EPSON ET-4750, ET-4760, L6190, ST-4000, ET-3750 Service Manual

...

Service Manual

Color Inkjet Printer

EPSON

ET-4750/ET-4760/L6190/ST-4000

series

ET-3750/ET-3760/L6170/ST-3000

series

ET-3700/ET-3710/L6160 series

ET-2750/ET-2760/L4160/ST-2000

series

ET-2700/L4150 series

Confidential

SEMF17-003

Notice

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

EPSON disclaims any and all rights in those marks.

Copyright © 2018 SEIKO EPSON CORPORATION.

P CS Quality Assurance Department

Confidential

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this product.

DANGER

Strictly observe the following cautions. Failure to comply could result in serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral devices when servicing the product or performing maintenance.

2. When performing works described in this manual, do not connect to a power source until instructed to do so. Connecting to a power source causes high voltage in the power supply unit and some

electronic components even if the product power switch is off. If you need to perform the work with the power cable connected to a power source, use extreme caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal injury or loss of life.

1. When using compressed air products; such as air duster, for cleaning during repair and maintenance, the use of such products containing flammable gas is prohibited.

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified repair technician.

2. No work should be performed on this product by persons unfamiliar with basic safety knowledge required for electrician.

3. The power rating of this product is indicated on the serial number/rating plate. Never connect this product to the power source whose voltages is different from the rated voltage.

4. Replace malfunctioning components only with those components provided or approved by Epson;

introduction of second-source ICs or other non-approved components may damage the product and void any applicable Epson warranty.

5. The capacitors on the Main Board may be electrically charged right after the power turns off or after driving motors which generates counter electromotive force such as when

rotating the PF Roller or when moving the CR Unit. There is a risk to damage the Main Board if the FFC is short-circuited with the capacitors on the Main Board electrically

charged, therefore, after the power turns off or after motors are driven, leave the printer untouched for approximately 30 seconds to discharge the capacitors before starting

disassembly/ reassembly.

Confidential

6. To prevent the circuit boards from short-circuiting, be careful about the following when handling FFC or cables.

When handling FFC, take care not to let the terminal section of FFC touch metal parts.

When connecting cables/FFC to the connectors on circuit boards, connect them straight to the connectors to avoid slant insertion.

7. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps, when accessing internal components.

8. Do not tilt this product immediately after initial ink charge, especially after performing the ink charge several times. Doing so may cause ink to leak from the product because it

may take some time for the waste ink pads to completely absorb ink wasted due to the ink charge.

9. Never touch the ink or wasted ink with bare hands. If ink comes into contact with your skin, wash it off with soap and water immediately. If you have a skin irritation, consult a

doctor immediately.

10. When disassembling or assembling this product, make sure to wear gloves to avoid injuries from metal parts with sharp edges.

11. Use only recommended tools for disassembling, assembling or adjusting the printer.

12. Observe the specified torque when tightening screws.

13. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the printhead

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

LCD

Scanner Sensor

Exterior parts

14. Never use oil or grease other than those specified in this manual. Use of different types of oil or grease may damage the component or give bad influence on the printer function.

15. Apply the specified amount of grease described in this manual.

16. Make the specified adjustments when you disassemble the printer.

17. When cleaning this product, follow the procedure described in this manual.

18. When transporting this product after filling the ink in the printhead, pack the printer without removing the adapters in order to prevent the printhead from drying out.

19. Make sure to install antivirus software in the computers used for the service support activities.

20. Keep the virus pattern file of antivirus software up-to-date.

21. When disassembling/reassembling this product, if you find adhesive power of the double-sided tape which secure the parts or FFC is not enough, replace the tape with new one

and attach it correctly to the specified points where the parts or FFC should be secured.

22. Unless otherwise specified in this manual, the labels attached on the returned product should be transferred to the corresponding attachment positions on the new one referring

to the labels on the returned product.

Confidential

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information necessary for properly performing maintenance and servicing the

product.

CHAPTER 1. OPERATING PRINCIPLES

Describes the electrical and mechanical basic operating principles of the product.

CHAPTER 2. TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 3. DISASSEMBLY/ASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of the product, and provides the standard operation time for servicing the

product.

CHAPTER 4. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 5. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 6. APPENDIX

Provides the following additional information for reference:

• Connector Diagram

• Protection for Transportation

Confidential

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional information on a specific topic or to warn of possible danger present during a procedure or an action.

Pay attention to all symbols when they are used, and always read explanation thoroughly and follow the instructions.

Indicates an operating or maintenance procedure, practice or condition that, if not strictly observed, could result in injury or loss of life.

Indicates an operating or maintenance procedure, practice, or condition that, if not strictly observed, could result in damage to, or destruction of, equipment.

May indicate an operating or maintenance procedure, practice or condition that is necessary to accomplish a task efficiently. It may also provide additional

information that is related to a specific subject, or comment on the results achieved through a previous action.

For Chapter 3 “Disassembly/Reassembly”, symbols other than indicated above are used to show additional information for disassembly/reassembly. For the details

on those symbols, see

"3.3 Disassembly/Reassembly Procedures (p94) ".

Confidential

Revision Status

Revision Date of Issue Description

A Aug. 31, 2017 First release

Revised

Chapter 3

Made change in "3.1 Overview (p76) "

• Made change in "3.1.2 Jigs (p76) "

• Made change in "3.1.4 Standard Operation Time for Servicing the Product (p80) "

Made change in "3.3 Disassembly/Reassembly Procedures (p94) "

• Made change in "3.3.3 Disassembly Flowchart (p96) "

B Feb. 26, 2018

C May. 11, 2018

• Made change in "3.3.4 Repairing Major Components Disassembly/Assembly Procedure (p112) "

Made change in "3.4 Detailed Disassembly/Reassembly Procedure for each Part/Unit (p141) "

Made change in "3.5 Routing FFCs/cables (p144) "

Chapter 4

Made change in "4.3 Mechanism Adjustment / Check (p165) "

• Made change in "4.3.1 Checking the Platen Gap (p165) "

Chapter 6

"6.2 Head Fuse (p180) " has been added.

Display Bugs fixes.

Hyper links have been fixed.

Revised

Add models (ST-2000, ST-3000, ST-4000)

D Sep. 19, 2018

E Mar. 25, 2019

□ Chapter3

■Made change in "3.1.1 Tools (p76) "

■Made change in "3.1.4 Standard Operation Time for Servicing the Product (p80) "

・The Fax outringer box has been deleted.

■Made change in "3.3.2 Functional differences between models and component parts (p95) "

■Made change in "3.3.3.1 Disassembly/Reassembly Flowchart (ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-

3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160 series) (p97) "

Revised

Add models (ET-4760 series, ET-3760 series, ET-3710 series, ET-2760 series)

Confidential

F Apr. 16, 2019

G Jan. 28, 2020

Revised

□ Chapter3

■Made change in "3.3.4.7 Main Board (p128) "

・Caution about Heat Conduction sheet has been added.

■Made change in "3.5 Routing FFCs/cables (p144) "

・" Holder Star Wheel Grounding Cable (ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-3000

series/ET-3700/ET-3710/L6160 series) (p148) "has been added.

Revised

□ Chapter2

■Made change in "2.1.1.3 Workflow for Errors when Printing Starts (p45) "

・Subscription Errors have been added.

□ Chapter3

■For ET-2700/L4150 series, Descriptions of Paper Set Detector Sensor Board have been deleted.

□ Chapter4

■Made change in "4.1 Required Adjustments (p150) "

・Caution of subscription models has been added.

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Contents

Chapter 1 Operating Principles

1.1 Printer Mechanism Overview ............................................................................. 12

1.1.1 Print Head .................................................................................................. 12

1.1.2 Carriage (CR) Mechanism ......................................................................... 14

1.1.3 Paper Loading/Feed Mechanism ............................................................... 15

1.1.4 Ink System Mechanism .............................................................................. 17

1.1.5 List of Motor and Sensor ........................................................................... 18

1.2 Scanner/ADF Overview ..................................................................................... 20

1.2.1 Scanner Mechanism ................................................................................... 20

1.2.2 ADF Mechanism (ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-

3760/L6170/ST-3000 series only) ............................................................ 20

1.3 Paper Loading/Feed Mechanism ........................................................................ 22

1.3.1 Overview .................................................................................................... 22

1.3.1.1 Paper Loading Method ....................................................................... 22

1.3.1.2 Paper Feed Path .................................................................................. 24

1.3.2 Operation Principle .................................................................................... 26

1.3.2.1 Drive Path ........................................................................................... 26

1.4 Ink System Mechanism ...................................................................................... 33

1.4.1 Overview .................................................................................................... 33

1.4.1.1 Mechanical Configuration .................................................................. 33

1.4.1.2 Cleaning .............................................................................................. 34

1.4.1.3 Controlling Waste Ink ........................................................................ 34

1.4.2 Operating Principles .................................................................................. 35

1.4.2.1 Drive Path ........................................................................................... 35

1.4.2.2 Operation of Each Mechanism ........................................................... 36

Chapter 2 Troubleshooting

2.1 Troubleshooting .................................................................................................. 40

2.1.1 Troubleshooting Workflow ....................................................................... 40

2.1.1.1 Workflow when the Power is ON (Printer) ........................................ 41

2.1.1.2 Workflow for Scanner Errors when the Power is ON ........................ 44

2.1.1.3 Workflow for Errors when Printing Starts ......................................... 45

2.2 Power-On Sequence ........................................................................................... 47

2.3 Fatal Error Code List .......................................................................................... 48

2.3.1 Displaying the Fatal Error Code ................................................................ 48

2.3.2 Fatal Error Code ........................................................................................ 48

2.3.2.1 Scanner ............................................................................................... 49

2.3.2.2 Printer (CR) ........................................................................................ 55

2.3.2.3 Printer (PF) ......................................................................................... 58

2.3.2.4 Printer (PW/PE Sensor) ...................................................................... 60

2.3.2.5 Printer (Power Supply) ....................................................................... 60

2.3.2.6 Printer (Head/CSIC) ........................................................................... 61

2.3.2.7 Printer (Others) ................................................................................... 62

2.3.2.8 System Error ....................................................................................... 62

2.4 Service Support Mode ........................................................................................ 63

2.4.1 Touch Panel 2.4 inch model ...................................................................... 63

2.4.2 LCD Model ................................................................................................ 64

2.4.3 Status Sheet Information ........................................................................... 66

Chapter 3 Disassembly/Assembly

3.1 Overview ............................................................................................................ 76

3.1.1 Tools .......................................................................................................... 76

3.1.2 Jigs ............................................................................................................. 76

3.1.3 Locations of the Parts/Units ...................................................................... 77

3.1.4 Standard Operation Time for Servicing the Product ................................. 80

3.1.5 Checks and Precautions before Disassembling ......................................... 86

3.1.5.1 Factors which Affect the Print Quality .............................................. 86

3.1.5.2 Minimizing Ink Leakage during Disassembly for Your Safety ......... 88

3.1.5.3 Ink Discharging Procedure ................................................................. 91

3.2 Common Cautions on Disassembly/Reassembly ............................................... 92

3.3 Disassembly/Reassembly Procedures ................................................................ 94

3.3.1 Parts/Components Need to be Removed Before Disassembly/Reassembly 94

3.3.2 Functional differences between models and component parts ...... 95

3.3.3 Disassembly Flowchart .............................................................................. 96

3.3.3.1 Disassembly/Reassembly Flowchart (ET-4750/ET-4760/L6190/ST-4000

9

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

series/ET-3750/ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/

L6160 series) ...................................................................................... 97

3.3.3.2 Disassembly/Reassembly Flowchart (ET-2750/ET-2760/L4160/ST-2000

series) ............................................................................................... 102

3.3.3.3 Disassembly/Reassembly Flowchart (ET-2700/L4150 series) ........ 107

3.3.4 Repairing Major Components Disassembly/Assembly Procedure .......... 112

3.3.4.1 Maintenance Box/Porous Pad Assy ................................................. 112

3.3.4.2 Exterior Parts .................................................................................... 113

3.3.4.3 ADF/SCN Unit or SCN Unit ............................................................ 121

3.3.4.4 Paper Guide Front Assy ................................................................... 123

3.3.4.5 Paper Guide Lower Porous Pad ........................................................ 124

3.3.4.6 Print Head ......................................................................................... 125

3.3.4.7 Main Board ....................................................................................... 128

3.3.4.8 Ink Tank ........................................................................................... 130

3.3.4.9 Paper Guide Upper Left ................................................................... 133

3.3.4.10 Paper Guide Upper Right ............................................................... 137

3.3.4.11 PF Roller ......................................................................................... 138

3.3.4.12 Housing Rear Assy ......................................................................... 140

3.4 Detailed Disassembly/Reassembly Procedure for each Part/Unit .................... 141

3.5 Routing FFCs/cables ........................................................................................ 144

Chapter 4 Adjustment

4.1 Required Adjustments ...................................................................................... 150

4.2 Adjustment Program ......................................................................................... 154

4.2.1 Operating Environment ........................................................................... 154

4.2.2 Adjustment and Inspection List ............................................................... 154

4.2.3 Details of the Adjustment Program ......................................................... 159

4.3 Mechanism Adjustment / Check ...................................................................... 165

4.3.1 Checking the Platen Gap ......................................................................... 165

4.3.1.1 Preparation ........................................................................................ 165

4.3.1.2 Confirmation procedure ................................................................... 167

4.3.2 Touch Panel Adjustment (ET-4750/ET-4760/L6190/ST-4000 series only) ..

168

5.1.2 Cleaning the nozzle plate section of the Print Head

(ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series) ...... 172

5.1.3 Cleaning the Exterior Parts/inside of the printer ..................................... 173

5.2 Lubrication ....................................................................................................... 173

