Page 1

technical manual

TM-U950/TM-U950P

EPSON

English

4005789

Page 2

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation. No patent liability is assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book, Seiko Epson Corporation assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for

damages, losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to

strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options or

any consumable products other than those designated as Original Epson Products or Epson Approved Products by

Seiko Epson Corporation.

EPSON is a registered trademark of Seiko Epson Corporation.

ESC/POS is a trademark of Seiko Epson Corporation.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 1996 by Seiko Epson Corporation, Nagano, Japan.

Page 3

EPSON

SEIKO EPSON CORPORATION

Printed in Japan E96010130-0000SE

Page 4

TM-U950/TM-U950P Technical Manual

FCC CLASS A

FCC Compliance Statement

For American Users

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which case the user will be required to correct the

interference at his own expense.

WARNING

The connection of a non-shielded printer interface cable to this printer will invalidate the FCC Verification of this

device and may cause interference levels which exceed the limits established by the FCC for this equipment.

You are cautioned that changes or modifications not expressly approved by the party responsible for compliance could

void your authority to operate the equipment.

FOR CANADIAN USERS

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus as set out in

the radio interference regulations of the Canadian Department of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de Class A prescrites dans le règlement sur le brouillage radioélectrique édicté par le Ministère des

Communications du Canada.

GEREÄUSCHPEGEL

Gemäß der Dritten Verordrung zum Gerätesicherheitsgecsetz (Maschinenlärminformations- Verordnung-3. GSGV) ist

der arbeitsplatzbezogene Geräusch-Emissionswert kleiner als 70 dB(A) (basierend auf ISO 7779).

Rev. A i

Page 5

Introduction

The TM-U950 printer is an ESC/POS™ compatible high-performance point of sale (POS) printer

which can handle receipt, journal, and slip paper. There are two models: the TM-U950 and the

TM-U950P. The TM-U950P has a parallel interface. Differences between the two models are

noted throughout this manual.

The main features of the TM-U950 and TM-U950P printers are the following:

❏ Usable with a wide range of slip paper types.

❏ Non-protruding interface connectors integrated in the body of the printer.

❏ Bidirectional logic seek for high throughput.

❏ Paper feed pitch of 1/144 inch.

❏ Integrated printer buffer with 32 byte or 2 KB capacity.

❏ Slip paper eject sensor.

❏ ASB (Automatic Status Back) function to send the printer status automatically.

❏ EPSON intelligent module connection (Not available on the TM-U950P).

❏ EPSON customer display series connection (Not available on the TM-U950P).

❏ Optional Magnetic Ink Character Recognition (MICR) reader that enables the printer to

perform consecutive reading and processing of MICR characters and printing endorsements

(not available for the TM-U950P).

ii Rev. A

Page 6

TM-U950/TM-U950P Technical Manual

About This Manual

❏

Chapter 1 provides general specifications and hardware configuration information.

❏

Chapter 2 provides general operating principles and printer mechanism configuration

information.

❏

Chapter 3 provides handling and maintenance information.

❏

Chapter 4 provides troubleshooting information.

❏

Chapter 5 provides printer disassembly, assembly, and adjustment instructions.

❏

Chapter 6 (Appendix) provides circuit board and exploded diagrams.

Notes and Cautions

Note:

Notes have important information and useful tips on the operation of your printer.

CAUTION:

Cautions must be observed to avoid damage to your equipment.

Rev. A iii

Page 7

Revision Sheet

Revision Page Altered Item and Contents

Rev. A

iv Rev. A

Page 8

Contents

TM-U950/TM-U950P Technical Manual

Chapter 1

Features ......................................................................................................................................................................................1-1

General Specifications .............................................................................................................................................................. 1-3

Printing Specifications...................................................................................................................................................... 1-3

Character Specifications .................................................................................................................................................. 1-4

Paper Specifications ......................................................................................................................................................... 1-5

Paper Roll Feed Mechanism ............................................................................................................................................ 1-9

Journal Paper Take-up Mechanism ................................................................................................................................ 1-9

Auto-cutter ........................................................................................................................................................................ 1-9

Electrical Specifications .................................................................................................................................................... 1-9

Stamp .................................................................................................................................................................................. 1-10

Ink Ribbon ......................................................................................................................................................................... 1-10

Dimensions, Weight, Finish ............................................................................................................................................ 1-11

Environmental Specifications ......................................................................................................................................... 1-11

Reliability ........................................................................................................................................................................... 1-12

Hardware Configuration .........................................................................................................................................................1-13

Main Unit Configuration ................................................................................................................................................. 1-13

Main Unit Specifications .................................................................................................................................................. 1-14

Connectors ......................................................................................................................................................................... 1-17

Interface .............................................................................................................................................................................. 1-19

Switches and Buttons ....................................................................................................................................................... 1-27

Functions .................................................................................................................................................................................... 1-31

Error Processing ................................................................................................................................................................ 1-31

Self-test ............................................................................................................................................................................... 1-32

Hexadecimal Dumping .................................................................................................................................................... 1-32

Printing Operation ............................................................................................................................................................ 1-33

Options .......................................................................................................................................................................................1-34

AC Adapter (PS-150) ........................................................................................................................................................1-34

Journal Lock ...................................................................................................................................................................... 1-34

Features and General Specifications

Chapter 2

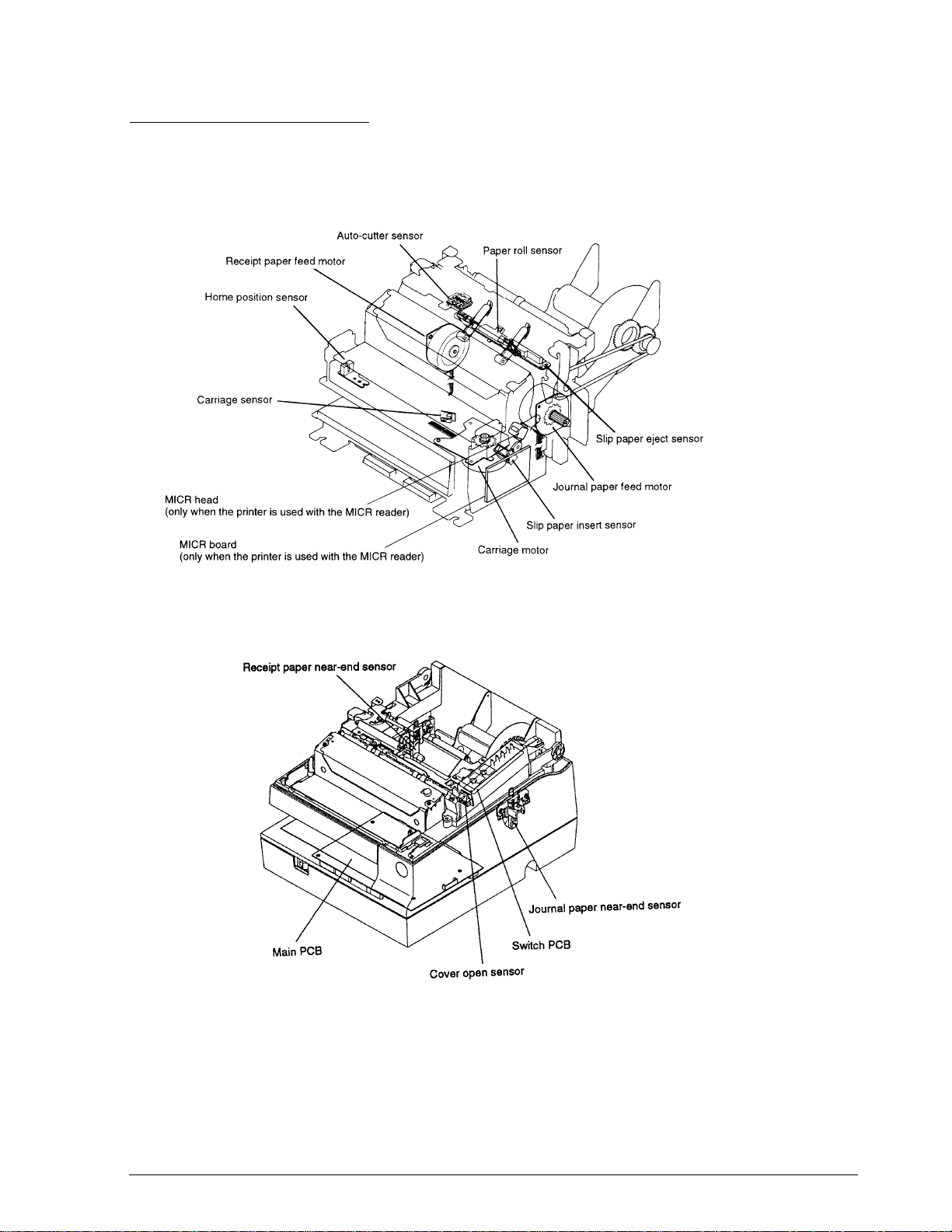

Printer Mechanism Components ............................................................................................................................................ 2-1

Printer Mechanism Operating Principles .............................................................................................................................. 2-2

Printing Assembly............................................................................................................................................................. 2-2

Sensor Assemblies.............................................................................................................................................................2-4

Paper Feed Assembly ....................................................................................................................................................... 2-9

Slip Paper Assembly ........................................................................................................................................................ 2-12

MICR Reader Assembly (for printers with a MICR reader) (not available for the TM-U950P) ........................... 2-16

Ribbon Feed Assembly .................................................................................................................................................... 2-18

Stamp Assembly (for printers with a stamp assembly) .............................................................................................. 2-19

Auto-cutter Assembly ...................................................................................................................................................... 2-20

Paper Roll Take-up Assembly ........................................................................................................................................ 2-23

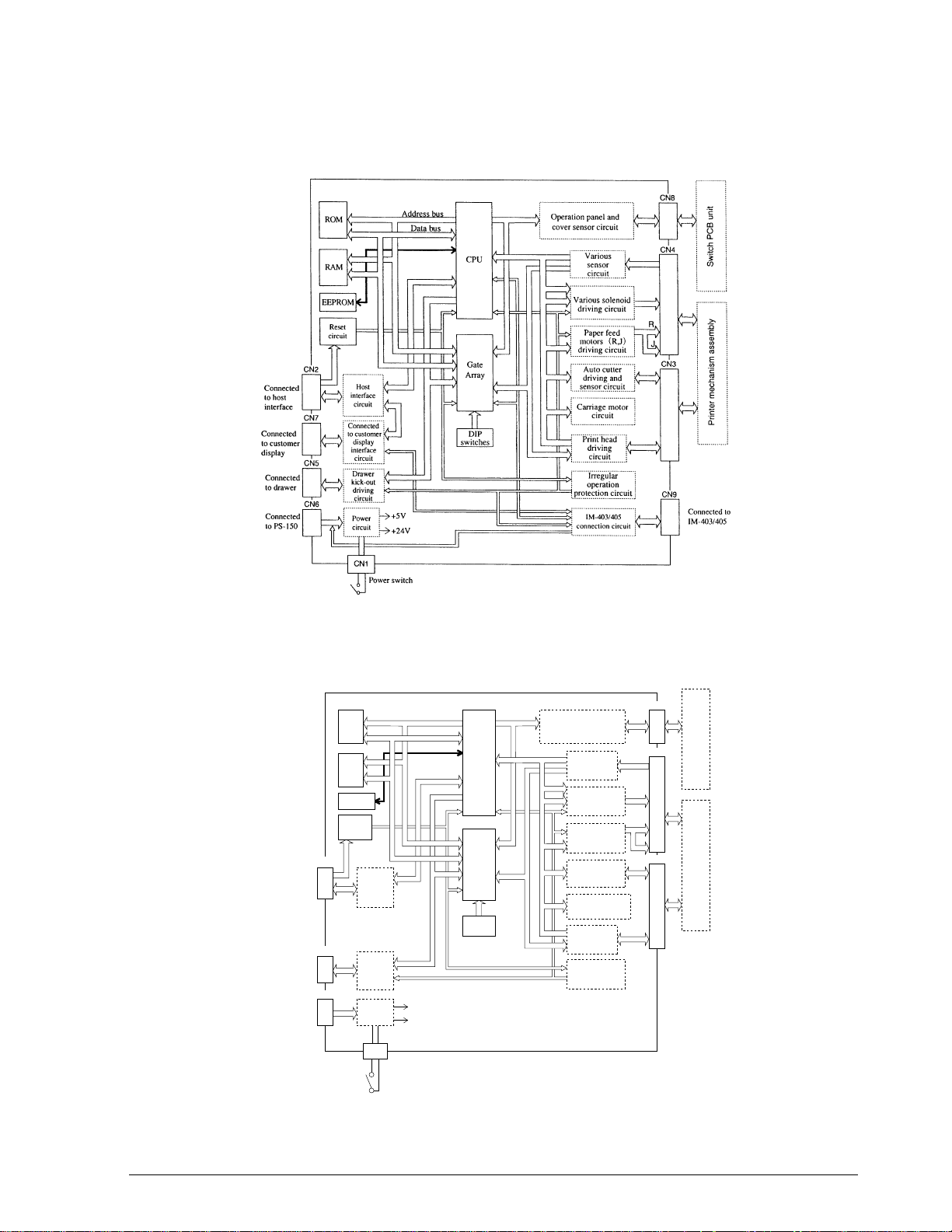

Electrical Circuitry Operating Principles .............................................................................................................................. 2-25

Hardware Configuration ................................................................................................................................................. 2-25

Main Board Operating Principle .................................................................................................................................... 2-30

MICR Board Operating Principle (on printers with a MICR reader) (not available for the TM-U950P) ............ 2-49

Mechanism Configuration and Operating Principles

Rev. A v

Page 9

Chapter 3 Handling and Maintenance

Handling .....................................................................................................................................................................................3-1

Handling Precautions .......................................................................................................................................................3-1

Loading the Paper Rolls ...................................................................................................................................................3-2

Removing the Paper Rolls ................................................................................................................................................3-4

