Page 1

SERVICE MANUAL

Color Inkjet Printer

Epson Stylus Photo R3000

CONFIDENTIAL

SEMF10-002

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or

by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be

detected, SEIKO EPSON would greatly appreciate being informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this

manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or registered

trademarks of their respective owners. EPSON disclaims any and all rights in those marks.

Copyright 2010 SEIKO EPSON CORPORATION

IJP CS Quality Assurance Department

Confidential

Page 3

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this

product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral devices when servicing the product or

performing maintenance.

2. When performing works described in this manual, do not connect to a power source until instructed to do so.

Connecting to a power source causes high voltage in the power supply unit and some electronic components

even if the product power switch is off. If you need to perform the work with the power cable connected to a

power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1. Always wear protective goggles for disassembly and reassembly to protect your eyes from ink in working. If

any ink gets in your eyes, wash your eyes with clean water and consult a doctor immediately.

2. When using compressed air products; such as air duster, for cleaning during repair and maintenance, the use

of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified repair technician.

2. No work should be performed on this product by persons unfamiliar with basic safety knowledge required for

electrician.

3. The power rating of this product is indicated on the serial number/rating plate. Never connect this product to

the power source whose voltages is different from the rated voltage.

4. Replace malfunctioning components only with those components provided or approved by Epson;

introduction of second-source ICs or other non-approved components may damage the product and void any

applicable Epson warranty.

5. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static

wrist straps, when accessing internal components.

6. Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several

times. Doing so may cause ink to leak from the product because it may take some time for the waste ink pads

to completely absorb ink wasted due to the ink charge.

7. Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with

soap and water immediately. If you have a skin irritation, consult a doctor immediately.

Confidential

Page 4

8. When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts

with sharp edges.

9. Use only recommended tools for disassembling, assembling or adjusting the printer.

10. Observe the specified torque when tightening screws.

11. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the printhead

Ink Supply Unit

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Exterior parts

12. Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may

damage the component or give bad influence on the printer function.

13. Apply the specified amount of grease described in this manual.

14. Make the specified adjustments when you disassemble the printer.

15. When cleaning this product, follow the procedure described in this manual.

16. When transporting this product after filling the ink in the printhead, pack the printer without removing the

ink cartridges in order to prevent the printhead from drying out.

17. Make sure to install antivirus software in the computers used for the service support activities.

18. Keep the virus pattern file of antivirus software up-to-date.

Confidential

Page 5

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information

necessary for properly performing maintenance and servicing the product.

CHAPTER 1. DISASSEMBLY / REASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product, and provides the

standard operation time for servicing the product.

CHAPTER 2. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 3. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 4. APPENDIX

Provides the following additional information for reference:

Power-On Sequence

Connector Diagram

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or

to warn of possible danger present during a procedure or an action. Pay attention to all symbols when they are

used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed,

could result in serious injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed,

could result in bodily injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to

accomplish a task efficiently. It may also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous action.

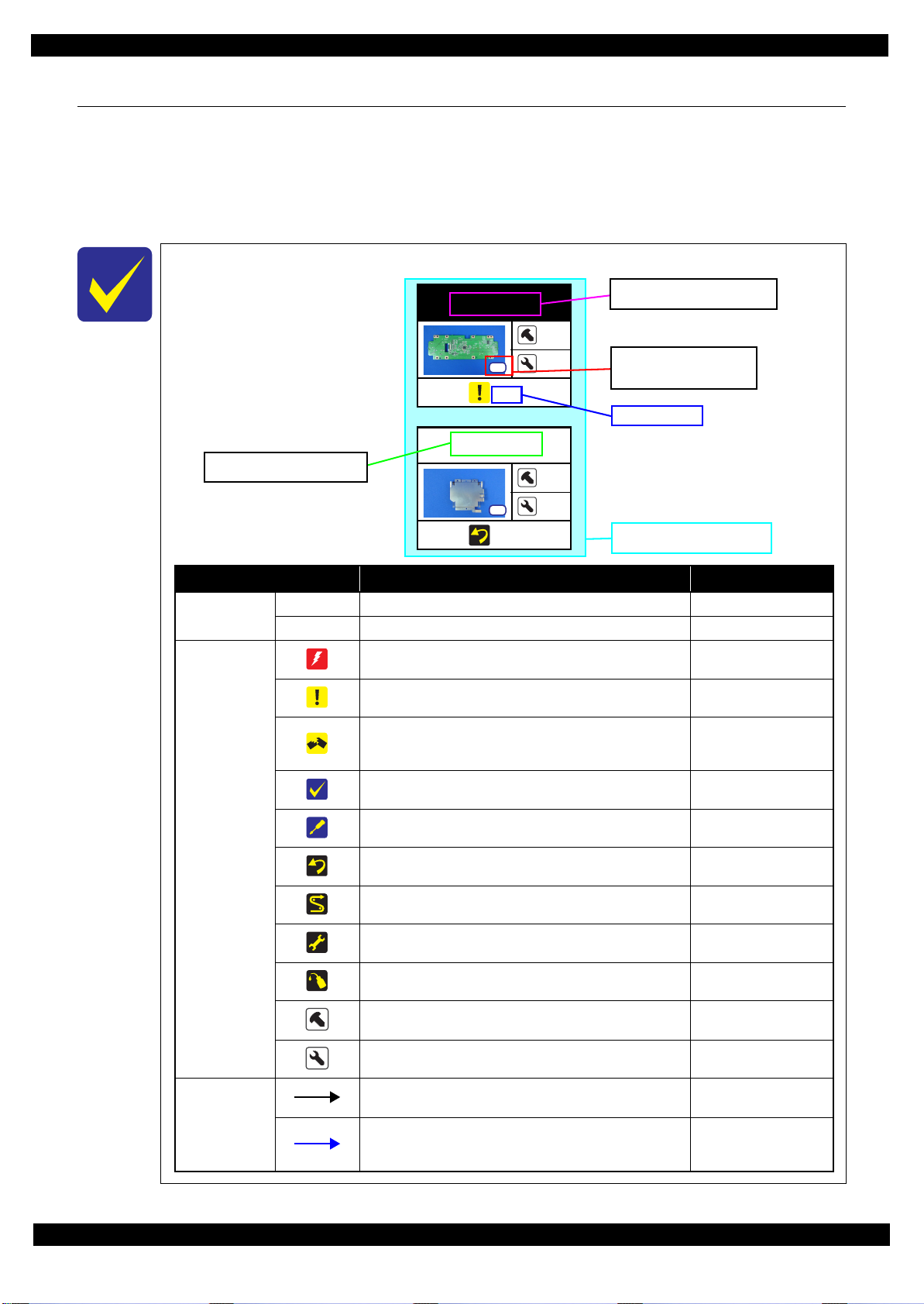

For Chapter 1 “Disassembly/Reassembly”, symbols other than indicated above are used to show additional

information for disassembly/reassembly. For the details on those symbols, see “1.2 Disassembly/Reassembly

Procedures (p12)”.

Confidential

Page 6

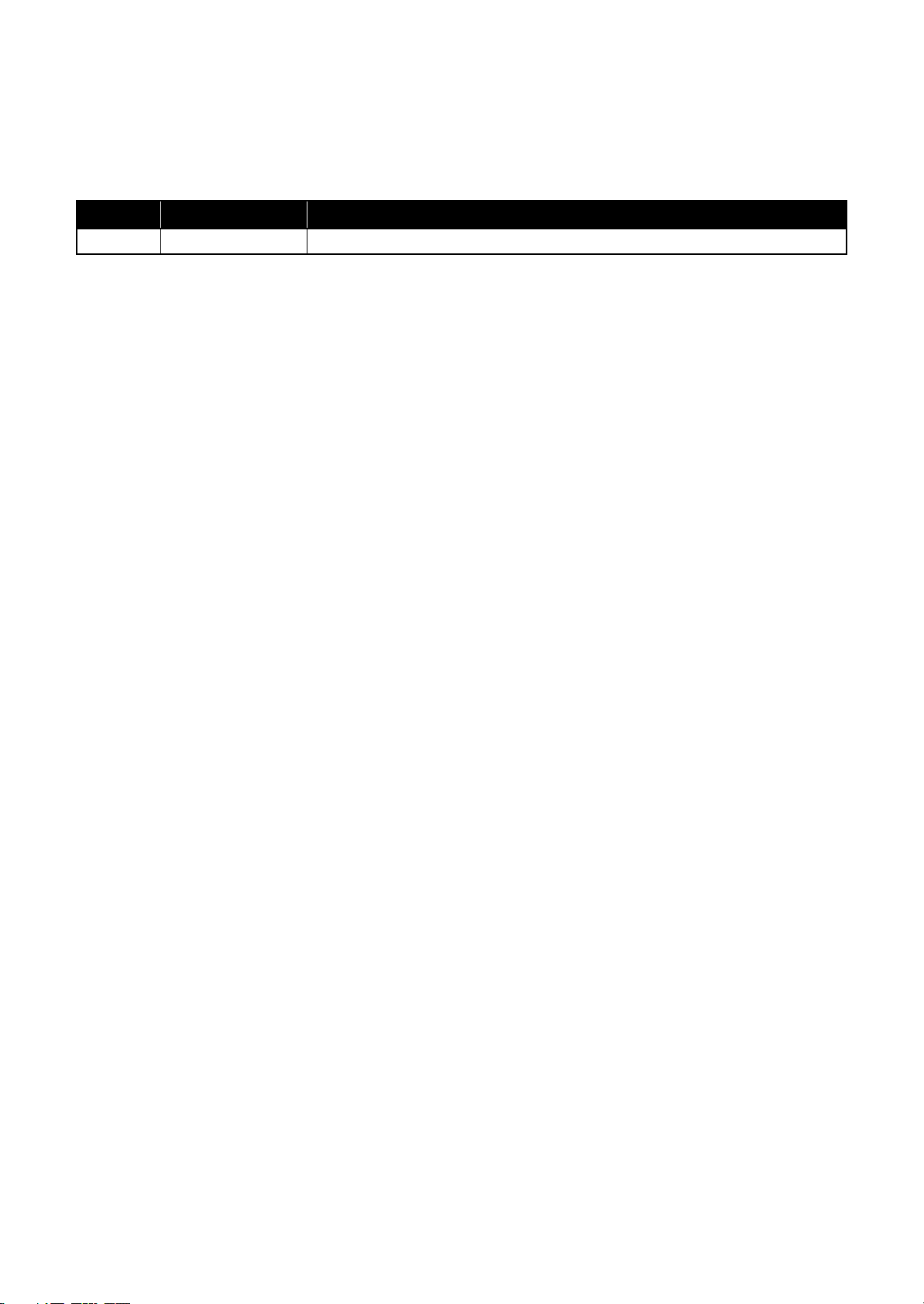

Revision Status

Revision Date of Issue Description

A December 24, 2010 First Release

Confidential

Page 7

Epson Stylus Photo R3000 Revision A

Contents

Chapter 1 Disassembly/Reassembly

1.1 Overview ................................................................................................................................................................... 9

1.1.1 Tools ................................................................................................................................................................. 9

1.1.2 Jigs .................................................................................................................................................................... 9

1.1.3 Precautions before Disassembling.................................................................................................................. 10

1.1.4 Preparation before Returning the Unit to the User ......................................................................................... 11

1.2 Disassembly/Reassembly Procedures ..................................................................................................................... 12

1.2.1 Standard Operation Time for servicing the product (TBD) ........................................................................... 13

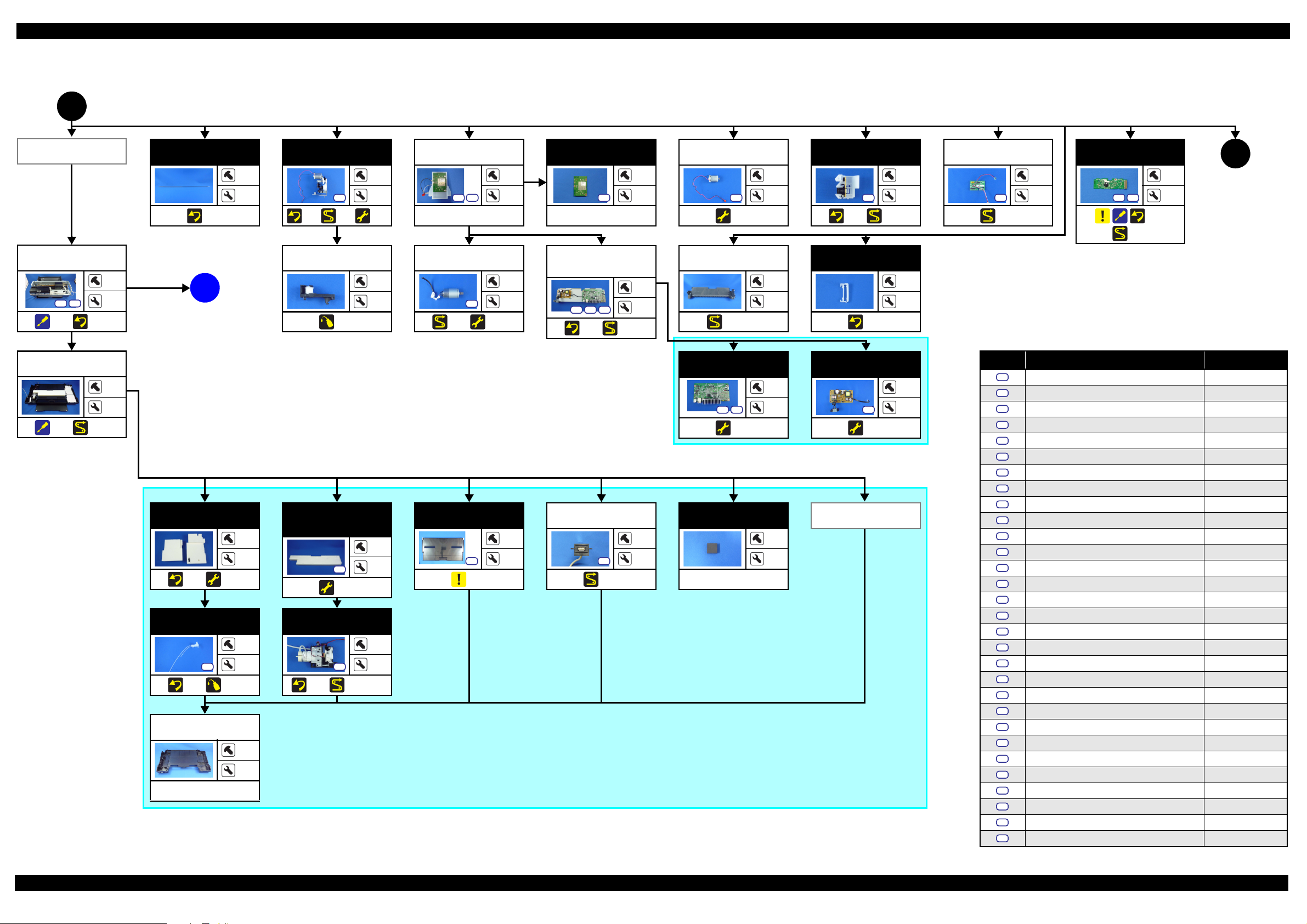

1.2.2 Disassembly/Reassembly Flowchart .............................................................................................................. 15

1.2.2.1 Housing Part .......................................................................................................................................... 15

1.2.2.2 Printer Mechanism Part ......................................................................................................................... 16

1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit........................................................................... 19

1.4 Routing FFCs/cables ............................................................................................................................................... 29

Chapter 2 Adjustment

2.1 Required Adjustments ............................................................................................................................................. 33

2.2 Details of Adjustments (TBD) ................................................................................................................................ 38

2.2.1 PF Timing Belt Tension Adjustment.............................................................................................................. 38

2.2.2 PF Roller Shaft Center Support Position Adjustment (TBD)......................................................................... 39

2.2.3 ASF Guide Roller LDs position adjustment................................................................................................... 44

2.2.4 PG Adjustment ............................................................................................................................................... 47

2.2.5 Mist Recovery check ...................................................................................................................................... 51

2.2.6 MAC address setting ...................................................................................................................................... 52

2.2.7 Head Angular Adjustment CR/PF (TBD) ...................................................................................................... 53

2.2.8 Colorimetric Calibration ................................................................................................................................. 55

2.2.8.1 Overview of the Colorimetric Calibration ............................................................................................. 56

2.2.8.2 Adjusting Method of the Colorimetric Calibration................................................................................ 58

Chapter 3 Maintenance

3.1 Overview ................................................................................................................................................................. 65

3.1.1 Cleaning .......................................................................................................................................................... 65

3.1.2 Lubrication...................................................................................................................................................... 65

3.2 Lubrication Points and Instructions......................................................................................................................... 66

Chapter 4 Appendix

4.1 Power-On Sequence ................................................................................................................................................ 70

4.2 Connector Diagram ................................................................................................................................................. 73

Confidential

7

Page 8

CHAPTER 1

DISASSEMBLY/REASSEMBLY

Confidential

Page 9

Epson Stylus Photo R3000 Revision A

1.1 Overview

This chapter describes procedures for disassembling the main parts/units of Stylus Photo R3000. Unless

otherwise specified, disassembled parts/units can be reassembled by reversing the disassembly procedure. See

the cautions or tips for disassembly/reassembly described in “1.3 Detailed Disassembly/Reassembly Procedure

for each Part/Unit (p19)”.

