Page 1

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

Product Number Rev. Revised item Date

L5S30348P01 00

www.panelook.com

REVISION HISTORY

Initial issue May. 07, 2007

QA STD Number

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Page 1/30

1. BASIC SPECIFICATIONS ................................................................................................................... 2

1.1 STRUCTURES ..................................................................................................................................................2

1.2 BLOCK DIAGRAM............................................................................................................................................3

1.3 I/O PINS ............................................................................................................................................................4

2. FUNCTIONS......................................................................................................................................... 5

2.1 OVERVIEW .......................................................................................................................................................5

2.1.1 Interface (LVDS) data assignment.......................................................................................................................5

2.1.2 Internal signals ....................................................................................................................................................5

2.1.3 Data and Color arrangement ...............................................................................................................................6

2.1.4 Data and Display Position....................................................................................................................................6

3. ABSOLUTE MAXIMUM RATINGS ......................................................................................................7

3.1 ELECTRICAL ABSOLUTE MAXIMUM RATINGS ........................................................................................... 7

3.2 ENVIRONMENTAL ABSOLUTE MAXIMUM RATINGS................................................................................... 7

4. ELECTRICAL SPECIFICATIONS........................................................................................................8

4.1 ELECTRICAL CHARACTERISTICS ................................................................................................................8

4.2 BACKLIGHT CHARACTERISTICS ..................................................................................................................9

4.3 TIMINGS..........................................................................................................................................................10

4.3.1 Interface ( LVDS ) signal timing parameteres ....................................................................................................10

4.3.2 Jitter tolerance ...................................................................................................................................................11

4.3.3 Interface signal timing parameters (DE MODE).................................................................................................12

4.3.4 Internal signals timing chart (DE MODE) ...........................................................................................................12

4.4 RECOMMENDED SEQUENCE ......................................................................................................................13

5. OPTICAL SPECIFICATION ............................................................................................................... 14

5.1 OPTICAL SPECIFICATION ............................................................................................................................14

5.2 DEFINITION AND CONDITION OF OPTICAL CHARACTERISTICS ............................................................15

6. INSPECTION...................................................................................................................................... 17

6.1QUALITY STANDARD .................................................................................................................................17

6.1.1 Standards ..........................................................................................................................................................17

6.1.2 Lot .....................................................................................................................................................................17

6.1.3 Inspection condition...........................................................................................................................................17

6.1.4 Treatment of defective products ........................................................................................................................17

6.1.5 Treatment of defective products in the acceptance inspection ..........................................................................17

6.1.6 Treatment of other problems .............................................................................................................................18

6.1.7 Warranty............................................................................................................................................................18

6.1.8 Applicable period of repair .................................................................................................................................18

6.2APPLICATION SCOPE ................................................................................................................................18

6.3DISPLAY APPEARANCE STANDARDS.....................................................................................................19

6.4EXTERNAL APPEARANCE STANDARDS.................................................................................................21

6.1 LABEL.............................................................................................................................................................22

6.1.1 Module label ......................................................................................................................................................22

6.1.2 Disposal label ....................................................................................................................................................22

6.1.3 Label position ....................................................................................................................................................22

7. DURABILITY...................................................................................................................................... 23

8. LCD MODULE USAGE AND PRECAUTIONS .................................................................................. 25

8.1 HANDLING......................................................................................................................................................25

8.2 DESIGN OF APPLICATION ...........................................................................................................................27

8.3 STORAGE....................................................................................................................................................... 29

8.4 DISPOSAL ......................................................................................................................................................30

8.5 OTHER PRECAUTIONS.................................................................................................................................30

OUTWARD DRAWINGS ................................................................................................ Attached sheet

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

R

R

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

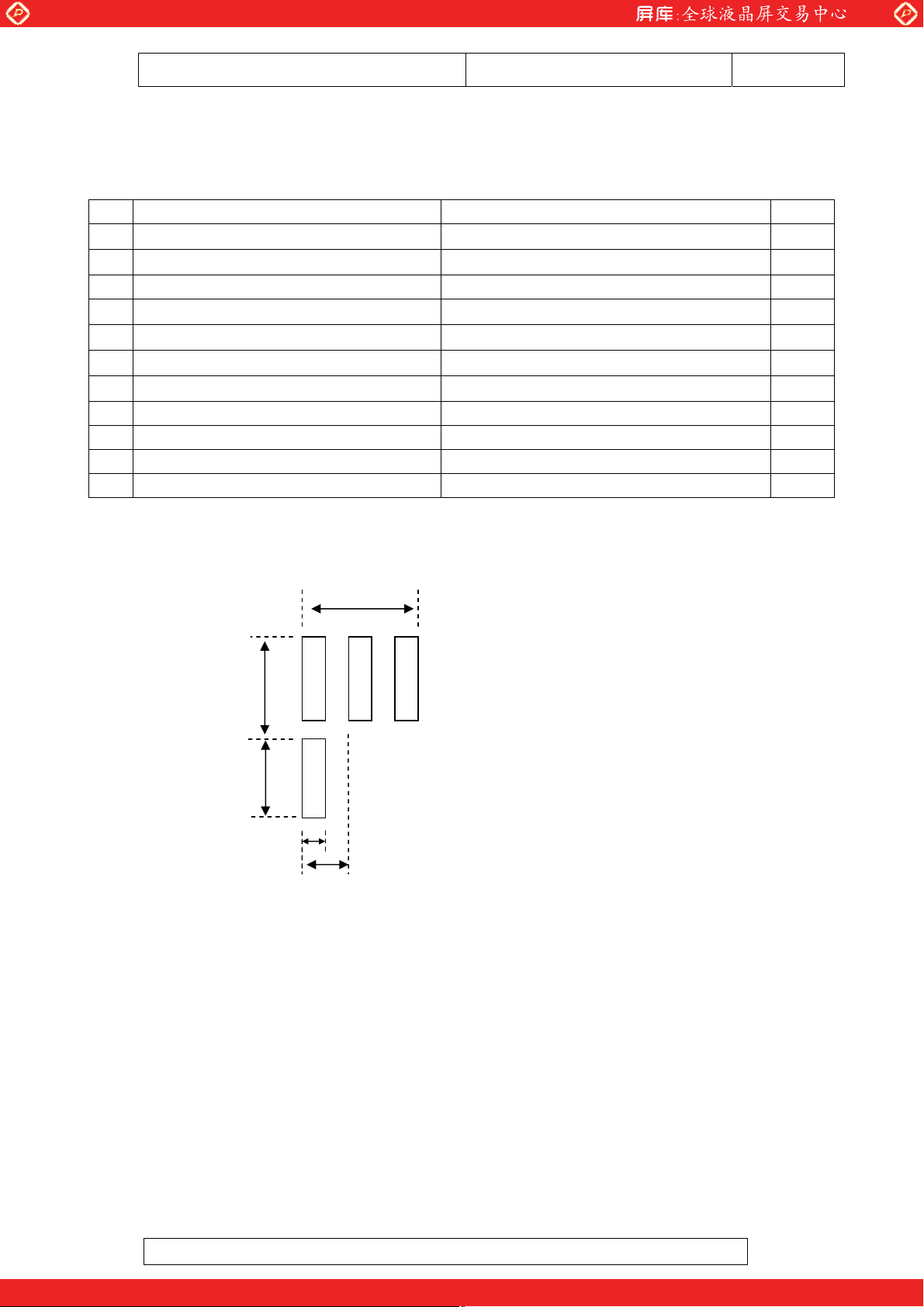

1.BASIC SPECIFICATIONS

1.1 STRUCTURES

No. PARAMETER SPECIFICATIONS UNIT

1 LCD structure

2 Outward

3 Weight 465 Typ. g

4 Active area [Screen dimension]

5 Bezel opening area

6 Number of dots

7 Dot pitch

8 Dot layout Vertical stripe -

9 Viewing direction 6 o’clock 10 Liquid crystal mode TN, Normally white, Transmissive type 11 Polarization plate Non-glare -

*1) See attached drawing for details.

Dot pitch

Dot

Pixel

G B

Dot

Dot pitch

TFT LCD -

284.0(W) x 215.6(H) x 6.8 Max. (T) mm

270.336(W) x 202.752(H) [13.3 inch] mm

273.6(W) x 206.0(H)

