Page 1

RC170 Option

Teach Pendant

Rev.5 EM079P1591F

TP1

Page 2

RC170 Option Teach Pendant TP1 Rev.5

ii

Page 3

RC170 Option

Teach Pendant

UTP1

Rev.5

Copyright © 2006-2007 SEIKO EPSON CORPORATION. All rights reserved.

TP1 Rev.5 i

Page 4

FOREWORD

Thank you for purchasing our robot products.

This manual contains the information necessary for the correct use of the Teach Pendant.

Please carefully read this manual and other related manuals before installing the robot

system.

Keep this manual handy for easy access at all times.

WARRANTY

The robot system and its optional parts are shipped to our customers only after being

subjected to the strictest quality controls, tests, and inspections to certify its compliance

with our high performance standards.

Product malfunctions resulting from normal handling or operation will be repaired free of

charge during the normal warranty period. (Please ask your Regional Sales Office for

warranty period information.)

However, customers will be charged for repairs in the following cases (even if they occur

during the warranty period):

1. Damage or malfunction caused by improper use which is not described in the manual,

2. Malfunctions caused by customers’ unauthorized disassembly.

3. Damage due to improper adjustments or unauthorized repair attempts.

4. Damage caused by natural disasters such as earthquake, flood, etc.

or careless use.

Warnings, Cautions, Usage:

1. If the robot system associated equipment is used outside of the usage conditions and

product specifications described in the manuals, this warranty is void.

2. If you do not follow the WARNINGS and CAUTIONS in this manual, we cannot be

responsible for any malfunction or accident, even if the result is injury or death.

3. We cannot foresee all possible dangers and consequences. Therefore, this manual

cannot warn the user of all possible hazards.

ii TP1 Rev.5

Page 5

TRADEMARKS

Microsoft, Windows, and Windows logo are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries. Other brand and

product names are trademarks or registered trademarks of the respective holders.

TRADEMARK NOTATION IN THIS MANUAL

Microsoft® Windows® XP Operating system

Microsoft® Windows® Vista Operating system

Throughout this manual, Windows XP, and Windows Vista refer to above respective

operating systems. In some cases, Windows refers generically to Windows XP, and

Windows Vista.

NOTICE

No part of this manual may be copied or reproduced without authorization.

The contents of this manual are subject to change without notice.

Please notify us if you should find any errors in this manual or if you have any comments

regarding its contents.

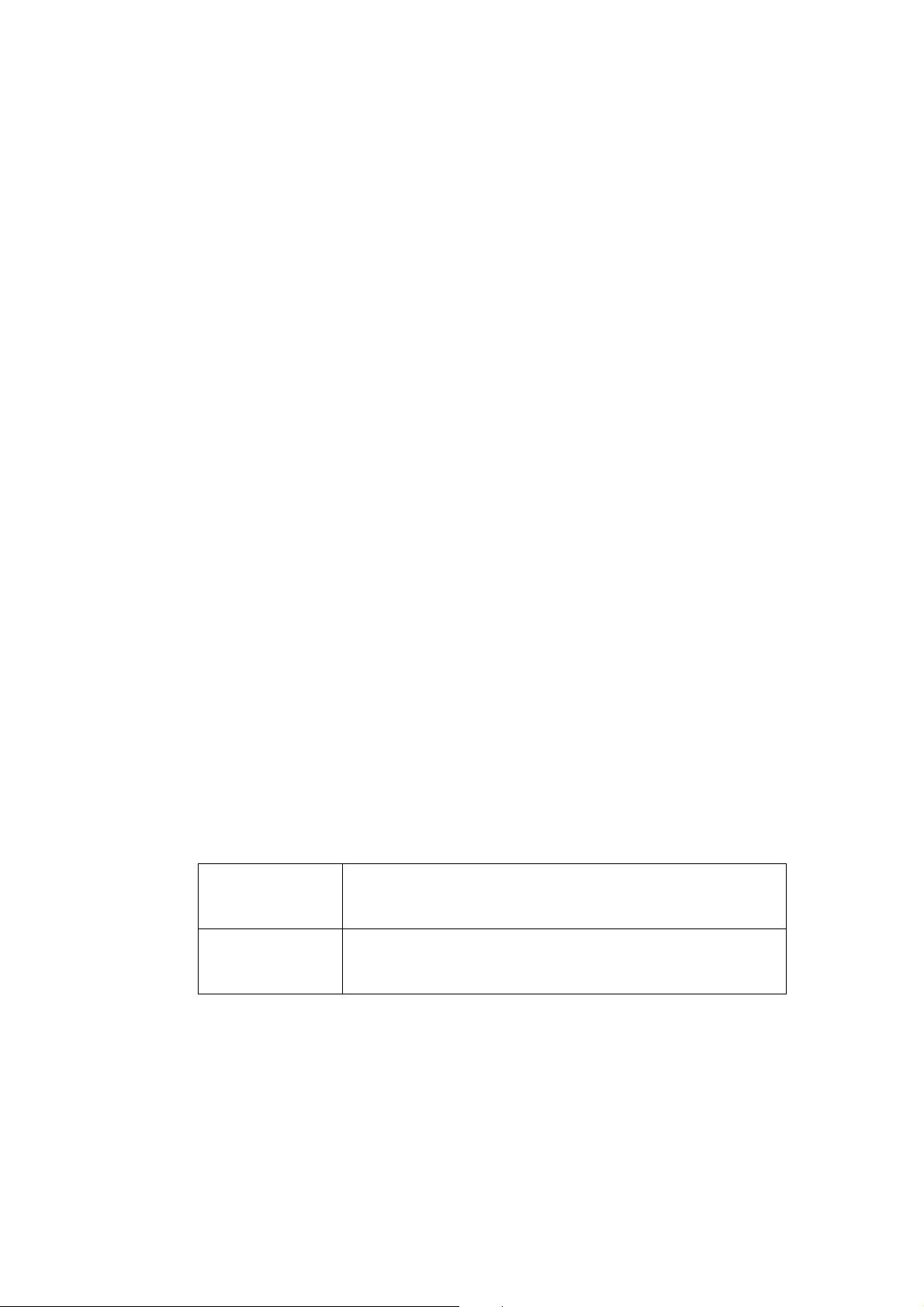

INQUIRIES

Contact the following service center for robot repairs, inspections or adjustments.

If service center information is not indicated below, please contact the supplier office for

your region.

Please prepare the following items before you contact us.

- Your controller model and its serial number

- Your manipulator model and its serial number

- Software and its version in your robot system

- A description of the problem

SERVICE CENTER

TP1 Rev.5 iii

Page 6

MANUFACTURER & SUPPLIER

TEL : +81-(0)266-61-1802

FAX : +81-(0)266-61-1846

Japan & Others

SEIKO EPSON CORPORATION

Suwa Minami Plant

Factory Automation Systems Dept.

1010 Fujimi, Fujimi-machi,

Suwa-gun, Nagano, 399-0295

JAPAN

SUPPLIERS

Factory Automation/Robotics

TEL : +1-562-290-5900

FAX : +1-562-290-5999

E-MAIL : info@robots.epson.com

Factory Automation Division

TEL : +49-(0)-2159-538-1391

FAX : +49-(0)-2159-538-3170

E-MAIL : robot.infos@epson.de

North & South America

Europe

EPSON AMERICA, INC.

18300 Central Avenue

Carson, CA 90746

USA

EPSON DEUTSCHLAND GmbH

Otto-Hahn-Str.4

D-40670 Meerbusch

Germany

Before Reading This Manual

Following descriptions are indicated throughout the manual by these symbols.

NOTE

)

TIP

)

NOTE

Do not connect the TP1 to following Robot Controllers. Connecting to following Robot

)

NOTE

)

iv TP1 Rev.5

Controllers may result in malfunction of the device since the pin assignments are different.

RC420 / RC520 / SRC5** / SRC-3** / SRC-2**

A coordinate point including the arm pose is defined as “position (point),” and the data is

called “point data.”

The “NOTE” sections describe important information to be

followed for operating the Robot system.

The “TIP” sections describe hints for easier or alternative

operations.

Page 7

TABLE OF CONTENTS

Functions & Installation

1 Safety 3

1.1 Conventions.................................................................................................3

1.2 Safety Precautions ......................................................................................3

1.3 EMERGENCY STOP................................................................................... 7

1.4 Mode Selector Key Switch........................................................................... 8

1.5 Using Teach Pendant in Safeguarded Area ................................................8

2 Specifications 9

2.1 Part Names and Functions ..........................................................................9

2.2 Standard Specifications.............................................................................11

2.3 Outer Dimensions......................................................................................11

3 Installation 12

3.1 Contents .................................................................................................... 12

3.2 Environmental Conditions.......................................................................... 12

3.3 Operating Precautions...............................................................................12

3.4 Connection ................................................................................................13

3.4.1 Typical cable connection............................................................... 13

3.4.2 Connection to the Controller .........................................................14

3.4.3 Operator Panel Connection...........................................................14

3.5 Power Supply ............................................................................................15

3.6 Wall Bracket (Option) ................................................................................16

4 Operation Mode (TEACH/AUTO) 18

4.1 Outline .......................................................................................................18

4.2 Switch Operation Mode ............................................................................. 19

5 Operation Panel (Key Description) 20

6 Enable Switch 23

TP1 Rev.5 v

Page 8

Table of Contents

Operation

1 Teaching Procedure 27

2 TEACH Mode 31

1.1 Jog Operation ........................................................................................... 27

1.2 Teaching ................................................................................................... 28

1.3 Direct Teaching......................................................................................... 29

2.1 [Jog & Teach]............................................................................................ 32

2.1.1 Specifying Point No. ..................................................................... 32

2.1.2 Specifying Jog Mode .................................................................... 32

2.1.3 Specifying Jog Speed................................................................... 33

2.1.4 Executing Step Jog ...................................................................... 33

2.1.5 Executing Continuous Jog............................................................ 33

2.1.6 ON/OFF........................................................................................ 33

2.1.7 Motor ON/OFF.............................................................................. 34

2.1.8 Executing Return to Home ........................................................... 34

2.1.9 Teaching....................................................................................... 34

2.1.10 Saving Point Data to File.............................................................. 35

2.1.11 Loading Point Data from File ........................................................ 35

2.2 Editing Points ............................................................................................ 36

2.2.1 Specifying Point No. ..................................................................... 36

2.2.2 Changing Point Label ................................................................... 36

2.2.3 Changing Coordinate Data and Pose Flag ................................... 36

2.2.4 Deleting Point Data ...................................................................... 36

2.3 Changing Jog Distance Data .................................................................... 37

2.3.1 Changing Distance Data............................................................... 37

2.3.2 Return Data to Defaults................................................................ 37

2.4 Arm/Tool/Local/ECP ................................................................................. 38

2.4.1 Changing Arm No......................................................................... 38

2.4.2 Changing Tool No. ....................................................................... 38

2.4.3 Changing Local No....................................................................... 38

2.4.4 Changing ECP No. ....................................................................... 38

2.5 Executing I/O Commands ......................................................................... 39

2.5.1 Switching Input/Output Status Display ......................................... 39

2.5.2 Output Bit ON/OFF....................................................................... 39

2.6 Executing Motion Commands ................................................................... 40

2.6.1 E2 Series / G Series..................................................................... 40

2.6.2 PS Series ..................................................................................... 40

vi TP1 Rev.5

Page 9

Table of Contents

2.7 Calibrating Origin : E2 Series / G Series ...................................................41

2.7.1 Calibration Procedures (E2 Series)...............................................42

2.7.2 Calibration Procedures (G Series) ................................................50

2.7.3 Setting Righty / Lefty (E2 Series / G Series) ................................. 57

2.8 Calibrating Origin : PS Series.................................................................... 60

2.9 Releasing Brake (PS series only) .............................................................. 66

3 AUTO Mode 68

3.1 Program Command Display.......................................................................70

3.2 I/O Monitor................................................................................................. 71

3.3 Memory I/O Monitor...................................................................................71

3.4 Task Monitor.............................................................................................. 72

3.5 System History ..........................................................................................73

3.6 Program Mode...........................................................................................74

3.6.1 Open Programs.............................................................................75

3.6.2 Building Projects ...........................................................................81

3.6.3 Backing up Projects ...................................................................... 82

3.6.4 Restore Projects ...........................................................................83

3.6.5 Import Files ...................................................................................84

3.6.6 Export Files...................................................................................85

3.6.7 Backup System.............................................................................87

3.6.8 Restore System ............................................................................89

3.6.9 Changing Speed Factor ................................................................91

3.6.10 Configuration.................................................................................91

3.6.11 Change Display Language............................................................93

3.6.12 Update System Software .............................................................. 94

3.7 Backup / Restore ....................................................................................... 96

3.8 Save Controller Statuses........................................................................... 97

3.9 Display Date and Time .............................................................................. 97

3.10 Adjust Brightness and Contrast ................................................................. 98

3.11 Error Messages ......................................................................................... 98

4 Password Setup 99

5 Troubleshooting 100

6 Maintenance Parts List and Option 101

TP1 Rev.5 vii

Page 10

Table of Contents

viii TP1 Rev.5

Page 11

Functions & Installation

This section contains information about functions and

installation of the Teach Pendant to be known before

operation and maintenance.

Page 12

Page 13

1. Safety

1.1 Conventions

Important safety considerations are indicated throughout the manual by the following

symbols. Be sure to read the descriptions shown with each symbol.

WARNING

WARNING

CAUTION

Functions & Installation 1. Safety

This symbol indicates that a danger of possible serious injury

or death exists if the associated instructions are not followed

properly.

This symbol indicates that a danger of possible harm to people

caused by electric shock exists if the associated instructions are

not followed properly.

This symbol indicates that a danger of possible harm to people

or physical damage to equipment and facilities exists if the

associated instructions are not followed properly.

1.2 Safety Precautions

For details of Safety, refer to Safety Chapter in the User’s Guide. Please read and

understand the chapter before using the robot system.

Only trained personnel should design and install the robot system. Trained

personnel are defined as those who have taken robot system training and

maintenance training classes held by the manufacturer, dealer, or local

representative company, or those who understand the manuals thoroughly and

have the same knowledge and skill level as those who have completed the

training courses.

Only authorized personnel who have taken the safety training should be allowed

WARNING

to execute teaching or calibration of the robot system.

The safety training is the program for industrial robot operator that follows the

laws and regulations of each nation. The personnel who have taken the safety

training acquire knowledge of industrial robots (operations, teaching, etc.).

The personnel who have completed the robot system-training class held by the

manufacturer, dealer, or locally-incorporated company are allowed to maintain

the robot system.

TP1 Rev.5 3

Page 14

Functions & Installation 1. Safety

Only authorized personnel who have taken the safety training should be allowed

to maintain the robot system.

The safety training is the program for industrial robot operator that follows the

laws and regulations of each nation. The personnel who have taken the safety

training acquire knowledge of industrial robots (operations, teaching, etc.),

knowledge of inspections, and knowledge of related rules/regulations. The

personnel who have completed the robot system-training and

maintenance-training classes held by the manufacturer, dealer, or locally

incorporated company are allowed to maintain the robot system.

Immediately press the EMERGENCY STOP switch whenever you suspect any

danger.

The Teach Pendant is equipped with an EMERGENCY STOP switch. Before

operating the Teach Pendant, make sure that the EMERGENCY STOP switch

on the Teach Pendant functions properly. Operating the Teach Pendant when

the switch does not function properly is extremely hazardous and may result in

serious bodily injury and/or serious damage to the equipment, as the switch

WARNING

cannot fulfill its intended function in an emergency.

When nothing appears on its display window, the Teach Pendant is not

connected with the Controller. In this case, the EMERGENCY STOP switch on

the Teach Pendant will not function.

WARNING

If the Teach Pendant is not connected to the controller, DO NOT place it within

easy reach during operation. You might press the EMERGENCY STOP switch

on the unconnected Teach Pendant by mistake to stop the robot system in an

emergency. Pressing the EMERGENCY STOP switch on the disconnected

Teach Pendant in an emergency is extremely hazardous and may cause

serious safety problems.

When entering the safeguarded area for teaching, change the mode of the

Teach Pendant to TEACH and take out the key for the mode selector key switch

and then enter the safeguarded area with the key. Leaving the key in the

mode selector key switch is extremely hazardous and may cause serious safety

problems as someone else may inadvertently change the mode to the automatic

operation.

Be sure to connect the cables between the Controller and the Teach Pendant

properly. Do not allow unnecessary strain on the cables. (Do not put heavy

objects on the cables. Do not bend or pull the cables forcibly.) The

unnecessary strain on the cables may result in damage to the cables,

disconnection, and/or contact failure. Damaged cables, disconnection, or

contact failure is extremely hazardous and may result in electric shock and/or

improper function of the system. Do not use the cables near heat or fire.

4 TP1 Rev.5

Page 15

CAUTION

Functions & Installation 1. Safety

Do not shock the Teach Pendant physically or place any object on Teach

Pendant. A liquid crystal display is used for the Teach Pendant display. If

the display is damaged, liquid crystal may leak out. Liquid crystal is harmful.

If it sticks on your skin or clothes, immediately wash your skin and clothes

thoroughly with clean water and soap immediately.

The Teach Pendant must be used within the environmental conditions

described in this manual. This product has been designed and manufactured

strictly for use in a normal indoor environment. Using this product in the

environment that exceeds the conditions may not only shorten the life cycle of

the product but also cause serious safety problems.

Do not disassemble, repair, or modify the Teach Pendant by yourself.

Improper disassembly, repair, or modification of the Teach Pendant may cause

not only improper function of the robot system but also serious safety problems.

Safety-related Requirements

Specific tolerances and operating conditions for safety are contained in the manuals for

the robot, controller and other devices. Be sure to read those manuals as well.

Robot systems safety standard and other examples are given in this chapter. Therefore,

to ensure that safety measures are complete, please refer to the other standards listed as

well.

(Note: The following is only a partial list of the necessary safety standards.)

EN 61000-6-2

Electromagnetic compatibility (EMC). Generic standards.

Immunity standard for industrial environments

EN 61000-6-4

Electromagnetic compatibility (EMC). Generic standards.

Emission standard for industrial environments

IEC 61131-2

Programmable controllers - Part 2: Equipment requirements

and tests

EN ISO 12100-1

Safety of machinery - Basic concepts, general principles for

design -- Part 1: Basic terminology, methodology

EN ISO 12100-2

Safety of machinery - Basic concepts, general principles for

design -- Part 2: Technical principles

EN 418

Safety of machinery - Emergency stop equipment, functional

aspects - principles for design

EN 614-1

Safety of machinery - Ergonomic design principles; part 1:

terminology and general principles

EN 894-1

Safety of machinery - Ergonomics requirements for the

design of displays and control actuators; Part 1: General

principles for human interactions with displays and control

actuators

EN 894-2

Safety of machinery - Ergonomics requirements for the

design of displays and control actuators; Part 2: Displays

TP1 Rev.5 5

Page 16

Functions & Installation 1. Safety

EN 894-3

Safety of machinery - Ergonomics requirements for the

design of displays and control actuators - Part 3: Control

actuators

EN 954-1

(ISO 13849-1)

EN 60204-1

UL 508

(=CSA C22.2 No.14)

EN 50178

EN 61131-1 (IEC1131-1)

EN 61131-2 (IEC1131-2)

UL 1740

ANSI/RIA R15.06,

(=CSA-Z434-94)

ISO 11161

EN 12417

EN 14070

Safety of machinery - Safety-related parts of control systems

-- Part 1: General principles for design

Safety of machinery. Electrical equipment of machines.

General requirements

Industrial Control Panels

Electronic equipment for use in power installations

Programmable controllers - Part 1: General information

Programmable controllers; part 2: equipment requirements

and tests

Industrial robots and robotic equipment

American National Standard; Industrial Robots and Robot

Systems - Safety Requirements

Industrial automation systems - Safety of integrated

manufacturing systems - Basic requirements

Machine tools. Safety. Machining centers

Safety of machine tools - Transfer and special-purpose

machines.

