Page 1

SERVICE

MANUAL

EPSON

EXCEED

YOUR VISION

Confidential

SEMF14-007

Page 2

Notice:

easyfixs.blogspot.com

• All rights reserved. No part

photocopying, recording,

The

•

• All effort have been made

•

EPSON is a registered trademark

General Notice:

Copyright©

contents

informed

The

above not withstanding SEIKO EPSO N CORPORATION can assume no responsibility for any errors

of

this manual are subject to change without notice.

of

them.

2014

or

to

Other product names used herein are for identification purpose only and may be trademarks

respective owners.

SEIKO EPSON

PRINTER

of

this manual may be reproduced, stored in a retrieval system,

otherwise, without the prior written permission

ensure the accuracy

of

SEIKO EPSON CORPORATIO

EPSON disclaims any and all rights

CORPORATION.

CS

QUALITY

of

the contents

ASSURANCE

of

this manual. However, should any errors be detected, SEIKO EPSON wou

N.

DEPARTME

of SEI

KO

in

those marks.

NT

or

transmitted

EPSON CORPORATION.

in

any form

in

this manual

or

or

by any means, electronic, mechanical,

or

the consequences thereof.

registered trademarks

of

ld

greatly appreciate being

their

Confidential

Page 3

PRECAUTIONS

easyfixs.blogspot.com

Precautionary notations throughout the text are categorized relative to I) Personal injury and 2) damage to equipment.

D

ANGE

R Signals a precaution which,

DANGER Heading

s.

if

ignored, could result in serious

or

fatal personal injury. Great caution should be exercised in performing procedures preceded by

WARNING

The precautionary measures itemized below should

Signals a precaution which,

if

ignored, could result

always be observed when performing repa ir/maintenance procedures.

in

damage to equipment.

DANGER

1.

ALWAYS DISCONNECT

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON

TECHNICIANS IN THEIR LINE

3.

WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL,

SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC

COMPONENTS.

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES

THE

PRODUCT FROM

OF

WORK.

THE POWER

THE UNIT BY PERSONS UNFAM

SOURCE

AND

DO

PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

ILI

AR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRON ICS

NOT CONNECT

THE

UNIT

TO A PO

TO

A VOID INJURIER FROM MET AL PARTS WITH SHARP EDGES.

WER

SOURCE UNTIL INSTRUCTED

WARNING

l.

REPAIRS ON EPSON PRODUCT SHOULD

2. MAKE CERTAIN

EPSON PRODUCT HAS A PRIMARY AC

3. ALWAYS VERIFY THAT

CIRCUIT

4. IN ORDER

STRAPS,

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH

OT

6. WHEN

PRODUCTS CONTAINING FLAMMABLE GAS

BOARDS AND/OR INDIVIDUAL CHIPS.

WHEN ACCESSING INTERNAL COMPONENTS.

HER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VO

USING COMPRESSED AIR PRODUCTS;

TO

THAT

PROT

THE

SOURCE VOLT AGES

THE

EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING

ECT

SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

BE

PERFORMED ONLY BY

IS

THE SAME AS

RA

TING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT

THOSE

SUCH

AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF

IS

PROHIBITED.

AN

EPSON CERTIFlED REPAIR TECHNICIAN.

THE

RATED VOLTAGE, LISTED

COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE ICs

ID

ANY APPLICABLE EPSON WARRANTY.

ON

THE

SER

IAL NUMBER/RA TING PLATE.

IT

TO

THE

POWER SOURCE.

OR

REPLACING PRINTED

SUCH

IF

TO

THE

DO

OR

Confidential

Page 4

About This Manual

easyfixs.blogspot.com

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures

be

herein are intended for the experienced repair technicians, and attention should

Manual Configuration

This manual consists

CHAPTER I.PRODUCT DESCRIPTIONS

CHAPTER 2.0PERATING PRINCIPLES

CHAPTER 3.TROUBLESHOOTING

CHAPTER 4.DISASSEMBL

CHAPTER 5.ADJUSTMENT

CHAPTER 6.MAINTENANCE

CHAPTER 7 APPENDIX

of

six chapters and Appendix.

Provides a general overview and specifi

Describes the theo

product.

Describes the step-by-step procedures for the troubleshooting.

Describes

he

t

Provides Epso n-approved methods for adjustment.

Provides preve

approved lubricants and adhesives required for servicin g the product.

Provides

the

product.

the

ry

of elec

trical and mechanical operations

YI

ASSEMBLY

step-by-step procedures for disassembling and assembling

ntive maintenance procedmes and

additional info1mation for r

cat

ions

of

the product.

the lists

epa

ir and maintenance.

ofEpson-

given to the precautions on the preceding page.

Symbols Used in this Manual

Various symbols are used throughout this manual eith

ec

ific topic or to warn

Indicat

es

that is necessary to keep the product

of the

information on a sp

or

procedure

NOTE,

an action.

CAUTION, or

I

II

CAUTION

I

•

Indicates an operating

if not

that,

equipment.

May indicate an

condition that is nece

provide additional information that is related

co

mment on the results achieved through a prev

Be

WARNING messages.

an operating

str

of

the printe

aware

ictly observed, could result

ope

r.

The instructions and procedures included

of possible danger prese

of all

symbols when they are used, and always read

or

maintenan

or

maintenance procedure, practice,

rating

or

ssa

ry

to accomplish a ta sk efficiently. It may also

ce

's

maintenance procedure, practice

er

to provide additional

nt during a

proce

dur

e,

practice

quality.

in

damage to,

to

or

a spec.

i:fic

ious action.

or condition

or

condition

destruction of,

or

subject,

or

•

Indicates

that,

a

Indicat

standard after disassembly and before re-assembly,

ity

Dl

an

operating

if

not strictly observed, could result

es

that a particular task must be carried out according to a

of

the components in question may be adversely affected.

or

maintenan

ce

procedure, practice

in

injury or loss

otherwise

or

condition

of life.

cer

tain

the qual-

Confidential

Page 5

Revision Status

easyfixs.blogspot.com

~;;1w11

ASq:tembe•

Qfui@Mi

12, 2-014FITTtRe1eas

Confidential

Page 6

L850

easyfixs.blogspot.com

senes

·

,

/1810

set

1es

· ·

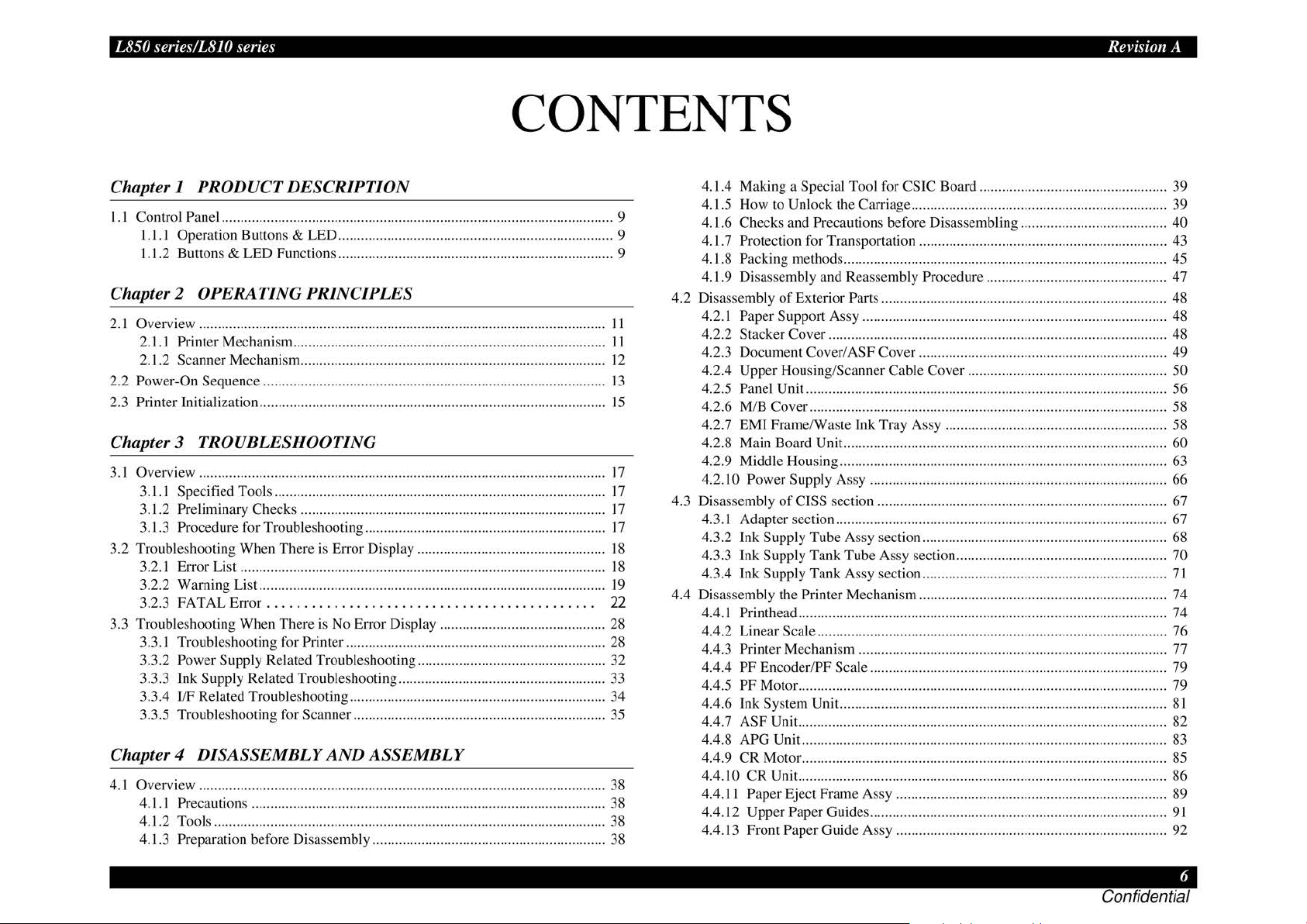

CONTENTS

Revision

A

Chapter I PRODUCT DESCRIPTION

I. I Control Panel ........................................................................................................ 9

1.1.l Operation Buttons & LED .................................. ....................................... 9

ED

1.1.2 Buttons & L

Functions ......................................................................... 9

Chapter 2 OPERA TING PRINCIPLES

2

.1

Overvi

ew

............................................................................................................

2.1.l

Printer Mechanism ...................................................................................

2.1.2 Scanner Mechanism

Power

-On

2.2

2.3

Printer Initialization ............................................................................................ 15

Sequence ...........................................................................................

................................................................................. 12

11

11

13

Chapter 3 TROUBLESHOOTING

3.1 Overview ............................................................................................................ 17

To

3.1.1 Specified

3.1.2 Preliminary Checks .............................................................................

3.1.3 Procedure for Troubleshooting ................................................................ 17

3.2

Troubleshootin g When

3.2.1 Error List ................................................................................................. 18

3.2.2 Warning List ............................................................................................ 19

FATA

3.2.3

3.3 Troubleshooting When

3.3.1 Troubleshooting for Printer .....................................................................

3.3.2 Power Supply R

3.3.3 Ink Supply Related Troubleshooting ....................................................... 33

3.3.4 I/F Related Troubleshooting ......................

3.3.5 Troubleshooting for Scann

Chapter 4

4.1 Overview ............................................................................................................ 38

4.1.l

4.1.2 Tools ........................................................................................................

4.1.3 Preparation b

DISASSEMBLY

Pr

ecautions ..............................................................................................

ols ........................................................................................

There

is Error Display .................................................. 18

L Error............................................

Ther

e is No Err

ela

ted Troubleshooting ..................................................

AND

efo

re Di sassembly .............................................................. 38

or

Display ............................................

..

............................................ 34

er

................................................................... 35

ASSEMBLY

....

17

17

22

28

28

32

38

38

4.1.4 Making a Special Tool for CSIC

4.1.5 How to

4.1.6 Checks and

4.1.7 Protection for Transportation .................................................................. 43

Packing methods ...................................................................................... 45

4.1.8

4.1.9

Di

4.2 Disassembly

4.2.1 Paper Support Assy .................................................................................

4.2.2 Stacker Cover ............................................................................. .............

4.2.3 Document Cover/A

4.2.4 Upper Housing/Scanner Cable Cover

4.2.5 Panel Unit ......................................................................................... ....... 56

4.2.6 M/B

EMI

4.2.7

4.2.8 Main Board Unit ............................................................................ ..........

4.2.9 Middle Housing ....................................................................................... 63

4.2.

