Page 1

Technical Reference Guide

M00079804

Rev. E

Page 2

TM-U330 Technical Reference Guide

Cautions

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson

Corporation.

❏ The contents of this document are subject to change without notice. Please contact us for the latest information.

❏ While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or abuse of this product or

unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to strictly comply with Seiko

Epson Corporation’s operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original Epson Products or Epson Approved Products by Seiko Epson

Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation in the United States and/or other countries.

All other trademarks are the property of their respective owners and used for identification purpose only.

ESC/POS Command System

Epson ESC/POS is a proprietary POS printer command system that includes patented or patentpending commands. ESC/POS is

compatible with most Epson POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises a set of highly

functional and efficient commands and also offers the flexibility to easily make future upgrades.

©Seiko Epson Corporation 2014-2018. All rights reserved.

ii

Page 3

About This Manual

Aim of the Manual

This manual was created to provide information on the TM-U330 printer for anyone who is developing

hardware, installations, or programs. Programmers will also want to consult other documents.

Contents of the Manual

Chapter 1, "General Information." General description of features plus specifications.

Chapter 2, "System Planning." Contains introduction of control methods and each

connection form.

Chapter 3, "Setup." Contains information on such matters as memory

switches, error processing for using TM-U330.

Chapter 4, "Troubleshooting." Contains useful information for using.

Chapter 5, "Application Development

Information."

Appendix "Character Code Table." Contains the supported character tables.

Contains useful information for programming.

iii

Page 4

TM-U330 Technical Reference Guide

Important Safety Information

This section contains important information intended to ensure safe and effective use of this product.

Please read this section carefully and store it in an accessible location.

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the

following carefully before handling the product.

!WARNING:

Warnings must be observed carefully to avoid serious bodily injury.

!CAUTION:

Cautions must be observed to avoid minor injury to yourself, damage to your equipment, or loss of data.

QNote:

Notes have important information and useful tips on the operation of your equipment.

Safety Precautions

!WARNING:

❏

Shut down your equipment immediately if it produces smoke, a strange odor, or unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your dealer or a Seiko

Epson service center for advice.

❏

Never attempt to repair this product yourself. Improper repair work can be dangerous.

❏

Never disassemble or modify this product. Tampering with this product may result in injury or fire.

❏

Be sure to use the specified power source. Connection to an improper power source may cause fire.

❏

Do not allow foreign matter to fall into the equipment. Penetration by foreign objects may lead to fire.

❏

If water or other liquid spills into this equipment, do not continue to use it. Continued use may lead to

fire. Unplug the AC cable immediately and contact your dealer or a Seiko Epson service center for advice.

❏

Do not use aerosol sprayers containing flammable gas inside or around this product. Doing so many

cause fire.

iv

Page 5

!CAUTION:

❏

Do not connect cables in ways other than those mentioned in this manual. Different connections may

cause equipment damage and burning.

❏

Be sure to set this equipment on a firm, stable, horizontal surface. Product may break or cause injury if it

falls.

❏

Do not use in locations subject to high humidity or dust levels. Excessive humidity and dust may cause

equipment damage or fire.

❏

Do not place heavy objects on top of this product. Never stand or lean on this product. Equipment may

fall or collapse, causing breakage and possible injury.

❏

Take care not to injure your fingers on the manual cutter

• When you remove printed paper

• When you perform other operations, such as loading/replacing roll paper

❏

To ensure safety, unplug this product before leaving it unused for an extended period.

❏

Before moving the product, unplug it and unplug all cables connected to it.

Notes on Usage

❏ Do not open the cover during printing or when the autocutter is being operated.

❏ Do not install the printer in a dusty place.

❏ Protect the printer from impact.

❏ Cords or other foreign objects must not be caught on the printer.

❏ Do not apply excessive force to the printer case.

❏ Do not place food or beverages such as coffee on the case of the printer.

Notes on Installation

When using the printer, be sure that the printer is installed horizontally.

Caution Labels

The caution labels on the product indicate the following precautions.

!KCAUTION:

The print head and the motor can be very hot during printing and immediately after printing. Touching it

may cause burns.

v

Page 6

TM-U330 Technical Reference Guide

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices

related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc.; you should use this product only after giving consideration to including

fail-safes and redundancies into your design to maintain safety and total system reliability. Because this

product was not intended for use in applications requiring extremely high reliability/safety, such as

aerospace equipment, main communication equipment, nuclear power control equipment, or medical

equipment related to direct medical care, etc., please make your own judgment on this product’s suitability

after a full evaluation.

vi

Page 7

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iii

Aim of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iii

Contents of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iii

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iv

Key to Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iv

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -iv

Notes on Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -v

Notes on Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -v

Caution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -v

Restriction of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -vi

Chapter 1 General Information

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Product Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Standard Parts Included with the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Related materials for TM-U330 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Ribbons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Roll paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Product Specifications Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Printing and paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Autocutter (for Type B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Paper Roll Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Other Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

External Dimensions and Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

External Dimensions and Mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Chapter 2 System Planning

Control Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Selecting a Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

ESC/POS Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Epson ePOS SDK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Software and Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

How to Get Software and Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Printer Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Connecting the Optional Customer Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter 3 Setup

Part Name and Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Part name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

The Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Setup Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Printer setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Installing or Replacing the Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing

Connecting the AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

the Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

vii

Page 8

TM-U330 Technical Reference Guide

Connecting the Printer to the Host PC / POS Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Adjusting Various Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

How to Confirm Current Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Memory Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Memory Switch Setting Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Adjusting Roll paper width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Adjusting Position of Roll Paper Near End Detector (factory option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Install a Printer Driver in the Host PC / POS Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Advanced Printer Driver (APD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Self Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Chapter 4 Troubleshooting

LED Blinking Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Error Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Removing a Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Autocutter Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Printer prints “?“ or Incorrect Data With Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Print Speed is Slow When Using Windows Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Printer doesn’t cut roll paper with the autocutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Chapter 5 Application Development Information

Various Status Categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Printer Status on APD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Cash Drawer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Advanced Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

ESC/POS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

NV memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

NV Bit-image Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Advanced Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

OPOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

ESC/POS command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Printing for journal used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

FAQ List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Q. Drawer kick does not operate properly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Q. Unable to print a part of Page 0 in Visual Basic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

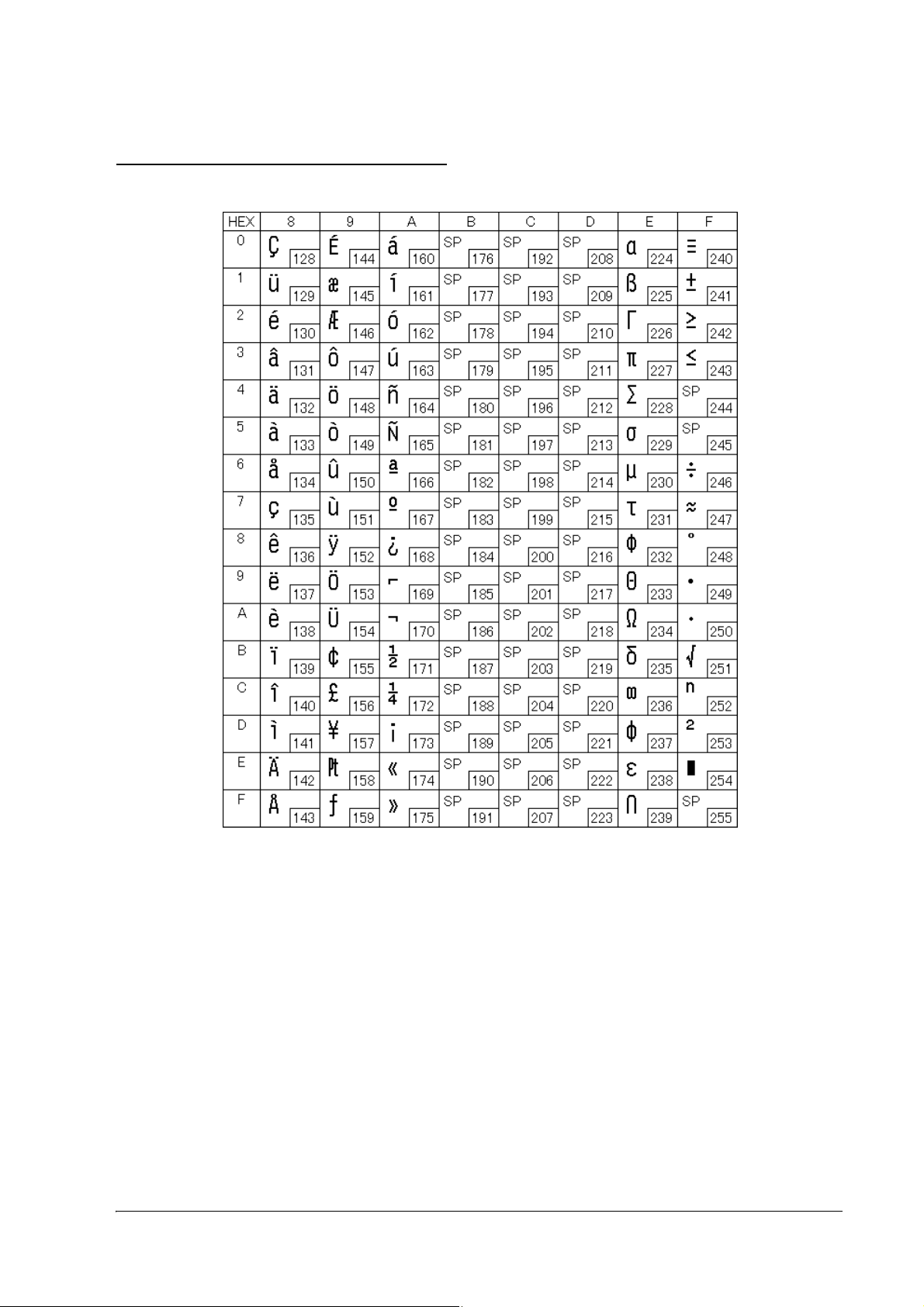

Appendix A Character Code Table

Common to all pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Page 0 (PC437: USA, Standard Europe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

International Character Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

viii

Page 9

TM-U330 Technical Reference Guide

Chapter 1

General Information

1.1 Features

The TM-U330 is a high reliable 24-pin impact dot matrix printer that provide precision text and graphics.

The TM-U330 has the same footprint as TM-U220.

1.1.1 General

❏ Compact and lightweight.

❏ 2 model types are provided. (See "Printer types" (page 1-2))

❏ Excellent reliability and long life due to adoption of a stepping motor both for moving the carriage

and for paper feeding.

❏ Supports paper roll with black mark

1.1.2 Printer handling

❏ Easy drop-in paper loading and easy maintenance

❏ Cable connectors are housed in the bottom of the printer.

❏ Built-in two drawer kick interface connectors

❏ Built-in autocutter (for type B)

1.1.3 Printing

❏ High-speed printing through logic-seeking control

❏ Two-color printing (black and red)

❏ Can print on various paper wide range (76 / 69.5 / 57.5 mm)

1.1.4 Software

❏ Command protocol is based on the ESC/POS proprietary command system.

❏ OPOS ADK and Windows printer driver are available.

❏ The Epson ePOS SDK is provided for iOS, Android and Windows application, and Web application

development.

The Epson ePOS SDK is a software development kit that integrates the ePOS-Print SDK and the

ePOS-Device SDK.

General Information 1-1

Page 10

1.2 Product Structure

1.2.1 Printer types

TM-U330 has 2 model types: B, D. The features are as following.