Read the “Safety Precautions (p3)” before disassembling and reassembling.

When you have to remove units or parts that are not described in this chapter, see the exploded diagrams of SPI

(Service Parts Information).

1.1.1 Tools

Use only specified tools to avoid damaging the printer.

Name Availability

(+) Phillips screwdriver #1 O 1080530

(+) Phillips screwdriver #2 O ---

Flathead screwdriver O ---

Flathead Precision screwdriver #1 O ---

Tweezers O ---

Longnose pliers O ---

Acetate tape --- 1003963

Nippers O ---

Note *1: Some of the tools listed above are commercially available.

*2: EPSON provides the tools listed with EPSON part code.

*1

EPSON Part Code

1.1.2 Jigs

*1

Name

Sonic tension gauge 1 --- 1294120

PF roller shaft position adjustment jig 1 --- TBD

Level block 1 --- 1304994

Adjustment gauge for PG adjustment 1 --- 1276333

Tester 1 O ---

Calibrator (i1 Basic UV-Cut) 1 O ---

Q’ty Availability

*2

EPSON Part Code

*2

Note *1: The jigs above are used for adjustment (See Chapter 2 “ Adjustment (p32) ”.) No jigs are required for disassembling/

reassembling this printer.

*2: Some of the tools listed above are commercially available.

Disassembly/Reassembly Overview 9

Confidential

Page 10

Epson Stylus Photo R3000 Revision A

Right

Hole

Phillips screwdriver

CW

CCW

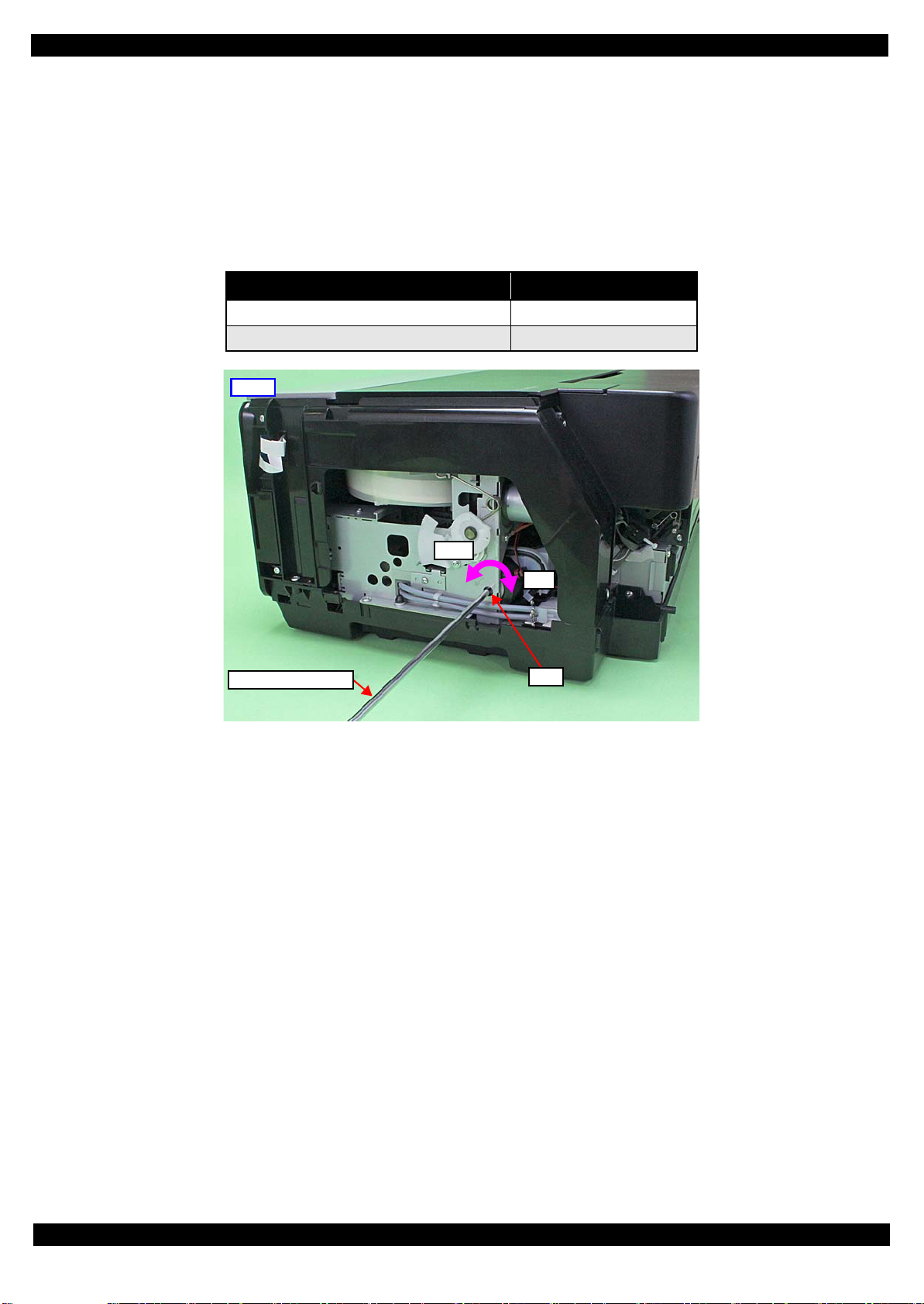

1.1.3 Precautions before Disassembling

Unlocking the carriage

Unlock the carriage by following the procedure below.

1. Remove the Rear Housing, Right Cover, and Right Decoration Plate.

2. Insert a phillips screwdriver into the hole of the frame on the right side of the printer, and rotate the white

shaft of the Ink System.

Table 1-1. Carriage Lock/Unlock

Direction of Rotation Carriage

Clockwise (CW) Locked

Counterclockwise (CCW) Unlocked

Figure 1-1. Unlock the Carriage

Handling the Ink Supply Unit

In order to prevent ink leakage, be careful of the following when handling the Ink Supply Unit.

(See “Ink Supply Unit (p22)” and “CR Contact Module (p22) ” for details.)

Unless otherwise specified in this manual, do not disassemble the Ink Supply Unit any further than specified as an

ASP. Otherwise, replace the Ink Supply Unit with a new one.

Be careful not to damage the film of the ink path.

When disassembling/reassembling the printer, be careful not to apply extra force on the joint part of the ink tube

and I/C Holder Unit, and on that of the ink tube and Ink Selector.

Disassembly/Reassembly Overview 10

Confidential

Page 11

Epson Stylus Photo R3000 Revision A

Front tray lock

Strong tape

Folded end

CR Unit

Strong tape

Attach strong tape with

its unfolded end sticking

out of the printer.

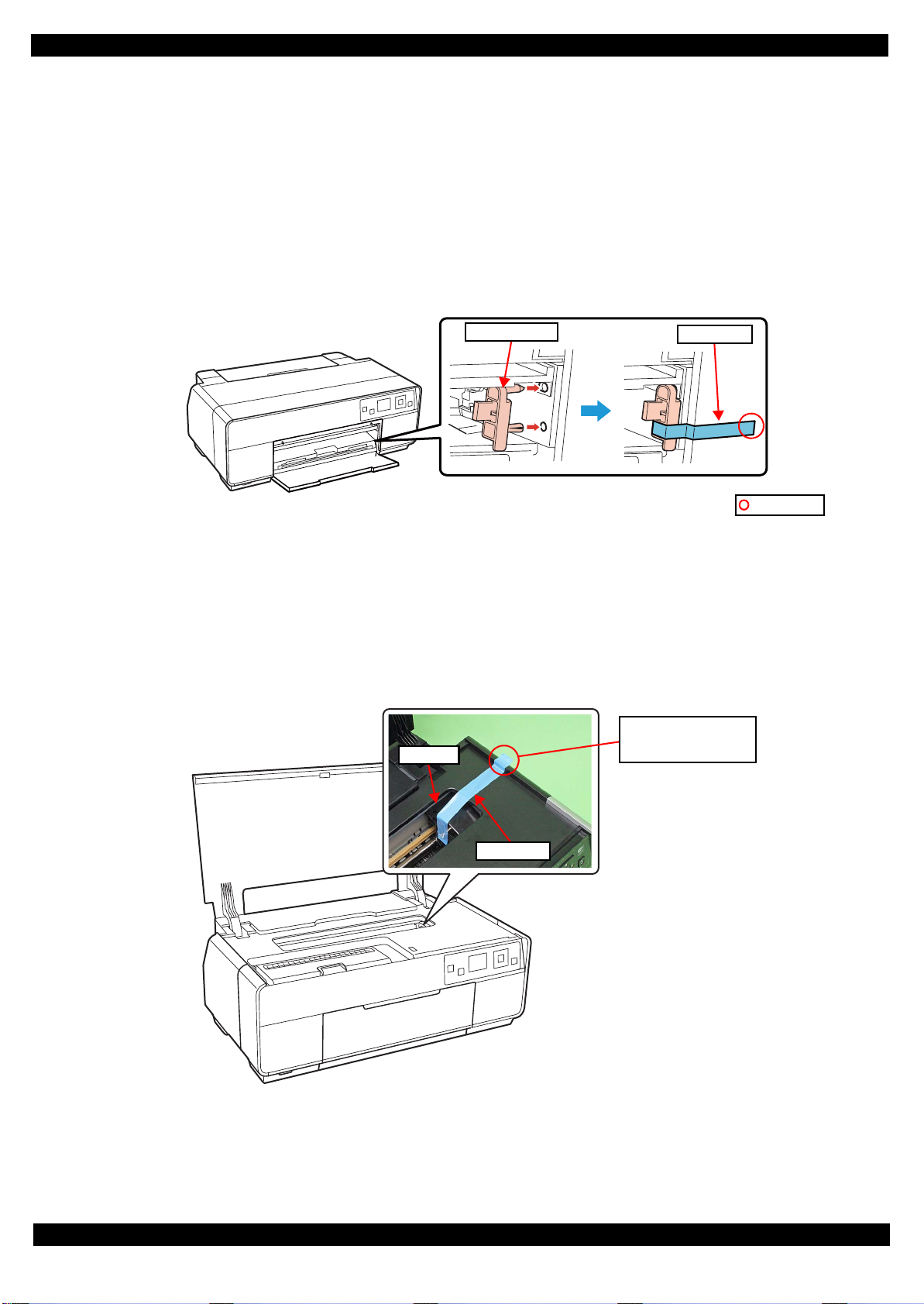

1.1.4 Preparation before Returning the Unit to the User

When returning the printer to the user, make sure to secure the specified points with tapes to avoid damaging the

printer during transport.

Attaching the front tray lock (tape length: 90

2 mm, tape width: 18 mm, fold one end by 5 mm)

Attach the front tray lock and secure it with strong tape as follows.

1. Attach the front tray lock on the position shown in Figure 1-2.

2. Attach the unfolded end of strong tape on the front tray lock as shown in Figure 1-2, and pull the tape and

apply it along the shapes of the Upper Housing Support Assy to secure the front tray lock.

Figure 1-2. Attaching and Securing the Front Tray Lock

Securing the CR Unit (tape length: 220

2 mm, tape width: 18 mm, fold one end by 5 mm)

Secure the CR Unit with strong tape as follows.

1. Open the printer cover and move the CR Unit to its home position.

2. Attach the unfolded end of strong tape on the CR Unit, and pull the tape and apply it along the shapes of

the Upper Housing Assy to the right side of the printer to secure the CR Unit.

Figure 1-3. Securing the CR Unit

Disassembly/Reassembly Overview 11

Confidential

Page 12

Epson Stylus Photo R3000 Revision A

LCD Shield

2

2

(p 15)

Panel Board

2

4

(p 15)

Item Description Reference

Parts/unit name

White-letter

Part/unit supplied as an ASP ---

Black-letter

Part/unit not supplied as an ASP ---

Icon

Indicates a practice or condition that could result in injury or

loss of life if not strictly observed.

Indicates the reference

page in blue-letter

Indicates a practice or condition that could result in damage to,

or destruction of equipment if not strictly observed.

Indicates the reference

page in blue-letter

Indicates the parts that are inevitably broken in the

disassembling procedure, and should be replaced with a new

one for reassembly.

---

Indicates necessary check items in the disassembling/

assembling procedure.

Indicates the reference

page in blue-letter

Indicates supplementary explanation for disassembly is given.

Indicates the reference

page in blue-letter

Indicates particular tasks to keep quality of the units are

required.

Indicates the reference

page in blue-letter

Indicates particular routing of cables is required.

Indicates the reference

page in blue-letter

Indicates particular adjustment(s) is/are required.

Chapter 2 “ Adjustment

(p32)”

Indicates lubrication is required.

Chapter 3 “ Maintenance

(p64)”

Indicates the number of screws securing the parts/units. ---

Indicates the points secured with other than a screw such as a

hook, rib, dowel or the like

---

Arrowed line

Indicates a disassembling procedure. ---

Indicates a removal procedure for a component of a part or

unit which is necessary to remove when proceeding to the

target part.

---

Shows removal/installation

as a unit/assy. is available.

Reference page

Black letters indicate a part/

unit not supplied as an ASP.

Shows the screw types and

the specified torque in the

“Screw type/torque list”.

White letters indicate a part/

unit supplied as an ASP.

