Page 1

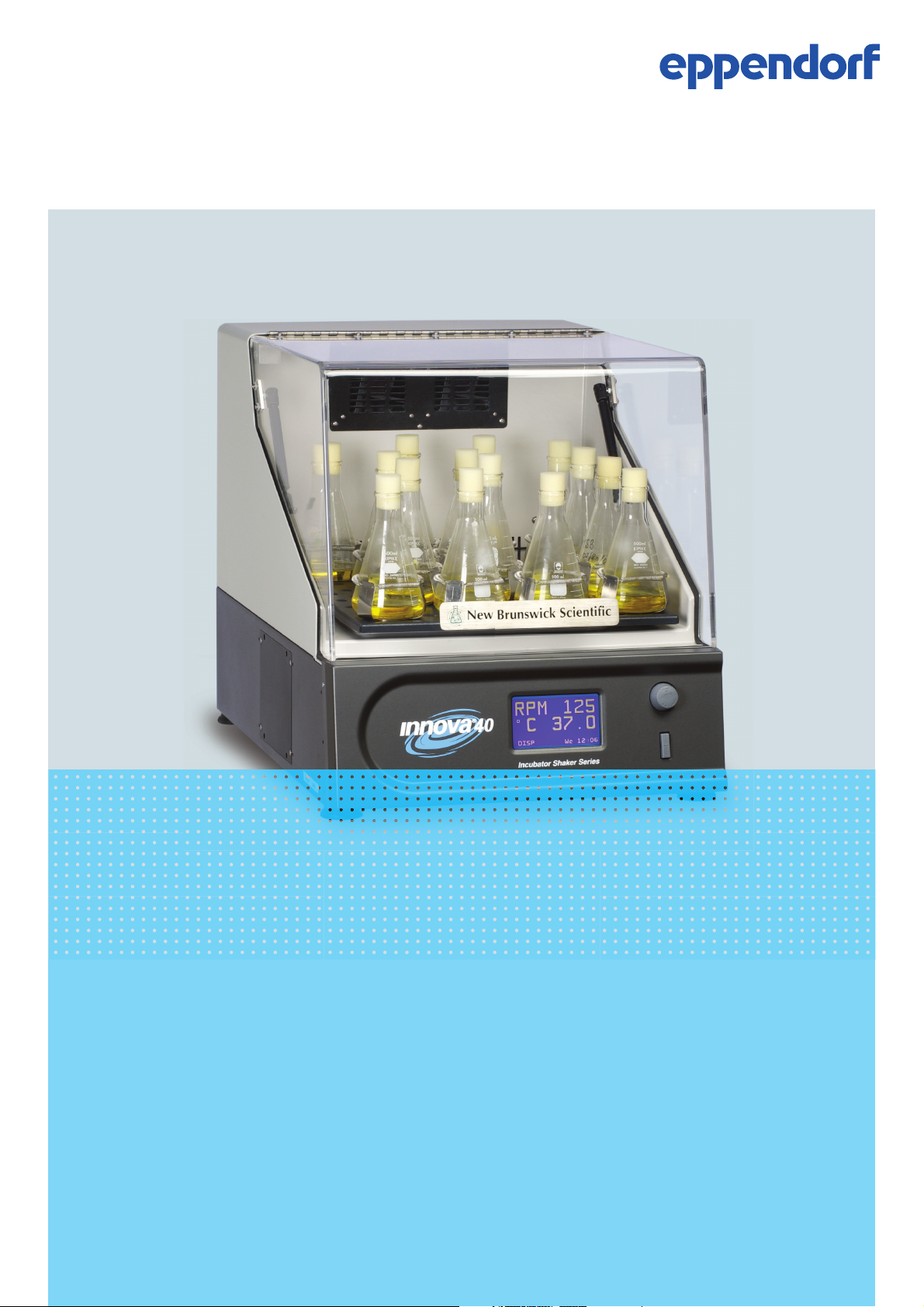

New Brunswick™ Innova®

40/40R Shaker

Operating manual

Page 2

Copyright © 2013 Eppendorf AG, Germany. No part of this publication may be reproduced without the

prior permission of the copyright owner.

®

Eppendorf

and the Eppendorf logo are registered trademarks of Eppendorf AG, Germany.

New Brunswick™ and the New Brunswick

®

Innova

is a registered trademark of New Brunswick Scientific Co., Inc., USA.

™

logo are trademarks of Eppendorf AG, Germany.

Trademarks are not marked in all cases with ™ or

®

in this manual.

M1299-0051-E/062013

Page 3

Table of contents

New Brunswick Innova 40/40R Shaker

English (EN)

Operating manualDraftNew Brunswick Innova 40/40R Shakerseeon p.Fig.Tab.p.

English (EN)Operating manual

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.1 Hazard icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2.2 Degrees of danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Delivery package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Software interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Drip pan resevoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.8 Remote alarm (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3

3 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Safety precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Selecting the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Install the platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Install flask clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Connecting to mains/power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Overview of operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Powering on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Changing screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.1 Screen names and descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4.2 Choose screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Opening the lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 Display Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6.1 Changing displayed parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6.2 Viewing the setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.6.3 Changing the setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.7 Summary screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.7.1 Changing setpoint values in the summary screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8 Setup screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8.1 Changing the day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8.2 Changing the time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8.3 To lock the settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8.4 To mute the audible alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.9 RS-232 screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 4

Table of contents

New Brunswick Innova 40/40R Shaker

4

English (EN)

5.9.1 Changing the communication mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.9.2 Changing the baud rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.10 Calibrate screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.10.1 Temperature offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.10.2 Calculating the temperature offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.10.3 Creating the temperature offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.10.4 Calibrating the shaking speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

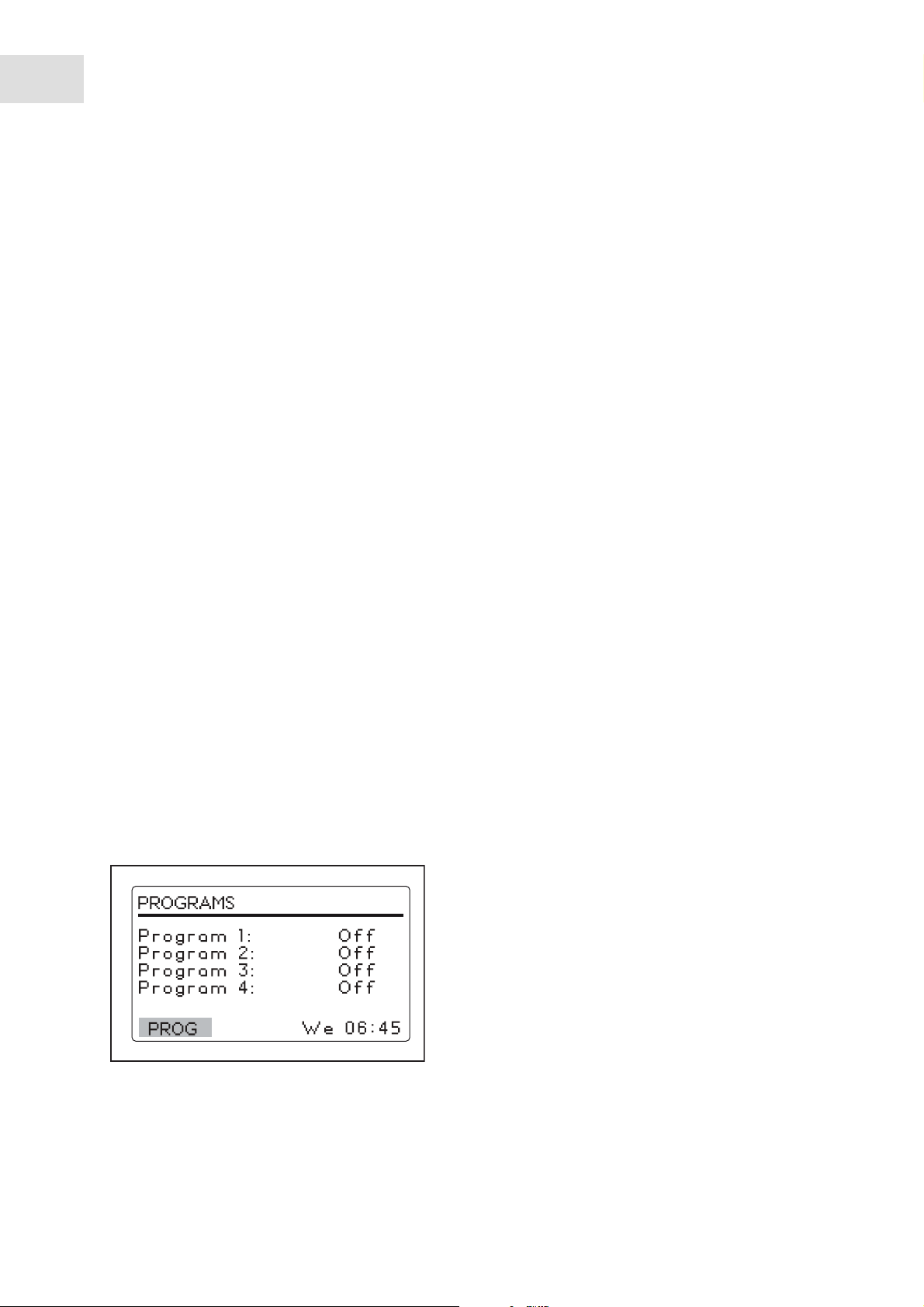

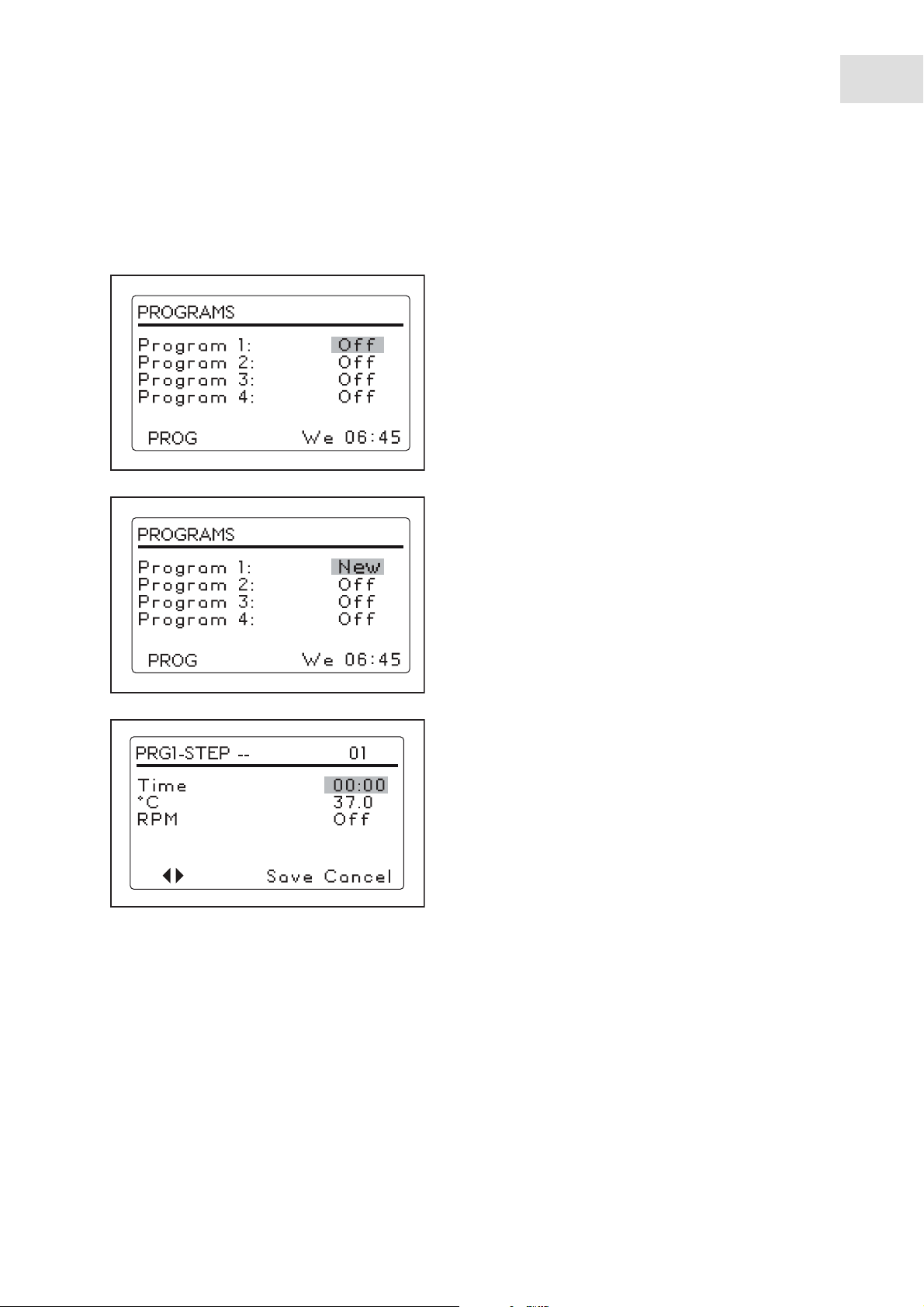

5.11 Programs screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.11.1 Create a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.11.2 Save the program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.11.3 Edit a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.11.4 Run and stop a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.12 Program the timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.13 Power interruption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 Remote programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Connecting to a computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1.1 Setting up serial connection with HyperTerminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1.2 Testing the connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Sending commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2.1 Example: Commanding set speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2.2 Example: Requesting measured values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.3 Set Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Program control commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.5 Report request commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.6 Set/Get date and time commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6.1 Example: Viewing date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6.2 Example: Programming date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.7 Index to command codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1 Routine maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2 Cleaning external and internal surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.3 Biohazard decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

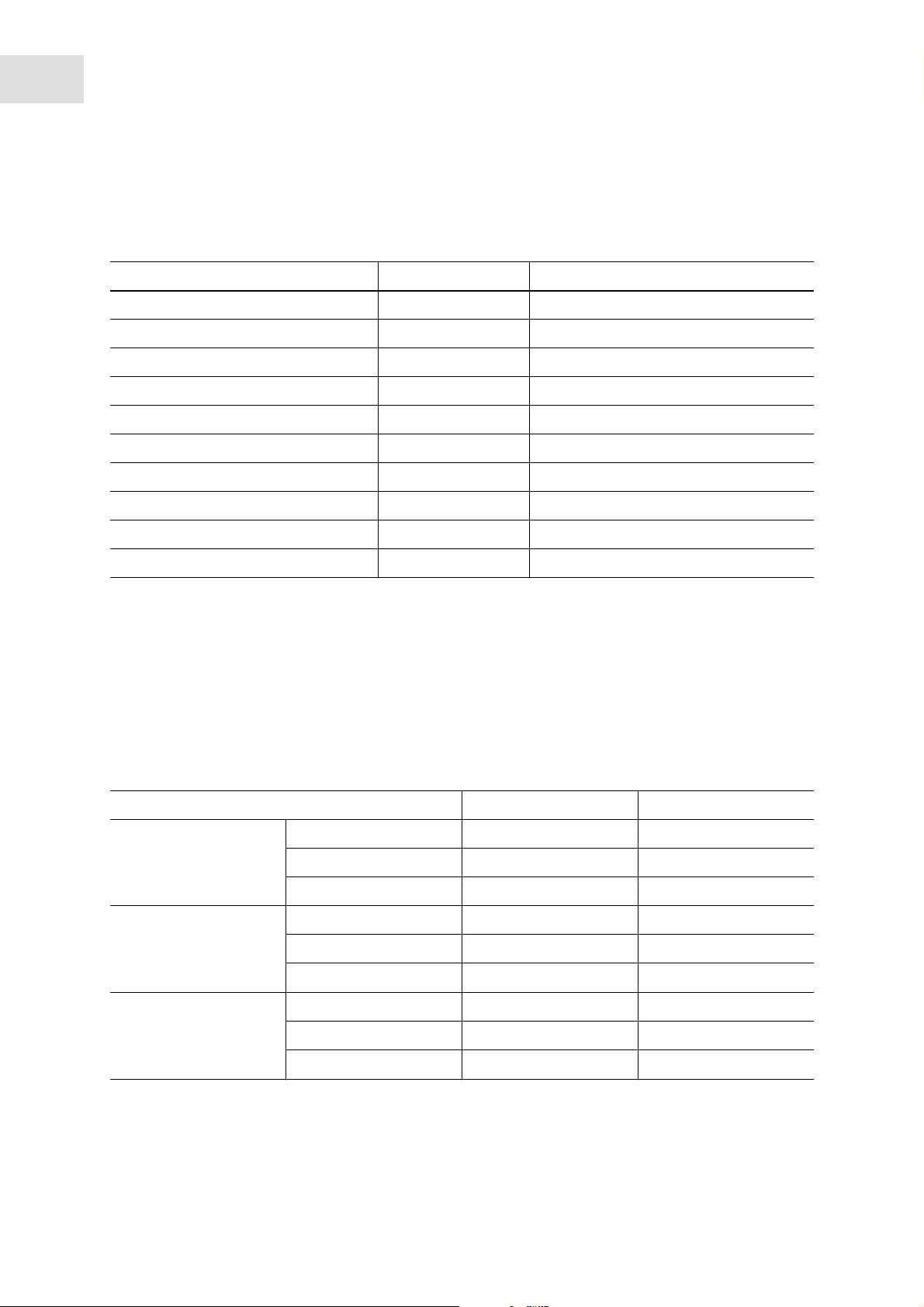

9.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.1 Shaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.2 Temperature system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.1.4 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.5 Dimensions and weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.6 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.7 Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.8 RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.1.9 ETL regulatory standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.1.10 CE regulatory standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 5

Table of contents

New Brunswick Innova 40/40R Shaker

English (EN)

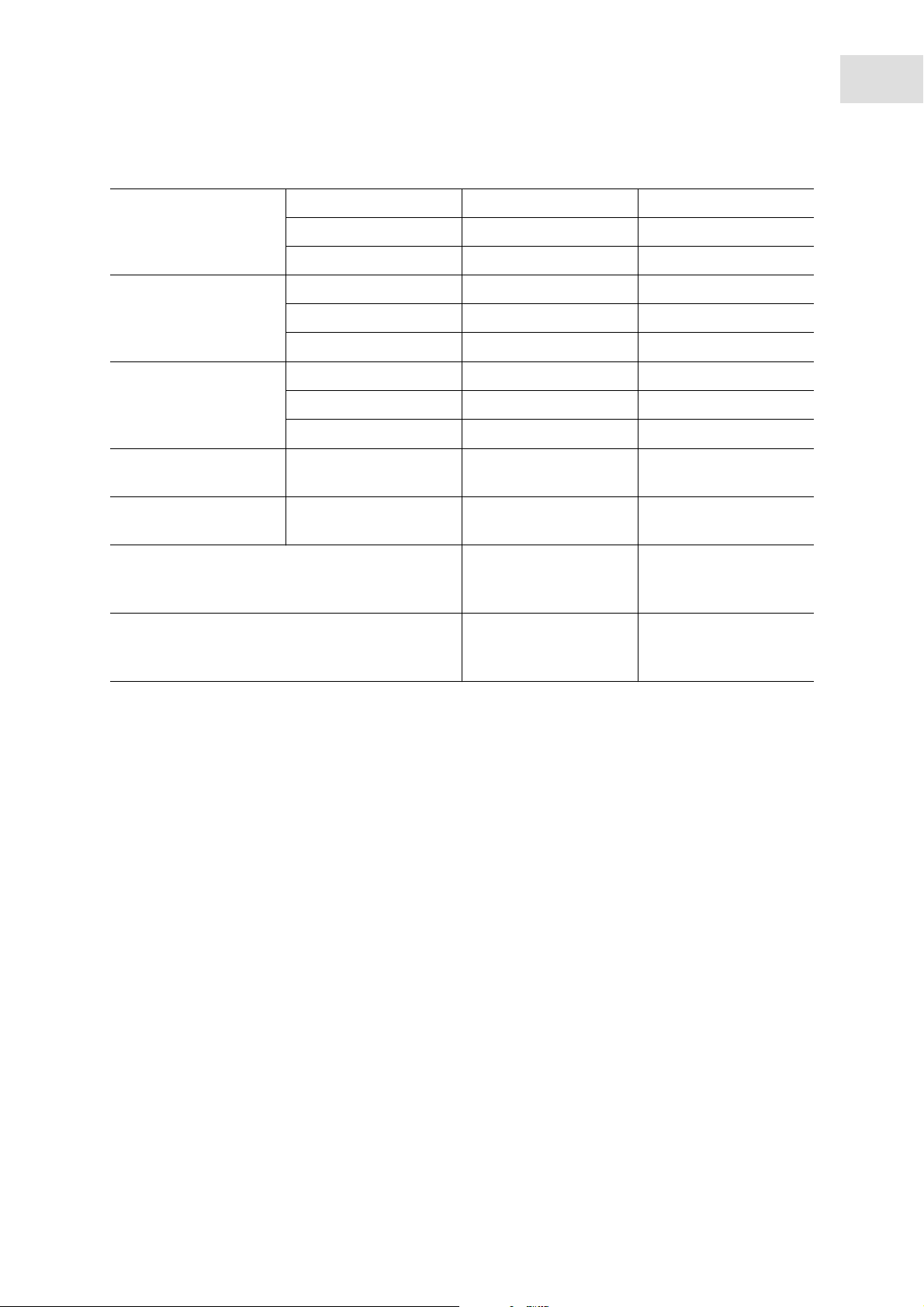

10 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.1 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.2.1 Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10.2.2 Replacement clamp hardware kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10.2.3 Test tube racks and other accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

