page 2

Preliminary

Information

Safety notes

and cautions

Installation

Operation

Cleaning, care

and maintenance

Technical data

Read these Instructions before use

Keep these ‘Instructions for use’ in a safe convenient place for future reference. Read in

conjunction with the Publications detailed in Section 1.4 and 1.5.

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquires, please quote the

Model and Serial Number of your Autoclave which is shown on the Serial Number plate, the

location of which is shown in Fig. 2 item 8. Please ensure you include all alpha and numeric digits

of the Serial Number.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

T el: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limited.

“Eschmann Equipment” is a trading name of Eschmann Holdings Limited.

“Little Sister” and “LS5” are trade marks of Eschmann Holdings Limited.

Patents Pending plus: Pat. US5090033 and Pat. GB2238407.

Copyright © 2005 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

Instructions for use

ST-IM61e May 2005

Page 3

VACUUM & NON-VACUUM AUTOCLAVES

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Limitations on use . . . . . . . . . . . . . . . . . . . . . 5

4 Electrical safety . . . . . . . . . . . . . . . . . . . . . . . 5

5 General safety . . . . . . . . . . . . . . . . . . . . . . . 5

6 Conditions for safe use . . . . . . . . . . . . . . . . . 5

7 Warning markings . . . . . . . . . . . . . . . . . . . . . 5

8 Safety features . . . . . . . . . . . . . . . . . . . . . . . 6

9 Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . 6

10 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

11 Control and panel details . . . . . . . . . . . . . . . 6

Mains switch . . . . . . . . . . . . . . . . . . . . . . 6

Push-button . . . . . . . . . . . . . . . . . . . . . . 6

Digital displays . . . . . . . . . . . . . . . . . . . . 6

Indicators . . . . . . . . . . . . . . . . . . . . . . . . 7

12 Initial preparation for use . . . . . . . . . . . . . . . 7

13 Loading the autoclave . . . . . . . . . . . . . . . . . . 7

14 Running a cycle . . . . . . . . . . . . . . . . . . . . . . 8

15 Special programmes/Functions/Tests . . . . . . 9

16 Cleaning and care . . . . . . . . . . . . . . . . . . . . 10

17 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 10

18 Printer instructions . . . . . . . . . . . . . . . . . . . 16

Installation . . . . . . . . . . . . . . . . . . . . . . 16

Output . . . . . . . . . . . . . . . . . . . . . . . . . 16

Paper roll renewal . . . . . . . . . . . . . . . . 16

Ribbon cartridge renewal . . . . . . . . . . . 17

Spares pack . . . . . . . . . . . . . . . . . . . . . 17

19 Technical data . . . . . . . . . . . . . . . . . . . . . . . 18

20 Accessories . . . . . . . . . . . . . . . . . . . . . . . . 18

LS5

Appendix 1 - Cycle B4 notes . . . . . . . . . . . . . . . 19

Appendix 2 - Safety checks . . . . . . . . . . . . . . . . 19

Appendix 3 - Daily record sheet . . . . . . . . . . . . 20

Table 1 Key to display A2 . . . . . . . . . . . . . . . . . 11

Table 2 Special functions . . . . . . . . . . . . . . . . . 12

Table 3 Error numbers and remedies . . . . . . . . 14

ST-IM61e P3/20

Page 4

1 Introduction

WARNING

Read these instructions before use and keep them in

a safe convenient place for future reference. The use

of this autoclave should be under the control of a

person with adequate sterilization training. The

operator remains responsible for ensuring that the

load is suitable for the process adopted. The autoclave

should only be used as specified by the manufacturer

and detailed within these instructions. Never tamper

with, bypass or interfere with any of the safety features.

There are no ‘operator’ serviceable parts inside the

autoclave. Eschmann Equipment is not responsible

for malfunction, or a reduced level of protection

provided by the equipment, if used in a manner not

specified by them. Only use in conjunction with

Eschmann accessories and mains lead.

RESERVOIR WATER QUALITY CAUTION

a. Eschmann recommend filling the reservoir with

‘Sterile Water for Irrigation’. This is low in

dissolved solids and has a low microbial count.

In the U.K. the Department of Health recommend

that ‘Sterile Water for Irrigation’ is used in benchtop Autoclaves (NHS Estates document

HTM2031).

b. If ‘Sterile Water for Irrigation’ is not being used

then Eschmann strongly recommend the use of

either distilled water, deionized water, purified

water or water treated by the reverse osmosis

process. These types of water are low in

dissolved solids and can help reduce the effects

of tap water detailed below.

c. DO NOT USE TAP WATER, this is high in

dissolved solids and can deposit lime scale,

block filters and cause damage to the pressure

vessel.

1.1 For Customers on the Mainland of England,

Scotland and Wales, or on the Isle of Wight ONLY, when

you receive your Autoclave ensure that you complete your

Service Guarantee and Registration Card, and then

FREEPOST it to Eschmann Equipment. Failure to return

this card means you will not benefit from our FREE

installation service, which will ensure your Autoclave is

correctly installed, plus a FREE service visit during the

following 12 months.

1.2 This manual applies to the following Autoclaves fitted

with software version 1.51 (see section 19.7) or later:-

SES Little Sister 5 Autoclave

(from Serial Number L5NC....) REF 87-060-01

SES Little Sister 5 Vacuum Autoclave

(from Serial Number L5SA3C1001) REF 87-060-25

It is also applicable to earlier models of the LS5 autoclave

that has been upgraded by Eschmann or their accredited

agents and has software version 1.51 (see section 19.7)

or later.

1.3 These Autoclaves are designed for the sterilization

of instruments, utensils and other items. Only the Vacuum

models can sterilize wrapped or pouched items and hollow

instruments. They operate automatically and have

programmes at 134°C and at 121°C (with and without

drying). For sterilization times, refer to section 19.

1.4 The Service Manual (ST-SM33) containing a

technical description, complete maintenance procedures

and an illustrated list of spare parts is available on request

from the Eschmann After Sales Service Department.

1.5 A Manual (ST-IM55) providing the ‘Manufacturers

recommended instructions for testing vacuum autoclaves’

to the applicable parts of HTM2010 and DB9804 is available

on request from the Eschmann After Sales Service

Department.

d. Eschmann also recommend changing the water

in the reservoir on a weekly basis, with the type

of water detailed in ‘a’ (or ‘b’) above. This will

reduce the build-up of contaminants in the water

that may cause blocked filters and/or damage

to the pressure vessel. Your local Health

Authority may suggest that you change the

reservoir water more frequently. Eschmann

advise you to follow your local Health Authority’ s

recommendations.

P4/20 ST-IM61e

Page 5

LS5

VACUUM & NON-VACUUM AUTOCLAVES

2 Hazards

2.1 The operator should be aware of the following

hazards:-

a. Burns to the operator caused by contact with hot

accessible surfaces of the load (use the ‘tray lifter’

to remove the sterilized load) and high temperature

internal surfaces of the chamber. Scalds to the

operator caused by hot water and/or steam from

the reservoir, from the chamber on opening the door

and from overfilling the reservoir.

b. The hazard of scalds and burns from contact with

hot surfaces are greater during validation when the

covers may be removed which also exposes the

risk of electric shock. V alidation should therefore only

be carried out by a qualified engineer.

c. Infection, caused by contact with water in the

reservoir if the reservoir is not drained and left to

dry as described in these instructions for use.

d. The autoclave indicates a successful cycle, but the

load remains non-sterile because the load is not

suitable for the cycle selected. All loads and loading

conditions should be validated. It is recommended that

the operator consults the instructions for use of the

items to be autoclaved and if in doubt consult a qualified

microbiologist (or in the UK an Authorized Person).

3 Limitations on use

5 General safety

IMPORTANT

The design of the autoclave pressure vessel is

approved by a third party to International Standards.

In order to ensure safety and to comply with UK

and/or International regulations, the vessel and

fittings should be inspected by a ‘competent person’

at intervals of no more than 14 months. This can be

carried out by an Eschmann trained engineer. Also

see Appendix 2.

5.1 The operator should follow these general safety

measures:-

a. Do not cover the ventilation ports at the rear.

b. Do not use abrasive powders, chemicals, or

solutions containing chlorine to clean the autoclave.

c. Do not attempt to open chamber door until unit has

cooled and internal pressure has fallen sufficiently to

allow the door to be opened, by pressing the

button.

d. If an error display appears during a cycle, do not

switch-off power until discharge of hot water or

steam into the reservoir has stopped.

6 Conditions for safe use

6.1 This autoclave has been designed for use in the

following conditions only:-

3.1 The operator should be aware of the following

limitations during use:

a. Never use trays or cassettes without perforations.

b. Do not process porous loads (e.g. drapes and

gowns) or fluids in this autoclave.

c. Items in pouches should only be processed as

detailed in these instructions.

d. Do not use in zones of risk associated with

flammable anaesthetics.

e. When sterilizing instruments not of solid metal

construction, the manufacturer of the instrument

must be consulted about its suitability for

autoclaving. (Note: The sterilizing temperature may

be exceeded during the drying phase).

4 Electrical safety

4.1 The operator should follow these electrical safety

measures:-

a. This equipment must be earthed.

b. Switch ‘off’ unit and disconnect from mains power

supply before renewing fuses, fitting the printer,

checking and cleaning the autoclave.

c. Do not attempt to service this equipment internally.

a. Indoor use.

b. Altitude from sea level up to 2000 metres.

c. Temperature 5°C to 40°C.

d. Maximum relative humidity 85% for the temperature

range above.

e. Mains supply voltage fluctuations not to exceed

±10% of the supply voltage.

Note: If it is required to operate this Autoclave outside of

these conditions, contact Eschmann Equipment at

the address given in these instructions.

7 Warning markings

7.1 The warning markings on this equipment have the

following meanings:

Caution; refer to accompanying documents

(i.e. these Instructions for Use).