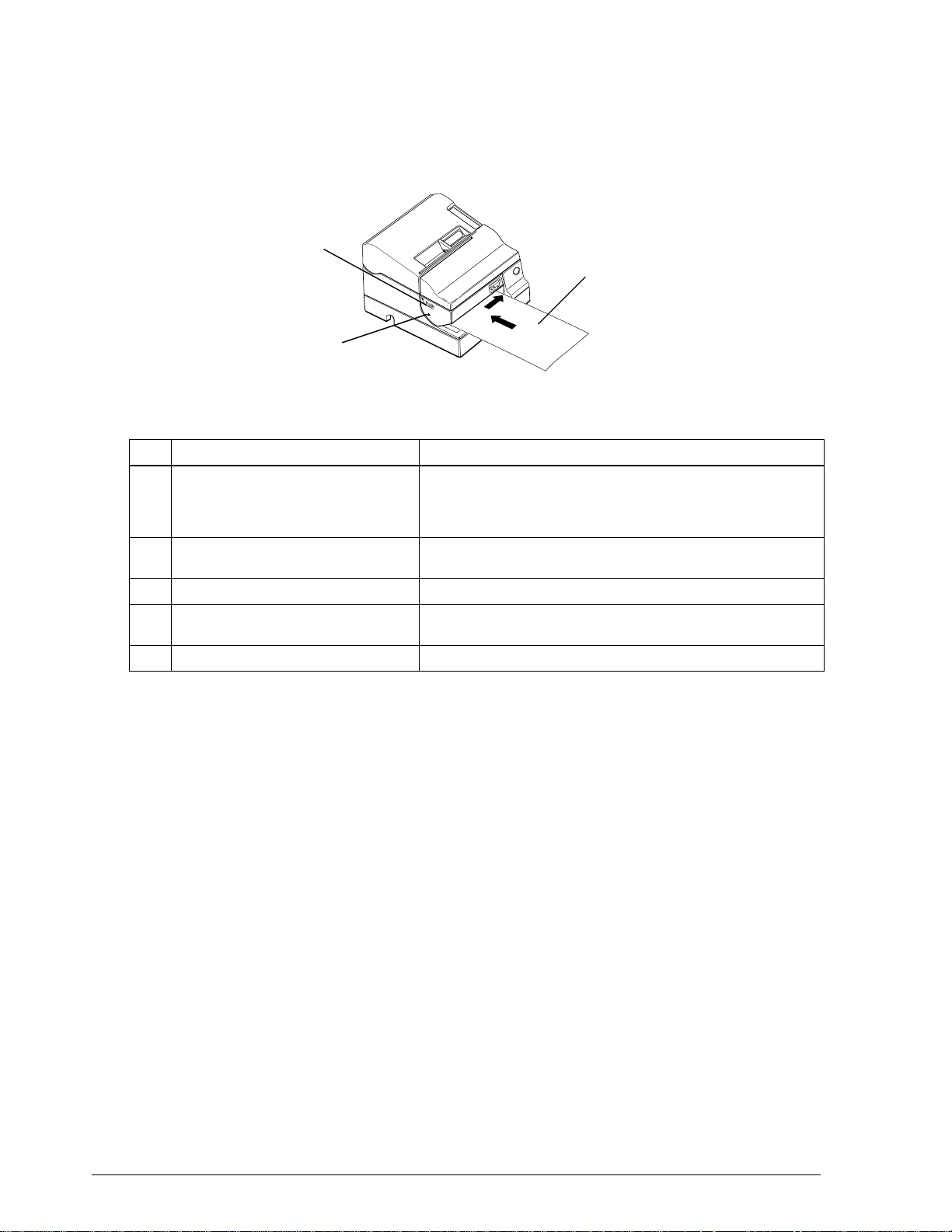

Inserting Slip Paper and Printing on Slip Paper ...........................................................................................................3-5

Printing on Personal Checks (only on printers with a MICR reader) (not available for the TM-U950P) ............3-6

Installing and Removing the Ribbon Cassette ..............................................................................................................3-8

Inserting the Stamp Set .....................................................................................................................................................3-9

Mounting the Power Switch Cover ................................................................................................................................3-10

Journal Lock Key Handling .............................................................................................................................................3-10

Removing the Jammed Paper ..........................................................................................................................................3-10

Maintenance ...............................................................................................................................................................................3-13

Periodic Checks .................................................................................................................................................................3-13

Cleaning ..............................................................................................................................................................................3-13

Lubrication .........................................................................................................................................................................3-14

Tool List ..............................................................................................................................................................................3-17

Measuring Equipment List ..............................................................................................................................................3-18

Lubricant List .....................................................................................................................................................................3-18

Chapter 4 Troubleshooting

Troubleshooting ........................................................................................................................................................................4-1

Self-test ................................................................................................................................................................................4-1

Troubleshooting Flowchart ..............................................................................................................................................4-4

Troubleshooting Tables ....................................................................................................................................................4-12

Major Part Replacements .........................................................................................................................................................4-23

Fuse replacement ...............................................................................................................................................................4-23

Print Head Unit Replacement .........................................................................................................................................4-23

Cutter Blade Replacement ................................................................................................................................................4-23

Error Types And Countermeasures ........................................................................................................................................4-24

Chapter 5 Disassembly, Assembly, and Adjustment

Small Part Specifications ..........................................................................................................................................................5-1

Actual Size E-type Retaining Rings ................................................................................................................................5-1

Disassembly ...............................................................................................................................................................................5-2

Replacing the Print Head Unit ........................................................................................................................................5-3

Replacing the Cutter Blade ..............................................................................................................................................5-5

Printer Mechanism Unit Assembly .........................................................................................................................................5-6

Sub-assembly A: Detector-Paper Assembly...................................................................................................................5-7

Sub-assembly B: Paper Guide-Upper Unit Assembly .................................................................................................5-8

Sub-assembly C: Paper Guide-Lower Unit Assembly..................................................................................................5-10

Sub-assembly D: Cutter Motor Mount Plate Assembly ...............................................................................................5-12

Sub-assembly E: Roller-Paper Hold Assembly..............................................................................................................5-12

Sub-assembly F: Cutter Frame Assembly.......................................................................................................................5-13

Sub-assembly G: Detector-Slip Ejection Assembly .......................................................................................................5-13

Sub-assembly H: Auto-cutter Unit Assembly ...............................................................................................................5-14

Sub-assembly I: Pulley Base-Carriage Transmission Assembly .................................................................................5-17

Sub-assembly J: Carriage-Head Assembly ....................................................................................................................5-17

Sub-assembly K: Assembling the MICR Head Holder Assembly (for printers with a MICR reader) .................5-18

Sub-assembly L-(1): Frame-Carriage Unit Assembly (for printers without a MICR reader) .................................5-22

Sub-assembly L-(2): Frame Carriage Unit Assembly (for printers with a MICR reader)........................................5-27

Sub-assembly M: Frame-Inner Assembly.......................................................................................................................5-35

Sub-assembly N: Detector-Slip Insertion Assembly .....................................................................................................5-36

Sub-assembly O: Solenoid J/S Changeover Assembly.................................................................................................5-36

Sub-assembly P: Paper Guide-Slip-Lower Assembly...................................................................................................5-37

vi Rev. A

Page 10

TM-U950/TM-U950P Technical Manual

Sub-assembly Q: Frame-Paper Take-up Assembly...................................................................................................... 5-38

Sub-assembly R: Assembling the motor-paper guide-J assembly (for printers with a MICR reader).................. 5-39

Main Assembly (Part 1) ................................................................................................................................................... 5-40

Adjustments ...................................................................................................................................................................... 5-53

Main Assembly (Part 2) ................................................................................................................................................... 5-59

Whole Unit Assembly .............................................................................................................................................................. 5-65

Sub-assembly A: N.E. Detector-J Assembly and N.E. Detector-R Assembly........................................................... 5-65

Sub-assembly B: Holder-Switch Circuit Board Assembly .......................................................................................... 5-67

Sub-assembly C: Journal Lock and Cover-Paper Take-up Assembly (Option) ...................................................... 5-68

Sub-assembly D: Cover Paper Take-up ......................................................................................................................... 5-69

Main Assembly .........................................................................................................................................................................5-70

Main Assembly 1: Main Circuit Board, P-ROM, and Plate-Main Mounting ........................................................... 5-70

Main Assembly 2: FFC, Power Cable, and Plate-Circuit Board Attachment ........................................................... 5-71

Main Assembly 3: Printer Mechanism Assembly Attachment on Plate-Main ........................................................ 5-72

Main Assembly 4: N.E. Detector-R and -J Assemblies Attachment .......................................................................... 5-73

Main Assembly 5: Printer Mechanism Assembly Attachment on Case-Lower Assembly .................................... 5-75

Main Assembly 6: Case-Upper Assembly Mounting .................................................................................................. 5-76

Main Assembly 7: Cover-Face and Cover-Main Assembly Attachment .................................................................. 5-77

Main Assembly 8: Cover-ROM Attachment ................................................................................................................. 5-78

Adjustments .............................................................................................................................................................................. 5-79

Adjustment G: Adjusting the Paper Roll Near-end Detector Location .................................................................... 5-79

Adjustment H: Detector-Slip Insertion Assembly Threshold Value Adjustment.................................................... 5-81

Adjustment I: MICR mechanism check.......................................................................................................................... 5-83

Chapter 6 Appendix

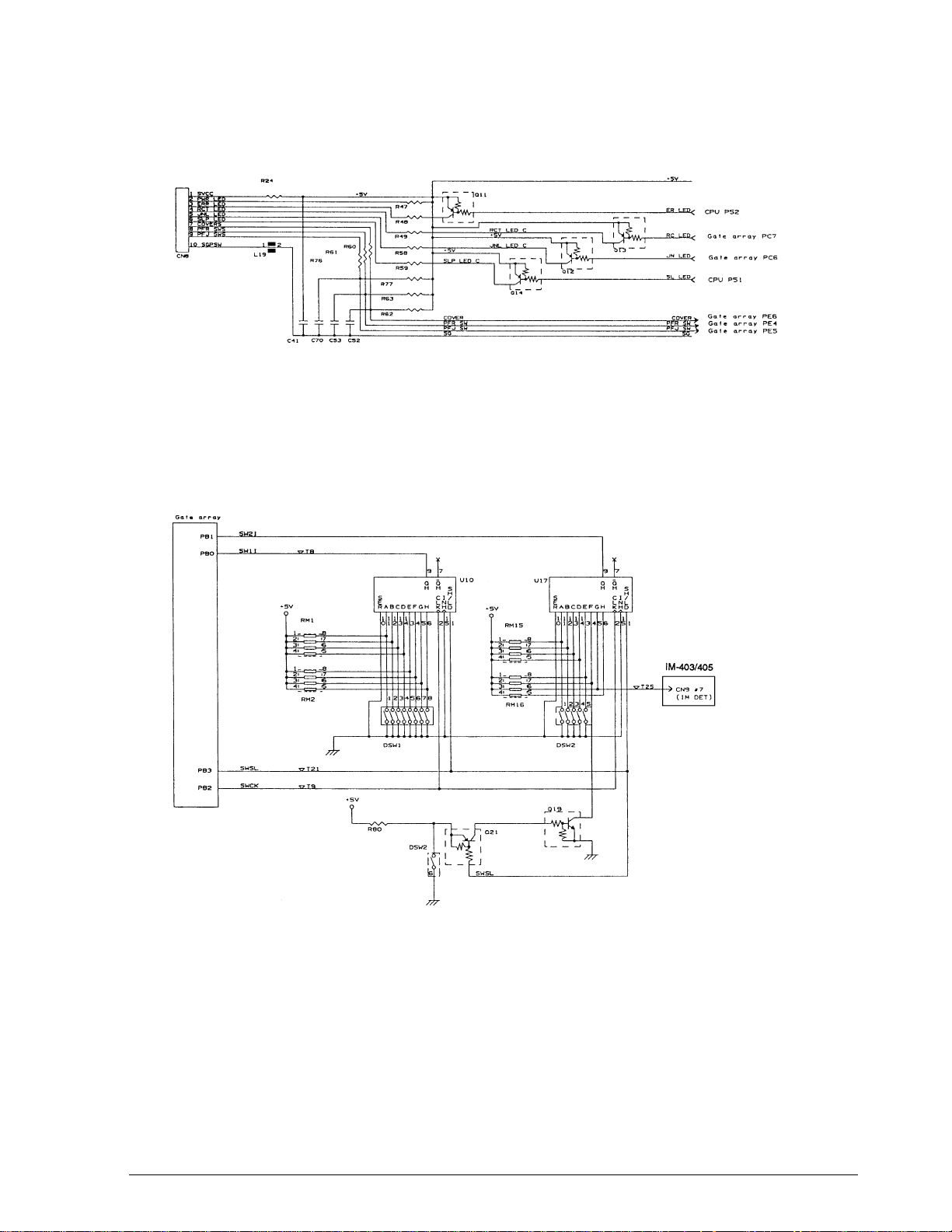

Electrical Circuit Drawings...................................................................................................................................................... 6-1

Circuit 1.............................................................................................................................................................................. 6-2

Circuit 2.............................................................................................................................................................................. 6-3

Circuit 3.............................................................................................................................................................................. 6-4

Circuit 4.............................................................................................................................................................................. 6-5

Circuit 5.............................................................................................................................................................................. 6-6

Circuit 6.............................................................................................................................................................................. 6-7

Circuit 7.............................................................................................................................................................................. 6-7

Circuit 8.............................................................................................................................................................................. 6-8

Main Unit Circuit Drawing for TM-U950..................................................................................................................... 6-9

Main Unit Circuit Drawing for TM-U950P .................................................................................................................. 6-10

MICR Board (for printers with a MICR reader) (Not available for the TM-U950P) .............................................. 6-11

Parallel Interface Circuit Board Diagram..................................................................................................................... 6-12

Main Circuit Board Parts Layout for TM-U950........................................................................................................... 6-13

Main Circuit Board Parts Layout for TM-U950P.........................................................................................................6-14

Parallel Interace Circuit Board Parts Layout................................................................................................................ 6-15

Overall Exploded Diagrams........................................................................................................................................... 6-16

Lubrication Points Diagram for Printers Without a MICR Reader (1/3) ................................................................ 6-26

Lubrication Points Diagram for Printers Without a MICR Reader (2/3) ................................................................ 6-27

Lubrication Points Diagram for Printers Without a MICR Reader (3/3) ................................................................ 6-28

Lubrication Points Diagram for Printers With a MICR Reader (1/4)...................................................................... 6-29

Lubrication Points Diagram for Printers With a MICR Reader (2/4)...................................................................... 6-30

Lubrication Points Diagram for Printers With a MICR Reader (3/4)...................................................................... 6-31

Lubrication Points Diagram for Printers With a MICR Reader (4/4)...................................................................... 6-32

Rev. A vii

Page 11

TM-U950/U950P Technical Manual

Chapter 1

Features and General Specifications

Features

The TM-U950 printer is an ESC/POS™ compatible high-performance point of sale (POS) printer

which can handle receipt, journal, and slip paper. There are two models: the TM-U950 and the

TM-U950P. The TM-U950P has a parallel interface. Differences between the two models are

noted throughout this manual.