5.2.1 Lubrication Points and Instructions ......................................................... 174

Chapter 6 Appendix

6.1 Connector Diagram .......................................................................................... 179

6.2 Head Fuse ......................................................................................................... 180

6.3 Protection for Transportation ........................................................................... 181

6.3.1 Securing the CR Unit ............................................................................... 181

6.3.2 Securing the ADF/SCN Unit (ET-4750/ET-4760/L6190/ST-4000 series/ET-

3750/ET-3760/L6170/ST-3000 series only) ........................................... 181

6.3.3 Securing the SCN Unit (ET-3700/ET-3710/L6160 series/ET-2750/ET-2760/

L4160/ST-2000 series/ET-2700/L4150 series) ...................................... 182

6.3.4 Securing the Panel Unit ........................................................................... 182

6.3.5 Securing the Stacker (ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-

3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160 series only) ...... 183

6.3.6 Securing the Stacker (ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/

L4150 series only) .................................................................................. 183

6.3.7 Securing the Duplex Unit (ET-4750/ET-4760/L6190/ST-4000 series/ET3750/ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160 series only)

184

6.3.8 Securing the Duplex Unit (ET-2750/ET-2760/L4160/ST-2000 series/ only)

184

6.3.9 Securing the Paper Support (ET-2750/ET-2760/L4160/ST-2000 series/ET-

2700/L4150 series only) ......................................................................... 185

Chapter 5 Maintenance

5.1 Cleaning ............................................................................................................ 171

5.1.1 Cleaning the CR Unit (ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/

ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160 series) ........ 171

10

Confidential

OPERATING PRINCIPLES

CHAPTER

1

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Nozzle plate

Cover Head

A#400

A#399

A#398

B#400

B#399

B#398

B#264

B#265

B#272

B#128

B#129

B#136

A#3

A#2

A#1

B#3

B#2

B#1

0.042 mm

1/600 inch

0.085 mm

1/300 inch

1.016 mm

24/600 inch

B#273

B#137

Cyan

Magenta

Yellow

Column A

Column B

Carriage movement direction

Paper feed direction

Column Color

ABk

B #1 - #128 Y

B #137 - #264 M

B #273 - #400 C

Not used

Not used

Black

Nozzle plate

Cover Head

1.1 Printer Mechanism Overview

This chapter describes overview of each mechanism inside the printer.

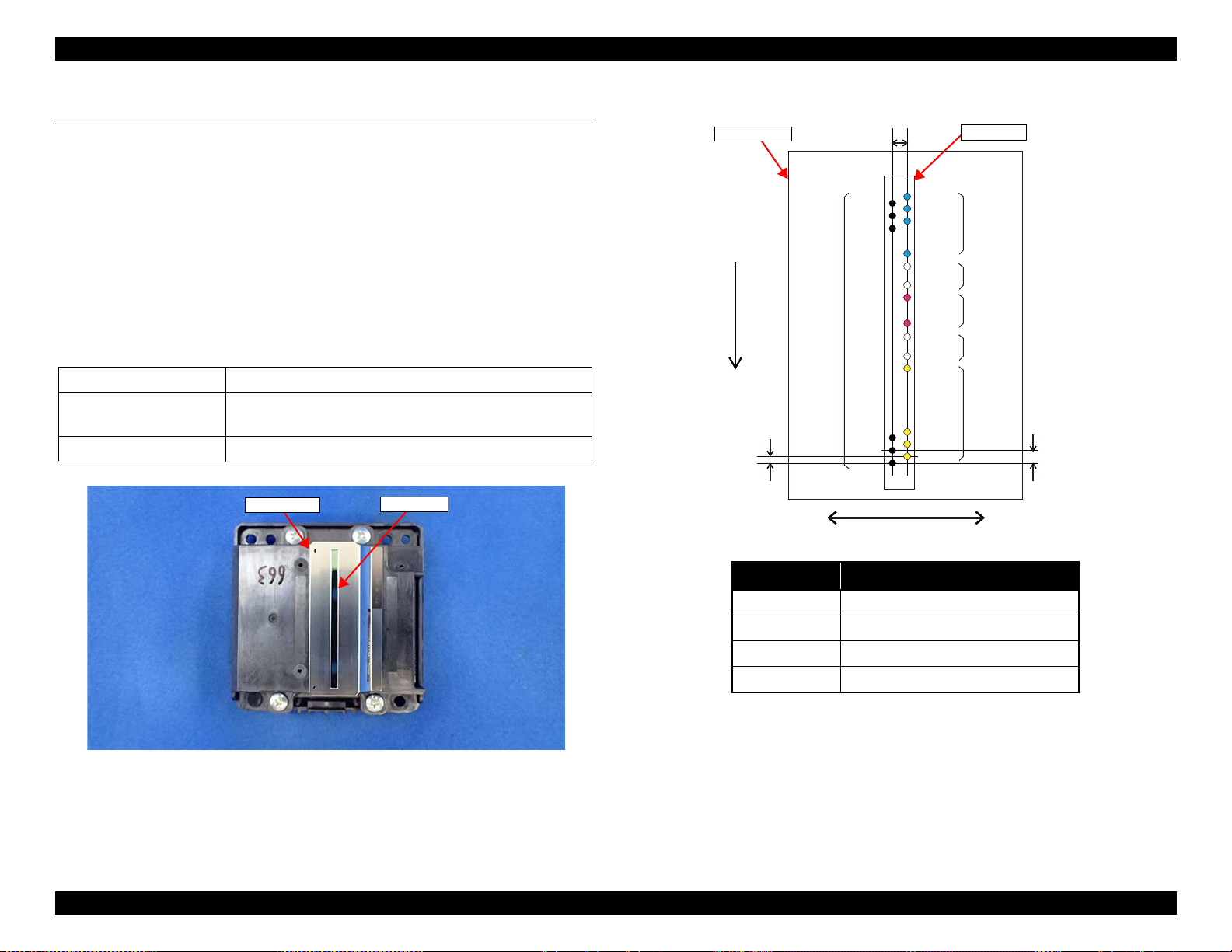

1.1.1 Print Head

μTFP1S head (p 12) is used for ET-4750/ET-4760/L6190/ST-4000 series/ET3750/ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160 series.

F2 head (p 13) is used for ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/

L4150 series.

ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-

3000 series

Color Four colors: black (Bk), cyan (C), magenta (M), yellow (Y)

Number of nozzles 784 nozzles:

Nozzle pitch 300 dpi

/ET-3700/ET-3710/L6160 series

Table 1-1. Nozzle Configuration

400 nozzles for Bk, and 128 nozzles for each of Y, M, and C

Operating Principles Printer Mechanism Overview 12

Figure 1-1. μTFP1S Print Head appearance

Figure 1-2. Nozzle layout (seen from the rear side)

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Nozzle plate

Cover Head

Black

Column A Column B

Carriage movement direction

Paper feed direction

Column Color

ABk

B #1 - #60 Y

B #62 - #120 M

B #122 - #180 C

Yellow

Cyan

Magenta

Not used

Not used

Not used

Nozzle plate

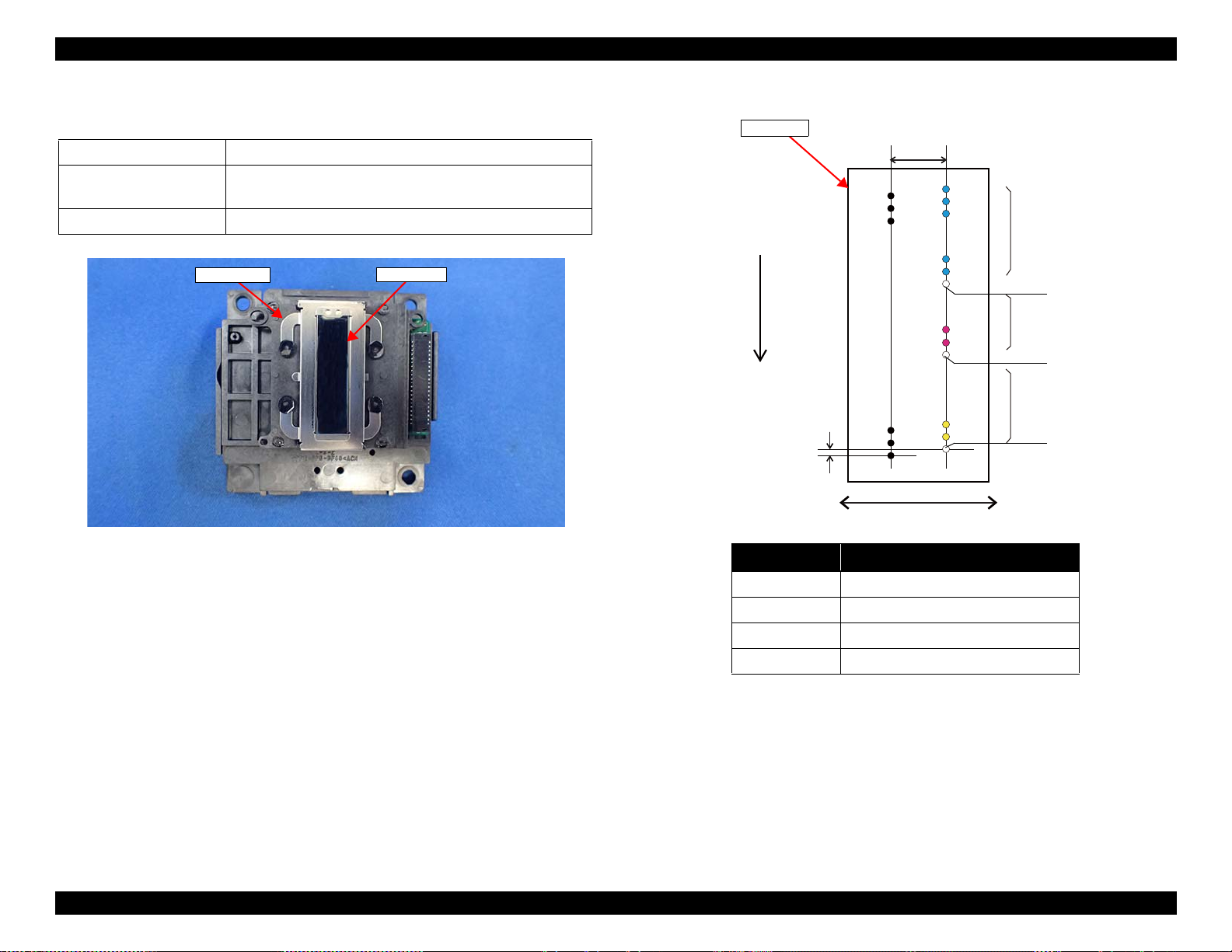

ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series

Table 1-2. Nozzle Configuration

Color Four colors: black (Bk), cyan (C), magenta (M), yellow (Y)

Number of nozzles 357 nozzles:

180 nozzles for Bk, 59 nozzles for each Y, M, and C.

Nozzle pitch 180 dpi

0.071 mm

1/360 inch

5.9266 mm

42/180 inch

A#180

A#179

A#178

A#3

A#2

A#1

B#180

B#179

B#178

B#123

B#122

B#121

B#63

B#62

B#61

B#3

B#2

B#1

Figure 1-3. F2 Print Head appearance

Operating Principles Printer Mechanism Overview 13

Figure 1-4. Nozzle layout (seen from the rear side)

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

CR Scale

CR Timing Belt

CR Unit

CR Motor

(Backside of the Main Frame)

CR Encoder Sensor

Section view

Main Frame

CR Unit

Main Frame

1.1.2 Carriage (CR) Mechanism

The major components of the carriage (CR) mechanism are the CR Unit, CR

Encoder Sensor, CR Scale, CR Motor, and CR Timing Belt. The CR

mechanism is a key mechanism to ensure stable print quality because printing

is performed by moving the CR Unit from side to side.

As shown on the right, Main Frame is holding the upper side and the lower side

of the CR Unit. The CR Unit is attached to the CR Timing Belt that is moved

by the CR Motor so that the assy can move from side to side to print. The

position and speed of the CR Unit are always monitored by the CR Encoder

Sensor and the CR Scale, and the CR Motor is controlled in accordance with

the information acquired by the CR Encoder Sensor.