1024 x R·G·B(W) x 768(H) -

0.088(W) x 0.264(H) mm

Page 2/30

mm

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

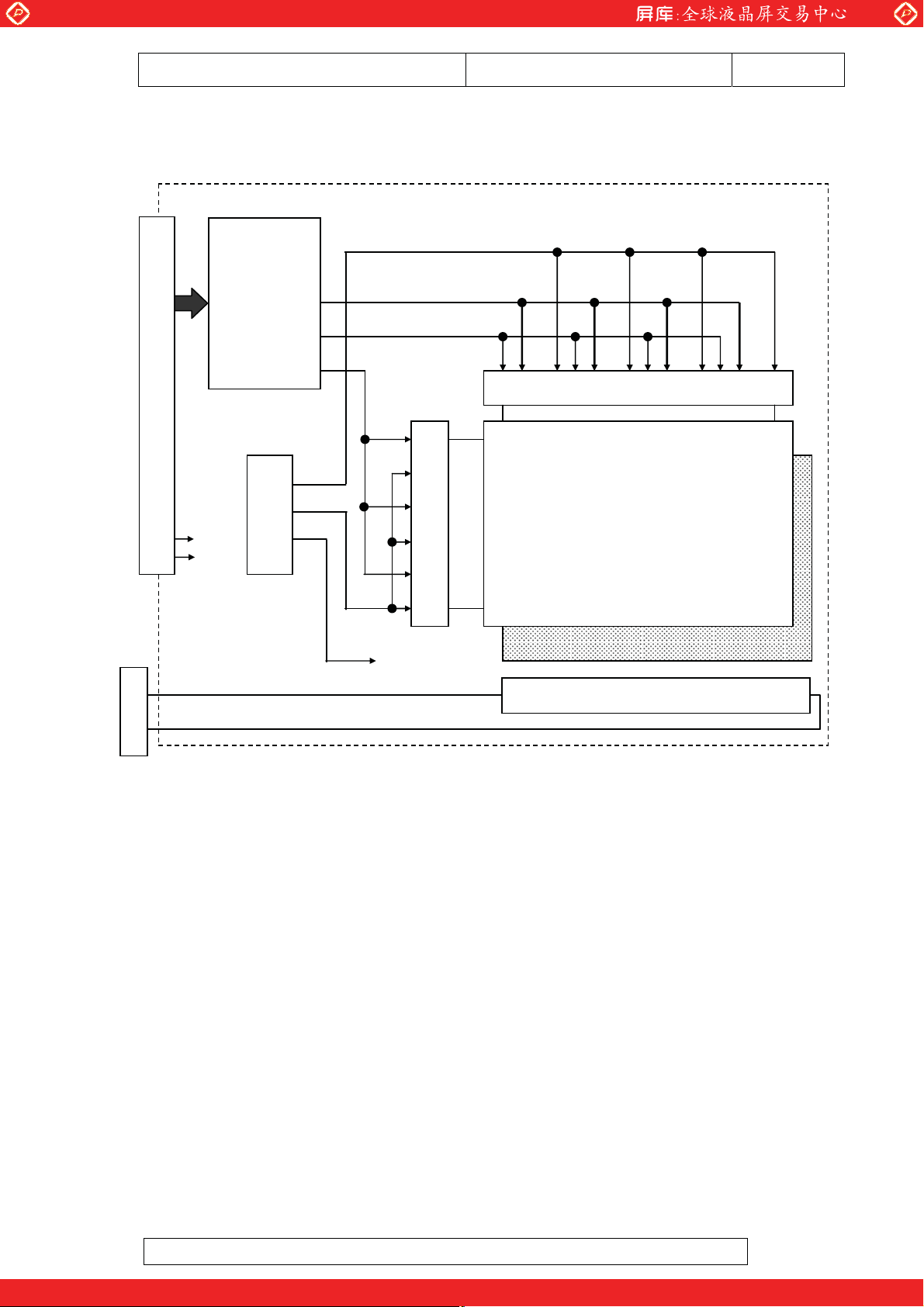

1.2 BLOCK DIAGRAM

CN1

VDD

VSS

FLCN 1

NOTE 1) This model is not equipped with an inverter circuit.

ASIC

TFT

Timing

Controller

(LVDS-Receiver)

DC/DC

Converter

DATA

Vcom

Gate Driver

768

Page 3/30

Source Driver

1024u(RGB)

TFT Panel

Back Light

CFL

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

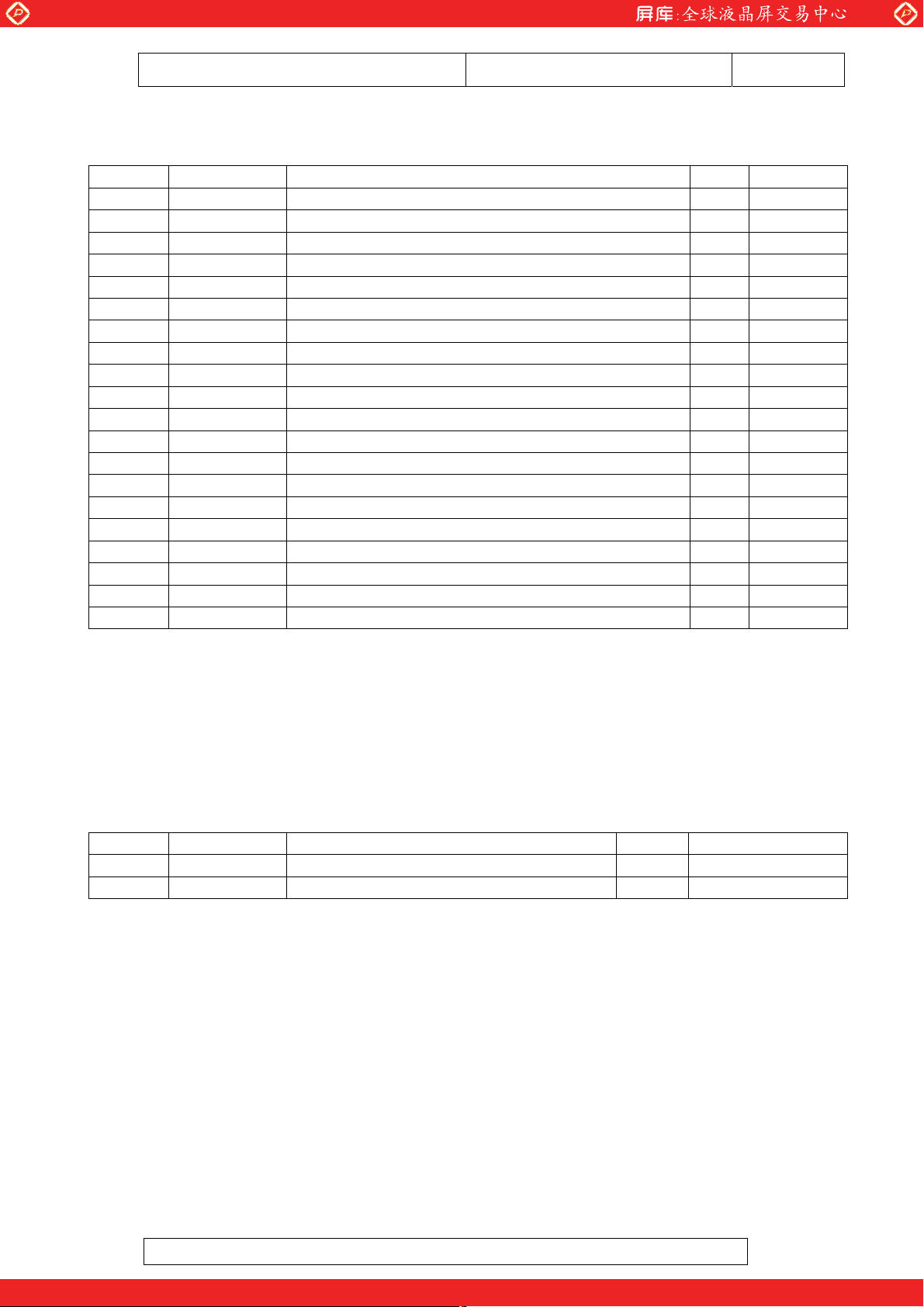

1.3 I/O PINS

LCM㧦CN1

PIN NO. SYMBOL FUNCTION

1 VDD Power Supply ( 3.3V +/- 0.3V)

2 VDD Power Supply ( 3.3V +/- 0.3V)

3 VSS Ground

4 VSS Ground

5 Rin0- LVDS Differential data input (-)

6 Rin0+ LVDS Differential data input (+)

7 VSS Ground

8 Rin1- LVDS Differential data input (-)

9 Rin1+ LVDS Differential data input (+)

10 VSS Ground

11 Rin2- LVDS Differential data input (-)

12 Rin2+ LVDS Differential data input (+)

13 VSS Ground

14 RCLK- LVDS Differential Clock input (-)

15 RCLK+ LVDS Differential Clock input (+)

16 VSS Ground

17 NC No Connection䋨Should be opened during operation䋩

18 NC No Connection䋨Should be opened during operation䋩

19 VSS Ground

20 VSS Ground

Page 4/30

I/O REMARKS

P

P

P

P

I

I

P

I

I

P

I

I

P

I

I

P

-

P

P

CN1: DF19KR-20P-1H (HIROSE)

Suitable mating connector : DF19G-20S-1C (HIROSE) Wire type

㧦DF19G-20S-1F (HIROSE) FPC type

I/O : Input / Output terminal, I : Input terminal, O : Output terminal, P : Power line terminal

NOTE 1) Internal termination resistors of LVDS input lines are 100 ohms.

NOTE 2)

Valid synchronous signals are DCLK and DE. HSYNC and VSYNC are not used.

Backlight : FLCN1

PIN NO. SYMBOL FUNCTION

1 H.V High voltage for CFL

2 LGND Low voltage for CFL

I/O REMARKS

P

P

FLCN1 : BHSR-02VS-1 (JST)

Suitable mating connector: SM02B–BHSS-1-TB (JST)

NOTE 1) I/O : Input / Output terminal, I : Input terminal, O : Output terminal, P : Power line terminal

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

R

4

R

3

R

2

R

0

0 (

5

(

)

0

4

9

3

2

8

7

6

5

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

2. FUNCTIONS

2.1OVERVIEW

2.1.1 Interface (LVDS) data assignment

Rin0 +/-

Rin1 +/-

Rin2 +/-

RCLK +/-

Rxout 6

G0 (LSB)

Rxout 13

B1

Rxout 20

DE

R5(MSB)

Rxout 12

B

Rxout 19

VSYNC

Rxout 5

LSB)

xout

R4

Rxout 11

G

MSB

Rxout 1

HSYNC

xout

R3

Rxout 1

G

Rxout 1

B5(MSB)

xout

R2

Rxout

G

Rxout 1

B4

xout 1

R1

Rxout 8

G

Rxout 1

B3

Rxout

R0 (LSB)

Rxout 7

G1

Rxout 14

B2

Page 5/30

2.1.2 Internal signals

SYMBOL FUNCTION

DCLK Data Clock

HSYNC Horizontal Sync. (This signal is invalid.)

VSYNC Vertical Sync. (This signal is invalid.)

DE Data Enable (positive)

R0 Red Data (LSB)

R1 Red Data

R2 Red Data

R3 Red Data

R4

R5

Red Data

Red Data (MSB)

G0 Green Data (LSB)

G1 Green Data

G2 Green Data

G3 Green Data

G4 Green Data

G5 Green Data(MSB)

B0 Blue Data (LSB)

B1 Blue Data

B2 Blue Data

B3 Blue Data

B4

B5

Blue Data

Blue Data (MSB)

NOTE 1) “DE mode “ only.

The valid synchronous signals are DCLK and DE. HSYNC and VSYNC are invalid.

NOTE 2) INTERNAL SIGNALS are loaded from LVDS - Receiver to TFT Timing controller

with LVDS sequence. (See BLOCK DIAGRAM.)

