Page 1

Service manual

TM200

Rev. No. : V. 1.10

TM200 Service Manual

Page 2

TM200 Service Manual

Contents

1 Features and General Description ....................................................... - 1 -

1.1 Printer Parts .............................................................................. - 1 -

1.2 Major Component Specifications............................................... - 6 -

1.3 Connectors................................................................................ - 6 -

1.4 Interfaces .................................................................................. - 7 -

1.5 Buttons, Switches, and Panel Lights......................................... - 9 -

1.6 Self-test................................................................................... - 14 -

1.7 Hexadecimal Dump................................................................. - 15 -

1.8 Paper Sensors ........................................................................ - 16 -

1.9 Standard Accessories.............................................................. - 16 -

1.10 Options.................................................................................... - 17 -

1.11 Consumables .......................................................................... - 17 -

1.12 External Power Supply Specifications ..................................... - 17 -

2 Mechanisms and Operation ............................................................... - 19 -

2.1 Component Connections Diagram .......................................... - 19 -

2.2 TM200 Printer Mechanism ...................................................... - 19 -

2.3 Main Circuit Board Unit ........................................................... - 21 -

2.4 I/F Circuit Board Assembly...................................................... - 24 -

2.5 Switch Circuit Board Assembly ............................................... - 24 -

3 Handling, Maintenance, and Repairs................................................. - 25 -

3.1 Handling.................................................................................. - 25 -

3.2 Problem Solving...................................................................... - 28 -

3.3 Clearing Paper Jams............................................................... - 29 -

3.4 Inspection and Maintenance ................................................... - 30 -

4 Troubleshooting ................................................................................. - 32 -

4.1 Symptoms and Solutions ........................................................ - 31 -

4.2 Error Types and Processing .................................................... - 33 -

5 Disassembly, Assembly, and Adjustment ........................................... - 35 -

5.1 Before Starting disassembly, assembly, and adjustment......... - 35 -

5.2 Using this Manual.................................................................... - 35 -

5.3 TM200 Disassembly, Assembly, and Adjustment .................... - 36 -

Door sensor block……………………………………………………- 37 -

Front sensor and paper sensor block………………………….……- 39 -

Autocutter module…………..........…………………………………- 42 -

Thermal head module…............……………………………………- 44 -

Main circuit board….…………………………………………………- 47 -

Appendix A Interface………………………………………………………- 50 -

Appendix B Exploded Diagram ......................................................... - 52 -

Appendix C Panel lights and indicators ........................................... - 53 -

Appendix D Parts number list ........................................................... - 55 -

Page 3

1 Features and General Description

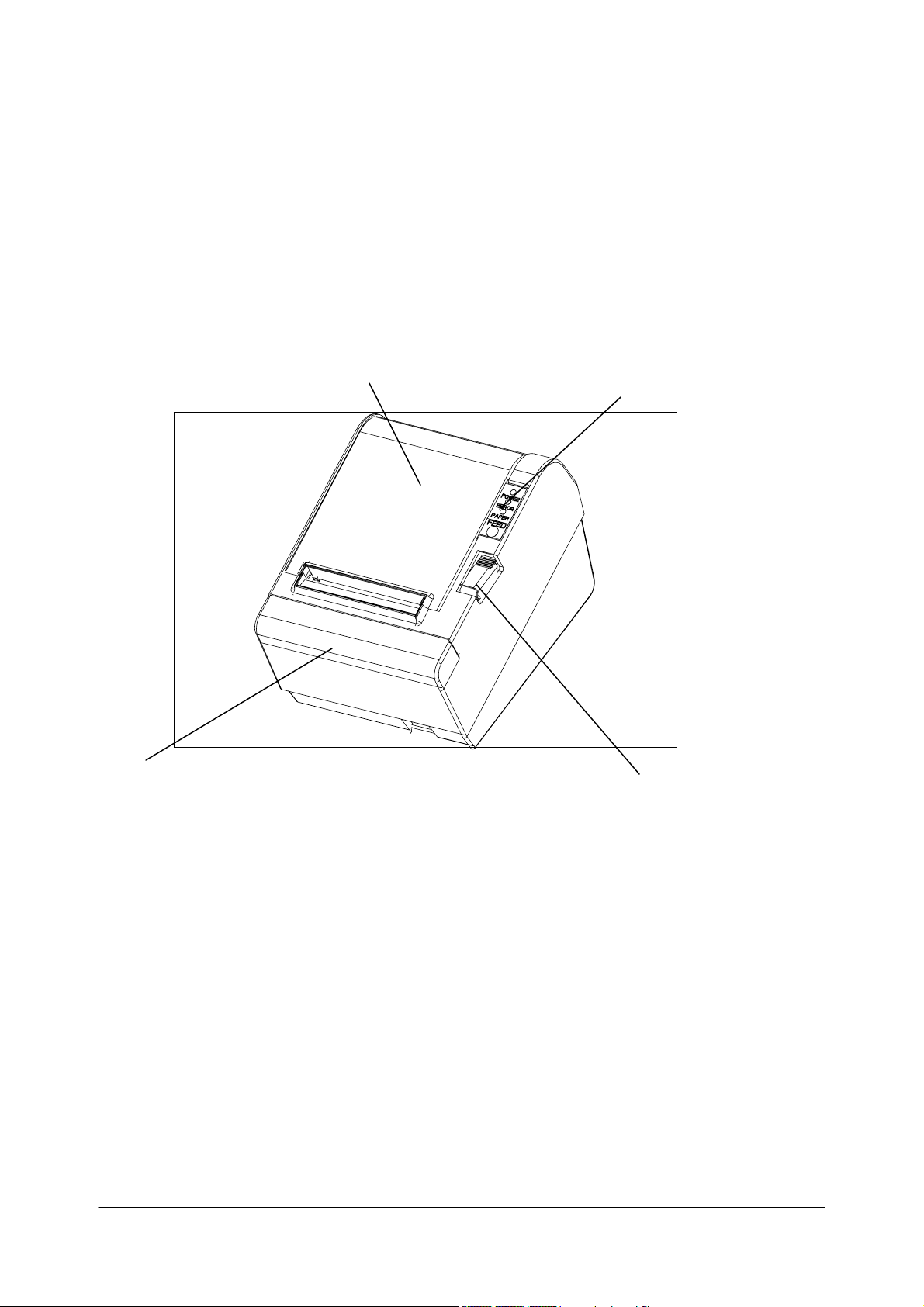

1.1 Printer Parts

Printer cover

Control Panel

TM200 Service Manual

Cutter cover

Cover open button

Figure 1-1 T

M200

ap

pearance

- 1 -

Page 4

TM200 Service Manual

Printing Spe

cifications

Printing method: Thermal line printing

Dot density: 203 dpi x 203 dpi (8 dot/mm)

Printing direction: Unidirectional with friction feed

Printing width: 72mm (2.83”), 576 dot positions

Characters per line (default): 48 (Font A)

64 (Font B)

Character spacing (default): 0.28 mm (0.1”) (2 dots) (Font A)

0.28mm (.01”) (2 dots) (Font B)

Programmable by control command.

Printing speed 180 mm / sec (approxi. 7.1” / sec)

60 lines / sec (computed value for 3.18mm (1/8”) feed)

28.4 lines / sec maximum

(4.23 mm (1/6”) feed, at 24V, 28。C (82。F

),

density level 2)

Paper feeding speed: Approximately 180 mm / sec (7.0”/sec) continuous paper

feeding

Receive Buffer Size 96K Bytes

Number of characters: Alphanumeric characters: 95

International characters: 32

Extended graphics: 128x7pages

(including one space page)

Traditional/ Simplified Chinese, Japanese, Kanji characters

Character structure: Font A: 12 x 24 (including 2-dot spacing horizontally)

Font B: 9 x 17 (including 2-dot spacing horizontally)

Kanji: 24 x 24

Default font: Font A

:

Notes

Printing speed may be sl

of control

commands.

There may be vari

t i

mage is recommended.

bi

Low transmi

ssion

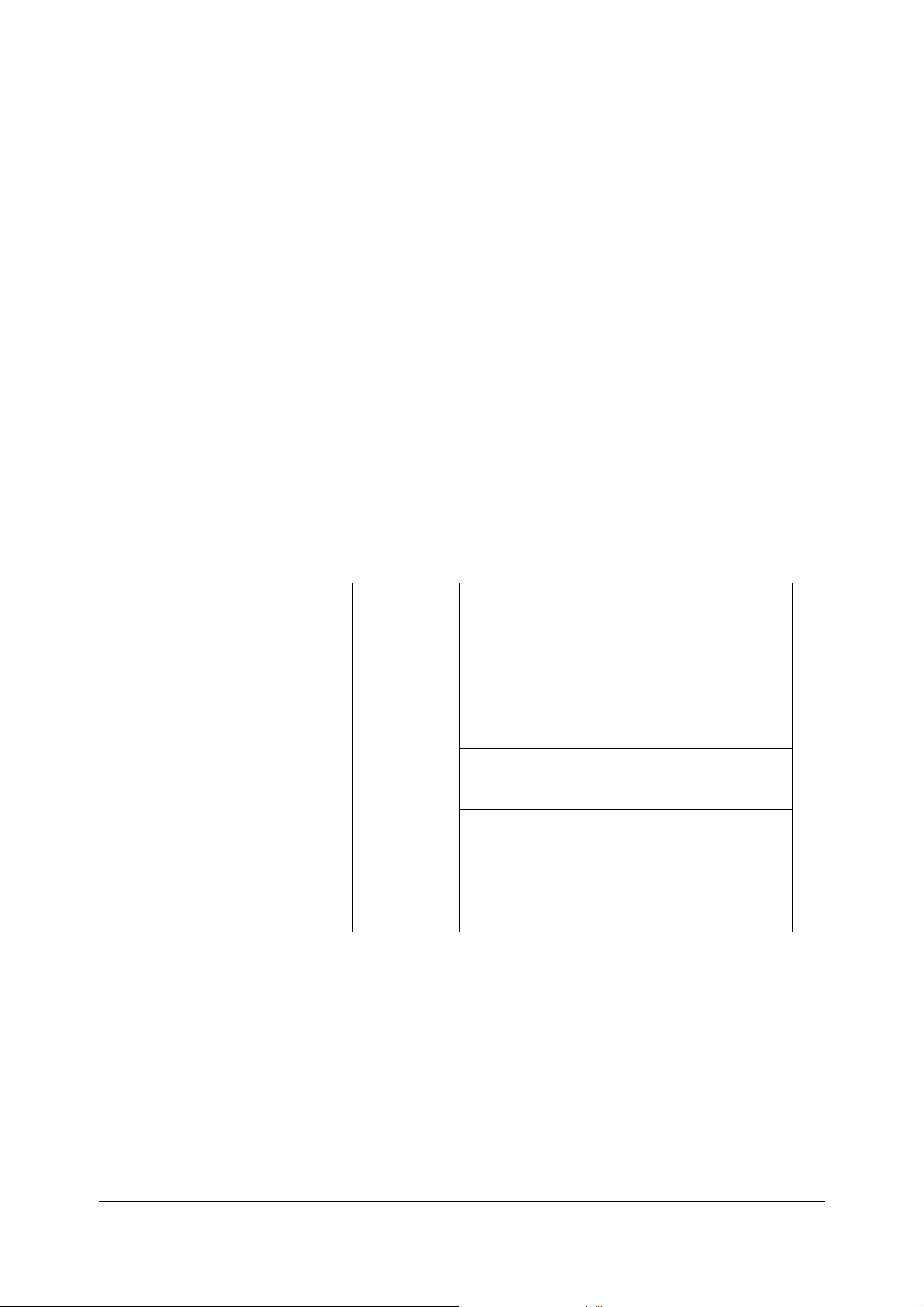

to the printer as quick

C

haract

Font A

12 x 24

24 x 24

B

9 x 17

Kanji

er size:

Standard

W x H (mm) CPL W x H (mm) CPL

1.23 x 2.97

(.05” x .11”)

0.87 x 2.10

(.035” x .08”)

2.97 x 2.97

(.11” x .11”)

* CPL = Characters Per Line

* Space between characters is not included

* Characters can be scaled up to 64 times as large as the standard sizes.