IO

Disassembly

4.3

4.3.1 Adapter section ........................................................................................ 67

4.3.2 Ink Supply

4.3.3 Ink Supply Tank

4.3.4

Ink

4.4

Disassembly

4.4.1 Printhead ..................................................................................................

4.4.2 Linear S

4.4.3 Printer Mechanism .................................................................................. 77

PF

4.4.4

PF

4.4.5

4.4.6

Ink

4.4.7

ASF

APG

4.4.8

4.4.9

CR

4.4.10

4.4.1 I Paper Eject Frame Assy ........................................................................ 89

4.4.12

4.4.13 Front

Unlock the Carriage .................................................................... 39

Pre

caution s before Disassembling .......................................

sassembly and Reassembly Procedure ................................................

of

Exterior Parts ............................................................................

SF Cover

Cover

............................................................................................... 58

Frame/Waste Ink Tray Assy ........................................................... 58

Pow

er

Supply

of

Supply

the

Encoder/PF Scale ............................................................................... 79

Motor ...................................................................................... ............

System Unit.. .....................................................................................

Unit. ................................................................................................. 82

Unit ................................................................................................. 83

Motor

CR

Unit. ................................................................................................. 86

Upp

er

Pap

Paper Guide Assy ........................................................................ 92

Assy

............................................................................... 66

CISS section ............................................................................. 67

Tube

Assy section ................................................................. 68

Tube

Assy section ........................................................ 70

Tank

Assy section ................................................................. 71

Printer Mechanism .................................................................. 74

cale

.............................................................................................

................................................................................................. 85

er

Guides ............................................................................... 91

Boa

rd .................................................. 39

......................................... .........................

.....................................................

40

47

48

48

48

49

50

60

74

76

79

81

Page 7

L850 series/LS

easyfixs.blogspot.com

JO

series Revision A

4.4.14 Waste Ink Pad s ......................................................................................

Chapter 5

5.1 Adjustment Items and Overview ........................................................................

5.1.1 Servicing Adjustment Item List... ............................................................

5.1.2 Required Adjustments ............................................................................. 99

5.2 Adjustment by the

5.2.1 Touch

5.2.2 Touch Panel Operation Check ...........................................

5.3 How to judge print samples by using the adjustment program ........................ 104

5.3.1

5.3.2 Head angular adjustment

5.3.3 Bi-D Adjustment ...................................................................................

5.3.4

5.3.5

PG Adjustment ................................................................................................. 108

5.4

5.5 Banding Reduction System (BRS)

Correction . . .........

5.5.1 Overview ............................................................................................... 1

5.5.2 Adjustment Procedure ........................................................................... 112

5.6 Scanner Original Adjustment ...........................................................................

Chapter 6

ADJUSTMENT

Panel Unit exchange .......................................................... lOl

Panel Calibration ........................................................................

...

.................

Top

Margin Adjustment ........................................................................ 104

...

.................................

PW Adjustment/First D

PF Adjustment ....................................................................................... 107

..

. . . . . . ................ .................. ................ ................. .........

ot

Position Adjustment .................................... 106

Adjustment/Paper Feed Amount Profile (PFP)

...

................................ 104

..

. . . .

..

MAINTENANCE

94

96

96

101

101

10

......... I I 0

10

I

15

5

6.1 Overview .......................................................................................................... 1

6.1.1 Maintenance Error .................................................................. ............... 119

6.1.2 Cleaning ...............................

6.1.3 Lubrication ............................................................................................

Chapter 7

7.1 Exploded Diagram I Parts List ......................................................................

APPENDIX

...

............................................................... I I 9

...

19

I

20

127

Page 8

easyfixs.blogspot.com

PRODUCT DESCRIPTION

Confidential

Page 9

L850 series/L8JO series Rei·ision A

easyfixs.blogspot.com

1.1 Control Panel

1.1.1 Operation Buttons & LED

The

following

Button

LED* Power

tables

explain

Button/LED

Power Turns the power ON/OFF.

Home Goes

Crop/ Changes a display method.

Di

splay Options

Help Displays the help.

Menu Detailed settings.

Cross Keys

(up/down/left/

right)

OK Selects.

Back

Stop

Start

+

-

the

Ta

ble 1-

functions

1.

of

Operation Buttons & LED

I

10

home screen.

Crops photos.

Moves

the

cursor.

Cancels or goes back.

Cancels a job.

Resets 1he settings.

copy/print/scan.

Starts

Solves errors.

Increase or decrease the number

Turns on when the power is on.

Flashes while processing.

the

buttons

Function

and

of

LED.

prints.

1.1.2 Buttons & LED Functions

Detailed

Note : ---:No change

information

Printer

Idle mode Effective keys blink

Power-off OFF

Warning Effective keys blink

Fatal error Effective keys blink

Printing/Scanning Effective keys blink

Preparing FW update Effective keys blink

li

nk

B

Blink

se

of

I:

2:

Network

Displaying the screen-saver

Power save mode

Response

Airprint Identify-Printer

on

the

LED

functions

Ta

ble 1-2. Buttons & LED Functions

Status

tting Effective keys blink

I

are

Buttons

OFF

OFF

---

Repeats turning On and

Repeats turning On and

Off

every 1.25 seco nds.

Off

every 0.5 seconds.

listed

below.

P1mcr

I

LED

ON

OFF

---

Blink 2

li

nk I

B

Blink I

--

---

---

Blink2

Note * · See

PRODUCT

Tab

le 1-2 for more information on the LED.

DESCRIPTION

Figure 1-

1.

Name of Buttons & LED

Stop/Clear

butt

on

Control Panel 9

Confidential

Page 10

easyfixs.blogspot.com

OPERATING PRINCIPLES

Confidential

Page 11

L850 series/L8JO series Revision A

easyfixs.blogspot.com

2.1 Overview

Description in Table 2-2. Scanner Mechanism (

to LSI 0 series.

•

Thjs section describes the operating principles

L8

IO seri

es.

p.12)

of

the printer mechanism of L8

is n

ot

applied

50

serie

s/

I 0 C

11

CD

I 2 Ca

D-R

Gui

de

Sensor

-R Tray Sensor

se Open Sensor

ble 2-1. Motor

s and Sensors (

Functio

n:

De1ec1i

on method: Mechanical con1act detector

n:

Func1io

ec1ion method: Mec

De1

Function:

Det

ection method: Mechanical contact detector

Printer

CD-R Guide up/down detection

C

D-R

Tray pr

hm1i

cal contact de1ector

Scanner U

nit

ese

open/cl

Mechanism)

nce de1ec1i

ose

detection

on

Ta

2.1.1 Printer Mechanism

L850 series/LS I 0 seri

Tab

Prinihead

2

CR

Motor

3

PFM

otor

4 PE

Senso

r

5 CR

Co

ntact ModLlle

6 CR Encoder

7 PF En

8 PW Sensor

9 APG Sensor

co

der

es

are equipped with the following printhead, motors and sensors.

le 2-1. Motors

and

Sensors (

F3

-MA

CH Turbo 2 h

Type:

Voltage:

ra

cteristics: Annalllre res

Cha

Dri

ve system:

Typ

e:

Voltage:

Cha

ra

cteristi

Dri

ve

system: PWM

Func1io

n:

Detection metho

lnk canrid

Typ

R

Typ

R

Function • Paper le

De1ec1ion method: Reflecti

Function:

Det

eso

eso

e:

lutio

e:

lution:

ec

ge detecti

n:

tion metho

ead

(6

DC motor

42V D

C±

Induc

tan

PWM

co

DC mot

42V D

cs:

C±

Armature r

Inductance : 17.2 mH (I kHz)

sys

Detecti

on

posit

ioning co

d:

Transmissive-1

on (CSIC)

Transmissive-type photo-

180 pulse/inch

Tr

ansmiss

180 pul

se/inch

(before and during priming)

• P

ape

r top ed

• Pap

er

• CD-R top, bottom, right a

(before printing)

APG positi

d:

Transm

iss

Printer

co

ce : 17.5 mH ± 25%

or

bottom ed

ve pho1

Mechanis m)

lors x 90 nozzles)

5% (voltage applied to the driver)

istance : 22.7 n ± 10%

nstant-current chopping

5% (voltage applied to the driver)

esis

ta

nce : 2 1.2 n ± I 0%

tem

of the paper tail end, Pape

ntr

ol

ype pho10

ive-type photo-interrupter

fl and right edge

ge

(before priming)

ge

(during printing)

osenso

r

on detection

ive-type photo-

-in1

int

int

sys

errupter

errupter

nd

lefl ed

errupter

tem

r leading ed

ges

ge

Figure

2-1

. Motors

and

Sensors (Print

er

Mechanis

m)

OPER

1\ TING

PR/NCI

PLES

(h•eniew I I

Confidential

Page 12

L850 series/L8JO series Revision A

easyfixs.blogspot.com

2.1.2 Scanner Mechanism

L850 series is eq uipped with the folJowing CIS Unit, motors and sensors.

Table 2-2.

R

CIS Unit

2 CR Motor Voltage: 42V DC ±

senso

3 Encoder

r

eso

16

bit per pixel (input), 8 bit p

Type: DC mot

Drive

Type: Lin

eso

R

Scanner Mec hanism

lution: 10,200 pi

sys

tem: VrefpWM input

lution 180

ear encode

pulse

xel

er

pixel (o

utpu

or

5%

(voltage appli

constant-current chopping

r

/inch

t)

ed

to

the driver)

OPER

1\ TING

Figure 2-2. Motors a

PR/NCI

PLES

nd

Sensors (Scanner Unit)