11 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

11.1 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

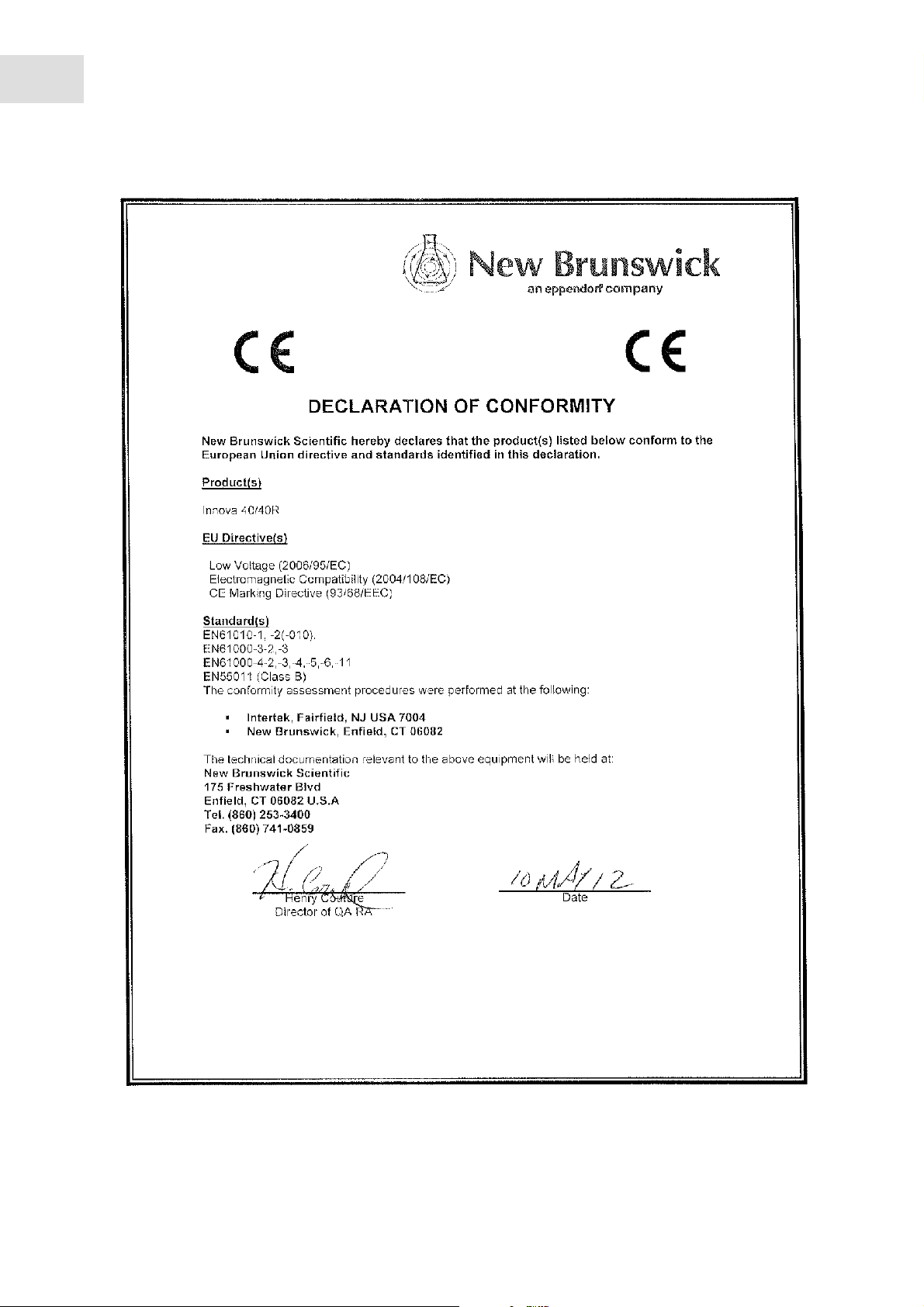

12 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5

Page 6

Table of contents

New Brunswick Innova 40/40R Shaker

6

English (EN)

Page 7

Operating instructions

New Brunswick Innova 40/40R Shaker

English (EN)

1 Operating instructions

1.1 Using this manual

Carefully read this operating manual before using the device for the first time.

Also observe the operating manual enclosed with the accessories.

The operating manual should be considered as part of the product and stored in a location that is easily

accessible.

When passing the device on to third parties, be sure to include this operating manual.

If this manual is lost, please request another one. The latest version can be found on our website

www.eppendorf.com (international) or www.eppendorfna.com (North America).

1.2 Danger symbols and danger levels

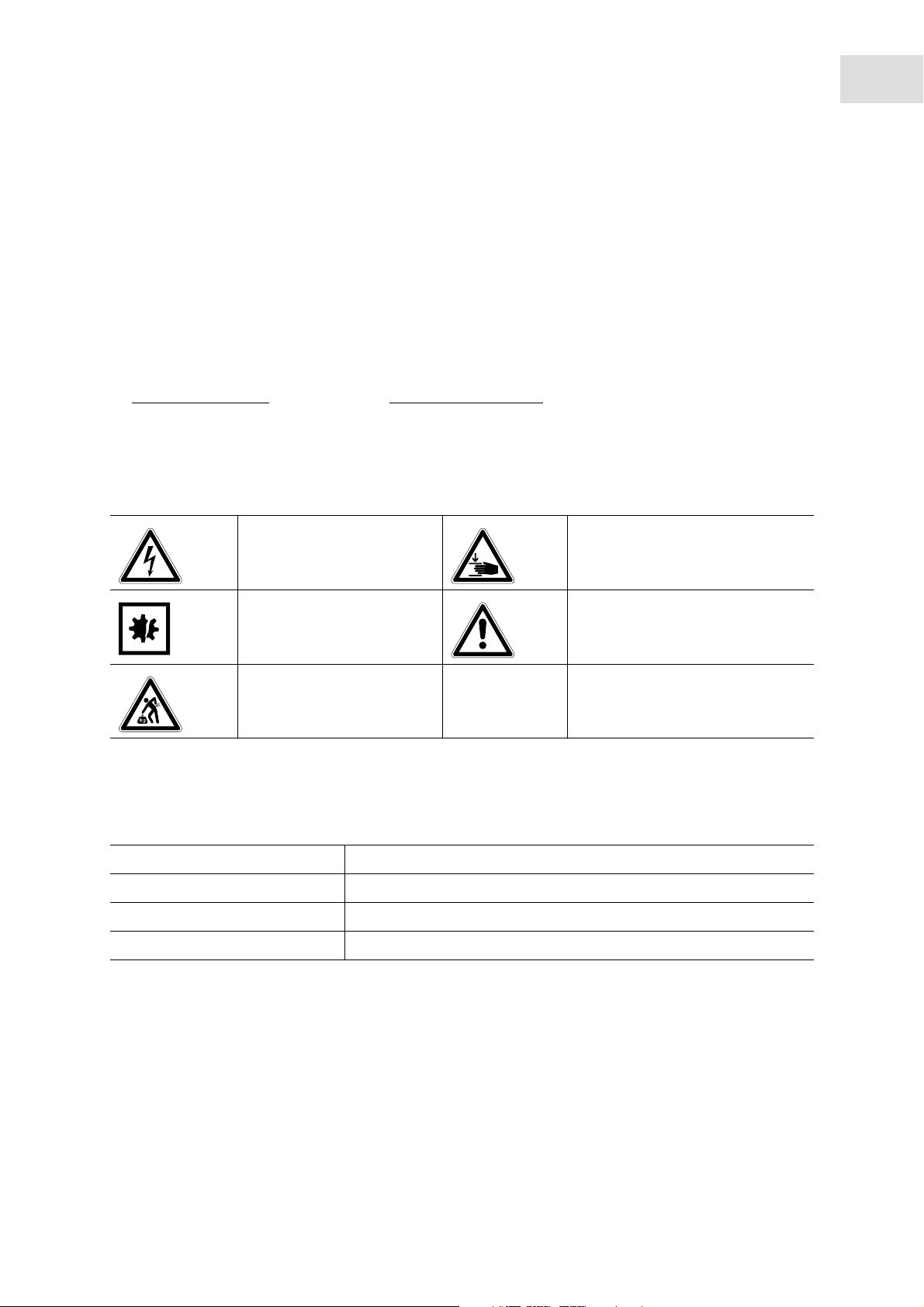

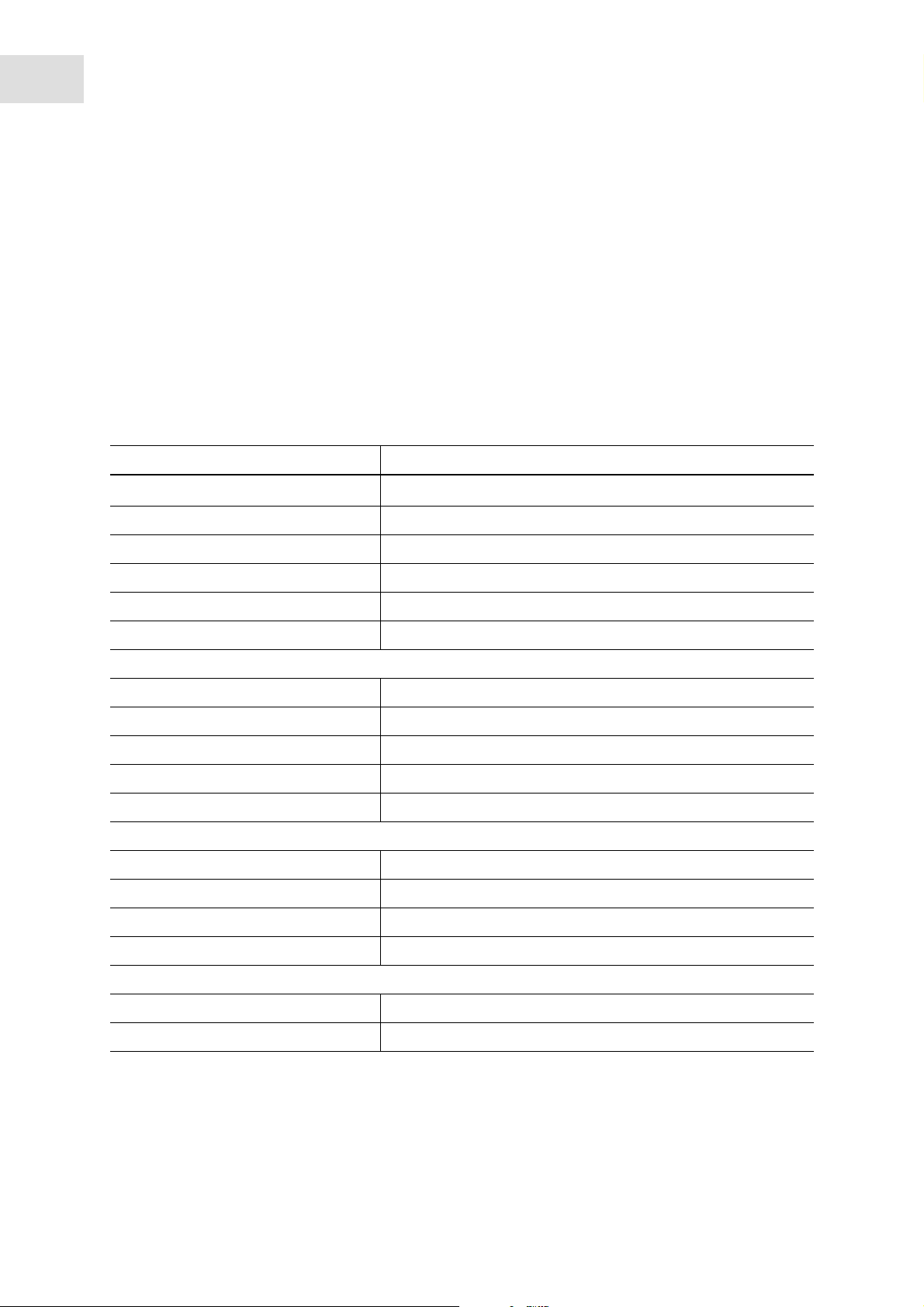

1.2.1 Hazard icons

7

Electric shock Crushing

Material damage Hazard point

Heavy loads

1.2.2 Degrees of danger

The following danger levels are used in safety messages throughout this manual.

DANGER Will lead to severe injuries or death.

WARNING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

Page 8

Operating instructions

New Brunswick Innova 40/40R Shaker

8

English (EN)

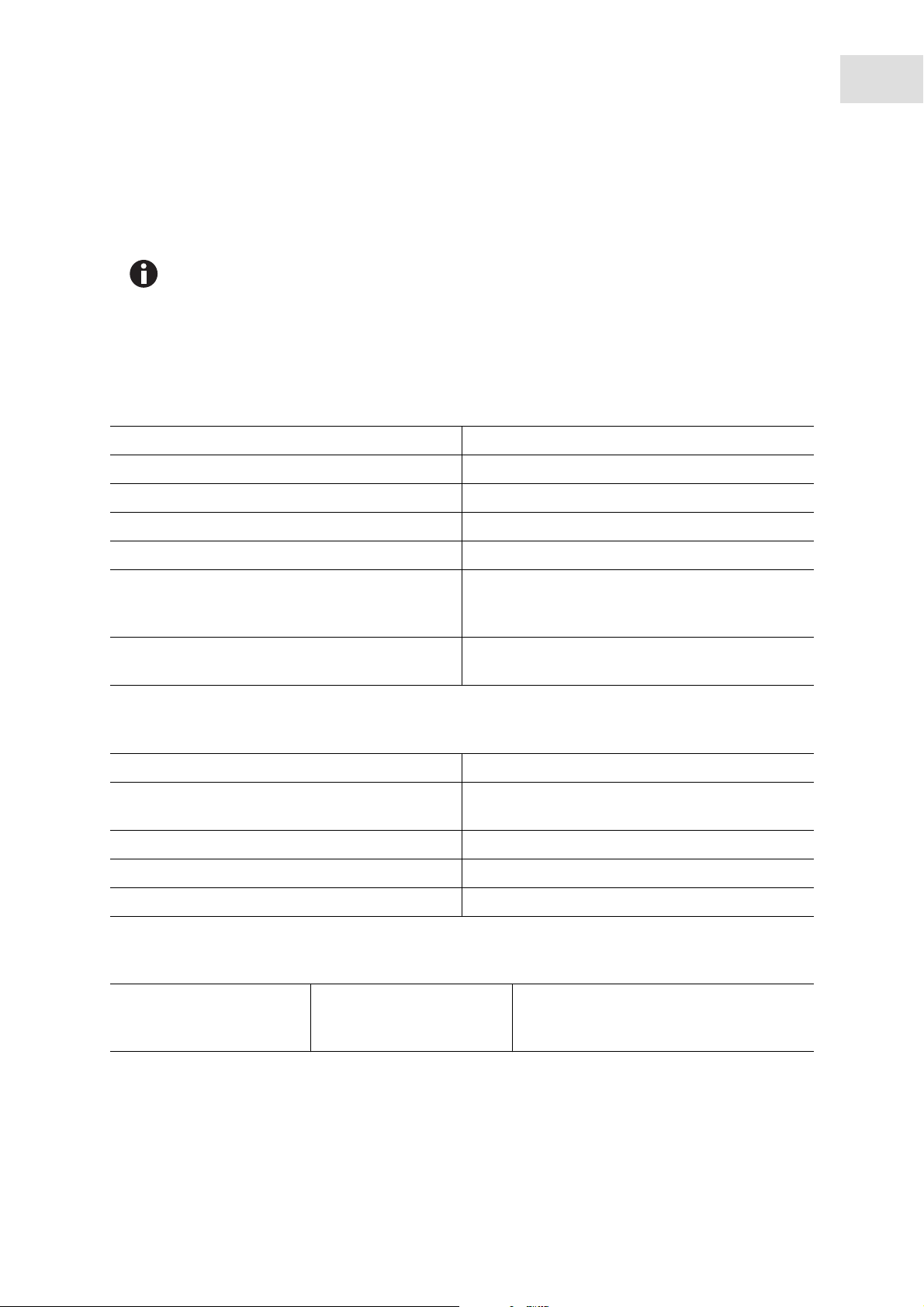

1.3 Symbols used

Example Meaning

You are requested to perform an action.

1.

2.

• List.

Perform these actions in the sequence described.

References useful information.

