Page 1

Instructions for use

SES 113

SES 113 B vacuum

SES 225 B vacuum

Page 2

Contents Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Suitable loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

EschmannCare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.0 Controls and displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.0 Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0 Running a cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 Direct Data Download instructions . . . . . . . . . . . . . . . . . . . . . 10

5.0 Printer instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.0 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

APPENDIX 1 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

APPENDIX 2 - Warnings and cautions . . . . . . . . . . . . . . . . . . . . . . 19

APPENDIX 3 - Loading the autoclave . . . . . . . . . . . . . . . . . . . . . . . 21

APPENDIX 4 - Daily Testing, Vacuum ( B type) autoclaves . . . . . . 22

APPENDIX 5 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

APPENDIX 6 - Cycle errors and faults and Display messages . . . . 24

APPENDIX 7 - Special Functions . . . . . . . . . . . . . . . . . . . . . . . . . .26

APPENDIX 8 - Accessories and spares . . . . . . . . . . . . . . . . . . . . . 32

Figures

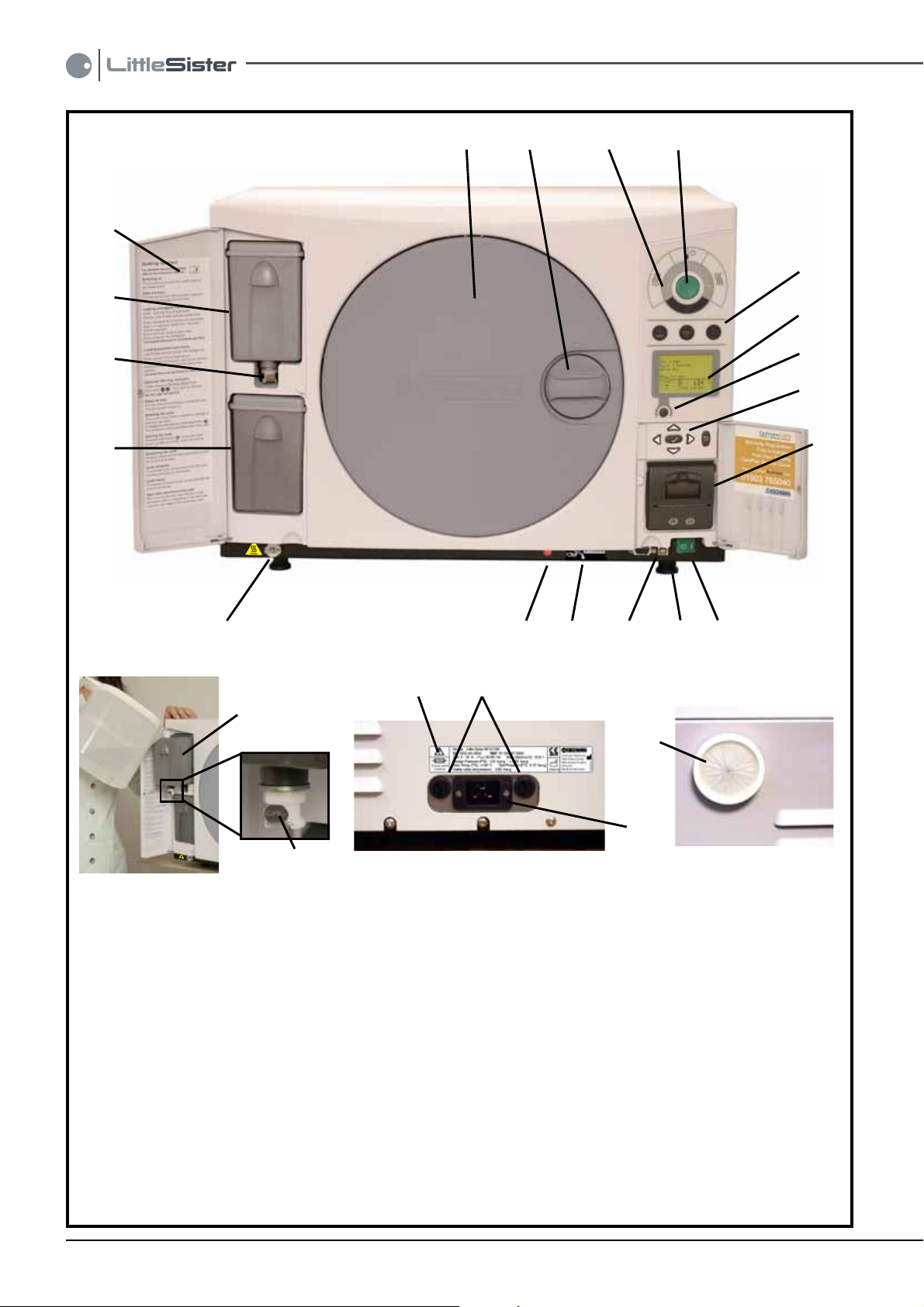

Fig. 1. Identification of the main parts of the autoclave . . . . . . . . . 4

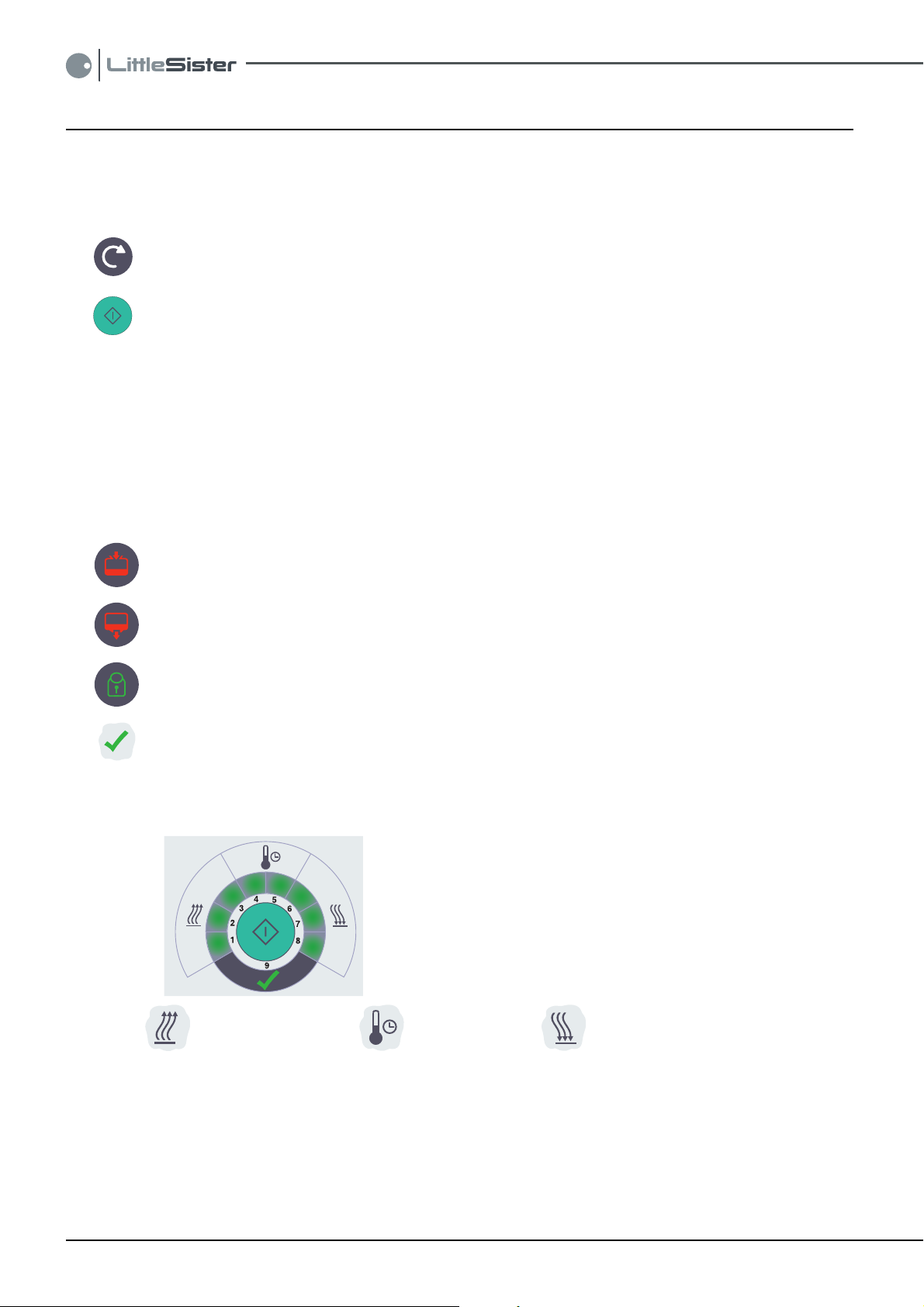

Fig. 2. The main information display and control buttons . . . . . . . .5

Fig. 3. Filling and draining the reservoirs . . . . . . . . . . . . . . . . . . . . 5

Fig. 4. DDD - Controls active, connected . . . . . . . . . . . . . . . . . . . 10

Fig. 5. DDD - Download button symbols . . . . . . . . . . . . . . . . . . . 10

Fig. 6. ‘Cycle Select’ and various display screens . . . . . . . . . . . . 11

Fig. 7. Various display screens . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fig. 8. Printer control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

P2/33 ST-IM84c

Page 3

SES 113 and 225

AUTOCLAVES

Introduction

The Eschmann Little Sister SES 113 and 225 autoclaves have been designed to meet the needs of the healthcare professional

and have been designed in accordance with European Standards (e.g. BS EN 13060) and Department of Health guidelines.

SES 113 Autoclave – The SES 113 is an ‘N’ type displacement autoclave with an 11 litre chamber. It is intended for the sterilization

of solid instruments which have not been wrapped.

SES 113 B Autoclave – The SES 113 B vacuum is a ‘B’ type vacuum autoclave with an 11 litre chamber. It is intended for the

sterilization of solid and hollow instruments, pouched or wrapped instruments and porous loads.

SES 225 B Autoclave – The SES 225 B vacuum is a ‘B’ type vacuum autoclave with an 22 litre chamber. It is intended for the

sterilization of solid and hollow instruments, pouched or wrapped instruments and porous loads.

Suitable loads

The following table details the types of load that may be successfully processed in each model. Please refer to the table in the

‘Technical Data’ section for details of the cycles available on each model.

Type of load and cycle type SES 113 SES 113 B Vacuum

SES 225 B Vacuum

Solid instruments for immediate use (N) 99

Solid instruments processed for aseptic storage (N) 99

Hollow/cannula instruments (B) 89

Single wrapped pouched instruments (B) 89

Single wrapped cassettes (B) 89

Single wrapped hollow instruments (B) 89

Double wrapped instruments (B) 89

Double wrapped hollow instruments (B) 89

Porous loads (B) 89

Warning markings

The warning markings on this equipment have the following meanings:

Caution; refer to accompanying documents (i.e. these Instructions for Use).