Caution; hot surface. This symbol warns the

operator of high surface temperatures on the outside

of the equipment.

WARNING: DO NOT USE TAP WATER

(see CAUTION in section 1)

ST-IM61e P5/20

Page 6

8 Safety features

8.1 The autoclave incorporates these safety features:a. Door Interlock Switch and Door Catch Interlock

Switch. These prevent a programme starting if the

door and catch are not properly closed.

b. Pressure Relief Valve (safety valve). This valve

safely releases excess pressure up to a maximum

of 2.85+10%barG.

c. Microcomputer. The microcomputer constantly

monitors all key functions. If an error arises, it stops

the cycle, discharges pressure, and causes the

appropriate message to be displayed

d. Overheat Control. The microcomputer operates in

conjunction with an independent manual reset thermostat to protect the heating element from overheating.

e. Band Heater Thermostat (vacuum units only). This

prevents the band heater exceeding a preset

temperature.

9 Declaration

9.1 The design of the autoclave pressure vessel is

approved by a third party to International Standards. This

equipment is defined as:-

Installation Category 2 (Overvoltage Category 2)

Pollution Degree 2 (in accordance with IEC664).

10 Installation

10.1 The Autoclave should be installed by a competent

person. UK Customers should arrange for this equipment

to be installed by an Eschmann Trained Engineer before

use. (For free installation and service, see section 1.1). All

programmes and functions can be deactivated or reactivated

by an Eschmann Trained Engineer, on request. The ability

to achieve this is protected from tampering, access can only

be gained by use of a ‘password’. Note that a levelling kit

(part number 1 12713) is available for the feet.

Cycle temperature button. Each time the button

is pressed the cycle temperature will alternate between

134°C and 121°C. The temperature selected will be

indicated by the LED C adjacent to the temperature.

Unwrapped load (with drying) cycle button. Press

the button to select a cycle for an unwrapped load

with a drying phase after sterilization. The LED C

adjacent to the button will illuminate to show that

this cycle has been selected.

Unwrapped load (without drying) cycle button.

Press the button to select a cycle for an unwrapped

load without a drying phase after sterilization. The

LED C adjacent to the button will illuminate to

show that this cycle has been selected. (Also see

Appendix 1)

Programme ‘P’ button. This button can be used in

combination with other buttons to activate special

programmes, functions and extended sterilization

cycle times. For more details see Section 15.

Cycle start button. (Always press and hold) Pressing

the button will start the selected cycle.

Open door button. (Always press and hold) When

the cycle has been completed (indicated on the process

display chart ) press the button to

open the door.

Single wrapped load (with drying) cycle button.

(Vacuum autoclaves only) Press the button to

select a cycle for a single wrapped load with a drying

phase after sterilization. The LED C adjacent to the

button will illuminate to show that this cycle has

been selected. See section 15.5 for daily testing

information.

11 Control and display details

1 1.1 Open out the illustration page at the very back of this

manual to familiarise yourself with the controls and displays

shown in Fig. 1 and Fig. 2.

11.2 Mains switch

The mains switch is positioned at the front of the autoclave

(bottom left). The symbol ‘I‘ indicates ‘on’ and the symbol

‘0’ indicates ‘off’ (see 10, Fig. 2).

11.3 Push buttons (see Fig. 1)

Display change button. Button is disabled during

sterilization and drying phases. At any other time press

the button to display the cycle counter in display

D1. If the autoclave is running a cycle the display will

show the cycle number in progress, or, if a cycle is not

running the counter will show the number of cycles

completed (including any aborted). The display will

revert to show the time of day five seconds after the

button is released.

11.4 Digital displays (see Fig. 1)

D1 Time, cycle counter, sterilization or drying time

(remaining), or error number display. This display

normally shows the time of day (to adjust the time

display see section 15.4, Special Functions, F8).

Whilst pressing button this display will show the

cycle counter (see in section 11.3). During the

sterilization or drying phase of a cycle (if applicable)

the display will show the number of minutes remaining

for that phase of the cycle. In the event of an error

occurring it will display an error code. For more details

on the error codes see Table 3.

D2 Temperature display. This display normally shows

the actual chamber temperature. During special

functions it may display other details see details in the

‘Special functions table’.

D3 Pressure display. This display normally shows the

measured chamber pressure. During special functions

it may display other details see details in the ‘Special

functions table’.

P6/20 ST-IM61e

Page 7

LS5

VACUUM & NON-VACUUM AUTOCLAVES

11.5 Indicators (see Fig. 1)

A1 Low water indicator. When this indicator is

illuminated the water reservoir is low and should be

refilled before the next cycle is started (see section

12.5).

A2 Process display indicator. This indictor

has 19 LEDs that illuminate to show the stage reached

during a sterilization cycle. Each LED indicates a

stage and this is detailed in Table 1.

A3 Door unlocked indicator. This indicator is

illuminated when the door is unlocked.

A4 Door locked indicator. This indicator is illuminated

when the door is locked.

C Selection indicators. These indicators illuminate to

show which function has been selected (cycle or

temperature).

12 Initial preparation for use

12.1 When lifting or moving the Autoclave (with at least

two people), place the hands under the base at each side

of the unit. Place the autoclave on a flat, level, water and

heat resistant surface and ensure there is a working

clearance of 150 mm on the left hand side. Do not cover

the ventilation ports at the rear of the autoclave. The

autoclave does not require wall clearance at the back and

can be positioned flush against a wall (unless an extraction

unit is fitted see 12.6). Also see section 10.1.

12.5 With the door open fill the reservoir via the filling

cup (item 2, Fig. 2) up to the ‘MAX’ mark* engraved inside

the filling cup. Eschmann recommend the use of ‘Sterile

Water for Irrigation’ alternatively distilled or deionized water,

or water treated by reverse osmosis process can be used.

DO NOT USE TAP WATER. Close the door onto the

secondary catch only .

* Note: Only two litres of water are required to operate the

autoclave, the reservoir does not require filling to the ‘MAX’

mark if only a few cycles are to be run before the reservoir

is drained (see 16.2).

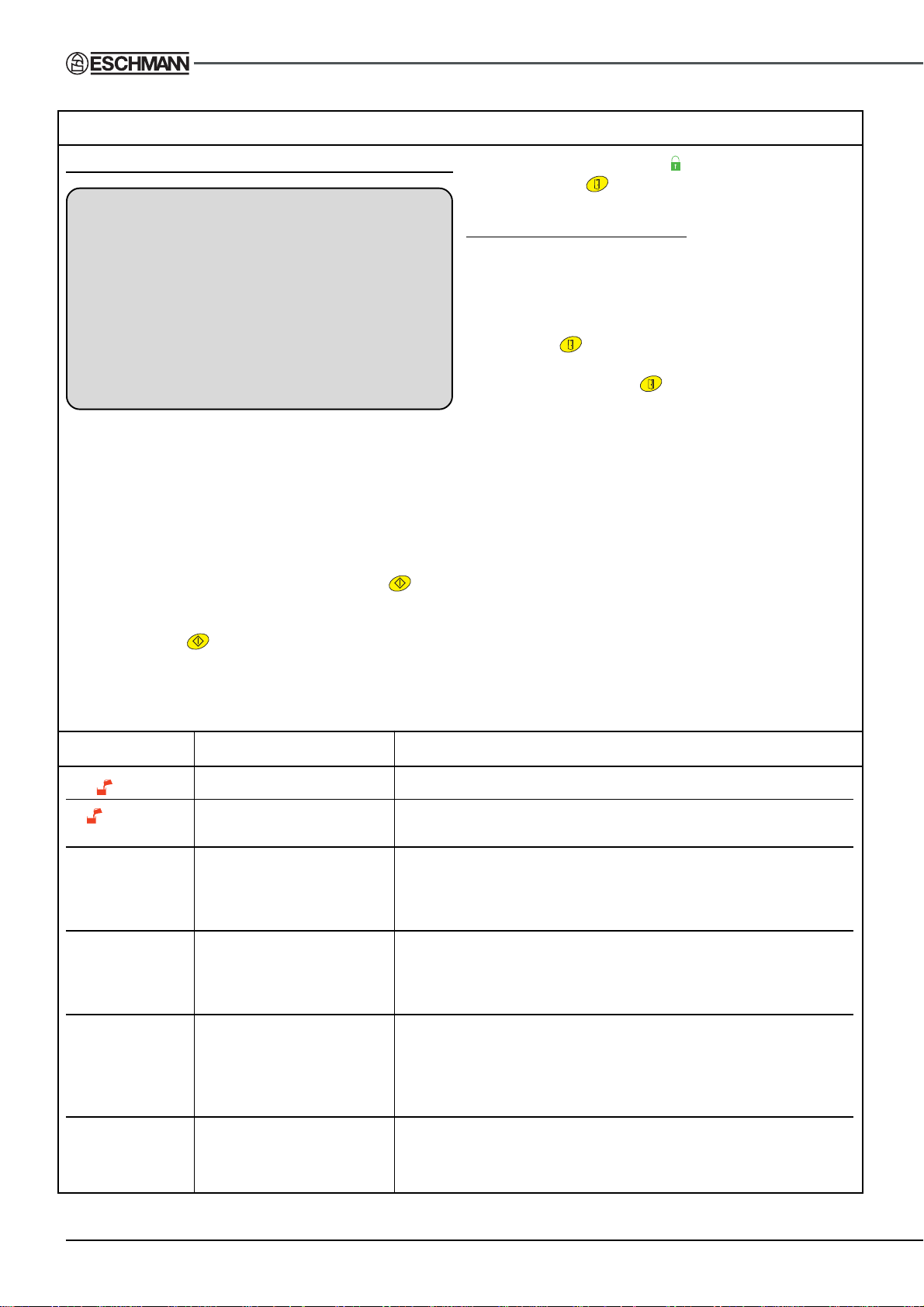

12.6 The autoclave has been designed to accept

standard 100mm domestic extraction ducting at the rear

of the unit. Before connecting the unit to an extraction

system (to remove exhaust steam) check which type of

reservoir is fitted. If it has 4 plugs (‘A’ in Fig.3) remove

them and reposition them in the holes marked ‘B’ in Fig. 3.

