Page 1

SERVICE MANUAL

A4 monochrome Laser Printer

EPSON AcuLaser M2000D

M2000DN

M2010D

M2010DN

Page 2

Notice:

The purpose of this manual is to provide the product knowledge and the technical information required for repair or maintenance of EPSON AcuLaser M2000D/M2000DN/

M2010D/M2010DN.

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means electronic, mechanical, photocopying, or

otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

This manual contains information and sensitive matters, special care should be taken when handling the manual.

The contents of this manual are subject to change without prior notice as a result of continuing improvements to the product’s performance and functions.

Some of the descriptions or the appearance of some parts in this manual may differ from those on an actual product.

Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners.

EPSON disclaims any and all rights in those marks.

Copyright © SEIKO EPSON CORPORATION 2008.

Imaging Products CS, PL & Environmental Management

Page 3

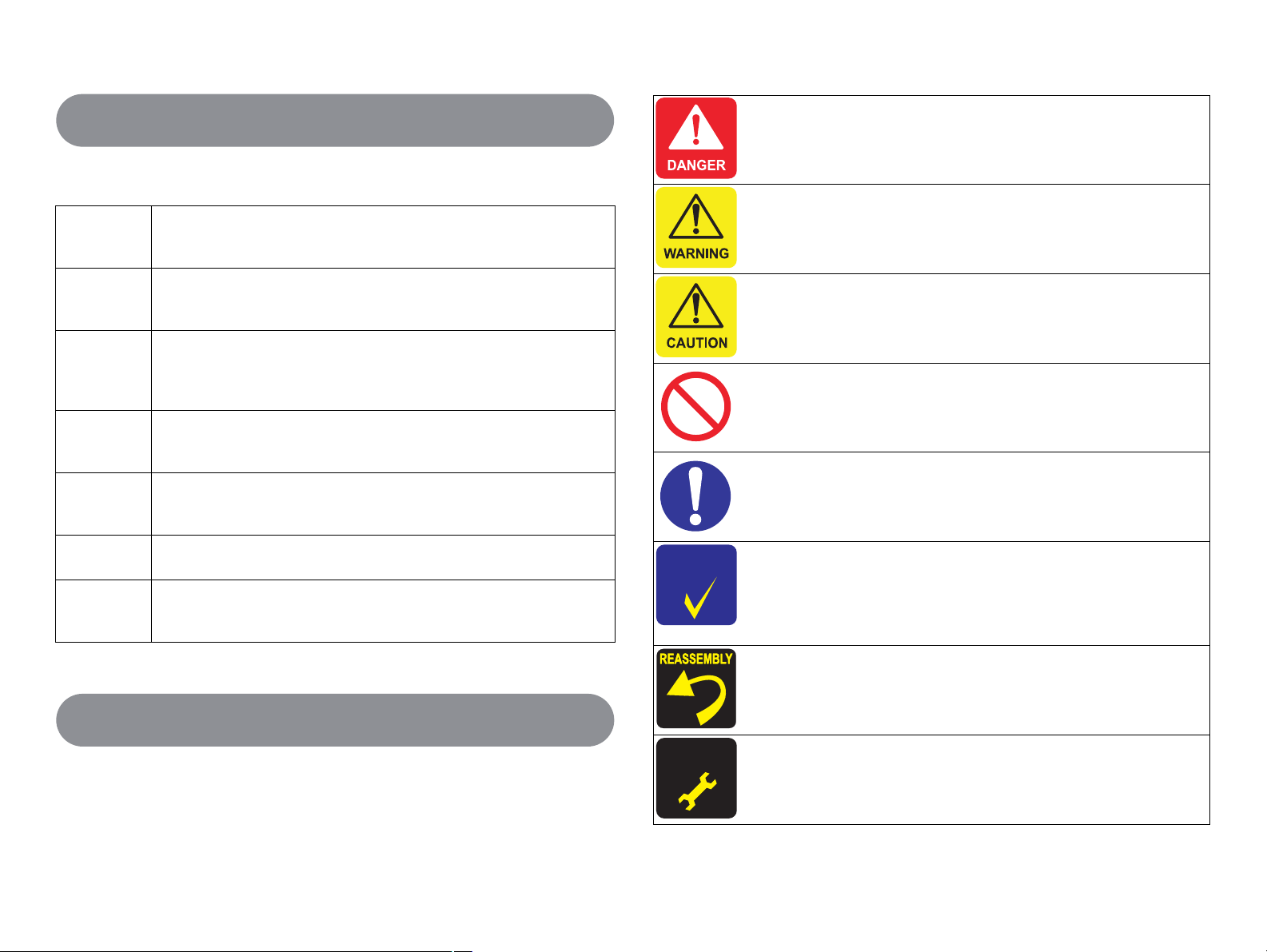

Manual Configuration

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, would result in injury or loss

of life.

This manual consists of the following seven chapters:

CHAPTER 1 PRODUCT DESCRIPTIONS

Describes the main features, basic specifications, consumable products,

periodic replacement parts, and controller interface of the product.

CHAPTER 2 OPERATING PRINCIPLES

Describes each mechanism configurations and explains fundamental

operating principle of major components including the control system.

CHAPTER 3 TROUBLESHOOTING

Describes the troubleshooting procedures that can help you diagnose and

resolve problems. The problems are sorted by displayed error codes and

phenomena of abnormal image output.

CHAPTER 4 DISASSEMBLY/ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling

of the product.

CHAPTER 5 ADJUSTMENT

Describes the settings and the adjustments to be performed during the

maintenance work.

CHAPTER 6 MAINTENANCE

Describes preventive maintenance procedures.

CHAPTER 7 APPENDIX

Provides the additional information such as panel operations, connector

pin layouts, parts list, and exploded diagrams for reference.

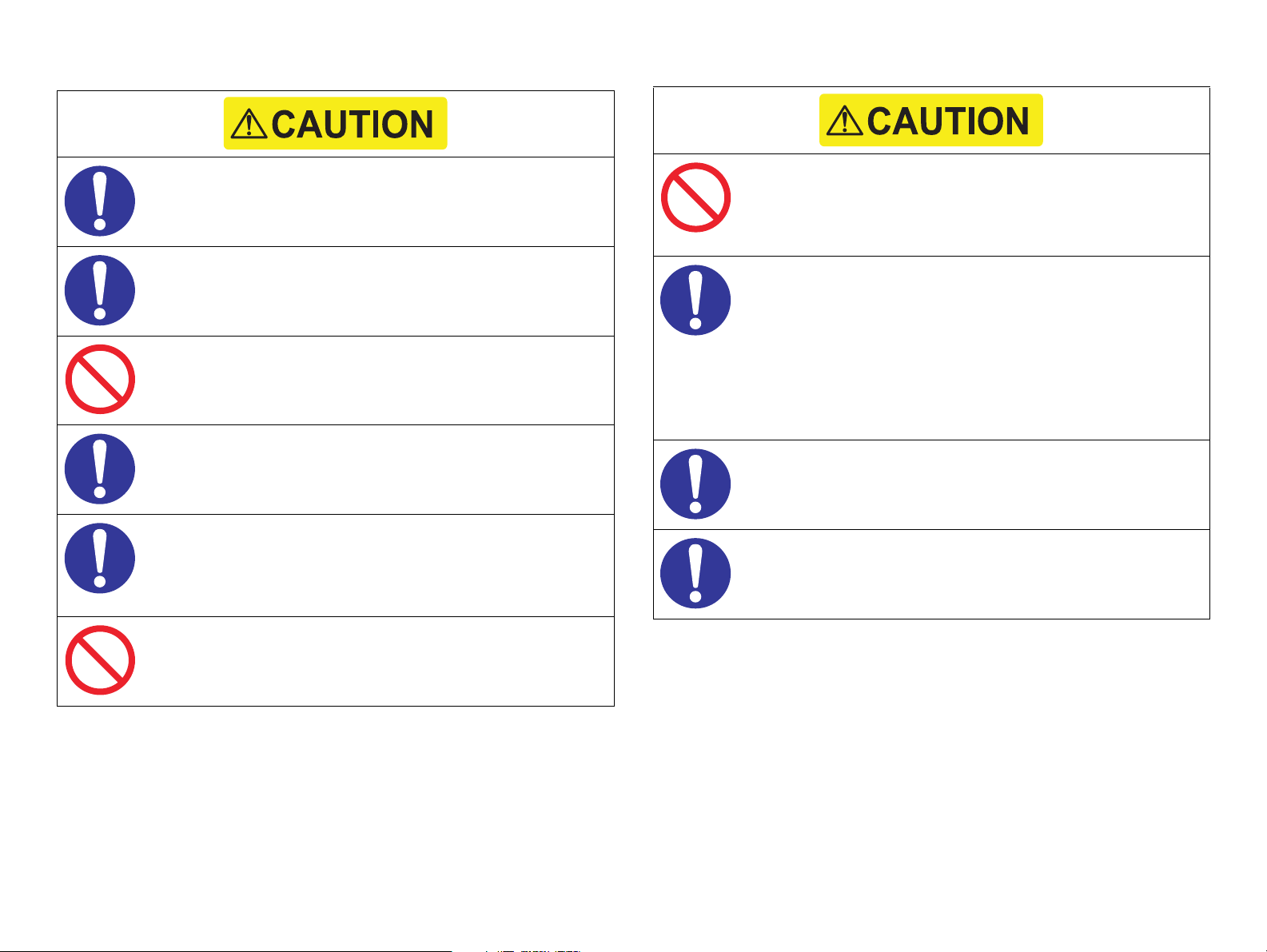

CHECK

P O I N T

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in personal

injury or may cause damage to, or destruction of equipment.

Indicates a prohibited action during maintenance work.

Indicates a mandatory action during maintenance work.

Indicates an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently.

Provides additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates a product reassembly procedure, practice or condition

that must be executed in accordance with the specified standards to

maintain the product’s quality.

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be sure to read and understand the information with these

symbols.

ADJUSTMENT

REQ U IRED

Indicates an operating or maintenance procedure, practice or

condition that must be executed in accordance with the specified

standards to maintain the product’s quality.

Page 4

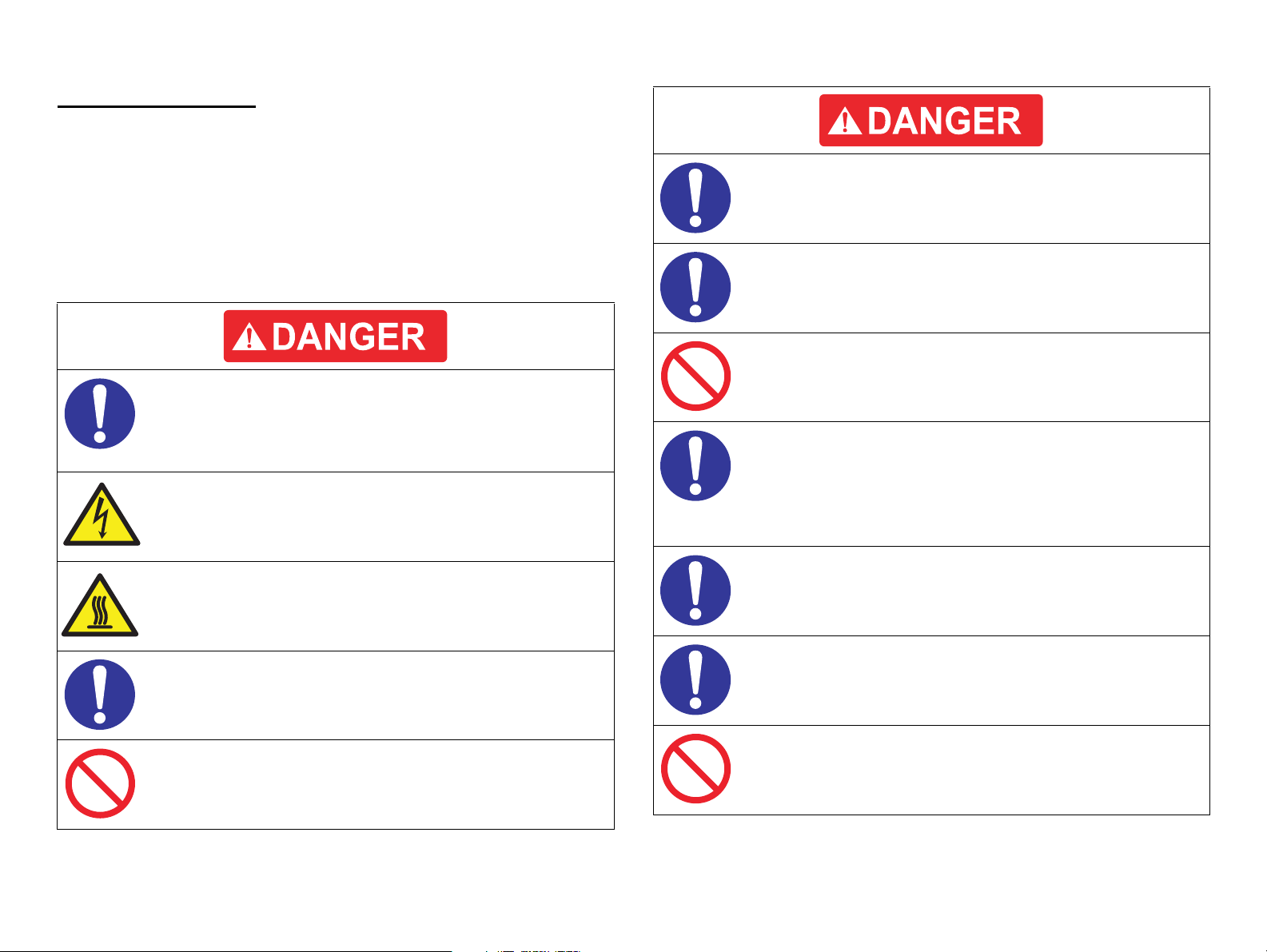

Safety

Safety-related Symbols

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, would result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in personal

injury or may cause damage to, or destruction of equipment.

Safety Equipment

Location of Safety Equipment

Never deactivate the safety equipment installed on the product for

any reason whatsoever. (e.g. Making a connection circuit bypasses

the safety equipment.)

List of Safety Equipment

Name Function/Purpose

Interlock switch Shuts off 24 V DC power line when the Top cover is opened.