1.2 Disassembly/Reassembly Procedures

This section describes procedures for disassembling the parts/units in a flowchart format. For some parts/units,

detailed procedures or precautions are provided (accordingly indicated by icons and cell’s color). Refer to the

explanations in the example chart below and perform an appropriate disassembling and assembling procedure.

(See “1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit (p19)”.)

For routing cables, see “1.4 Routing FFCs/cables (p29)”.

The example below shows how to see the charts on the following pages.

S12

S4

Disassembly/Reassembly Disassembly/Reassembly Procedures 12

Confidential

Page 13

Epson Stylus Photo R3000 Revision A

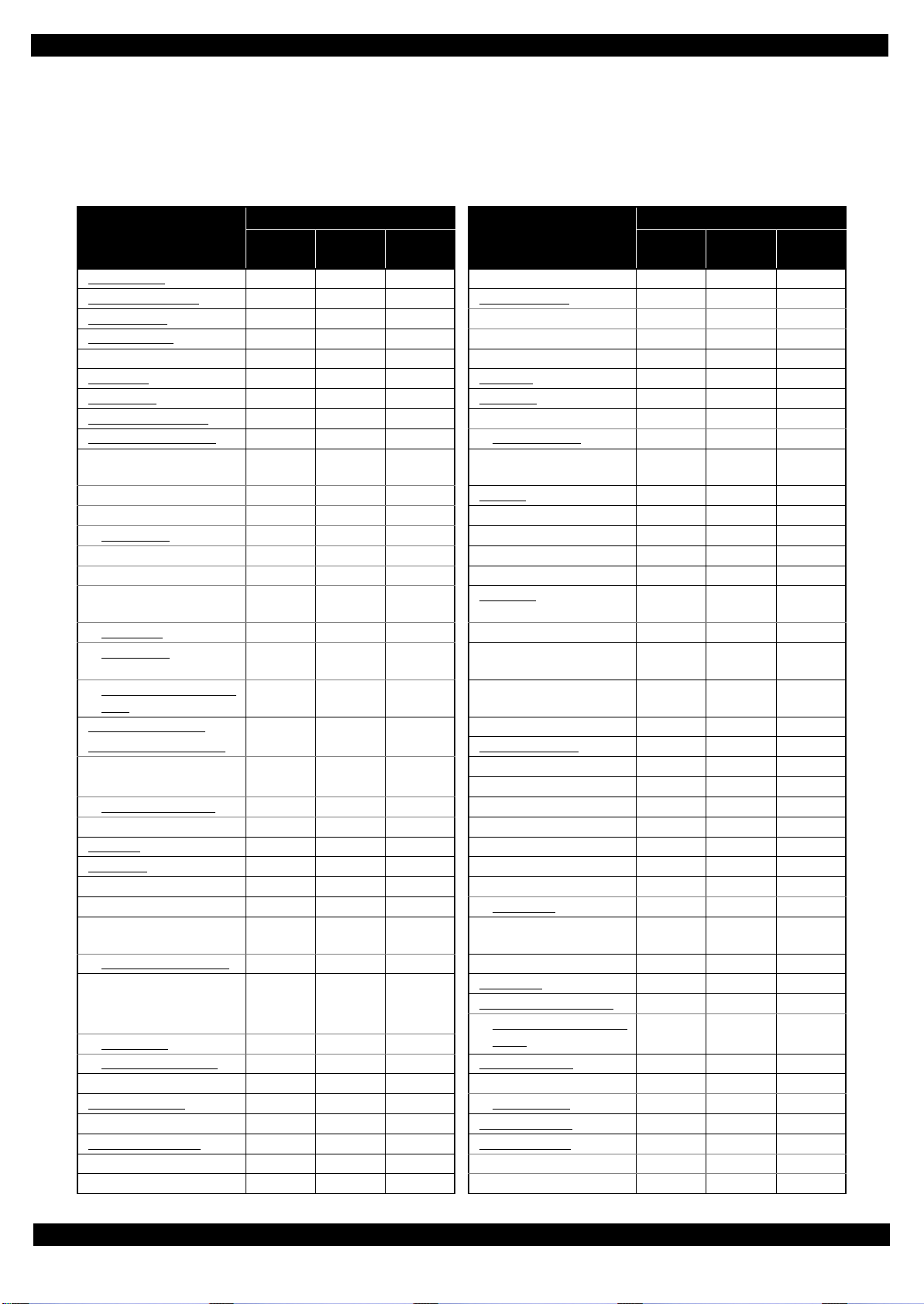

1.2.1 Standard Operation Time for servicing the product (TBD)

The following are the standard operation time for servicing the product. Those are based on the MTTR result

measured using a prototype.

The underlined parts/units are supplied as After Service Parts.

Table 1-2. Standard Operation Time (TBD)

Time (second)

Parts/Unit

Rear Housing CR Relay Board

Paper Support Assy

Stacker Cover Ink Selector

CSIC Terminal

Adjust Printer Cover Printhead Mounting Plate

Left Cover

Right Cover Head FFC

Left Decoration Plate CR Support Plate

Right Decoration Plate

Upper Housing Support

Assy (w/Panel Unit)

Panel Shield Plate CR Unit

Cover Open Sensor PF Frame

Panel Board

LCD Mounting Plate PF Roller

LCD LD Roller Guide

Panel Buttons

(w/OK Button)

OK Button ASF Motor

Panel Cover

Upper Housing Support

Assy

Upper Housing Assy

(w/Upper Printer Cover)

Upper Printer Cover

Holder

Upper Printer Cover

Upper Housing Printer Mechanism

CR Scale

APG

Assy Middle Frame

APG Motor Mist Board Assy

Driven Pulley Mist Board

Wireless LAN Module

Assy

Wireless LAN Module

Board Assy

(Main Board/Power

Supply Board)

Main Board

Power Supply Board Star Wheel Assy

PF Motor Stopper Tray Unit

PF Encoder Assy

ASF Relay Board Ink Tube Holder

CR Contact Module Front Tray Assy

Roll Paper Guide Assy Tray Support Assy

CR Cover Front Tray

Replace-

ment

Adjust-

ment

Total

Parts/Unit

Ink Supply Unit

I/C Holder Unit

Printhead

Ink Tube Guide

CR Guide Plate

Rear Paper Guide

ASF

Assy

Paper Guide

(under ASF Assy)

Shield Plate Assy Upper

Main Board

Release Holder Assy

PE Detector Assy

CR Motor

Release Flag Assy

Upper Paper Guide Assy

Lower Paper Guide

Mist Board Cable Holder

Lower Frame

Ink System

Front Paper Guide Assy

Porous Pad Front Paper

Guide

Tray Detector

Replace-

ment

Time (second)

Adjust-

ment

Total

Disassembly/Reassembly Disassembly/Reassembly Procedures 13

Confidential

Page 14

Epson Stylus Photo R3000 Revision A

Table 1-2. Standard Operation Time (TBD)

Time (second)

Parts/Unit

Lower Housing Assy PictBridge Holder Assy

Waste Ink Pad

Lower Paper Guide Ink

Pad Tray

Stacker Assy Lower Housing

Replace-

ment

Adjust-

ment

Total

Parts/Unit

Foot

Waste Ink Tube

Decomp Pump Assy

Replace-

ment

Time (second)

Adjust-

ment

Total

Disassembly/Reassembly Disassembly/Reassembly Procedures 14

Confidential

Page 15

Epson Stylus Photo R3000 Revision A

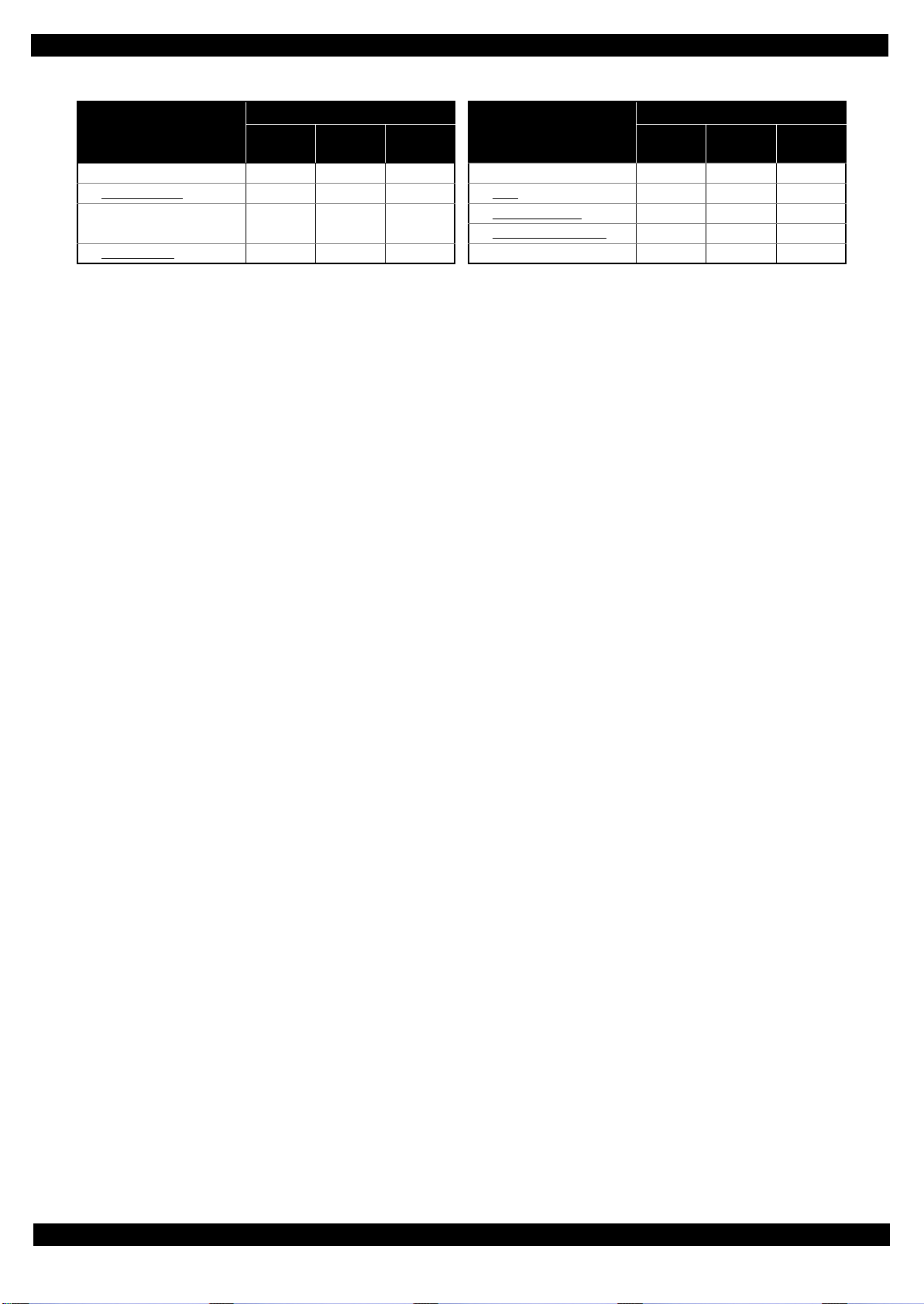

1.2.2 Disassembly/Reassembly Flowchart

1.2.2.1 Housing Part

START

Rear Housing

S9

S20

(p 19)

Left Cover

S5

(p 19)

Left

Decoration Plate

(p 19)

Adjust Printer

Cover

Upper Housing

Support Assy

(w/Panel Unit)

S6

(p 19) (p 29)

Upper Housing

Assy (w/Upper

Printer Cover)

S13

(p 19)

1

(p 16)

Paper Support

Assy

3

12

---

---

4

Stacker Cover

---

CSIC Terminal

---

2

---

---

2

Adjust Printer

Cover

S5

---

1

---

Right Cover

1

4

S5

(p 19)

1

4

Panel Shield

Plate

S12

(p 20)

Panel Board

S12

(p 20)

10

2

2

4

Cover Open

Sensor

---

2

(p 29)

Screw type/torque list

Right

Decoration Plate

---

3

(p 19)

---

3

LCD Mounting

Plate

S4

(p 20)

LCD

---

OK Button

2

2

---

Panel Buttons

(w/OK Button)