The main features of the TM-U950 and TM-U950P printers are the following:

❏ Usable with a wide range of slip paper types.

❏ Non-protruding interface connectors integrated in the body of the printer.

❏ Bidirectional logic seek for high throughput.

❏ Paper feed pitch of 1/144 inch.

❏ Integrated printer buffer with 32 byte or 2 KB capacity.

❏ Slip paper eject sensor.

❏ ASB (Automatic Status Back) function to send the printer status automatically.

❏ EPSON intelligent module connection (Not available on the TM-U950P).

❏ EPSON customer display series connection (Not available on the TM-U950P).

❏ Optional Magnetic Ink Character Recognition (MICR) reader that enables the printer to

perform consecutive reading and processing of MICR characters and printing endorsements

(not available for the TM-U950P).

Rev. A Features and General Specifications 1-1

Page 12

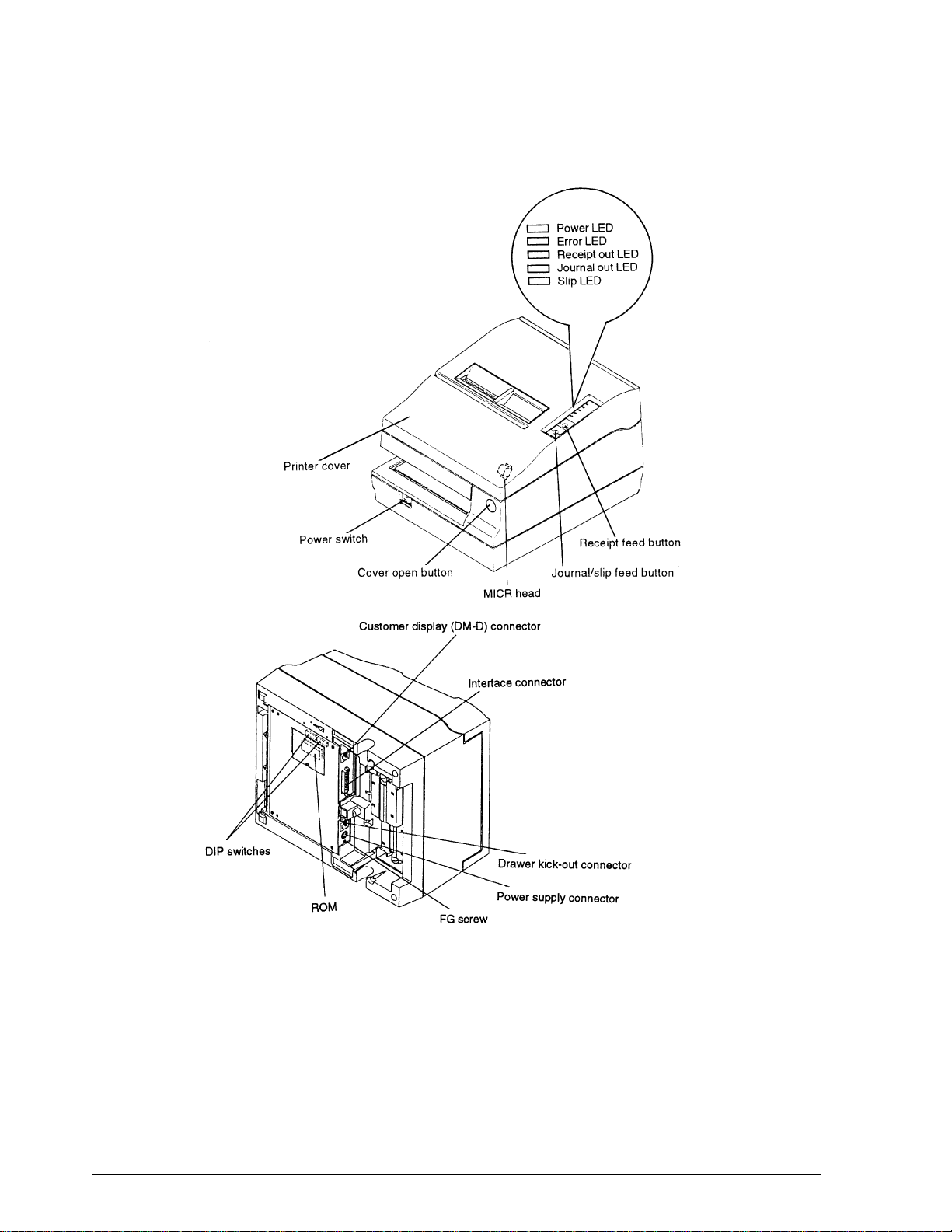

Figure 1-1. TM-U950 Appearance

1-2 Features and General Specifications Rev. A

Page 13

General Specifications

Printing Specifications

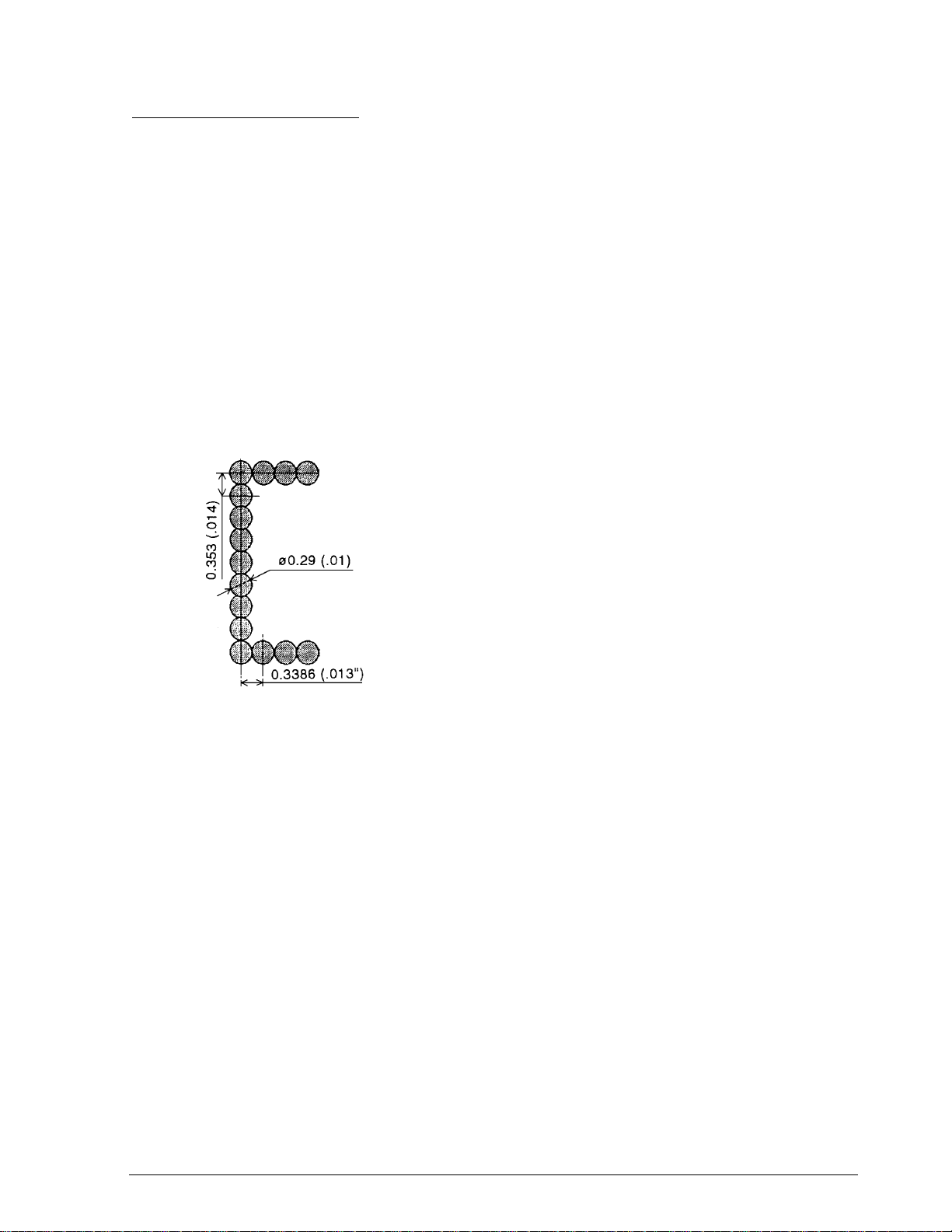

Operation principle

Serial impact dot-matrix printer

Print head wire layout

Serial 9-pin

Dot pitch

0.353 mm (1/72”)

Dot wire diameter

0.29 mm (.01”)

TM-U950/U950P Technical Manual

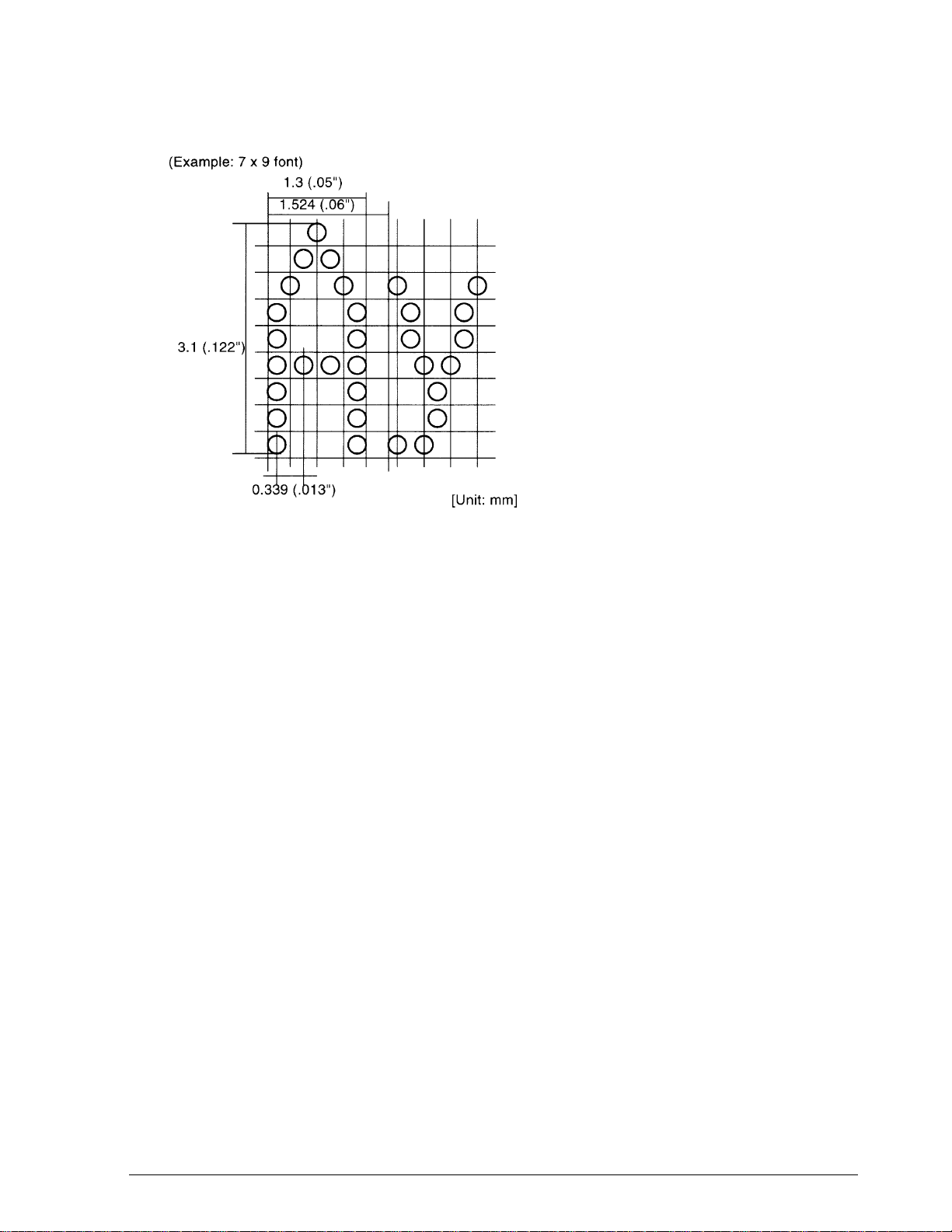

Figure 1-2. Dot Configuration

Print direction

Bidirectional logic seek

Print width (printable area)

Paper roll: 61.1 mm (2.41”)

Slip paper: 135.6 mm (5.34”)

Paper feed pitch

4.233 mm (1/6”) (default setting) adjustable (by commands) in 1/144-inch steps

Paper feed principle

Friction feed

Paper feed rate

Approx. 3.4 IPS (continuous paper); 60.3 ms per line (1/6-inch paper feed)

Rev. A Features and General Specifications 1-3

Page 14

Printing format

See CPI in Table 1-2.

Character spacing

See Table 1-2.

Total dot count

70 mm paper roll (2.76”): 180 dots (360 positions) per line

Slip paper: 400 dots (800 positions) per line

Printing speed

See Table 1-2.

