Page 1

n

E

Register your instrument!

www.eppendorf.com/myeppendorf

ual075

N)

manual

®

epMotion

5075

Hardware manual

Page 2

©

Copyright

2013 Eppendorf AG, Hamburg. No part of this publication may be reproduced without the prior

permission of the copyright owner.

Trademarks

Eppendorf

®

, the Epppendorf logo, epMotion®, Eppendorf Tubes ®, and epT.I.P.S.® are registered

trademarks of Eppendorf AG.

®

LightCycler

and MagNA Pure® are registered trademarks of Roche Diagnostics.

epMotion VAC sealing foil U.S. Pat. No. 6,666,978

epMotion optical sensor U.S. Pat. No. 6,819,437

epMotion gripping tool U.S. Pat. No. 7,462,327

Registered trademarks are not marked in all cases with

®

or ™ in this manual.

The software of the device (firmware) contains open source software. License information is available on

request from Eppendorf AG.

Only for epMotion M5073, M5073c, 5075m and 5075mc: Limited Use Label License NOTICE TO

PURCHASER; LIMITED LICENSE FOR RESEARCH USE ONLY.

This product and its use may be covered by one or more patents owned by Gen-Probe Incorporated. The

purchase price for this product includes only limited, nontransferable rights under certain claims of certain

patents owned by Gen-Probe Incorporated to use this product for research purposes only. No other rights

are conveyed. Purchaser is not granted any rights under patents of Gen-Probe Incorporated to use this

product for any commercial use. Further information regarding purchasing a license under patents of

Gen-Probe Incorporated to use this product for any other purposes, including, without limitation, for

commercial use, may be obtained by contacting Gen-Probe Incorporated, Attn: Business Development

Department, 10210 Genetic Center Drive, San Diego, California 92121-4362, U.S.A.

5075 900.840-00/062013

Page 3

Table of contents

epMotion

®

5075

English (EN)

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.1 Danger symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.2 Danger levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 Revision history. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.1 epMotion 5075 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.2 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1.3 MultiCon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Delivery package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.1 epMotion 5075l and epMotion 5075lg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.2 epMotion 5075t and epMotion 5075tg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.3 epMotion 5075v and epMotion 5075vg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.4 epMotion 5075vt and epMotion 5075vtg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.5 epMotion 5075m and epMotion 5075mg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.6 Accessories for all versions of the epMotion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2.7 Accessories for epMotion with epBlue ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2.8 Accessories for epMotion with epBlue GxP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.2 Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.3 Thermal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.4 Thermomixer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.3.5 Magnetic separation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.6 Vacuum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.7 CleanCap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3

3 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.1 Intended use of the epMotion 5075 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 Information on product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 Hazard symbols and safety devices on the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Installing the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page 4

Table of contents

®

4

epMotion

5075

English (EN)

5 Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1 Worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.1 Layout of the epMotion 5075I worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.2 Layout of the epMotion 5075t worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.1.3 Layout of the epMotion 5075v worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.4 Layout of the epMotion 5075vt worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1.5 Layout of the epMotion 5075m worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Optical sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3 Thermal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.3 Equipping the thermal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4 Thermomixer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.1 Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.3 Equipping the thermomixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.5 Magnet finger module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.5.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.5.2 Equipping the magnet finger module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.6 Vacuum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.6.1 Vac Frame vacuum frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.6.2 VAC Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.6.3 Silicone mat for VAC Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.6.4 Vac Thermo Lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.6.5 Elution plate adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.6.6 Loading the vacuum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.7 CleanCap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.7.1 HEPA filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.7.2 UV lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.8 Barcode reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.9 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.9.1 Dispensing Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.9.2 Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Dispensing liquids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Basic procedure for dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.1 Operating principle of dispensing tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1.2 Liquid aspiration up to the remaining volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.1.3 Bottom tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.1.4 Transporting and dispensing liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2 Dispensing modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.2.1 Dispensing mode: Pipette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.2.2 Dispensing mode: Multidispense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.2.3 Mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3 Special features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.3.1 Liquid aspiration from bottom of vessel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.3.2 Liquid aspiration from high vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.3.3 Liquid dispensing at the height of the vessel edge. . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.4 Liquid aspiration from a filter plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Page 5

Table of contents

®

epMotion

5075

English (EN)

7 Labware – vessels, plates and pipette tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.1 Tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.2 Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.2.1 Deepwell plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.2.2 Microplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2.3 Filter plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2.4 Channeling plate 96 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2.5 PCR plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.2.6 Tube plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.3 Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.4 epT.I.P.S. Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.4.1 epT.I.P.S. Motion Racks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.4.2 epT.I.P.S. Motion Reloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

7.4.3 Tip holder for epT.I.P.S. Motion Reloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.4.4 epT.I.P.S. Motion SafeRacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8 Labware accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.1 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.1.1 Racks for 24 vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.1.2 Rack for 96 vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.1.3 Rack LC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.1.4 Thermorack and Rack 0.5/1.5/2.0 mL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.1.5 PrepRack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.1.6 ReagentRack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.1.7 Reservoir Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.1.8 ReservoirRack 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.1.9 Reservoir Rack modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

8.2 Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.1 Height adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.2.2 Vac holder vacuum holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.3 Thermoadapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.2.4 Thermoadapter LC samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.2.5 Thermoadapter Frosty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8.3 Thermoblocks and Thermoadapters for PCR plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.3.1 Equipping the thermoblock with 0.2 mL vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.4 Waste container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.1 Waste container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.2 Waste funnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.4.3 LiquidWasteTub with lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5

Page 6

Table of contents

®

6

epMotion

5075

English (EN)

9 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1 First steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1.1 Switching on the epMotion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1.2 Using the MultiCon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.1.3 Using the epMotion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.2 Loading the worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.2.1 Display the loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.2.2 Positioning tools on the worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9.2.3 Positioning the epT.I.P.S. Motion on the worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2.4 Positioning the waste container on the worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2.5 Positioning labware on the worktable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.3 Executing an application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.3.1 Performing a test run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.3.2 Starting the application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.3.3 Controlling the application run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.4 Completing your work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.4.1 Cleaning up the worktable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.4.2 Switching off the epMotion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.1 Decontamination and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.1.1 Carrying out wipe decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

10.1.2 Carrying out spray decontamination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.1.3 Carrying out UV irradiation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.1.4 Autoclaving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

10.2 Decontamination before shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.3 Servicing the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.4 Servicing the vacuum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.4.1 Replacing the seals of the vacuum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.4.2 Replacing the silicone mat of the vacuum lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.5 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.6 Carrying out firmware updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.7 Checking the dispensing volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.8 Maintaining the dispensing tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.8.1 Exchanging the sealing rings on the eight-channel dispensing tool . . . . . . . . . . . . . 103

10.9 Customer service functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.1 Error search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

11.2 General errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.2.1 Optical sensor errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.2.2 Dispensing errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

11.2.3 Software errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

12 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Page 7

Table of contents

®

epMotion

5075

English (EN)

13 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.1 Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.2 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.3 Weight/dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.4 Noise level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

13.5 Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13.6 MultiCon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13.7 Additional specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13.7.1 Optical sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13.7.2 Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13.7.3 Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

13.8 Enhancements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.8.1 Thermal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.8.2 Thermomixer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.8.3 Magnet finger module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.8.4 Vacuum unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

13.8.5 Barcode reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.8.6 HEPA filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.8.7 UV lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13.9 Dispensing tool errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.9.1 Pipetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

13.9.2 Dispensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

13.10 Test conditions for dispensing tool errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

7

14 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.2 epT.I.P.S. Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

14.3 Plates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

14.4 Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

14.5 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

14.6 Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

14.7 Thermoblocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

14.8 Accessories for the vacuum chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

14.9 MagSep kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

14.10 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

14.11 Modification kits and enhancements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Page 8

Table of contents

epMotion

8

English (EN)

®

5075

Page 9

Operating instructions

epMotion

English (EN)

1 Operating instructions

1.1 Using this manual

Your epMotion operating manual consists of hardware instructions and software instructions. Short

instructions are available for optional software enhancements.

The operating manual is part of the product.

®

5075

9

The current version of the operating manual can be found on our webpage: www.eppendorf.com

.

Read the operating manual in full before using the device.

Store the operating manual at an easily accessible location.

The device may only be transferred with the operating manual.

If the operating manual is lost, replace it immediately. Please contact Eppendorf AG for further details.

1.2 Danger symbols and danger levels

The safety instructions in this manual appear with the following danger symbols and danger levels:

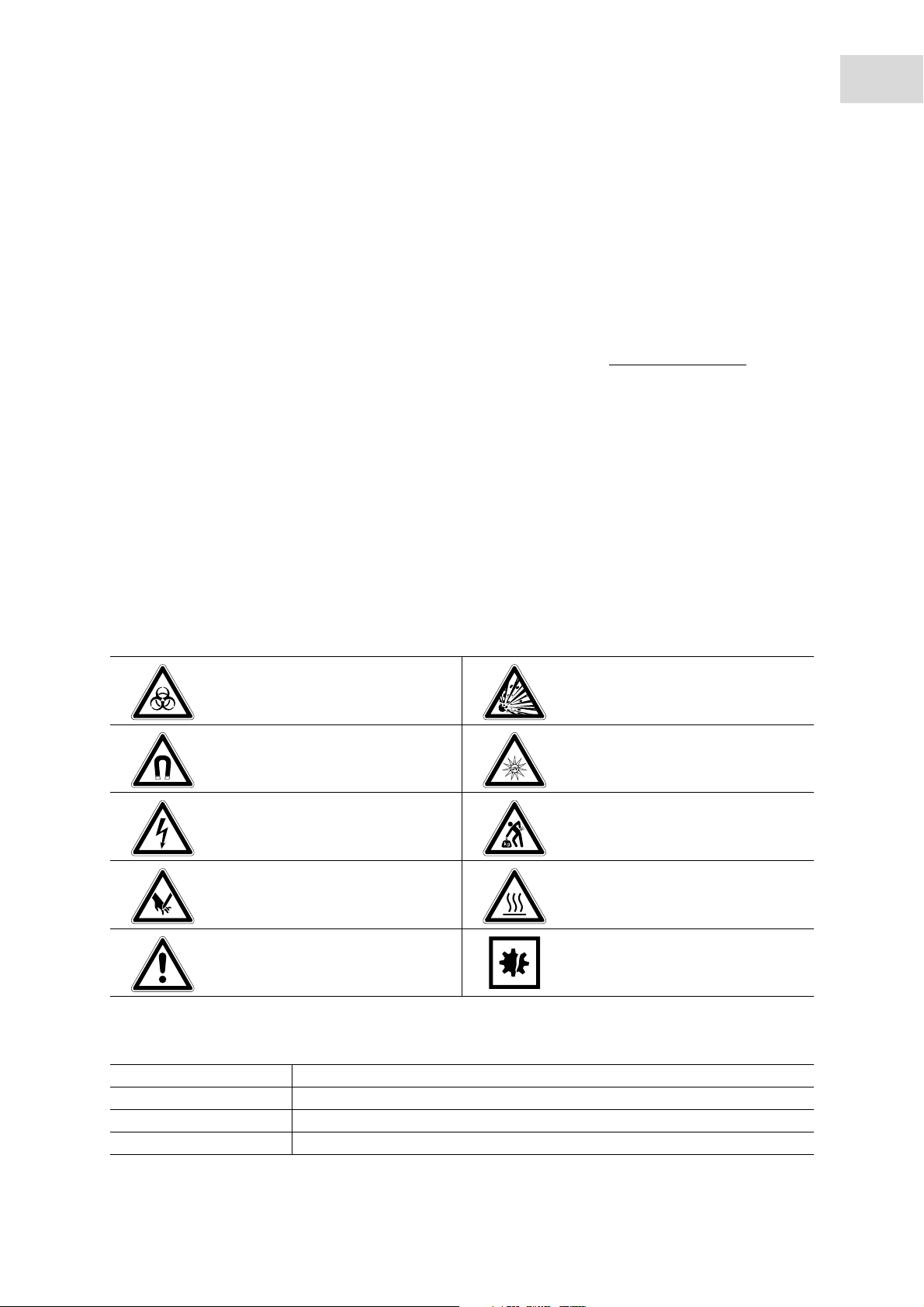

1.2.1 Danger symbols

Biohazard Explosion

Strong magnetic field UV radiation

Electric shock Heavy loads

Cuts Hot surface

Hazard point Material damage

1.2.2 Danger levels

DANGER Will lead to severe injuries or death.

WARN ING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

Page 10

10

Operating instructions

epMotion

English (EN)

®

5075

1.3 Symbols used

Depiction Meaning

1.

2.

Actions in the specified order

Actions without a specified order

• List:

Text Display or software texts

Additional information

1.4 Abbreviations used

BCR

Barcode reader

DNA

Deoxyribonucleic acid (DNA)

DWP

Deepwell plate

epT.I.P.S.

eppendorf Totally Integrated Pipetting System

HEPA

High-Efficiency Particulate Air (filter)

LH

Liquid handling

MTP

Micro test plate

PCR

Polymerase chain reaction

PDF

Portable Document Format

TMX

Thermomixer

USB

Universal Serial Bus

UV

Ultraviolet radiation

VAC

Vacuum unit

Page 11

Operating instructions

epMotion

English (EN)

1.5 Glossary

A

Application

Programs for a specific application. An application includes the procedure and the equipping of the

worktable.

B

Barcode reader

Device for scanning a barcode.

C

CleanCap

Optional epMotion equipment. The CleanCap includes a HEPA filter and UV lamp.

®

5075

11

D

Destination labware

Labware that liquid is dispensed into during the application. Destination labware refers to a plate or rack.

Destination position

Position that liquid is dispensed into during the application.

Destination vessel

The vessel into which liquid is dispensed during the application.

Dispensing tool

Tool that aspirates and dispenses liquid. Single-channel dispensing tools and eight-channel dispensing

tools are available for various volume ranges.

E

epBlue

Software for creating and administering applications and labware. The epMotion is controlled using the

software. epBlue is used to manage access to epMotion. epBlue can be expanded. The ID module enables

barcode tracking. The GxP module enables electronic documentation in support of 21 CFR Part 11.

Eppendorf Quality

Eppendorf Quality is an Eppendorf AG purity grade for consumables. Eppendorf Quality meets the

requirements for standard products, e.g., precision, accuracy, wetting behavior and tightness.

epT.I.P.S.® Motion

epMotion pipette tips. Only epT.I.P.S.® Motion can be used on the epMotion for all features. epT.I.P.S.®

Motions are available with or without a filter.

Page 12

12

Operating instructions

®

epMotion

5075

English (EN)

F

Filling volume

Maximum liquid volume of a labware. The epMotion uses the gripper to transport the labware up to the

filling volume. The epMotion aspirates liquid from the labware up to the filling volume. The filling volume is

higher than the working volume.

G

Gripper

Tool that transports labware.

H

Height adapter

Adapter for low labware. The height differences among the labware will be offset to decrease the tool

holder paths, thereby decreasing the run time of the application as well.

HEPA filter

Air filter. The air filter prevents particles such as dust and germs from the environment entering the

epMotion work room.

I

Intermediate labware

Labware that is used to dispense and aspirate liquids during the application.

Intermediate position

Position that is used to dispense and aspirate liquids during the application.

Intermediate vessel

Vessel that is used to dispense and aspirate liquids during the application.

L

Labware

Racks, plates, tips, etc. which are placed on the worktable.

Location

Area on the worktable where the labware is placed.

M

MagSep

System consisting of the magnetic finger module, thermomixer and PrepRack and reagents for nucleic acid

preparation with the epMotion.

MultiCon

epMotion operator panel. You can control your epMotion using the control unit and the epBlue software.

Page 13

Operating instructions

epMotion

English (EN)

P

PCR clean

PCR clean is an Eppendorf AG purity grade for consumables. PCR clean meets the requirements for

standard products, e.g., precision, accuracy, wetting behavior, tightness. PCR clean also meets the

requirements with regard to absence of human DNA, DNase, RNase and PCR inhibitors.

Consumables with the PCR clean purity grade are controlled and certified by an external laboratory.

Certificates are available for downloading from our webpage www.eppendorf.com

.

Procedure

Sequence of commands that are executed one after the other. Part of an application.

R

Rack

Mount for tubes or pipette tips.

®

5075

13

Random error

Precision. Standard deviation of the average value of the dispensed volumes.

Remaining volume

Volume that cannot be aspirated from a vessel. The distance from the pipette tip to the vessel bottom,

defined in the software, and the defined immersion depth of the pipette tip in the liquid, must be observed.

Therefore, the pipette tip cannot aspirate the volume. The remaining volume depends on the vessel

geometry.

Reservoir

Reservoirs are used to hold reagents. Reservoirs are hung in a Reservoir Rack or placed directly on the

worktable.

S

SafeRack

Rack with ep.T.I.P.S. Motion pipette tips. The SafeRack features a partition that prevents the contamination

of adjacent tips. Use the SafeRacks if you would like to use tips several times.

Source labware

Labware that liquid is aspirated from during the application. Source labware refers to a plate or rack.

Source position

Position that liquid is aspirated from during the application.

Source vessel

The vessel from which liquid is aspirated during the application.

Sterile

Sterile is an Eppendorf AG purity grade for consumables. Sterile meets the requirements for standard

products, e.g., precision, accuracy, wetting behavior, tightness. Sterile also meets the requirements with

regard to sterility and freedom from pyrogens.

Page 14

14

Operating instructions

®

epMotion

5075

English (EN)

Systematic error

Accuracy. Deviation of the average value of the dispensed volumes from the selected volume.

T

Thermal module

Thermal module for labware that is integrated in the worktable.

Thermoadapter

Heat-conductive adapter for holding plates.

Thermoblock

A thermoadapter that is permanently connected to a PCR plate or PCR tube.

Thermorack

Temperable rack for smaller vessels, e.g., Safe-Lock tubes for 0.5 mL, 1.5 mL or 2 mL.

V

Vacuum unit

The vacuum unit uses a vacuum to suck liquid from a filter plate. The vacuum unit consists of a vacuum

manifold, vacuum pump and Vac Frame.

Vessel

Tube or single well of a plate.

W

Work volume

Liquid volume of a labware. The epMotion fills a vessel with low levels of contamination up to the working

volume. The working volume is less than the filling volume.

Worktable

Work surface of the epMotion where labware and tools are placed. In the software, the epMotion worktable

is shown as the epBlue worktable.

Page 15

Operating instructions

1.6 Revision history

Revision history of the epMotion 5075 hardware operating manual, order no. 5075 900.840.