If the plugs are not provided block of the holes marked ‘B’

in Fig. 3 with suitable adhesive tape and carefully make

four holes (6mm diameter) as shown ‘A’ in Fig. 3. Do not

allow any swarf to enter the reservoir or make the holes

lower than indicated.

WARNING

This equipment must be earthed. Ensure that the

mains plug is easily accessible during use as this

is the means of disconnection.

12.2 The unit is supplied with an IEC mains input socket

at the rear (see C, Fig. 3) and a selection of mains input

leads. If the lead has a fused plug the correct fuse will be

installed. If an alternative plug is fitted ensure that the plug

is earthed and check that the fuse (if it is a fused plug) is

appropriate for the voltage of the equipment (see rating

plate on base of cabinet item 8, Fig. 2). Connect the

required ‘Eschmann’ lead to the rear socket, DO NOT use

equivalents.

12.3 Connect unit to mains power supply and switch on

by selecting unit power switch ‘0-I’ to ‘I’ (10, Fig. 2). V arious

displays will illuminate to show the autoclave has been

connected correctly , and is ‘on’.

12.4 T o open the chamber door (16, Fig. 2) press button

B7 (Fig. 1) and then push the secondary catch (item 15,

Fig. 2) to the left (when viewed from the front) to release

the door. Remove the tissue paper from the door and

accessories from within the chamber. Remove all packing

pieces carefully and dispose of these and the carton in

accordance with applicable recycling practices.

3

13 Loading the autoclave

CAUTION

When loading the autoclave take care that you do

not damage the door or front face of the chamber,

especially the door seal and mating face. Damage

to these parts can adversely affect performance.

When loading pouches ensure they do not make

‘paper cuts’ in the door seal.

13.1 Check you have read the limitations on use

(section 3) and the technical specification.

13.2 Operators should note that as load types and load

arrangements vary greatly, validation of particular load

arrangements is essential (e.g. wrapped cassettes and

maximum loads). Steam penetration can also be affected

by extremes of humidity. If in doubt, seek advice from a

qualified microbiologist or Authorised Person.

13.3 The autoclave is designed to sterilize instruments,

not to wash or clean them, therefore before loading

instruments into trays cassettes or pouches they should

be pre-washed. Preferably instruments should be washed

ST-IM61e P7/20

Page 8

in an ultrasonic cleaner or washer/disinfecter to remove

amalgam, debris, etc., then rinsed to remove all traces of

proprietary cleaners, chemicals or disinfectants. Residue

from these products could result in a blockage of the water

recycling system. If instruments are not cleaned this may

compromise the efficiency of the sterilization process.

13.4 When loading the autoclave note the guidelines that

follow for each type of autoclave:-

Vacuum and Non-Vacuum Units - Unwrapped solid

items, buttons and

Load unwrapped solid items loose on trays or into

cassettes. Do not overload trays or cassettes (see

TECHNICAL DATA for maximum tray loads). Avoid

‘bunching’ items together and ensure all items are

positioned so that they drain freely . Only use Eschmann

trays or cassettes and ensure that the load does not

block the holes in them. Loaded trays and cassettes

should then be placed in the sterilizing chamber. All items

must be positioned so that they drain freely and do not

trap rising air bubbles. (Also see Appendix 1)

Vacuum Units ONLY - Validated hollow instruments

including narrow lumens (e.g. dental handpieces),

single wrapped hollow or solid instruments

(see 2.1 d) button .

Sterilization of instruments, or other items in pouches

should only be done using the special pouch rack. A void

packing pouches too tightly and note that paper/film

pouches must be loaded such that the film sides of

adjacent pouches are face to face and sterilized using

this cycle with drying. Only use pouches recommended

for steam sterilization, see Accessories section 20. Items

should not be multiwrapped unless the load configuration

has been validated by a suitably qualified person (possibly

using an extended drying time). Also see section 15.5.

14 Running a cycle

14.1 Select mains ‘on/off’ switch to ‘I’ (on) (item 10, Fig. 2)

and open the door by releasing the secondary catch (item

15, Fig. 2). NOTE: If the door was locked closed when

switching ‘on’ indicator will flash and the button

should be pressed to unlock the door, the secondary catch

can then be released.

14.2 Load the autoclave with the items to be sterilized as

detailed in section 13.

14.3 Check that the low water level indicator ( , Fig. 1)

is not illuminated, if it is fill reservoir (see section 12.5).

14.4 Close the door and hold it firmly shut until the

automatic door lock operates. This is shown by indicator

switching off and indicator switching on. NOTE: A

cycle cannot be selected with the door open. When running

repeated cycles the display will retain the last cycle selected

(shown by the illumination of indicators C).

14.5 The autoclave will automatically select a 134°C

unwrapped cycle with drying for Non-vacuum

autoclaves or a 134°C wrapped cycle with drying for

Vacuum autoclaves (unless these cycles have been

disabled see section 10.1). If this is the required cycle pass

on to section 14.6.

T o select a different temperature press the button. Each

time is pressed the cycle temperature will alternate

between 134°C and 121°C. The temperature selected will

be indicated by the LED C adjacent to the temperature.

To select the required programme press the appropriate

button on the control panel ( , or ). The indicator C

for the selected programme will remain illuminated to show

which cycle has been selected. 134°C cycles can be

extended see section 15.

NOTE: Cycle temperature and programme can be selected

in either order and changed independently of each other

until the required ones have been selected. In the case of

low water a ‘beep’ will sound and the ‘low water indicator’

( Fig. 1) will flash.

14.6. Press the cycle start button . The autoclave can

be configured to have adjustable sterilization and drying

times (see section 10.1). The appearance of ‘ ’ in display

D2 indicates that the autoclave has been configured so

that these times can be adjusted. If these have been

enabled for a cycle (‘ ’ in display D2) follow section 14.6.2

‘i-iii’ before continuing with section 14.7; if they are not

enabled (‘ ’ does not appear in display D2) for that cycle

follow section 14.6.1 before continuing with section 14.7.

14.6.1 The sterilizing cycle will now proceed

automatically and the printer (if fitted) will commence

printing. Vacuum cycles may pause to cool the

chamber if it is above a preprogrammed limit. As the

cycle progresses indicator will show the

cycle stage reached (see Table 1) and the digital

displays D2 and D3 will display the actual chamber

temperature and pressure respectively. During the

sterilization or drying phase of a cycle (if applicable)

the display D1 will show the number of minutes

remaining for that phase of the cycle. If a printer is

fitted see section 17.5. Now pass on to section 14.7.

14.6.2 (i) As ‘ ’ has appeared in display D2 this cycle

allows the sterilization time to be increased. D2 will

show ‘ ’ and display D1 will flash and show the

current sterilization time in minutes and seconds.

T o increase this time press and hold the button,

to reduce this time press and hold the button,

until the sterilization time is the desired value. Press

button to accept this time. Pressing the

button at any point before the cycle starts causes

the autoclave to move back one stage in this

process.

14.6.2 (ii) If the cycle has a drying phase, ‘ ’ will

appear in display D2 to indicate that this cycle allows

the drying time to be increased. If ‘ ’ does not

appear in display D2 pass on to section 14.6 2 (iii).

Display D2 is showing ‘ ’ and display D1 will flash

and show the current drying time in minutes. To

increase this time press and hold the button, to

P8/20 ST-IM61e

Page 9

LS5

VACUUM & NON-VACUUM AUTOCLAVES

reduce this time press and hold the button, until

the drying time is the desired value. Press button

to accept this time. Pressing button at any

point before the cycle starts causes the autoclave

to move back one stage in this process.

14.6.2 (iii) The sterilizing cycle will now proceed

automatically and the printer (if fitted) will commence

printing (vacuum cycles may pause to cool the

chamber if it is above a preprogrammed limit). As

the cycle progresses indicator will show

the cycle stage reached (see T able 1) and the digital

displays D2 and D3 will display the actual chamber

temperature and pressure respectively. During the

sterilization or drying phase of a cycle (if applicable)

the display D1 will show the number of minutes

remaining for that phase of the cycle. If a printer is

fitted see section 17.5.

14.7. If a cycle “with drying” is selected then

commencement of the drying phase is indicated by

(see Table 1). On non-vacuum units the door

opens automatically (onto secondary catch) prior to the

start of drying. On vacuum units the door cannot be opened

until the drying phase has been completed.

14.8 On completion of a sterilizing cycle ‘without drying’,

indicated by (see Table 1) and an audible signal,

the door can be released by pressing . (Also see

Appendix 1).

14.9 Open the door fully and remove the load USING

THE TRAY LIFTER and leave the door open on the

secondary catch when not in use.

14.10 If during a cycle an error is detected display D1 will

display an error number (see section 17.3).

15 Special programmes/functions/tests

15.1 Extended sterilization time.

Pressing the ‘P’ button (indicator C adjacent to will

illuminate) before pressing the start button extends

the sterilization time from 3 minutes 5 seconds to 18

minutes. This extended cycle only works on the 134°C

cycles (not 121°C cycles). Pressing the ‘P’ button again

before starting the cycle will cancel the function (indicator

C will go out). Alternatively press the ‘P’ button (during

any cycle) when Phase 3 LEDs 2-7 are illuminated (see

Table 1) to increase the sterilization time by one sixth of

the selected sterilization time (one Phase 3 LED will go off

for each press, to indicate this).

15.2 Extended drying time.

The drying time can be extended in 5 minute steps to a

maximum of 50 additional minutes by pressing the ‘P’

button when ‘Phase 5 - LED1’ is illuminated (see T able

1). Each time the ‘P’ button is pressed the drying time will

be increased (by 5 minutes, or back to 0 after 50) and the

time added to the normal drying time will be displayed in

display D1. After a few seconds display D1 will revert to

the total remaining drying time. NOTE: Autoclave ‘beeps’

when ‘Phase 5 - LED1’ illuminates.