48

64

24

ower depending on th

ations in printing speed. To

speed may

1.23 x 5.92

(.05” x .24”)

0.87 x 4.20

(.035” x .17”)

2.97 x 5.92

(.11” x .24”)

cause in

ly as possible.

Double-height

termittent printing. It is recommended

48

64

24

e data transmission sp

preven

t this for

Double-width

W x H (mm) CPL W x H (mm) CPL

2.47 x 2.97

(.10” x .11”)

1.73 x 2.10

(.07” x .08”)

5.92 x 2.97

(.24” x .11”)

eed and

logo printi

24

32

12

the combi

ng, using a

to

transmit data

Double-weight/

Double-height

2.47 x5.92

(.10” x .24”)

1.73 x 4.20

(.07” x .17”)

5.92 x 5.92

(.24” x .24”)

nation

downl

oad

24

32

12

ed

- 2 -

Page 5

Auto

cutter

Pa

rtia

l cut:

Full cut:

No

te:

Paper Spec

To prevent dot

0.

04 inch) or more befo

ifications

di

splacement, after cutti

re printin

Paper type:

Pa

per ro

Pa

per ro

CAUTION:

Paper must not be pasted to the paper roll.

Printable Area

Form:

Paper width:

ll size:

Roll diameter:

Take-u

ll diam

p pape

eter:

r ro

ll width:

Pa

per roll

Internal Buf

Receive

Non-volatile

Electrical Sp

Supply voltage:

fer

buffer

selectable

bi

t image

ecifications

as 2KB or 96KB

bu

ffer: 128KB

Cutting with

(sel

ect

Cutting without un

ng,

g.

Sp

ecified

Pape

r roll

79

.5 ±0.5 mm (3.13"

Maxi

mum 83 mm

80

+ 0.5 / -1

Inside: 12 mm (0.47")

Outside: 18 mm (0.

The prin

(

3.13"

± 0.02") is 72.2

using the DI

+24

VDC ±

emperature)

t

one poin

able by

ESC I or

paper must be fed ap

therma

.0 mm

table area of a pape

P swit

7%

TM200 Service Manual

t center

GS

cut (sel

l roll pa

± 0.02")

(3.2

7")

71")

± 0.2 mm (2.84" ± 0.008") (576 do

ch.

Cu

rrent

consumption (at 24V, normal

un

cut

V

)

ect

able by

proxi

mately 1 mm (1

per

r with width of

ESC i )

4/360

79.5 ± 0.

or

5 mm

ts)

High-sp

Standby:

Note :

Maxi

eed

mode:

mum 1A for drawer kick-out driving.

(Font A alphanumer

Peak: Approximately 7.8A

Mean: Approximately 0.2A

Mean: Approximately 1.8A

ic character

- 3 -

pr

inting for

all

columns

)

Page 6

EMI and Saf

ety Standards Applied

T

hese standards are only valid

Europe

:

No

rth America:

Oceania:

Co

ndit

ions of acceptab

1. This compo

nent has been judged on the

for Information T

and

1950

submitted

CSA22.2 No. 9

fo

2. T

he terminals and

Reliability

Life

:

MTBF:

MCBF:

External Dimensions an

for products which bear

CE marking: Directive: 89/336/EE

Safety standa

EMI:

Safety standa

EMI:

ility

echnology

rds: EN60950

rds: UL1950/CSA

Equipment

50. sub-clause 2.9, whi

r Listing.

d We

co

nnectors have no

Mechanism:

T

hermal

head:

Autocutter:

ight:

EN550

E

N6100-3-3:1995+A1:2001

EN550

IEC61000 IEC61000-

FCC Class A

AS/N

TM200 Service Manual

a mark or st

C

22:1998 Cla

24:1998, including

C22.2 No.

ZS3548

basis

, i

ncl

ss A

4-2, IEC

61000-4-

4-6, IEC

61000-4-8,

950

of the required

uding Electrica

ch wo

uld

t been evaluated for

15,000

,000 li

nes

10

0 millio

1,200,0

n pulses, 50 Km

00 cuts

atement

3, IEC61000-

spacin

l Busi

on t

he main unit.

4-4, IEC

61000-4-5,

g in the St

ness Equi

cover the component it

field

wiring.

pment, UL

(End of life is defined to have been reached

it reaches t

when

eriod.)

p

360,00

0 hours

(Failure is defined

ccurring during t

o

ur

e period.)

fail

52,000

,000 li

(Thi

s is

an av

ilures rela

fa

ilures up

fa

he begi

nni

as a rand

ng of t

he wear out

om failure

he time of the random

nes

erage failure interval ba

ting to wear out and random

to

the li

fe of 15 m

illion li

andard

self

sed

nes.)

if

on

Height:

Width:

De

pth:

Weig

ht:

Approxi

Ap

Ap

Approxi

(ex

mately 138.7 mm (5.46")

proximately 146.5 mm (5.77")

proximat

cep

ely

195 mm (7.68")

mately 1.4 kg (

t for

the

paper roll)

3.08 lb)

- 4 -

Page 7

Environmen

Temp

Humidity:

tal Conditions

erature:

Op

St

orage:

Op

St

orage:

erating:

erating:

TM200 Service Manual

5

to 45℃

–10

10

10

(41 to

to

50℃ (14 to 122℉)

to

90%

RH

to

90%

RH (e

113℉)

xcept fo

(excep

r paper)

t fo

r paper)

- 5 -

Page 8

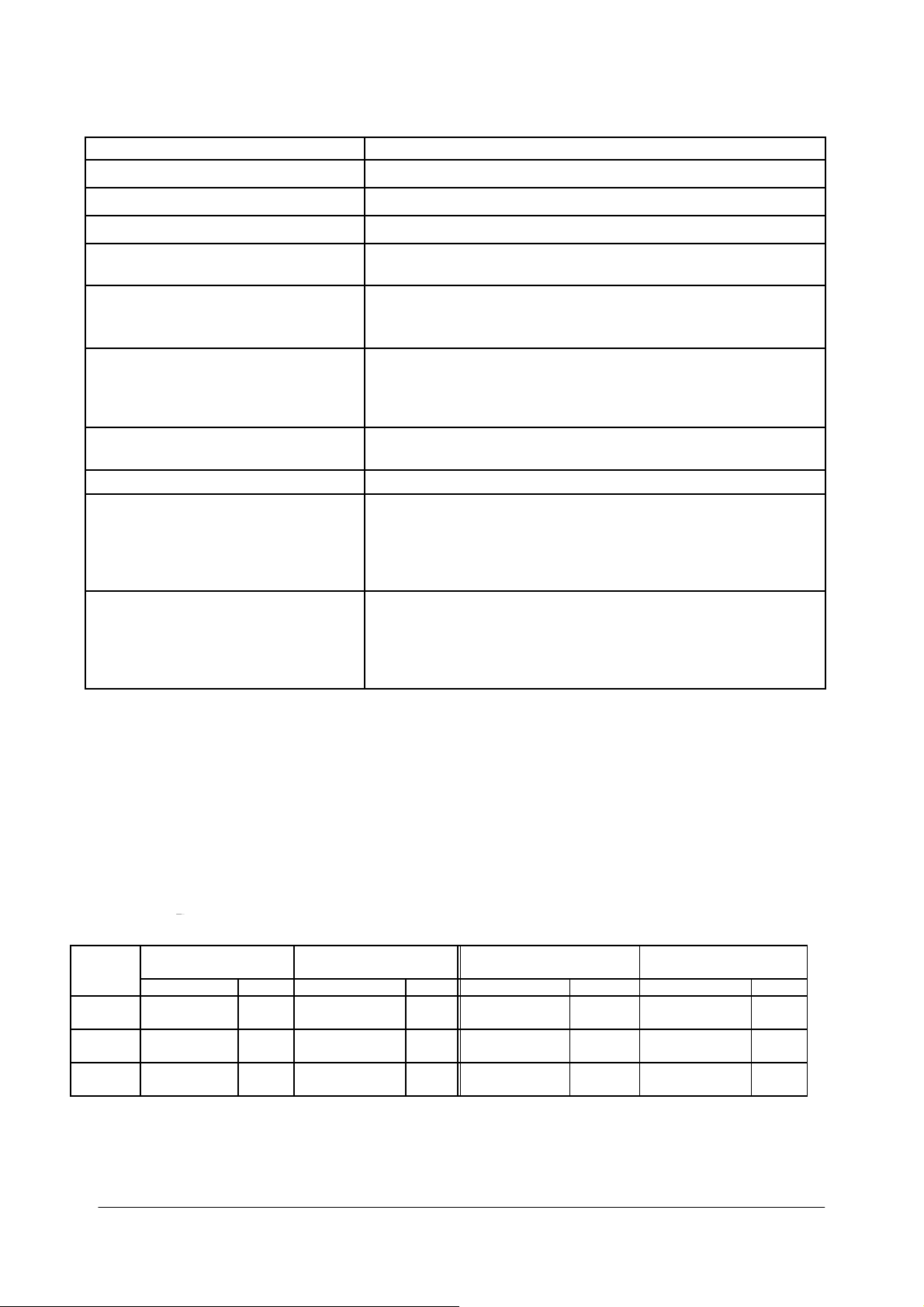

1.2 Major Component Specifications

TM200 Service Manual

TM200

Pri

nter Mechanism

Paper Feed Motor

Type:

Drive voltage:

Winding

Print Head

Dot number:

Dot density:

Resistance:

resistan

Unit

ce:

Paper-end Sensor

Paper Roll Near-end Sens

Autocutter Unit

Type:

Cutter motor voltage:

Current consumption:

1.3 Connectors

or

4-ph

24

VDC ± 10

11.5

576

0.

125 mm/do

Av

erag

Reflectio

Reflectio

DC brush moto

24

VDC ± 7%

80

0 mA peak (at

70

mA averag

ase, 48-polarit

%

± 10% at 25

do

ts

t (203

e 600 ± 4.6%

n ty

pe p

n ty

pe p

e (room temper

y, PM-type stepping motor

° C (

hot

hot

r

sta

77° F), pe

DP

o sensor

o sensor

rti

ng,

r phase

I)

low

temperature)

ature)

Interface Drawer kick-out Power supply

Power Supp

ly Connector

This co

nnect

or is used

Pin number

1

2 GND

3 NC

Shell

to

connect the pr

S

ignal nam

+

24 VD

C

Frame

GN

inter to an external powe

e

D

- 6 -

Figure 1-2 Power su

r source.