TM-U330B: Autocutter is installed

TM-U330D: Autocutter is not installed

Interface type:

Serial interface model: Built-in USB + RS-232C

Parallel interface model: Built-in USB + Bidirectional parallel (IEEE1284)

LAN interface model: Ethernet (10BASE-T, 100BASE-TX)

1.2.2 Standard Parts Included with the Printer

❏ Exclusive ribbon cassette [ERC-45(B/R)]

❏ Power switch cover

❏ AC adapter

❏ AC cable

❏ Wire saddle

*

*

❏ User’s Manual

* May not be included depending on the printer model.

1.2.3 Related materials for TM-U330

TM-U330 has the related materials listed in the following table.

Category Name Description

Options DF-10 Affixing tape for fixing the printer

DM-D110, DM-D210 Direct connection customer display (available only for some serial interface

models and some USB models)

(See the below NOTE also.)

POS

accessories

Please contact your dealer to get these.

DM-D series These are customer displays. (Line Display)

1-2 General Information

Page 11

TM-U330 Technical Reference Guide

1.3 Consumables

1.3.1 Ribbons

This printer needs a ribbon cassette to print receipts. We provide 2 ribbon cassettes:

❏ EPSON ribbon cassette, ERC-45 (B) (Life: 3,000,000 characters / Color: Black)

❏ EPSON ribbon cassette, ERC-45 (B/R) (Life: 1,500,000 characters / Color: Black)

(Life: 750,000 characters / Color: Red)

Note:

These ribbon cassette life numbers are under the Epson test conditions.

1.3.2 Roll paper

We provide roll paper and carbon roll paper with 1 copy for this printer. The widths are 76 mm, 69.5 mm,

and 57.5 mm {3.00"/2.74"/2.26"}.

Note:

The paper 69.5 mm wide is usable only when the mark sensor is disabled.

General Information 1-3

Page 12

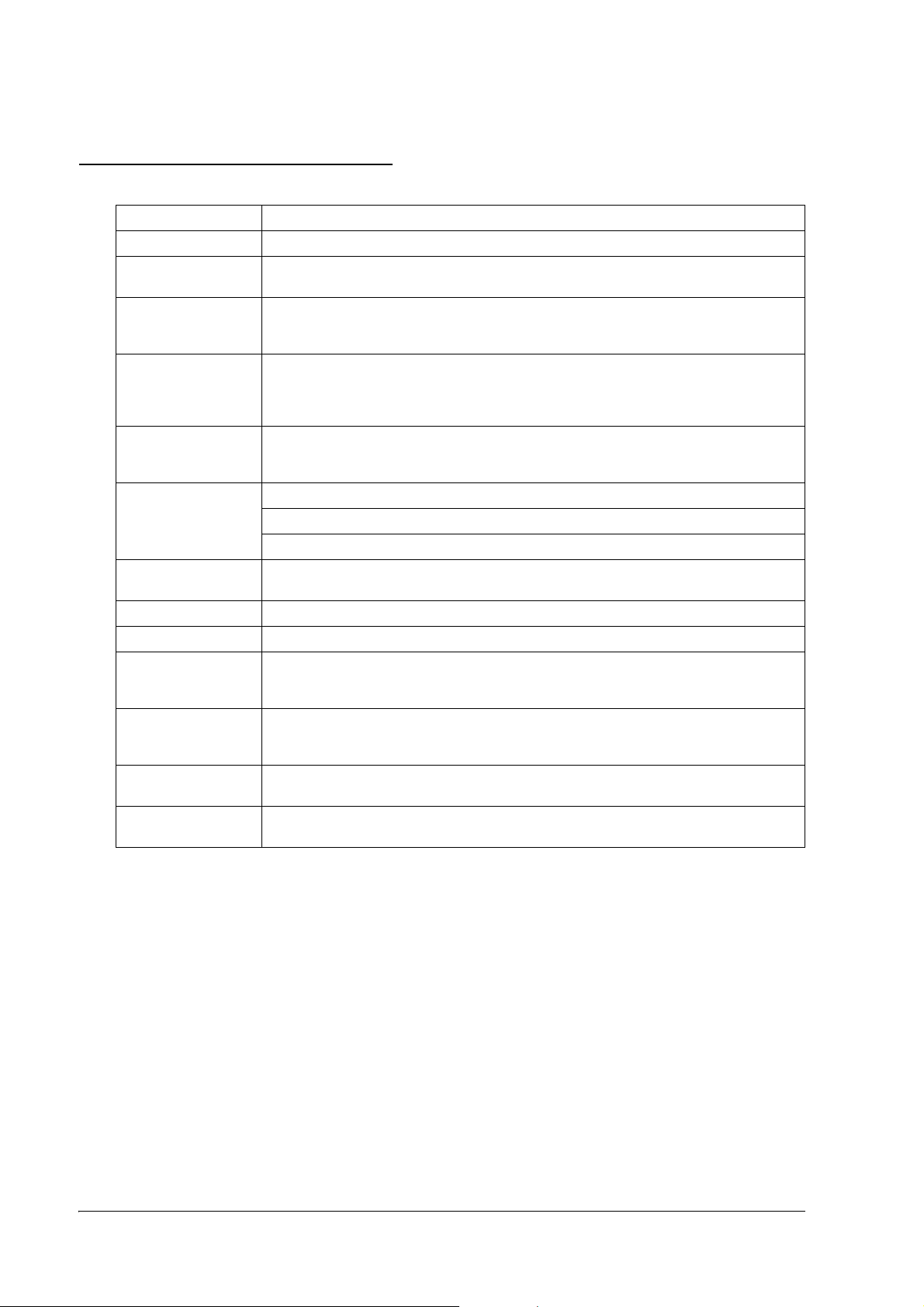

1.4 Product Specifications Overview

Print method serial impact dot matrix

Paper width 76 mm / 69.5 mm / 57.5 mm {3.00"/2.74"/2.26"}

Auto cut type

(TM-U330B only)

Character sets 95 alphanumeric, 2 international character sets

Font size

(width x height)

Interface (compatible) Serial interface model: Built-in USB + RS-232C

Buffer Receive buffer: Selectable as 4KB or 40 bytes using a Memory switch 1-2.

Barcode/Twodimensional symbol

Power supply Included AC adapter

Operating voltage DC+24V ±7%

Power consumption

(except for drawer kick

driving)

Temperature During operation: 0 to 50 C {41to 122 F}. (At 34 C {93F} or higher, there are humidity restrictions;

Humidity During operation:10 to 90% (no condensation)

Weight (mass) TM-U330B: Approximately 2.8 kg {6.17 lb}

Partial cut (cutting with one point on right edge left uncut)

Extended graphics: 128 3 pages

GB18030-2000: 28553 (for Simplified Chinese characters model)

Alphanumeric Font A: 9 x 24

Alphanumeric Font B: 7 x 24

Chinese font: 24 x 24

Font B is the default of alphanumeric.

Parallel interface model: Built-in USB + Bidirectional parallel (IEEE1284)

LAN interface model: Ethernet (10BASE-T, 100BASE-TX)

Non-volatile graphics data buffer: 256KB

User NV memory: 8KB

Code39, Code128, QR code

*

Operating: Approximately 32.6W

Standby: Approximately 1.8W

refer to "Environmental Conditions" (page 1-11)

During storage: -10 to 50 C {14 to 122 F} (excludes paper and ribbon)

During storage:10 to 90% (no condensation; excludes paper and ribbon)

TM-U330D: Approximately 2.6 kg {5.73 lb}

*: - Supported by the firmware version 1.01 ESC/POS or later.

- Since the recognition rate for barcodes and 2D symbols varies depending on ink ribbon density and gradation, module width,

environmental temperature, paper type, and reader performance, the reader might be unable to recognize some barcodes and 2D

symbols. Please check the recognition rate before using this product.

- When printing bar codes, HRI characters must be added.

1-4 General Information

Page 13

TM-U330 Technical Reference Guide

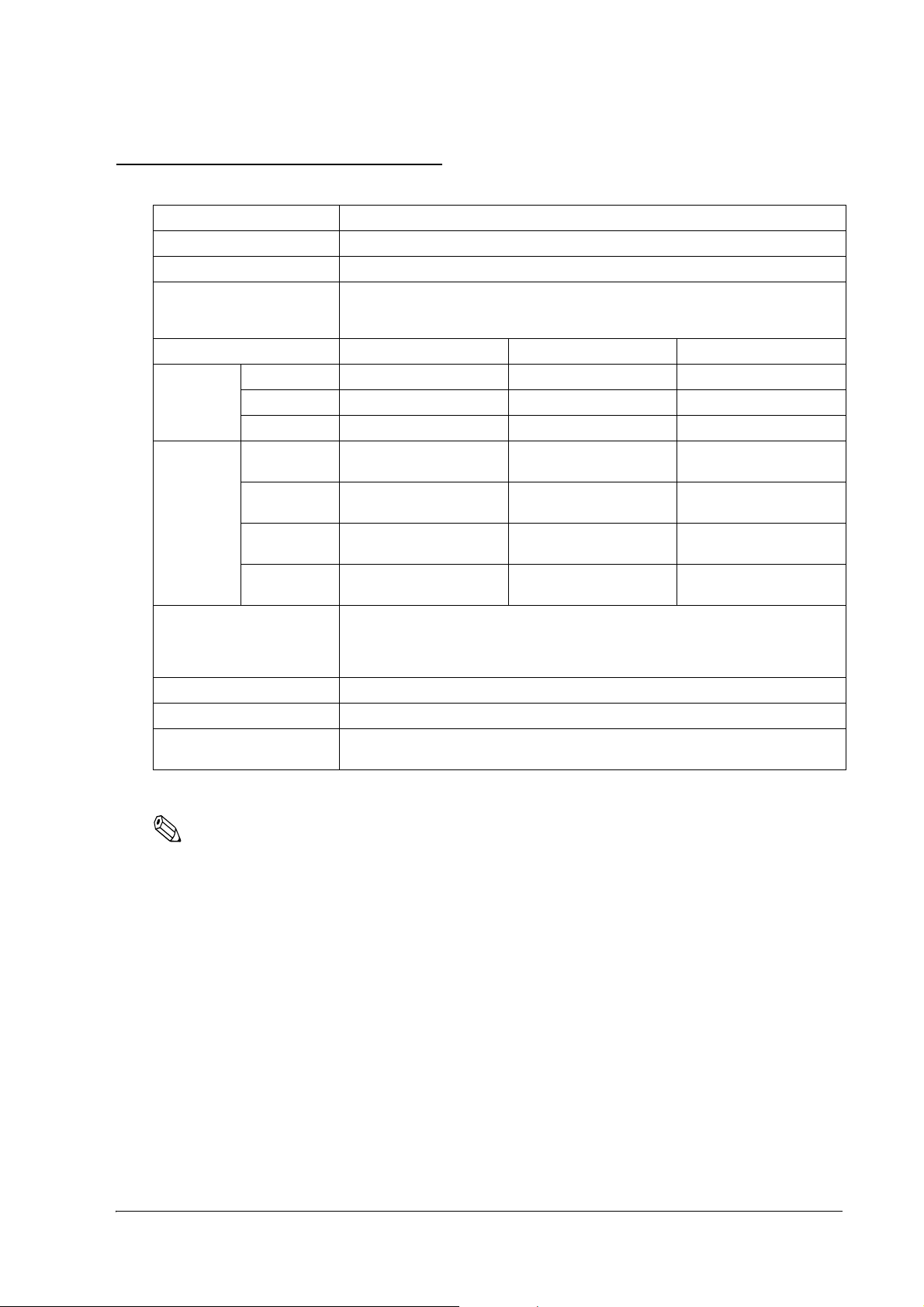

1.5 Printing and paper Specifications

Printing method Serial impact dot matrix

Head wire configuration 24-pin serial configuration

Printing direction Bidirectional printing (logic seeking)

Print speed * Alphanumerics: Approximately 5.0 lps (printing 42 columns per line at 17.1 cpi)

Paper width 76 mm {3.00"} 69.5 mm {2.74"} 57.5 mm {2.26"}

Printing

width

Characters

per line

Character spacing Alphanumeric: 0 dot

120 dpi base 300 dots 270 dots 225 dots

240 dpi base 600 dots 540 dots 450 dots

180 dpi base 450 dots 405 dots 337 dots

Alphanumeric

Font A

Alphanumeric

Font B

Chinese

(180/90 dpi)

Chinese

(80 dpi)

Chinese: Approximately 5.0 lps (printing 80 dpi font, 22 columns per line at 10 cpi)

(except data transmission and processing time)

33 cpl 30 cpl 25 cpl

42 cpl 38 cpl 32 cpl

16 cpl 15 cpl 12 cpl

22 cpl 20 cpl 16 cpl

Chinese: 3 dots

The spacing of alphanumeric and Chinese are changeable by ESC/POS command.