6 TP1 Rev.5

Page 17

1.3 EMERGENCY STOP

Immediately press the EMERGENCY STOP switch whenever you suspect any danger.

The Teach Pendant is equipped with an EMERGENCY STOP switch. Before

operating the Teach Pendant, make sure that the EMERGENCY STOP switch on the

Teach Pendant functions properly. Operating the Teach Pendant when the switch

does not function properly is extremely hazardous and may result in serious bodily

WARNING

injury and/or serious damage to the equipment, as the switch cannot fulfill its intended

function in an emergency.

When nothing appears on its display window, the Teach Pendant is not connected with

the Controller. In this case, the EMERGENCY STOP switch on the Teach Pendant

will not function.

When the EMERGENCY STOP switch is pushed, stops the programs execution and halts

the robot excitation. Programs and point data will not be damaged.

When pushed, the EMERGENCY STOP switch mechanically holds that state and

electrically holds the emergency stop state.

Functions & Installation 1. Safety

Reset EMERGENCY STOP

Follow these steps to reset Emergency Stop condition.

(1) Remove the cause of the Emergency Stop and verify that it is safe to operate the robot

again.

(2) Release the EMERGENCY STOP switch. To release the mechanical latch, turn the

EMERGENCY STOP switch to the right.

(3) Turn the Teach Pendant mode selector key switch to “Teach”.

(4) Press the <Reset> key on the operation

E-STOP Lamp

panel to reset the Emergency Stop.

(5) Make sure that the E-STOP lamp on the

operation panel is OFF.

<Reset> Key

TP1 Rev.5 7

Page 18

Functions & Installation 1. Safety

1.4 Mode Selector Key Switch

The mode selector key switch is used to select TEACH or AUTO operation mode. For

safety, if the mode is changed during program execution, all tasks will be stopped.

Mode switching during task execution

AUTO → TEACH

(1) Press the <Stop> button to stop all tasks normally.

(2) Turn the mode selector key switch to “Teach”.

TEACH → AUTO

Turn the mode selector key switch to “Auto” and close the latch release input.

1.5 Using Teach Pendant in Safeguarded Area

When the mode selector switch of the Teach Pendant is switched to “Teach” mode, the

operator can jog and move the robot to predefined points in slow speed when the enable

switch is gripped and the safeguard is open.

Personnel that will be using the Teach Pendant should be thoroughly trained on how to

use it.

Follow these guidelines when using the Teach Pendant in the safeguarded area:

(1) Before entering the safeguarded area to use the Teach Pendant, turn the mode selector

key switch to “Teach”.

(2) Enter the safeguarded area and perform the teaching operations.

(3) Leave the safeguarded area and close the safeguard.

(4) Return the mode selector key switch to “Auto”.

(5) Close the latch release input. (For details on the pin assignments of the

EMERGENCY connector, refer to Setup & Operation 9.3 Pin Assignments in the

RC170 controller manual.)

8 TP1 Rev.5

Page 19

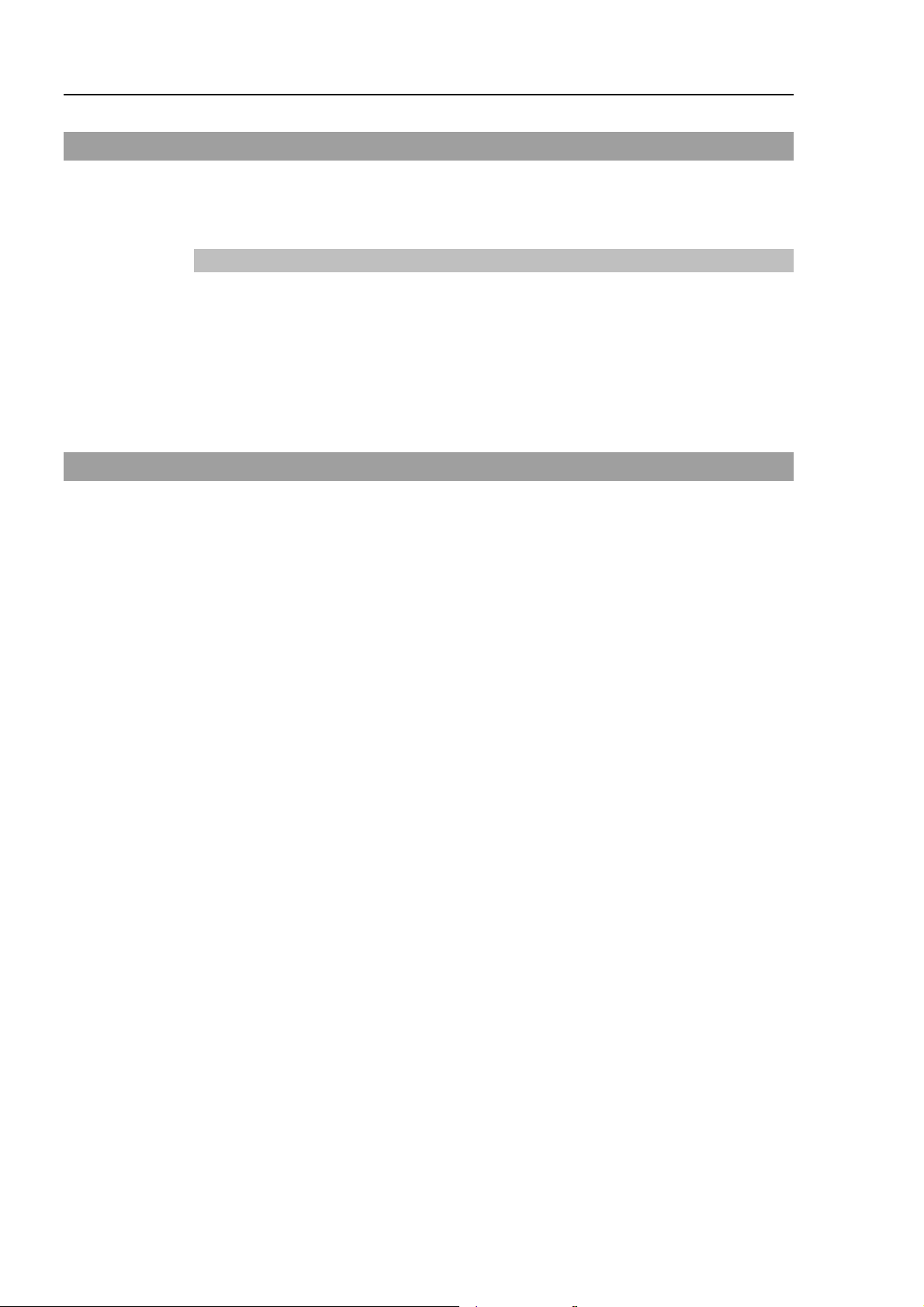

2. Specifications

2.1 Part Names and Functions

Front view

(1)

Functions & Installation 2. Specifications

(2)

(3)

(4)

Back view

(5)

(6)

(7)

TP1 Rev.5 9

Page 20

Functions & Installation 2. Specifications

(1) Mode Selector Key switch

The mode selector key switch is used to change the operation mode between TEACH

and AUTO. The mode can be fixed by pulling out the key. When the mode is

switched while a program is executing, the program will be stopped.

Close the latch when switching the mode from TEACH to AUTO.

For the procedure to switch the mode, refer to Setup & Operation 1.4 Mode Selector

Key Switch.

(2) EMERGENCY STOP switch

When this switch is pushed, the Emergency Stop state is held both mechanically and

electrically. Pushing the switch stops the program, removes power to robot motors and

stops the manipulator motion immediately.

To cancel the Emergency Stop state, first turn the EMERGENCY STOP switch to the

right to release the mechanical latch. Switch the mode selector key switch to “Teach”.

Press the <Reset> key to reset the electrically held Emergency Stop state. The

E-STOP lamp goes OFF.

For the procedure to reset the EMERGENCY STOP switch, refer to Setup & Operation

1.3 EMERGENCY STOP.

(3) Display

Displays various kinds of information.

(4) Operation Panel

Teaching operation, automatic operation and data input are available.

(5) Connection Cable

This is a cable to connect the Teach Pendant and the Controller.

The connector is attached at the end of the cable.

(6) Enable switch

This is a three-position switch. Motion and I/O output commands are available while

the switch is gripped when the Teach Pendant is operated in TEACH mode. The

switch turns ON when it is at the midpoint, and it turns OFF when it is fully gripped or

released.

(7) Handle

Use this part as the hand strap while operating the Teach Pendant.

10 TP1 Rev.5

Page 21

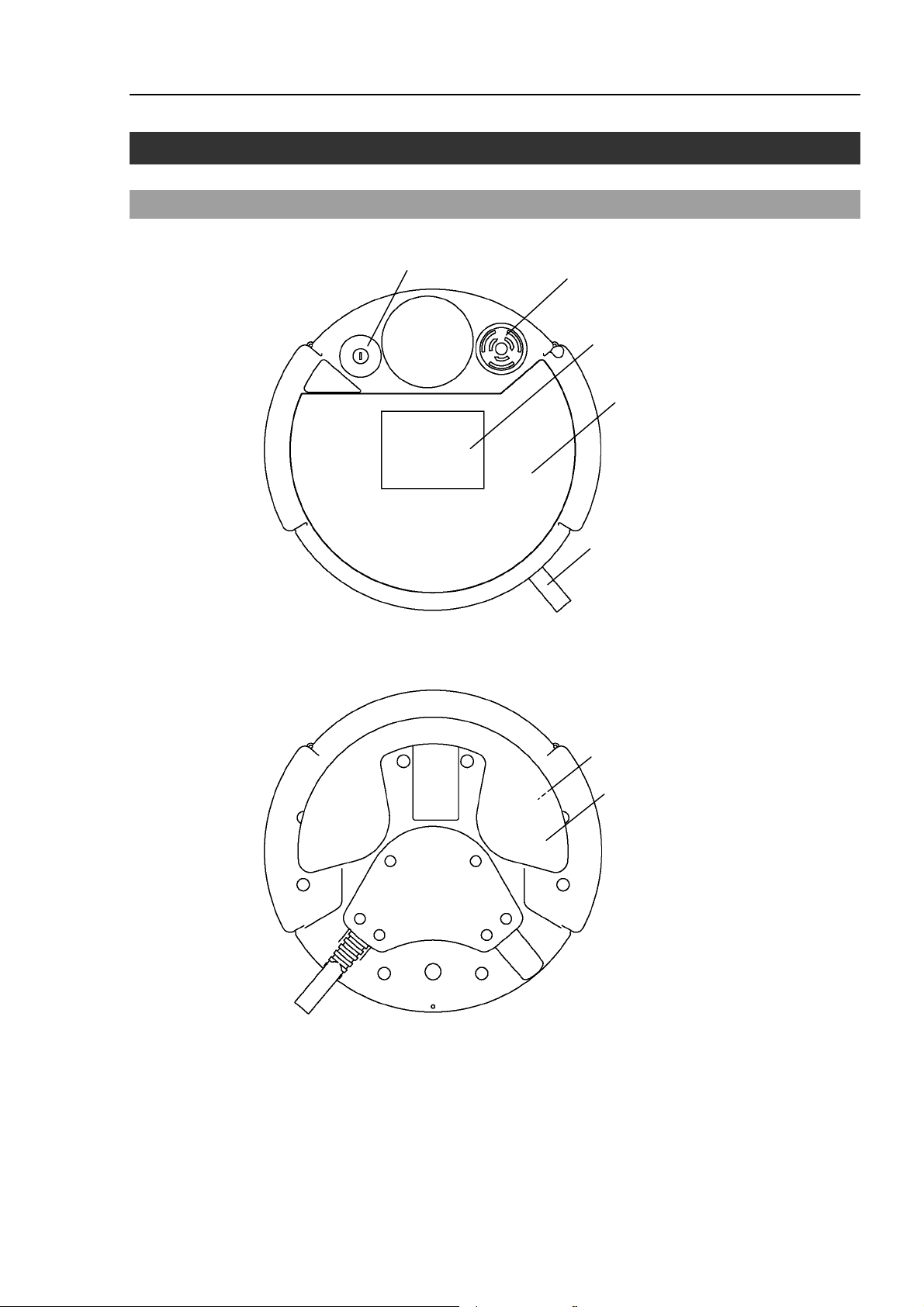

2.2 Standard Specifications

Item Specification

Functions & Installation 2. Specifications

Rated voltage

General

specifications

Display

specifications

Serial interface

specifications

Electric power consumption

Weight

Display element

Contrast

Back light

Electrical characteristics

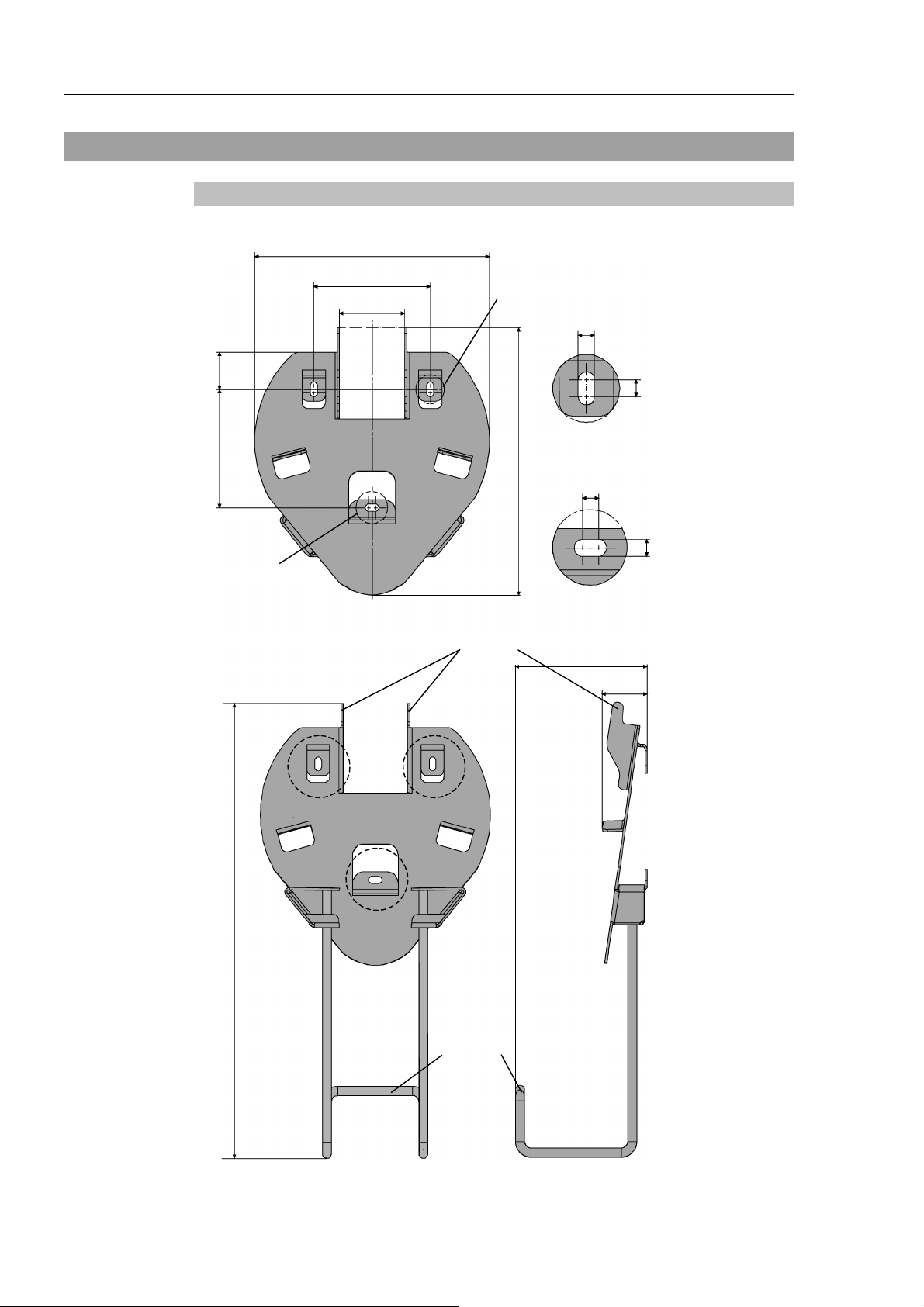

2.3 Outer Dimensions

DC24 V

6 W or less

1075 g

(include EMERGANCY STOP switch and the

mode selector key switch, excluding cables)

F-STN type Black and white LCD

8-level (Gray scale)

LED (Color : White)

Compliant with RS-422A standard

°

8

240

37

NOTE

Use the installation metal in the attachment when attaching the Teach Pendant to a panel,

or the like.

55 22 251.9

(Unit : mm)

TP1 Rev.5 11

Page 22

Functions & Installation 3. Installation

3. Installation

3.1 Contents

TP1 (with cables) : 1 unit

Mode selector key : 2 units

3.2 Environmental Conditions

The Teach Pendant must be used in an environment that conforms to the following

requirements to ensure safe and reliable operation.

Item Condition

Ambient temperature

Ambient relative

temperature

Protection structure

Environment

- Keep away from dust, oily smoke, salinity, metal powder

0 to 50 deg C (with minimal variation)

5 to 95%

IP65 (excluding the connector)

- Keep away from flammable or corrosive solvents and

and other contaminants.

gases.

3.3 Operating Precautions

CAUTION

Do not drop the Teach Pendant or hit hard against other objects to avoid

damage, as the case of the Teach Pendant may be damaged since the main

body is made of resin.

Use the hand strap to prevent dropping the Teach Pendant during operation.

Do not hit the touch panel of the Teach Pendant against a hard object or put

excessive pressure on it. The touch panel is made of glass. Therefore, if

excessive pressure is put on it, it may be damaged.

Do not press or rub the surface of the front panel push buttons with a hard

object such as a tool. The surface of the buttons may be damaged as they are

easily scratched.

Wipe the dirt and oils adhering to the surface of the Teach Pendant display with

a soft cloth dampened with a neutral detergent or an alcohol solvent.

If using the mounting bracket, check that the bracket and screws are not bent or

loosened.

12 TP1 Rev.5

Page 23

A

3.4 Connection

This section indicates the connection of the Controller and the Teach Pendant.

Be sure to connect the cables of Controller and Teach Pendant properly. Do

not allow unnecessary strain on the cables. (Do not put heavy objects on the

cables. Do not bend or pull the cables forcibly.) The unnecessary strain on the

cables may result in damage to the cables, disconnection, and/or contact failure.

Damaged cables, disconnection, or contact failure is extremely hazardous and

may result in improper function of the system.

Make sure that the pins are not bent when connecting the connector.

CAUTION

Connecting the connector with the pin bent may cause malfunction and result in

improper function of the system.

The connector connected to the end of the cable is a general-purpose type

connector. When connecting the connector, note that the waterproof efficiency

and dustproof efficiency of the connector do not comply with IP65.