pply connector

Page 9

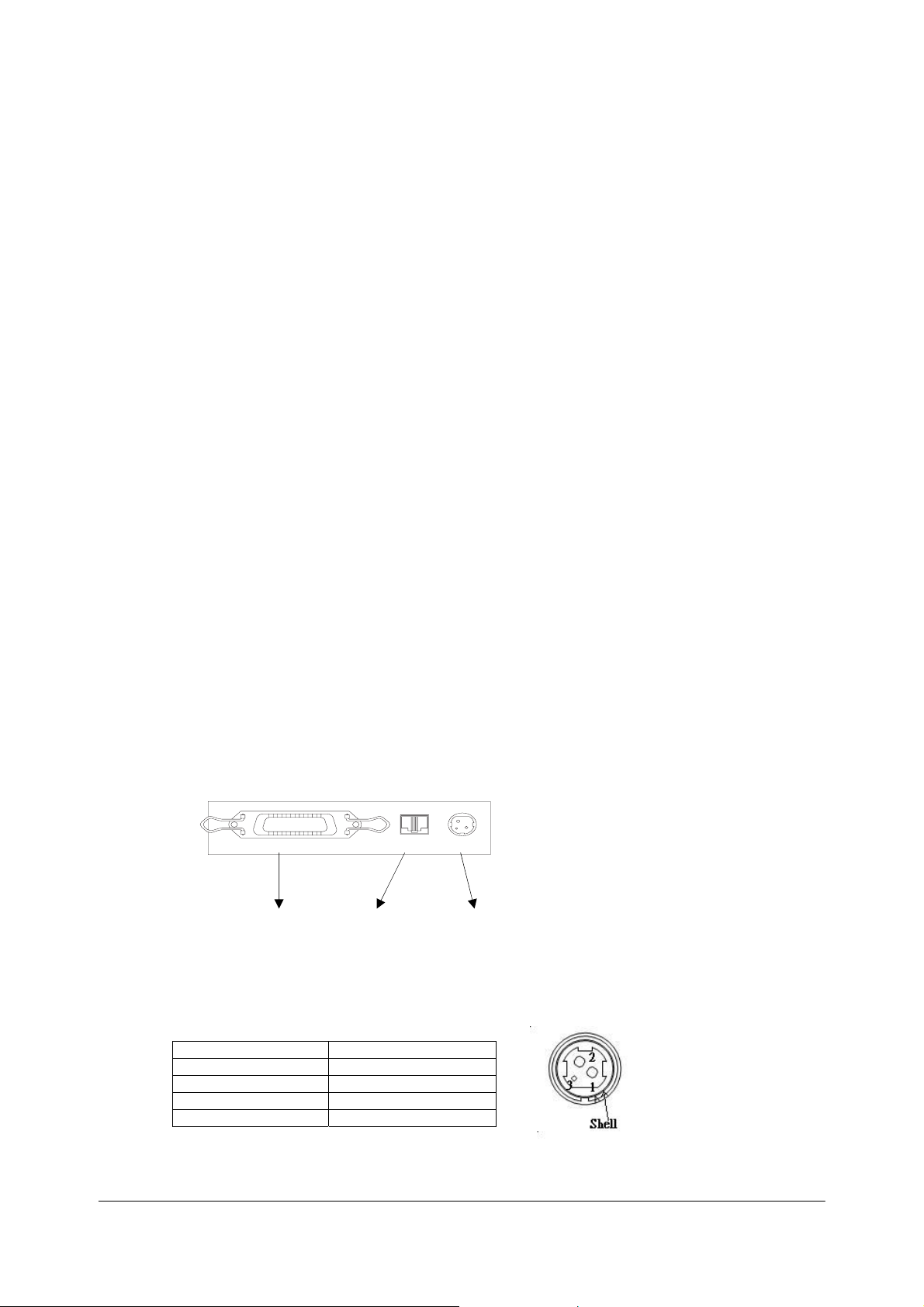

Drawer Kick

-out Connector

The pu

the host can confirm t

(ASB

lse speci

) comm

fied

ands.

Drawer kick

Pin Number Si

1

2

3

4

5

6

+24 V is

alwa

CAUTION:

Pin

4 must be used only for the drawer.

Figure 1-3 Drawer kick-out

Drawer kick-out driv

Output

CAUTION:

To av

oid an

24 or more.

be

signal: O

over

by

ES

C p

is out

he stat

us of t

-out c

onnector pin

gnal Name

Frame GND

D

rawer kick-out dr

D

rawer open

+24 V

D

rawer kick-out dr

Signal GND

ys output thro

e si

gna

l

current, the resi

put to this connector. For the seri

he inpu

/clo

ugh

co

t si

assi

gnment

ive signal 1

se signal

ive signal 2

pin 4 duri

nnector

O

gnal

by using the

s

Direction

—

Output

ng power

ut

put

utput current: 1A or

voltage:

Input

—

Output

—

on

stance of th

e drawer

TM200 Service Manual

al

DL

E EOT

.

Appr

oximately 24

le

ss

kick-out solenoid

interfac

,

GS

e model,

r

, or

GS a

V

must

1.4 Interfaces

RS-232 seria

Spec

l interface

ifica

tion

s:

Data transmi

Sy

nchroniz

Ha

ndshaking:

B

aud

Data word length:

Parity:

St

op bi

Conn

ation:

ra

te:

ts:

ector (printer

ssion:

side):

Serial

Asynchrono

DT

R/DSR or XON/XOFF

4800, 9600, 19200, 38400

7 or 8

bi

No

ne, ev

1

or mor

Female D

us

ts

en, od

e

SUB-25

d

pi

bp

n conne

con

s

ctor

tro

l

- 7 -

Page 10

Note:

The ha

ndshakin

settings.

g, data

Data transmi

Sw

itching between on

lin

T

he pr

inter does no

ff

line:

o

When t

he cover is open

When an erro

r ha

When the pr

ty pa

emp

e paper roll ne

th

ESC c 4)

inter st

per

supply is detected

Inte

rface connecto

e table below.

in th

r te

rminal a

T

M200

serial printer status and signals:

Pin number Signal name Signal

1 FG --- Frame ground

2 TXD Output Transmit data

3 RXD Input Receive data

4 RTS Output Same as DTR signal (Pin 20)

6 DSR Input

7 SG --- Signal ground

word length, baud

tted

from the prin

e and offl

ine

t have an

rate, and parity

ter has 1 stop bi

online/offline swit

s occurred

ops printing due

to a pa

by either

ar- end de

tector with a printi

ssignments and signal functio

direction

Function

This signal indicates whether the host computer

can receive data.

SPACE indicates that the host computer can

receive data, and MARK indicates that the host

computer cannot receive data.

When DTR/DSR control is selected, the printer

transmits data after confirming this signal (except

when transmitting data by DLE EOT, and GS a).

When XON/XOFF control is selected, the printer

does not check this signal.

TM200 Service Manual

depend

on the DIP switch

t (fixed

)

ch. The printer goes

per-end(i

pa

per

n cases when an

roll end det

ng halt feat

ns are de

ector or

ure using

scribed

- 8 -

Page 11

Serial int

erface connection example.

Host

(DTE ex. 8251)

TXD –––––––––––––––– RXD

DSR –––––––––––––––– DTR

Printer

TM200 Service Manual

CTS ––––––––––––––––

RXD –––––––––––––––– TXD

DTR –––––––––––––––– DSR

FG

–––––––––––––––– FG

–––––––––––––––– SG

SG

RTS

Note:

Set the han

Transmit data to the printer after turning

dshaking

so that the transmitted da

on the power and init

ta can be received.

1.5 Buttons, Switches, and Panel Lights

Power Switch

Type:

Function:

Note:

Turn on the power only after co

Panel Button

FEED button:

Note:

The ESC c 5

di

sabl

ed the

comman

button, it

Rocker switch

T

he power switch turns the power

nnecting the power supply.

If you

push this button once

feeds pape

ESC

2

and

will feed paper co

Pa

per

feedin

performed when the

be

d en

ables or di

will not func

tion

r for one li

ESC 3

. If yo

nti

g using the F

sables the panel button. When

.

and

ne based

u hold on

nuou

sly.

EED

printer cover is open.

ializing

on or off.

the print

release it, t

on t

he li

ne spacing set b

the button

button canno

the command

er.

he printer

, the prin

t

ter

y

- 9 -

Page 12

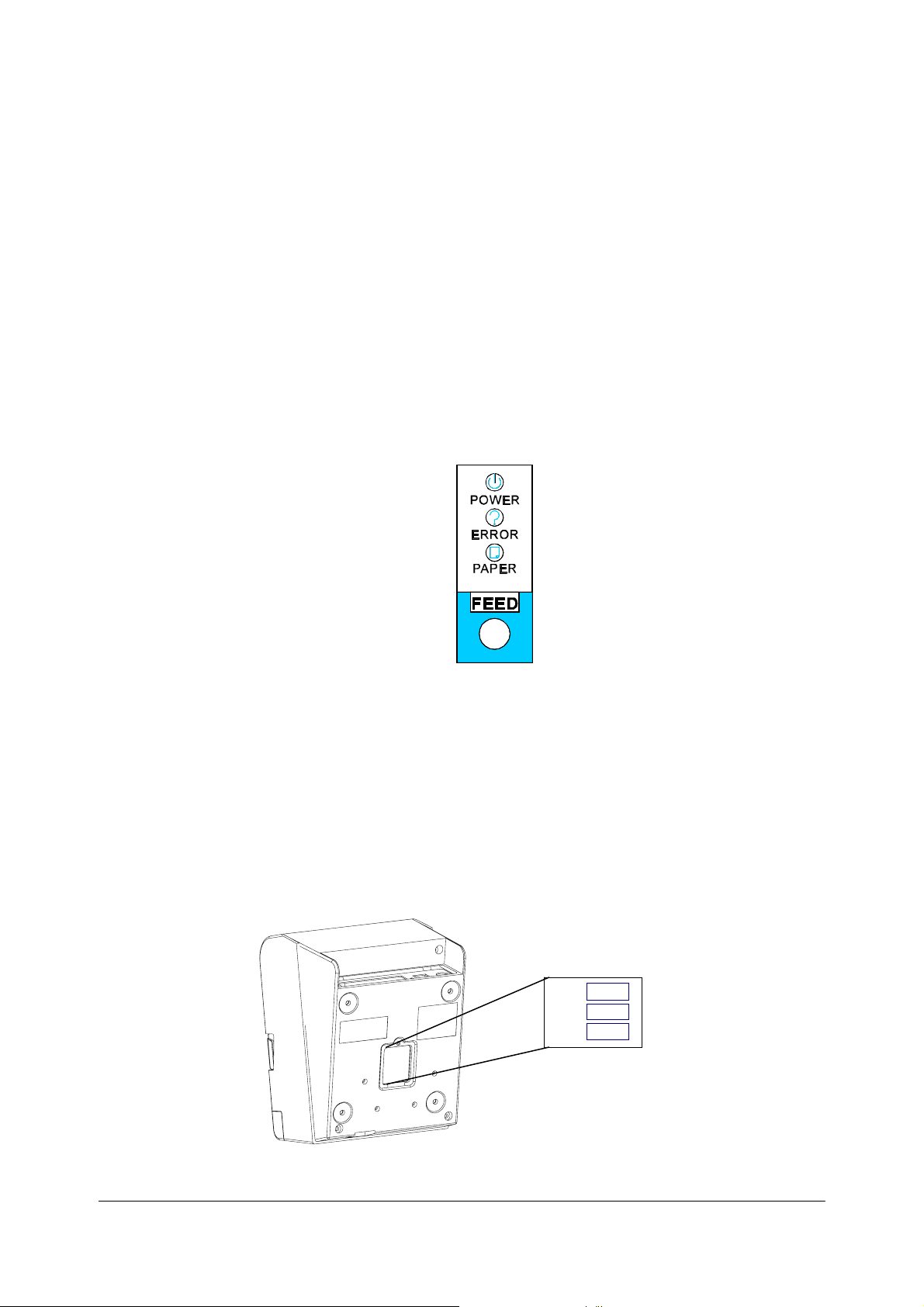

Pane

l light

s

POWER:

ERROR:

PAPER:

TM200 Service Manual

Green

On: Power is on.

Off:

Red

On: O

Off:

Blinking:

Red

On:

Off:

Blinking

Power

is no

t on.

ffline (excep

using the FEED

state)

Normal condition.

Error

T

he pa

per

Pape

r is loaded

Sel

f-test

t during pape

button and the error

roll near

(norma

standb

y st

end is de

l condition)

ate

r feeding

tected.