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

2.1.3 Data and Color arrangement

INPUT DATA

DISPLAY

COLOR

BLACK L L L L L L L L L L L L L L L L L L

RED H H H H H H L L L L L L L L L L L L

GREEN L L L L L L H H H H H H L L L L L L

BASIC

COLOR

BLUE L L L L L L L L L L L L H H H H H H

CYAN L L L L L L H H H H H H H H H H H H

MAGENTA H H H H H H L L L L L L H H H H H H

YELLOW H H H H H H H H H H H H L L L L L L

WHITE

BLACK L L L L L L L L L L L L L L L L L L

RED(1) L L L L L H L L L L L L L L L L L L

RED(2) L L L L H L L L L L L L L L L L L L

RED

: : : :

: : : :

RED(61) H H H H 䌌 HLLLLLLL L L LLL

RED(62) H H H H H 䌌 LLLLLLL L L LLL

RED(63)

BLACK L L L LLLLLLLLLL L L LLL

GREEN(1) L L L LLLLLLLLHL L L LLL

GREEN(2) L L L LLLLLLL䌈䌌L L L L L L

GREEN

: : : :

: : : :

GREEN(61) L L L L L L H H H 䌈䌌H L L L L L L

GREEN(62) L L L L L LHHHHH䌌 L L L L L L

GREEN(63)

BLACK L L L LLLLLLLLLL L L LLL

BLUE(1) L L L LLLLLLLLLL L L LLH

BLUE(2) L L L LLLLLLLLLL L L LHL

BLUE

: : : :

: : : :

BLUE(61) L L L LLLLLLLLLH H H H䌌䌈

BLUE(62) L L L LLLLLLLLLH H H HH䌌

BLUE(63)

Page 6/30

RED DATA

MSB LSB MSB LSB MSB LSB

R5 R4 R3 R2 R1 R0 G5 G4 G3 G2 G1 G0 B5 B4 B3 B2 B1 B0

H H H H H H H H H H H H H H H H H H

H H H H H H L L L L L L L L L L L L

L L L L L L HHHH䌈䌈L L L L L L

L L L LLLLLLLLLH H H HHH

GREEN DATA BLUE DATA

NOTE 1) Chromaticity (n) --- "n" indicates grayscale's number.

2.1.4 Data and Display Position

1㨯1 1㨯2

2㨯1

.

.

.

.

767㨯1

768㨯1 768㨯2

VpHp R G B

. . . . . . . .

. . . . . . . . .

EPSON IMAGING DEVICES CORP㧚

1㨯1023 1㨯1024

2㨯1024

.

.

.

.

767㨯1024

768㨯1023 768㨯1024

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Page 7/30

3. ABSOLUTE MAXIMUM RATINGS

3.1 ELECTRICAL ABSOLUTE MAXIMUM RATINGS

Ta= 25 deg C

PARAMETER SYMBOL RATINGS UNIT REMARKS

Power supply voltage VDD-VSS 4.0 V

LVDS Input voltage VIN

CFL current IL 7.0 mA

VHV 2000 Vrms CFL supply voltage

V

LGND 100 Vrms

NOTE 1)㩷 VIN: Rin0-/+, Rin1-/+, Rin2-/+, RCLK-/+

3.2 ENVIRONMENTAL ABSOLUTE MAXIMUM RATINGS

PARAMETER SYMBOL CONDITIONS

TST Storage -20 60 Ambient

temperature

OP Operation 0 50

T

Humidity - Ta=40 deg C

max.

Vibration - Storage - 1.5 G NOTE 3)

Shock - Storage - 50 G XYZ 6ms / direction

VSS – 0.3 㨪 VDD + 0.3

RATINGS

MIN MAX

- 85 %RH No condensation

V NOTE 1)

Ta= 25 deg C

UNIT REMARKS

deg.C NOTE 1)

NOTE 2)

NOTE 1) Care should be taken so that the LCD module may not be subjected to the temperature

beyond this specification

NOTE 2) Ta> 40 deg. C : Absolute humidity must be less than 85% RH/40 deg.C

NOTE 3) 10-200Hz, 30min/cycle, X/Y/Z each one cycle and except for resonant frequency.

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

4. ELECTRICAL SPECIFICATIONS

4.1 ELECTRICAL CHARACTERISTICS

VDD =3.3V , fCLK = 65MHZ, fH = 48.4kHz, fV = 60Hz, Ta = 25 deg C

PARAMETER SYMBOL CONDITIONS

MIN TYP MAX

Power supply voltage VDD-VSS

LVDS input Threshold

voltage

Common mode voltage

of LVDS input

VTH

VTL

CM

V

High level - - +100

Low level -100 - -

1.125 1.25 1.375 V

Power supply current IDD NOTE 1) - 250 - mA

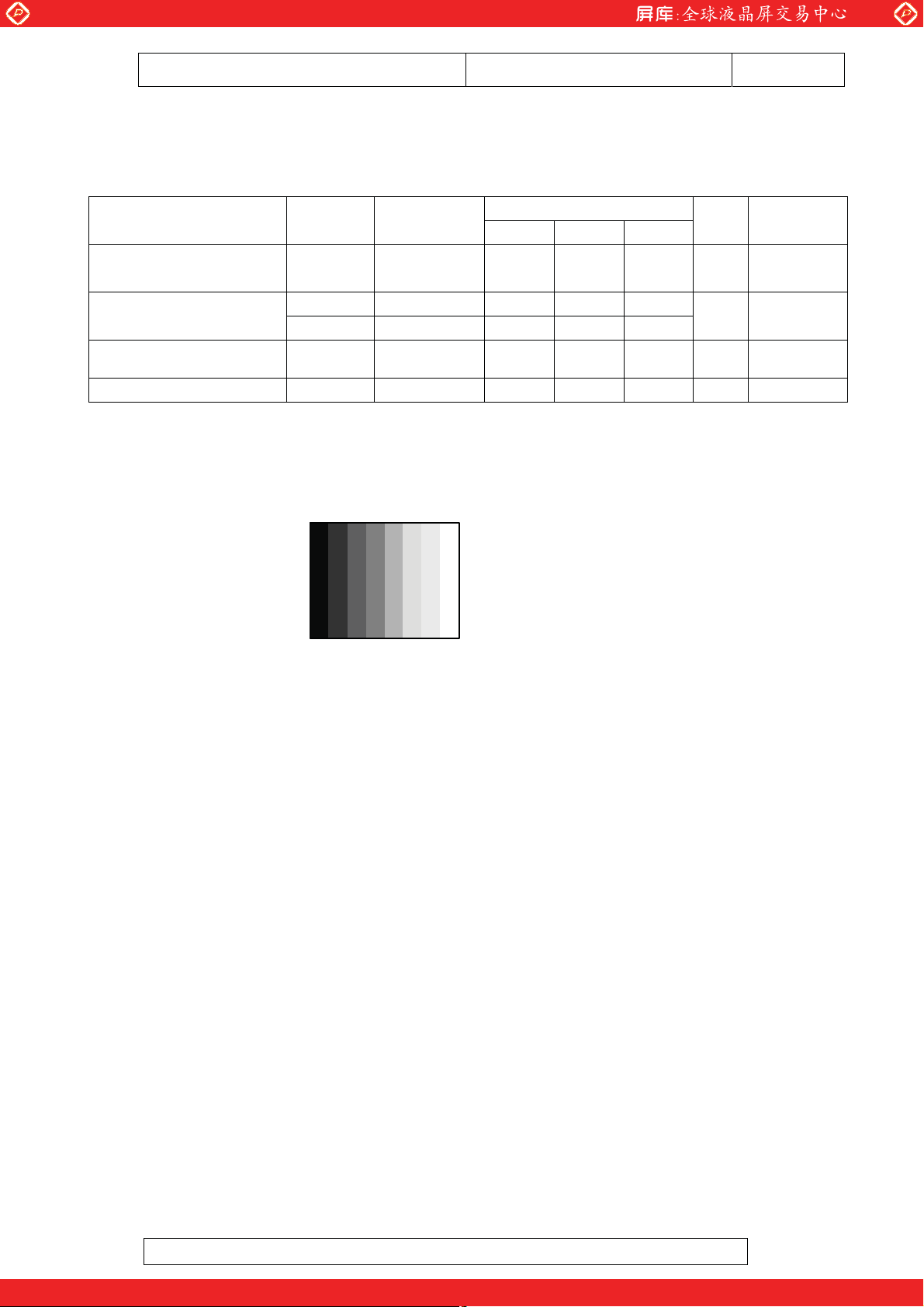

NOTE 1) Display pattern of Typ. value is 64 grayscales.

NOTE 2) V

CM : Common mode voltage of LVDS input.

< 64 grayscales >

RATINGS

3.0 3.3 3.6 V

Page 8/30

Unit REMARKS

Terminal

Post

CM=1.25V

mV

V

NOTE 2)

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Page 9/30

4.2 BACKLIGHT CHARACTERISTICS

Ta= 25 deg.C

PARAMETER

SYMBOL CONDITIONS

MIN TYP MAX UNIT REMARKS

CFL voltage VL - 630 - Vrms at IL=6.0mArms

CFL current IL 3.0 - 6.5 mArms

Driving frequency fL 40 - 65 kHz

Discharge starting

voltage

CFL lifetime

S - - 1350 Vrms at Ta=0 degC

V

tOL

20000

- - Hours

at I

L=6.0 mArms

continuous

operating

NOTE 5)

NOTE 1) There may be a display flickering by interaction of the backlight driving conditions

(especially for the Inverter frequency f

L) and the module's horizontal frequency fH.

Therefore, sufficient confirmation should be made when using inverter.

NOTE 2) The open circuit voltage of the Inverter should be designed higher than the discharge

starting voltage recorded in this table, and also should be applied more than 1 second. If

not applied as mentioned above, the backlight may not start properly.