I

Oi•eniew I 2

Confidential

Page 13

L850 series/L8JO series Revision A

easyfixs.blogspot.com

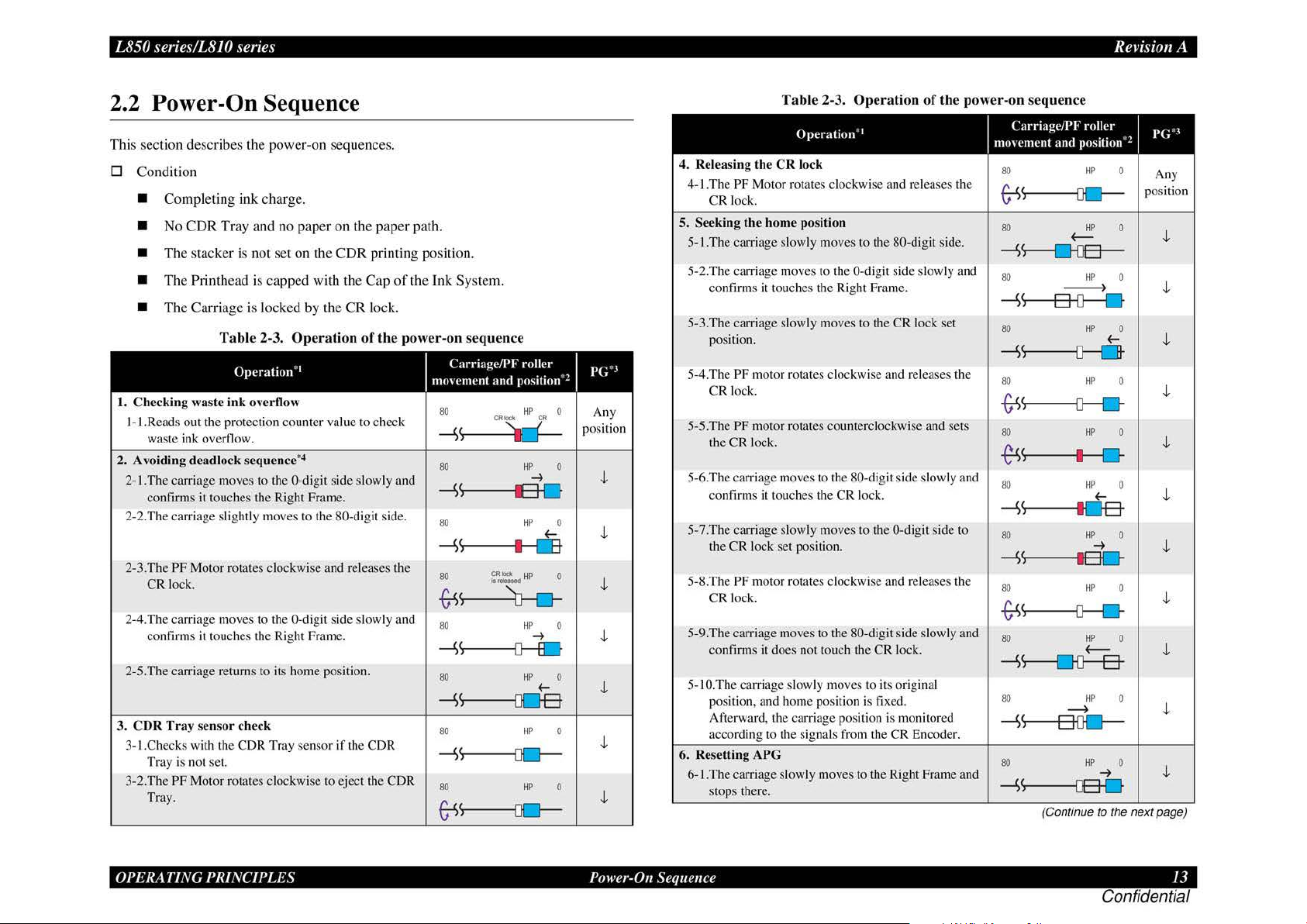

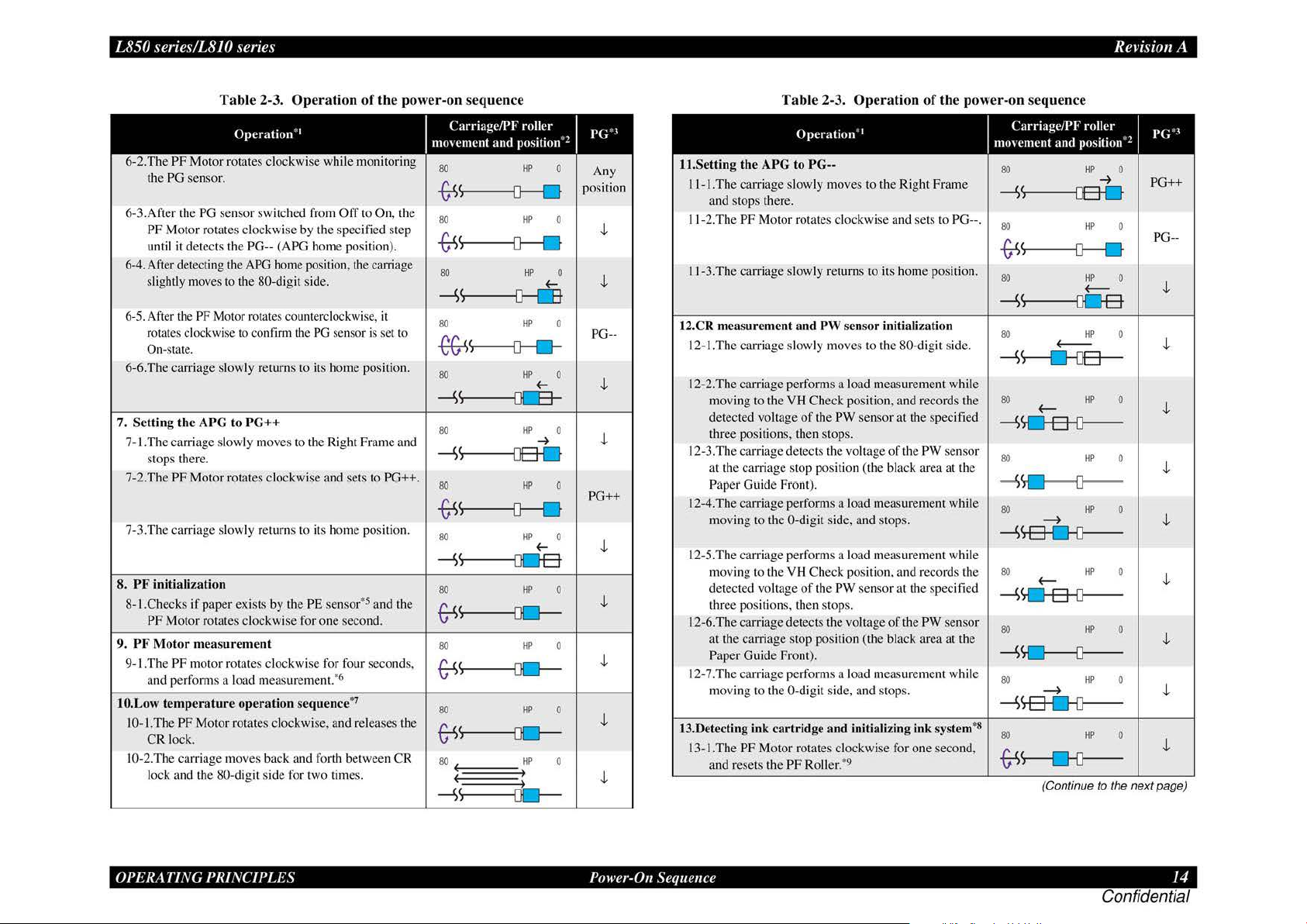

2.2 Power-On Sequence

This

section desc

D

Cond

•

Complet

•

No CDR

•

The stac

•

The Printhead is

•

The

I.

Checking waste

I- I .Reads out the protection count

waste ink overflow.

2. Avoiding

2-1.The carriage moves to the 0-digit side slowly and

confirms it touches the Right Frame.

2-2.The carriage slig

2-3.The PF Motor rotates clockwi

CR lock.

2-4.The carriage moves to the 0-digit side slowly and

confirms it touches the Right Frame.

2-5.The carriage returns to its home position.

3.

CDR

Tray sens

3-1.Checks with the C

Tray is not set.

3-2.The PF Motor rotates clockwi

Tray.

rib

es the

iti

on

ing ink

Tray and

ker

is

Carriage

Tab

Operation

ink

deadlock sequence

htl

or

check

pow

er-

on sequences.

charge.

no

pap

er on the

not

set

on the

CDR

printing position.

capped

is l

ocked

le 2-3.

overtlow

y moves to the 80- digit side.

DR

with

by

Operation

1

"

er

4

•

se

Tray senso

se

the

Cap

the

CR

lock.

of

value to ch

and releases the

r if the CDR

to eject the CDR

paper

path.

of

the

Ink

System.

the power-on sequence

I

Carriage/PF

eck

1110\c111ent

80

and

CRIOc•

-s~

80

-S'

I

80

-S'

I

80

trs

80

-s

80 HP 0

-s

80

-S

80

~

;~~

~

~

~

)-----{}0-

<,----{JO-

roller I

position"

HP 0

CR

HP 0

-+

EI

D

HP

0

f-

I

LE

0

HP

HP

0

-+

f-

HP 0

HP 0

2

p(;".I

Any

position

J,

J,

J,

J,

J,

J,

J,

Table 2-3.

Operation

4.

Releasing the

4-1.

Th

e PF Motor rotates clockwise and releases the

CR

Seeking the

5.

5-1.The

5-2.The carria

confams

5-3.The carriage slowly moves to the CR lock set

position.

5-

4.T

he

CR

5-5.The PF motor rotates counterclockwise and sets

the

5-6.The carria

confirms it touches the

5-7.The

the

5-8.The PF motor rotates clockwise and releases the

CR

5-9.The carria

confinns it does not touch the CR lock.

5-1

O.The

position, and home pos

Afterward , the carriage position is monitored

according to the sig

6. R

ese

tting APG

6- l.Th

ecarriage slowly moves to the Right Frame and

stops there.

CR

lock

lock.

hom

e position

car

ria

ge slow

ly moves to the 80-digit sid

ge

moves to the 0-digit side slow

it

touches the Right Frame.

PF

motor rotates clockwi

lock.

CR

loc

k.

ge

moves to the 80-digit side slowly and

car

riage slowly moves to rhe 0-di

CR

lock set position.

lock.

ge

moves to the 80-digit side slowly and

car

riage slowly moves to its original

Operation

1

"

se

and releases the

CR

lock.

iti

on is

fix

ed.

nal

s from the CR Encode

of

the power-on sequence

git

side to

Carriage/PF roller I

1110\c111ent

80

~

80

e.

-S

ly

and

80

-S

80

-S

80

-6:1>

80

~(

80

and position'

HP

~

HP

(--

s----£HJB-

HP

~

<,---a-{}----0

HP 0

s---D---CJ-

HP

~

HP

I

I

0-

HP

f-

p(;'.I

2

0

Any

posit-ion

0

J,

0

J,

f-

J,

0

J,

0

J,

0

J,

-S<,--------t[JB

80

-S'

I

80

-6:1>

~

80

-S

s------nD----8-

80

-S

r.

s----aoc;J-

80

10

~

HP

-+

0-

HP

HP

~

HP

HP 0

-+

0

t

0

J,

0

J,

0

J,

J,

-ss------os-o

(Continue

to

the next page)

OPER

1\ TING

PR/NCI

PLES

Power-On Sequence I 3

Confidential

Page 14

L

easyfixs.blogspot.com

5,1

senes

r ·

8

6-2.The

the PG sensor.

6-3.After the

PF Motor rotates clockwise by the specified step

until it detects the PG-- (APO home position).

6-4. After detecting the

slightly moves

6-5. After the PF Motor rotates counterclockwise,

rota1e

On

6-6.The carriage slowly returns to its home position.

7. Sett

7-.1.

The

stops there.

7-2.The

7-3.The carriage slowly returns to

8.

PF

initializat

8-1.Checks if paper exists by the PE sensor•5 and the

PF

PF

Moto

9.

9-LThe

and performs a load measuremen1.*6

10.L

ow

10-1.The PF Motor rotates clockwise, and releases the

CR lock.

10-2.The

lock and the 80-digit side for two times.

,

senes

/1810

PF

Motor rotates clockwise while monitoring

PG sensor switched from

s clockwise to confirm the

-stat

e.

ing the APG to

carriage slowly moves to the Right Frame and

PF

Motor rotates clockwise and $ets to PG++.

ion

MotOr rotat

r m

easurement

PF

motor rotates clockwise for four seconds.

temperature

ca

rria

ge

· Revision A

Ta

ble 2-3. Ope

Operation

APO

to

the 80-digit side.

PG++

es

clockwise for one second.

operation sequence

moves back and forth between CR

· 1

home

rat

ion of the power-on sequence

Off

to On,

posi1ion, 1he

PG

i1s

carriage

sensor is set to

home position.

"

it

1he

Carriage/PF

mo\cment

80

-s-s

~

80

trs

S---------U----

80

--'>

s---------o--rn

80

-e&i>

s----D---0--

80

--'>

s---rn:a-

80

-'>

<,----------QB-

80

trs

S------0----0

80

--'>

s-oc:JB

80

~

<,----------{)Q

80

and

roller

position"!

HP

0

HP

0

HP

0

(--

HP

0

HP

0

(--

HP

0

~

HP

0

HP

0

(--

Ill' 0

HP

0

J>(;".I

Any

posirion

.J,

.J,

PG--

.J,

.J,

PG++

.J,

.J,

.J,

~

~

,

HP

HP

0

.J,

0

.J,

80

~

s-----oc-

80

~

_i;

~

Tab

le 2-3. Op

Operation

11.Setting the APG to

I I-I .The carriage slowly moves to the Right Frame

and stops there.

J

1-

2.The

PF

Motor rotates clockwise and sets to PG--.

11

-3.The carriage slowly returns to its home position.

12.CR measurement a nd

12-1.The carriage slowly moves to the 80-digit side.

12-2.The carriage performs a load measurement while

moving to the VH Check position. and records the

detected vollage

three positions, then stops.

12-3.The carriage detects the

at the carriage stop position (the black area at the

Paper Guide Front).

12-4.The carriage performs a load measurement while

moving to the 0-digit side, and stop

12-5.The carriage perfo1ms a load measurement while

moving to the

detected voltage

thr

ee

positions, then stops.

12-6.

Th

e carriage detects the voltage

at

the carriage stop position (the black area at the

Paper Guide Front) .

12-7 .The carriage performs a load measurement while

moving to the 0-digit side, and stops.

13.Detecting ink cartridge

13-1.The

PF

Motor rotates clockwise for one second,

and resets the

PG--

PW

of

the

YH

Check position, and records the

of

the PW sensor at the specified

and

PF

Roller. •9

erat

ion of the power-on sequence

·•

sensor initialization

PW

sensor at the specified

voltage

of

the PW sensor

s.

of

the PW sensor

initializing ink system*

Carriage/PF

1110\ement and position' !