15.3 Accelerated condense.

The condensing time can be reduced by approximately 3

minutes (but more steam may be liberated by the

autoclave) if the ‘P’ button

LED1’ is illuminated (see Table 1). NOTE: Autoclave

‘beeps’ when ‘Phase 4 - LED1’ illuminates.

is pressed when ‘Phase 4 -

15.4 Special functions.

Switch ‘off’ the mains switch (item 10, Fig.2). Press and

hold in the ‘P’ button whilst switching the mains switch

back ‘on’ to make available several special functions as

detailed in the special functions table. When the autoclave

is switched on in this way display D1 only will be illuminated

(with other displays as required depending on which function

is selected). Initially display D1 will show F0, each time the

‘P’ button is pressed, this will increase from F0 up to F8

(F4, F5, F6 vacuum autoclave only and with door closed),

and then back to F0 again, until either the start button is

pressed to select that function, or, the autoclave is switched

‘off’ or is pressed (with the door open) to cancel special

function selection.

15.5 Daily Testing, Vacuum autoclaves

IMPORTANT:

The Eschmann LS5 Vacuum Type-S and QuickVac

Steam Penetration Test Device (hereafter called

‘Device’) has been developed and validated solely

for use in the Eschmann LS5/SES2555 Vacuum

T ype-S and Eschmann QuickV ac Steam Sterilizers.

Use of the ‘Device’ in any other sterilizer , or use with

any other type of indicator, may give dangerously

misleading results. The ‘Device’ must only be used

and stored as detailed in the ‘Instructions for Use’

supplied with the ‘Device’. Failure to replace the

‘Device’ after 100 uses could lead to failure of the

‘Device’ and dangerously misleading results.

15.5.1 In order to sterilize products and devices by

steam, steam must be able to penetrate through to and

contact all surfaces. Items such as packaging, pouches,

narrow or hollow instruments are not easy to penetrate

with steam. For this reason, the LS5/SES2555 vacuum

autoclave has been fitted with a pump to remove air and

thus allow steam to penetrate into the load. The Eschmann

LS5 V acuum Type-S and QuickV ac Steam Penetration T est

Device (order REF 87-040-71) has been designed to test

the steam penetration ability of the autoclave, by presenting

a defined challenge to the autoclave. The device consists

of a plastic tubular device with an indicator receptacle at

the end and is supplied with indicator strips. The device

must be replaced after 100 uses. This device satisfies the

requirement to perform a daily steam penetration test as

given in:

EN 554:1994 Sterilization of medical devices - Validation

and routine control of sterilization by moist heat, British

Standards Institution, clause 6.3.4

DB 2002(06) Device Bulletin, Benchtop Steam Sterilizers-

Guidance on purchase, Operation and Maintenance,

Medical Devices Agency, clause 5.3.1

ST-IM61e P9/20

Page 10

SN 2002(24) Safety Notice, Steam penetration tests in

vacuum benchtop sterilizers, Medical Devices Agency .

DB 2000(05) Device Bulletin, Guidance on the Purchase,

Operation and Maintenance of V acuum Benchtop Steam

Sterilizers, Medical Devices Agency, clause 5.3.1

DB 9804 Device Bulletin, The validation and periodic

testing of benchtop vacuum steam sterilizers, Medical

Devices Agency, clause 5.1

Note: Some of the above documents are available on

the Medical Devices Agency’ s website, www.medicaldevices.gov.uk

15.5.2 Frequency of use

To comply with the requirements of the regulatory

documents listed above, the steam penetration test must

be conducted at the commencement of each day that the

autoclave is to be used. This ‘verifies’ the suitability of

the autoclave’s air removal stage for the day ahead.

‘Appendix 3’ provides an example of a ‘Test Log’ that can

be photocopied and used to record the results. Eschmann

recommend the daily use of the device and the ‘T est Log’.

15.5.3 Conducting the test

Cycle (includes a drying phase) should be used to run

this test, or special function F6 (reduced cycle time as no

drying), if the autoclave is cool and dry before loading it

with the ‘Device’. Remember the ‘Device’ must be removed

within 10 minutes of the cycle end.

16 Cleaning and care

WARNING

Chlorine, even in the concentrations found in tap

water, can cause stainless steel to crack and could

damage the chamber. Disconnect from the mains

electrical supply before cleaning the Autoclave. Also

see Appendix 2.

16.1 Keep chamber trays, door seal and chamber face

clean. These should only be cleaned with a lint-free cloth.

Clean the outside of the autoclave by wiping down with a

cloth dampened with a 70% solution of industrial methylated

spirit (IMS) and water. Allow to dry by evaporation.

NOTE: Do not use abrasive powders, chemicals, or

solutions containing chlorine to clean the autoclave.

CAUTION

In common with other systems containing static

water reservoirs, water used in this unit can become

contaminated over a period of time, or following an

aborted cycle, and should be treated as a potential

risk of infection.

16.2 The reservoir should be drained weekly and allowed

to dry. To drain the reservoir release the reservoir tap

(item 12, Fig. 2) with the drain tube (item 11, Fig. 2) from

its clips (item 13, Fig. 2) at the bottom of the door and

open the tap by releasing the clip (see inset photographs

of open and closed tap in Fig. 2). Replace the drain tube

into its clips and ensure that it does not become trapped

when closing the door. Refill the reservoir (see section

12.5). Regular cleaning of the reservoir will reduce the

effects of excessive contaminants (e.g. handpiece

lubricant) which could be detrimental to the function of the

autoclave. For guidance on clean steam management and

HTM2031 contact Eschmann.

16.3 Attention to the following will increase the life of the

your Autoclave:-

a. Always leave the chamber door open on its

secondary catch when not in use.

b. At weekly intervals, lightly clean door seal and

chamber face with a lint-free cloth.

c. At weekly intervals remove any dirt or debris

that has collected around the gauze filter (item 7,

Fig. 2).

d. At monthly intervals remove any dirt or debris around

the gauze filter (item 7, Fig. 2) then gently pull it out

of its recess. Clean the recess and the filter carefully .

Replace the filter before using the autoclave again.

e. Replace the antibacterial filter on vacuum units (item 1,

Fig. 2) every three months. To remove the filter pull

gently whilst twisting. Replace by pushing a new one

into the rubber mount (small spigot facing out).

17 Maintenance

(ENSURE YOU HAVE READ SECTIONS 2-8)

17.1 Fuse Renewal

Fuses are fitted at the front of the autoclave (item 9, Fig. 2).

For fuse ratings refer to ‘TECHNICAL DAT A’. To extract a

fuse switch ‘off’ the unit and disconnect from the mains

power supply , insert a screwdriver or small coin in the slot

of the fuse holder and twist it counter-clockwise. After

inspecting or renewing a fuse, reverse the above procedure

to re-secure fuse holder.

17.2 Preventive Maintenance Agreement

We would strongly recommend that a ‘P.M.A.’ is taken out

on your Autoclave. Although the autoclave requires minimal

maintenance, it is important to have the autoclave checked

and calibrated at regular intervals. This ensures that the

exacting conditions necessary for sterilization are

maintained throughout the unit’s working life.

17.3 Errors and faults

a If, after switching ‘on’ power there is no visual display ,

first check power supply connections, both fuses at

the front of the unit (see Fuse Renewal) and the

fuse in the mains plug (if it is a fused plug).

b If an error occurs during a cycle (i.e. any time after

pressing the start button ), the cycle will abort

and provided power supply to the unit is maintained,

the error number will be indicated by the visual

display D1 (displays D2 and D3 will be continue to

show actual temperature and pressure).

c If power fails during a cycle, check supply

conditions and fuses at the front of the unit and in

the mains plug if fused, also check the mains lead

P10/20 ST-IM61e

Page 11

is correctly connected at both ends. Once power

is restored the display D1 will show the error

number (D2 and D3 will be blank) until cleared by

switching the autoclave ‘off’ and then ‘on’ whilst

depressing the start button . Release button

when the display appears.

d Most errors will require investigation by an

Eschmann trained engineer who will need to know

the model serial number (see the serial number plate

item 8, Fig. 2) and error number. To display the last

error number in display D1 press buttons and

together at any time.

e Errors that can be corrected by the operator are

detailed in the error table, see Table 3.

f Should the heating element reset thermostat

operate (in a nil water condition) this can be reset

by pressing the ‘reset button’ on the underside of

the autoclave (approximately 11cm in on the left

hand side underneath the unit as indicated on the

side of the unit).

17.4 Service

The Eschmann After Sales Service Department is staf fed

and equipped to provide advice and assistance during

normal office hours. T o avoid delays when making enquires,

please quote the Model and Serial Number of your

Autoclave (NOTE: For location of the serial number plate

see item 8, Fig. 2). If reporting an error please quote the

displayed error number. All correspondence relating to the

after sales service of Eschmann Equipment should be

addressed to :

LS5

VACUUM & NON-VACUUM AUTOCLAVES

TABLE 1

KEY TO DISPLAY A2

Phase 1

LED 1 Cycle started.

LED 2 Chamber minimum fill achieved.

LED 3 Chamber filled with water.

Phase 2

LED 1 Heater on.

LED 2 Approximately 90°C reached.

LED 3 Final heating phase started.

Phase 3

LED 1 Sterilization phase started.

LED 2-7 One sixth of the sterilization time

completed for each LED illuminated.

Phase 4

After Sales Service Department

Eschmann Equipment,

Peter Road, Lancing, West Sussex, BN15 8TJ

Tel: +44 (0) 1903 765040 Fax: +44 (0) 1903 875711

Also see Appendix 2.

