Page 1

®

Service Manual

Service Manual

Service ManualService Manual

B0 Wide-Format Professional Inkjet Printer

EPSONStylusPro9000

SEIJ98008

Page 2

EPSON Stylus Pro 9000 Revision B

NOTE:

The contents of this book may change at anytime without notice.

No patent liability is assumed with respect to the use of information contained herein.

SEIKO EPSON CORPORATION assumes no liability for problems or damages resulting from the use of the information contained

herein.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Other product names used herein are for identification purposes only and may be trademarks of their respective owners. EPSON

disclaims any and all rights in those marks.

Copyright 1999 SEIKO EPSON C ORPORATION.

2

Page 3

EPSON Stylus Pro 9000 Revision B

PRECAUTIONS

There are cautionary notes throughout the text to help you avoid personal injury or equipment damage.

W ARNING

Signals a precaution which, if ignored, could result

in serious or fatal personal injury. Great caution

should be exercised in performing procedures

preceded by a WARNING heading.

Always observe the measures listed below when performing repair or maintenance procedures.

CAUTION

Signals a precaution which, if ignored, could result

in damage to equipment.

WARNING

1. Always disconnect the product from both the power source and host computer before performing any maintenance or repair procedure.

2. No work should be performed on the unit by persons unfamiliar with basic safety measures dictated for all electronics technicians in their line of

work.

3. In performing testing described in this manual, do not connect the unit to a power source until instructed to do so. When the power supply cable

must be connected, use extreme caution in working on the power supply and other electronic components.

CAUTION

1. Repairs on EPSON products should be performed only by an EPSON-certified repair technician.

2. Make certain that the source voltageis the same as the rated voltage listed on the serialnumber/ratingplate. If the EPSON producthas a primary

AC rating different from the available power source, do not connect it to the power source.

3. Always verify that the EPSON product has been disconnected from the power source before removing or replacing printed circuit boards and/or

individual chips.

4. To protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps, when accessing internal

components.

5. Replace malfunctioning components only with those components recommended by the manufacturer; introduction of second-source ICs or other

nonapproved components may damage the product and void any applicable EPSON warranty.

3

Page 4

EPSON Stylus Pro 9000 Revision B

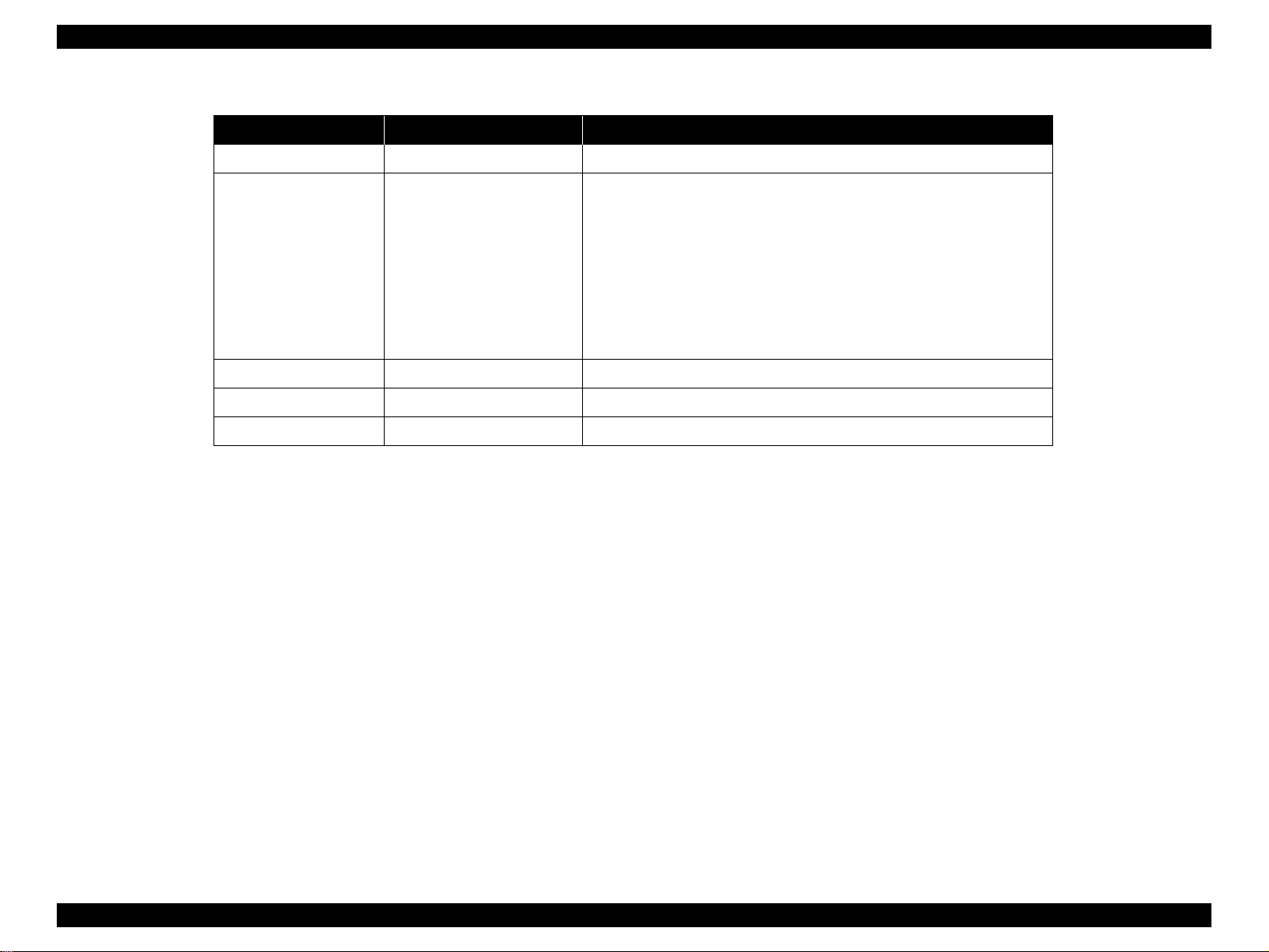

Revision Status

Revision Issued Date Description

A 1/26/1999 Original

The following chapters are revised:

Chapter-1: descriptions for firmware update procedures are corrected.

Chapter-2: descriptions for electrical circuit operation are added.

B 5/28/1999

Chapter-3: Note on usingself-diagnostic mode is added.

Chapter-4: instructions on disassembling the ink system components

are added.

Chapter-5: New tool informaiton is added / “CR Cover position

adjustment” procedure is modified. / Paper sensors adjustment is

added.

4

Page 5

EPSON Stylus Pro 9000 Revision B

Contents

Product Description

Features ...................................................................................................... 10

Professional Color Printing Features ...................................................... 10

Consumable Products & Options ........................................................... 11

SPECIFICATIONS ...................................................................................... 12

Print Specifications.......................................................................... 12

Paper-Feed Specifications .............................................................. 12

Paper Specifications........................................................................ 13

Electrical Specifications................................................................... 16

Conformity/Safety Approvals........................................................... 16

Reliability ......................................................................................... 16

Environmental Specifications .......................................................... 17

Ink Cartridge Specifications............................................................. 18

Acoustic Noise................................................................................. 18

Controller Specifications.................................................................. 18

Cutter Specifications........................................................................ 18

Printer Dimensions & Weight........................................................... 19

Control Panel ............................................................................................. 19

Buttons ............................................................................................ 20

LED indicators ................................................................................. 20

Control Panel Messages ........................................................................ 21

Control Panel Settings ............................................................................ 22

SelecType menu.............................................................................. 22

Test Print Menu............................................................................... 23

Printer Status Menu......................................................................... 23

User Paper Settings ........................................................................ 23

Cutter Replacement Menu............................................................... 24

Gap Adjustment Menu..................................................................... 24

Maintenance Errors ................................................................................ 24

Service Errors ......................................................................................... 25

Service Related Printer Settings ............................................................ 26

Maintenance Mode.......................................................................... 26

Maintenance Mode 2....................................................................... 26

Self-Diagnostic Mode...................................................................... 26

Firmware Update .................................................................................... 27

Updating the Firmware via the PC................................................... 27

Updating the Firmware Via Memory Card....................................... 27

Jumper Settings ..................................................................................... 27

Interfaces ................................................................................................... 28

Serial interface ................................................................................ 28

Parallel interface.............................................................................. 29

TYPE-B Optional interface .............................................................. 31

Buffer operation............................................................................... 31

Initialization ................................................................................................ 32

Interface selection ..................................................................................... 32

Operating Principles

Component List & Illustrations ................................................................ 34

Print Mechanism Components ............................................................... 34

Carriage Components ..................................................................... 35

Paper Feed Path & Components .................................................... 35

Ink System Components ................................................................. 36

Electrical Circuit Boards .................................................................. 36

Description of Components ..................................................................... 37

Carriage Mechanism .............................................................................. 37

CR Guide Rail ................................................................................. 37

Carriage........................................................................................... 38

Paper Feed Assembly ............................................................................ 40

PF Rail............................................................................................. 40

Sensors ........................................................................................... 41

Cleaning Mechanism .............................................................................. 42

Ink Supply Mechanism ........................................................................... 43

Sensors ........................................................................................... 44

Printer Mechanism Operation Outline ..................................................... 46

Carriage Mechanism ....................................................................... 46

5

Page 6

EPSON Stylus Pro 9000 Revision B

Platen Gap Mechanism ................................................................... 46

Paper Feed Mechanism .................................................................. 47

Summary of Control Circuit Operations .................................................. 51

Reset Circuit ........................................................................................... 52

CR/PF Motor Driver Circuit ..................................................................... 52

Head SLID Motor Driver Circuit .............................................................. 53

Pump Motor Driver Circuit ...................................................................... 53

Printhead Driver Circuit .......................................................................... 54

Sensors .................................................................................................. 55

Troubleshooting

Outline ........................................................................................................ 57

Test Points ............................................................................................. 57

Troubleshooting Using the Error Messages ........................................... 57

Errors that require a service technician .................................................. 59

Maintenance Req. 0100 .................................................................. 59

Service Req. 00000100................................................................... 59

Service Req. 00000101................................................................... 59

Service Req. 00010000................................................................... 59

Service Req. 00010001................................................................... 59

Service Req. 00010002................................................................... 60

Service Req. 00010003................................................................... 60

Service Req. 00010004................................................................... 60

Service Req. 00010005................................................................... 60

Service Req. 00010006................................................................... 61

Service Req. 00010007................................................................... 61

Service Req. 00010008................................................................... 61

Service Req. 00010009................................................................... 61

Service Req. 0001000A................................................................... 61

Service Req. 0001000C .................................................................. 61

Service Req. 0001000D

Service Req. 0001000E................................................................... 61

Service Req. 0001000F................................................................... 62

Service Req. 00010010................................................................... 62

Service Req. 00020000 (NVRAM error)

Service Req. 00020001 (Internal RAM error)

Service Req. 00020002 (SRAM error)

Service Req. 00020003 (DRAM error) ............................................ 62

Service Req. 10000004 (CPU GNRL ILLEGAL INSTRCTNS)

Service Req. 10000006 (CPU SLOT ILLEGAL INSTRCTNS)

Service Req. 10000009 (CPU CPU ADDRESS ERROR)

Service Req. 1000000A (CPU DMAC/DTC ADDRESS ERROR)

Service Req. 1000000B (CPU WATCHDOG TIME-OUT ERROR)

Service Req. 100000## (CPU VECTOR 32~63)............................. 62

General Errors ........................................................................................ 63

Ink Low............................................................................................ 63

Paper Out ........................................................................................ 63

Load xxx Paper ............................................................................... 63

Load Paper...................................................................................... 63

Paper Jam ....................................................................................... 64

Cover Open ..................................................................................... 64

Paper Not Cut.................................................................................. 64

Paper Not Straight........................................................................... 64

Reload Paper .................................................................................. 65

Push Lever Down............................................................................ 65

Compartment Open......................................................................... 65

Ink Out............................................................................................. 66

No Ink Cartridge.............................................................................. 66

Remove Paper ................................................................................ 66

Option I/F Error................................................................................ 66

Troubleshooting Based on Your Printout ............................................... 67

Dot Missing...................................................................................... 67

Uneven Printing/Poor Resolution.................................................... 68

Smudged or Marred Printout (Front) ............................................... 68

Smudged or Marred Printout (Reverse side)................................... 68

White or Black Banding ................................................................... 68

Disassembly & Assembly

Summary .................................................................................................... 70

Warnings ................................................................................................ 70

Tools ...................................................................................................... 71

Screw List ............................................................................................... 71

Disassembly Flow ..................................................................................... 72

Removing the Housing ........................................................................... 73

Maintenance Cover Removal.......................................................... 73

H Top Cover Removal..................................................................... 74

6

Page 7

EPSON Stylus Pro 9000 Revision B

L/R Side Covers Removal ............................................................... 75

Front Cover Assembly Removal...................................................... 76

Roll Cover Assembly Removal........................................................ 77

Lower Paper Guide Removal .......................................................... 78

Upper Paper Guide Removal .......................................................... 79

Circuit Board Removal ........................................................................... 80

Power Board Removal..................................................................... 80

C277MAIN Board Removal ............................................................. 81

Printer Mechanism Disassembly ............................................................ 82

Replacing the Waste Ink Pads ........................................................ 83

Replacing the Printheads ................................................................ 85

Removing the CR Motor/Pulley Assembly....................................... 88

Removing the PF Motor Assembly.................................................. 89

removing the hd_SLID motor assembly .......................................... 90

Maintenance Assembly Removal & Disassembly ........................... 91

removing the INterlock switch (L/R)................................................. 93

removing the P_THICK SENSOR ................................................... 94

removing the P_REAR Sensor........................................................ 94

removing the P_FRONT sensor ...................................................... 95

removing the LEVER POSITION SENSOR / hd_SLID HP sensor.. 95

removing the CR-HP sensor and encoder....................................... 96

Ink System Machanism Disassembly ..................................................... 98

Removing the I/C Holder Assembly .................................................... 98

Disassembling the I/C Holder ........................................................... 105

Adjustment

Summary .................................................................................................. 107

Caution ................................................................................................. 107

Adjustment Tools .................................................................................. 107

Adjustment Items .................................................................................. 108

Adjustment Steps .................................................................................... 110

Parameter Backup ................................................................................ 110

Requirements for Backup.............................................................. 110

Backup & Download Procedures................................................... 110

Other/Notes ................................................................................... 111

Firmware Update .................................................................................. 112

Updating Via the PC...................................................................... 112

Updating From a Memory Card..................................................... 112

Self-Diagnostics ................................................................................... 113

Entering Self-Diagnostic Mode ......................................................... 113

Self-Diagnostic Mode Menus ........................................................... 114

Adjustment Menu ................................................................................. 115

Adj Cap Position............................................................................ 117

Adj Check Skew............................................................................ 117

Adj Input Rank............................................................................... 118

Adj Check Nozzle.......................................................................... 119

Adj x Head Slant (B/C heads)........................................................ 120

Adj B/C Head Height ..................................................................... 121

Adj Bi-D ......................................................................................... 122

Head Gap Adjustment................................................................... 124

Flush Point Right and Left Adjustment .......................................... 125

Feed Adjustment........................................................................... 126

Adj Top & Bottom .......................................................................... 127

Adj Rear Sensor Position .............................................................. 128

Test Pattern Print .......................................................................... 129

Clean Head (drain ink)................................................................... 129

Counter Clear ................................................................................ 130

Test Menu ............................................................................................ 131

Version .......................................................................................... 132

Control Panel................................................................................. 132

Sensors ......................................................................................... 133

Sensor Adjustment........................................................................ 134

Encoder......................................................................................... 135

Fan ................................................................................................ 135

Elec. .............................................................................................. 135

Cleaning menu ..................................................................................... 137

Print menu ..................................................................................... 137

Parameter menu .................................................................................. 137

"Initialize" Items............................................................................. 137

"Update" Items............................................................................... 138

Mechanism Adjustment ........................................................................ 138

Carriage Cover Height Adjustment................................................ 139

Cutter Position Adjustment............................................................ 140

CR Steel Belt Tension Adjustment................................................ 141

PF Belt Tension Adjustment.......................................................... 141

Gear Backlash Adjustment............................................................ 142

I/H Lever Position Adjustment ....................................................... 142

P THICK Sensor Assembly Adjustment ........................................ 143

7

Page 8

EPSON Stylus Pro 9000 Revision B

Cover R/L Sensor Assembly ......................................................... 144

Maintenance & Setup

General Maintenance Issues .................................................................. 146

Periodic Maintenance Items ................................................................. 147

Product Life Information ....................................................................... 147

Important Maintenance Items During Service Operations .................... 148

Lubrication ............................................................................................ 148

Unpacking and Installing ........................................................................ 149

The Packaging ..................................................................................... 149

Before Opening the Large & Medium boxes ................................. 149

Contents of the Packaging ................................................................... 150

Medium-size box ........................................................................... 150

Large box....................................................................................... 150

Unpacking and Assembling .................................................................. 151

From unpacking to assembling the Stand ..................................... 151

Assembling the Printer body.......................................................... 154

Appendix

Wiring Diagrams ...................................................................................... 159

Parts List .................................................................................................. 161

Exploded View Diagram .......................................................................... 167

Component Layout .................................................................................. 182

Circuit Diagrams ...................................................................................... 184

8

Page 9

PRODUCTDESCRIPTION

CHAPTER

Page 10

EPSON Stylus Pro 9000 Revision B

1.1 Features

The EPSON Stylus Pro 9000 is an ultra-wide, 6-color ink jet printer with

professional color output. It has the same printheads as the EPSON Stylus

Color 5000. The EPSON Stylus Pro 9000 provides the following major features

and more.