Note:

The panel lights can tell you a lot of information about the situation of the printer,

please refer to

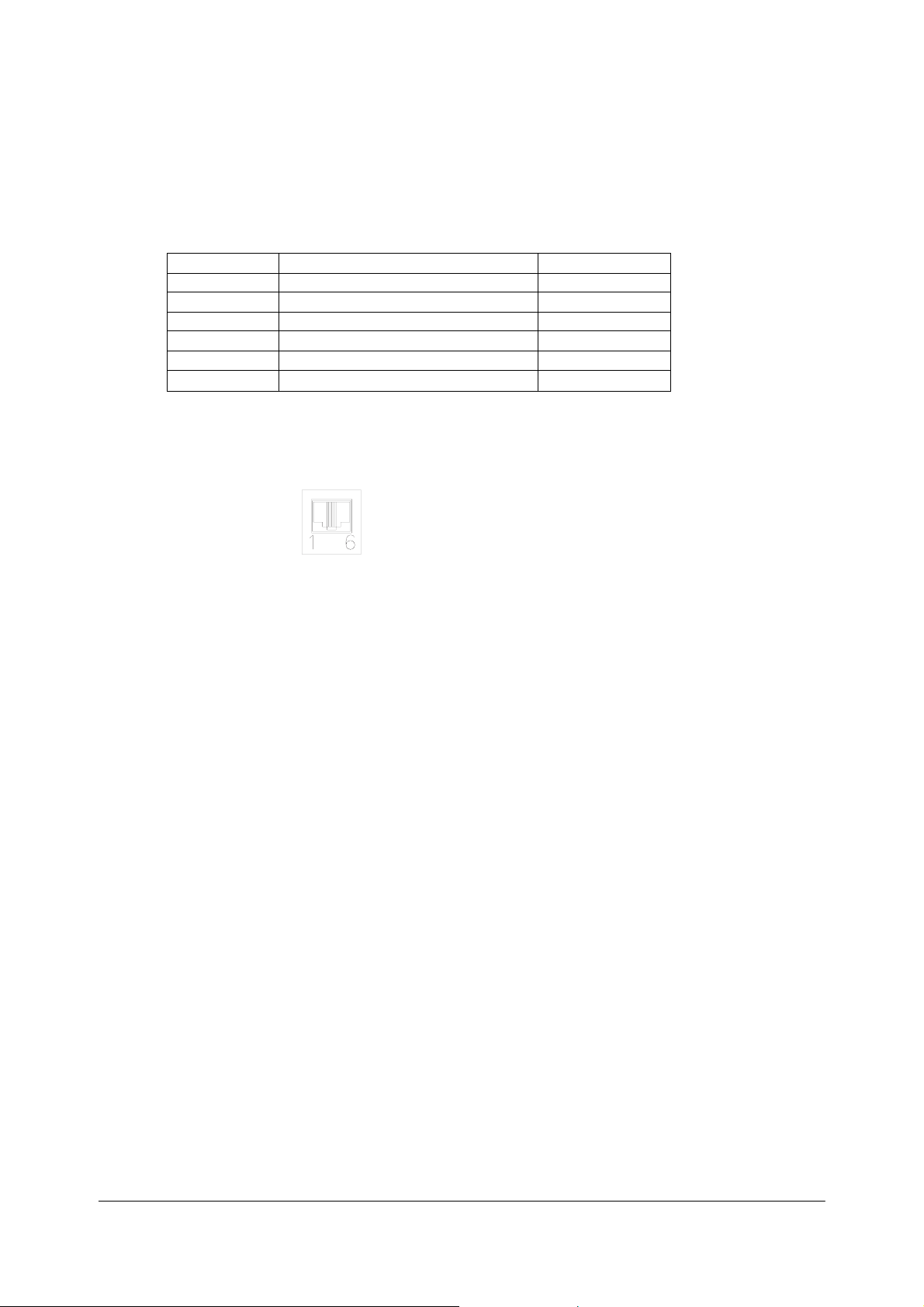

DIP Switche

s

Serial interface mode

T

he DI

P swit

ches are loca

Fi

gure 1-4 P

Appendix C

l

ted

at

Fi

gure 1-5

anel

butto

for details.

the bottom of

DIP switches

n and

the case.

SW3

SW2

SW1

indicators

- 10 -

Page 13

TM200 Service Manual

g

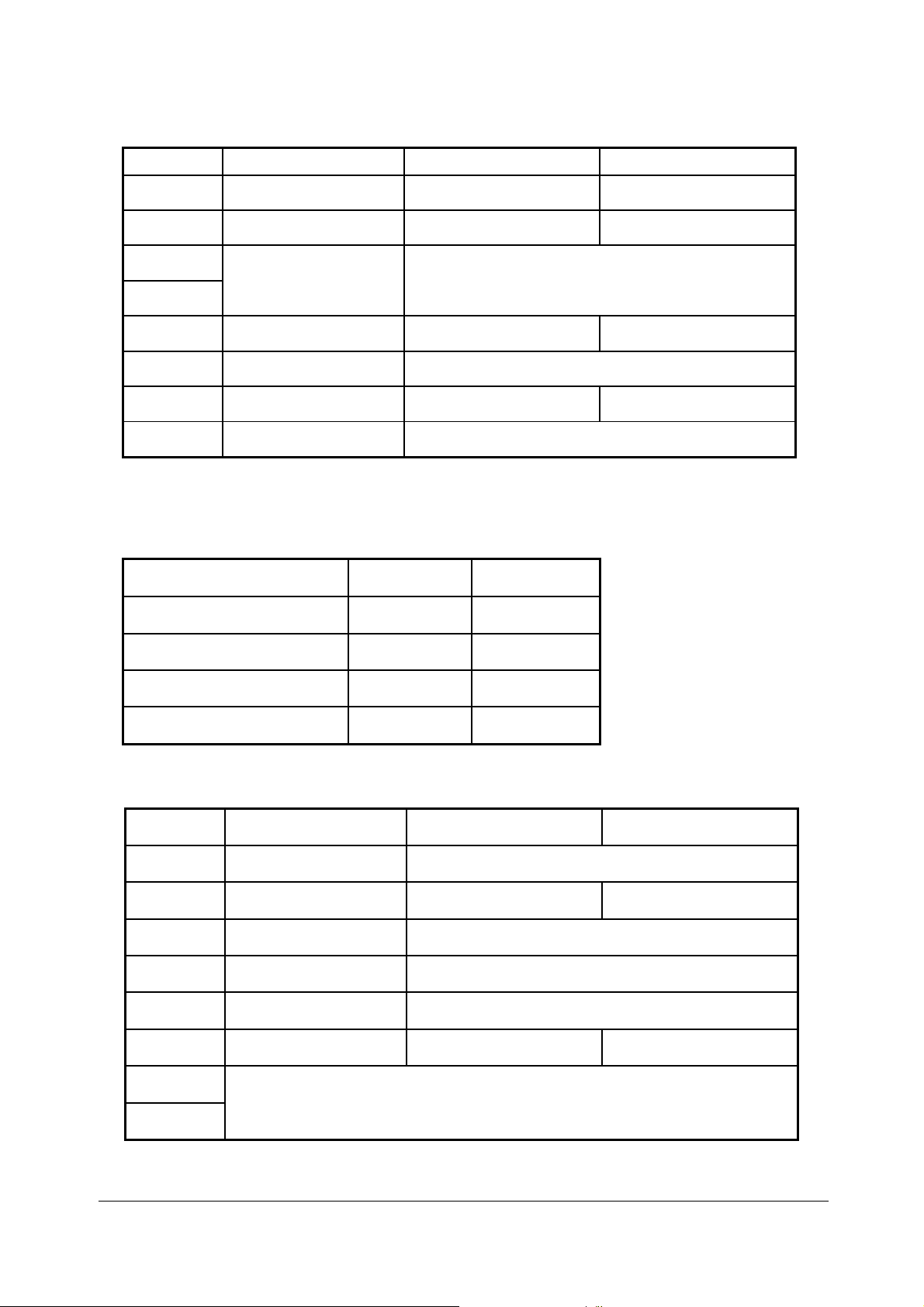

DIP switch 1

DIP switch

1-1 Print emulation TM200(default) EPSON Emulation

1-2 Paper near end sensor Vertical Horizontal(default)

1-3

1-4

1-5 Cutter setting Disable Enable(default)

1-6 Stop bit Fixed to OFF (1 bit)

1-7 Cutter mode Full Partial(default)

Function ON OFF

Selects print density Refer to the table as below

1-8

Reserved: do not change

settin

s

Fixed to OFF

Note:

TM200 accept ESC/POS command. Dip 1-1 for different printing format, ON(TM200)

for 48 characters per line, OFF(EPSON Emulation) for 42 Characters per line.

Print Density Selection

Print Density SW 1-3 SW 1-4

1 Low power consumption

mode

2 (Normal) OFF(default) OFF(default)

3 ON OFF

ON ON

4 (Dark) OFF ON

DIP switch 2

DIP switch

2-1 Reserved Reserved

Function ON OFF

2-2 Receive buffer capacity 2K bytes 96K bytes(default)

2-3 Handshaking Fixed to OFF

2-4 Data word length Fixed to OFF (8 bits)

2-5 Parity check Fixed to OFF (None)

2-6 Parity selection Even Odd(default)

2-7

Transmission speed (See the table below)

2-8

- 11 -

Page 14

Transmission Speed

Transmission Speed

(BPS) – bits per second

4800 OFF ON

9600 ON OFF

19200 OFF(default) OFF(default)

38400 ON ON

DIP switch 3

SW 2-7 SW 2-8

TM200 Service Manual

DIP switch

3-1 Buzzer1 setting Disable Enable(default)

3-2 Buzzer 2 setting Disable Enable(default)

3-3 ~ 3-8 Undefined - -

Function ON OFF

Note:

In order to connect Serial port, the host setting should be set as:

Data bits 8 bits

Parity check None

Stop bits 1 bit

Flow control (suggest to set for None) None

- 12 -

Page 15

TM200 Service Manual

P

arallel interface model

DIP sw

itch 1

DIP sw

itch

Function ON OFF

1-1 Print emulation TM200(default) EPSON Emulation

1-2 Paper near end sensor Vertical Horizontal(default)

1-3

Selects print density Refer to page as below

1-4

1-5 Cutter setting Disable Enable(default)

1-6 Parallel port supports EPP SPP/EPP(default)

1-7 Cutter mode Full Partial(default)

1-8

Reserved: do not change

settings

Fixed to OFF

Note:

TM200 accept ESC/POS command. Dip 1-1 for different printing format, ON (TM200)

for 48 characters per line, OFF (

Print Density Selection

Print Density SW 1-3 SW 1-4

1 Low power consumption mode ON ON

2 (Normal) OFF(default) OFF(default)

3 ON OFF

4 (Dark) OFF ON

EPSON Emulation) for 42 Characters per line.

switch

DIP

DIP sw

2-1 Auto line feed Always enabled Always disabled(default)

2-2 Receive buffer capacity 2K bytes 96K bytes(default)

2

itch

Function ON OFF

2-3 ~ 2-8 Undefined - -

DIP sw

DIP sw

3-3 ~ 3-8 Undefined - -

itch

3

itch

Function ON OFF

3-1 Buzzer1 setting Disable Enable(default)

3-2 Buzzer 2 setting Disable Enable(default)

- 13 -

Page 16

TM200 Service Manual

1.6 Self-test

T

he pr

inter has a sel

Control circuit

Printer mechanisms

Prin

t quality

Control soft

DI

P switch

NOTE:

This test is independent of any other equipment or software.

Running the self test

1. Make sure the printer is turned off and the printer cover is closed properly.

2. Make sure a paper roll has been installed properly.

3. While holding down the FEED button, turn on the printer using the switch on the front

of the printer to begin the self test. The self test prints the printer settings, and then

prints the following, cuts the paper, and pauses.

4. Press the FEED button to continue printing. The printer prints a pattern using the

built-in character set.

5. The self test automatically ends and cuts the paper after printing the following.

Please re-start to exit SELF-TEST

f-test

function that checks the foll

functions

ware version

settings.

owing:

If you want to continue SELF-TEST

Please press the FEED button

*** completed ***

- 14 -

Page 17

1.7 Hexadecimal Dump

TM200 Service Manual

Hexadecim

al Dump Function

This function prints t

er

numb

s and in their corresponding characters.

he data tra

nsmitted from t

he host

computer

in hexadeci

Performing a Hexadecimal Dump

To use the hex dump feature, follow these steps:

1. After you make sure that the printer is off, open the cover.

2. Hold down the FEED button while you turn on the printer.

3. Close the cover.

4. Run any software program that sends data to the printer. The printer prints

“Hexadecimal Dump” and then all the codes it receives in a two-column format.