Caution; hot surface.

EschmannCare

Eschmann recommends direct installation and commissioning in the UK for all its autoclaves by its own EschmannCare team of

professional engineers. Eschmann also recommends a programme of after sales service and maintenance for all Eschmann

autoclaves, using only the correct Eschmann spare parts. Service and maintenance programmes can include PSSR 2000 certification

and testing to HTM 2010 (DB9804).

The EschmannCare service department is staffed and equipped to provide advice and assistance during normal office

hours. To avoid delays when making enquiries, please quote the Model and Serial Number of your Autoclave which is

shown on the Serial Label, the location of which is shown in Fig. 1, item 20 please include all alpha and numeric digits.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers EschmannCare, Peter Road, Lancing, West Sussex

BN15 8TJ, England. Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers Contact your local distributor. In case of doubt contact Eschmann Equipment.

ST-IM84c P3/33

Page 4

24

1 24

3

5

18

17

16

15

18

20 21

14

6

7

8

9

10111213

23

22

19

1 Autoclave door

2 Door handle

3 Process display (Fig. 2)

4 Start button (Fig. 2)

5 Indicators (Fig. 2)

6 Digital display (Fig. 2)

7 Cycle select button (Fig. 2)

8 Control buttons (Fig. 2)

9 Printer

10 Mains ‘on/off’ switch

11 Adjustable foot

12 USB port

Part rear view

13 Serial Label (front)

14 Overheat indicator

15 Waste water drain

16 Waste water reservoir (Fixed)

17 Fresh water drain

18 Fresh water reservoir (Slides out to fill))

19 Drain release clip

20 Serial label (back)

21 Mains fuses

22 IEC Mains connection

23 Antibacterial air filter (B type units only)

24 Basic instructions (UK models only)

Fig. 1. Identification of the main parts of the autoclave

P4/33 ST-IM84c

Part rear view

Page 5

SES 113 and 225

AUTOCLAVES

Fig. 2. The main information display and control buttons

(shown with all indicators illuminated and a typical ‘Cycle select’ display)

Filling the fresh water reservoir (slide out) Draining the waste water reservoir (fixed)

Each reservoir has a capacity of 3.36 litres.

Fig. 3. Filling and draining the reservoirs

Drain tube (before

connection, direct end into

a suitable container of at

least 4 litres capacity )

ST-IM84c P5/33

Page 6

1.0 Controls and displays

Mains switch (Fig. 1, item 10)

The mains switch is positioned on the front of the autoclave. The symbol ‘I‘ indicates ‘on’ and the symbol ‘0’ indicates ‘off’.

The switch illuminates green when ‘on’.

Push buttons

Cycle select button (Fig. 1, item 7). Press to select a sterilization cycle. The Autoclave Manager may have enabled

more than one cycle. Cycle details will be shown in the main display. After scrolling the available cycles which may

include the test cycles (T1 and T3), the ‘Cycle Count’ (the number of cycles started) will be displayed.

Start (cycle) button (Fig. 1, item 4). Press to start the selected cycle.

Control Buttons. The control buttons shown in Fig. 2 are behind the hinged panel (below the main display). Their

use is explained in Appendix 7, ‘Special functions’. They are not required during ‘normal’ use of the autoclave.

Note: When a button is pressed a ‘beep’ will sound (unless disabled, refer to Appendix 7 - ‘Audio’).

Digital display (Fig. 2)

The digital display provides the information required during ‘normal’ use of the autoclave (e.g. to select the required

cycle) and to provide information on the cycle status. It may display other details, instructions and warnings as detailed

in this manual and configuration information when using the ‘Special Functions’.

Indicators (Fig. 2)

‘Low water’ indicator. When illuminated the fresh water reservoir (top one) should be refilled before a new cycle

is started (section 2). It will flash if the reservoir is low and an attempt to start a cycle is made.

‘Drain reservoir’ indicator. When illuminated the waste water reservoir (bottom one) is full and should be emptied

before a new cycle is started (section 2). It will flash if the reservoir is full and an attempt to start a cycle is made.

Door indicator. This is illuminated to indicate the door is locked, or flashing to indicate the door should be

opened or closed (the digital display provides a related message). It will be off after you close the door prior to starting

a cycle.

Cycle complete indicator. This is illuminated at the end of a successful completed cycle.

Progress indicators. The display has indicators that illuminate in turn as the cycle progresses. The main stages are identified

by three symbols. The symbols and stages are detailed below:

1 – Cycle started

2 – Water fill completed

3 – Heating to sterilization temperature

4 – Sterilization started

5 – Sterilization stage passed halfway

6 – Condensing

7 – Drying started (vacuum only)

8 – Less than 1 minute remaining to cycle completion

9 – Cycle completed successfully

Pre conditioning. Sterilizing. Post sterilization cooling/drying.

P6/33 ST-IM84c

Page 7

SES 113 and 225

AUTOCLAVES

2.0 Getting started

WARNING

Read these instructions before use and keep them in a safe convenient place for future reference. The use of this

autoclave should be under the control of a person with adequate training (the Autoclave Manager*).

The Autoclave Manager* is responsible for ensuring that the correct sterilization cycle is used for the items being

sterilized, ensuring that records are kept correctly and keeping the amended PIN code confidential (refer to Appendix 7 Special functions).

The autoclave should only be used as specified by Eschmann as detailed within these instructions. Never tamper with,

bypass or interfere with any of the safety features. There are no ‘user’ serviceable parts inside the autoclave. Eschmann

Equipment is not responsible for malfunction, or a reduced level of protection provided by the equipment, if it is used in a

manner not specified in these instructions.

Only use Eschmann accessories and mains leads. Any spare parts required must be supplied by Eschmann. They must

be fitted in accordance with the Service Manual or the instructions supplied with them by EschmannCare engineers or

engineers who have been trained by Eschmann.

* Autoclave Manager - The person who is ultimately accountable for the operation of the premises. Depending on the nature

of the organisation, this may be the owner, or other person of similar authority. In small, autonomous installations the manager

might also be the user.

Autoclave Installation

Full installation details are provided in APPENDIX 1, this includes a list of items supplied with the autoclave and a note to observe

if the autoclave is relocated.

Ensure the autoclave has been correctly installed before use, by an EschmannCare trained engineer (contact the EschmannCare

team on 01903 765040). Installation will also include initial training covering the use of these autoclaves. It is essential that the

autoclave is levelled and connected to the electrical mains supply correctly. On request and during installation, programmes and

autoclave configuration can be adjusted by the EschmannCare engineer. (To protect against tampering, access for such

adjustment can only be gained by use of a PIN code).

Direct Data Download (DDD) Software Installation

Refer to the instructions provided with the Direct Data Download Software and install the DDD application.

Warnings and Cautions

Before using the autoclave ensure you understand the ‘Warnings and Cautions’ which are set out and summarised in

APPENDIX 2 .

RESERVOIR CARE AND WATER QUALITY CAUTION

a. Eschmann recommends filling the water reservoir with ‘Sterile Water for Irrigation’. This is low in dissolved solids

and has a low microbial count. In the U.K. the Department of Health recommends that ‘Sterile Water for Irrigation’

is used in bench-top Autoclaves (NHS Estates document HTM2031).

b. If ‘Sterile Water for Irrigation’ is not being used then Eschmann strongly recommends the use of either distilled

water, deionized water, purified water or water treated by the reverse osmosis process. These types of water are

low in dissolved solids and can help reduce the effects of tap water detailed below.

c. DO NOT USE TAP WATER, this is high in dissolved solids and can deposit lime scale, block filters and cause damage

to the pressure vessel.

d Don’t leave water standing in the reservoir for more than a few hours. If you are not sure how long the water has

been there, change it. Also contents of part used containers of sterile water for irrigation should be discarded

(microbiological purity will be compromised once opened).

e At the end of the working day, or whenever the sterilizer is to be left unused for several hours, drain both the water

reservoirs and leave them to dry.

Fill the reservoir

Open the left hand access door (Fig. 3) and slide the (top) fresh water reservoir out about 100 mm. Press down gently the

back of the reservoir cover, slide it forward and remove it (Fig. 3).

DO NOT USE TAP WATER. Fill the reservoir up to the ‘MAX’ mark engraved on the internal mesh cover (3.36 litres maximum).

When the reservoir is filled to the ‘MAX’ mark the autoclave will run 8 cycles before it needs to be filled again

Replace and slide the reservoir cover back until it clicks into position and return the reservoir to its normal (rear) position before

using the autoclave. Close the left hand access door.

ST-IM84c P7/33

Page 8

3.0 Running a cycle

Switching ‘on’ and ‘off’.

Switch the autoclave ‘on’ using the mains switch (Fig. 1, item 10). The digital display and applicable indicators will illuminate

to show the autoclave has been switched ‘on’. After normal checks and a ‘Welcome’ message (shown for 30 seconds, for

the first few cycles) the ‘Cycle select’ screen will be displayed (Fig. 6). If the door is closed the green door indicator will flash

to indicate the door should be opened, together with a display message ‘Open Door’. To switch the autoclave ‘off’ press ‘0’

on the mains switch.

Notes: 1 At times, the message ‘PLEASE WAIT’ may be displayed for a few seconds.

2 ‘B’ type autoclave - If running test T1, run it directly after switching ‘on’ (a cold and dry chamber).

For notes on T1, refer to Appendix 7 - Special Functions.

To open the door.

The autoclave must be switched ‘on’. Once the normal ‘Cycle select ‘ display is shown (Fig. 6) turn the door handle

anticlockwise until vertical (12 o’clock position). The green door indicator light will flash.

To close the door onto the secondary catch.

With the handle vertical push the door closed gently and turn the door handle 45° clockwise (2 o’clock position). It will meet

a stop at this position and the door will only be partially closed. The door should be shut onto the secondary catch at all times

when the autoclave is not in use.

To close the door fully.

With the handle vertical push the door shut firmly and turn the door handle clockwise until horizontal (3 o’clock position). The

door indicator light will stop flashing and will not be illuminated.

Loading

Note: Prior to sterilization, instruments should be thoroughly cleaned, ideally in an Eschmann Instrument Washer Disinfector.

Open the door fully. The door indicator light will flash, indicating the door should be closed (after loading) together with a display

message ‘Close Door’. Following the guidance provided in APPENDIX 3 and local procedures, load the autoclave with the

items to be sterilized.

Reservoir warning

If a Reservoir Warning Indicator (detailed on page 6) is illuminated ( ), fill or drain reservoir as indicated referring

to page 7 (Fill the reservoir) or page 9 (Draining a reservoir) as required.

Closing door

Close the door fully. The green door indicator light will stop flashing and will not be illuminated.