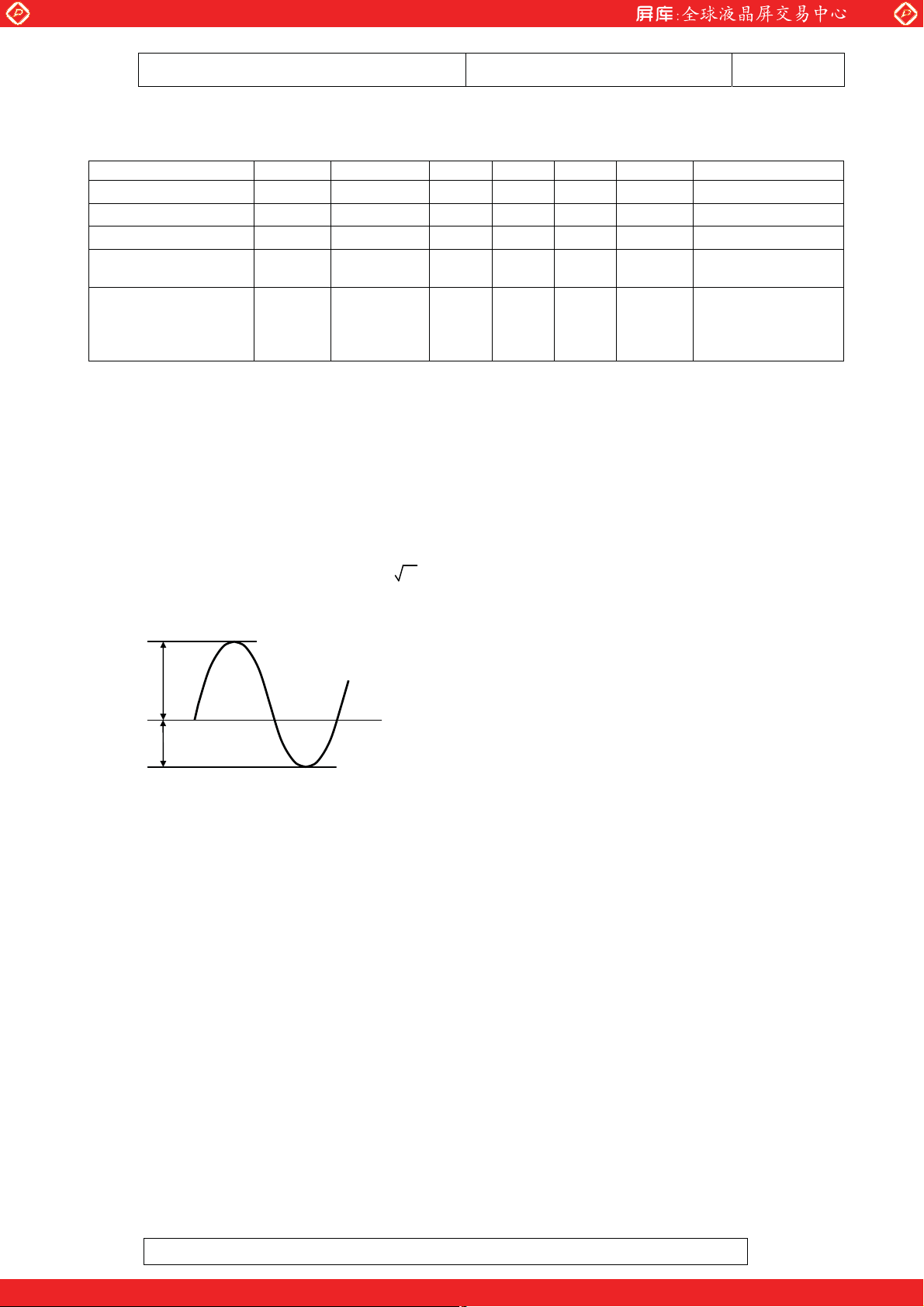

NOTE 3) Asymmetrical waveform will cause a degradation of lifetime by unevenness of mercury.

Therefore, the current waveform should have an unbalancing-ratio of less than 10%, and

an amplitude-ratio of less than 2 ±10%. The current waveform should be measured by

actual final product.

Ip

-p

I

Current Waveform

Unbalance rate = | Ip - I-p | / IL x 100 (%)

Wave-height rate = I

p (or I-p) / IL

p :High peak

I

-p :Low peak

I

L :RMS

I

NOTE 4) Be sure to use a Ground Referenced type for the Inverter. Don't use a Ground Floating

type.

NOTE 5) The value that corresponds to the items written below is the definition of CFL life (when the

CFL is lit at Ta= 25, IL= 6.0mA):

1) when the brightness of the CFL falls to 50% or less of its initial value,

2) when the lighting start voltage does not fulfill the value written above

NOTE 6) The regulation of the CFL life is when the direction of the CFL tube axis (longer length of the

LCD module) is installed horizontally in the module. The life of the CFL may shorten when

the LCD module is used vertically due to mercury migration within the CFL tube.

NOTE 7) The CFL life will differ depending on the environmental temperature the LCD module is

used in. If the CFL is used in a cold/ hot environment for a long period of time, the

brightness will decrease drastically which may lead to a shorter CFL life.