The first column contains the hexadecimal codes and the second column gives

the ASCII characters that correspond to the codes.

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 ← ! ← & ☻ @ @

1B 25 01 1B 63 34 00 1B ←%☺← c 4 ←

41 42 43 44 45 43 47 48 ABCDEFGH

5. Close the cover and turn off the printer or reset it to turn off the hex dump

mode. (or to terminate hex dump, press FEED button three times, and

when you see

the hex dump mode was turned off.

*** completed ***

Note:

In

suf

fic

ient prin

Ending hexadecimal dumping

Hexadecimal dumping end

e interface

th

after printing ha

t da

ta to

fil

l th

e la

st li

s by turnin

s finished.

ne can be printed by

g the power o

ff or resetting the printer via

setting

th

e prin

mal

ter offlin

e.

- 15 -

Page 18

1.8 Paper Sensors

T

he pr

inter has 2 paper

Pa

per roll near-end

T

he sensor detect

When the pa

near-end of the pa

Pape

r roll end

sensor

This sensor de

When t

he sensor detects

Note:

After instal

printing.

Cover Open

When t

cov

e

r is op

he cover

ened

Note:

Be sure to u

Do not open

Do not open

may

Cover Open

T

he cover open sensor monitors the printer

during printi

vers when t

reco

When t

inter

pr

ng, t

he sensor detects

goes offl

Note:

Whether the cover is open

sensor.

ling n

Button

open button (located to the

. When th

se the co

the co

the co

be

da

maged.

Sensor

he

ERROR

he cover

ine. The

sensor

sensor

s a ne

per roll diameter becomes suffici

per roll and

tect

s whet

ew paper roll, close the printer cover; then th

s as follows:

ar-end

her pape

a pa

e cover is cl

ver open button

ver during printing.

ver during the auto

light

bl

is closed

a cover

printer r

.

open whil

ecovers when the cover is closed

or not

of a paper roll.

the PAPER indicato

r is pr

esent or not.

per-end, t

osed, the cover op

inks and the printe

does not affect the status

he printer

ri

ght

of the

to op

en the printer cover.

cutter is

cover. W

e th

e pr

operating; oth

hen the sensor detects a cover open

inter is in the standby

TM200 Service Manual

ently small, the sensor detects a

r lights on.

stop

s pr

cover) is pr

en butt

r stops printi

reported by the paper roll end

inting.

e printer restarts

essed, the printer

on is la

tched

erw

ise the mechanism

ng. T

he printer

status, the

.

.

1.9 Standard Accessories

Sample paper roll

User

Exclusive extern

Disc x 1

Communication printer cable

's Manual

x

1 roll

al power supply uni

- 16 -

t and power cord

Page 19

1.10 Options

1.11

Standard cable cover set (included wall mounting bracket)

Top waterproof cover

Consumables

TM200 Service Manual

Specified p

Specified

Packaged roll paper

Note:

The foll

Original paper:

Note:

Do not use any paper other than these specified above. Oth

reliab

aper

paper

owing

ili

ty and print

Roll pa

Original paper: TF50KS-E Nip

Co.,

Original paper: PD

In Japa

In North Amer

In Europe: Nakagawa Mfg. (Europe) GmbH

In Sout

paper can be used in

AF50KS-E

P3

50 (F3

U

.S.A.)

(

PD

190R

quality are affected ad

per: NT

Ltd.

n: Na

heast

stead of the specified paper above.

Oji

P080-80

kagawa, Seisak

ica: Na

Asia:

Jujo Thermal Oy (Finland)

80)

, P3

10 Kanzaki

Pape

versely.

pon

160R

Oji Pape

ujo

kagawa Mfg. (USA) Inc.

N.A.K. Mfg.

r Mfg.

(Mal

Specialty

Co. Ltd.

erw

ise, print head

Pape

r Industries

r Mfg.

aysi

a) SDN BHD

Papers, I

Co. Ltd.

nc.

1.12 External Power Supply Specifications

Inpu

t specif

Rated input voltage

Rated fr

H

A

Po

z Rate

Po

wer switch

wer LED

ications

equency

d inpu

t cu

rrent

90

to

264 VAC

50

/60 Hz ± 3

Less

than 100

None

None

- 17 -

V

Page 20

Output specificat

Output voltage

Rated outp

Rated outp

Output peak

ions

ut curr

ut power

ent

current

TM200 Service Manual

24

VDC ± 5%

2.5 A

Approxi

4.

5 A (within 300 ms duty 1/6)

mately 60 W

- 18 -

Page 21

2 Mechanisms and Operation

2.1 Component Connections

TM200 Service Manual

This printer

is made up

of t

he following major

TM200 prin

ter

mechanism (switch ci

I/

F ci

rcuit board

assembly

Main circui

t b

oar

d unit

2.2 TM200 Printer Mechanism

This printer

following

consists of three

illu

stration shows t

mechanisms:

he external co

compo

rcuit board assembly)

a prin

nfiguration of t

nents:

ter

mechanism

he TM200

and

a cu

tter module. The

.

Figu

re 2

.1 T

M200

external configur

ation

- 19 -

Page 22

Printer Mec

hanism

Thermal head Module

T

he thermal

act with t

cont

with the thermal head’

e

rfor

p

rinting

P

head

is desig

he plat

med when heat is generated by

is perf

ormed according to

1. T

he pr

int

signal

send

rr

co

espond

to each dot t

2. Resist

3. T

ors at ea

he heat ener

h

rough the protective

t

f

the paper.

o

ch el

gy g

en. T

s heating

s a

ectrode

ener

ned

so it

he roll

pa

element at

pr

escribed ene

o be pr

generate heat

ated

by t

layer to t

s heating

per

the followin

inted.

he resistors is transmit

he pa

element is positioned

wrap

ped

ar

ound

a prescr

the

heating

rgizing pulse to t

.

per’s he

ibed

element

g steps:

at-sensitive layer, c

TM200 Service Manual

wher

th

e pl

aten is kept

pr

essure,

.

ted to the roll pa

he el

and

ect

rodes that

ausing co

e it

pr

comes i

in cont

inting

per

surfa

lorati

is

nto

act

ce

on

The paper outle

so

acc

o

t

rin

p

rin

p

t of the printer is c

me reason, ther

u

mulation

be 80mm or less). Th

t pit

ch becoming unev

ter

afte

e is en

of two or three normal

r t

he pa

per

Figure 2

ough ro

is reduces the chance of receipt paper be

en. Paper

outlet

.2 Frame cove

overed,

om in the sp

le

that ac

is opened.

r open

and even

ace between the pl

ngth

receipts (the leng

cumula

if paper output become

tes can be easily pulled

- 20 -

aten

and

th of

one sheet

coming be

s blocked for

fr

ame cover

is a

nt and of t

ou

t of t

for

ssumed

he

he

Page 23

Au

toc

utter

Module

This printer

nd a

a

T

he autocutte

a

per. It is a

p

oll

paper thr

r

ationa

st

to

fixed

Autocutter op

T

he frame cover

sing

Clo

wit

h th

r

oug

b

Cutter blade knob

T

he movabl

f

ormed. In addition

per

frame co

sition

po

is equipped

manu

ry blade to separate completely from the moving blade. T

the fr

eration

the frame cover causes t

e paper cutter

ht i

nto

e blad

ver

cannot be opened

.

wi

th an aut

al cutter fo

r ha

separate

ough an autocutt

ame cover,

can be closed

relative position.

r manu

s two opposing

cutter blade-ty

whil

frame, and the stationary blade and

e is in the ho

to safety

ocut

ter

module

al cutt

ing.

cutter blades that

pe mecha

er mech

e the

while the movable blade is in t

me position whenev

or close

anism slit. Op

moving

he st

consid

blad

ationary blade to come in

erations, this enables a mech

d while

for cutting

operat

nism that do

e is attached to

er cutt

the movable blad

e like

es not re

ening

the

movable blad

er operation is not bein

TM200 Service Manual

of t

he roll paper

a sci

ssors to cu

quire p

frame cover causes t

he stationary blad

th

e main fr

he home po

to partial cont

e are

anism in whi

e is no

t in t

t t

assage of t

ame.

sition

.

act

g

he home

he

he

e is

ch th

he

e

2.3 Main Circuit Board Unit

The main

CPU and CPU

T

Con

Drawer

Po

Filter circuit

circui

CPU

RAM

ROM

te array

Ga

Reset ci

M200 co

T

Pa

Autocu

Detect

+24V out

+5V output

rcuit

ntrol circui

hermal

head drive circuit

per

feed

motor driv

tte

r drive circui

or circuits

trol panel

kick

wer supply circ

s

put

circuit

t board

perip

cont

rol

control

uits

ci

rcuit

unit is made up of t

heral logic ci

ts

e ci

rcuit

t

ci

rcuits

circuit

rcuits

he following

electrical ci

rcuits:

- 21 -

Page 24

CPU

perip

heral logic ci

RA

M (128K byte)

RAM is used for tempor

Data receive

Pattern data pr

Da

Flash memo

RS-

232C

ta used for

ry (2M or 8M

A printer

The

performed

sub

control program and cha

co

ntrol pro

in accord

-

memory for

interface specifications

Sel

ect

ion betw

TM200

Co

ntrol Circuit

Thermal head driver

T

he pr

int

head

ots

per line. Al

d

the

print

head, and send

sign

CLOCK

co

STROBE2, while energizing time

#

Changes in head

ther

nfir

mist

al, to t

med

by latch signal #LATCH

or built into the

Paper feed moto

T

he pa

per

gizing direction switching

ener

ial-purpose IC controls the paper feed motor in

spec

using Q1, Q2, Q3, an

r dr

feed

Autocutter drive

T

he autocut

r circuit

ter driver use MOSFET

De

tector

Pa

per end se

circuits

T

he thermal

cted via switch circui

conne

d sign

en

nsor ci

pr

al

FP_Sensor is in

Cover open se

nsor circuit

rcuits

ary

storage of

d fr

om the interface (receive buffer)

inted by

CPU r

gram

such it

the print

out

ines (flags, pointers, et

bits)

controls basic printer

ance wit

h th

ems as expanding

th

head

racter

is prog

e foll

generator data is

ram. Another

een two si

gnal

s (pin 6 (DSR) or

circuit

of t

l pri

he driver

temp

iver circ

motor

rcuit

inter mecha

he r

eceipt printe

nt hea

d control is performed via a gate array. A

ing

of print si

sets the pr

erature causes fl

hea

d, which is outp

uit

is co

nstant

d Q4 signals.

nism is

t board a

put to th

r mechanism is a

gnal

int/non-print st

. Pr

int ti

is controlled by

uctuation of t

-current d

signals (PH1,PH2,PH3

to control DC motor.

equi

ssembly to

e DSP’s port.

owing:

unit (printer buffer)

op

erations, and

charact

pi

DATA-IN, wh

me con

ut as temperature signal

riv

en by a

pped

c.)

written into flash memory.

all CPU cont

flash memory

er g

enerator da

n 25

(INI

T)) is possible.

ther

mal typ

ich is sync

atus of each dot.

trol is performed by #

the gate array.

he resistan

special-pur

and

PH

4) fr

accordance with these signals

wi

th a

paper end

the ma

in circuit

TM200 Service Manual

rol

is

works as a

ta.

e print hea

driver is built

hronized

Data

STROBE

ce valu

board unit

e of th

THERMISTOR.

pose I

C. Th

om the CPU

sensor, whi

d with

into

with t

he

is

1 and

e

e

. T

he

ch is

. The paper

576

- 22 -

Page 25

T

he cover open sensor is lo

connected via Door Sensor board

nal

sig

INPUT_4

is inpu

Control Pan

This co

PAPER

wer circ

po

Drawer Kick

When si

ansi

tr

whi

ca

n be obtained

el Control Circuit

ntrol panel is

)

and one button (F

uit. The

ERROR

Control Circuit

gnals KICK_OUT_X1

stor array and

ch indicates whet

from t

located

outputting

Power Supp

ly Circuit

T

he tabl

Powe

+24V Co

T

he +24V power

split into 3.3V and 1.8V.