Cycle selection

The digital display indicates the default cycle. If another cycle is required press the ‘Cycle select’ button ( ) until the

required cycle is displayed. Ensure the cycle is appropriate for the load (refer to section 6).

Starting cycle

Press the ‘Start (cycle)’ button . The green door indicator light will illuminate indicating the door is locked and cannot

be opened until cycle completion. The printer (if fitted) will start printing a cycle record (refer to section 5). Indicators will show

the status of the cycle. The digital display will indicate the chamber temperature, pressure and an animated progress bar. The

‘Cycle Count’ can be displayed if the ‘Cycle select’ button is pressed during a cycle (Fig. 6 and 7).

Note: Cycles cannot be started when the green door indicator is flashing and the ‘Open Door’ message is displayed. Open

and then close the door to correct this situation should it occur.

Cycle errors

WARNING

When a cycle is aborted and/or an error display is indicated, the load must be treated as non-sterile. The load

must be sterilized by running the cycle again. If wrapped or pouched, new packaging must be used.

If the autoclave detects a fault it will display a message (e.g. ‘Door not closed’, Fig. 6) or if it detects an error it will display ‘CYCLE

FAILED’ or ‘SYSTEM ERROR’, there will be five rapid ‘beeps’ and illuminated progress indicators will flash. Refer to ‘Errors and

Faults’ Appendix 6. Anyone who becomes aware of a fault when using the autoclave should report it immediately to the Autoclave

Manager and all necessary remedial action should be taken before the autoclave is used again.

Should the overheat cutout trip, its indicator light (Fig. 1, item 14) will illuminate, refer to Appendix 6.

Completed cycles

Completion of a successful cycle will be indicated by illuminating and the display showing ‘Cycle Complete’ and ‘Ready

to Open’, the normal end of cycle display (refer to Fig. 6). There will be three audible ‘beeps’ (unless disabled). Open the door

fully (

take care - the load will be hot

Note: On ‘N’ type autoclaves ONLY, at the end of cycles with drying, the beep (if enabled) will continue intermittently. During

these ‘beeps’ open the door and remove the load. It should still be hot enough to self-dry. If the door is not opened during

the intermittent ‘beeps’ the load may not dry when removed. Items sterilized using an ‘N’ type cycle are for immediate

use only.

) and remove the load using the tray lifter.

P8/33 ST-IM84c

Page 9

SES 113 and 225

AUTOCLAVES

Unloading the chamber

WARNING: TAKE CARE WHEN UNLOADING, THE LOAD AND CHAMBER MAY BE VERY HOT. Use the tray lifter as

detailed in the following section. If running consecutive cycles, Eschmann recommends waiting for five minutes between

cycles with the door open to allow the chamber conditions to stabilise. If the autoclave is not to be used for several minutes

close the door onto the secondary catch (as detailed opposite).

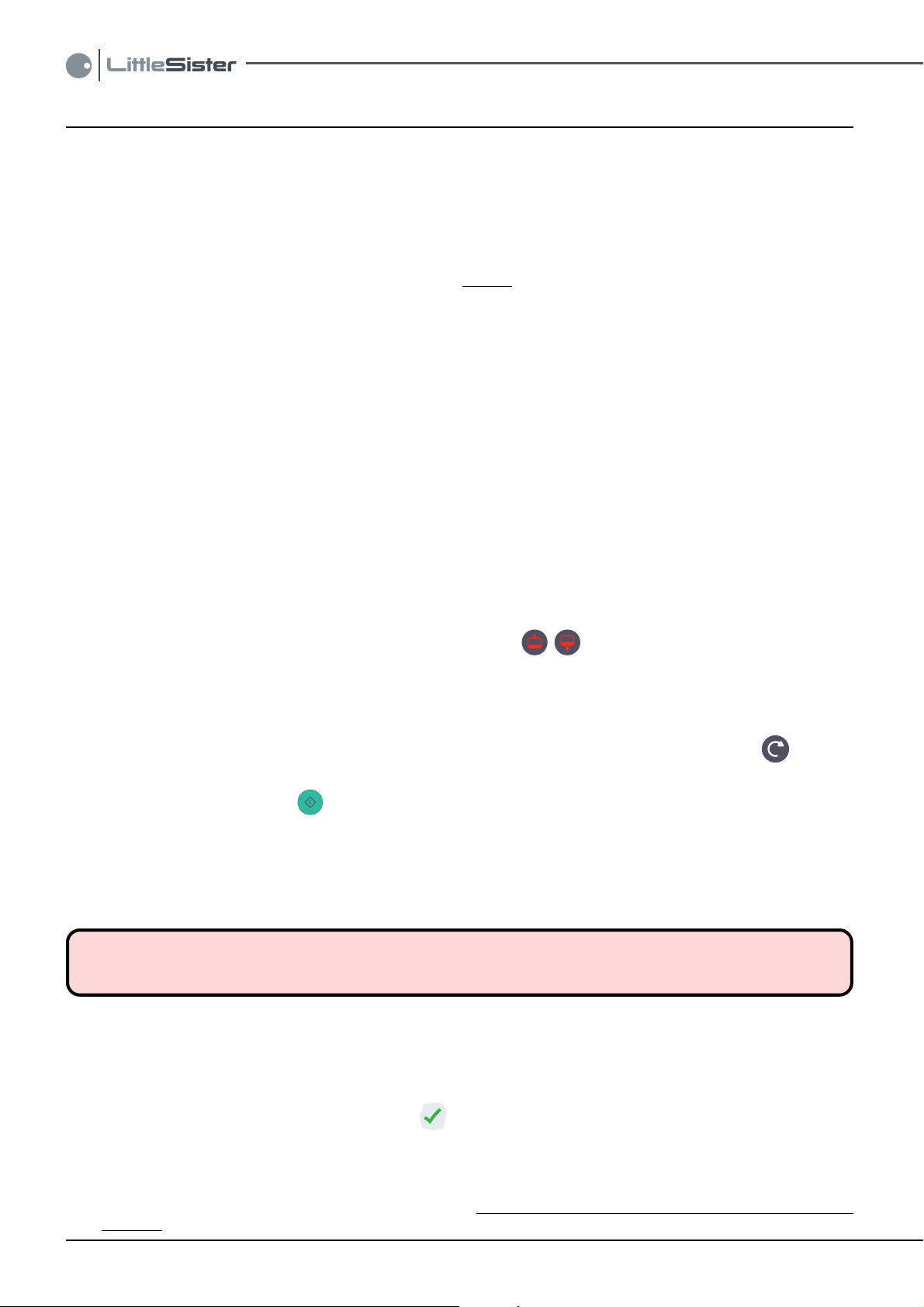

Using the tray lifter.

The tray lifter has one bottom support and two pairs of top clips. The top pair is for Hand Free instrument Transfer (HFiT)

cassettes and the bottom pair is for trays. Do not use the top clips when lifting trays. The spacing of the top clips enables HFiT

cassettes to be held at the side or end. Refer to illustrations below:

Tray in bottom clips

CORRECT

When using a tray lifter to hold pouch racks or the porous load basket, ensure the rack or basket is correctly located as

illustrated below:

Tray in top clips

INCORRECT

HFiT cassette gripped

at the side.

End bar of pouch rack or basket

located in tray lifter’s top centre clip.

Second bar of pouch rack or basket

located in the tray lifter’s top channel.

HFiT cassette gripped

at the end.

Stopping a cycle

In the unlikely event of needing to stop a cycle (e.g. wrong cycle selected) press the ‘Cancel (Exit)’ button (Fig. 2). This will

induce ‘Cycle Error No. 02’. Refer to ‘Errors and Faults’ Appendix 6 to clear this error and start the cycle again.

Draining a reservoir

The ‘waste water’ reservoir will need emptying when illuminates.

WARNING: TAKE CARE THE WASTE WATER MAY BE VERY HOT. Using the drain tube supplied (if lost a replacement

can be ordered, Part No. 115036) drain the water into a container of at least 4 litres capacity, or a sink. Plug the drain tube’s

connector into the drain socket (Fig. 1, item 15) this automatically opens the socket’s drain valve, if the plug cannot be pushed

into the drain, push the drain release clip (Fig. 1, item 19) until it clicks and then insert the plug. Release the red clip on the

end of the drain tube with the drain tube pointing into the container or sink. Note that a direct drain kit (REF 87-271-55) can

be fitted, please contact EschmannCare for details. Also note that the waste water reservoir is fixed.

To release the drain tube from the autoclave push the drain release clip (Fig. 1, item 19). Don’t forget to close the red clip.

To drain the fresh water reservoir pull it forward about 100mm (as for filling, Fig. 2) and drain the water into a 4 litre container

as detailed above, but plug the drain tube’s connector into the fresh water reservoir’s drain socket (Fig. 1, item 17).

After use (end of day)

When the autoclave is not in use switch it ‘off’ at the mains switch (Fig. 1, item 10). Also leave the door open on the secondary

catch with the chamber empty. Note: Whenever a B type autoclave is switched ‘on’ the chamber is heated.

At the end of the day and/or week ensure the instructions for care of the autoclave are followed as detailed in Appendix 5.

It is recommended that the ‘waste water’ and the ‘fresh water’ reservoirs should be drained and allowed to dry, at

the end of each day.

Display ‘beep’ and Special function’ notes

At programmed intervals the autoclave will display special messages (e.g. ‘Service required’), refer to Appendix 6.

The autoclave will sound 5 rapid ‘beeps’ if there is a fault, 3 slower ‘beeps’ on cycle complete and one ‘beep’ per key press.

The ‘beep’ can be disabled using the ‘Special Functions’, refer to Appendix 7.

‘Special functions’ should only be used by the Autoclave Manager or an EschmannCare engineer, refer to Appendix 7.

ST-IM84c P9/33

Page 10

4.0 Direct Data Download instructions

Introduction

The Eschmann Little Sister SES 113 and 225 autoclaves include Direct Data Download (DDD) application software as

standard. All cycle records are stored on the unit. IMPORTANT After 20,000 cycles the autoclave’s memory may be getting

full and data storage could stop, please contact Eschmann for details of how the autoclave’s memory can be replaced.

DDD allows cycle records to be downloaded via a USB cable direct to a PC or Laptop. Cycle records can then be stored directly

on the PC, printed out using a conventional printer, several records to a page or, ‘pasted’ directly into the computerised patient

record. DDD enables the implementation of instrument/patient management and traceability. DDD application removes the

need for an integral printer and the issues relating to accurately managing this type of paper based data.

Using the DDD application

If in doubt refer to the instructions supplied within the Application CD or contact Eschmann.

The DDD application software should be installed on a PC, refer to the instructions provided with the DDD Software.

To open the DDD application click on the DDD icon on the Desktop of your PC or Laptop.