80

--'>

S---OS-O

80

trs

S------0---0

80

--'>

s------aoa

80

--'>

s------o-oa--

80

---'>

~

80

"'"""

~

80

--'>

SB-0-D----

80

--'>

s.o-a--o----

80

---'>

~

80

---'>

~

8

80

-&s

s----n-o---

(-----

~

~

~

~

(Continue

roller

HP

HP

HP

(---

HP

HP

HP

HP

HP

HP

HP

HP

0

~

0

0

0

0

0

0

0

0

0

0

to

the next page)

p(;'.I

PG++

PG--

.J,

.J,

.J,

.J,

.J,

.J,

.J,

.J,

.J,

OPER1\TING

PRINCIPLES

Power-On Sequence

14

Conf1dent1al

Page 15

L850 series/L8JO series Revision A

easyfixs.blogspot.com

Tab

le 2-3.

Operation

Operation

J 3-2.The carriage slowly moves

13

-3.T

he

carriage

the ink end sensor. The ink remaining is detected

after

comp

13-4.The carriage slowly returns

14.

CR lock

1

4-1.The

carriage slow

position.

14-2.The

14-3.

Note

PF

the

CR

The carriage sl

*I:

The

Clockwise: Paper is fed normally

Counterclockwise:

*2: The

Red:

Whit

*3:

lndicates the PG position. "Any position" means that the PG position is not

recognized because

*

4:

Checks

*5:

Eject the

*6:

When paper exists, the existing m

therefore, the

*7: Executes

*8:

The empt

*9:

ff

mov

leting tbe check.

setting

Motor rotates counterclockwise, and sets

lock.

owly

rotation

direction

condition

CR

Jock is

e:

CR

lock is released

if the carri

paper

when the detected temperature

y suction operation may occur depending on 1he situation.

paper re

main

· 1

to

es

to

the 80-digit side to chec k

to

ly moves to the

returns to its h

of

th

Paper is fed backward

of

the

CR

lock is

set

APG is not reset yet.

age

is

not deadlock such

if

any.

PF Motor

s in

does

1he

primer, !he PF

of

the power-on sequence

the 0-digit side.

its

home

position.

CR

lock

set

ome

position.

e

PF

Motor

is as

as

fol.lows.

as

eas

urement value saved in EEPROM is read out;

not rotate.

is

under 5 °C (41

Roll

er

rotates

Carriage/PF

mo\cment

80

~

s--a::n----

80

<

~

c,.o-ao--

80

~

s-a----ab-

80

~

s-----oao-

80

~s

80 HP 0

--

and

~

roller

position"!

HP

HP 0

HP 0

HP

~

HP 0

I D-

~

~s--------tDB

follows.

the

CR lock

is

caught in the gap

°F)

by the thennistor

by

steps enough

10 ejec

t lhe paper forcibly.

J>(;".I

0

PG--

.J,

.J,

0

.J,

.J,

.J,

of

the carriage.

on the Printhead.

2.3 Printer Initialization

Th

ere are

fom

kinds

of

initialization method

initialization.

1.

Hardware initialization

This

print

er

is initialized when turning the printer

the cold-reset command (remote

When printer is initialized, the following actions are performed.

(a) Initializes printer mechanism

(b) Clears input

data

buffer

(c) Clears print buffer

(d) Sets default values

2. Operator initia

li

zation

Initialization when resetting the

(a) Clears input data buffer

(b) Clears print buffer

(c)

Set

s default values

3. Software initialization

The

ESC@command

also initialize the printer.

When printer is initialized, the following actions are performed.

(a) Clears print

(b)

Sets default values

4.

IEEE

1284.4 "r

The

printer recognized the IEEE 1284.4 "r

When print

• Initializat ion when an

buff

er

s"

command

er

is initialized, the following action is performed.

initialization

e1Tor

(a) Initializes printer mechanism

(b) Clears input data buffer

(c) Clears print buffer

(d) Sets d

efa

ult values

• Initialization in normal operation

(a) Clears input data buffer

(b) Clears print buffer

(c)

Sets default values

, and the following explains each

pow

RS command) .

USB

sof

tware, and the following are performed.

s"

command.

occurs.

er on,

or

printer recognized

OPER1\ TING

PR/NCI

PLES

Printer lnitiali:.atio11 I 5

Confidential

Page 16

easyfixs.blogspot.com

TROUBLESHOOTING

Confidential

Page 17

L850

easyfixs.blogspot.com

series/L8JO series

Rei

·isio

11

A

3.1 Overview

Description in this c

But

3.2.3.1

Scanner

series.

•

This chapter describes troubleshooting.

3.1.1 Specified Tools

L850 series/LS I 0 series does not require any specified tools for troubleshooting.

3.1.2

Before starting troubleshooting, be sure to verify that the following conditions are a

Preliminar

•

The

power

the voltage at

•

The

POWER

miswiring

•

The

Unit must

•

The

Unit should

or

low temperature, too high

•

The

Unit should not be located near waterworks, near humidifiers, near

heaters

or

be

exposed to blast from an air conditioner.

•

The

Unit should not be located

are produced.

•

The

Unit should not

rays

of

the sun.

•

The

Unit must be placed on a strong and steady level table (without an

inclination larger than 5 degrees).

•

There

must be no vibration generating source placed

•

The

paper used must conform to the specification.

•

There

must be no error in handling

•

Check the inside

clips, staples, bits

• Clean

the

y Checks

supply voltage must

the

wall outlet.)

CORD

in

the POWER CORD.

be

grounded properly.

not

near flames, in a dusty atmosph

of

of

inside

of

hapt

er is applied

FATAL E

be

within the specification limits.

must be free from damage, short circuit

be

located

be

the Unit, and remove foreign matters,

paper, paper dust

the Unit and the rubber rolls.

in a place

or

low humidity,

in

a place where volatile

located in a place where it

of

rror

s (

where

ere

the Unit.

or

toner.

to

L850 series/L810 series.

p.22

) is not applied to L810

it

can

be

or

abrupt temperature change.

or

in

a place where the Unit can

can

be exposed to direct

in

(Measme

or

breakage,

exposed

or

contact with this Unit.

if

to

too

inflammable gases

any, such as paper

ll

high

met

or

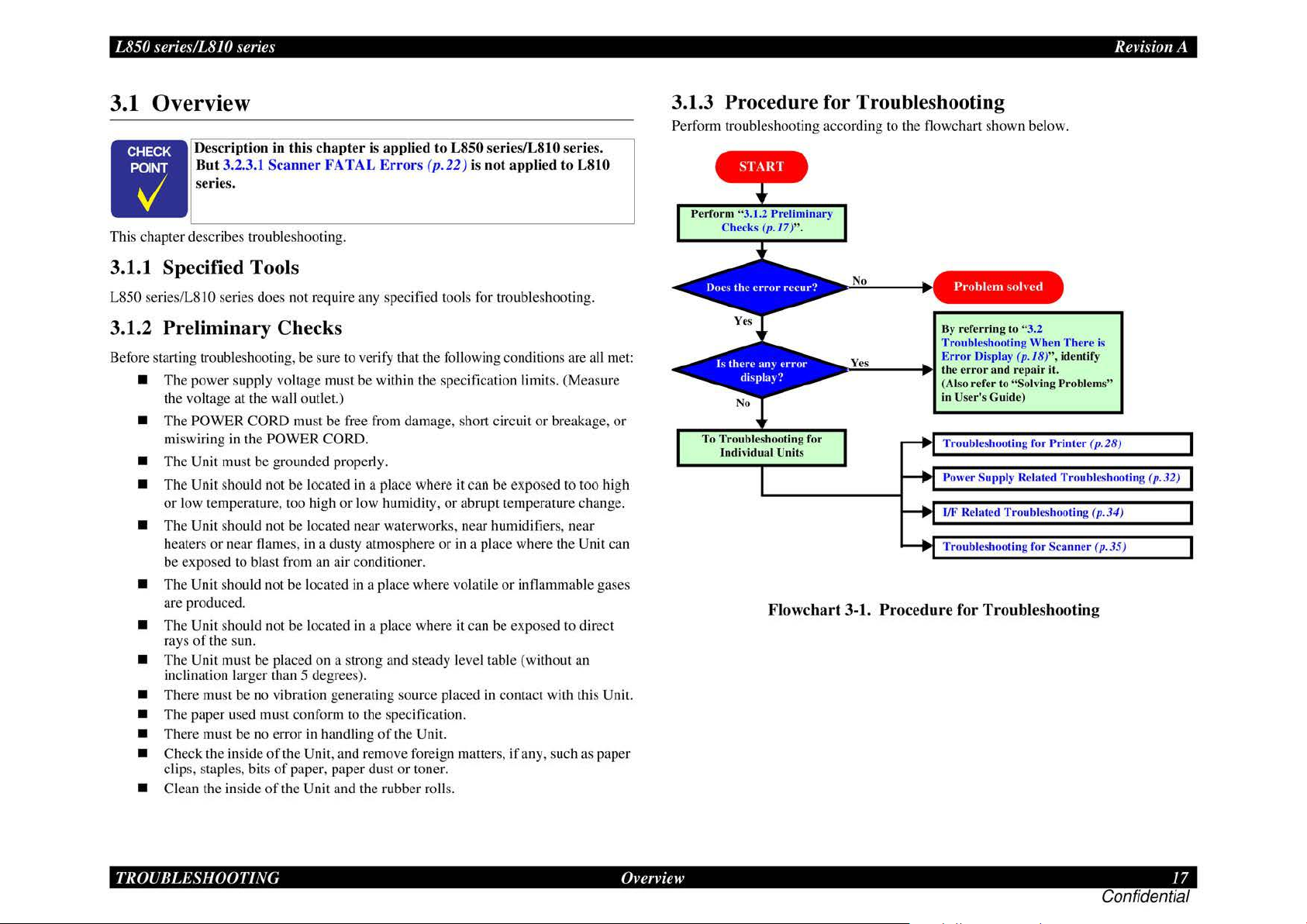

3.1.3

Perform troubleshooting according to the flowchart shown below .

Procedure

Perfo

rm

"3.1.2 Preliminary

Che

ck

To T

ro

ubleshooting for

individual

s (p .

17)".

Units

Flowcha

for Troubleshooting

No

Yes Error

• l..:;.::;:....

rt

__

3-1.

Procedure for

Problem

By

referri

Troubleshooting When There is

--11~

th

(Also refer to "Solving Problem

in

Troubles

Power Supply Related Troubleshooting (

I

Tr

ng

Display (p.18)

e error and repa

User's Guide)

ho

/F

Relat

ed Troubleshooting (p

oubleshooting for Scann

Troubl

solv

ed

to

"3.2

oting for

eshooting

",

ir

it.

Prin

identify

ter (p. 28)

er ( p. 35)

s"

.3

4)

p.

32)