+5V Cont

A +5

The

T

he RS-2

nte

i

e as below

r supp

Voltage Value Main Applications

1.8V Power supply for the CPU core

3.3V Power supply for the CPU I/O pins

+5V (VCC)

+24V

ntrol Circuit

rol Circuit

V regu

switching regu

rface’s on

lator

32 power

shows sup

ly voltage values and applic

supply is split betw

circui

lator

supply is g

board

driver.

cated

t to t

he CPU.

on the mainboard

EED

). The POWER LE

and PAPER LEDs ar

and KICK_OUT_X2

the drawer driv

her or

not the draw

he host

interface.

ply voltage values and their applications.

Logic circuit power supply

Interface board power supply

Detector power supply

Thermal head logic circuit power supply

Printer mechanism power supply

Paper feed motor

Thermal head

Autocutter

Drawer kick driver power supply

t switc

hes the input +2

IC

swit

ches t

enerated

TM200 Service Manual

next

to

the therma

assembly to the main circuit board unit. Detector

. It ha

D drives

e con

e signal

er is op

en, is input to the CPU, and this stat

ations

een t

he pr

inter

4V po

he input

by

+24V, and +5V voltage is output.

a ch

arge up circui

l printer

s thr

ee LEDs (POWER,

when +5V is supplied by t

trolled by the CPU.

from CPU go active, it

. The OPEN_CLOSE signal,

mechanism, and

power

wer supply and conver

supply and +5V. Then

t built into t

he RS-232

it is

ERROR,

he

causes

us

ts it to +5V.

- 23 -

Page 26

2.4 I/F Circuit Board

This

printer uses a TM series univer

fferent in

di

terfaces by changing t

RS-

232 Interf

ace

I

EEE

1284

Interface

USB

Multi interface (Parallel and Serial)

Interf

ace

2.5 Switch Circuit Board

sal

inte

rface, which

he interface board.

allows support

TM200 Service Manual

of a variet

y of

Switch circui

Paper

LE

t board has

FEED button

D (

POWER, ERROR, PAPER)

the follo

wing

buil

t-in el

ectrica

l circuits:

- 24 -

Page 27

3 Handling, Maintenance, and Repairs

3.1 Handling

TM200 Service Manual

Transport Pr

ecautions

Take t

he following

tran

sporting it:

CAUTION:

We recommend that each unit

LABAU Technology Corp..

Remove the paper

Make

sure that the paper

Setup Precautions

Note:

The co

ver of the unit i

Operationa

l Precautions

Observing the following oper

CAUTION:

Conn

conne

Do

turning po

i

c

Never

During no

knob by

t

T

damaged. Never

obj

Never

hand

T

t

ect t

he interface cable, power

ctor

s of the unit.

not

tu

rn unit power

wer off whil

n

the cutt

over.

o

op

he heating

ects.

he head

ouch component

er blade being exposed, whic

pull out

rmal

hand. Doin

en the pa

touch the pr

. Do

ing

and mo

steps to protect

from the un

s sec

Do no

e a paper cu

paper whil

operat

per roll cover.

elemen

so ca

ion, never op

g so ca

t of t

al

low

these component

inter mechanism’

n soil the heating

tor

areas are very hot during and

s in these areas dir

th

e unit ag

be pa

it.

roll cover

ured in place with tape. Remove the ta

ationa

l preca

cable,

t use undue forc

off duri

e the paper roll cover is open.

he printer

ng normal

t op

en the cutter cover

n cause the cutter blade to be expo

mechanism’s thermal

s (ther

elemen

ectly with yo

ainst vibration and impact whenev

cked individual

is securely closed.

uti

ons prot

and dr

e when plugging cabl

op

eration is being performed. Doin

h w

ill make it

s to

come i

mal head’s) heating el

t and

ects

awer

cable to t

eration. Be especially

impossi

and

nto

cont

affect

proper op

immediat

ur hand.

ly in th

e boxes suppl

pe before using the unit.

the unit

head

against dama

he applicable

es in

to connect

careful to avoid

g so can result

ble to open the paper roll

rotate

the cutt

sed, maki

and the d

act with metal

ement with your

eration.

ely

after

er man

ng it impossibl

river IC ar

or

pr

inting

er

ied b

ge.

ors.

ual

e easi

ot

her ha

. Do not

y

e

ly

rd

- 25 -

Page 28

Paper Prec

autions

CAUTION:

Be

of

o

T

t

hermal

pap

Take t

in

Do no

sure to

this man

p

eration of the thermal

hermal

pa

pa

er

to color

he paper roll out

a high temper

t use

Loading paper ro

Note:

Be sure to use

a

per

glued

p

Make sure that the printer

1.

Open t

2.

he pa

per

use only pape

ual

. Ther

per

star

per

against

and

ature and

this

unit to prin

r that conforms

mal paper that includes Na, K, or

head’s

ts t

o color at

the effects of he

charact

of t

heating

around 70°C. Take care

ers on the paper to fade.

he pr

inter when yo

humidity

t on label

with

the sp

element.

at, li

ght, and

u will not

environment.

paper.

ll

paper rolls

that meet the specifications. Do not u

to the core because the printer cannot detect th

roll

cover by pressi

is not r

eceivi

ng data; ot

ng t

he cover-open button.

herwise, data may be lost.

TM200 Service Manual

ecifi

cations in t

C1 io

ns can affect

to protect

humidity, which can ca

use t

e paper en

he precedin

proper

unused and prin

he pr

inter fo

se pap

r a long

er rolls that have the

d correctly.

g sect

use t

he

ti

ion

ted

me

Remove the used pape

3.

r roll core if

ther

e is o

- 26 -

ne.

Page 29

Insert the

4.

5. Be sure to

paper roll as s

note

the corr

hown.

ect direction that t

he pa

per

comes off the ro

TM200 Service Manual

ll.

6. Pull out

a smal

l amo

unt

of paper,

as shown. Then close t

he cove

r

- 27 -

Page 30

p

3.2 Problem Solving

TM200 Service Manual

Errors

See Chapter 4,

Paper roll cover does not ope

1. Turn the printer off and press the cover open button to open the cover.

2. Remove the jammed paper and put the roll back in the printer and close the cover.

(Take care not to touch the print head.)

3. If paper is caught in the automatic cutter and the printer cover cannot be opened,

open the cutter cover as shown below.

4. Then turn the knob until you see cutter blade back to the lowest position, as

shown in the illustration below. This returns the cutter blade to the normal

position. Also notice that there is a label near the cutter to assist you.

Error Types and Processing.

n (

When paper

jams, turn the

knob until the

cutter blade back

to lower

osition.

paper ro

ll cover button does not work)

5. Close the cutter cover.

6. Open the printer cover.

7. Remove the jammed paper.

Note:

Other than a

ect

such as a push pin or paper clip. If

obj

ri

bed above to return the cutter to its normal posi

desc

paper jam, the autocutter lockin

Do

not op

en the cutter cov

er unless yo

- 28 -

g up could have b

this is the case, follow the same

tion

.

u find

that the paper roll cov

een

ca

used by

er does not open.

a foreign

proced

ure

Page 31

3.3 Clearing Paper Jams

TM200 Service Manual

CAUTION:

Take care no

n damage th

ca

Do not

ho

t.

1. Op

en t

2. Next,

3. Grasp the lead

4. Correct

t to

let metal objects co

e head.

touch t

he pa

he thermal

per

roll

cover.

Note:

See th

e previous section

turn power o

ing

ff.

end

of th

Note:

Be sure to remov

malfunc

to

the problem

e all of

tion

.

that caused the paper jam and reload the pape

Note:

See the section “Loadin

me into c

head

or radiation plat

for steps to take if

e receipt paper

the paper. Leaving part of the pa

g pap

er roll” for details on

and

ontact with

e. Pr

inting

the paper roll cover does not open.

pull the jammed paper.

how to load

the thermal

can cause t

hem to beco

per in the unit can

r roll into the unit

paper roll.

he

ad. Me

me very

cau

se the sensor

tal

.

- 29 -

Page 32

Maintenanc

Setup

Paper particles,

p

aper

fo

reign m

Dirt

sid

in

components

Springs

Operation

Cleaning

Therma

Caution:

3.4 Inspection and Maintenance

Pr

oper performa

e

s it po

mak

it

which

is desi

e Procedures

The insp

n

spect

i

asis, and

b

have a more detailed te

scra

, lint, an

e

ps,

atter

d dust

ect

ion, whi

l head

Turn off the

Note that th

hot during

about 10

printer power before cleaning.

normal operation, creating

minutes afte

nce of t

ssible for this unit

he inspection and

to

perform for

maint

gned.

ion pro

periodic inspection, whi

Inspection item

Check for proper connection of cables.

Check for proper insta

Make sure the paper roll

cu

Open the paper ro

sure

or other foreign matter present.

Check for dirt, lint, and dust in th

path.

Ch

surface of or in the paper end sensor.

Ch

white with

Check the frame

other spring

disc

Check for ab

operation an

cedur

es descri

ch ca

n be

performed

chnical knowle

tt

er cover are closed.

ll co

there are no larg

eck for any fore

eck if the platen

paper particles.

onnection.

ign matter on th

roller has becom

shutter spring and all

s fo

r d

efo

nor

mal noise duri

d any ab

bed

he

re ar

by

the individ

ch should be

dge

of

llation of

ver and ma

e pieces of paper

rmation an

nor

co

mal

pa

ver and

e pape

d

ng

printing.

e therma

l head (the

rmal

elemen

the danger of burn injury.

r turning printer

po

wer

the year

e divided between two types: daily

the

per roll.

ke

e

e

t an

of

TM200 Service Manual

enanc

e pr

oced

ures described below

s of tr

ouble-fr

ual

s who use the

performed by

unit.

Action

Reconnect any cables that have

o

me loos

c

Correctly

Clos

e all covers.

Clean out any paper or foreign

matter.

r

Use a

vacuu

move all dirt,

re

Wipe away fo

or some other so

Wipe o

moistened with water.

If you discover

in

new one.

Co

wit

Chap

ff t

stall the sp

rrect any problems in acco

h the

ter 4.

d radiation

ee op

unit on a dail

individuals who

e.

insta

ll pa

per ro

m cleaner to

lint, and dust

reign m

ft material.

he roller with a cotton swa

a problem, correctly

ring or

replace it

Troubleshooting Guide in

plate)

becomes very

Be sure to wait fo

f before b

eginning

th

eration for

y

ll.

completely

.

att

er with paper

with a

rdance

e cleaning.

b

r

- 30 -

Page 33

1.

2. Clean t

Caution:

Never

ther

3.