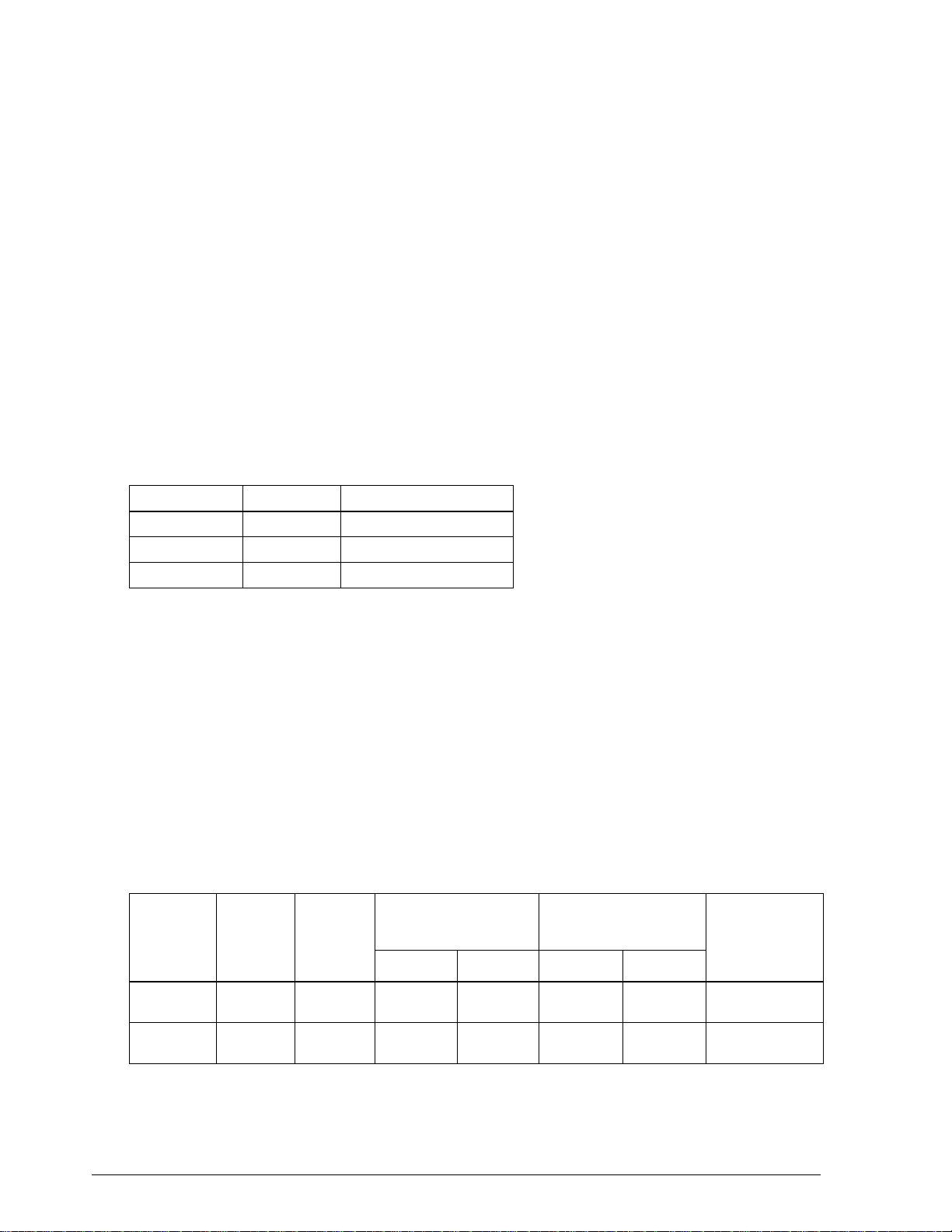

As shown in the table below, the TM-U950 has three printing modes, which differ in printing

speed and head power time (impact).

Table 1-1. Printing Operation Mode

Operation mode Printing speed Head power time (impact)

Standard High Standard

Copy Low Copy

Low-speed Low Standard

Character Specifications

Character set

Alphanumeric: 95

International: 32

Extended graphics: 128 x 8 pages

Character matrix

(Alphanumeric, international, extended graphics)

7 x 9 (spacing: 2 half-dots)

0 x 9 (spacing: 3 half-dots)

Larger spacing can be set by using ESC SP.

Table 1-2. CPI, CPS, CPL, Character Size

CG Mode

(Horizontal

dots x

vertical

dots)

9 x 9 3 dots 12.5 233 200 30 66

7 x 9 2 dots 16.7 311 267 40 88

Character

Spacing

(half dots)

Characters

Per Inch

(CPI)

Characters Per Second

(CPS) (Carriage moving

speed)

High speed Low speed Paper roll Slip paper

Characters Per Line (CPL)

Character Size

Width x Height

1.6 mm x 3.1 mm

(0.6” x .12”)

1.3 mm x 3.1 mm

(0.5” x .12”)

1-4 Features and General Specifications Rev. A

Page 15

Figure 1-3. Character Size

TM-U950/U950P Technical Manual

Paper Specifications

Paper type

❏ Paper roll

Wood-free paper (single layer only)

❏ Slip paper

Plain paper

Carbon copy paper

Pressure-sensitive paper

Paper dimensions

❏ Paper roll

Paper width: 69.5 + 0.5 mm (2.74 + 0.02”)

Maximum diameter: 83 mm (3.27”)

Paper thickness: 0.06 to 0.09 mm (.002 to .004”)

Paper weight: 52.3 to 64 g/m

2

(13.9 to 171 lbs)

(45 to 55 kg/1000 sheets; 788 x 1091 mm)

(20.41 to 24.94 lbs/1000 sheets; 31.02 x 42.95”)

Core diameter: 10 mm (0.39”) or more

Rev. A Features and General Specifications 1-5

Page 16

❏ Slip paper

Dimensions: 70 x 70 to 210 x 297 mm (W x H)

(2.76 x 2.76 to 8.27 x 11.69”)

Thickness: 0.09 to 0.36 mm (.004 to .014”)

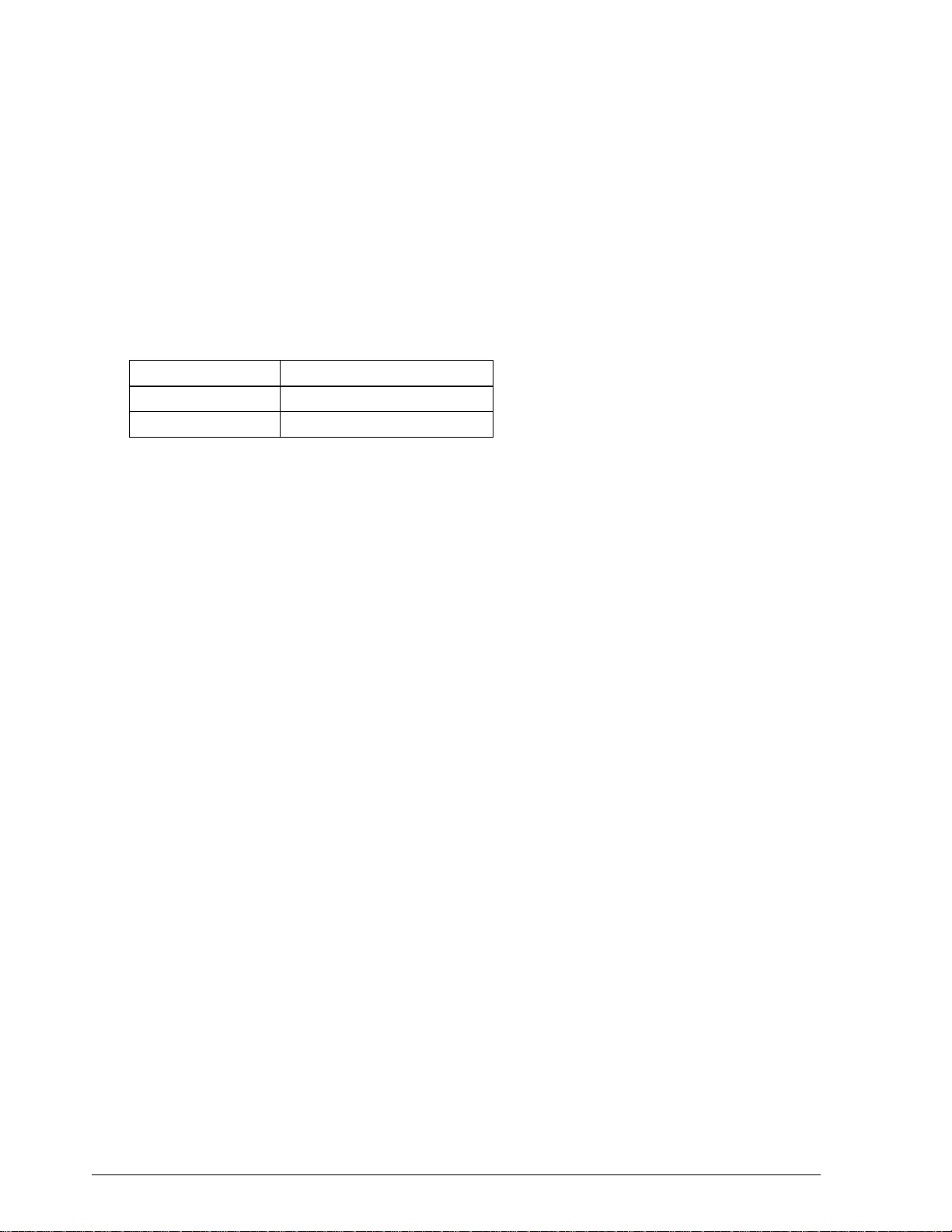

Temperature and copying capability

As copying capability is influenced by the ambient temperature, printing must be performed

under the conditions described in Table 1-3.

Table 1-3. Relationship Between Ambient Temperature and Number of Copies

Number of Copies Ambient Temperature

Original + 4 copies approx. 20

Original + 1 to 3 copies 5

to 40°C (41° to 104°F)

°

to 40°C (68° to 104°F)

°

Paper thickness and copying capability

❏ Plain paper (single sheet): 0.09 to 0.2 mm

(.0035 to .0079”)

❏ Carbon copy paper (original + 4 copies)

Backing paper 0.06 to 0.15 mm (.002 to .006”)

Copy paper and original paper 0.04 to 0.07 mm (.0016 to .003”)

Carbon paper Approx. 0.035 mm (.001”)

Total thickness 0.30 mm (.012”) or less (1 to 1 + 3)

0.36 mm (.014”) or less (1 + 4)

❏ Pressure-sensitive paper (original + 4 copies)

Backing paper 0.06 to 0.15 mm (.002 to .006”)

Copy paper and original paper 0.06 to 0.075 mm (.002 to .003”)

Total thickness 0.24 mm (.009”) or less (1 to 1 + 3)

0.30 mm (.012”) or less (1 + 4)

Note:

When using multi-ply paper that consists of an original and three copies, be sure to print with a 9 x 9 font.

If a 7 x 9 font is used, some characters on some of the copies may not be readable.

Check paper (only when the printer is used with the MICR reader)

Paper type: Normal paper

Total thickness: 0.09 to 0.2 mm (.0035 to .0079”)

1-6 Features and General Specifications Rev. A

Page 17

TM-U950/U950P Technical Manual

Size: 68 to 102 mm x 152 to 210 mm

(2.68 to 4.02” x 2.98 to 8.27”)

Weight: 70 to 90 kg paper

Notes on setting the print operation mode

❏ The GS E command sets print mode (printing speed and print head energizing time).

❏ When the power is turned on, normal mode is selected as the default. The printer

automatically switches from normal mode to copy mode when slip is selected by ESC c 0.

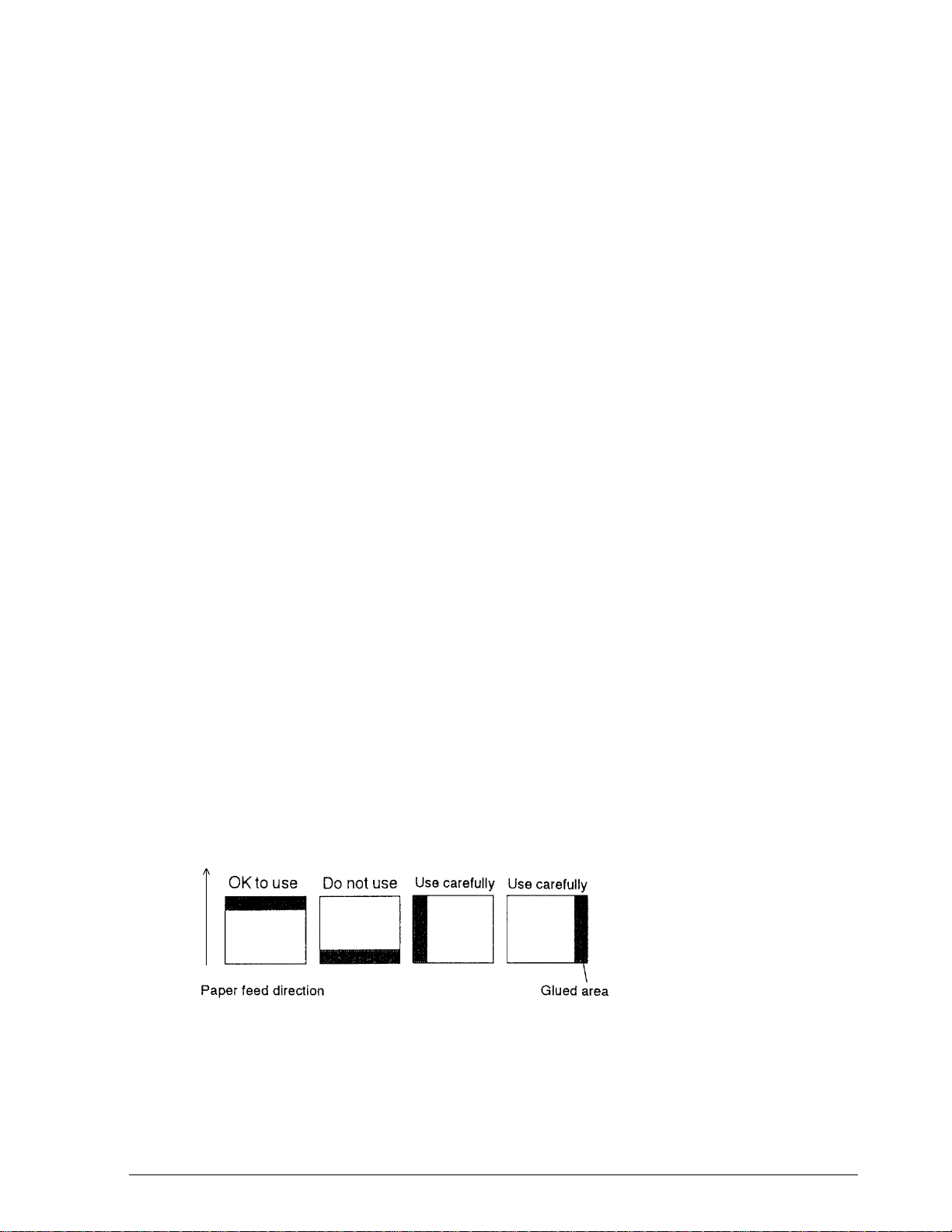

Notes on slip paper

❏ The slip paper must be flat, without curls or wrinkles, especially at the top edges. Otherwise,

the paper may rub against the ribbon and become dirty.