TROUBLESHOOTING

Overview

17

Confidential

Page 18

L850 series/L8JO series

easyfixs.blogspot.com

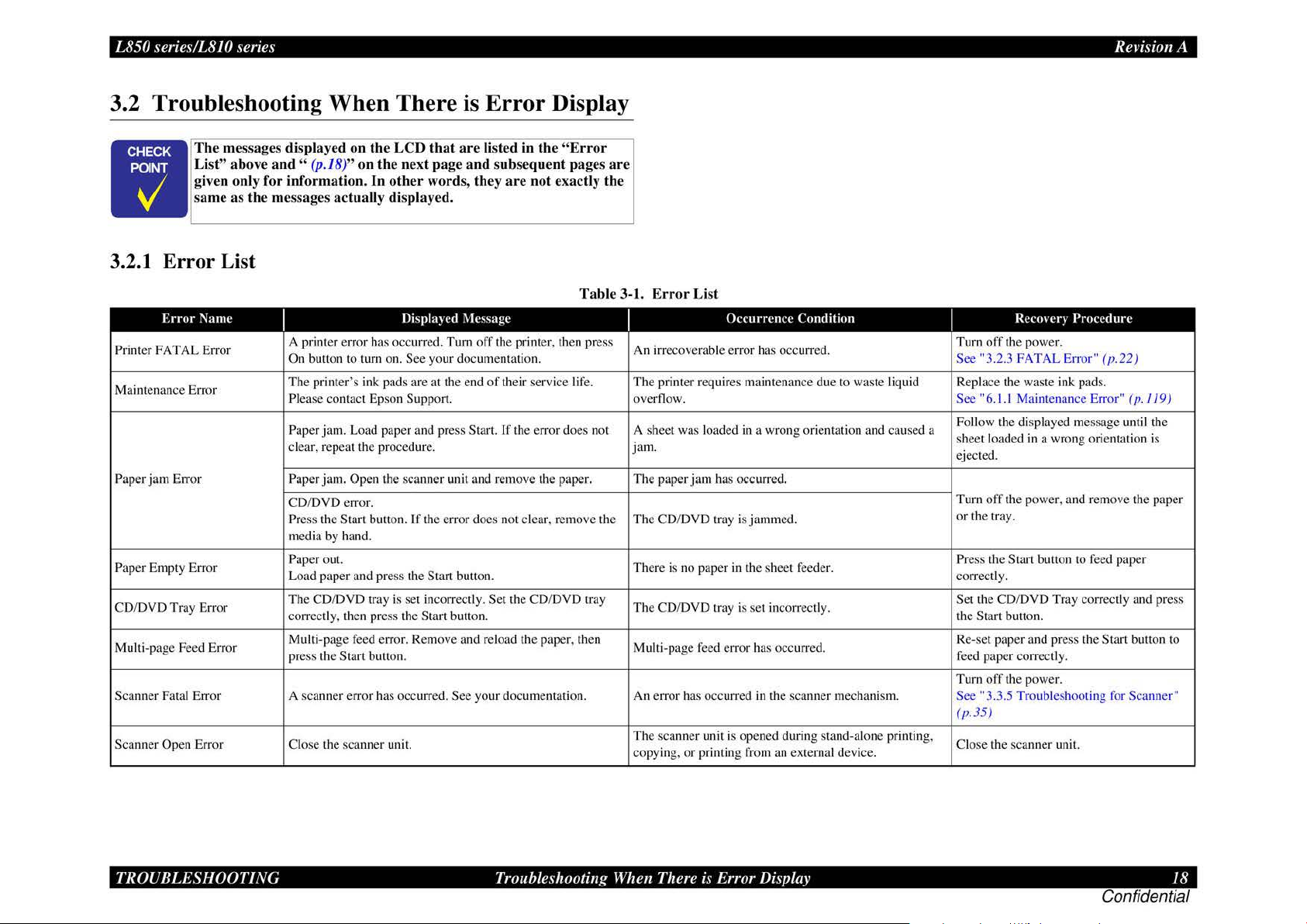

3.2 Troubleshooting When There is Error Display

Th

e messages displayed on the LCD

abo

List"

ve

n only for information.

gi

ame as

s

the messages actually displayed.

•

3.2.1 Error List

ve

and

" (p.18)" on the next page and subs

In

that are listed in th e "Err

oth

er word

s, they

equent

are

not exactly the

or

pages are

Rei

·isio

11

A

Error

Name

Printer

FATAL Error

Maintenance Error

Paper

jam

Error Paper jam. Open tbe scanner unit and remove the pape r. The paper

Paper Empty Error

CD/DVD Tray Error

Multi-page Feed Error

Scanner Fatal Error A scanner error has occurred.

Scanner Open Error Close the sca nn

I

A printer error has occurred. Turn

On button to turn on. See your documentatio

The

printer

's

Plea

se

contact Epson Support.

Paper jam. Load paper and press Start.

clear, repeat the procedure.

CD/DVD error.

Press the Start burton.

media by hand.

Paper out.

Load paper

The CD/DVD tray is set incorrectly. Set the CD/DVD tray

correctly, then press the

Multi-page feed error. Remove and reload the paper, then

press the

and press the Start button.

Start butto

Displa~

ink pads are at the end

If

the error does not clear, remove the

Start bullon.

n.

er

unit.

ed

\lessage

off

the printer, then press

of

their service li

If

See

your documentatio

n.

the error

Table 3-1. E

fe.

does n

ot

n.

rror

List

I

irrecoverable error has occurred.

An

The

printer requires maintenan

overflow.

A sheet was loaded

jam.

The

CD/DVD tray is jammed.

Th

ere is no paper

The

CD/DVD tray is set incorrectly.

Mu

lti-page feed err

An error has occurred in the scanner mechanism.

The

sca

nner unit is opened during stand-alone printing,

copy

in

g,

Occurrence

in

jam

has occurred.

in

the sheet feeder.

or

or

printing from an external device.

Condition

ce

due to waste liquid

a wrong orientation and caused a

has occurred.

Reem

er~

I

Turn

off

the power.

See

"3.2.3 FATAL Error"

Replace the waste ink pads.

See "6.

1.1

Maintenance Error"

Follow the displayed message until the

sheet loaded in a wrong o

ejected.

Turn o

ff

the power, and remove the paper

or

the tray.

Pr

ess the Start button to feed paper

cor

rectly.

Set the CD/DVD Tray

the

Start button.

Re-set paper and press the

feed paper

Turn

See

(p

.35)

Clo

correctl

off

the power.

"3.3.5 Troubleshooting for Scanner"

se

the scanner uni

Procedure

cor

y.

t.

(p

.22)

(p

.119)

ri

entation is

rectly and press

Start button to

TROUBLESHOOTING

Troubleshooting When There

i~

·

Error Display 18

Confidential

Page 19

L850 series/L8JO series

easyfixs.blogspot.com

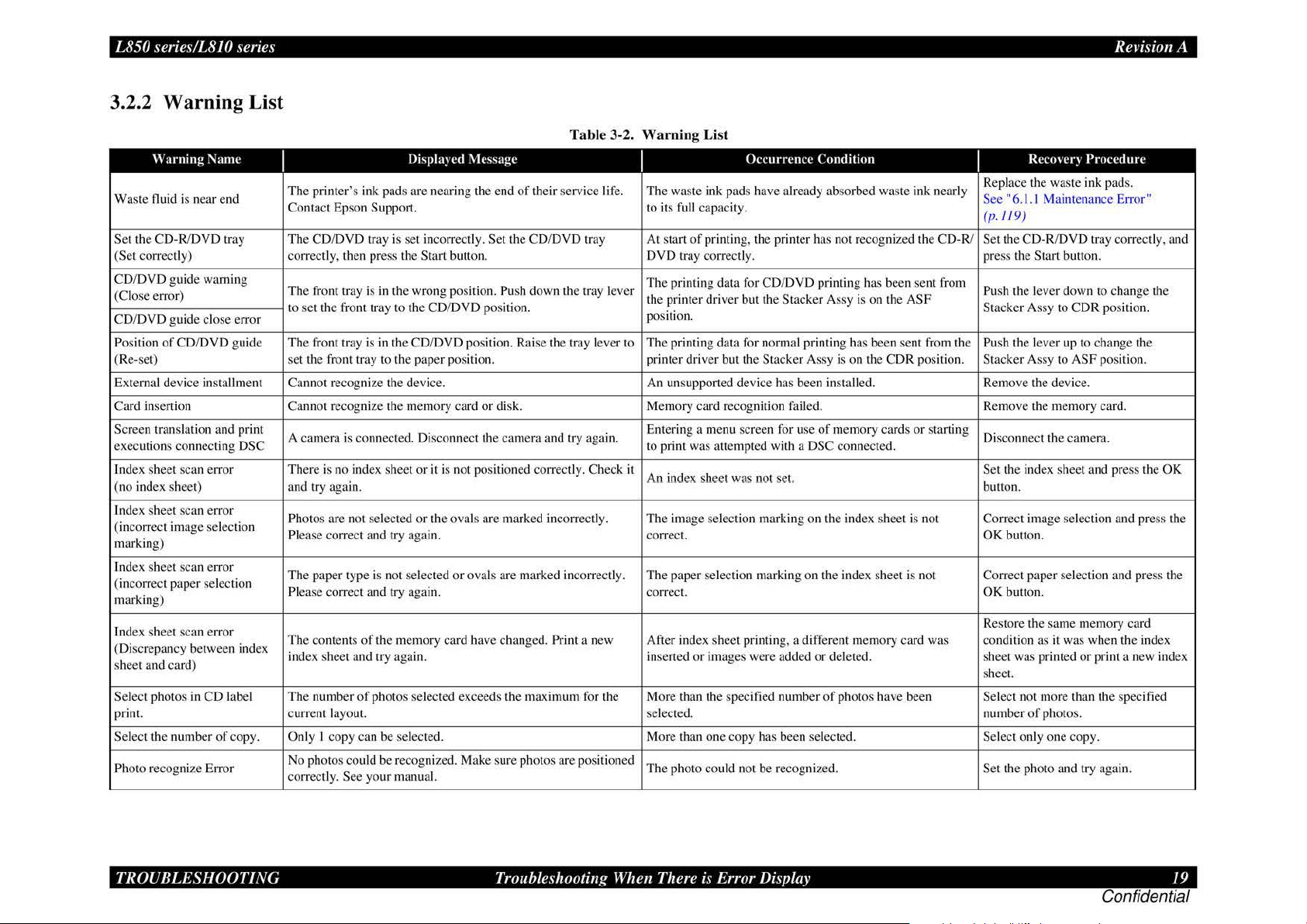

3.2.2 Warning List

Table 3-2. Warning List

Warning

Waste fluid is n

S

et

the CD-R/DVD tr

(Set correctl

CD/DVD g

(C

lose error)

CD/DVD guide cl

Position

of CD/DVD guide

(Re-set)

External d

inserti

Card

Screen translation and print

exec

uti

ons conn

Index sheet scan error There is no index sheet or it is not positioned correctly. Check it

(no index sheet) and try again. button.

l.ndex sheet scan error

ec

(incorr

marking)

index sheet scan error

incorrect paper selection

(

marking)

Index sheet scan error

(Di

sc

repancy between index

sh

ee

t a

nd card)

Select phot

print. current

Select the number

Ph

oto recognize

Name

ea

r end S

ay

y)

ui

de

warning

ose

error

evice installm ent

on Cannot r

ect

ing DSC to print was attempted with a DSC connected.

t image selecti

os

in CD label

of copy. Only I copy can be selected. More than one copy has been selected. Select only one cop

Err

or

I

The pr

Co

The CD/DVD tray is set incorrectl

correct

The front tray is in the wrong positio

to

Th

se

Ca

A camera is

Ph

on

Pl

Th

Please

The

index sheet and try

Th

No photos

corr

l>ispla~

l'd i\

kssage

inter

's ink pads are nearing the end

ntact Epson Suppo

ly, then press the Sta rt button. DVD tray correctl

se

t the front tray to the CD/DVD positio

e front tr

ay

t the fro

nt

tray to the paper position. printer driv

nnot recogni

ecognize

co

otos are not selected or the

ease correct and try again.

e paper type is not selected or ovals are marked inco1Tectl

correct and try again.

contems of the memory card have changed. Print a new After index sheet printin

e number of photos selected exceeds the maximum for the More than the specified number

layout.

co

uld be recognized. Make sure photos are positioned

ectly. See

rt. to its

is

in

the CD/

DVD

positio

ze

the device. An unsupport

the memory card or disk. Memory card recognition failed. Remove the memory card.

nnected. Disconnect the

ova

ag

ain.

your manu a

l.

of

their servi

y. S

et

the CD/

DVD

tray At start

n.

Push down the tr

n.

n.

Rai

se

the t

ray

came

ra and try aga

ls are marked incorrectl

ce life

ay

I

. The waste ink pads have already absorbed waste ink nearl

full capacity.

of

The printing data for CD/

lever

the printer driver but the

positio

n.

lever to

y.

Th

e printing data for normal printing has been sent from the

Entering a menu screen for u

in.

An ind

ex

The im

age selection marking on the index sheet is not

correc

t.

y.

The paper

correc

t.

inserted or images were added or deleted. sheet was printed or print a new index

selec

ted. number of photos.

Th

e photo could not be recognized.

Occurrcnn· Condition

printing, the printer has not recognized the CD-R/ Set the CD-R/DVD tray correctl

y.

DVD

Stacker Assy is

er

but the Sta

ed device

sheet was

se

lection marking on the index sheet is not

cker

has been installe

se

not

set.

g,

a different memory card was

printing has been sent from

on

the ASF

Assy is on the CDR positio

d.

of

memory cards or starting

of

phot

os

have been Select not more than the specified

I

pl

Re

y

ee

(p

.

11

press the Start button.

Push the lever down to change the

Sta

cke

Push the lever up to chan

n.

Stacker Assy to

Remove the device.

Di

sconnect the camera.

Set the index sheet and press the

Correc

OK

Correc

OK

es

R

co

ndition as it was when the index

sh

ee

Se

t the photo and try again.

Rei·isio11

Rcl'oHr~

ace

the was te ink pads.

"6.

1.1

9)

r Assy to CDR positio

t image selection and press the

button.

t paper selection and press the

butto

n.

tore the sa

t.

Procedure

Maintenan

ASF pos

me

memory card

ce

Error"

n.

ge

the

ition.

y.