Paper feeding method Friction feed

Paper feed speed 35 lps {Approximately 5.8"/s} (during continuous feeding)

Line spacing Initial setting: Approximately 4.23mm {1/6"}

Can be set in units of approximately 0.141mm {1/180"} by ESC/POS command

*: This printer adjusts print speed when it prints graphic data, etc.

Note:

lps: lines per second

cpl: Characters per line

cpi: Characters per inch (25.4 mm)

General Information 1-5

Page 14

Character Dimensions, Characters Per Inch, Characters Per line

Character configuration Character

Horiz. x Vert. Character

type

Font B

(7 x 24)

Font A

(9 x 24)

Kanji Font

(24 x 24)

*: Change using the FS S command (default 3).

ANK 1.48 x 3.38 0 42 38 32 17.1

ANK 1.91 x 3.38 0 33 30 25 13.3

Kanji

(180/90dpi)

Kanji

(80dpi)

dimensions W

x H (mm)

3.38 x 3.38 3

2.54 x 3.38 3

Note:

Font B is the default. (7 × 24)

1.5.1 Autocutter (for Type B)

Dot spacing

between characters

*

*

Paper width (mm) and

Characters per line (cpl)

76 69.5 57.5

16 15 12 7.5

22 20 16 10

Characters

per inch (cpi)

Cutting method: By separated-blade scissors

Cutting type: Partial cut (one point uncut)

Note:

It is recommended to feed approximately 2.116 mm or more in advance before printing to prevent dot

displacement after cutting.

1-6 General Information

Page 15

1.5.2 Paper Roll Supply

Supply method: Drop-in method

Paper roll end detection: Detection method: Mechanical microswitch

Detection position: Positioned within the paper path for the roll paper;

detects the end of the roll paper

Near-end detector: Detection method: Mechanical microswitch

Inner diameter of the roll paper core: 10.5 to 12.5 mm

Near-end adjustment: Adjusting screw

Remaining amount: Fixed position

#1 approximately 8 mm

#2 approximately 5 mm

(The adjusting screw has two positions.)

See "Adjusting Position of Roll Paper Near End Detector (factory

option)" (page 3-22).

TM-U330 Technical Reference Guide

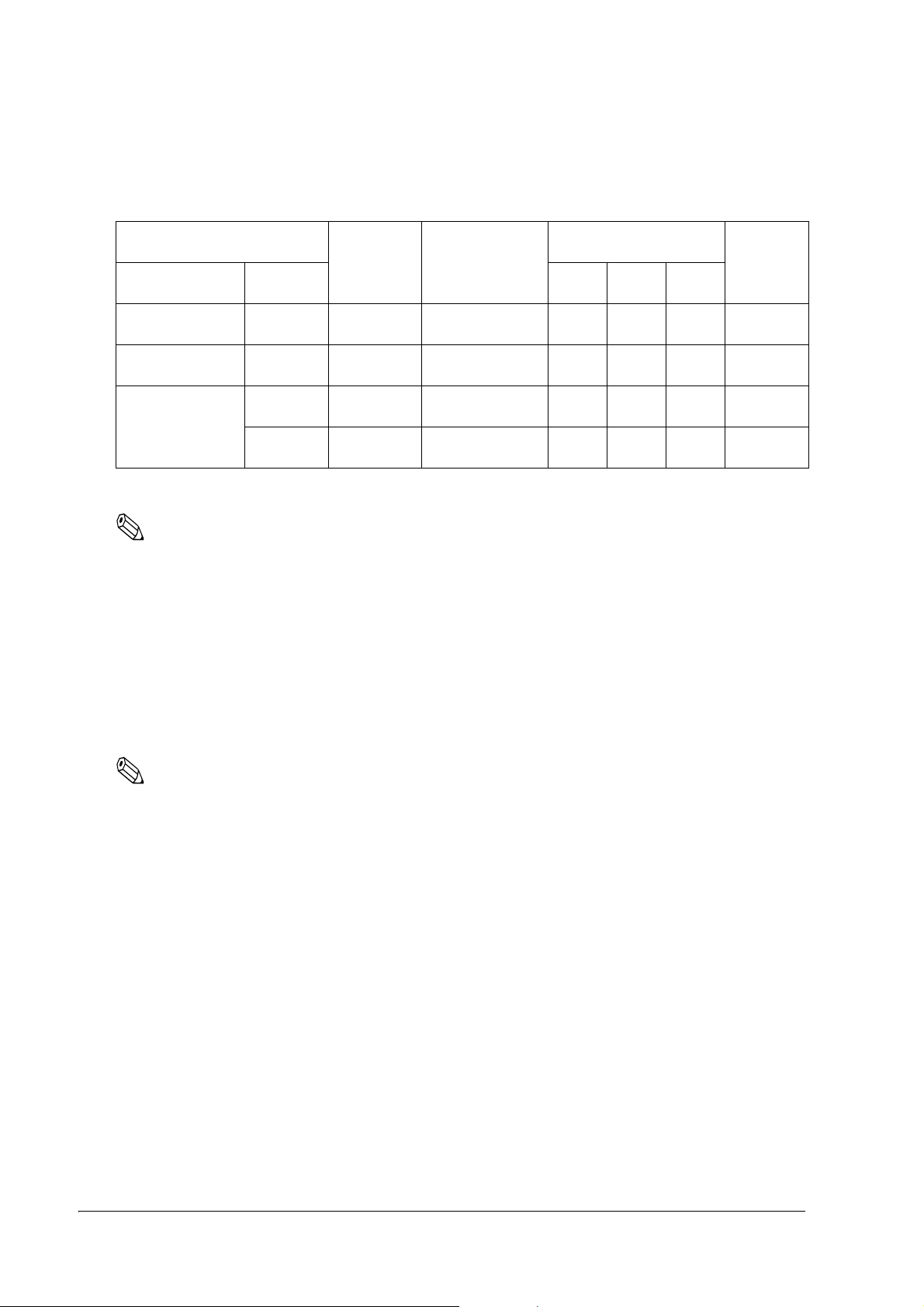

1.5.2.1 Paper Specifications

Roll paper width: 76

0.5 mm (3" 0.02") / 69.5 0.5 mm (2.74" 0.02")

0.5 mm (2.26" 0.02")

/ 57.5

Maximum diameter: 83 mm (3.27")

Core: When there is no near-end detector, always be sure to use roll paper

that is not glued to the core.

Normal paper

specifications:

Paper thickness: 1 sheet: 0.06 to 0.085mm {0.0024 to 0.0033"}

2

Weight: 52.3 to 64 g/m

{14 to 17 lb}

(45 to 55 kg/1000 sheets 1091 788mm)

Carbon paper

specifications:

Number of copies: Original 1 sheet + one copy sheet

Thickness: 0.05 to 0.08 mm {0.002 to 0.0031"}

(thickness of one sheet);

Recommended paper:

Paper by Mitsubishi - Carbonless paper (blue)

Top sheets:

N40Hi (paper thickness: 0.06mm {0.0024"},

2

mass: 47.2 g/m

{12.6 lb}

Bottom sheet

N60 (paper thickness: 0.08mm {0.0031"},

2

mass: 68.0 g/m

{18 lb}

The copying capability is affected by the ambient temperature, and is

guaranteed for the temperature ranges of 5 - 50°C {41 - 122°F}.