Afte

Platen

ro

Wipe t

he pl

t

Paper

roll

Cl

ean the pa

Exterior dirt

Use a clea

uni

wa

Caution:

Do not use al

agen

mage to plastic and

da

Dirt,

lint, dust

Use a vacuum cl

Op

en t

he pa

per

roll

cover.

he t

hermal

t

hermal

IPA).

mal element.

head

touch the ther

r confirmi

ller on

receipt side

he platen

aten roller gear.

en

d sensor on receipt side

per roll end sensor with

elemen

wi

th a

ng that t

roller

surface with a cotton

t (the area that l

cotton swab

Head Thermal element

mal elemen

he alcoho

moistened with

Radiation plate

t with your hand.

l solven

a cotton swab moist

n, dry

t clean, wipe with a cloth moistened

ter

and

a mild

ts for cl

clot

neutral de

cohol,

eaning.

eaner

h to wi

benzene, thinner, trychl

pe off dirt fr

tergent

Such

agen

rubbe

to

completely remove al

.

ts can

r components.

ooks li

ke it

is marked

an alcoho

Doing

t has dried up

swab moistened

om the

exterior

wi

th a small amount

oroethylene, ketone or other si

cause deformation, deterior

l dirt, lin

comp

ened with a little

of the unit. If this does not

t, and dust.

with a thin bl

l solvent (ethanol

so can

with a little wate

damage the

letely

, cl

of water or a

TM200 Service Manual

ack

li

ne) of t

, meth

ose the paper roll cover.

r while ro

water.

ation, an

get the

solution of

milar

d

anol

tatin

he

, or

g

- 31 -

Page 34

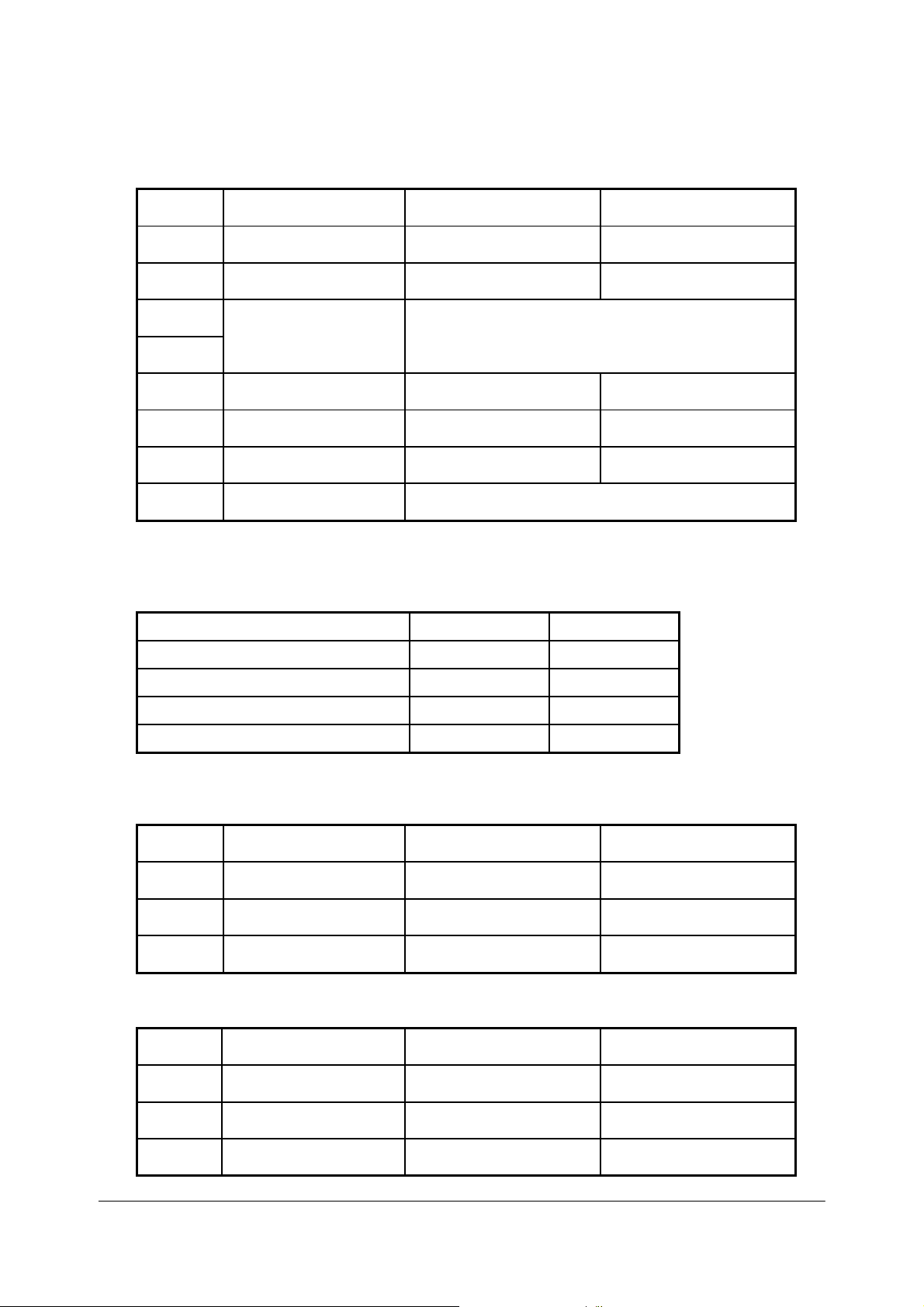

4 Troubleshooting

4.1 Symptoms and Solutions

TM200 Service Manual

This explains how

“Ch

eckpo

e

termi

d

Table 4-

Symp

Power does

Power

c

ompleted

Or, POWER

There are missing dots

in

th

The print is thin.

Unevenness occurs in

the concentratio

the

print.

Pape

Paper jams

Missing ch

characte

ERRO

ne the cause of th

1 Symptoms and checkp

tom

on self chec

LED

e print

r feed failure.

aracters/misprinted

rs/fon

R LED is lit.

ints” co

not turn on

lumn indicate t

k is no

does

not light.

n of

t breakdown.

to find

.

t

Receipt

pr

inting

Receipt

p

rinting

Receipt

pr

inting

Th

ermal

printer

the source of a problem using

he order to

e pr

oblem after ch

use to check

ecking t

he first item, pro

oints

Checkpoints (by Priority)

1. Check the power supply unit.

the po

wer supply

2. Check the main circuit board unit.

3.

Unplug the printer. Then

nn

ector

co

bac

coil has burned out and

4.

Replace the I/F circuit

1. Clean the thermal print head. (See page

2.

Replace the t

Replace the main

3.

1. Clean the thermal print

2. Adju

switches). (See page 12

3.

Replace the t

4.

Replace the main circ

1. Clean the thermal print head. (See page

2.

Replace the t

3.

Replace the main

1. Check that the roll paper

2.

Check the rece

3.

Replace the main

Rem

ove

“Clearing Paper Jams.”

1. Check the DIP switch settin

2. Replace t

1.

Close the cove

2. Install a new pape

from the main board

k

in

, and po

st DIP

the

wer it on

hermal print head module. (See page 44

swit

ches DSW 1-3 and 1-4 (print density sele

hermal print head module. (S

hermal print head module. (S

ipt paper feed motor.

jammed

he interface cable. (See page 47)

r.

the symptom. The numbers in the

the problem. If

Check that 24V is coming out

unplug each moto

. This will let you

is pulling down the po

board.

circ

uit board unit. (See page 47

head. (See page

uit bo

circ

uit board. (See page 47

circ

uit board. (See page 44)

paper by followin

r roll.

on

)

ard unit. (See

is prop

gs.

you cannot

ceed to t

e by o

ne; plug the printer

know if any moto

erly

loaded.

g the directio

he next

r or coil's

wer.

30

)

30)

ee page

page 47

30

)

ee page

)

ns in

number.

r or

)

)

ction

44

)

)

44

)

of

- 32 -

Page 35

4.2 Error Types and Processing

Printer Operatio

T

he pr

inter exec

St

ops all pr

Flashes the ER

Data Receive E

If one of

the followin

Parity error

Framing error

Overrun e

n when an Error Occurs

utes

the follo

inter oper

ROR LED.

rro

r (only with the se

g errors occu

rror

wing

ations.

op

erations upon det

rial interface model)

rs during serial inte

TM200 Service Manual

ect

ing

an er

ror.

rface communications, the printer ig

nores the data

- 33 -

Page 36

Lo

cations of the Main Elements on the

T

he following shows the locations of the main element

CPU (U1)

Autocutter drive

(J5~J8)

Thermal Head

power MOS

(Q14, Q15)

Ma

in Circuit

s on t

he main ci

Board Unit

rcuit bo

ard

TM200 Service Manual

unit.

ROM (U10, Low

byte)

ROM (U12, High

byte)

Paper feed motor

driver (U31)

- 34 -

Page 37

TM200 Service Manual

5 Disassembly, Assembly, and Adjustment

5.1 Before Starting disassembly, assembly, and adjustment

Be

sure to observe the followin

just

ment.

ad

Caution:

Disc

onnect the power

continues to flow through i

turned off.

dama

Perfor

ge to the pri

Disconnect

Perform al

di

sassemb

Neve

r touch an FPC

co

nnect

all

l disa

ly can cause seriou

ors can result in improper connection.

g important points whenever performing disassembly

supply unit

nternal

ming work with

nter.

peripherals connec

ssembly in

accordan

or its co

from the printer before begi

circuitr

out disconnecting the power

ted to th

s dama

nnect

ors with

y ev

en when

e printer

ce with the proc

ge to the printer.

your

fingers. Getting dirt on the FP

before beginning work.

edures in this manual. Incorrect

the printer’s po

, a

ssembly, or

nning work. Current

wer

switch

supply can ca

use serious

C or its

is

5.2 Using this Manual

This section explai

Titles

T

he titles that appear

ajor part

m

s and blocks.

Disassembl

T

he pr

performe

Disassembly of some parts and

ocedures described

pr

y, Assembly, and Adjustment Procedures

oced

ures

d fr

Perform

the procedures in this manual in revers

ns a number of general conv

inside the sections of this manual descri

No

in this man

om beginning

in this manual.

t all of the part

ual

are

arranged so the entir

to end.

bl

ocks may

entions used in

s (se

rvice part

be impo

e to

this manual.

be the assembly and di

s) are

indicated

as titles.

e printer

ssible unless perfor

assemble the printer.

is disassembled when

med in

sassembly of

ac

cord

ance with t

he

- 35 -

Page 38

5.3 TM200 Disassembly , Assembly, and Adjustment

TM200 Service Manual

There are 5 block of TM200 showing as following,

Door sensor block

Paper out sensor block and paper sensor block

Autocutter module

Thermal head module

Main circuit board

Please following the steps for d

isassembly,

- 36 -

Page 39

Door sensor block

1. Loose 4 screws beside the thermal cover and move them.

TM200 Service Manual

2. Screwing 4 screws (the place indicated by the red circle on the photo) on the bottom of the unit.

3. Reverse the printer, move the body cover apart.

Note:

You may use your thumb push down the lever while the other fingers forcing up the body

cover.

- 37 -

Page 40

4. Open the up cover.

5. Move the 2 screws are circled indicated on the photo.

TM200 Service Manual

To install, reverse t

he removal pr

ocedures.

- 38 -

Page 41

TM200 Service Manual

Paper out sensor block and paper sensor block:

1. Loose 4 screws beside the thermal cover and move them.

2. Screwing 4 screws (the place indicated by the red circle on the photo) on the bottom of the unit.

3. Reverse the printer, take the body cover apart.

Note:

You may use your thumb push down the lever while the other fingers forcing up the body

cover.

- 39 -

Page 42

TM200 Service Manual

4. Remove the screws on the bottom of the printer mechanism.

5. Remove 2 screws circled on the photo and all the connections between printer mechanism and main

circuit board. Then, you can depart printer mechanism from its main board.

- 40 -

Page 43

TM200 Service Manual

6. Paper sensor connecter beside the printer mechanism as the photo.

7. Remove the screw on the bottom of the printer mechanism as circled on photo, the paper out sensor

could be moved then.

To install, reverse t

he removal pr

ocedure.

- 41 -

Page 44

TM200 Service Manual

Autocutter module:

1. Loose 4 screws beside the thermal cover and move them.

2. Screwing 4 screws (the place indicated by the red circle on the photo) on the bottom of the unit.

3. Reverse the printer, take the body cover apart.

Note:

You may use your thumb push down the lever while the other fingers forcing up the body

cover.

- 42 -

Page 45

4. Remove the 2 screws beside the autocutter and the connections from circuit board.

o

install, reverse t

T

he removal pr

ocedure.

CAUTION :

When you installed the autocutter module, you must foll

foll

ow th

em, it could cause an autocutter operation failure.

ow th

e steps below. If yo

(1) Secure th

e ri

ght

side screw.

(2)

Secure th

e left

side screw.