❏ There must be no glue on the bottom edge of slip paper. It is desirable for the glue to be on

the top edge. Choose slip paper carefully when the glue is on the right or left edge, since

paper feeding and insertion are affected by gluing conditions (e.g., glue quality, method,

and length) and glue location (see Figure 1-4). Be especially careful when slip paper is wide

and has the glue on the right or left edge, since meandering may occur.

❏ Since the slip insertion sensor uses a photo sensor, paper that has holes at the sensor

position, or is translucent, must not be used (see Figure 1-5).

❏ Since the slip ejection sensor uses a reflective photo sensor, paper that has holes or dark

portions with low reflection (less than 40% reflection) at the sensor position must not be

used (see Figure 1-6).

❏ Be sure to perform slip printing with a paper roll loaded to avoid incorrect paper feeding

due to paper jams.

❏ Use thinner paper (N30 or equivalent) between the top and bottom sheets of multi-ply

paper. If thick paper is used, the copy capability is lowered.

Notes on using personal check paper (for printers with an MICR reader)

❏ The personal checks must be flat, without curls, folds, or wrinkles (especially at the edges).

Otherwise, the check may rub against the ribbon and become ink-stained.

Figure 1-4. Slip Paper Glued Area

Rev. A Features and General Specifications 1-7

Page 18

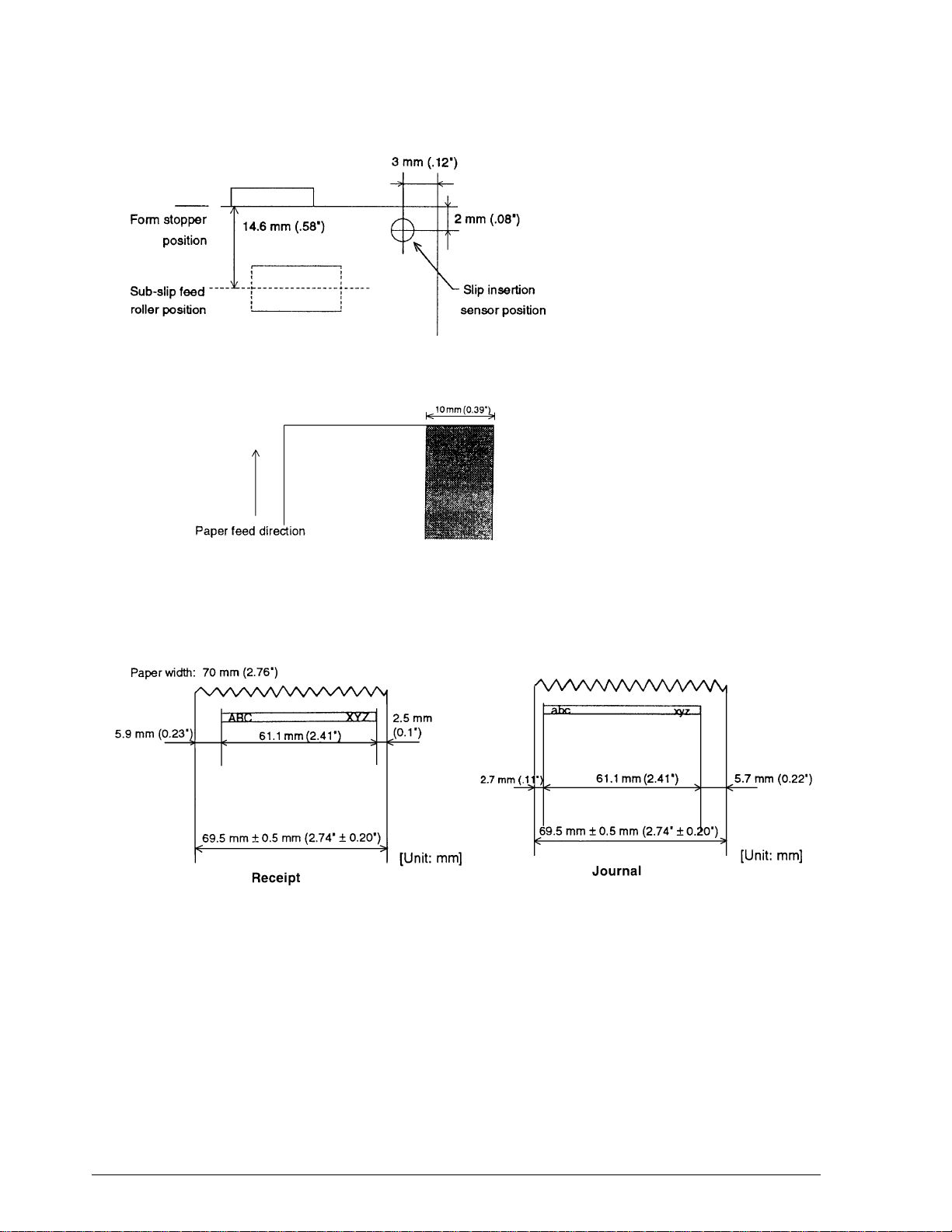

Figure 1-5. Slip Insertion Sensor Position

Figure 1-6. Paper Holes and Low Reflection Prohibited Area

Print area

❏ Paper roll

Figure 1-7. Paper Roll Print Area

1-8 Features and General Specifications Rev. A

Page 19

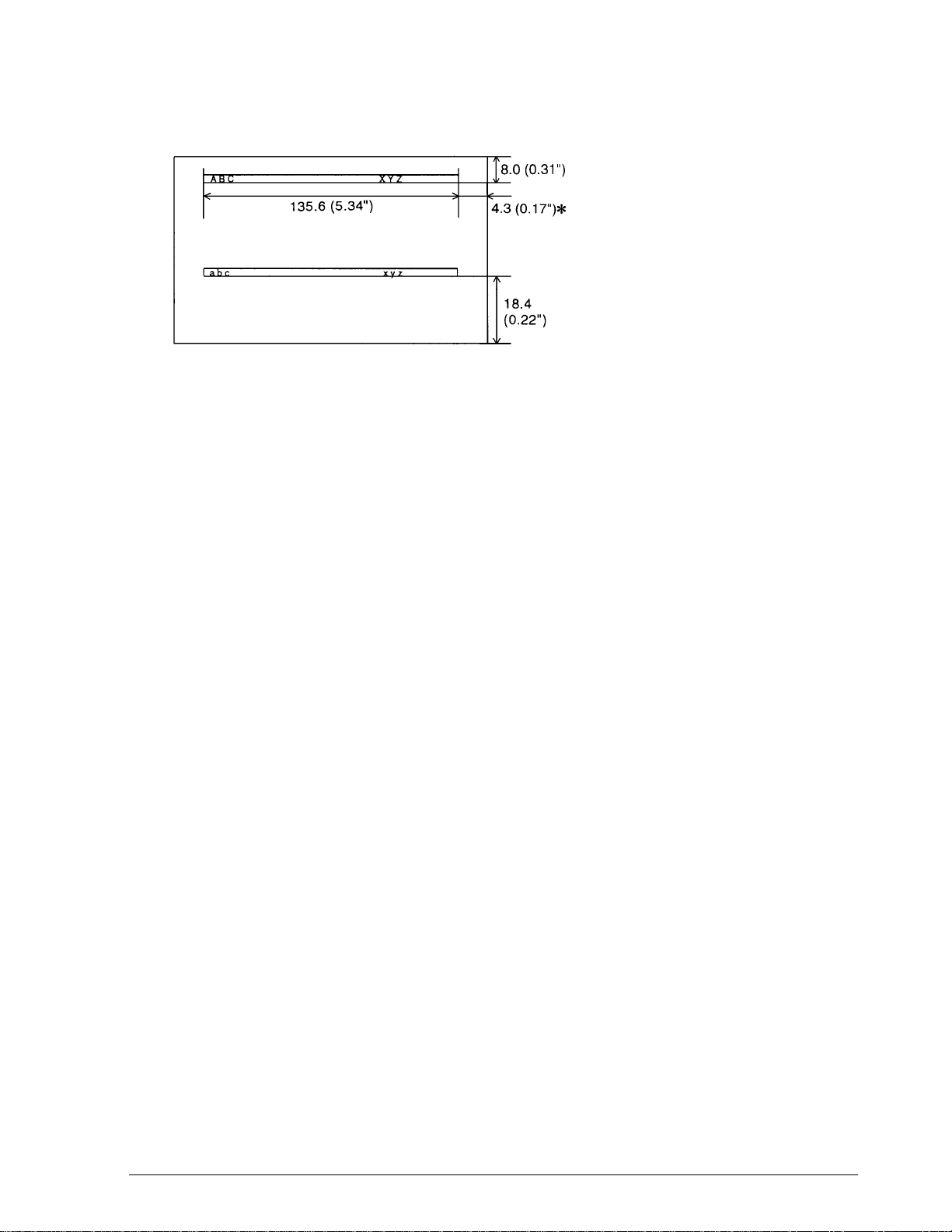

❏ Slip paper

Figure 1-8. Slip Paper Print Area

*Note

When the printer uses an MICR reader, this width is 5.0mm (0.20”).

Paper Roll Feed Mechanism

Feed principle

Drop-in loading

TM-U950/U950P Technical Manual

Paper roll near-end detection

Separate sensors for receipt paper and journal paper.

Journal Paper Take-up Mechanism

Automatic take-up by journal paper feed motor.

Auto-cutter

Auto-cutter is installed only on receipt side, for full and partial cuts.

Electrical Specifications

Printer operation voltage (using supplied AC adapter)

+24 V DC ± 10%

Ripple voltage: 300 mVpp or less (only when the printer is used with the MICR reader)

Current consumption

❏ During printing

Average approx. 1.8 A

(R/J, α - N, 40-character printing)

Peak approx. 8 A

❏ During slip paper feed to printing position:

Average approx. 0.3 A (for approx. 1.4s)

Rev. A Features and General Specifications 1-9

Page 20

❏ During standby

Average approx. 0.3 A

❏ Operating MICR reader

(when the printer used with the MICR reader)

Mean - approximately 2.3 A

(Approximately 1.4 seconds)

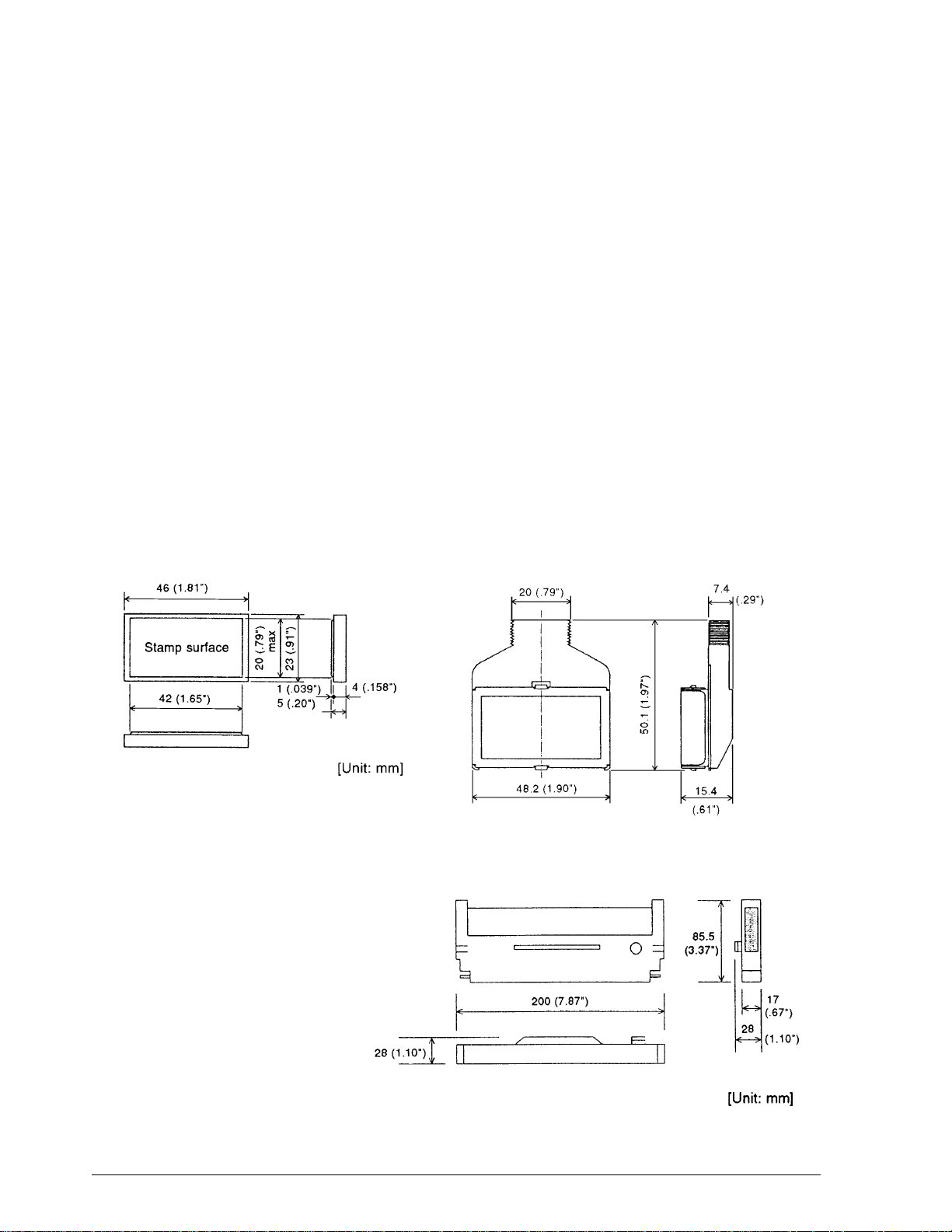

Stamp

Stamp mechanism is available as a factory option for the receipt side.