---

---

---

---

2

---

4

4

14

Panel Cover

---

Upper Printer

Cover Holder

4

---

S12

---

4

10

---

Upper Housing

Support Assy

---

---

Upper Printer

Cover

---

Upper Housing

---

---

---

---

---

---

---

Symbol Screw type Torque

S1

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 2.5 0.5 kgf·cm

S2

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 3.5 0.5 kgf·cm

S3

C.B.P-TITE SCREW,2X6,F/ZN-3C 2.0

S4

C.B.P-TITE SCREW,2X6,F/ZN-3C 3.0 1.0 kgf·cm

S5

C.B.P-TITE SCREW,3X10,F/ZB-3C 6.0

S6

C.B.P-TITE SCREW,3X10,F/ZN-3C 6.0 1.0 kgf·cm

S7

C.B.P-TITE SCREW,3X18,F/ZN-3C 6.0

S8

C.B.P-TITE SCREW,3X6,F/ZN-3C 4.0 0.5 kgf·cm

S9

C.B.P-TITE SCREW,3X8,F/ZB-3C 6.0

S10

C.B.P-TITE SCREW,3X8,F/ZN-3C 4.0 0.5 kgf·cm

S11

C.B.P-TITE SCREW,3X8,F/ZN-3C 5.0

S12

C.B.P-TITE SCREW,3X8,F/ZN-3C 6.0 1.0 kgf·cm

S13

C.B.P-TITE SCREW,4X8,F/ZN-3C 8.0

S14

C.B.SCREW,2.5X14,F/ZN-3C 3.0 1.0 kgf·cm

S15

C.B.SCREW,2.5X6,F/ZN-3C 3.5

S16

C.B.SCREW,3X4,F/ZN-3C 4.0 0.5 kgf·cm

S17

C.B.SCREW,3X6,F/ZN-3C 8.0

S18

C.B.S-TITE SCREW,2.5X6,F/ZN-3C 4.0 0.5 kgf·cm

S19

C.B.S-TITE SCREW,3X4,F/ZN-3C 8.0

S20

C.B.S-TITE SCREW,3X6,F/ZN-3C 6.0 1.0 kgf·cm

S21

C.B.S-TITE SCREW,3X6,F/ZN-3C 8.0

S22

C.B.S-TITE SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

S23

C.B.S-TITE(P2)SCREW,3X10,F/ZN-3C 6.0

S24

C.B.S-TITE(P4)SCREW,3X6,F/ZN-3C 8.0 1.0 kgf·cm

S25

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 5.0

S26

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

S27

C.C.SCREW,3X4,F/ZN-3C 4.0

S28

C.P.SCREW,2.6X3,F/ZN-3C 3.0 0.5 kgf·cm

S29

C.P.SCREW,3X10,F/ZN-3C 6.0

S30

C.P.SCREW,3X4,F/ZN-3C 6.0 1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

Flowchart 1-1. Disassembly Flowchart of Housing Part

Disassembly/Reassembly Disassembly/Reassembly Flowchart 15

Confidential

Page 16

Epson Stylus Photo R3000 Revision A

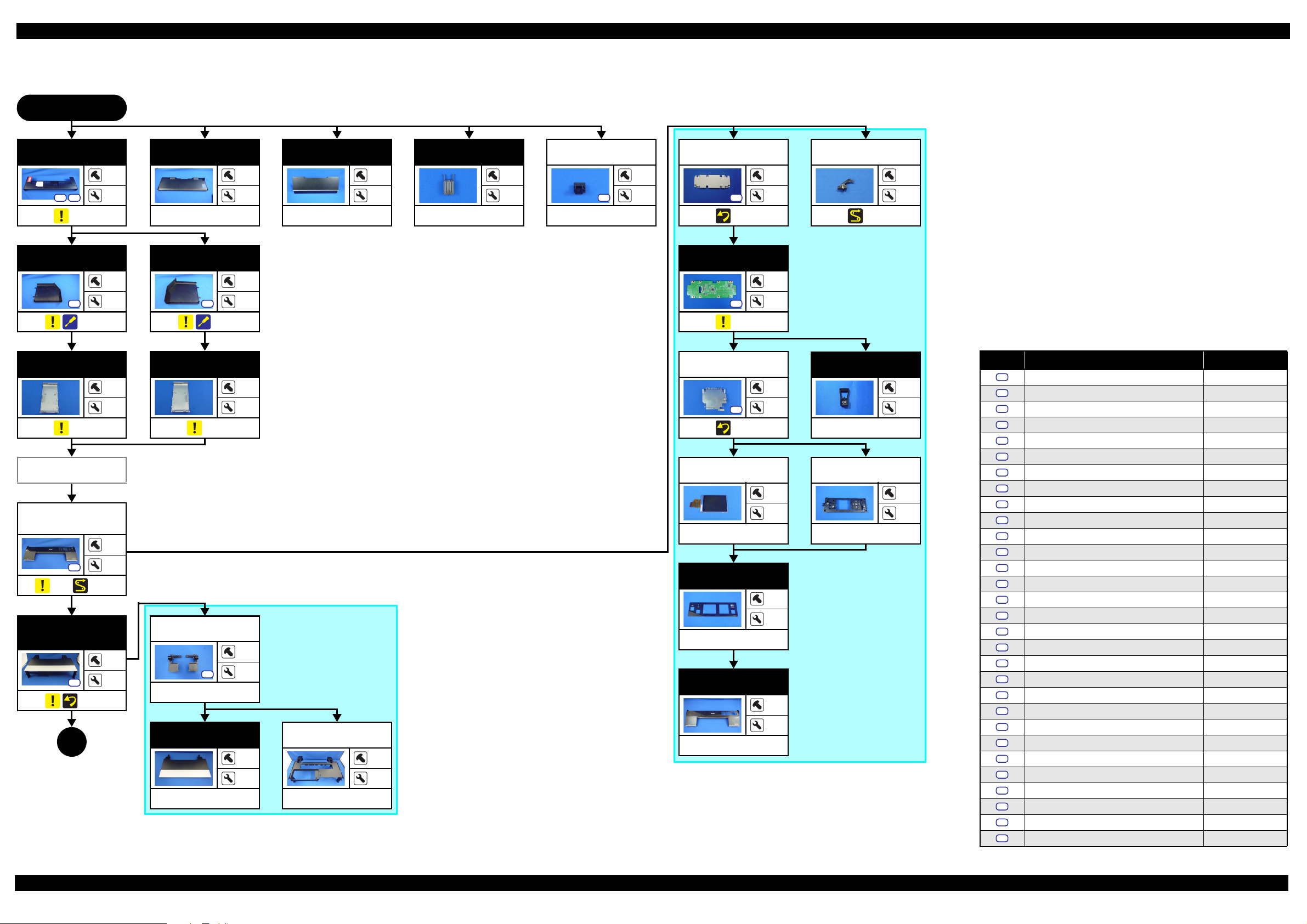

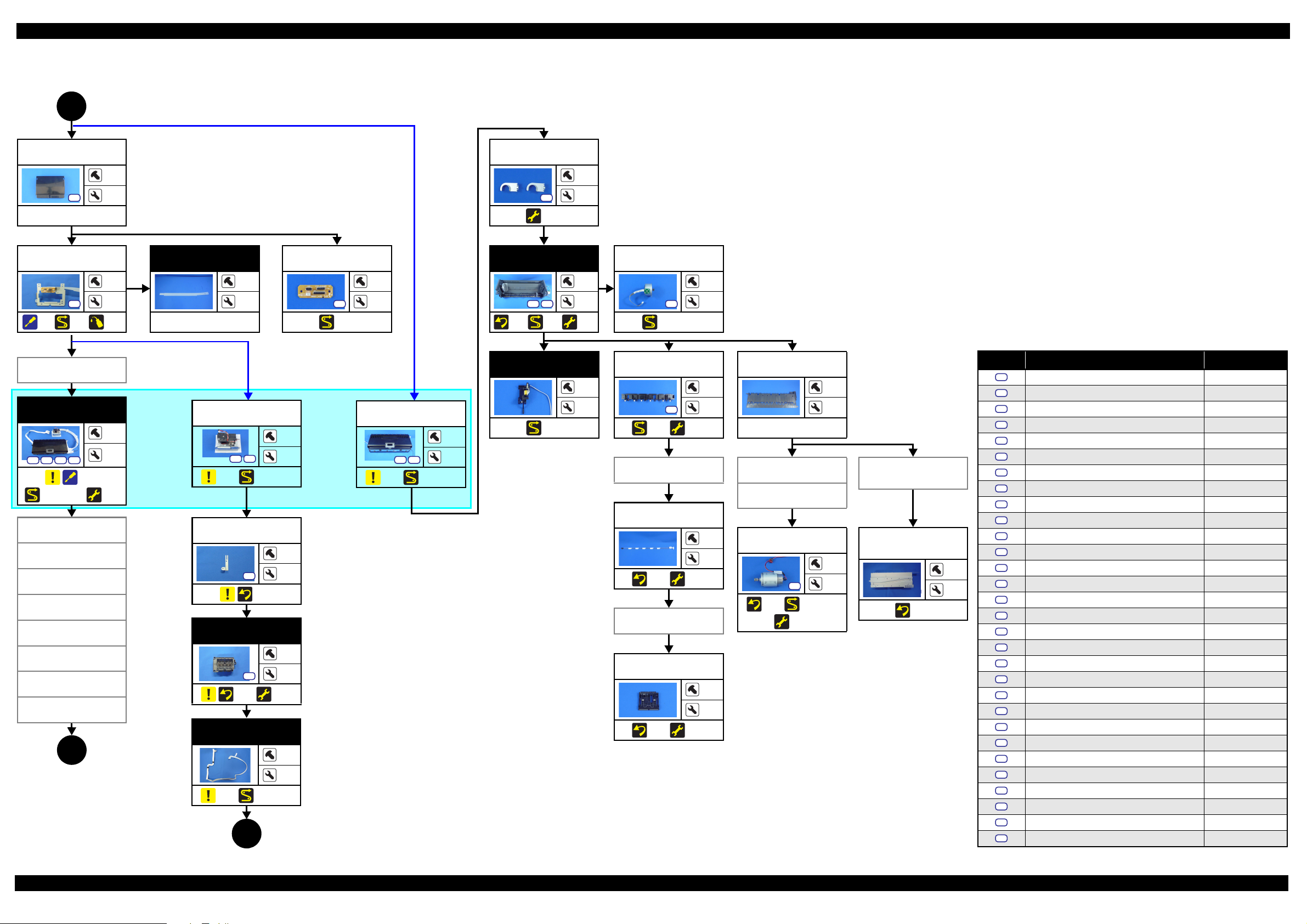

1.2.2.2 Printer Mechanism Part

(p 15)

1

Wireless LAN

Module Assy

Printer

Mechanism

S13 S23

(p 21) (p 21)

Lower Housing

(p 21) (p 29)

*

Assy

CR Scale

---

3

(p 20)

(p 20)

APG Assy

S21

(p 30)

---

(p 32)

3

Driven Pulley

6

A

2

---

---

(p 18)

(p 66)

Wireless LAN

Module Assy

S5

S20

---

PF Motor

S27

(p 30) (p 32)

3

---

2

---

Wireless LAN

Module

S12

---

Board Assy (Main

Board/Power

Supply Board)

S20 S23 S29

(p 28) (p 30)

APG Motor

3

2

S28

(p 32)

Roll Paper

Guide Assy

7

---

(p 29, p 30)

2

---

---

2

PF Encoder Assy

S22

(p 27) (p 30)

Ink Tube Holder

(p 20)

1

4

---

6

ASF Relay

Board

S12

(p 30)

CR Contact

Module

1

---

S21

S7

(p 22)

(p 30)

13

9

2

(p 17)

Screw type/torque list

*: The Printer Mechanism in this flowchart is not the one established as an ASP. The Printer Mechanism as an ASP excludes the

Main Board

following parts from the Printer Mechanism in this flowchart. When replacing the Printer Mechanism specified as an ASP, adjustments

---

---

are required. See Chapter 2 “ Adjustment (p32)” for details.

• ASF Assy

• LD Roller Guide

• Board Assy (Main Board/Power Supply Board)

• Head FFC

•Printhead

• Printhead Mounting Plate

Waste Ink Pad

Lower Paper

Guide Ink Pad

Tra y

---

---

S12

(p 20) (p 32)

Waste Ink Tube

(p 32)

Decomp Pump

Assy

1

S12

(p 20) (p 66)

---

S6

(p 20) (p 29, p 30)

4

• CR Support Plate

• CR Cover

• Ink Supply Unit

• Ink Tube Holder

S20 S30

(p 32)

---

• Paper Guide (under ASF Assy)

• Shield Plate Assy Upper Main Board

Stacker Assy

1

---

S6

(p 19)

4

---

PictBridge

Holder Assy

S6

(p 29)

2

---

Foot

---

---

---

3

---

Power Supply

Board

S20

(p 32)

Stacker Co ve r

4

---

Lower Housing

---

---

---

Symbol Screw type Torque

S1

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 2.5 0.5 kgf·cm

S2

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 3.5 0.5 kgf·cm

S3

C.B.P-TITE SCREW,2X6,F/ZN-3C 2.0

S4

C.B.P-TITE SCREW,2X6,F/ZN-3C 3.0 1.0 kgf·cm

S5

C.B.P-TITE SCREW,3X10,F/ZB-3C 6.0

S6

C.B.P-TITE SCREW,3X10,F/ZN-3C 6.0 1.0 kgf·cm

S7

C.B.P-TITE SCREW,3X18,F/ZN-3C 6.0

S8

C.B.P-TITE SCREW,3X6,F/ZN-3C 4.0 0.5 kgf·cm

S9

C.B.P-TITE SCREW,3X8,F/ZB-3C 6.0

S10

C.B.P-TITE SCREW,3X8,F/ZN-3C 4.0 0.5 kgf·cm

S11

C.B.P-TITE SCREW,3X8,F/ZN-3C 5.0

S12

C.B.P-TITE SCREW,3X8,F/ZN-3C 6.0 1.0 kgf·cm

S13

C.B.P-TITE SCREW,4X8,F/ZN-3C 8.0

S14

C.B.SCREW,2.5X14,F/ZN-3C 3.0 1.0 kgf·cm

S15

C.B.SCREW,2.5X6,F/ZN-3C 3.5

S16

C.B.SCREW,3X4,F/ZN-3C 4.0 0.5 kgf·cm

S17

C.B.SCREW,3X6,F/ZN-3C 8.0

S18

C.B.S-TITE SCREW,2.5X6,F/ZN-3C 4.0 0.5 kgf·cm

S19

C.B.S-TITE SCREW,3X4,F/ZN-3C 8.0

S20

C.B.S-TITE SCREW,3X6,F/ZN-3C 6.0 1.0 kgf·cm

S21

C.B.S-TITE SCREW,3X6,F/ZN-3C 8.0

S22

C.B.S-TITE SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

S23

C.B.S-TITE(P2)SCREW,3X10,F/ZN-3C 6.0

S24

C.B.S-TITE(P4)SCREW,3X6,F/ZN-3C 8.0 1.0 kgf·cm

S25

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 5.0

S26

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

S27

C.C.SCREW,3X4,F/ZN-3C 4.0

S28

C.P.SCREW,2.6X3,F/ZN-3C 3.0 0.5 kgf·cm

S29

C.P.SCREW,3X10,F/ZN-3C 6.0

S30

C.P.SCREW,3X4,F/ZN-3C 6.0 1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

Flowchart 1-2. Disassembly Flowchart of Printer Mechanism Part (1)

Disassembly/Reassembly Disassembly/Reassembly Flowchart 16

Confidential

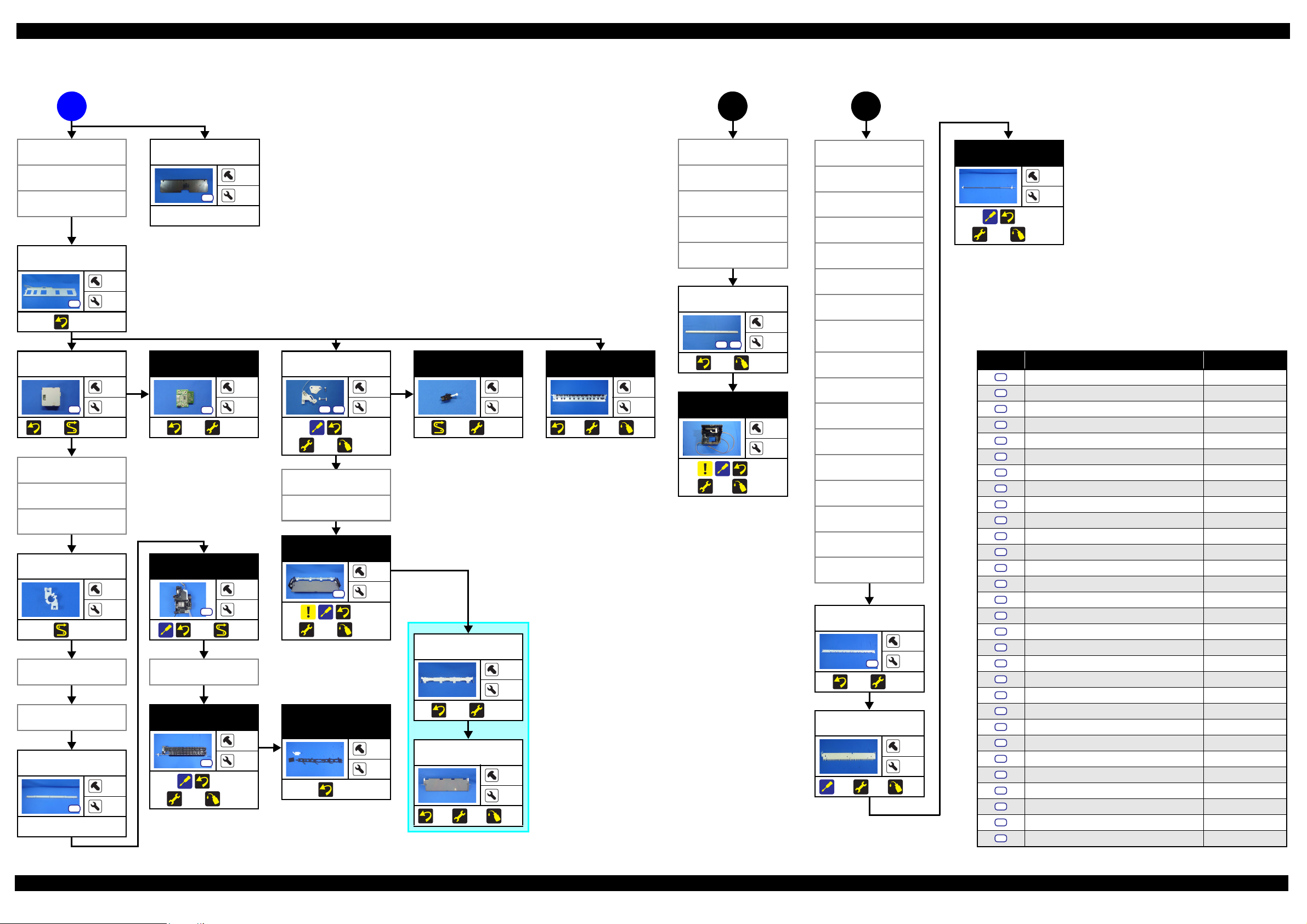

Page 17

Epson Stylus Photo R3000 Revision A

(p 16)