17.5 Printer message

If a printer is fitted to your autoclave note that at specified

intervals it will print a message to remind you that ‘Service

and Certification’ is due. When this message appears

Eschmann recommend that you contact them to arrange

this as soon as possible (see contact details in section

17.4 above).

LED 1 Condensing stage started

LED 2 Water removed from chamber .

LED 3 Pressure approaching ambient.

Phase 5

LED 1 Start of drying phase.

LED 2 Drying phase 50% completed.

LED 3 Cycle completed (audible beep).

ST-IM61e P11/20

Page 12

TABLE 2 - SPECIAL FUNCTIONS

(See section 15.4 which provides instructions for accessing these special functions)

DISPLAY FUNCTION METHOD OF USE

F0 Protected functions To use this function requires the knowledge of the PIN code. This is normally

restricted to a trained service engineer who has access to this code and the

autoclave ‘Service Manual’. Therefore access to protected functions is not

available to the operator.

F1 Printer test (Note: The printer should be loaded with paper before entering this special

functions mode). With display D1 showing F1 press the start button to start

the printer test, a character set printout, display D1 shows F11. To stop the test

press button , the printer will stop at the end of the test cycle, display D1

shows F0. To resume normal use switch ‘off’ the mains switch (item 10, Fig. 2)

and then switch back ‘on’, or press with the door open.

F2 Cycle history With display D1 showing F2 press the start button to start printing a summary

of the last five cycles completed by the unit (cycle temperature, cycle type, cycle

count, date and time at start of cycle, date and time at end of cycle and the cycle

result). Display D1 returns to F0. To resume normal use switch ‘off’ the mains

switch (item 10, Fig. 2) and then switch back ‘on’, or press with the door open.

F3 Set delayed start With display D1 showing F3 press the start button to enter the delayed start

time setting mode and delayed start initiation, display D1 will show .

If the start hour displayed in D2 is correct (as set last time) and the minutes can

be assumed correct (as set last time) press the start button to programme

the autoclave to start automatically at this set time. The display D1 will change to

F0 when is pressed. Press with the door open to exit the setting mode.

If the start time is not correct when entering function F3 (display D1 showing

, display D2 showing the hour set in 24 hour clock mode) press to

increase the hour (or to reduce it). Press to confirm the hour when it is

correct. Display D1 will show , to increase the minutes (shown in D2)

press , or to reduce them. Press to confirm the minutes. The display

D1 will show F0. Press with the door open to exit the setting mode.

The autoclave should be left switched ‘on’ with the required load in place, the

door shut and the required cycle selected as follows. When the door is shut a ‘ ’

flashes ‘on and off’ after the time in display D1. This continues while the program

selection and any adjustments to it are made (see sections14.6.2 if ‘ ’ appears

in display D2). When cycle selection has been completed and is pressed to

confirm them, the ‘ ’ stops flashing. The cycle selected will be run automatically ,

starting at the time set, a ‘ ’ will be displayed in D1 after the time to show that a

delayed start time has been set. (Also see Appendix 1)

On completion of the cycle the autoclave is ready for the load to be removed and

normal use resumed without the need to exit from the special functions mode.

Note: If the same delayed start time is required each day the setting can be

entered quickly once display D1 shows F3, by pressing ( ).

F4 Leak Test With display D1 showing F0 close the autoclave door (if open), press until

display D1 shows F4, press . Indicator will flash, press to open the door,

(Vacuum Autoclave ONL Y)

Note. To conduct this test the

chamber temperature must be

below 50°C to avoid an Error 38,

and the door closed before

selecting F4.

indicator will illuminate. Close the door , will illuminate, press this starts

an automatic leak test which checks to see if the autoclave system is still pressure

tight. Display D3 will show the chamber pressure, after a few minutes display D2

will show the pressure rise to the nearest 0.1kPa.

T able 2 is continued over page

P12/20 ST-IM61e

Page 13

LS5

VACUUM & NON-VACUUM AUTOCLAVES

TABLE 2 (continued) - SPECIAL FUNCTIONS

DISPLAY FUNCTION METHOD OF USE

F4 Leak Test (continued) After a further 10 minutes if the pressure has not risen by more than 1.3kPa

display D2 will show indicating the autoclave has passed the test (or

to indicate the autoclave has failed the test) and an audible sound will be heard.

Press button and wait until display D2 and D3 go blank. To resume normal

use switch ‘off’ the mains switch (item 10, Fig. 2) and then switch back ‘on’, or

press with the door open.

F5 Air detection test For details on how to conduct this test consult manual ST-IM55 (issue ‘d’ or later).

(Vacuum Autoclave ONL Y)

F6 Steam penetration test. With display D1 showing F0 close the autoclave door (if open), press until

(Vacuum Autoclave ONL Y)

Note. To conduct this test the

door must be closed before

selecting F6. Also see 15.5.3.

display D1 shows F6, press . Indicator will flash, press to open the door,

indicator will illuminate. Place the Eschmann LS5 V acuum Type-S and QuickV ac

Steam Penetration T est Device in it’ s pouch (see test device instructions for use)

and into the chamber. Close the door , will illuminate, press the start button ,

this will start a special cycle (no drying), D2 and D3 will show temperature

and pressure as normal during the cycle. At the end of the cycle the normal

audible sound will be heard. Press to open the door , display D1 will be showing

F0. Remove the test pack and review the result within 10 mi nutes (see Test Device

instructions for use). T o resume normal use switch ‘off’ the mains switch (item 10,

Fig. 2) and then switch back ‘on’, or press with the door open. (NOTE: This

function can also be used to carry out HTM2010 Performance Qualification (PQ)

Tests in conjunction with the manuals detailed in sections 1.4 and 1.5).

F7 Disinfect function (NOTE: The ex-factory condition is for this function to be disabled. It can be enabled,

Note. To conduct this test the

door must be closed before

selecting F7.

F8 Adjust date and time With display D1 showing F8 press the start button to enter the adjust date

if required, during installation by an Eschmann trained engineer.) With display D1

showing F0 close the autoclave door (if open), press until display D1 shows

F7, press . Indicator will flash, press to open the door, indicator will

illuminate. Load the autoclave with the load to be disinfected and close the door,

will illuminate. Press the start button to start the disinfect function (a 2.5 minute

disinfect time at 1 10°C), D1 will continue to show F7 during the cycle and D2 and

D3 will show temperature and pressure. At the end of the cycle the normal audible

sound will be heard. Press to open the door and remove the load. Display D1

will be showing F0. To resume normal use switch ‘off’ the mains switch (item 10,

Fig. 2) and then switch back ‘on’, or press with the door open.

and time function. Display D1 will show and D2 will show the year, to

increase the year press (or to reduce it) when correct press button to

confirm the year. The display D1 will show and D2 will show the month in

numerical format, to increase the month press (or to reduce it) when

correct press button to confirm. The display D1 will show and D2 will

show the day in numerical format, to increase the day press (or to reduce

it) when correct press button to confirm. The display D1 will show and

D2 will show the hour, to increase the hour press (or to reduce it) when

correct press button to confirm. The display D1 will show and D2 will

show the minute, to increase the minute press (or to reduce it) when

correct press button , display D1 shows F0 display D2 and D3 will be blank.

The time and date are now set (seconds were set to zero when was pressed).

Press with the door open to continue normal use.

ST-IM61e P13/20

Page 14

TABLE 3 - ERROR NUMBER DETAILS AND REMEDIES

Clearing error display and restarting a cycle

WARNING

If an error display appears during a cycle, do not

attempt to open the chamber door until the unit has

cooled (for safety below 50°C) and internal pressure

has fallen sufficiently to release the door, see below

‘3 Check pressure’. Where a cycle is aborted and/or

an error display is indicated the load should be treated

as non-sterile. The load should be re-wrapped if

wrapped and then sterilized by running the cycle again.

Also note the Caution after section 16.1 concerning

the contamination of water in the reservoir.

1 Record error number : For future reference record

the error number before clearing the display . In the event

of mains power failure, power must be restored to the

autoclave to achieve this. (Also see 17.3d)

2 Clear error and reset autoclave : T o clear the error

display and reset the autoclave wait until any audible

discharge of water and steam has stopped and switch OFF

the autoclave with the mains switch (item 10 Fig. 2). Wait

10 seconds, press-and-hold-in the ‘Start button’ ( Fig.1)

whilst switching back ON with the mains switch (item 10

Fig. 2), immediately the normal display appears release

the ‘Start button’ ( Fig.1).

3 Check pressure : Before attempting to open the

door note the pressure reading, this should be below

104kPa before the door is opened.

4 Open the door : Note will be flashing, open the

door by pressing . If the door fails to open see NOTE

below, there may still be water in the autoclave.

NOTE: Door opening problems. Although unlikely, there

may be up to a litre of water (which could be HOT) still in

the chamber. Be prepared to collect this water in a suitable

container. A built-in safety feature inhibits door opening

unless the following procedure is adopted. Switch OFF at

mains switch (item 10 Fig. 2). Press-and-hold-in the ‘Door

open button’ ( Fig.1) whilst switching back ON with the

mains switch (item 10 Fig. 2) wait two seconds and then

before releasing button (which will open the door)

hold a container in place under the door to collect any

(HOT) water.

5 Check and prepare the aborted load : Loads must

be considered non-sterile if an error occurs and should be

resterilized. All aborted wrapped loads should be dried,

placed in new pouches and reprocessed.

6 Check chamber before starting another cycle :

The chamber should be allowed to dry and cool before

starting another cycle. To start another cycle select the

cycle and start the autoclave in the normal manner.

7 If the error persists or an error number occurs that

is listed at the end of this table then call the Eschmann

After Sales Service Department (see section 17.4) or

contact your approved service engineer. Do not attempt to

solve an error using tools or tampering with the autoclave.