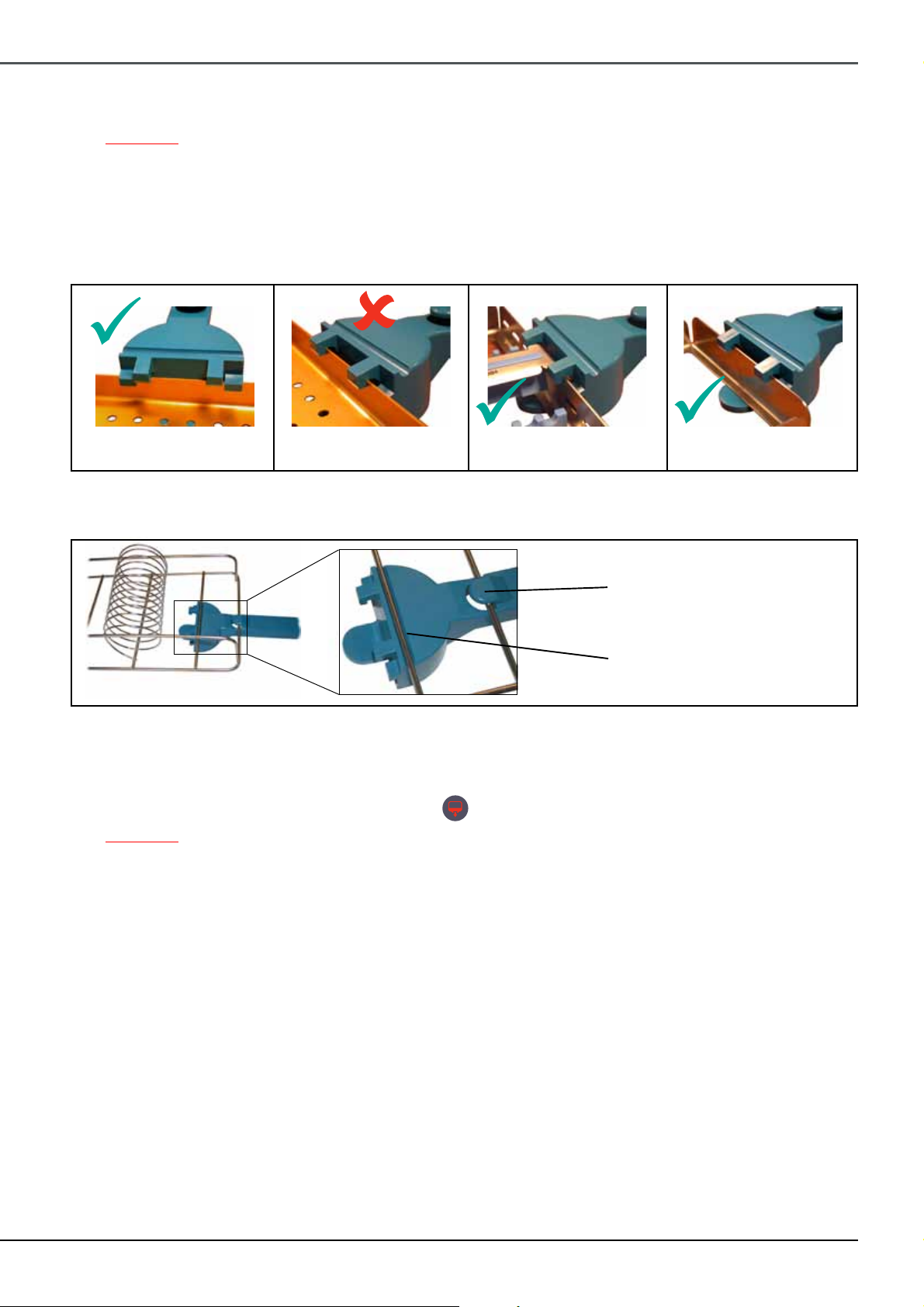

Using the cable provided connect the PC to the autoclave’s USB port (Fig. 1, item 12). Switch on the autoclave. The application

will access the autoclave, refer to Fig. 4.

Start

Stop

Disk

button

Progress

bar

Fig. 4 Controls active, Connected

Click the ‘disk button’ (Fig. 4) to select the type of download required. The image shown next to the ‘disk button’ indicates which

files you are about to download, refer to Fig. 5. For single files enter the cycle number in the box provided.

Single file Files not downloaded All files

Fig. 5 Type of download, symbols

After selection, click the green button to start the download. If required click the red button to stop. The ‘Progress bar’ (Fig. 4)

shows the download progress and the following:

Off = Normal

Green = File retrieval is complete, all files retrieved OK.

Red = An error occurred that prevented the retrieval.

Yellow = Retrieved all files but at least one was corrupt.

To view files, browse to the user allocated folder storing these files. If the letter ‘E’ appears by the cycle number, this file is

corrupt. You may try to retrieve this again as a single file. If in doubt refer to the instructions within the DDD Application CD.

P10/33 ST-IM84c

Page 11

SES 113 and 225

AUTOCLAVES

Fig. 6 ‘Cycle Select’ and various display screens

ST-IM84c P11/33

Page 12

Fig. 7 Various display screens

P12/33 ST-IM84c

Page 13

5.0 Printer instructions

SES 113 and 225

AUTOCLAVES

All Eschmann Little Sister SES 113 and 225 autoclaves

incorporate direct data download via a USB port. They may also

be bought with a built-in printer. Installation of a printer can also

be arranged at a later date through the EschmannCare service

team (contact 01903 765040) and order REF 87-270-23 a printer

for these autoclaves, fitted with 1 roll of paper and 4 spare rolls.

(Note: This must be fitted by an EschmannCare Engineer)

The following instructions only apply to autoclaves fitted with a

printer.

IMPORTANT OPERATOR NOTES

Follow the notes and cautions below when changing the

paper roll. Do not pull on the paper whilst the printer is in

operation, since it may damage the printer.

5.1 Printer Output

The printer output (refer to example below) gives the following

information:

Autoclave type - Eschmann Little Sister SES 113B

Autoclave Serial number [SRN] - A unique code

Cycle type [CYC] (e.g. B134) followed by,

Cycle count (e.g. 00345)

Time and Date started [STD] - hh:mm:ss dd\mm\yy

Cycle information - Cycle stage codes (key to codes is below)

with time, pressure and temperature.

Sterilization information - Time, pressure and temperature

every 20 seconds during sterilization.

Maximum sterilization temperature [TMX]

Minimum sterilization temperature [TMN]

Time and Date finished [ETD] - hh:mm:ss dd\mm\yy

Status [STS] followed by

Error number [ERR] - If applicable

If an error occurs during a cycle, it is recorded with time and

date on the printout and the message ***FAIL***, errors are

designated by error codes, refer to Appendix 6.

Key to codes on printout (if not detailed above) are:

TPV - Time of vacuum pulse

TPP - Time of pressure pulse

TSS - Start of sterilization

TSE - End of sterilization

TDS - Start of drying phase

TDE - End of drying phase

ETD - End time and date

STS - Status at cycle end

Cycle Complete

or

***FAIL***

5.2 Interpretation of printer output

The most important part of the printout that should be checked

is the final line coded [STS], this should be followed by

Complete

the cycle not match the correct parameters the indication

following [STS] is

error number, refer to ‘Appendix 6 - Errors and Faults’.

Other aspects of the printout that can be checked if required are

as follows, but note that any deviation will result in the

message above:-

121°C Cycles:

134°C Cycles:

indicating a successful cycle. Should any aspect of

***FAIL***

[TSS], [TSE], [TMX], [TMN]

Temperature - >121°C <124°C

Time [TSS] - Time [TSE] not less than 15 minutes

[TSS], [TSE], [TMX], [TMN]

Temperature - >134°C <137°C

Time [TSS] - Time [TSE] not less than 3 min. 20sec.

. This will be accompanied by an

Cycle

***FAIL***

5.3 Printer operation

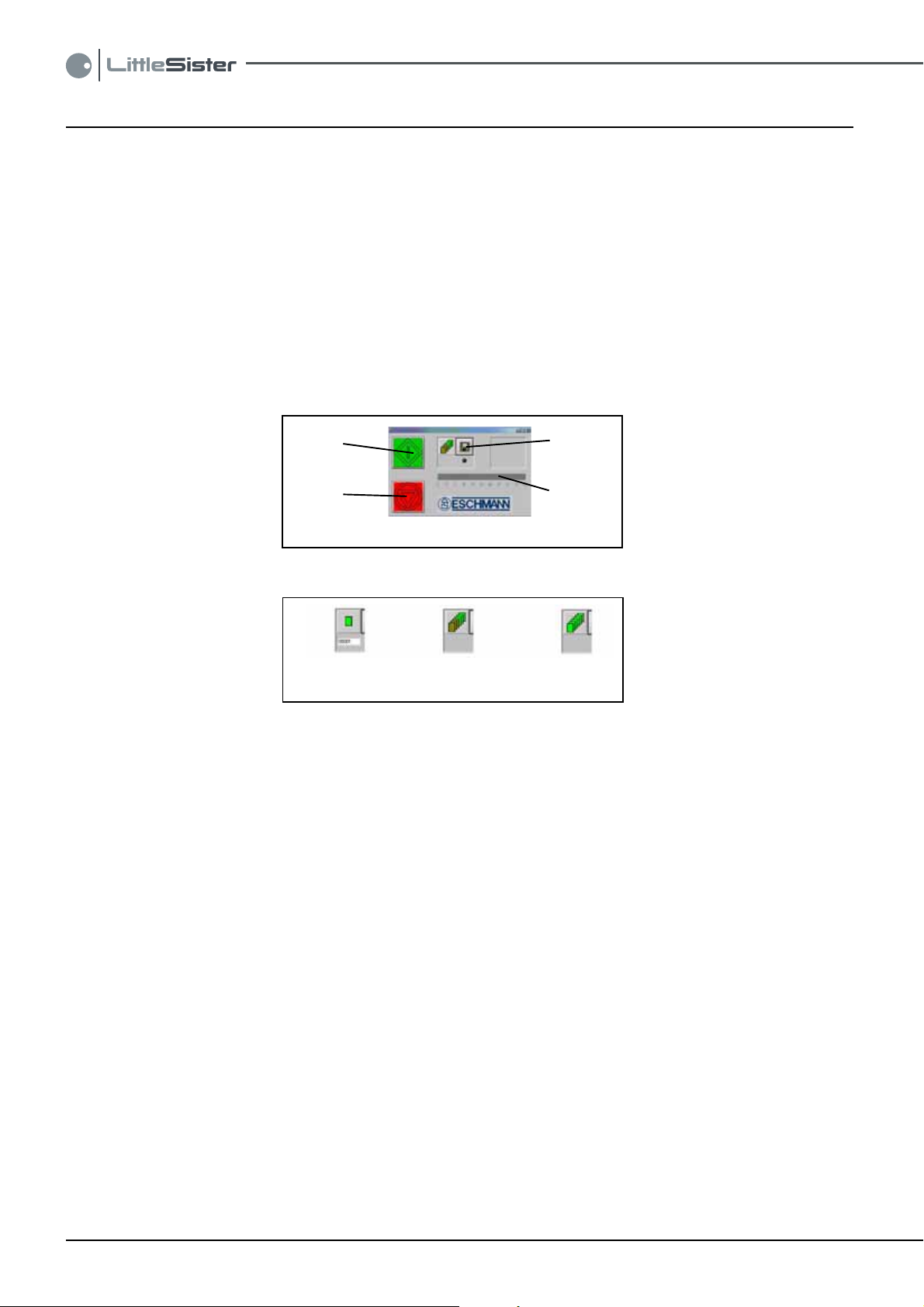

Fig. 8 Printer control panel

5.3.1 Status LED

The printer incorporates a Status LED (Fig. 8) to report its

condition. If there is a fault, the LED will flash in sequence. The

fault can be identified by observing the flash sequence detailed

below.