1.1.1 Professional Color Printing Features

Large-size/poster printing

up to B0-wide paper (1118 cm/44 inches) including print-registration marks

Excellent Photo-quality printing

1440 (H) x 720 (V) dpi combined with EPSON’s Microdot printing

High-speed printing

64 nozzles per color (same printhead as the EPSON Stylus Pro 5000)

The RISC-CPU and high-speed color raster ASIC quickly process

detailed print data

A0/Normal Paper: 10 min. approx. (360x360 dpi/Speed)

A0/Glossy Paper: 30 min. approx. (720x720 dpi/Quality)

A0/Glossy Paper: 55 min. approx. (1440x720 dpi/SuperFine)

Low running cost

Six separate ink cartridges so you only have to replace the empty ink

cartridge (each cartridge holds 220 ml)

Auto Rotate feature saves paper by automatically rotating an image if

the width is shorter than the height

Wide compatibility

The following interface alternatives are available:

IEEE-1284 bidirectional parallel interface (supports ECP mode)

Macintosh serial interface (approx. 1.8Mbps)

One Type-B expansion slot for an optional interface

User-friendly features:

Two roll holders for easy switching between paper types

Standard roll-paper cutter

Optional roll-paper take-up reel for automatically winding up your long

printouts

Product Description Features 10

Page 11

EPSON Stylus Pro 9000 Revision B

1.1.2 Consumable Products & Options

The following table lists the consumable items and options available for use

with the EPSON Stylus Pro 9000.

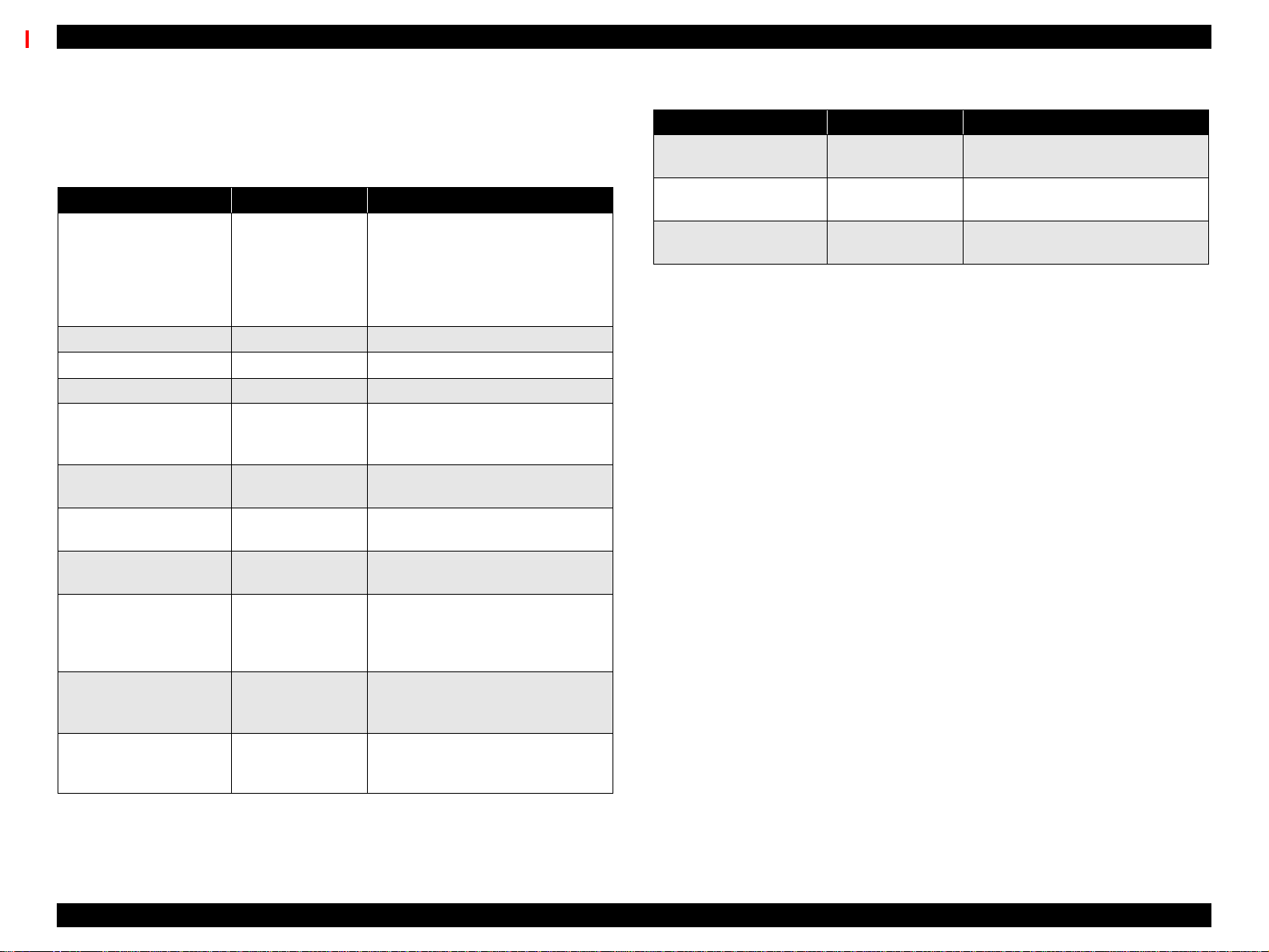

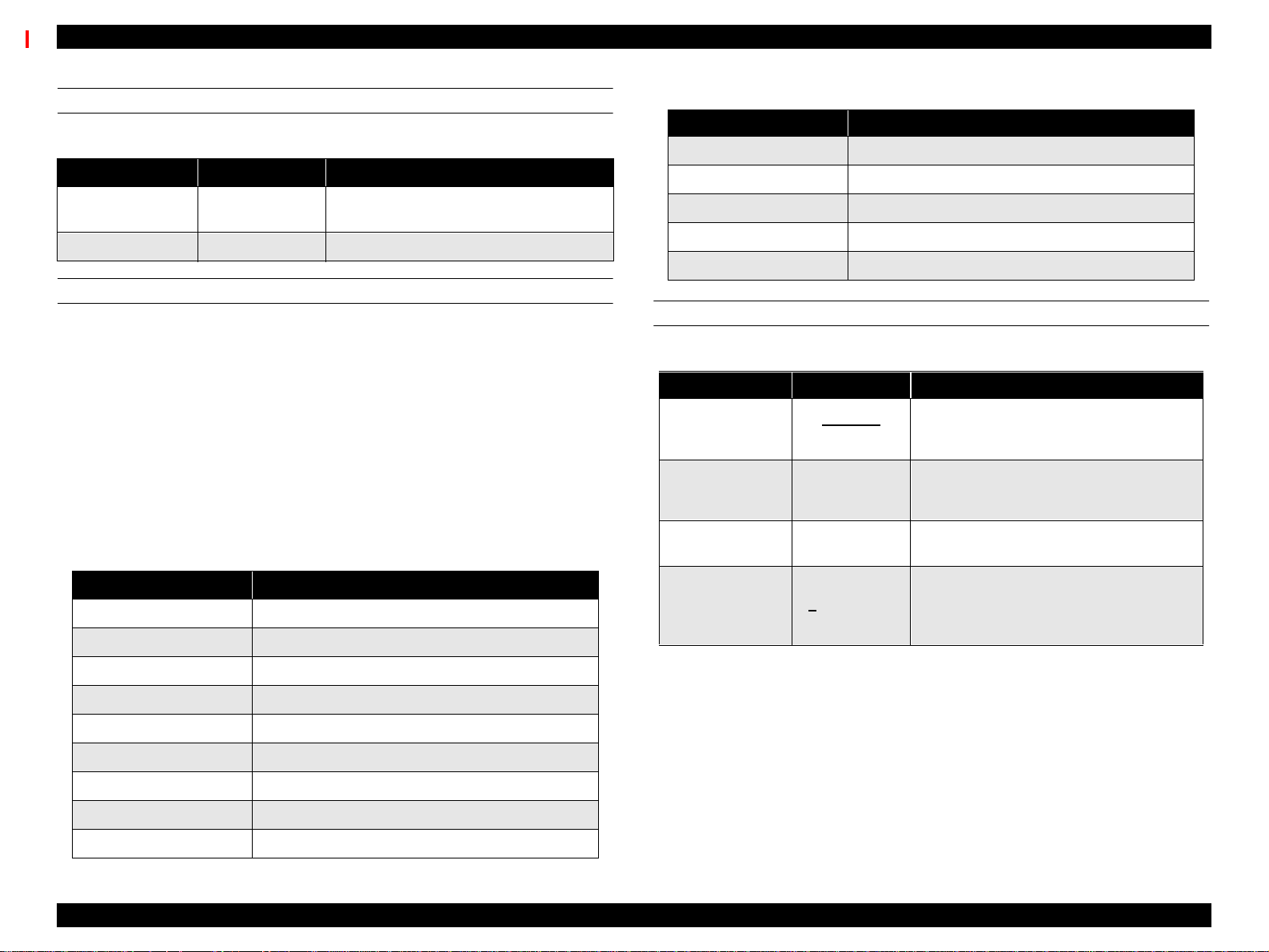

Table 1-1. Consumable Products & Available Options

Name Code Product

T407¬¬¬

T410¬¬¬

Ink cartridges

Papercutterblade C815131 Consumable item

Roll Feed Spindle 2” C811021* For two-inch diameter roll paper

Roll Feed Spindle 3” C811031** For three-inch diameter roll paper

Auto Take-Up Reel Unit

Photo Paper (Glossy)

Semigloss Photo Roll

Paper

Matte Roll Paper

Photo Quality Ink Jet

Paper

Photo Paper

Photo Quality Glossy

Film

T409¬¬¬

T408¬¬¬

T412¬¬¬

T411¬¬¬

C81508¬

C815091 (core

only)

S041225

S041224

S041222

S041223

S041221

S041220

S041079

S041068/S041045

S041069/S041043

S041070/S041044

S041142

S041143

S041156

S041073

S041074

S041075

Black Ink

Cyan Ink

Magenta Ink

Yellow Ink

Light Cyan Ink

Light Magenta Ink

Printed roll-paper option

36 in. wide/20.7m long

44 in. wide/20.7m long

36 in wide/25m long

44 in wide/25m long

36 in wide/25m long

44 in wide/25m long

A2

A3

A3 Wide/B

B

A3

A3 Wide/B

B

A3

A3 Wide/B

B

Table 1-1. Consumable Products & Available Options (continued)

Name Code Product

Rip Station 5100 PS

Server Series

Multi-protocol Ethernet

interface card

100Mbps Multi-protocol

Ethernet interface card

Note*:Tworollscanbeinstalledatthesametime.

Note **: Can only be installed in the upper spindle holder.

EAI - C850092

Other - C850093

C82362¬ Type-B 10Base-T

C82363¬ Type-B 100Base-T

Fiery Adobe® PostScript® 3™

Server

Product Description Features 11

Page 12

EPSON Stylus Pro 9000 Revision B

1.2 SPECIFICATIONS

PRINT SPECIFICATIONS

Print method: On-demand MACH (Multi-layer Actuator Head) ink

jet E-MACH type

Nozzle configuration: Black: 64 nozzles

Color: 320 nozzles/64 nozzles for each color (Yellow,

Magenta, Cyan, Light Magenta, and Light Cyan)

Print direction: Bi-directional with logic seeking

(high-speed return and skip only)

Print speed: See the following table:

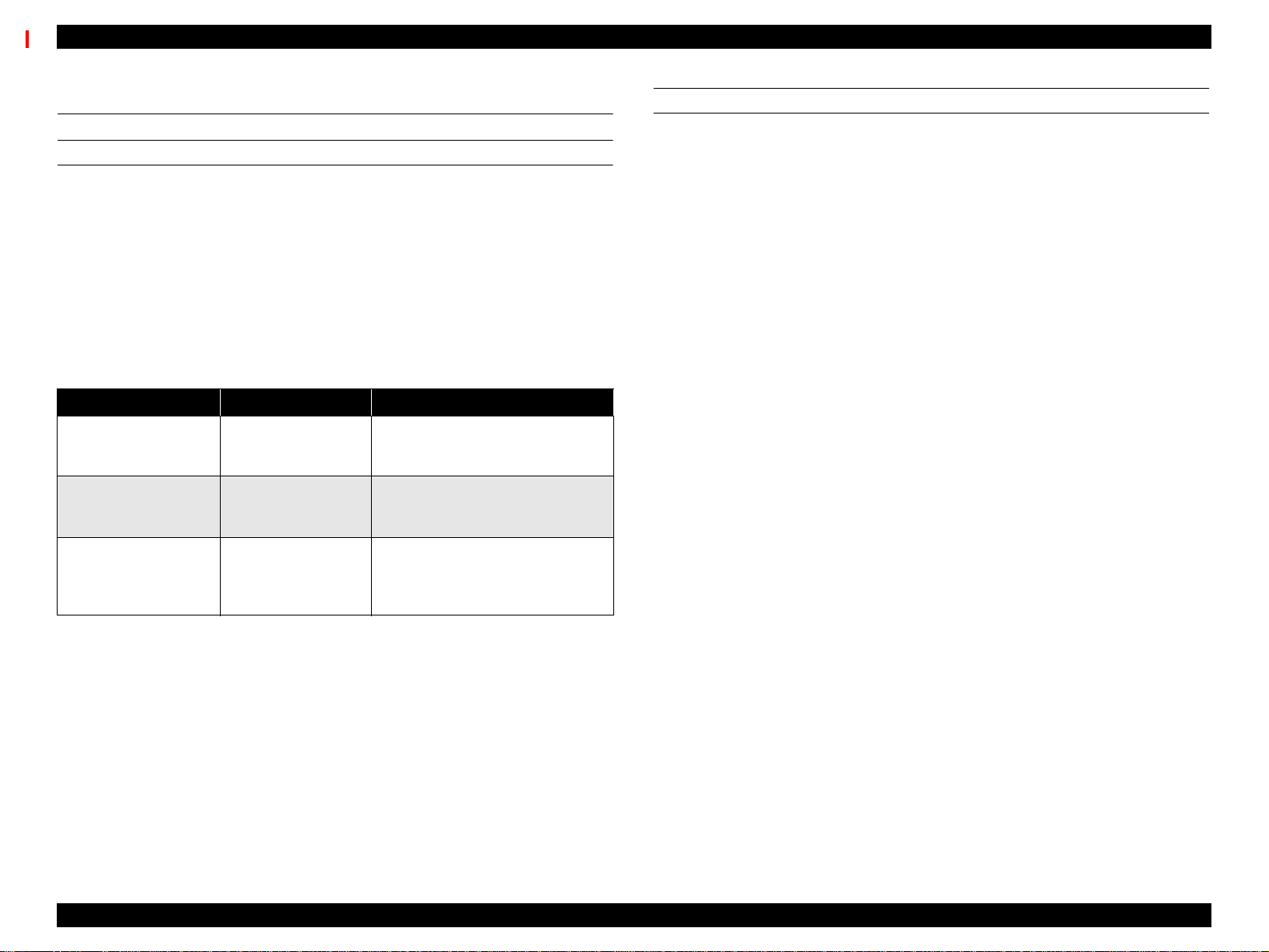

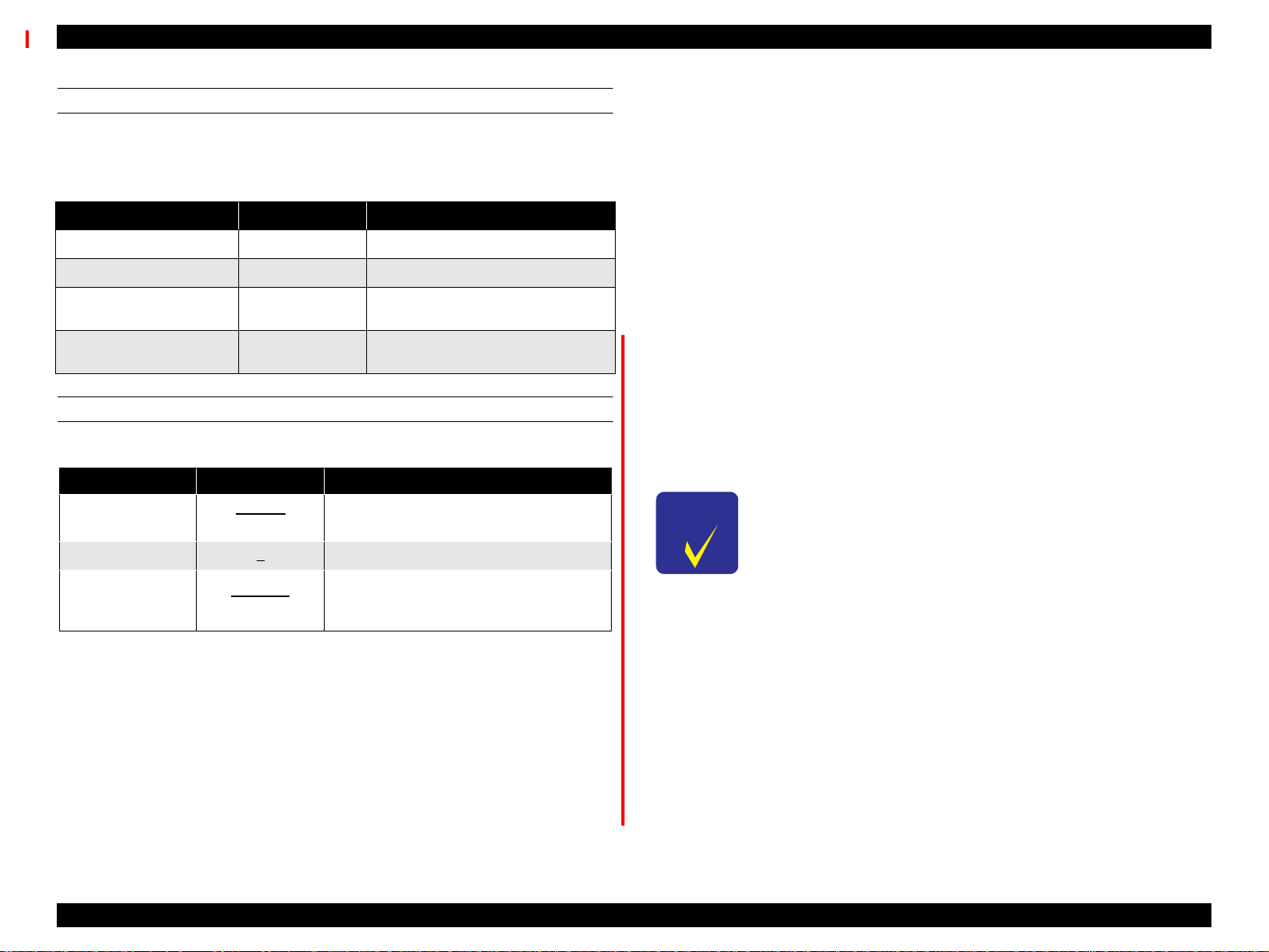

Table 1-2. Print Speed

Print Mode A0 Print Time Environment

Matte Paper Approx. 15 min.

Glossy Paper Approx. 30 min.

Glossy Paper Approx. 55 min.

• Speed selected in printer driver

• 720 x 360 dpi

• Mode = Bi-D/FOL/300cps

• Quality selected in printer driver

• 720 x 720 dpi

• Mode = Bi-D/FOL/300cps

• Advanced Photo selected in

printer driver

• 1440 x 720 dpi

• Mode = Bi-D/4-pass FOL/300cps

PAPER-FEED SPECIFICATIONS

Feeding method: Friction feed

Line spacing: 1/6 or 1/720” programmable

Paper loading: Roll paper (two 2-inch rolls can be loaded at the

same time)

Single sheets loaded one at a time

Paper volume: 2” core roll paper = diameter of paper wound on roll

of less than 103mm (4.05”)

3” core roll paper = diameter of paper wound on roll

of less than 150mm (5.9”)

Single sheets = one sheet at a time

Feed speed: 200 ± 10 ms (when feeding at 1/6”)

2.5”/second (when continuously feeding)

Control code: ESC/P Raster (commands are not open to public)

Product Description SPECIFICATIONS 12

Page 13

EPSON Stylus Pro 9000 Revision B

PAPER SPECIFICATIONS

Size, roll paper {

Minimum paper requirements

Paper meeting the requirements described below

can be used with this printer, but neither the feeding

nor printout quality is guaranteed.

•Paper Size = Width 297~1118mm

•Roll Size = 2” or 3” core

•Paper Thickness = 0.08~0.5mm (0.003~0.019”)

{

Normal paper

For paper meeting the following requirements, the

feeding operation only is guaranteed.

•Paper Size = Width 297~1118mm

•Roll Size = 2” or 3” spindle

•Paper Thickness = 0.08~0.11mm (0.003~0.0043”)

•Paper Weight = 64~90gf/m

•Paper Quality = Normal paper, recycled paper

*1: Use at normal room temperature

*2: The printer exerts between 300~500gf to peel

}

(8.27~44.02”)

Length 720mm~45m

(28.35~1771.65”)

paper thickness = 103mm or less (4.05”)

(two 2” rolls)

150mm or less (5.9”)

(one 3” roll)

}

(8.27~44.02”)

Length 720mm~45m

(28.35~1771.65”)

paper thickness = 103mm or less (4.05”)

(two 2” rolls)

150mm or less (5.9”)

(one 3” roll)

2

(17~24 lb.s)

(15~25°C (59~77°F)

40~60% humidity)

off the rear edge of roll paper from the core

*3: Paper feeding is normal until the rear

edge of

the paper separates from the core. At the

point where the rear edge is free, print quality

is not guaranteed.

•Upper spindle = last 400mm (15.75”) not

guaranteed

•Lower spindle = last 300mm (11.8”) not

guaranteed

{

Special paper

}

For special paper meeting the following

requirements, the feeding operation and print quality

are optimized.

Table 1-3. Special Paper Specifications

Paper Code Paper Size Roll Size

Matte Paper S041220 44” x 25m

S041221 36” x 25m

Semigloss Photo

Paper

Photo Paper

Glossy

S041223 44” x 25m

S041222 36” x 25m

S041224 44” x 25m

S041225 36” x 25m

2” core/ paper thickness

(radius) of 103mm or less

*1: Use at normal room temperature

(15~25°C (59~77°F)

40~60% humidity)

*2: Paper feeding is normal until the rear edge of

the paper separates from the core. At the

point where the rear edge is free, print quality

is not guaranteed.

•Upper spindle = last 400mm (15.75”) not

guaranteed

•Lower spindle = last 300mm (11.8”) not

guaranteed

Product Description SPECIFICATIONS 13

Page 14

EPSON Stylus Pro 9000 Revision B

Size, single sheets {

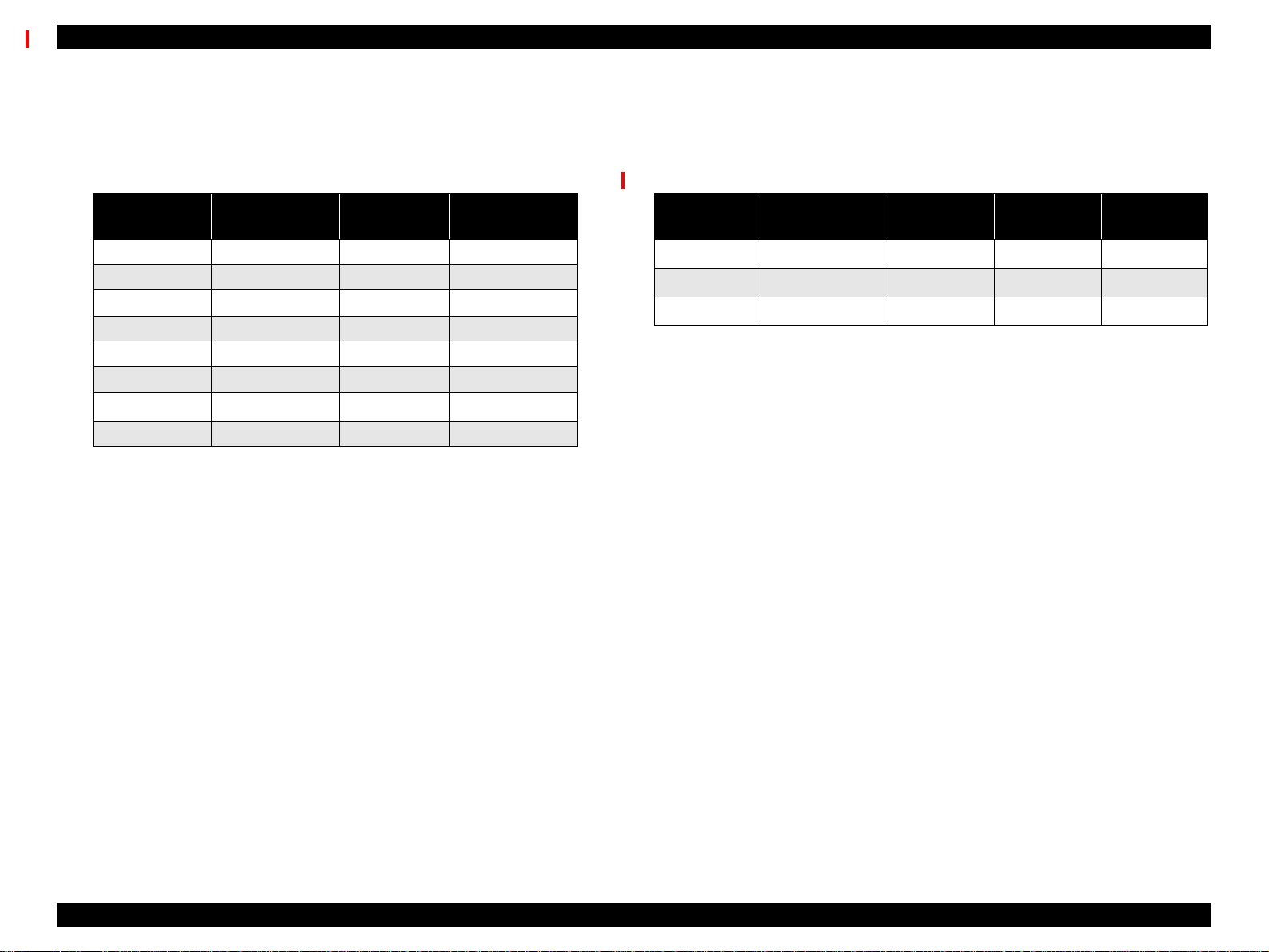

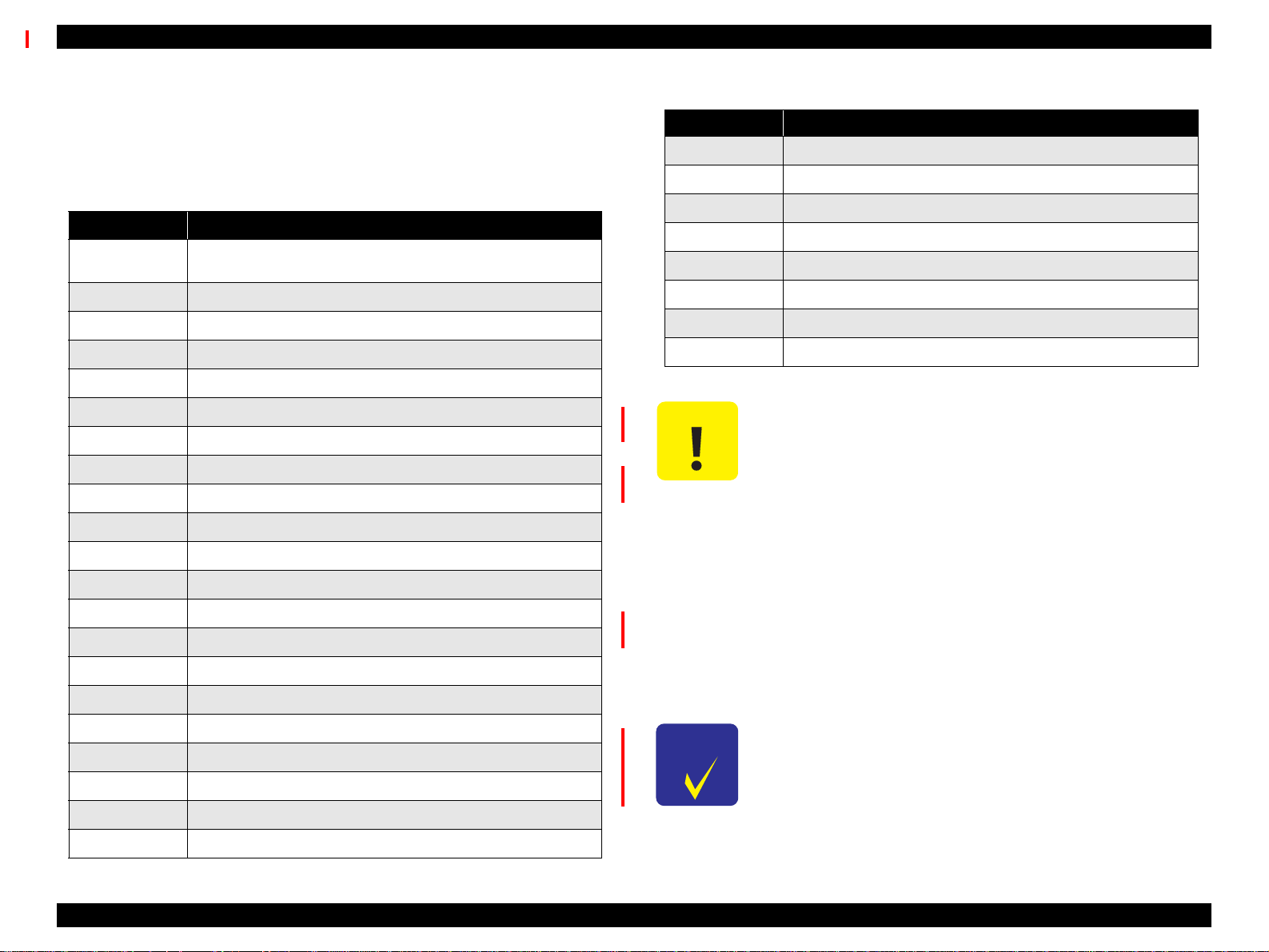

Table 1-4. Usable Single Sheet Paper Specifications

Size

B0 Wide 1118 x 1580mm A2 420 x 594mm

B0 1030 x 1456mm A3 Wide/B 329 x 483mm

B1 728 x 1030mm A3 297 x 420mm

B2 515 x 728mm ANSI E 34 x 44”

B3 364 x 515mm ANSI D 22 x 34”

A0 Wide 914 x 1292mm ANSI C 17 x 22”

A0 841 x 1189mm

A1 594 x 841mm

Minimum paper requirements

}

Paper meeting the requirements described below

can be used with this printer, but neither the feeding

nor printout quality is guaranteed.