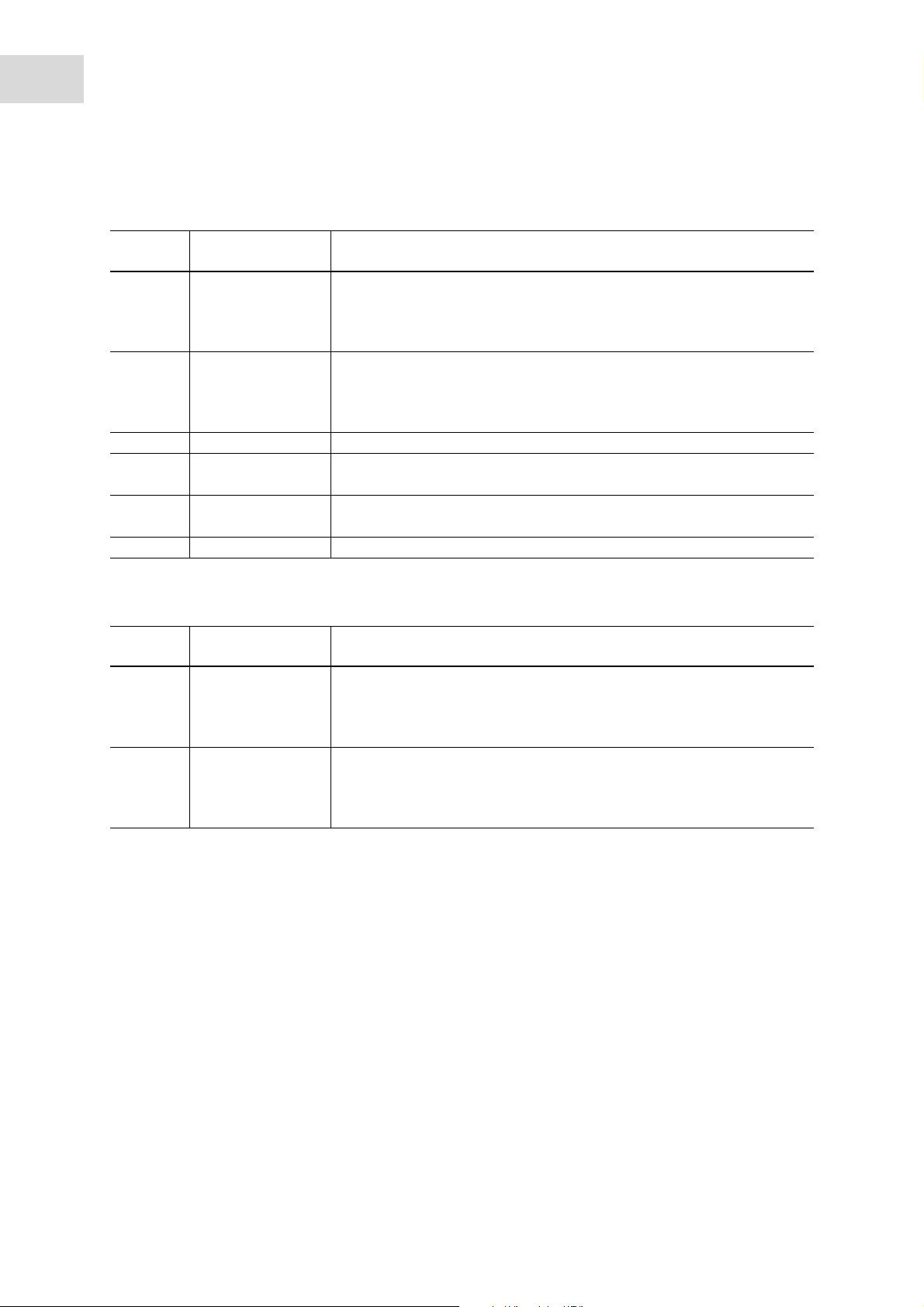

Version of the operating manual Date Changes

Version 00 June 2013 Created new

epMotion

English (EN)

®

5075

15

Page 16

16

Operating instructions

®

epMotion

5075

English (EN)

Page 17

Product description

epMotion

English (EN)

2 Product description

2.1 Main illustration

The epMotion 5075 is available with various features. Details of the worktable for your device (see

Worktable on p. 33).

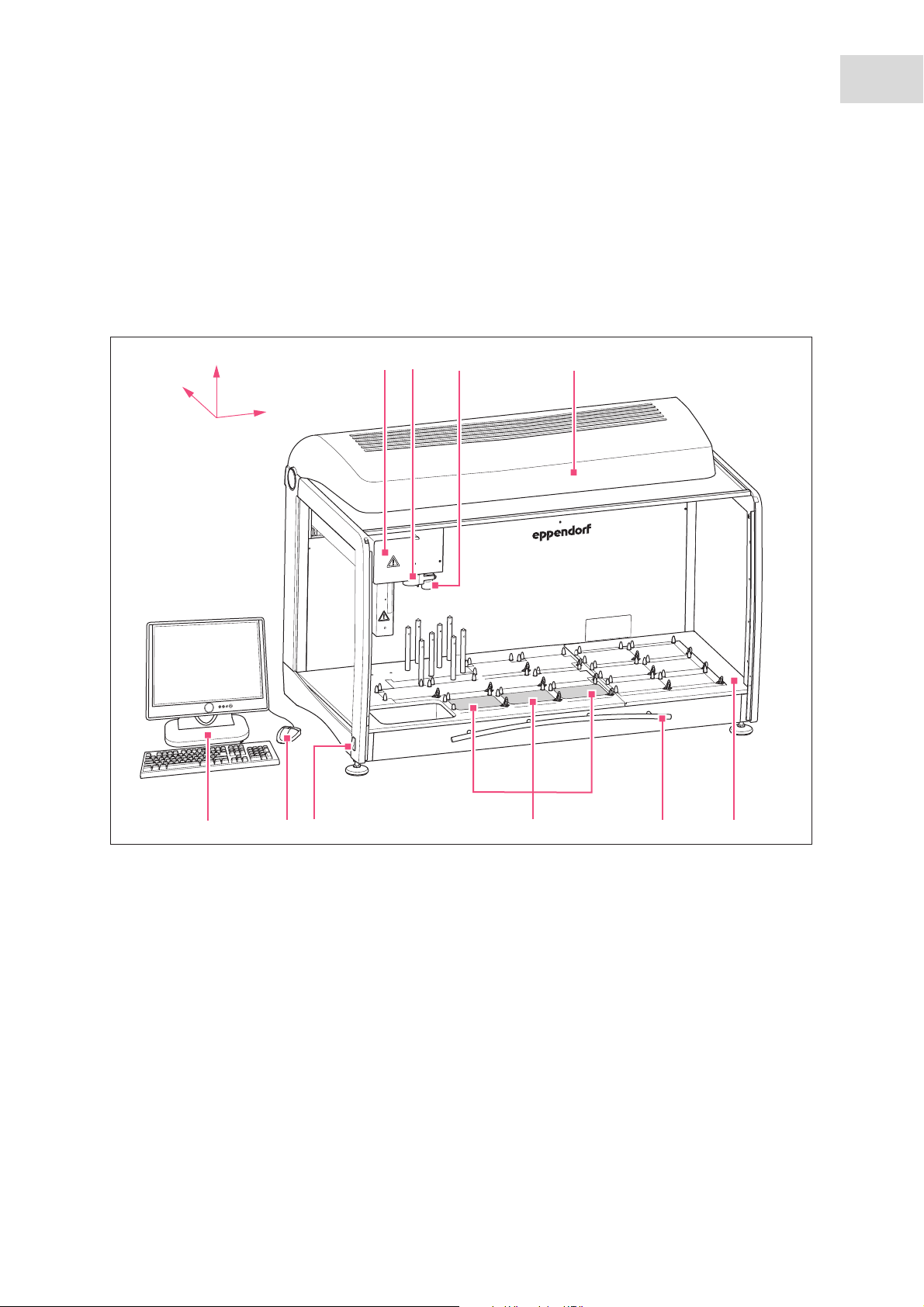

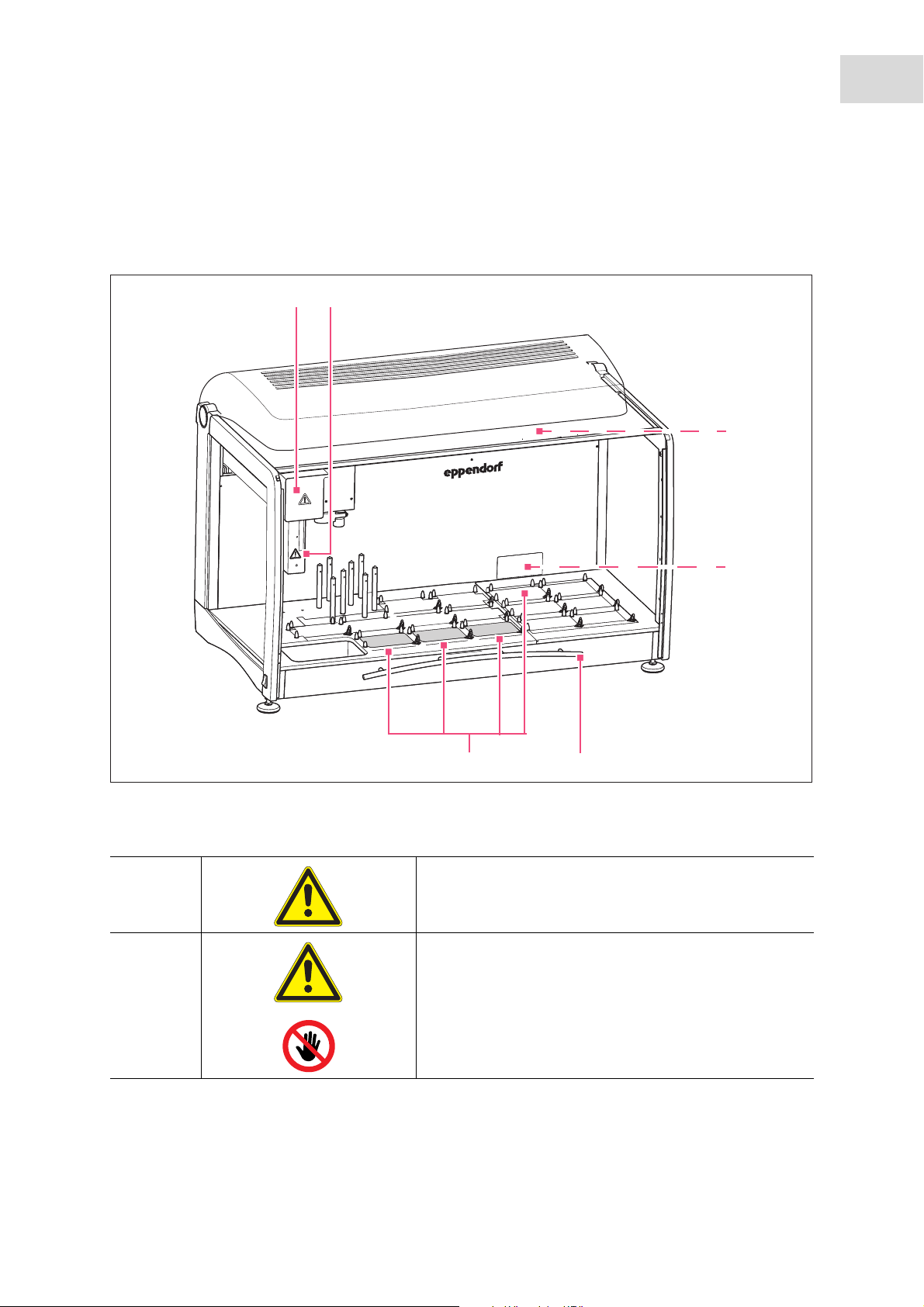

2.1.1 epMotion 5075

Abb. 2-1: Main illustrati on epMotion 5075I

z

y

x

2

1

3

4

®

5075

17

8

10

9

Fig. 2-1: Main illustration epMotion 5075I

1Carrier

The carrier moves in X-direction, Y-direction and

Z-direction.