LED On continually Printer On

LED Off Printer Off

LED flashing * * * Paper out, fit new roll

LED flashing ** ** ** Thermal head too hot,

allow head to cool.

ST-IM84c P13/33

Page 14

5.3.2 Loading paper

CAUTION

DO NOT USE ALTERNATIVE PAPER ROLLS

The quality and size of paper rolls used in the

printer, should only be supplied by Eschmann.

Do not close the lid with one finger

as shown below.

The printer will automatically detect when the printer’s paper

has run out and report this using the Status LED (section 5.3.1).

Use the Paper feed button to feed through the last few

centimetres of paper and fit a new roll as follows:

i Pull the top of the opaque centre window (at the finger hold)

forward until the lid is released from its locked position. To

avoid damage do not use excessive force.

ii Remove any paper remaining in the paper recess.

iii Reel off a few centimetres from a new roll of paper. Hold

approximately 50 mm of paper outside the printer as you

place the new roll into the paper’s recess with the roll

unwinding from the back and bottom of the roll when placed

in the recess (left picture below). Note the paper can only

be printed on one side (the outside of the roll), do not

place the roll in back to front.

v Now tear the spare paper away by pulling the printout down

towards the tear bar and tear from one side to the other

across the serrated edge.

5.3.3 Removing a printout

Push the paper feed button to advance the paper about 5 mm if

required. To remove a printout from the printer, pull the printout

down towards the tear bar and tear from one side to the other

across the serrated edge as ‘5.3.2 - v’.

5.3.4 Printer door

During use the printer door can be closed, the printout will feed

through the recess in the bottom of the door. When closing the

door hold the printout down and take care not to trap any paper

in the door.

iv Close the lid by applying equal amounts of pressure on

each side, ensure the lid is in the locked position.

5.4 Printer maintenance

Power On Self Test

The self test procedure is initiated by supplying power to the

printer (i.e. switch the autoclave on) whilst depressing the paper

feed button (Fig. 8) until the printer starts printing the test print.

Head Thermal Limit

After extensive printing the print head temperature may rise to

an unacceptable level. The Status LED will report when this

occurs (section 5.3.1). Printing will be suspended until the head

temperature returns to normal levels, once cooled the printout

will continue and no information will be lost.

Spares Pack

A spare printer roll will be provided with the autoclave, when

you require more please contact the EschmannCare team on

01903 765040 and order the following:

REF 87-270-45 a set of 4 thermal paper rolls for the

Eschmann Little Sister SES 113/113 B vacuum autoclaves.

P14/33 ST-IM84c

Page 15

6.0 Technical data

SES 113 and 225

AUTOCLAVES

6.1 Electrical

Supply 230 V (±10%) or 220 V (-6%, +15%), see

rating plate. 50/60 Hz a.c.

For use with alternating current

Loading at 220 V 1.85 kW 10 A (max.)

Loading at 230 V 2.0 kW 10 A (max.)

Fuses: 2 - T12.5A 440 V (Part No. 112474)

Protection Class I

6.2 Sterilizing and test data

Sterilizing time (refer to Note below):

3 minutes 20 seconds at 134/137 °C, or

15 minutes at 121/124 °C

‘B’ type cycle drying time (if selected) is 15 minutes.

Maximum time for T1 - less than 20 minutes

Maximum time for T3 - less than 25 minutes

Operating pressure:

1.03 bar at 121 °C, 1.23 bar at 124 °C

2.03 bar at 134 °C, 2.32 bar at 137 °C

For basic cycle details refer to section 6.12 and for more

detailed cycle information sections 6.13 to 6.14.

Note. An Eschmann trained engineer can increase the

sterilization times (up to a max. of 30 minutes) on request,

contact the EschmannCare team on 01903 765040.

6.3 Maximum Loads

113 autoclave

Maximum load per tray, pouch rack or cassette is 1.5 kg.

Maximum load for the porous load basket is 0.87 kg.

Maximum weight per item is 1.5 kg.

Maximum total load is 3 kg.

225 autoclave

Maximum load per tray, pouch rack or cassette is 1.5 kg.

Maximum load for the porous load basket is 1.0 kg.

Maximum weight per item is 1.5 kg.

Maximum total load is 6 kg.

6.4 Water and reservoir

Reservoir capacity - 3360 ml (maximum)

Minimum fill - 750 ml (approx.)

Volume used for 1 cycle - 350 ml (approx.)

6.5.1 Dimensions and Weight (approx.) 113 autoclave

Dimensions:

582 mm wide, 435 mm high*, 530 mm deep

*435±5 mm depending on adjustment of feet.

Weight:

SES 113 - 35.0 kg, SES 113 B vacuum - 39.5 kg

Shipping (includes unit, accessories and packing):

Dimensions (WxDxH): 720 x 720 x 640 mm

Weight: SES 113 - 46.5 kg, SES 113 B vac. - 51.5 kg

The useable space is defined as:

Porous load basket: 280 x 147 x 87 mm (external)

Trays cassettes etc.: 290 mm by cross section

shown (dimensions in mm)

6.5.2 Dimensions and Weight (approx.) 225 autoclave

Dimensions:

582 mm wide, 435 mm high*, 580 mm deep

*435±5 mm depending on adjustment of feet.

Weight:

SES 225 B vacuum - 48 kg

Shipping (includes unit, accessories and packing):

Dimensions (WxDxH): 720 x 720 x 640 mm

Weight: SES 225 B vac. - 60 kg

The useable space is defined as:

Trays carrier 370 mm length by cross section shown.

Chamfers

197 mm

197 mm

20 x 20 mm

6.6 Standards compliance

These autoclaves have been designed in accordance

with the following standards:

BS EN 13060: 2004 BS EN 61326: 1998 Class A

BS EN 980: 2003 BS EN 1041:1998

PD 5500: 2006 EN 61010-2-041: 1997

BS EN 61010-1: 1993 BS EN ISO 14971: 2007

6.7 Applicability

This manual applies to the following autoclave models:-

SES 113 Autoclave (N type) (from Serial Number

L1NA.... or S1NA.... or S1XA....) REF 87-11*-**

SES 113 B Vacuum Autoclave (B type) (from Serial

Number L1BA.... or S1BA....) REF 87-12*-**

SES 225 B Vacuum Autoclave (B type) (from Serial

Number L2BA.... or S2BA....) REF 87-13*-**

*-** indicate model variant numbers

6.8 Environmental considerations

During cleaning and disinfection procedures any potentially

contaminated waste materials produced during these actions,

should be handled in accordance with local procedures and

National legislation for the disposal of potentially contaminated

waste.

At the end of the working life of the autoclave it should be

dismantled and recycled as much as possible in line with the

recommended procedure available from Eschmann Equipment

and in accordance with local procedures and National legislation.

6.9 Technical Lifetime

The Eschmann Little Sister SES 113 and 225 autoclaves are

designed to have a technical lifetime of 36,000 operating cycles

(10 years normal use) subject to their being used in accordance

with these instructions, and subject to proper maintenance and

repair.

6.10 International Symbols

This symbol indicates that the equipment is for

use on alternating current.

This symbol indicates that fuses adjacent to the

symbol have a rating and type as detailed.

ST-IM84c P15/33

Page 16

This symbol warns the user to read the accompanying documents, these ‘Instructions for use’.

SN This symbol indicates the unit serial number is

as indicated adjacent to the symbol.

REF This symbol indicates the catalogue number is

as indicated adjacent to the symbol.

This symbol indicates that the date of manufacture

is as indicated adjacent to the symbol.

This symbol indicates the manufacturer is as

indicated adjacent to the symbol.

This symbol warns the user of potentially hot

surfaces.

This symbol indicates that this product was

placed on the market after 13th August 2005. At

the end of its working life it should be deposited

at an appropriate facility to enable recycling. For

information on how to recycle this product

responsibly contact Eschmann.

6.11 Miscellaneous

For ‘Conditions for safe use’ refer to Appendix 2.

The autoclave will be ready for use (after initial installation and

setup) in less than 1.0 minute.

The pressure relief valve is nonadjustable and set to 2.85 bar*.

* Catalogue numbers ending ‘...4-80’ or ‘...3-80’ have an

adjustable pressure relief valve set during manufacture to

2.85 bar.

P16/33 ST-IM84c

Page 17

SES 113 and 225

AUTOCLAVES

6.12 Basic cycle information

CYCLE DETAILS

Cycle No. Cycle Type Load Type, Cycle Information

1 N134 °C Solid instruments (unwrapped), non vacuum and no drying.

2** N121 °C Solid instruments (unwrapped), non vacuum and no drying.

3 N134 °C Dry Solid instruments (unwrapped), non vacuum with drying.

4** N121 °C Dry Solid instruments (unwrapped), non vacuum with drying.

5 B134 °C Solid or Hollow instruments, vacuum cycle without drying.

6** B121 °C Solid or Hollow instruments, vacuum cycle without drying.

7 B134 °C Dry Solid or Hollow instruments and porous loads, vacuum cycle with drying

(items can be pouched, single or double wrapped).

8* B121 °C Dry Solid or Hollow instruments and porous loads, vacuum cycle with drying

(items can be pouched, single or double wrapped).

T1 Test 1 Chamber integrity test. MUST NOT be used to process loads.

T3 Test 3 Steam penetration test. MUST NOT be used to process loads.

* This cycle is not normally installed on any autoclave.

** Not installed on SES 225 B vacuum autoclave

Note: On ‘N’ type autoclaves ONLY, at the end of cycles with drying, a beep will continue intermittently. Refer

to section 3 ‘Completed cycles’.

6.13 Detailed cycle information

The operating cycles are detailed in the diagrams and explanation text provided in 6.13 and 6.14. These sections detail the

maximum temperature for each sterilization cycle (within the useable space). The autoclave can be fitted with a printer producing

cycle records, interpretation of the printout is detailed in section 5.

Note: The configuration of the load support system is detailed in Appendix 3.