Operating Principles Printer Mechanism Overview 14

Figure 1-5. Carriage (CR) mechanism

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Cassette

Slider Trans

Holder Cam Assy

PF Motor

PF Roller

Pick up Roller Assy

Intermediate roller

(inside the Duplex Unit)

EJ Roller

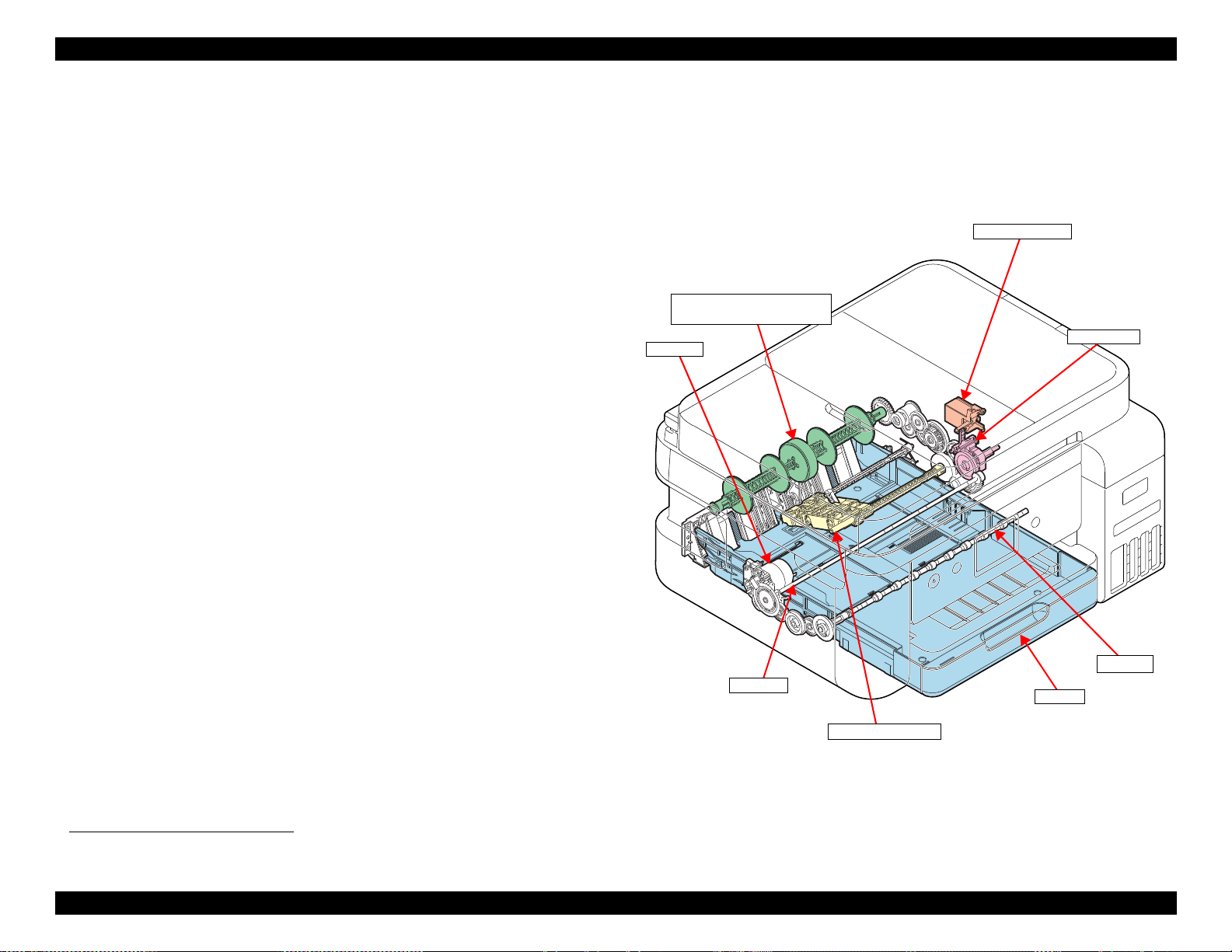

1.1.3 Paper Loading/Feed Mechanism

Paper loading mechanism differs between ET-4750/ET-4760/L6190/ST-4000

series/ET-3750/ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160

series and ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series.

ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-3000

series/ET-3700/ET-3710/L6160 series employ the front paper loading, and ET2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series employ the rear

paper loading. The both paper loading mechanisms are driven by the PF Motor,

and the motor is also used for driving the paper feeding mechanism.

The printer is also equipped with a paper feeding mechanism for auto

duplexing as well as other existing products. The mechanism flips paper after

printing on the front side is finished, and feeds the paper to print on the back

side.

ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-

3000 series/ET-3700/ET-3710/L6160 series

A sheet of paper is fed inside the printer from the Paper Cassette by the Pick up

Roller Assy.

*1

Because the Pick up Roller Assy needs to be stopped each after it feeds a sheet

of paper, it is necessary to control the transmission of a drive force to the assy.

The control is achieved by the Slider Trans and the Holder Cam Assy. When

the Slider Trans is moved by the CR Unit, the state of engagement between the

transmission gear on the Trans Slider and the Pick up Roller driving gear

changes, which enables switching between transmitting the PF Motor driving

force to the Pick up Roller Assy and not transmitting it.

Even after the CR Unit is detached from the Slider Trans for printing, position

of the Slider Trans is kept by the Holder Cam Assy.

The paper fed by the Pick up Roller Assy is conveyed by the intermediate

roller, PF Roller, and EJ Roller which are included in the paper feeding

mechanism.

*1. See "1.3 Paper Loading/Feed Mechanism" (p 22) for more details.

Figure 1-6. Paper loading/feed mechanism (1)

Operating Principles Printer Mechanism Overview 15

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Paper Back Lever

Hopper

PF Motor

PF Roller

LD Roller

Intermediate roller

(inside the Duplex Unit)

EJ Roller

Change Lever

Clutch

Cam

ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series

Paper is fed inside the printer from the ASF Rear by the LD Roller.

The ASF Rear is equipped with a Hopper, Paper Back Lever, Change Lever,

LD Roller, and clutch. The Change Lever and the clutch work for transmitting

a driving force from the PF Motor to the LD Roller and for not transmitting it.

The Hopper and the Paper Back Lever driven by the cam on the LD Roller

Shaft prevent multi-feed and ensure accurate paper feeding.

Paper fed by the ASF Rear is conveyed by the PF Roller and the EJ Roller

which are included in the paper feeding mechanism.

Unlike the front paper loading, intermediate roller is used only when flipping

paper for duplex printing.

Figure 1-7. Paper loading/feed mechanism (2)

Operating Principles Printer Mechanism Overview 16

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Ink system mechanism

Maintenance Box/

Porous Pad Assy

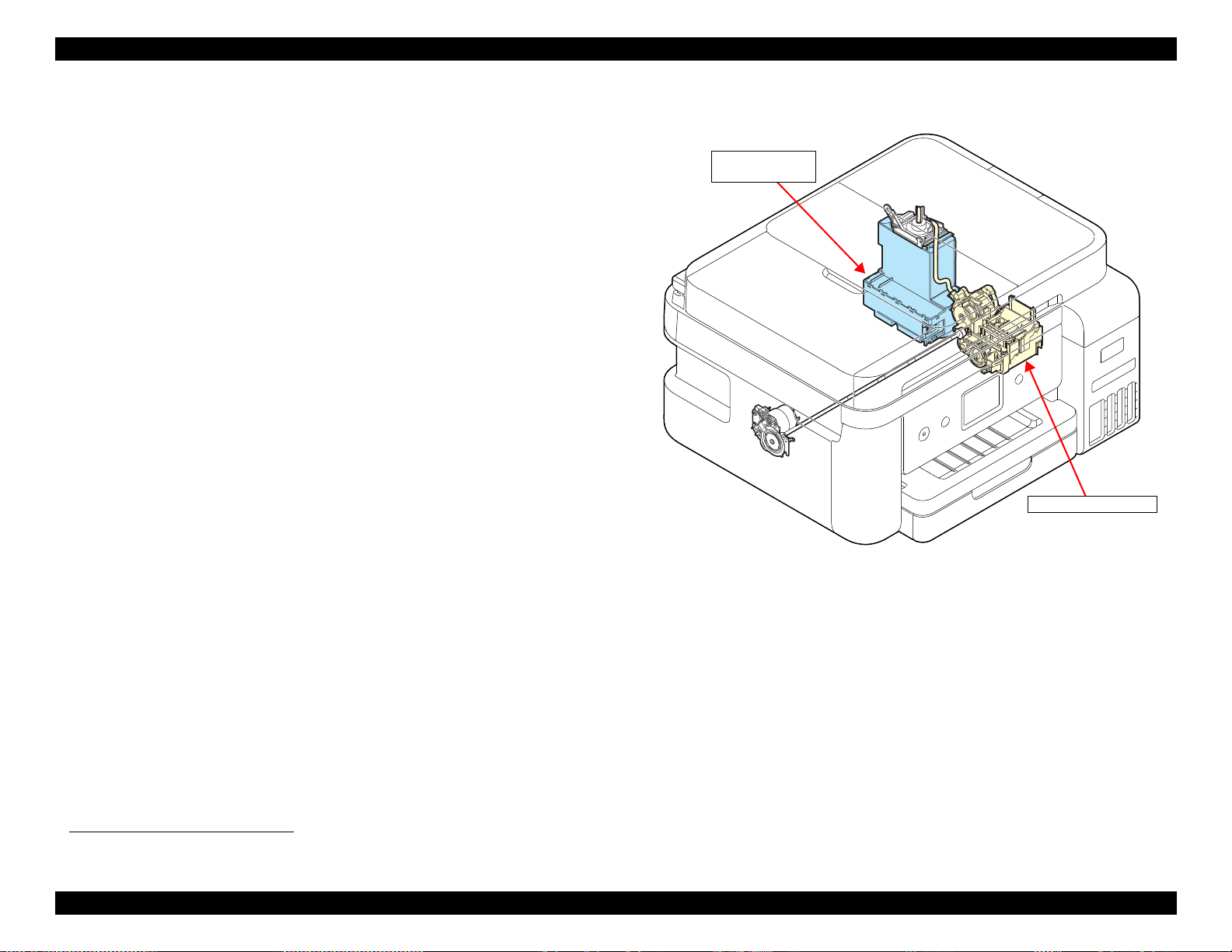

1.1.4 Ink System Mechanism

The major components of the ink system mechanism*1 are a cap, pump unit,

and waste ink tube.

The ink system mechanism employs the slide type capping. When the CR Unit

returns to its capping position (home position), the Print Head is capped. The

pump mechanism, wiper mechanism, and the CR Lock mechanism are driven

by the PF Motor to clean the Print Head.

Waste ink sucked when cleaning the Print Head is collected in the Maintenance

Box/Porous Pad Assy through the pump mechanism.

User replaceable Maintenance Box is installed to ET-4750/ET-4760/L6190/

ST-4000 series/ET-3750/ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/

L6160 series. A CSIC mounted on the Maintenance Box keeps track of how

much waste ink has been collected.

On the other hand, the Porous Pad that cannot be replaced by user is installed to

ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series. The

EEPROM on the Main Board keeps track of how much waste ink has been

collected.

Figure 1-8. Ink system mechanism

*1. See "1.4 Ink System Mechanism" (p 33) for more details.