2 Tool holder

Holds dispensing tools.

epMotio n 5 07 5

7

6

5

6 Front hood

Safety device for protection from movable, UV

radiation parts and contamination.

7 Thermal module (optional)

Plate for heating and cooling labware.

3Optical sensor

Detects levels, tips and labware.

4CleanCap (optional)

contains HEPA filter and UV lamps

5Worktable

Work surface for tools and labware.

8 Mains power switch

9Mouse

10 MultiCon

Control unit used to control the epMotion.

Page 18

18

1

2

3

Product description

®

epMotion

5075

English (EN)

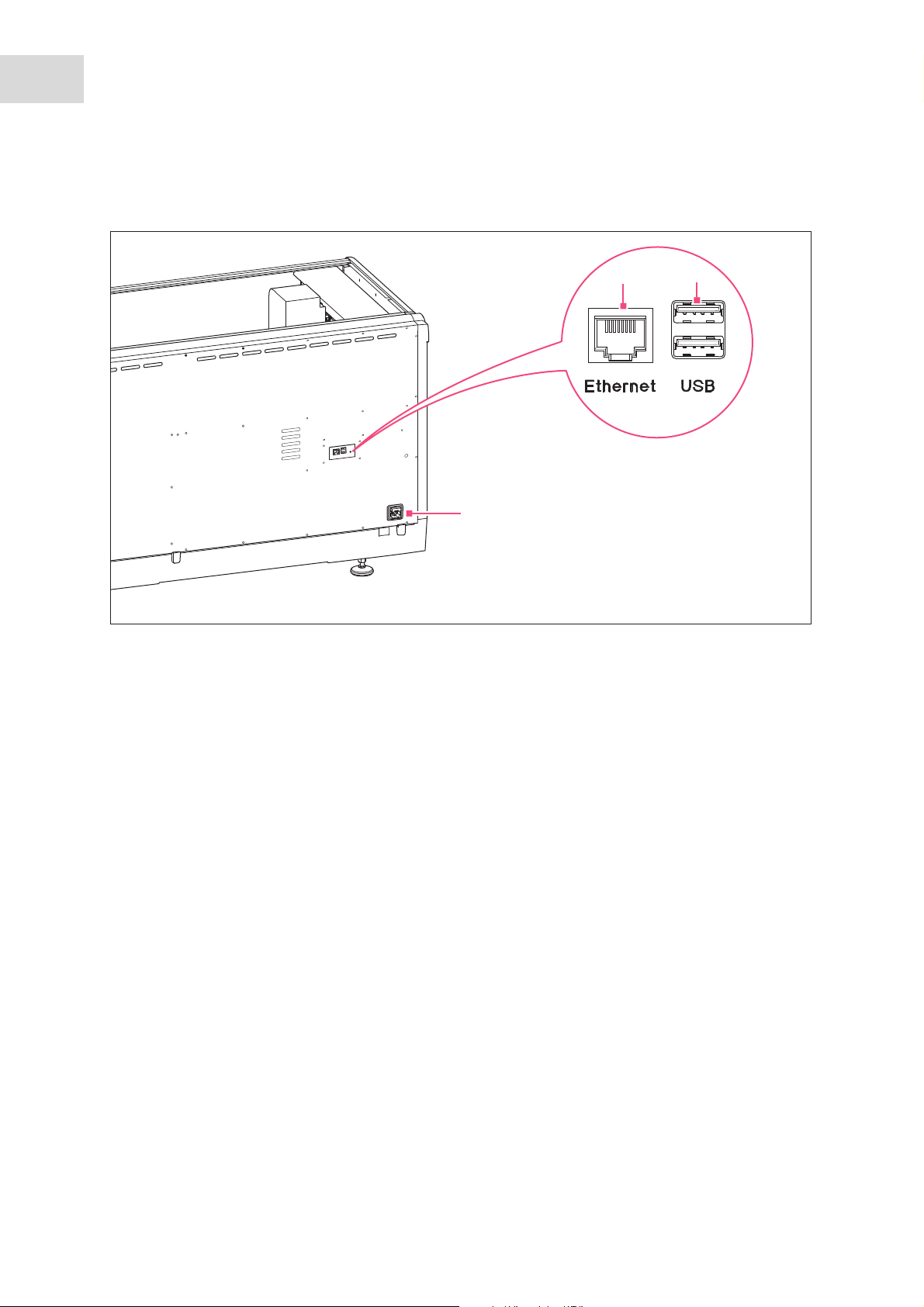

2.1.2 Interfaces

Abb. 2-2: Interfaces epMoti on 5075

Fig. 2-2: Interfaces epMotion 5075

1Ethernet

3 Mains power connection

Connection for the cable to the MultiCon

2USB

Connection for a USB storage medium for

firmware updates.

Only devices which meet the requirements of IEC 950/EN 60950-1 (UL 1950) standards may be connected

to the interfaces.

2.1.3 MultiCon

Information can be found in the operating manual of the MultiCon.

Only devices which meet the requirements of IEC 950/EN 60950-1 (UL 1950) standards may be connected

to the interfaces.

Page 19

Product description

epMotion

English (EN)

2.2 Delivery package

The epMotion is available in various versions. Your device has been equipped according to your

specifications. For some software modules additional accessories are available.

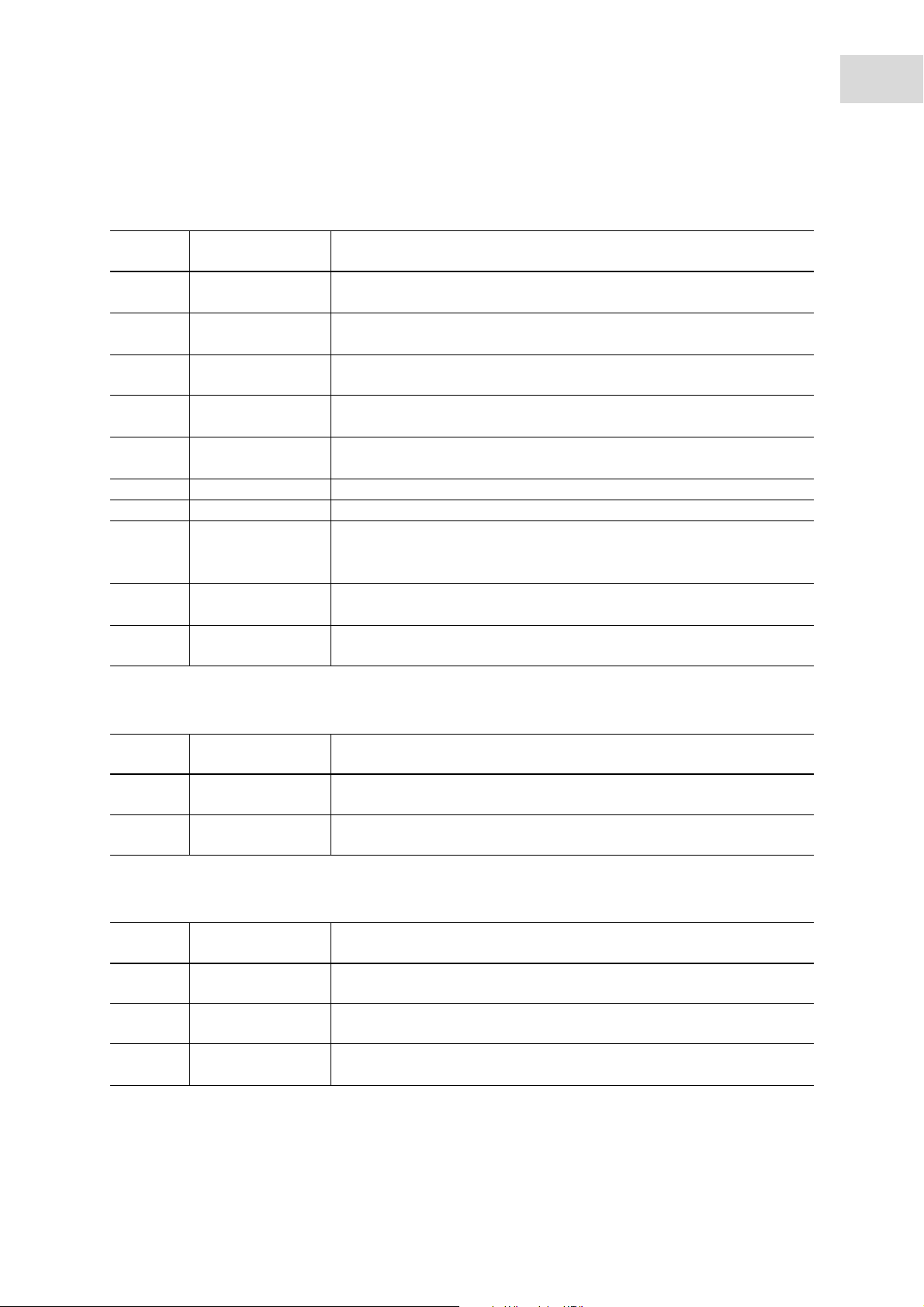

2.2.1 epMotion 5075l and epMotion 5075lg

®

5075

19

Quantity Order no.

(International)

1 5075 000.271 100 V - 240 V, 50 / 60 Hz

or 1 5075 000.275 100 V - 240 V, 50 / 60 Hz

Description

Automated pipetting system epMotion 5075l

main device; with MultiCon, keyboard, mouse,

installed software epBlue

Automated pipetting system epMotion 5075lg

main device; with MultiCon, keyboard, mouse,

installed software epBlue GxP

2.2.2 epMotion 5075t and epMotion 5075tg

Quantity Order no.