2

CR Cover

S20

---

CR Support

Plate

S12

(p 21) (p 29)

Wireless LAN

Module Assy

Ink Supply Unit

S1

S15 S21 S22

(p 22)

(p 26, p 29, p 30)

Printhead

Mounting Plate

Print head

Head FFC

CR Scale

LD Roller Guide

ASF Assy

Lower Housing

Assy

Lower Paper

Guide

4

(p 18)

(p 66)

(p 32)

LD Roller Guide

1

2

Ink Tube Guide

4

7

---

---

3

CR Relay Board

S20

(p 29)

2

---

(p 24)

S17

(p 32)

ASF Assy

S21 S26

(p 30)

(p 32)

2

4

ASF Motor

4

2

S12

(p 29, p 30)

2

---

Screw type/torque list

PE Detector Assy

---

Ink Selector*

5

---

S1

S15

2

---

I/C Holder Unit*

S21 S22

3

(p 29)

---

4

Release Holder

Assy

S21

(p 29) (p 32)

3

3

APG Assy

(p 10) (p 26, p 29)

(p 10) (p 26, p 30)

Paper Guide

(under ASF Assy)

---

APG Assy

---

2

Board Assy (Main

Board/Power

Supply Board)

Driven Pulley

Release Flag

Printhead

Mounting Plate

S2

(p 21)

Print head

S2

(p 21) (p 32)

1

---

3

---

Assy

(p 23) (p 32)

PE Detector Assy

Upper Paper

Guide Assy

---

4

CR Motor

S16

(p 23) (p 29, p 30)

(p 32)

2

---

Shield Plate Assy

Upper Main

Board

S21

(p 28)

---

2

Head FFC

(p 23) (p 32)

---

---

(p 26) (p 29, p 30)

*: The Ink Selector and I/C Holder Unit are the parts of the Ink Supply Unit. However, if the disassembly is

3

(p 18)

Flowchart 1-3. Disassembly Flowchart of Printer Mechanism Part (2)

not for replacement of the Ink Supply Unit, it is faster that only either of the Ink Selector or I/C Holder

Unit is removed to proceed the next step. Therefore, they are listed in this flowchart separately.

Symbol Screw type Torque

S1

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 2.5 0.5 kgf·cm

S2

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 3.5 0.5 kgf·cm

S3

C.B.P-TITE SCREW,2X6,F/ZN-3C 2.0

S4

C.B.P-TITE SCREW,2X6,F/ZN-3C 3.0 1.0 kgf·cm

S5

C.B.P-TITE SCREW,3X10,F/ZB-3C 6.0

S6

C.B.P-TITE SCREW,3X10,F/ZN-3C 6.0 1.0 kgf·cm

S7

C.B.P-TITE SCREW,3X18,F/ZN-3C 6.0

S8

C.B.P-TITE SCREW,3X6,F/ZN-3C 4.0 0.5 kgf·cm

S9

C.B.P-TITE SCREW,3X8,F/ZB-3C 6.0

S10

S11

S12

3

2

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

C.B.P-TITE SCREW,3X8,F/ZN-3C 4.0 0.5 kgf·cm

C.B.P-TITE SCREW,3X8,F/ZN-3C 5.0

C.B.P-TITE SCREW,3X8,F/ZN-3C 6.0 1.0 kgf·cm

C.B.P-TITE SCREW,4X8,F/ZN-3C 8.0

C.B.SCREW,2.5X14,F/ZN-3C 3.0 1.0 kgf·cm

C.B.SCREW,2.5X6,F/ZN-3C 3.5

C.B.SCREW,3X4,F/ZN-3C 4.0 0.5 kgf·cm

C.B.SCREW,3X6,F/ZN-3C 8.0

C.B.S-TITE SCREW,2.5X6,F/ZN-3C 4.0 0.5 kgf·cm

C.B.S-TITE SCREW,3X4,F/ZN-3C 8.0

C.B.S-TITE SCREW,3X6,F/ZN-3C 6.0 1.0 kgf·cm

C.B.S-TITE SCREW,3X6,F/ZN-3C 8.0

C.B.S-TITE SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

C.B.S-TITE(P2)SCREW,3X10,F/ZN-3C 6.0

C.B.S-TITE(P4)SCREW,3X6,F/ZN-3C 8.0 1.0 kgf·cm

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 5.0

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

C.C.SCREW,3X4,F/ZN-3C 4.0

C.P.SCREW,2.6X3,F/ZN-3C 3.0 0.5 kgf·cm

C.P.SCREW,3X10,F/ZN-3C 6.0

C.P.SCREW,3X4,F/ZN-3C 6.0 1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

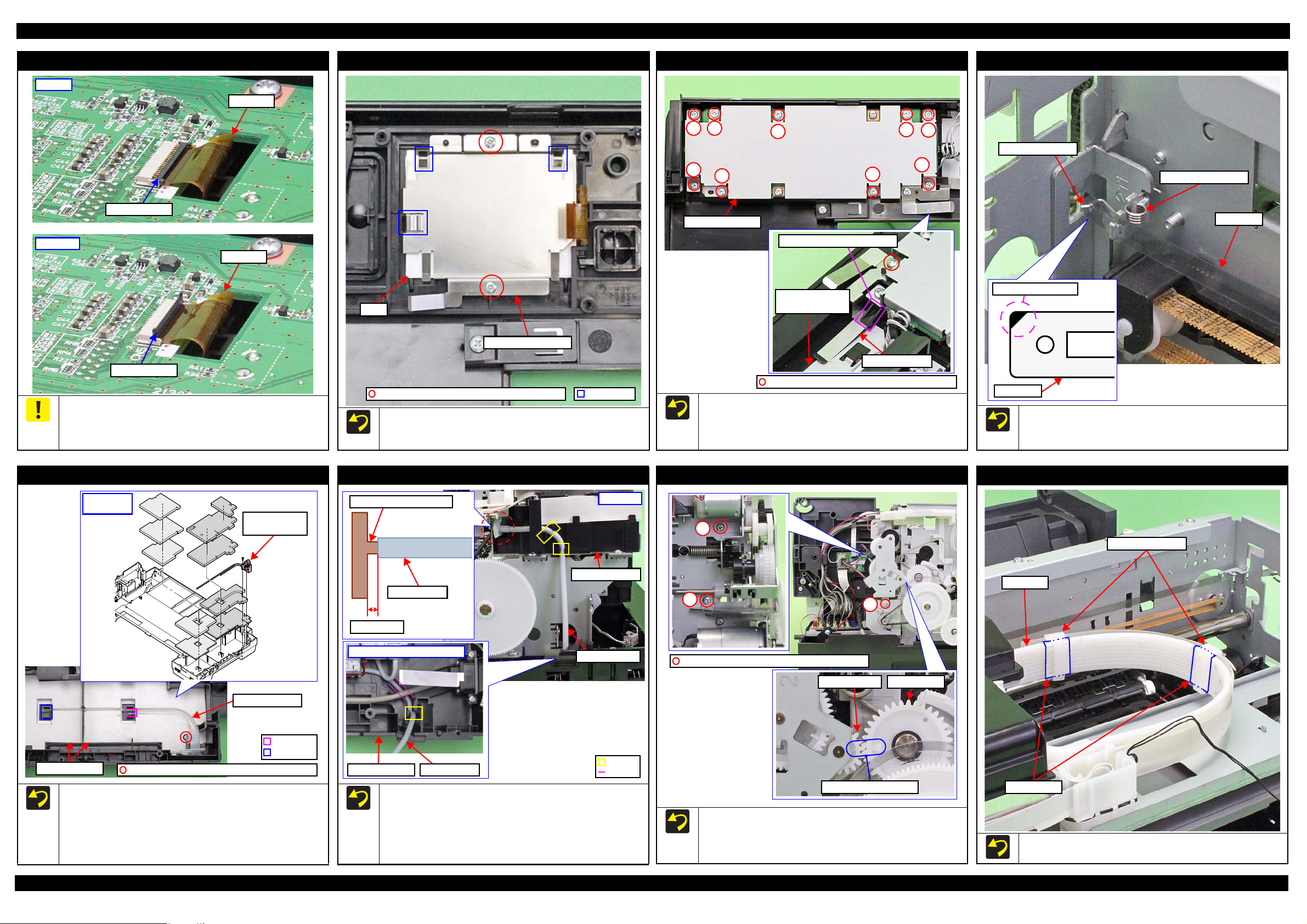

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

Disassembly/Reassembly Disassembly/Reassembly Flowchart 17

Confidential

Page 18

Epson Stylus Photo R3000 Revision A

(p 16)

A

CR Cover

CR Support

Plate

Ink Supply Unit

Middle Frame

S21

(p 23)

Mist Board Assy

S21

(p 27) (p 30, p 31)

LD Roller Guide

ASF Assy

Paper Guide

(under ASF Assy)

Mist Board

Cable Holder

(p 31)

Lower Paper

Guide

Stopper Tray

Unit

Lower Frame

S21

---

(p 17)

3

Lower Paper

Guide

S26

---

1

3

APG Assy

Driven Pulley

CR Scale

I/C Holder Unit

APG Assy

Driven Pulley

Middle Frame

CR Guide Plate

Middle Frame

6

10

CR Guide Plate

5

S24S18

Mist Board

1

1

S20

(p 27) (p 32)

2

---

Stopper Tray

Unit

S21S10

(p 25)

(p 32) (p 66)

Tray Detector

2

---

(p 30) (p 32)

---

4

Star Wheel Assy

(p 26)

(p 32)

---

(p 66)

2

Star Wheel Assy

Lower Paper

Guide

(p 21) (p 67)

CR Unit

(p 24)

(p 32)

(p 67)

---

---

---

Front Tray Assy

Ink System

---

2

S21

(p 24) (p 30)

4

2

S8

(p 25)

(p 32) (p 67)

Star Wheel Assy

3

---

Tray Support

Assy

---

---

Front Paper

Guide Assy

1

S11

4

2

(p 26)

(p 32) (p 68)

---

Porous Pad

Front Paper

Guide

(p 26)

---

---

(p 25) (p 32)

Front Tray

(p 25)

(p 32)

---

---

(p 67)

Mist Board Assy

Mist Board

Cable Holder

Paper Guide

(under ASF

Stopper Tray

Lower Frame

Ink System

Star Wheel Assy

Front Paper

Guide Assy

Release Holder

Release Flag

PE Detector Assy

Upper Paper

Guide Assy

PF Frame

(p 23) (p 32)

Rear Paper

(p 23)

4

CR Unit

Assy)

Unit

Assy

Assy

S19

Guide

(p 32)

(p 17)

(p 66)

PF Roller

---

---

(p 27)

(p 32) (p 66)

Screw type/torque list

Symbol Screw type Torque

S1

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 2.5 0.5 kgf·cm

S2

C.B.P-TITE SCREW,2.5X8,F/ZN-3C 3.5 0.5 kgf·cm

S3

C.B.P-TITE SCREW,2X6,F/ZN-3C 2.0

S4

C.B.P-TITE SCREW,2X6,F/ZN-3C 3.0 1.0 kgf·cm

S5

C.B.P-TITE SCREW,3X10,F/ZB-3C 6.0

S6

C.B.P-TITE SCREW,3X10,F/ZN-3C 6.0 1.0 kgf·cm

S7

C.B.P-TITE SCREW,3X18,F/ZN-3C 6.0

S8

C.B.P-TITE SCREW,3X6,F/ZN-3C 4.0 0.5 kgf·cm

S9

C.B.P-TITE SCREW,3X8,F/ZB-3C 6.0

S10

S11

S12

S13

S14

S15

S16

6

---

---

3

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

C.B.P-TITE SCREW,3X8,F/ZN-3C 4.0 0.5 kgf·cm

C.B.P-TITE SCREW,3X8,F/ZN-3C 5.0

C.B.P-TITE SCREW,3X8,F/ZN-3C 6.0 1.0 kgf·cm

C.B.P-TITE SCREW,4X8,F/ZN-3C 8.0

C.B.SCREW,2.5X14,F/ZN-3C 3.0 1.0 kgf·cm

C.B.SCREW,2.5X6,F/ZN-3C 3.5

C.B.SCREW,3X4,F/ZN-3C 4.0 0.5 kgf·cm

C.B.SCREW,3X6,F/ZN-3C 8.0

C.B.S-TITE SCREW,2.5X6,F/ZN-3C 4.0 0.5 kgf·cm

C.B.S-TITE SCREW,3X4,F/ZN-3C 8.0

C.B.S-TITE SCREW,3X6,F/ZN-3C 6.0 1.0 kgf·cm

C.B.S-TITE SCREW,3X6,F/ZN-3C 8.0

C.B.S-TITE SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

C.B.S-TITE(P2)SCREW,3X10,F/ZN-3C 6.0

C.B.S-TITE(P4)SCREW,3X6,F/ZN-3C 8.0 1.0 kgf·cm

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 5.0

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C 8.0 1.0 kgf·cm

C.C.SCREW,3X4,F/ZN-3C 4.0

C.P.SCREW,2.6X3,F/ZN-3C 3.0 0.5 kgf·cm

C.P.SCREW,3X10,F/ZN-3C 6.0

C.P.SCREW,3X4,F/ZN-3C 6.0 1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

1.0 kgf·cm

0.5 kgf·cm

1.0 kgf·cm

Flowchart 1-4. Disassembly Flowchart of Printer Mechanism Part (3)