Operating Principles Printer Mechanism Overview 17

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

A

1

B

C

2

3

4

5

6

7

8

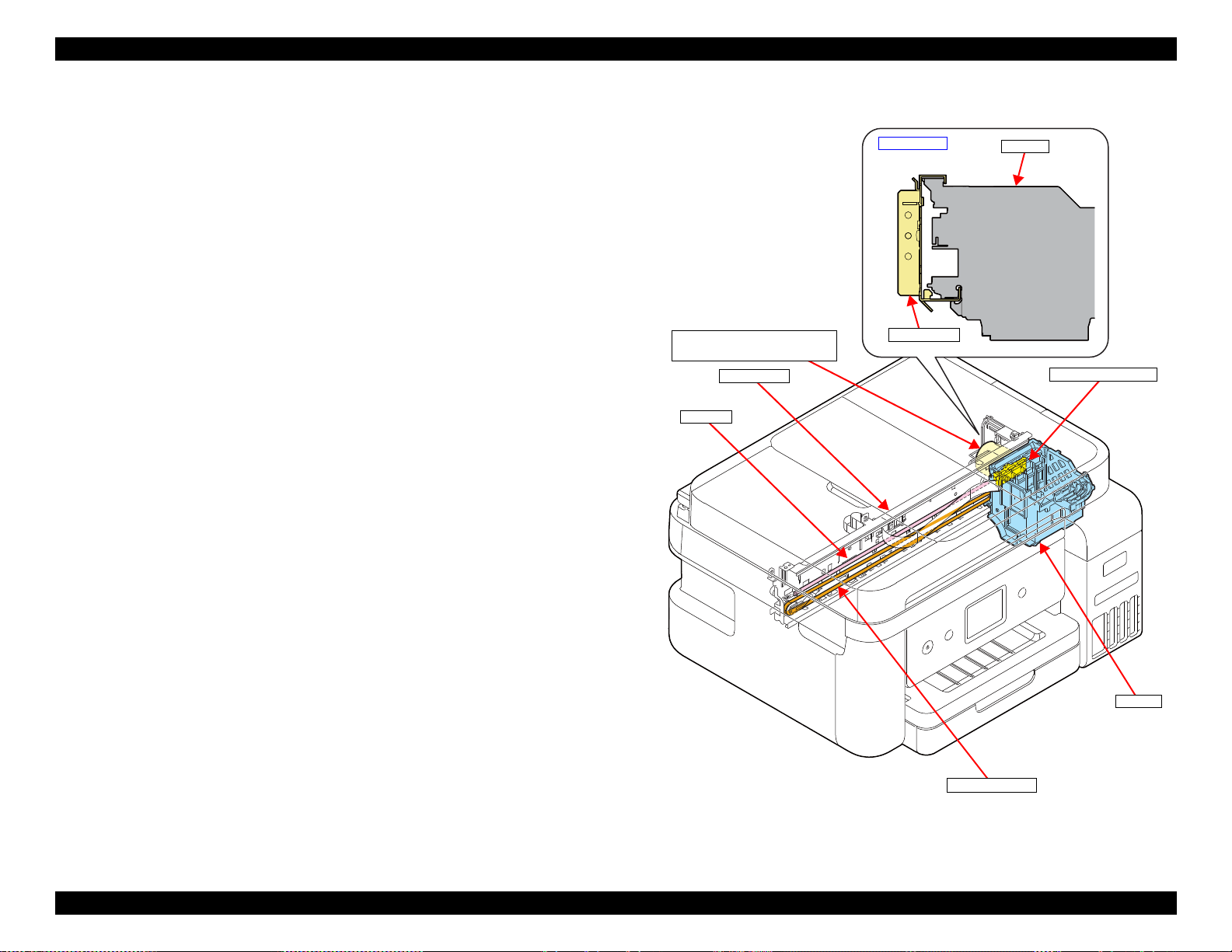

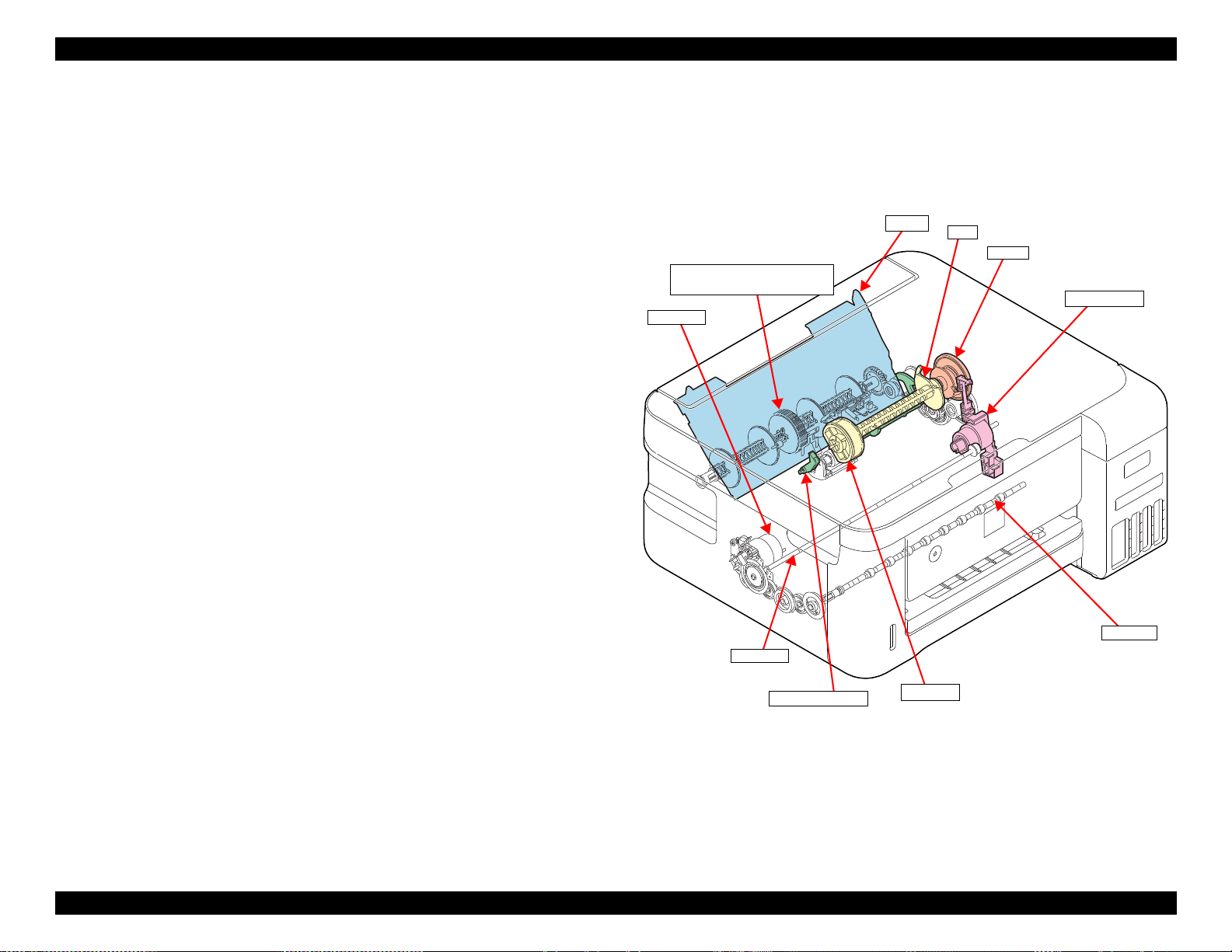

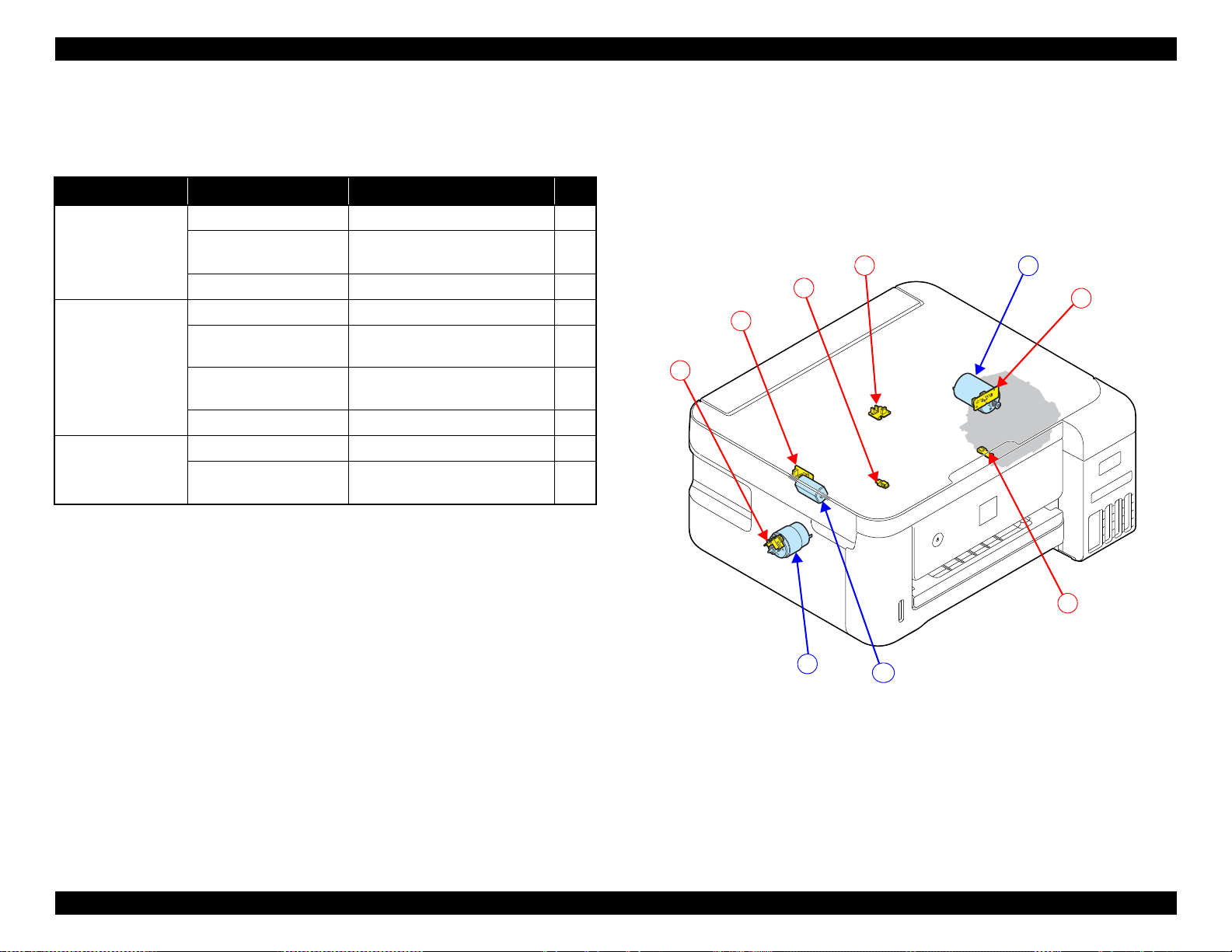

1.1.5 List of Motor and Sensor

This section describes the types and positions of the motors and sensors.

ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-

3000 series/ET-3700/ET-3710/L6160 series

Table 1-3. Motor and Sensor List

(ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-3000

series/ET-3700/ET-3710/L6160 series)

Mechanism name Motor/sensor name Motor/sensor type No.

Carriage

mechanism

CR Motor DC Motor A

CR Encoder Transmission-type photo

interrupter

PW Sensor Reflection-type photo interrupter 2

Paper loading/feed

mechanism

Others Ink Cover Open Sensor Mechanical contact 6

Scanner SCN Motor DC Motor C

PF Motor DC Motor B

PF Encoder Transmission-type photo

interrupter

Cassette Sensor Mechanical contact 4

PE Sensor Reflection-type photo interrupter 5

SCN Motor Encoder Transmission-type photo

interrupter

ADF PE Sensor Transmission-type photo

interrupter

1

3

7

8

Figure 1-9. List of motor and sensor

(ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-

3000 series/ET-3700/ET-3710/L6160 series)

Operating Principles Printer Mechanism Overview 18

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

A

1

B

C

2

3

4

5

6

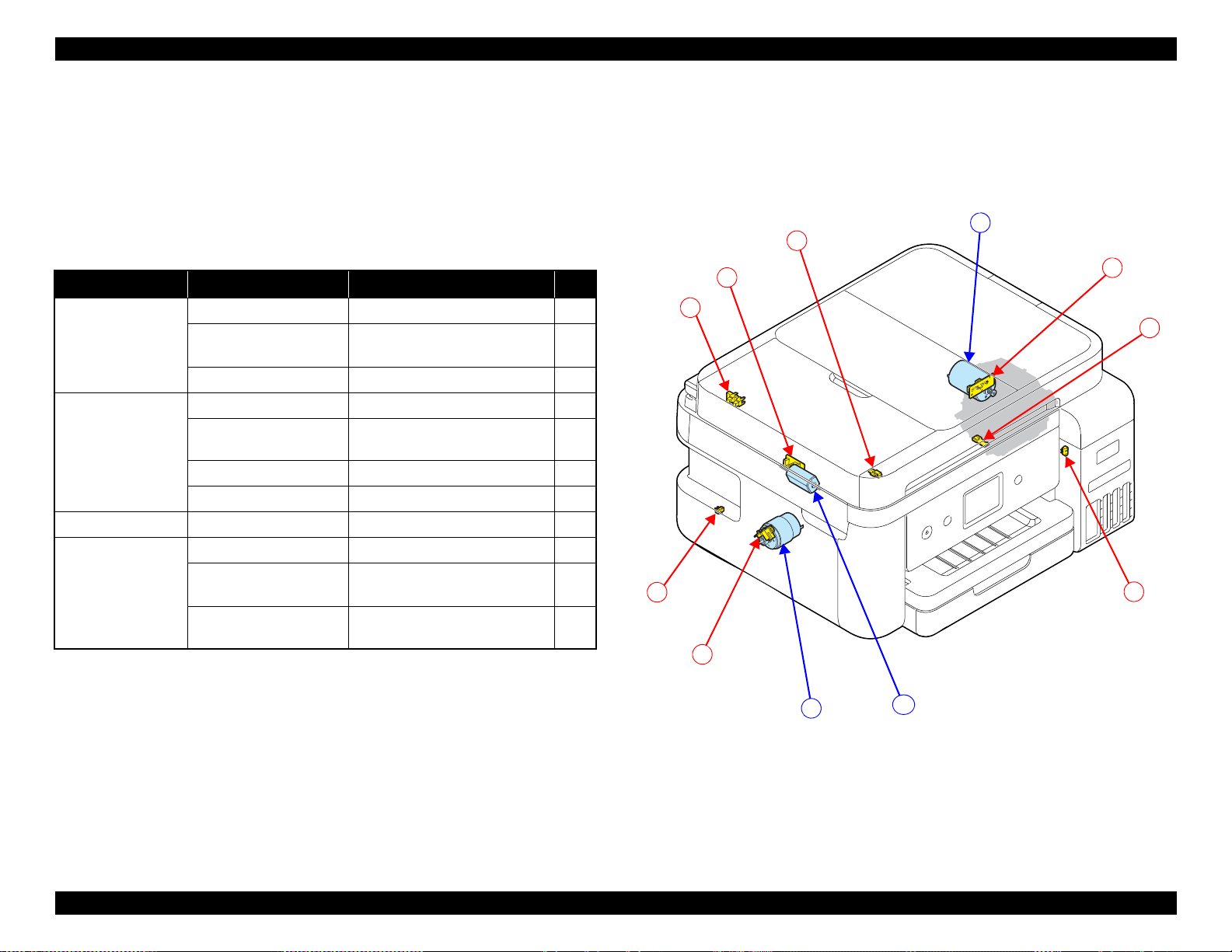

ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series

Table 1-4. Motor and Sensor List (ET-2750/ET-2760/L4160/ST-2000 series/ET-

2700/L4150 series)

Mechanism name Motor/sensor name Motor/sensor type No.