(International)

1 5075 000.272 100 V - 240 V, 50 / 60 Hz

or 1 5075 000.276 100 V - 240 V, 50 / 60 Hz

Description

Automated pipetting system epMotion 5075t

main device with thermomixer; with MultiCon, keyboard, mouse,

installed software epBlue

Automated pipetting system epMotion 5075tg

main device with thermomixer; with MultiCon, keyboard, mouse,

installed software epBlue GxP

2.2.3 epMotion 5075v and epMotion 5075vg

Quantity Order no.

(International)

1 5075 000.273 100 V - 240 V, 50 / 60 Hz

or 1 5075 000.277 100 V - 240 V, 50 / 60 Hz

1– Reservoir 400 mL

1 5075 785.005 vacuum frame

1 5075 778.009 adapter for Vac Frame

1 5282 000.018 Gripper

Description

Automated pipetting system epMotion 5075v

main device with vacuum unit; with MultiCon, keyboard, mouse,

installed software epBlue

Automated pipetting system epMotion 5075vg

main device with vacuum unit; with MultiCon, keyboard, mouse,

installed software epBlue GxP

Vac Frame 2

Vac Holder

Page 20

20

Product description

epMotion

English (EN)

®

5075

2.2.4 epMotion 5075vt and epMotion 5075vtg

Quantity Order no.

(International)

1 5075 000.274 100 V - 240 V, 50 / 60 Hz

or 1 5075 000.278 100 V - 240 V, 50 / 60 Hz

1– Reservoir 400 mL

1 5075 785.005 vacuum frame

1 5075 778.009 adapter for Vac Frame

1 5282 000.018 Gripper

Description

Automated pipetting system epMotion 5075vt

main device with vacuum unit and thermomixer; with MultiCon,

keyboard, mouse, installed software epBlue

Automated pipetting system epMotion 5075vtg

main device with vacuum item and thermomixer; with MultiCon,

keyboard, mouse, installed software epBlue GxP

Vac Frame 2

Vac Holder

2.2.5 epMotion 5075m and epMotion 5075mg

Quantity Order no.

(International)

1 5075 000.270 100 V - 240 V, 50 / 60 Hz

or 1 5075 000.279 100 V - 240 V, 50 / 60 Hz

Description

Automated pipetting system epMotion 5075m

main device with magnet finger module and thermomixer; with

MultiCon, keyboard, mouse, installed software epBlue

Automated pipetting system epMotion 5075mg

main device with magnet finger module and thermomixer; with

MultiCon, keyboard, mouse, installed software epBlue GxP

Page 21

2.2.6 Accessories for all versions of the epMotion

Product description

epMotion

®

5075

English (EN)

21

Quantity Order no.

(International)

1 - With USB connection cable

1 - With USB connection cable

1

1 - Compatible with the country where the order was placed or defined

1 - For connecting the MultiCon to a network

1- Tool for transport securing device

1 5075 753.006 Waste box

1 5075 900.840 epMotion 5075

1 5073 900.866 software operating manual epBlue with MultiCon

optional 1 5075 751.607 with HEPA air filter and UV-lamp

optional 2-

-

Description

Mouse

Keyboard

Cable

For connecting the MultiCon to the epMotion

Mains power cable

USB-Ethernet adapter

Operating Manual

CleanCap

UV tube

For epMotion with CleanCap

2.2.7 Accessories for epMotion with epBlue ID

Quantity Order no.

(International)

1

1

–

Barcode reader

Description

USB dongle eLicenser

with hardware key code card

With USB connection cable and table stand

2.2.8 Accessories for epMotion with epBlue GxP

Quantity Order no.

(International)

1

1

1 5075 900.874 epBlue GxP

–

–

Description

USB dongle eLicenser

with hardware key code card

Documentation folder

Folder for certificates and documentation

Operating Manual

Page 22

22

Product description

epMotion

English (EN)

®

5075

2.3 Features

The epMotion 5075 is available with different features. All available features are described in this manual.

2.3.1 Function

The epMotion 5075 is an automatic system for dispensing liquids using dispensing tools and ep.T.I.P.S.

Motion pipette tips.

The epMotion 5075 dispenses liquids in the volume range 1 µL – 1 000 µL.

The dispensing tool aspirates liquid from source vessels and dispenses this liquid in destination vessels.

The dispensing tool works according to the piston-stroke principle. For the epMotion, dispensing tools are

available for 3 different volume ranges.

The epMotion features an optical sensor. The sensor checks:

• Type and location of labware

• Quantity and position of pipette tips in the rack

• Filling level of vessels

You control the epMotion 5075 via the MultiCon control unit with the epBlue software.

You can use the epBlue software to define dispensing processes and compile them into an application. To

do so, you select source vessels and destination vessels, define the procedure and define the transfer

pattern.

2.3.2 Gripper

A gripper is available for the epMotion. The gripper stacks and transports labware.

2.3.3 Thermal module

The epMotion can be equipped with a maximum of 3 thermal modules.

2.3.4 Thermomixer

The epMotion can be equipped with a thermomixer.

Page 23

Product description

epMotion

®

5075

English (EN)

2.3.5 Magnetic separation

The epMotion can be equipped with a thermomixer and a magnet finger module for separating magnetic

particles.

This epMotion is a system for preparing nucleic acids. MagSep reagent kits are available for this system.

2.3.6 Vacuum unit

The epMotion can be equipped with a vacuum unit.

With this unit, the epMotion can perform a fully automated nucleic acid purification.

2.3.7 CleanCap

As an option, the epMotion can be equipped with a CleanCap.

23

The CleanCap contains a UV lamp and a HEPA filter.

Additional information on your epMotion is available at: www.eppendorf.com/automation

.

Page 24

24

Product description

®

epMotion

5075

English (EN)

Page 25

Safety

®

epMotion

English (EN)

5075

3Safety

3.1 Intended use

3.1.1 Intended use of the epMotion 5075

The device is intended for use in laboratories for research, development, and industrial and routine work,

as well as for training purposes. The areas of applications include – but are not limited to – the fields of life

sciences, biotechnology, chemistry and clinical research.

All epMotion 5075 (l, t, v, vt, m) pipetting systems are designed for the monitoring of contamination-free,

precise and correct dispensing and transferring of liquids and to automatically check the combining of

liquids.

The autoclavable dispensing tools work in a volume range from 1 L to 1000 L.

The epMotion5075v with integrated vacuum station, for instance, performs fully automated nucleic acid

purification.

25

The epMotion 5075m with an integrated thermomixer is used for applications which allow mixing and

incubating with open tubes and it performs fully automated nucleic acid purification with magnetic

particles.

The epMotion 5075t with an integrated thermomixer is used for applications which allow mixing and

incubating with open tubes.

The device meets the basic, essential requirements of the EC Directives and Standards that are listed in the

declaration of conformity, but the product is not registered with the FDA.

These automated pipetting systems are exclusively intended for use indoors and may only be used by

skilled personnel who have received adequate training.

3.2 User profile

This device may only be operated by skilled personnel.

The skilled personnel must have received training on this device. The training must have been conducted

by Eppendorf AG or an authorized partner of Eppendorf AG.

The skilled personnel must have read the operating manual carefully. The skilled personnel must have read

the operating manuals of all software components carefully.

Page 26

26

Safety

epMotion

English (EN)

®

5075

3.3 Information on product liability

In the following cases, the designated protection of the device may be compromised. Liability for any

resulting property damage or personal injury is then transferred to the operator:

• The device is not used in accordance with the operating manual.

• The device is used outside of its intended use.

• The device is used with accessories or consumables which are not recommended by Eppendorf.

• The device is maintained or repaired by people not authorized by Eppendorf.

• The user makes unauthorized changes to the device.

3.4 Warnings for intended use

DANGER! Risk of explosion.

Do not operate the device in areas where work is completed with explosive substances.

Do not use this device to process any explosive or highly reactive substances.

Do not use this device to process any substances which may generate an explosive

atmosphere.

DANGER! Damage to health due to escaping aerosols.

When working with substances that can be hazardous to health, harmful aerosols may form

and escape from the vacuum pump.

Contact Eppendorf AG before using this type of substances.

WARNING! Lethal voltages inside the device.

Ensure that the housing is always closed and undamaged so that no parts inside the device

can be contacted by accident.

Do not remove the housing of the device.

Do not allow any liquids to penetrate the inside of the housing.

Do not allow the device to be opened by anyone except service personnel who have been

specifically authorized by Eppendorf.

WARNING! Electric shock due to damage to device or mains cable.

Only switch on the device if the device and mains cable are undamaged.

Only use devices that have been properly installed or repaired.

In case of danger, disconnect the device from the mains supply by pulling the power plug

from the device or the mains socket or, by using the isolating device intended for this

purpose (e.g. emergency stop switch in the laboratory).

Page 27

Safety

®

epMotion

English (EN)

WARNING! Risk from incorrect supply voltage

5075

Only connect the device to voltage sources which correspond to the electrical

requirements on the name plate.

Only use sockets with a protective earth (PE) conductor and suitable power cable.

WARNING! Damage to health due to infectious liquids and pathogenic germs.

When handling infectious liquids and pathogenic germs, observe the national regulations,

the biological security level of your laboratory, the material safety data sheets, and the

manufacturer's application notes.

Wear personal protective equipment.

For full instructions regarding the handling of germs or biological material of risk group II

or higher, please refer to the "Laboratory Biosafety Manual" (Source: World Health

Organization, current edition of the Laboratory Biosafety Manual).

WARNING! Health hazard from skin contact with infectious substances.

27

Wear protective gloves.

WARNING! Danger due to flammable and infectious liquids in the waste container.

Pipette tips in the waste container may contain flammable or infectious liquids.

Wear personal protective equipment.

Handle the pipette tips and sample materials from the waste container in accordance with

the material safety data sheets, safety regulations and laboratory guidelines.

WARNING! Damage to health due to contaminated device and accessories.

Decontaminate the device and the accessories before storage and shipping.

CAUTION! Risk of injury due to carrier movement.

The carrier may still be moving when the front hood of the epMotion is opened.

Wait until the carrier stops moving before reaching into the device.

CAUTION! Cuts due to broken glass.

A damaged touchscreen leads to cuts on the hands.

Only use the MultiCon if it is not damaged.