Page 5

Safety System Wiring Schematic

A

LVPS

Left

cooling

fan motor

Zero cross

signal circuit

Power switch

C input

Fuser heater

lamp control

circuit

Switching

regulator

circuit

Interlock

switch

+24V1

FAN

ZCROSS

SLEEP

+5V1

+24V2

HEATN

+3.3V1

THERM

Fuser unit

Fuser thermistor

Fuser

heater lamp

Fuser thermal cutout

Page 6

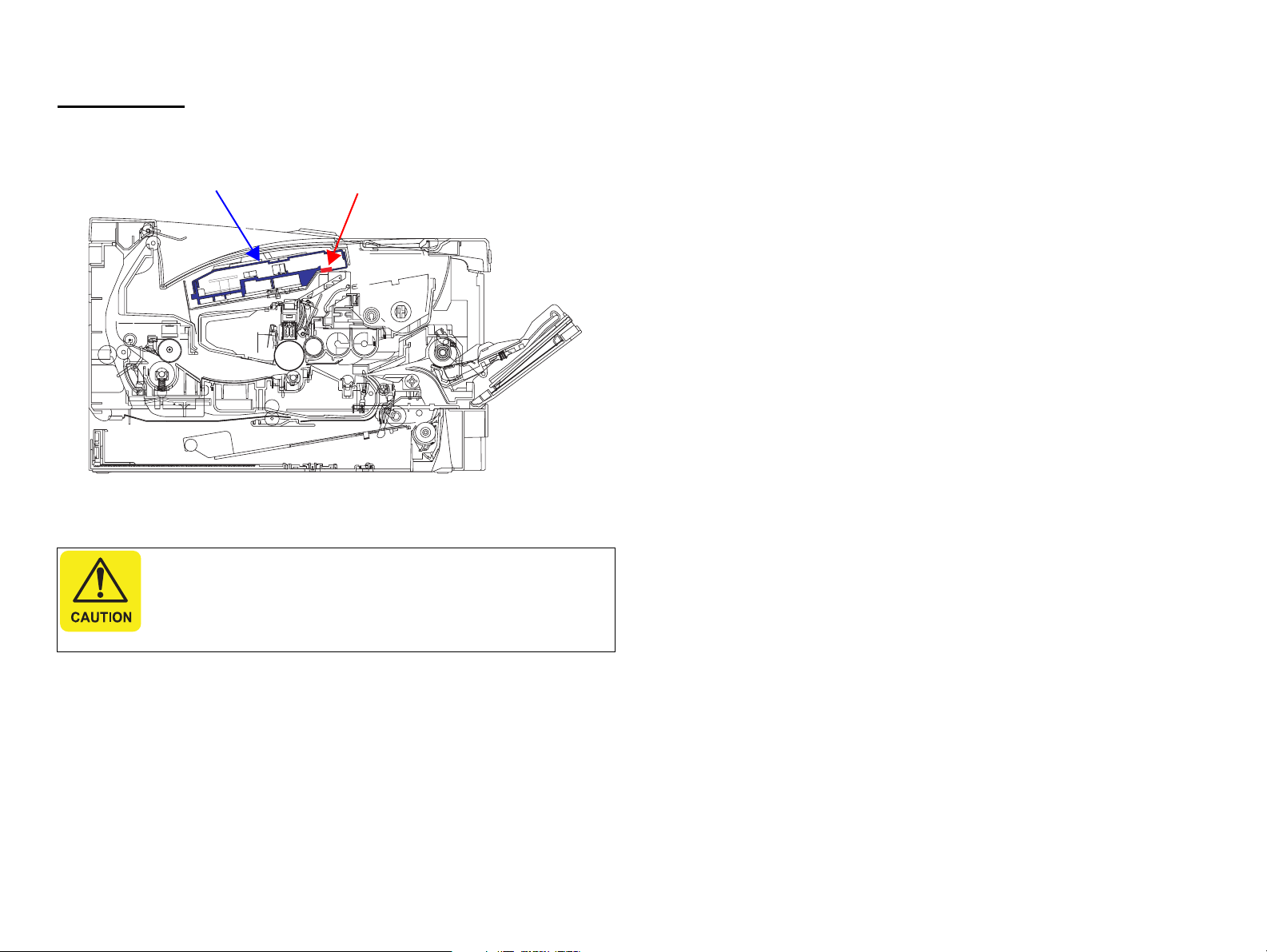

Laser Beam

Laser Opening Location

Handling Precautions

Disassembling and adjustment procedures not specified herein

may result in hazardous radiation exposure.

Do not disassemble or attempt to adjust the Laser Scanner unit

for any reason whatsoever. When the Laser Scanner unit

malfunctions, replace it with a new one.

Laser OpeningsLaser Scanner Unit

Page 7

Prohibited Matters

Never deactivate the safety equipment installed on the product for any reason

whatsoever.

Never modify the safety equipment or replace it with part not approved by

EPSON. Doing so may cause the safety functions to stop working properly, and

may result in fire or injury.

Never modify the product. If you are instructed to do so, however, fully

understand the instruction and perform the modification.

To prevent an electric shock, burn, injury, etc., always turn the

printer off and unplug the power cord before starting maintenance

work. When the power supply cable must be connected to measure

voltage or for any other task, strictly follow the instructions and use

extreme caution in working on electronic components.

Pay particular attention to the high-voltage part indicated with the

symbol on the left.

Do not touch the high temperature parts indicated with the symbol

on the left. Those parts are extremely hot immediately after use. If

you need to replace those parts, leave the printer until it cools.

Connect the printer to an electrical outlet that matches the printer’s

rated voltage and power requirements.

Do not connect any other devices to the electrical outlet supplying

the printer. Doing so can cause overloading of the electrical circuit

and may cause a fire.

Do not use extension cords or power adapters to plug multiple

devices into the same outlet. Power plug and electrical outlet should

be free from dust or foreign objects.

The printer should be properly grounded to prevent electric shock.

The grounding terminal should be one of the followings:

a. One of the electrical outlet

b. One that is grounded by a D-type grounding construction.

(The former third-type grounding construction; grounding

resistance under 100 Ω).

Power cord should not be deformed or damaged. If the cord is

damaged, replace it with a new one dedicated for the product.

Use the specified service parts for repair and maintenance.

When using compressed air products; such as air duster, for

cleaning during repair and maintenance, the use of such products

containing flammable gas is prohibited.

After replacing the Fuser Unit or any other parts to which AC

voltage is applied, be sure to check the part is properly installed and

the connecting cables are not caught between metal parts.

Otherwise a fire or an electric shock may occur.

Fuse on the Power Supply Unit must not be replaced under any

circumstances.

Page 8

Before performing repair and maintenance work, read and

understand the documents of the product (e.g. service manual).

Be sure to follow the specified steps and use the prescribed tools

described in the documents.

When disassembling or assembling the product, make sure to wear

gloves to avoid injury from metal parts with sharp edges.

Take care not to drop any screws, washers, or clips inside the

printer body. Should it fall in, do not boot up your printer until the

part has been safely removed.

After reassembling the printer, make sure all the parts and the

screws are put back in place and the cables are not caught between

metal parts.

Do not use vacuum cleaner for home use to clean up spills of

powdered toners. The very fine particles can cause fire/explosion.

Sweep them thoroughly with a broom or wipe them with a cloth

moistened with neutral detergent. If a large amount of toner is

spilled, use a toner vacuum designed specifically to clean toner.

Ozone gas is generated by the printer as a by-product of the

printing process. The amount of gas is too small to be harmful,

however, some users may feel uncomfortable under the following

conditions. It is desirable to advice the users to ventilate the room

when using the printer.

When using the printer for a long period of time in a room with

poor ventilation.

When printing a large amount of documents at a time.

When using multiple printers in the same room.

In order to protect sensitive microprocessors and circuitry, use

static discharge equipment, such as anti-static wrist straps, when

accessing internal components.

Though toner and developer are safe for human body, they may

cause irritation to skin and eyes. If toner gets into your eyes, wash it

away immediately with water. If irritation continues, see a physician.

If toner gets in your mouth, rinse immediately with plenty of water.

If swallowed, induce vomiting and consult a physician.

Do not throw used toner cartridges or toner into the flames.

Do not use thinner or alcohol when cleaning the product as it may

result in discoloration or deformation.

Page 9

Revision History

This manual is revised when the system, component, or part of the product is modified as a result of continuing improvements to the product’s performance and functions.

See the table below for recent updates.

Revision Date of Issue Description

A January 16, 2008 First Release

B February 1, 2008 All chapters:

Some connector numbers described in all chapters were corrected.

Chapter 3:

Service request errors were changed.

Chapter 4:

An adjustment point was added in the Developing Unit removal procedure.

“ Disassembly Flowchart” (p.76) was changed.

“ Disassembly Flowchart” (p.120) was changed.

PF Paper Conveyance Clutch figure was changed.

Chapter 5:

Firmware update was added in “5.1 Adjustment Item” (p.141).

“5.2.2 Updating firmware” (p.145) was added.

Chapter 7:

Some explanations in “7.3.1 Status Sheet” (p.166) were corrected.

Page 10

Contents

Chapter 1PRODUCT DESCRIPTION

1.1 Product Specifications. ......................................................................................... 4

1.1.1 Basic Specifications. .................................................................................. 4

1.1.2 Paper Specifications .................................................................................. 8

1.1.3 Replacement Parts . .................................................................................. 11

1.1.4 Controller Specifications. ........................................................................ 12

1.2 List of Printer Messages . .................................................................................... 13

Chapter 2OPERATING PRINCIPLES

2.1 Electrical parts layout. ........................................................................................ 16

2.2 Technical Explanation of Print Process. ............................................................. 20

2.2.1 Charging ................................................................................................... 20

2.2.2 Exposure ................................................................................................... 21

2.2.3 Development. ........................................................................................... 22

2.2.4 Transfer/Separation . ................................................................................ 23

2.2.5 Cleaning. .................................................................................................. 24

2.2.6 Fusing ....................................................................................................... 25

2.2.7 Paper exit section. .................................................................................... 26

2.2.8 Duplex/conveying section . ...................................................................... 27

2.3 Paper Feed ........................................................................................................... 28

2.3.1 Cassette paper feed section. ..................................................................... 28

2.3.2 MP tray paper feed section. ..................................................................... 29

2.3.3 Paper conveying section . ......................................................................... 30

2.3.4 Optional cassette paper feed section. ....................................................... 31

Chapter 3TROUBLESHOOTING

3.4 Troubleshooting................................................................................................... 37

3.4.1 Paper Jam Error........................................................................................ 37

3.4.2 LED Indication ......................................................................................... 40

3.4.3 Controller-related Service Call Errors. .................................................... 47

3.4.4 Image Quality Problems. ......................................................................... 57

3.4.5 Electrical Problems. ................................................................................. 61

3.4.6 Mechanical Problems . ............................................................................. 63

Chapter 4DISASSEMBLY AND ASSEMBLY

4.1 Preliminary Check............................................................................................... 66

4.1.1 Tool List ................................................................................................... 66

4.1.2 Parts/Units that Should Not be Disassembled. ........................................ 66

4.1.3 How to Read this Chapter . ..................................................................... 67

4.2 List of Disassembly/Reassembly Parts/Units. .................................................... 69

4.3 Main Unit Disassembly/Reassembly. ................................................................. 70

4.3.1 Group 1..................................................................................................... 70

4.3.2 Group 2..................................................................................................... 75

4.3.3 Group 3..................................................................................................... 82

4.3.4 Group 4..................................................................................................... 87

4.3.5 Group 5..................................................................................................... 92

4.3.6 Group 6..................................................................................................... 98

4.3.7 Group 7................................................................................................... 106

4.3.8 Group 8................................................................................................... 113

4.3.9 Group 9................................................................................................... 119

4.3.10 Group 10............................................................................................... 126

4.3.11 Group 11............................................................................................... 131

4.3.12 Group 12............................................................................................... 136

3.1 Troubleshooting Flowchart . ............................................................................... 33

3.2 Initial Checks. ..................................................................................................... 33

3.3 Symptoms............................................................................................................ 34

3.3.1 Errors indicated by the LEDs . ................................................................. 34

3.3.2 Print Quality Problems . ........................................................................... 34

3.3.3 Electrical Problems. ................................................................................. 36

3.3.4 Mechanical Problems . ............................................................................. 36

Chapter 5ADJUSTMENT

5.1 Adjustment Item................................................................................................ 141

5.2 Adjustment ........................................................................................................ 142

5.2.1 Writing USB ID. .................................................................................... 142

5.2.2 Updating firmware . ............................................................................... 145

Page 11

Chapter 6MAINTENANCE

6.1 Cleaning............................................................................................................. 151

Chapter 7APPENDIX

7.1 Connection Summary . ...................................................................................... 155

7.1.1 Connection Diagram. ............................................................................. 155

7.1.2 Board Connection Summary ................................................................. 156

7.2 Control Panel Special Operations. .................................................................... 162

7.2.1 Operation Method & Functions. ............................................................ 162

7.2.2 Special Menu . ........................................................................................ 165

7.3 Information Sheet . ............................................................................................ 166

7.3.1 Status Sheet . .......................................................................................... 166

7.3.2 Engine Status Sheet . .............................................................................. 168

7.3.3 Print Log Report . ................................................................................... 170

7.4 Exploded Diagram / Parts List . ........................................................................ 172

Page 12

PRODUCT DESCRIPTION

CHAPTER

1

Page 13

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

1.1 Product Specifications

AcuLaser M2000D/M2000DN/M2010D/M2010DN is a non-impact monochrome

page printer that takes advantage of a laser and electrophotographic technologies.

