WTM-TM-VISIR

OPERATOR MANUAL

FOR THE

Weapon Mounted Mini Thermal Monocular (WTM)

Rev. 2 05 December 2011

SAFETY SUMMARY

GENERAL

This manual contains operating instructions and

maintenance procedures which may cause injury or death to

personnel, or damage to equipment if not properly followed.

Prior to performing any task, the WARNINGs, CAUTIONs

and NOTEs included in that task shall be reviewed and

understood.

DEFINITIONS

Safety headings used in this manual and their respective

definitions are as follows:

WARNING

Highlights an essential operating or maintenance

procedure, practice, condition or statement, which,

if not strictly observed, could result in injury to, or

death of, personnel or long term health hazards.

CAUTI ON

Highlights an essential operating or maintenance

procedure, practice, condition or statement, which,

if not strictly observed, could result in damage to,

or destruction of, equipment or loss of mission

effectiveness.

NOTE

Highlights an essential operating or maintenance

procedure, condition or statement.

i

Safety

Class

Unaided 1

Aided 2

NOHD

OD

NOHD

OD

Visible Laser Pointer

3R

65m

0.68

455m

0.68

IR Laser Pointer

3R

14m

0.02

123m

0.02

SAFETY PRECAUTIONS

The following general safety precautions supplement the

specific WARNINGs, CAUTIONs and NOTEs that appear

elsewhere in this manual.

Laser Radiation

Depending on the particular model, the Weapon Mounted

Mini Thermal Monocular (WTM) is equipped with either a

Visible or Infrared (IR) Laser Pointer. The IR laser is

invisible to the naked eye. Regardless of model, the

following general safety precautions apply at all times:

• Do not stare into the laser beam.

• Do not look into the laser beam through binoculars

or telescopes.

• Do not point the laser beam at mirror-like surfaces.

• Do not shine the laser beam into another individuals’

eyes.

Nominal Ocular Hazard Distances (NOHD) for safe

operation and required Optical Densities (OD) are listed in

Table i-1.

Table i-1 Laser Safety Parameters

Laser

1

Viewing without magnifying optics.

2

Viewing with 7x magnifying optics.

ii

WARNING

Exposure to the WTM’s laser beam inside the

NOHDs listed in Table i-1 can cause irreversible

damage to the human eye.

WARNING

IR lasers are detectable by an enemy using night

vision devices. Detection is easier in smoky,

foggy, or rainy conditions. To reduce the risk of

detection by an enemy using night vision devices,

avoid prolonged activation of the WTM’s IR Laser

Pointer.

WARNING

Emission of stray light from the eyepiece (even

with the eyecup installed) may be detectable by

the enemy.

WARNING

• Do not short circuit, puncture, incinerate or

disassemble.

• Do not attempt to recharge.

• Prior to use, inspect all batteries for cracks, dents,

leakage, or bulging. Never install a defective battery

in the WTM.

WARNING

Do not use the WTM with a mix of old and new

batteries, or batteries of different brands.

iii

WARNING

Lithium batteries can explode or cause burns if

disassembled, shorted, recharged, exposed to

water, fire, or high temperatures (above 100°C or

212°F). Do not place loose batteries in a pocket

or other container containing metal objects. Do

not store batteries with hazardous or combustible

materials. Store in a cool, dry, ventilated area.

WARNING

Use of incorrect batteries poses a risk of fire or

explosion. Be aware that batteries do exist with

similar physical characteristics to the DL123A

battery, but with a different voltage and/or polarity

path. Ensure that only 3V lithium batteries with a

raised positive (+) terminal are installed in the

WTM.

WARNING

Use of off-brand batteries poses a risk of fire or

explosion. Ensure that only 3V lithium batteries

produced by well-known battery manufacturers

such as Duracell®, Rayovac®, or Panasonic® are

installed in the WTM. These batteries are

specifically designed for use in high performance,

high-drain devices, and contain built-in fault and

heat protection features.

iv

WARNING

Remove the WTM from the weapon before

inspecting, cleaning, or performing other

maintenance functions on the WTM.

CAUTION

Do not ship or store the WTM with batteries

installed.

CAUTION

Use of acetone or gun cleaning agents containing

perchloroethylene or methylene chloride may

permanently damage the WTM system.

CAUTION

Pointing the WTM directly at the sun without the

lens cover installed may permanently damage the

thermal assembly.

v

TABLE OF CONTENTS

SAFETY SUMMARY ....................................................................... i

TABLE OF CONTENTS ................................................................ vi

LIST OF FIGURES ...................................................................... viii