DISPLAY CAUSE REMEDY

is on Water level too low . Fill reservoir as detailed in section 12.5

flashing Cycle started and water. Fill reservoir as detailed in section 12.5

level is too low

Err01 Mains supply failure a. Check local supply conditions and all fuses.

during a cycle b. Check supply plug wiring and power cable for possible breaks.

c. Check if Autoclave has been switched OFF accidentally .

d. Follow ‘Clearing error display and restarting a cycle’.

Err03 Fill error Follow ‘Clearing error display and restarting a cycle’ but before

starting a new cycle check the reservoir water fill level and dry the

water level sensors (item 17, Fig. 2). If door fails to open see

section 4 of ‘Clearing error display and restarting a cycle’.

Err04 Low water a. Check the autoclave is not over loaded.

b. Check that the load cannot collect water (e.g. a kidney dish

not inverted) re-position load if required so that it can drain.

c. Dry the water level sensors (item 17, Fig. 2).

d. Follow ‘Clearing error display and restarting a cycle’.

Err10, 13, 14, A programmed test has Follow ‘Clearing error display and restarting a cycle’ but before

23, 24 and 25 detected a possible fault starting a new cycle check door seal and chamber sealing face

and aborted the cycle. are clean and not damaged. Damaged seals need replacing.

(continued over page)

P14/20 ST-IM61e

Page 15

LS5

VACUUM & NON-VACUUM AUTOCLAVES

TABLE 3 - ERROR NUMBER DETAILS AND REMEDIES (continued from page 14)

DISPLAY CAUSE REMEDY

Err26 Water sensing error a. Check load is not touching water sensors (item 17, Fig. 2) and

early in cycle re-position load if required.

b. Dry the water level sensors (item 17, Fig. 2).

c. If door fails to open see section 4 of ‘Clearing error display

and restarting a cycle’.

d. Follow ‘Clearing error display and restarting a cycle’.

Err27, 28 Heating error Follow ‘Clearing error display and restarting a cycle’ but check

29 and 30 the reset button before starting a new cycle, see section 17.3 ‘f’.

Err 33 Water sensing error a. Gauze filter blocked, see section 16.3 ‘c’ and ‘d’.

later in cycle b. Check load is not touching water sensors (item 17, Fig. 2) and

re-position load if required.

c. Dry the water level sensors (item 17, Fig. 2).

d. If door fails to open see section 4 of ‘Clearing error display

and restarting a cycle’.

e. Follow ‘Clearing error display and restarting a cycle’.

Err35 Door failed to open Follow ‘Clearing error display and restarting a cycle’ but note

during drying phase that it may be required to assist opening the

door manually .

Err36 Door unlocked during cycle a. Follow ‘Clearing error display and restarting a cycle’.

b. Check that when door is closed, green LED (item A4 Fig. 1) is

illuminated. If red LED (item A3 Fig. 1) is illuminated contact

Eschmann Equipment (see section 17.4).

Err38, 39, 40 Chamber temperature Follow ‘Clearing error display and restarting a cycle’ but

or pressure error allow the autoclave to cool down before starting another cycle.

Err 44, 45 Water level sensor error a. Check load is not touching water sensors (item 17, Fig. 2) and

re-position load if required.

b. Dry the water level sensors (item 17, Fig. 2).

c. If door fails to open see section 4 of ‘Clearing error display

and restarting a cycle’.

d. Follow ‘Clearing error display and restarting a cycle’.

Err46 Door not opening a. Try gentle assistance to open the door.

after several attempts b. T emperature etc. may be too high, wait 5-10 minutes then

follow ‘Clearing error display and restarting a cycle’.

c. If door still fails to open see section 4 of ‘Clearing error

display and restarting a cycle’.

Any other Miscellaneous Follow ‘Clearing error display and restarting a cycle’ and if

error code problem repeats contact Eschmann Equipment (see section 17.4).

ST-IM61e P15/20

Page 16

18 Operating instructions for printer

IMPORTANT OPERATOR NOTES

Follow the notes and cautions below when changing

the paper roll and ink ribbon cartridge. Also do not

pull on the paper whilst the printer is in operation,

it may damage the print head. Using knives, etc. to

remove a paper jam will also damage the print head.

Always open the front panel and use the paper feed

button (item 15 Fig. 4.3) to clear the jam.

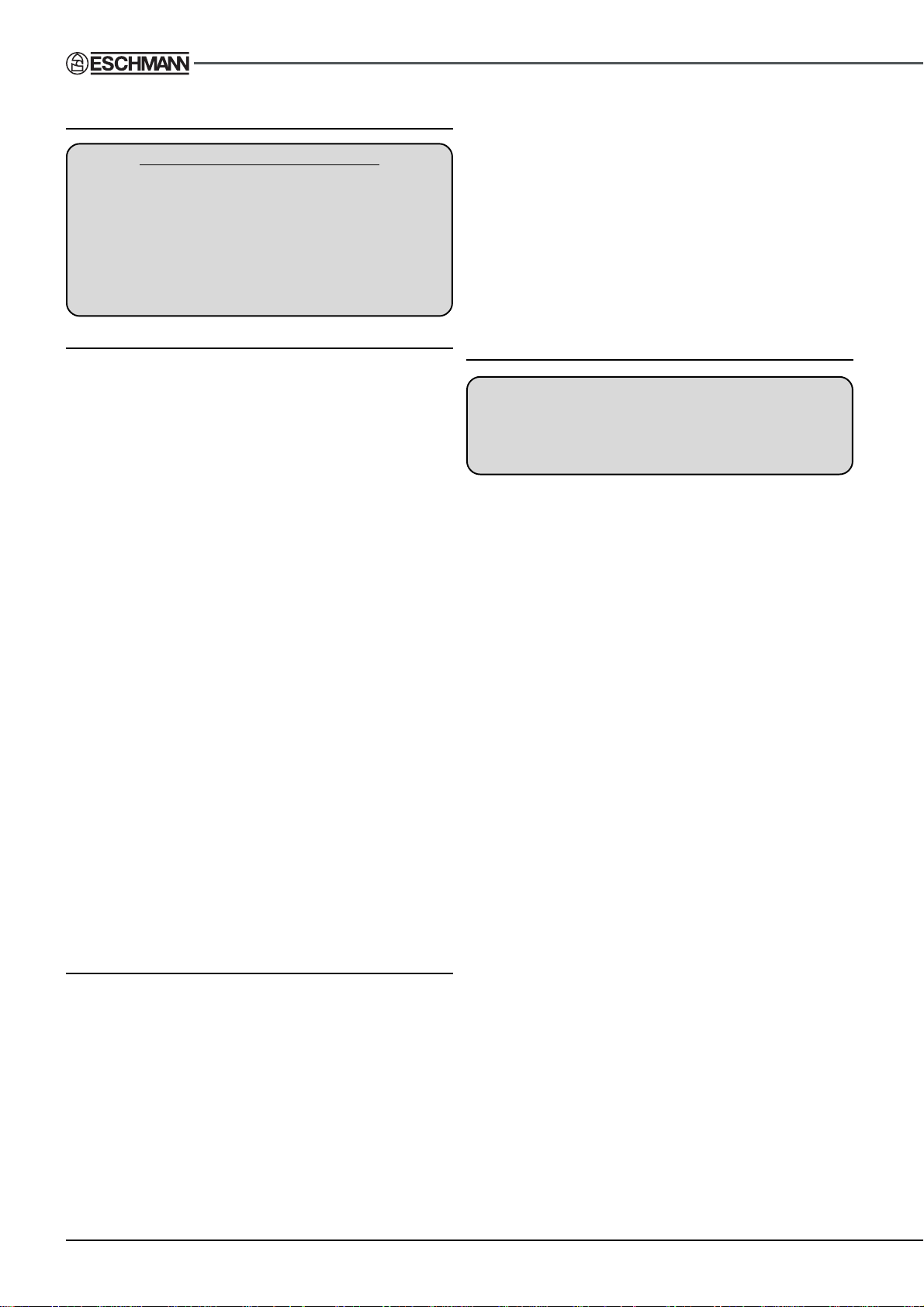

18.1 Printer installation (REF 87-066-66)

Install the printer unit in the autoclave as follows:

a Remove the printer from its packaging and remove

the mains power supply from the autoclave.

b T o gain access to the printer compartment open the

printer door (13, Fig. 4.2 and 4.4) by turning the door

latch (17, Fig. 4.4) anticlockwise with a small coin

or suitable screwdriver.

c Remove the printer connector (2, Fig. 4.1) from its

storage pocket (3, Fig. 4.1) and gently pull out the

ribbon cable (1, Fig. 4.1) from within the autoclave.

(Note. Do not connect the printer at this stage as it

is possible to connect it the wrong way round and

twist the ribbon cable).

d Orientate the printer unit as shown in Fig. 4.2 and

locate the hole in the left hand printer bracket arm

(10, Fig. 4.2) over the spring pivot pin (4, Fig. 4.1).

Gently push the printer into place so that the right

hand spring pivot pin (5, Fig. 4.1) clicks into place in

the hole in the right hand printer bracket arm (11,

Fig. 4.2). When correctly located the printer should

hinge freely about the pivot pins and when positioned

vertically the printer door should close easily without

interfering with the printer.

e Push the printer connector (2, Fig. 4.1) into place

on the pins at the back of the printer unit without

twisting the ribbon cable (1, Fig. 4.1).

f Ensure that the printer ribbon (16, Fig. 4.2) is still in

place (if not replace it as detailed in section 18.4c)

and insert a paper roll as detailed in sections

18.3 b-e. Then carry out a printer test as detailed in

section 15.4 referring to Table 2, section F1.

18.2 Printer Output

The printer output gives the following information:

Manufacturer’s name - Eschmann Equipment

Machine type - e.g. Little Sister 5 N

Serial number - an alpha numeric code

Cycle type - e.g. 134C - wrapped

Date and Time started - dd:mm:yy hh:mm:ss

Counter reading - Five digits with leading zeros

Cycle information - Cycle stage code and time,

temperature and pressure every 20 secs. Maximum

and minimum sterilization temperatures.