1.1.1 Basic Specifications

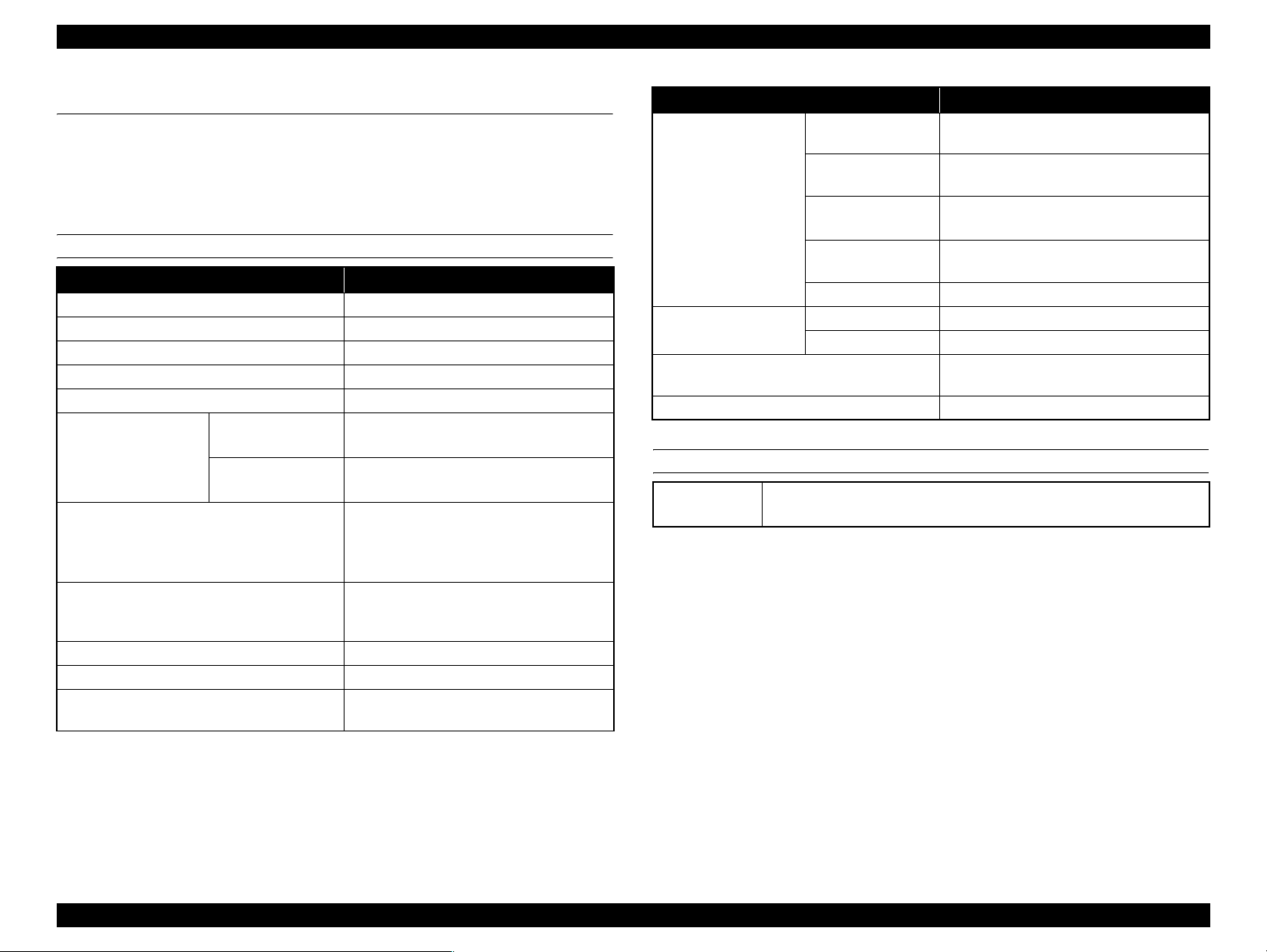

PRINTER SPECIFICATIONS

Item Spec.

Resolution 600 dpi, 1200 dpi

Print speed (Single-sided / Duplex) 28 ppm / 14 ppm

Warm-up time (23°C, 50% RH) Less than 17 seconds

Control Panel No LCD

CPU 64bit RISC CPU (300MHz)

RAM

Interfaces Standard model: Hi-Speed USB 2.0 (1.1

Printer Language ESC/Page (B/W), FX, ESCP2, I239X,

Dimensions (Main unit) 378 mm (W) x 390 mm (D) x 255 mm (H)

Weight (Main unit) Less than 11.5 kg

Power supply AC 110 V: 60 Hz

Standard Standard model: 32MB

Network model: 64MB

Max. Standard model: 288MB

Network model: 320MB

compatible) and Parallel Port

Network model: Hi-Speed USB 2.0 (1.1

compatible) and Ethernet Port

PCL5e, PCL6, Adobe PostScript3 and

PDF1.3

AC 220 ~ 440 V: 50 Hz / 60 Hz

Item Spec.

Power consumption

(100V/110V/220-240V)

Noise Printing 53 dB

Storage and transportation conditions Temperature: 0 ~ 35 °C

Life 100,000 pages or five years

Max. 110 V: 780 W

220 V ~ 240 V: 840 W

Printing 110 V: 449 W

220 V ~ 240 V: 465 W

Ready

(Eco Fuser ON)

Sleep 110 V: 3 W

Stand by 0 W

Standby 30 dB

110 V: 7 W

220 V ~ 240 V: 7 W

220 V ~ 240 V: 3 W

Humidity: 15 ~ 80% RH

OPTIONAL UNIT

Optional paper

cassette unit

Capacity: Up to 250 sheets

Paper size: A4, A5, B5, Letter, Executive, LGL 13” (GLG), F4”

PRODUCT DESCRIPTION Product Specifications 4

Page 14

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

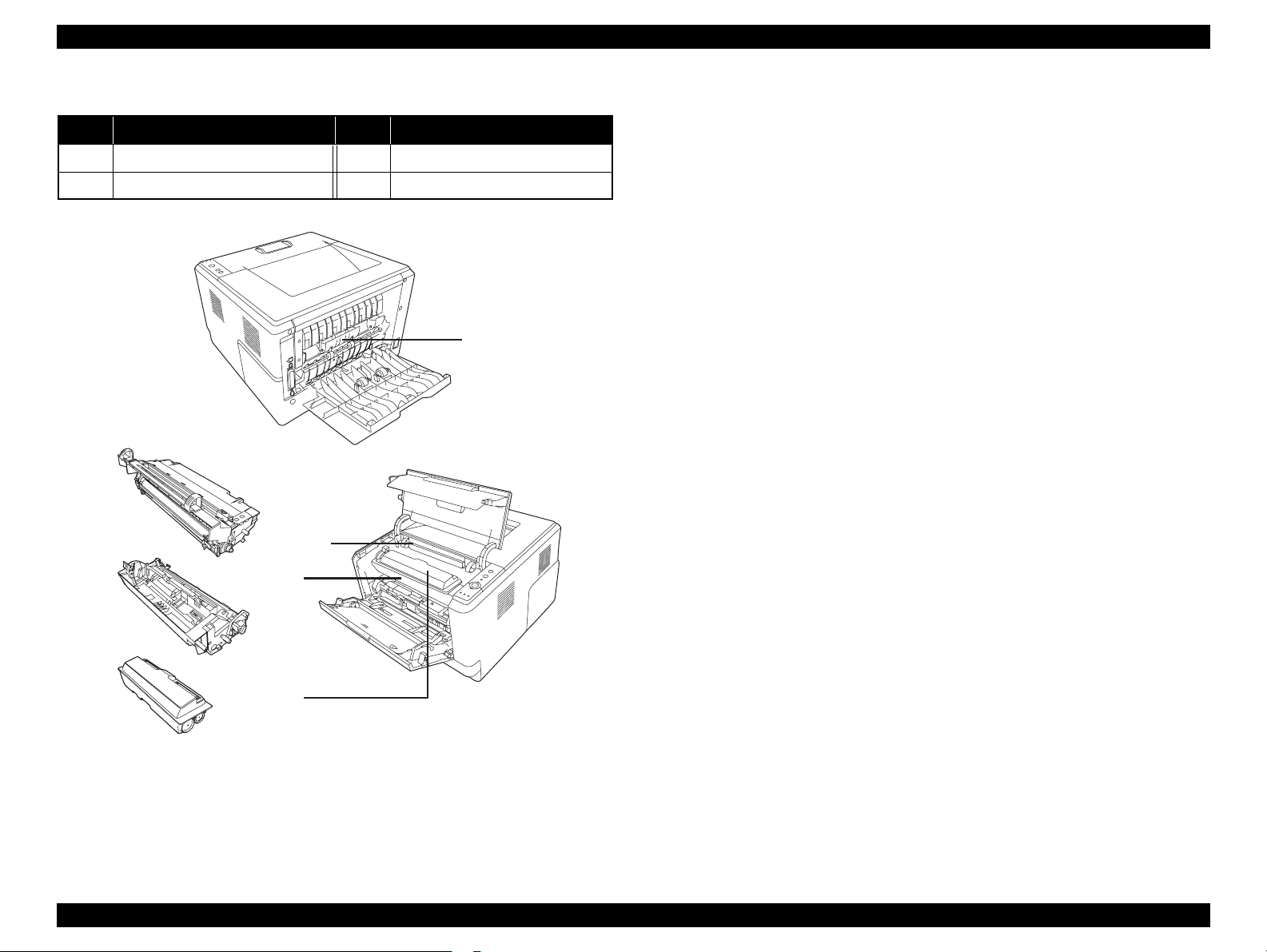

EXTERNAL VIEW AND PART NAMES

Table 1-1. Part Names

No. Name No. Name

1 Top cover (Cover A) 4 MP tray

2 Control Panel 5 Subtray

3 Standard lower paper cassette 6 Stopper

1

2

6

5

3

4

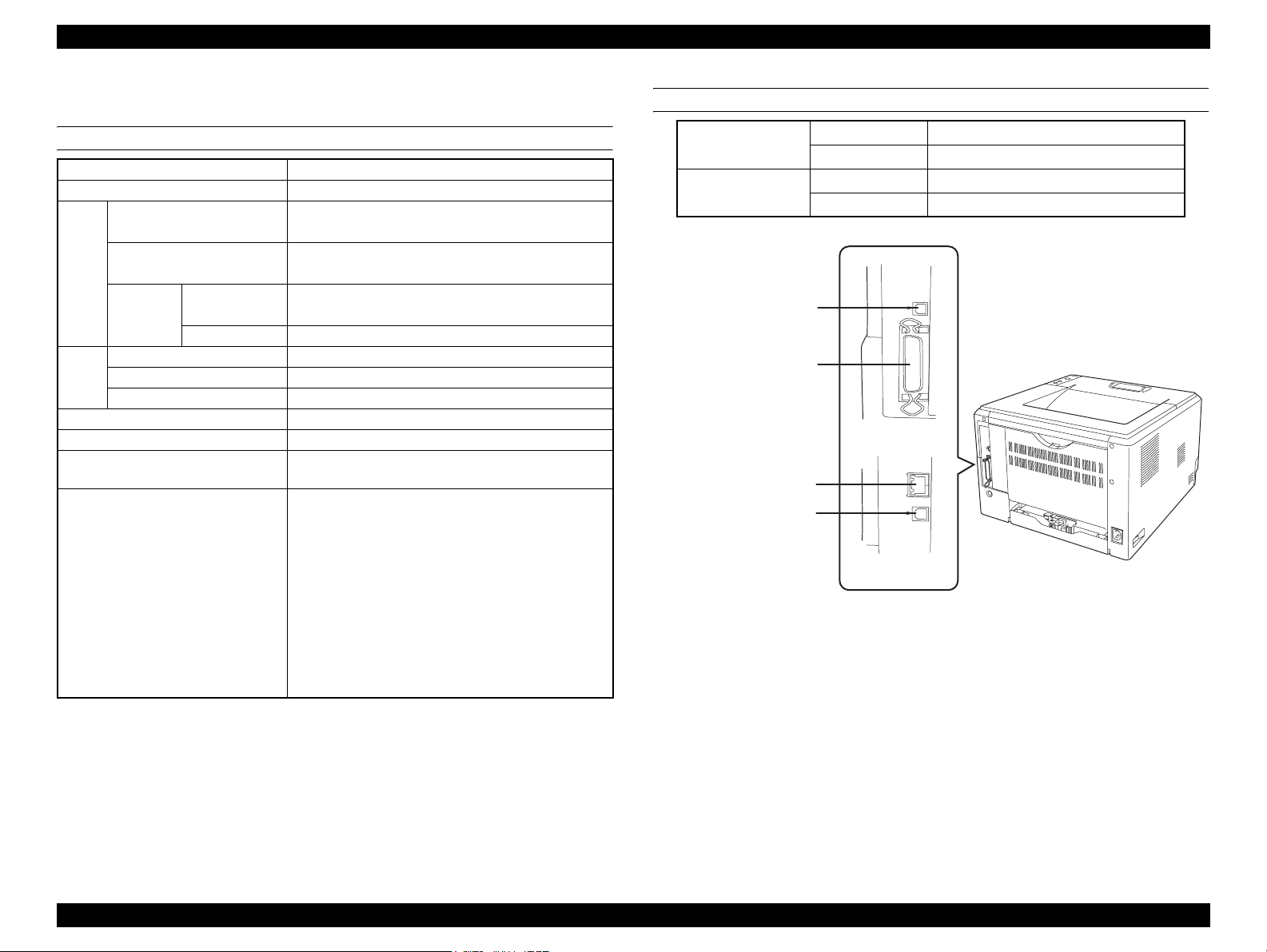

Table 1-2. Part Names

No. Name No. Name

1 Rear cover 5 USB interface connector

2 AC inlet 6 Network interface connector

3 Power switch 7 Parallel interface connector

4 Option cover

5

1

2

7

3

[Standard model]

6

5

Figure 1-1. Front view

[Network model]