LIST OF TABLES .......................................................................... ix

CHAPTER 1 ...................................................................................... 1-1

INTRODUCTION ......................................................................... 1-1

SECTION I .............................................................................. 1-1

GENERAL INFORMATION ............................................... 1-1

1.1 SCOPE .................................................................. 1-1

1.2 MODEL NUMBER AND EQUIPMENT NAME ...... 1-2

1.3 MANUFACTURER ................................................ 1-2

1.4 PURPOSE OF EQUIPMENT ................................ 1-2

1.5 ABBREVIATIONS AND ACRONYMS .................. 1-3

SECTION II ............................................................................. 1-4

EQUIPMENT DESCRIPTION ........................................... 1-4

1.6 SYSTEM DESCRIPTION ...................................... 1-4

1.7 TECHNICAL SPECIFICATIONS .......................... 1-5

CHAPTER 2 ...................................................................................... 2-1

OPERATING INSTRUCTIONS ................................................... 2-1

1.8 MAJOR COMPONENTS ....................................... 1-6

SECTION I .............................................................................. 2-1

PREPARATION FOR USE ............................................... 2-1

2.1 PREPARATION FOR USE ................................... 2-1

2.2 BATTERY HANDLING .......................................... 2-2

2.3 MOUNTING PROCEDURES ................................ 2-3

2.4 ZEROING PROCEDURES ................................... 2-9

2.5 OBJECTIVE LENS AND EYEPIECE .................. 2-11

SECTION II ........................................................................... 2-13

OPERATING INSTRUCTIONS ....................................... 2-13

2.6 FEATURES AND CONTROLS ........................... 2-13

2.7 POWER ............................................................... 2-14

2.8 BUTTON FUNCTIONS ....................................... 2-15

2.9 CALIBRATION .................................................... 2-16

2.10 DIOPTER ADJUSTMENT ................................. 2-16

2.11 GAIN ADJUSTMENT ........................................ 2-17

2.12 OBJECTIVE FOCUS ........................................ 2-18

2.13 STARTUP PROCEDURES ............................... 2-18

vi

TABLE OF CONTENTS - Continued

2.14 LASER POINTER ............................................. 2-19

SECTION III .......................................................................... 2-20

SYSTEM MENU .............................................................. 2-20

2.15 MENU NAVIGATION ........................................ 2-20

2.16 MAIN MENU ...................................................... 2-20

SECTION IV ......................................................................... 2-30

EXTERNAL VIEWING / IMAGE DOWNLOAD ............... 2-30

CHAPTER 3 ...................................................................................... 3-1

MAINTENANCE .......................................................................... 3-1

APPENDIX A ................................................................................... A-1

END ITEM COMPONENTS AND REPAIR PARTS ................... A-1

2.17 IMAGE ADAPTER CABLE................................ 2-30

SECTION I .............................................................................. 3-1

OPERATOR MAINTENANCE ........................................... 3-1

3.1 TROUBLESHOOTING .......................................... 3-1

3.2 INSPECTION / CLEANING................................... 3-3

3.3 CORRECTIVE MAINTENANCE PROCEDURES 3-5

SECTION II ............................................................................. 3-7

SERVICE / PACKING AND UNPACKING ........................ 3-7

3.4 RETURN INSTRUCTIONS ................................... 3-7

3.5 WARRANTY INFORMATION ............................... 3-8

3.6 NON-WARRANTY INFORMATION ...................... 3-8

vii

LIST OF FIGURES

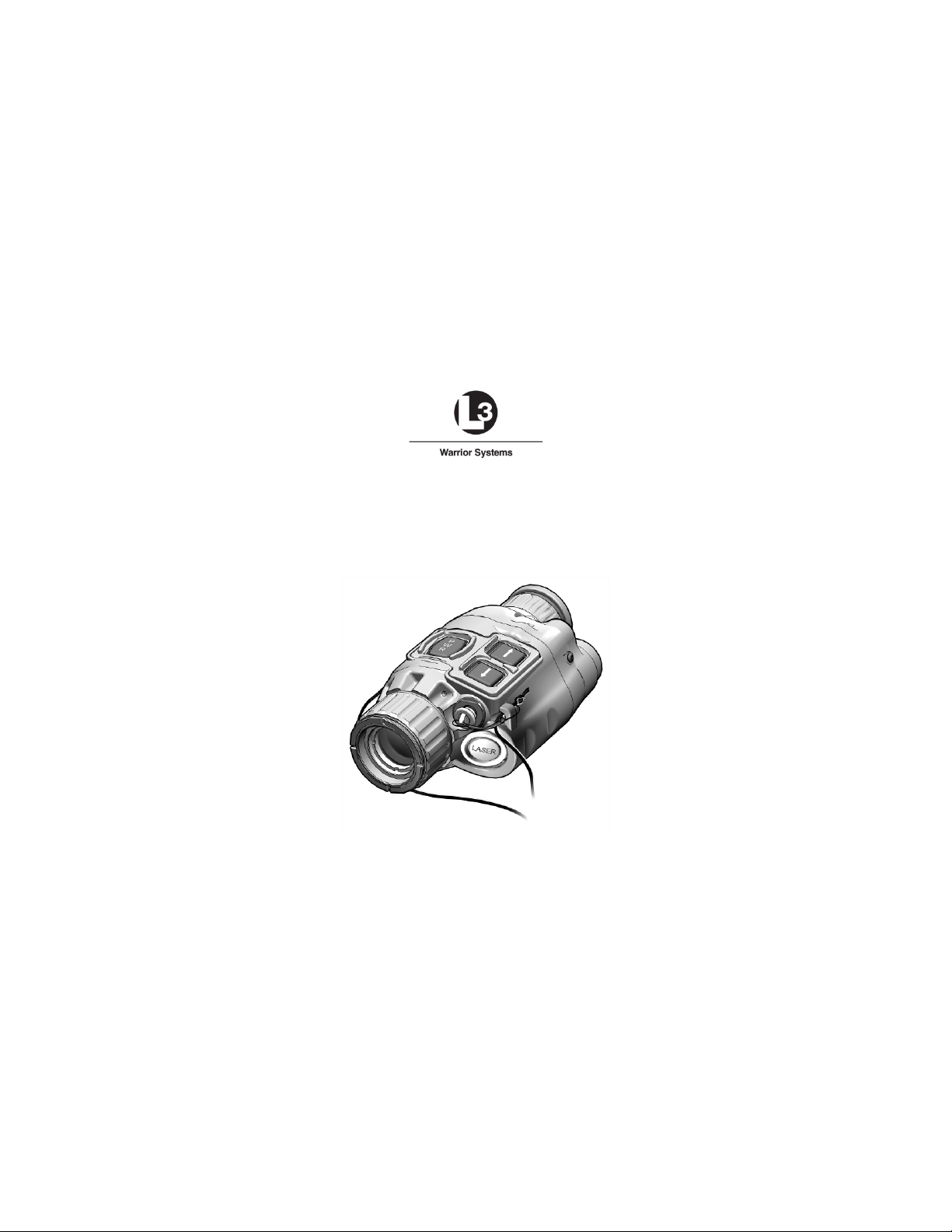

Figure 1-1 Weapon Mounted Mini Thermal Monocular (W TM) ....... 1-1

Figure 1-2 Major Components ......................................................... 1-6

Figure 2-1 Battery Installation .......................................................... 2-2

Figure 2-2 WTM Mounting Bracket .................................................. 2-3

Figure 2-3 AN/PVS-7/14 Helmet Mount Adapter ............................. 2-4

Figure 2-4 Installing the AN/PVS-7/14 Helmet Mount Adapter ....... 2-5

Figure 2-5 Weapon Mount Adapter ................................................. 2-6