Functions & Installation 3. Installation

NOTE

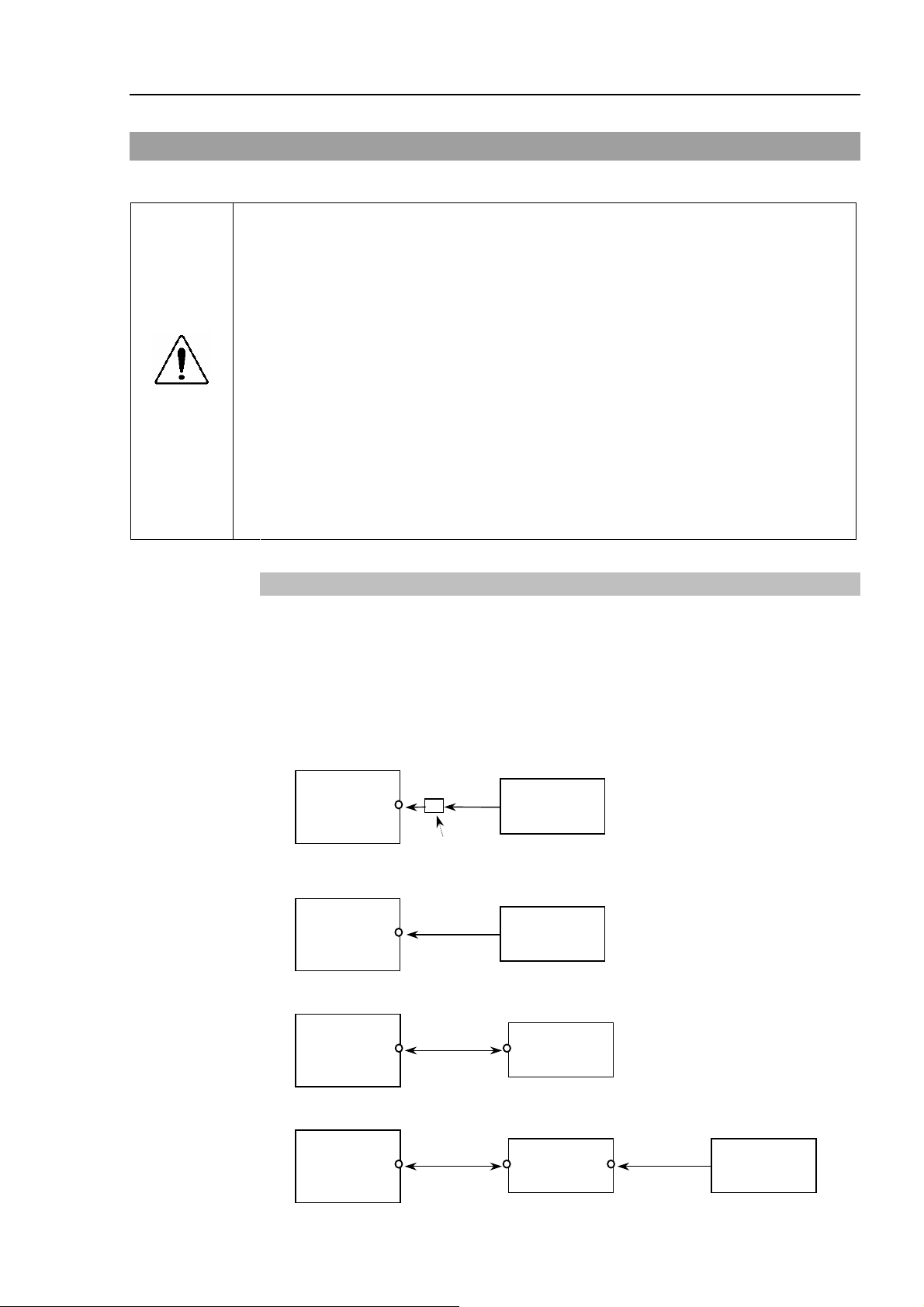

3.4.1 Typical cable connection

The Teach Pendant and the Operator Panel is connected to TP/OP port of controller.

When nothing is connected to the TP/OP port, Emergency Stop status occurs to the

Controller. When the Teach Pendant or the Operator Panel is not connected, connect the

TP/OP bypass plug.

Example

A: Only using Teach Pendant (TP Cable A)

Controller

B: Only using Teach Pendant (TP Cable B)

Controller

C: Only using Operator Panel

TP Cable

A

Conversion Kit CK1

TP Cable

B

Teach

Pendant

Teach

Pendant

Controller

OP Cable

Operator

Panel

D: Using Teach Pendant and Operator Panel

Controller

OP Cable TP Cable

Operator

Panel

Teach

Pendant

TP1 Rev.5 13

Page 24

Functions & Installation 3. Installation

NOTE

The shape of the cable connector used in connection A and D differs to connection B.

NOTE

NOTE

TP Cable A : Circular connector to connect to the Operator Panel.

(Direct connection is available with conversion kit CK1.)

TP Cable B : D-sub connector to connect directly to the Controller.

When Teach Pendant with Operator Panel cable is inserted to the TP port of the

Operator Panel, both Operator Panel and Teach Pendant are available.

(Connection D)

Do not connect TP1 to the following Robot Controllers. Connecting to the

following Robot Controllers may result in malfunction of the device since the pin

assignments are different.

RC420 / RC520 / SRC5** / SRC-3** / SRC-2**

3.4.2 Connection to the Controller

(1) Make sure that the Controller and the Robot is connected properly.

(2) Connect the connector of the Teach Pendant cable to the TP/OP port of Controller.

(3) Turn ON the controller.

NOTE

NOTE

NOTE

Teach Pendant insert and removal from the Controller are available when the

Controller power is ON.

When Teach Pendant connector is removed from the Controller with the mode

selector key switch of Teach Pendant that is in “Teach” position, the operation mode

will remain in TEACH mode. The operation mode cannot be switched to AUTO

mode. Make sure to remove the Teach Pendant after switching the operation mode

to “Auto” mode.

3.4.3 Operator Panel Connection

(1) Make sure that the Controller and the Robot is connected properly.

(2) Connect the connector of the Operator Panel to the TP/OP port of Controller.

(3) Turn ON the Controller.

(4) Connect the connector of Teach Pendant to the Operator Panel.

Teach Pendant insert and removal from the Controller are available when the

Controller power is ON.

Make sure that the Controller is turned OFF when inserting or removing the Operator

Panel.

NOTE

14 TP1 Rev.5

When Teach Pendant connector is removed from the Controller with the mode

selector key switch of Teach Pendant that is in “Teach” position, the operation mode

will remain in TEACH mode. The operation mode cannot be switched to AUTO

mode. Make sure to remove the Teach Pendant after switching the operation mode

to “Auto” mode.

Page 25

3.5 Power Supply

The power of the Teach Pendant is supplied via the TP/OP connector on the Controller.

After the completing the Controller and the Teach Pendant communication, the following

screen will appear on the display of the Teach Pendant.

TEACH mode

AUTO mode

Functions & Installation 3. Installation

TP1 Rev.5 15

Page 26

Functions & Installation 3. Installation

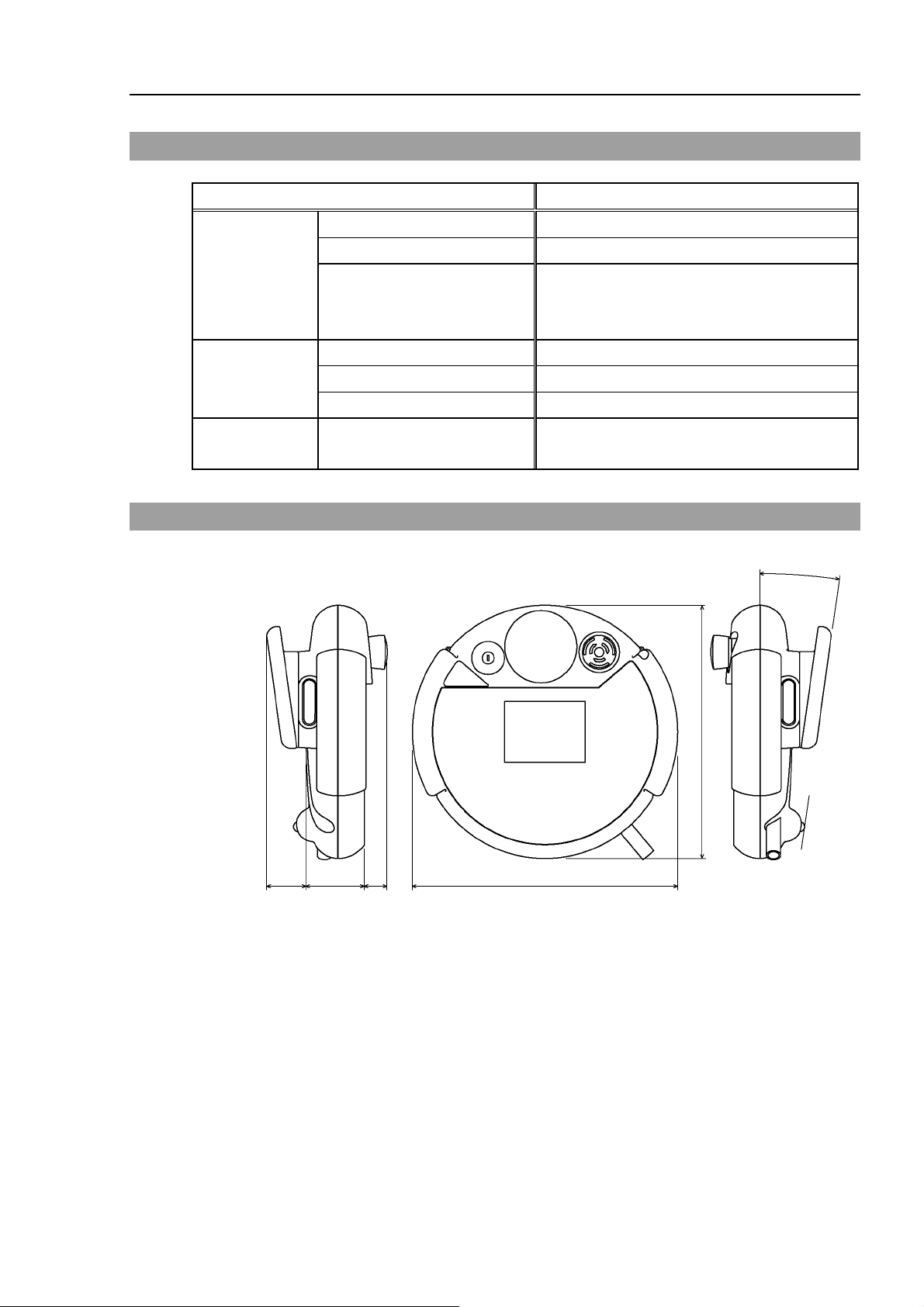

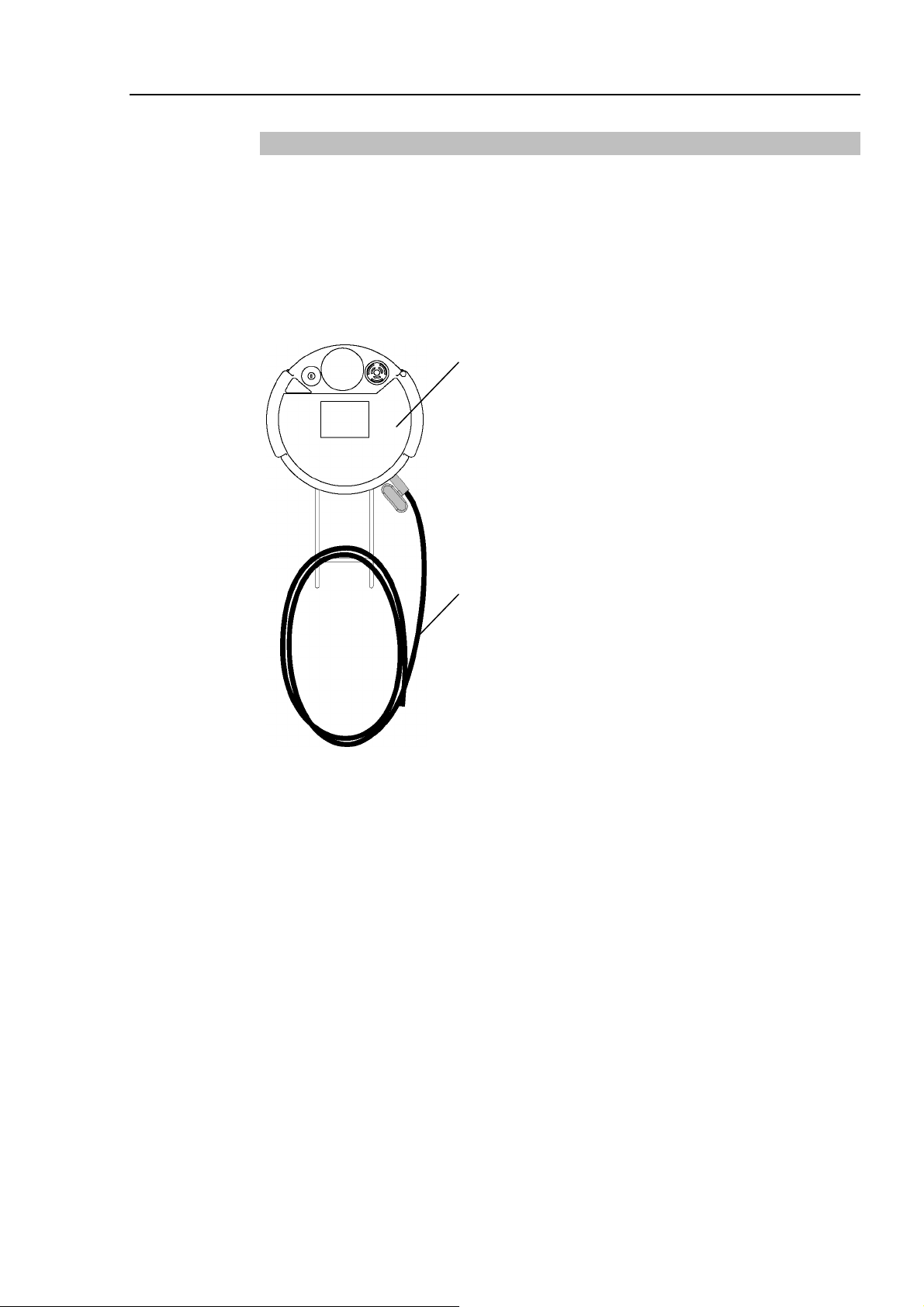

3.6 Wall Bracket (Option)

Outer Dimension

31.4

100

[Unit :mm]

201.4

100

56.2

J

6

6

Detail : J

226

6

6

K

Front View

Hook A

Detail : K

118

392.9

39.6

Hook B

Back View Side View

16 TP1 Rev.5

Page 27

Functions & Installation 3. Installation

Mount and Use

Mount the Teach Pendant with the wall bracket in the following procedures.

(1) Secure the wall bracket to the wall with three screws (positions are indicated by

dotted line in the Outer Dimension).

(2) Hang the handle of the Teach Pendant to Hook A.

(3) Hang the cable of the Teach Pendant to Hook B.

Teach Pendant

Cable

TP1 Rev.5 17

Page 28

Functions & Installation 4. Operation Mode (TEACH/AUTO)

4. Operation Mode (TEACH/AUTO)

NOTE

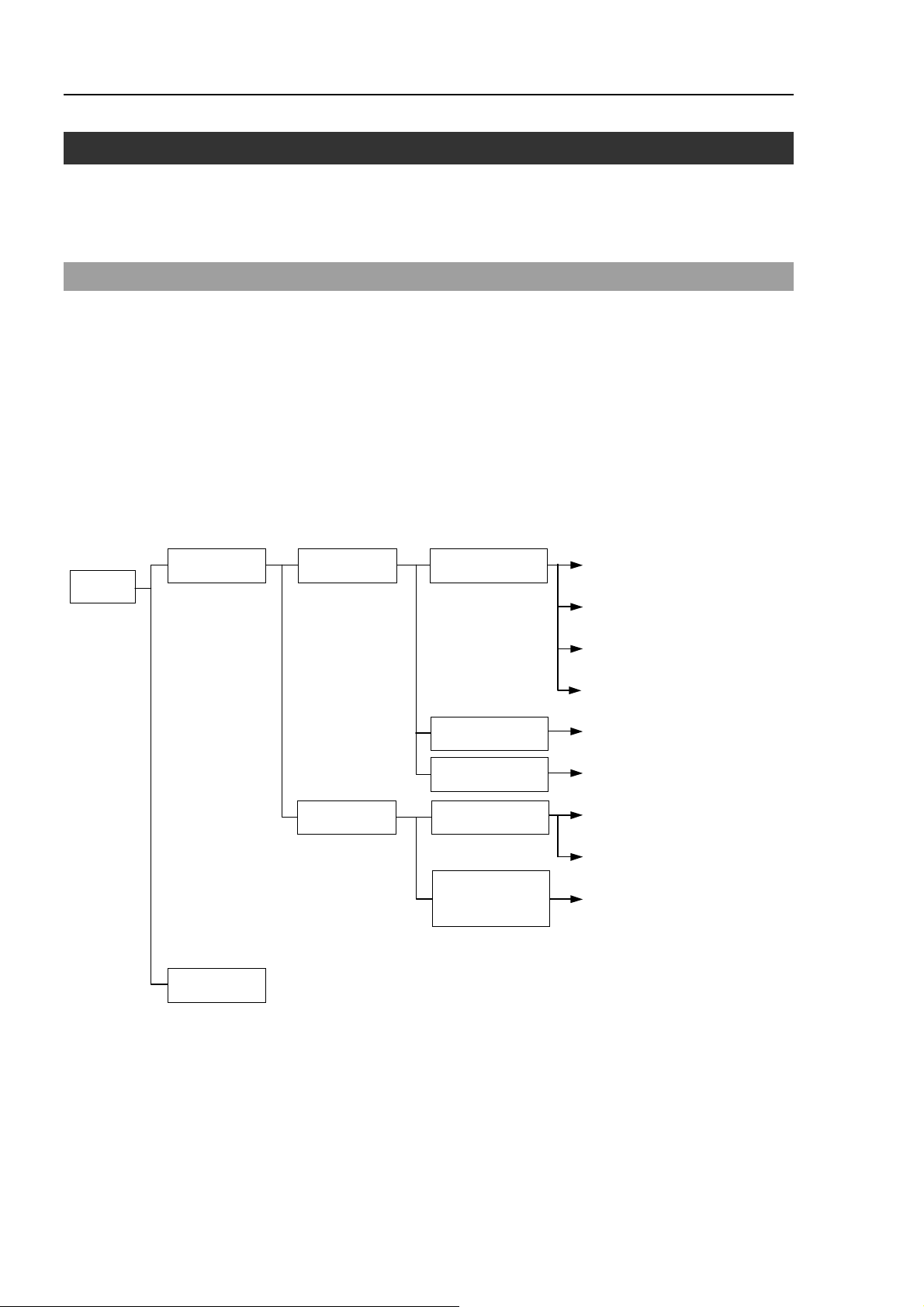

4.1 Outline

RC170

TEACH mode Teaching Jog & Teach

A coordinate point including the arm pose is defined as “position (point),” and the data is

called “point data.”

Robot system has two operation modes TEACH mode and AUTO mode.

TEACH mode

This mode enables point data teaching and check close from the

Robot using the Teach Pendant.

Robot operates in Low power status.

AUTO mode

This mode enables automatic operation (program execution) of the

Robot system at the manufacture operation, besides, programming,

debug, adjustment, and maintenance of the Robot system.

This mode cannot operate Robots or run program with the Safety

Door open.

2.1 Jog & Teach

2.3 Changing

the Jog Distance data

2.4 Arm / Tool / Local / ECP

AUTO mode

Maintenance

Point Editor

Motion Command

Calibration

Brake Release

(Six-axis)

2.5 Executing I/O Commands

2.2 Editing Points

2.6 Executing Motion Commands

2.7 Calibration

(E2 series / G series)

2.8 Calibration

(PS series)

2.9 Releasing the Brake

(PS3 only)

18 TP1 Rev.5

Page 29

Functions & Installation 4. Operation Mode (TEACH/AUTO)

4.2 Switch Operation Mode

Change the TEACH mode and AUTO mode with the mode selector key switch on the

Teach Pendant.