4

Figure 1-2. Rear view

PRODUCT DESCRIPTION Product Specifications 5

Page 15

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

Table 1-3. Part Names

No. Name No. Name

1 Fuser unit 3 Developer unit

2 Photoconductor unit 4 Toner cartridge

1

2

3

2

3

4

4

Figure 1-3. Inside the printer

PRODUCT DESCRIPTION Product Specifications 6

Page 16

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

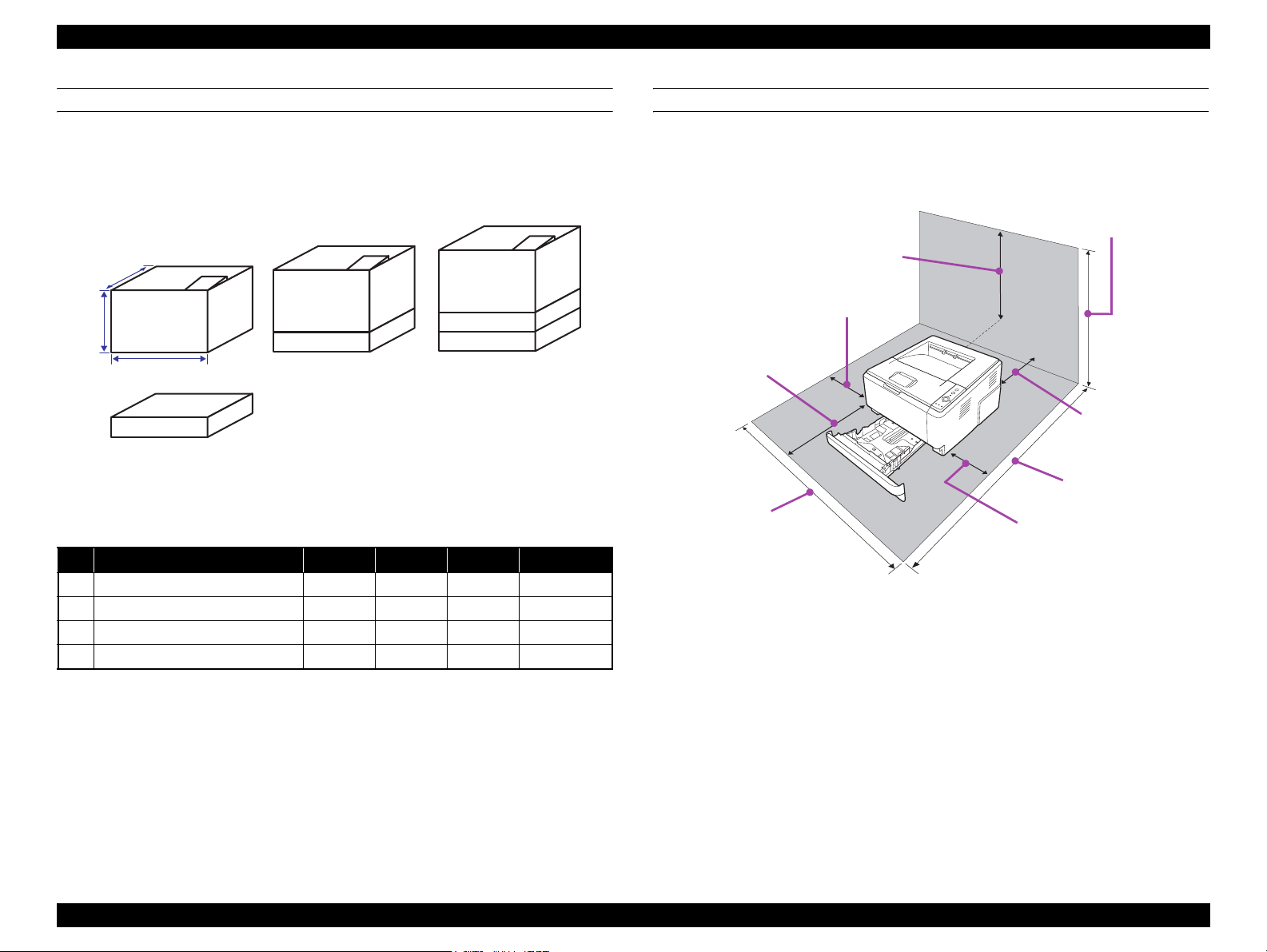

DIMENSIONS AND WEIGHT

The following figure shows the dimensions and weight of the printer.

NOTE 1 : Manufacturing tolerance is ±5 mm in dimensions and ±0.5 kg in weight.

2 : Imaging cartridges are not included in the weight of the main unit.

D

No. 2

H

NO. Configuration W*1 D H Weight

1 Main unit 379mm 390mm 255mm 11.5kg or less

2 Main unit + One Option Feeder 378mm 390mm 355mm 14.5kg

3 Main unit + Two Option Feeders 378mm 390mm 454mm 17.5kg

4 Option Feeder 375mm 390mm 100mm 3.0kg

No. 1

W

No. 4

Figure 1-4. Dimensions and Weight

Table 1-4. Dimensions and Weight List

No. 3

INSTALLATION SPACE REQUIREMENTS

The following figure shows the dimensions of the space required around the printer.

Be sure to provide the space for installation, operation, and maintenance.

455mm*

200mm

300mm

500mm

200mm

1,090mm

978mm

300mm

* 655 mm is required when two option feeders are installed.

Figure 1-5. Installation Space Requirements

PRODUCT DESCRIPTION Product Specifications 7

Page 17

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

1.1.2 Paper Specifications

SUPPORTED PAPERS

Table 1-5. Supported Papers

Paper Feeder Paper Type Paper Size

Capacity

(Height)

Weight

Standard Cassette Standard paper*/Plain paper/Recycled paper A4, A5, B5, LT, HLT, LGL,GLG, EXE, F4 250 sheets 60 ~ 90 g/m

Fine quality paper A4, A5, B5, LT, HLT, LGL, GLG, EXE, F4 28 mm 91 ~ 120 g/m

MP tray Standard paper*/Plain paper/Recycled paper A4, A5, B5, LT, HLT, LGL, GLT, GLG, EXE, F4 50 sheets 60 ~ 90 g/m

Fine quality paper A4, A5, B5, LT, HLT, LGL, GLT, GLG, EXE, F4 5 sheets 91 ~ 120 g/m

Special media Transparency A4, LT 5 sheets ---

Postcard Postcard 20 sheets 190 g/m

Label A4, LT 5 sheets ---

Thick paper A4, A5, B5, LT, EXE 5 sheets 121~ 220 g/m

Envelope C5, C6, DL, Com10, Monarch, ISO-B5 5 sheets ---

User defined Width: 70.00 mm ~ 215.90 mm

Length: 148.00mm ~ 356.00 mm*

1

50 sheets 60 ~ 90 g/m

5 sheets 91 ~ 220 g/m

Duplex unit Standard paper*/Plain paper/Recycled paper A4, LT --- 60 ~ 105 g/m

Option Cassette Standard paper*/Plain paper/Recycled paper A4, A5, B5, LT, LGL, GLG, EXE, F4 250 sheets 60 ~ 120 g/m

Fine quality paper A4, A5, B5, LT, LGL, GLG, EXE, F4 28 mm 91 ~ 120 g/m

* : Standard paper: Xerox Premier 80gsm

*1: When 297mm or longer length paper is used, the user needs to support the rear end of the paper with his/her hand.

2

2

2

2

2

2

2

2

2

2

2

PRODUCT DESCRIPTION Product Specifications 8

Page 18

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

UNSUITABLE PAPERS

The following types of paper should not be used, otherwise decreased print quality,

paper misfeeds, or damage to the printer may occur.

Specially-treated papers, such as carbon-backed, non-carbon, heat-sensitive,

pressure-sensitive, or acid paper

Extremely thick or extremely thin papers

Damp paper

Art paper, coated paper for color printers

Extremely smooth or extremely rough paper, or paper with uneven surface

Perforated paper or paper with punched hole

Folded, curled, wrinkled, or torn paper

Paper of a non-standard shape (not rectangular)

Label that peels off easily

Papers with glue, staples, or paper clips

Inkjet printer paper (Photo Quality Ink Jet Paper, Glossy Paper, Glossy Film, etc.)

Printouts printed by a heat-transfer printer or an inkjet printer

Transparency for other color laser printers or color photocopiers

Printouts printed by another color/monochrome laser printer or a photocopier

Sheets of paper stuck together using glue or the like

Postcards for inkjet printers

Iron-on Transfer Paper (for inkjet printers or laser printers)

Paper that deteriorates or discolors at 225 °C or lower

When using illustrated postcards, paper feed rollers may be soiled with paper dust

and these cards may not be fed properly. In this case, clean the rollers with

reference to Chapter 6 “MAINTENANCE” (p.150)

PRODUCT DESCRIPTION Product Specifications 9

Page 19

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

PRINTABLE AREA

Maximum print area (Printing is guaranteed)

Paper width: 215.9 mm x Length: 356.0 mm

Guaranteed print area

Area excluding 4-mm margins on all four edges

4.0 mm 4.0 mm

4.0 mm4.0 mm

ENVELOPE ORIENTATION

Envelope Size

Feeding

Direction

↑

DL, C6, Com10, Monarch C5, ISO-B5

POSTCARD ORIENTATION

Postcard type

Feeding

Direction

↑

Postcard Front side printing Postcard Reverse side printing

Load envelopes on the MP tray with the side to be printed face

up.

Proper paper feeding is not guaranteed for printing on the

backside of envelopes.

Do not use envelopes that have a tape or glue.

Table 1-6. Guaranteed Print Area

PAPER EJECT/CAPACITY

Paper eject Capacity Remarks

Face down 250* sheets 200* sheets for duplex printing.

* : When standard paper (A4) is used.

PRODUCT DESCRIPTION Product Specifications 10

Page 20

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

1.1.3 Replacement Parts

Consumables

Toner Cartridge : 8,000 pages / 3,500pages

Periodic replacement parts

This printer does not include any parts or units needing periodic replacement.

PRODUCT DESCRIPTION Product Specifications 11

Page 21

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

1.1.4 Controller Specifications

BASIC SPECIFICATIONS

CPU VR5500 (300MHz)

Enhanced Technology RIT (NICE)

RAM Standard (on-board) Standard model: 32MB

Network model: 64MB

Maximum Standard model: 288MB

Network model: 320MB

Expansion Type SDRAM 90pin DIMM

(64MB, 128MB, 256MB)

Numbers of slot 1 slot

ROM Type 16-bit width (3.3V)

Program 16MB

Font Included in the program

EEPROM Serial type 128Kbit

Control panel Three buttons and six LEDs. No LCD

Printer language ESC/Page (B/W), FX, ESC2, I239X, PCL5e, PCL6,

Adobe PostScript3 and PDF1.3

Auxiliary software

Status Sheet printing

EpsonNetConfig (Web) (Network model only)

USB Ext I/F Status Sheet

Network Status Sheet printing (Network model

only)

PS3 Status Sheet printing

PS3 Font List printing

PCL Font Sample printing

Hex dump

MAINTENANCE MODE (only for Engine Status

Sheet and Print Log Report)

EXTERNAL INTERFACES

Standard model USB

Parallel

Network model USB

Network 100BaseTX/10BaseT

USB

Parallel

Network

USB

Figure 1-6. External Interfaces

2.0 HS

IEEE1284 compliant

2.0 HS

[Standard model]

[Network model]

PRODUCT DESCRIPTION Product Specifications 12

Page 22

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

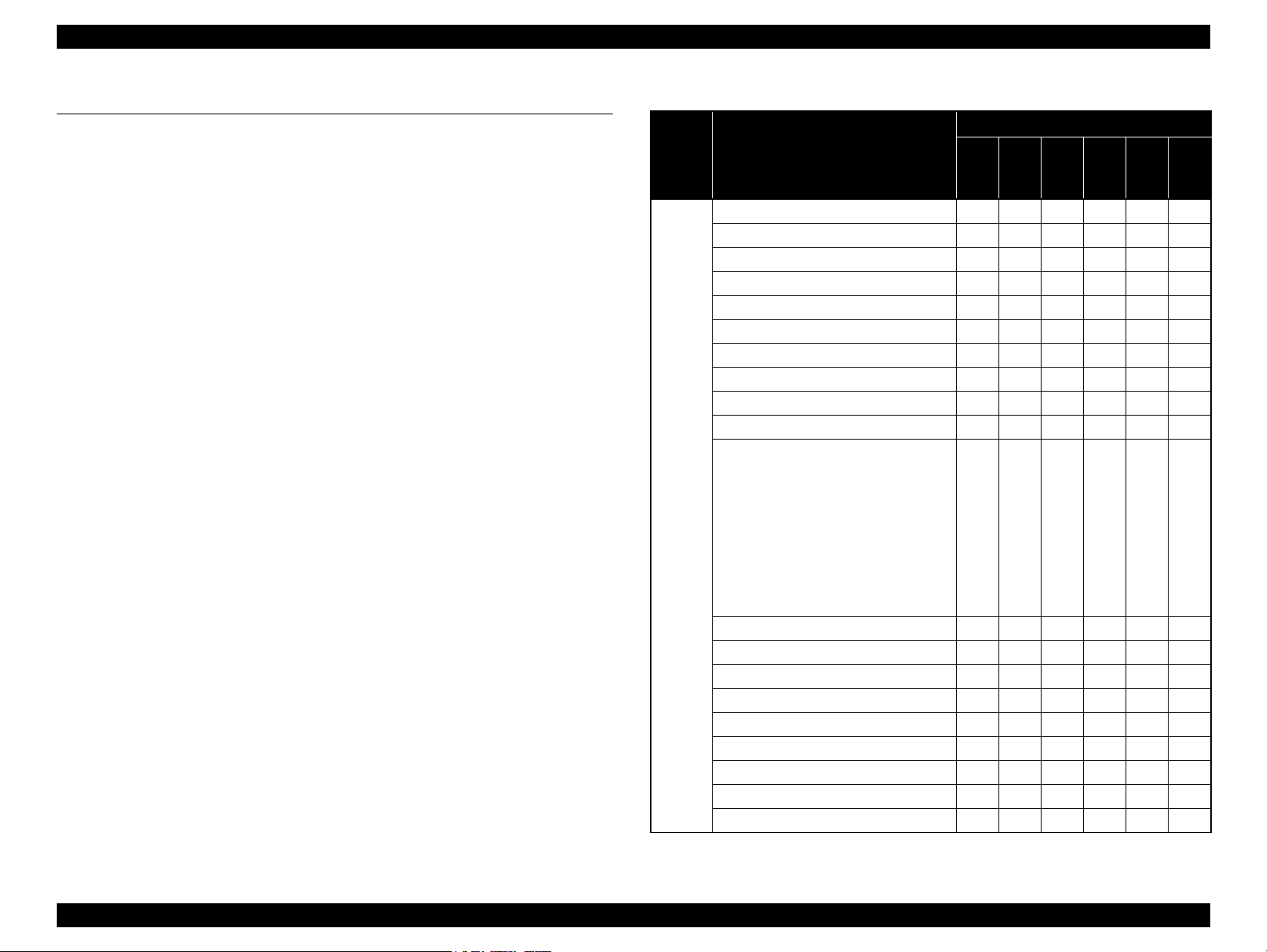

1.2 List of Printer Messages

The following table shows the printer’s LEDs indications in each printer status.