TM200 Service Manual

u do not

- 43 -

Page 46

TM200 Service Manual

Thermal head module

1. Loose 4 screws beside the thermal cover and move them.

2. Screwing 4 screws (the place indicated by the red circle on the photo) on the bottom of the unit.

3. Reverse the printer, take the body cover apart.

Note:

You may use your thumb push down the lever while the other fingers forcing up the body

cover.

- 44 -

Page 47

TM200 Service Manual

4. Remove the 2 screws beside the autocutter and the connections from circuit board.

5. Stretch your forefinger to the bottom of the thermal head module and force up to depart it from the

printer mechanism.

6. Remove the connections from circuit board.

o

install, reverse t

T

he removal pr

ocedure.

- 45 -

Page 48

CAUTION:

Note that the (thermal

danger

before beginnin

of burn inju

g the pr

head) becomes very hot during

ry. Be

sure to wait fo

ocedures.

When perf

measures to pr

e (thermal he

th

orming proc

otec

t against el

ad).

edures, be sure to use a gr

ectr

ostatic

Never

touch the ther

of the (the

rmal head) with

mal elemen

your hand.

t (the ar

Doing

Whenever th

otton

c

swab mois

ere is dirt or an

ten

ed with

y other foreign matter on the (thermal hea

alcoh

ol.

When you installed the autocutter module, you must foll

foll

ow th

em, it could cause an autocutter operation failure.

(1)

(2)

Secure th

Secure th

e ri

ght

e left

side screw.

side screw.

r about

charge.

ea th

at looks li

so can

normal operation,

10 minutes after tu

oun

ded wris

Failur

e to do so can re

ke it is marked with a thi

damage the heatin

ow th

t band

e steps below. If you do not

TM200 Service Manual

creating th

rning printer power of

or ta

ke other

sult

in

damage to

n black line)

g element.

d), clean it

off

wi

th

a

e

f

- 46 -

Page 49

TM200 Service Manual

Main circuit board

1. Loose 4 screws beside the thermal cover and move them.

2. Screwing 4 screws (the place indicated by the red circle on the photo) on the bottom of the unit.

3. Reverse the printer, take the body cover apart.

Note:

You may use your thumb push down the lever while the other fingers forcing up the body

cover.

- 47 -

Page 50

TM200 Service Manual

4. Remove the screws on the bottom of the printer mechanism.

5. Remove 2 screws circled on the photo and all the connections between printer mechanism and main

circuit board. Then, you can depart printer mechanism from its main board.

- 48 -

Page 51

TM200 Service Manual

6. Remove the two screws on the circuit board, you could depart it then.

7. Reverse the board, you could find the ROMs.

To install, reverse t

he removal pr

ocedures.

Caution:

When performing this proc

measures to pr

Internal circuit boar

cooled sufficiently be

There are 2 ROMs on the board, the one is LOW bye(U10), the other one is HIGH byte(U12),

please make sure the ROM be placed to the correct place.

Af

ter removing

har

ge dama

c

otect against electrostati

d components become hot during normal

th

ese circ

ge by pl

edures, be sure to use a

fore perfor

uit boards,

acing them in an an

ming this

be sure to protect th

c charge.

pr

ocedure.

ti-stati

gr

oun

c bag.

ded wrist band and

use.

Make sure they have

em against electros

take

tatic

other

- 49 -

Page 52

Appendix A Interface

I

EEE

12

84 Bidirectiona

Specifications

Data transmi

ssion:

Sy

nchroniz

ation:

Handshaking:

Signal

leve

ls:

Reverse communi

Switching b

T

he pr

in either of the followings:

1.

When t

etween online and offline

inter

is not

he po

nitialized by

i

cation (Pri

equipped with any onli

wer is tu

the reset

2. During t

he self-t

est.

3. W

hen t

he cover is op

4. Durin

5. W

g paper feed

hen t

he pr

detected by

lt

du

ha

e to paper shortage en

ing

inter stops

ei

ther

the paper roll

6. Durin

g macr

o executing st

7. W

hen a temporary abnormality occu

8. W

hen an error ha

s occu

l Parallel Interface

8

-bit Parallel

Externally su

P-/Ack

TTL compatible

nter

rned on

signal from

en.

using th

printing due to

andby

rred.

pplied P-/STROBE

and

P-BUSY

Host

): Nibble or Byte Mode

signals

ne/offl

or

until the printer b

the interface.

e paper feed butt

a pa

end de

abled

stat

tector or the paper roll near

by

ESC c

us.

rs in the power

ine switch

ecomes

on.

per-end (i

4

).

si

gnals

. Th

e pr

inter is pl

ready

for data tr

n cases when empty

-end det

sup

ply voltage.

TM200 Service Manual

aced into offli

ansmissi

pa

per

supply is

ector wi

ne status

on after it

th a printing

is

- 50 -

Page 53

Interface Pi

n Assignments

Pin Pin Name Pin Description and Function

1 P-/STROBE Data Strobe

2 PRINTER_D0 Data Bit 0

3 PRINTER_D1 Data Bit 1

4 PRINTER_D2 Data Bit 2

5 PRINTER_D3 Data Bit 3

6 PRINTER_D4 Data Bit 4

7 PRINTER_D5 Data Bit 5

8 PRINTER_D6 Data Bit 6

9 PRINTER_D7 Data Bit 7

10 P-/ACK Acknowledge receipt of Data

11 P-BUSY Strobe received, Waiting on Acknowledge

12 P-PE Paper Out / Paper Error

13 P-SELECT Daisy-Chain Device Select Signal

14 P-/AF Auto-Feed paper

15 NC*

16 GND GND

17 GND GND

18 NC

19~30 GND GND

31 P-/INIT Cancel Current Job (May be called /PRIME)

32 P-/ERROR

33 GND

36 P-/SEL IN Select In; Taking low or high sets printer on line or off

line

* NC: Not Connected

TM200 Service Manual

- 51 -

Page 54

Appendix B Exploded diagram

TM200 Service Manual

52

Page 55

TM200 Service Manual

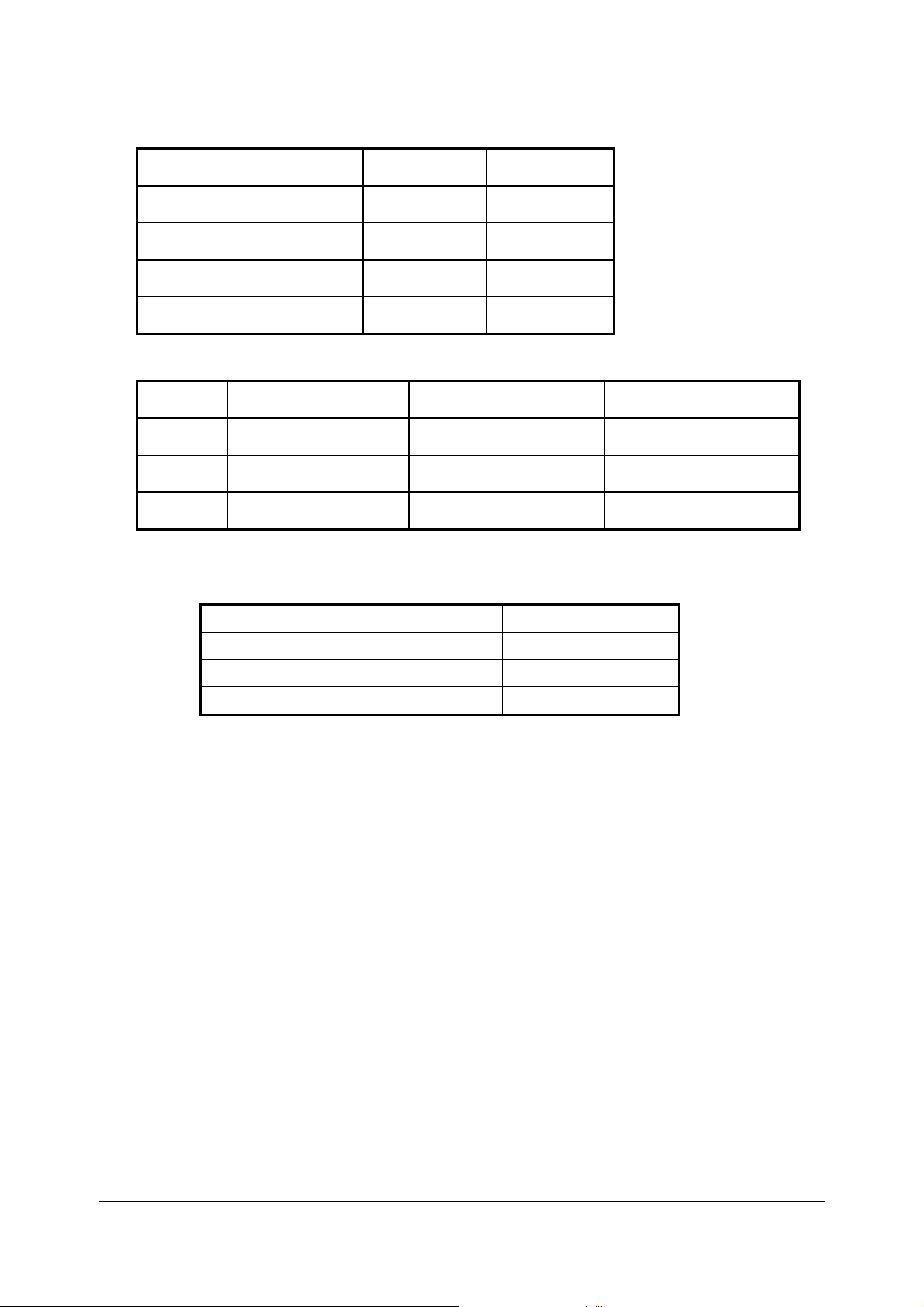

Appendix C Panel lights and indicators

Indication LED light Panel status

Normal operation status z Power - Green

z Error - OFF

z Paper - Green

Upper cover is open z Power - Green

z Error - Red light

blinking

z Paper - Green

Paper end, or sensor can’t

detect paper roll

Paper near end z Power - Green

z Power - Green

z Error - OFF

z Paper - Red and

Green light blinking

z Error - OFF

z Paper - Red

Upper cover is open, or

sensor cannot detect

paper roll

Autocutter doesn’t work z Power - Green

Paper jam z Power - Green

z Power - Green

z Error - Red blinking

z Paper - Red and

Green blinking

z Error - Red

z Paper - Green

z Error - Red blinking

z Paper - Green

- 53 -

Page 56

Indication LED lights Panel status

Enter ISP mode (DIP

switch 1-8 on)

The printer was ready for

receiving data from the host

(after press FEED button)

Ready for ISP z Power - Green

z Power - Green

z Error - OFF

z Paper - OFF

z Power - Green

z Error - Red

z Paper - OFF

z Error - Red

z Paper - Red

TM200 Service Manual

ISP is finished z Power - Green light

blinking

z Error - Red light

blinking

z Paper - Red light

blinking

- 54 -

Page 57

Appendix D Parts number list

Item Part Number Descriptions

1 BK04001M TM200 Mainboard

2 BK04002D3 Parallel port interface board

3 CB00033A Parallel printer cable, white color, 36 pin

4 CB00033B Parallel printer cable, black color, 36 pin

5 BK04009F1 Serial (RS232 32K buffer) port interface board

6 CB04008D Serial printer cable, white color, 9 to 25 pin

7 CB04008E Serial printer cable, black color, 9 to 25 pin

8 BK04008C1 USB port interface board

9 CB04011A USB printer cable, white color,

10 CB04011B USB printer cable, black color

11 BK04010B3 Multi port(Parallel & RS232) interface board

12 CB04012A Parallel printer cable, white color, 25 pin

13 CB04012B Parallel printer cable, black color, 25 pin

14 CB04013A Serial printer cable, white color, 25 to 25 pin

15 CB04013B Serial printer cable, black color, 25 to 25 pin

16 BK04201A Thermal head module