In accordance with BS EN 13060 the relevant type tests for the cycles listed, are as below:

Type tests

Dynamic sterilizer chamber pressure X

Air Leakage X

Empty chamber X X

Solid load X X

Small porous loads X

Full porous load X

Hollow load A X

Dryness, solid load X

Dryness, porous load X

Residual air

X: in compliance with all applicable clauses of BS EN 13060

Sterilization cycle type and cycle number

B type cycle N type cycle

ST-IM84c P17/33

Page 18

6.14 Detailed ‘N’ type cycle (N type autoclave) information

Stage on

diagram

1 Water enters chamber (i.e. the boiler is filled with the correct volume of water)

2 Pressure rises during initial heating to 90 °C

3 Air removal stage, temperature held at 90 °C

4 Pressure rises (i.e. heating to sterilization temperature)

N134 - 134 °C to 137 °C (approx. 318 kPa) N121 - 121 °C to 124 °C (approx. 215 kPa)

5 Sterilization, temperature and pressure held (i.e. at temperature and pressure as above)

6 Chamber pressure reduced to atmospheric (i.e. condensing and draining chamber)

Stage detail

6.15 Detailed ‘B’ type cycle information

Stage on

diagram

1 Pressure drops to below 15 kPa (Initial vacuum)

2 Pressure increase as chamber (i.e. boiler) fills with the required volume of water

3 Initial pressure rise during initial heating (temperature is pressure related)

B134 pressure is - 175 to 185 kPa B121 pressure is - 125 to 135 kPa

4 Pressure maintained as above, the precondition hold

5 Pressure drops to below 30 kPa, the steam penetration pulse

6 Pressure rises (i.e. heating to sterilization temperature)

B134 - 134 °C to 137 °C (approx. 318 kPa) B121 - 121 °C to 124 °C (approx. 215 kPa)

7 Sterilization, temperature and pressure held (i.e. at temperature and pressure as above)

8a,b,c

Note: For cycles with drying there are several drying pulses, the chamber is then returned to atmospheric pressure.

Cycle without drying

Cycle with drying

- drying pulses of varying pressure

- pressure returned to atmospheric pressure

Stage detail

P18/33 ST-IM84c

Page 19

SES 113 and 225

AUTOCLAVES

APPENDIX 1 - Installation

These Autoclaves should be installed by an EschmannCare or Eschmann Trained Engineer. For Warranty Registration, Free

Installation and Free User Training contact EschmannCare on 01903 765040.

Programmes and autoclave configuration can be adjusted by an EschmannCare or Eschmann Trained Engineer, on request. To

protect against tampering, access for such adjustment can only be gained by use of a PIN code, refer to ‘User PIN number’ below.

The Autoclave should be lifted or moved by at least two people. Observe good manual handling techniques at all times, with

hands placed under the base each side of the autoclave.

Unpacking

Remove the outer packaging and all packaging pieces carefully and place the autoclave on a flat, water and heat resistant

surface. Ensure there is a working clearance of 50mm around the unit. Do not cover the ventilation ports at the rear or side of the

autoclave. The following items should be checked and placed to one side (some will be packed within the chamber). All packaging

should be recycled in accordance with local recycling practices. DO NOT connect to the mains until setup has been completed.

Items included with the autoclave:

Instructions for Use Mains power cable

Levelling bull’s-eye Spare printer roll (if printer fitted)

Drain tube Tray carrier and tray lifter

Furniture (model specific) DDD Software (CD, Manual and USB cable)

Misc. Documentation

Setup

Adjustable feet enable the autoclave to be levelled correctly. To adjust the feet slacken the locking nut,

adjust the height as required and tighten the locking nut. The autoclave should be adjusted (when the

chamber is cold) until level in all directions using the bull’s-eye levelling device supplied. Note that on ‘B’

type units the band heater will warm the chamber when switched on, once the door has been opened switch

the autoclave off until levelled. The levelling device should be positioned directly on top of the flat heater

plate inside and at the back of the chamber. IMPORTANT Remove levelling device before use and if moved

to a new location after installation, check the autoclave is levelled again, adjusting if required.

Mains connection

WARNING

This equipment must be earthed. Ensure that the mains plug is easily

accessible during use as this is the means of disconnection.

The autoclave is supplied with an IEC mains input socket at the rear and a mains power cable. If the cable has a fused plug the

correct fuse will be installed. Connect the mains power cable (as supplied) to the mains supply and to the rear IEC mains socket

(Fig. 1, item 22). DO NOT use equivalent mains leads. Switch the mains supply ‘on’ if controlled by a switch.

If changing the plug, ensure that the plug is earthed. Check the fuse (if a fused plug) is appropriate for the equipment. The

connections to observe when connecting a mains plug are:

Yellow/Green - Earth Brown- Live Blue - Neutral

Switch the autoclave ‘on’ using the mains switch (Fig. 1, item 10). The switch is marked ‘0’ for ‘off’ and ‘I’ for ‘on’ it illuminates

green when ‘on’. The digital display and applicable indicators will illuminate to show the autoclave has been switched ‘on’. After

normal checks and a ‘Welcome, Please contact Eschmann’ message (shown for 30 seconds, for the first few cycles) the ‘Cycle

select’ screen will be displayed. To switch the autoclave ‘off’ press ‘0’ on the mains switch.

Opening/Closing the door

To open the door.

handle anticlockwise until vertical (12 o’clock position). The green door indicator light will flash.

To close the door onto the secondary catch only.

45° clockwise (2 o’clock position). It will meet a stop at this position and the door will only be partially closed. The door should be

shut onto the secondary catch at all times when the autoclave is not in use.

To close the door fully

o’clock position). The door indicator light will stop flashing and will not be illuminated.

The autoclave must be switched ‘on’. Once the normal ‘Cycle select ‘ display is shown (Fig. 6) turn the door

With the handle vertical push the door closed gently and turn the door handle

. With the handle vertical push the door shut firmly and turn the door handle clockwise until horizontal (3

User PIN number

The autoclave is supplied with the ‘User’ PIN number 00001. This should be changed before the autoclave is used, the new PIN

number should ONLY be available to the Autoclave Manager. Refer to Appendix 7 - Special Functions to change the PIN number.

Direct drain kit

If you require the waste reservoir to drain directly (e.g. into an adjacent sink) a direct drain kit can be fitted (REF 87-251-55).

Please contact EschmannCare (Tel. 01903 765040) for information.

ST-IM84c P19/33

Page 20

APPENDIX 2 - Warnings and cautions

The grouped warnings and cautions below should be followed at all times, all users/operators should be made aware them.

Potential Hazards

The operator should be aware of the following hazards:-

a. All autoclaves operate with steam at high temperatures and pressure. The autoclave door must only be opened when the

machine indicates it is safe to do so. Care must be taken to avoid contact with any residual steam or hot water. The

Eschmann ‘tray lifter’ must be used to remove trays etc. Contact with hot internal surfaces of the chamber and door must

be avoided. Water in the waste reservoir can be very hot, take care when draining to avoid contact with the hot water.

b. During certification, service and maintenance work it may be necessary to remove covers. This increases the risk of

exposure to hot surfaces and electrical systems. Accordingly all service and maintenance work should be carried out by an

Eschmann engineer or at the least by an engineer recently trained and certified by Eschmann.

c. If reservoirs are not emptied and left to dry after use (preferably on a daily basis) water may become contaminated.

d. If the load is not suitable for the cycle selected, the load may remain non-sterile. It is recommended that the user consults the

‘Instructions for Use’ of the items to be processed. If in doubt contact EschmannCare or an expert on sterilizing processes

such as an Authorized Person (AP) in the UK.

Limitations on use

The operator should be aware of the following limitations during use:

a Do not process hollow, pouched or wrapped items or porous loads, using an ‘N’ type cycle.

b. Never use trays or cassettes without perforations.

c. Do not process fluids in this autoclave.

d. Items in pouches should only be processed as detailed in these instructions.

e. Do not use autoclaves near inflammable materials or gases (e.g. anaesthetics).

f. When sterilizing instruments not of solid metal construction, the manufacturer of the instrument must be consulted about

its suitability for processing in an autoclave.

Electrical safety

The user should ensure the following electrical safety measures are followed:-

a. This equipment must be earthed.

b. The autoclave is switched ‘off’ and disconnected from the mains power supply before renewing fuses, checking and

cleaning the autoclave.

c. No attempt is made to service this autoclave internally.

General safety

IMPORTANT

The design of the autoclave pressure vessel is certified by a third party accredited test house to International Standards.

In order to ensure safety and to comply with UK and/or International regulations, the vessel and fittings should be

inspected by a ‘competent person’ at regular intervals. Eschmann recommends this should be carried out at least

once every 14 months by an Eschmann trained engineer.

The operator should follow these general safety measures:-

a. Do not cover any of the ventilation grills or attempt to use the autoclave if the covers are damaged, loose or missing or if

the door seal is damaged or missing.

b. Always refer to the ‘Errors and Faults’ section of Appendix 6 if the normal cycle select display is not shown on the display

or it is blank or corrupted.

c. Ensure the fresh water reservoir lid is in place and returned to its normal (rear) position before using the autoclave. Check

the fresh water reservoir inlet filter is cleaned if dirty or replaced if damaged.

d. Do not use abrasive powders, chemicals, or solutions containing chlorine to clean the autoclave.

e. Do not attempt to open the chamber door until the message ‘Ready to Open’ has been displayed.

NOTE: This may be accompanied by the message “CAUTION HOT” when the chamber is above 55 °C.

f. If an error display appears during a cycle, do not switch-off power, refer to ‘Errors and Faults’ Appendix 6.

g. Do not place heavy items on top of the autoclave or containers with liquids (e.g. cups etc.).

h. Do not operate this autoclave if obviously damaged, deformed or if parts are missing.

P20/33 ST-IM84c

Page 21

SES 113 and 225

AUTOCLAVES

Environmental conditions for safe use

This autoclave has been designed for use in the following conditions only:-

a. Indoor use.

b. Pressure 700 to 1060 mbar

c. Temperature: 5 °C to 40 °C.

d. Relative humidity: 20% to 90% non-condensing.

e. Mains supply voltage fluctuations: Not to exceed ±10% of the 230 V supply.

Note: If it is required to operate this Autoclave outside of these conditions, contact Eschmann Equipment.

Warning markings

The warning markings on this equipment have the following meanings:

Caution; refer to accompanying documents (i.e. these Instructions for Use).

Caution; hot surface.

Safety features

Eschmann autoclaves are designed to be safe and effective. No changes should be made to them except by an EschmannCare

engineer. In particular, the following safety features must not be interfered with, circumvented or overridden:-

a. Door closed (position) sensor and door locks (position) sensors. These prevent a cycle starting if the door is not closed and

locked.

b. Pressure Relief Valve (safety valve). This valve safely releases excess pressure up to a maximum of 2.85+10% barG.