The meanings of the symbols used in the table are as follows.

O:Lights

---: Lights or flashes depending on the condition

X: Off

Δ1: Flashes on and off at intervals of 0.3 seconds

Δ2: Flashes on and off at intervals of 0.6 seconds

Δ3: Flashes on for 0.6 seconds and off for 2.4 seconds

Table 1-7. List of Printer Messages

Sort Printer Status

ROM CHECK XXXOXX

RAM CHECK XXOXXX

Unable Clear Error X --- --- --- X ---

Self Test XOXXXX

Reset All Δ1

Reset --- --- --- --- --- --Cancel All Print Job Δ1 Δ1 --- X Δ1 ---

Cancel Print Job (by panel) Δ1 X --- X Δ1 ---

Writing ROM P --- --- --- --- X Δ1

Form Feed X --- --- --- --- Δ1

Status Sheet

ESC/Page Font Sample

PCL Font Sample

Status

ESCP2 Font Sample

FX Font Sample

1239X Font Sample

PS3 Status Sheet

PS3 Font List

Engine Status Sheet

Warming Up X --- --- --- Δ1 ---

Offline Δ3 --- --- --- X ---

Cancel Print Job (by host) Δ1 --- --- --- Δ1 ---

Filling toner xx*1 min --- Δ3 Δ3 Δ3 --- --Sleep: X --- --- --- Δ3 ---

Ready X --- --- --- O ---

(Printing) X --- --- --- --- ---

(Communication with inactive I/F) --- --- --- --- --- ---

(Job being executed (ready)) --- --- --- --- --- ---

LEDs status

Error

Memory

X X X Δ1 Δ1

X --- --- --- --- Δ1

Toner

Paper

Ready

Data

*1: "xx" indicates remaining time period (minutes).

PRODUCT DESCRIPTION List of Printer Messages 13

Page 23

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

Table 1-7. List of Printer Messages

LEDs status

Sort Printer Status

Error

Memory

Toner

Paper

Ready

Reserve Job Canceled X Δ1 --- --- --- ---

Form Data Canceled X Δ1 --- --- --- ---

Can't Print X Δ1 --- --- --- ---

Collate Disabled X Δ1 --- --- --- ---

Warning

Image Optimum X Δ1 --- --- --- ---

Check Paper Type X --- --- Δ1 --- ---

Need Memory X Δ1 --- --- --- ---

Toner Low X --- Δ1 --- --- ---

Worn Main unit Δ3 --- X --- --- ---

NonGenuineToner X --- Δ3 --- --- ---

*2: For details on the Service Req error code, see “3.4.3 Controller-related Service Call

Errors” (p.47).

*3: “WWWW” indicates the jammed or opened point. See “3.4.1 Paper Jam Error”

(p.37).

*4: “sss” indicates the Page Size setting of the control panel.

*5: “ttt” indicates the Paper Source setting (except for “Auto”) of the control panel.

*6: “sss” indicates the paper size setting in the Tray Menu of the control panel.

Table 1-7. List of Printer Messages

LEDs status

Sort Printer Status

Data

Service Req Cffff

*2

Error

Memory

Toner

Paper

OOOOOO

Service Req Eggg OXXXOO

Optional RAM Error OOXXX---

Write Error ROM P OOXXX---

Jam WWWW

*3

OXXOX---

Install Imaging Cart OXOXX---

Image Cart ID Error OXOXX---

NonGenuine Toner Δ1

XOXX---

Image Cart R/W Error OXOXX---

Replace Main Unit O Δ2

Δ2 Δ2 X ---

WWWW*3 Open OXXXX---

Error

Install LC1 O X X Δ1 X ---

Install LC2 OXXΔ1 X ---

Manual Feed sss

*4

Δ2 X X Δ2 Δ2 ---

Can't Print Duplex Δ1 X X O X ---

Paper Out ttt*5 sss

*6

O X X Δ1 X ---

Replace Toner O X O X X ---

Paper Set ttt*5 sss

*6

Δ1 X X Δ1 X ---

Print Overrun Δ1 O X X X ---

Mem Overflow Δ1 O X X X ---

Duplex Mem Overflow Δ1 O X X X ---

Invalid Data Δ1 O X X X ---

Invalid PS3 O O X X X ---

Data

Ready

PRODUCT DESCRIPTION List of Printer Messages 14

Page 24

OPERATING PRINCIPLES

CHAPTER

2

Page 25

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.1 Electrical parts layout

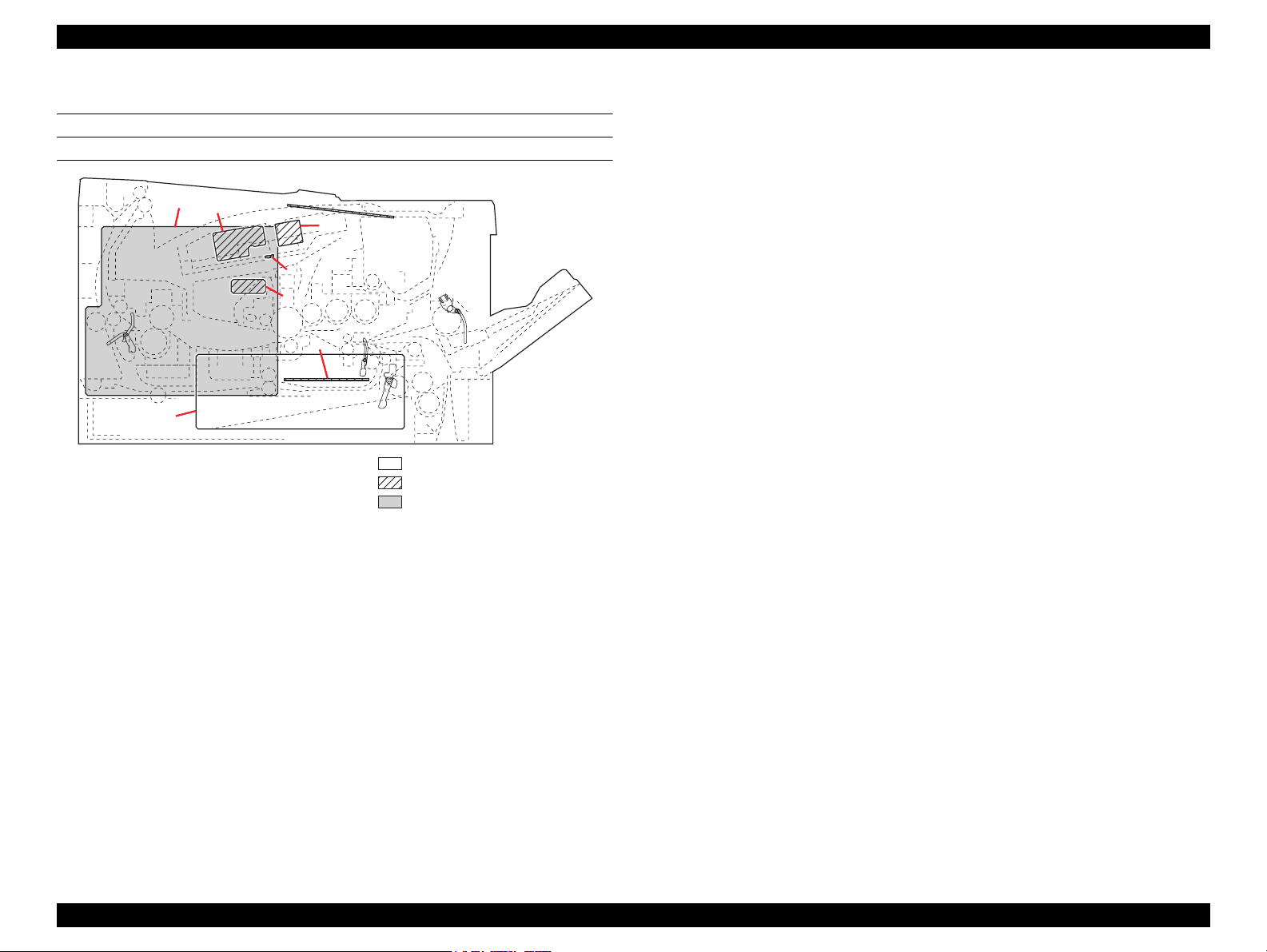

POWER WRITING BOARDS

1

5

6

8

7

3

2

Figure 2-1. Power Writing Boards

1. Main Board Assy.

Main controller section:

Controls the software such as the print data processing and provides the

interface with computers.

Engine section:

4

Controls printer hardware such as high voltage/bias output control, paper

conveying system control, and fuser temperature control, etc.

2. LVPS

After full-wave rectification of AC power source input, switching for converting

to 24 V DC for output. Controls the fuser heater lamp.

3. HVPS

Generates main charging, developing bias, transfer bias.

4. Control Panel Board

Consists the LED indicators and key switches.

5. APC PWB

Generates and controls the laser beam.

Machine left

Machine inside

Machine right

6. PD PWB

Controls horizontal synchronizing timing of laser beam.

7. Zener PWB

Adjusts the drum surface potential.

8. Eraser lamp PWB

Eliminates the residual electrostatic charge on the drum.

OPERATING PRINCIPLES Electrical parts layout 16

Page 26

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

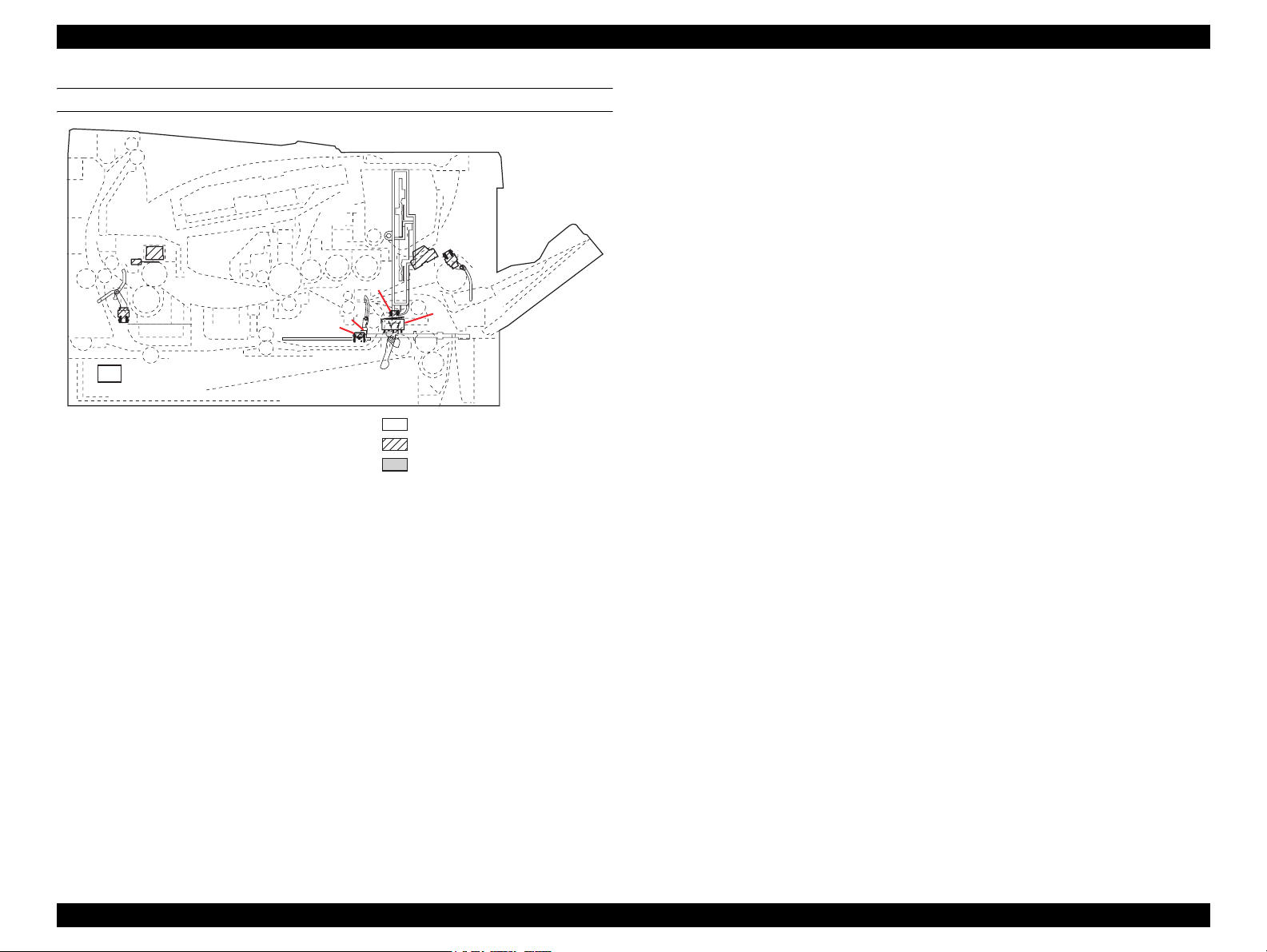

SWITCHES AND SENSORS

10

9

7

1

Figure 2-2. Switches and sensors

1. Power switch

Turns ON/OFF the AC power source.

2. Interlock switch

Shuts off 24 V DC power line when the top cover is opened.

3. Cassette switch

Detects open/close cassette.

6

5

4

3

8

2

4. Registration sensor

Detects the timing of primary paper feed.

5. Paper sensor

Detects the presence of paper in the cassette.

6. MP paper sensor

Detects the presence of paper on the MP tray.

7. Exit sensor

Detects paper jam in the fuser or duplex conveying section.

Machine left

Machine inside

Machine right

8. Toner sensor

Detects the quantity of toner in a toner container.

9. Fuser thermistor

Measures the heat roller temperature.

10. Fuser thermal cutout

Shuts off the power source to the fuser heater lamp when the heat roller reaches

extremely high temperature.