Page 9

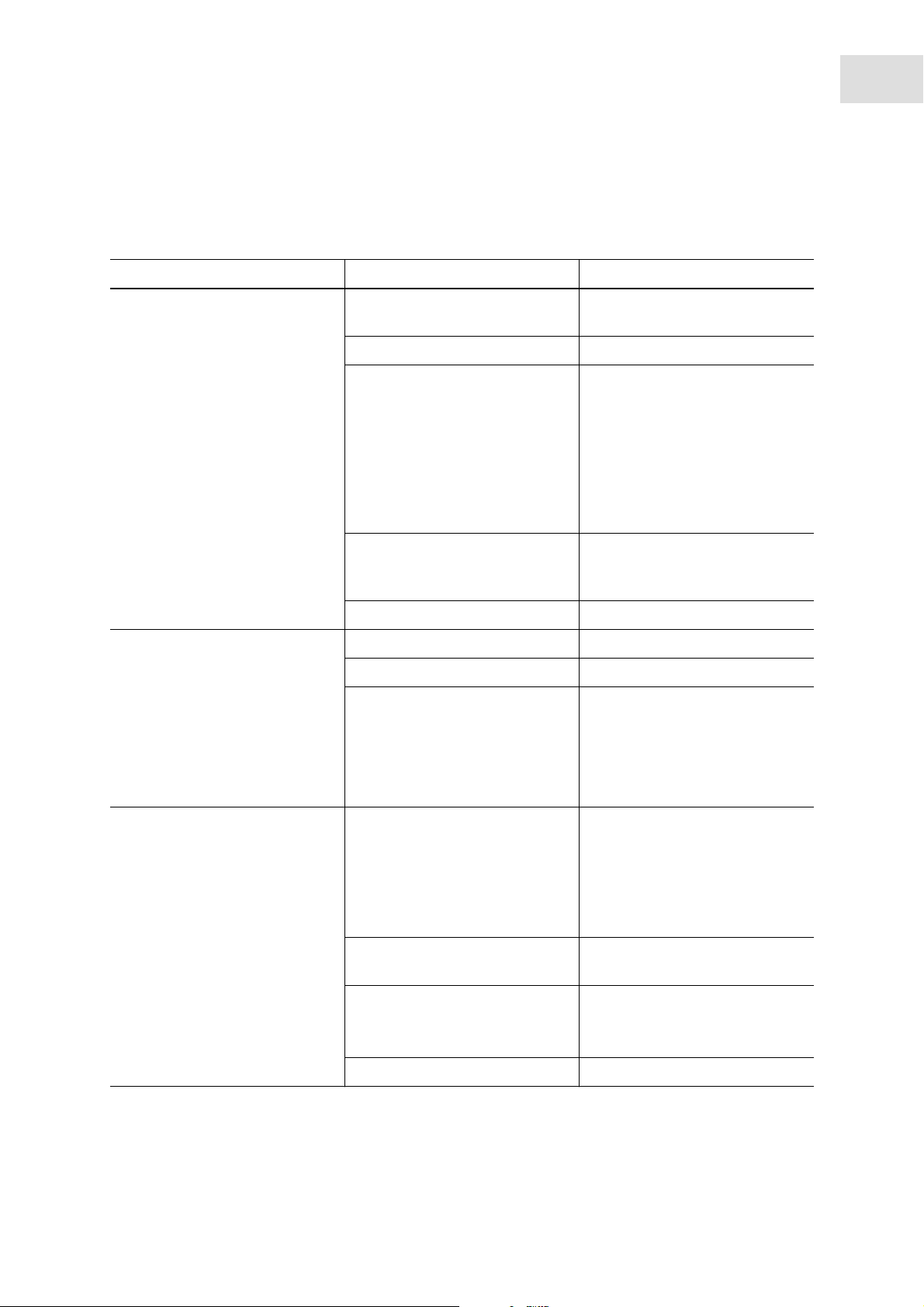

2 Product description

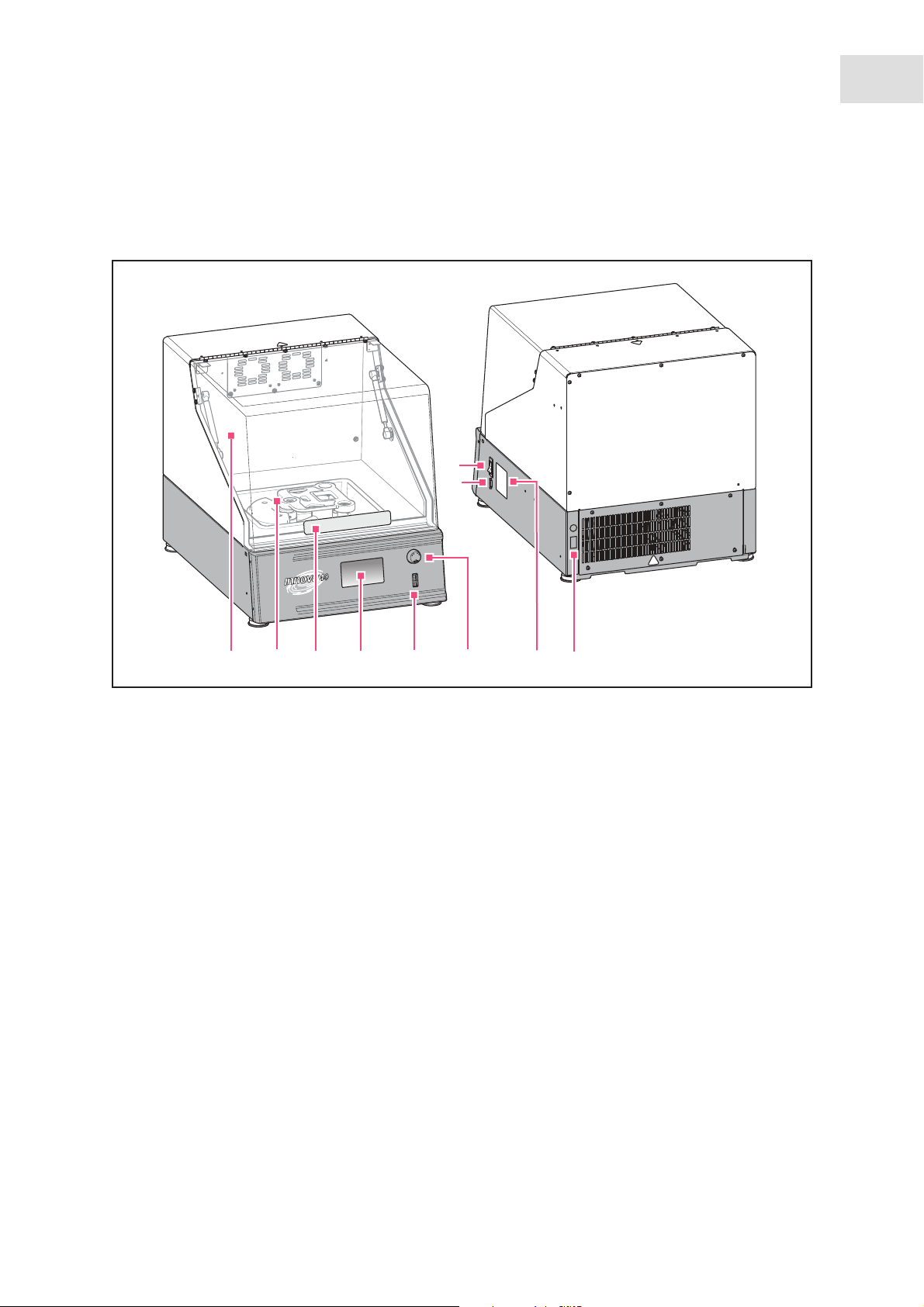

2.1 Main illustration

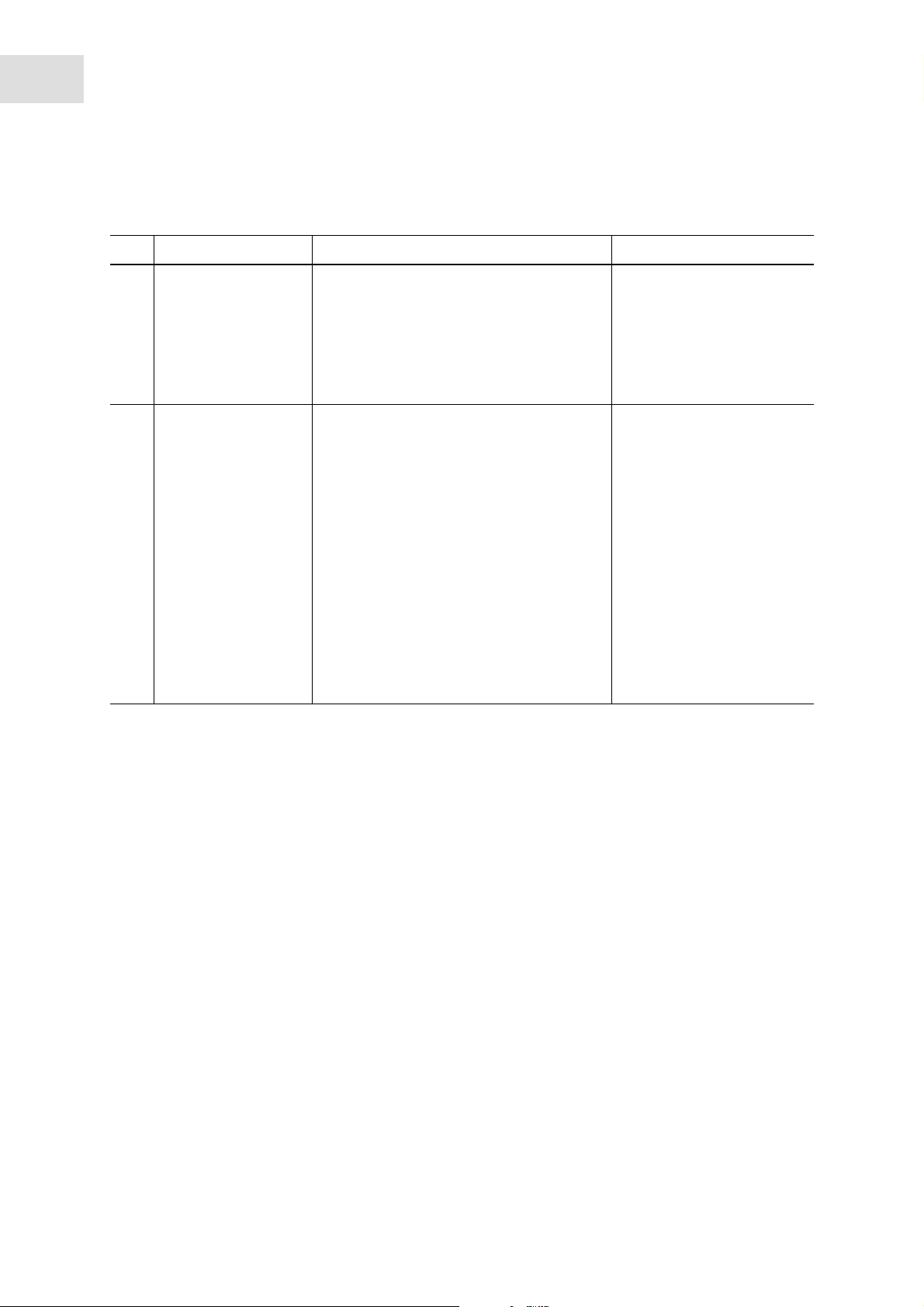

Abb. 2-1: Front and rear view of the New Brunswick Innova 40/40R Shaker

Product description

New Brunswick Innova 40/40R Shaker

9

English (EN)

7

8

SELECT

Incubator Shaker Series

2

1

3

4

5

6

9

10

Fig. 2-1: Front and rear view of the New Brunswick Innova 40/40R Shaker

1 Lid

With automatic stop function

2 Drive

Triple eccentric drive - orbit is model-dependent

3 Lid handle

4 Display

Graphical user interface with display of

parameters and parameter values

5 Start/Stop switch

Starts and stops shaking

6 Control knob

Changes screens and selects operating conditions

7 Mains/Power switch

Switch device on or off (circuit breaker that turns

power on and off to the entire device)

8 RS-232 interface

Read out parameter values and control

operational functions using computer

applications or also used to connect to

BioCommand SFI

9 Name plate

Model number, documentation number, serial

number and electrical connection data

10 Mains/Power connection

Connect the power cable

Page 10

10

Product description

New Brunswick Innova 40/40R Shaker

English (EN)

2.2 Delivery package

NOTE: Use of the Innova 40/40R Shaker requires a platform, which is a separate item (see Platforms on

p. 53).

WARNING! Shaker is very heavy!

Do not attempt to lift the Innova 40/40R Shaker by yourself.

Always ask for assistance or use a lifter or other suitable equipment when raising or

handling the unit.

Check the delivery package for completeness.

Check all parts for damage in transit.

Retain the shipping box and packing material for subsequent storage or transport of the

device.

2.3 Features

The Innova 40/40R Shaker is a bench top orbital shaker that uses a triple eccentric counterbalanced drive

mechanism.

Operation

The Innova 40/40R Shaker may be operated in the following ways:

• Continuously: at a set speed and temperature, until user stops device.

• Timed mode: run at a set speed, time, and temperature, after which the shaker automatically shuts off.

• Shaker's programmable controller: run through multiple temperature and speed changes for an extended

period of time.

• Computer through an RS-232 interface.

Orbit

• Horizontal plane rotary motion.

• Available in 1.9 cm (3/4 in) or 2.5 cm (1 in) diameter circular orbit.

Refrigeration (Innova 40R only)

The refrigeration system in the Innova 40R is a variable-capacity system designed with self-checks to

maintain the setpoint, to balance pressure within the system, and to keep the evaporator from freezing.

When the shaker is powered up, there is a 4 min time delay prior to compressor start-up.

Page 11

Product description

New Brunswick Innova 40/40R Shaker

English (EN)

Temperature control

Ambient temperature is measured at 1 M from the exterior of the unit.

• Innova 40R provides temperature control from 15 °C below ambient temperature to 80 °C with a

minimum setpoint of 4 °C.

• Innova 40 provides temperature control from 5 °C above ambient temperature to 80 °C.

Both these ranges depend on relative humidity and other ambient factors, as well as the options installed

on the device.

Safety

• Drive Interrupt shuts off power to shaker when lid opens.

• Acceleration/deceleration circuit prevents sudden starts and stops, minimizing both splashing and

mechanical damage.

• Independent mechanical sensing switch also shuts the motor off in unbalanced condition.

11

Alarms

Innova 40/40R Shaker is equipped with visual and audible alarms that alert the user to the following

conditions:

• The end of a timed run.

• Deviations from speed setpoint.

• Deviations from temperature setpoint.

• Power failure.

• Lid is open.

Platforms

To accommodate customer needs, a wide variety of platforms can be used with the Innova 40/40R Shaker

(see Platforms on p. 53):

• Universal platforms are the most flexible, providing hole patterns for flask clamps, test tube racks and

other accessories.

• Dedicated platforms are supplied with 1 size flask clamps attached.

Flasks/Tubes

Erlenmeyer flasks (up to 3 L), and a wide variety of tubes and plates can be accommodated using the New

Brunswick shaker accessories (see Accessories on p. 53).

Other accessories

Test tube racks, microplate holders, and test tube rack holders as well as sticky pads and stick tape are also

available (a universal platform is needed for all test tube racks and holders) (see Accessories on p. 53).

Page 12

12

Product description

New Brunswick Innova 40/40R Shaker

English (EN)

2.4 Software interfaces

The RS-232 port is located below the Mains/Power switch on the right side of the control panel. It can be

used to connect a computer to the shaker for control of operating conditions or data logging

applications (see Remote programming on p. 37).

The customer is responsible for securing the proper driver to interface with the RS-232.

2.5 Drip pan resevoir

The Innova 40/40R Shaker is equipped with a plastic liner to protect the electronics and temperature

controls. An optional drip pan (part number M1250-9906) is recommended to protect the drive mechanism

in case of accidental spills and/or broken glassware.

2.6 Heater

Whenever the heater is on, the heater on icon will appear in the display . The heater automatically stops

running when the lid is opened.

The heater has the following features:

• 1000 ohm platinum RTD.

• Pulse width modulation on a 2.5 s duty cycle (this cycle time is fast enough to prevent noticeable

changes in air temperature).

• Long-life, low-watt density resistance-type heater with high temperature thermostat.

2.7 Alarms

If an alarm condition exists, the field in the lower right corner will alternate the day and time with

characters indicating the nature of the alarm condition, accompanied by an audible alarm (unless

muted) (see To mute the audible alarm on p. 29).

Page 13

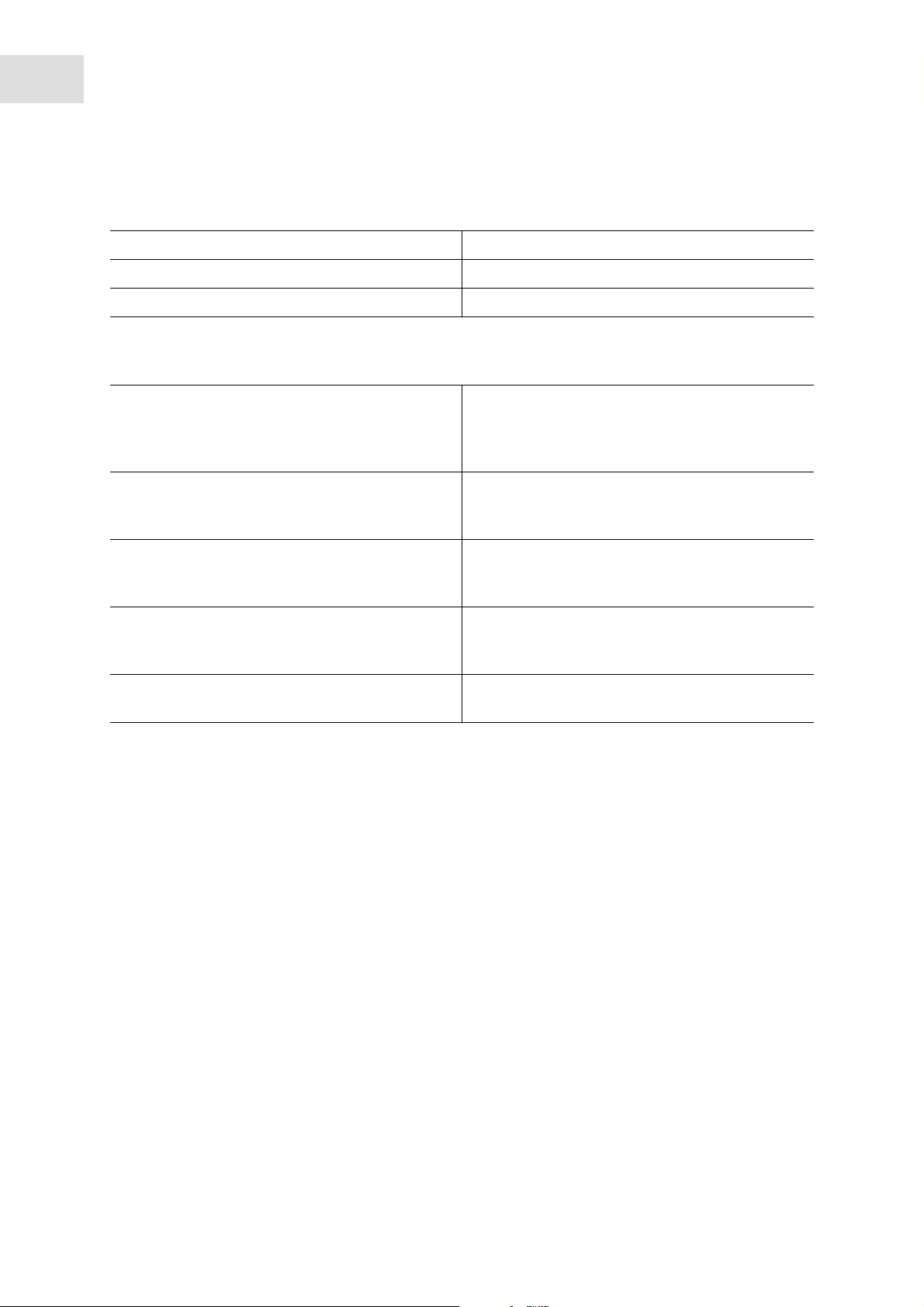

Tab. 2-1: Alarm descriptions

Indication Description

TEMP

RPM

Product description

New Brunswick Innova 40/40R Shaker

English (EN)

• Indicates that the temperature has deviated more than ±1 °C from

setpoint after achieving control temperature range.

• After door is opened, alarm will be disabled for 5 min while chamber

recovers to setpoint.

• Indicates that the speed has deviated more than ±5 rpm from setpoint

after achieving operating speed setpoint.

• After door is opened, alarm will be disabled for 5 min while chamber

recovers to setpoint.

13

POWER

HRS • Indicates when timed run is completed.

• Indicates that the unit is powering up (both at normal power-up and after

power interruption); will flash until the control knob is moved.

2.8 Remote alarm (optional)

The Innova 40/40R Shaker can be equipped with a factory-installed remote alarm component (part number

M1320-8029). When it is hooked up to your relay and receiving equipment, this device will send

notification of an alarm condition to the remote location you choose.

Page 14

14

Product description

New Brunswick Innova 40/40R Shaker

English (EN)

Page 15

Safety

New Brunswick Innova 40/40R Shaker

English (EN)

3 Safety

3.1 User profile

The device may only be operated by trained lab personnel who have carefully read the operating manual

and are familiar with the device functions.

3.2 Safety precautions

Before operating the shaker, verify that anyone involved with its operation has been instructed in both

general safety practices for laboratories and specific safety practices for this apparatus.

• The user is also responsible for following local guidelines for handling hazardous waste and

biohazardous materials that may be generated from the use of this equipment.

15

WARNING! Risk of explosion and injury or death!

Do not use equipment with flammable substances or organisms with flammable

by-products.

NOTICE! Damage to device!

Never run shaker without a platform.

3.3 Warnings for intended use

WARNING! Heavy!

Do not attempt to lift the Innova 40/40R Shaker by yourself.

Ask for assistance or use suitable equipment when raising or handling the device.

WARNING! Risk of electric shock and/or damage to unit!

Check that the voltage and frequency of your unit are compatible with mains/power supply.

Remove caution label from back of unit.

Set the circuit breaker on the right side of the unit to the OFF position.

WARNING! Risk of electric shock and/or damage to device!

Use a grounded power supply.

Page 16

16

Safety

New Brunswick Innova 40/40R Shaker

English (EN)

WARNING! Risk of electric shock and/or damage to the device!

Before cleaning device, turn off and unplug from mains/power supply.

WARNING! Risk of electric shock when replacing fuses!

Turn off shaker and disconnect from mains/power supply.

WARNING! Risk of explosion and injury or death!

Do not use equipment with flammable substances or organisms with flammable

by-products.

WARNING! Injury from hazardous biological material!

Use respiratory protection when cleaning spills where aerosolization is suspected.

Wear gloves, safety glasses, and laboratory coat when cleaning.

NOTICE! Damage to device!

Never run shaker without a platform.

Page 17

Installation

New Brunswick Innova 40/40R Shaker

English (EN)

4 Installation

4.1 Selecting the location

WARNING! Heavy!

Do not attempt to lift the Innova 40/40R Shaker by yourself.

Ask for assistance or use suitable equipment when raising or handling the device.

Select the location for the device according to the following criteria:

• Suitable power connection.