Also refer to section 6.11 for autoclaves fitted with an adjustable pressure relief valve.

c. Independent cycle control and monitoring. There are two microcomputers independently monitoring each other and other

autoclave components. Either is able to stop a cycle and place the autoclave into a safe condition in the event of a failure.

In the case of a venting valve failure the autoclave may not be able to eject water and steam (i.e. pressure will remain until

cool) and the door will remain locked until the pressure / temperature has dropped to a safe level.

d. Overheat Control. The microcomputer operates in conjunction with an independent manual reset thermostat to protect the

heating element from overheating.

e. Band Heater Thermostat. This prevents the band heater exceeding a preset temperature.

f. Pressure door switch. Prevents the door being opened when the residual chamber pressure is too high by removing power

to a door lock so that it locks the door closed.

Safety Checks

The user should ensure that the following safety checks are carried out:

Daily (by User)

i Check that the door opens and closes easily.

ii Check the door seal and chamber face for any signs of damage.

iii Check for any obvious escape of steam or water during a cycle.

iv For type ‘B’ autoclaves run a steam penetration test (Helix or Bowie Dick type).

If any problems are found, please contact an EschmannCare engineer (Tel. 01903 765040). Do not use the autoclave until repair

has been effected.

Annually

i Check that the pressure relief valve operates correctly at the set pressure.

ii Inspect the pressure system for integrity.

iii Check calibration.

iv Check door locking mechanism for integrity.

NOTE: Annual inspections should only be undertaken by properly trained engineers. EschmannCare comprehensive service

contracts cover preventive maintenance and repair to ensure trouble free operation of the autoclave, including annual inspections

of the pressure system to satisfy the requirements of all relevant legislation and guidelines, including the Pressure Systems

Safety Regulations 2006. Please contact the EschmannCare team for details (Tel. 01903 765040). The EschmannCare team can

also provide testing and certification against HTM2010, DB9804 and DB2002 (06). Refer to Eschmann’s Instructions for Testing

Vacuum Autoclaves (ST-IM85) or contact the EschmannCare team.

(by an EschmannCare engineer)

ST-IM84c P21/33

Page 22

APPENDIX 3 - Loading the autoclave

CAUTION

When loading the autoclave take care that you do not damage the door or front face of the chamber, especially the

door seal and mating face. Damage to these parts can adversely affect performance. When loading pouches ensure

they do not make ‘paper cuts’ in the door seal. Do not reprocess single-use items.

The autoclave is designed to sterilize instruments, it does not wash or clean them. Effective cleaning and drying of items prior to

sterilization is an essential part of the decontamination cycle. Air retained within the load can also prevent steam contact. Prior to

sterilization, instruments should be thoroughly cleaned, ideally in an Eschmann Instrument Washer Disinfector (contact the

EschmannCare team on 01903 765040 for more information).

When placed in an autoclave, items with hinges or ratchets should be open and unlocked. Multiple-part items should be dismantled

or only loosely assembled to allow steam penetration. Once loaded the autoclave cycle should be started, do not leave items

awaiting processing in the autoclave.

Check the suitability of nonmetallic items for processing in an autoclave and that the temperatures are acceptable.

Load types and load arrangements should conform to that specified below and detailed in section 6.3. If in doubt about loads and

processing details please discuss this directly with EschmannCare.

Eschmann Instrument Management System (EiMS)

This autoclave uses furniture and accessories from the Eschmann instrument Management System. Instrument trays and Hands

Free instrument Transfer (HFiT) cassettes are available in a variety of sizes and colours designed to help initiate instrument

traceability within the surgery environment. ‘Examination’ sized accessories enable a ‘one set of instrument-per tray-per patient’

policy to be adopted. Full details can be found in the accompanying EiMS brochure, also refer to Appendix 8.

Unwrapped solid items (‘N’ or ‘B’ type cycles)

Place unwrapped solid items loose on trays or into hands-free instrument transfer (HFiT) cassettes. Do not overload trays or HFiT

cassettes (TECHNICAL DATA details maximum tray loads and maximum load). Avoid ‘bunching’ items together and ensure all items

are positioned so that they do not touch and drain freely. Only use trays or HFiT cassettes supplied by Eschmann. Loaded trays and

HFiT cassettes should then be placed in the sterilizing chamber. All items must be positioned so that they drain freely and do not trap

rising air bubbles. Unwrapped items are for immediate use only. For details on the choice of cycle refer to Section 6.

Hollow instruments including items with narrow lumens (e.g. dental handpieces) porous loads

and single wrapped (e.g. pouched) hollow or solid instruments (‘B’ type cycles ONLY)

Items in pouches should only be sterilized using the special pouch rack (which holds 9 pouches) with only one instrument per

pouch (otherwise instruments touch together in the pouch, restricting steam from penetrating all surfaces). Avoid packing pouches

too tightly and note that paper/film pouches must be loaded such that the film sides of adjacent pouches are face to face and

sterilized using a ‘B’ type vacuum cycle with drying. Only use pouches recommended for steam sterilization (i.e. conform to

EN868), details are provided below. Ensure all seals have been made correctly to maintain sterility post sterilization.

All items must be positioned so that they drain freely and do not trap rising air bubbles. Wrapped item can be stored for later use.

For details on the choice of cycle refer to Section 6.

The following sterilisation pouches are available from Eschmann:

Pouch, box of 200 small (90 mm x 230 mm) REF 87-033-10

Pouch, box of 200 medium (133 mm x 254 mm) REF 87-033-18

Pouch, box of 200 large (190 mm x 330 mm) REF 87-033-29

The configuration of the load support system follows, the load should be confined to the usable space as defined in

section 6.5. Full details on the cassettes etc. can be found in the accompanying EiMS brochure, also refer to Appendix 8.

SES 113 and SES 113 B vacuum Autoclave load capacity

The tray carrier (load configuration) has four levels that can accommodate the following:

Top: 1 x examination tray or HFiT 10 cassette (140 mm x 180 mm).

Upper Middle: 1 x standard tray or HFiT 20 cassette (280 mm x 180 mm), or 2 x examination trays or HFiT 10 cassettes.

Lower Middle: 1 x standard tray or HFiT 20 cassette, or 2 x examination trays or HFiT 10 cassettes.

Bottom: 1 x examination tray or HFiT 10 cassette.

SES 113 B vacuum Autoclave ONLY load capacity

If all trays are removed, one porous load basket (external dimensions 280 x 147 x 87 mm) or one 9 slot pouch rack can be

accommodated.

SES 225 B vacuum Autoclave load capacity

The tray carrier (load configuration) has five levels that can accommodate the following:

15 x examination trays or HFiT 10 cassettes with instruments or

5 x standard trays or HFiT 20 cassettes and 5 x examination trays or HFiT 10 cassettes with instruments.

P22/33 ST-IM84c

Page 23

SES 113 and 225

AUTOCLAVES

APPENDIX 4 - Daily Testing

Vacuum ( B type) autoclaves

IMPORTANT:

The Steam Penetration Test Device (hereafter called ‘Device’) must only be used and stored as detailed in the

‘Instructions for Use’ supplied with the ‘Device’. Failure to do so could lead to failure of the ‘Device’ and dangerously

misleading results.

In order to sterilize products and devices by steam, the steam must be able to penetrate through to and contact all surfaces. Items

such as packaging, pouches and narrow or hollow instruments are not easy to penetrate with steam. For this reason, the SES 113 B

vacuum autoclave has been fitted with a pump to actively remove air and thus allow steam to penetrate into the load.

The ‘Device’ (order REF 87-272-32) which complies with BS EN 13060 for B type autoclaves hollow load A, has been designed

to test the steam penetration ability of the autoclave, by presenting a defined challenge to the autoclave. The ‘Device’ consists of

a plastic tubular device with an indicator receptacle at the end and is supplied with indicator strips. The ‘Device’ must be replaced

after 250 uses. This ‘Device’ satisfies the requirement to perform a daily steam penetration test as given in:

EN 554:1994 Sterilization of medical devices - Validation and routine control of sterilization by moist heat, British Standards

Institution, clause 6.3.4

DB 2002(06) Device Bulletin, Benchtop Steam Sterilizers-Guidance on purchase, Operation and Maintenance, Medical Devices

Agency, clause 5.3.1

SN 2002(24) Safety Notice, Steam penetration tests in vacuum benchtop sterilizers, Medical Devices Agency.

DB 2000(05) Device Bulletin, Guidance on the Purchase, Operation and Maintenance of Vacuum Benchtop Steam Sterilizers,

Medical Devices Agency, clause 5.3.1

DB 9804 Device Bulletin, The validation and periodic testing of benchtop vacuum steam sterilizers, Medical Devices Agency,

clause 5.1

Note: Some of the above documents are available on the MHRA’s website, www.mhra.gov.uk

Frequency of use

To comply with the requirements of the documents listed above, Test T1 (chamber integrity test) and Test T3 (steam penetration

test) must be conducted at the start of each day the autoclave is to be used. If the tests are passed it ‘verifies’ the suitability of the

autoclave’s air removal stage for the day ahead. Eschmann recommends the daily use of the ‘Device’ and a ‘Test Log’.

EschmannCare can provide a ‘Test Log’ for this purpose, please contact EschmannCare (Tel. 01903 765040) and order Part No.

113885.

Conducting the tests

To run T1 refer to Appendix 7 - Special Functions, for T3 proceed as follows:

Full instructions are provided with the device. The autoclave should be loaded with the ‘Device’ ONLY. Use the T3 cycle (or T3 via

the special functions, if T3 has been disabled as a cycle) to run the test. Remember the ‘Device’ must be removed within 10

minutes of the cycle end. Compare the indicator test strip with the device’s instructions.

HTM2010/DB2002(06)/DB9804 Testing

Where there is a requirement to satisfy the guidance in HTM2010, DB2002 (06) and DB9804 then further Daily, Weekly, Quarterly

and Annual Testing may be required. Our recommendations on these testing requirements are detailed within our ‘Manufacturer’s

recommended Instructions for Testing Vacuum Autoclaves’ (reference ST-IM85).

N and B type autoclaves

For details on the automatic control test for HTM2010 please contact EschmannCare.

ST-IM84c P23/33

Page 24

APPENDIX 5 - Maintenance

Cleaning and care

CAUTION

Chlorine, even in the concentrations found in tap water, can cause stainless steel to crack and could

damage the chamber. Disconnect from the mains electrical supply before cleaning the Autoclave. Do not use flammable

liquids, abrasive powders, chemicals, or solutions containing chlorine to clean the autoclave.