Recommended stamp: Fuji Copian CSP-2042C

Recommended ink: Fuji Copian Super Ink

Print area: 42 x 20 mm (1.65 x 0.79”)

(W x H)

Dimensions of stamp pad: See Figure 1-9.

Dimensions of stamp set: See Figure 1-10.

[Unit: mm]

Figure 1-9. Stamp Pad Dimensions Figure 1-10. Stamp Set Dimensions

Ink Ribbon

Ribbon cassette

ERC-31 (P)

ERC-31 (B)

Color

Purple: ERC-31 (P)

Black: ERC-31 (B)

Ribbon life (18 dots per character)

7,000,000 characters

1-10 Features and General Specifications Rev. A

Figure 1-11. Ribbon Cassette Dimensions

Page 21

TM-U950/U950P Technical Manual

Dimensions, Weight, Finish

Dimensions

251 x 298 x 194.5 mm (9.88 x 11.73 x 7.66”) (W x D x H)

Weight

Approx. 5.6 kg (12.3 lbs)

Color

EPSON Standard Gray

Environmental Specifications

Temperature

Operation: 5° to 40°C (41° to 104°F)

Storage: -10° to +50°C (14° to 122°F) (except ribbon)

Humidity

Operation: 30 to 80% (non-condensing; limit above 30°C: 30°C, 80%)

Storage: 30 to 90% (non-condensing; except ribbon)

Vibration resistance (in standard EPSON packing)

Frequency: 5 to 55 Hz

Acceleration: 2 G

Sweep: 5 minutes (one way)

Time: 1 h

Directions: X, Y, Z

No visible external or internal problems or operation failure after the above vibration test.

Shock resistance (in standard EPSON packing)

❏ With packing

Drop height: 50 cm (19.69”)

Angle: 1 angle, 3 surfaces, 6 sides

No visible external or internal problems or operation failure after the above drop test.

❏ Without packing

Drop height: 5 cm (1.97”)

Angle: 4 sides, one-point support

No damage when dropped while printer is off.

Rev. A Features and General Specifications 1-11

Page 22

Noise

63 dB (operating, measured in ANSI bystander position; printing on receipt and journal paper

roll)

Reliability

Mechanics

MCBF 5,000,000 lines (auto-cutter and stamp once every 15 lines)

Life expectancy 7,500,000 lines (The printer’s life is considered over when the

printer cannot function due to worn-out main parts such as

motor, solenoids, frames, and shafts.)

Life expectancy of print head 150,000,000 characters (average 2 dot/wire/1 character)

MICR reader mechanism (only when the printer is used with the MICR reader):

MCBF: 160,000 passes

Life: 240,000 passes

1 pass: reading characters to printing endorsements on a

U.S. personal check (152 mm (5.98”) long)

The MICR reader is defined to have reached the end of its

life when it cannot function properly because of wearing out

of the main parts (magnetic head, head holding roller, etc).

Certifications

Japan: EMI: VCCI Class 1

North America: EMI: FCC Class 1

Safety standards: UL1950-2TH-D3

C-UL

Europe: CE marking (printer with MICR reader under application)

EN55022

EN50082-1

EN45501 (except when connected to IM)

Safety standard: TÜV

1-12 Features and General Specifications Rev. A

Page 23

Hardware Configuration

Main Unit Configuration

Printer mechanism

TM-U950/U950P Technical Manual

Figure 1-12. TM-U950 Printer Mechanism Main Unit Configuration

Electrical circuit and unit on cases

Figure 1-13. TM-U950 Electrical Circuit and Unit on Cases Main Unit Configuration

Rev. A Features and General Specifications 1-13

Page 24

Main Unit Specifications

Paper feed motors

Receipt and journal paper feeding is performed by dedicated feed motors. Slip paper feeding is

performed by using the journal paper feed motor and a journal/slip switching solenoid.

Motor type

4-phase, 48-pole PM type stepping motor

Drive voltage

24 V DC + 10% (including voltage drop caused by drive transistor)

Winding resistance

Journal paper feed motor 35 Ω ± 7% at 25°C (77°F), per phase

Receipt paper feed motor: 42 Ω ± 7% at 25°C (77°F), per phase

Current consumption (per motor)

❏ Journal paper feed motor

Peak current: 1.94A in worst case

Average current: 615 mA at rated speed; 25°C (77°F), 24 V DC, 500 pps

930 mA max. in worst case

Hold current 92.5+42.5 mA per phase at normal hold, 25°C (77°F)

❏ Receipt paper feed motor

Peak current: 1.5 A in worst case

Average current: 510 mA at rated speed; 25°C (77°F), 24 V DC, 500 pps

770 mA max. in worst case

Hold current: Approx. 130 ± 50 mA per phase at normal hold, 25

Drive frequency

500 pps (minimum pulse interval 2.00 ms)

Drive principle

Constant voltage drive, 2-2 phase induction

Carriage motor

Motor type

4-phase, 48-pole PM type stepping motor

C (77°F)

°

1-14 Features and General Specifications Rev. A

Page 25

Drive voltage

24 V DC ± 10% (including voltage drop caused by drive transistor)

Winding resistance

TM-U950/U950P Technical Manual

9 Ω ± 7% at 25

C (77°F), per phase

°

Current consumption (per motor)

Peak current: 1.5 A in worst case

Average current: 550 mA at rated speed

Hold current: 150 mA± 8% per phase

Drive frequency

Standard mode: 1400 pps (pulse interval 714 µs)

Copy mode: 1200 pps (pulse interval 834 µs)

Drive principle

Constant-current chopper drive, 2-2 phase induction

Carriage feed pitch

0.3386 mm (1/75”) per pulse

Print head unit (print solenoids)

Number of solenoids: 9

Drive voltage: 24 V DC ± 10% (including voltage drop caused by drive

transistor)

DC resistance: 6.65 Ω ± 4% at 25°C (77°F)

Near-end sensors (journal, receipt)

A sensor is provided for the receipt and journal paper roll respectively. The sensors check the

diameter of each roll and activate the near-end alarm when the diameter falls below a userdetermined value.

Sensor type: Microswitch

Voltage: 5 V DC ± 5%

Output level: Low when near-end is detected

Paper roll sensors (journal, receipt) (*)

A sensor is provided in the paper path (receipt and journal side, respectively) of the printer

mechanism. These sensors check for the presence of paper, and accordingly control loading of

the paper roll.

Sensor type: Microswitch

Switch rating: 10 to 100 mA, 5 V DC (resistive load)

Contact condition: On when paper is present

(*) If the paper roll sensor detects the “no paper” condition while the cover is open, semi-

automatic loading can be performed by inserting the paper roll into the paper path.

Rev. A Features and General Specifications 1-15

Page 26

Slip paper insert sensor

This sensor is located in the slip paper loading path to detect the insertion of slip paper.

Sensor type: Photosensor

Voltage: 5 V DC ± 5%

Input current: Approx. 20 mA

Output level: High when slip paper is detected

Slip paper eject sensor

This sensor is located in the slip paper eject path to detect ejection of slip paper. If ejection is not

detected, the printer does not proceed to the next step.

Sensor type: Photosensor

Voltage: 5 V DC ± 5%

Cover open sensor (*)

This sensor detects the condition of the printer cover. If the cover is open, the printer

automatically goes off-line after the current printing operation and the carriage returns to the

home position at slow speed. The printer goes back on-line when the cover is closed.

Sensor type: Photosensor

Voltage: 5 V DC ± 5%

Input current: 10 mA

Output level: High when cover open is detected

(*) If the paper roll sensor detects the “no paper” condition while the cover is open, semi-

automatic loading can be performed by inserting the paper roll into the paper path.

Auto-cutter sensor

Sensor type: Mechanical contact sensor

Voltage: 5 V DC ± 5%

Current rating: 0.1 to 0.5 mA

Home position sensor

This sensor detects the carriage initial position (on the receipt paper side) and the carriage

abnormal operation.

Sensor type: Photosensor

Voltage: 5 V DC ± 5%

Output level: High when the carriage home position is detected

Carriage sensor

This sensor outputs signal synchronized with the carriage operation, and detects whether the

carriage operation is abnormal.

Sensor type: Photosensor

Voltage: 5 V DC ± 5%

Output level: High when sensor plate is detected

1-16 Features and General Specifications Rev. A

Page 27

TM-U950/U950P Technical Manual

MICR Reader (when the printer is used with the MICR reader)

(Not available for the TM-U950P)

Available fonts: E-13B, CMC7

Recognition rating: 98% or more (at 25

C)

°

Recognition rating is defined as follows:

Total number of checks - (number of sheets misread

and those not identified)

Recognition rating (%) =

× 100

Total number of checks

Check paper used for test is EPSON standard check paper. Checks must be flat, without curls,

folds, or wrinkles.

Connectors

All connectors are located on the rear panel of the printer. (Refer to Figure 1-1.)

Connector panels

14 25

8

1

1

Customer display

(DM-D) connector

Interface

connector

13

1

Drawer kick-

out connector

6

2

1

3

Power

connector

Interface connector Drawer kickout Power connector

Figure 1-14. Rear Panel Connectors

Interface

See the Interface section in this chapter.

Power supply connector

This connector is for the AC adapter.

Connector type: TCS7960-53-2010 (Hoshiden) or equivalent

Table 1-4. Power Supply Pin Assignment

Pin number Function

1 24 VDC

2 Signal ground

3NC

Shell Frame ground

connector

TM-U950PTM-U950

Note:

Be sure to ground the printer via the frame ground terminal on the metal strip on the rear panel.

Rev. A Features and General Specifications 1-17

Page 28

Drawer kick-out connector (modular connector)

Pulse specified by ESC p command is output to this connector. The host can confirm the status of

the input signal by using the DLE EOT, ESC u, GR r, or GS a (ASB) commands.

Connector type:

Printer side 52065-6615 (Molex) or equivalent

User side 6-position 6-contact (RJ12 telephone jack)

Table 1-5. Drawer Kick-out Connector Pin Assignment

Pin number Signal name I/O

1Frame ground —

2 Drawer kick-out drive signal 1 (*1) O

3 Drawer open/close signal (*2) I

4 + 24 V —

5 Drawer kick-out drive signal 2 (*1) O

6 Signal ground —

(*1) Drawer kick-out drive signal

The signal specified by the ESC p command is output from pins 2 and 5 of the connector.

Output voltage: Approx. 24 V

Output current: 1 A max.

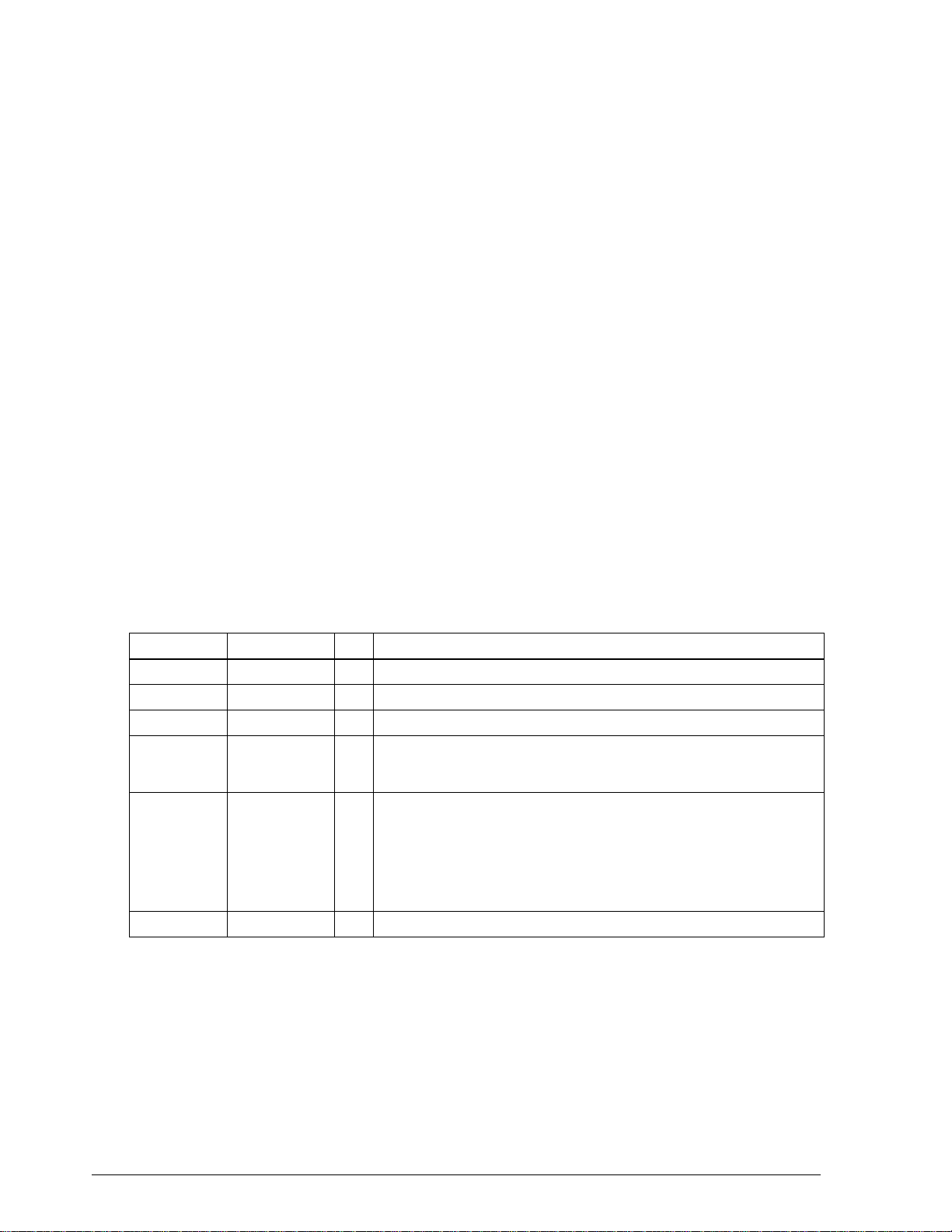

Output waveform: The waveform of the signal at pins 2 and 5 is shown in

Figure 1-15. (The ON time n1 and OFF time n2 are

determined by the ESC p command.)

n1 x 10ms n2 x 10ms

Figure 1-15. Drawer Kick-out Drive Signal Timing

(*2) Drawer open/close signal

The host computer can check the drawer open/close status with the DLE EOT, ESC u, GR r, or

GS a (ASB) commands.