Carriage

mechanism

Paper loading/feed

mechanism

Scanner SCN Motor DC Motor C

CR Motor DC Motor A

CR Encoder Transmission-type photo

interrupter

PW Sensor Reflection-type photo interrupter 2

PF Motor DC Motor B

PF Encoder Transmission-type photo

interrupter

ASF Rear Paper existence

Sensor

PE Sensor Reflection-type photo interrupter 5

SCN Motor Encoder Transmission-type photo

Mechanical contact 4

interrupter

1

3

6

Figure 1-10. List of motor and sensor

(ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series)

Operating Principles Printer Mechanism Overview 19

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Scanner Unit

CIS Sensor

SCN Motor

ADF Unit

ADF PE Sensor

Pick up Roller

EJ Roller

PF Roller

SCN Motor

EJ Roller

Pick up Roller

Transmission

gear

ADF Document

Lever

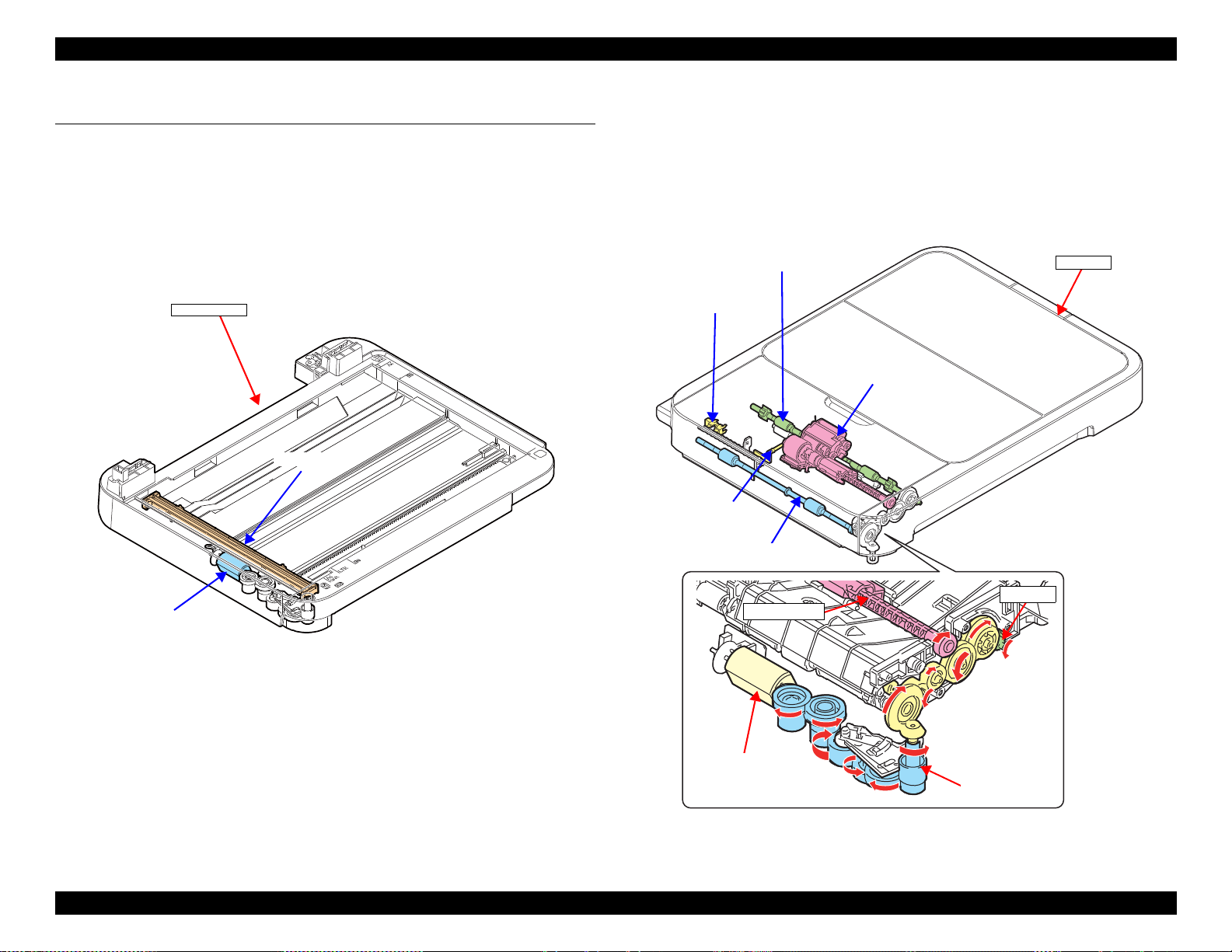

1.2 Scanner/ADF Overview

1.2.1 Scanner Mechanism

The scanner mechanism consists of a CIS sensor that scans documents and the

SCN motor that drives the scanner carriage. The CIS sensor and the SCN motor

are integrated as the scanner carriage, and it moves along the rail on the scanner

housing to scan documents.

1.2.2 ADF Mechanism (ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET-3760/L6170/ST-3000 series only)

The PF Roller, EJ Roller, and Pick up Roller of the ADF mechanism are driven

by the SCN Motor. The drive force of the motor is transmitted through the

transmission gear. The ADF mechanism does not support auto duplex

scanning.

Figure 1-11. Scanner mechanism

Figure 1-12. ADF mechanism

Operating Principles Scanner/ADF Overview 20

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

Pick up Roller Separation roller

PF Roller

EJ Roller

CIS Sensor

Lever of ADF PE Sensor

ADF Document Lever

No document on ADF

Document is present on ADF

ADF document lever

ADF document lever

Sub document

lever

Sub document lever ADF document lever

ADF top

ADF inside

ADF bottom

When scanning document, the document is fed inside the ADF as shown

below.

Figure 1-13. Document Feed Path

Presence or absence of document on the ADF is detected by the ADF

Document Lever and the scanner CIS Sensor. The lever moves up or down

depending on the presence or absence of document, and the end of the lever is

scanned by the CIS Sensor. According to the scan result, the printer determines

whether document is present or not.

Additionally, there is a Sub Document Lever beside the ADF Document Lever.

If the CIS Sensor cannot scan the end of the Sub Document Lever, the printer

determines that the scanner (SCN) unit is open or the CIS Sensor is

malfunctioning.

Operating Principles Scanner/ADF Overview 21

Figure 1-14. ADF document lever

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

1.3 Paper Loading/Feed Mechanism

1.3.1 Overview

1.3.1.1 Paper Loading Method

Paper loading method differ between ET-4750/ET-4760/L6190/ST-4000

series/ET-3750/ET-3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160

series and ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150 series,

but the both paper loading mechanisms are driven by the PF Motor.

Table 1-5. Paper Loading Method and Drive Force

Drive

force

(motor)

PF Motor PF encoder/

Motor control

PF scale

Front paper loading

• Turn the Slider Trans to

ASF mode, drive the

Pick up Roller Assy, and

load paper from the

cassette.

• Paper loaded from the

cassette is fed to the PF

Roller by the

intermediate roller

inside the duplex unit.

• Drive the PF Roller/EJ

Roller to convey the

paper.

Paper loading operation

model

Rear paper loading

model

• Drive the LD Roller and

load paper from the ASF

Rear.

• Drive the Hopper/Paper

Back Lever to prevent

multi-feed.

• Drive the PF Roller/EJ

Roller to convey the

paper.

• To flip paper for duplex

printing, drive the

intermediate roller

inside the duplex unit.

The paper is flipped and

then fed to the PF

Roller.

The following describes which paper loading method is used

for which model.

Front paper loading

ET-4750/ET-4760/L6190/ST-4000 series/ET-3750/ET3760/L6170/ST-3000 series/ET-3700/ET-3710/L6160

series/

Rear paper loading

ET-2750/ET-2760/L4160/ST-2000 series/ET-2700/L4150

series

Operating Principles Paper Loading/Feed Mechanism 22

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

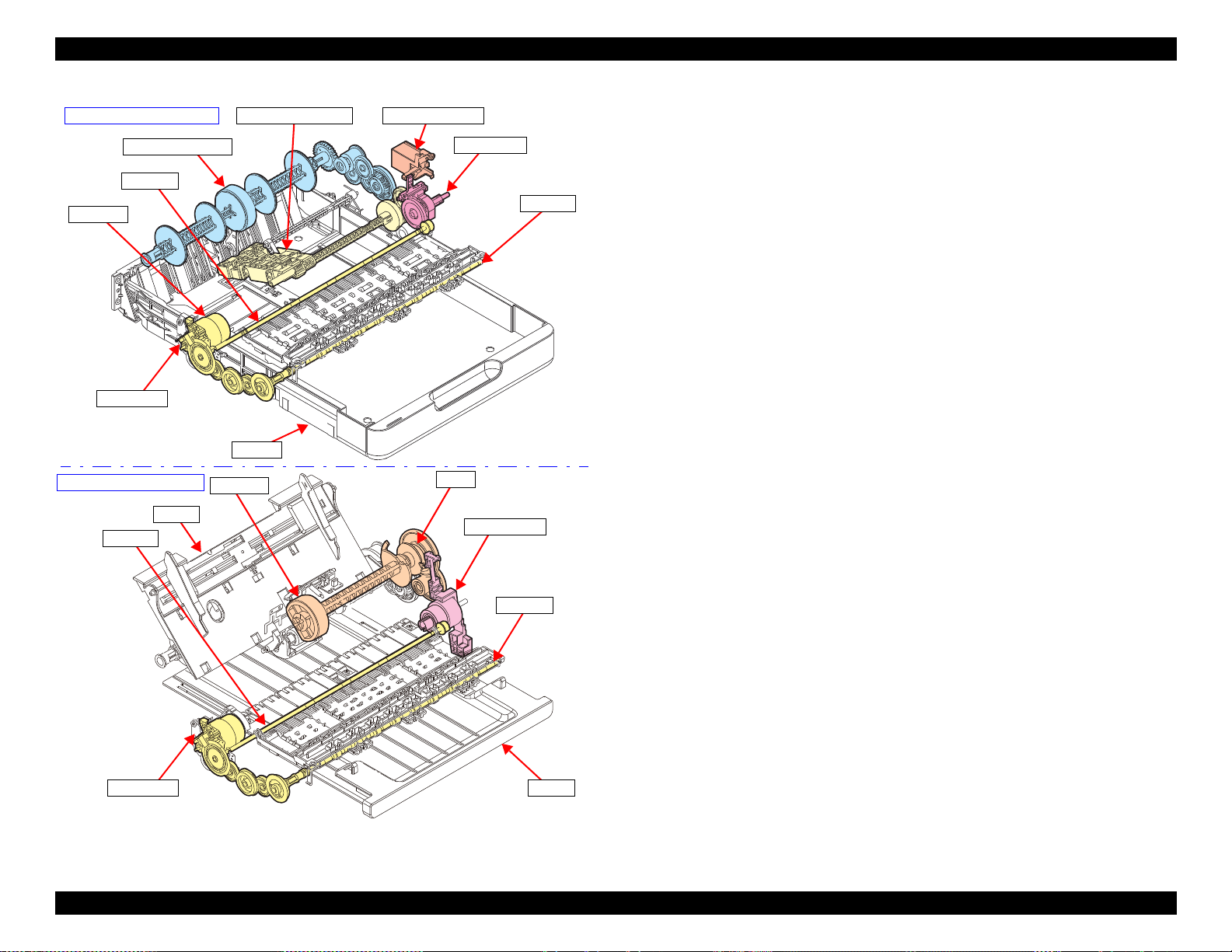

Intermediate roller

Pick up Roller Assy

PF Roller

EJ Roller

PF Motor

Holder Cam Assy

Slider Trans

Cassette

PF Encoder

Hopper

LD Roller

Change Lever

Clutch

PF Encoder

PF Roller

EJ Roller

Stacker

Front paper loading model

Rear paper feeding model

Figure 1-15. Paper loading/feed mechanism

Operating Principles Paper Loading/Feed Mechanism 23

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

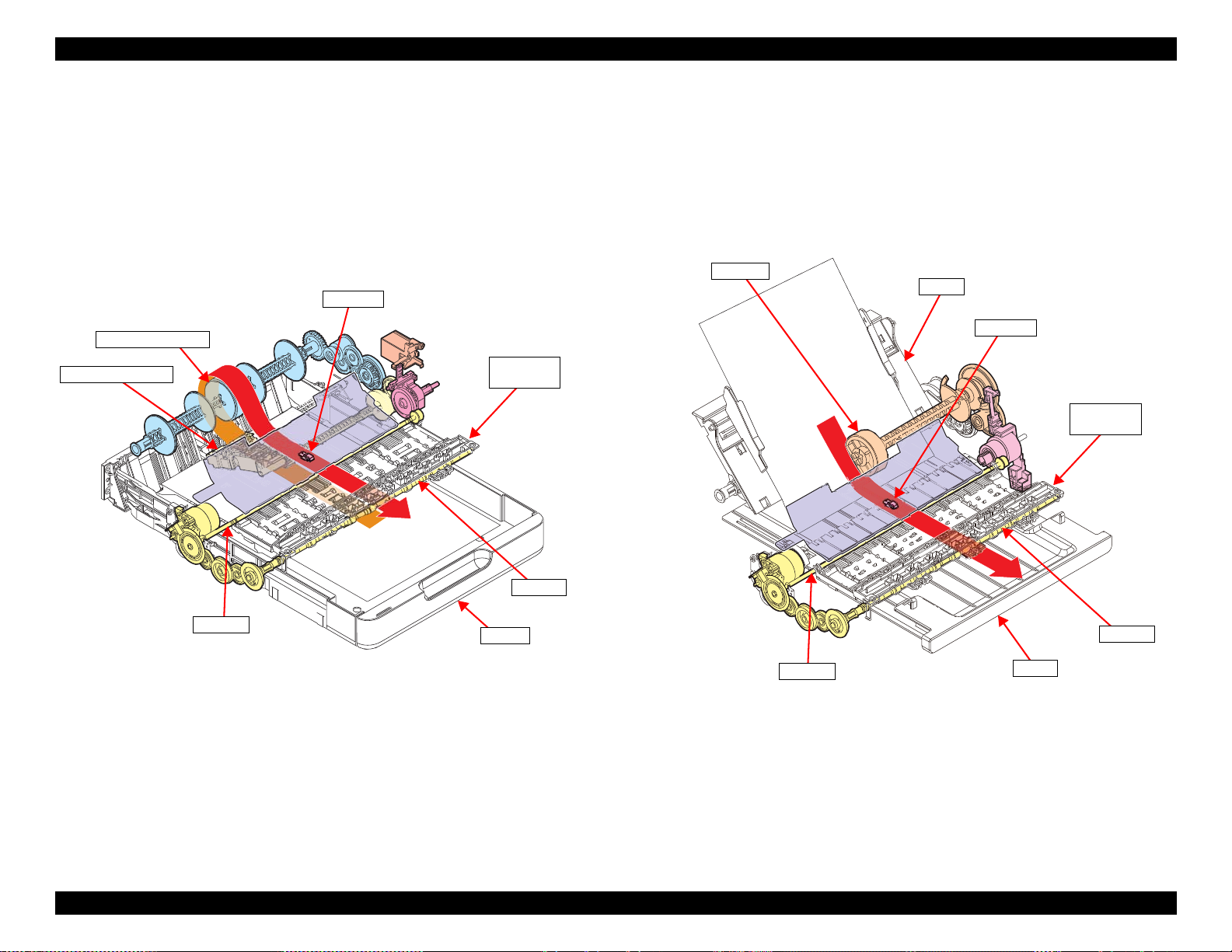

Cassette

EJ Roller

Star Wheel

Holder Assy

PF Roller

Intermediate roller

PE Sensor

Pick up Roller Assy

Stacker

EJ Roller

Star Wheel

Holder Assy

PF Roller

PE Sensor

LD Roller

Hopper

1.3.1.2 Paper Feed Path

1.3.1.2.1 Front Paper Loading

Paper loaded into the cassette is fed to the intermediate roller by the Pick up

Roller Assy, and then arrives at the PE Sensor position.