Keep chamber trays, door seal, chamber and chamber face clean. The door seal and chamber face should be checked for damage

and cleaned every day using only a lint-free cloth moistened ideally with ‘Sterile Water for Irrigation’ or as a minimum the same

water used in the reservoir (refer to section 2). Clean the outside of the autoclave by wiping down with a cloth dampened with a 70%

solution of industrial methylated spirit (IMS) and water. Allow to dry by evaporation. The tray lifter should be cleaned and sterilized

regularly (e.g. once a week).

CAUTION

In common with other systems containing static water reservoirs, water in this autoclave can become contaminated

over a period of time, or an aborted cycle, and should be treated as a potential risk of infection.

It is recommended that the reservoirs are drained daily and allowed to dry. Do not leave water in either reservoir when the

autoclave is not in use. To drain the reservoirs refer to section 2.0. Refill the fresh water reservoir (refer to section 2) only when

required. For guidance on clean steam management and HTM2031 contact Eschmann.

Attention to the following will increase the life of the your Autoclave:-

a. Always leave the chamber empty and the door open on its secondary catch when not in use.

b. Replace the antibacterial air filter (Fig. 1, item 23) on vacuum autoclaves every three months (order Part No. 115190). To

remove the filter pull gently whilst twisting. Replace by pushing a new one into the mount.

c. At weekly intervals remove the chamber furniture and clean out any dirt or debris that has collected around the filter mesh

cone in the base at the back of the chamber. At monthly intervals remove any dirt or debris around the filter and then gently

pull it out of its recess. Clean the recess and the filter carefully. Replace the filter before using the autoclave again. If the

filter is damaged or blocked it should be replaced (order Part No. 391037).

d. On a weekly basis rinse out the fresh water reservoir with ‘Sterile Water for Irrigation’ drain and allow to dry.

Check the drain tube and the ‘O’ ring on its connector regularly, replace if damaged (order Part No. 115036).

Fuse Renewal

Fuses (Part No. 112474) are at the rear of the autoclave (Fig. 1, item 23). For fuse ratings refer to ‘TECHNICAL DATA’. To extract

a fuse switch ‘off’ and disconnect the autoclave from the mains supply. Insert a screwdriver or small coin in the slot of the fuse

holder and twist it counter-clockwise. After inspecting or renewing a fuse, reverse the above procedure to secure the fuse. Internal

fuses should not be replaced by the user, this should only be performed by an Eschmann trained service engineer.

Service

The Service Manual (ST-SM48) which also contains an illustrated spare parts list and a Manual (reference ST-IM85) providing the

‘Manufacturer’s recommended instructions for testing vacuum autoclaves’ to the applicable parts of HTM2010 and DB9804, are

available from EschmannCare.

The EschmannCare team is staffed and equipped to provide advice and assistance during normal office hours. To avoid delays

when making enquiries, please quote the Model and Serial Number (refer to Fig. 1, item 20) and the error number displayed (if

applicable). All correspondence relating to the after sales service of Eschmann Equipment should be addressed to :

EschmannCare, Eschmann Equipment, Peter Road, Lancing, West Sussex, BN15 8TJ

Tel: +44 (0) 1903 765040 Fax: +44 (0) 1903 875711

CarePlan service cover

EschmannCare CarePlan service cover should be taken out for your Autoclave. An autoclave will only continue to function

correctly if it is properly serviced and maintained. CarePlan provides the assurance that the exacting conditions necessary for

sterilization are maintained throughout the autoclave’s working life.

Safety Checks

Refer to ‘General safety’ and ‘Safety Checks’ in Appendix 2.

Cycle History

When the message ‘Please Download Your Cycle Data For Archiving’ appears consult the ‘Direct Data Download Software’ CD

package supplied with the autoclave and download the autoclave data to a PC.

Certification

Eschmann can offer certification to PSSR 2006 regulations as part of our CarePlan maintenance packages. This certification

entails inspecting the pressure vessels and testing a number of safety critical devices to ensure continued safe operation for the

next year.

P24/33 ST-IM84c

Page 25

SES 113 and 225

AUTOCLAVES

APPENDIX 6 - Cycle errors and faults and Display messages

Cycle errors and faults

The autoclave is continually checking the parameters required for effective sterilization, if a problem is encountered a CYCLE

FAILED or SYSTEM ERROR message will be displayed, followed by an error number and ‘Please Wait...’. There will be five rapid

‘beeps’ and also any illuminated progress indicators will flash.

For future reference record the type and error number before continuing.

The autoclave returns to a safe condition and displays either ‘Enter PIN Code’ or ‘Press Enter and Cancel’, depending on

configuration, refer to Appendix 7. The factory set PIN code is 00001 (this should be changed refer to Appendix 7 - Special

Functions).

CYCLE FAILED and SYSTEM ERROR message.

The cycle will abort and provided power supply to the autoclave is maintained, the message ‘CYCLE FAILED, Please

Wait...’ or ‘SYSTEM FAILED, Please Wait...’ and an error number will be displayed. Finally the message ‘Enter PIN Code’

or ‘Press Enter and Cancel’ will be displayed refer to ‘Enter PIN Code’ or ‘Press Enter and Cancel’ below. Follow the

section below ‘Attending to an error’ and run the cycle again.

Overheat cutout (Error 8).

If the heating element reset thermostat operates (e.g. in a nil water condition) indicated by the overheat indicator light

illuminating (Fig. 1, item 14) and ‘Error 8’, proceed as follows. Allow the autoclave to cool and press the ‘reset button’ on

the underside of the autoclave (position indicated by the serial label, Fig. 1, item 13) then clear the error in the normal way.

DO NOT clear the error first and then press the reset button, the unit will try to reset with the thermostat tripped inducing

errors.

No mains power.

If after switching ‘on’ power, there is no visual display, check the power supply and connections, both fuses at the back of

the autoclave (refer to Fuse Renewal) and the fuse in the mains plug.

‘Enter PIN Code’ Message*.

Enter the user PIN code as follows (refer to Fig. 2 for button information). Press ‘Up’ or ‘Down’ to select the first digit, press

‘Enter (Select)’ to accept this digit and move to the next. The accepted digit changes to an asterisk (*) to protect the PIN.

Continue to select and enter the PIN. If the PIN is incorrect you will be asked for it again.

‘Press Enter and Cancel’ Message*.

Press the ‘Enter (select)’ and ‘Cancel (Exit)’ buttons together (refer to Fig. 2 for button detail) and hold until error clears.

* Selection of which message is displayed is via the SETTINGS menu, refer to Special Functions Appendix 7.

Attending to a cycle error.

Items must be considered non-sterile if an error occurs and all items in the load should be reprocessed before use. All

items should be removed and dried. If applicable new pouches or wrapping should be used.

CAUTION

Take care during the following procedure the water, chamber and load could be very hot and potentially contaminated.

Remove the tray carrier and check for water in the rear of the chamber (350 ml maximum), drain any found using for

example a suitable syringe and tube. Replace the tray carrier. The chamber should be allowed to dry before starting

another cycle.

Errors that can be ‘corrected or checked’ by the operator are detailed in the error table on page 25, ensure these checks

(if applicable) are performed before running the cycle again.

For errors that are not detailed try running the cycle again checking procedures during loading. If the same error persists

contact the EschmannCare team (Tel. 01903 765040).

Do not attempt to solve an error using tools or tampering with the autoclave. The engineer will need to know the Model,

Serial Number (refer to label in Fig. 1, item 20) and the error number displayed.

Display messages

Certification Expired

The ‘certification date’ has been set in the factory to 18 months after manufacture. When the date is reached, the digital display

will show the message:

Certification Expired Please contact Eschmann

This message will be displayed for 5 seconds and appears when the power is switched ‘on’ and after each cycle. It will not be

displayed if the ‘service due’ message has been triggered because ‘service due’ takes precedence.

ST-IM84c P25/33

Page 26

Service Due

The ‘service due date’ will be set in the factory for 10 months after manufacture or 1500 cycles (i.e. whichever comes first). When

the date or cycle count is reached, the digital display will show the message:

Service Required Please Contact Eschmann

This message will be displayed for 5 seconds and appears when the power is switched ‘on’ and after each cycle.

Warranty Reminder

The ‘warranty reminder’ will be set in the factory to appear until 30 Cycles have been completed. If still active the digital display will

show the message:

Welcome Please contact Eschmann to register for FREE installation and training

Whilst still active, the message will be displayed for 30 seconds when the power is switched ‘on’. Please contact Eschmann and

you will be advised which buttons to press (when this message is displayed) to cancel the message irrespective of the cycle count.

Warranty arrangements will also be advised and initiated.

Cycle Errors Table

Error Cause Items to check before running another cycle

1 Power failure during cycle Check mains supply, check mains connections, check mains fuses

and mains lead fuse. Run cycle again.

2 User ‘cycle abort’ Correct reason for ‘Cycle abort’. Run required cycle.

3 Door lock failed Visually check door locks for a cause of failure (e.g. foreign body

stopping door lock operating), check door is firmly closed. Correct

visual faults (if possible) then run cycle again.

4 Initial vacuum pulse timeout Visually check for obstructions in door seal area, clean door seal

and its mating face. Run cycle again.

6 Water in chamber at cycle start Empty water from chamber, check load is dry and run cycle again.

7 Failed to fill boiler Ensure fresh water reservoir is full and run cycle again.

8 Overheat cutout has tripped or a leak Refer to ‘Overheat cutout’ section page 24. If cutout has not

tripped visually check for obstructions in door seal area, clean door

seal and its mating face. Run cycle again.

17 Boiler water level low during cycle Consider reducing load (Note: Error may be due to a particularly

cold load). Check fresh water reservoir level. Run cycle again.

19 Temperature/pressure error Visually check for obstructions in door seal area, clean door seal

and its mating face. Run cycle again.

20 Temperature error Check chamber and load is dry. Run cycle again.

25 Not enough water in fresh water tank Fill fresh water reservoir. Run cycle again.

26 Too much water in waste water tank Empty waste water reservoir. Run cycle again.

29 Air detected in chamber Check door seal for damage and cleanliness in door seal area. Clean

door seal and its mating face. Run cycle again.

30 Pressure fell too much during leak test Leave Autoclave to cool for a few minutes then repeat test.

31 Pressure rose too much during leak test Visually check for obstructions in door seal area, clean door seal and

its mating face. Ensure chamber is dry Run cycle again.

37 Temperature change during leak test Leave Autoclave to cool for a few minutes then repeat test.

47 Temperature/pressure error Visually check for obstructions in door seal area, clean door seal

and its mating face. Run cycle again.

48-95 Various errors during cycle Refer to ‘Overheat cutout’ section page 24. If cutout has not

tripped visually check for obstructions in door seal area, clean door

seal and its mating face. Run cycle again.

102 User setup corrupted All user settings will need to be reset as the autoclave will revert back

to the original factory defaults, refer to Appendix 7 and enter your

user settings (refer to list provided on page 26). Run cycle again.

103 Button locked pressed A button may have stuck momentarily. Run cycle again.

P26/33 ST-IM84c