Dimensions

(W x H)

Size

ANSI B 11 x 17”

Dimensions

(W x H)

Paper Thickness: 420~728mm (16.54~28.66”) long

paper = 0.08~1.5mm

(0.003~0.059”)

728~1580mm (28.66~62.2”) long

paper = 0.08~0.5mm

(0.003~0.019”)

Special paper

{

}

For special paper meeting the following

requirements, the feeding operation and print quality

are optimized.

Table 1-5. Special Paper Specifications

Size

A3 297 x 420mm OK OK OK

A3 Wide 329 x 483mm OK OK OK

A2 420 x 594mm OK - -

Notes:

*1: Print quality optimized when printing uni-direction printing

*2: Japan only

Dimensions

(W x H)

SuperFine

*1

PhotoPrint

Paper 2

Glossy Film

*2

{

Normal paper

}

For paper meeting the following requirements, only

the feeding operation is guaranteed.

Paper Thickness = 0.08~0.11mm (0.003~0.0043”)

•Paper Weight = 64~90gf/m

2

(17~24 lb.s)

Paper Quality: Normal, recycled paper

*1: Load short edge first (portrait)

Product Description SPECIFICATIONS 14

Page 15

EPSON Stylus Pro 9000 Revision B

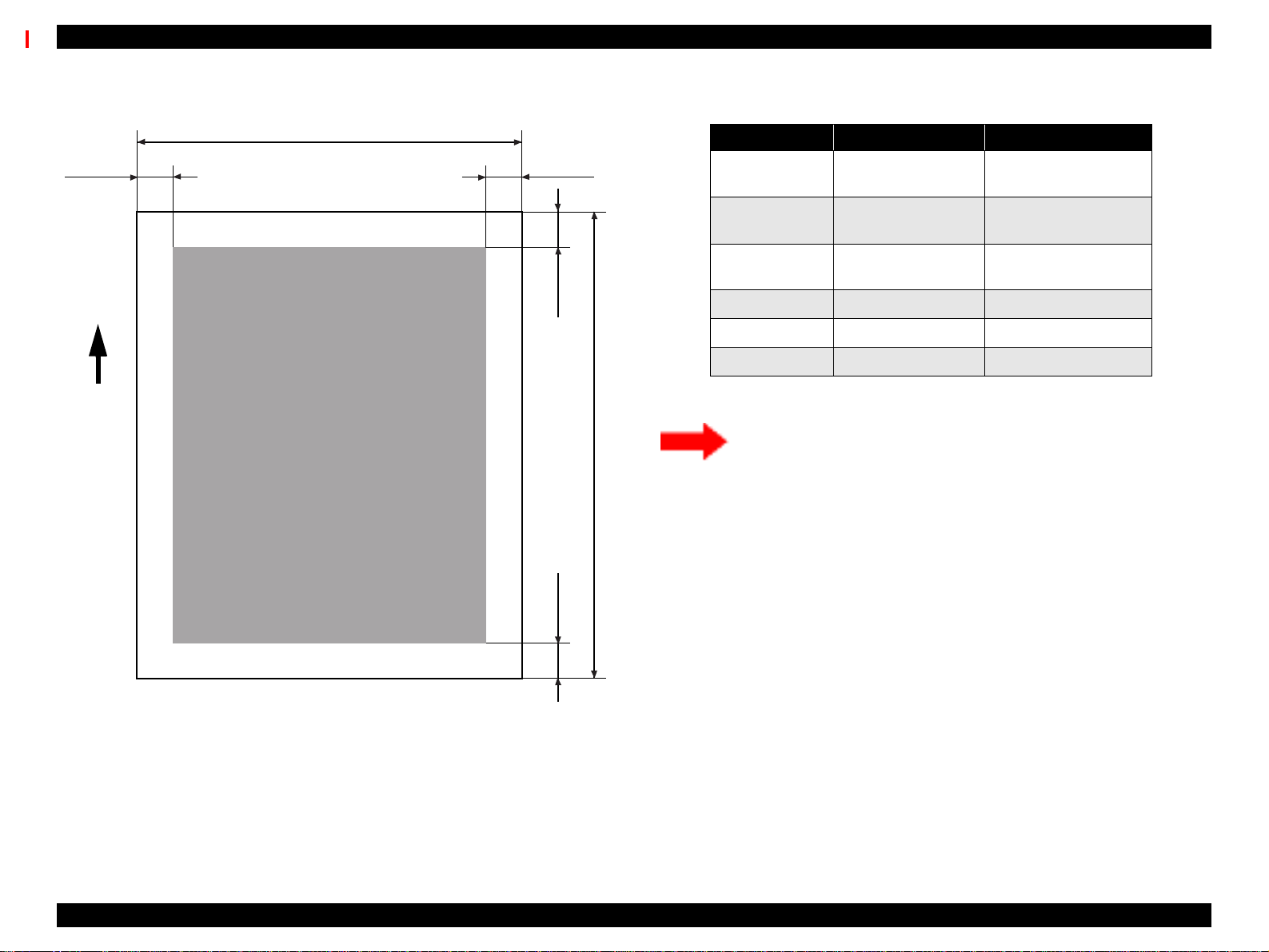

Printable area: See the following illustration and table for details.

PW

LM

RM

TM

Paper

Feed

Printable Area

PL

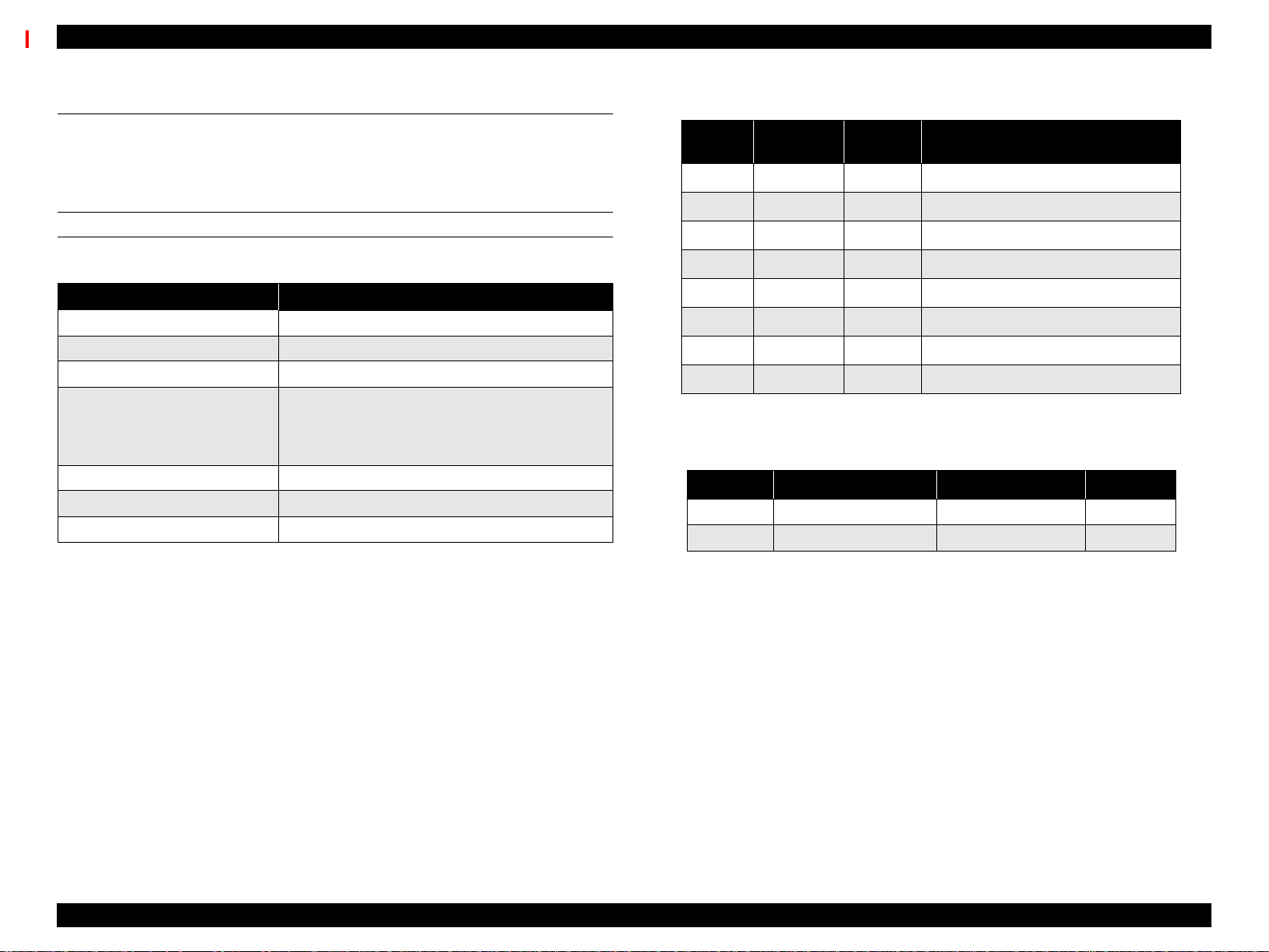

Table 1-6. Printable Area

Heading Roll Paper Cut Sheets

PW (width)

PL (length)

LM (left margin)

TM (top) 3mm/15mm* 3mm

RM (right) 3mm/15mm* 3mm

BM (bottom) 3mm/15mm* 14mm

Note: *The size of the margin is determined by the control panel setting.

There are three margin settings on the control-panel;

• 3mmAll margins are set to 3mm

• 15mmAll margins are set to 15mm

• T/B 15mmTM and BM are 15mm, while LM and RM are 3mm

297 ~ 1118mm

(8.27 ~ 44.02”)

720mm ~ 45m

(8.27~1771.65”)

3mm/15mm*

(0.12~0.59”)

297 ~ 1118mm

(8.27 ~ 44.02”)

420~1580mm

(16.54~62.2”)

3mm

BM

Figure 1-1. Printable Area

Product Description SPECIFICATIONS 15

Page 16

EPSON Stylus Pro 9000 Revision B

Table 1-7. Print Area/Margin Optimization for Roll Paper

To Optimize for Select this setting

largest printable area and decrease chance of paper

rubbing printheads

exact paper size and decrease chance of paper rubbing

printheads

largest printable area and exact paper size 3mm

Paper Release Lever: {

Release lever is up

}

Top/Bottom 15mm

The feed path is open and you can load, remove or

change the position of paper in the feed path.

{Release lever is down}

The feed path is closed and loaded paper is locked in

place. You can print on the loaded paper.

(It is not possible to change the lever position during

printing.)

ELECTRICAL SPECIFICATIONS

Table 1-8. Electrical Specifications

100V Model 220-240V Model

Rated voltage range AC100~240V

Input voltage range AC90~264V

Rated frequency range 50 to 60Hz

15mm

CONFORMITY/SAFETY A PPROVALS

Safety Standards:

US Model UL 1950, CSA 22.2 No. 950

European Model EN60950 (VDE)

EMC:

US Model FCC part 15 subpart B class B

CSA C108.8 class B

European Model EN 55022 (CISPR Pub. 22) class B

EN 61000-3-2

EN 61000-3-3

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

Australian Model AS/NZS 3548 class B

International Energy Star Compliant

(EPA MOU2.1 Category Large Format Printer)

RELIABILITY

Useful life: Printer = 18,000 pages at B1 size

Printheads = 2,000,000,000 dots/nozzle

Cutter = 2,000 times

Input frequency range 49 to 61Hz

Rated current 1.0A 0.5A

Power consumption

Insulation resistance 10MΩ minimum (between AC line and chassis, DC 500 V)