Cycle ended message - ‘Cycle Complete’ & time or ,

*** CYCLE F AILED*** , dd:mm:yy hh:mm:ss followed

by the error number

If an error occurs during the cycle, it is recorded with date

and time on the printout and the message ‘CYCLE FAILED’.

Errors are designated by error codes as Table 3.

Cycle stage codes on the printout are:

TPV* - End of vacuum pulses

TPP* - End of first pressure pulse

TSS - Start of sterilization

TSE - End of sterilization

TDS - Start of drying phase

TDE - End of drying phase

(* Vacuum Autoclaves ONLY)

18.3 Paper Roll Renewal

CAUTION

DO NOT USE ALTERNATIVE PAPER ROLLS

The quality and size of paper rolls used in the printer,

can only be supplied by Eschmann Equipment.

T o gain access to the printer compartment open the printer

door (13, Fig. 4.2 and 4.4) by turning the door latch (17,

Fig. 4.4) anticlockwise with a small coin or suitable

screwdriver. Replace the printer paper roll as follows:

a. Gently rotate the printer unit down from its vertical

position as shown in Fig. 4.2, to horizontal as shown

in Fig. 4.3. If any paper remains in the printer, cut it

free with scissors where it enters the back of the

paper feed slot (12, Fig. 4.2) and gently ease it from

the front of the printer whilst pressing the paper feed

button (15, Fig. 4.3) on the back of the printer unit.

(Note. DO NOT pull the paper through the printer

and NEVER pull the paper backwards).

b. Remove the paper roll holder (19, Fig. 4.3) with the

old roll core from the recess (6, Fig. 4.1) behind the

printer. Take a new roll of paper and separate the

end from the roll. Remove any paper that is damaged

or has adhesive on it, then using scissors, trim the

paper end to approximately 60° as shown in Fig. 4.3.

c. Locate the new paper roll onto the roll holder in the

direction of arrow A in Fig. 4.3 with the roll unwinding

from the bottom towards you as shown in Fig. 4.3.

Replace the roll holder with the new roll of paper

back into the recess (6, Fig. 4.1) behind the printer

unit by moving it in the direction of arrow B as shown

in Fig. 4.3. If the roll is not in the correct orientation

paper will not feed through the printer smoothly .

d. Insert the cut end of the paper into the rear of the

paper insert slot (12, Fig. 4.2). Gently push the paper

through the slot whilst pressing the paper feed button

(15, Fig. 4.3) until the printer mechanism grips the

paper and pulls it through to the front of the printer,

DO NOT pull the paper. Check that the printer ribbon

lies flat and not twisted.

e. Turn the paper roll by hand to take up any slack

paper and then carefully return the printer unit to

the vertical position. Pass the paper from the front

of the printer through the slot in the printer door

(7, Fig. 41 and 4.4) and close the door. To lock the

latch (17, Fig. 4.4), press and rotate until it snaps

P16/20 ST-IM61e

Page 17

locked. Gently pull paper showing through the door

feed slot to take up any slack, DO NOT PULL HARD

and then tear off against the cutting edge of the slot.

18.4 Ribbon Cartridge Renewal

CAUTION

DO NOT USE ALTERNATIVE RIBBONS

Only use ribbons that have been supplied by

Eschmann Equipment. Replace the ribbon cartridge

before it becomes dry. They contain a protective

lubricant for the print head. Replace during every

third paper roll replacement.

Renew the ribbon cartridge as follows:

LS5

VACUUM & NON-VACUUM AUTOCLAVES

4.1

a. Open the printer door, remove the old paper roll and

spring clip (18, Fig. 4.2).

b. Support the printer in the vertical position and grip

the end of ribbon cartridge at the end marked ‘PUSH’

(Fig. 4.2, item 9). Remove the cartridge by pulling it

towards you gently .

c. Install new cartridge with faceted disc (item 14,

Fig. 4.2) facing out and to the right, by inserting the

right hand side onto its drive shaft first, and then

CAREFULLY press cartridge into place where

marked ‘PUSH’ (Fig. 4.2, item 9). Replace spring

clip (18, Fig. 4.2).

d. Ensure ribbon is taut. If necessary tighten ribbon by

turning faceted disc (Fig. 4.2, item 14) on cartridge,

clockwise, using finger or fingernail.

e. Replace paper roll and close printer door.

18.5 Spares Pack

A spares pack is available comprising five paper rolls and

two ribbon cartridges (see accessories section 20).

Key to Fig. 4

1 - Printer ribbon cable

2 - Printer connector

3 - Connector storage pocket

4 - Spring pivot pin (left)

5 - Spring pivot pin (right)

6 - Printer roll recess

7 - Printer door paper feed slot

8 - Printer unit

9 - ‘PUSH’ indication

10 - Left hand printer bracket arm

1 1 - Right hand printer bracket arm

12 - Paper feed slot

13 - Printer door

14 - Faceted disc

15 - Paper feed button

16 - Printer ribbon

17 - Door latch

18 - Cartridge ribbon spring clip

19 - Paper roll holder

4.2

4.3

4.4

ST-IM61e P17/20

Page 18

19 Technical data

20 Accessories

19.1 Electrical

Supply 230V 50/60 Hz a.c.

For use with alternating current

Loading at 230V 2.0kW 10A (max.)

Fuses 12.5A (Part.No. 112474) (x2)

T3.15A (Part.No.696207) (x1)

- not operator replaceable.

19.2 Sterilizing data

Sterilizing time at 134/137°C is 3min.5sec., at 121/

124°C is 15min. and at 134/137°C (extended, see

section 15.1) is 18min.

Drying time (if selected) is from 17 minutes (but can

be extended, see section 15.2).

Operating pressure at 121°C is 1.03 bar, at 124°C

is 1.23 bar, at 134°C is 2.03 bar and at 137°C is

2.32 bar.

Note: If the autoclave is configured to have

adjustable sterilization and drying times the above

times can be altered during cycle selection (see

section 14.6).

19.3 Maximum Loads

Trays (set of 4 different colours) . . . . . . REF 87-040-11

Tray lifter . . . . . . . . . . . . . . . . . . . . . . . . REF 87-040-90

Chiropody tray . . . . . . . . . . . . . . . . . . . . REF 87-041-12

Cassette (tray with lid) . . . . . . . . . . . . . . REF 87-040-87

Cassette furniture . . . . . . . . . . . . . . . . . REF 87-041-44

Universal cassette holder . . . . . . . . . . . REF 87-040-92

Vertical cassette holder . . . . . . . . . . . . .REF 87-040-96

Bacterial filter (pack of 10) . . . . . . . . . . . REF 82-961-68

Printer . . . . . . . . . . . . . . . . . . . . . . . . REF 87-066-66

Printer spares pack . . . . . . . . . . . . . . . . REF 87-034-05

Pouch Rack . . . . . . . . . . . . . . . . . . . . . . REF 87-040-66

Pouch (small) . . . . . . . . . . . . . . . . . . . . REF 87-033-10

Pouch (medium) . . . . . . . . . . . . . . . . . . REF 87-033-18

Pouch (large) . . . . . . . . . . . . . . . . . . . . . REF 87-033-29

Steam penetration test device* . . . . . . . REF 87-040-71

* Contains one device and 100 test strips

Tray - 1.5kg maximum per tray

Cassette - 2.0kg maximum per cassette

Chamber - 8.0kg maximum total load

19.4 Water reservoir capacity

8.0 litre

19.5 Weight (approx.)

Non-Vacuum Net = 42.5kg

Non-V acuum Shipping = 55.5kg.

For V acuum add 6.5kg.

19.6 Safety standards

EN 61010-1 (1993) inc. Amendment 2 (1995)

EN 61010-2-041 (1996)

19.7 Software version

The version of software loaded onto this autoclave

is briefly displayed each time the autoclave is

switched on in display D1 (e.g. 1.51).

P18/20 ST-IM61e

Page 19

LS5

VACUUM & NON-VACUUM AUTOCLAVES

APPENDIX 1

Special notes when using non-drying cycle B4

Section 14.8 states that the door can be opened when

the cycle ‘without drying’ has been completed (indicated

both visually and audibly, see 14.8). Opening the door

allows the load to dry and avoids excessive

condensation build up in the chamber. If the door is not

opened at the end of the cycle a pool of water may form

in the chamber (from trapped condensation) and the

load will be wet. This pool of water may then come out

of the chamber when the door is eventually opened.

Eschmann therefore recommend the following:-

1 When running the cycle ‘without drying’ always open

the door immediately the cycle has finished and

unload the chamber as soon as possible.

2 If the cycle ‘without drying’ is to be run overnight

using the special function F3, always ensure the

cycle is timed to finish when personnel have returned

at the start of the next day (to open the door and

unload the chamber).

3 Do not start a cycle ‘without drying’ at the end of the

day if personnel are not going to be present when

the cycle has finished (to open the door and unload

the chamber).

4 If in doubt use either of the cycles ‘with drying’ to

eliminate the potential problem.

NB. Eschmann do not recommend running a cycle

‘without drying’ (B4) if the chamber door is not

opened shortly after the cycle has been completed

and the load removed as soon as possible.

APPENDIX 2

SAFETY CHECKS

Operators should ensure that the following safety checks

are carried out.

Weekly

i Check that the door opens and closes easily.

ii Check the door seal for any signs of damage.

iii Check the secondary door catch latches effectively.

iv Check for any obvious escape of steam or water

during a cycle (apart from the normal escape via

reservoir vents).

Any of the above defects should be attended to by a

‘Competent Person’ immediately and the autoclave

should not be used until repair has been effected (see

note below).

Annually

i Check that the pressure relief valve operates

correctly at the set pressure.

ii Inspect the pressure system for integrity .

iii Check door microswitches and interlocks.

iv Check door locking mechanism for integrity

v Check pressure indicators for correct operation.