• Access to RS-232 port.

• Surface where you place the device must be smooth, sturdy, and able to accommodate 90 kg (200 lb).

• Ambient temp of 10 °C – 35 °C.

• Relative humidity of 20 % – 80 %.

• Surrounding area must be well ventilated.

• Allow 7.6 cm (3 in) around shaker for ventilation.

17

Ensure there is at least this much space for the Innova 40/40R Shaker:

Space requirements Width: 68.6 cm (27 in)

Depth: 83.2 cm (33 in)

Height: 106.7 cm (42 in)

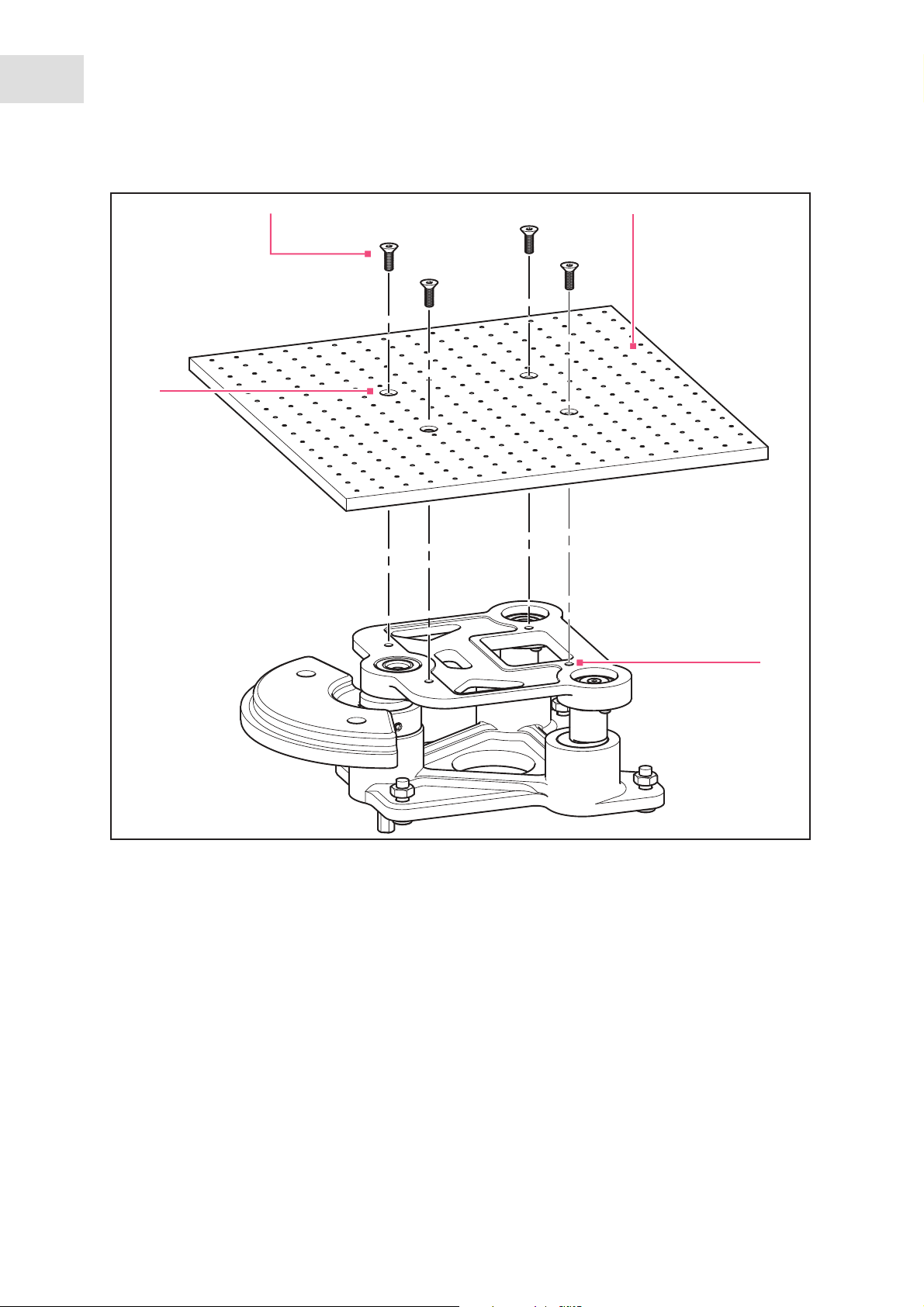

4.2 Install the platform

The Innova 40/40R Shaker can be used with a variety of New Brunswick platforms that will accept a wide

range of clamps for flasks, test tubes, etc. A platform, which is required for operation, is a separate item,

not included with the shaker assembly (see Platforms on p. 53).

NOTICE! Damage to device!

Never run shaker without a platform.

Tools required (provided):

• Allen key, 4 mm (5/32 in)

A platform must be installed on the device prior to use. To install:

Page 18

18

Installation

New Brunswick Innova 40/40R Shaker

English (EN)

Abb. 4-1: Platform installation

1

4

2

3

Fig. 4-1: Platform installation

1 Allen screws

2 Platform

3 Platform holes

4 Housing plate holes

1. Set the Mains/Power switch off.

2. Open the lid.

3. With the Allen key provided, loosen and remove the 4 allen screws installed on the top plate of the

bearing housing (set screws aside for reuse).

4. Place the platform on top of the plate of the bearing housing and align the holes.

Page 19

Installation

New Brunswick Innova 40/40R Shaker

English (EN)

5. Reinstall and secure the 4 screws.

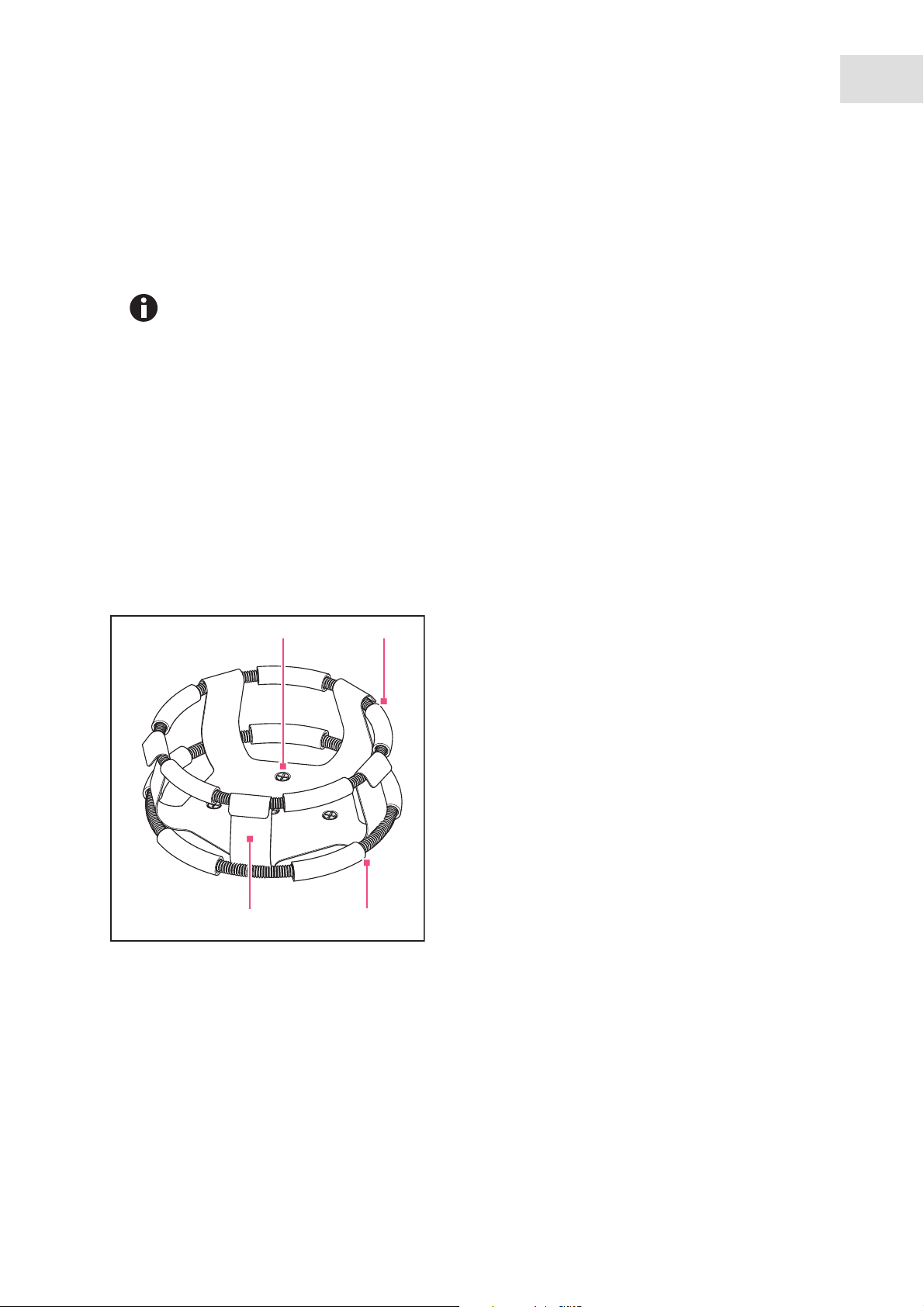

4.3 Install flask clamp

New Brunswick flask clamps are used on a variety of shaker platforms. Flat head screws of

different lengths and thread pitch are used to secure the clamp.

Materials needed:

• Phillips screwdriver

• 10 – 24 × 5/16 in (7.9 mm) flat Phillips screws

Flask clamps purchased for use with universal platforms require installation (see Accessories on p. 53).

Clamps are installed by securing the base of the clamp to the platform with the correct type and number of

screws. All clamps are shipped complete with hardware.

19

Clamps for 2 L and 2.8 L flasks are shipped with an additional girdle to keep the flasks in place. The girdle

is an assembly of springs and sections of rubber tubing. One girdle is already in place on the clamp, the

other is packed separately.

Abb. 4-2: Double girdle clamp

1

4

2

3

Fig. 4-2: Double girdle clamp

1 Clamp mounting holes (with screws)

2 Upper girdle with girdle tubes

Secures the flask within the clamp.

3 Lower girdle with girdle tubes

Prevents the flask from spinning

4 Clamp body (legs and base)

Page 20

20

Installation

New Brunswick Innova 40/40R Shaker

English (EN)

To install these double girdle clamps:

1. Place clamp on platform, aligning it mounting holes with the holes on the platform.

2. Secure the clamp in place using Phillips screwdriver and screws provided.

3. With the first girdle in place, as delivered, on the upper part of the clamp body, insert an empty flask

into the clamp.

4. After making sure the sections of tubing are located between the clamp legs, roll the first girdle down

the legs of the clamp as far as it can go.

The tubing sections will rest against the platform, and the springs will be under the clamp base.

5. Place the second girdle around the upper portion of clamp body (just as the first girdle was initially).

6. Make sure that its spring sections rest against the clamp legs, while its rubber tubing sections sit

against the flask, in between the clamp legs.

• 1 L and larger flask clamps are fastened with 5 screws.

Description Part No. Quantity Application

S2116-3051 1 5/16 in (7.9 mm) thick

10 – 24 × 5/16 in (7.9 mm)

4.4 Connecting to mains/power supply

Please read the following warning!

NOTICE! Risk of damage to the unit!

The Innova 40/40R Shaker is designed to be operated with a load on the platform.

Do not operate without a loaded platform.

WARNING! Risk of electric shock and/or damage to unit!

Check that the voltage and frequency of your unit are compatible with mains/power supply.

Remove caution label from back of unit.

Set the circuit breaker on the right side of the unit to the OFF position.

aluminum, phenolic and

stainless steel platforms.

WARNING! Risk of electric shock and/or damage to device!

Use a grounded power supply.

Only after taking the preceding precautions, plug the power cord into the mains/power supply.

Page 21

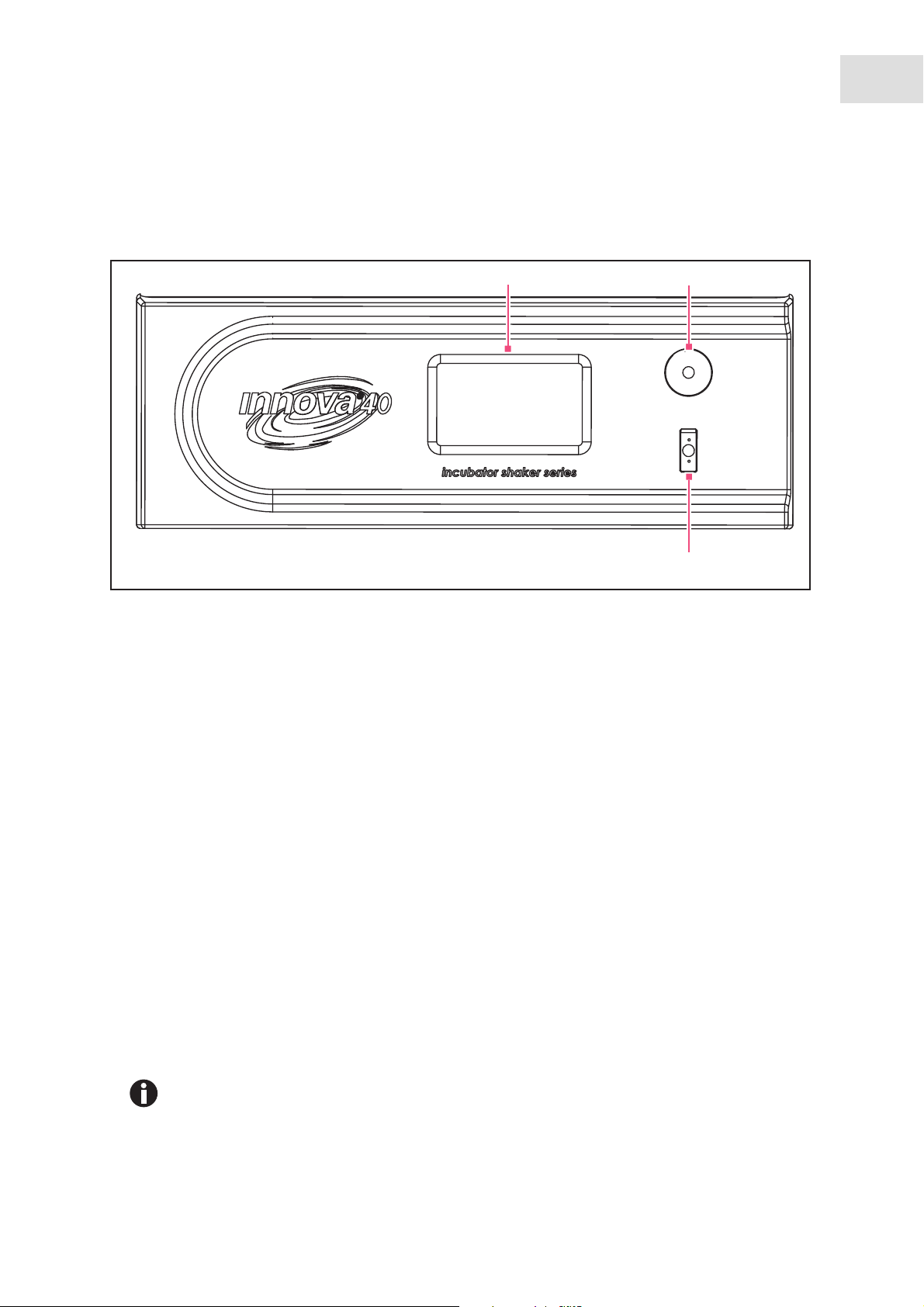

5 Operation

5.1 Overview of operating controls

Abb. 5-1: Front panel of Innova 40/40R Shaker

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

1

2

21

3

Fig. 5-1: Front panel of Innova 40/40R Shaker

1 Display

LCD

2 Control knob

Used to change screens and select operating

conditions

3 Start/Stop switch

Stops or starts shaker agitation

Activates timer when a using timed run

5.2 Powering on

1. Close the lid.

2. Turn Mains/Power switch to the On position.

The display will come on (briefly displaying product information, and then move into the DISP screen.

An audible alarm will sound.

3. Turn the Control knob to turn alarm off. The audible alarm can be muted (see To mute the audible alarm

on p. 29).

When the shaker begins to operate, the display will track the speed as it accelerates to the last entered

setpoint. The shaking action may be started or stopped by pressing the Start/Stop switch on the front

panel.

The shaker will not operate if the lid is open. This is indicated by the lid open icon appearing

in the bottom line of the display (see Fig. 5-2 on p. 22).

Page 22

22

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

5.3 Operation

When the unit is powered up using the Start/Stop switch located on the front panel (see Fig. 5-1 on p. 21),

the initial display screen will remain for a short time while the system boots up.

Then the main screen, called DISP for Display, appears. This screen will indicate the same parameters that

were in effect when the power was turned off.

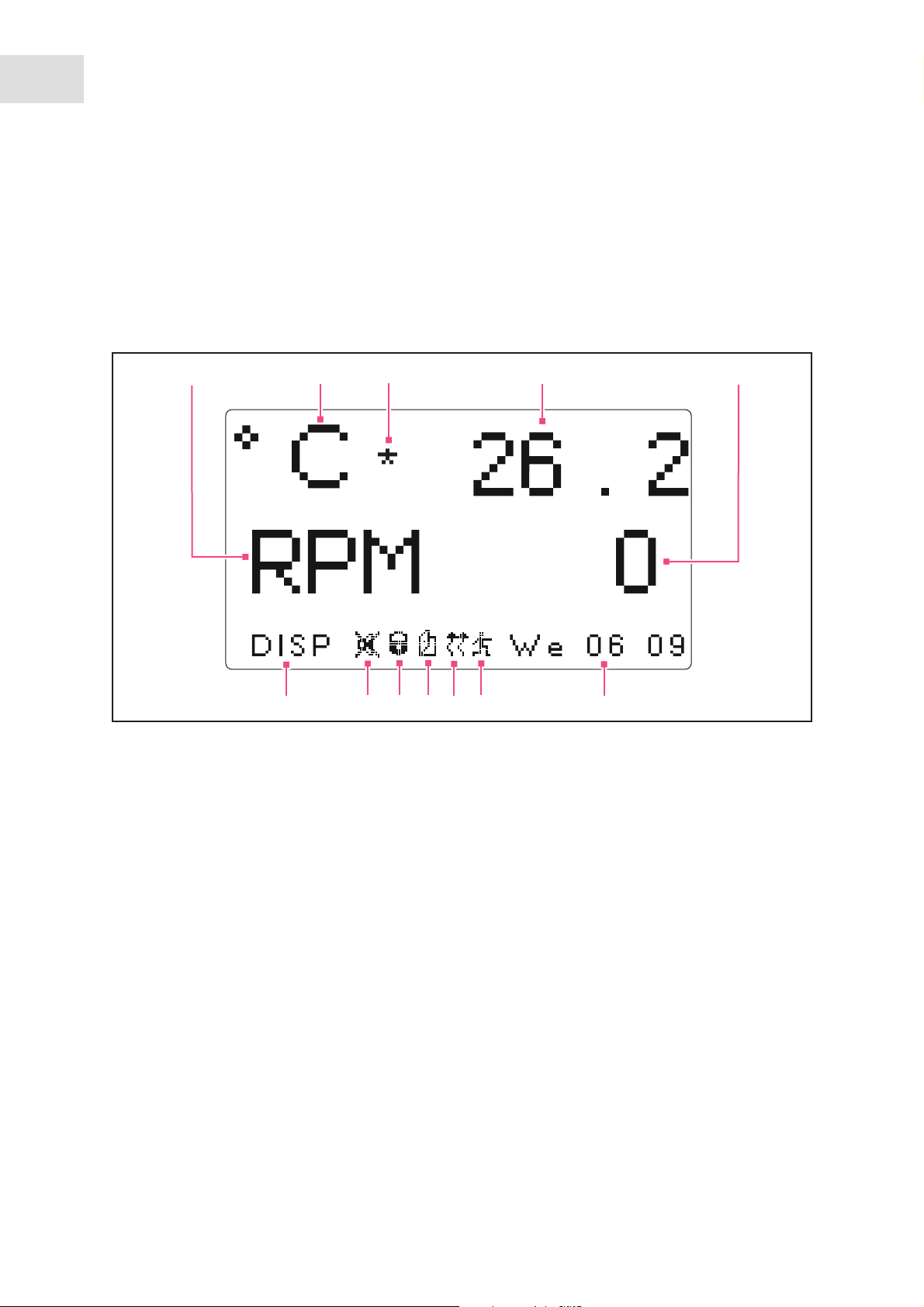

Abb. 5-2: Display screen

12

2

11

1

Fig. 5-2: Display screen

1 Speed

Parameters in rpm (revolutions per minute).