OPERATING PRINCIPLES Electrical parts layout 17

Page 27

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

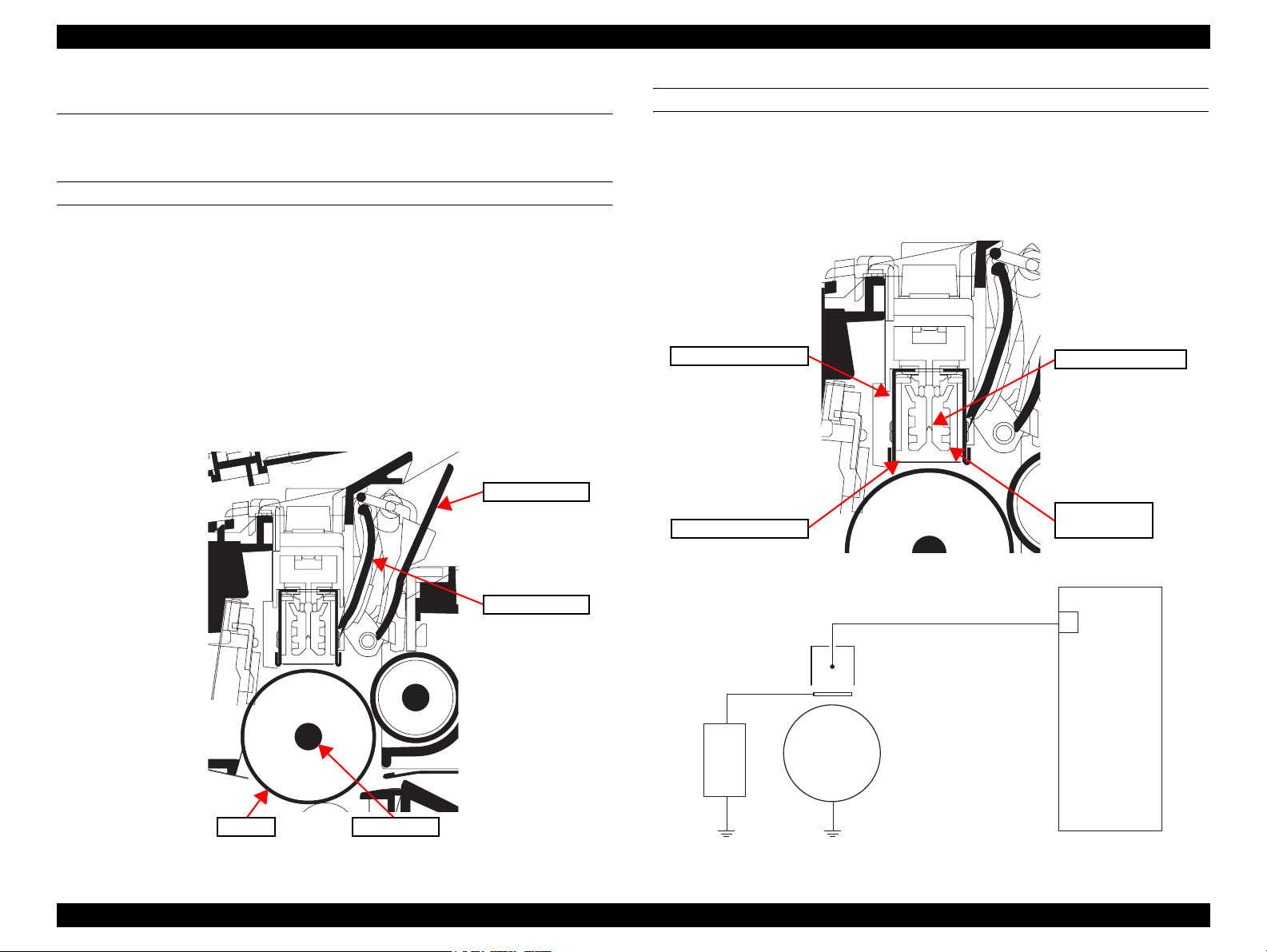

OTHER ELECTRICAL COMPONENTS

8

2

4

10

1

Figure 2-3. Other electrical components

3

6

597

Machine left

Machine inside

Machine right

1. Main motor

Drives the paper feed/conveying section and fuser unit.

2. Polygon motor

Drives the polygon mirror.

3. Right cooling fan motor

Cools the interior of machine.

4. Left cooling fan motor

Cools the interior of machine.

5. Registration clutch

Controls the secondary paper feed.

6. Paper feed clutch

Controls the paper cassette paper feed.

7. Developing clutch

Controls the toner feed.

8. Duplex solenoid

Controls the paper conveying at the duplex conveying section.

9. MP paper feed solenoid

Controls the MPF bottom plate of the MP tray.

10. Fuser heater lamp

Heats the heat roller.

OPERATING PRINCIPLES Electrical parts layout 18

Page 28

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

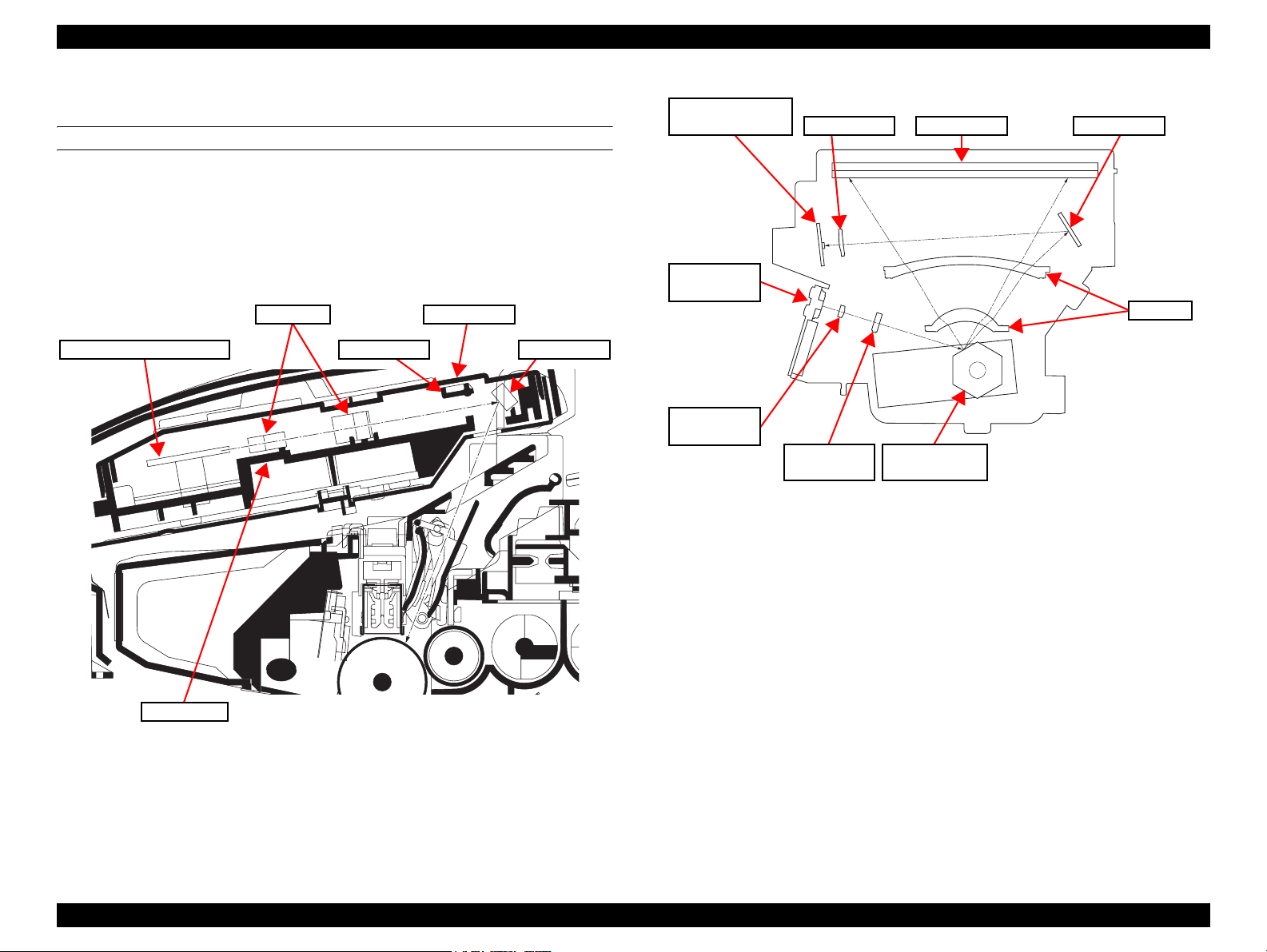

OPTION PAPER FEEDER

5

Figure 2-4. Option Paper Feeder

1. PF Main Board

Controls electrical components in the paper feeder and serial communications with

1

4

3

the printer.

2. PF paper sensor

Detects the presence of paper in the cassette.

2

6

7

3. PF cassette switch

Detects the existence of the cassette.

4. PF paper feed sensor

Detects paper jam in the paper feeder.

5. PF paper feed motor

Machine left

Machine inside

Machine right

Drives the paper feed mechanism in the paper feeder.

6. PF paper feed clutch

Controls the drive of the paper feed roller.

7. PF paper conveying clutch

Controls the drive of the middle roller.

OPERATING PRINCIPLES Electrical parts layout 19

Page 29

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2 Technical Explanation of Print Process

2.2.1 Charging

DRUM SECTION

The durable layer of organic photoconductor (OPC) is coated over the aluminum

cylinder base. The OPC tend to reduce its own electrical conductance when exposed to

light. After a cyclic process of charging, exposure, and development, the electrostatic

image is constituted over the OPC layer. Since the OPC is materialized by resin, it is

susceptible to damage caused by sharp edges such as a screwdriver, etc., resulting in a

print quality problem. Also, finger prints can cause deterioration of the OPC layer,

therefore, the drum (in the drum unit) must be handled with care. Substances like water,

alcohol, organic solvent, etc., should be strictly avoided. As with all other OPC drums,

the exposure to a strong light source for a prolonged period can cause a print quality

problem. The limit is approximately 500 lux for less than five minutes. If the drum

(drum unit) remains removed from the printer, it should be stored in a cool, dark place.

Drum cover A

MAIN CHARGER UNIT

As the drum rotates in a “clean (neutral)” state, its photoconductive layer is given a

uniform, positive (+) corona charge dispersed by the main charger wire. Due to highvoltage scorotron charging, the charging wire can get contaminated by oxidization

after a long run. Therefore, the charger wire must be cleaned at a specific interval.

Cleaning the charging wire prevents print quality problems such as black streaks.

Main charger shield

Main charger wire

Main charger

Main charger grid

wire cleaner

Figure 2-6. Main charger unit

Drum cover B

Main charger wire

Zener

PWB

Main charger shield

Main charger grid

Drum

Main charger output

M

HVPS

Drum Drum shaft

Figure 2-5. Drum section

Figure 2-7. Drum unit and main charger unit block diagram

OPERATING PRINCIPLES Technical Explanation of Print Process 20

Page 30

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.2 Exposure

LASER SCANNER UNIT (LSU)

The charged surface of the drum is then scanned by the laser beam from the laser

scanner unit.

The laser beam (780 nm wavelength) beam is dispersed as the polygon motor revolves

to reflect the laser beam over the drum. Various lenses and mirror are housed in the

laser scanner unit, adjust the diameter of the laser beam, and focalize it at the drum

surface.

Polygon motor (mirror)

F-θ lens

LSU shutter

LSU cover

LSU mirror

Pin photo diode

sensor (PD PWB)

Laser diode

(APC PWB)

Callimator

lens

LSU mirror

Cylindrical

lens

Figure 2-9. Laser scanner unit

Polygon motor

(mirror)

PD mirrorSOS lens

F-θ lens

LSU flame

Figure 2-8. Exposure section

OPERATING PRINCIPLES Technical Explanation of Print Process 21

Page 31

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.3 Development

The latent image constituted on the drum is developed into a visible image. The

developing roller contains a 3-pole (S-NS) magnet roller and an aluminum cylinder

rotating around the magnet roller. Toner attracts to the magnet sleeve since it is

powdery ink made of black resin bound to iron particles. Developing blade,

magnetized by magnet, is positioned approximately 0.3 mm above the magnet sleeve to

constitute a smooth layer of toner in accordance with the magnet sleeve revolution.

The developing roller is applied with the AC-weighted, positive DC power source.

Toner on the magnet sleeve is given a positive charge. The positively charged toner is

then attracted to the areas of the drum which was exposed to the laser light. (The gap

between the drum and the magnet sleeve is approximately 0.32 mm.) The non-exposed

areas of the drum repel the positively charged toner as these areas maintain the positive

charge.The developing roller is also AC-biased to ensure contrast in yielding by

compensating the toner’s attraction and repelling action during development.

Developing

blade

Developing

roller

Magnet roller

Magnet sleeve

Developing

clutch

Figure 2-11. Developing section block diagram

Developing bias output

B

HVPS

DLPDRN

Main Board Assy.

YC808-6

Blade

magnet

Magnet

sleeve

Magnet

roller

DLP

screw A

DLP

screw B

DLP case

Figure 2-10. Development section

OPERATING PRINCIPLES Technical Explanation of Print Process 22

Page 32

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.4 Transfer/Separation

The transfer/separation section consists of the transfer roller, discharger brush and

paper chute guide. A high voltage generated by the HVPS (High Voltage Power

Supply) is applied to the transfer roller for transfer charging. Paper after transfer is

separated from the drum.

DC brush holder

Discharger brush

Discharger

brush

Transfer roller

Paper chute guide

Transfer bushes

Figure 2-12. Transfer/separation section

Transfer

roller

Transfer bias

T

HVPS

GND

Figure 2-13. Transfer/separation section block diagram

OPERATING PRINCIPLES Technical Explanation of Print Process 23

Page 33

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.5 Cleaning

After the transferring process, the drum needs to be physically cleaned of toner which

is residual after the development process. The cleaning blade is constantly pressed

against the drum and scrapes the residual toner off to the sweep roller. The waste toner

is collected at the output end of the sweep roller and sent back to the toner container,

into the waste toner reservoir.

After the drum is physically cleaned, it then must be cleaned to the electrically neutral

state. This is necessary to erase any residual positive charge, ready to accept the

uniform charge for the next print process. The residual charge is canceled by exposing

the drum to the light emitted from the eraser lamp (PWB). This lowers the electrical

conductivity of the drum surface making the residual charge on the drum surface

escape to the ground.