General Information 1-7

Page 16

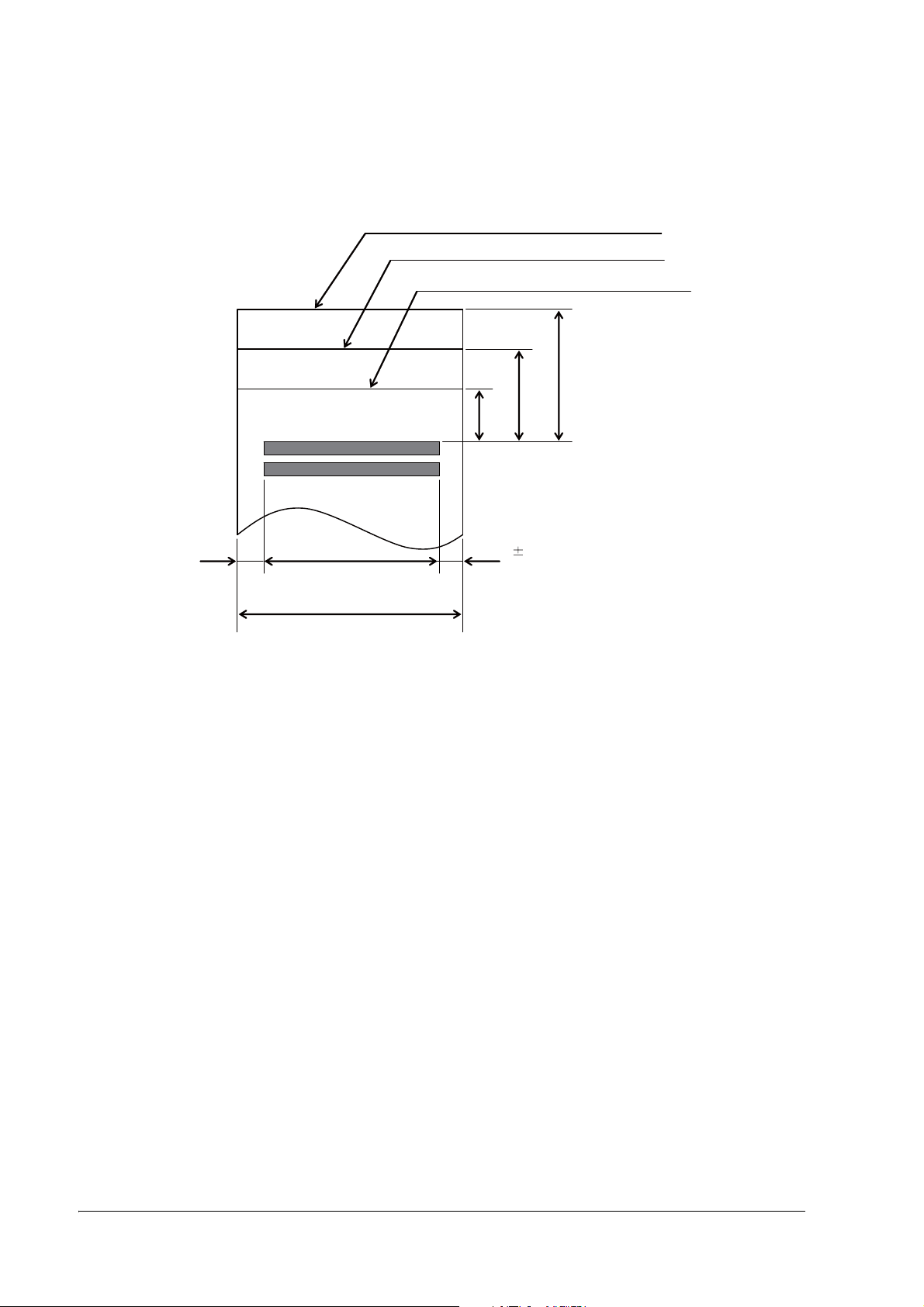

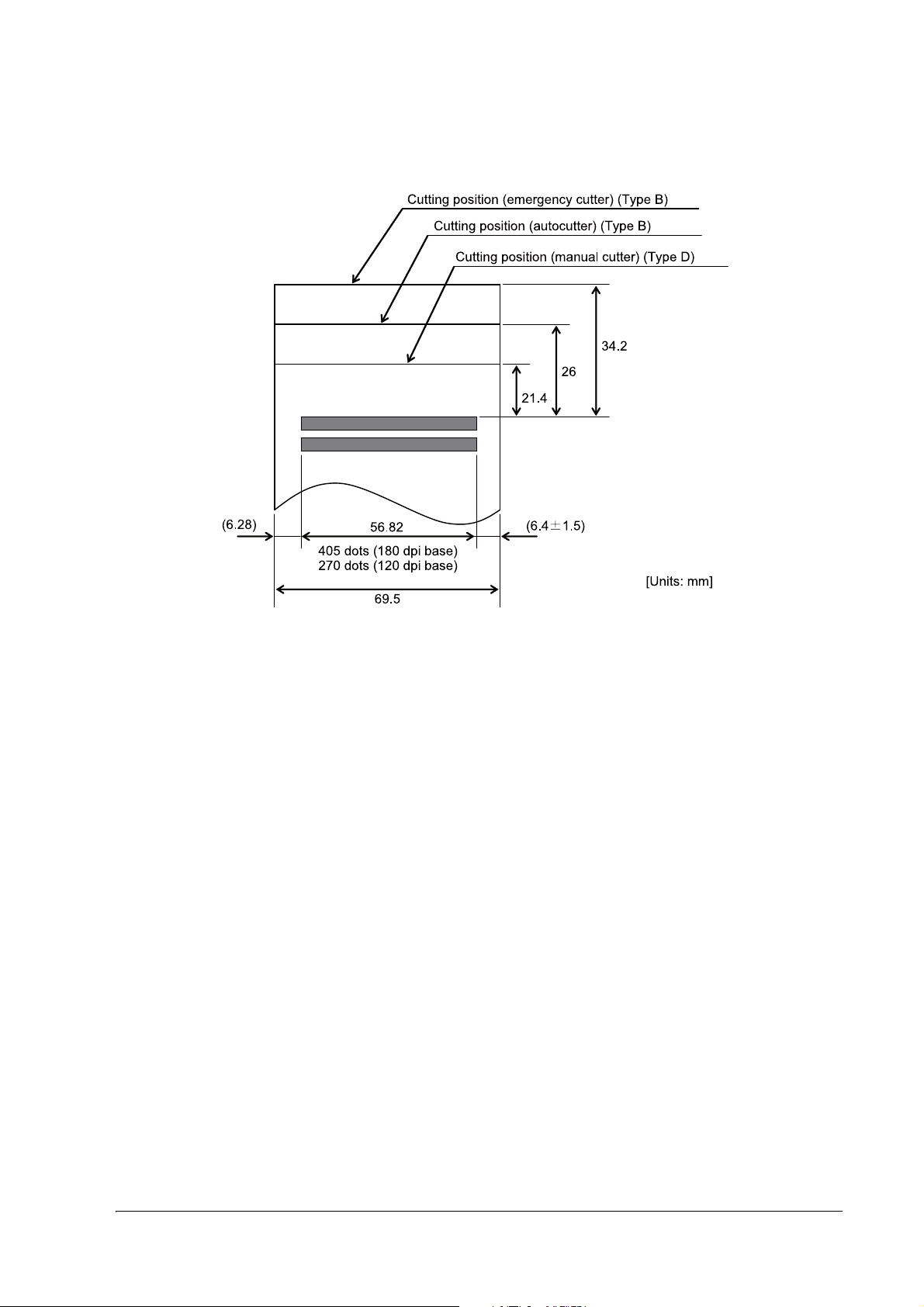

1.5.2.2 Printable Area

Cutting position ( emergency cutter) (Type B)

Cutting position (autocutter) (Type B)

Cutting position (manual cutter) (Type D)

34. 2

26

21.4

(6. 46)

63.14

450 dots (180 dpi base)

300 dots (120 dpi base)

76

Printable area for 76 mm width paper

(6.4

1.5)

[Units: mm]

1-8 General Information

Page 17

TM-U330 Technical Reference Guide

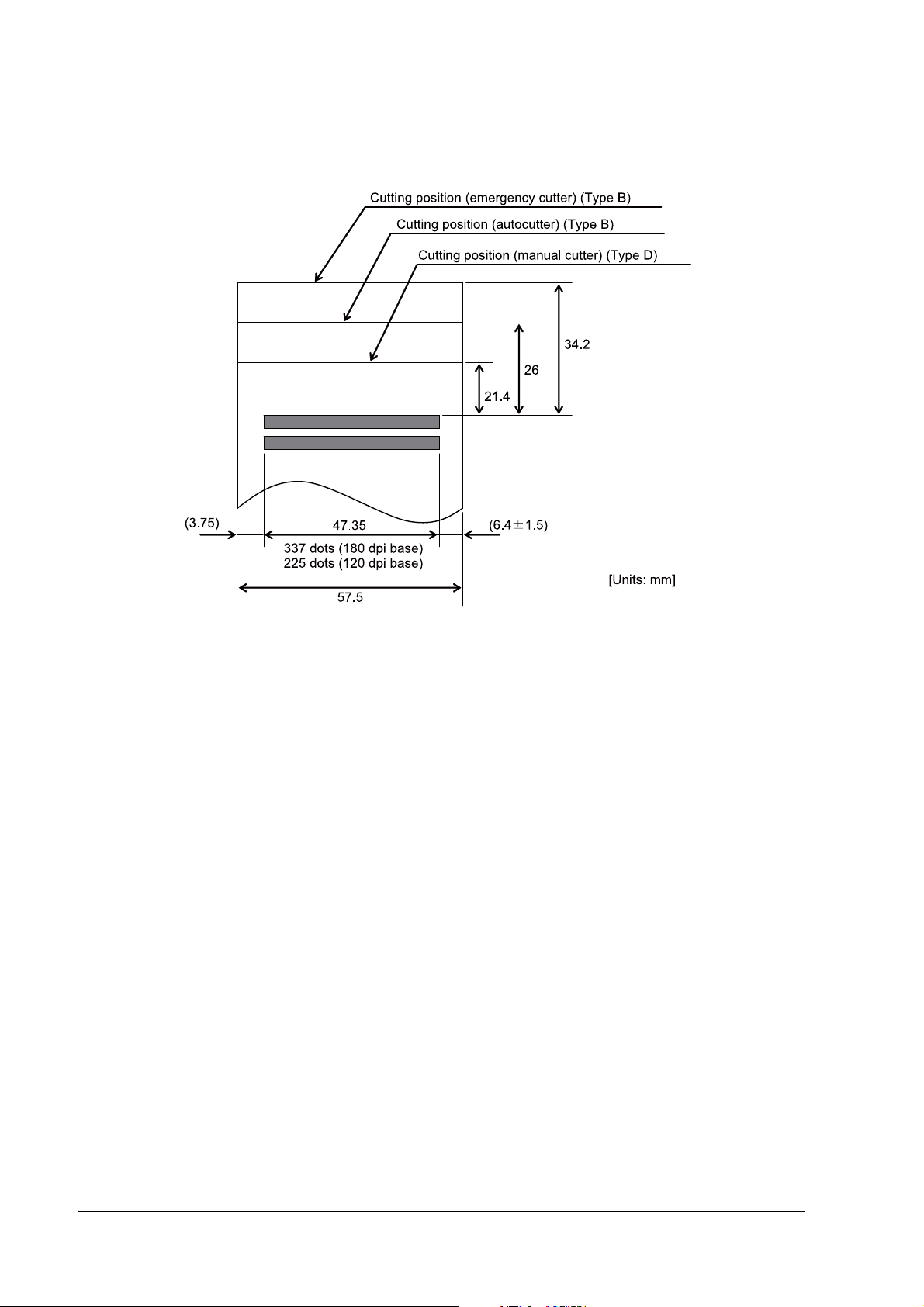

Printable area for 69.5 mm width paper

General Information 1-9

Page 18

Printable area for 57.5 mm width paper

1-10 General Information

Page 19

1.6 Other Specifications

1.6.1 Reliability

Life: Mechanism: 10,000,000 lines

Print head: 200 million characters (using an average of 1 dot/wire per character).

(The printing pattern is Epson test pattern).

Autocutter: 1,000,000 cuts

End of life is defined as the point at which the printer reaches the beginning of the

wear-out period.

MTBF: 180,000 hours

Failure is defined as a Random Failure occurring at the time of the Random Failure

Period.

MCBF: 24,000,000 lines

This is an average failure interval based on failures relating to Wearout and Random

Failures up to the life of 10 million lines.

TM-U330 Technical Reference Guide

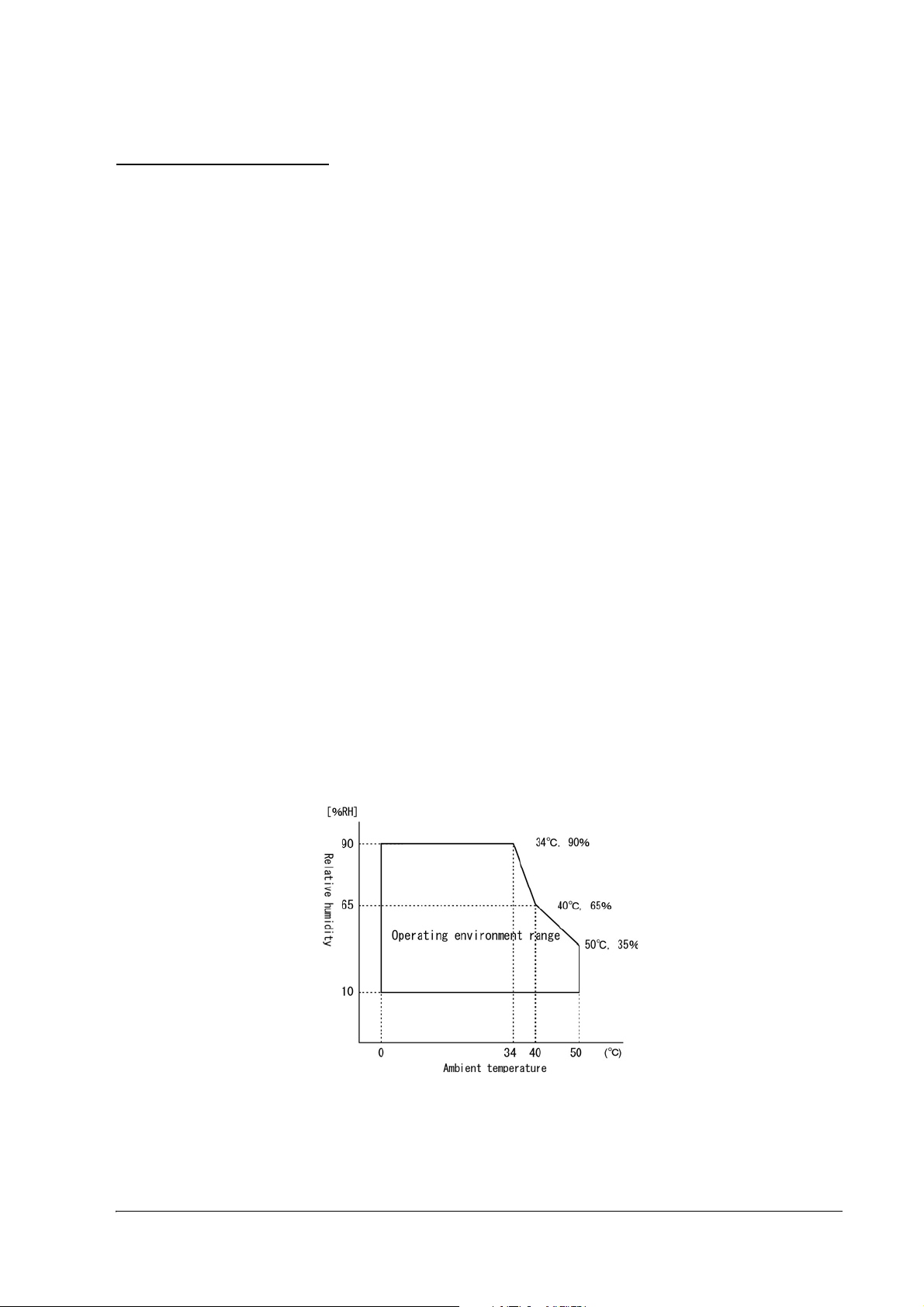

1.6.2 Environmental Conditions

Temperature: During operation: 0 to 50 C {41 to 122 F}.