Figure 2-6 Installing the Weapon Mount Adapter ............................ 2-7

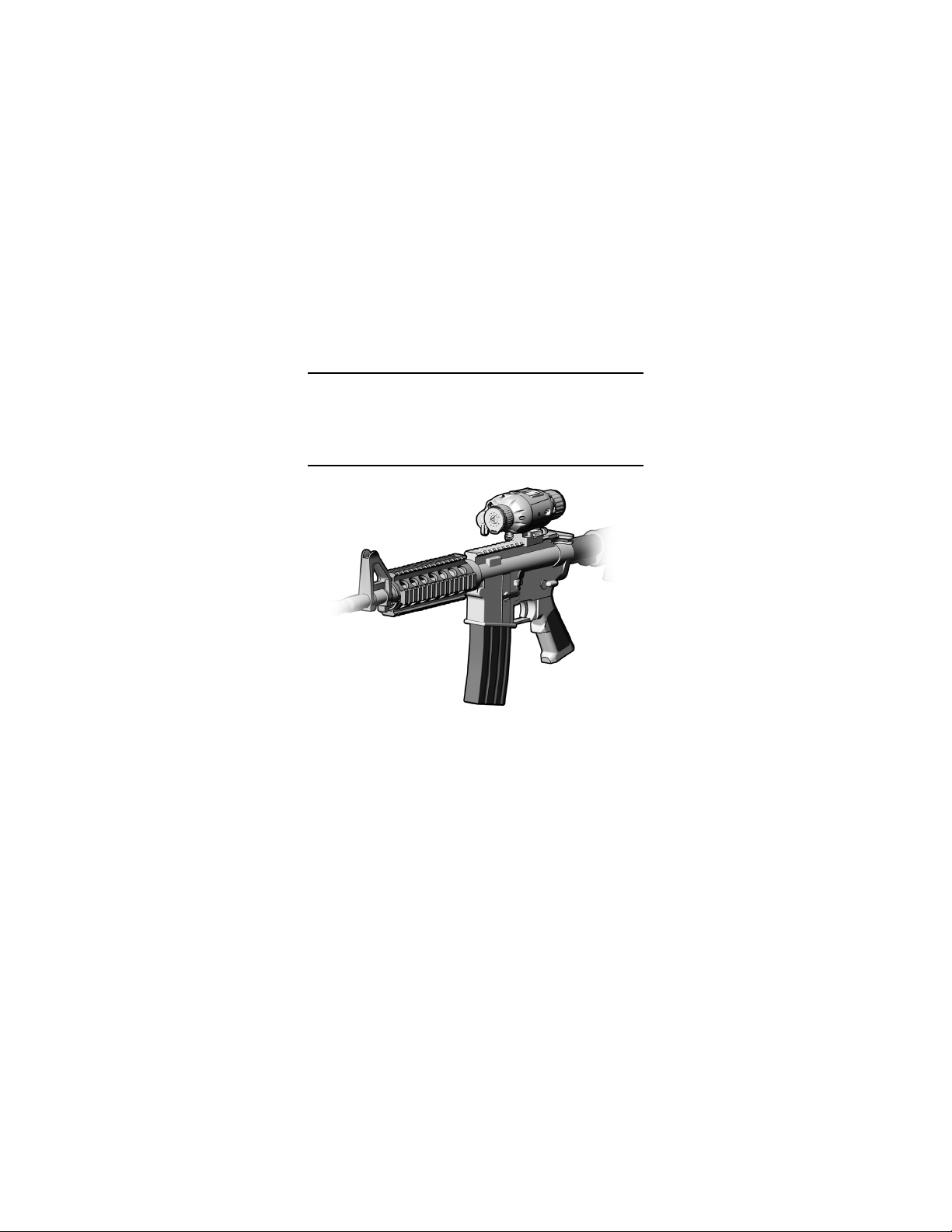

Figure 2-7 Weapon Mount Adapter Installed ................................... 2-8

Figure 2-8 Features and Controls .................................................. 2-13

Figure 2-9 Features and Controls – Continued ............................. 2-14

Figure 2-10 Gain Control ............................................................... 2-17

Figure 2-11 Display with Laser Pointer Activated .......................... 2-19

Figure 2-12 Main Menu .................................................................. 2-20

Figure 2-13 Menu – ZOOM 1X / ZOOM 2X ................................... 2-21

Figure 2-14 Menu – White Hot / Black Hot .................................... 2-21

Figure 2-15 Menu – Calibration (CAL) ........................................... 2-22

Figure 2-16 Menu – Picture (PIC) .................................................. 2-23

Figure 2-17 Menu – Review (REV) ................................................ 2-24

Figure 2-18 Menu – Review Sub-Menu ......................................... 2-24

Figure 2-19 Menu – RS170 / VGA ................................................. 2-26

Figure 2-20 Menu – RETICLE

Figure 2-21 Menu – RETICLE Sub-Menu ..................................... 2-27

Figure 2-22 Menu – HAND / HELMET .......................................... 2-29

Figure 2-23 Menu - EXIT ............................................................... 2-29

Figure 2-24 Image Adapter Cable ................................................. 2-30

Figure 3-1 Replacing Neck Cord ..................................................... 3-5

Figure 3-2 Replacing Battery Cap Lanyard ..................................... 3-6

Figure A-1 End Item Components .................................................. A-1

Figure A-2 WTM Assembly ............................................................. A-3

....................................................... 2-27

viii

LIST OF TABLES

Table i-1 Laser Safety Parameters ..................................................... ii

Table 1-1 W TM Models .................................................................... 1-2

Table 1-2 Technical Specifications .................................................. 1-5

Table 1-3 List of Major Components ............................................... 1-7

Table 2-1 Reticle Adjustments ....................................................... 2-10

Table 2-2 Mounting Configurations and Weapon Offsets ............. 2-11

Table 2-3 PWR Button Operation .................................................. 2-15

Table 2-4 UP / DOWN Button Operation ....................................... 2-15

Table 2-5 LED Status Indicators .................................................... 2-33

Table 3-1 Troubleshooting Procedures ........................................... 3-1

Table A-1 List of End Item Components ......................................... A-2

Table A-2 List of Repair Parts ......................................................... A-3

ix

x

CHAPTER 1

INTRODUCTION

SECTION I

GENERAL INFORMATION

Figure 1-1 Weapon Mounted Mini Thermal Monocular

(WTM)

1.1 SCOPE

This manual is intended for use by operators of the Weapon

Mounted Mini Thermal Monocular (WTM). It provides a

system description, operational procedures, and

maintenance responsibilities. Complete familiarization with

this manual prior to using the equipment will ensure safe

operation and maximum effectiveness of the WTM.