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

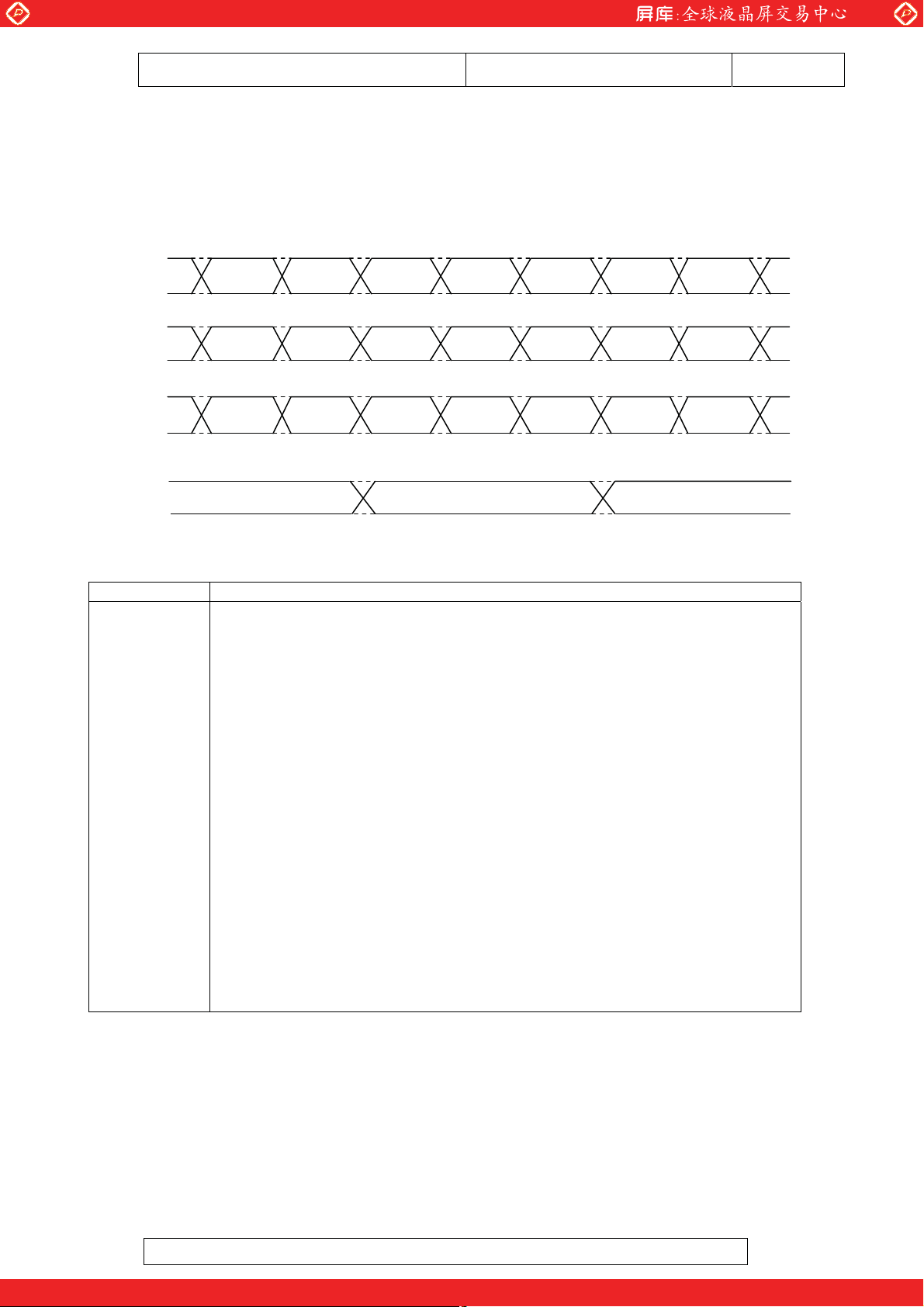

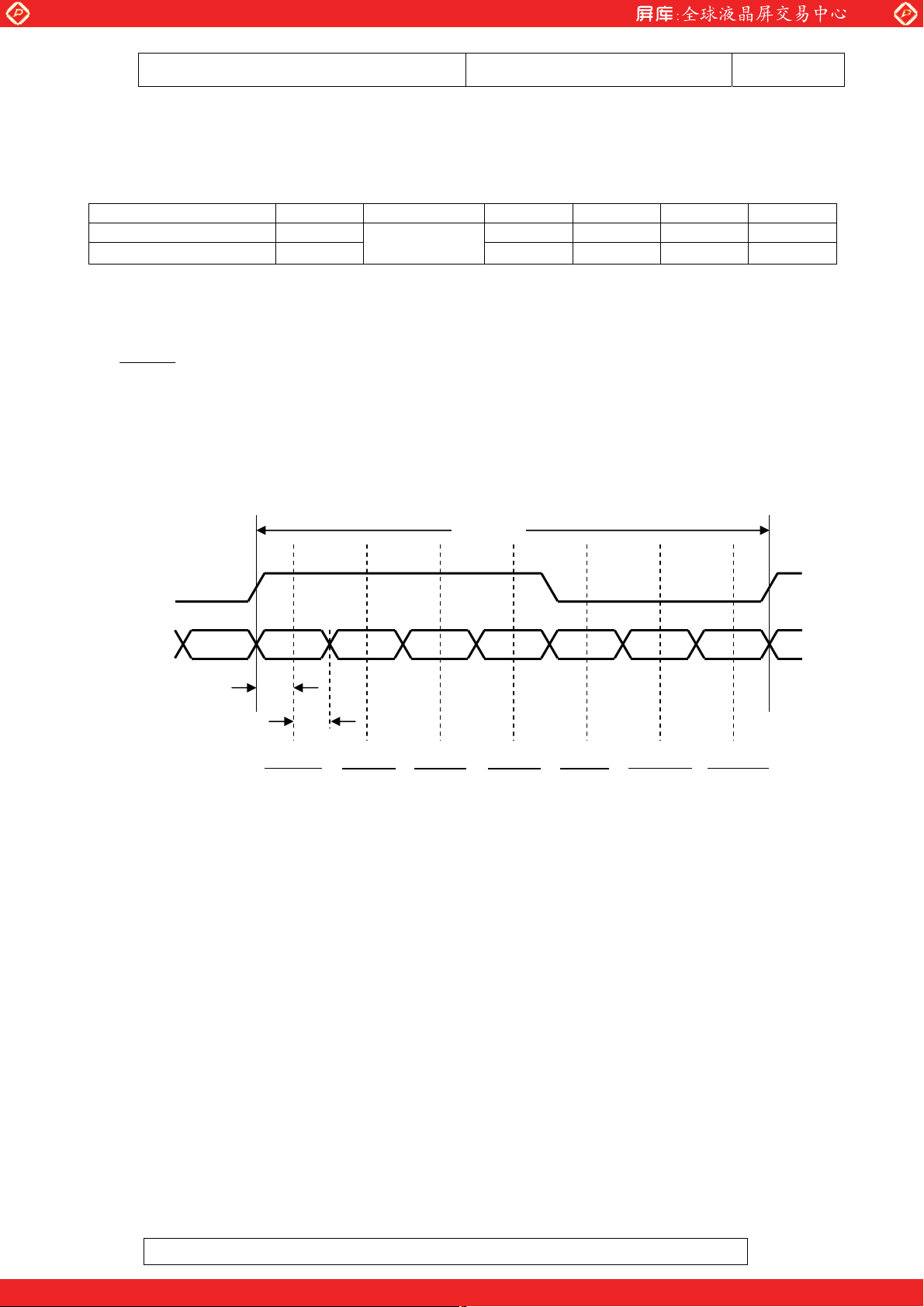

4.3TIMINGS

4.3.1 Interface ( LVDS ) signal timing parameteres

VDD = 3.3V , fCLK = 65MHz , Ta = 25 deg.C

PARAMETER SYMBOL

Data setup time tsu 420 - - ps

Data hold time thd

CONDITION MIN TYP MAX UNIT

t

CLK=15.4ns

420 - - ps

The timing waveform in Figure 1 indicates the ideal strobe point of the LVDS input data:

n · tCLK

n : odd number

14

t

CLK : LVDS input clock period

The data setup time is "tsu" and the data hold time is "thd".

14

tCLK

7 tCLK

14

9 tCLK

14

11 tCLK

14

13 tCLK

RCLK +/-

Rin x +/-

㩷 tsu

thd

1 tCLK

14

Figure 1. LVDS data-input-timing waveform diagram

3 tCLK

14

5 tCLK

Page 10/30

14

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

p

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

4.3.2 Jitter tolerance

PARAMETER SYMBOL

MIN TYP MAX UNIT

Simple cycle jitter tcj1 - - 300 ps

Clock-period change rate tcj2 - - 25 ps / cycle

period (ns)

LVDS in

25.4

25.3

25.2

25.1

25.0

ut clock cycle Jitter example

24.9

24.8

0 50 100 150

cycle

Page 11/30

Figure 2 Example of impermissible cycle jitter

Assuming that the period of a given clock cycle "n" is represented by "tCLK", for example, the period

of cycle "n + 1" may be tolerated up to t

CLK ± 300 [ps]. However, if period fluctuations continue, the

limit to that change rate, rather than this tolerable range, constitutes the "clock-period change rate."

For 28 to 32 cycles in Figure 2, the lowest clock period during this interval is 24.9 [ns], and the

highest clock period is 25.3 [ns].

25.3 - 24.9 = 0.4 [ns]

0.4 / 5 (cycles) = 0.08 [ns]

Because a period fluctuation of 80 [ps] per cycle exists here, the rated "clock-period change rate" in

the above table is not achieved.

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

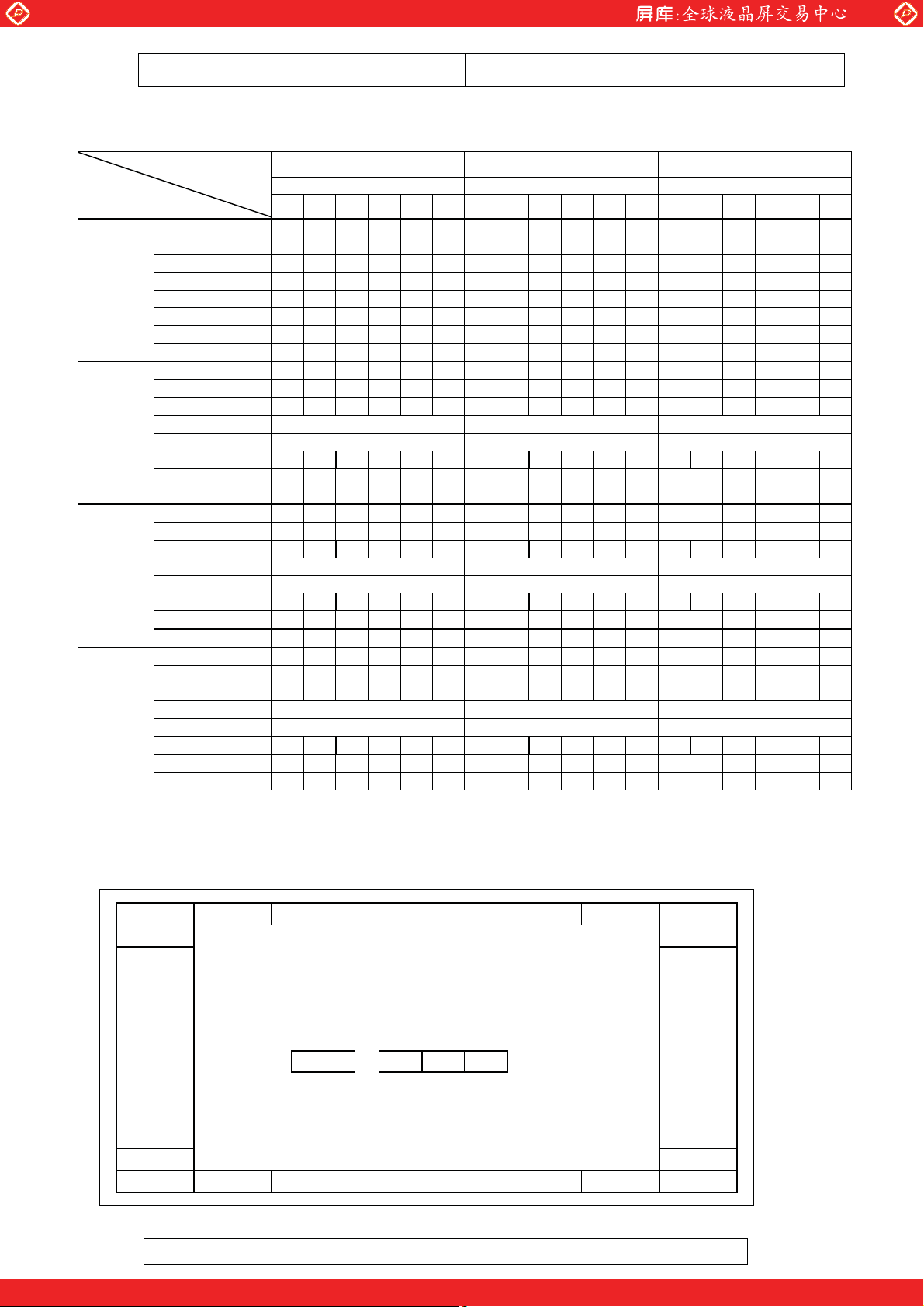

Page 12/30

4.3.3

Interface signal timing parameters (DE MODE)

PARAMETER SYMBOL MIN TYP MAX UNIT REMARKS

Clock Frequency fCLK 60.0 65.0 66.6 MHz (fCLK=1/tCLK)

Horiz. Period tHP 1270 1344 1450 tCLK

Horiz. DE tHDE 1024 1024 1024 tCLK

Horiz. Frequency fH 44.6 48.4 49.5 KHz (fH=1/tHP)

Vert. Period tVP 780 806 900 tHP fV=60Hz typical

Vert. DE nVDE 768 768 768 tHP

Vert. Frequency fV 55 60 62 Hz fV=1/tVP

NOTE 1) These signal timing parameters are specified at the digital inputs of LVDS transmitter.

With respect to setup time and hold time for DE and DATA signals, please refer to input

signal specification of LVDS transmitter.

Recommended LVDS transmitter : SN75LVDS84 (TI)

NOTE 2) Values recorded in this table indicate the properly operating conditions of the internal logical

functions. They don't guarantee the display quality or the display situation.

4.3.4

Internal signals timing chart (DE MODE)

DE

DE

Shrink

HP

t

tHDE

tVP

1 2 - - - - - n-1 n

n

VDE

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

4.4 RECOMMENDED SEQUENCE

VDD

LVDS

CFL

(Recommend)

0< t1< 25ms

0V

0V

0 < t

ON

OFF

10%

2< 65ms

100ms < t3

Power-on

90%

5ms < t6< 200ms

5 < 50ms

0 < t

VALID DATA

Power-off

90%

VTH

VTL

0ms < t

10%

VCM

4

Page 13/30

150ms < t

VDD=3.3V

7

NOTE 1) LVDS input should be set to "L" level or "Hi-Z.", when the power is turned off.