(At 34 C {93F} or higher, there are humidity restrictions as listed below. )

Humidity: During operation:10 to 90% (no condensation)

During storage:10 to 90% (no condensation; excludes paper and ribbon)

Operating temperature and humidity range

General Information 1-11

Page 20

Vibration resistance: When packed:

Frequency: 5 to 55 Hz

Acceleration: 19.6m/s

Sweep: 10 minutes (half cycle)

Duration: 1 hour

Directions: x, y, and z

No external or internal damage should be found after the vibration test, and

the unit should operate normally.

Impact resistance: When packed:

Package: EPSON standard package

Height: 60 cm (2 feet)

Directions: 1 corner, 3 edges, and 6 surfaces

No external or internal damage should be found after the drop test, and the

unit should operate normally.

When unpacked:

Height: 5 cm (2")

Directions: Lift one edge and release it (for all 4 edges).

When the printer is not printing, no external or internal damage should be

found after the drop test.

2

{2 G}

1.6.3 Installation

Install the printer horizontally as a basic position.The printer also must be installed so that it does not

move or vibrate during paper cutting or the drawer kick operation. Affixing tape is available as an option.

1-12 General Information

Page 21

1.7 External Dimensions and Mass

[Unit: mm]

1.7.1 External Dimensions and Mass

Model type External Dimensions Mass

Width Height Depth

Type B 160 mm

{Approximately 6.3"}

Type D 160 mm

{Approximately 6.3"}

(All the numeric values are typical.)

Color: EPSON standard color (ECW, EDG)

1.7.1.1 Overview (Type B)

144 mm

{Approximately 5.7"}

144 mm

{Approximately 5.7"}

248 mm

{Approximately 9.8"}

248 mm

{Approximately 9.8"}

TM-U330 Technical Reference Guide

Approximately 2.8 kg

Approximately 2.6 kg

General Information 1-13

Page 22

1.7.1.2 Overview (Type D)

[Unit: mm]

1-14 General Information

Page 23

TM-U330 Technical Reference Guide

Chapter 2

System Planning

This section provides you information for system planning.

2.1 Control Method

Use a driver, ESC/POS commands, or Epson ePOS SDK to control the printer.

2.1.1 Selecting a Driver

Choose one of the drivers listed in "Printer Drivers" (page 2-2), depending on the application operating

environment.

For information about the driver operating environment, see the installation manual for each driver.

2.1.2 ESC/POS Commands

ESC/POS is the Epson original printer command system. With ESC/POS commands, you can directly

control all the TM printer functions, but detailed knowledge of printer specifications or combination of

commands is required.

For information about ESC/POS commands, see the product specification. You need a non-disclosure

agreement with Epson to get the product specification. Contact the dealer for more details.

2.1.3 Epson ePOS SDK

The Epson ePOS SDK is an SDK for developing iOS, Android and Windows applications, and Web

applications. You can use the Epson ePOS SDK to control the printer with simple code.

Additionally, you can control customer displays, bar code scanners and other POS peripherals connected

to this product, and TM printers connected to the network.

The following packages are provided.

❏ Epson ePOS SDK for iOS

❏ Epson ePOS SDK for Android

❏ Epson ePOS SDK for Universal Windows apps

❏ Epson ePOS SDK for JavaScript

Note:

For detailed information about Epson ePOS SDK, see the User's Manual of Epson ePOS SDK.

System Planning 2-1

Page 24

2.2 Software and Manuals

The following software and manuals are provided for application development.

2.2.1 How to Get Software and Manuals

You can obtain software and manuals from the following URL.

http://download.epson-biz.com/?service=pos

2.2.2 Printer Drivers

Software Manual

EPSON Advanced Printer Driver (APD):

In addition to ordinary Windows driver functions, this driver has

controls specific to POS, such as controls for paper cut, a cash drawer,

or customer display. The Status API (Epson original DLL) that monitors

printer status and sends ESC/POS commands is also attached to this

driver.

OPOS ADK:

This OCX driver can control POS peripherals using OLE technology

Because controlling POS peripherals with original commands is not

required on the application side, efficient system development is

possible.

EPSON TM Virtual Port Driver:

This driver is a Serial-USB and Parallel-USB conversion driver to make an

EPSON TM/BA/EU printer connected via USB accessible from a POS

application through virtual COM ports and a virtual LPT port. Without

making changes in the POS application that controls devices

connected through serial or parallel interfaces, devices connected via

USB can be directly controlled with ESC/POS commands.

❏ APD Install Manual

❏ APD Printer Manual

❏ APD Printer Specification

❏ Status API Manual

❏ Sample Program Guide

❏ OPOS Installation Manual

*1

.

❏ User’s Manual

❏ Application Development Guide

❏ UnifiedPOS Retail Peripheral Architecture

❏ Sample Program Guide

TM Virtual Port Driver User’s Manual

*2

*1 OLE technology developed by Microsoft divides software into part blocks. The OPOS driver is presupposed to be used with a

development environment, such as Visual Basic, unlike ordinary Windows drivers. It is not a driver to be used for printing from

commercial applications.

*2 This guide describes general information on how to control printers using the OPOS ADK (in the chapter “POS Printer” and

“Appendix”). It does not describe Epson’s specific functions.

2-2 System Planning

Page 25

TM-U330 Technical Reference Guide

2.2.3 Utilities

CAUTION:

After using the following utilities via the USB interface, be sure to disconnect the USB cable, turn off the

printer, and then turn it back on.

❏

EpsonNet Config

❏

Deployment Tool

❏

Printer Network Setting (included in APD)

Software Manual

TM-U330 Utility:

Use for checking and setting the following functions:

❏ Current settings

❏ Storing logos

❏ Paper reduction

❏ Printing control

❏ Interface

❏ Backup/restore

❏ Operation check

❏ Cut Positioning

EpsonNet Config:

Use for wireless LAN setting. For Windows and Mac.

Monitoring Tool:

Use to check a list of status for the Epson printers connected to the

network.

Use with Monitoring Tool and TM-U330 Utility to check the status and

make settings from the administrator's computer for the printer that is

directly connected to the network, or the printer that is connected to

the client computer over a network by USB.

Deployment Tool:

Use to configure network settings and printer/driver settings in a

batch. It enables deploying more than one printer/driver efficiently and

quickly for initial installation.

TM-U330 Utility User’s Manual

EpsonNet Config manual (operation guide) or EpsonNet

Config online help

Monitoring Tool User’s Manual

Deployment Tool User’s Manual

2.3 Connecting the Optional Customer Display

You can connect the customer display to this product.

For more information, refer to "DM-D110/DM-D210 Technical Reference Guide".

System Planning 2-3

Page 26

Chapter 3

roll paper cover

ribbon cassette cover

power switch

control panel

manual cutter

Setup

3.1 Part Name and Basic Operation

3.1.1 Part name

3.1.1.1 Connectors

Do not connect a telephone line to the drawer kick connector or the display module connector; otherwise

the printer and the telephone line may be damaged.

You can connect up to four cables to the printer. They all connect to the connector panel (on the bottom

rear of the printer), which is shown below.

Note:

This illustration shows the serial interface model. The other interface connector looks slightly different.

WARNING:

3-1 Setup

Page 27

3.1.2 The Control Panel

The layout varies according to the model.

❏ POWER LED

❏ ERROR LED

❏ PAPER OUT LED

❏ FEED button

3.1.2.1 LED

POWER

On: Power supply is stable.

Off: Power supply is not stable.

TM-U330 Technical Reference Guide

ERROR

When this light is on but not blinking, it means that the printer is offline. Check to see if a cover is open.

When this light is blinking, there is an error. See “LED Blinking Pattern” in Chapter 4.

PAPER OUT

On: The roll paper near end (*1) or real end is detected.

Off: Paper is loaded (normal condition).

Flashing: Self-test waiting state for test print.

Note:

The roll paper near-end sensor is available as an factory option. If the printer is not equipped with the roll paper

near-end sensor, the roll paper near-end is always detected as paper present. See "Adjusting Position of Roll Paper

Near End Detector (factory option)" (page 3-22) for information on adjusting the detector.

3.1.2.2 Control Panel Buttons

The control panel has paper button that you may have to use, although most paper handling functions will

be handled by your software.

FEED

Use this button to feed roll paper or to start a roll paper self test. (See "Self Test Procedure" (page 3-23).)

Note:

The FEED button can be disabled by using an ESC/POS command.

Setup 3-2

Page 28

3.2 Setup Flow

5. Complete set up

2. Adjust various settings (If you need to)

❏ Memory switches

❏ Paper width

(Adjust the spacer & Memory switches)

❏ Roll Paper Near End Detector

(For equipped model only)

(See "Adjusting Various Settings" (page 3-14))

4. Driver setup

❏OPOS

❏ APD

(See "Install a Printer Driver in the Host PC / POS

Terminal," page 3-23)

When you select Direct

control method (ESC/

POS command,) you

don’t need to install any

drivers.

1. Printer set up

❏Install Ribbon Cassette

❏Install Paper Roll

❏ Connect the Printer to the Power Supply

(See "Printer setup," page 3-5)

3. Connect the Printer to the host PC/POS terminal

(See "Install a Printer Driver in the Host PC / POS Terminal" (page 3-23))

You have to set up your printer to use it. And you can adjust some features by customizing them. This

section describes the setup.

The set up flow of preparing to use printer is below.

3-3 Setup

Note:

When you use OPOS (OCX driver from EPSON) or the Advanced Printer Driver, you need to install the driver.

When you use ESC/POS commands, you don’t have to install drivers. For information on these drivers, see

“Control Method” on page 2-1 and "Install a Printer Driver in the Host PC / POS Terminal" (page 3-23).

Page 29

TM-U330 Technical Reference Guide

The following sections describe the setup. The flow of preparing to use printer is listed below.

1. Printer setup

•Install Ribbon Cassette ("Installing or Replacing the Ribbon Cassette" (page 3-5))

•Install Paper Roll ("Installing the Roll Paper" (page 3-7))

•Connect the Printer to the Power Supply ("Connecting the AC Adapter" (page 3-9))

2. Adjust various setting ( If you need to)

When you use this printer with a serial interface, you have to adjust the communication settings.

See "Memory Switches" (page 3-14) for how to set them.

•Memory switches ("Memory Switches" (page 3-14))

The Memory switches set serial communication conditions, roll paper width, cover

open status handling, etc...

•Paper width ("Adjusting Roll paper width" (page 3-21))

The paper width is set by the spacer & Memory switch setting.