Disassembly/Reassembly Disassembly/Reassembly Flowchart 18

Confidential

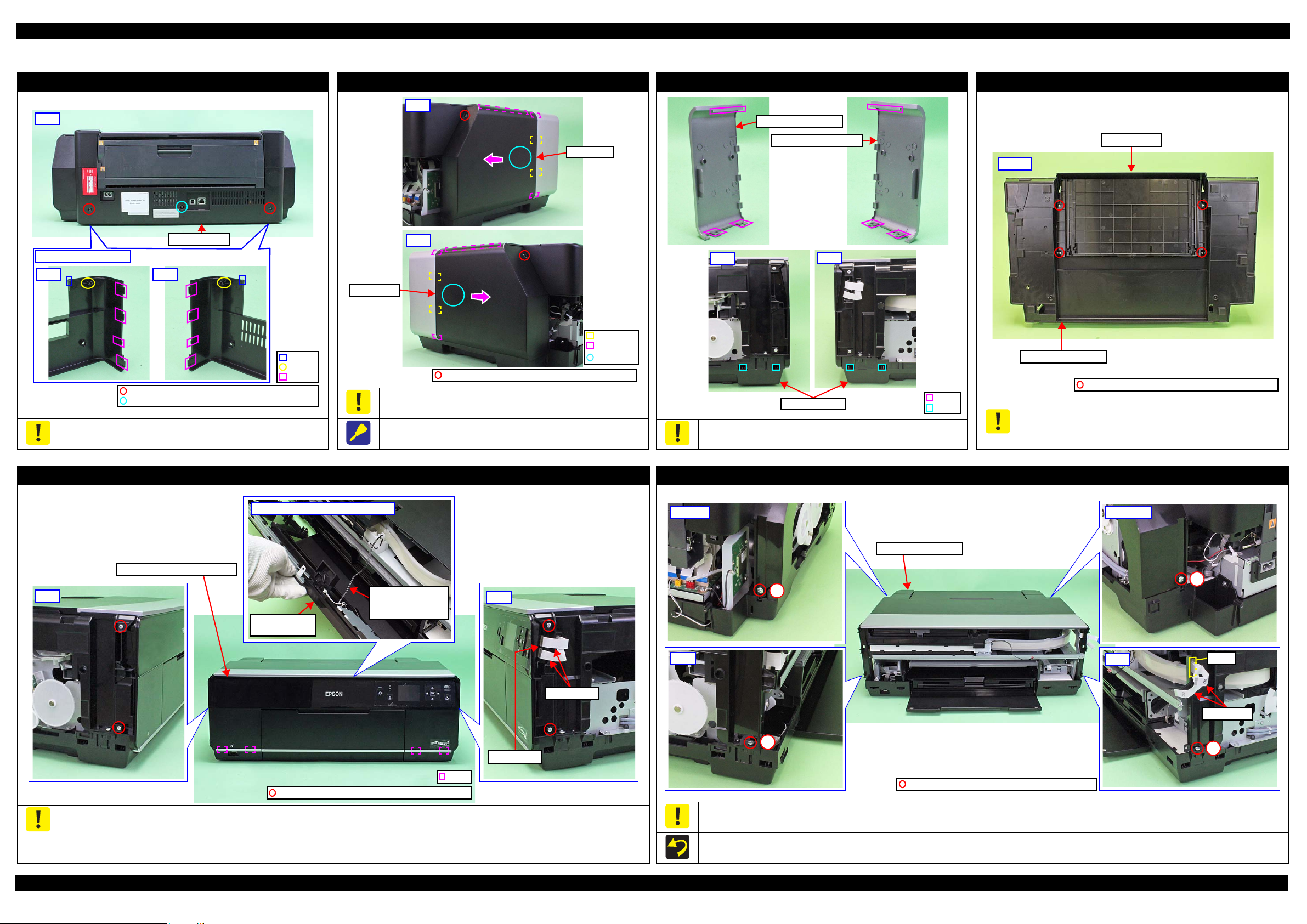

Page 19

Epson Stylus Photo R3000 Revision A

Rear Housing

Left Right

Rear

C.B.S-TITE SCREW,3X6,F/ZN-3C (6 ± 1 kgf·cm)

C.B.P-TITE SCREW,3X8,F/ZB-3C (6 ± 1 kgf·cm)

Back of Rear Housing

Dowel

Rib

Hook

Rib

Hook

Section A

Left Cover

Right

Left

Right Cover

C.B.P-TITE SCREW,3X10,F/ZB-3C (6 ± 1 kgf·cm)

Left

Right

Left Decoration Plate

Right Decoration Plate

Hook

Rib

Lower Housing

C.B.P-TITE SCREW,3X10,F/ZN-3C (6 ± 1 kgf·cm)

Bottom

Stacker Assy

Lower Housing Assy

Hook

C.B.P-TITE SCREW,3X10,F/ZN-3C (6 1 kgf·cm)

Upper Housing Support Assy

Left

I/C Holder Unit

Cover Open Sensor

Cable

Back of Upper Housing Support Assy

Upper Housing

Support Assy

Panel FFCs

Panel Board

Right

2

3

4

Panel FFCs

Right

Hole

1

Left

Upper Housing Assy

C.B.P-TITE SCREW,4X8,F/ZN-3C (8 ± 1 kgf·cm)

Rear rightRear left

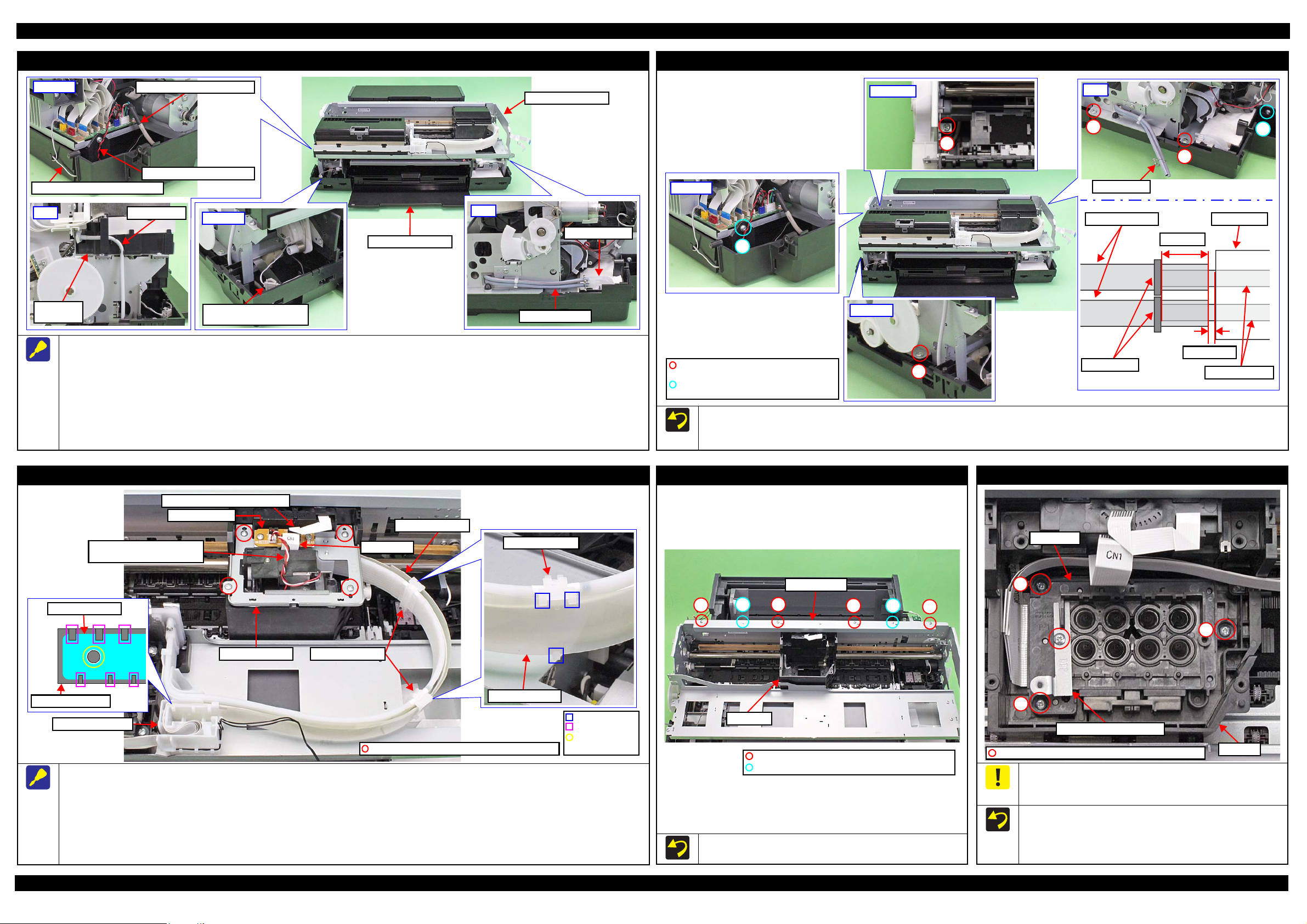

1.3 Detailed Disassembly/Reassembly Procedure for each Part/Unit

Rear Housing

Be careful not to damage the hooks (x2), dowels (x2) and ribs (x8)

that secure the Rear Housing.

Left / Right Cover

Remove the Left/Right Cover carefully not to damage the hooks

(x2 each) and ribs (x3 each) that secure the Left/Right Cover.

When removing the Left/Right Cover, slide it in the direction of the

arrow shown above while slightly pushing the section A.

Left / Right Decoration Plate

Be careful not to damage the ribs (x3 each) that secure the Left/

Right Decoration Plate and hooks (x4) of the Lower Housing.

Stacker Assy

Be careful for ink to flow out then because if tilting is too soon after

the initial ink charge or a similar situation, the ink still on the Waste

Ink Pad which is not yet absorbed flows over out of the printer.

Upper Housing Support Assy (w/Panel Unit)

Disconnect the Panel FFCs (x2) from the connectors on the Panel Board before removing the Upper Housing Support Assy.

Be careful not to damage the hooks (x4) that secure the Upper Housing Support Assy.

Be careful to remove the Upper Housing Support Assy because the I/C Holder Unit Cover Open Sensor Cable is connected to the sensor on the

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 19

back of the Upper Housing Support Assy.

Pull out the Panel FFCs(x2) from the hole of the Upper Housing Assy before removing the Upper Housing Assy.

Tighten the screws in the order indicated in the figure above.

Upper Housing Assy (w/Printer Cover Upper)

Confidential

Page 20

Epson Stylus Photo R3000 Revision A

Locked

LCD FPC

Connector Lock

Unlocked

LCD FPC

Connector Lock

Protrusion

LCD Mounting Plate

LCD

C.B.P-TITE SCREW,2X6,F/ZN-3C (3 ± 1 kgf·cm)

1

2

3

4

5

6

7

8

9

Panel Shield Plate

C.B.P-TITE SCREW,3X8,F/ZN-3C (6 ± 1 kgf·cm)

Grounding Plate

Protrusion of Panel Buttons

Housing Support

reinforcing plate

CR Scale

Torsion Spring, 0.39

CR Scale

Black triangle mark

Longer spring leg

Section B

Section A

Waste Ink Tube

/ Tube Holder

Waste Ink Pads

C.B.P-TITE SCREW,3X8,F/ZN-3C (6 ± 1 kgf·cm)

Waste Ink Tube

Installation

order

1 mm or less

Joint for Decomp Tube

Decomp Tube

Hook

Left inside of Lower Housing

Decomp Tube

I/C Holder Unit

Lower Housing

Decomp Tube

Groove

Left side

PG Cam LeftSpur Gear,14.4

Align triangle marks.

3

C.B.S-TITE SCREW,3X6,F/ZN-3C(8 1kgf·cm)

1

2

Ink Tube Holders

Ink Tube

Acetate Tape

Panel Board

LCD Mounting Plate

Panel Shield Plate

CR Scale

Before disconnecting the LCD FPC, unlock the connector lock that

secures the LCD FPC. When connecting the LCD FPC, make sure

to insert the LCD FPC into the connector to the full and secure it

with the connector lock.

Waste Ink Tube / Waste Ink Pad

When installing the LCD Mounting Plate, make sure the LCD is

located inside the protrusions (x3) of the LCD Mounting Plate, and

then secure the plate with the screws.

Decomp Pump Assy

Install the Panel Shield Plate under the protrusion of the Panel

Buttons as shown above. Make sure that the plate contacts the

Housing Support reinforcing plate, and secure it with the screw.

Tighten the screws in the order indicated in the figure above.

APG Assy

Attach the CR Scale to the spring leg with the black triangle

mark upward on the left side of the printer.

Attach the Torsion Spring, 0.39 as shown above.

Ink Tube Holder

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 20

When installing the Waste Ink Tube/Waste Ink Pads (x10),

confirm the shapes of them and install them in the order shown

above.

When installing the Waste Ink Tube, route it through the

groove of the Waste Ink Pads, and insert the end of the shorter

tube to the section A and longer one to the section B.

When connecting the Decomp Tube to the joint of the I/C

Holder Unit, make sure the gap between the end of the Decomp

Tube to the base of the joint is 1 mm or less, and then secure

the tube with the hooks (x2).

Route the Decomp Tube through the groove of the Lower

Housing and secure the tube with the hook.

When installing the APG Assy, align the marks on the Spur

Gear,14.4 and PG Cam Left to match their phases as shown

above.

Tighten the screws in the order indicated in the figure above.

When installing the Ink Tube Holders (x2), install them on the

locations where the acetate tape (x2) is attached on the Ink Tube.

Confidential

Page 21

Epson Stylus Photo R3000 Revision A

Front left

Connector of Stopper Tray

Sensor Relay Cable

Rear left

Stopper Tray Sensor Relay Cable

PictBridge Holder Assy Cable

Decomp Pump Motor Cable

Left

Decomp Tube

I/C Holder

Unit

Right

Ink System Tube

Waste Ink Tube

Lower Housing Assy

Printer Mechanism

2

3

Right

6

Tube Clamp

C.B.S-TITE(P2)SCREW,3X10,F/ZN-3C

(6 ± 1kgf·cm)

C.B.P-TITE SCREW,4X8,F/ZN-3C

(8 ± 1kgf·cm)

1 mm or less

5 2 mm

Ink System Tubes

Tube Clamps

Tube Holder

Waste Ink Tubes

5

Rear left

4

Upper left

1

Front Left

Ink Tube Holder

Ink Tube Guide

Ink Tube Guide

Cable Holder Front

Positioning hole

and Dowel

Rib

Hook

Cable Holder Front

CR Support Plate

Ink Selector Motor Cable

Ink Selector Sensor Cable

CR Encoder / PW Sensor FFC

Head FFC

Ink Tube Holders

Ink Tube Guide

C.B.P-TITE SCREW,3X8,F/ZN-3C (6 ± 1 kgf·cm)

CR Relay Board

C.B.S-TITE(P4)SCREW,3X6,F/ZN-3C(8 1kgf·cm)

C.B.S-TITE SCREW,2.5X6,F/ZN-3C(4 0.5kgf·cm)

CR Unit

CR Guide Plate

1

23

45

6

2

1

3

CR Unit

Printhead

C.B.P-TITE SCREW,2.5X8,F/ZN-3C(3.5 0.5kgf·cm)

Printhead Mounting Plate

Printer Mechanism (1)

Disconnect the following cables/tubes when removing the Printer Mechanism from the Lower Housing Assy.

Disconnect the following cables from the connector on the Main Board.

• PictBridge Holder Assy Cable (CN3)

• Stopper Tray Sensor Relay Cable (CN1)

• Decomp Pump Motor Cable (CN22)

Disconnect the Decomp Tube.

Disconnect the Ink System Tube from the Waste Ink Tube.

Disconnect the relay connector of the Stopper Tray Sensor Relay Cable.

Printer Mechanism (2)

Tighten the screws in the order indicated in the figure above.

When connecting the Ink System Tube to the Waste Ink Tube, make sure the gap between the end of the Ink System Tube and the Tube Holder is

1 mm or less, and attach the Tube Clamp 5

2 mm from the end of the Ink System Tube.

CR Support Plate

When removing the CR Support Plate, follow the procedure below.

1. Disconnect the following cables/FFCs from the connectors on the CR Relay Board.

• Ink Selector Motor Cable (CN2) • Ink Selector Sensor Cable (CN5)

• Head FFC (CN1) • CR Encoder / PW Sensor FFC (CN6)

2. Remove the screws (x4) that secure the CR Support Plate.

3. Release the hooks (x3 each) of the Ink Tube Holders (x2) and remove the Ink Tube Guide from the Ink Tube Holders (x2).