Next, skew is corrected, and printing on the paper is performed while the paper

is being fed by the PF Roller and EJ Roller/Star Wheel Holder Assy, then the

paper is ejected to the Stacker.

1.3.1.2.2 Rear Paper Loading

Paper put on the Hopper is fed by the LD Roller and arrives at the PE Sensor

position.

Next, skew is corrected, and printing on the paper is performed while the paper

is being fed by the PF roller and EJ Roller/Star Wheel Holder Assy, then the

paper is ejected to the Stacker.

Operating Principles Paper Loading/Feed Mechanism 24

Figure 1-16. Paper feed path of front paper loading

Figure 1-17. Paper feed path of rear paper loading

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

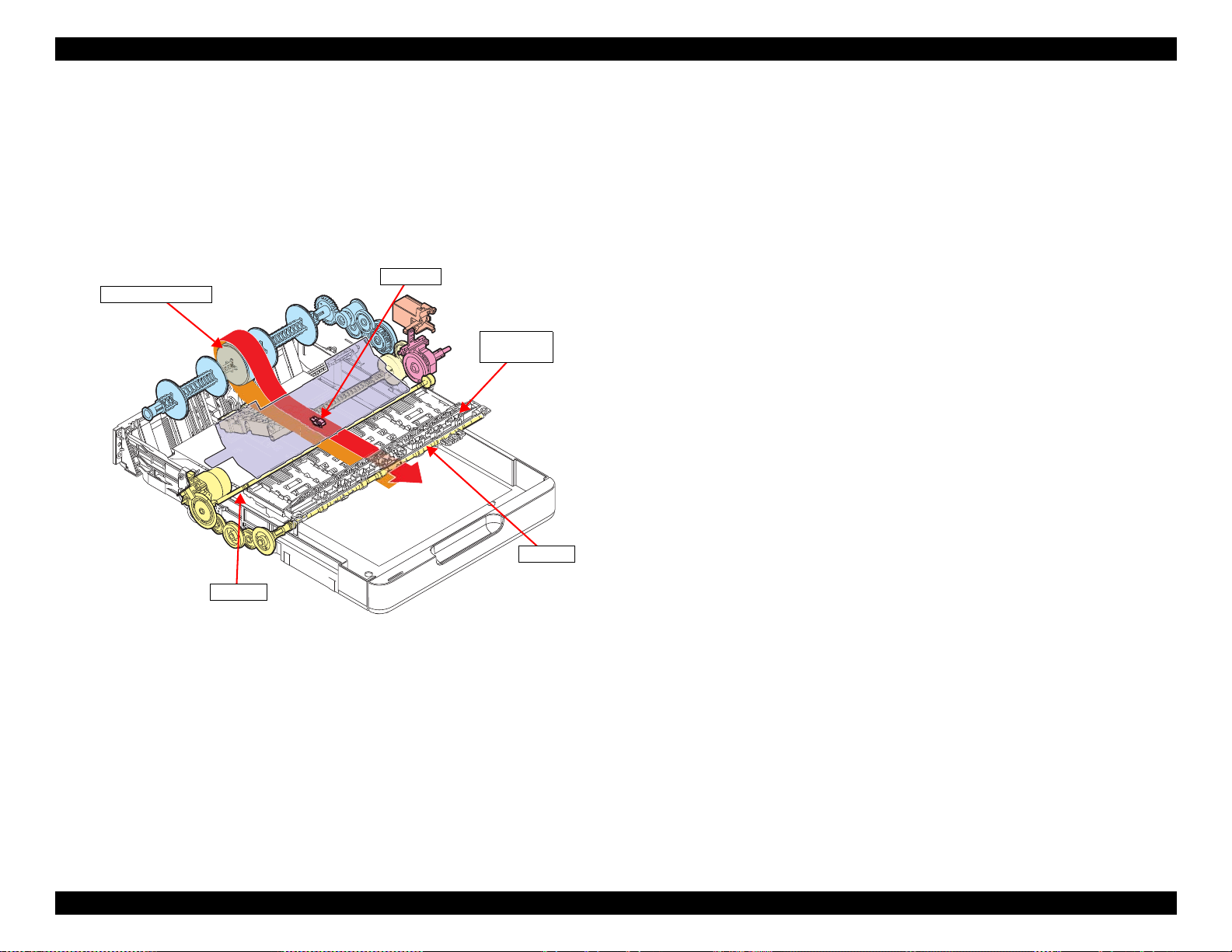

EJ Roller

Star Wheel

Holder Assy

PF Roller

PE Sensor

Intermediate roller

1.3.1.2.3 Paper Loading Path for Auto Duplex Printing

When printing on one side is finished, the printer waits for the ink on the one

side to dry keeping the paper nipped between the PF Roller and Driven Roller.

After a predetermined drying time has passed, the PF Roller and EJ Roller are

rotated in the reverse direction to pull the paper inside the auto duplex unit.

When the leading edge of the paper is detected by the PE Sensor, skew is

corrected, and then printing on the back side is performed.

Figure 1-18. Paper feed path for auto duplex printing (back side printing)

Operating Principles Paper Loading/Feed Mechanism 25

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

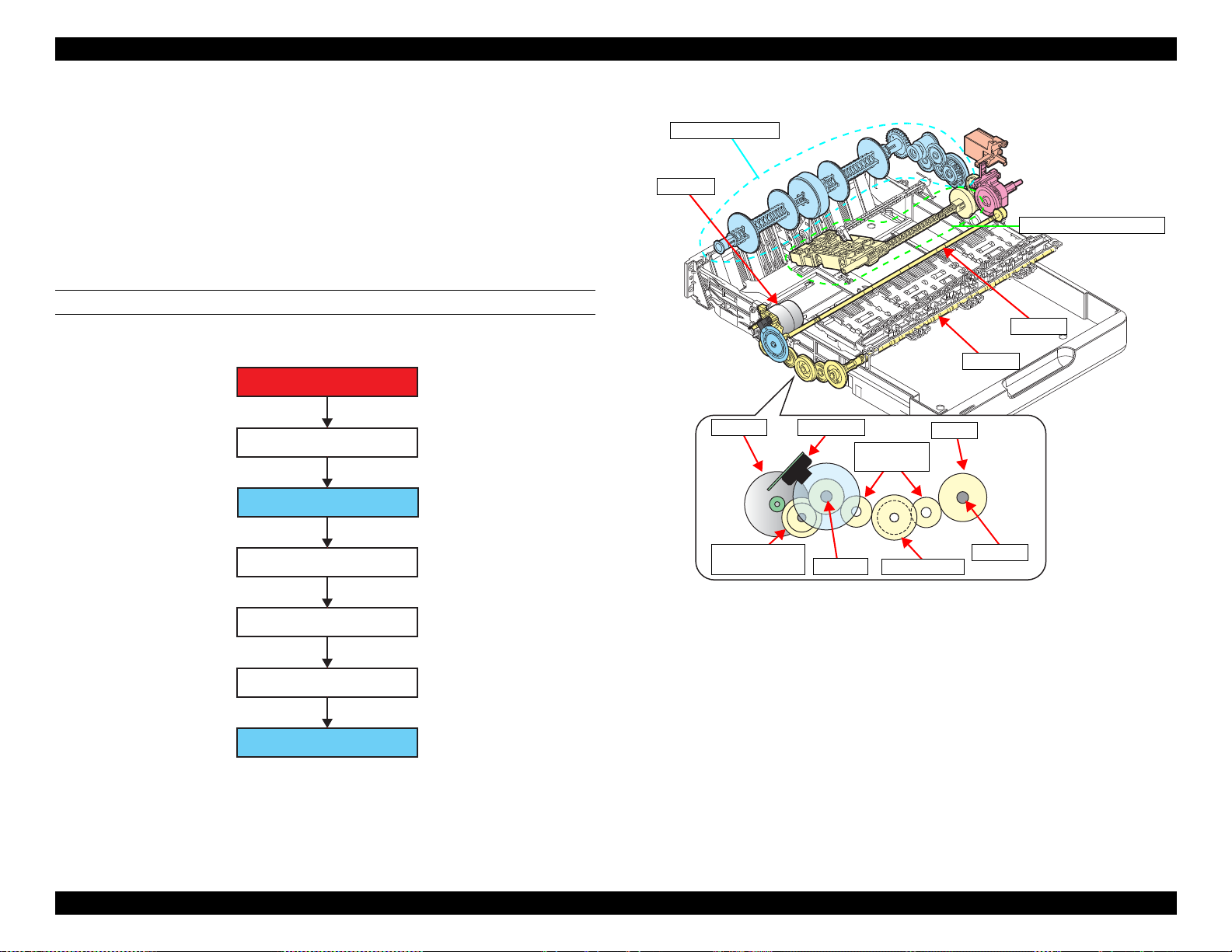

PF Motor

Compound gear PF1

PF Roller

Spur gear PF1

Spur gear PF2

EJ Roller

Spur gear PF1

PF Roller

PF Motor PF Encoder

Compound gear

PF1

Spur gear PF2

Spur gear

PF1

EJ gear

EJ Roller

PF Roller

EJ Roller

Duplex unit system

Pick up Roller Assy system

PF Motor

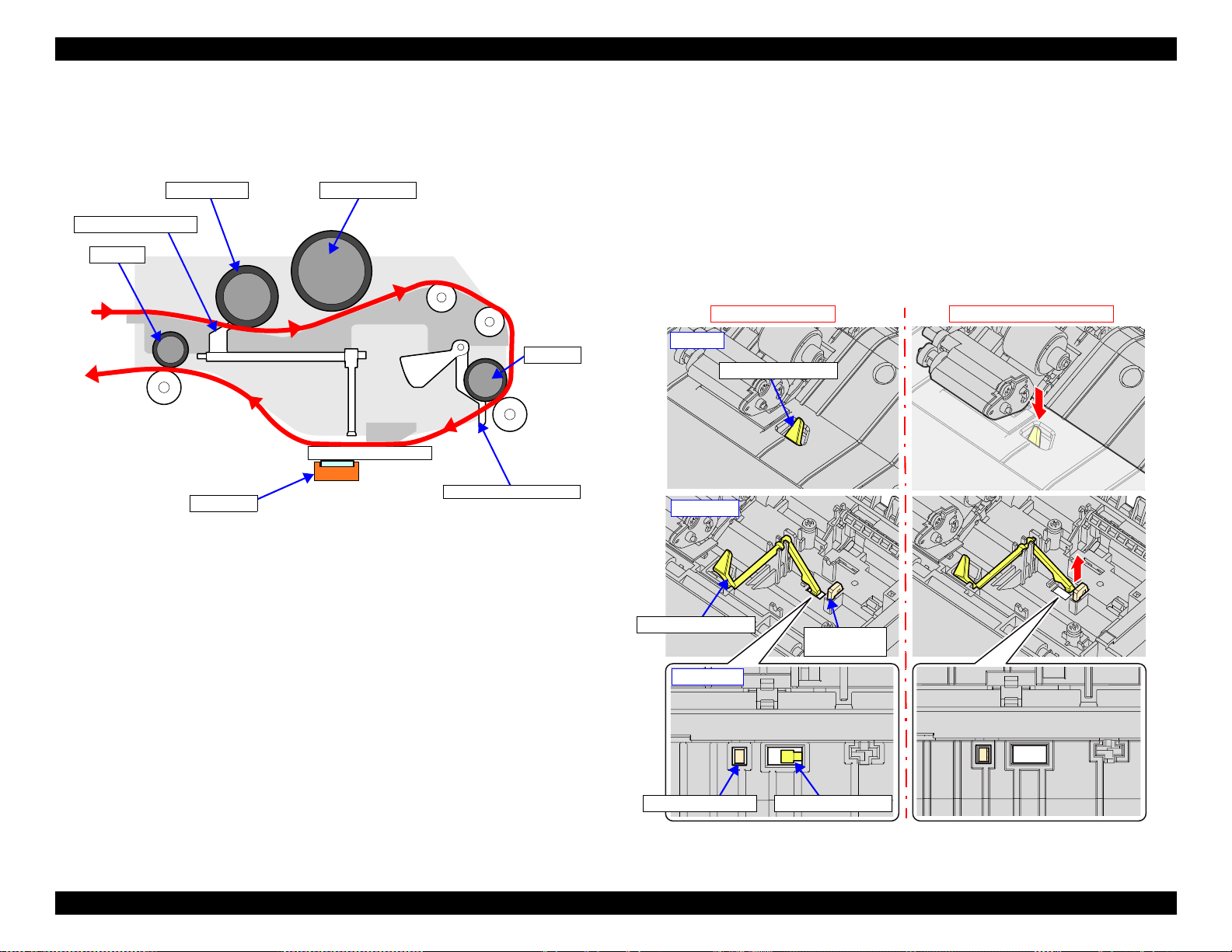

1.3.2 Operation Principle

1.3.2.1 Drive Path

1.3.2.1.1 Drive Path of Front Paper Loading Model

The drive force of the PF Motor is transmitted to the PF Roller and EJ Roller

through the compound gear and the spur gear, and then transmitted from the PF

Roller to the paper feed mechanism. There are two drive paths; duplex unit

system

DRIVE PATH FROM PF MOTOR TO PF ROLLER/EJ ROLLER

(p 27) and Pick up Roller Assy system (p 28).