TEACH mode

AUTO mode

Turn the mode selector key switch to “Teach” for TEACH mode.

Pauses the executing program when operation mode is switched to

TEACH mode.

The operating Robot stops by Quick Pause.

Turn the mode selector key switch to “Auto” and change the latch

release input signal to ON position for AUTO mode.

TP1 Rev.5 19

Page 30

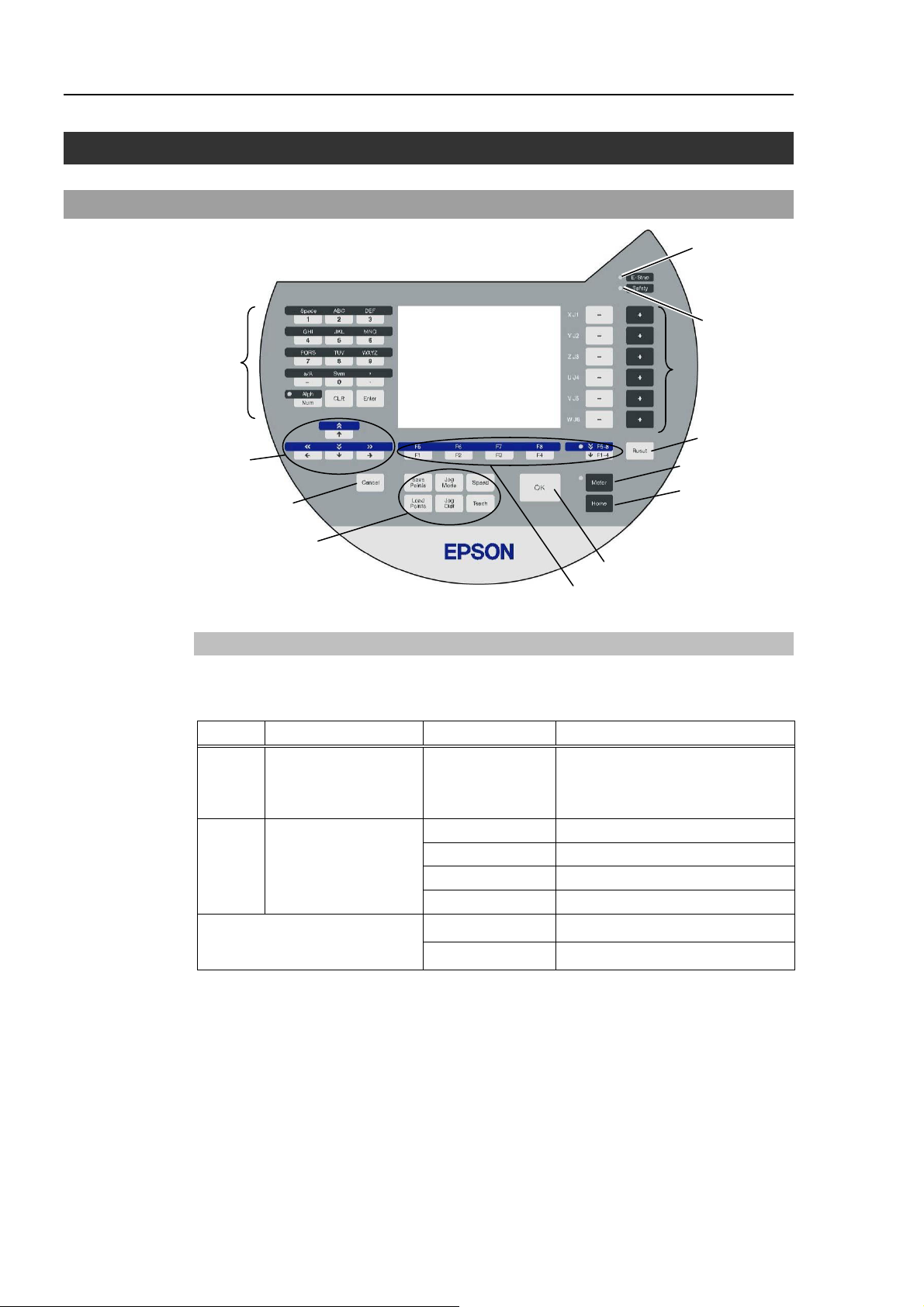

Functions & Installation 5. Operation Panel (Key Description)

5. Operation Panel (Key Description)

Key Description

Alphabet and Number

Input keys

Arrow keys

Cancel key

Teaching keys

Alphabet and Number Input Keys

Input mode alphabet/number switches by turning ON/OFF the “Alph” lamp.

Press the <Alph/Num> key to turn ON/OFF the “Alph” lamp.

OK key

Function keys

E-STOP lamp

Safety lamp

Jog keys

Reset key

Motor key

Home key

Alph Mode Key Function

OFF Number input mode

From 0 to 9

- (minus)

Number input

.(period)

ABC to WXYZ Alphabet input

ON Alphabet input mode

SP (space) Space input

a/A Case selector

Sym Symbol input

CLR Clear number and alphabet

Common

Enter Set number and alphabet

20 TP1 Rev.5

Page 31

Functions & Installation 5. Operation Panel (Key Description)

Arrow Keys

Mode switches by turning ON/OFF the “F5-8” lamp.

Press the <F1-4 / F5-8> key to turn ON/OFF the “F5-8” lamp.

F5-8 Mode Key Function

+1 the value

↑

Move the cursor up

OFF Normal mode

ON Scroll mode

−1 the value

↓

Move the cursor down

Move the cursor to the left

←

Move the cursor to the right

→

<<

+10 the value

Move to previous page

>>

−10 the value

Move to next page

<< High speed cursor motion to the left

>> High speed cursor motion to the right

NOTE

Function Keys

Press the <F5-8> key to turn ON/OFF the “F5-8” lamp. The display changes.

Example : Jog&Teach Screen

<F1> <F2> <F3> <F4>

<F5> <F6> <F7> <F8>

Example : Press the <F3> key to display the Motion screen.

When a function key is not assigned to a screen, the key is invalid. Example : <F7>

“F5-8” OFF

“F5-8” ON

TP1 Rev.5 21

Page 32

Functions & Installation 5. Operation Panel (Key Description)

Jog Keys

Jog key is available only in TEACH mode.

Key Function

−

Move the target joint (X to W, J1 to J6) to − direction

+ Move the target joint (X to W, J1 to J6) to + direction

Teaching Keys

Teaching key is available only in TEACH mode.

Key Function

Save Points Save the point data to a file

Load Points Read the point data from a file

Jog Mode Specify the Jog mode

Jog Dist Specify the Jog distance

Speed Specify the Jog speed

Teach Save the current position data

Other keys

Key Function

Cancel Cancel the setting and go back to the previous screen

OK Save the setting and move on to the next screen

Reset Set the initial setup status

Motor* Switch the motor power ON/OFF

Home* Move the robot to home position

* Keys with this mark are available only in TEACH mode.

Lamp

Lamp Function

E-Stop Turns ON when the EMERGENCY STOP switch is pressed

Safety Turns ON when the safeguard is open

22 TP1 Rev.5

Page 33

6. Enable Switch

In TEACH mode, several operations require use of the 3-position enable switch located on

the left rear of the pendant. The enable switch can be operated either hand.

When the enable switch is required to execute an operation, you must grip the switch to

the center (enable) position. To do this, pull the switch with the left hand fingers until it

just stops at the center detent. If you pull harder, or let go, then the switch will be

disengaged and the operation will be canceled.

Enable Switch (for Left Hand)

Functions & Installation 6. Enable Switch

Enable Switch (for Right Hand)

Back view Left side viewRight side view

How to press the Enable switch

Grip the enable switch by the finger on the hand holding the handler.

Example

: When gripping by the left hand

Handle

TP1 Rev.5 23

Page 34

Functions & Installation 6. Enable Switch

24 TP1 Rev.5

Page 35

Operation

This section contains information about operation of the

Teach Pendant and maintenance procedure.

27

Page 36

Page 37

1. Teaching Procedure

The basic jog operation and teaching procedure is indicated.

Switch the mode selector switch to “Teach” to display the following screen.

NOTE

)

A coordinate point including the arm pose is defined as “position (point),” and the data is

called “point data.”

Operation 1. Teaching Procedure

1.1 Jog Operation

Move the Robot to the teaching position by one of the following operation (Step Jog

operation, Continuous Jog operation).

Step Jog Operation

In Step Jog, moves the Robot by pressing the Jog key each time.

Jog distance of the Robot is configured before hand.

Press the <Jog Dist> key to specify the [Jog Dist] (Long, Medium, Short).

Execute the step jog by gripping the enable switch as pressing the Jog key.

Continuous Jog Operation

In Continuous Jog, moves the Robot while pressing the Jog key.

Press the <Jog Dist> key to select “Cont Jog” for the [Jog Dist].

Execute the continuous jog by gripping the enable switch as pressing the Jog key.

TP1 Rev.5 27

Page 38

Operation 1. Teaching Procedure

1.2 Teaching

Apply the Robot position to the specified point number.

(1) Specify the point number by changing the value in the [Point] using the <↑> and

<↓> keys.

[Label] display changes by changing the point number.

(2) Press the <Teach> key.

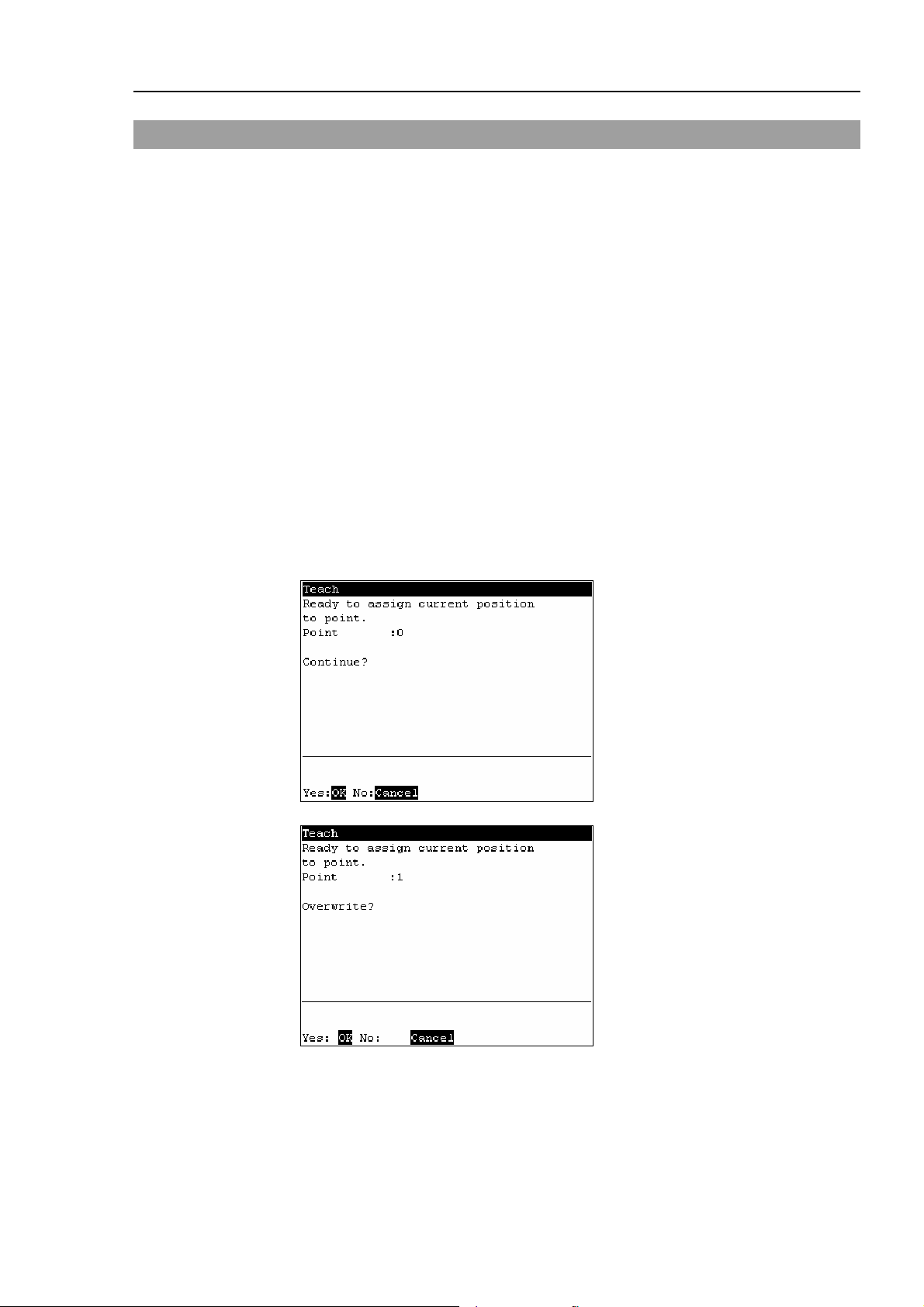

(3) The following screen appears.

When the point number is already used, the following screen appears.

(4) Press the <OK> key to assign the robot position.

(5) Press the <Save Points> key to display the following screen.

Enter the file name and press the <Enter> key.

(6) Press the <OK> key to save the file.

28 TP1 Rev.5

Page 39

1.3 Direct Teaching

“Direct teach” is a way to teach the Robot directly by setting the teaching joint to

servo-OFF.

Apply the Robot position to the specified point number.

(1) Specify the point number by changing the value in the [Point] using the <↑> and

<↓> keys.

[Label] display changes by changing the point number.

(2) Press the <Jog Dist> key to select “Free Joint” for the [Jog Dist].

Set each joint to servo ON or OFF.

<+> key : Lock : Servo OFF the joint

<−> key : Free : Servo ON the joint

<F2> key : All Lock : Servo OFF all the joint

<F3> key : All Free : Servo ON all the joint

(3) Servo OFF joint can be moved with hands.

Move the Robot arm to the position to teach.

Operation 1. Teaching Procedure

(4) Press the <Teach> key.

(5) The following screen appears.

When the point number is already used, the following screen appears.

(6) Press the <OK> key to assign the robot position.

TP1 Rev.5 29

Page 40

Operation 1. Teaching Procedure

(7) Press the <Save Points> key to display the following screen.

Enter the file name and press the <Enter> key.

(8) Press the <OK> key to save the file.

30 TP1 Rev.5

Page 41

2. TEACH Mode

Switch the mode selector key switch to “Teach” to enter the TEACH mode. In this mode,

jog, teaching, operation commands, I/O commands, and other operations and commands

can be executed using the Teach Pendant.

Note, however, that the program cluster cannot be executed.

Jog&Teach

F1

F2

F5

2.1 Jog & Teach

F6

Point Editor

Edit Distance

Arm/Tool/Local/ECP

Operation 2. TEACH Mode

2.2 Editing Points

2.3 Changing the Jog Distance Data

2.4 Arm / Tool / Local / ECP

F4

F3

F8

NOTE

)

I/O Command

Motion Command

Maintenance

A coordinate point including the arm pose is defined as “position (point),” and the data is

Calibration

Brake

2.5 Executing I/O Commands

2.6 Executing Move Commands

2.7 Calibrating (E2 series / G series)

2.8 Calibrating (PS series)

2.9 Releasing the Brake (PS3 only)

Jog&Teach F1………………

…………………….......

…………………….......

Screen nam e

Function key

Reference page

Teaching

Maintenance

called “point data.”

TP1 Rev.5 31

Page 42

Operation 2. TEACH Mode

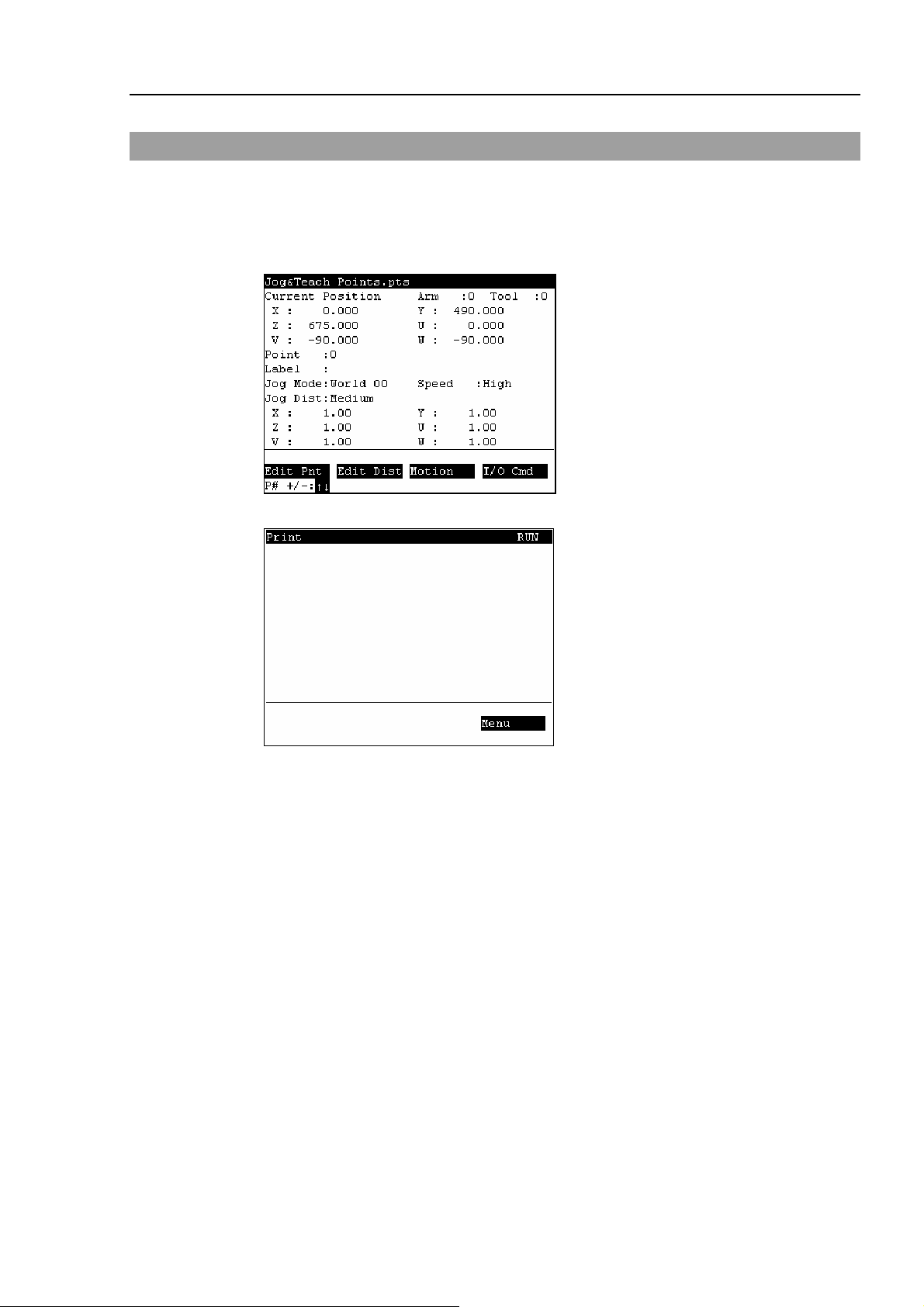

2.1 [Jog & Teach]