NOTE 2) LVDS input should be set to "L" level or "H" level, when the power is turned on. Don't set

them to "Hi-Z."

NOTE 3) Although no sequence for CFL is specified here, properly maintained timing is

recommended as described above. If the backlight is turned on before or after the LVDS

signal input, the display may be disordered by the changing of the LCD signals from the

timing controller (included in this module). Liquid crystal material or driving circuit can not

be damaged by the disorder of the display.

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

5. OPTICAL SPECIFICATION

5.1 OPTICAL SPECIFICATION

VDD = 3.3V, fCLK = 65MHZ, fH = 48.4kHz, fV = 60Hz, Ta = 25deg.C

PARAMETER CONDITIONS SYMBOL

Contrast ratio

RED - x

RED - y

GREEN - x

Display Color

Response

GREEN - y

BLUE - x

BLUE - y

WHITE - x

WHITE - y

B -> W

W -> B

Brightness

Brightness uniformity

Viewing angle CR>10

T= 0 deg.

T= 0 deg.

T= 0 deg.

T= 0 deg.

T= 0 deg. GB

Page 14/30

RATINGS

MIN. TYP. MAX.

UNIT

CR 300 500 - - NOTE)2,4,7

Rx 0.56 0.59 0.62

Ry 0.32 0.35 0.38

Gx 0.29 0.32 0.35

Gy 0.53 0.56 0.59

Bx 0.12 0.15 0.18

By 0.08 0.11 0.14

Wx 0.285 0.315 0.345

Wy

tr - 20 -

tf - 5 -

0.300 0.330 0.360

ms NOTE)3,4,7

B 380 480 - cd/m

- - 1.60 - NOTE)5,6,7

B 30 45 R 40 50 T 10 25 -

deg.

L 40 50 -

DEFINITION

- NOTE)4,7

2

NOTE)4,6,7

NOTE)

1, 2, 4,7

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

g

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

5.2 DEFINITION AND CONDITION OF OPTICAL CHARACTERISTICS

Display face

Left

TB

Normal(T=0deg.)

TL

TR

TT

Top

BLACK

WHITE DATA

100%

B

90%

Bottom

10%

0%

VT

Ri

ht

NOTE1) Viewing Angle NOTE3) Response:

NOTE2) Contrast ratio "CR"

Page 15/30

BLACK

VH

White brightness

CR =

Black brightness

NOTE 4) Measured at the center of the active area ( point 3 in NOTE 6 )

NOTE 5) Brightness uniformity "GB "

GB=

Maximum brightness of the 5points

Minimum brightness of the 5points

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

p

p

p

p

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

NOTE 6) Measurement points

1/6Vp

1/2V

5/6V

NOTE 7) Measuring conditions

(1) Instrument : BM-5A (TOPCON Corp.), Field= 2 degree

(2) Measurement distance : 50 cm

(3) Ambient temperature Ta : 25±2

(4) Display : White screen, Red screen, Green screen, Blue Screen, Black Screen

(5) Display : V

(6) Measuring after 30min. elapsed from CFL starting on.

(7) CFL tube current : IL= 6.0 mArms

CFL Inverter : CXA-L0612A-VJL (TDK)

1/6Hp

1/2H

1 2

5/6H

3

4

5

Vp: vertical pixel number

Hp: horizontal pixel number

deg C

DD = 3.3V, fCLK = 65MHz, fH = 48.4kHz, fV = 60Hz

Page 16/30

Active area

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

6. INSPECTION

6.1QUALITY STANDARD

6.1.1 Standards

The standards are the quality level used to judge whether or not product lots pass during acceptance

inspections of products delivered to your company. The standards are shown below.

Inspection method: Compliant with ANSI/ASQC Z1.4-1993, ordinary inspection level Τ, inspection

by one time sampling.

AQL

Defect type AQL Definition

Major defects 0.4% Accompanied with functional abnormalities

Minor defects 1.5% Out of the range of "6.3 EXTERNAL APPEARANCE STANDARDS", but

6.1.2

Lot

Page 17/30

no functional abnormalities

Lot means the unit includes all products delivered to your company at one time.

6.1.3

Inspection condition

(1) Environmental condition

Under 20 to 25deg.C, 60±15%RH.

Operative inspections are done under 800 to 2000 lx environment.

Especially related to transparence are performed under at most 50 lx environment.

(2) Inspection method

Inspect the screen by naked eye from a distance of about 30cm on a vertical direction front

on.

(3) Driving condition

According to the specification

6.1.4

Treatment of defective products

When defective products were found in your company's acceptance inspection and manufacturing

process or field, we treat them according to the rules below.

6.1.5

Treatment of defective products in the acceptance inspection

(1) When a product has failed to pass your company's acceptance inspection, please notify to

EPSON IMAGING DEVICES CORP. within 3 weeks from delivery. Otherwise, EPSON

IMAGING DEVICES CORP. will regard that it had been accepted.

(2) When a lot has failed to pass your company's acceptance inspection, please return the entire

lot to EPSON IMAGING DEVICES CORP. EPSON IMAGING DEVICES CORP. will investigate

the causes of defects and will report both the causes and the responses taken to them.

Non-defective products shall be delivered to replace all defective products within

nonconforming lots.

Non-defective products shall be delivered to replace all defective products within conforming lots.

(3)

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

6.1.6

Treatment of other problems

Page 18/30

If any troubles should occur concerns our products that have been assembled at your company's

manufacturing processes, both companies shall jointly investigate and resolve the causes.

6.1.7

Warranty

EPSON IMAGING DEVICES CORP. warrants this product for a period of 12 months from production

date indicated on the Lot Label attached to the product.

Warranty period for repaired products shall be 6 months from production date indicated on the repair

Lot Label attached to the product.㩷

During this period, supplier responsible failures shall be repaired free of charge.

6.1.8

Applicable period of repair

Applicable period of repair shall be 24months from production date indicated on the Lot Label

attached to the product.

After 24 months, we cannot provide you our repair service.

㩷㩷

6.2APPLICATION SCOPE

The application scope is limited to the viewing area.

The product should be judged non-defective if all defects are outside of the viewing area and do not

interfere with product quality or the assembly process.

Each "dot" means the smallest display unit for R, G or B.

A set of three adjacent R, G and B dots comprise one pixel.

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Page 19/30

6.3DISPLAY APPEARANCE STANDARDS

If any item is defined with a boundary sample, the boundary sample takes precedence.

No. ITEM CRITERION CLASS

Display

1

problems

Missing lines No missing lines permitted. Major

2

Dot defects Defined allowable ranges should be met for each white, black, R, G, B

3

Inconsistent

4

display

Refuses and

5

scratches on

polarizer or

glass

*2)

Must not include any nonfunctioning or failure to display the correct

pattern corresponding to input signal.

raster.

The limits apply to the entire display area. *1)

Those visible through the 5% ND-Filter are to be considered bright

dot defects.

Bright spot in 60% or more of dot aperture is defined as a bright dot

defect, less than 60% is permitted.

Black spot in 60% or more of typical pixel aperture is defined as a

black dot defect, less than 60% is permitted.

Should not be prominent.

If necessary, boundary samples should be provided.

<Dot shape>

Allowable range

1. distinctly recognized

size d (mm) numbers

d҇0.2 permitted

0.2㧨d҇0.3 5

0.3㧨d҇0.5 2

2. blurred

size d (mm) numbers

d҇ 0.64 permitted

0.64㧨d҇1.50 2

1.50㧨d 0

Major

defect

defect

Minor

defect

Minor

defect

Minor

defect

Criterion is applied also to pin-holes.

Defects must not be crowded.

Distinctly recognized spot is the one which can be seen at raster

pattern.

Blurred spot is the one which can not be seen at raster pattern but

can be seen at gray scale pattern.

<Line shape>

1. Scratch

L: Length (mm) W: Width (mm) numbers

permitted W҇0.03 permitted

.҇5.0 0.03㧨W҇0.10 3

- 0.10㧨W allowed

2. Black and white lines

L: Length (mm) W: Width (mm) numbers

permitted W҇0.03 permitted

.҇1.0 0.03㧨W҇0.15 4

- 0.15㧨W allowed

Minor

defect

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Page 20/30

No. ITEM CRITERION CLASS

Bubbles in

6

polarizer

(display area)

*2)

Allowable range

size d (mm) numbers

d҇0.2 permitted

0.2㧨d҇0.3 5

Minor

defect

0.3㧨d҇0.5 2

0.5㧨d 0

*1: dot defect's allowable range

No. Item Bright dot defect Black dot defect total

1 Defects counts 5 5

10

2 Combined defects 2 2

Adjacent 2 bright dots and 2 black dots are counted as one dot respectively.

Linked three or more dots: none

Defects must be at least 5mm apart from one another.

*2: outward of refuses, scratches and bubbles

Dot shape Line shape

d=(a+b)/2

a

L

b

Gentle curve Curved arch Multiple curves

L

L (a)

W

W (b)

W

W (b)

L (a)

Any defect outside the viewing area can be ignored.

When viewing with the naked eye, any bent or dot-shaped item must be measured and checked

according to the dot shape defect's standard.

Refer to the following examples of measurement methods.

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Page 21/30

6.4EXTERNAL APPEARANCE STANDARDS

No. ITEM CRITERION CLASS

1 Different

Not permitted. Major defect

specifications

2 Missing parts All parts must be complete. Major defect

3 Damaged resist on

Copper patterns on FPC must not be visible. Minor defect

FPC

4 Circuit pattern Must not be peeled or separated from FPC. Major defect

5 Conductive

refuses

No solder refuses or solder balls easily moving.

Fixed conductive refuses over 0.2mmǾ are not permitted.

Minor defect

Should not be crowded.

(crowded: means gathering more than 5pcs within Ǿ=5mm㧕

6 Dirt Should not be prominent.

Minor defect

Dirt on backside is permitted.

7 Dirt or scratch on

Should not be prominent. Minor defect

interface pins

8 Plating Must not be peeled, no rust, no discoloration. Minor defect

9 Soldering Solder omissions are not permitted at any solder point.

Solder bridges are not permitted.

Cold soldering is not permitted.