Figure 1-20. Drive path from PF Motor to PF Roller/EJ Roller (2)

Figure 1-19. Drive path from PF Motor to PF Roller/EJ Roller (1)

Operating Principles Paper Loading/Feed Mechanism 26

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

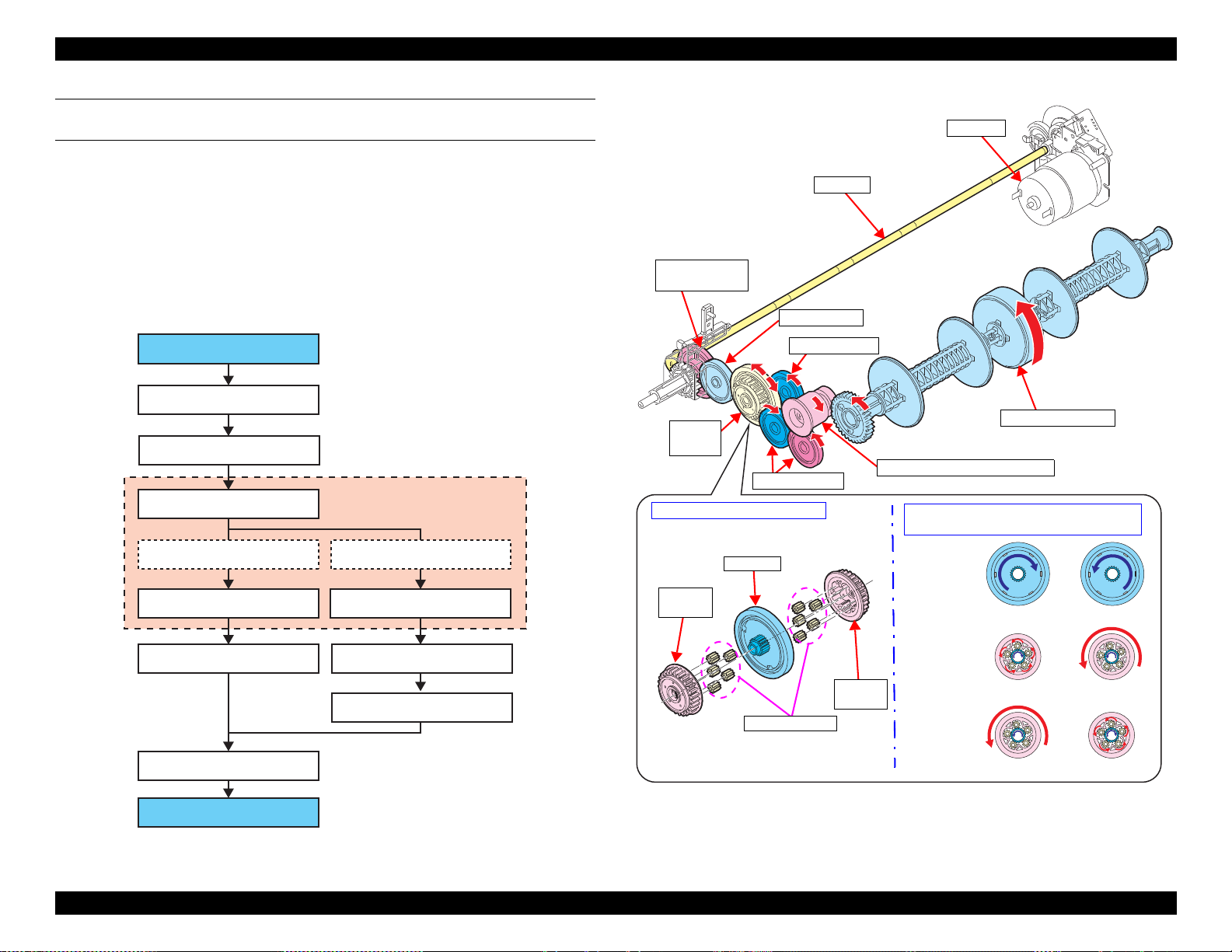

PF Roller (spur gear 9)

Compound gear 28.8-14.4

Spur gear 22.8

One way clutch

External gear B (80 digit side)

Intermediate roller

Spur gear 17.28

Sun gear

Planetary gear (x5)

Planetary gear (x5)

External gear A (0 digit side)

Spur gear 17.28

Spur gear 17.28

Spur gear 16/spur gear duplex

One way

clutch

PF Roller

Intermediate Roller

PF Motor

Structure of one way clutch

Planetary gear

Sun gear

External

gear A

External

gear B

External

gear A

External

gear B

Sun gear

Rotational direction of sun gear and motion

of external gear seen from 0 digit side

Idle

Idle

Clockwise

Counterclockwise

Rotate

Rotate

Compound gear

28.8-14.4

Spur gear 22.8

Spur gear 17.28

Spur gear 17.28

Spur gear 16/Spur gear duplex

DRIVE PATH FROM PF ROLLER TO INTERMEDIATE ROLLER

(DUPLEX UNIT SYSTEM)

The intermediate roller always rotates in the paper feed direction because of the

one way clutch, regardless of the PF roller rotational direction.

The one way clutch is consist of the sun gear, the external gear (x2) on both

sides of the sun gear, and the planetary gear (x5 each) inside the external gear.

When the sun gear rotates, either one of the external gears idle being

disengaged from the planetary gears, while the external gear on the other side

rotates being engaged with the planetary gears. In this way, the one way clutch

is designed to rotate either one of the two external gears at a time, and which

one to rotate depends on the rotational direction of the sun gear.

Figure 1-21. Drive Path From PF Roller to Intermediate Roller (1)

Operating Principles Paper Loading/Feed Mechanism 27

Figure 1-22. Drive Path From PF Roller to Intermediate Roller (2)

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

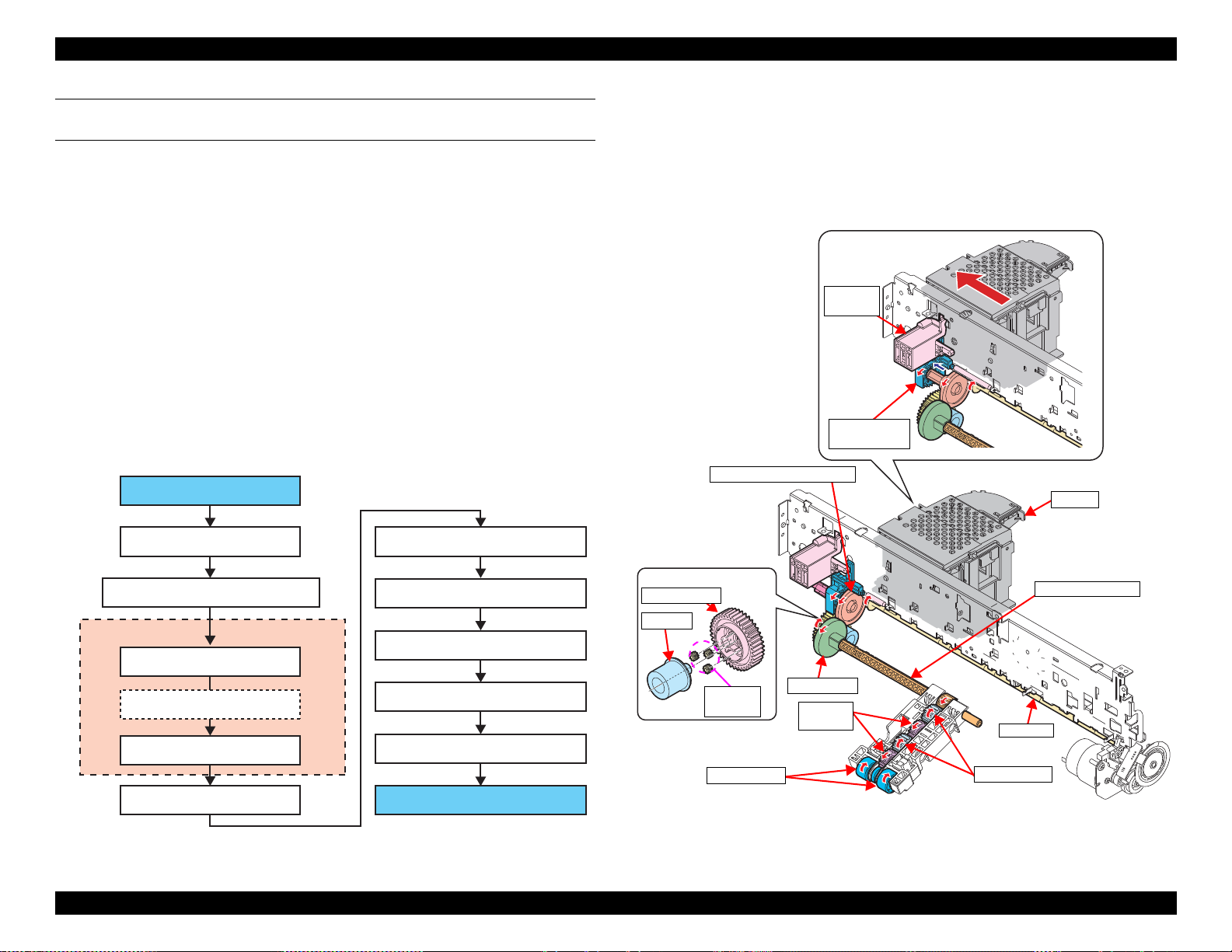

PF Roller (spur gear 9)

Compound gear 28.8-14.4

Spur gear 17.6 (Slider Trans)

One way clutch

Sun gear

Planetary gear (x3)

External gear

Spur gear 28

Pick up drive shaft

Spur gear 16B

Spur gear 16

Spur gear 16B

Spur gear 16

Pick up Roller

One way clutch

When drive force

of P F M ot or is not

transmitted

Spur gear 17.6

(Slider Trans)

Pick up drive shaft

Spur gear

16

Spur gear 16B

PF Roller

Spur gear 28

Compound gear 28.8-14.4

CR Unit

Planetary

gear

Sun gear

External gear

Holder

Cam Assy

Pick up Roller

DRIVE PATH FROM PF ROLLER TO PICK UP ROLLER (PICK UP ROLLER

ASSY SYSTEM)

If the Pick up Roller Assy is always driven by the PF motor, it continues

feeding paper without stopping regardless of the progress of printing on the

previous sheet. To prevent this, the Slider Trans interrupts the motor drive to

the Pick up Roller Assy when the assy needs to stop.

While the Pick up Roller Assy needs to move, the Slider Trans is pulled toward

the opposite side of the carriage home with the tension spring. The

transmission gear interlocked with the Slider Trans engages with the Pick up

Roller driving gear (one way clutch) that moves the Pick up Roller Assy, so the

Pick up Roller Assy can be driven by the PF Motor. If the CR Unit pushes the

Change Lever to the 0 digit side, the transmission gear disengages from the one

way clutch. As a result, the driving force of the PF Motor is shut down.

The CR Unit pushes the Slider Trans to the 0 digit side to stop the Pick up

Roller Assy after a sheet of paper is fed into the printer, however, the CR Unit

cannot stay at the position because it needs to move for printing. Therefore,

instead of the CR Unit, the Change Lever’s disengaged status is kept by the

cam of the Holder Cam Assy during printing.

The one way clutch controls the Pick up Roller to rotate only in the paper feed

direction. The operation principle and the structure are basically the same with

the one used in the drive path to the intermediate roller

(p 27). Therefore, while

the PF Roller is rotating in the direction opposite to the paper feed direction,

the Pick up Roller does not rotate even when the drive force is transmitted

through the Slider Trans.