Dielectric strength

Current leakage 0.25mA maximum

operating = 100W or less

standby mode = 30W or less

AC 1.0KVrms per minute

AC 1.2KVrms per second

Product Description SPECIFICATIONS 16

Page 17

EPSON Stylus Pro 9000 Revision B

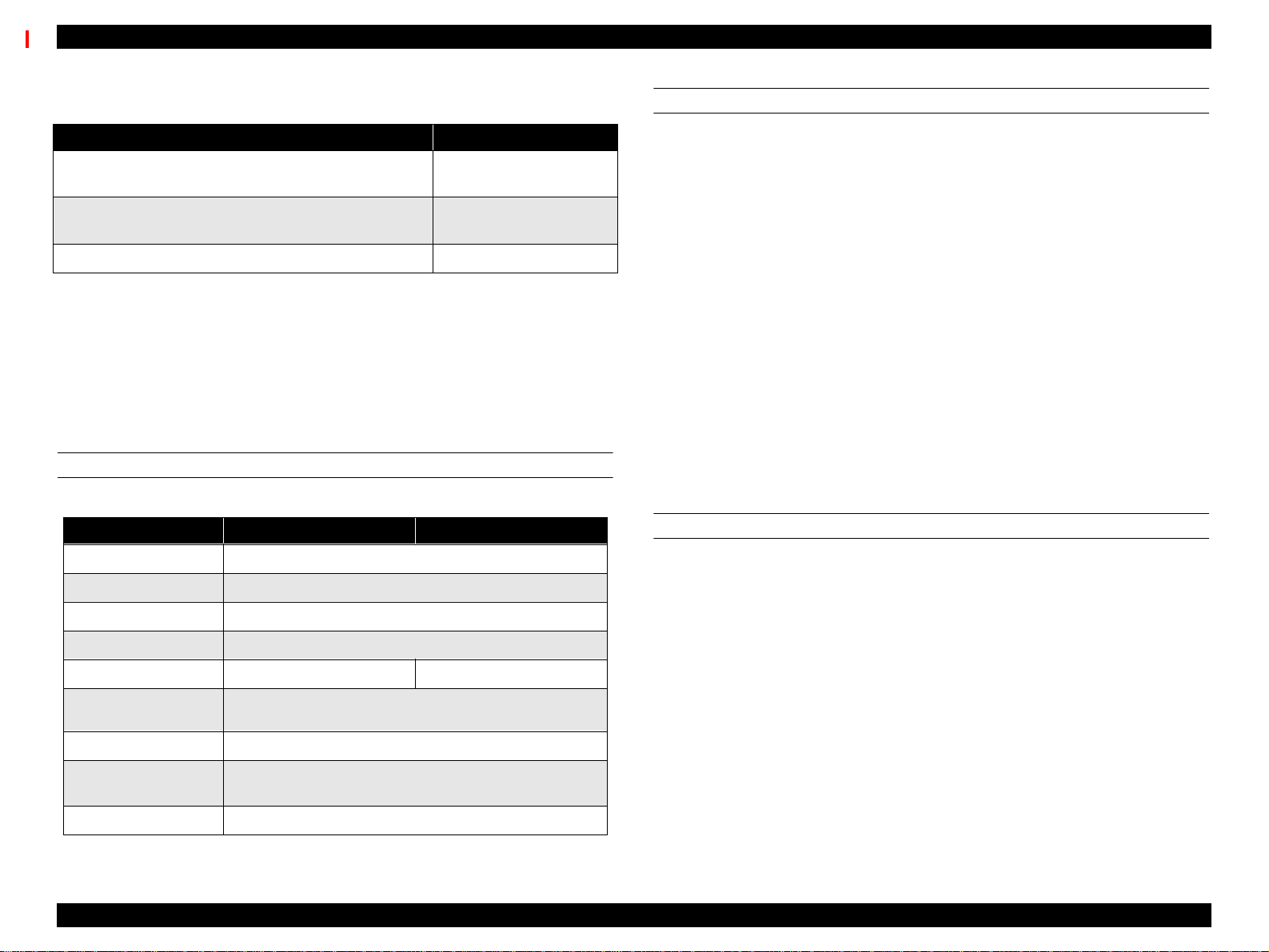

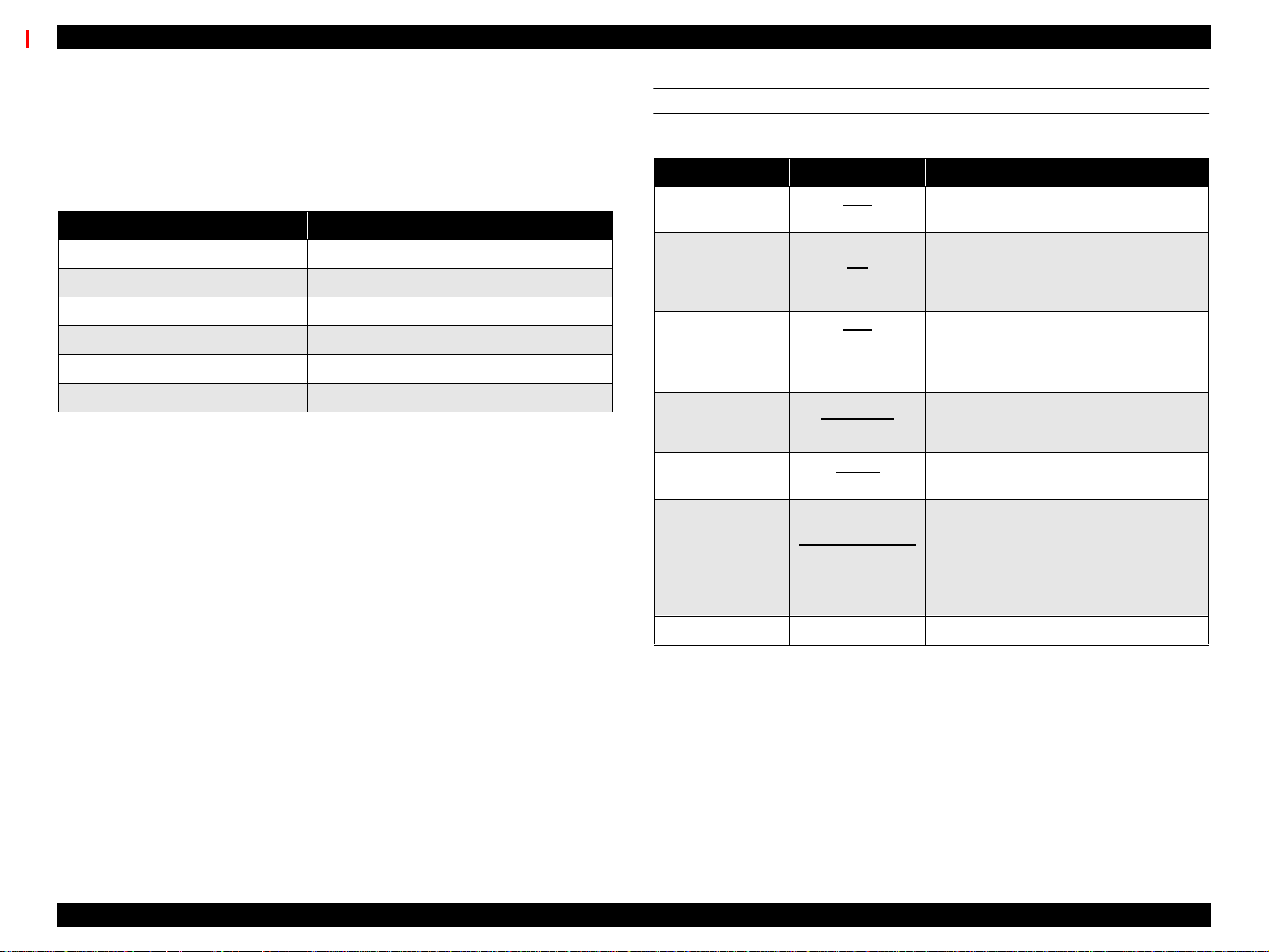

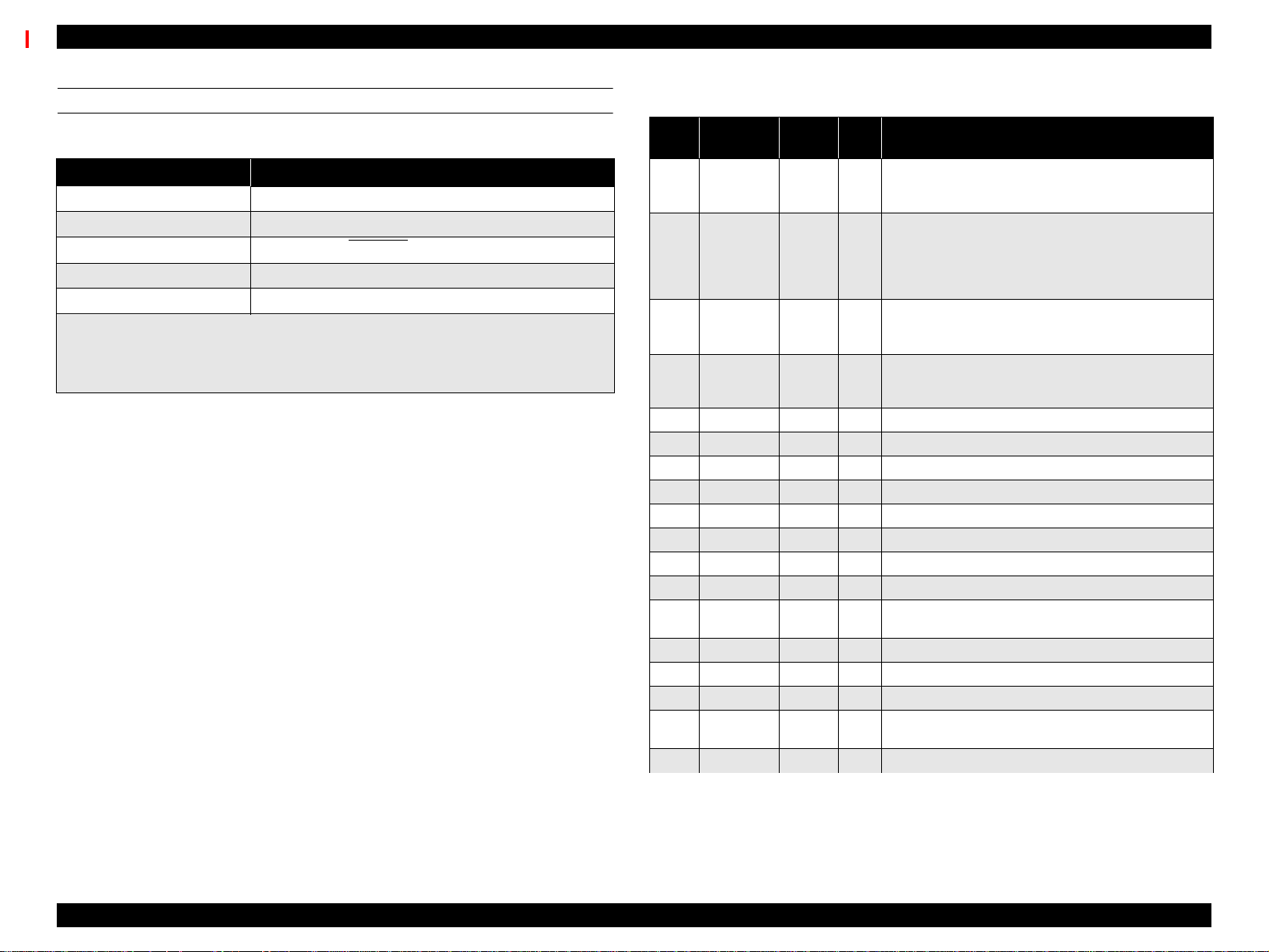

ENVIRONMENTAL SPECIFICATIONS

Temperature/Humidity: See the following table.

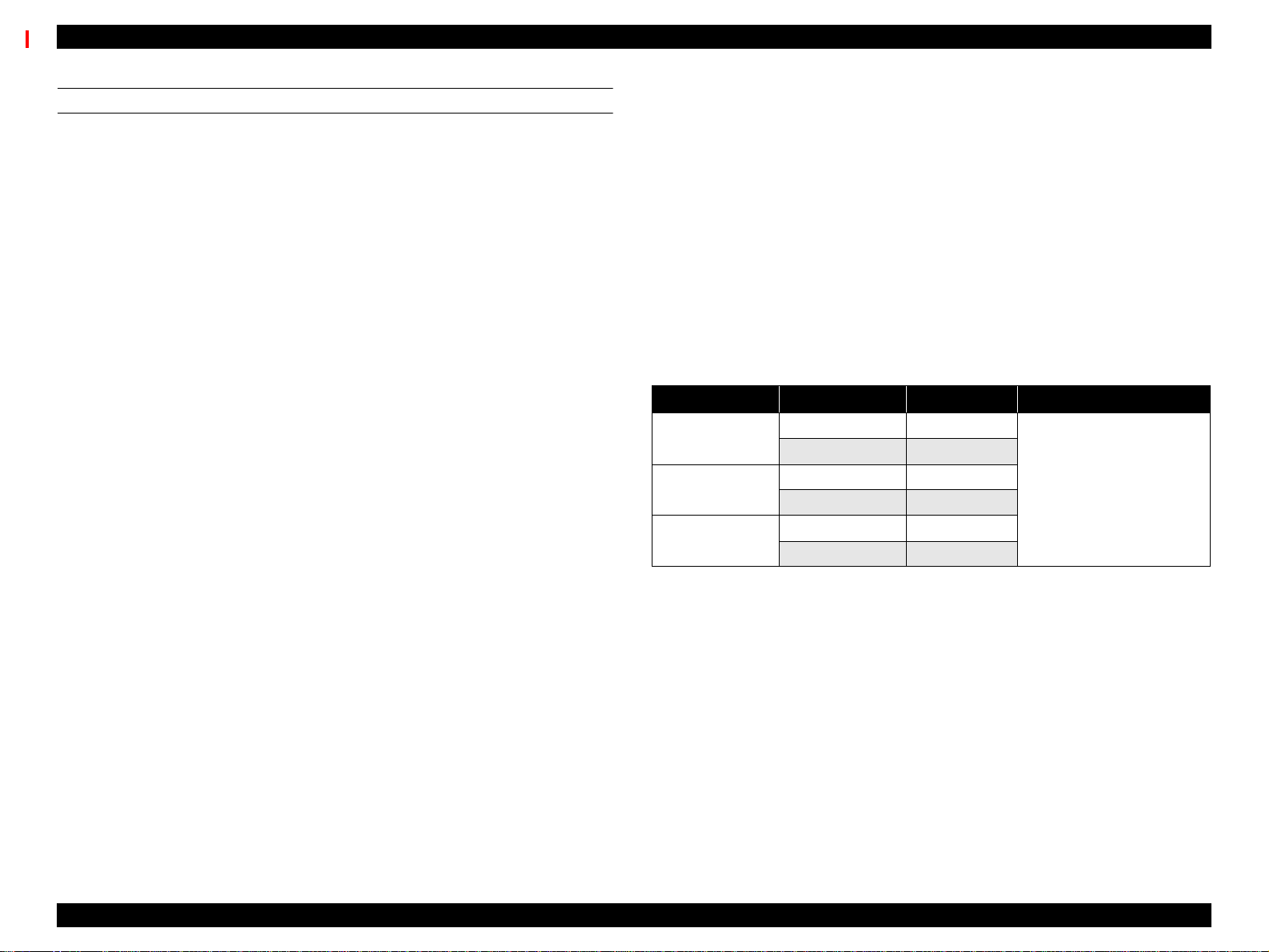

Table 1-9. Temperature & Humidity

Condition Temperature Humidity Notes

Operating

Storage

Transportation

Notes:

1) When storing the printer, make sure the printheads are in the home, capped, position.

2) Before transporting the printer, remove the ink cartridges and turn the ink valves screws to

the closed position. Also make sure the p rintheads are in the home, capped, position. After

transporting the printer, install new ink cartridges.

3) When the t emperature drops below -15°C (5

freezes. The ink thaws completely after three hours at 25°C (77

15~35°C

(59~95°F)

-20~40°C

(-4~104°F)

-20~60°C

(-4~140°F)

30~80%

20~85%

5-85%

°F), the ink in the cartridges and printheads

• Less than a month at

40°C (104°F)

• Less than 120 hours at

60°C (140°F)

• Without condensation

°F).

Humidity (%)

Temp.

(°C)

Figure 1-2. Print Temperature and Humidity

Resistance to

Vibration & Shock: See the following table.

Table 1-10. Vibration & Shock Resistance

Condition

Operating 0.15G

Storage 0.50G

Vibration

Resistance

10~55Hz

10~55Hz

Shock

Resistance

1G

less than 1ms

2G

less than 2ms

Notes

X/Y/Z direction

Product Description SPECIFICATIONS 17

Page 18

EPSON Stylus Pro 9000 Revision B

INK CARTRIDGE SPECIFICATIONS

Shape: Each ink cartridge is uniquely shaped so the

cartridges cannot be inserted in the wrong slots.

Ink colors: Black, Cyan, Magenta, Yellow, Light Cyan, Light

Magenta

Ink volume: 220 ± 5 ml

Ink avail. for printing: 190 ± 14ml

Print capacity: A0 = approx. 28 pages at 720dpi and 40% coverage

A0 = approx. 11 pages at 720dpi and 100% coverage

Dimensions: 25.1 x 260 x 105.3mm (WxDxH)

Weight: Approx. 370~385g (cartridge only)

Effective period: 2 years from production (in the sealed packaging)

plus time used (at room temp.)

Storage temperature: See the table below.

Table 1-11. Ink Cartridge (Environmental) Specifications

Situation Temperature Notes

Transporting

Storage

Installed

-30~60°C

(-22~140°F)

-30~40°C

(-22~104°F)

-20~40°C

(-4~104°F)

• Less than month at 40°C (104°F)

• Less than 120 hours at 60°C (140°F)

Less than a month at 40°C (104°F)

Less than a month at 40°C (104°F)

n Do not refill or reuse cartridges; they are consumable items.

n Do not use ink that beyond its expiration date. See above.

n To use ink that has been frozen [below 5 °F(-15°C)], let it

thaw at least 3 hours at room temperature.