1-1

Model

Laser Pointer

Rail

Visible

Laser Pointer

Picatinny

(MIL-STD-1913)

Laser Pointer

(MIL-STD-1913)

Laser Pointer

1.2 MODEL NUMBER AND EQUIPMENT NAME

This manual applies to the WTM models listed in Table 1-1.

WTM-000-A14

WTM-000-A16

WTM-000-A17

Table 1-1 WTM Models

Infrared (IR)

Infrared (IR)

Picatinny

Weaver™

Because this manual applies to several different WTM

models, pictures contained herein may not be representative

of the exact model purchased or issued.

1.3 MANUFACTURER

L-3 Communications Corporation

Warrior Systems Division

Insight Operations

9 Akira Way

Londonderry, NH 03053 USA

1.4 PURPOSE OF EQUIPMENT

The WTM is a battery operated, handheld or weapon

mounted thermal imaging device with an integrated Laser

Pointer (IR or Visible) and a digital camera.

1-2

BNC

Bayonet Neill-Concelman

C

Celsius

CAL

Calibration

cm

Centimeter

CW

Clockwise

F

Fahrenheit

IR

Infrared

ITAR

International Traffic in Arms Regulations

m

Meter

mrad

Milliradian

mW

Milliwatt

nm

Nanometer

PC

Personal Computer

PIC

Picture

RECAL

Recalibrate

RMA

Return Material Authorization

USB

Universal Serial Bus

V

Volt

VGA

Video Graphics Array

WHOT

White Hot (polarity)

WTM

Weapon Mounted Mini Thermal

Monocular

1.5 ABBREVIATIONS AND ACRONYMS

Abbreviations and acronyms used in this manual are listed

as follows:

BHOT Black Hot (polarity)

CCW Counterclockwise

LED Light Emitting Diode

NOHD Nominal Ocular Hazard Distance

REV Review

1-3

SECTION II

EQUIPMENT DESCRIPTION

1.6 SYSTEM DESCRIPTION

The WTM is a battery operated, thermal imaging device with

an integrated Laser Pointer (IR or Visible) and digital

camera. It may be mounted to a standard tripod, an

AN/PVS-7 / PVS-14 helmet assembly, or to any weapon

equipped with a Picatinny (MIL-STD-1913) or Weaver rail.

The thermal imaging capability of the WTM allows for

observation and target identification under adverse

conditions including light rain, smoke, light snow, and low

light to total darkness. It will not allow the user to see

through glass, water, or heavy rain / snow.

Models equipped with a Visible Laser Pointer provide for

target acquisition in low light conditions without the need for

night vision devices. Models equipped with an IR Laser

Pointer provide for target acquisition in low light or complete

darkness when used in conjunction with night vision devices.

With the integrated camera, the WTM allows for acquisition,

storage, download, and recall of viewed thermal images.

Thermal images may also be transferred to a personal

computer.

The WTM is a ruggedized system designed for operation in

battlefield environments.

1-4

WEIGHT AND DIMENSIONS

Weight (with batteries)

< 16.0 ounces

Length

5.2 inches

Height

2.2 inches

POWER AND PERFORMANCE

Power Source

2 DL123A lithium batteries

Battery Operating Life1

4 hours continuous operation

Field of View

≥28° diagonal

Operating Temperature

-29°F (-34°C) to 120°F (49°C)

Immersion

66 feet for 2 hours

IR LASER POINTER

(If equipped)

Output Power

0.6 mW (± 0.1 mW)

Wavelength

840 nm (+10 / -20 nm)

VISIBLE LASER POINTER

(If equipped)

Output Power

4.3 mW (± 0.5 mW)

Beam Divergence

0.5 mrad (± 0.3 mrad)

Wavelength

645 nm (+10 / -5 nm)

1.7 TECHNICAL SPECIFICATIONS

Table 1-1 provides technical specifications for the WTM.

Table 1-2 Technical Specifications

Width 2.8 inches

Storage Temperature -40°F (-40°C) to 160°F (71°C)

Beam Divergence 0.5 mrad (± 0.3 mrad)

1

Performance will vary depending on actual environmental and atmospheric

conditions.