Eraser lamp (PWB)

Main frame

Waste toner reservoir

ERASER

Eraser

lamp

(PWB)

Drum

Figure 2-15. Cleaning section block diagram

YC816-1

Main Board Assy.

Drum unit

Sweep roller Cleaning blade

Figure 2-14. Cleaning section

OPERATING PRINCIPLES Technical Explanation of Print Process 24

Page 34

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.6 Fusing

The toner on the paper is molten and pressed into the paper as it passes between the

heat roller and the press roller in the fuser unit. The heat roller has a heater lamp inside

which continuously turns on and off by the fuser thermistor to maintain the constant

temperature onto the heat roller surface. The heat roller is resin coated by florin to

prevent toner from accumulating on the roller after a long run. Care must be taken

while handling the heat roller not to scratch the roller surface as doing so may result in

print problems. Fuser temperature is optimized to the paper type. The heat roller has

four separators (claws) which are continuously in contact with its surface. These

separators (claws) prevent the paper on which toner has been fused from being wound

around the heat roller causing paper jam. The press roller is made of the heat-resistant

silicon rubber. This roller is used to strongly press the paper towards the heat roller by

means of press springs. The temperature of the heat roller is constantly monitored by

the main board assy. using the fuser thermistor. Should the temperature of the heat

roller exceed the predetermined value, the fuser thermal cutout is activated to

effectively disconnect the heater lamp from power.

Actuator

(exit sensor)

Separators

Press roller

Exit sensor

Upper fuser

frame

Fuser thermistor

Fuser thermal

Fuser lever L (R)Press spring holders

Figure 2-16. Fuser section

cutout

Fuser heater

lamp

Heat roller

Lower fuser

frame

Fuser

bushes

Press

springs

Fuser unit

HVPS

HEATN

SLEEP

ZCROSS

THERM

Main Board ASSY.

YC811-5

YC811-6

YC811-3

YC811-16

Fuser thermal cutout

Fuser

heater

lamp

Fuser

thermistor

L

N

YC102-1

YC102-3

LVPS

YC103-6

YC103-7

YC103-8

Figure 2-17. Fuser section block diagram

OPERATING PRINCIPLES Technical Explanation of Print Process 25

Page 35

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.7 Paper exit section

The paper exit section transports the paper which passed the fuser unit towards the top

tray. The paper which passed through the fuser unit turns on the actuator (exit sensor)

in the fuser unit, and is led by the guide comprised of the rear cover, frame and the FD

cover guide, finally reaching the upper FD roller. The paper is delivered to the top tray

by the rotation of the upper FD roller.

Exit pulley

Upper FD roller

Top tray

FD cover

Fuser exit pulley

Middle pulley

Rear cover

Actuator

(exit sensor)

Fuser unit

EXITN

Exit sensor

Figure 2-19. Paper exit section block diagram

Main Board ASSY.

YC807-3

Exit roller

Exit sensor

Figure 2-18. Paper exit section

OPERATING PRINCIPLES Technical Explanation of Print Process 26

Page 36

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.2.8 Duplex/conveying section

The duplex/conveying section consists of conveying path which sends the paper sent

from the eject section to the paper feed/conveying section when duplex printing.

Duplex solenoid

DUDR1

DUDR2

YC817-1

YC817-3

DU

roller

DU cover B DU holder

Lower base

cover

Middle

pulley B

Figure 2-20. Duplex/conveying section

Feed

roller

Feed

pulley

Fuser unit

Main Board ASSY.

EXITN

YC807-3

Exit sensor

Figure 2-21. Duplex/paper conveying section block diagram

OPERATING PRINCIPLES Technical Explanation of Print Process 27

Page 37

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.3 Paper Feed

Paper feed/conveying section consists of the paper feed unit that feeds paper from the

cassette and the MP tray paper feed unit that feeds paper from the MP tray, and the

paper conveying section that conveys the fed paper to the transfer/separation section.

2.3.1 Cassette paper feed section

Retard

guide

Retard

roller

Bottom plate

Feed

holder

Actuator Cassette base

(paper sensor)

Paper

sensor

Pickup

roller

Paper feed

roller

Retard

holder

Main Board ASSY.

Main motor

Paper feed

Clutch

MMOTRDYN

MOTCLK

REMOTEN

FEDDRN

PAP ER

YC805-3

YC805-4

YC805-5

YC808-4

YC806-3Paper sensor

Figure 2-23. Cassette paper feed section block diagram

Figure 2-22. Cassette paper feed section

OPERATING PRINCIPLES Paper Feed 28

Page 38

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.3.2 MP tray paper feed section

Paper feed

roller

MPF

separation

pad

MPF turn

guide

separator

MP paper

MPF

MPF

frame

MPF

sensor

friction pad

MPF bottom

plate

Figure 2-24. MP tray paper feed section

Actuator

(MP paper sensor)

MPF

base

MPF guide

R/L

middle traytray

Main Board ASSY.

MMOTRDYN

Main motor

MP paper

feed solenoid

MP paper sensor

MPF MPF upper

Figure 2-25. MP tray paper feed section block diagram

MOTCLK

REMOTEN

MPFDRN

HANDSN

YC805-3

YC805-4

YC805-5

YC809-2

YC804-3

OPERATING PRINCIPLES Paper Feed 29

Page 39

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.3.3 Paper conveying section

Lower

registration roller

Registration

sensor

Upper

registration roller

Figure 2-26. Paper conveying section

Actuator

(registration sensor)

Feed pulley

Main motor

HVPS

Registration

sensor

Main Board ASSY.

Registration

clutch

MMOTRDYN

MOTCLK

REMOTEN

REGDRN

REGN

YC805-3

YC805-4

YC805-5

YC808-2

YC811-11

Figure 2-27. Paper conveying section block diagram

OPERATING PRINCIPLES Paper Feed 30

Page 40

AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

2.3.4 Optional cassette paper feed section

Actuator

(PF paper feed sensor)

Feed

bracket

Middle

roller

Retard

holder

Paper

pad

feed roller

Cassette

Retard

roller

PF Main

Board

Top

frame

PF paper

sensor

Bottom

plate

Actuator

(PF paper

sensor)

Cassette base

PF paper feed

Top

cover

PF cassette

switch

sensor

Feeder

pin

Pickup

roller

Bottom

holder

PF middle

pulley

Retard

guide

Cassette

cover

Printer

LVPS

Paper feeder 1

PF Main Board

Cassette

open/close

detection circuit

PF cassette

switch

PF paper

sensor

Paper

detection

circuit

Main Board ASSY.

+3.3 V

+24 V

PFSEL signal

processing

PFSEL

UART

Paper feeder

interface connector

CPU

Control

circuit

PF paper

feed sensor

PF paper

feed motor

PF paper

feed clutch

PF paper

conveying clutch

Figure 2-28. Optional cassette paper feed section

+3.3 V

+24 V

PFSEL

UART

Paper feeder 2

Paper feeder

interface connector

Figure 2-29. Paper feeder block diagram

OPERATING PRINCIPLES Paper Feed 31

Page 41

TROUBLESHOOTING

CHAPTER

3

Page 42

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

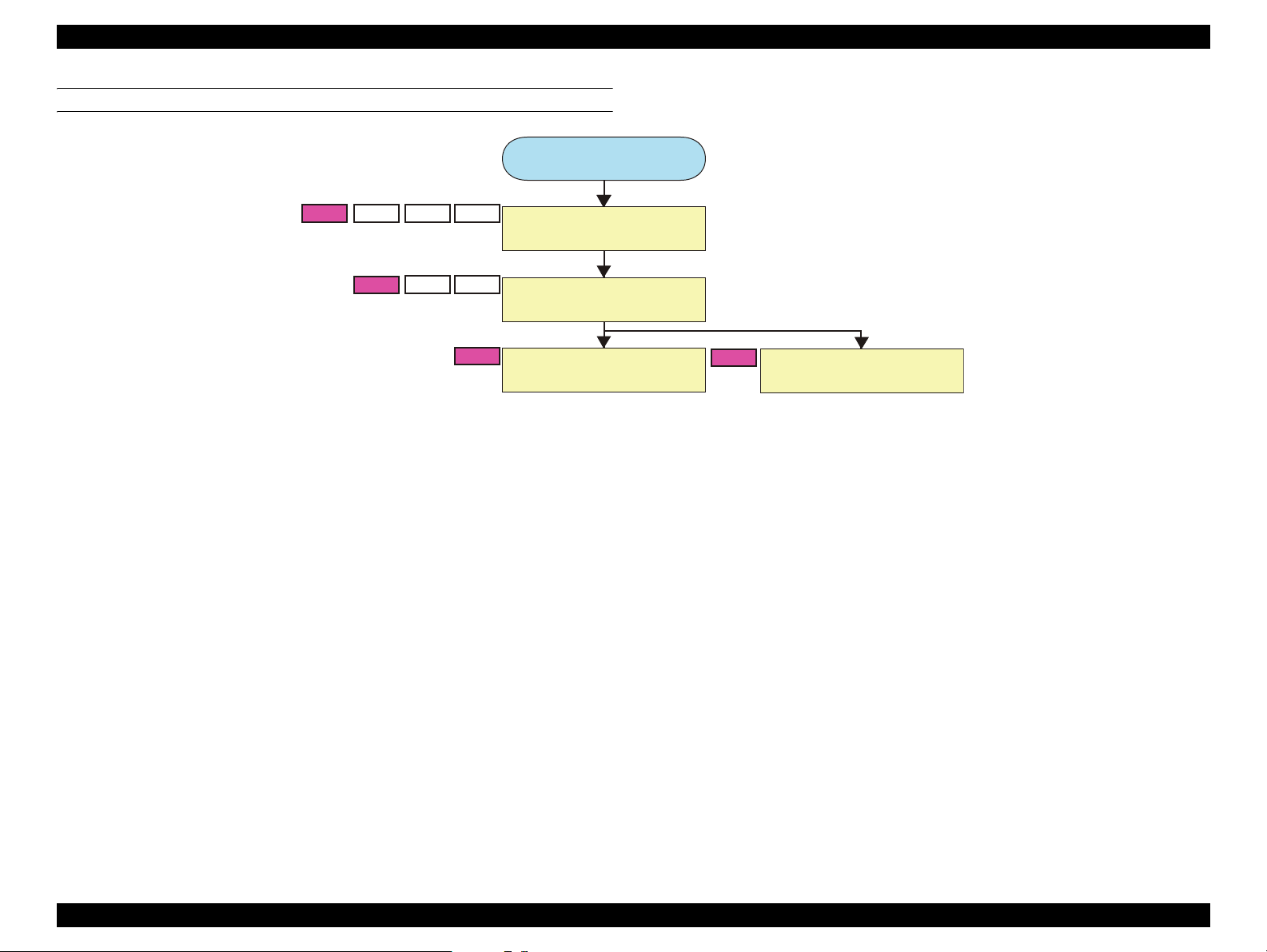

3.1 Troubleshooting Flowchart

Troubleshoot a problem of printer operation or print quality following the flowchart

shown below.

Start

Initial check

3.2 Initial Checks (page 33)

Recovered?

YES

NO

End of work

3.2 Initial Checks

The followings must be checked before starting troubleshooting.

Do the following ambient conditions satisfy the specification?

Surrounding space

Temperature and humidity

Does the paper type or paper condition satisfy the specification?

Are the consumables Epson-brand?

Is there significant contamination inside the printer?

Have the firmwares for the controller and engine controller been upgraded to the

latest version?

Find the cause of the problem

3.3 Symptoms (page 34)

Troubleshooting

3.4 Troubleshooting (page 37)

TROUBLESHOOTING Troubleshooting Flowchart 33

Page 43

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

3.3 Symptoms

3.3.1 Errors indicated by the LEDs

The status of the LEDs are indicated as shown below in the following table.

Lights

Flashes on and off at intervals of 0.3 seconds.

Flashes on and off at intervals of 0.6 seconds.

Flashes on for 0.6 seconds and off for 2.4 seconds.

Off

LED Indication Description Reference

A paper jam error is occurring.

Page 37

An error other than paper jam is occurring.

3.3.2 Print Quality Problems

Symptom Reference

Bands or smudges that appear at regular

intervals.

Bands or smudges appear on the printout at

regular intervals.

Page 57

Completely blank

Completely blank pages are printed.

Page 57

Completely black

Page 40

Completely solid black pages are printed.

Page 58

TROUBLESHOOTING Symptoms 34

Page 44

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

Symptom Reference

Areas of images are missing

Areas of the printed image are missing.

Black dots

Black dots appear on the printout.

ABC

123

ABC

123

Page 58

Page 59

Symptom Reference

Vertical line

A vertical black line appears on the printout.

Light or faint image

The printed image is light or faint.

ABC

123

Page 59

Page 59

Horizontal line

A horizontal black line appears on the printout.

ABC

123

TROUBLESHOOTING Symptoms 35

Page 59

Dirt on the background

The background is dark or dirty, or toner

smudges appear partially on the printout.

ABC

123

Page 60

Page 45

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

Symptom Reference

Toner smudges

Toner smudges appear on the top edge or nonprinted side of the page.

Wavy image

The printed image on the upper right side

(scanning start position) of the page is wavy.

ABC

123

Page 60

Page 60

3.3.3 Electrical Problems

Symptom Reference

The machine does not operate when the power switch is turned on.

Right cooling fan motor does not operate.

Left cooling fan motor does not operate.

Power supply fan motor does not operate.

Registration clutch does not operate.

Paper feed clutch does not operate.

Developing clutch does not operate.

MP paper feed solenoid does not operate.

Duplex solenoid does not operate.

Eraser lamp does not turn on.

The machine does not detect paper loaded in the cassette.

A paper jam in the paper feed/conveying section or fuser section is indicated

when the power switch is turned on.

The machine does not detect that the top cover is closed.

3.3.4 Mechanical Problems

Symptom Reference

No primary paper feed.

No secondary paper feed.

Skewed paper feed.

Multiple sheets of paper are fed at one time.

Paper jams.

Toner drops on the paper conveying path.

Abnormal noise is heard.

Paper becomes wrinkled, creased, or curled.