Input signal level (connector pin 3)

Low = 0 to 0.8 V

High = 2 to 5 V

1-18 Features and General Specifications Rev. A

Page 29

TM-U950/U950P Technical Manual

Notes

❏

Use a shielded cable for the drawer connection.

❏

It is not possible to drive two drawers at the same time.

❏

Use a solenoid rated for at least 24 Ω as the drawer kick-out solenoid. Otherwise, excessive current

may damage the solenoid.

❏

The drawer must be powered from the printer (connector pin 4).

❏

Do not drive the drawer continuously.

Customer display connector (not supported on the TM-U950P)

This connector is for Epson customer display (DM-D series). Do not connect other customer

displays.

Connector type: Receptacle 52065-8845 (Molex) or equivalent

Table 1-6. Customer Display Connector Pin Assignment

Pin number Signal name I/O

1Frame ground—

2NC —

3TXD O

4DTR O

5DSRI

6 Signal ground —

7 +24V DC —

8 Power ground —

Interface

Serial interface

Data transfer principle Serial (RS-232 interface)

Synchronization Asynchronous

Handshake (*) DTR/DSR or XON/XOFF

Signal level

MARK: -3 to -15 V (logical “1”/OFF)

SPACE: +3 to +15 V (logical “0”/ON)

(Voltage measured at connector, referenced to SG)

Baud rate (*) 1200, 2400, 4800, 9600 bps

Word length (*) 7 or 8 bit

Rev. A Features and General Specifications 1-19

Page 30

Parity (*) None, even, odd

Number of stop bits 1 or more

Connector type D-SUB 25 female or equivalent

(*)Can be set with DIP switches on the bottom of the unit (See Tables 1-9 and 1-10.)

On-line/off-line switching

This printer has no on-line/off-line switch. It automatically goes off-line in the following cases:

❏ During self-test.

❏ When the cover is open.

❏ When the paper feed button (receipt or journal/slip) is used to advance the paper.

❏ When printing has stopped due to no paper (“no paper” condition selected with ESC c 4).

❏ During the interval between power-on (including reset using the interface) and the end of

the initialization sequence, until data can be received.

❏ When an error has occurred

❏ During the macro execution switch waiting status.

Table 1-7. Interface Connector Specifications and Functions

Pin number Signal name I/O Function

1FG—Frame ground

2 TXD O Transmit data

3 RXD I Receive data

4RTSO

6DSRI

7SG—Signal ground

DIP SW1-6 off: Same as DTR signal (Pin20)

DIP SW1-6 on: Logical product of DTR signals of DM-D and TM (if both are

SPACE, the printer can receive data.

Indicates whether the host is ready to receive data. SPACE indicates

“ready,” and MARK indicates “not ready.” If DTR/DSR control is used, the

printer checks this signal before sending data (except when sending

data by GS ENG, DLE ENQ, GS a). If XON/OFF control is used, this signal is

not checked.This signal can be used to reset the printer according the

DIP switch settings. The printer is reset when the signal is MARK with more

than 1 ms pulse width.

1-20 Features and General Specifications Rev. A

Page 31

Table 1-7. Interface Connector Specifications and Functions

Pin number Signal name I/O Function

1) When DTR/DSR control is selected, this signal indicates whether the

20 DTR O

25 INIT I

printer is busy. MARK indicates busy and SPACE indicates not busy. The

busy condition is changed using DIP switch 5 of the bank 2 as shown in

Table 1-7a.

2) When XON/OFF control is selected, the signal indicates whether the

printer is correctly connected and is ready to receive data. SPACE

indicates “ready”. The signal is always SPACE except in the following two

cases:

(o) During the interval between power-on and the time when the printer

is ready to receive data.

(o) During the self-test.

Changing the DIP switch setting enables this signal to be used as a reset

signal for the printer. The printer is reset when the signal remains SPACE for

1 ms or more.

Table 1-7a. Pin 20 Information

Printer status

During the interval between

power-on (reset using interface)

and the time when the printer is

ready to receive data.

During the self-test BUSY BUSY

When the cover is open. — BUSY

During paper feeding with the

paper feed button.

When the printing has stopped

due to a paper-end.

When an error has occurred. — BUSY

When the receive buffer becomes

full (*1).

DIP SW 2-5 status

ON OFF

BUSY BUSY

—BUSY

—BUSY

BUSY BUSY

TM-U950/U950P Technical Manual

(*1) The “buffer full” condition in this case starts when remaining buffer space falls to 16 bytes or

less and ends when it becomes 26 bytes or more. The printer ignores the data when the

remaining space in the receive buffer is 0 bytes.

Note

Pins 8 - 19 and 21 - 24 are not used.

Rev. A Features and General Specifications 1-21

Page 32

XON/XOFF control

When XON/XOFF control is selected, the XON and XOFF output timing is as described below.

(XON code: 11H; XOFF code: 13H) Transmit timing differs depending on the DIP switch 5 of the

bank 2.

Table 1.8. XON/XOFF Transmit Timing

Printer status

When the printer goes on-line after the power-on or reset with

interface.

When the receive buffer is released from the buffer full state. Transmit Transmit

XON transmission

When the printer changes to on-line. (*1) — Transmit

When the printer recovers from an error by the DLE ENQ 1 or DLE

ENQ 2.

When receive buffer becomes full. Transmit Transmit

XOFF transmission

When the printer changes to off-line. (*2) — Transmit

DIP SW 2-5 status

ON OFF

Transmit Transmit

—Transmit

(*1) XON is not transmitted when the receive buffer is full.

(*2) XOFF is not transmitted when the receive buffer is full.

Notes on setting DIP switch 2-5 on

❏

The printer stops printing mechanism operation but does not go off-line when an error has occurred,

printing stops due to a paper-end, or paper is fed using the paper feed button.

❏

When setting DIP SW 2-5 on to enable handshaking with the host computer, be sure to check the

printer status by the GS a command and automatic status transmission function. In this setting, the

default values of n for GS a is 2, and the printer automatically transmits the changes in on-line/offline.

❏

When using DLE EOT, DLE ENQ, and GS ENQ, be sure that the receive buffer does not become full.

a) When using a host that cannot transmit data when the printer is busy:

If an error has occurred, DLE EOT, DLE ENQ, and GS ENQ cannot be used when the printer is

busy due to receive buffer-full.

b) When using a host that can transmit data when the printer is busy:

When the receive buffer becomes full while transmitting data, DLE EOT, DLE ENQ, or GS ENQ

using between the bit image data is processed as bit image data. The data transmitted when the

receive buffer is full may be lost.

1-22 Features and General Specifications Rev. A

Page 33

The following illustrates an example serial interface connection:

TM-U950/U950P Technical Manual

Host (DTE example 8251)

TXD

DSR

CTS

RXD

DTR

FG

SG

When connected to a DCE-type device, data should not be

sent non-stop (without handshake).

DTE = Data Terminal Equipment

DCE = Data Circuit Terminating Equipment

Printer

RXD

DTR

RTS

TXD

DSR

FG

SG

Figure 1-16. Serial Interface Connection Example

Parallel interface

(Bidirectional parallel interface in accordance with the IEEE 1284 nibble/byte modes).

Copyright © 1994 by the Institute of Electrical and Electronic Engineers, Inc.

Compatibility mode

(Data transmission from host to printer: Centronics compatible)

Data transmission: 8-bit parallel

Synchronization: Externally supplied nStrobe signals

Handshaking: nAck and Busy signals

Signal levels: TTL compatible

Connector: 57RE-40360-830E(DDK) or equivalent (IEEE 1284 Type B)

Reverse mode

(Data Transmission from printer to host)

The STATUS data transmission from the printer to the host is accomplished in the Nibble or

Byte mode.

This mode allows data transmission from the asynchronous printer under the control of the

host. Data transmission in the Nibble mode are made via the existing control lines in units of

four bits (Nibble). In the Byte mode, data transmission is accomplished by making the 8-bits

data lines bidirectional.

Neither mode can operate at the same time as the compatibility mode, so switching is always

required.

The 1284 Nibble/Byte modes may be subject to change without notice.

Rev. A Features and General Specifications 1-23

Page 34

TM-U950P printer status and signals

Pin No. Source Compatibility mode Nibble mode Byte mode

1 Host nStrobe HostClk HostClk

2 Host/Printer Data0 (LSB) Data0 (LSB) Data0 (LSB)

3 Host/Printer Data1 Data1 Data1

4 Host/Printer Data2 Data2 Data2

5 Host/Printer Data3 Data3 Data3

6 Host/Printer Data4 Data4 Data4

7 Host/Printer Data5 Data5 Data5

8 Host/Printer Data6 Data6 Data6

9 Host/Printer Data7 (MSB) Data7 (MSB) Data7 (MSB)

10 Printer nAck PtrClk PtrClk

11 Printer Busy PtrBusy/Data3, 7 PtrBusy

12 Printer PError

13 Printer Select Xflag/Data1, 5 Xflag

14 Host nAutoFd HostBusy HostBusy

15 NC ND ND

16 GND GND GND

17 FG FG FG

18 Printer Logic-H Logic-H Logic-H

19 to 30 GND GND GND

31 Host nInit nInit nInit

32 Printer nFault nDataAvail/Data0, 4 nDataAvail

33 GND ND ND

34 Printer DK_STATUS ND ND

35 Printer +5V ND ND

36 Host nSelectIn 1284-Active 1284-Active

AckDataReq/

Data2, 6

AckDataReq

NC: Not connected, ND: Not defined

Notes:

❏ A prefix "n" to signal names refers to low active signals.

❏ If the host does not have any one of the signal lines listed above, two-way communication

fails.

❏ For interfacing, signal lines should use twisted pair cables with the return sides connected to

the signal ground level.

1-24 Features and General Specifications Rev. A

Page 35

TM-U950/U950P Technical Manual

❏ Interfacing conditions should be all based on the TTL level. In addition, both the rise time

and fall time of each signal must be 0.5 µs or less.

❏ Data transmission should not ignore the signal nAck or Busy. An attempt to transmit data

with either signal, nAck or Busy, ignored can cause lost data. (Data transmission to the

printer should be made after verifying the nAck signal or while the Busy signal is low.)

❏ Interface cables should be as short as possible.

Precautions on receiving status from the printer

The printer status transmission is available by using the both-way communication facility in the

Nibble/Byte mode in accordance with the IEEE 1284 mode.

The following precautions must be taken for receiving the status from the printer.

❏ The allowable capacity of the printer’s internal buffer is 100 bytes. Status signals exceeding

this capacity will be discarded. To prevent possible loss of status data, the host should

always be ready for data reception (reverse mode).

❏ When ASB is used, the host should be in the wait state for data reception (reverse idle

mode). When this state is not available, the host should enter the reverse mode to always

monitor the presence of data.

❏ When ASB is used, preference should be given to the ASB status for transmission over the

other status signals. Any accumulated ASB status signals left for transmission from the last

to the newest ASB status transmission should be transmitted together at one time as one

ASB status showing the change has been made, followed by the latest ASB status.

Example: In the normal (wait) state, the ASB status is configured as follows:

1st status 2nd status 3rd status 4th status

0000 0000 0000 0000 0000 0000 0000 0000

When the following sequence of operations is performed, near end detection, cover open, cover

closed, the following pieces of data are accumulated.

1st status 2nd status 3rd status 4th status

1 0000 0000 0000 0000 0000 0011 0000 0000 Near end detection

2 0010 1000 0000 0000 0000 0011 0000 0000 Cover open

3 0000 0000 0000 0000 0000 0011 0000 0000 Cover closed

When the ASB status is received following this, a total of 8 bytes of ASB will be transmitted as

follows.

1st status 2nd status 3rd status 4th status

Accumulated ASB (1+2+3) 0010 1000 0000 0000 0000 0011 0000 0000

+ 1st status 2nd status 3rd status 4th status

The latest ASB (3) 0000 0000 0000 0000 0000 0011 0000 0000

Rev. A Features and General Specifications 1-25

Page 36

Switching between on-line and off-line

The TM-U950P printer does not have an on-line/off-line button. The printer goes off-line in the

following conditions:

❏ Between the time when the power is turned on (including reset using the interface) and

when the printer is ready to receive data.

❏ During the self-test.

❏ When the cover is open.

❏ During paper feeding using the paper feed button.

❏ When the printer stops printing due to a paper-end (when the paper-end sensor detects a

paper end or when the paper near-end sensor is enabled by ESC c 4 and detects a paper-

end).

❏ During the macro execution standby state. (The macro is executed by pressing the paper

feed button.)

❏ When an error has occurred.

Notes on setting DIP switch 2-5 to ON

The printer mechanism stops but does not become busy when an error has occurred, the cover is

open, printing stops due to a paper end, or paper is fed using the PAPER FEED button.