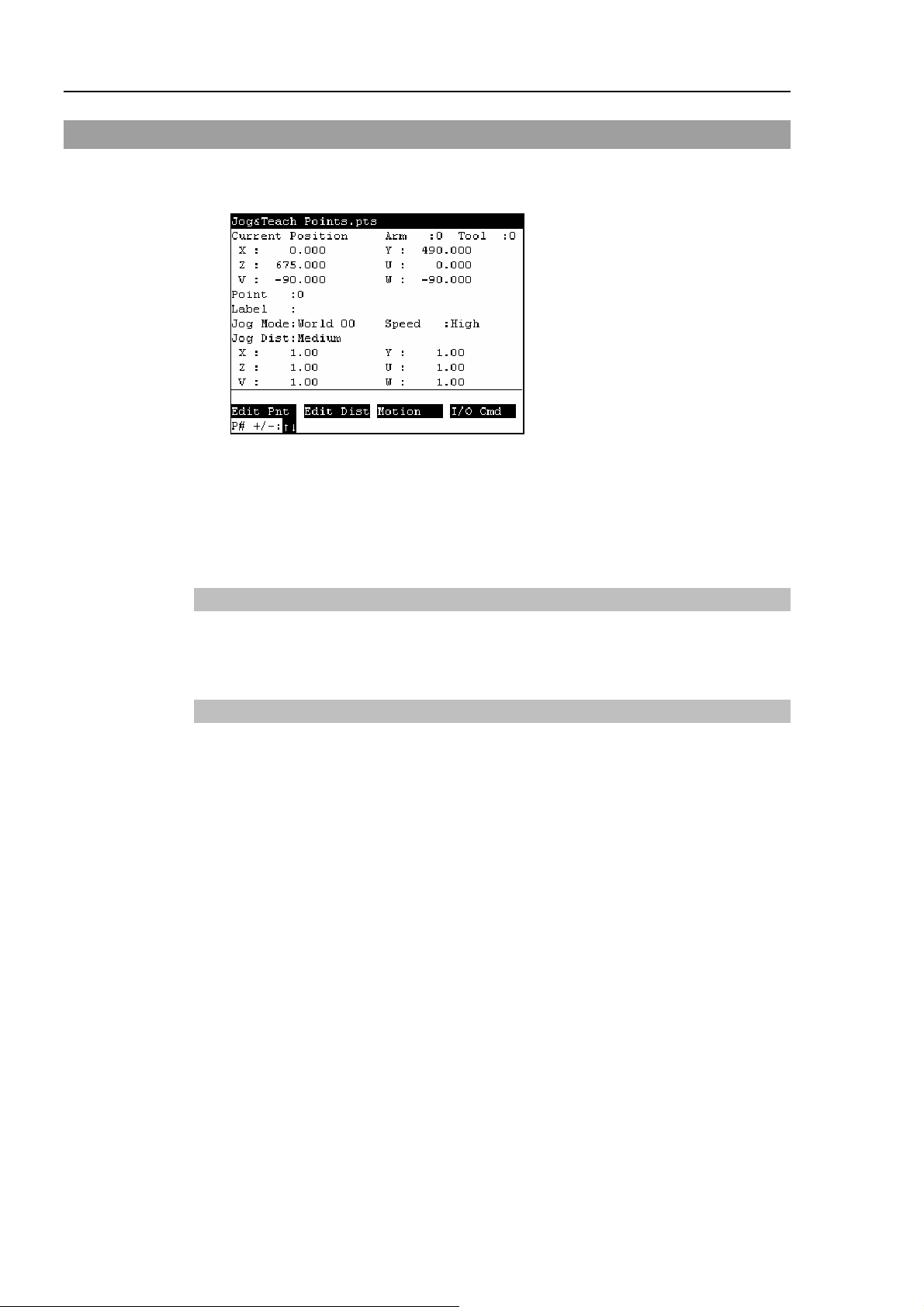

This section indicates settings in the [Jog&Teach] screen.

(1) Switch the mode selector key switch to “Teach” to display the following screen.

(2) Set the data items currently displayed in the [Jog&Teach] screen.

(See 2.1.1 to 2.1.6.)

(3) Note down the robot position. (See 2.1.9.)

(4) Back up the point data to a file. (See 2.1.10.)

2.1.1 Specifying Point No.

Change the value at [Point] using the <↑> and <↓> keys to specify a point No.

Changing the point No. changes the indication at [Label].

2.1.2 Specifying Jog Mode

Press the <Jog Mode> key and specify the [Jog Mode]. (World, Tool, Joint, ECP)

The default setting is “World”.

World : Jogs the robot along the X, Y, Z axes in the current local, tool, arm, and ECP.

For robots with 4 DOF, you can also jog U (roll).

For robots with 6 DOF, you can jog U (roll), V (pitch), and W (yaw). This is

the default setting.

Tool : Jogs the robot in the coordinate system defined by the current tool.

Joint : Jogs each joint of the robot.

A separate set of jog buttons will appear when using joint mode when using

non-Cartesian robots.

ECP : Jogs the robot along the axes of the coordinate system defined by the current

external control point. Coordinates are World coordinates.

32 TP1 Rev.5

Page 43

Operation 2. TEACH Mode

2.1.3 Specifying Jog Speed

Press the <Speed> key and select the speed at [Speed]. (Low, High)

: Low jog speed

Low

: High jog speed

High

2.1.4 Executing Step Jog

By step jog operation, the robot moves when the Jog key is pressed.

Set the distance that the robot moves beforehand.

(1) Press the <Jog Dist> key and select the distance at [Jog Dist].

: Long jog distance

Long

Medium

Short

: Medium jog distance

: Short jog distance

(2) To execute step jog, grip the Jog key with the enable switch held down.

2.1.5 Executing Continuous Jog

With continuous jog, the robot moves continuously while the Jog key is held down.

(1) Press the <Jog Dist> key and select “Cont Jog” at [Jog Dist].

(2) To execute continuous jog, grip the enable switch while pressing the Jog key.

2.1.6 ON/OFF

Specify On/Off for each joint.

When performing direct teaching (manually moving the robot by hand to perform

teaching), set the joint to Off.

Press the <Jog Dist> key and select “Free Joint” at [Jog Dist].

Set On/Off for each joint.

<+> key :

<−> key :

<F2> key :

<F3> key :

Lock : Sets the joint to Off.

Free : Sets the joint to On.

All Lock : Sets all joints to Off.

All Free : Sets all joints to On.

TP1 Rev.5 33

Page 44

Operation 2. TEACH Mode

2.1.7 Motor ON/OFF

Press the <Motor> key to switch the motor ON and OFF.

TIP

This can be executed at any time in TEACH mode.

)

2.1.8 Executing Return to Home

Press the <Home> key to return the robot to its home position.

TIP

This can be executed at any time in TEACH mode.

)

2.1.9 Teaching

The robot position is assigned to the specified point No.

(1) Press the <Teach> key.

(2) The following screen appears.

TIP

)

When the point number is already used, the following screen appears.

(3) Press the <OK> key to assign the point data.

(4) Press the <Save Points> key.

This can also be executed in the [Point Editor] screen.

34 TP1 Rev.5

Page 45

Operation 2. TEACH Mode

2.1.10 Saving Point Data to File

(1) Press the <Save Points> key.

(2) The following screen appears. Enter the file name, and press the <Enter> key.

(3) Press the <OK> key to save the positions to the file.

TIP

)

TIP

)

This can also be executed in the [Point Editor] screen.

2.1.11 Loading Point Data from File

(1) Press the <LoadPoints> key.

(2) The following screen appears. Move the cursor to select a file.

(3) Press the <OK> key to load the point data in the file memory.

This can also be executed in the [Point Editor] screen.

TP1 Rev.5 35

Page 46

Operation 2. TEACH Mode

2.2 Editing Points

This section indicates settings in the [Point Editor] screen.

(1) Press the <F1> key in the [Jog&Teach] screen. The following screen appears.

(2) Set the data items currently displayed in the [Point Editor] screen. (See 2.2.1 to

2.2.4.)

(3) Note down the robot position. (See 2.1.9.)

(4) Back up the point data to a file. (See 2.1.10.)

2.2.1 Specifying Point No.

(1) Specify the point number by changing the value in the [Point] using the <↑> and

<↓> keys.

Chang the point No. to change the indication at [Label].

(2) Press the <Enter> key.

(3) Press the <OK> key to apply the memory.

2.2.2 Changing Point Label

(1) Press the <F1> key and move the cursor to [Label].

(2) Enter the label name at [Label] to set the name.

(3) Press the <Enter> key.

(4) Press the <OK> key to apply the memory.

2.2.3 Changing Coordinate Data and Pose Flag

(1) Press the <F2> key and move the cursor to [Position: X].

(2) Move the cursor to each joint, and set the coordinate data/pose flag.

(3) Press the <Enter> key.

(4) Press the <OK> key to apply the memory.

2.2.4 Deleting Point Data

Press the <F3> key to delete the point data.

36 TP1 Rev.5

Page 47

2.3 Changing Jog Distance Data

This section indicates settings in the [Jog Distance] screen.

Press the <F2> key in the [Jog&Teach] screen.

The following screen appears.

When a value has been changed, press the <Enter> key to apply the value, and be sure to

press the <OK> key to save the settings.

Operation 2. TEACH Mode

2.3.1 Changing Distance Data

Set the distance for each joint.

(1) Move the cursor to [Distance], press the <Jog Dist> key to select the distance (Long,

Medium, Short) that is to be changed.

(2) Move the cursor to each joint, and set the value.

2.3.2 Return Data to Defaults

Press the <F1> key to return jog distance data to their defaults.

TP1 Rev.5 37

Page 48

Operation 2. TEACH Mode

2.4 Arm/Tool/Local/ECP

This section indicates settings in the [Arm/Tool/Local/ECP] screen.

Press the <F5> or <F6> key in the [Jog&Teach] screen.

The following screen appears.

When a value has been changed, press the <Enter> key to apply the value, and be sure to

press the <OK> key to save the settings.

2.4.1 Changing Arm No.

(1) Press the <F1> key and move the cursor to [Arm].

(2) Set the arm number.

2.4.2 Changing Tool No.

(1) Press the <F2> key and move the cursor to [Tool].

(2) Set the tool number.

2.4.3 Changing Local No.

(1) Press the <F3> key and move the cursor to [Local].

(2) Set the local number.

2.4.4 Changing ECP No.

(1) Press the <F4> key and move the cursor to [ECP].

(2) Set the ECP No.

38 TP1 Rev.5

Page 49

2.5 Executing I/O Commands

This section indicates settings in the [I/O Command] screen.

Press the <F4> key in the [Jog&Teach] screen.

The following screen appears.

2.5.1 Switching Input/Output Status Display

Operation 2. TEACH Mode

Press the <F3> key to switch between the “Inputs” status and the “Outputs” status

display.

2.5.2 Output Bit ON/OFF

(1) Press the <F3> key to display the “Outputs” status.

(2) Move the cursor to the output bit that you want to change.

(3) Switch the ON/OFF status of the output bit.

<F1> key:

<F2> key:

On

Off

TP1 Rev.5 39

Page 50

Operation 2. TEACH Mode

2.6 Executing Motion Commands

2.6.1 E2 Series / G Series

This item indicates the procedure for executing motion commands when using E2 series /

G series robots.

(1) Press the <F3> key in the [Jog&Teach] screen.

The following screen appears.

Move the cursor to the desired motion command, and press the <OK> key.

(2) The motion command screen appears.

Set the information required for the command, and press the <Enter> key to apply

the settings.

(3) Press the <OK> key to execute the command.

2.6.2 PS Series

This item indicates the procedure for executing motion commands when using PS series

robots.

(1) Press the <F3> key in the [Jog&Teach] screen. The following screen appears.

Move the cursor to the desired motion command, and press the <OK> key.

(2) The motion command screen appears.

Set the information required for the command, and press the <Enter> key to apply

the settings.

(3) Press the <OK> key to execute the command.

40 TP1 Rev.5

Page 51

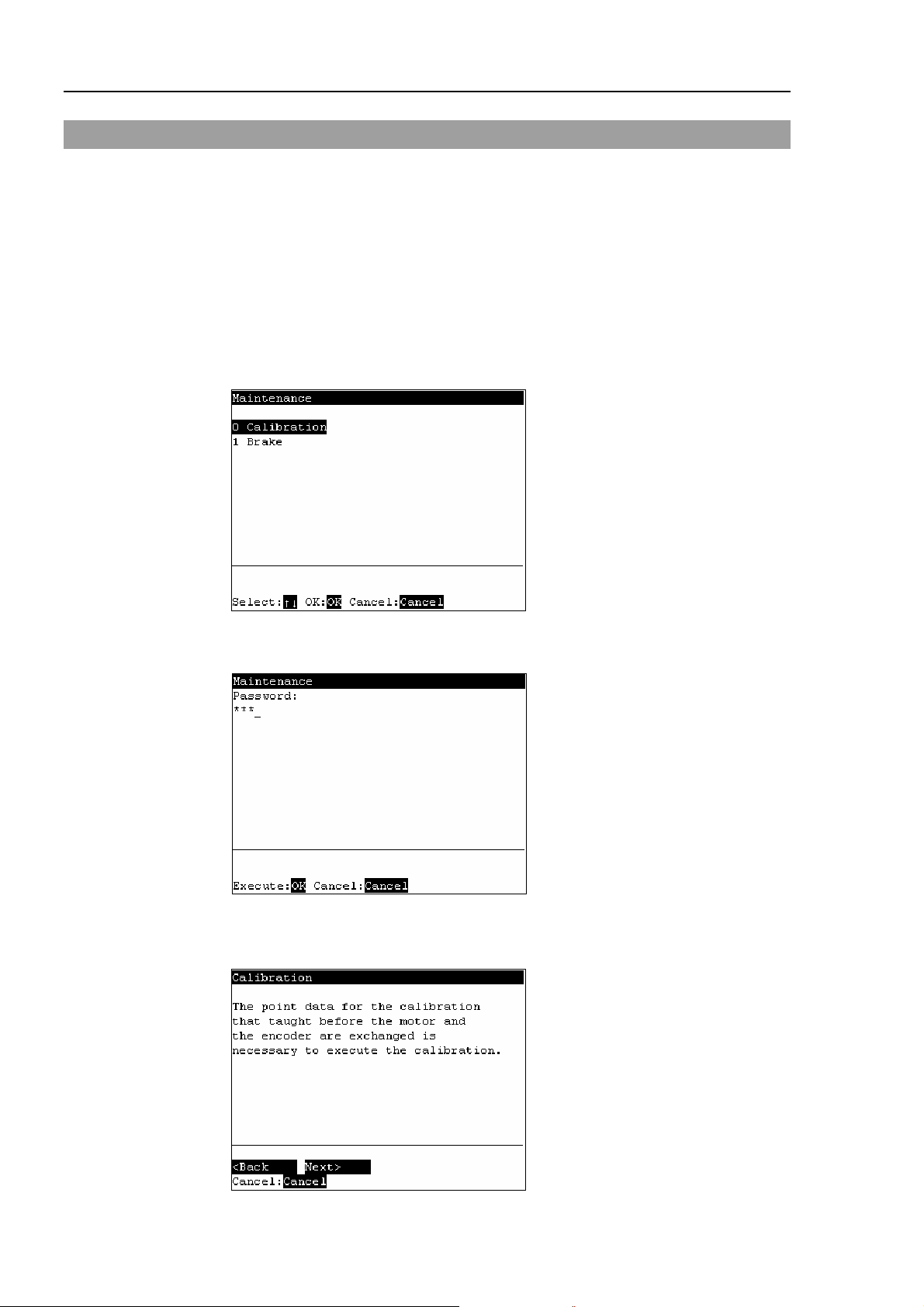

2.7 Calibrating Origin : E2 Series / G Series

This item indicates the procedure to calibrate the origin when using E2 series / G series

robots.

Follow the procedure below to display the [Calibration] screen.

(1) Press the <F8> key in the [Jog&Teach] screen

(2) The following screen appears.

Move the cursor to “0 calibration” and press the <OK> key.

NOTE

)

The following screen appears when the password is set up.

Enter the password (1 to 16 characters) and press the <OK> key.

Operation 2. TEACH Mode

For password setting, refer to Operation 4. Password Setup.

(3) The following calibration menu screen appears.

TP1 Rev.5 41

Page 52

Operation 2. TEACH Mode

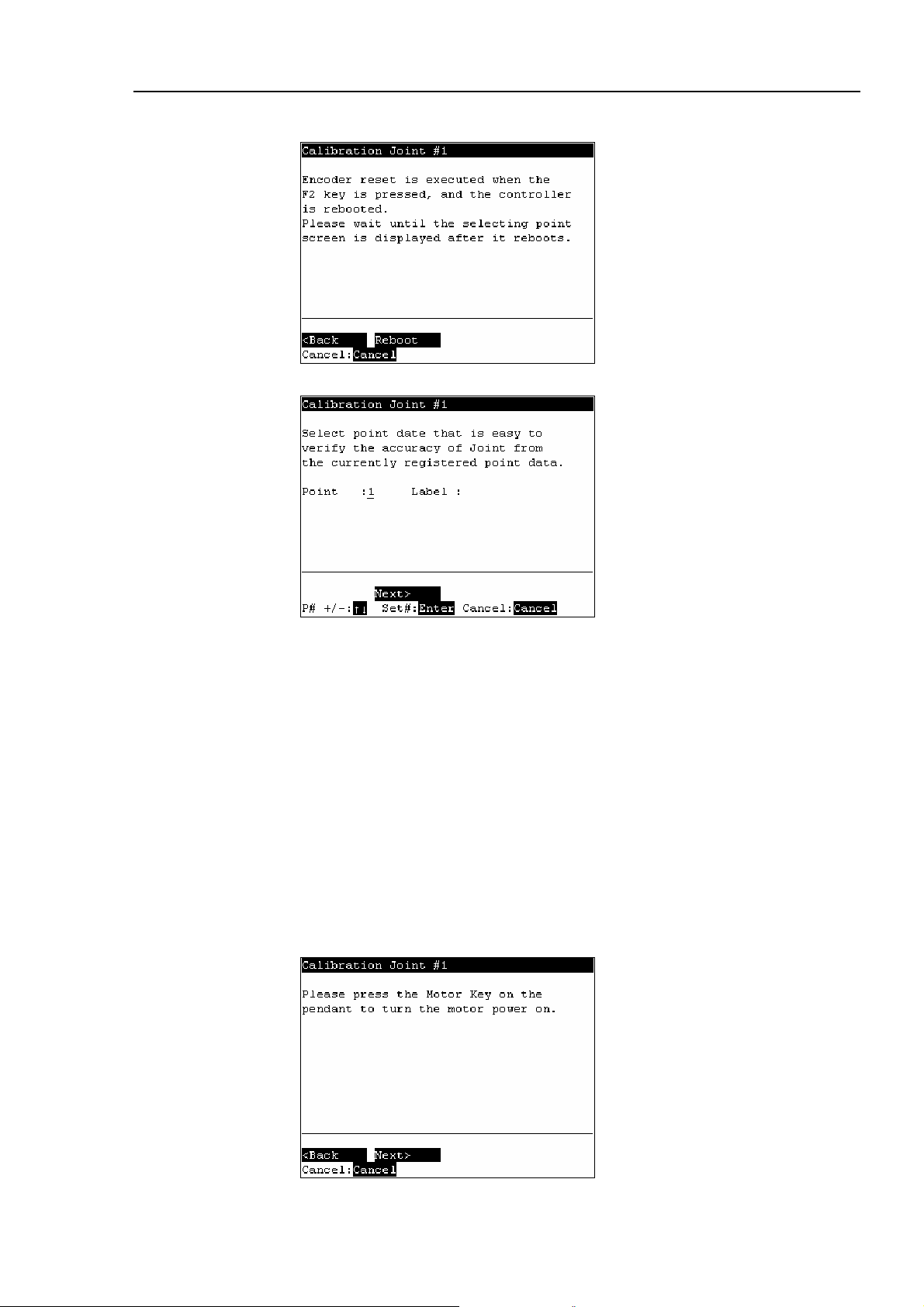

2.7.1 Calibration Procedures (E2 Series)

■

Calibrate Joint #3 first when aligning origins of more than one joint. When Joint

CAUTION

#3 is too low, it may collide with peripheral equipment during the calibration of

the other joints and may damage the peripheral equipment.