•Roll Paper Near End Detector (For model equipped with the detector)

("Adjusting Position of Roll Paper Near End Detector (factory option)" (page 3-22))

3. Connect the Printer to the Host PC/POS Terminal (and Cash Drawer)

("Install a Printer Driver in the Host PC / POS Terminal" (page 3-23))

4. Driver set up (If you use driver)

("Install a Printer Driver in the Host PC / POS Terminal" (page 3-23))

5. Complete the setup

Setup 3-4

Page 30

3.3 Printer setup

3.3.1 Installing or Replacing the Ribbon Cassette

CAUTION:

The print head becomes very hot during printing. Allow it to cool before you replace the ribbon cassette.

1. Open the ribbon cassette cover.

2. Turn the knob 2 or 3 times in the direction of the arrow.

!CAUTION:

Use the EPSON ERC-45 ribbon cassette for your printer.

Never turn the ribbon cassette’s feed knob in the opposite direction of the arrow marked on the cassette;

otherwise the ribbon cassette may be damaged.

3-5 Setup

Page 31

TM-U330 Technical Reference Guide

3. Insert the ribbon in the position and push the ribbon cassette down until it clicks.

Make sure the ribbon is installed between the print head and the platen without wrinkles or creases.

4. Again turn the ribbon cassette’s knob 2 or 3 times in the direction of the arrow.

CAUTION:

Be careful not to touch the print head with your fingers when turning the ribbon cassette knob because the

print head is hot and you might be burned.

5. Close the ribbon cassette cover.

Setup 3-6

Page 32

3.3.2 Installing the Roll Paper

✄

ON

!CAUTION:

❏

Be sure to use roll paper that meets the specifications.

❏

Be sure not to touch the manual cutter. Otherwise your fingers might be injured.

1. Using scissors, cut the leading edge of the roll paper.

2. Turn on the printer.

3. Open the roll paper cover.

3-7 Setup

Page 33

TM-U330 Technical Reference Guide

4. Insert the roll paper.

Note the direction the paper comes off the roll.

QNote:

When using 2-ply roll paper, be sure that the top and bottom sheets are aligned at the paper exit.

5. Close the roll paper cover.

Setup 3-8

Page 34

3.3.3 Connecting the AC Adapter

AC adapter

AC cable

!WARNING:

❏

Never insert the AC cable plug into a socket that does not meet the rated voltage requirements of the

printer.

Doing so may result in damage to the printer.

❏

Should a fault ever occur, immediately turn off the power to the printer and unplug the AC cable from

the wall socket.

3.3.3.1 Connecting the AC cable

1. Make sure the printer is turned off.

2. Connect the AC cable to the AC adapter.

3. Connect the DC cable of the AC adapter to the power supply connector.

4. Insert the AC plug into a wall socket.

3-9 Setup

Page 35

TM-U330 Technical Reference Guide

3.3.4 Connecting the Printer to the Host PC / POS Terminal

All cables are connected to the connector panel located on the lower rear side of the printer.

Connector panel

Note:

The figure above shows the connector panel for the serial interface model printer. The shape of the interface

connector varies according to the type of interface used.

Be sure to turn off the power supply for both the printer and the host computer unit before connecting the various

cables.

You need an appropriate serial, parallel, USB, or Ethernet interface cable to connect your computer to the printer.

For the serial model, it is important that you use a null modem cable, not any other serial cable, and for the

parallel model use an IEEE 1284 cable.

3.3.4.1 Serial Interface

Before connecting any of the cables, make sure that both the printer and the host PC are turned off.

1. Plug the cable connector securely into the printer’s interface connector.

2. If the cable connector has screws on it, tighten the screws on both sides of the connector.

3. If your interface connector has a grounding wire, attach it to the printer using the screw labeled FG,

which is next to the interface connector.

4. Attach the other end of the cable to the host PC.

Setup 3-10

Page 36

3.3.4.2 Parallel Interface

1. Press the connector on the end of the interface cable firmly into the interface connector on the

connector panel.

2. Press down the clips on either side of the connector to lock it in place.

3. For interface cables equipped with a ground line, attach the ground line to the screw hole marked "FG"

on the printer.

4. Connect the other end of the interface cable to the host computer.

3.3.4.3 USB Interface

1. Attach the locking wire saddle at the location shown in the figure below.

2. Hook the USB cable through the locking wire saddle, as shown in the figure below.

Note:

Hooking the USB cable through the locking wire saddle, as shown in the figure below, will prevent the

cable from coming unplugged.

Attaching locking wire saddle

3. Connect the USB cable from the host computer to the USB upstream connector.

3-11 Setup

Page 37

TM-U330 Technical Reference Guide

3.3.4.4 Ethernet interface

!CAUTION:

❏

When Ethernet cables are installed outdoors, make sure devices without proper surge protection are

cushioned by being connected through devices that do have surge protection.

Otherwise, the devices can be damaged by lightning.

❏

Never attempt to connect the customer display cable, drawer kick cable, or the standard telephone line

cable to the Ethernet connector.

Note:

The display module connector on the TM printer cannot be used when the UB-E** is installed.

Connect an Ethernet cable to the Ethernet connector by pressing firmly until the connector clicks into

place.

Setup 3-12

Page 38

3.3.4.5 Connecting a Drawer

DK

CAUTION:

Be sure to connect a drawer that meets printer specifications. Connecting a drawer of the wrong

specifications may result in damage to both the drawer and the printer.

Never connect the telephone line to the drawer kick connector (labeled “DK”). Doing so may result in

damage to both the telephone line and the printer.

Never connect the drawer cable to the customer display connector (labeled “DM-D”). Doing so may result in

damage to both the drawer cable and the printer.

1. Connect the drawer cable to the drawer kick connector (labeled “DK”) on the connector panel.

2. The connecting is finished.

Connecting drawer

3-13 Setup

Page 39

TM-U330 Technical Reference Guide

3.4 Adjusting Various Settings

This printer is able to be adjusted for the items below:

❏ Memory switch (serial communication conditions, roll paper width, cover open status handling, etc...)

❏ Roll paper width (76mm / 69.5mm / 59.5mm)

Adjusting the spacer & memory switch

❏ Position of roll paper near end detector (factory option)

The current settings can be confirmed by a self test. (See "Self Test" (page 3-23).)

3.4.1 How to Confirm Current Settings

You can use a self-test to confirm the current settings. See "Self Test" on page 3-23.

3.4.2 Memory Switches

This printer has “Memory switch“ set which is software switches. The memory switch set consists of the

following:

❏ Msw1, Msw2, Msw5, Msw8

❏ Customize value

❏ Serial communication condition

❏ USB communication condition

Note:

Settings of the memory switch are stored in the NV memory; therefore, even if the printer is turned off, the settings

are maintained. Excessive use of this function may destroy the NV memory. As a guideline, do not use this

function more than 10 times a day.

When you use OPOS or APD, generally you don’t need to adjust memory switch because OPOS or APD are able to

set these items automatically.

The memory switch can also be set by using the TM-U330 Utility.

Setup 3-14

Page 40

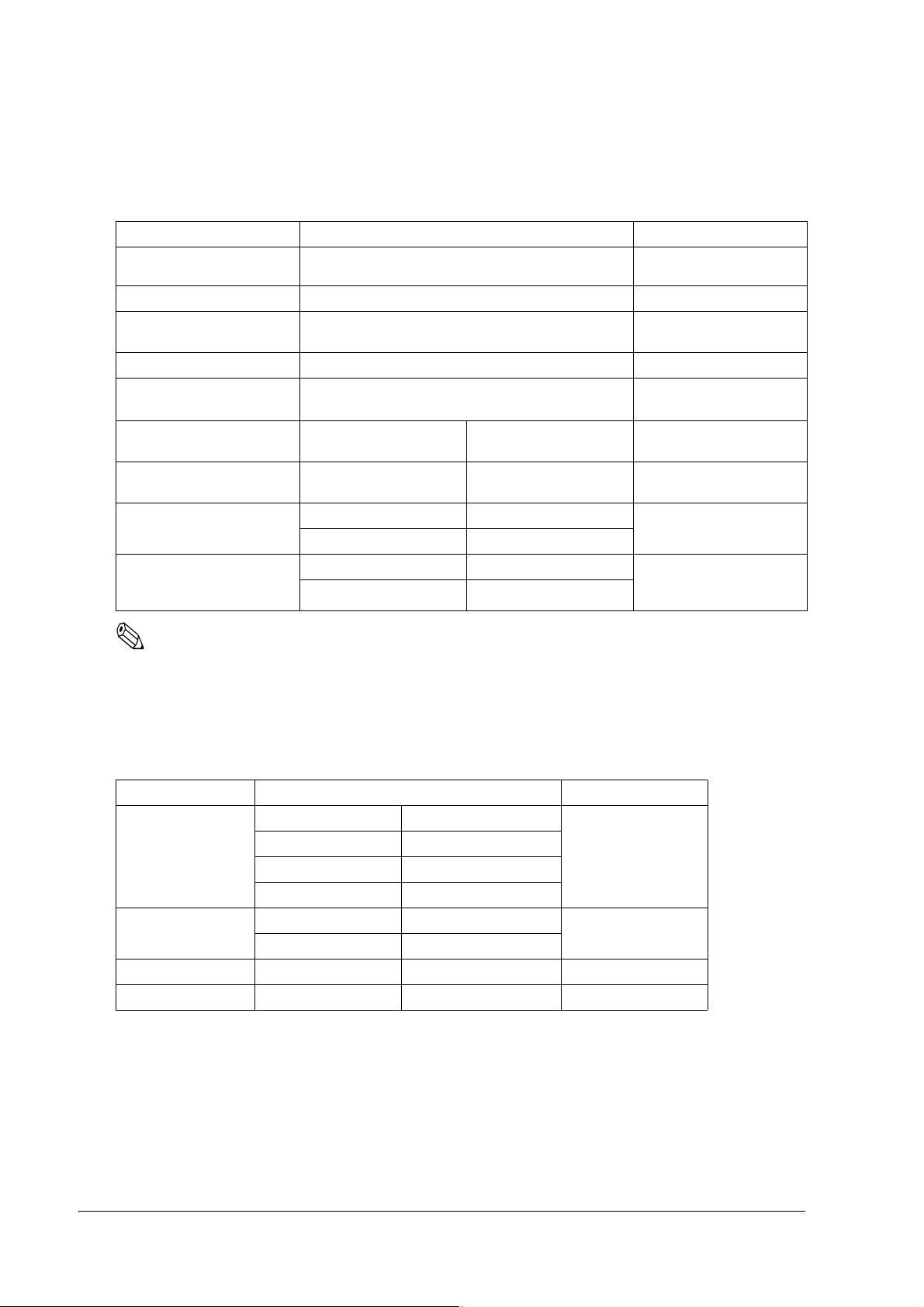

Msw1

SW Function Off On Default

1-1 (reserved) - - Off

1-2 Receive buffer capacity 4 KB 40 bytes Off

1-3 Condition for BUSY Receive buffer full or

Offline

1-4 Data processing for receive error Replaced with "?" Ignored Off

1-5 Automatic line feed Disabled Enabled Off

1-6 (reserved) - - Off

1-7 #6 pin of RS-232 Not used Used for reset signal Off

1-8 #25 pin of RS-232 Not used Used for reset signal Off

Receive buffer full Off

Note:

[Msw1-4], [Msw1-7], [Msw1-8]: Valid only for serial interface

[Msw1-5]: Valid only for parallel interface

[Msw1-8]: Fixed to On with LAN interface model

Msw2

SW Function Off On Default

2-1 (reserved) - - On

2-2 Autocutter function Disabled Enabled On (TM-U330B)

2-3 Character code system for the simplified

Chinese (for Simplified Chinese

characters model)

2-4 (reserved) - - Off

2-5 (reserved) - - Off

2-6 (reserved) - - Off

2-7 (reserved) - - Off

2-8 (reserved) - - Off

GB18030 GB2312 Off

Off (TM-U330D)

3-15 Setup

Page 41

TM-U330 Technical Reference Guide

Msw5

SW Function Off On Default

5-1 USB power-saving Enabled Disabled Off

5-2 (reserved) - - Off

5-3 Paper sensor to output paper end

signals

5-4 (reserved) - - Off

5-5 (reserved) - - Off

5-6 (reserved) - - Off

5-7 (reserved) - - Off

5-8 (reserved) - - Off

Enabled both paper end

sensor and near-end

sensor

Disabled Off

Note:

[Msw5-1]: Valid only when the USB interface communication condition is set to the Vendor-defined class and the

system configuration is set so that the USB driver can support the USB power-saving function.