2 Temperature

Parameters in degrees Celsius.

3 Temperature offset

This icon appears to the right of ºC if the

Temperature Offset feature is being used.

3

10

ehcälfreboreztuneB nehcsifarg red fua negieznA dnu elobmyS red thcisrebÜ:2 .bbA

4

9

7

8

6

5

7 Program running

Icon appears when user-defined program is

running.

8 Heater on

Icon appears when heater is on

9 Lid open

Icon appears when lid is open

4 Temperature

Temperature parameter value

5 Speed

Speed parameter value

6 Day & 24-hour time

10 Parameters locked

This icon appears when the possibility to make

manual or programmed parameter changes is

disabled (locked). This is controlled by settings

on the SET screen.

11 Audible alarms muted

Icon appears when audible alarms are muted

12 Screen name

Page 23

Parameter name and meanings:

Parameter name Meaning

RPM Shaking speed, in revolutions per minute.

°C Chamber temperature, in degrees Celsius.

HRS Programmed time remaining, in hours.

5.4 Changing screens

5.4.1 Screen names and descriptions

There are 6 screens on the display:

Tab. 5-1: Screen names and descriptions

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

23

Screen name

(displayed in

bottom-left corner)

DISP Display Displays 2 user-selectable parameters and measured values.

SUMM Summary Displays all parameters, measured values, and setpoints.

SET Set Set day of the week, set time, enable or mute alarm, lock, or

COMM Communication Set the communication mode and baud rate (see RS-232 screen

CAL Calibration Allows user to enter a temperature offset.

PROG Program Allows user to set up 1 – 4 programs, each with 1 – 15 steps

Meaning Description

Change setpoint values (see Display Screen on p. 24).

Change all parameters, measured values, and setpoints (see

Summary screen on p. 26).

unlock operating parameters (see Setup screen on p. 27).

on p. 29).

Allows user to calibrate speed (see Calibrate screen on p. 31).

(see Programs screen on p. 32).

5.4.2 Choose screens

In this example, we are changing from the DISP (display) screen to the SET (setup) screen:

Page 24

24

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

mrihcsdliB:3 .bbA DISP

mrihcsdliB:5 .bbA SETUP

5.5 Opening the lid

1. Turn the Control knob to highlight DISP in the

bottom-left corner of the screen.

2. Press the Control knob until it clicks.

DISP will flash.

3. Turn the Control knob to choose the SET screen.

4. Press the Control knob until it clicks to save your

selection.

You changed from the DISP screen to the SET

screen.

Repeat the procedure to select any screen.

Open the lid by grasping the handle and lifting up.

When you close the lid, make sure it closes snugly (shaker will not operate until lid is closed all the way).

5.6 Display Screen

The DISP screen displays 2 parameters and the measured values. Use this screen to:

• Change displayed parameters.

• View measured values.

• View and change setpoints.

Abb. 5-3: Display screen

mrihcsdliB:3 .bbA DISP

Fig. 5-3: Display screen

Page 25

5.6.1 Changing displayed parameters

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

25

mrihcsdliB:3 .bbA DISP

1. Turn Control knob to highlight the parameter you

wish to replace. For this example, we will change

the parameter RPM to HRS.

2. Press the Control knob until it clicks.

RPM will flash.

mrihcsdliB:3 .bbA DISP

3. Turn the Control knob until the desired

parameter appears in the highlighted field.

4. Press the Control knob to save the parameter.

• If you do not press the Control knob to save your selection, after a few seconds the screen

will revert to its previous settings.

5.6.2 Viewing the setpoints

You can verify the setpoints in the DISP screen. The parameter values displayed are the measured values.

The setpoint values are user-selected. They may differ depending on many variables.

mrihcsdliB:3 .bbA DISP

1. Turn the Control knob to highlight the actual

(measured) parameter value.

2. Press the Control knob to display the setpoint.

The setpoint will flash.

3. Click Control knob in again to return to normal

display.

Page 26

26

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

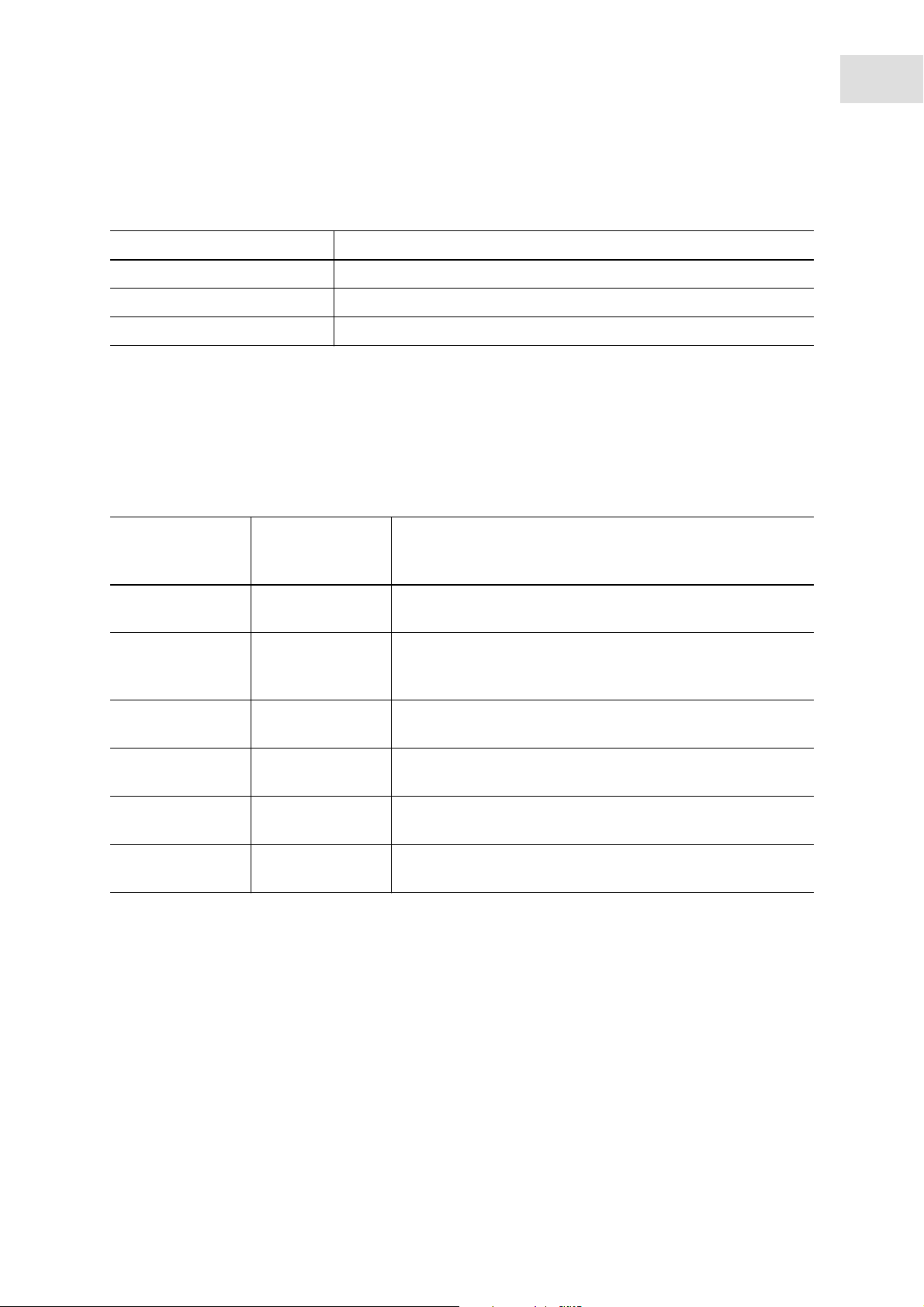

5.6.3 Changing the setpoints

mrihcsdliB:3 .bbA DISP

1. Use the Control knob to highlight the measured

(actual) value (26.2 °C in figure).

2. Press the Control knob.

The setpoint will flash.

mrihcsdliB:3 .bbA DISP

3. Turn the Control knob to change the setpoint to

desired value (20.2 °C in figure).

The Control knob will change by increments of

(0.1 °C). If you spin the Control Knob fast, the

value will change by larger increments.

4. Click the Control knob in to save the new

setpoint.

The display will automatically return to the

measured actual value.

• If you highlight an item, change it, but do not save your selection, after a few seconds the

screen will revert to its previous setting.

5.7 Summary screen

In the SUMM (summary) you can see both the, ACTUAL (measured) values and the SET (user-selected

setpoint values).

• ACTUAL values are the current measured values in the shaker. You cannot change the

values on the screen.

Abb. 5-4: Summary screen

Fig. 5-4: Summary screen

• SET values are the values the user selects.

mrihcsdliB:4 .bbA SUMM

Page 27

New Brunswick Innova 40/40R Shaker

5.7.1 Changing setpoint values in the summary screen

Like in the DISP screen, you can change the setpoints in the SUMM screen:

Operation

27

English (EN)

mrihcsdliB:4 .bbA SUMM

1. Turn the Control knob to select the desired

setpoint. For this example, we will highlight 100

to change the RPM setpoint.

2. Click the Control knob in.

Setpoint value will flash.

mrihcsdliB:4 .bbA SUMM

3. Turn the Control knob clockwise to increase the

value or turn counter-clockwise to decrease the

value. For this example we will change the

setpoint from 100 to 110.

Click the Control knob in to save the new

setpoint value.

4. Repeat the procedure to change the other

setpoint values.

• If you turn the Control knob but did not save the setpoint value, after a few seconds the

screen will revert to its previous settings.

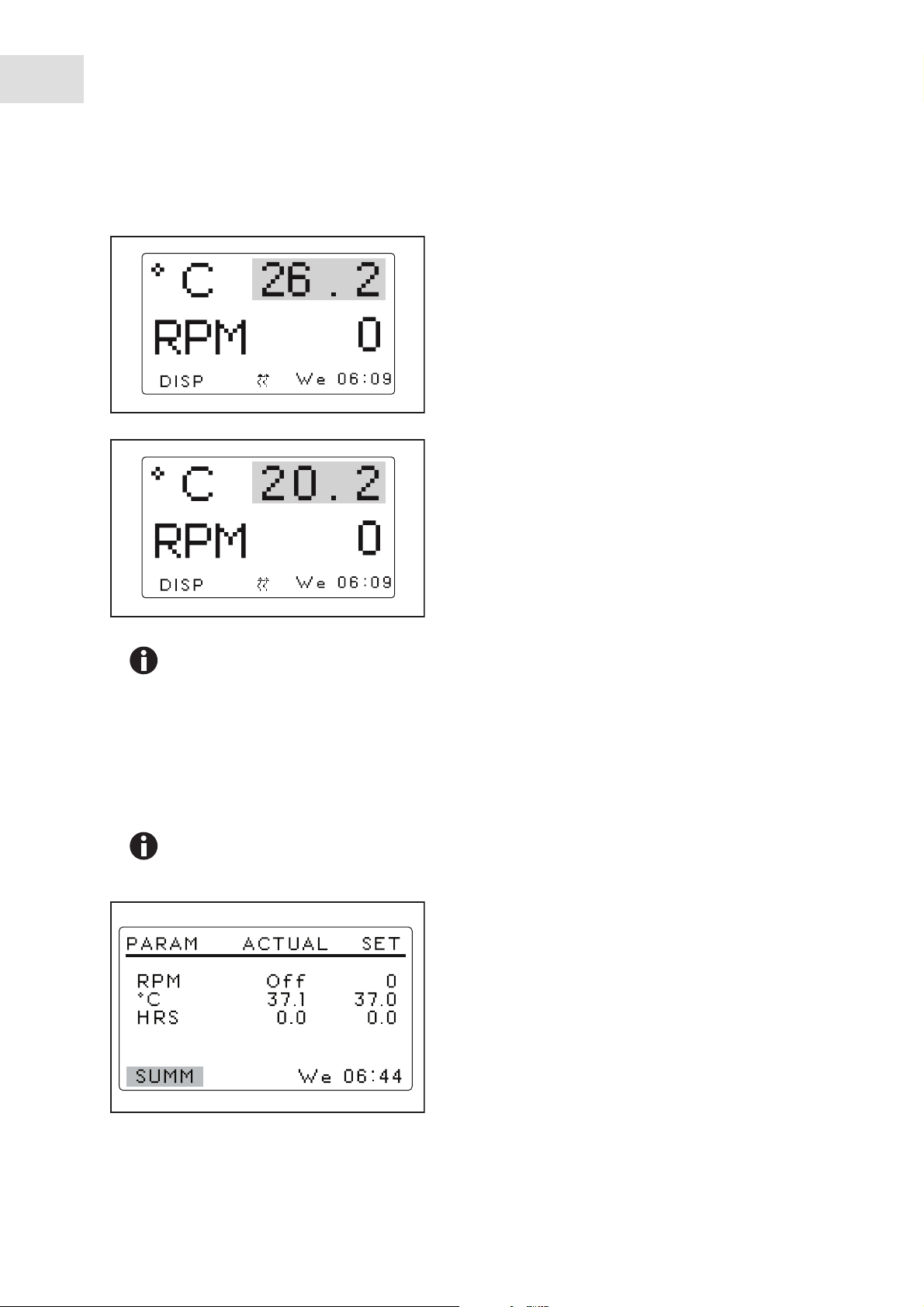

5.8 Setup screen

In the SET (setup) screen you can set the day of the week and the time (on a 24 h clock). This screen also

allows you to lock all of your settings from further changes, and to mute or enable the audible alarm.

Abb. 5-5: Setup screen

mrihcsdliB:5 .bbA

Fig. 5-5: Setup screen

Page 28

28

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

5.8.1 Changing the day

In the SET screen:

mrihcsdliB:5 .bbA

• If you do not press the Control knob to save your choice, after a few seconds the screen

will revert to its previous settings.

5.8.2 Changing the time

In the SET screen:

mrihcsdliB:5 .bbA

1. Turn the Control knob to highlight the day (Wed

in figure).

2. Press the Control knob.

The day will flash.

3. Turn the Control knob to select a different day.

4. Press the Control knob to save your selection.

1. Turn the Control knob to highlight the time.

2. Press the Control knob.

The time (06:44) will flash.

3. Turn the Control knob clockwise or

counterclockwise to select a different time.

Clockwise moves the time forward,

counterclockwise moves the time back.

One click clockwise or counterclockwise will

move the time in 1 min increments. Turning the

Control knob faster will change the time more

rapidly.

4. Press the Control knob to save your selection.

5.8.3 To lock the settings

In the SET screen:

1. Turn the Control knob to highlight the Lock status.

2. Press the Control knob.

The current status of the Lock (On or Off) will flash.

3. Turn the Control knob to select On or Off.

4. Press the Control knob to make a selection.

When you select On, the Lock icon will appear at the bottom of the screen. This icon will remain on

display on all screens until you turn the Lock function Off.

Page 29

5.8.4 To mute the audible alarm

In the SET screen:

1. Turn the Control knob to highlight the Mute

status (On or Off).

2. Press the Control knob.

The current status of the alarm (On or Off) will

flash.

3. Turn the Control knob to select On or Off.

4. Press the Control knob to save your selection.

When you set Mute to On, the mute icon will

appear at the bottom of the screen. This icon will

be displayed on all screens until you turn Mute to

Off.

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

29

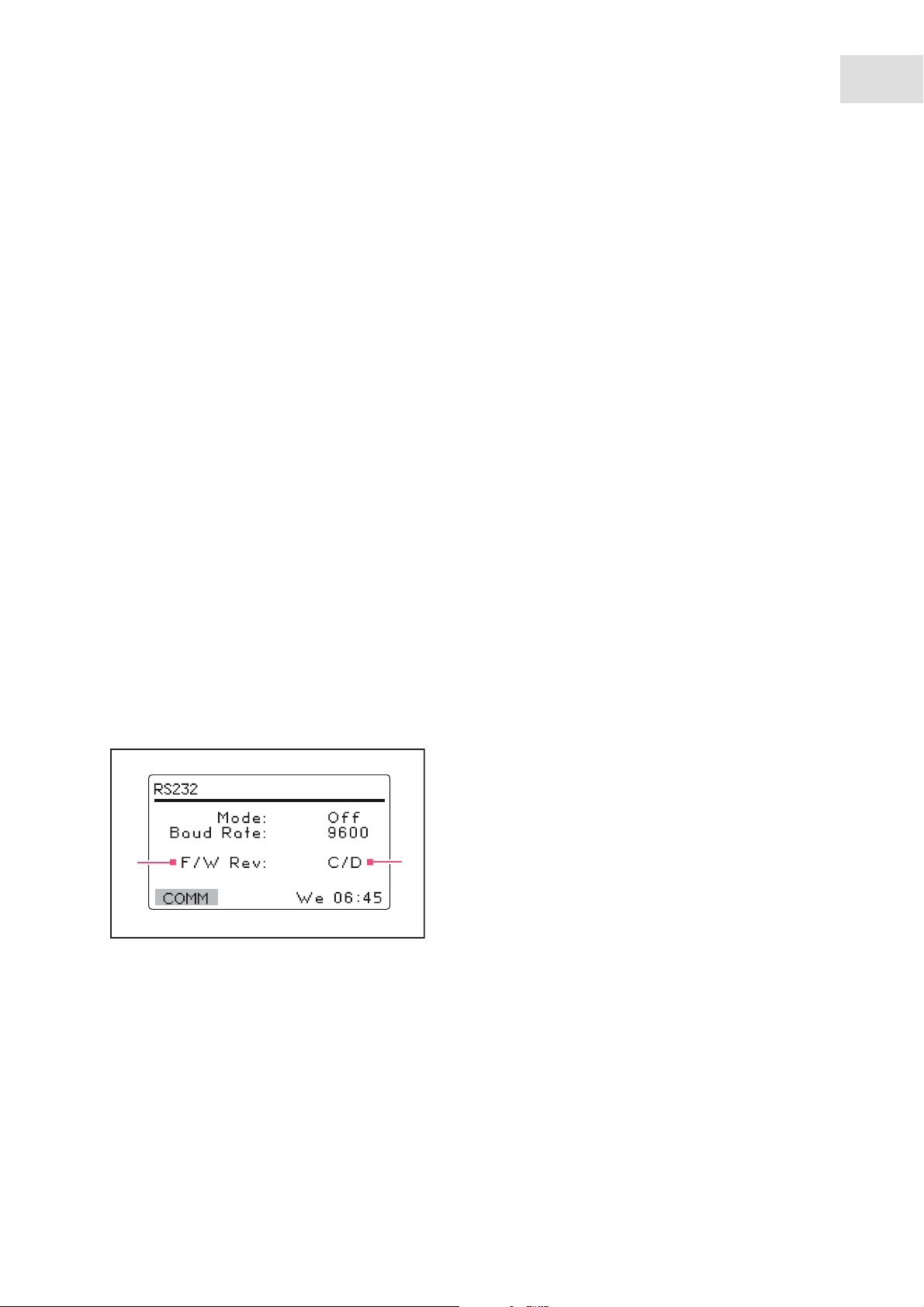

5.9 RS-232 screen

This COMM screen (communication) is used if you have connected a PC to the RS-232 port. Software such

as New Brunswick™ BioCommand

screen to:

• Select the RS-232 port Mode.

• Select the Baud Rate appropriate to your PC.

Abb. 5-6: Communication screen

mrihcsdliB:7 .bbA RS232

1

Fig. 5-6: Communication screen

1 FirmWare Revision (this line is for information

only).

®

allows you to record and log data from your shaker. Use the RS-232

2

2 In this sample screen, the Display is at Revision

C and the FirmWare Control Board at Revision

D.

Page 30

30

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

5.9.1 Changing the communication mode

In the RS232 screen:

1. Turn the Control knob to highlight the Mode status (see Tab. on p. 30).

2. Press the Control knob.

The current setting will flash.

3. Turn the Control knob to select make your selection (see Tab. on p. 30).

4. Press the Control knob to save your setting.

Tab. 5-2: Communication mode

Mode Application

Off The RS-232 port is not open to communication in either direction.

Slave The shaker can be fully controlled from the computer.

Talk The shaker sends current value reports to the computer once per

Monit (Monitor) The shaker responds only to "Report Requests".

5.9.2 Changing the baud rate

In the RS232 screen:

1. Turn the Control knob to highlight the current setting.

The settings are: 9600, 19200, and 38400.