10 Parts soldering There must be fillet

Major defect

Major defect

Minor defect

Minor defect

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

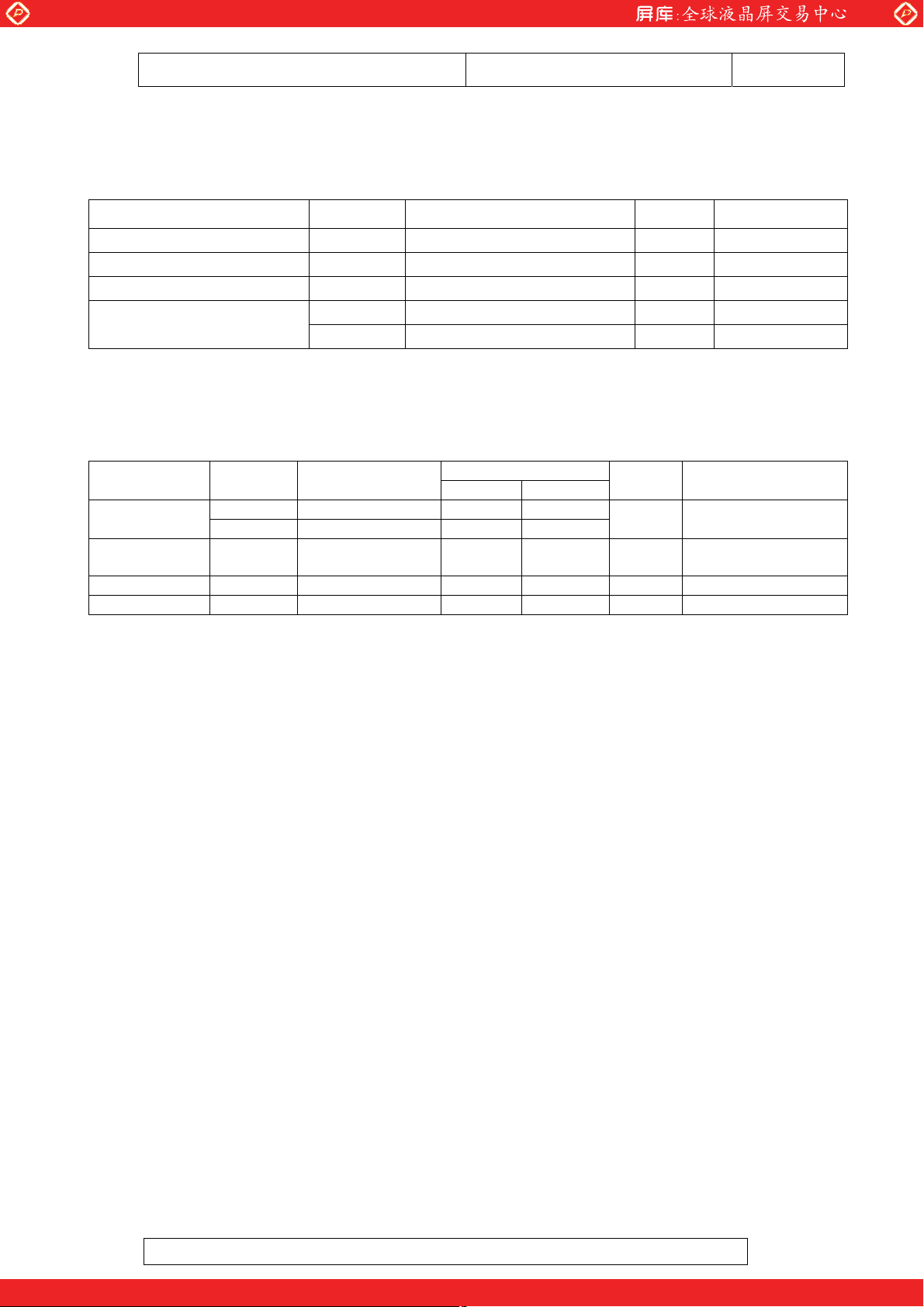

7. PACKING

7.1 LABEL

7.1.1 Module label

L5S30348P01

***********7507

******************

7.1.2 Disposal label

COLD CATHODE FLUORESCENT LAMP IN LCD PANEL CONTAINS A SMALL AMOUNT OF MERCURY.

PLEASE FOLLOW LOCAL ORDINANCES OR REGULATION FOR DISPOSAL.

TFT-LCM

MADE IN JAPAN

(engraved)

EPSON Imaging Devices’s Product number

Module Lot No.

The last 4 digits indicate a production date.

(Ex.) May.07.2007

Panel Lot No.

Production country

Page 22/30

Production Month

Month : Code Month : Code

Jan. : 1 Jul. : 7

Feb. : 2 Aug. : 8

Mar. : 3 Sep. : 9

Apr. : 4 Oct. : X

May : 5 Nov. : Y

Jun. : 6 Dec. : Z

7.1.3 Label position

Module Label

Disposal Label (engraved)

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

8. DURABILITY

Reliability Test Item and Test Condition / Method

No. ITEMS CONDITION

1 Continuous operating test

at high temperature

2 Continuous operating test

at low temperature

3 Storage test at high

temperature

4 Storage test at low

temperature

5 Continuous operating test

at high temperature and

high humidity

6 Thermal shock test Hold the cycle test 120 times on the condition as follows :

7 Vibration test

(non-operating)

8 Shock test

(non-operating)

9 Electrostatic discharge test

(non-operating)

10 Shock test

(after packing)

11 Falling test

(after packing)

Apply rated voltage in an atmosphere of 50 ± 2 C and operate

240 hours.

Apply rated voltage in an atmosphere of 0 ± 2 C and operate 240

hours.

After allowing to stand for 240 hours at 60 ± 2 C, leave for 2 hours

at the room temperature and humidity for checking.

After allowing to stand for 240 hours at -20 C, leave for 2 hours at

the room temperature and humidity for checking.

After allowing to stand for 120 hours at 40 ± 2 C and 85% RH of

rela-tive humidity, leave for 2 hours at the room temperature and

humidity for checking.

Hold the cycle test 1 times in the direction of X, Y, Z respectively

on the condition as follows :

Vibration frequency : 10 ~ 200 Hz

Sweep : 30 min.

Acceleration : 1.5 G

Shock test condition is as follows :

Give the test on the condition as follows :

Give the air discharges at the center of the glass and 4 points on

the Bezel at each side, every 3 times.

Vibration frequency : 10 ~ 50 Hz

Acceleration : 1.0 G (Z direction) , 0.7G (XY direction)

Sweep : (10 ~ 50 Hz)/10 min

Repetition : 1 time

Direction : ±XYZ

Figure 1 shows fall parts.

It falls so that parts in Figure 1(A ~ F) may collide with floor.

(It falls in alphabetical order)

Table 1 shows height of fall.

-20 ± 2 C : 60 minutes

60 ± 2 C : 60 minutes

Acceleration : 50 G

Acting time : 6 ms

Direction : ±XYZ

Capacity : 200 / 100

Resistance : 0 / 1.5

machine model / human body model

pF

k

Applied voltage : ± 7.5 kV

Page 23/30

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

Surface H

Surface G

Angle D

Edge A

Figure 1

Edge B

Surface F

Surface E

Angle C

Page 24/30

Table 1

Part A B C D E F G H

Height of

80 80 80 80 100 100 100 100

Falling (cm)

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

9. LCD MODULE USAGE AND PRECAUTIONS

9.1 HANDLING

1) Broken glass:

Be careful to broken glass of display face. When display face is damaged, please be careful

enough not to cut hands by a piece of glass. The surface of a LCD module is covered by plastic

film, and glass is hard to be scattered, but there can be the hurt when touching a broken portion.

And because CFL is also made of glass, please be careful equally.

2) Broken panel:

Do not touch the liquid which flowed out of a panel. When a panel was damaged and the liquid flow,

don't breathe in the liquid, drink it, and touch it. When the liquid stuck to a hand or clothes, wipe it

off in soap or alcohol immediately, then wash in water. When the liquid touched to eyes, wash eyes

with washing water more than 15 minutes, and undergo a medical treatment of a doctor.

3) Preventing of stain and dust:

Handle a LCD module as much as possible in a room with a few dusts. In addition, when in

acceptance inspection or installing process, wear a finger case or the soft gloves which do not

make a dust to prevent stain of display face of a module.

4) Protection board of display face:

Remove a protection board of display face as later as possible in assembling process to prevent

dust or scratch onto display face.

5) Wiping off of stain on display face:

When display face of a LCD module was stained, please wipe it off lightly with cotton or soft clean

cloth. When even they are not removed, wipe it off lightly with cotton or soft clean cloth which

soaked with water. Be careful that water does not flow into the LCD module inside.

6) Water drops on display face:

Don't leave display face with water drops on. When water drops stuck, please wipe it off with cotton

or soft cloth immediately. Display face changes color and get a stain when leaving drops of water.

In addition, when water drops flow into the LCD module inside, there might cause a trouble.

7) Disassemble or modify of LCD module:

Do not attempt to disassemble, rework or modify the LCD module by any means. There is the

possibility of electric shock, destruction of electronic parts, scratch on a display face, or dust

passing into a LCD module. And if using disassembled, reworked or modified LCD module,

electronic parts might emit smoke or outbreak a fire by dust or malfunction of electronic parts. A

product guarantee becomes not available for a LCD module which disassembled, reworked or

modified by user.

Page 25/30

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

8) Countermeasures to static electricity:

C-MOS LSI and an electronic part of the LCD module inside can be destroyed by static electricity.

In order not to apply static electricity to a LCD module, spread a conductive mat to a floor and a

work desk. In addition, worker should mount a ground band. Make consideration to prevent of static

electricity while at work.

9) Inserting a CFL connector:

Insert a CFL connector justly. A connector for between a CFL power supply circuit and a CFL of a

LCD module incorporated backlight should not be inserted slantways or half-ways. And confirm it

by all means. When it is not inserted justly, a circuit and a part might emit smoke or be damaged by

burning by the high voltage of a CFL power supply circuit. In addition, when there is the possibility

that it is not inserted justly, be sure to insert a connector after having confirmed LCD module that

switched off a CFL power supply circuit. In addition, please does not use except a recommended

CFL connector.