CAUTION! Poor safety due to incorrect accessories and spare parts.

The use of accessories and spare parts other than those recommended by Eppendorf may

impair the safety, functioning and precision of the device. Eppendorf cannot be held liable or

accept any liability for damage resulting from the use of incorrect or non-recommended

accessories and spare parts, or from the improper use of such equipment.

Only use accessories and original spare parts recommended by Eppendorf.

Page 28

28

Safety

epMotion

English (EN)

®

5075

NOTICE! Spilled liquid can cause damage to the device.

Switch off the device.

Disconnect the power plug.

Collect the spilled liquid. Observe the specifications for the liquid in the material safety

data sheets.

NOTICE! Size of disposables can change through autoclaving.

Do not use autoclaved disposable products in automated applications.

NOTICE! Data loss and malfunction due to malicious software.

Malicious software (e.g., a computer virus) on the USB storage medium can be transferred to

the MultiCon.

Before connecting the USB storage medium to the MultiCon, check the USB storage

medium using a current antivirus software.

NOTICE! Data loss due to missing data backup or incorrect storage of storage media.

User accounts, applications, labware and protocols are saved in a database. If this database

becomes damaged (e.g., due to a hardware defect), this information will be lost.

Eppendorf is not liable for data loss or any associated damages.

Regularly backup your database using the backup function in the software.

Save the secured data on an external storage medium.

Store the external storage media according to the manufacturer’s specifications.

NOTICE! Malfunction due to third-party software.

Third-party software can impair the functioning of the epBlue software.

Only install software approved by Eppendorf.

Page 29

epMotion

epMotio n U 50 75epMotio n 5 07 5

6

5

1

2

3

4

English (EN)

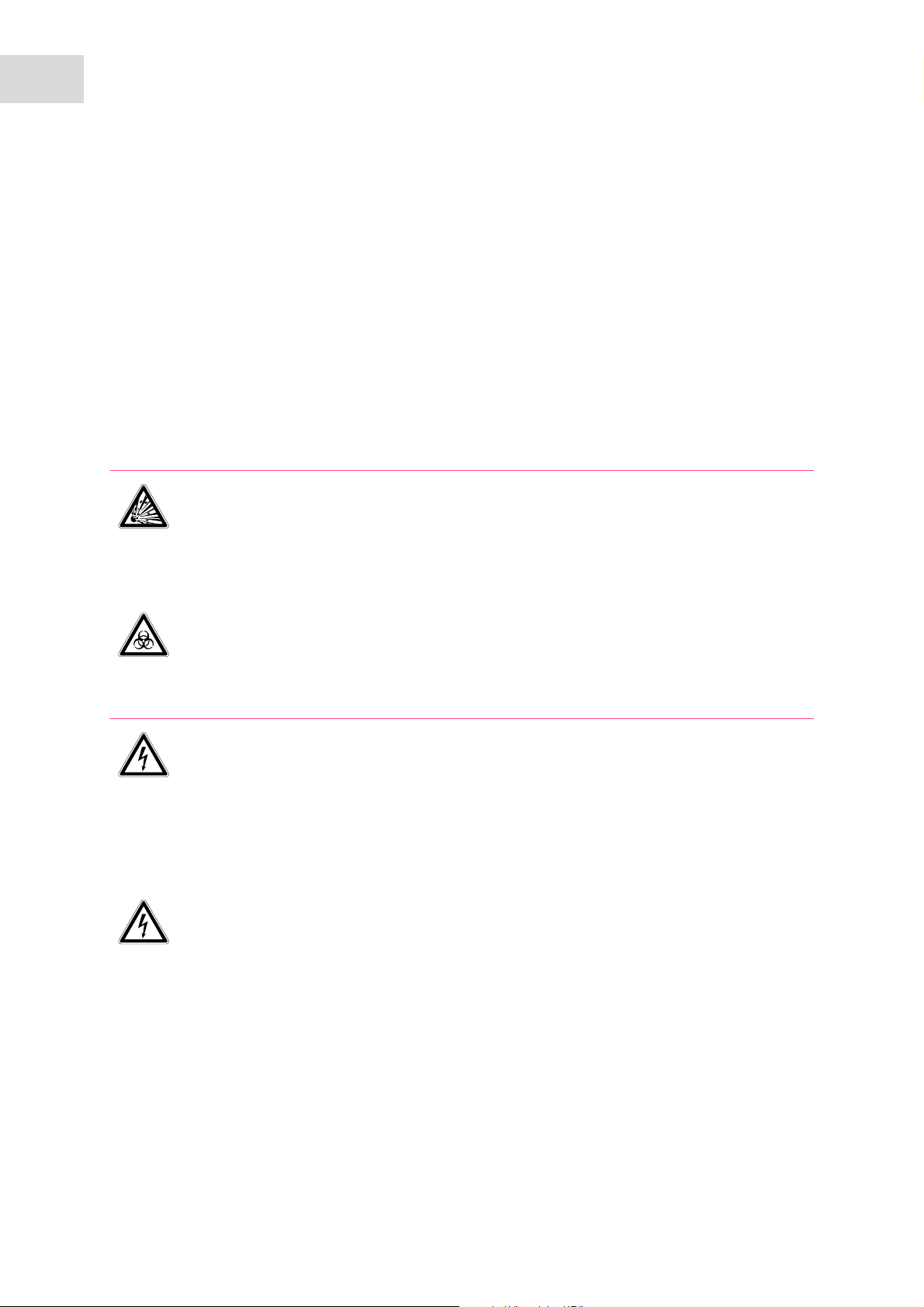

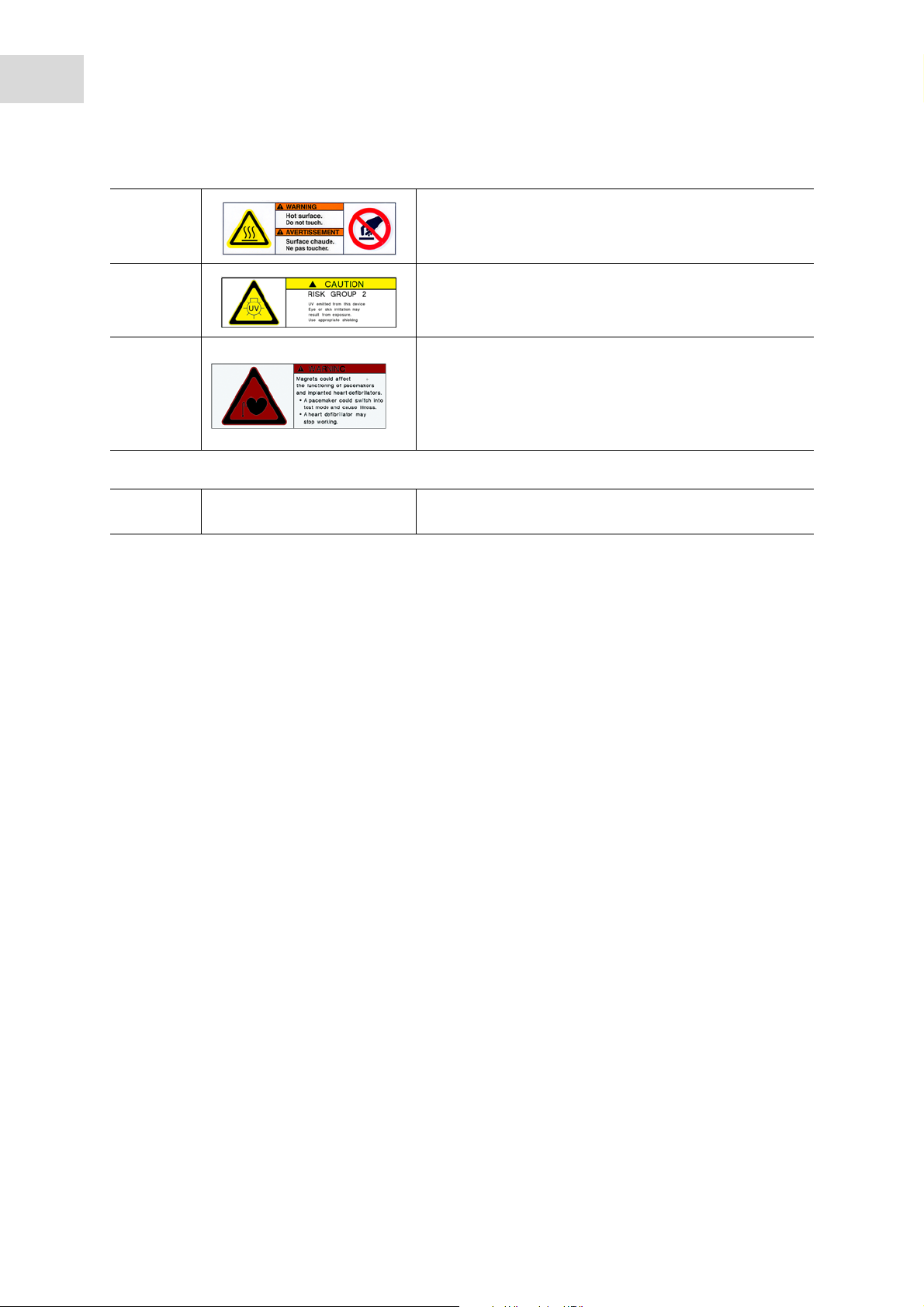

3.5 Hazard symbols and safety devices on the device

This section explains the warning symbols on the epMotion and the location of the safety devices.

Abb. 3-1: Hazard symbols on the epMotion 5075

Safety

®

5075

29

Fig. 3-1: Hazard symbols on the epMotion 5075

Tab. 3-1: Hazard symbols

1 WARNING

Observe the operating manual.

2 WARNING

The carrier may continue moving after the front panel has

been opened.

Wait until the carrier stops moving before reaching into

the device.

Page 30

30

Safety

®

epMotion

5075

English (EN)

3DANGER

Risk of burns from the hot surface.

Wait until the surface has cooled before touching it.

5NOTICE

Danger due to UV radiation.

Wear personal protective equipment.

6 The label is located on the magnetic finger module and is

only visible to the service technician.

WARN ING

Danger due to strong magnetic field.

Do not work on the device if you wear a pacemaker.