2. Press the Control knob.

The current setting will flash.

3. Press the Control knob to save your selection.

minute.

Page 31

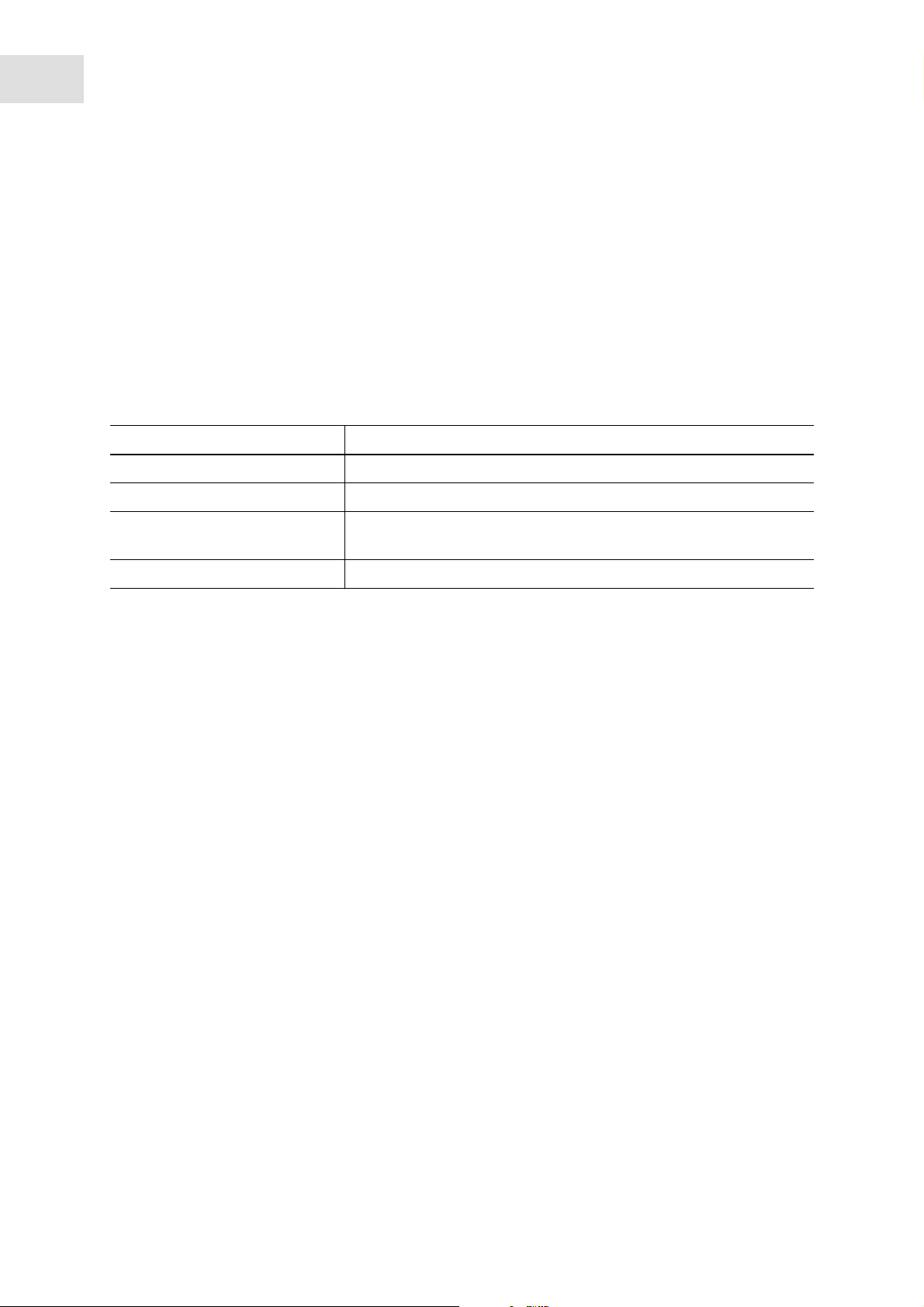

5.10 Calibrate screen

Use the CAL (calibrate) screen to:

• Create a temperature offset.

• Calibrate shaking speed.

Abb. 5-7: Calibrate screen

mrihcsdliB:8 .bbA CALIBRATE

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

31

Fig. 5-7: Calibrate screen

5.10.1 Temperature offset

There is a temperature offset function on the Innova 40/40R Shaker that allow you to match a reference

point temperature inside the chamber with the actual value displayed. The actual value displayed may not

equal the temperature at different points of the shaker chamber due to many variables.

If you wish to have the actual value displayed on the shaker match a diffferent point of the chamber, you

must:

1. Calculate the temperature offset desired.

2. Create the temperature offset in the CAL screen.

5.10.2 Calculating the temperature offset

In the CAL screen:

1. Allow the shaker enough time to equilibrate to setpoint temperature.

2. Record the displayed setpoint temperature (temp1).

3. Record the temperature inside the chamber (temp2). You may record the temperature inside a flask or

at any point inside the temperature.

4. Use the formula: temp2 - temp1 = °C offset

Page 32

32

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

5.10.3 Creating the temperature offset

In the CAL screen:

1. Calculate the temperature offset value to plug in

(see Calculating the temperature offset on p. 31).

2. Turn the Control knob to select the °C Offset value

(0.0 in figure).

3. Enter the °C offset desired.

5.10.4 Calibrating the shaking speed

The Innova 40/40R Shaker is calibrated at the factory. The speed does not need to be recalibrated until a

major operating component (e.g. a drive belt) is changed. This should be done by a qualified service

technician.

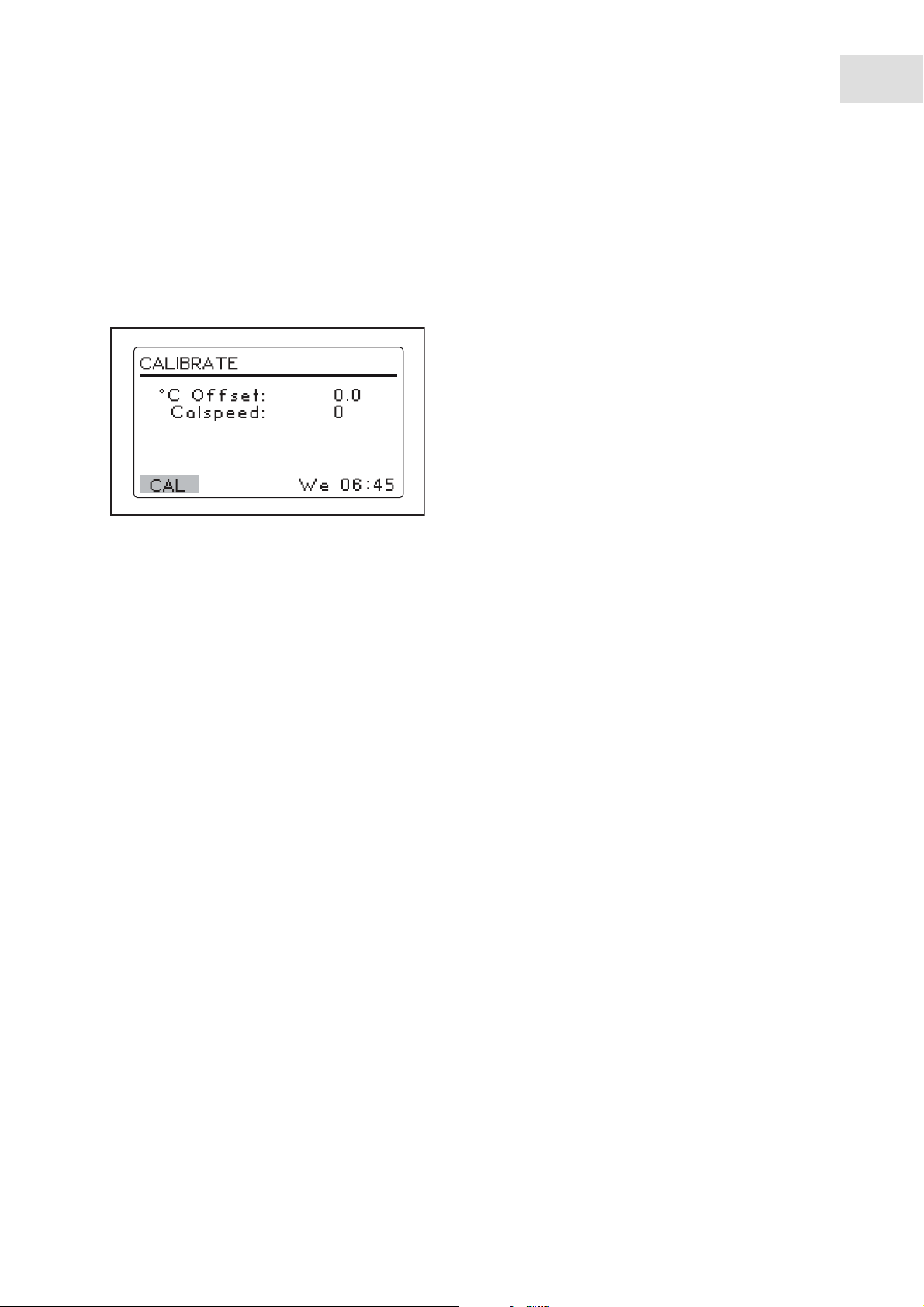

5.11 Programs screen

Use the PROG screen to program steps for the shaker. The resident software for the Innova 40/40R Shaker

can store up to four programs, each having as many as 15 steps. Each step can be programmed in 1 min

increments, for total periods of 0 hr 1 min – 99 hr 59 min.

To enter the programming mode, use the Control knob to select the PROG screen.

In the PROG screen you can:

• Run a program.

• Create a New program.

• Edit a program.

• Turn Off a program.

Abb. 5-8: Program screen

mrihcsdliB:9 .bbA PROGRAMS

Fig. 5-8: Program screen

Page 33

5.11.1 Create a program

To write a new multi-step program in the PROG screen:

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

33

mrihcsdliB:9 .bbA PROGRAMS

mrihcsdliB:9 .bbA PROGRAMS

mrihcsdliB:11 .bbA PRG1, STEP 1

1. Use the Control knob to highlight the mode of

Program 1 (Off in figure).

2. Press the Control knob.

The selected field will flash.

3. Turn the Control knob until the field says New.

4. Press the Control knob to select New.

The screen will change and you can start

programming Step 1.

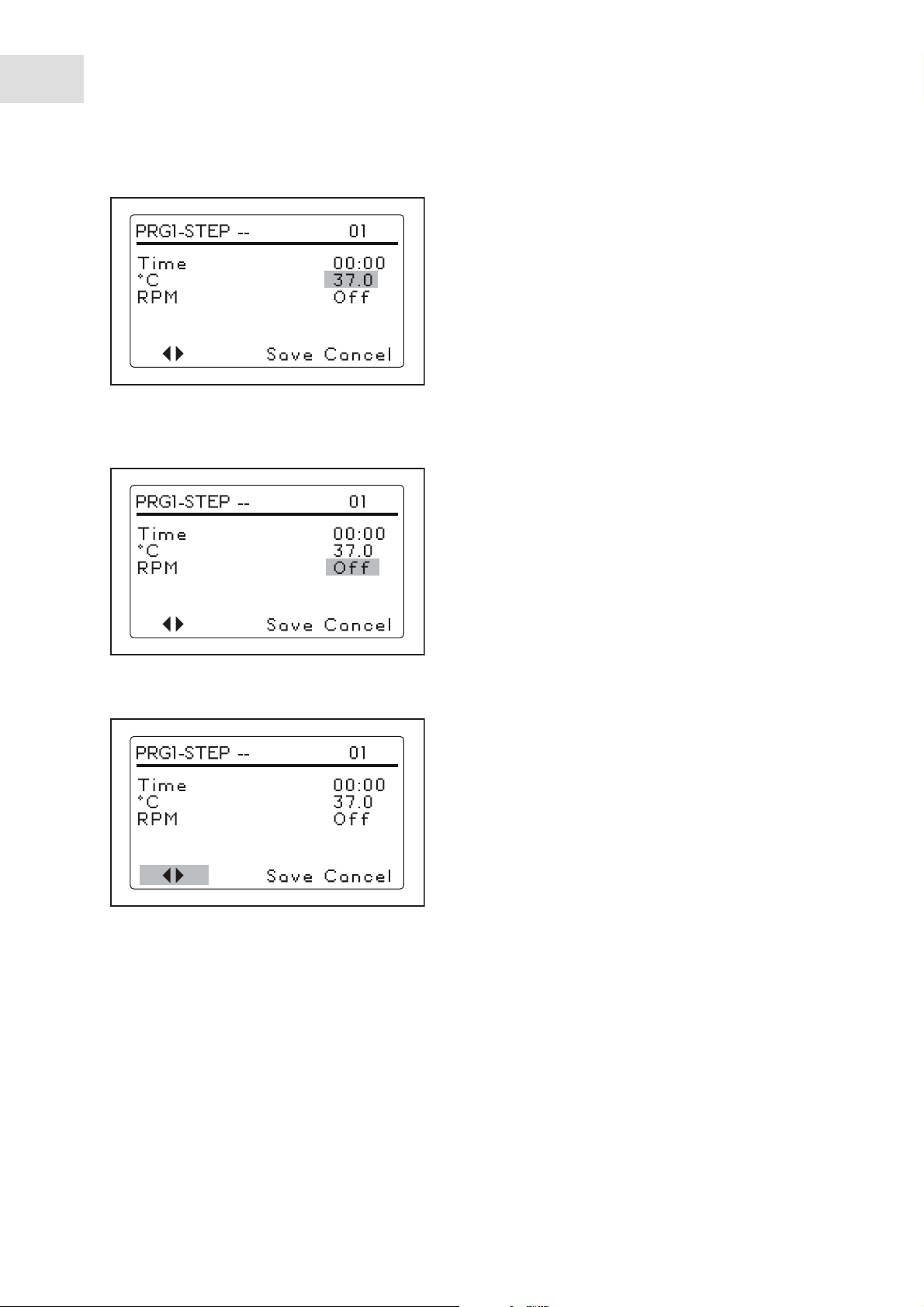

5. Turn the Control knob to highlight the Time

value.

6. Press the Control knob.

The time will flash.

7. Turn the Control knob until the desired running

duration for this step (from 00:01 – 99:59)

8. Press the Control knob to save the setting.

Page 34

34

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

mrihcsdliB:11 .bbA PRG1, STEP 1

mrihcsdliB:11 .bbA PRG1, STEP 1

9. Turn the Control knob to highlight the °C value.

10.Press the Control knob.

The °C value will flash.

11.Set the temperature desired and press the

Control knob to save your setting.

12.Turn the Control knob to highlight the RPM value

(Off in the sample figure).

13.Press the Control knob.

The RPM value will flash.

14.Turn the Control knob to select a speed.

mrihcsdliB:11 .bbA PRG1, STEP 1

5.11.2 Save the program

To save a program:

1. Highlight Save and press the Control knob.

Save will flash.

15.Press the Control knob to save your selection.

16.To program a second step, use the Control knob

to highlight the double arrows in the bottom-left

corner of the screen.

17.Press the Control knob.

The double arrows will flash.

18.Turn the Control knob 1 click clockwise to go to

the Step 2 screen.

19.Press the Control knob to start programming

Step 2 like you did with Step 1. You can program

up to 15 Steps.

2. Press the Control knob again to save the program.

Page 35

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

The LCD will display Process Running — Saving Profile for a few seconds and then return to the main

PROG screen.

5.11.3 Edit a program

Use the Edit mode to open a program you have already created and saved, in order to modify your settings

following the same procedures.

5.11.4 Run and stop a program

Use the Run mode to turn a specific program on. Only one program can run at a time. When you change the

mode to Run, the screen will show the Run icon (see Fig. 5-2 on p. 22).

To stop a program, change the program mode to Off.

35

5.12 Program the timer

By setting an HRS setpoint in the DISP or SUMM screen, the shaker may be set to automatically stop after a

preset time period of 0 hr 1 min – 99 hr 59 min.

If the time is set to 0:00, the shaker will operate continuously until either the lid is opened or the Start/Stop

switch is pushed.

5.13 Power interruption

In the event of a power failure, the Innova 40/40R Shaker is equipped with an automatic restart function.

The shaker's non-volatile memory retains all stored information.

If the shaker was in operation prior to the power interruption, the shaker will begin to operate at its last

entered setpoints. The alarm POWER will flash on the display, indicating that a power interruption has

occurred. Turn the Control knob in any direction to acknowledge the visual alarm. The flashing will stop.

Page 36

36

Operation

New Brunswick Innova 40/40R Shaker

English (EN)

Page 37

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

6 Remote programming

You can use a communications program (such as HyperTerminal) to send commands to the shaker from

your PC.

• HyperTerminal is not included with Windows Vista or Windows 7.

6.1 Connecting to a computer

Before setting up communication software, check the Mode and Baud Rate parameter settings found on the

RS232 screen of the shaker (see RS-232 screen on p. 29).

Set the shaker’s Mode parameter to Slave.

Set the appropriate Baud Rate.

37

6.1.1 Setting up serial connection with HyperTerminal

1. Connect the RS-232 cable between the computer and the shaker’s RS-232 port.

2. Start HyperTerminal and follow the steps for setting a new connection.

3. Select the COM port you will be using, then set the COM parameters to the following values:

Baud rate Enter the setting on your shaker

Data bits 8

Parity None

Stop bits 1

Flow control None

6.1.2 Testing the connection

1. Turn the shaker off.

2. Start HyperTerminal.

3. Turn the shaker on.

If a connection is made, the shaker will send and OK to the communication software.

6.2 Sending commands

With the command program, the user send commands to the Innova 40/40R Shaker by computer.

• The serial interface uses an echo character protocol that is implemented to indicate that a valid

character has been received by the shaker.

• For every character sent by the user computer, the Innova 40/40R Shaker will return a matching

Page 38

38

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

character.

• This echo character should be read by the computer and compared to the character that was sent.

• When sending a command in HyperTerminal, do not allow the pause between any two

characters of you message to last longer than 10 s.

• After 10 s the shaker's serial port will reset itself.

This is the command set format:

<Command><Space><Arg1><Space><Argn><CR>

• Most Commands are defined as 2 capital characters using the ASCII character set (see Index to

command codes on p. 44).

• If a command has several arguments (Argn), the ASCII space control character separates each

argument.

• The command is sent using the ASCII carriage return (CR) control character.

• The line feed control character may also be included but must follow the carriage return character.

When a command is sent that returns data, the characters returned are in ASCII format. Each additional

argument returned will be separated by the ASCII space or tab control character. Refer to the selected

command for the actual format. Data returned is terminated with a carriage return line feed control

character sequence.

6.2.1 Example: Commanding set speed

In the following example, the computer will set the shaker speed to 250 rpm:

In HyperTerminal, type CS<Space>250<CR>.

The shaker echos CS<Space>250<CR>

The shaker is set to 250 rpm

Do not actually type the angled brackets. <Space> means press the space bar <CR> means

press the carriage return.

Page 39

6.2.2 Example: Requesting measured values

Type RV<CR>.

The shaker echos RV<CR>

The shaker will report:

• Arg1 (Speed rpm)

• Arg2 (Temperature °C)

• Arg3 (Humidity %)

• Arg4 (CO

• Arg5 (Grow lamp 0 = Off, 1 = On)

• Arg6 (UV lamp 0 = Off, 1 = On)

These values will be separated by <Tab>.