1-5

5

2 6 3

7

8

11

10

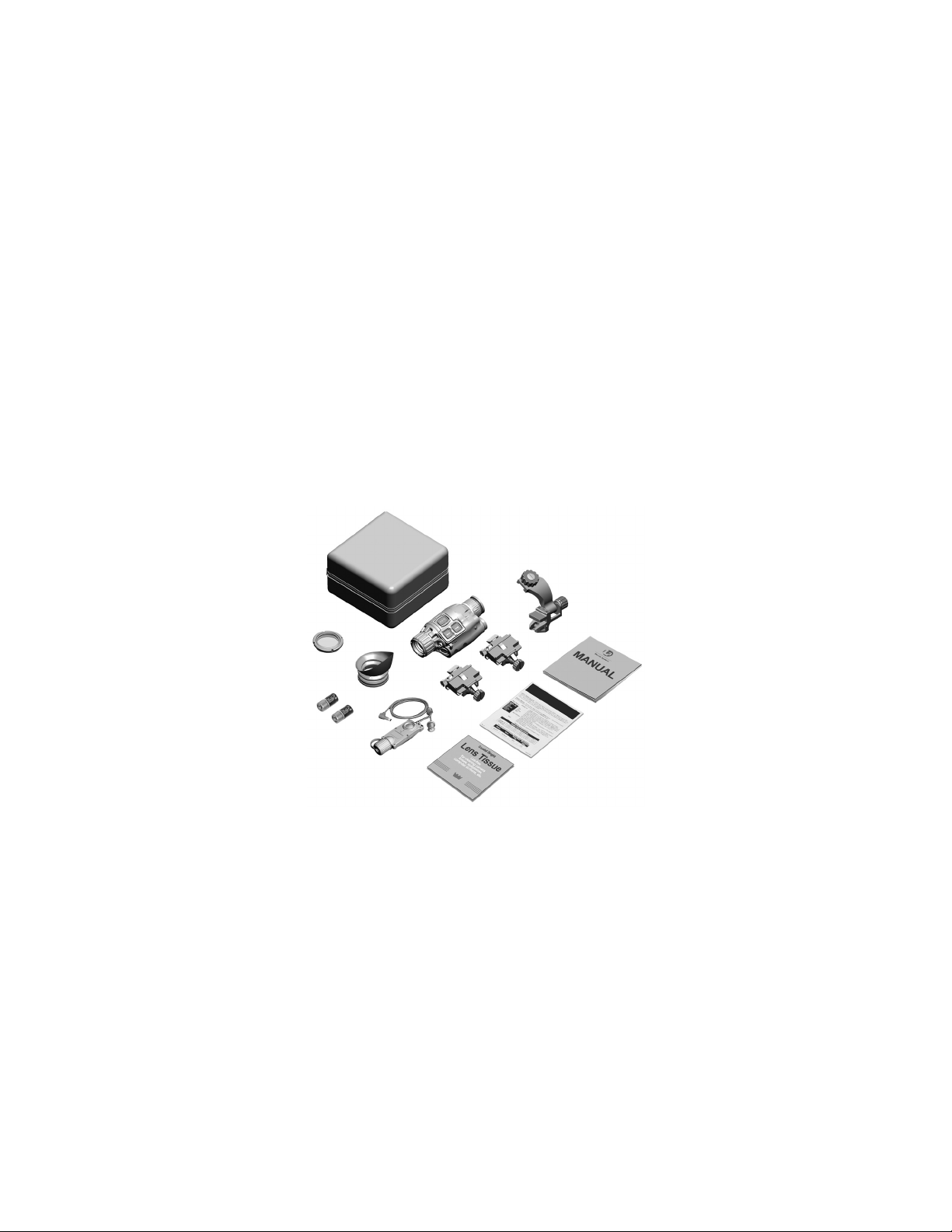

1.8 MAJOR COMPONENTS

The WTM is available in several models with a wide array of

accessory items. Figure 1-2 shows components and parts

for the entire family of WTM configurations. Therefore, some

of the items shown may not be applicable to your specific

configuration. Table 1-3 provides a brief functional

description of each item. The “Key” column in Table 1-3

corresponds to the label numbers in Figure 1-2.

1

12

1-6

9

Figure 1-2 Major Components

4

Major

Component

1

Soft Carrying

Protects the WTM and accessories

2

Helmet Adapter,

Allows the WTM to be installed on a

helmet mount.

3

Operator Manual

Provides detailed operating and

WTM.

4

Guide

procedures for the WTM.

WTM.

7

Picatinny

Mount Adapter

Allows the WTM to be mounted to any

(MIL-STD-1913) rail.

8

Weaver Mount

Adapter

Allows the WTM to be mounted to any

weapon equipped with a Weaver rail.

1.8 LIST OF MAJOR COMPONENTS – Continued

Table 1-3 List of Major Components

Key

Function

5

6

Case

AN/PVS-7/14

Quick Reference

Lens Tissue

Image Adapter

Cable

(MIL-STD-1913)

while in a field environment.

helmet equipped with an AN/PVS-7/14

maintenance instructions specific to the

Provides at-a-glance operating

Used to clean the optical lenses of the

Used to connect the WTM to an

external monitor for viewing live

imagery, or to a computer so that stored

thermal images may be viewed or

downloaded.

weapon equipped with a Picatinny

1-7

Major

Component

9

WTM Assembly

The WTM is a battery operated,

10

Eyecup

When attached, reduces emission of

stray light from the eyepiece.

11

Batteries,

DL123A (2)

Two 3V lithium batteries used to power

the WTM.

environments.

1.8 MAJOR COMPONENTS – Continued

Table 1-3 List of Major Components – Continued

Key

weapon-mounted or handheld thermal

imaging device with an integrated Laser

Pointer (IR or Visible) and digital

camera.

Function

12

1-8

Night Adaptive

Filter / Demist

Shield

When attached, prevents fogging of the

eyepiece and reduces backlighting and

loss of night vision in low light

CHAPTER 2

OPERATING INSTRUCTIONS

SECTION I

PREPARATION FOR USE

2.1 PREPARATION FOR USE

Unpacking the Equipment

Open the soft carrying case and verify that all major

components listed in Table 1-3 are present. Check the WTM

to ensure the following additional items are included:

a. Battery Cap Assembly

b. Video Jack Plug

c. Objective Lens Cover

d. Neck Cord

If any of the major components or items listed above are

missing, seek guidance from the equipment issuing

authority.

Inspection of the Equipment

Before use, inspect all pieces of equipment for any damage

such as cracks, loose parts, faulty cables, or other visible

defects. If any damage or defects are noted, seek guidance

from the equipment issuing authority.

2-1

2.2 BATTERY HANDLING

Battery Inspection

Before installation, inspect the batteries for any cracks,

dents, leakage, or bulging. Never install a defective battery

in the WTM.

WARNING

Ensure the WTM is OFF before attempting to

install, remove, or replace batteries.

Battery Installation

Access the battery compartment by turning the battery cap

counterclockwise. Install two fresh DL123A lithium batteries

with the positive terminals facing out as shown in Figure 2-1.

Replace the battery cap and turn clockwise to tighten.

Figure 2-1 Battery Installation

CAUTION

Do not ship or store the WTM with batteries

installed.

2-2

MOUNTING

MOUNTING

GROOVE

2.2 BATTERY HANDLING – Continued

Low Batte ry Indicator

A low battery message will appear in the eyepiece display

when approximately 15 minutes of continuous operation

remain. If the batteries are not replaced promptly when the

“LOW POWER” message appears, the display quality will

deteriorate rapidly.