Msw8

SW Function Off On Default

8-1 Black mark sensor Disabled Enabled Off

8-2 (reserved) - - Off

8-3 Status when paper end Offline Online Off

8-4 (reserved) - - Off

8-5 Selection of the cover open status Paper end Cover open Off

8-6 Error signal output when an error occurs Enabled Disabled Off

8-7 Recovery conditions from receive buffer

BUSY

8-8 Printer cover open during operation Automatic recoverable

Remaining 138 bytes Remaining 256 bytes Off

Recoverable error Off

error

Note:

Msw 8-5:

When Off is selected, a bit of the "roll paper end sensor" in each status that is transmitted from the printer is

changed every time the roll paper cover is open or closed. When On is selected, a bit of the "roll paper cover open /

close" in each status that is transmitted from the printer is changed every time the roll paper cover is open or closed.

Msw 8-8:

When Off is selected, a bit of the "automatic recoverable error" in each status that is transmitted from the printer is

changed every time the roll paper cover is open. When On is selected, a bit of the "mechanical error" in each status

that is transmitted from the printer is changed every time the roll paper cover is open.

Setup 3-16

Page 42

Customize value

Function Selectable value Default

Roll paper width 57.5 mm, 69.5 mm, 76 mm 76 mm

Roll paper text control mode Mode 1, Mode 2, Mode 3 Mode 1

Select interface type Fixed UIB, fixed Built-inUSB, auto change between UIB/Built-

inUSB

Execute commands while offline Enable/Disable Disable

Set amount of cut justification for

paper

–37 to 598 mm 0 mm

Auto change between UIB/

Built-inUSB

Auto paper saving function

Reduce top margin

Auto paper saving function

Reduce bottom margin

Auto paper saving function

Amount of reduction

Auto paper saving function

Amount of reduction for carriage

returns

Do not reduce margin space Reduce margin space Do not reduce margin space

Do not reduce margin space Reduce margin space Do not reduce margin space

Do not reduce Reduce by 25% Do not reduce

Reduce by 50% Reduce by 75%

Do not reduce Reduce by 25% Do not reduce

Reduce by 50% Reduce by 75%

Note:

When the mark sensor is enabled, you cannot set a paper width of 69.5 mm.

When the mark sensor is enabled, the Auto paper saving function is disabled.

Serial communication condition

Function Selectable value Default value

Baud rate 1200 bps 2400 bps 115200 bps

4800 bps 9600 bps

19200 bps 38400 bps

57600 bps 115200 bps

Parity None Odd None

Even -

Handshake DSR/DTR XON/XOFF DSR/DTR

Data length 7 bit 8 bit 8 bit

3-17 Setup

Page 43

TM-U330 Technical Reference Guide

USB interface communication condition

Function Selectable value Default value

Class Vendor-defined class Printer class Vendor-defined class

IEEE1284 Device ID Do not send IEEE1284 Device IDSend IEEE1284 Device ID Send

3.4.3 Memory Switch Setting Mode

The following items are specified in the memory switch setting mode:

❏ Serial Interface Settings

❏ Interface Selection

❏ USB Interface Settings

❏ Command Execution (Offline)

❏ Autocutter

❏ Black Mark Sensor

❏ Interface Signal Settings

3.4.3.1 Starting the memory switch setting mode

Use the following procedure to start the memory switch setting mode.

1. Open the roll paper cover.

2. Turn the power on while pressing the paper FEED button.

3. Press the FEED button twice while ERROR LED is lit.

4. Close the cover. The printer prints the enabled settings of the memory switches and instructions.

5. Follow the instructions to process the switch setting.

Note:

In Memory switch setting mode, the flashing paper out LED indicates user operations are necessary.

3.4.3.2 Ending memory switch setting mode

To finish Memory switch setting mode, turn off the printer, or select "Exit" to return to the first selection

guide.

Setup 3-18

Page 44

3.4.3.3 Operating procedure

Entering Memory Switch Setting Mode

Selecting Items to Set

Selecting the set value

Ending Memory Switch Setting Mode

0: Exit

1: Print Current Settings

2: Serial Interface Settings

3: Interface Selection

4: USB Interface Settings

5: Command Execution (Offline)

After briefly pressing the FEED button (less than one second) for the number of times shown in the

print result, hold down the button for more than one second, and then select the setting items.

The setting selected as the setting item, the current settings and initial settings are printed.

Depending on the setting item, you may need to continue making the setting item before the

settings are printed.

Select a setting by briefly pressing the FEED button (less than one second) for the number of times

applicable to the setting, and then hold down the button for more than one second to confirm your

selection.

After saving the settings, the Memory switch setting mode is printed, and the Paper LED flashes.

1.Open the roll paper cover and turn the power on while pressing the paper FEED button.

2.Press the paper FEED button twice while ERROR LED is lit.

3.Close the cover.

The printer prints the setting guideline.

Turn off the printer, or select "Exit" to return to the first selection guide.

The procedures used for this process are described below.

3-19 Setup

Page 45

3.4.3.4 Setting items for Memory switch setting mode

Setting Items Options

1: Print Current Settings -

2: Serial Interface

Settings

3: Interface Selection UIB, Built-in USB, Auto

4: USB Interface

Settings

5: Command Execution (Offline) Enable, Disable

6: Other settings 1: Autocutter TM-U330B: Enable, Disable

1: Baud Rate 1200 bps, 2400 bps, 4800 bps, 9600 bps, 19200 bps, 38400

2: Parity None, Odd, Even

3: Handshaking DTR/DSR

4: Data Bits 7 bits, 8 bits

1: Class Vendor Class, Printer Class

2: Black Mark Sensor Enable, Disable

3: Interface Settings 1: Output Paper-end

Signals

2: Error Signal Enable

3: Pin 6 Reset Signal Enable, Disable

4: Pin 25 Reset Signal Enable, Disable

bps, 57600, bps, 115200 bps

TM-U330D: Enable, Disable

Enable, Disable

, Disable

TM-U330 Technical Reference Guide

* The initial setting is underlined.1st page 2nd page 3rd page

, XON/XOFF

Setup 3-20

Page 46

3.4.4 Adjusting Roll paper width

leading the wires

between the holder

and frame

Roll paper guide

Roll paper holder

B

C

A

Roll paper

guide

position of fixing

the screws

(left side)

position of fixing

the screws

(right side)

A: paper width76 mm

B: paper width69.5mm

C: paper width57.5mm

The TM-U330 accommodates 76 mm {3"},69.5 mm {2.74"}, 57.5 mm {2.26"} wide paper rolls.

Note:

When you use a near-end detector equipped model, be sure not to pinch the lead wires of the near-end detector

between the roll paper guide and the roll paper holder, and to push the lead wires inside so that the lead wire of the

paper-end detector does not contact the motor gear.

When replacing the wires, be sure that the wires do not catch between the roll paper guide and the roll paper

holder.

3-21 Setup

1. Make sure the power supply is disconnected.

2. Open the roll paper cover.

3. Take off the roll paper guide from the printer by loosening the two screws.

4. Push the roll paper guide on the appropriate width (See figure above.)

Page 47

TM-U330 Technical Reference Guide

Detector

adjustment screw

Knob

#2 setting

#1 setting

Detector lever

Seeing at outside for roll paper spacer

5. Tighten the spacer with two screws included with the guide. (See figure above.)

6. Set the memory switch (customize value) for the paper width. (See "Memory Switches" (page 3-14))

3.4.5 Adjusting Position of Roll Paper Near End Detector (factory option)

Below are two reasons for the roll paper to require an NE detector adjustment.

❏ To adjust the location of detection for the diameter of the roll paper core.

❏ To adjust the amount of remaining paper.

The procedure is as following.

1. Make sure the power supply is disconnected.

2. Open the roll paper cover, and remove the paper roll.

3. Loosen the detector adjustment screw with a coin or similar tool.

4. Adjust the detector by sliding the lever in the direction shown below.

The table below shows the point at which the near-end detector is triggered. Note that this figure is a

calculated value, and there may be some variations, depending on the printer.

Detection point of roll paper near-end

Detector position (attaching point of the

detector adjustment lever) Trigger point (included the thickness of paper roll core)

#1 setting Approx. 8 mm

#2 setting Approx. 5 mm

5. Tighten the detector adjustment screw.

6. Check to be sure that the detecting lever moves freely.

Setup 3-22

Page 48

3.5 Install a Printer Driver in the Host PC / POS Terminal

EPSON provides printer drivers for the TM-U330. The drivers are OPOS and Advanced Printer Driver

(APD). They are for the Windows environment.

3.5.1 OPOS

When you install and set up, please refer to the User's Manual, the file is automatically created at the

installation of OPOS ADK.

3.5.2 Advanced Printer Driver (APD)

When you install and set up the APD, please refer to the “EPSON Advanced Printer Driver Install

Manual.“

3.6 Self Test

The self test lets you know if your printer is operating properly. It checks the control circuits, printer

mechanisms, print quality, control software version, and the memory switch settings.

This test is independent of any other equipment or software, so it is a good idea to run it when you first set

up the printer and if you have any trouble. If the self tests work correctly, the problem is in the other

equipment or the software, not the printer.

3.6.1 Self Test Procedure

1. Make sure the printer is turned off and the roll paper cover is closed properly.

2. While holding down the FEED button, turn on the printer using the switch on the front of the printer.

The self test prints the printer settings and then prints the following, cuts the paper, and pauses. (The

PAPER OUT light blinks.)

If you want to continue

SELF-TEST printing,

please press FEED button.

3. Press the FEED button to continue printing. The printer prints a pattern using the built-in character

set.

4. The self test automatically ends and cuts the paper after printing the following:

*** completed ***

The printer is ready to receive data as soon as it completes the self test.

Note:

If you want to pause the self test manually, press the FEED button. Press the FEED button again to continue the self

test.

3-23 Setup

Page 49

TM-U330 Technical Reference Guide

Chapter 4

Troubleshooting

This section describes general troubleshooting.