NOTE:

Annual inspections should only be undertaken by a

‘Competent Person’. Eschmann can provide

comprehensive service contracts which cover

preventive maintenance to ensure trouble free operation

of your autoclave as well as six monthly and annual

inspections of the pressure system to satisfy the

requirements of the Pressure Systems Safety

Regulations 2000.

ST-IM61e P19/20

Page 20

APPENDIX 3

LS5/SES2555 VACUUM AUTOCLAVE DAILY RECORD SHEET

AUTOCLAVE DETAILS: Serial No.: Dept.: Site:

TEST STRIP DETAILS

DETAILS

LOT

CYCLE *

& NUMBER

PASS or

FAIL ** SIGNATURE

DATE &

ATTACH DEVICE TEST STRIP HERE

* Cycle (should be B8 or special function F6), press B1 for Cycle Number.

* * If cycle fails record error code number in the column.

P20/20 ST-IM61e

Page 21

Page 22

Eschmann Equipment, Peter Road, Lancing, West Sussex, BN15 8TJ, England.

Tel: +44 (0) 1903 753322. Fax: +44 (0) 1903 875789. www.eschmann.co.uk

Page 23

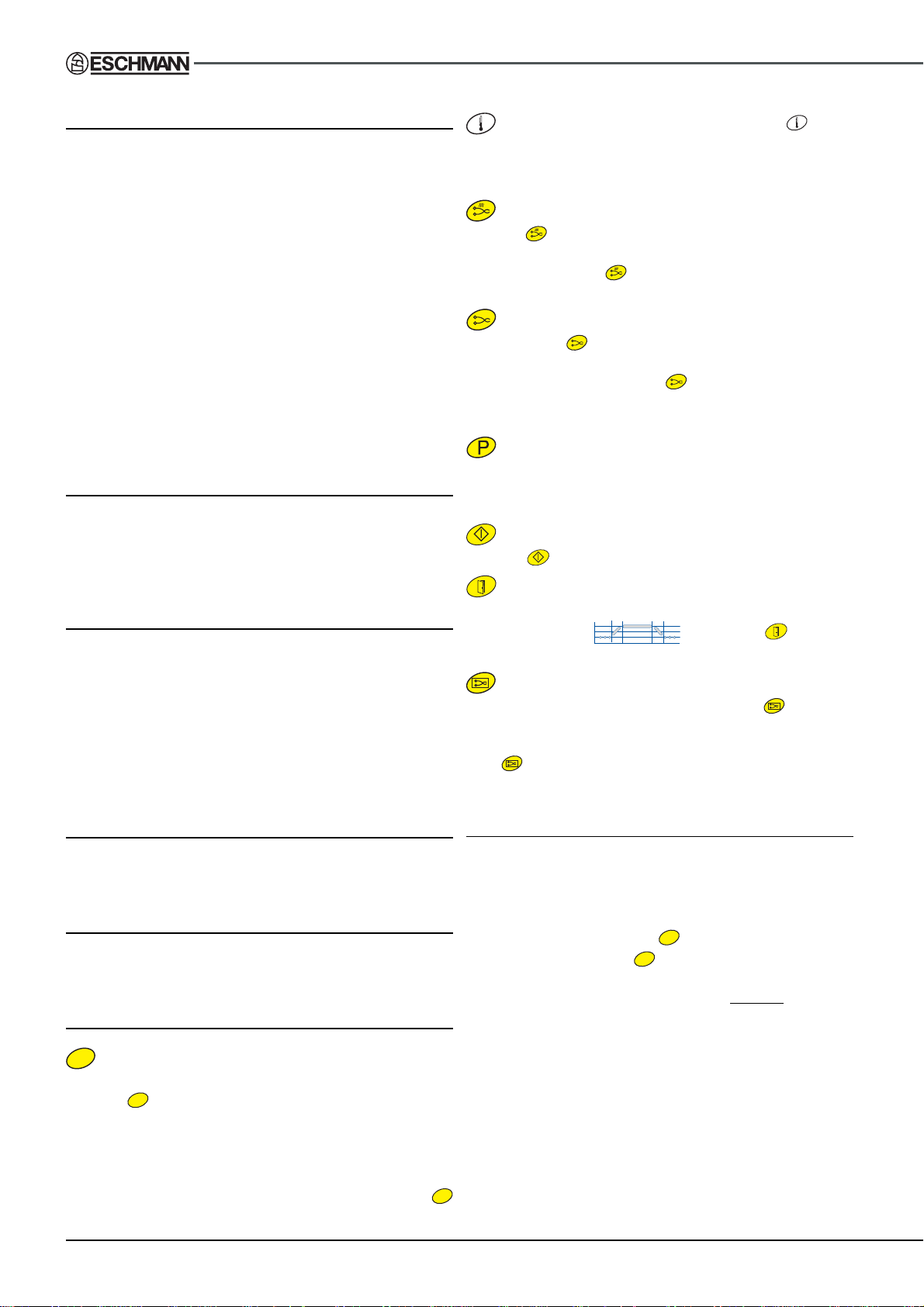

KEY:-

1

3

4

˚C

1

2

1

˚

C

˚C

A1 Low water indicator.

A2 Process display indicator.

A3 Door unlocked indicator.

A4 Door locked indicator.

B1 Display change button.

B2 Cycle temperature button.

B3 Unwrapped load (with

drying) cycle button.

B4 Unwrapped load (without

drying) cycle button.

B5 Programme ‘P’ button.

B6 Cycle start button.

B7 Open door button.

B8 Single wrapped load (with

drying) cycle button.

C Selection indicators.

D1 Time / cycle counter

& Sterilization / drying time (remaining)

& Error number display.

D2 Temperature display.

D3 Pressure display.

1

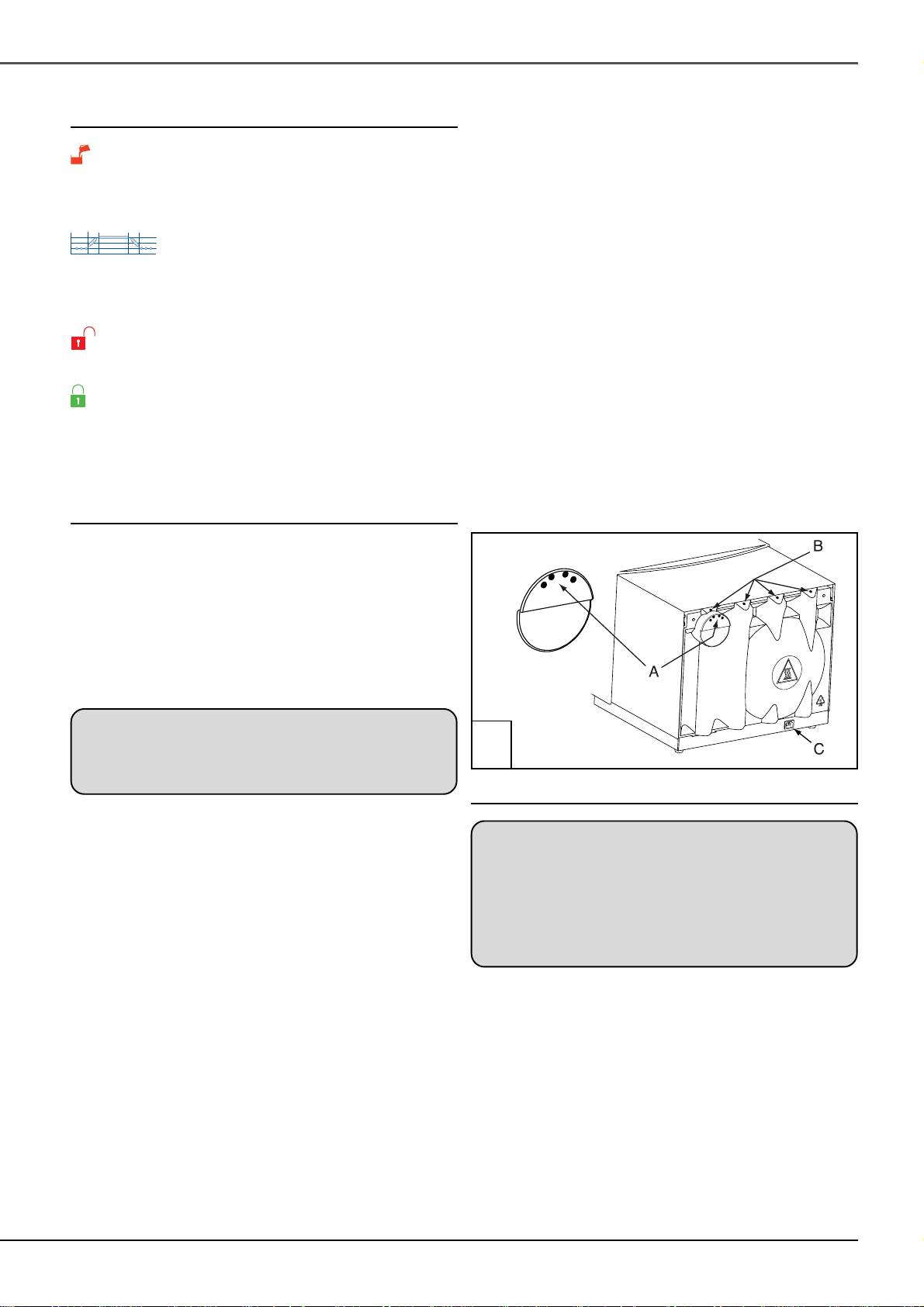

KEY:-

1 Filter

2 Water filling cup

3 Remote computer connector

4 Printer

5 Printer door

6 Paper feed slot

7 Chamber filter

8 Serial label

9 Mains fuses

10 Mains ‘on/off’ switch

11 Drian tube

12 Drain tube tap (open and closed)

13 Drain tube retaining clips

15 Secondary catch

16 Autoclave door

17 Water level sensors

Open

Closed

2

ST-IM61e

Loading...

Loading...