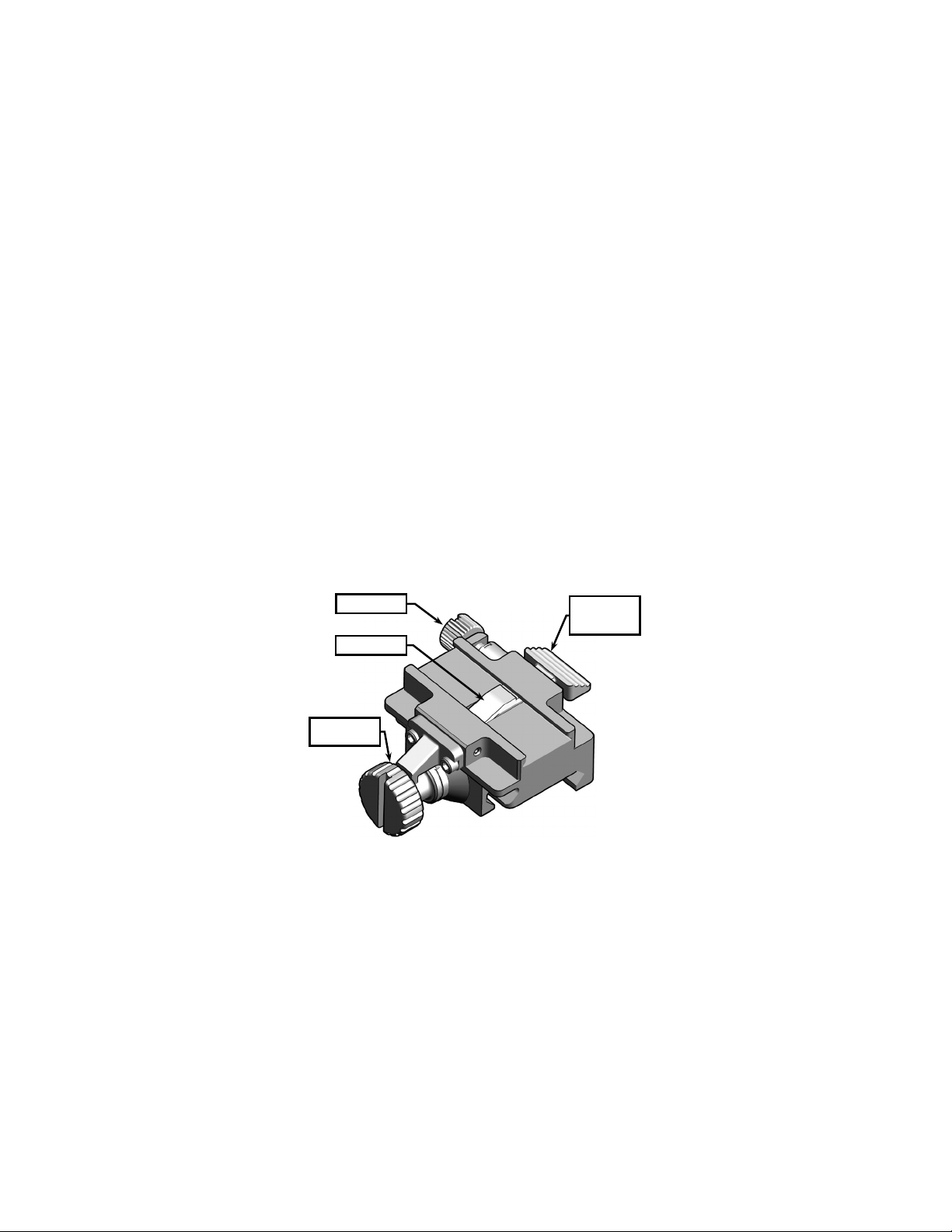

2.3 MOUNTING PROCEDURES

The WTM uses a versatile mounting bracket and adapters to

mount to a standard tripod, an AN/PVS-7 / PVS-14 helmet

assembly, or to any weapon equipped with a Picatinny

(MIL-STD-1913) or Weaver rail.

BRACKET

Figure 2-2 WTM Mounting Bracket

2-3

RELEASE

KNOB

2.3 MOUNTING PROCEDURES – Continued

WARNING

Be sure the WTM is OFF before attempting to

mount to a weapon, tripod, or helmet assembly.

Mounting to a Tripod

The WTM mounting bracket contains two screw holes with

female threading to accept a standard ¼”-20 tripod screw.

Align the threads and rotate the WTM clockwise until

securely mounted.

AN/PVS-7/14 Helmet Mount Adapter

The Helmet Mount Adapter allows the WTM to be installed

on an AN/PVS-7 / PVS-14 helmet assembly.

ADJUSTMENT

KNOB

Figure 2-3 AN/PVS-7/14 Helmet Mount Adapter

2-4

2.3 MOUNTING PROCEDURES – Continued

1. Hold the WTM with the eyepiece toward the operator and

the mounting bracket oriented as shown in Figure 2-4.

2. Slide the helmet mount adapter onto the WTM’s mounting

bracket.

3. Rotate the release knob clockwise or counterclockwise so

that the helmet mount adapter will seat properly in the

mounting groove of the mounting bracket.

4. The WTM may now be attached to a helmet mount.

Figure 2-4 Installing the AN/P VS-7/14 Helmet Mount

Adapter

Once mounted to an AN/PVS-7/14 helmet assembly, the

WTM can be moved in an arc to provide best alignment with

the operator’s eye.

2-5

KNOB

LEVER POST

QUICK

LEVER

2.3 MOUNTING PROCEDURES – Continued

1. Unscrew the adjustment knob to its full and open position.

2. Gently push the WTM away from the operator’s head and

rotate clockwise or counterclockwise until proper

positioning is achieved. Tighten the adjustment knob to

lock the WTM in place.

Mounting to a Weapon

Weapon mount adapters are available that allow the WTM to

be installed on any weapon equipped with a Picatinny

(MIL-STD-1913) or Weaver rail. Regardless of the type of

adapter that you are issued, the procedure for attachment to

the WTM is the same.

LEVER LOCK

CLAMPING

RELEASE

2-6

Figure 2-5 Weapon Mount Adapter

2.3 MOUNTING PROCEDURES – Continued

WARNING

Be sure the weapon is clear and safe before

proceeding.

Figure 2-6 Installing the Weapon Mount Adapter

1. Hold the WTM with the eyepiece toward the operator, and

the mounting bracket oriented as shown in Figure 2-6.

2. While pressing the quick release lever, slide the weapon

mount adapter onto the mounting bracket.

3. Let go of the quick release lever. Slide the weapon

mount adapter until the lever post engages the mounting

groove on the mounting bracket.

4. Turn the lever lock clockwise as tightly as fingers allow.

5. The WTM may now be attached to a weapon.

2-7

2.3 MOUNTING PROCEDURES – Continued

Mount the WTM to the weapon rail as follows:

RECOIL LUG

Figure 2-7 Weapon Mount Adapter Installed

1. Loosen the clamping knob on the weapon mount adapter

until the jaws have sufficient space to fit over the

weapon’s rail.

2. Position the weapon mount adapter on the rail, ensuring

that the recoil lug is seated in the desired recoil groove of

the rail.

3. Turn the clamping knob clockwise as tightly as fingers

allow, then use a coin or similar flat object in the slot of

the clamping knob to turn it an additional 180 degrees.