4. Release the Ink Tube Guide from the ribs (x6) and dowel of the Cable Holder Front, and remove the CR Support Plate.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 21

Tighten the screws in the order indicated in the figure above.

CR Guide Plate

Printhead / Printhead Mounting Plate

Do not use the electric screwdriver when installing the Printhead

and/or the Printhead Mounting Plate. Doing so applies extra force

when tightening the screw and affects the platen gap.

When installing the Printhead, follow the procedure below.

1. Temporarily tighten the screws (x3) and loosen them half turn.

2. Press the Printhead to the rear of the printer, and tighten the

screws (x3) in the order indicated in the figure above.

Confidential

Page 22

Epson Stylus Photo R3000 Revision A

Ink tube connection part: Do not disassemble

I/C Holder Unit side

C.B.S-TITE SCREW,3X8,F/ZN-3C

(8 ± 1 kgf·cm)

C.B.S-TITE SCREW,3X6,F/ZN-3C

(8 ± 1 kgf·cm)

C.B.SCREW,2.5X6,F/ZN-3C

(3.5 ± 0.5 kgf·cm)

C.B.P-TITE SCREW,2.5X8,F/ZN-3C

(2.5 ± 0.5 kgf·cm)

Ink Tube Holders

I/C Holder Unit

I/C Holder Unit

Ink Selector side

Hook

Head FFC

Ink Tube Holder

CR Unit

Ink Selector

Ink tube connection part: Do not disassemble

Middle Frame

Head FFC

CSIC FFC

Cable Holder Left

Cable Holder Rear

I/C Holder Unit

Cable Holder Front

I/C Holder Unit Cover

Open Sensor Cable

Middle Frame

C.B.P-TITE SCREW,3X18,F/ZN-3C (6 1kgf·cm)

Inside Ink Box

1

4

2

3

Step 7

Ink Box

Ink Box

Step 9

CR Contact Modules

Ink Box

CSIC FFC

Hook

Rib

Step 8, 9

CR Contact Module Covers

Film

Bottom part of Ink Box: Do not dissemble

Ink Tube connection

Do not loosen screws

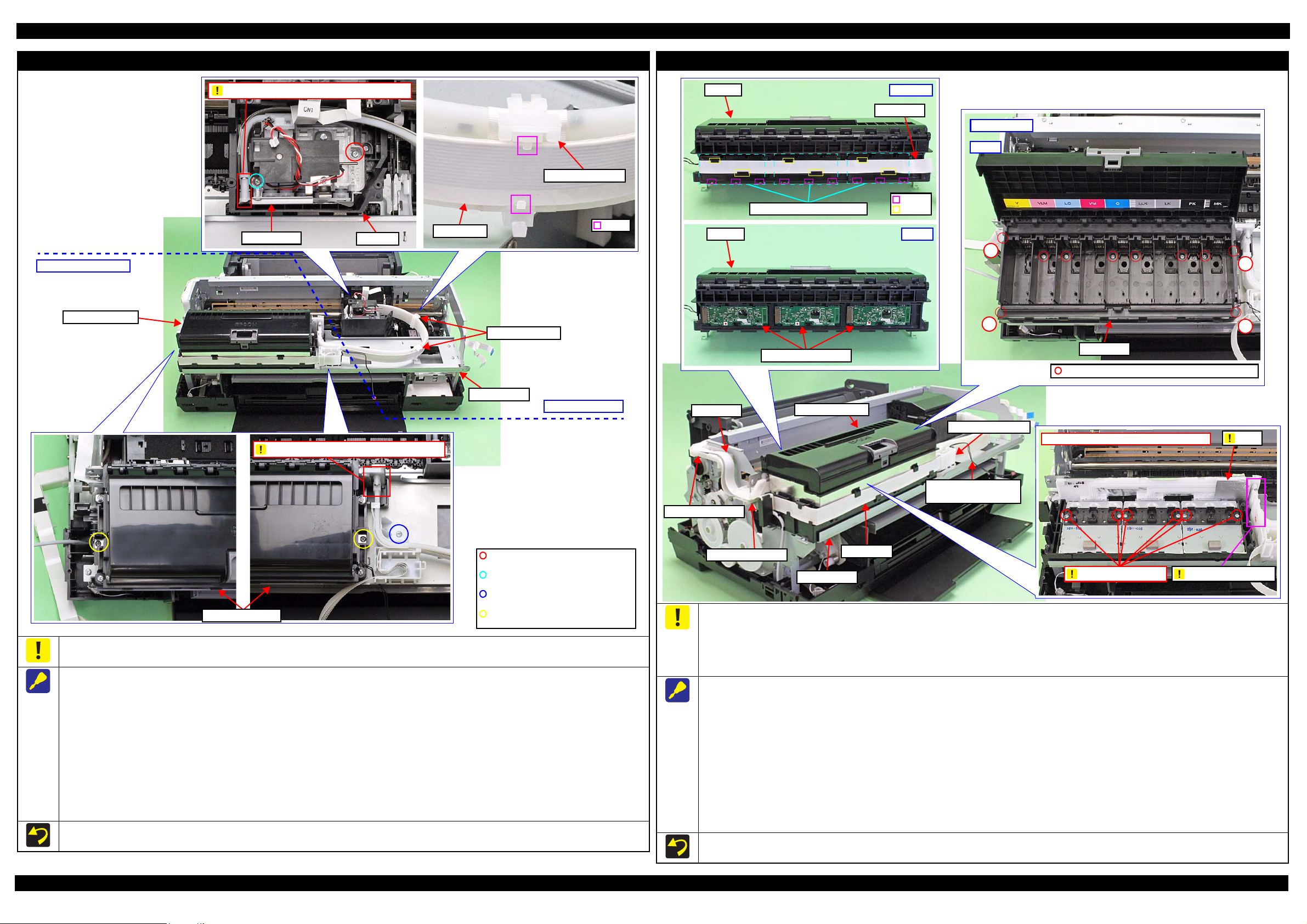

Ink Supply Unit

CR Contact Module

To prevent ink leakage, make sure not to separate the ink tubes from the I/C Holder Unit or the Ink Selector by removing the screws (x2). Loosening

the screws even just once will cause ink leakage, therefore, make sure to replace the Ink Supply Unit with a new one.

When removing the Ink Supply Unit, follow the procedure below.

1. Release the Head FFC from the hooks (x2 each) of the Ink Tube Holders (x2). Be careful not to damage the Head FFC then.

2. Remove the screws (x2) that secure the Ink Selector, and remove the Ink Selector from the CR Unit.

3. Disconnect the Decomp Tube from the I/C Holder Unit. (p 21)

4. After removing the Cable Holder Rear and Cable Holder Left from the frame, disconnect the Head FFC and CSIC FFC from the connectors

on the Main Board, and then release the FFCs from the Cable Holder Rear and Cable Holder Left. (p 30)

5. Remove the screws (x3) that secure the I/C Holder Unit, and remove the I/C Holder Unit.

When removing the Ink Selector on the way to the target part, perform only Step 1 and 2 above. Be careful not to contaminate the surroundings

with ink from the Ink Selector when taking subsequent steps.

When removing the I/C Holder Unit on the way to the target part, perform only Step 3 to 5 above. Place the removed I/C Holder Unit on the 0-

digit side of the Middle Frame when taking subsequent steps.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 22

Do not use the electric screwdriver when installing the Printhead. Doing so applies extra force when tightening the screw and affects the platen gap.

To prevent ink leakage, make sure of the following when disassembling/reassembling the unit.

Do not remove the screws (x6) on the bottom of the Ink Box. Loosening the screws even just once will cause ink leakage, therefore, make sure to

replace the Ink Supply Unit with a new one.

Be careful not to damage the film of the ink path.

Be careful not to apply extra force on the Ink Tube connection.

When removing the CR Contact Modules (x3), follow the procedure below.

1. Disconnect the Head FFC and CSIC FFC from the connectors on the Main Board, and remove the Cable Holder Rear and Cable Holder Left

from the frame. (p 30)

2. Remove the Cable Holder Rear and Cable Holder Left from the CSIC FFC. (p 30)

3. Release the Head FFC from the ribs of the I/C Holder Unit. (p 29)

4. Release the I/C Holder Unit Cover Open Sensor Cable from the rib and hook of the Cable Holder Front. (p 29)

5. Remove the screws (x3) that secure the I/C Holder Unit. (p 22)

6. Remove the screws (x4) on the corners of the Ink Box and screws (x6) inside the Ink Box that secure the Ink Box.

7. Release the CSIC FFCs (x3) from the ribs (x6) of the Ink Box, and disconnect the CSIC FFCs (x3) from the connectors on the CR Contact

Modules (x3).

8. Release the hooks (x3 each) of the CR Contact Module Covers, and remove the CR Contact Module Covers and CR Contact Modules.

Tighten the screws in the order indicated in the figure above when securing the screws (x4) on the corner of the Ink Box.

Confidential

Page 23

Epson Stylus Photo R3000 Revision A

PF Frame

Main Frame

1

2

3

4

56

C.B.S-TITE SCREW,3X4,F/ZN-3C(8 1kgf·cm)

CR Motor

Red Cable

Black Cable

Rear right

Center

Step 1

Main Frame

Upper left

Step 1

Main Frame

Right

Bush, 8

Step 1

Rear Paper Guide

PF Roller

Step 2Step 3

Engagement point

with PF Roller

Positioning dowel

Main Frame

Upper Paper Guide Assy

The fourth roller of Upper Paper

Guide Assy from the 0-digit side

has shorter rubber parts.

Front

Torsion spring

Hook

Rear

Torsion spring

Hole

The rubber parts on roller are shorter.

0-digit side

130-digit side

Release Flag Assy

Gear Section

Rear left

1

2

3

4

5

6

Middle Frame

PF Frame

CR Motor

Rear Paper Guide

Tighten the screws in the order indicated in the figure above.

When installing the CR Motor, attach it with its red cable to the left

side of the printer.

Upper Paper Guide Assy

When removing the Rear Paper Guide, follow the procedure below.

1. Push the positioning dowels (x3) in the direction of the red arrow to release them.

2. Slide the Rear Paper Guide approx. 5 mm to the left to release the right side of the Rear Paper Guide from the Bush, 8.

3. Lift the rear side of the Rear Paper Guide and release it from the PF Roller, and then remove the Rear paper Guide.

Release Flag Assy

Middle Frame

Make sure to install the Upper Paper Guide Assy whose roller has shorter rubber parts on the fourth position from 0-digit side.

When attaching the torsion spring, insert the spring leg (straight side) into the hole of the Upper Paper Guide Assy, and engage the other leg to

the hook of the frame.

When installing the Release Flag Assy, install it with its gear

section upward.

Tighten the screws in the order indicated in the figure above.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 23

Confidential

Page 24

Epson Stylus Photo R3000 Revision A

Right

PG Torsion Spring Right

Step 8

PG Cam Right

Washer,

6.9X0.5X10.4

Step 3

Left

PG Torsion Spring Left

Step 3

C.B.S-TITE(P4) SCREW,3X10,F/ZN-3C

Step 4

Parallelism

Adjust Bushing

PG Cam Left

Step 8

Washer,

6.9X0.5X10.4

Left

CR Shaft Spacer

Step 5

Dent

Step 6

CR Shaft

Left CR Shaft

Mounting Plate

Step 7

Right

Dent

Step 6

CR Shaft

Step 9

Right CR Shaft Mounting Plate

Washer,

8.2X0.5X15

Leaf Spring,

8.2X0.25X15

CR Motor

Step 1

CR Shaft

CR Unit

C.B.SCREW,3X4,F/ZN-3C (4 ± 0.5 kgf·cm)

Timing Belt

1

2

3

Grounding Wire

ASF Assy

Grounding

wire

Main Frame

C.B.S-TITE(P4)SCREW,3X8,F/ZN-3C(8 1kgf·cm)

C.B.S-TITE SCREW,3X6,F/ZN-3C(8 1kgf·cm)

Cross-section

Ink System

Ink System

Clamp B

Clamp AHole

Pump Motor Cable

Ink System Tube

Support Plate

C.B.S-TITE SCREW,3X6,F/ZN-3C (8 ± 1 kgf·cm)

Right

CR Unit

ASF Assy

Tighten the screws in the order indicated in the figure above.

Attach the terminal of the grounding wire in the direction shown in the “Cross-section” figure.

Ink System

Be careful not to let the grease of the CR Shaft adhere to the Timing Belt of the CR Unit.

When removing the CR Unit, follow the procedure below.

1. Remove the screws (x2) that secure the CR Motor, and remove the CR Motor from the frame.

2. Mark the contact point on the Parallelism Adjust Bushing with the frame. (p 48)

3. Remove the PG Torsion Spring Left / Right.

4. Loosen the screw that secure the Parallelism Adjust Bushing, and turn the Parallelism Adjust Bushing in the direction of the arrow shown above.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 24

5. Remove the CR Shaft Spacer.

6. Lift the CR Shaft, and move both ends of it to the dent of the frame.

7. Remove the Left CR Shaft Mounting Plate.

8. Remove the Washer, 6.9X0.5X10.4 (x1 each) that secure the PG Cam Left/Right, and remove the PG Cam Left/Right from the CR Shaft.

9. Slide the CR Shaft to the left to disengage it from the frame, and from the right end of the CR Shaft, remove the Right CR Shaft Mounting Plate,

Washer, 8.2X0.5X15, and Leaf Spring, 8.2X0.25X15 in order.

10. Remove the left end of the CR Shaft from the frame, and remove it together with the CR Unit.

11. Remove the CR Shaft from the CR Unit.

When installing the CR Motor, install it by referring to “ CR Motor (p23)”.

Be careful not to mistake the PG Torsion Spring Right and PG Torsion Spring Left when installing them because they look alike.

Make sure to install the Parallelism Adjust Bushing correctly to the location with the marking drawn when removing it.

When removing the Ink System, follow the procedure below.

1. Release the Ink System Tube from the clamp A and pull out from the hole of the frame.

2. Release the Pump Motor Cable from the clamp B.

3. Remove the screws (x2) that secure the Support Plate, and remove the Support Plate.

4. Remove the screws (x2) that secure the Ink System, and remove it downward while avoiding the frame.

When securing the Ink System Tubes (x2) with the clamp A, make sure to arrange the shorter one to the bottom as shown.

Confidential

Page 25

Epson Stylus Photo R3000 Revision A

Step 5

Step 6

Right: Step 2-4

E-ring, 3

Spur Gear, 14.4

Torsion Spring, 187.9

Parallel Pin, 1.5

Front Tray Shaft

The location where

frame may interfere.

Front Right Tray Guide

Left: Step 4, 5

Front Left Tray Guide

The location where frame

may interfere.

The location where Front Paper

Guide Assy may interfere.

Front Right Tray Guide

Dowel

Hook

C.B.P-TITE SCREW,3X6,F/ZN-3C (4 ± 0.5 kgf·cm)

Front Tray

Front Tray Assy

The Front Tray is raised if

the gear is in this position.

Reassemble the Front Tray Assy with the Front Tray raised.

Stopper Tray Front Assy

Compression

Spring

This side is facing

to frame.

Attach Cover spring/

Compression spring

to shaft (longer side).

Cover Spring

Shaft

(shorter

side)

Link

Lever

Align shaft (shorter side)

of Link Lever to cam

groove of Stopper Tray.