Operating Principles Paper Loading/Feed Mechanism 28

Figure 1-23. Drive path from PF roller to Pick up Roller Assy (1)

Figure 1-24. Drive path from PF roller to Pick up Roller Assy (2)

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

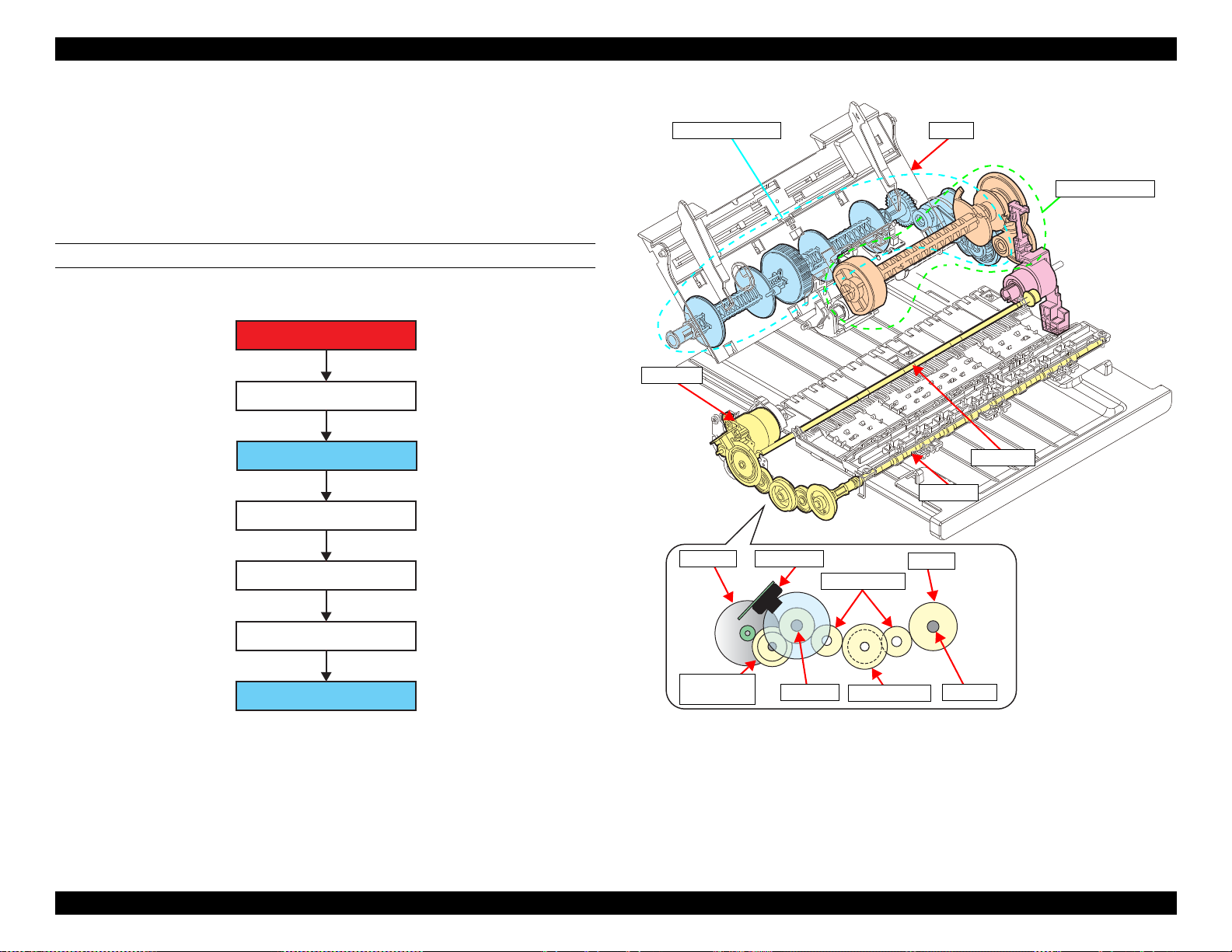

PF Motor

Compound gear PF1

PF Roller

Spur gear PF1

Spur gear PF2

EJ Roller

Spur gear PF1

PF Roller

PF Motor

PF Encoder

Compound

gear PF1

Spur gear PF2

Spur gear PF1

EJ gear

EJ Roller

PF Roller

EJ Roller

Duplex unit system

ASF Rear system

PF Motor

Hopper

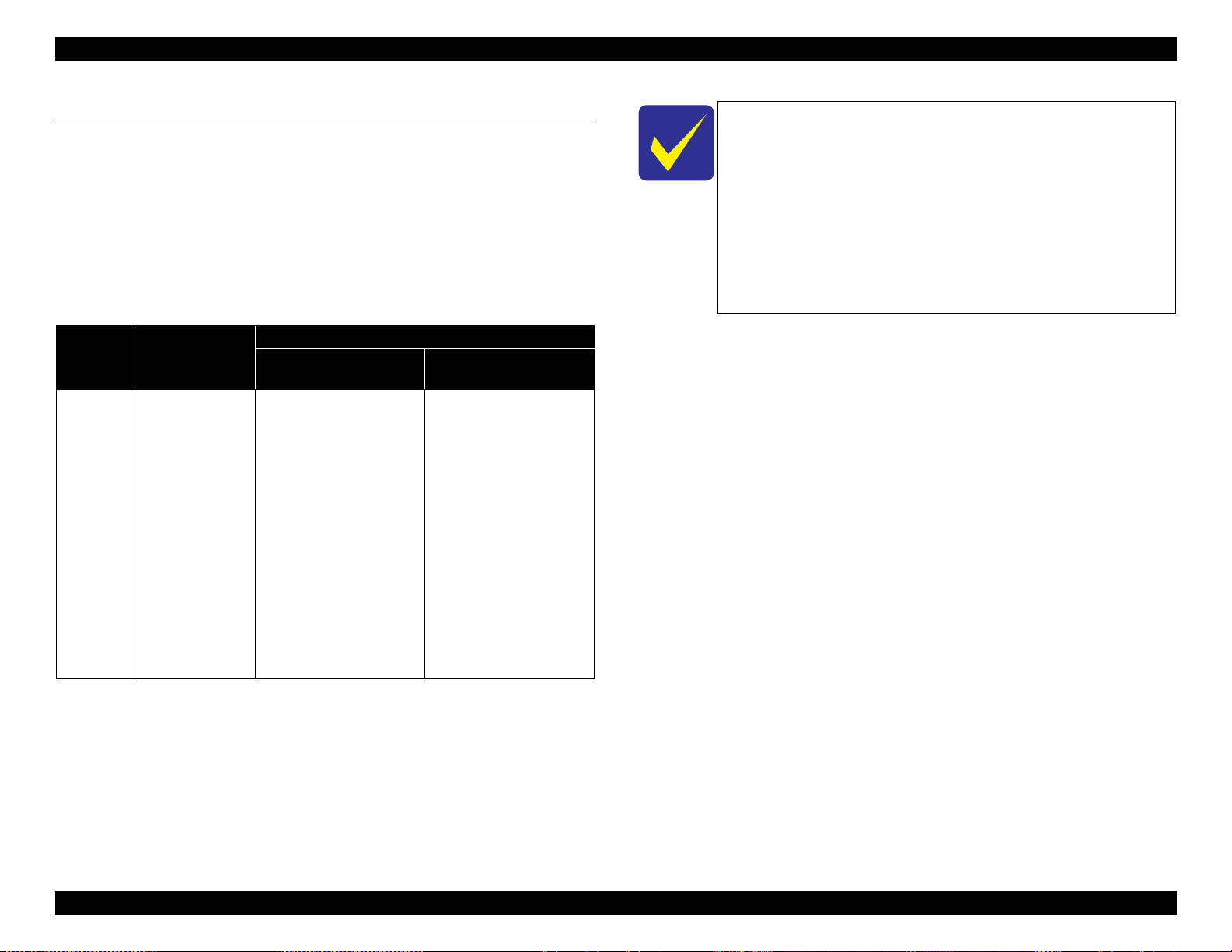

1.3.2.1.2 Drive Path of Rear Paper Loading Model

The drive path of the rear paper loading model is mostly the same with the

front paper loading model. The driving force of the PF Roller is transmitted to

the PF Roller and the EJ Roller through the compound gear and the spur gear,

and then transmitted from the PF Roller to the paper feed mechanism. There

are two drive paths; duplex unit system

(p 30) and ASF Rear system (p 31).

DRIVE PATH FROM PF MOTOR TO PF ROLLER/EJ ROLLER

Figure 1-25. Drive path from PF Motor to PF Roller/EJ Roller (1)

Figure 1-26. Drive path from PF Motor to PF Roller/EJ Roller (2)

Operating Principles Paper Loading/Feed Mechanism 29

Confidential

EPSON ET-4750/4760/3750/3760/3700/3710/2750/2760/2700/L6190/L6170/L6160/L4160/L4150/ST-4000/ST-3000/ST-2000 series Revision G

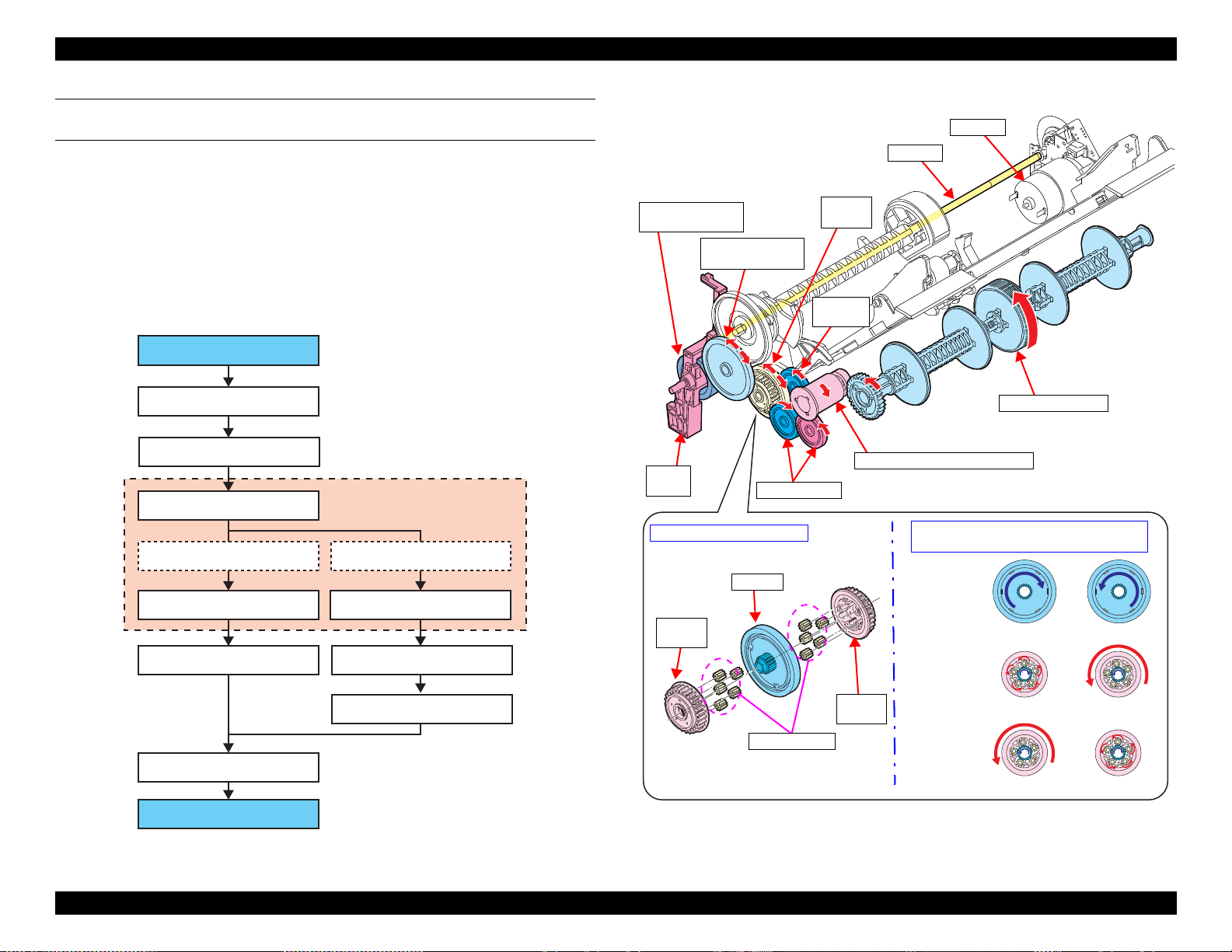

PF Roller (spur gear PF)

Compound gear 27.2-22.2

Compound gear 38.4-15.6

One way clutch

External gear B (80 digit side)

Intermediate roller

Spur gear 21.6

Sun gear

Planetary gear (x5)

Planetary gear (x5)

Spur gear 21.6

Spur gear 21.6

Spur gear16/spur gear duplex

External gear A (0 digit side)

One way

clutch

PF Roller

Intermediate roller

PF Motor

Planetary gear

Sun gear

External

gear A

External

gear B

External

gear A

External

gear B

Sun gear

Rotate

Idle

Clockwise

Counterclockwise

Idle

Rotate

Compound gear

38.4-15.6

Spur gear 21.6

Spur gear

21.6

Spur gear 16/Spur gear duplex

Compound gear

27.2-22.2

Change

Lever

Structure of one way clutch

Rotational direction of sun gear and motion

of external gear seen from 0 digit side

DRIVE PATH FROM PF ROLLER TO INTERMEDIATE ROLLER

(DUPLEX UNIT SYSTEM)

The intermediate roller always rotates in the paper feed direction because of the

one way clutch, regardless of the PF roller rotational direction.

The one way clutch is consist of the sun gear, the external gear (x2) on both

sides of the sun gear, and the planetary gear (x5 each) inside the external gear.

When the sun gear rotates, either one of the external gears idle being

disengaged from the planetary gears, while the external gear on the other side

rotates being engaged with the planetary gears. In this way, the one way clutch

is designed to rotate either one of the two external gears at a time, and which

one to rotate depends on the rotational direction of the sun gear.

Figure 1-27. Drive Path From PF Roller to Intermediate Roller (1)

Operating Principles Paper Loading/Feed Mechanism 30

Figure 1-28. Drive Path From PF Roller to Intermediate Roller (2)

Confidential

Loading...

Loading...