4. Zero the WTM to the host weapon on a 25-meter range

per section 2.4.

2-8

2.3 MOUNTING PROCEDURES – Continued

NOTE

The WTM may be placed at any position (forward

and aft) on the rail that is most convenient for the

operator. If, however, the WTM is removed from

the rail, the operator must make note of the

position at which it was zeroed, and return it to

that same position to ensure that zero is

maintained.

NOTE

If, for whatever reason, the lever lock becomes

loose, retighten and perform the 25-meter zeroing

procedure described in section 2.4.

2.4 ZEROING PROCEDURES

This procedure is used to zero the WTM to the host weapon

on a 25-meter range.

NOTE

Each click of the WTM reticle moves the shot

group 3.1cm at 25 meters (when in ZOOM 1X).

Other click equivalents are provided in Table 2-1.

Changing the position of the reticle corresponds to

a subsequent change in shot group movement

(i.e., the UP button will move the strike group up).

2-9

Shot Group Movement

10 m

25 m

100 m

150 m

300 m

ZOOM 1X

1.2cm

3.1cm

12cm

18.5cm

36.9cm

ZOOM 2X

0.6cm

1.5cm

6cm

9.25cm

8.45cm

2.4 ZEROING PROCEDURES – Continued

Table 2-1 Reticle Adjustments

1. On a 25-meter zeroing target, mark the designated strike

point and designated strike zone using the target offset

values in Table 2-2.

2. Mount the target on an “E” silhouette or other suitable

surface at 25 meters.

3. Mount the WTM to the weapon.

4. Power up the WTM as described in section 2.7.

5. Align the WTM reticle with the center of the target per

section 2.16, RETICLE.

6. Fire a 3-round shot group and note the center of the shot

group relative to the designated strike point.

7. Adjust the position of the reticle to move the center of the

shot group to the designated strike point.

8. Fire another 3-round shot group and again observe the

center of the new shot group relative to the designated

strike point.

9. When 2 out of 3 rounds are in the designated strike zone,

the WTM / weapon combination is zeroed.

2-10

0.0

2.9D

2.4 ZEROING PROCEDURES – Continued

Table 2-2 Mounting Configurations and Weapon Offsets

Weapon Mount

M4/M4A1 Top Mount 300m

Range Zeroed

To

25m Target Zero

Offset Squares

2.5 OBJECTIVE LENS AND EYEPIECE

Objective Lens

Whenever the WTM is not being used, the objective lens

cover should be fitted over the objective lens to protect it

from possible damage. The objective lens cover should also

be installed when calibrating the WTM (see section 2.9).

Night Adaptive Filter / Demist Shield

When installed, the night adaptive filter / demist shield

prevents the eyepiece from fogging, and reduces

backlighting and loss of night vision in low light

environments. The filter / shield is installed as follows:

1. Place the filter / shield over the eyepiece with the

threaded side down.

2. Carefully turn the filter / shield clockwise to screw it into

the eyepiece assembly.

3. Insert the end of a pen, paper clip, or similar item into one

of the four retaining ring grooves. Rotate the retaining

ring clockwise to tighten.

2-11

2.5 OBJECTIVE LENS AND EYEPIECE – Continued

Eyecup

When attached, the eyecup reduces emission of stray light

from the eyepiece. To install, gently snap into place over the

eyepiece assembly. Rotate the eyecup to obtain a proper

eye socket and cheek weld.

2-12

POWER

BUTTON

DIOPTER

BUTTONS

VIDEO JACK

PLUG

LASER

BUTTON

SECTION II

OPERATING INSTRUCTIONS

2.6 FEATURES AND CONTROLS

Figures 2-8 and 2-9 show the features and controls for the

WTM. This section provides details regarding their function

and operation.