A

y, and

OK

TROUBLESHOOTING

Troubleshooting When There

i~

·

Error Display 19

Confidential

Page 20

L850 series/LS

easyfixs.blogspot.com

JO

series Revision A

Table 3-2.

Warning

Scan to memory error

(no card) attempted with no memory card inserted.

Scan to memory error There is not enough free space on the memory card

(insufficient card capacity) canceled. sufficient capacity.

Scan to memory error

(card write-protect) save data. protected.

Scan to memory error Cannot create a folder on the memory card

(folder not created)

Scan to memory error

(card removed) been removed.

Scan to memory error

(save error)

Format check (backup)

Format check (scan)

Format Warning

(Format error) (scan) out the media while formatting it.

Format Warning

(card write-protect) (scan) protected and try again.

Format Warning

(card removed) (scan)

Head Cleaning Replace ink Adapter before cleaning print head. Head cleaning was attempted in the Ink Low state.

Backup error External device

(no external connection) Backup canceled. started.

Backup error

(insufficient external media

capacity)

Backup error

(insufficient memory card

capacity)

Backup error (no card)

Backup error

(File name and Folder levels

Error)

l\ame

I

No

memory card

The memory card

canceled.

The memory card

An

error occurred while saving. Save canceled. Data saving was not achieved for some reason. Check the source data

Cannot recognize the memory card

format it?

A problem occurred while formatting . Formatting canceled.

The memory card

The memory card or disk was removed. Format canceled. The media is removed when formatting is to be started. Insert media and try again.

Insufficient space on the backup device. Cannot back up files.

No memory card

Backup canceled. File name is too long

folder levels. levels

Displa)ed

or

disk inserted.

or

disk is write-protected. Operation canceled.

or

disk was removed. Operation canceled.

or

disk is write-protected. Operation canceled. As the memory card was write-protected, formatting failed.

is

not connected

in

slot. Backup canceled.

:\lessage

Save

canceled.

or

disk. Operation

or

disk.

Do

you want to

or

media is not inserted.

or

there are too many The file name is too long,

or

disk. Save

Warnin

g List (continued)

I

Execution

The

memory card capacity is insufficient.

As

the memory card is write-protected, it is not possible to Insert a memory card not write-

A folder could not be created

Data saving was not executed, since the memory card had

The

media for backup cannot be recognized.

The memory

An error has occurred

The

external device was not connected when backup was

The capacity

saved is insufficient. space.

No

backup sour

in

folder hierarchy. hierarchy.

Occurrence

of

scanning to a memory card function was

ca

rd cannot be recognized.

in

of

the media on which the backup data is to be Insert media that has sufficient free

ce

exists. Insert the memory card.

Condition

on

the memory card. Check the data on the memory card.

formatting the card.

or

the source has eight

Or

you pulled Press the

or

I

Insert a memory card.

Insert a memory card.

Execute

Cancel the head cleaning,

the ink Adapters.

Connect the external device.

more Check the file name and the folder

RecO\er)

Insert a memory card that has a

or

OK

media.

Insert a memory card not write-

Procedure

cancel formatting.

button and check the

or

media.

or

replace

TROUBLESHOOTING

Troubleshooting When There is Error Display

20

Confidential

Page 21

L850 series/LS

easyfixs.blogspot.com

Warning

Backup error

In adjustment

expansion value border may appear around your photo. Borderless Expansion Value.

JO

series Revision A

Ta

l\ame

of

borderless You can change the amount

I

Backup Error.

or

Code FFFFFFFF*

Err

Displa)ed

of

ble 3-2. Warnin

:\lessage

image expansion, but a white This message is always displayed during adjustment

g List (continued)

I

An error has occurred at the external device. Check the external device.

Occurrence

Condition

of

the

I

Accept it.

RecO\er)

Procedure

* · The actual messages are displayed as error codes corresponding to the cause

Note

of

the error.

TROUBLESHOOTING

Troubleshooting When There is Error Display 21

Confidential

Page 22

L850 series/L8JO series

easyfixs.blogspot.com

Rei·isio11

A

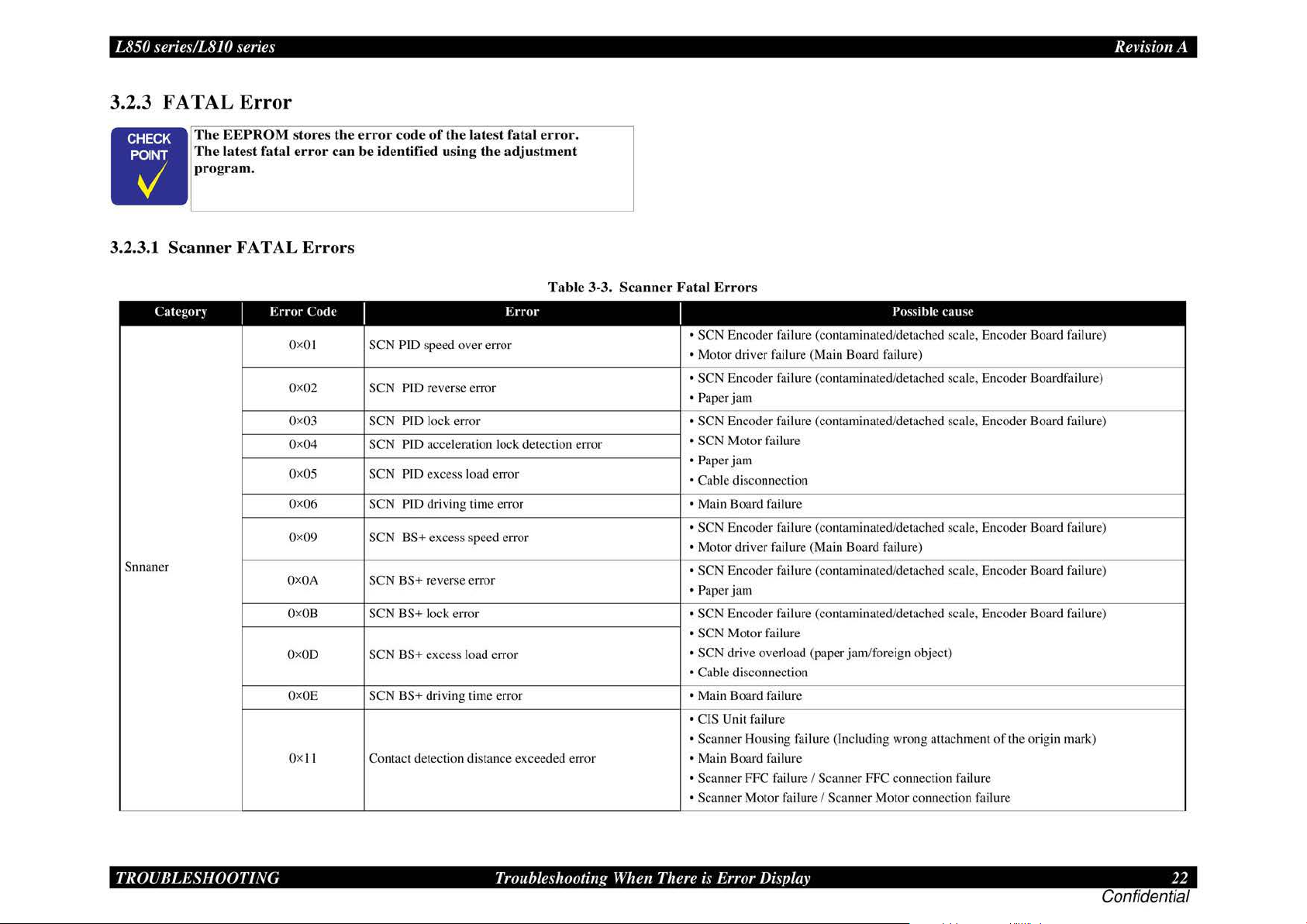

3.2.3

FAT

AL

Error

The EEPROM

The

latest fatal e

program.

•

3.2.3.1 Scanner FATAL

l'ategor~

Snnaner

I

E

rror Code

OxO

Ox02

Ox03

Ox04 SCN PID acceleration lock detection error

Ox

Ox06

Ox09

OxOA

Ox

OxOD

Ox

Qx

stores the e

rror

rror

code

of

the

can be identified using the

Errors

I

I SCN PID speed over error

Pill

reverse error

PIO lock error •

PID excess load error

PID driving time error • Main Board

BS+ excess speed error

ntact detection distance exceeded er

OS

OB

OE

l I

SCN

SCN

SCN

SCN

SCN

SCN BS+ reverse error

SCN BS+ lock error • SCN En

SCN BS+ excess load error

SCN BS+ driving time error • Main Board failure

Co

lat

est fatal e

adj

ustment

Erro

r

rror.

Tab

le 3-3.

ror

Scan

ner Fatal Error

s

I

• SCN Encoder failure (contaminated/detached scale, Encoder Board

• Motor driver failure (Main Board failure)

• SCN En

• Paper jam

• SCN Motor

• Paper

•

• SCN Encoder failure (contaminated/detach

•

• SCN

• Paper jam

• SCN Motor

• SCN drive overload (paper

• Cabl

• CIS Unit failure

• Scanner Housing failure (Incl

• Main Board failure

• Scanner FFC

• Scanner

coder

SCN Encode

jam

Cab

le disconnection

Motor

driver failure

Encoder

coder

e disconnection

Motor

failure (contaminated/detached scale, Encoder Boardfailure)

r fail ure (contaminated/detached scale, Encoder Boiu·d

fai

lure

fai

lure

(Ma

in Board failure)

fai

lure (contam inated/detached scale, Encoder Board failure)

failure (contaminated/detached scale, En

fai

lure

jam

fai

lure I Scann

failure I Scanner Motor connection

Possihle

/foreign object)

uding wrong attachment

er

FFC connection failure

cau

se

ed

scale, Encoder Board failure)

coder

Board failure)

of

the orig

fai

lure

in

fai

lure)

fai

lure)

mark)

TROUBLESHOOTING

Troubleshooting When There

i~

-

Error Display 22

Confidential

Page 23

L850 series/LS

easyfixs.blogspot.com

Categtir)

Snnaner

JO

series Revision A

Tab

I

Error

Code

Oxl2

Oxl3

Ox20 LED light error

I

Opposite side contact detection distance • CIS Unit failure

exceeded error

Opposite side wrong contact detection • CIS Unit failure

distance error

le 3-3. Scan n

Error

er

Fatal Errors

I

• Scanner Housing failure (Includ ing wrong attachment

• Main Board failure

• Scanner FFC failure I Scanner FFC connection failure

• Scanner Motor failure I Scanner Motor connection failure

•S

canner housing failure (Including wrong attachment

Main Board failure

•

• Scanner FFC failure I Scanner FFC connection failure

• Scanner Motor failure I Scanner Motor connection failure

• CIS Unit failure

• Main Board failure

Possible

cause

of

the origin mark)

of

the origin mark)

TROUBLESHOOTING

Troubleshooting When There is Error Display 23

Confidential

Page 24

L850 series/L8JO series

easyfixs.blogspot.com

Rei·isio11

A

Table 3-4.

Catcgor~

DC err

(C

R motor) motor operating sequence

or

I

Error

Code

I

OxO

J CR PID speed over err

Ox02

Ox08 CR PlD rever

OxOA

OxOB

oxoc

OxOD

CR load positioning lock error

CR load positioning accumulation moving • PF Adjustment

distance error

CR load positioning speed over error

CR

CR PlD

PTD

lock error

aveT

Error

or

se

rotation detection error

i max error

I

An error occurr

Printer

Cause

ed

Mechanism

in the CR

3.2.3.2 Prin

ter

Mechanism FAT AL Err

Fatal Errors

I

D Checking the operation

Move the CR

D

Making the followi.ng adjustments:

• Bi-D Adjustment

• PW Adjustment

D Checking t

• Checking the head FFC (CN 10/11/12) for disconn

• Checking the lead wires

• Checking the

• Checking

• Checking the CR Guide Shaft for adhesion

• Checking the Linear Scale for adhesion

• Checking the CR Encoder for adhesion

• Checking the PW Sensor for adhesion of dirt or damage

• Checking the CR Belt for damage

• Checking the

• Main Board (p.66)

• Power Supply Board (p.66)

Uni! by hand, and check to see if it moves smoothly.

he foll

CR

the printer frame for adhesion

CR

of

the CR Unit:

owing parts and replacing the defective

of

the CR Motor (CN 14) for disconnection

Encoder FFC (CN I6) for disconnection

Motor and replacing it if necessary (p.85)

Remed~

of

dirt

of

of

dirt

of

dirt

or

improper tension (p.85)

ors

one

ect

ion

or

breakage

or

breakage

or insufficient lubricati

dirt

or

insufficient lubrication

or

damage (p.

or

damage ( p. I

(p

76)

I)

. I I)

or brea

on

kag

(p

e

. 123)

(p

.122)

TROUBLESHOOTING

Troubleshooting When There

i~

·

Error Display 24

Confidential

Page 25

L850 series/L8JO series

easyfixs.blogspot.com

Tab

le 3-4.