4.1 LED Blinking Pattern

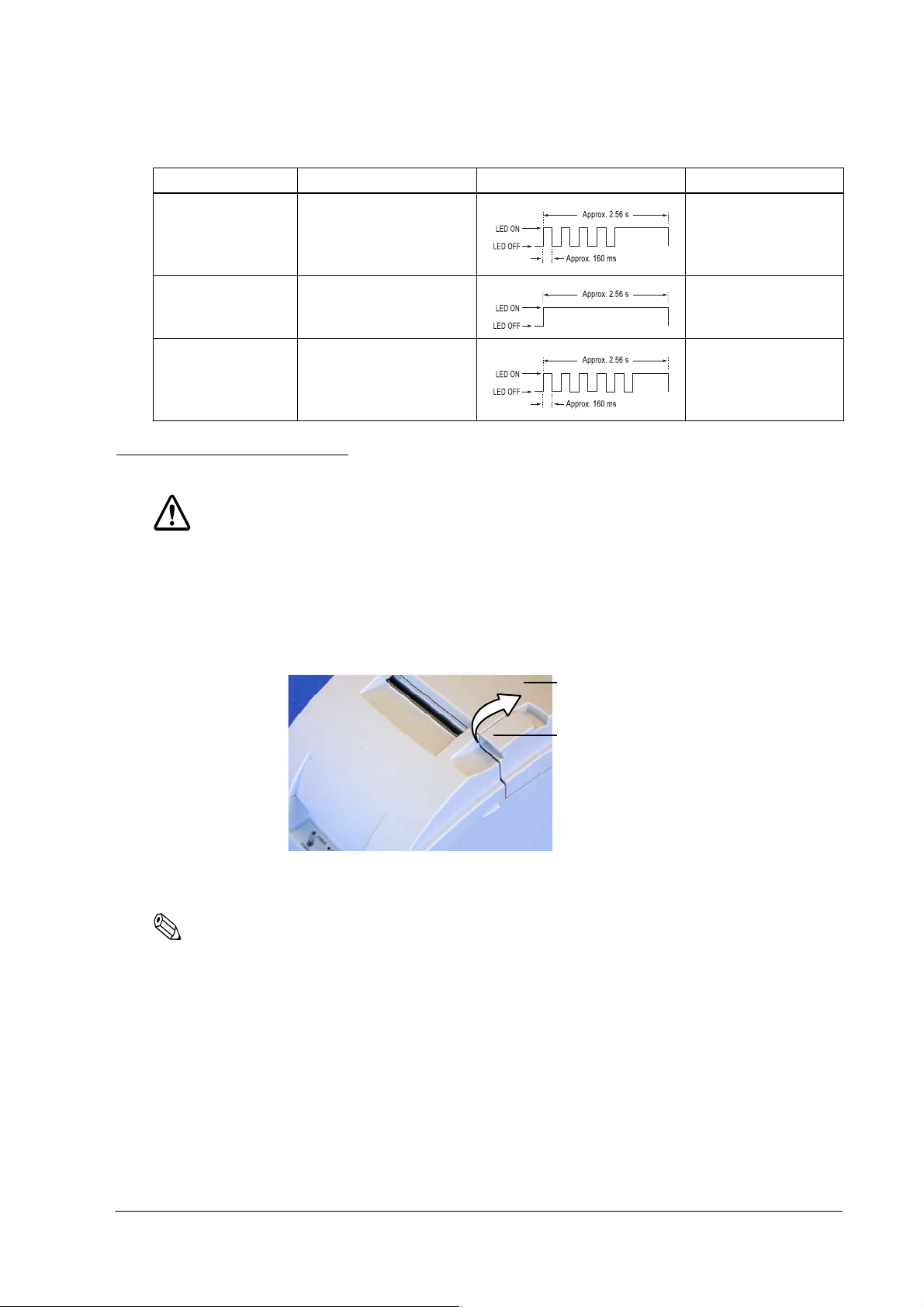

4.1.1 Error Types

The printer stops all printer operations for the selected paper section, goes offline, and the ERROR LED

blinks when an error is detected.

4.1.1.1 Errors that automatically recover

ERROR Description ERROR LED Blinking Pattern Recovery

Roll paper cover open

error (when recoverable

error is selected)

(*1)

The roll paper cover is opened

when printing.

Recovers automatically

when the cover is closed.

Print head temperature

(*2)

error

Black Mark (BM) Error The mark is undetectable if

The temperature of the print

head is extremely high.

paper is fed for 598 mm or

more.

Recovers automatically

when the print head cools.

B, D type:

Open/close the roll paper

cover.

Note:

(*1) This conditions are selected by MSW 8-5, 8-8. When MSW 8-5 (mapping of the cover open status) is off,

the error hasn’t occurred but there is a “paper end error” instead. If MSW 8-8 is off, this error is handled as

an automatically recoverable error.

(* 2) Print head temperature error is not abnormal.

Troubleshooting 4-1

Page 50

4.1.1.2 Recoverable Errors

When a recoverable error occurs, after the cause of the error is removed, the printer can recover from the

error by receiving an error recovery command without turning off the power:

ERROR Description ERROR LED Blinking Pattern Recovery

Roll paper cover open

error (*1)

The roll paper cover is

opened when printing.

Recovers by error recovery

command with the cover closed

Autocutter error

(TM-U330B only)

Home position detection

error

(This is “Mechanical

error“)

The autocutter does not

work correctly

The home position cannot

be detected due to a paper

jam

Recovers by error recovery

command. (See "Autocutter Jam"

(page 4-4))

Recovers by error recovery

command

Note:

(*1) These conditions are selected by MSW 8-5 and 8-8. When MSW 8-5 (mapping of the cover open status)

is OFF, the error does not occur and a “paper end error” occurs instead. If MSW 8-8 is ON, this error is

handled as a recoverable error.

4.1.1.3 Errors that are impossible to recover:

ERROR Description ERROR LED Blinking Pattern Recovery

R/W error in memory or

gate array

High voltage error The power supply voltage is

After R/W checking, the printer

does not work correctly.

Writing to, reading out, or

erasing the NV memory for

image scanning results does not

work correctly.

extremely high.

Impossible to recover

Impossible to recover

Low voltage error The power supply voltage is

extremely low.

4-2 Troubleshooting

Impossible to recover

Page 51

TM-U330 Technical Reference Guide

Roll paper cover

Tab

ERROR Description ERROR LED Blinking Pattern Recovery

CPU execution error The CPU executes an incorrect

address or I/F board is not

connected.

Impossible to recover

Circuit error There is an error in the head

temperature or the motor driver

IC temperature.

UIB error There is an error in the I/F board. Impossible to recover

Impossible to recover

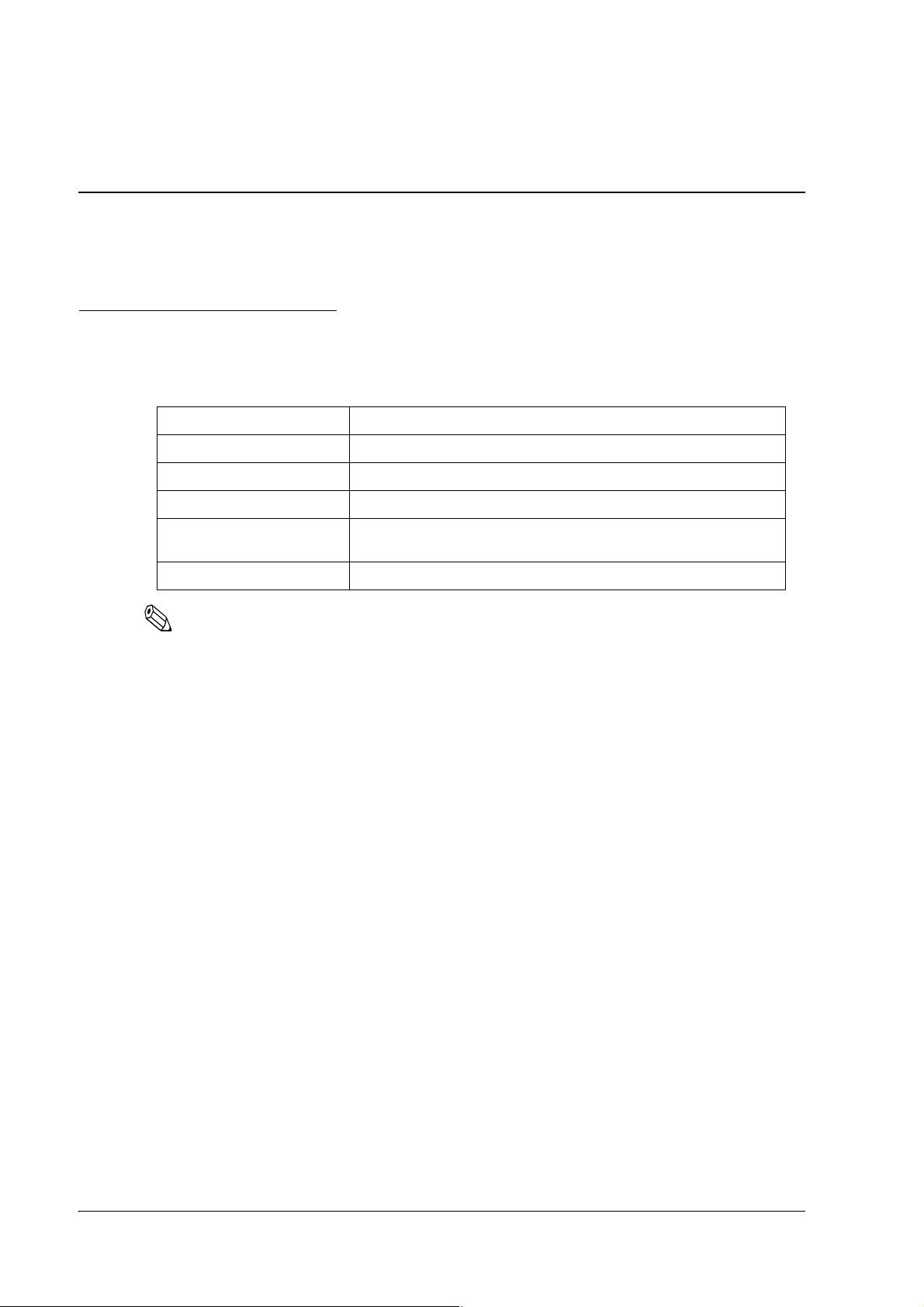

4.2 Removing a Paper Jam

CAUTION:

Be sure not to touch the manual cutter. Otherwise your finger might be injured.

1. Turn the power off.

2. Open the roll paper cover by using the tab, as shown in the below illustration.

3. Remove the jammed paper.

Note:

When you turn the power off by mistake during the printing operation, the cutter blade may stop in the paper

feed line. So the paper may not be fed in the first operation normally when you turn the power on. If the

phenomenon happens again after removing the jammed paper, try the solution "Autocutter Jam" (page 4-4).

Troubleshooting 4-3

Page 52

4.3 Autocutter Jam

Cutter cover

Autocutter unit

Lever

Hole

Knob

If a foreign object such as a push pin or paper clip drops in the autocutter and causes the auto cutter to lock

up, the printer enters an error state and begins the recovery operation automatically.

If the problem is not serious, the autocutter returns to its normal position without any intervention by the

user.

If the autocutter does not return to its normal position by itself, follow the steps below to fix the problem:

1. Open the roll paper cover, and remove the jammed object if there is one.

2. Turn off the printer, and close the roll paper cover, and turn it back on. Then the cutter blade returns

to the normal position. If you would like not to turn off the printer, send an error recovery command

and initialize printer command instead.

3. If the cutter blade doesn’t return to the normal position, return the cutter blade to the normal position

by rotating the autocutter knob in the direction of the arrow. When it is returned to the normal

position, a lever comes into the center of hole in the autocutter frame.

4-4 Troubleshooting

4. Close the roll paper cover.

Page 53

TM-U330 Technical Reference Guide

4.4 Printer prints “?“ or Incorrect Data With Serial Interface

If one of the following errors occurs during serial interface communication, the printer prints “?” or

ignores the data, depending on the setting of the memory switch Msw1-4.

❏ Parity error

❏ Framing error

❏ Overrun error

4.5 Print Speed is Slow When Using Windows Printer Driver

When the printer prints a Windows font using the EPSON Advanced Printer Driver, the print speed is

slow. To improve the print speed, use a printer font.

4.6 Printer doesn’t cut roll paper with the autocutter

TM-U330D does not have an autocutter unit. If you use the model, you can’t use the autocutter function.

Use the manual cutter.

Troubleshooting 4-5

Page 54

Chapter 5

Application Development Information