Tab. 3-2: Safety device

4 The housing protects the user from UV radiation, magnetic

fields, contamination and movable parts.

Page 31

Installation

®

epMotion

English (EN)

5075

4 Installation

4.1 Selecting the location

Information on ambient conditions, dimensions and weights can be found in the technical data (see Weight/

dimensions on p. 111).

Select the location for the device according to the following criteria:

Electrical connections

• Mains connection in accordance with the name plate.

• The device mains/power switch and cutting unit of the power system circuit (e.g., FI protective switch)

can be accessed during operation.

Location

• The ambient conditions match the specifications in the technical data.

• The location is well ventilated.

• The location is protected from direct sunlight.

• The location is not next to heat sources, such as heaters or drier compartments.

• There is an adequate amount of space available for the device. The minimum distances to other devices

and walls is 6 cm.

• The device can be safely and easily operated at this location.

31

Workplace

• The lab bench is permanently mounted.

• The lab bench is designed for the weight of the device.

• The lab bench has a horizontal, plane work surface.

• The lab bench has a non-slip surface.

• The lab bench is vibration-free.

• There are no vibrating devices on the lab bench.

4.2 Installing the device

The epMotion may only be installed and commissioned by skilled personnel authorized by

Eppendorf.

Information on transport (see Transport on p. 109).

Page 32

32

Installation

epMotion

®

English (EN)

5075

Page 33

5Hardware

TM 1

TM 2

TM 3

Waste

A2

T0 T1

T4

T2

T3

A3 A4 A5

B3 B4 B5B2B1B0

C1 C2 C3 C4 C5

TM 1

TM 2

TMX

Waste

A2

T0 T1

T4

T2

T3

A3

A4 A5

B3 B4 B5B2B1B0

C1 C2 C3 C4 C5

5.1 Worktable

5.1.1 Layout of the epMotion 5075I worktable

Abb. 5-1: Worktable for epMotion 5075I

Hardware

epMotion

English (EN)

®

5075

33

Fig. 5-1: Worktable for epMotion 5075I

A2-C5

T0

Locations for labware

C1-C3

Waste

With up to 3 thermal modules as an optional

feature

T1-T4

Locations for dispensing tools

5.1.2 Layout of the epMotion 5075t worktable

Abb. 5-2: Worktable for epMotion 5075t

With a gripper as an optional feature

Location for waste container

Fig. 5-2: Worktable for epMotion 5075t

A2-C5

Locations for labware

C1-C2

With 2 thermal modules as an optional feature

A4

Thermomixer

T1-T4

Locations for dispensing tools

T0

With a gripper as an optional feature

Waste

Location for waste container

Page 34

34

TM 1

TM 2

TM 3

VAC

Waste

A2

T0 T1

T4

T2

T3

A3 A4

B4

B3B2B1B0

C1 C2 C3 C4

TM 1

TM 2

TMX

Waste

A2

T0 T1

T4

T2

T3

A3

A4

B3B2B1B0

C1 C2 C3 C4

VAC

B4

Hardware

®

epMotion

5075

English (EN)

5.1.3 Layout of the epMotion 5075v worktable

Abb. 5-3: Worktable for epMotion 5075v

Fig. 5-3: Worktable for epMotion 5075v

A2-C5

T1-T4

Locations for labware

C1-C3

T0

With 3 thermal modules as an optional feature

B4

Waste

Vacuum unit

5.1.4 Layout of the epMotion 5075vt worktable

Abb. 5-4: Worktable for epMotion 5075vt

Fig. 5-4: Worktable for epMotion 5075vt

Locations for dispensing tools

Location for gripper

Location for waste container

A2-C5

Locations for labware

C1-C2

With up to 2 thermal modules as an optional

feature

A4

Thermomixer

B4

Vacuum unit

T1-T4

Locations for dispensing tools

T0

Location for gripper

Waste

Location for waste container

Page 35

5.1.5 Layout of the epMotion 5075m worktable

TM 1

TM 2

Waste

A2

T0 T1

T4

T2

T3

A3

A4 A5

B3 B4 B5B2B1B0

C1 C2 C3 C4 C5

TMX

MagSep

Abb. 5-5: Worktable for epMotion 5075m

Fig. 5-5: Worktable for epMotion 5075m

Hardware

epMotion

English (EN)

®

5075

35

A2-C5

Locations for labware

C1-C2

With up to 2 thermal modules as an optional

feature

A4

Thermomixer

MagSep

Magnet finger module

T1-T4

Locations for dispensing tools

T0

With a gripper as an optional feature

Waste

Location for waste container

Page 36

36

Detector

Diaphragm

Z

Z

0

Imaging optics

Light source

Semi-transparent

mirror

Diaphragm

Hardware

®

epMotion

5075

English (EN)

5.2 Optical sensor

Abb. 5-6: Optical sensor principle

Fig. 5-6: Optical sensor principle

On the carrier, the optical sensor is located to the right of the tool holder.

The optical sensor records the intensity of the reflected light using a lateral infrared light source,

semi-transparent mirror, fixed lens and the procedure in z-direction. Height z

is defined as the point with

0

the highest intensity which enables the detection of the level in a vessel or the presence of labware.

The optical sensor can detect horizontal, plane surfaces. The surface of the liquid must be at an angle of

90° ± 3° to the optical axis.

The surfaces of liquids can be strongly bent by the vessel geometry or the physical properties of the liquid

or vessel. The optical sensor may not detect the level on strongly bent surfaces. If this is the case, the user

must enter the liquid volume.

The optical sensor has a detection limit for vessel levels. The detection limit depends on the vessel

geometry. Generally, levels of 3 mm or higher can be detected.

The following functions of the optical sensor can be activated:

• Liquid detection

Determines the filling level for positions of labware, which has the Liquid detection option activated.

• Tip detection

Checks to see if the pipette tips defined in the application are available.

Determines the quantity and position of tips in the rack.

Works only with epT.I.P.S. Motion in TipHolders and Racks from Eppendorf.

• Location detection

Detects the labware coding.

Checks to see if the labware on the epMotion worktable matches the labware on the epBlue worktable.

Information on setting the optical sensor, and a detailed description of all functions, can be

found in the software operating manual.

Page 37

5.3 Thermal module

Based on the model, your epMotion can be equipped with one or more thermal modules.

5.3.1 Safety notes

WARNING! Danger due to flammable or explosive liquids.

Do not use explosive substances.

Do not heat any highly flammable substances.

Heat highly flammable substances in small quantities below boiling point only.

Do not exceed the boiling point of solutions.

CAUTION! Burns from hot metal surfaces.

The metal surface heats up during operation. The software displays the current temperature of

the metal surface.

Hardware

epMotion

English (EN)

®

5075

37

Wait until the metal surface has cooled down completely.

CAUTION! Burns from hot labware.

Labware will be tempered during operation.

Do not touch temperature-controlled labware.

Wait until the labware has cooled down completely.

NOTICE! Material damage due to non-heat-resistant labware.

Samples and labware will become damaged if you do not use heat-resistant labware.

Observe the labware specifications.

At set temperatures in excess of 100 °C, only use labware made of metal, polypropylene

(PP) or polycarbonate (PC).

5.3.2 Configuration

Abb. 5-7: Thermal module

Fig. 5-7: Thermal module

Thermal modules temper liquids in a temperature range of 0 °C – 110 °C.

Page 38

38

Hardware

®

epMotion

5075

English (EN)