Cakgor)

DC

error

(PF motor) motor operating sequence

A

PG

Motor drive

time error

motor

I

Error

Code

I

OxFB

Ox

OxFC

OxFA

OxEF Position error

OxFO

Ox70 APG error (normal drive error)

Ox71

Ox72

OxDJ CR (PID) drive time-out

OxD2

OxD3

OxD4

PF

acceleration lock error

FE

PF

speed over error insp

Measurement value error

limiting control

DTY

_max error

APG home seek

Error in APG drive by

CR

(load positioning) drive lime-out

PF

(PID) drive time-out

PF

(BS) drive time-out

Error

in

PF

BS control

in

PF BS control

e1Tor

in

PF

Duty

fac

tory command

Prin

ter Mec

I

An error occurred in the

An error occurred in the

APG operating sequen

The

motor kept operating

for more than

e.

tim

hani

Cause

the spec

sm

Fata

l Errors (continued)

Remed)

D Checking the

Check the

ect

D Ch

ecking the operation

Operate the

D Making the following adjustments:

Bi

-D Adjustment

•

PF

Adjustment

•

PF

• PW Adjustment

D Checking

• Checking the

• Checking the

• Checking the

• Checking the PF encoder for adhesion

• Checking the Upper Paper Guides for improp

• Ch

ecking the

• Main Board

• Power Supply Board (p.66)

0 Ch

ec

position

D Check

• Insta

ll

• Standalone

• Rein stallation of the

D Checking the following parts and replace the defective one:

ce

ified

• APG

• ASF Unit (p.82)

• APG

• PG L

• Main Board (p.66)

• Power Supply Boa

Checking the mechanism and operation:

D

Check the mechanism and operation

Checking the conn

D

0 Checking the motor in

• Main Board

• P

ower

PF mechanism

PF

mechanism for paper

ion.

PF

mechanism

the follow

king the installation

of

the sensor and connection

in

g t

he

ati

on

operation

Unit (p.83)

Sensor(p.

eft Cam (p.86)

Supply Board (

ing par

PF

Encoder FFC (CN8) for disconnection

lead wir

PF

scale for adhesion

PF

Motor and replacing it

(p.66)

drive

of

of

the composite

11)

.

rd

ect

(p.66)

by

visual inspection:

jam

or adhesion

of

the

PF

mechanis

by

hand , and check to see if it operates smoothly.

ts

and replace the defective one:

es

of

the

PF

Motor (C N 1

of

dirt or damage (p.

of

dirt

if

of

the APG Sensor:

of

the connector (CN7)

the APG Unit:

gear of

the ASF Unit - APG Unit

of

the APG Unit

APG Unit (phas

(p. 66)

ion

of

the connectors and routing

qu

estion and the following parts and replacing the defective part:

p.

66)

e)

of

the motor

of foreign mailers by visual

m:

or

3) for disconnection

or

dam

age

er

installation (p. 91)

necessary

(p

. 79)

in questio

of

breakage

or breakage

79)

(p.

79)

n.

the lead wires

Rei·isio11

A

TROUBLESHOOTING

Troubleshooting When There

i~

·

Error Display 25

Confidential

Page 26

L850 series/L8JO series

easyfixs.blogspot.com

Cakgor)

Factory

command

error

I

Error

Code I

Ox30

Ox40

Head system

error

Ox41

Ox42

Ox43

ox

so Home seek error

oxs1

Sequence

error

Ox52

Ox53

Ox56

Ox60

Ox6J

Sens

or

error

Ox62

Ox63

Tab

le 3-4.

Error

E

rTOr

by EEPROM verify command

Transistor ambient temperature abnormal

Error in X-Hot detection before priming

Error in X-Hot detection after flushing

Head ambient temperature abnormal • Replace the Head FFC

CR unlocking error

CR locking error

Paper detect error before initial charge

completion

Ob

structed sequence error at ink Adapter

replacement

PW detection error (

PW detection error (Low check error)

Tray detection (CDR detector

Paper detection error

Hi

check error)

2)

error

Prin

ter Mec

I

The

thermistor on the

printhead detected

abnormal temperature.

An error occurred in the

ca

rri

age operating See Remedy for

se

quence.

PW detector trouble

Sensor u·ouble

Cause

---

hani

sm

Fata

D Checking the following parts and replace the defective one:

• Main Board (p.66)

+Power Supply Board (p.66)

D Checking the following parts and replace the defective one:

• Printhead (p.

• Main Board (p.66)

+Power Supply Board (p.66)

0 Checking the PW Sensor (

• Checking the

• Checki.ng the connection

D Making

• PW Adjustment

0 Checking the following parts a

+Head

+CR Unit (p.86)

+Main Board (p.66)

• Power Supply Board (

0 Checking the operation

0 Checking the following parts and replace the defective one:

• PE Sensor( p.

• PW Sensor(

+CD-R Tray Sensor

+Main Board (p.66)

• Power Supply Board (

l Errors (continued)

74)

DC

error (

PW

Sensor for adhesion

the foll

owi.ng adjustments:

FFC

11

)

p. 11)

(p. I/)

Remed)

CR

motor)

p.

11

):

of

dirt and dust

of

the FFC

nd

replace the defective one:

p.

66)

of

the actuator and the connection

p.

66)

of

the connector.

Rei·isio11

A

TROUBLESHOOTING

Troubleshooting When There

i~

·

Error Display 26

Confidential

Page 27

L850 series/L8JO series

easyfixs.blogspot.com

Tab

le 3-4. Pri

Cakgor)

Maintenance

en-or maintenance parts

Abnormal An

operation cleaning

I

Error

Ox

Qx88

Qx89

Code

I

AO

Waste ink overflow

se

rted tray error during cleaning

in

Obstruction detection error during

cleaning

Error

nter

I

Life expiration

er

ror occurred during

Mechanism

Cause

of

Fatal Errors

D Replace al I the maintenance parts, and clear the maintenance counter.

Ma

(

D Pulling out the CDR Tray

0 Checking the CDR Tray Sensor ( p.

• Checking the

• Checking the connection

D Checking the connection

0 Checking the following

• CDR Tray Sensor(p.

• CDR Tray

0 Checking the operation

Move the CR

0 Checking the following parts and replacing the defective one:

• Checking the lead wires

• Checking the CR Encoder FFC (CN

• Checking the printer frame for adhes ion

• Checking the CR Guide Shaft for adhesion

• Checking the Linear Scale for adhesion

• Checking the CR Encoder for adhesion

• Checking the CR Belt for damage

• Checking the

• Main Board (p.66)

intenan

(continued)

Remed)

ce

Err

or

(p.11

9).)

11

):

CDR

Tray Sensor for adhesion

of

the connector

of

the FFC

pans

and replace the defective one:

I

/)

of

the CR Unit:

Unit by hand, and check to see if it moves sm

of

the CR Motor (CN 14) for disconnection

I 6) for disconnection

or

CR

Motor and replacing it if necessary (p.85)

of

dirt

of

the

CDR

of

di1·t

or insufficient lubrication

of

dirt

of

dirt

or

damage (

of

di11

or

damage

improper tension (p.86)

or

dust

Tray Sensor

oot

or

breakage

or insufficient lubrication

p.

76)

(p.11)

hly.

.

or

breakage

Rei·isio11

(p

.123)

(p

.122)