ACOUSTIC NOISE

Approximately 50 dB

CONTROLLER SPECIFICATIONS

CPU: 32 bit RISC-CPU (SH7043) 33Mhz

ROM: [Program]

CPU Internal = 128KB ROM

External = 1MB (Flash ROM/4Mbit x 2)

[Font] not-installed (Windows/Macintosh required)

RAM: 18MB (fixed)

(16MB: SIMM/2MB: IC18,19)

Interface: [Standard]

IEEE1284 Bidirectional Parallel Interface

Macintosh Serial Interface

Type-B Card Slot (x1) for optional interface

CUTTER SPECIFICATIONS

Attributes: Consumable item that is replaced by the user, and it

is made of very hard steel, so the blade can easily be

chipped.

Life: Can cut well over 2,000 pages, but the actual wear-

and-tear depends on the type and thickness of the

paper used.

The cutter life can be determined by manually using

it to cut a piece of normal paper. If the cutter easily

cuts the paper, it is OK.

The cutter position is determined by the carriage

cover position; see “Carriage Cover Height

Adjustment” on page 139 and “Cutter Position

Adjustment” on page 140 for more information.

Product Description SPECIFICATIONS 18

Page 19

EPSON Stylus Pro 9000 Revision B

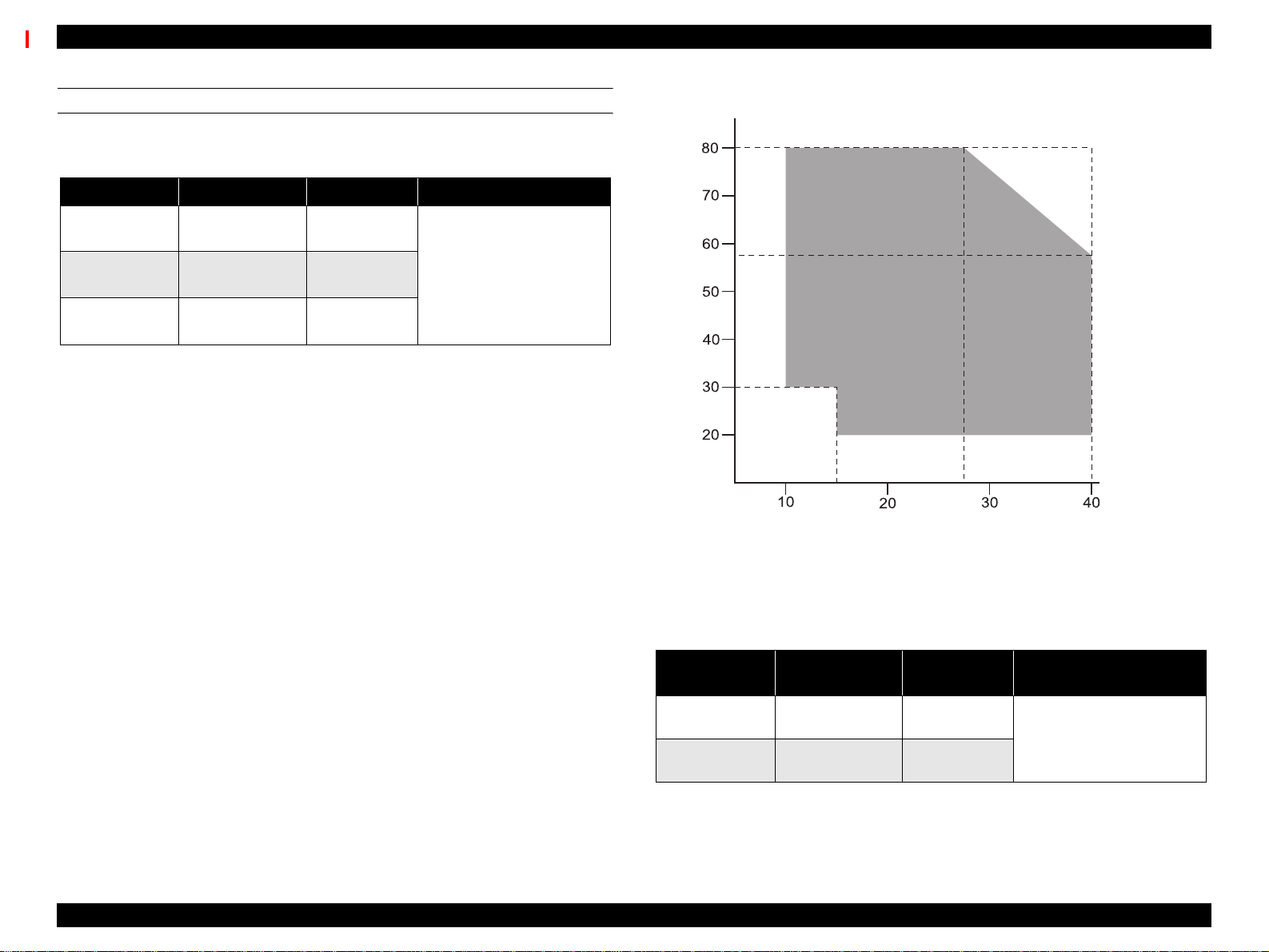

PRINTER DIMENSIONS & WEIGHT

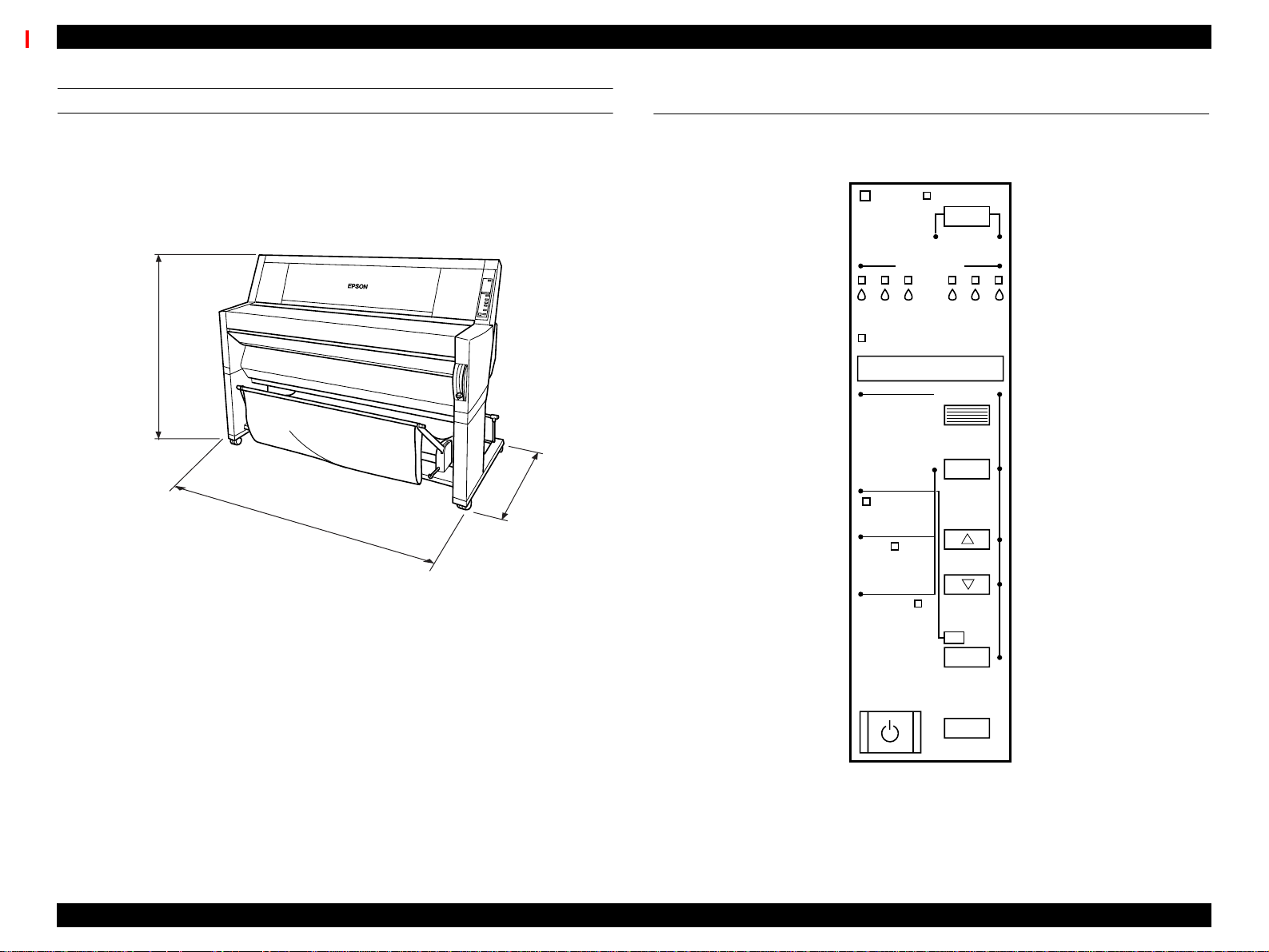

Dimensions: 1688 x 699 x 1259mm (WxDxH)

(66.46 x 27.52 x 49.57 inches)

Weight: 96Kg (211.91 lb.s)

Printer alone = 74Kg (163.32 lb.s)

Stand = 22Kg (48.59 lb.s)

1259mm

(49.57”)

1688mm

(66.46”)

Figure 1-3. Printer Dimensions

699mm

(27.52”)

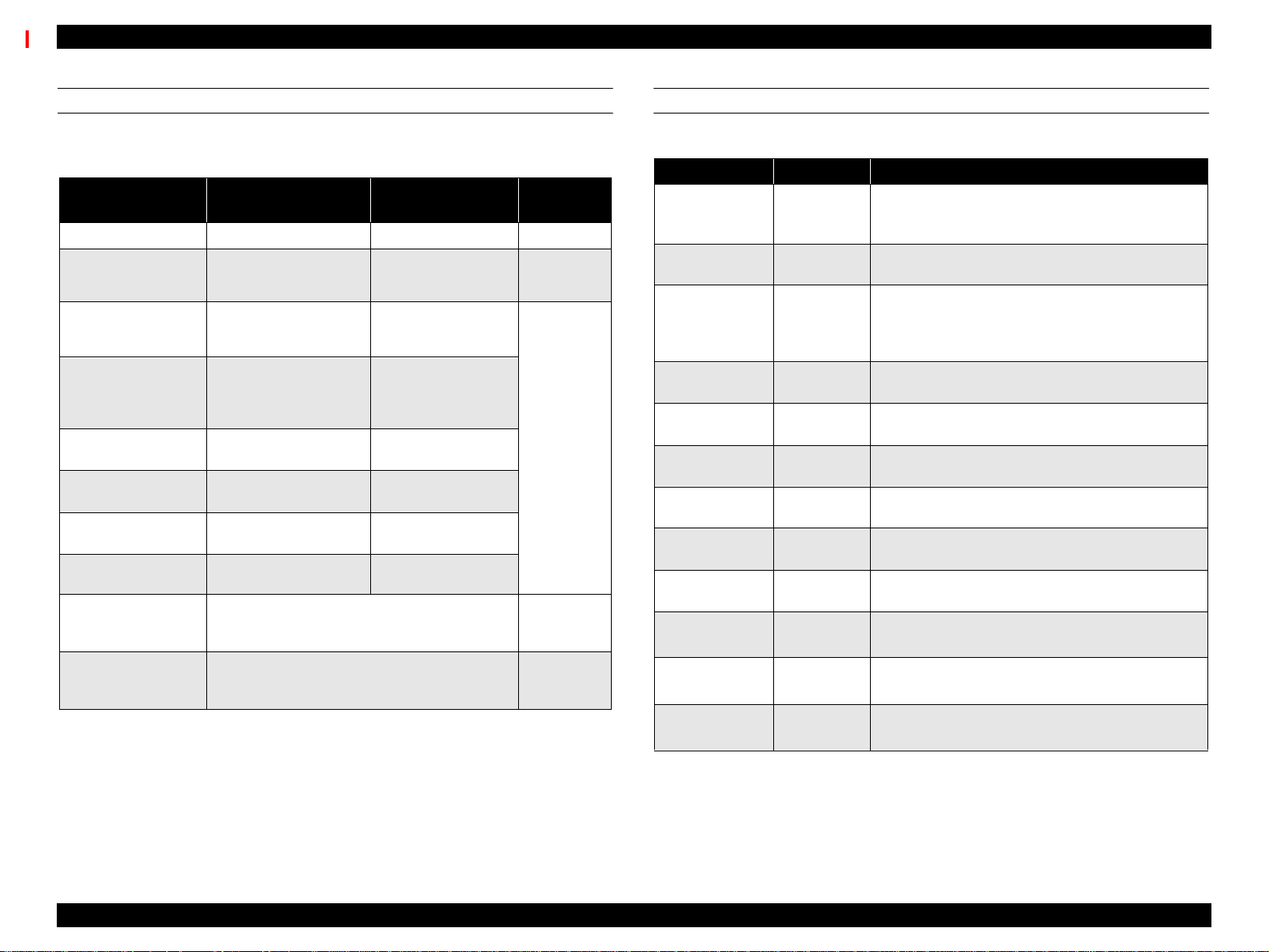

1.3 Control Panel

This section describes the control panel, the buttons, the lights, and the way

you make settings.]

Ink Out

Paper Source

Pause

Reset

3 sec.

SelecType

Item

+

Paper Feed

_

Operate

KC LCMLMY

Paper Out

Roll

Auto Cut

Roll

Cutter Off

Sheet

Cut /Eject

Enter

Power

Cleaning

3 sec.

Figure 1-4. Control Panel

Product Description Control Panel 19

Page 20

EPSON Stylus Pro 9000 Revision B

BUTTONS

All of the buttons on the control panel, and their functions, are described below.