10) Power supply when in a handling of LCD module:

Be careful to electric shocks. When handling a LCD module, do it after switching the power supply

off by all means. While in operation, there is the possibility of electric shocks by touching on a CFL

electrode, a cable, a connector, or a CFL power supply circuit, because the high voltage is applied.

11) Power supply in connecting operation:

Switch off the power supply of the parent application at the time of installing process by all means.

When inserting or pulling off a connector of a LCD module with having switched on the parent

application, it can be damaged in an electric circuit of a LCD module. When power supply have to

be turned on by testing or inspection process, use a driving circuit which satisfies the ON/OFF

sequence for power supply and input signals.

12) Heating-up of CFL circumference:

Warn a burn when operating backlight including a CFL. A CFL circumference becomes high

temperature.

13) How to insert a connector:

When inserting a cable in a connector of a LCD module or take it off, make attention so that strong

external force is not added to a connector of the LCD module. PWB and inside connection of a

TCP driver can be damaged by a strong external force. When installing a LCD module to a target,

make attention not to put these cables between the case of target and the LCD module. A

connector of a parent application and an input connector of LCD module should not be inserted

slantways or half-ways. And confirm it by all means. When it is not inserted justly, a circuit and a

part might emit smoke or be damaged by burning by the high voltage of a CFL power supply circuit.

14) Handling of a cable for backlight:

A CFL cable for backlight should not be pulled or damaged. They might cause troubles by the

damage of soldering on the root of a CFL or a CFL.

15) Immediately discontinue using the CFL when if it darkens drastically or turns pink because

depletion of effective mercury may be occurring within the CFL tube which may make the

temperature rise. Due to these characteristics, the CFL may break or generate smoke

Page 26/30

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

9.2 DESIGN OF APPLICATION

1) Absolute maximum ratings:

Follow the absolute maximum ratings specified in this document by all means. The absolute

maximum rating is the rating which LCD module must not be violated. When using a LCD module

at the condition beyond those, a burning / destruction of electronic parts or a permanent damage of

characteristics may be caused. Therefore, make appropriate design not to violate the absolute

maximum ratings with consideration of environmental temperature, deviation of input signals, and

electronic parts tolerances.

2) Polarity of power supply to a CFL:

Polarity of a CFL cable from CFL power supply should be designed as that the high voltage cable

and the low voltage cable cannot be assembled conversely. In addition, because there might be a

brightness degradation of backlight or a starting failure if the CFL cable is too long, do a design

becoming the cable shortest as much as possible.

3) Torsion and bending while in the process of installing:

Make sure that stresses, warps and twists are not applied to the LCD module when installing to a

target frame. Even if stresses are temporary, it may be the cause of failure to the LCD module.

4) Preventing of a mechanical shock:

Be careful not to give a strong mechanical shock such as drops or shocks. There can be a cause of

trouble such as a scratch of display face or a malfunction of LCD module.

5) Preventing of a pressure onto display face:

Make attention that no strong external force such as pushing strongly onto display face of a LCD

module. Because there can be a scratch on display face or a cause of trouble of a LCD module.

6) Preventing of a scratch on display face:

Make attention not to rub or push a display face of a LCD module by a rigid thing such as tools. In

addition, be sure not to put a heavy thing such as a tool on display face and not to pile up LCD

modules each other. A polarizer used for display face is easy to get a scratch or traces and it might

be damaged.

7) Preventing unevenness of the display:

EPSON Imaging Devices recommends use of all installation holes shown in this document. Screws

used should have proper dimensions according to the specifications. The housing case must be

designed carefully in order to prevent stresses, warps and curves on all directions of the LCD

module. If stresses, warps, and curves are applied to the LCD module, the display may turn out

uneven.

Page 27/30

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

8) Power supply of a CFL:

In the LCD module which backlight with CFL is incorporated in, be sure to design a CFL power

supply circuit to be able to be applied the open circuit voltage more than 1 second. If it is less than

it, there might be the possibility that a CFL does not turn on. In addition, a current control type

inverter should be used that can control a tube current. If using a voltage controlled type inverter,

excess current might flows in a high temperature environment, and, a starting characteristics of a

CFL may degrades in a low temperature environment.

In addition, please design the power supply of the backlight so that it would turn off quickly in the

following conditions:

a) when the LCD module turns dark or changes pink drastically,

b) when an overcurrent flows in the lamp cable,

c) when the inverter is unloaded

9) Countermeasures to heating-up:

When operating backlight with CFL, temperature in the target application which incorporated a LCD

module is raised. Therefore, give measures to radiate of heat such as holes of a case to satisfy

temperature specifications of a LCD module.

10) Noise of Power supply:

Because the spike noise existing in a power supply is a cause of malfunction of a driving circuit in a

LCD module or an abnormality of display, spike noise on VDD must be within 100 mV

violate the absolute maximum rating).

11) Power sequence:

Before LCD module is switched on, please make sure that power supply and input signals of

system, testing equipment, etc. meet the recommended power sequence. The protection circuit will

operate if the power supply sequence can not be kept and the LCD module may shut down.

12) Protection for power supply:

Please study to adapt protection for power supply against trouble of LCD module, depending on

usage condition of system. Fuse installed on LCD module should be never modified. Any

modification to make the function of fuse ineffective may cause burning or break of printed wiring

board or other components at circuit trouble.

13) Protection against electric shock

High voltage is applied to CFL connector, inverter circuit and CFL at lighting. Please make design

not to expose or be accessible to such high voltage parts to avoid electric shock.

14) Recommendation for use of a protection cover and a UV cut filter:

EPSON Imaging Devices recommends use of a transparent protection cover on a liquid crystal

display aperture to prevent scratch and dust of display face and invasion of water, when using

under a too cruel condition in such as outdoors. Furthermore, EPSON Imaging Devices

recommends use of a U.V. cut filter (cuts equal to or less than 390 nm) when it is exposed to direct

rays of the sun for a long time. Please consider it so that dew condensation does not occur in the

cover.

Page 28/30

P-P (but never

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

15) Temperature dependence of display:

The response (optical response) of display varies with temperature. The response becomes slow at

low temperature. In addition, brightness and chromaticity vary with temperature, too.

16) Starting delay and lifetime under low temperature:

The starting characteristic of a CFL degraded under low temperature (the time before light being

stable gets longer from power supply ON). In addition, please operate a CFL at room temperature

as possible, because the lifetime shortens when operating under low temperature by the

characteristics itself.

17) Dew condensation:

In an environment of sudden temperature change, there might be a dew condensation on surface

or inside of a LCD module. Because it causes a degradation of display or malfunction, be sure to

make consideration for design that dew condensation does not occur.

18) Image sticking:

19) Dirty and uneven display:

Dirt and unevenness sometimes partly appear with the increase in the total operation time.

20) Change of Color CIE coordinates:

When LCD module is used for a long time, the color of the parts in backlight changes, and it cause

the shift of the display color.

9.3 STORAGE

1) Storage and transport:

Keep a LCD module with a packing form of shipment in a dark room which direct rays of the sun

does not irradiate with low temperature, with low humidity, and with no dew condensation. In

addition, keep it in an environment with little temperature change because there is the possibility

that dew condensation occurs by a sudden temperature change. When dew condensation occurs, it

may be a cause of operation abnormality or trouble.

2) Transport:

Because the master carton may be damaged or shape transformed by an excessive load applied,

store and transport with piled up in lower than the number which recorded in a master carton label.

Product Number L5S30348P01 Revision Number 00

a) Image sticking may appear when the same pattern (still image, character etc.) have been

displayed for a long period of time.

b) When the LCD module is continuously displayed with a letterbox mode, Image sticking

may appear on the display.

We recommend that the LCD module is displayed with the full-screen mode in order to

prevent image sticking from occurring.

c) Image sticking normally disappears by displaying a gray-screen for a while. However

when the image sticking is remarkable, it may not disappear even if the gray screen is

displayed on the LCD module.

Page 29/30

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

Product Number L5S30348P01 Revision Number 00

3) Handling:

Because a LCD module is a product having precision electronic parts and glass products, it might

be damaged by an excessive shock or a dropping. Although a LCD module does protected with

master carton, handle it carefully to reduce a shock in transshipping, transporting and loading.

9.4 DISPOSAL

1) Disposing LCD modules:

When disposing LCD modules, consult a company specialized in industrial waste treatment which

is permitted by the government or the local authority. When disposing CFL, obey the regulations or

rules given by the local government because mercury is contained in the CFL.

9.5 OTHER PRECAUTIONS

1) This product is developed and produced to use for general electronic equipment (OA instrument

products, communication terminal instrument products, consumer electronics products, game

instrument products). The specifications does not correspond to a usage or a device that extremely

high reliability or safety are needed. ( i.e. aviation / space instruments, nuclear energy control

instruments, life-support equipment. )

2) Observe conditions and precautions in this document in use of this product. Even if in a range

of condition, use this product with considerations for safety design as a total system and instrument,

so that an accident resulting in injury, a fire accident, or the social damage will not occurs.

3) This product does not design as an anti-radiation device.

4) Any contents of this publication do not guarantee or approve the rights of enforcement for a

third person (party) about the intellectual property and others.

5) EPSON Imaging Devices forbids firmly modifying or copying a part or all of this publication

without a documented permission.

6) The contents stated in this document and the product may be subject to change without prior

notice.

When you kindly study to use product, please ask our distributor or us for the latest information.

Page 30/30

EPSON IMAGING DEVICES CORP㧚

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 33

q

Global LCD Panel Exchange Center

www.panelook.com

UNITmm

ue 0.20 N㨯m Max.

EPSON IMAGING DEVICES CORP. Product Number L5S30348P01 Rev. No. 00

OUTWARD DRAWINGS

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Note1 : Unspecified dimension tolerances are +/-0.5 mm

CN : DF19KR-20P-1H (HIROSE)

FLCN1 : BHSR-02VS-1(JST)

Note2 : Screw tor

www.panelook.com

Page 34

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 36

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 37

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 38

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...