A

TROUBLESHOOTING

Troubleshooting When There

i~

·

Error Display 27

Confidential

Page 28

L850 series/LS

easyfixs.blogspot.com

JO

series Revision A

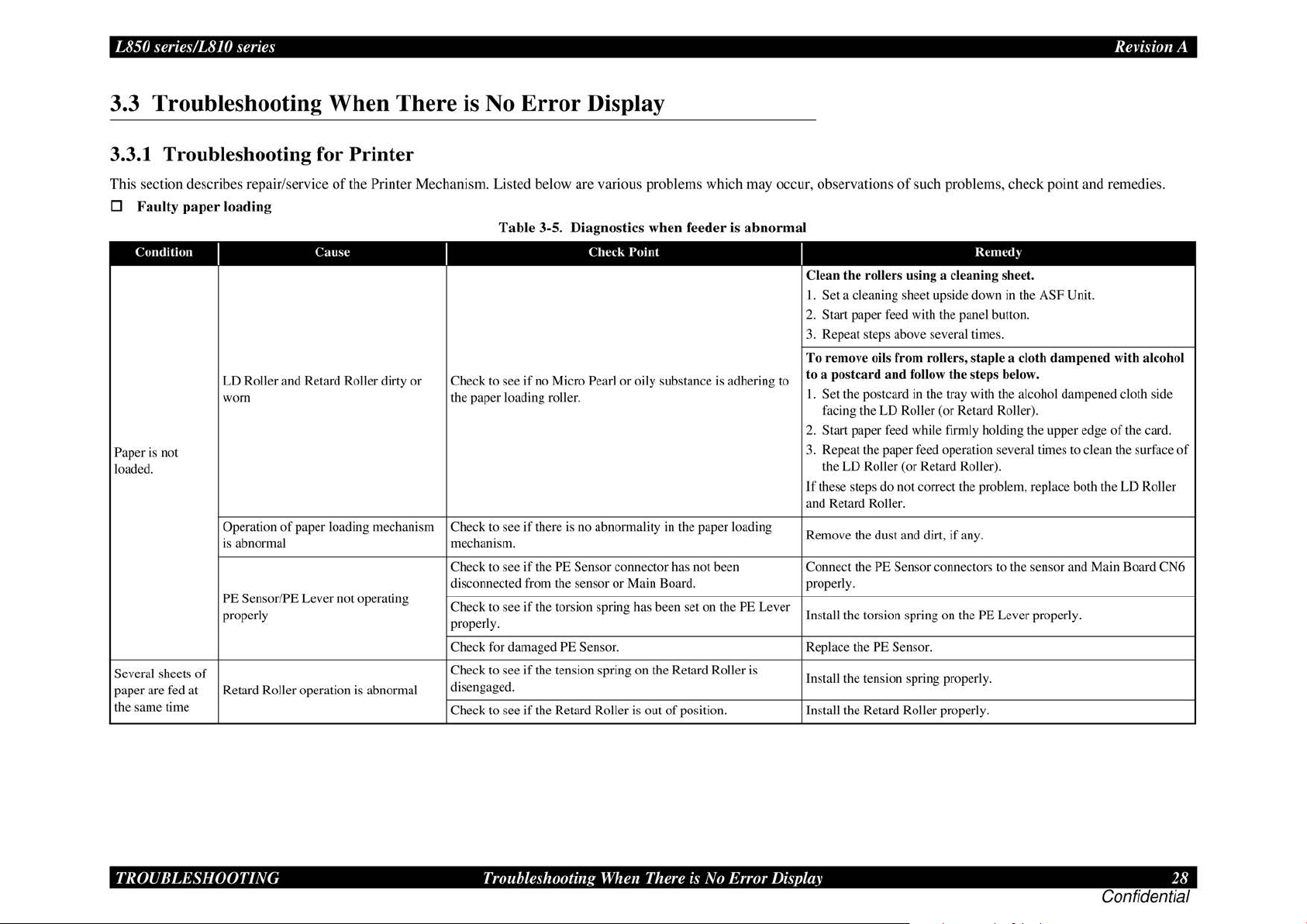

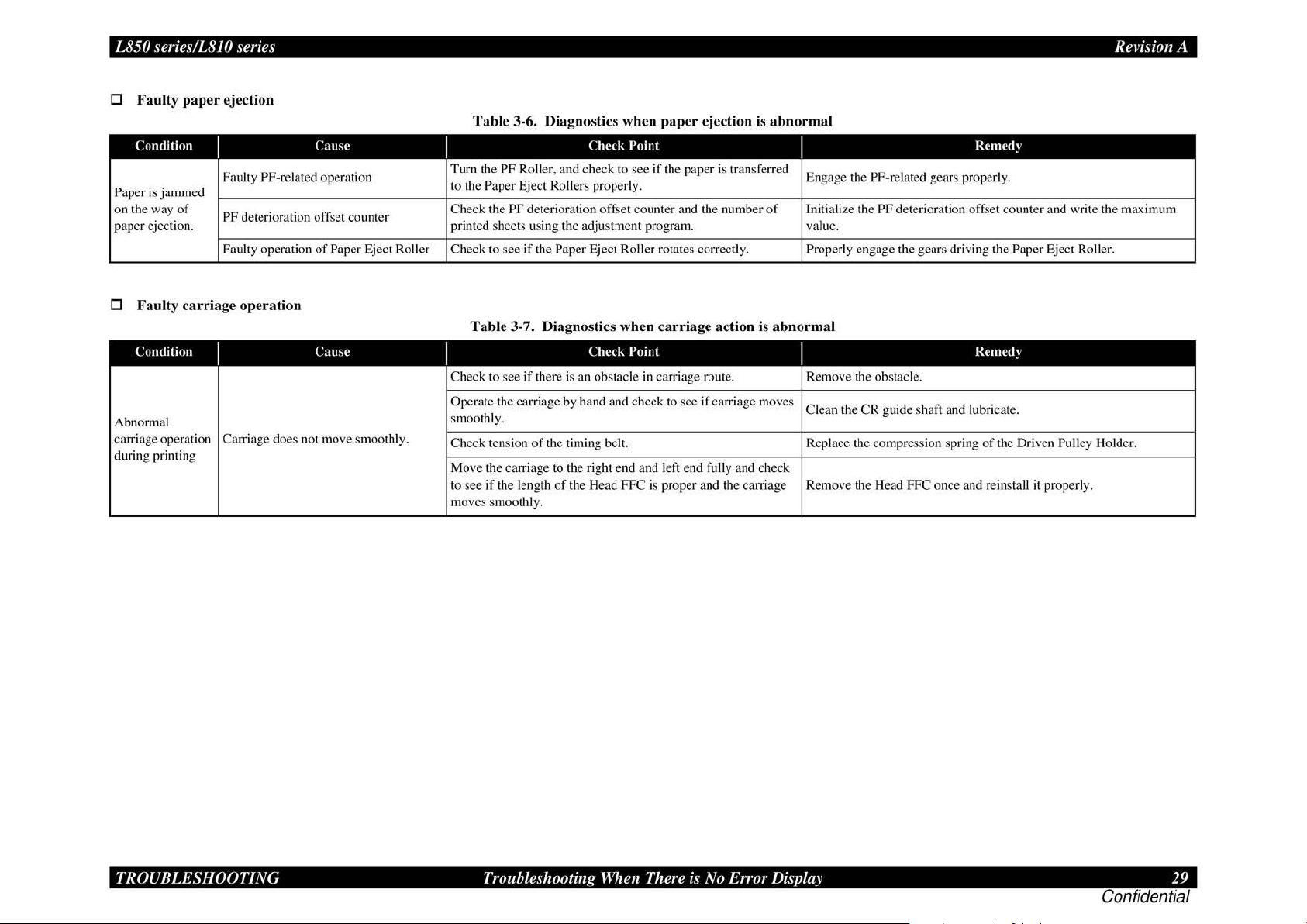

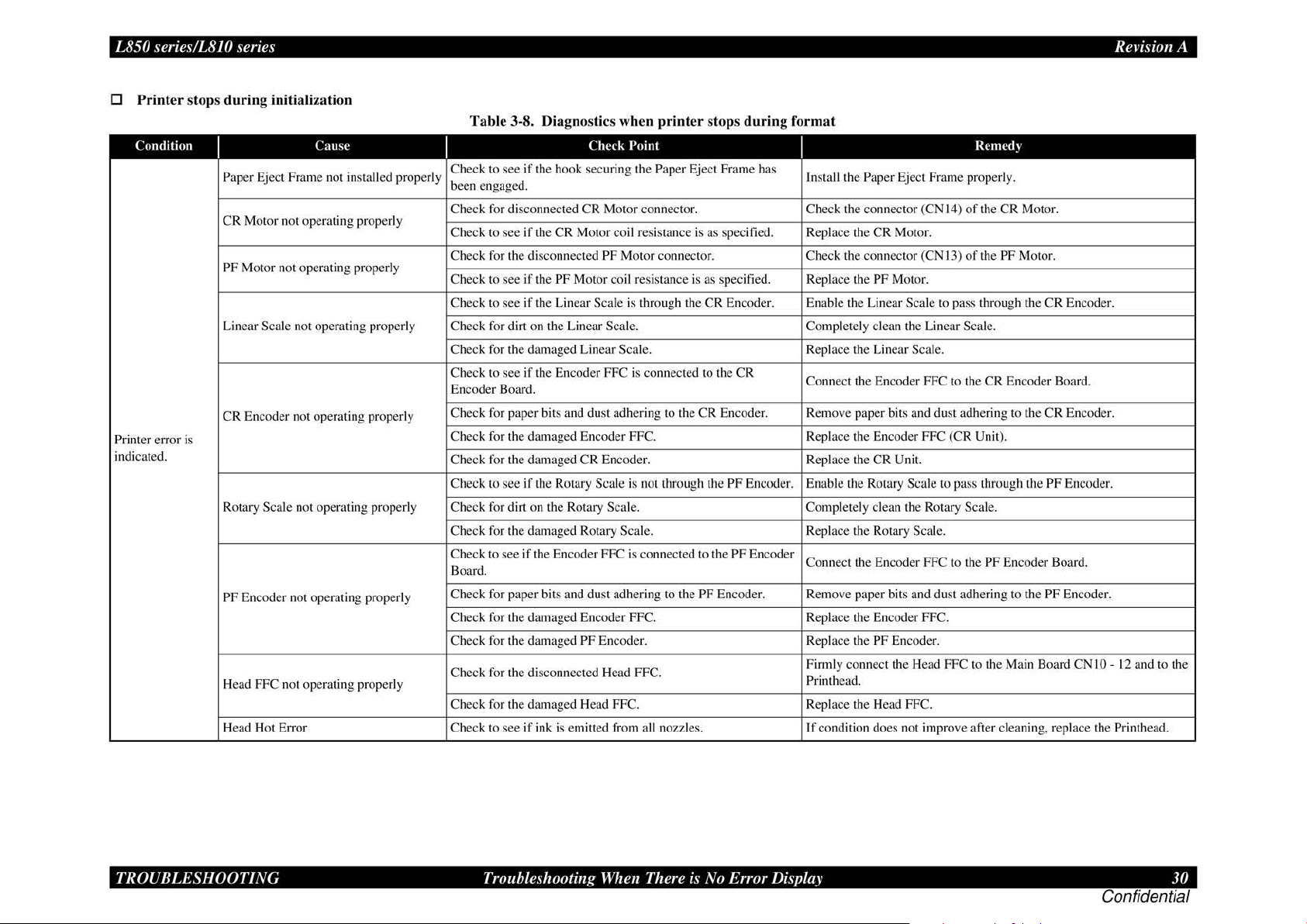

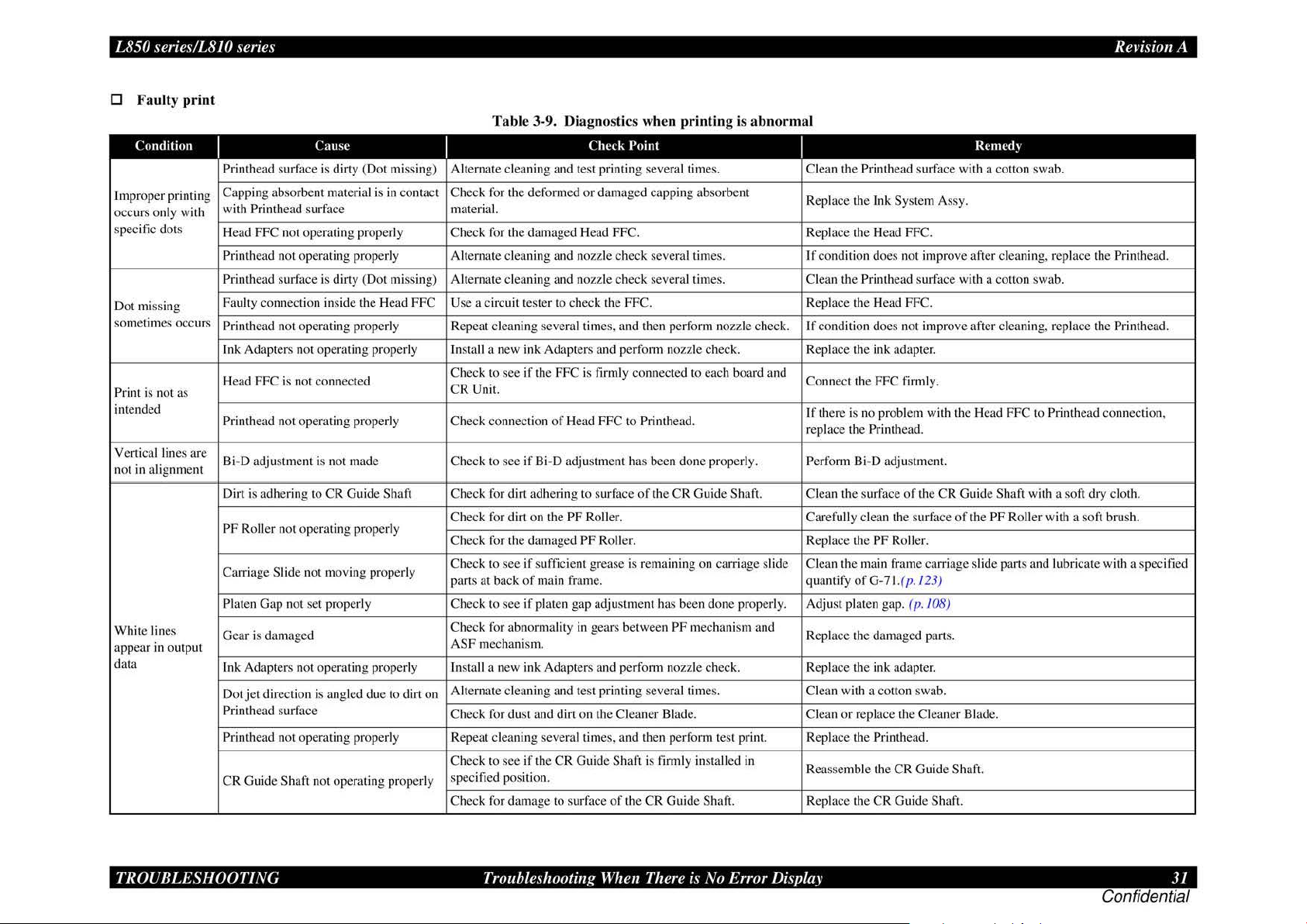

3.3 Troubleshooting When There is No Error Display

3.3

.1

Troubleshooting for Printer

This section describes repair/service

D

Fa

ulty

paper

loading

Condition

Paper is not

loaded.

Several

sheets

paper are

the same time

fed

I

LD Roller and Retard Roller dirty or Check to see

worn the paper loading roller.

Operation

is abnormal mechanism.

PE Sensor/PE Lever not operating

properly

of

at Retard Roller operation is abnorma.l

Cause

of

paper loading mechanism Check to see

of

the Printer Mechanism. Listed below are various problems which may occur, observations

Tab

le 3-5. Diagnostics when feeder is abnormal

Check

I

if

no Micro Pearl or oily substance is adhering to

Point

I

Clean the

I.

Set

a cleaning sheet upside down

2. Start paper feed with the panel button.

3. Repeat steps above

To

remove oils from roller

ostcard

to a p

I.

Set the postcard

facing the LD Roller (or Retard Roller).

Start paper feed while firmly holding the upper edge

2.

3. Repeat the paper

the LD Roller (or Retard Roller).

If these steps do not correct the problem, replace both the

and Retard Roller.

if

there is no abnormality

Check to see if the PE

disconnected

Check to see

properly.

Check

Check to see

di

se

ngaged.

Check to see if the Retard Roller is

fr

if

fo

r damaged PE Sensor. Replace the PE Sensor.

if

Sensor connector has not been Connect the PE Sensor connectors to the sensor and Main Board CN6

om the sensor

the torsion spring

the tension spring on the Retard Roller is

or

in

the paper loading

Main Board. properly.

has

been set on the PE Lever

out

of

position. Install the Retard Roller properly.

Remove the dust and

ll

the torsion spring on the PE Lever properly.

Insta

Install the tension spring properly.

of

such problems, check point and remedies.

roller

s using a cleaning sheet.

se

veral times .

s, sta

and

follow

the