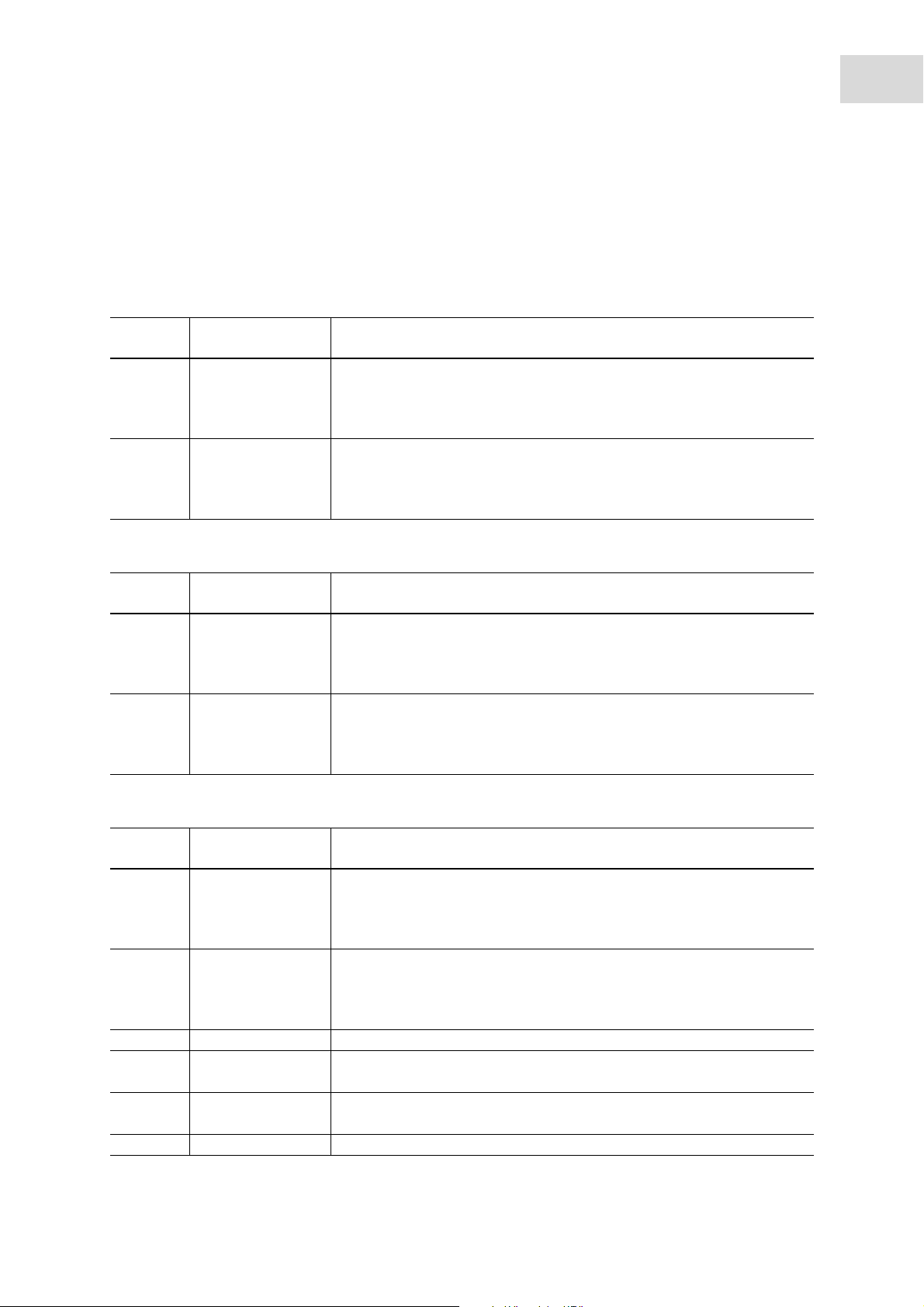

Tab. 5-1: Temperature control duration for labware with thermal module

Labware on the

thermal module

Water filling

volume per well

Cooling from

25°C to 4°C

Heating from

25°C to 37°C

in µL

Temperature

setting in °C

Thermal module

min Temperature

setting in °C

528

without labware

Thermoadapter with

50 3 7 38 5 104 11

96-well twin.tec

PCR plate skirted

Thermoblock with 96-well

50 3 6 37 4 101 10

twin.tec PCR plate skirted

Thermoadapter with

10 3 5 37 5 103 8

384-well twin.tec

PCR plate skirted

Thermoblock with

10 3 5 37 5 98 7

384-well twin.tec

PCR plate skirted

24-unit thermorack with

350 3 24 37 16 101 35

0.5 mL Safe-Lock tubes

24-unit thermorack with

1200 3 30 38 18 104 44

1.5 mL Safe-Lock tubes

24-unit thermorack with

1700 3 25 37 17 100 40

2.0 mL Safe-Lock tubes

Heating from

25°C to 95°C

min Temperature

setting in °C

min

This information applies at an ambient temperature of 25 °C for the border positions in the labware. The

thermal modules were tempered at the target temperature before the labware was positioned.

Information on setting the thermal module and a detailed description of all functions can be

found in the "Operation" chapter of the software instructions.

5.3.3 Equipping the thermal module

When you use a thermoblock or thermoadapter, plates with uneven bases will be optimally tempered, e.g.,

PCR plates.

Equip the thermal module as follows:

1. Place the plate on the thermoadapter or thermoblock.

2. Place the plate, with thermoadapter or thermoblock, on the thermal module.

Page 39

5.4 Thermomixer

Based on the model, your epMotion can be equipped with a thermomixer.

5.4.1 Safety notes

WARNING! Danger due to flammable or explosive liquids.

Do not use explosive substances.

Do not heat any highly flammable substances.

Heat highly flammable substances in small quantities below boiling point only.

Do not exceed the boiling point of solutions.

CAUTION! Burns from hot metal surfaces.

The metal surface heats up during operation. The software displays the current temperature of

the metal surface.

Hardware

epMotion

English (EN)

®

5075

39

Wait until the metal surface has cooled down completely.

CAUTION! Burns from hot labware.

Labware will be tempered during operation.

Do not touch temperature-controlled labware.

Wait until the labware has cooled down completely.

NOTICE! Contamination of samples and the device due to high mixing frequency.

If the speed is set too high, liquid will spray out of the vessels. Labware may become loose

from the holder and fly around.

Observe the maximum speeds of the labware in the operating instructions.

5.4.2 Configuration

Abb. 5-8: Thermomixer

Fig. 5-8: Thermomixer

The thermomixer tempers and mixes liquids and suspensions.

Page 40

40

Hardware

®

epMotion

5075

English (EN)

The thermomixer works in a temperature range of 4 °C – 95 °C. The lowest temperature the thermomixer

reaches is 15 °C below ambient temperature. If the ambient temperature is 20 °C, the thermomixer reaches

at least 5 °C.

Tab. 5-2: Maximum speed for labware on the thermomixer

Labware Maximum speed in rpm

Tubes 1000

DWP 96 1200

DWP 384 1200

MTP 6 1000

MTP 96 2000

MTP 384 2000

PCR 96 2000

PCR 384 2000

Reservoir Rack Cannot be mixed

Thermorack/Thermoblock 1000

Thermoadapter 96 1000

Thermoadapter 384 1000

Thermorack TMX 1300

PrepRack 1300

Information on setting the thermomixer, and a detailed description of all functions, can be

found in the software instructions.

5.4.3 Equipping the thermomixer

When you use a thermoblock or thermoadapter, plates with uneven bases will be optimally tempered, e.g.,

PCR plates.

Equip the thermomixer as follows:

1. Place the plate on the thermoadapter or thermoblock.

2. Place the plate, with thermoadapter or thermoblock, on the thermomixer.

The plate will be fastened to the thermomixer during the application.

Page 41

5.5 Magnet finger module

Based on the model, your epMotion can be equipped with a magnet finger module.

5.5.1 Configuration

Abb. 5-9: Magnet finger module

Hardware

epMotion

English (EN)

®

5075

41

Fig. 5-9: Magnet finger module

The magnet finger module is located behind the thermomixer.

The magnet finger module is used to separate suspended magnetic particles.

The magnet finger module has 3 fingers that can be moved horizontally. Strong permanent magnets are

located on each finger. The 3 magnet fingers move toward the vessels via the lateral openings in the

PrepRack. The magnetic field separates the magnetic particles on the tube inner wall. The dispensing tool

can remove liquid from the vessels, or dispenses liquid in the vessels, while the magnetic particles are held

in place.

The PrepRack is required to perform a separation (see p. 74).

The separation period can be defined using the epMotion software.

For a full nucleic acid purification, you can use the MagSep kits supplied by Eppendorf AG.

5.5.2 Equipping the magnet finger module

The geometry of the used vessels is important for the quality of the separation. Use 2.0 mL

Safe-Lock tubes.

Equip the magnet finger module as follows:

1. Equip the PrepRack with vessels.

2. Place the equipped PrepRack on the thermomixer.

The PrepRack will be fastened on the thermomixer when the application is started.

Page 42

42

Hardware

®

epMotion

5075

English (EN)

5.6 Vacuum unit

Abb. 5-10: Vacuum unit with vacuum frame

Fig. 5-10: Vacuum unit with vacuum frame

The vacuum unit uses a vacuum to suck liquid from a filter plate into a collection vessel. The vacuum is set

via the software and generated by a vacuum pump. The vacuum unit consists of a vacuum chamber,

vacuum pump and vacuum frame and a lid.

You can use the following labware as collection vessels:

•Micro test plate (MTP)

• Deepwell plate (DWP)

•Tube plate

• 400 mL reservoir

• 300 mL reservoir

The gripper places filter plates, VAC Lid and Vac Thermo Lid on the vacuum frame. The gripper transports

the vacuum frame with the attached filter plate.

5.6.1 Vac Frame vacuum frame

Abb. 5-11: VAC Frame 1

Fig. 5-11: VAC Frame 1

The vacuum frame is placed on the vacuum unit. The filter plate is positioned on the vacuum frame.

The frame of the plate must sit on top of the VAC Frame rubber. Otherwise, a vacuum cannot be created.

The Vac Frame is available in 2 different heights for this.

The vacuum frame is positioned on the vacuum unit or on the vacuum holder. The vacuum frame cannot be

positioned directly on the worktable.

The vacuum frame is transported with the gripper.

Page 43

5.6.2 VAC Lid

1

2

3

Abb. 5-12: VAC Lid

Fig. 5-12: VAC Lid

Hardware

epMotion

English (EN)

®

5075

43

1VAC Lid

3Pins

2Silicone mat

Use the VAC Lid if do not want to apply the vacuum to the entire plate. Place the VAC Lid on the vacuum

unit and cover any bores that are not required with the silicone mat. The VAC Lid contains 96 bores. The

bores correspond to the positions of the wells on the filter plate.

The VAC Lid is positioned on the vacuum unit or on the gripper holder.

The VAC Lid is transported with the gripper.

5.6.3 Silicone mat for VAC Lid

Abb. 5-13: Bores in the VAC Lid covered with silicone mat

Fig. 5-13: Bores in the VAC Lid covered with silicone mat

If you are not using some of the filter plate wells you can cover the corresponding bores in the VAC Lid with

a silicone mat. The air does not flow through the covered bores. The vacuum only affects the wells that are

in use.

Silicone mats are available in different sizes. You can cover 16, 32, 48, 64 or 80 bores with the silicone mat.

The silicone mat has the number of bores it covers punched into it.

To attach a silicone mat on the VAC Lid, place the silicone mat on the pins of the VAC Lid.

Page 44

44

Hardware

®

epMotion

5075

English (EN)

5.6.4 Vac Thermo Lid

Abb. 5-14: VAC Thermo Lid

Fig. 5-14: VAC Thermo Lid

The Vac Thermo Lid has a block with a high heat capacity. The Vac Thermo Lid is heated on a thermal

module. On the vacuum unit, air is sucked in through the slits in the Vac Thermo Lid. The air heats up on

the block and flows through the filter plates.

With the Vac Thermo Lid, you can optimize automated nucleic acid preparation. You can minimize the

alcohol in filter plates, the risk of contamination from alcohol is reduced.

The Vac Thermo Lid can be placed on a thermal module and on the vacuum unit.

The gripper transports the Vac Thermo Lid.

The Vac Thermo Lid cannot be placed on the thermomixer.

5.6.4.1 Using the Vac Thermo Lid

CAUTION! Burns from the hot base of the Vac Thermo Lid.

When you temper the Vac Thermo Lid, its base becomes hot.

Wait until the base of the Vac Thermo Lid has cooled down completely.

1. Place the Vac Thermo Lid on a thermal module.

Do not place a reservoir rack with reservoirs in the transport route of the Vac Thermo Lid.

Reservoir racks with reservoirs collide with the VAC Thermo Lid on the gripper.

2. Heat the Vac Thermo Lid to the required temperature before starting the application.