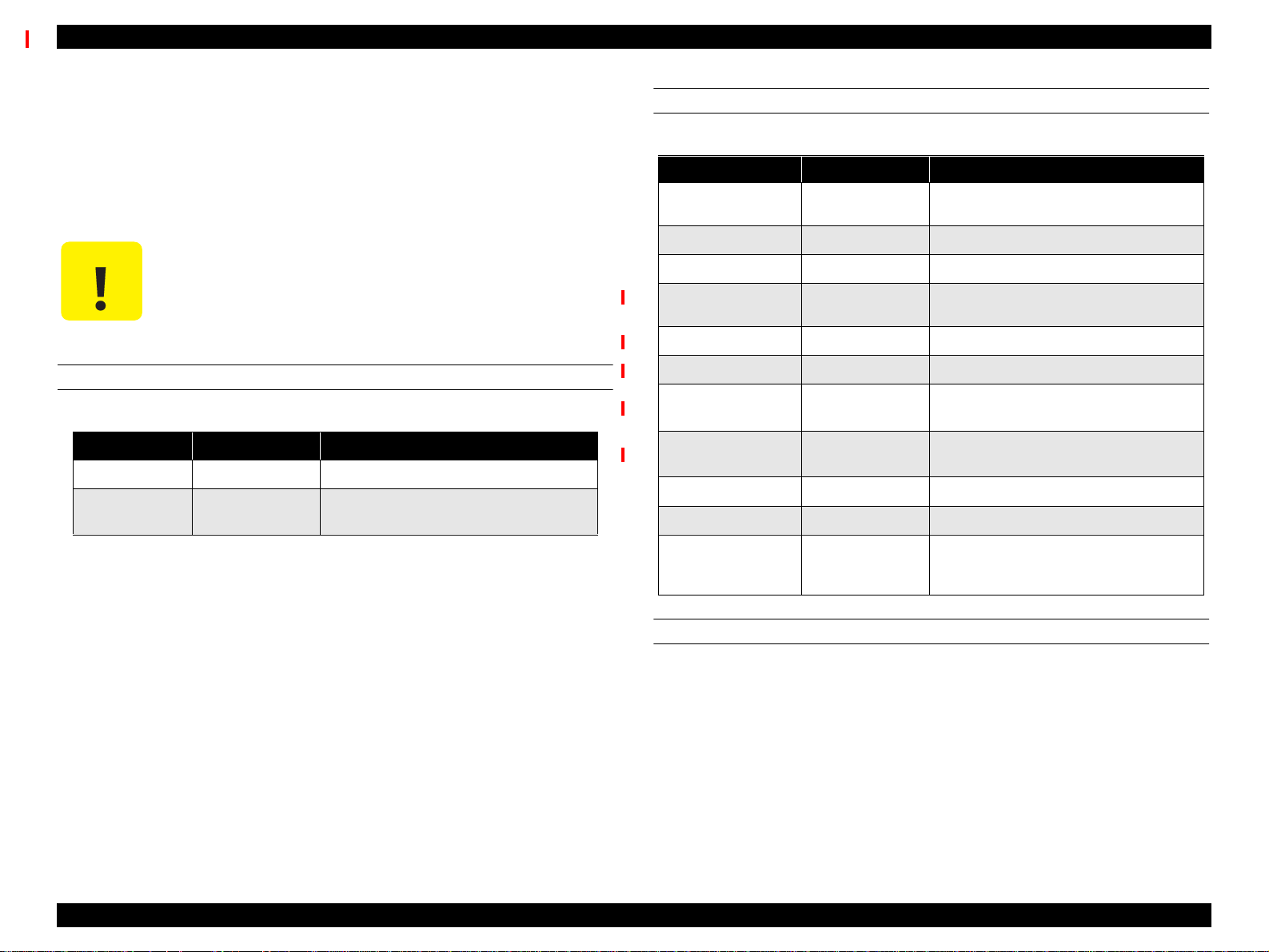

Table 1-12. Control Panel Buttons & Functions

Button

(Second function)

Power Power on/off N/A N/A

Pause

(Reset)

SelecType

Cut/Eject

(Enter)

Paper Feed ↑ Feeds paper backward *2

Paper Feed ↓

(-)

Paper Source

(Item)

Cleaning

Paper Source

Cut/Eject

Paper Feed ↓

Paper Source

Cut/Eject

Cleaning

Notes:

1: Interrupts ink drying and runs the specified operation.

2: 1.27cm/second paper feed for 2 seconds after key is pressed.

7.62cm/second paper feed if pressed for over two seconds.

Maximum feed of 20cm with one press of the button.

3: 1.27cm/second paper feed for 2 seconds after key is pressed.

7.62cm/second paper feed if pressed for over two seconds.

Function

(Normal)

• Switch - online/off-line

• Reset (press for three

seconds

Enters SelecType mode

(when printerisinStandby

mode)

Selects *1

• Auto Cut

• Cutter Off

• Sheet

Feeds paper forward *3

Selects pa per source

Cleans both heads if

pressed for three seconds

SelecType

Function

N/A

Selects menu or major

category

Confirm and save value

Cycles backward/

increases value

Cycles forward/

decrease value

Selectsitemorminor

category

N/A

N/A

N/A

Power-On

Function

Maintenance

mode

N/A

Maintenance

Mode 2

Firmware

Update Mode

LED INDICATORS

Table 1-13. LED Indicators

LED Status Condition

•On

Operate

Paper Out

•Flashing

•On

•Flashing

•On

Pause

Ink Out Y

Ink Out LM

Ink Out LC

Ink Out M

Ink Out C

Ink Out K

Paper Source

(Auto Cut)

Paper Type

(Cut Off)

Paper Type

(Single Sheet)

Note: *Also occurs if no cartridge is installed or the wrong cartridge is installed.

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

•On

•Flashing

On Roll paper will automatically be cut.

On

On Single sheet printing mode.

• Power on

• Receiving data or performing power-down

sequence

• No paper loaded

• Paper jam

• Printer ready

• Performing head cleaning or the printer is in ink

drying phase. Also flashes during ink charging

operation.

•Inkout*

•Inklow

•Inkout*

•Inklow

•Inkout*

•Inklow

•Inkout*

•Inklow

•Inkout*

•Inklow

•Inkout*

•Inklow

Roll paper will not be cut. (When using the optional

Take-up Roller, you need to select this setting.)

Product Description Control Panel 20

Page 21

EPSON Stylus Pro 9000 Revision B

1.3.1 Control Panel Messages

Printer status and error messages appear on the control panel display. The

table below lists the messages by order of importance.

Table 1-14. LCD Messages

Display Message Meaning

Service Call nnnnnnnn *2

Maintenance Call nnnn *3

Wait *1

Switching Power Off

Install Ink Cartridge

Cover Open

Option I/F Card Error

Lower Release Lever

Load xxx Paper

Paper Jam

Paper Not Cut

Paper Skew

Paper Out

Reload Pa per

Compartment Open

Replace Cartridge

Press Pause Button

Pause

Fatal error

Printer requires maintenance from qualified service

person (such as replace w aste ink tank)

Resetting Timer IC

Clearing NVRAM

Performing reset operation

Performing ink sequence operation

Initializing the printer

Dealing with initial paper operation

Preparing to shut down.

Replacing ink cartridge.

The cover is open.

A Type-B interface error has occurred.

Paper Release lever is in the release position.

Wrong paper loaded.

Paper is caught inside the printer.

Printer did not cut the paper (when Auto Cut selected)

Paper was fed at an angle, and the printer stopped to

prevent printing the page offcentered.

End of roll or sheet (or the paper detect sensor may

have dust or grime blocking its operation)

Paper check error

Replacing ink cartridge

An ink cartridge is empty

Waiting for paper initialize start t rigger

Pause state.

Table 1-14. LCD Messages (continued)

Display Message Meaning

Ink Drying xx *1

Ink Low

Printing *1

Ready *1

Reset

Restart Printer

Notes:

*1: If the printer’s platen gap setting is set to Thick, a “W” will appear in the last space on the

LCD display.

*2: See “Service Errors” on page 25.

*3: See “Maintenance Errors” on page 24.

Printer waits xx minutes before the next print job to

allow ink on previous print job t ime to dry.

Prepare a replacement cartridge for the color ink

indicated.

Processing print data.

Can receive and print data.

In the process of re-initializing.

Turn the printer off and turn it on again.

Product Description Control Panel 21

Page 22

EPSON Stylus Pro 9000 Revision B

1.3.2 Control Panel Settings

To access the control panel settings, press the SelecType button while the

printer is not printing. The printer enters the SelecType mode and cannot print.

The following table lists LCD display messages in SelecType mode.

Table 1-15. Control Panel Settings

Display Message Menu

SelecType Menu SelecType menu, page 22

Test Print Menu Test Print Menu, page 23

Printer Status Menu Printer Status Menu, page 23

Paper Settings Menu User Paper Settings, page 23

Cutter Replacement Menu Cutter Replacement Menu, page 24

Head Alignment Menu Gap Adjustment Menu, page 24

Selectinga menu provides you with detailed options.

SELECTYPE MENU

Table 1-16. SelecType Menu

Display Message Item Notes

PLATEN GAP

PAGE LINE

INTERFACE

PARALLEL

INTERFACE

CODE PAGE

ROLL PAPER

MARGIN

INITIALIZEPANEL Run Initialize control panel setup values

Notes:

* The printed image is the same size as a printed image using the 3mm setting; however, the

printer adds 12mm of paper clearance (for a total margin of 15mm) to the top and bottom edges

to make paper feeding more stable and to prevent the paper from rubbing the printheads.

Also, the underlined it em equals the default.

Auto

Thick

ON

OFF

Auto

Parallel

MAC

Option

Compatible

ECP

PC437

PC850

Top/Bottom 15mm

15mm

3mm

Adjusts the platen gap. (Normally, leave

set to Auto.)

When Auto Cut Off is selected on the

control panel, this setting determines

whether a line for manual cutting is

printed.

Determines which interface the printer

checks for data. Auto continuously checks

all interfaces and is good for normal use.

Determines the data transfer rate when

using this interface.(Normally, leave set to

Compatibility.)

Character code setting. (PC437:

expanded graphics/PC850: multi-lingual)

Roll sheet margin setting.

• Top/Bottom15mm*: the top and bottom

margins = 15mm while left and right

margins = 3mm

• 15mm: all margins = 15mm

• 3mm all margins = 3mm

Product Description Control Panel 22

Page 23

EPSON Stylus Pro 9000 Revision B

TEST PRINT MENU

Table 1-17. Test Print Menu

Display Message Item Notes

NOZZLE CHECK

PATTERN

STATUS SHEET Print Prints the current printer settings.

Print

Checkthe printout, any missing lines mean

the nozzle(s) are clogged.

PRINTER STATUS MENU

All consumable items and maintenance parts either run out of their contents or

wear out. To determine how much contents (ink) or useful life remains,

compare the message and value shown on the control panel display to the

corresponding value below and the messages in the table below.

E*****F 100~81% full/life remaining

E**** F 80~61% full/life remaining

E*** F 60~41% full/life remaining

E** F 40~21% full/life remaining

E* F 20~1% full/life remaining (generates a warning)

E F Less than 1% full/life remaining (generates an error)

Table 1-18. Printer Status Menu

Display message Meaning

VERSION Shows the firmware version.

INK REMAINING (C) Shows the amount of remaining ink - Cyan

INK REMAINING (M) Shows the amount of remaining ink - Magenta

Table 1-18. Printer Status Menu (continued)

Display message Meaning

WASTE INK Maintenance information

CR MOTOR Maintenance information

PF MOTOR Maintenance information

HEAD UNIT Maintenance information

CLEANING UNIT Maintenanceinformation

USER PAPER SETTINGS

Table 1-19. User Paper Settings Menu

Display Message Item Notes

PAPER NUMBER

THICKNESS

PATTERN

PAPER

THICKNESS NO.

DRYING TIME 0~30 Minutes

Note: The underlined item equals the default.

Standard

1~4

Print

1~17

Select Standard for Epson special paper.

Select the appropriate number for thick

paper.

Prints a pattern to detect the paper

thickness. If “Paper Number” is set to

“Standard”, this message does not appear.

If “Paper Number” is set to “Standard”, this

message does not appear.

Determines the length of time the printer

allows the ink to dry. When printing on roll

paper, the printer will wait the specified time

after printing

INK REMAINING (LC) Shows the amount of remaining ink - LightCyan

INK REMAINING (LM) Shows the amount of remaining ink - Light Magenta

INK REMAINING (Y) Shows the amount of remaining ink - Yellow

INK REMAINING (K) Shows the amount of remaining ink - Black

CUTTER LIFE Shows the remaining useful life of the cutter

TOTAL PRINTS Shows the total number of printed documents

Product Description Control Panel 23

Page 24

EPSON Stylus Pro 9000 Revision B

CUTTER REPLACEMENT MENU

The following table includes the steps/messages that must be followed to

replace the cutter.

Table 1-20. Cutter Replacement Messages

Display Message Item Notes

CUTTER REPLACEMENT Execute Prepare a replacement cutter and

OPEN LOWER COVER - Open the front cover.

REPLACE CUTTER -

CLOSE LOWER COVER -

Remove the old cutter and install a

new one.

Close the front cover. The printer is

ready.

GAP ADJUSTMENT MENU

Table 1-21. Platen Gap Adjustment Menu

Display Messages Item Notes

ADJUSTMENT

PATTERN

SELECT #1-12 1~4~7 Choose a pattern from #1 to #12.

PAPER

THICKNESS

Note: The underlined item equals the default.

Print All

Print #1~12

Standard

0.0~1.6mm

Selectswhichpatternstoprint.(Allpatterns

or selected patterns only.)

Select the thickness, to 0.1mm, of the

paper you are using to check the platen

gap. Normally, leave set to Standard.

1.3.3 Maintenance Errors

There are several consumable parts in the printer, and the printer employs

separate counters to keep track of each one. The “Maintenance Req. 0100”

message appears on the display to warn that the Waste Ink pads are about

99% full and need to be replaced soon.

The printer can continue to print even though the “Maintenance Req. 0100*

message appears instead of the “Ready” or “Printing” message. However,

when the waste ink counter determines the Waste Ink pads are 100% full, the

“Service Req 00000100” message appears and the printer can no longer print.

To clear the Maintenance error, perform the following.

Replace: The following seven items are need to be replaced.

- Waste Ink Pads (R/L)

- Pump Assembly

- Cap Assembly

-FBox(R/L)

- Cleaner, Head

CHECK

PO INT

Required Adjustments: The following adjustments are need to be performed

The above mentioned seven items are available as a kit.

Description: MAINTENANCE KIT

Parts code: 1048434

after replacing the corresponding items.

- Waste Ink Counter Clear

(See “Maintenance Mode 2” on page -26.)

- Cleaner Counter

(See “Maintenance Mode 2” on page -26.)

- Cutter Position Adjustment

(See “Cutter Position Adjustment” on page 140.)

Product Description Control Panel 24

Page 25

EPSON Stylus Pro 9000 Revision B

1.3.4 Service Errors

When “Service Req nnnnnnnn” appears on the LCD display, a fatal error

requiring a service technician has occurred. The nnnnnnnn indicates what

needs to be fixed to return the printer to a working state.

Table 1-22. Service Error Code List

Service Code Explanation

00000100

00000101 Ink tubes

00010000 PF Motor Encoder Check error

00010001 PF Motor out of step

000100002 PF Motor overcurrent

000100003 PF Motor in-position time-out error

000100004 CR Motor Encoder Check error

000100005 CR Motor out of step

000100006 CR Motor overcurrent

000100007 CR Motor in-position time-out error

000100008 Servo interrupt watchdog time-out error

000100009 System interrupt watchdog time-out error

00010000A CR origin sensor error

00010000B PF origin sensor error

00010000C PG origin sensor error

00010000D Cover sensor error (00)

Waste ink pads are full and need to be replaced. *1

(Replace the unit and reset the counter.)

Table 1-22. Service Error Code List (continued)

Service Code Explanation

000200002 SRAM Check Error

000200003 DRAM Check Error

100000004 CPU Vector 4 - General illegal instruction

100000006 CPU Vector 6 - Slot illegal instruction

100000006 CPU Vector 9 - CPU address error

10000000A CPU Vector 10 - DMAC\DTC address error

10000000B CPU Vector 11 - Watchdog time-out error

1000000** CPU Vector 32~63

CAUTION

When replacing the following parts to clear “Service Req.

00000100” error, you need to clear the corresponding

counter using “Maintenance Mode 2”.

[Effective parts]

n Waste Ink Pads (right/left)

n F Box (left/right)

n Pump Assembly

n Cap Assembly

n Cleaner, Head

[Effective counters]

n Init. Waste Ink

n Init. Cleaning Unit

00010000E Cover sensor error (01)

00010000F CR motor PWM output error

000100010 PF motor PWM output error

000200000 NVRAM Error

000200001 Internal RAM Check Error

CHECK

PO INT

The above mentioned parts ar e also available as a KIT.

Description: MAINTENANCE KIT

Parts code: 1048434

Product Description Control Panel 25

Page 26

EPSON Stylus Pro 9000 Revision B

1.3.5 Service Related Printer Settings

When the printer is not functioning properly, there are three modes that help

you detect what is wrong and can help you fix the problem. These modes are

“Maintenance Mode”, “Maintenance Mode 2”, and “Self-Diagnostic Mode”. To

enter a mode, press and hold down the appropriate button (described below)

while turning on the printer.

CAUTION

MAINTENANCE MODE

Power-on button: Pause

Message Item Explanation

Hex Dump Print Prints the print data in hexadecimal form

Language

The following explanations regarding control panel service

functions and for service and support purposes only, none

ofthisinformationistobesharedwiththeenduser.