This will look like:

250 29 90 0 0 0

2

%)

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

39

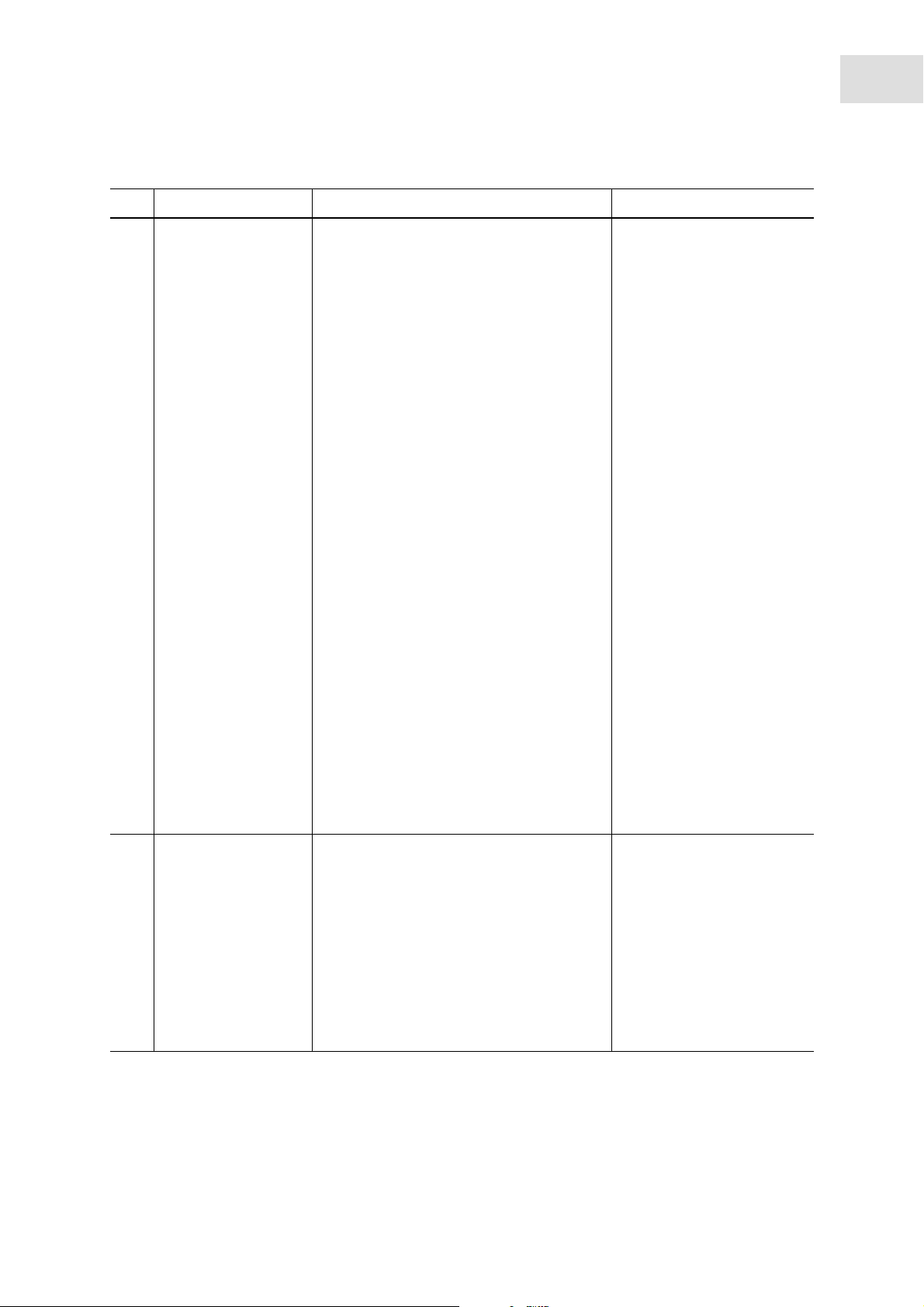

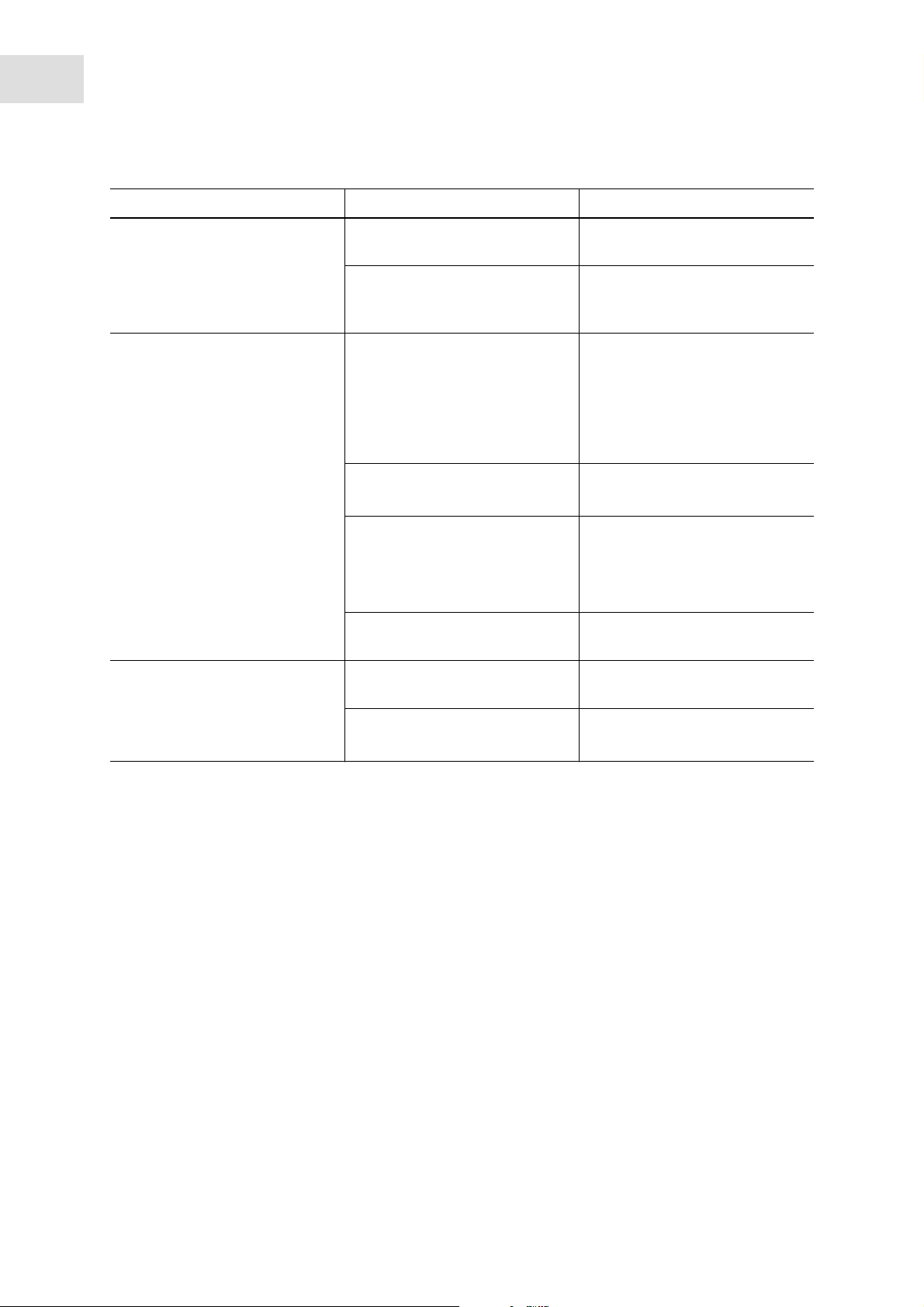

6.3 Set Commands

Code Meaning Command format Return data

CS Command speed CS<Space><Arg1><CR>•Arg1 = Speed setpoint

CT Command temperature CT<Space><Arg1><CR>•Arg1 = Temperature

setpoint

Page 40

40

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

6.4 Program control commands

Code Meaning Command format Return data

PC Clear program

(clears program steps)

PM Program mode

(returns status of

current program run/

hold mode)

PC<Space><Arg1><Space><Arg2><CR>

Note: If Arg2 is not included, all 15 steps of

selected program will be cleared.

PM<CR>•Arg1 =

• Arg1 =

Program number

(1 – 4)

• Arg2 =

Step number

(1 – 15)

Run/hold status

(0 = end, 1 = run)

• Arg2 =

Program number

(1 – 4)

• Arg3 =

Step number

(1 – 15)

Note: If a program has not

been selected to run, a 0 will

be returned for program

number and step number

Page 41

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

Code Meaning Command format Return data

41

PR Read program step in

memory

PR<Space><Arg1><Space><Arg2><CR>•Arg1 =

Profile number

(1 – 4)

• Arg2 =

Step number

(1 – 15)

Note: if ARG2 = * (asterik) all

steps returned

• Arg9 =

Grow lamp

(0 = off, 1 = on)

• Arg8 =

UV lamp

(0 = off, 1 = on)

• Arg7 =

Step minutes

(0 – 59)

• Arg6 =

Step hours

(0 – 99)

• Arg5 =

setpoint %

CO

2

(future option, returns

0.0)

• Arg4 =

Speed setpoint rpm

• Arg3 =

Temperature setpoint °C

PS Program stop/start

(stops or starts a

program)

PS<CR>

With no other parameters, any program

currently running will be stopped.

PS<Arg1><Space><Arg2><CR>

• Arg1 =

Program number

(1 – 4)

• Arg2 =

Step number

(1 – 15)

Note: If Arg2 is not included,

the program will start in

Step 1.

Page 42

42

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

Code Meaning Command format Return data

PW Write Program step to

memory

PW<Space><Arg1><Space>...<Arg7><CR>•Arg1 = Program number

(1 – 4)

• Arg2 = Step number (1 –

15)

• Arg3 = Temperature

setpoint °C

• Arg4 = Speed setpoint

rpm

• Arg5 = CO

setpoint %

2

• Arg6 = Step (0 – 99)

• Arg7 = Step min (0 – 59)

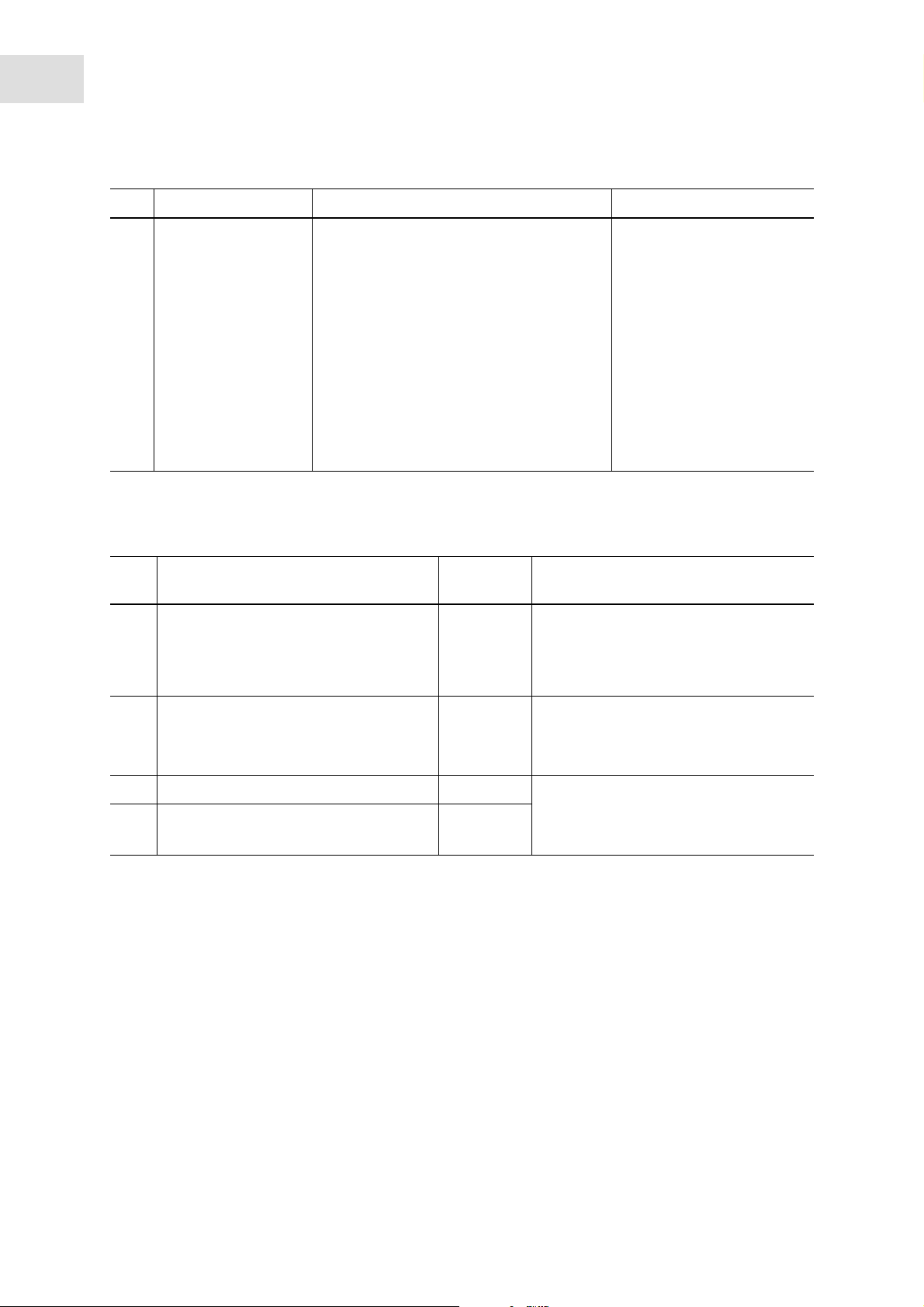

6.5 Report request commands

Code Meaning Command

format

RI Report software version RI<CR>•Arg1 = Display module software

Return data

version

• Arg2 = Control module software

version

RP Report parameter list (ASCII text header) RP<CR>•Arg1 = Speed rpm

• Arg2 = Temperature °C

• Arg3 = CO

2

%

RV Report measured values RV<CR>•Arg1 = Speed rpm

RS Report setpoint values RS<CR>

• Arg2 = Temperature °C

• Arg3 = CO

2

%

Page 43

Remote programming

New Brunswick Innova 40/40R Shaker

6.6 Set/Get date and time commands

Code Meaning Command format Return data

43

English (EN)

=D Set date and

time

?D Viewing date

and time

=D<Space><Arg1><Space><Arg2>...<Arg7><

CR>

• Arg1 = Hours (0 – 23)

• Arg2 = Minutes (0 – 59)

• Arg3 = Seconds (0 – 59)

• Arg4 = Year (00 – 99)

• Arg5 = Month (01 – 12)

• Arg6 = Date (1 – 31)

• Arg7 = Day (1 – 7)

– 1 = Monday

– 2 = Tuesday

– 3 = Wednesday

– 4 = Thursday

– 5 = Friday

– 6 = Saturday

– 7 = Sunday

?D<CR>•Arg1 = Hours (0 – 23)

• Arg2 = Minutes (0 – 59)

• Arg3 = Seconds (0 – 59)

• Arg4 = Year (00 – 99)

• Arg5 = Month (01 – 12)

• Arg6 = Date (1 – 31)

• Arg7 = Day (1 – 7)

– 1 = Monday

– 2 = Tuesday

– 3 = Wednesday

– 4 = Thursday

– 5 = Friday

– 6 = Saturday

– 7 = Sunday

For example, the following command:

6.6.1 Example: Viewing date and time

1. Type =?.

The shaker will return 03 30 00 13 07 04 07

This means the shaker date and time is set to July 04, 2013 03:30:00 am.

Page 44

44

Remote programming

New Brunswick Innova 40/40R Shaker

English (EN)

6.6.2 Example: Programming date and time

To set the date to Wednesday March 26, 2013 01:30:12 am

Type =D<Space>01<Space>30<Space>12<Space>13<Space><03><Space>26<Space>03<CR>

This will look like:

01 30 12 13 03 26 03

6.7 Index to command codes

Tab. 6-1: Command codes

Command Code Meaning

CC Command CO

CH Command Relative Humidity

CL Command Grow Lamp

CS Command Speed

CT Command Temperature

CU Command UV Lamp

PC Clear Program

PM Program Mode

PR Read Program Step in memory

PS Program Stop/Start

PW Write Program Step to memory

RI Report Software Version

RP Report Parameter List

RS Report Setpoint Values

2

RV Report Measured Values

=D Set Date and Time

?D Get Date and Time

Page 45

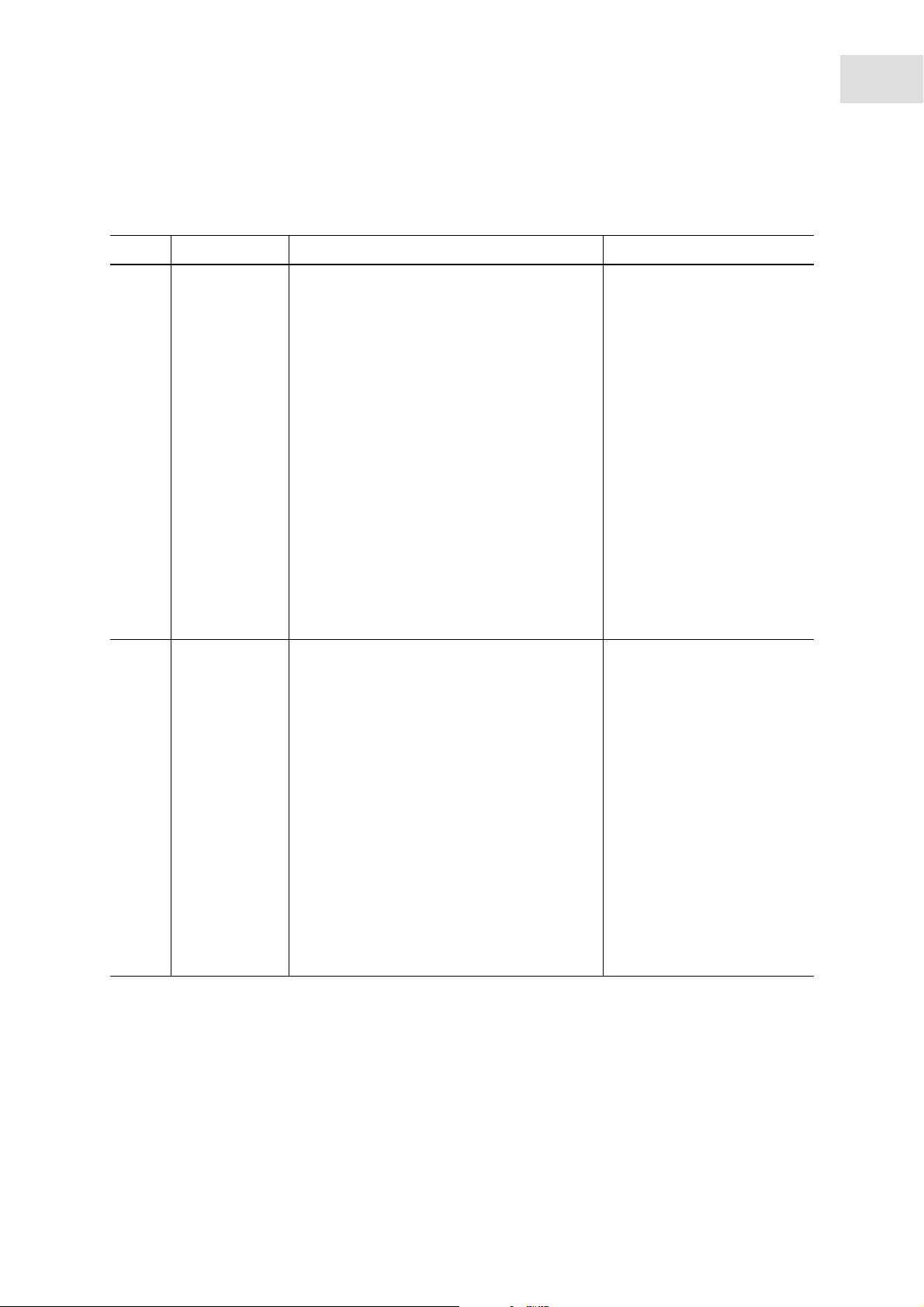

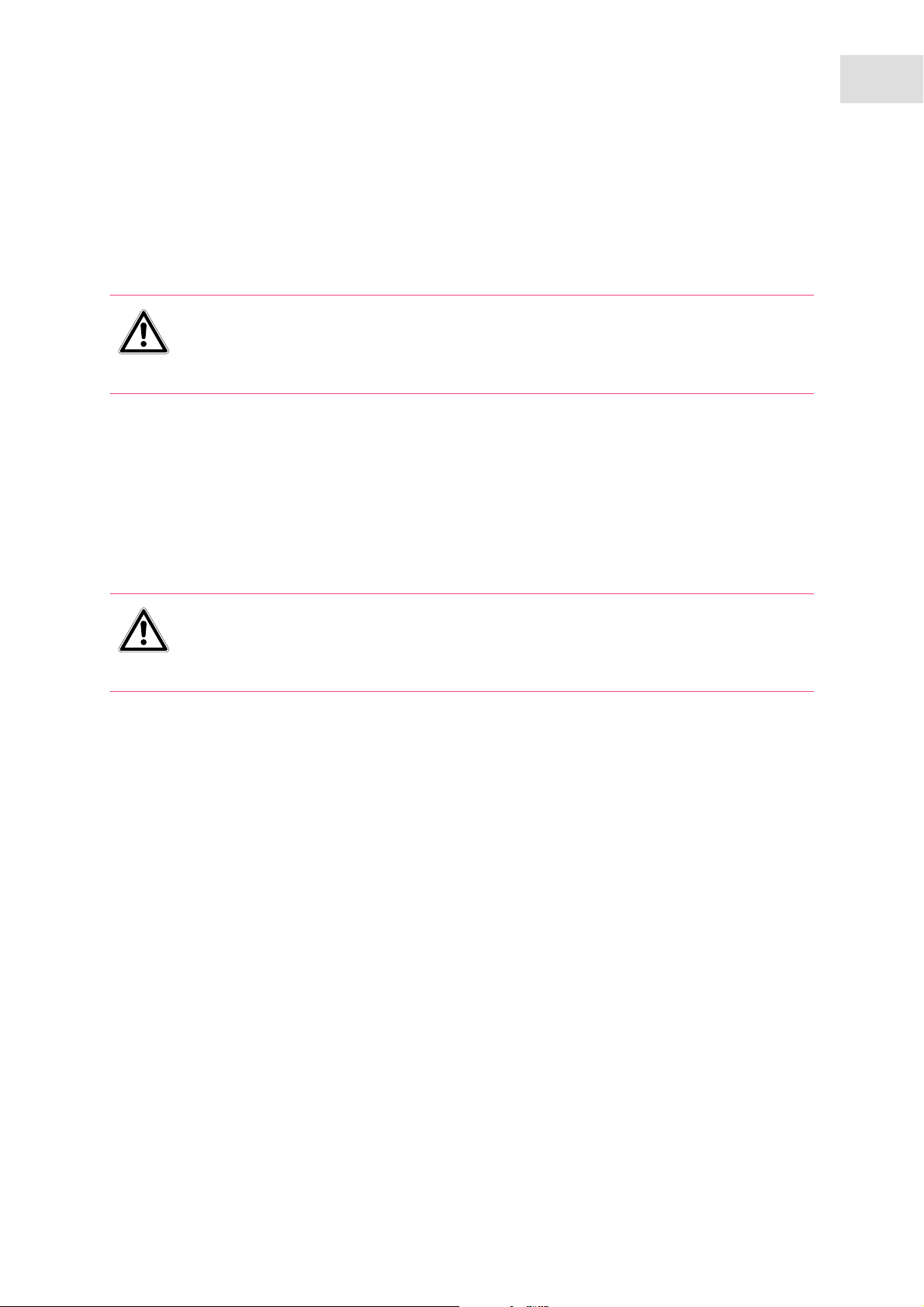

7 Troubleshooting

7.1 Troubleshooting

Symptom Cause Solution

Troubleshooting

New Brunswick Innova 40/40R Shaker

English (EN)

45

Shaker does not run. • Power cord is not plugged in.