The same calibration procedure is used for all joints. Follow the steps below to calibrate

each joint.

When calibrating Joint #4, you must calibrate Joint #3 and #4 at the same time. You

cannot calibrate Joint #4 alone because of the structure of the Manipulator.

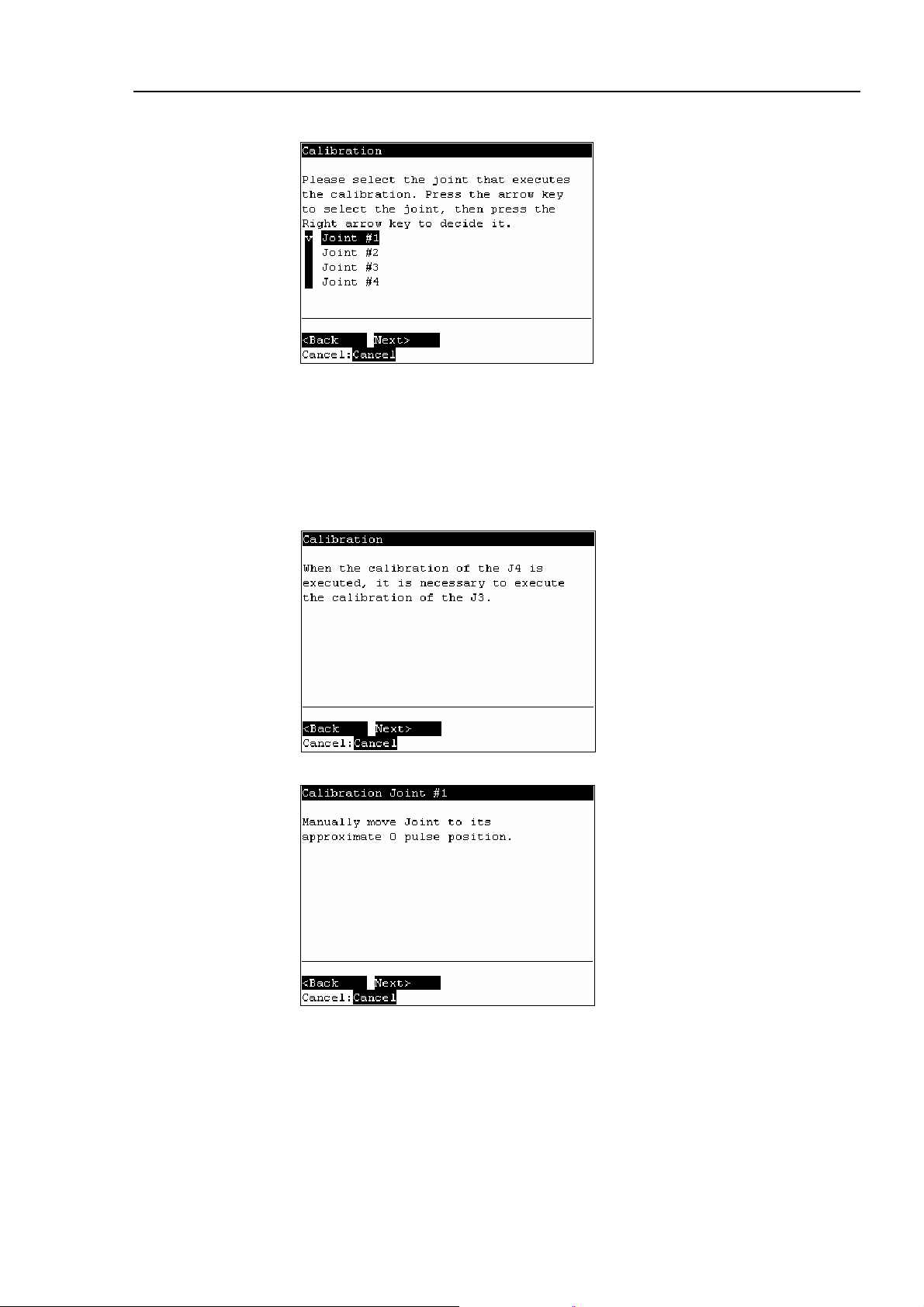

(1) In the [Calibration] screen, move the cursor to “0 Joint #1-4”, and press the <OK>

key.

(2) The following screen appears. Press the <F2> key.

(3) The following screen appears.

42 TP1 Rev.5

Page 53

Operation 2. TEACH Mode

Move the cursor to the joint to calibrate. Press the <→> key to select the joint and

press the <F2> key.

<→> key : Joint selection

<←> key : Joint selection reset

The following screen appears when selection Joint #4 and Joint #3 is selected

automatically.

(4) When a message appears regarding the capacitor charge, leave the power ON for 3

or more minutes to sufficiently charge the capacitor. Press the <F2> key to display

the following screen.

(5) The following screen appears.

TP1 Rev.5 43

Page 54

Operation 2. TEACH Mode

d

(6) Manually move the joint that needs origin alignment to its approximate 0 pulse

position.

0 pulse position of Joint #1 : position aligned with X-axis in Manipulator coordinate

system

0 pulse

0 pulse position of Joint #2 : position where Arms #1 and #2 are in a straight line

(Regardless of the Joint #1 direction)

0 pulse

0 pulse position of Joint #3 : upper limit position in motion range

Upper limit:

0 pulse

0 pulse position of Joint #4 : position where the flat surface on the shaft faces towar

the tip of Arm #2

0 pulse

44 TP1 Rev.5

Page 55

Operation 2. TEACH Mode

A

(7) Press the <F2> key. The following screen appears.

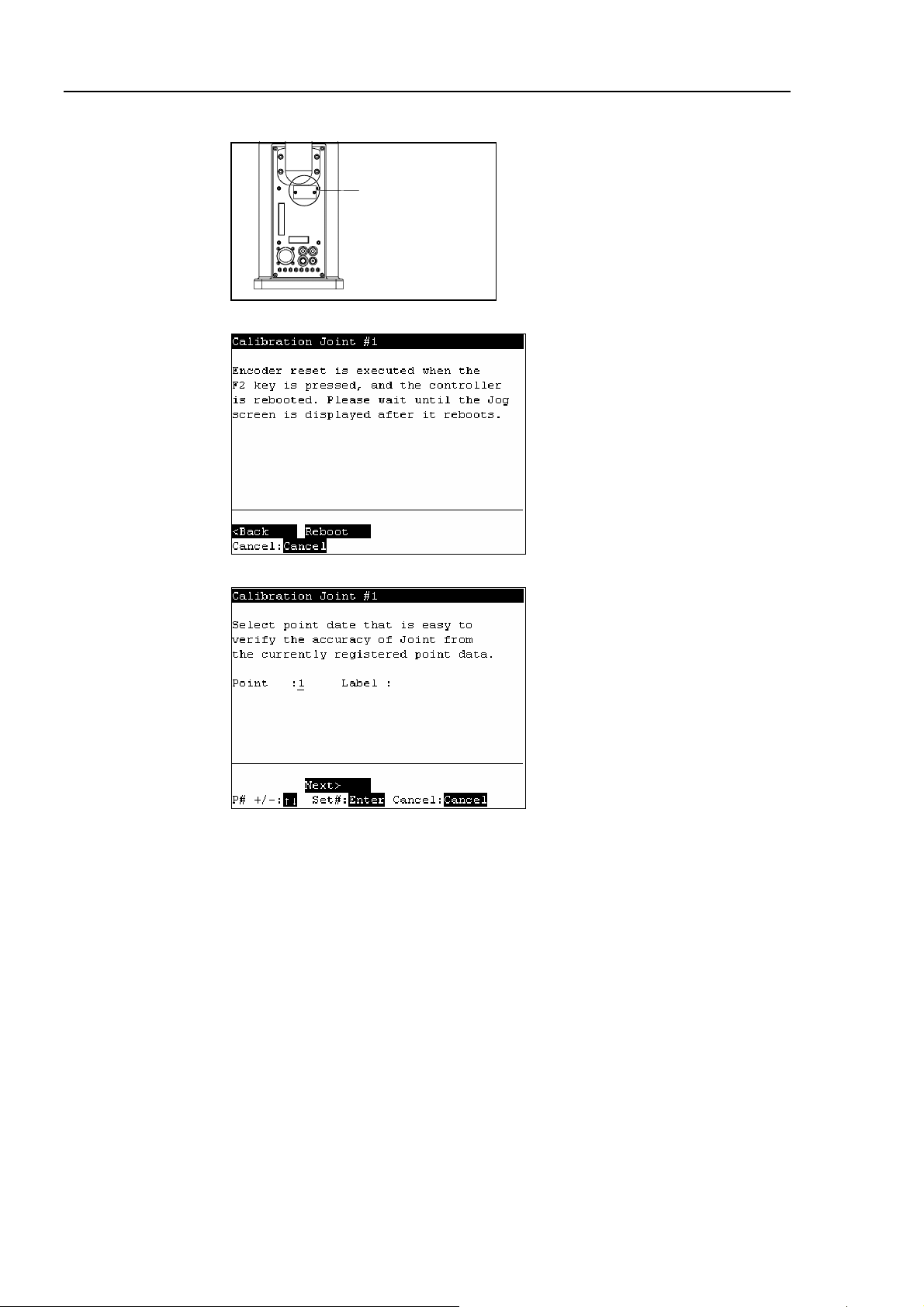

(8) Remove the acrylic panel on the sensor monitor on the base connector plate.

crylic Panel

(9) Set one of the DIP switches (SD1)“1” to “4” corresponding to the calibrating Joint to

its ON position.

Sensor monitor

DIP switch

(SD1)

Reset switch

(SW1)

(10) Press and hold the reset switch (SW1) for 1 or more seconds.

(11) Press the <F2> key to display the following screen.

TP1 Rev.5 45

Page 56

Operation 2. TEACH Mode

A

(12) Turn OFF the DIP switch and mount the acrylic panel on the sensor monitor.

crylic Panel

(13) Press the <F2> key. The following screen appears. Press the <F2> key again.

NOTE

)

(14) Controller reboots and the following screen appears.

Select one of the currently registered point data that is easy to verify the accuracy of

the calibrating joint using the <↑> and <↓> keys, and press the <Enter> key.

Press the <F2> key.

The Manipulator does not move to the exact point because the specified origin is

determined visually. Although the error is less than one revolution of the motor, be

careful not to allow the Manipulator to interfere with peripheral equipment.

One revolution of the Joint #1 motor: ± 4.5 degrees

One revolution of the Joint #2 motor: ± 7.2 degrees

One revolution of the Joint #3 motor: ± 13.4 mm

One revolution of the Joint #4 motor: ± 22.5 degrees

46 TP1 Rev.5

Page 57

Operation 2. TEACH Mode

(15) The following screen appears.

Press the <Motor> key to turn ON the motor. Press the <F2> key.

(16) The following screen appears. Press the <OK> key to stop the servo control for all

joints to enable the joints to be moved manually.

Press the <F2> key to display the following screen.

(17) The following screen appears. Manually move and position the joint that needs

origin alignment while pushing the Joint #3 brake release button and lowering Joint

#3. Press the <F2> key.

TP1 Rev.5 47

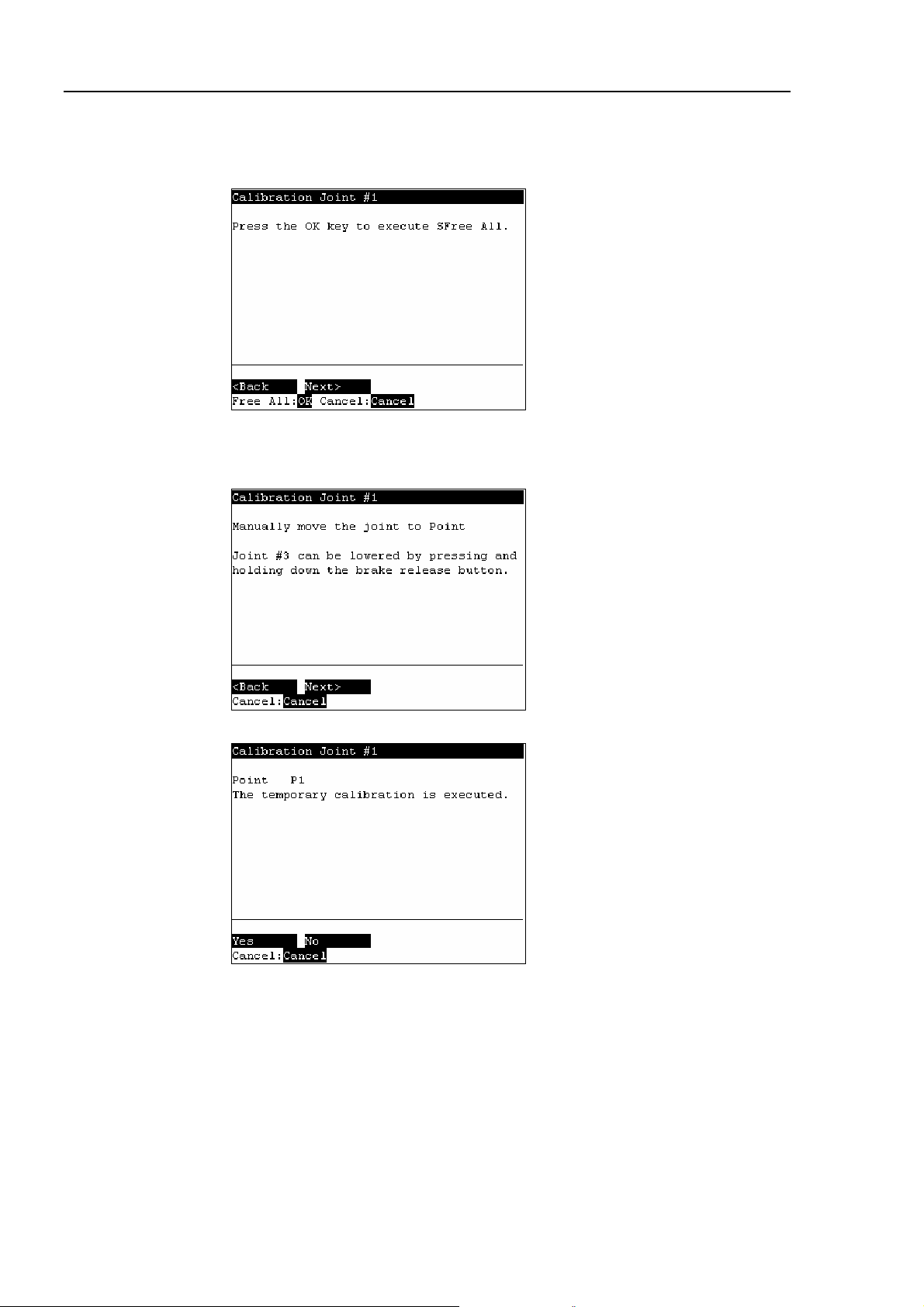

Page 58

Operation 2. TEACH Mode

(18) The following screen appears. Press the <F1> key to execute temporary calibration.

The following screen appears after executing the temporary calibration.

Press the <OK> key to servo control all joints.

Press the <F2> key.

(19) The following screen appears.

Move the joints except the calibrated joints to the point data position by the motion

command. For an example the motion command will be executed to Joint #1 and

#2 when Joint #4 is calibrated.

Press the <OK> key while gripping the enable switch to execute Go P1.

48 TP1 Rev.5

Page 59

Operation 2. TEACH Mode

The following screen appears during Go P1 execution.

(20) The following screen appears after Go P1 execution.

Set the calibrated joints to the selected point data position accurately by the jog

motion.

Press the Jog key to move the joint to the basic pose as accurate as possible.

Press the <F2> key.

(21) The following screen appears. Press the <F1> key.

TP1 Rev.5 49

Page 60

Operation 2. TEACH Mode

(22) The origin calibration completed screen appears.

NOTE

For righty or lefty setting, refer to 2.7.3 Setting Righty / Lefty.

)

2.7.2 Calibration Procedures (G Series)

■

Calibrate Joint #3 first when aligning origins of more than one joint. When Joint

CAUTION

#3 is too low, it may collide with peripheral equipment during the calibration of

the other joints and may damage the peripheral equipment.

The same calibration procedure is used for all joints. Follow the steps below to calibrate

each joint.

When calibrating Joint #4, you must calibrate Joint #3 and #4 at the same time. You

cannot calibrate Joint #4 alone because of the structure of the Manipulator.

(1) In the [Calibration] screen, move the cursor to “0 Joint #1-4”, and press the <OK>

key.

(2) The following screen appears. Press the <F2> key.

50 TP1 Rev.5

Page 61

Operation 2. TEACH Mode

(3) The following screen appears.

Move the cursor to the joint to calibrate. Press the <→> key to select the joint and

press the <F2> key.

<→> key : Joint selection

<←> key : Joint selection reset

The following screen appears when selection Joint #4 and Joint #3 is selected

automatically.

(4) The following screen appears.

TP1 Rev.5 51

Page 62

Operation 2. TEACH Mode

d

(5) Manually move the joint that needs origin alignment to its approximate 0 pulse

position.

0 pulse position of Joint #1 : position aligned with X-axis in Manipulator coordinate

system

0 pulse

0 pulse position of Joint #2 : position where Arms #1 and #2 are in a straight line

(Regardless of the Joint #1 direction)

0 pulse

0 pulse position of Joint #3 : upper limit position in motion range

Upper limit:

0 pulse

0 pulse position of Joint #4 : position where the flat surface on the shaft faces towar

the tip of Arm #2

0 pulse

52 TP1 Rev.5

Page 63

Operation 2. TEACH Mode

(6) Press the <F2> key. The following screen appears. Press the <F2> key again.

(7) Controller reboots and the following screen appears.

NOTE

)

Select one of the currently registered point data that is easy to verify the accuracy of

the calibrating joint using the <↑> and <↓> keys, and press the <Enter> key.

Press the <F2> key.

The Manipulator does not move to the exact point because the specified origin is

determined visually. Although the error is less than one revolution of the motor, be

careful not to allow the Manipulator to interfere with peripheral equipment.