English

Japanese

Determines which language is used to

display messages on the LCD display.

MAINTENANCE MODE 2

Power-on button: Paper Source + Cut/Eject + Paper Feed ↓

Message Item Explanation

INIT. ALL Execute

INIT. NVRAM Execute Initializes NVRAM

INIT. TIMER Execute Initializes timer

INIT. CR MOTOR Execute

INIT. PF MOTOR Execute Initializes PF Motor counter

INIT. HEAD UNIT Execute Initializes Head unit counter

INIT. CLEANING

UNIT

INIT. TOTAL

PRINTS

INIT. INK Execute Initializes ink counter

INIT. WASTE INK Execute Initializes waste ink counter

DETECT INK

LABEL

Execute Initializes cleaning unit counter

Execute Initializes total print counter

ON

OFF

Initializes NVRAM, Timer, life counters,

and mechanical counters

Initializes CR Motor counter (after

replacing ink tubes)

Determines whether the Ink ID sensor

checks the Ink ID label on the ink

cartridge.

SELF-DIAGNOSTIC MODE

Power-on button: Paper Feed ↓ + Cut/Eject + Cleaning

This mode is used primarily for replacing worn-out printer parts and adjustment

operations. For details, see Chapter 5, "Adjustment".

Product Description Control Panel 26

Page 27

EPSON Stylus Pro 9000 Revision B

1.3.6 Firmware Update

The firmware contained onthe Main Board is Flash ROM; therefore if you need

to replace the Main Board or update the firmware, select one of the following

methods.

CAUTION

UPDATING THE FIRMWARE VIA THE PC

1. Make sure the PC is connected to the printer using the parallel port.

Compatible mode connection only.

2. While pressing and holding the following buttons, turn on the printer.

Paper Source + Cut/Eject + Cleaning

3. From the PC, send the firmware-update file to the printer using the

following command. At the DOS prompt, enter

n If for any reason power is cut off during the update

operation (using either method), restart the update

operationtoreturntheprintertonormalstatus.

n Use the following PC card for update.

Name: #F725 Flash Memory Card

Code: 1050073

copy

(filename)

prn:

UPDATING THE FIRMWARE VIA MEMORY CARD

For details on this operation, see Chapter 5, "Adjustment".

1. Copy firmware data file to the PC card.

CHECK

PO INT

2. Make sure the printer is off.

3. Remove the access cover towards the rear of the Paper Guide U, and

insert the Flash memory card containing the updated firmware into the card

slot (CN20).

4. Turn the printer on.

5. “Update complete” appears indicating the Flash ROM has been properly

updated.

6. Turn the printer off, remove the memory card, and turn the printer back on.

The firmware data file to be copied to the PC card is

XXXXXXXX.BIN (Binary format data).

1.3.7 Jumper Settings

CHECK

PO INT

The firmware data file for downloading v ia the PC is

XXXXXXXX.MOT (Motrola format data).

The factory default settings for jumper and DIP switch on the Main Board

(C277MAIN) are as follows.

Table 1-23. Jumper Settings

Type Number Setting

Jumper JP1 Shorted

4. “Update complete” appears indicating the Flash ROM has been properly

updated.

5. Turn the printer off and back on.

Jumper JP2 Shorted

DIP-SW SWD1 “1” (1-4) OFF (Open)

DIP-SW SWD1 “2” (2-3) OFF (Open)

Product Description Control Panel 27

Page 28

EPSON Stylus Pro 9000 Revision B

1.4 Interfaces

The EPSON Stylus Pro 9000 is equipped with parallel and Macintosh serial

interfaces and a card slot for an optional Type-B interface. This section

provides information on each interface.

SERIAL INTERFACE

Table 1-24. Serial Interface

Description

Transmission mode Based on RS-423

Synchronization Synchronous

Transfer speed About 1.8 Mbps

Start bit: 1 bit

Data format

Handshaking X-ON/X-OFF, DTR protocol

Adaptable connector 8-pin mini-DIN

RecommendedI/F cable Apple system peripheral-8 cable (M0197)

Data bit: 8 bits

Parity bit: None

Stop bit: 1 bit

Table 1-25. Pin Assignment

Pin No.

1 SCLK O Synchronous clock signal

2 CTS I Clear To Send

3 TXD- O Transmit Data (-)

4 SG I (Signal Ground)

5 RXD- I ReceiveData(-)

6 TXD+ O Balanced Transmit Data (+)

7 DTR O Data Terminal Ready

8 RXD+ I Balanced Receive Data (+)

X-ON/X-OFF, DTR protocol:

Signal

Name

I/O Description

Table 1-26. X-On/X-Off and DTR Protocol

State Buffer Space X-ON/X-OFF DTR

Busy Less than 3072 bytes Send X-OFF code OFF

Ready More than 5120 bytes Send X-ON code ON

Product Description Interfaces 28

Page 29

EPSON Stylus Pro 9000 Revision B

PARALLEL INTERFACE

Table 1-27. Parallel Interface - Com patibility Mode

Item Description

Transmission mode 8-bit parallel, IEEE-1284 compatibility mode

Synchronization By STROBE pulse

Handshaking By BUSY and ACKNLG

Logic Level

Connector

TTL compatible level (IEEE-1284 Level 1 device)

57-30360 (Amphenol) or equivalent 36-pin

signal

Note 1: Use a twisted-pair cable.

Note 2: The BUSY signal is set high before setting the -ERROR signal low or the PE

signal high. The BUSY signal remains high until all these signals return to their normal

state.

The BUSY signal is high:

n During data entry

n When the input data buffer is full

n When the -INIT signal is low, or during hardware initialization

n During a printer error

n When the parallel interface is not selected

The ERROR signal is low when there is a:

n Printer hardware error (fatal error)

n Paper-out error

n Paper-jam error

n Ink-out error

NOTE: The PE signal is high during a paper-out error.

Table 1-28. Connector Pin Assignments - Forward Channel

Pin

No.

2-9

10

11

12

13

14

15

16

17

18

19-30

31

32

33

34

35

36

Note: “In/Out” is signal direction as viewed from printer.

Signal

Name

STROBE

1

DATA0~7

ACKNLG

BUSY

PE

SLCT

AFXT

NC Not connected

GND Ground for twisted pair return

Chassis Ground for frame/body

Logic H Pulled up to +5V via 3.9Kohm

GND Ground for twisted pair return

-INIT

ERROR

GND

NC

+5V

SLCTIN

The interface condition is normally TTL Level, and each high/low signal takes 0.2uS or less.

The printer only sends data after receiving the ACKNLG confirmation or when the BUSY signal

is low.

Return

Pin

19 I

20-27 I

28 O

29 O

28 O

28 O

30 I

30 I

29 O

---- ----

---- ----

---- O

30 I

In/

Out

Data reception pulse, 0.5uS or greater pulse width

required. Usual state is HIGH, and reads data after

going to LOW state.

The DATA0 through DATA7 signals represent data bit s

0 to7, respectively. Each signal is at high level w hen

data is logical 1 and low level when data is logical 0.

These signals are used to transfer the 1284 extensibility

request values to the printer.

When LOW the printer has finished preparing to receive

signals and can accept data. Pulse width is about 1uS or

3uS Printer clock signal.

HIGH means the printer cannot receive data. This

occurs when the printer is receiving data or when the

printer is in an error state.

HIGH means no paper is loaded. (LOW means an error.)

Always HIGH. Pulled up to +5V via 1.0Kohm

Not used

Pulse width of 50uS or more means LOW pulse, and the

falling edge of LOW signal causes the printer to initialize.

LOW means printer error

Ground for twisted pair return

Not connected

HIGH during normal operation. Pulled up to +5V via

1.0Kohm

Not used

Functional Description

Product Description Interfaces 29

Page 30

EPSON Stylus Pro 9000 Revision B

Table 1-29. Nibble Mode

Description

Transmission mode IEEE-1284 nibble mode

Synchronization Refer to IEEE-1284 specification

Handshaking Refer to IEEE-1284 specification

Signal level TTL level (IEEE-1284 level 1 device)

Connector 57-30360 (Amphenol) or equivalent

Data transfer timing Refer to IEEE-1284 specification

When the printer receives the hexadecimal values 00H or 04H, the printer

responds in the following manner:

00H: The printer enters reverse channel mode, allowing data to be sent to

the host.

04H: The printer sends the device ID to the host; the device ID consists of

the following strings:

Data requests/

device ID

<00H><4EH>

MFG: EPSON

CMD: ESCPL2, BDC

MDL: Stylus[SP]Pro[SP]9000;

CLS: PRINTER

DES: EPSON[SP]Stylus[SP]Pro[SP]9000

Note: [00H] denotes a hexadecimal value of zero.

[SP] equals space code 20H

Table 1-30. ECP Mode

Description

Transmission mode IEEE-1284 ECP mode

Synchronization Refer to IEEE-1284 specif ication

Handshaking Refer to IEEE-1284 specification

Signal level IEE E-1284 level 1 device

Adaptable connector 57-30360 (Amphenol) or equivalent

Data transfer timing Ref er to IEEE-1284 specification

When the printer receives the hexadecimal values 10H or 14H, the

printer responds in the following manner:

10H: The printer enters reverse channel mode, allowing data to be sent

to the host.

14H: The printer sends the device ID to the host; the device ID cons ists

of the following strings:

Data requests/

device ID

<00H><4EH>

MFG: EPSON

CMD: ESCPL2, BDC

MDL: Stylus[SP]Pro[SP]9000

CLS: PRINTER

DES: EPSON[SP]Stylus[SP]Pro{SP]9000

Note: [00H] denotes a hexadecimal value of zero.

[SP] equals space code 20H

Product Description Interfaces 30

Page 31

EPSON Stylus Pro 9000 Revision B

Table 1-31. Connector Pin Assignments - Reverse Channel

Pin

Signal Name

No.

1 HostClk 19 I Host clock signal.

2-9 Data0-7 20-27 I

10 PeriphClk 28 O Printer clock signal

PeriphAck/

11

PtrBusy

12 AckData Req 28 O

13 Xflag 28 O

14 HostBusy 30 I Host busy signal.

15 NC Not connected

16 GND Signal ground

17 Chassis GND Chassis ground

Return

Pin

29 O

In/

Out

The DATA0 through DATA7 signals

represent data bits 0 to7, respectively. Each

signal is at high level when data is logical 1

and low level when data is logical 0. These

signals are used to transfer the 1284

extensibility request values to the printer.

Printer busy signal and reverse channel

transfer data bit 3 or 7.

Acknowledge data request signal and

reverse channel transfer data bit 2 or 6.

X-flag signal and reverse channel transfer

data bit 1 or 5.

Functional Description

TYPE-B OPTIONAL INTERFACE

The EPSON Stylus Pro 9000 supports a Type-B interface (level 2).

Reply message (short version):

n When using Co-ax/Twin-ax interface card:

Main type: MTP48p, PW127cl10cpi, PRG (KAxxxx)rev,

AP1200ma

Product name: Stylus[SP]Pro[SP]9000

Emulation type: ESCPL2-00

Entity type: EPSONLQ2

n When not using a different (not Co-ax/Twin-ax) interface card:

Main type: MTP48p, PW127cl10cpi, PRG (KAxxx)rev,

AP1200ma, SPD0fast

Product name: Stylus[SP]Pro[SP]9000

Emulation type: ESCPL2-00

Entity type: ESPONLQ2

BUFFER OPERATION

When there is no space left in the buffer (4Kb or less), the EPSON Stylus Pro

9000 sends the host a BUSY signal. If the host receives this signal for a long

time, it times out and stops sending data.

18 Logic-H O Pulled up to +5V via 3.9K ohm resister.

19-30 GND Groundfor twisted pair return

31 /INIT 30 I Not used.

32 /DataAvail 29 O

33 GND Ground for twisted pair return

34 NC Not connected

35 +5V ---- O Pulled up to +5V via 3.3K ohm resister.

36 1284-Active 30 I 1284 Active Signal

Data available signal and reverse channel

transfer data bit 0 or 4.

Product Description Interfaces 31

Page 32

EPSON Stylus Pro 9000 Revision B

1.5 Initialization

This section describes the initialization procedures for the EPSON Stylus Pro

9000. There are three ways to initialize the EPSON Stylus Pro 9000:

Hardware initialization:

When the power is turned on or a cold-reset command is sent to the printer

(remote RS command), the printer does the following:

Initializes the printer mechanism

Clears the input data buffer

Clears the print buffer

Restores the default values

Software initialization:

When the printer receives an ESC@ command, it does the following:

Clears the print buffer

Restores the default values

Control panel (operator) initialization:

When the Reset button is pressed or the printer receives an -INIT signal

(negative pulse) from the parallel interface, the printer:

Caps the printheads

Ejects the paper if a cut sheet is loaded

Clears the input data buffer

Clears the print buffer

Resets the default values

The default values are shown below.

Page Position: Current paper position as page-start position

Line feed: 1/6”

Right margin: 440th character

1.6 Interface selection

The printer has three built-in interfaces: parallel, serial, and Type-B (an

optional interface requiring an interface card). These interfaces are selected

automatically or manually through the control panel.

Manual Selection:

Select the desired interface through the default setting mode, described

below under Maintenance Mode (Level 1).

Automatic Selection:

Automatic interface selection is enabled by the default setting mode,

described below under Maintenance Mode (Level 1). When the automatic

selection is active, the printer passively scans all interfaces. The interface

that receives data first is selected as the active interface. When the host

stops sending data and the printer has been in a standby state for 10

seconds, the printer returns to an idle state. Otherwise, the interface

remains active.

Other things to keep in mind about interface selection:

The host checks whether the logic signal is low or high before requesting

data through the reverse channel.

If the parallel interface is not selected, it enters a BUSY state and the logic

signal is set low.

When the serial interface is not selected, the DTR (data terminal ready)

signal is set to MARK.

When the optional type-B interface is not selected, the off-line bit is set to

Main Status Register (MNSTS).

When the printer is initialized or returns to an idle state, the parallel

interface enters a ready condition, the serial DTR signal is set to low, and

the off-line bit of the Main Status Register (MNSTS) is reset.

The /INIT signal on the parallel interface is not active while that interface is

in Nibble or ECP Mode, or is not selected.

Left margin: 1st character

Character pitch: 10 CPI

Print mode: Text mode (non-raster graphics mode)

Product Description Initialization 32

Page 33

OPERATINGPRINCIPLES

CHAPTER

Page 34

EPSON Stylus Pro 9000 Revision B

2.1 Component List & Illustrations

This section explains the print mechanism and operating principles for the

EPSON Stylus Pro 9000.

2.1.1 Print Mechanism Components

The printer mechanism of EPSON Stylus Pro 9000 consists of the following

mechanism parts.

Component Explanation

Carriage Assembly Carriage section:

printheads (B head/C head)

PG Motor

Linear Encoder

HP sensor

PG sensor

Paper Width sensor

Paper cutter-drive component

Carriage guide rail section:

CR Motor

Paper Feed Mechanism Paper feed rail:

Grid roller assembly

Secondary roller assembly (opposite the grid rollers)

PF Motor (Rotary Encoder internal part)

Paper Suction Fans

P_FRONT Sensor (detects front edge)

P_REAR Sensor (detects rear edge)

Paper Thickness Sensor

Paper Release-Lever Position Sensor

Cleaning Assembly

Pump Assembly/Pump Motor

Cap Assembly

CR Lock Mechanism

Component Explanation

Ink Delivery System I/C Holder Assembly

Ink Cartridge Holder/Valve Mechanism

I/H Lever Position Sensor

Ink Cartridge Detect Sensor

Ink Low Sensor

Ink ID Sensor

Other CoverPosition Sensor (interlock switch)

Operating Principles Component List & I llustrations 34

Page 35