Cam groove

E-ring, 3

Washer,

4.3X0.8X8

Stopper Tray

Torsion Spring, 187.9

C.B.P-TITE SCREW,3X8,F/ZN-3C(4 ± 0.5kgf·cm)

C.B.S-TITE SCREW,3X6,F/ZN-3C(8 ± 1kgf·cm)

EJ Link Left

Front Left Tray Guide

Washer,

26X0.5X4.7

Washer,

3.1X0.5X5.4

Extension Spring, 0.70

Tray Support Assy

EJ Link Right

Washer,

26X0.5X4.7

Front Right Tray Guide

Washer,

3.1X0.5X5.4

Extension Spring, 0.70

Tray Support Assy

Gear section of Front Tray

Washer,

3.1X0.5X5.4

Parallel Pin, 1.5Spur Gear, 14.4

Tray Support Assy

Back of Front Tray Assy

Front Tray

Front Tray Assy

Stopper Tray Unit

When removing the Stopper Tray Unit, follow the procedure below.

1. Remove the Torsion Spring, 187.9.

2. Remove the screws (x2) that secure the Stopper Tray Front Assy and remove the Stopper Tray Front Assy.

3. Remove the Lever Link with Cover Spring and Compression Spring.

4. Remove the E-ring, 3 and Washer, 4.3X0.8X8, and remove the Stopper Tray.

When attaching the Cover Spring to the Link Lever, attach it as shown above.

After reassembling the Stopper Tray Unit, confirm the Torsion Spring, 187.9 is correctly attached.

Tray Support Assy / Front Tray

When disassembling/reassembling the Front Tray Assy, there are some locations where the frame and the Front Paper Guide Assy may interfere.

Therefore, be careful not to deform the frame when working.

When removing the Front Tray Assy, follow the procedure below.

1. Remove the screw that secure the Mist Board Assy.

2. Remove the Torsion Spring, 187.9 on the right side of the Front Tray Assy.

3. Remove the E-ring, 3, and remove the Spur Gear, 14.4 and Parallel Pin, 1.5.

4. Remove the screws (x3) that secure the Front Tray Assy.

5. Release the hook and dowel of the Front Left Tray Guide from the frame and slide it to the front of the printer, and then lift the left side of the

Front Tray Assy.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 25

6. Release the hook and dowels (x2) of the Front Right Tray Guide from the frame and slide it to the front of the printer while avoiding the Front Paper

Guide Assy, and then remove the Front Tray Assy by pulling out the Front Tray Shaft and Front Right Tray Guide from the hole of the frame.

Reassemble the Front Tray Assy with the Front Tray raised. After reassembly, make sure the Front Tray Assy is secured with the hooks and

dowels, and then secure it with the screws.

After reassembling the Front Tray Assy, confirm the Torsion Spring, 187.9 is correctly attached.

Before reassembling the Tray Support Assy/Front Tray, confirm the Washer,3.1X0.5X5.4 (x2) and Washer,26X0.5X4.7 (x2) are correctly

attached.

When reassembling the Front Tray Assy, install each part as shown above, and secure them with their dedicated washer, parallel pin, and extension spring.

Before reassembling the Tray Support Assy/Front Tray, confirm the Washer,3.1X0.5X5.4 (x2) and Washer,26X0.5X4.7 (x2) are correctly attached.

Confidential

Page 26

Epson Stylus Photo R3000 Revision A

Star Wheel Assy

Dowel

Rib

Dowel position

EJ Slider Right

EJ Slider Left

EJ Link Left

Front Left Tray Guide

Left

Front Right Tray Guide

EJ Link RIght

Right

Head FFC

Printhead connecting side

Double-sided tape

attachment position

Dowel

Rib

Hook

EJ Slider Left

Step 1, 2

EJ Slider Right

C.B.S-TITE SCREW,3X8,

F/ZN-3C (8 ± 1 kgf·cm)

EJ Roller Front

EJ Roller Rear

EJ Grounding Spring

C.B.S-TITE SCREW,3X8,F/ZN-3C (5 ± 1 kgf·cm)

Right

Spring foot A

Spring foot B

Step 3, 4, 7

EJ Roller Rear

Washer

EJ Roller Front

Washer,

6.9X0.5X10.4

Left

Step 5

Bush, 8

Step 6

Front Paper Guide Assy

Step 8

Step 7

Front Paper Guide Assy

Bottom

Leg of Porous Pad Front Paper Guide

Leg of EJ Ink Guide Left/Right

OK

Rib of Porous Pad Front

Paper Guide is hidden.

NG

Rib of Porous Pad Front

Paper Guide is sticking out.

Front Paper Guide

1: EJ Ink Guide Right

3: EJ Ink Guide Left

4: Porous Pad Left Paper Guide

2: Porous Pad Front Paper Guide

Porous Pad Front Paper Guide

Rib

Leg

Star Wheel Assy

Head FFC

Front Paper Guide Assy

Attach the dowels on the left/right of the Star Wheel Assy from

the left one first into their attachment positions shown above.

Insert the ribs on the left/right of the Star Wheel Assy to the

grooves on the EJ Frame Slider Left/Right.

When installing the EJ Ink Guide Left/Right, Porous Pad Front Paper Guide and Porous Pad Left Paper Guide, install them in the order shown

above.

After installing the Porous Pad Front Paper Guide, make sure the legs (x10) of the Porous Pad Front Paper Guide and legs (x3) of the EJ Ink

Guide Left/Right are fully pulled out and they drop down straight from the hole of the Front Paper Guide Assy.

Make sure that all ribs (x47) of the Porous Pad Front Paper Guide are fitted into the grooves of the Front Paper Guide, and no pad lifts off from

the platen.

To prevent degradation of print quality due to interference of the

Head FFC (x2) with the CR Unit movement, the Head FFC (x2) are

folded with the jig and bundled together with double-sided tape.

When handling the Head FFC, take care not to make an extra fold

on it other than original ones. Furthermore, do not peel the FFC

apart or change the attachment locations.

Porous Pad Front Paper Guide

When removing the Front Paper Guide Assy, follow the procedure below.

1. Release the hooks (x3) and dowels (x2) of the EJ Slider Left, and remove the EJ Slider Left.

2. Remove the screw that secure the EJ Slider Right and release the dowels (x2) and rib, and then remove the EJ Slider Right.

3. Remove the EJ Grounding Spring on the right side of the Front Paper Guide Assy.

4. Remove the screw that secure the Front Paper Guide Assy.

5. Remove the Washer,6.9X0.5X10.4 from the EJ Roller Front.

6. Release the dowel of the Bush, 8 and rotate the Front Paper Guide Assy upward and align it with the cutout of the frame.

7. Slide the Front Paper Guide Assy to the left, and release the dowels (x2) on the right side of it from the frame.

8. Lift the front side of the Front Paper Guide Assy and detach the EJ Roller Front from the cutout of the frame, and then remove the Front Paper

Guide Assy while avoiding the parts around it.

When installing the EJ Grounding Spring, follow the procedure below.

1. Engage the Spring Foot A to the groove of the EJ Roller Front.

2. Engage the bent section of the EJ Grounding Spring on the inner side of the washer outside the EJ Roller Rear.

3. Engage the Spring Foot B to the hook of the frame.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 26

Confidential

Page 27

Epson Stylus Photo R3000 Revision A

Bush, 8

Left

Step 4

PF Roller

Compression Spring, 4

E-ring, 7

Left

Step 3

PF Grounding Spring

PF Roller

Step 1

Groove

Cutout

Bush, 8

Right

Step 2

PF Roller

Step 5

Mist Board AssyMist Board Cable Holder

Upper surface of

Mist Board

Rib and positioning hole

Insert shield plate of Mist Board Assy

under Mist Board Cable Holder.

Mist Board Cable Holder

Left

Board holder

Shield Plate Lower

Mist Board

C.B.S-TITE SCREW,3X6,F/ZN-3C (6 ± 1 kgf·cm)

Mist Board Assy

Right

Inside Mist Board Assy

PF Scale

PF Encoder Assy

PF Encoder

PF Scale

PF Roller

Mist Board Assy

When installing the Mist Board Assy, insert the shield plate of the

Mist Board Assy under the Mist Board Cable Holder, and align rib

of the Mist Board Assy with the positioning hole of the frame.

Mist Board

When attaching the Mist Board to the Shield Plate Lower, follow

the procedure below.

1. Attach the board holders (x3) to the Mist Board on the position

shown above.

2. Align the board holders (x3) on the corners of the Shield Plate

Lower, and attach the Mist Board to the Shield Plate Lower.

When removing the PF Roller, follow the procedure below.

1. Remove the PF Grounding Spring.

2. Release the dowel of the Bush, 8 on the right side of the PF Roller, and rotate it upward and align it with the cutout of the frame.

3. Remove the E-ring, 7 and slide the Compression Spring, 4 to the right.

4. Release the dowel of the Bush, 8 on the left side of the PF Roller, and rotate it upward and align it with the cutout of the frame.

5. Pull out the PF Roller to the left side from the hole of the frame and remove it from the frame.

When attaching the PF Grounding Spring, engage the longer bent leg to the groove of the PF Roller, and engage the other leg to the cutout of the

frame to secure the spring.

PF Scale / PF Encoder Assy

After installing the PF Encoder Assy, confirm the PF Encoder does not touch the PF Scale.

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 27

Confidential

Page 28

Epson Stylus Photo R3000 Revision A

Screwdriver

150 mm or more

C.B.S-TITE SCREW,3X6,F/ZN-3C (8 ± 1 kgf·cm)

Shield Plate Assy Upper Main Board

1

Rear

2

3

Front

Lower Frame

Gap

A

Paper Guide (under ASF Assy)

Shield Plate Assy Upper Main Board

Shield Plate Assy Upper Main Board

When tightening the screw that secures the Shield Plate Assy

Upper Main Board, use a screwdriver with the shaft length of

150 mm or more and tighten the screw straight. Otherwise, you

have to screw it obliquely and can not tighten it correctly

because the grip of the driver hits the lower frame.

Tighten the screws in the order indicated in the figure above.

Board Assy

After installing the Board Assy, confirm the gap shown above is

uniform. If not, the Shield Plate Assy Upper Main Board pushes up

the Paper Guide (under ASF Assy). In such a case, loosen the

screw (A) and adjust the Shield Plate Assy Upper Main Board

position until the gap become even, then tighten the screw (A).

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 28

Confidential

Page 29

Epson Stylus Photo R3000 Revision A

Panel Board

Panel FFCs

Upper Housing

Hole

Cover Open Sensor Cable

Upper Housing Support Assy

Hook

I/C Holder Unit Cover Open Sensor Cable:

make one turn around hook.

I/C Holder

Unit

Front

Cable Holder

Front

Rib

Hook

Head FFC

Upper

Cable Holder Front

I/C Holder Unit Head FFC

Rib

Cable Holder Front

I/C Holder Unit Cover

Open Sensor Cable

Decomp Pump Assy

Rib

Hook

Decomp Pump Motor Cable

Stopper Tray

Sensor Relay Cable

PictBridge Holder Assy CableDecomp Pump Motor Cable

Make two turns

around hook.

Groove

Rib

CR Encoder / PW Sensor FFC

Head FFC

Route Ink Selector Motor Cable

and Ink Selector Sensor Cable

through cutout of Ink Selector.

CR Relay Board

Ink Selector

CR Support Plate

Cable Holder

Acetate Tape B: 18 x 30 mm

Right

Rib

Acetate Tape A

Double-sided tape Reference line

PE Detector

Assy

PE Sensor Cable

Clamp

Release Holder AssyPanel FFC

Cross-section

2

1

3

4

Pump Motor Cable

Roll Paper Guide

Open Sensor Cable

ASF Motor Relay Cable

CR Motor Cable1

2

3

4

5

Cable Holder5

6

6

Shield Plate Assy Upper

Main Board

Cable Holder

Groove of Shield Plate

Assy Upper Main Board

1.4 Routing FFCs/cables

Upper Housing Support Assy

Route the Panel FFCs though the hole of the Upper Housing, and connect it to

the connector on the Panel Board.

Cover Open Sensor

When routing the Cover Open Sensor Cable, follow the procedure below.

1. Make one turn around the hook of the Upper Housing Support Assy

without slack between the Cover Open Sensor and the hook.

2. Connect the cable to the connector on the Panel Board.

3. Roll up the slack cables between the connector on the Panel Board and the

hook as shown above.

Head FFC

Route the Head FFC through the I/C Holder Unit and Cable Holder Front as shown above.

When routing the I/C Holder Unit Cover Open Sensor Cable, make one turn around the hook of the I/C Holder Unit and route through the ribs (x4) of the

Cable Holder Front, and then make one turn around the hook of the Cable Holder Front.

PictBridge Holder Assy / Decomp Pump Assy

When routing the Decomp Pump Motor Cable through the Decomp Pump

Assy, route the cable through the following ribs and hooks.

• Ribs (x3) and hook on the upper side of the Decomp Pump Assy

• Hooks (x4) and ribs (x2) on the side of the Decomp Pump Assy

Route the following cables through the ribs and grooves of the Lower Housing.

• Decomp Pump Motor Cable

• PictBridge Holder Assy Cable

• Stopper Tray Sensor Relay Cable

Disassembly/Reassembly Routing FFCs/cables 29

Route the following cables/FFCs as shown above and connect them to the

connectors on the CR Relay Board.

Ink Selector Motor Cable (CN2)

Ink Selector Sensor Cable (CN5)

Head FFC (CN1)

CR Encoder / PW Sensor FFC (CN6)

CR Support Plate / Ink Selector

Upper side of the Board Assy

Route the Panel FFC through the ribs (x2) along with the reference line as shown above, and secure it with double-sided tape and two pieces of acetate tape A.

Route the PE Sensor Cable through the ribs (x6) of the Release Holder Assy, and secure it with the clamp.

Attach acetate tape B (18 x 30 mm) on the position shown above.

Route the cables through the groove on the Shield Plate Assy Upper Main Board arranging them in the order shown in “cross-section” above, and secure

them with the Cable Holders (x2).

Confidential

Page 30

Epson Stylus Photo R3000 Revision A

CN # Name CN # Name CN # Name

CN1

Stopper Tray

Open Sensor Relay Cable

CN8 Head FFC CN20

Roll Paper Guide

Open Sensor Cable

CN9 Head FFC CN22 Decomp Motor Cable

CN2 CSIC FFC CN10 Head FFC CN115 CR Motor Cable

CN3 PictBridge Holder Cable CN11 Head FFC CN116 PF Motor Cable

CN4 Panel FFC CN12 Head FFC CN117 Pump Motor Cable

CN5 Panel FFC CN13 Mist Board FFC CN118 APG Motor Cable

CN6 ASF Relay Board FFC CN15 CSIC FFC CN119 ASF Motor Cable

CN7 Wireless LAN Module Cable CN19 CSIC FFC

Route Panel FFC

over ASF Assy.

Reference line

Double-sided tape

PF Encoder FFC

Panel FFC

Around ASF Relay Board

Route PE Sensor Cable

under rib of ASF Assy.

ASF Relay Board

APG HP Sensor Cable

APG Position

Sensor Cable

Double-sided tape

PF Encoder FFC

Secure PF Motor

Cable with clamp.

ASF Motor

Cable

Pump Motor

Cable

CR Motor

Cable

Roll Paper Guide

Open Sensor Cable

APG Motor Cable

PF Motor Cable