One revolution of the Joint #1 motor: ± 4.5 degrees

One revolution of the Joint #2 motor: ± 7.2 degrees

One revolution of the Joint #3 motor: Z180 : ± 11.94 mm

Z330 : ± 23.87 mm

One revolution of the Joint #4 motor: ± 24.06 degrees

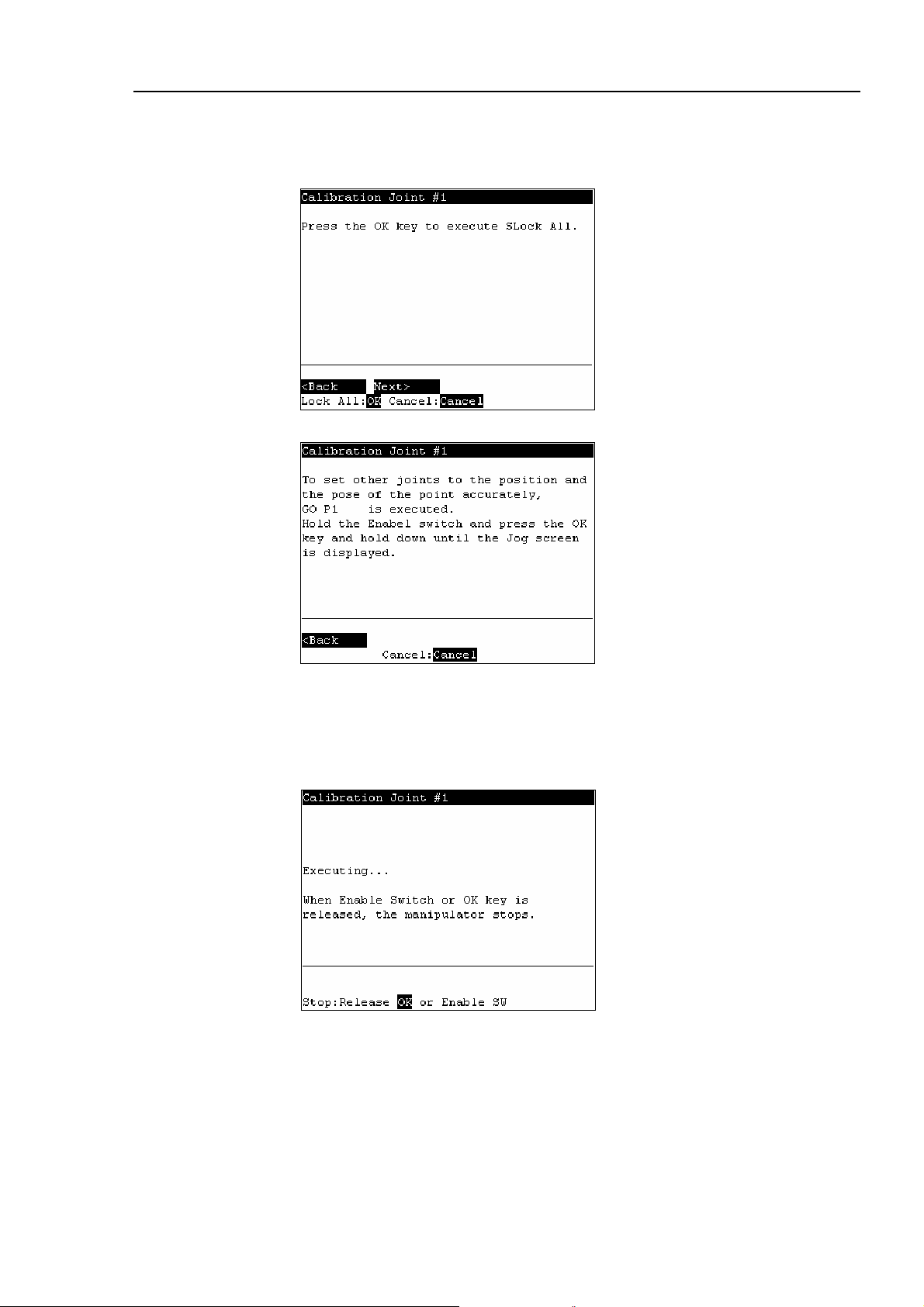

(8) The following screen appears.

Press the <Motor> key to turn ON the motor. Press the <F2> key.

TP1 Rev.5 53

Page 64

Operation 2. TEACH Mode

(9) The following screen appears. Press the <OK> key to stop the servo control for all

joints to enable the joints to be moved manually.

Press the <F2> key to display the following screen.

(10) The following screen appears. Manually move and position the joint that needs

origin alignment while pushing the Joint #3 brake release button and lowering Joint

#3. Press the <F2> key.

(11) The following screen appears. Press the <F1> key to execute temporary calibration.

54 TP1 Rev.5

Page 65

Operation 2. TEACH Mode

The following screen appears after executing the temporary calibration.

Press the <OK> key to servo control all joints.

Press the <F2> key.

(12) The following screen appears.

Move the joints except the calibrated joints to the point data position by the motion

command. For an example the motion command will be executed to Joint #1 and

#2 when Joint #4 is calibrated.

Press the <OK> key while gripping the enable switch to execute Go P1.

The following screen appears during Go P1 execution.

TP1 Rev.5 55

Page 66

Operation 2. TEACH Mode

(13) The following screen appears after Go P1 execution.

Set the calibrated joints to the selected point data position accurately by the jog

motion.

Press the Jog key to move the joint to the basic pose as accurate as possible.

Press the <F2> key.

(14) The following screen appears. Press the <F1> key.

NOTE

)

(15) The origin calibration completed screen appears.

For righty or lefty setting, refer to 2.7.3 Setting Righty / Lefty.

56 TP1 Rev.5

Page 67

Operation 2. TEACH Mode

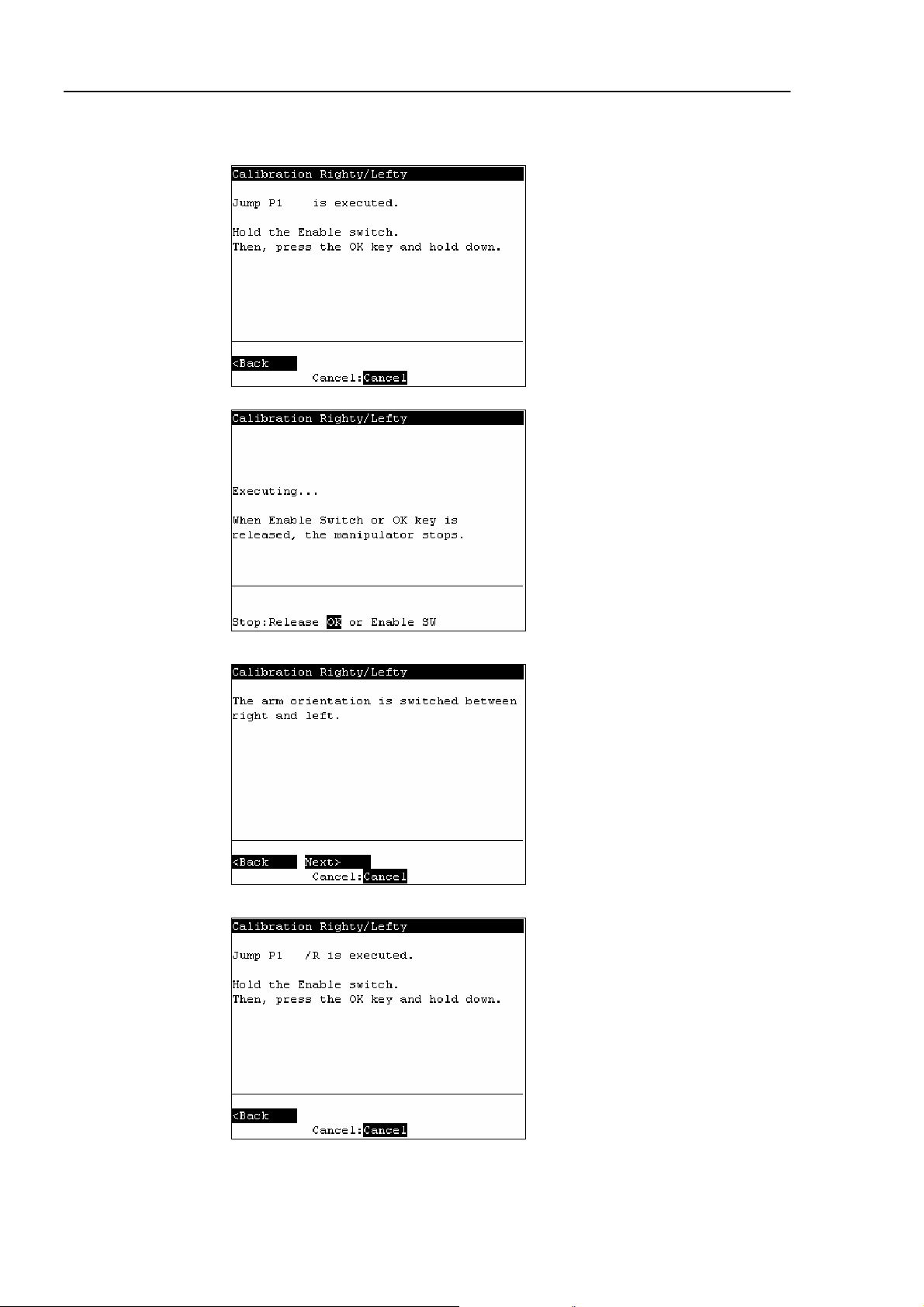

2.7.3 Setting Righty / Lefty (E2 Series / G Sereis)

(1) In the [Calibration] screen, move the cursor to “Righty/Lefty”, and press the <OK>

key.

(2) The following screen appears. Select one of the point data in the accessible area

that is easy to verify the accuracy for both right and left arm orientations using the

<↑> and <↓> keys and press the <Enter> key.

Press the <F2>key.

(3) The following screen appears. Press the <Motor> key to turn ON the motor.

Press the <F2> key.

TP1 Rev.5 57

Page 68

Operation 2. TEACH Mode

(4) Continue to press the <OK> key with the enable switch held down to execute Jump

P1.

The following screen appears during Jump P1 execution.

(5) The following screen appears after Jump P1 execution. Press the <F2> key.

(6) The following screen appears.

Switch the arm orientation between right and left and move to the same point.

Press the <OK> key while gripping the enable switch to execute Jump P1.

58 TP1 Rev.5

Page 69

Operation 2. TEACH Mode

The following screen appears during Jump P1.

(7) The following screen appears after executing Jump P1.

Set the calibrated joints to the basic pose accurately by the jog key.

Press the <F2> key.

(8) The following screen appears.

Press the <F1> key.

(9) The origin calibration completed screen appears.

TP1 Rev.5 59

Page 70

Operation 2. TEACH Mode

2.8 Calibrating Origin : PS Series

This section indicates the procedure to calibrate the origin when using PS series robots.

The same calibration procedure is used for all joints. Follow the steps below to calibrate

each joint.

When calibrating Joint #5, you must calibrate Joint #5 and #6 at the same time. You

cannot calibrate Joint #5 alone because of the structure of the Manipulator.

(1) Press the <F8> key in the [Jog&Teach] screen.

(2) The following screen appears.

Move the cursor to “0 calibration” and press the <OK> key.

NOTE

The following screen appears when the password is set up.

)

Enter the password (1 to 16 characters) and press the <OK> key.

For password setting, refer to Operation 4. Password Setup.

(3) The following screen appears. Press the <F2> key.

60 TP1 Rev.5

Page 71

Operation 2. TEACH Mode

(4) The following screen appears.

Move the cursor to the joint to calibrate. Press the <→> key to select the joint and

press the <F2> key.

<→> key : Joint selection

<←> key : Joint selection reset

The following screen appears when selecting Joint #5 and Joint #6 is selected

automatically.

(5) The following screen appears. Press the <F2> key.

TP1 Rev.5 61

Page 72

Operation 2. TEACH Mode

(6) The Controller reboots and the following screen appears.

Press the <Motor> key to turn ON the motor. Press the <F2> key.

(7) The following screen appears.

Press the Jog key and move the joint close to 0 pulse.

When the joint does not move to 0 pulse, move the joint to the set basic pose marked

in Setup & Operation Setting the Basic Pose for Calibration in the Manipulator

manual.

Press the <F2> key.

(8) The following screen appears. Press the <F2> key.

62 TP1 Rev.5

Page 73

Operation 2. TEACH Mode

(9) Select a point data that is easy to verify the accuracy of the joint that needs origin

alignment from the currently registered point data using the <↑> and <↓> keys, and

press the <Enter> key.

Press the <F2> key.

(10) The following screen appears.

Press the <Motor> key to turn ON the motor. Press the <F2> key.

(11) The following screen appears.

Press the Jog key to move the joint to the basic pose as accurate as possible.

Press the <F2> key.

TP1 Rev.5 63

Page 74

Operation 2. TEACH Mode

(12) The following screen appears. Press the <F1> key to execute temporary calibration.

(13) The following screen appears after executing the temporary calibration.

Move the joints except the calibrated joints to the point data position by the motion

command. For an example the motion command will be executed to Joint #1 to #4

when Joint #5 is calibrated.

Press the <OK> key while gripping the enable switch to execute Go P0.

The following screen appears during Go P0 execution.

64 TP1 Rev.5

Page 75

Operation 2. TEACH Mode

(14) The following screen appears after Go P0 execution.

Move the calibrated joints to the selected point data position accurately by the jog

motion. For an example, Joint #5 and #6 is the calibrated joints.

Press the Jog key to move the joint to the basic pose as accurate as possible.

Press the <F2> key.

(15) The following screen appears. Press the <F1> key.

(16) The origin calibration completed screen appears.

TP1 Rev.5 65

Page 76

Operation 2. TEACH Mode

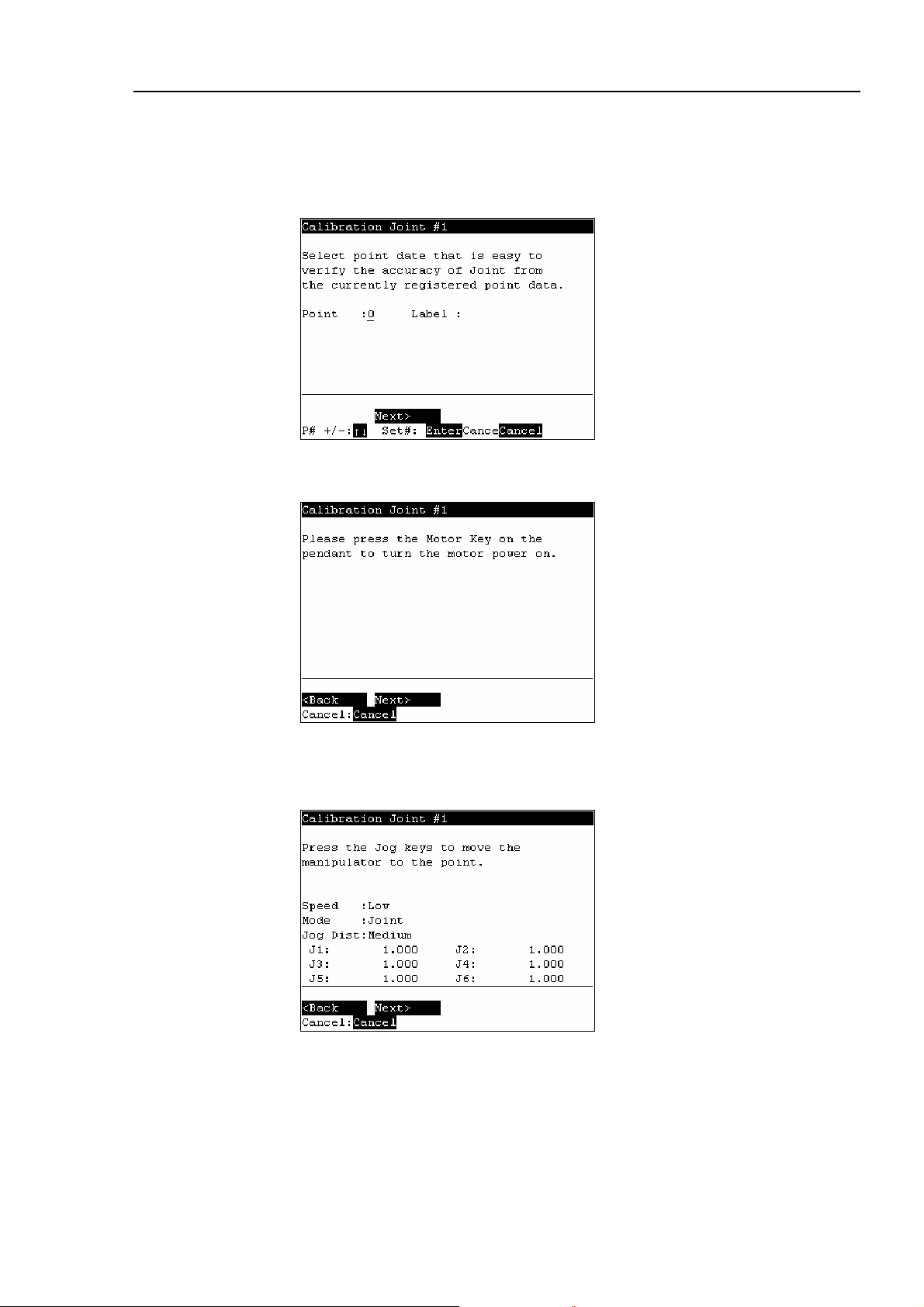

2.9 Releasing Brake (PS series only)

This section indicates the brake ON / OFF switching for each joint.

(1) Press the <F8> key in the [Jog&Teach] screen.

(2) The following screen appears.

Move the cursor to “1 Brake” and press the <OK> key.

The following screen appears when the password is set up.

Enter the password (1 to 16 characters) and press the <OK> key.

For password setting, refer to Operation 4. Password Setup.

(3) The following screen appears.

66 TP1 Rev.5

Page 77

To turn the brake ON

(4) Press the <Jog+> key of the joint whose brake On/Off setting is to be switched.

(5) Press the <OK> key. The brake is locked.

To turn the brake OFF

(4) Press the <Jog-> key of the joint whose brake On/Off setting is to be switched.

(5) The brake Off confirmation message appears. Confirm the message and press the

Operation 2. TEACH Mode

<F1> key.

(6) The brake is released, and the specified joint moves manually.

TP1 Rev.5 67

Page 78

Operation 3. AUTO Mode

3. AUTO Mode

Switch the mode selector key switch to “Auto” to enter the AUTO mode. In this mode,

jog, teaching, operation commands, I/O commands, and other operations and commands

can be executed using the teaching pendant.

Note, however, that the program cluster cannot be executed.

Auto Mode

Print Panel

I/O monitor

Memory I/O monitor

Tasks

System history

Program mode

Open Program

3.1 Program Command

3.2 I/O Monitor

3.3 Memory I/O Monitor

3.4 Task Monitor

3.5 System History

3.6 Program Mode

3.6.1 Opening Programs

Input

Save

Exit

Search

Jump

Auto Mode

Backup/restore

Saving controller

Displaying the date

Adjusting the

brightness and

Error messages

Screen name

See item

Building projects

Backing up projects

Restoring projects

Importing files

Exporting files

System backup

Restoring the system

Changing the

Configuration

Display language

Updating system

Program editor

Enabling

execution

3.6.2 Building Projects

3.6.3 Backing up Projects

3.6.4 Restoring Projects

3.6.5 Importing Files

3.6.6 Exporting Files

3.6.7 Backing up the System

3.6.8 Restoring the System

3.6.9 Changing Speed

3.6.10 Configuration

3.6.11 Changing the Display

3.6.12 Updating the System

3.7 Backup/Restore

3.8 Saving Controller Statuses

3.9 Displaying Date and Time

3.10 Adjusting Brightness and

3.11 Error Messages

68 TP1 Rev.5

Page 79

Operation 3. AUTO Mode

Switch the mode selector key switch to “Auto” to display the [Print] screen. Follow the

description on the screen and press the <F4> key to display the [Main Menu] screen.

TIP

)

Menus with “...” at the end have following procedures after selecting the menu and

cannot be executed only by pressing the <OK> key.

TP1 Rev.5 69

Page 80

Operation 3. AUTO Mode

3.1 Program Command Display

This screen displays messages from the program and requests responses.

The [Print] screen appears when the mode selector key switch is switched to “Auto”.

To display the [Print] screen from the [Main Menu] screen, move the cursor to [Print

Panel], and press the <OK> key.

When only a message appears

Program Example :

PRINT #24,“Test Print”

The [Main Menu] screen appears.

<F4>

When a message appears and a response is requested

Program Example :

PRINT #24,“Test Print”

INPUT #24,a$

Input the response to the message at the cursor position. (Characters or numerical

values)

Deletes all entered characters or numerical values.

<F1>

The [Main Menu] screen appears.