When setting DIP switch 2-5 to ON to enable handshaking with the printer, be sure to check the

printer status using the GS a command and the ASB function. In this setting, the default value

of n for GS a is 2. The printer automatically transmits the printer status, depending on on-line/

off-line changes.

When using DLE EOT, DLE ENQ and GS ENQ, be sure that the receive buffer does not become

full.

❏ When using a host that cannot transmit data when the printer is busy and if an error occurs,

DLE EOT, DLE ENQ and GS ENQ cannot be used when the printer is busy due to a receive

buffer-full state.

❏ When using a host that can transmit data when the printer is busy and the receive buffer

becomes full while transmitting bit-image data, a DLE EOT, DLE ENQ or GS ENQ used

while sending bit-image data is processed as bit-image data, not as acommand. Secondly,

any data transmitted when the receive buffer is full may be lost. Thirdly, data sent during

data entry or data sent when the printer is busy may be lost regardless of the DIP switch

setting.

Example: Check the printer status using ESC v or ESC u after transmitting each line of data

and use the 2K byte receive buffer. Transmit one line of data so that the receive buffer does

not become full.

1-26 Features and General Specifications Rev. A

Page 37

TM-U950/U950P Technical Manual

Switches and Buttons

The power switch is located on the front side of the printer, at the lower left. The operation panel

buttons are located on the right top side of the printer. Two banks of DIP switches are located on

the bottom of the printer. (See Figure 1-1.)

Power switch

Turns the printer on or off.

Power switch cover guards the power switch from incorrect operation.

For using the cover see Mounting the Power Switch Cover in Chapter 3.

Operation panel buttons

The ESC c 5 command determines whether or not the operation panel buttons are active.

❏ RECEIPT FEED button

Type: Non-locking push button

Function: If this button is pushed once and released, the printer feeds

receipt paper for one line based on the line spacing set by ESC 2

and ESC 3. If this button is held down, the printer feed paper

continuously.

The paper is fed after the carriage is moved to the center of the

receipt paper roll.

❏ JOURNAL/SLIP FEED button

Type: Non-locking push button

Function: If this button is pushed once and released, the printer feeds

journal paper for one line based on the line spacing set by ESC 2

and ESC 3. If this button is held down, the printer feeds paper

continuously.

When this button is pushed in slip mode (slip LED lights or

blinks), the printer feeds slip paper.

In 2-sheet mode, the paper is fed after the carriage is moved to the

center of the journal paper roll.

In slip mode, the paper is fed after the carriage is moved to the

right edge of the slip paper.

Notes

❏

When the printer cover is open, these buttons are active regardless of the ESC c 5 setting.

❏

Be careful not to catch your finger in the printer when you push these buttons with the printer cover

open.

Rev. A Features and General Specifications 1-27

Page 38

DIP switch settings for the TM-U950

Table 1-9. DIP Switch Bank 1

Switch number Function ON OFF

1 Data word length 7 bit 8 bit

2 Parity check Yes No

3 Parity type Even Odd

4

5

6 Connection of customer display (*) Connected Not connected

7 Data reception error handling Disregard Print “?”

8 Handshake XON/XOFFD DTR/DSR

Data transfer rate

Transfer rate (bps) 4 5

1200 On On

2400 Off On

4800 On Off

9600 Off Off

(*) Effective when a direct connection customer display is connected to the DM-D connector of

the printer.

Table 1-10. DIP Switch Bank 2

Switch number Function ON OFF

1 Automatic CR Always yes Always no

2 Reception buffer size 32 bytes 2048 bytes

3 Font selection (default setting) 9 x 9 7 x 9

4 Carriage speed (paper roll initial setting) Low speed High speed

5 Handshake operation (condition for BUSY) Receive buffer full Off line or receive buffer full

6 Internal use Fixed —

7 Interface pin 6 reset signal Used Not used

8 Interface pin 25 reset signal Used Not used

❏ When the interface connector pin 6 is used to reset the printer, the printer is reset at MARK

with the RS-232C level.

❏ When the interface connector pin 25 is used to reset the printer, the printer is reset at SPACE

with the RS-232C level, and is reset at high with the TTL level.

Notes

❏

DIP switches (excluding switches 1, 7, and 8 of switch bank 2) are effective only while the printer

power is turned on. If the DIP switch setting is changed after the printer power is turned on, the

change is not effective.

❏

If DIP switch 7 or 8 of the switch bank 2 is on while the printer power is turned on, the printer may be

reset, depending on the signal state. DIP switches should not be operated while the printer power is

turned on

1-28 Features and General Specifications Rev. A

Page 39

TM-U950/U950P Technical Manual

DIP switch settings for the TM-U950P

Table 1-9a. DIP Switch Bank 1

Switch number Function ON OFF

1Undefined——

2Undefined——

3Undefined——

4Undefined——

5Undefined——

6 Internal use — Fixed

7Undefined——

8Undefined——

Table 1-10a. DIP Switch Bank 2

Switch number Function ON OFF

1 Auto line feed Always enabled Always disabled

2 Receiver buffer 32 bytes 2048 bytes

3 Font selection (default) 9x9 7x9

4

5 Handshaking (BUSY condition) Receive buffer-full Off-line or receive buffer-full

6 Internal use Fixed —

7Undefined — —

8 Internal use Fixed —

Carriage moving speed

(default for paper roll printing)

Low High

Note

❏

DIP switches are effective only while the printer power is turned on. If the DIP switch setting is

changed after the printer power is turned on, the change is not effective.

Rev. A Features and General Specifications 1-29

Page 40

Indicators

The indicators are located on the operation panel. (See Figure 1-1.)

POWER LED (green)

On: Stable power (+5 V) is supplied.

Off: Stable power (+5 V) is not supplied.

ERROR LED (red)

On: Printer is off-line (except when paper is being advanced with the FEED buttons

and during self test printing).

Off: Normal operation

Flashing: An error has occurred. (See Error Types and Countermeasures on page 4-23).

RECEIPT OUT LED (red)

On: Near-end condition or paper end is detected for paper roll at receipt side.

Off: Paper roll at receipt side is sufficient.

Flashing: Stand by for test printing

JOURNAL OUT LED (red)

On: Near-end condition or paper end is detected for paper roll at journal side.

Off: Paper roll at journal side is sufficient.

Flashing: Stand by for test printing

SLIP LED (green)

On: Slip paper mode

Off: Two-sheet (paper roll) mode

1-30 Features and General Specifications Rev. A

Page 41

TM-U950/U950P Technical Manual

Blinking: Stand by for slip paper insertion

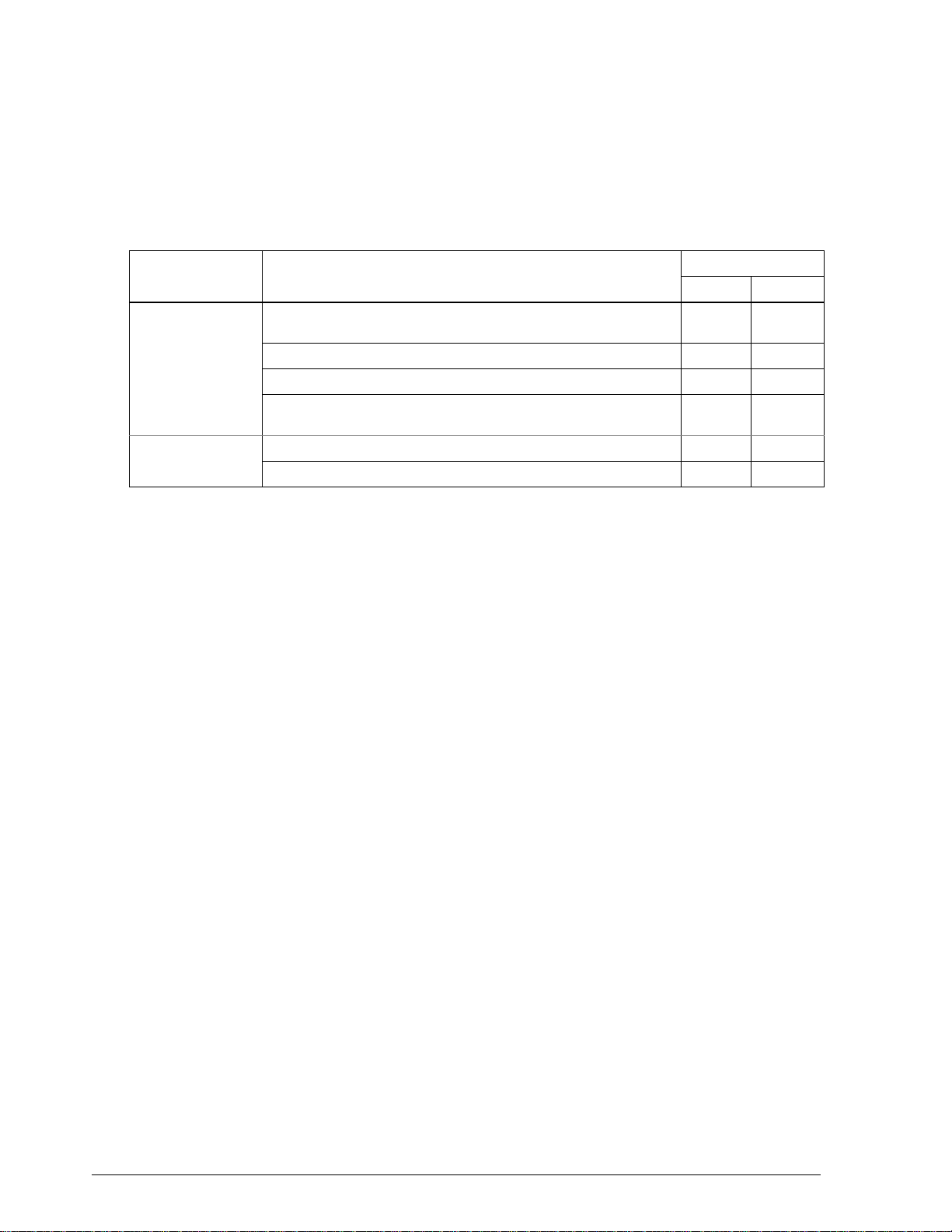

Blinking pattern

Blinking: Stand by for slip paper removal

Blinking pattern

Blinking: Personal check waiting state (when the printer is

used with the MICR reader)

Functions

Error Processing

Error detection

When the printer detects an error, it carries out the following operation sequence:

❏ All running operations are stopped.

❏ The printer goes off-line

❏ The ERROR LED flashes. (See Error Types and Countermeasures on page 4-23.)

Error recovery

The commands DLE ENQ 1 and DLE ENQ 2 are used to recover from a recoverable error (*1).

Notes

❏

If slip paper is selected and DLE ENQ 1 is used to recover from a recoverable error, the printer ejects

the remaining slip paper and repeats the loading process.

❏

When recovering from a slip paper eject error, the printer ejects the paper but does not repeat loading.

❏

When the printer recovers from an error using DLE ENQ 2 while slip paper is selected, the printer

first ejects the slip, then goes to 2-sheet mode.

❏

When an unrecoverable error (*2) has occurred, turn off the printer as soon as possible.

(*1) Errors (6) to (10) in Table 4-5 in Chapter 4 are the recoverable errors.

(*2) Errors (1) to (5) in Table 4-5 in Chapter 4 are the unrecoverable errors.

Rev. A Features and General Specifications 1-31

Page 42

Data receive error

When an error is detected in data received by the printer (parity, framing, or overrun error), the

data is either ignored or replaced to “?”, depending on the DIP switch setting.

Self-test

The self-test checks the following items:

❏ Control circuit operation

❏ Printer mechanism operation

❏ Print quality

❏ Control ROM version (on status printout)

❏ DIP switch settings (on status printout)

❏ MICR reader circuit function check (for printers with an MICR reader)

For details about the self-test, please see Self-test in Chapter 4.

Hexadecimal Dumping

Hexadecimal dumping function

This function prints the data transmitted from the host computer in hexadecimal numbers and

in its corresponding characters.

Starting hexadecimal dumping

Open the cover and turn the power on while pressing the RECEIPT FEED button, then close the

cover. The printer first prints “Hexadecimal Dump” on the paper roll and prints the received

print data in hexadecimal numbers and in its corresponding characters.

Notes

❏

If no characters correspond to the data received, the printer prints “.”.

❏

During hexadecimal dumping, any commands other than DLE EOT, DLE ENQ, and GS ENQ do

not function.

Ending hexadecimal dumping

Hexadecimal dumping ends by turning the power off or resetting the printer after printing has

finished.

1-32 Features and General Specifications Rev. A

Page 43

TM-U950/U950P Technical Manual

Printing example.

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 : .!.&.@@

1B 25 01 1B 63 34 00 1B : .%..C4..

41 42 43 44 45 46 47 48 : ABCDEFGH

Printing Operation

Sensors and printing operation

The ESC c 4 command can be used to select whether the printer should stop or continue printing

when the “no paper” condition is detected. The following sensors are involved:

Two-sheet mode: Journal near-end sensor

Receipt near-end sensor

Journal paper sensor (*1)

Receipt paper sensor (*1)

Slip paper mode: Slip paper insert sensor

(*1) The journal and receipt paper roll sensors are used for auto-loading and cannot be used for

paper-end detection. Printing may not be stopped even if the sensors are selected by ESC c

4. Therefore, use the near-end sensors to detect the paper roll end.

When “stop printing” is selected

❏ Two-sheet mode

When the “no paper” condition is detected, the printer automatically goes off-line. To resume

printing, close the cover after inserting a new paper roll.

❏ Slip paper mode

When the “no paper” condition is detected, the printer continues to print on the printable area,

ejects the paper, and waits for the paper to be removed. The printer then stands by for paper

insertion.

Buffer full printing

After the maximum number of characters per line has been received and processed, the line is

printed and the paper is advanced automatically when additional data is received.

Rev. A Features and General Specifications 1-33

Page 44

Options

AC Adapter (PS-150)

Specifications

Input specifications

Rated input voltage: 90 to 110 V AC

(specified at time of purchase): 108 to 132 V AC