Page 61

Page 63

TROUBLESHOOTING Symptoms 36

Page 46

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

3.4 Troubleshooting

3.4.1 Paper Jam Error

When a paper jam error occurs, check the message displayed on the EPSON Status

Monitor, or the jam code printed on the Engine Status Sheet in order to find out the

jammed point, and check the relevant sensors, rollers, or any other relevant parts for

any abnormality.

FINDING JAMMED POINT

When a paper jam error message appears

EPSON Status Monitor Message Jammed Point

Remove cassette 3 and then remove any jammed paper.

Remove cassette 2 and then remove any jammed paper.

Remove cassette 1 and then remove any jammed paper.

Temporarily remove the paper from the MP tray.

Open cover B and remove any jammed paper.

Open the DM tray from either the front or the rear, whichever is accessible

from the space from which cassette 1 was removed, and then remove any

jammed paper.

Open cover A and remove the developer unit and photoconductor unit, and

then carefully remove any jammed paper.

c

d

e

f

ij

h

g

TROUBLESHOOTING Troubleshooting 37

Page 47

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

When a paper jam error message does not appear

Print the Engine Status Sheet and check the jam code on the printout to find out the

jammed point and the cause. The jam code is expressed in 8-digit hexadecimal.

00 NN NN NN

Fixed to 00 (1) (2) (3)

(1) Jammed point information*

Jam code Explanation

80 Reserved

40 Cassette 3 (option)

20 Cassette 2 (option)

10 Cassette 1

08 MP tray

04 Cover B

02 DM tray

01 Photoconductor unit (inside the printer)

(2) Jam cause information

Jam code Explanation Jammed point

10

11

12

20

21

22

30

Paper did not reach the registration sensor.

Paper did not go forward from the registration sensor.

The registration sensor detected paper at power-on.

Paper did not reach the fuser sensor.

Paper did not go forward from the fuser sensor.

The fuser sensor detected paper at power-on.

Paper did not reach the PF sensor of the optional

cassette 1.

efh

g

g

g

i

i

d

Jam code Explanation Jammed point

31

32

40

41

42

A1

A3

E0

F0 to FF Other paper jam errors

Paper did not go forward from the PF sensor of the

optional cassette 1.

The PF sensor of the optional cassette 1 detected

paper at power-on.

Paper did not reach the PF sensor of the optional

cassette 2.

Paper did not go forward from the PF sensor of the

optional cassette 2.

The PF sensor of the optional cassette 2 detected

paper at power-on.

Paper did not reach the exit sensor.

Paper did not go forward from the exit sensor.

An error occurs during printing and the printer engine

was stopped in the middle of an operation.

d

d

c

c

c

j

h

---

---

(3) Feeder

Jam code Explanation

00 MP tray

01 Cassette 1

02 Cassette 2 (option)

03 Cassette 3 (option)

07 Duplex printing

TROUBLESHOOTING Troubleshooting 38

Page 48

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

* : When no applicable code is found in the above table, the paper jam is occurring at

multiple points. In such case, convert the hexadecimal jam code into binary, and check

the binary code to find out the multiple points with reference to the table below.

Binary jam code Jammed point

10000000

01000000

00100000

00010000

00001000

00000100

00000010

00000001

Reserved

Cassette 3 (option)

Cassette 2 (option)

Cassette 1

MP tray

Cover B

DM tray

Photoconductor unit (inside the printer)

Example for reading the binary code:

05

00000101

00000100

Hexadecimal jam code

Binary jam code

00000001

JAMMED POINT

The diagram below shows the jammed points.

(

Fuser/Paper ejection section

(

Duplex/Conveying section

Optional Cassette 1

Optional Cassette 2

(

(

)

)

)

)

(

Cassette 1

MP tray

)

A: Registration sensor

B: Paper sensor

C: MP paper sensor

D: Exit sensor

E: PF sensor

F: PF sensor

Cover B

Photoconductor unit

(inside the printer)

TROUBLESHOOTING Troubleshooting 39

Page 49

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

3.4.2 LED Indication

The status of the LEDs are indicated as shown below in the following table.

Lights

Flashes on and off at intervals of 0.3 seconds.

Flashes on and off at intervals of 0.6 seconds.

Flashes on for 0.6 seconds and off for 2.4 seconds.

Off

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

Unable to write to ROM module Writing to the program ROM could not be

performed.

Developer unit or toner cartridge installed

incorrectly

Incompatible toner cartridge The installed toner cartridge is the one for

The printer failed to detect the toner

cartridge.

another destination.

Main Board Assy. Reboot the printer to make the printer

perform the writing operation again.

Replace the Main Board Assy. (See

P. 92)

Toner cartridge Install the toner cartridge correctly.

Replace the toner cartridge. (See P. 70)

Toner cartridge Replace the toner cartridge with the correct

one. (See P. 70)

TROUBLESHOOTING Troubleshooting 40

Page 50

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

Non-genuine toner cartridge installed The installed toner cartridge is not Epson-

brand.

Trouble with toner cartridge The printer detected that the toner cartridge

was faulty.

Cover A open The cover A is open. Cover A Close the cover A.

The printer does not detect that the cover A

is closed.

Cassette not installed The paper cassette is not installed. Paper cassette Install the cassette to the printer.

The printer does not detect that the cassette

is installed.

Printer set to Manual Feed “Manual Feed” is selected on the printer

driver.

Toner cartridge Replace the toner cartridge with an Epson-

brand cartridge. (See P. 70)

Toner cartridge Replace the toner cartridge. (See P. 70)

The actuator that presses the interlock

switch on the cover A is damaged.

Poor assembling or damage of the link

mechanism that presses the interlock

switch.

The interlock switch is faulty. Replace the interlock switch (LVPS). (See

Poor assembling or damage of the link

mechanism that presses the paper cassette

detection sensor.

The paper cassette detection sensor is

faulty.

Replace the cover A (top cover). (See

P. 113)

Check if the link mechanism is assembled

correctly. If not, reassemble it. If the

mechanism is damaged, replace it.

P. 75)

Check if the link mechanism is assembled

correctly. If not, reassemble it. If the

mechanism is damaged, replace it.

Replace the paper cassette detection sensor

(HVPS). (See P. 75)

Load paper into the MP tray and press the

Start/Stop button.

---

TROUBLESHOOTING Troubleshooting 41

Page 51

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

Unable to perform duplex printing The paper size or type is not supported for

Load paper supported for duplex printing.

duplex printing.

---

Paper out No paper is loaded on the paper feeder.

The printer does not detect paper loaded on

the feeder.

Poor assembling or damage of the actuator

for detecting paper.

---

Load paper on the feeder.

Check if the actuator is assembled correctly.

If not, reassemble it. If the actuator is

damaged, replace it.

Check if the paper sensor is connected to

the Main Board Assy. correctly.

Replace the paper sensor. (See P. 87)

Toner cartridge at end of service life The toner cartridge has reached the end of

Poor connection or damage of the paper

sensor.

Toner cartridge Replace the toner cartridge. (See P. 70)

its life.

Incorrect paper size The paper size selected in the printer

Load the correct sized paper on the feeder.

driver does not match with that of the

loaded paper.

---

Page contains too much data to process The spool file is deleted in the middle of

printing and another print job is started, or

the data is abnormal due to a

communication error.

Insufficient printer memory Processing operation is interrupted due to

insufficient memory or invalid operation to

the memory.

---

---

Delete the spool file using the printer driver,

and then press the Job Cancel button on the

printer.

Lower the print quality setting in the

printer driver.

Reduce the resolution of the image to be

printed.

Add more memory to the printer.

TROUBLESHOOTING Troubleshooting 42

Page 52

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

Not enough printer memory to print using

duplex function

The back of the page cannot be printed

because the memory is insufficient to

process the data for duplex printing. In this

case, only front side is printed.

---

Turn the frontside-printed paper over

and reload it on the printer, and then

press the Start/Stop button to print on the

back of the paper.

Lower the print quality setting in the

printer driver.

Reduce the resolution of the image to be

printed.

Add more memory to the printer.

Unable to process print data There is something wrong with the print

data.

PostScript module incompatible The installed PS3ROM module cannot be

---

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

Delete the spool file using the printer driver,

and then press the Job Cancel button on the

printer.

used by the printer.

General error E001

(Main Board EEPROM error)

The EEPROM (U800) on the Main Board

Assy. is inaccessible.

Mounting failure of the EEPROM (U800) Check if the EEPROM (U800) is properly

mounted. If not, fix it.

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

EEPROM (U800) is faulty. Replace the EEPROM (U800).

TROUBLESHOOTING Troubleshooting 43

Page 53

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

General error E002

(Main motor error)

The main motor ready signal could not be

detected within 2 seconds after the motor

becomes ON.

Poor connection between the main motor

(CN1) and the Main Board Assy. (YC805).

Reconnect the connector properly.

Check the connector cable for electric

continuity. If no continuity is found,

replace the cable.

There is some problem in the main motor

drive transmission path.

Check if the rollers and gears are

smoothly rotating. If not, apply grease to

the bearings and gears.

Check if any of the gears are damaged.

If so, replace the damaged gears.

The main motor is faulty. Replace the main motor. (See P. 92)

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

General error E004

(Polygon motor error)

The polygon motor ready signal could not

be detected within 6 seconds after the motor

becomes ON.

Poor connection between the polygon

motor (laser scanner unit) and the Main

Board Assy. (YC819).

Reconnect the connector properly.

Check the connector cable for electric

continuity. If no continuity is found,

replace the cable.

The laser scanner unit is faulty. Replace the laser scanner unit. (See P. 119)

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

General error E005

(Horizontal synchronization signal error)

The controller could not detect the

horizontal synchronization signal within the

The laser scanner unit is faulty. Replace the laser scanner unit. (See P. 119)

specified time period.

General error E008

(Fuser heater cable disconnection)

The fuser heater lamp was turned ON, but

the fuser temperature did not rise.

Poor connection of the fuser thermistor. Check if the connector (YC105) on the

LVPS is properly inserted. If not, reconnect

it.

Poor connection of the fuser heater lamp

connector.

Check if the connector (YC102) on the

LVPS is properly inserted. If not, reconnect

it.

Mounting failure of the fuser thermistor. Replace the fuser unit. (See P. 106)

Fuser thermal cut-out has been activated.

Mounting failure of the fuser heater lamp.

The fuser heater lamp has breaks.

TROUBLESHOOTING Troubleshooting 44

Page 54

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

General error E009

(Abnormally high fuser heater temperature)

General error E010

(Fuser thermistor short-circuit)

The fuser thermistor detected abnormal

high temperature.

The A/D value input from the fuser

thermistor is “0” (zero).

The fuser thermistor shorted out. Replace the fuser unit. (See P. 106)

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

Poor connection of the fuser thermistor. Check if the connector (YC105) on the

LVPS is properly inserted. If not, reconnect

it.

The fuser thermistor has breaks. Replace the fuser unit. (See P. 106)

Mounting failure of the fuser thermistor.

Fuser thermal cut-out has been activated.

Mounting failure of the fuser heater lamp.

The fuser heater lamp has breaks.

General error E011

(Zero cross signal error)

The Main Board Assy. did not receive the

zero cross signal during a specified time

period.

Poor connection between the HVPS

(YC202) and the Main Board Assy.

(YC811).

Reconnect the connector properly.

Check the connector cable for electric

continuity. If no continuity is found,

replace the cable.

Poor connection between the LVPS

Reconnect the connector properly.

(YC103) and the HVPS (YC201).

The LVPS is faulty. Replace the LVPS. (See P. 75)

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

General error E016

(Option cassette unit communication error)

The communication between the Main

Board Assy. and the PF main board of the

option cassette unit cannot be established.

Mounting failure of the option cassette unit. Check if the unit is properly mounted. If

not, fix it.

Poor connection between the Main Board

Assy. (YC818) and the PF interface

connector.

Reconnect the connector properly.

Check the connector cable for electric

continuity. If no continuity is found,

replace the cable.

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

Poor connection between the PF main board

(YC5) and the PF interface connector.

Reconnect the connector properly.

Check the connector cable for electric

continuity. If no continuity is found,

replace the cable.

The PF main board is faulty. Replace the PF main board. (See P. 136)

TROUBLESHOOTING Troubleshooting 45

Page 55

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

EPSON Status Monitor Message Explanation Possible cause / Error-causing Part Check point / Remedy

General error E998

(Engine communication error)

Communication error between the

controller on the Main Board Assy. and the

engine controller.

The firmware of the engine controller is

faulty.

The Main Board Assy. is faulty. Replace the Main Board Assy. (See P. 92)

Reinstall the engine controller firmware.

(See P. 148)

TROUBLESHOOTING Troubleshooting 46

Page 56

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

3.4.3 Controller-related Service Call Errors

Remedy

When a controller-related error occurs, first check on the initial check items listed

below. If the printer still does not recover, troubleshoot the problem with reference

to the tables given on the following pages. Find the error you face in the tables,

and replace the error-causing parts one by one.

Initial check

Is the printer properly grounded?

Are the connectors properly connected to the controller board?

Is the DIMM properly installed on the controller board?

Does the printer recover by turning the power off and back on several times?

Is there any equipment that causes noise around the printer?

When turning the printer off and on for the above initial check,

wait for several seconds before turning it back on. Do not turn it

back on immediately after power-off.

TROUBLESHOOTING Troubleshooting 47

Page 57

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

Error-causing parts

The status of the LEDs are indicated as shown below in the following table.

Light

Off

LED

indication

Classification Error code Explanation

C/D 0017 Occurrence of an interrupt exception

C/D 0081 TLB change exception

C/D 0082 TLB exception (load or fetch)

C/D 0083 TLB exception (store)

Error-causing parts (or factor)

Main Board Assy.

Causative Not causative Causative

Causative Not causative Causative

Causative Not causative Causative

Option

RAM DIMM

Noise or other

factor

Causative Not causative Causative

TROUBLESHOOTING Troubleshooting 48

Page 58

EPSON AcuLaser M2000D/M2000DN/M2010D/M2010DN Revision B

LED

indication

Classification Error code Explanation

C/D 0084 Address error exception (load or fetch)

C/D 0085 Address error exception (store)

C/D 0086 Bus error exception (store)

C/D 0087 Bus error exception (loading or storing data)

Error-causing parts (or factor)

Main Board Assy.