<F4>

70 TP1 Rev.5

Page 81

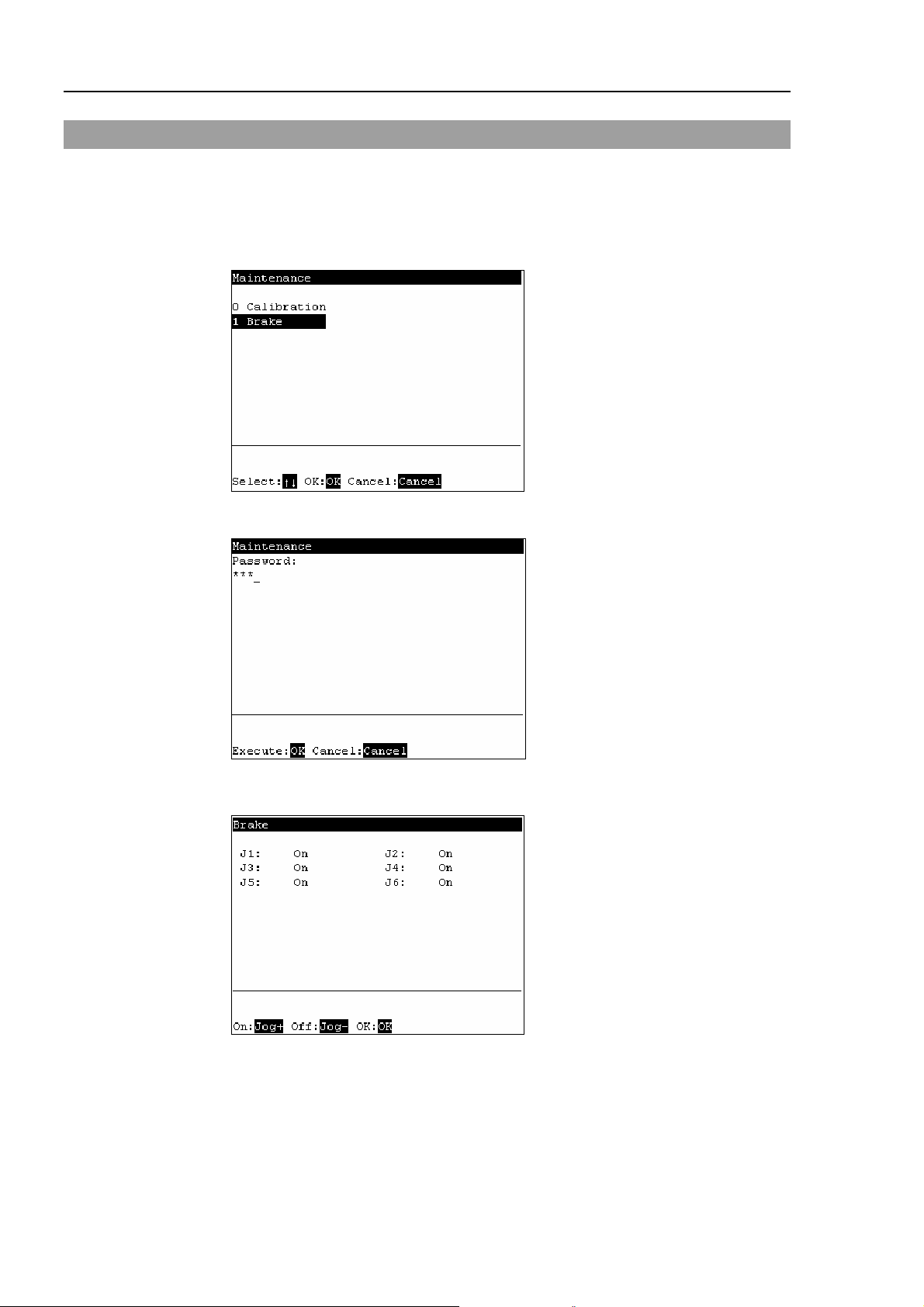

3.2 I/O Monitor

This screen displays the bit status of I/O.

In the [Main Menu] screen, move the cursor to [1 I/O Monitor], and press the <OK> key.

I/O status (Inputs, bit units)

“*” (asterisk) is displayed before the label name for remote setting display to separate

remote setting and I/O label.

Switches between Inputs and Outputs.

<F1>

Switches the I/O bit status display (Bit units or port units).

<F2>

Operation 3. AUTO Mode

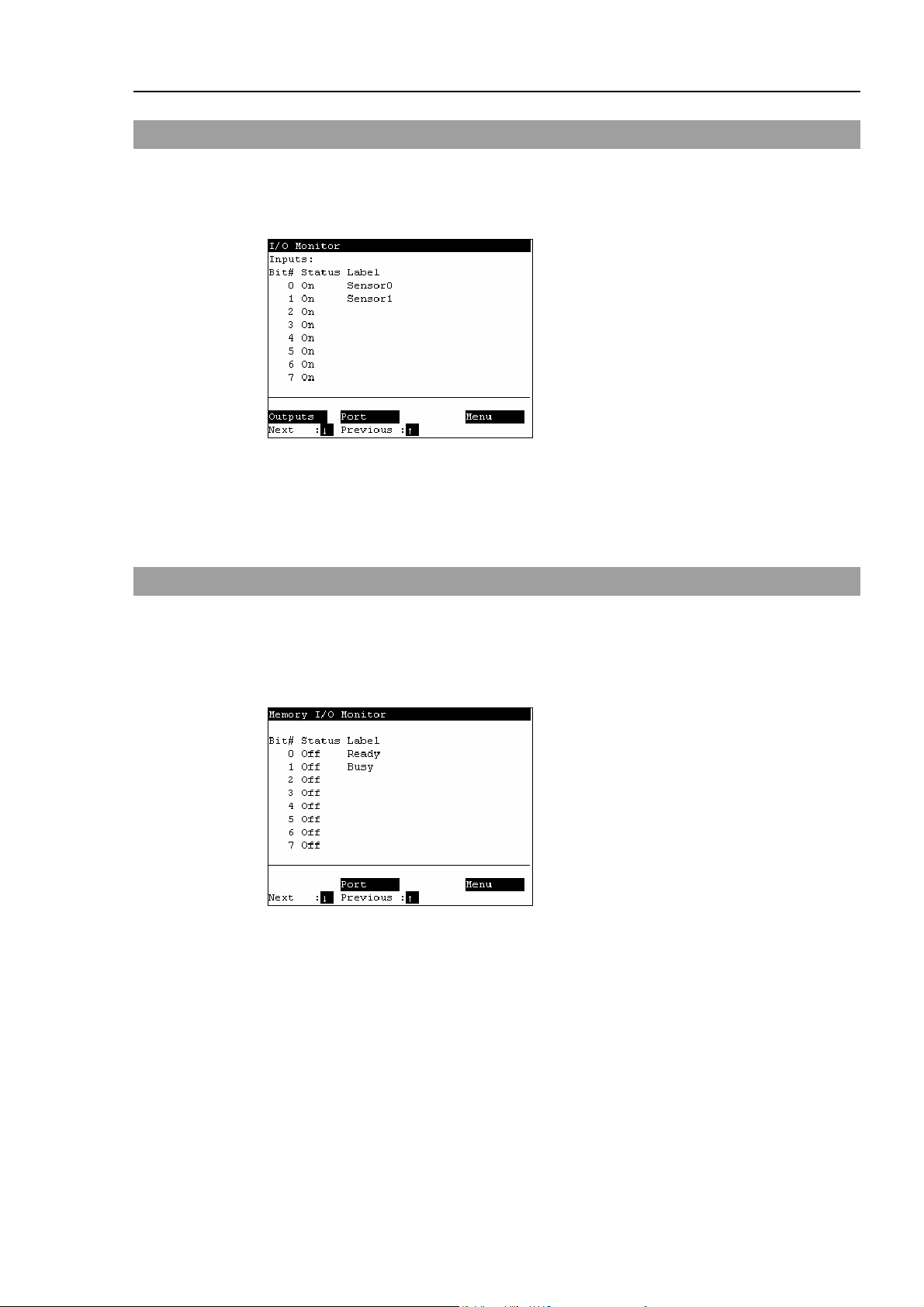

3.3 Memory I/O Monitor

This screen displays the bit status of memory I/O.

In the [Main Menu] screen, move the cursor to [2 Memory I/O Monitor], and press the

<OK> key.

Memory I/O status (bit units)

Switches the I/O bit status display (Bit units or port units).

<F2>

TP1 Rev.5 71

Page 82

Operation 3. AUTO Mode

3.4 Task Monitor

This screen displays the status of tasks.

In the [Main Menu] screen, move the cursor to [3 Task Monitor], and press the <OK> key.

When the task name is too long to display the whole name, a tilde is attached at the end of

the task name as “LongTaskNa~”.

When the task is “NoPause task”, “*P” is attached at the end of the task name.

When the task is “NoEmgAbort task”, “*E” is attached at the end of the task name.

Displays the line number and task name in the program specified by the cursor.

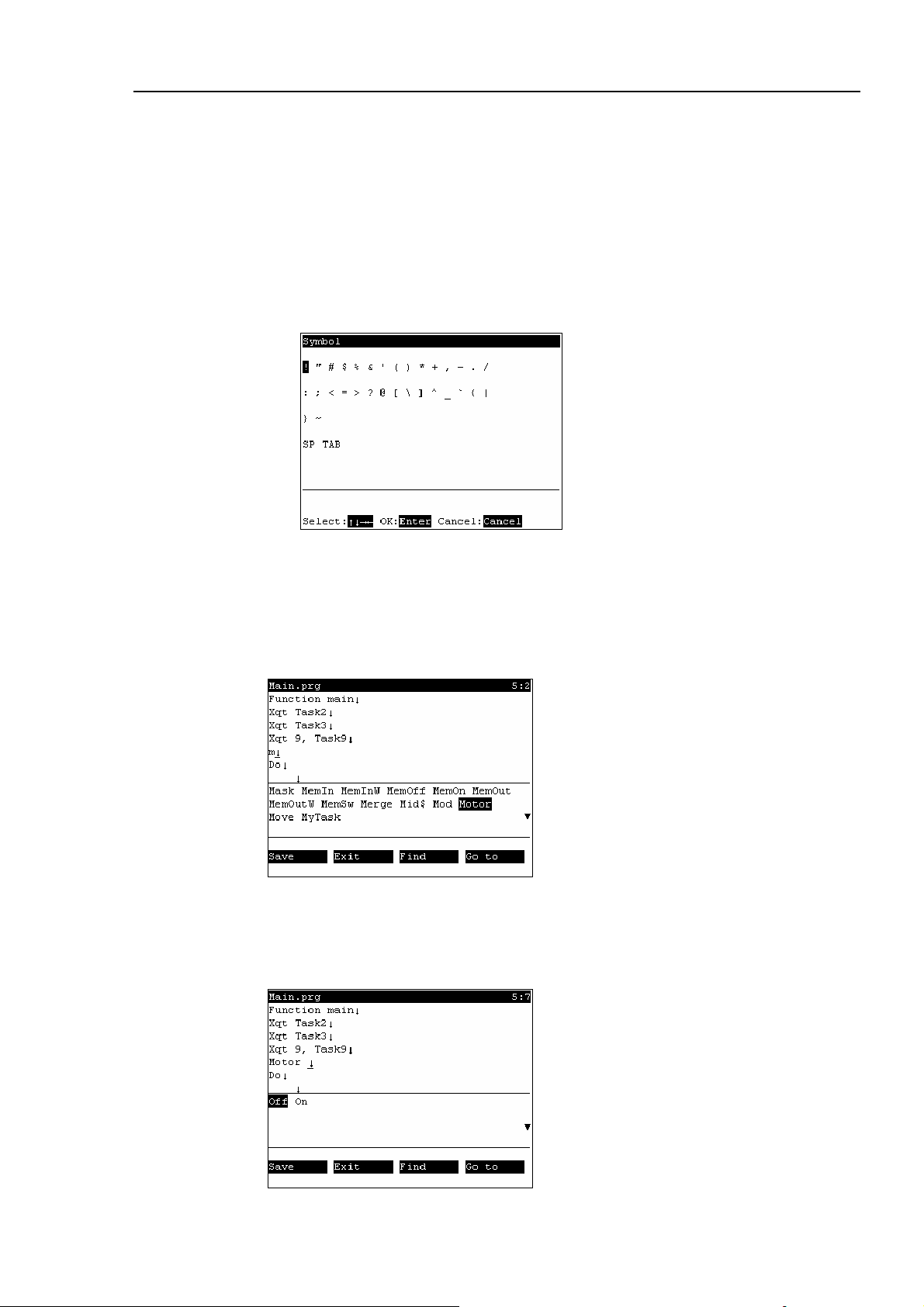

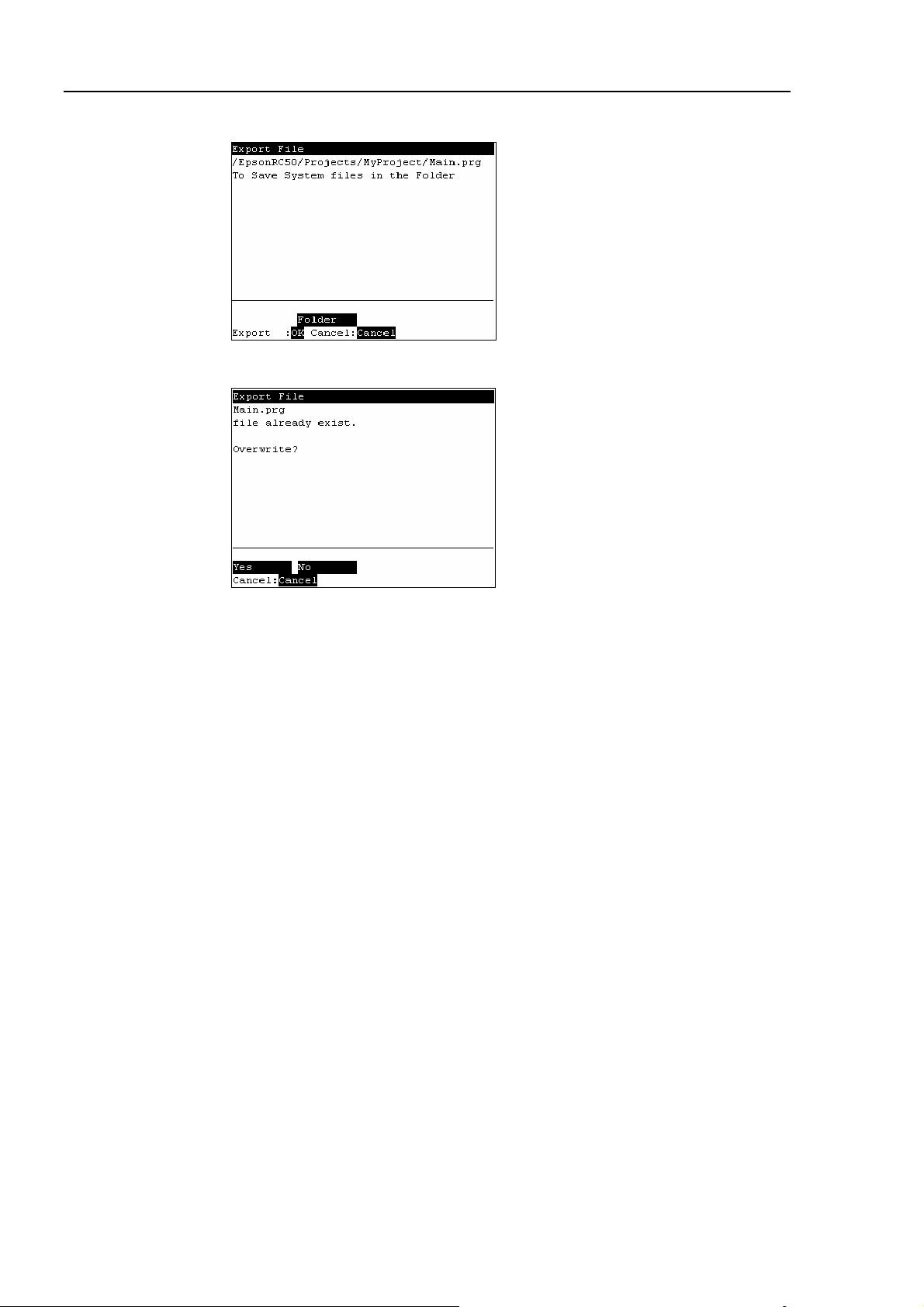

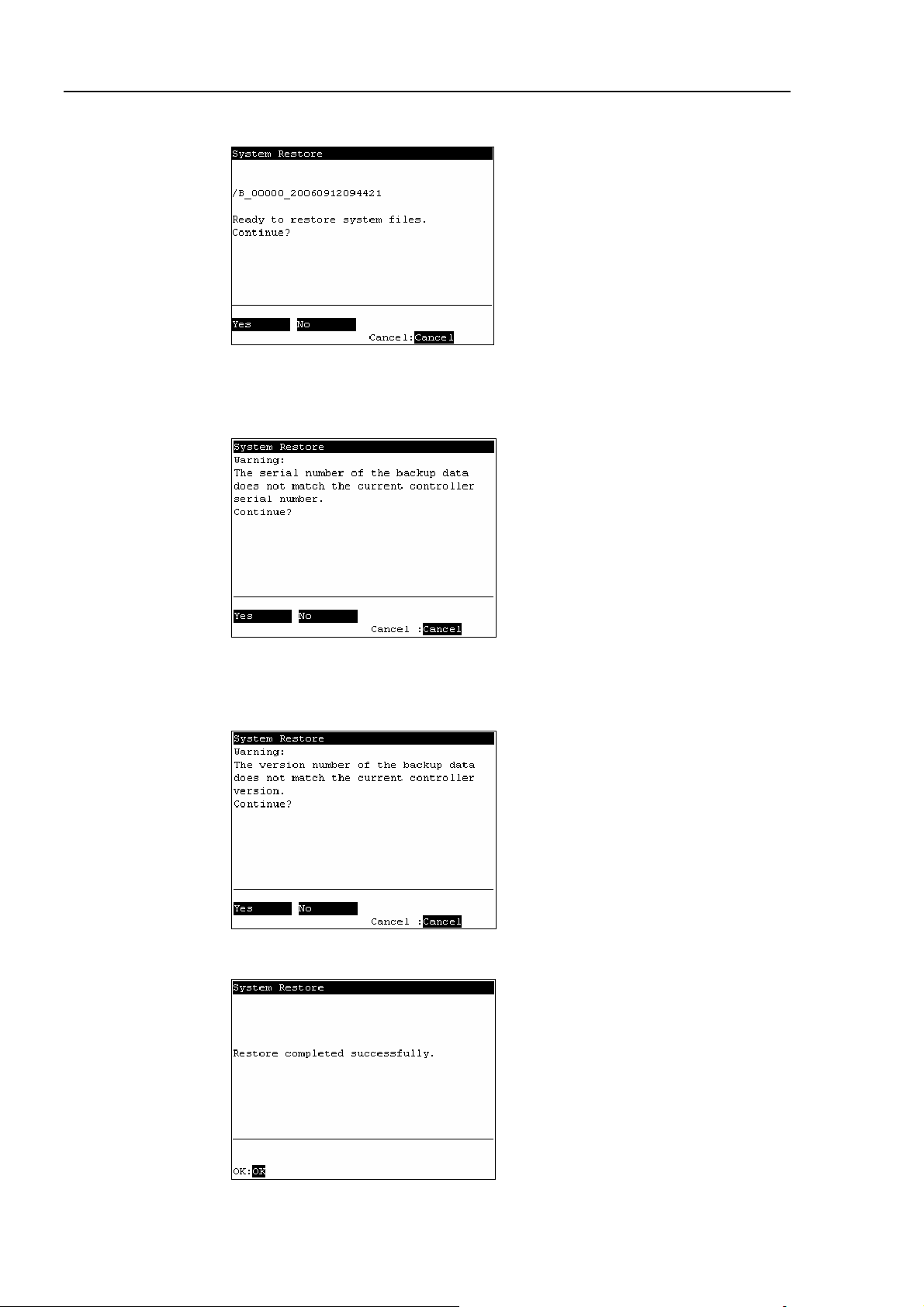

<F1>