• Lid is ajar.

• Defective main board.

• On/Off switch is broken.

• Defective display board.

• Jammed shaking mechanism.

• Defective motor.

• Drive belt out of alignment or

worn.

• Shaking speed has been set to

0 by program running or by

computer interface.

• Improperly installed fuse.

Shaker runs slowly and/or there is

no speed indication.

• Improperly installed fuse.

• Incorrect speed calibration.

• Defective main board.

• Defective motor.

• Drive belt out of alignment or

worn.

Plug in power cord to working

mains/power outlet.

Ensure lid is closed firmly.

Call for service.

Reset shaking speed.

Remove and reinstall fuse.

Remove and reinstall fuse.

Recalibrate shaking speed.

Call for service.

Shaker does not run at set speed. • Shaker is running in Program

mode (look for Run icon in

display).

• Shaker speed has been

changed by computer

interface.

• Shaker is overloaded and/or

you are using baffled flasks.

• Defective motor.

• Drive belt out of alignment or

worn.

• Speed not calibrated correctly.

Remove some contents and

balance load.

Call for service.

Check speed calibration.

Page 46

46

Troubleshooting

New Brunswick Innova 40/40R Shaker

English (EN)

Symptom Cause Solution

Excessive operating noise. • Load out of balance. Unload all contents and

reload.

• Loose components in platform,

subplatform, and/or drive

assembly.

Shaker does not reach set

temperature.

Incorrect temperature indication. • Temperature Offset has been

• Shaker is running in Program

mode (look for Run icon in

display).

• Shaker speed has been

changed by RS-232 command/

computer interface.

• Heater fuse blown.

• Compressor fuse blown.

• Compressor over-pressure

switch activated.

• Defective heater.

• Defective refrigeration system.

• Ambient temperature too high

or too low.

programmed.

• Defective RTD assembly.

• Defective main board.

Call for service.

Replace fuse.

Call for service.

Adjust the room temperature.

Look for Offset icon in display.

Call for service.

Page 47

Maintenance

New Brunswick Innova 40/40R Shaker

English (EN)

8 Maintenance

8.1 Routine maintenance

No routine maintenance schedule is required for the Innova 40/40R Shaker

WARNING! Personnel injury and equipment damage!

When cleaning the unit, always turn off the shaker and disconnect the power cord from the

power supply.

We recommend you occasionlly wipe down the shaker with a non-abrasive household cleaner.

We also suggest that the area around the shaker be vacuumed or swept to remove dust and other debris,

ensuring proper air flow in and around the shaker.

47

8.2 Cleaning external and internal surfaces

WARNING! Personnel injury and equipment damage!

When cleaning the unit, always turn off the shaker and disconnect the power cord from the

power supply.

The unit may be cleaned using a damp cloth or any standard household or laboratory cleaner to wipe down

its outer surfaces. Do not use abrasive or corrosive compounds to clean this instrument, as they may

damage the unit.

8.3 Biohazard decontamination

It is the responsibility of the user to carry out appropriate decontamination procedures if hazardous

material is spilled on or inside the equipment. Before using any cleaning or decontamination method other

than those suggested by the manufacturer, users should check with Eppendorf that the proposed method

would not damage the equipment.

Commercially available household bleach solutions, when diluted at a 1:10 ratio, are effective in routine

decontamination of the instrument. The method for decontaminating a spill depends upon the nature of the

spill.

Spills involving fresh cultures or samples known to have low concentrations of biomass should be flooded

with decontamination solution and soaked for 5 minutes before cleanup. Spills involving samples with high

concentrations of biomass, or involving organic matter, or occurring in areas warmer than room ambient

temperature, should be exposed to decontamination solution for at least one hour before cleanup.

Page 48

48

Maintenance

New Brunswick Innova 40/40R Shaker

English (EN)

WARNING! Personnel injury!

Personnel involved in the cleanup of any spill should wear gloves, safety glasses, and a

laboratory coat or gown during the cleanup process. Respiratory protection should be

considered for spills where aerosolization is suspected.

Page 49

Technical data

New Brunswick Innova 40/40R Shaker

English (EN)

9 Technical data

9.1 Specifications

Use of baffled flasks will significantly reduce maximum speed for any shaker.

These specifications assume a maximum load of 15.5 kg (34 lb), including platforms, clamps, glassware

and contents.

9.1.1 Shaking

Speed 25 rpm – 500 rpm

Control accuracy ±1 rpm

Stroke 1.9 cm (3/4 in) or 2.5 cm (1 in)

49

Indication Displayed in 1 rpm increments

Alarm signal with speed deviation ±5 rpm

Drive mechanism Triple-eccentric counterbalanced drive with 9

permanently lubricated ball bearings. Driven by a

solid-state brushless motor

Heaters Low watt-density, resistance heaters with

high-temperature safety thermostat cut-out.

9.1.2 Temperature system

Innova 40 temperature range 5 °C above ambient temperature to 80 °C

Innova 40R temperature range 15 °C below ambient temperature (minimum 4 °C)

to 80 °C

Control accuracy ±0.1 °C °C at 37 °C

Indication Displayed in 0.1 °C increments

Alarm signal with temperature deviation ±1 °C

9.1.3 Power supply

Power supply 100 V ±10 %, 50 – 60 Hz

120 V ±10 %, 60 Hz

230 V ±10 %, 50 Hz

40: 800 VA

40R: 1500 VA

Page 50

50

Technical data

New Brunswick Innova 40/40R Shaker

English (EN)

9.1.4 Ambient conditions

Ambience Only for use indoors.

Ambient temperature 10 °C – 35 °C

Relative humidity 20 % – 80 %, non-condensing

9.1.5 Dimensions and weight

Dimensions Width: 55.9 cm (22 in)

Depth: 76.2 cm (30 in)

Height: 61 cm (24 in)

Lid open height: 102 cm (40 in)

Chamber dimensions Width: 51.4 cm (20.3 in)

Depth: 54.4 cm (21.5 in)

Height: 35.6 cm (14 in)

Platform dimensions Width: 46 cm (18 in)

Depth: 46 cm (18 in)

(Select universal or dedicated styles.)

Space requirements Width: 68.6 cm (27 in)

Depth: 83.2 cm (33 in)

Height: 106.7 cm (42 in)

Weight Innova 40 net weight: 60 kg (133 lb)

Innova 40R net weight: 79 kg (175 lb)

9.1.6 Alarms

There is a visible and audible warning indication when:

• Speed deviates more than ±1 rpm from setpoints.

• Temperature deviates more than ±1 °C from setpoints.

• When timer has expired.

Audible alarm can be muted.

9.1.7 Display

• 240 × 128 backlit LCD

9.1.8 RS-232

• Remote control.

• Remote monitoring.

• Remote data logging.

Page 51

9.1.9 ETL regulatory standards

• UL 61010A-1

• UL 61010A-2-010

• CAN/CSA-C22.2 No. 1010.1

• CAN/CSA-C22.2 No. 1010.2.010

9.1.10 CE regulatory standards

For CE regulatory standards:(see Fig. 5-8 on p. 60)

Technical data

New Brunswick Innova 40/40R Shaker

English (EN)

51

Page 52

52

Technical data

New Brunswick Innova 40/40R Shaker

English (EN)

Page 53

10 Ordering Information

10.1 Replacement parts

We recommend that you have on hand:

Tab. 10-1: Spare parts kit M1352-6000

Description Quantity

V-Belt 1

Gas springs 2

Fuse, 8 A 4

10.2 Accessories

Ordering Information

New Brunswick Innova 40/40R Shaker

English (EN)

53

When ordering accessories, you may be asked to provide the model number and serial number of your

shaker. This information is on the electrical specification plate, located on the rear panel of the unit.

10.2.1 Platforms

Description Capacity Part No.

Universal Platform (Tab. on p. 54) M1250-9902

125 ml Erlenmeyer flask

Dedicated Platform

1

250 ml Erlenmeyer flask

Dedicated Platform

1

500 ml Erlenmeyer flask

Dedicated Platform

1

1 L Erlenmeyer flask Dedicated

Platform

1

2 L Erlenmeyer flask Dedicated

Platform

1

2.8 L Fernbach flask Dedicated

Platform

1

34 M1194-9904

25 M1194-9905

16 M1194-9906

9 M1194-9907

5 M1194-9908

4 M11949-9932

Utility carrier with cushioned

– M1194-9909

crossbars

Utility tray with non-skid rubber

– M1194-9910

surface

Sticky pad platform – M1250-9903

Page 54

54

Ordering Information

New Brunswick Innova 40/40R Shaker

English (EN)

Clamps for Universal Platform are sold separately.

Tab. 10-2: Universal platform flask capacities

Flask Type Capacity Part No.

10 ml 109 ACE-10S

25 ml 64 M1190-9004

50 ml Erlenmeyer Flasks 45 M1190-9000

125 ml Erlenmeyer Flasks 21 M1190-9001

250 ml Erlenmeyer Flasks 18 M1190-9002

500 ml Erlenmeyer Flasks 14 M1190-9003

1 L Erlenmeyer Flasks 8 ACE-1000S

2 L Erlenmeyer Flasks 5 ACE-2000S

2.8 L Fernbach Flasks 4 ACSB-2800S

3 L Erlenmeyer Flasks 4 ACE-3000S

10.2.2 Replacement clamp hardware kits

Eppendorf flask clamps come complete with mounting screws. Additional screws are available separately in

packs of 25 (Part number S2116-3051P).

10.2.3 Test tube racks and other accessories

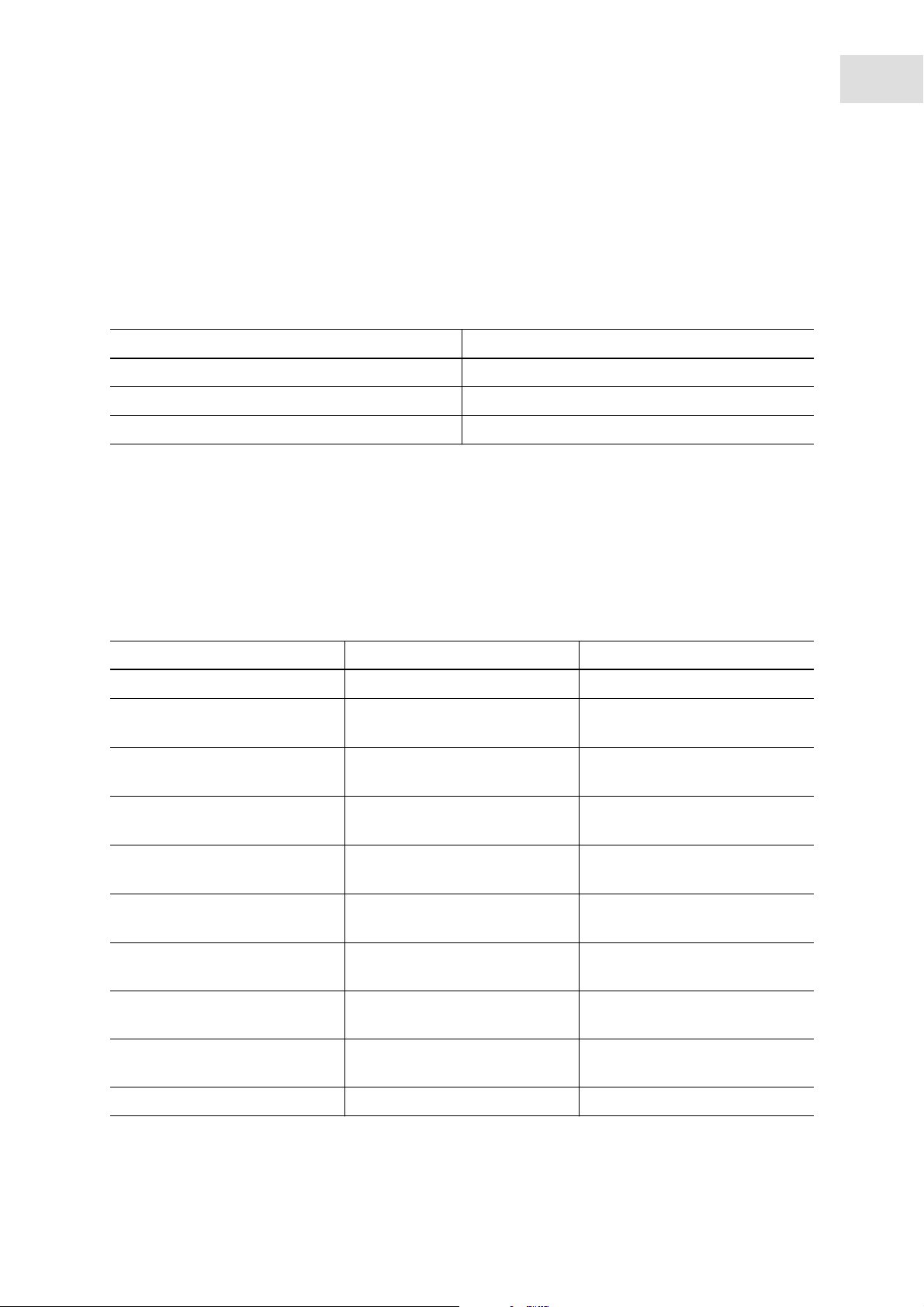

Tab. 10-3: Racks and Trays

Accessory Description Part Number Platform Capacity

Adjustable angle Test

Tube Rack for tubes

8 mm – 11 mm diameter

Adjustable angle Test

Tube Rack for tubes

12 mm – 15 mm

diameter

80 tube capacity M1289-0100 7

60 tube capacity M1289-0010 9

48 tube capacity M1289-0001 9

60 tube capacity M1289-0200 7

44 tube capacity M1289-0020 9

34 tube capacity M1289-0002 9

Adjustable angle Test

Tube Rack for tubes

15 mm – 18 mm

diameter

42 tube capacity M1289-0300 7

31 tube capacity M1289-0030 9

24 tube capacity M1289-0003 9

Page 55

Ordering Information

New Brunswick Innova 40/40R Shaker

English (EN)

55

Adjustable angle Test

Tube Rack for tubes

18 mm –21 mm diameter

30 tube capacity M1289-0400 7

23 tube capacity M1289-0040 9

18 tube capacity M1289-0004 9

Adjustable angle Test

Tube Rack for tubes

22 mm – 26 mm

diameter

Adjustable angle Test

Tube Rack for tubes

26 mm – 30 mm

diameter

Microplate holder rack

22 tube capacity M1289-0500 7

16 tube capacity M1289-0050 9

13 tube capacity M1289-0005 9

20 tube capacity M1289-0600 7

16 tube capacity M1289-0060 9

12 tube capacity M1289-0006 9

3 deep well or 9 standard M1289-0700 16

(stacked)

Microplate holder rack

5 deep well or standard TTR-221 4

(single layer)

Angled Test Tube Rack Holder

1

for user-supplied

test tube racks that are 10 mm – 13 mm (4 in – 5 in)

wide and up to 38 mm (15 in) long.

1

Angled Test Tube Rack Spacer Bar

for use with

TTR-210 to accommodate test tubes racks that are

less than 13 mm (5 in) wide.

TTR-210 4

TTR-215 NA

1

Universal Platform Required

Page 56

56

Ordering Information

New Brunswick Innova 40/40R Shaker

English (EN)

Page 57

Transport, storage and disposal

New Brunswick Innova 40/40R Shaker

English (EN)

11 Transport, storage and disposal

11.1 Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

Information on the disposal of electrical and electronic devices in the European Community:

Within the European Community, the disposal of electrical devices is regulated by national regulations

based on EU Directive 2002/96/EC pertaining to waste electrical and electronic equipment (WEEE).

According to these regulations, any devices supplied after August 13, 2005, in the business-to-business

sphere, to which this product is assigned, may no longer be disposed of in municipal or domestic waste. To

document this, they have been marked with the following identification:

57

Because disposal regulations may differ from one country to another within the EU, please contact your

supplier if necessary.

In Germany, this is mandatory from March 23, 2006. From this date, the manufacturer has to offer a

suitable method of return for all devices supplied after August 13, 2005. For all devices supplied before

August 13, 2005, the last user is responsible for the correct disposal.

Page 58

58

Transport, storage and disposal

New Brunswick Innova 40/40R Shaker

English (EN)

Page 59

Declaration of conformity

New Brunswick Innova 40/40R Shaker

English (EN)

12 Declaration of conformity

The Innova 40/40R Shaker has been tested to ETL standards, to comply with UL and CAN/CSA electrical

safety standards (see ETL regulatory standards on p. 51).

As attested in the CE Declaration of Conformity, the Innova 40/40R Shaker also conform to the appropriate

CE standards.

59

Page 60

60

Declaration of conformity

New Brunswick Innova 40/40R Shaker

English (EN)

Page 61

Index

New Brunswick Innova 40/40R Shaker

English (EN)

61

Index

A

Accessories......................................................11, 53

Alarms .................................................11, 11, 12, 13

Ambient humidity..................................................17

Ambient temperature ............................................17

ASCII .....................................................................38

B

Baud rate .........................................................30, 37

Biohazard decontamination ..................................47

C

Chamber temperature ...........................................49

Changing screens..................................................23

Clamp

Double girdle clamp.........................................19

Clamp installation..................................................19

Clamp screws ........................................................19

Cleaning ................................................................47

Display screen................................................. 24, 50

Disposal ................................................................ 57

Drip pan ................................................................ 12

F

Flask clamp installation ........................................19

Flasks .................................................................... 11

Front panel............................................................ 21

G

Getting the time .................................................... 43

H

Heater ...................................................................12

HyperTerminal................................................ 37, 37

I

Icons

Alarm on .......................................................... 22

Lid open..................................................... 22, 22

Lock on ............................................................ 22

Program running ............................................. 22

Command codes....................................................44

Command format...................................................38

Commanding set speed.........................................38