LASER LED

UP / DOWN

ADJUSTER

EYEPIECE

Figure 2-8 Features and Controls

VIDEO JACK

2-13

LASER

POINTER

LENS COVER

BATTERY CAP /

COMPARTMENT

FOCUS RING

2.6 FEATURES AND CONTROLS – Continued

OBJECTIVE

Figure 2-9 Features and Controls – Continued

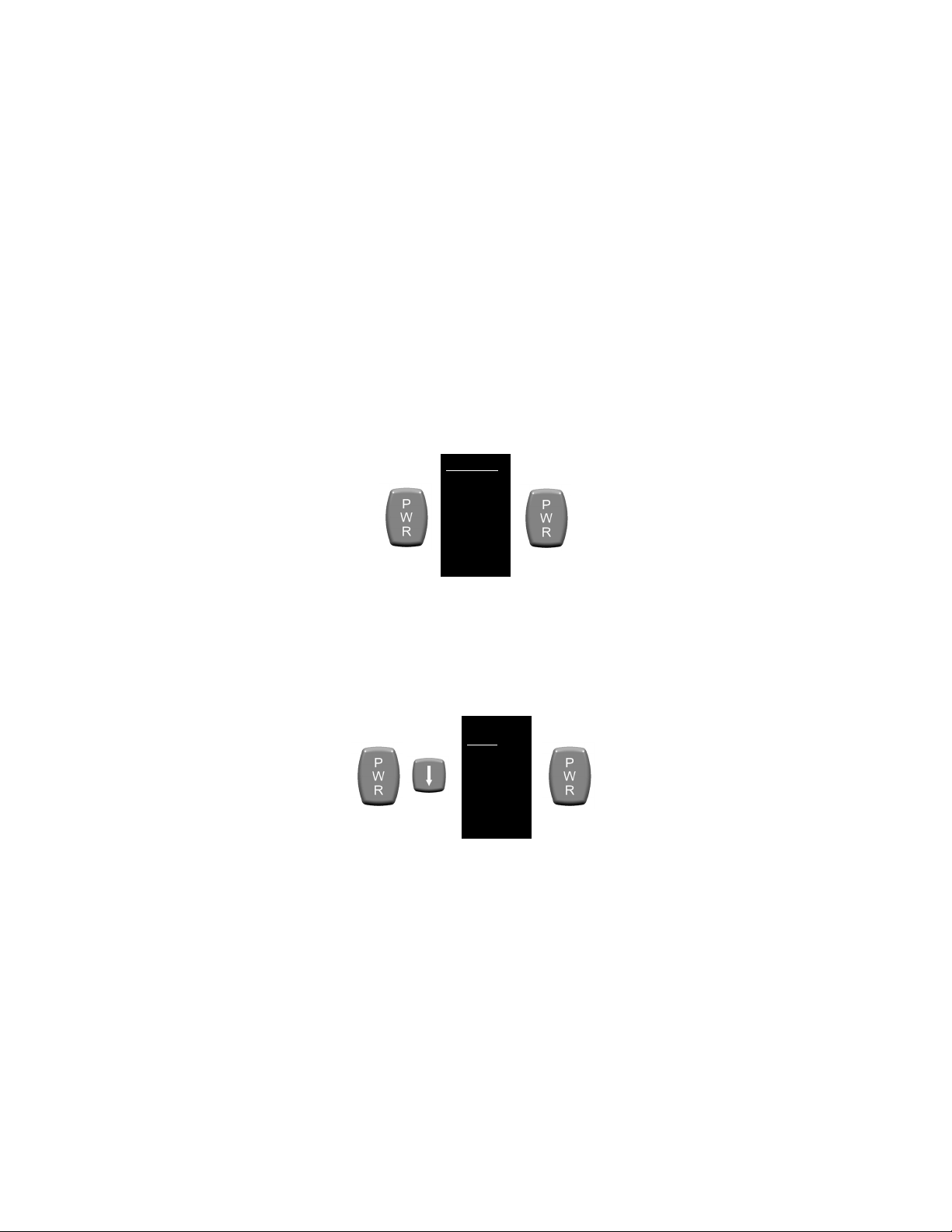

2.7 POWER

To turn on the WTM, press the PWR button and wait 2 to 5

seconds for the system prompt, and then press the PWR

button again. The WTM will power up with the same settings

selected as when the system was last turned off.

To turn off the WTM, press and hold the PWR button for

approximately 3 seconds as the messages OFF? then OFF!

appear sequentially in the eyepiece display. Release the

PWR button when the eyepiece display turns dark.

2-14

System

Status

press again

Press (and hold) for about 3

turns off

Calls up Main

item

System

Status

How Button is

Pressed

ON

Single tap

Scrolls through the menu

Displayed

ON

Displayed

Press and hold

simultaneously

2.8 BUTTON FUNCTIONS

WTM buttons are multi-functional and produce different

results depending on the system status (i.e., ON, OFF) and

how the buttons are pressed. See Tables 2-3 and 2-4.

Menu Displayed

Table 2-3 PWR Button Operation

How Button is Pressed Result

Press, wait 2 to 5 seconds

OFF

ON

ON Single tap

ON

for system prompt, then

seconds until display screen

Single tap

Turns on WTM

(see section 2.7)

Turns off WTM

(see section 2.7)

Menu

Activates the

highlighted menu

Table 2-4 UP / DOWN Button Operation

Result

Menu Displayed

ON

Menu NOT

Menu NOT

(either button)

Single tap

(either button)

both buttons

items

Calls up gain control

(see section 2.11)

Initiates a calibration

(see section 2.9)

2-15

2.9 CALIBRATION

After prolonged use, or after transitions from one

temperature extreme to another, a degradation of the

thermal image may be noticed. In these instances, and

during initial startup, the WTM should be calibrated to

optimize the viewed thermal image.

Calibration is accomplished by simultaneously pressing (and

holding) the UP / DOWN buttons, or via the system menu

(see section 2.16, Calibration (CAL)). Regardless of which

method is used, the objective lens cover must first be placed

over the objective lens. Failure to do so may result in a

distorted picture or the presence of ghost images in the

eyepiece display.

The WTM is equipped with an internal sensor that detects

significant changes in temperature. When this condition

occurs, the message “RECAL” will appear in the eyepiece

display indicating that the operator should calibrate the WTM

as described above.

2.10 DIOPTER ADJUSTMENT

The eyepiece may be focused to accommodate differences

in individual operators’ eyesight. Diopter adjustments may

be made as follows:

1. With the system powered on, press the PWR button to

call up the Main Menu.

2. While looking through the eyepiece display, rotate the

diopter adjuster until the menu text appears sharp and

clear.

2-16

MIN

Status Bar

2.11 GAIN ADJUSTMENT

When the Main Menu is NOT displayed, pressing either the

UP or DOWN button calls up the gain control settings. Gain

controls are presented in the eyepiece display as shown in

Figure 2-10.

GAIN

MAX

|

― ―

|

Figure 2-10 Gain Control

Gain is adjusted by pressing the UP / DOWN buttons to

move the status bar along the MAX / MIN line. If the UP /

DOWN buttons are not pressed within three seconds, the

gain control scale will disappear and the WTM will revert to

normal viewing mode. Once adjusted, the gain will remain at

the applied setting (even if the WTM is turned off) until

readjusted by the operator.

Repeatedly pressing the UP / DOWN buttons will move the

status bar in single increments. Pressing and holding the

UP / DOWN buttons will auto-scroll the status bar in multiple

increments.

2-17

2.12 OBJECTIVE FOCUS

The objective lens must be focused for the viewing distance

being observed. Rotate the objective focus ring for best

image clarity. A change in viewing distance requires that the

objective lens be refocused. If already focused for a

distance of at least 15 meters (49 feet), no change in focus

is required between this distance and infinity. When the

WTM is not being used, install the objective lens cover over

the objective lens to protect it from possible damage.

2.13 STARTUP PROCEDURES

To achieve optimal performance and image clarity, the

following procedures should be accomplished in the order

presented, each time the WTM is to be used:

1. Turn on the WTM by pressing the PWR button. Wait 2 to

5 seconds for the system prompt and press the PWR

button again.

2. Install the objective lens cover and perform a calibration

as described in section 2.9.

3. Access the Main Menu by pressing the PWR button.

While looking through the eyepiece display, rotate the

diopter adjuster until the menu text appears sharp and

clear.

4. Remove the objective lens cover and adjust the gain

setting as described in section 2.11 to achieve a

comfortable contrast level.

5. While looking through the eyepiece at an object at least

one meter away, rotate the objective focus ring to obtain

the best (sharpest) thermal image.

2-18

2.14 LASER POINTER

With the WTM powered on, pressing (and holding) the

LASER button activates the laser pointer until pressure is

released from the button. Continuous activation is

accomplished by double-tapping the LASER button. While

in continuous mode, pressing the LASER button again

(single-tapping) turns off the laser.

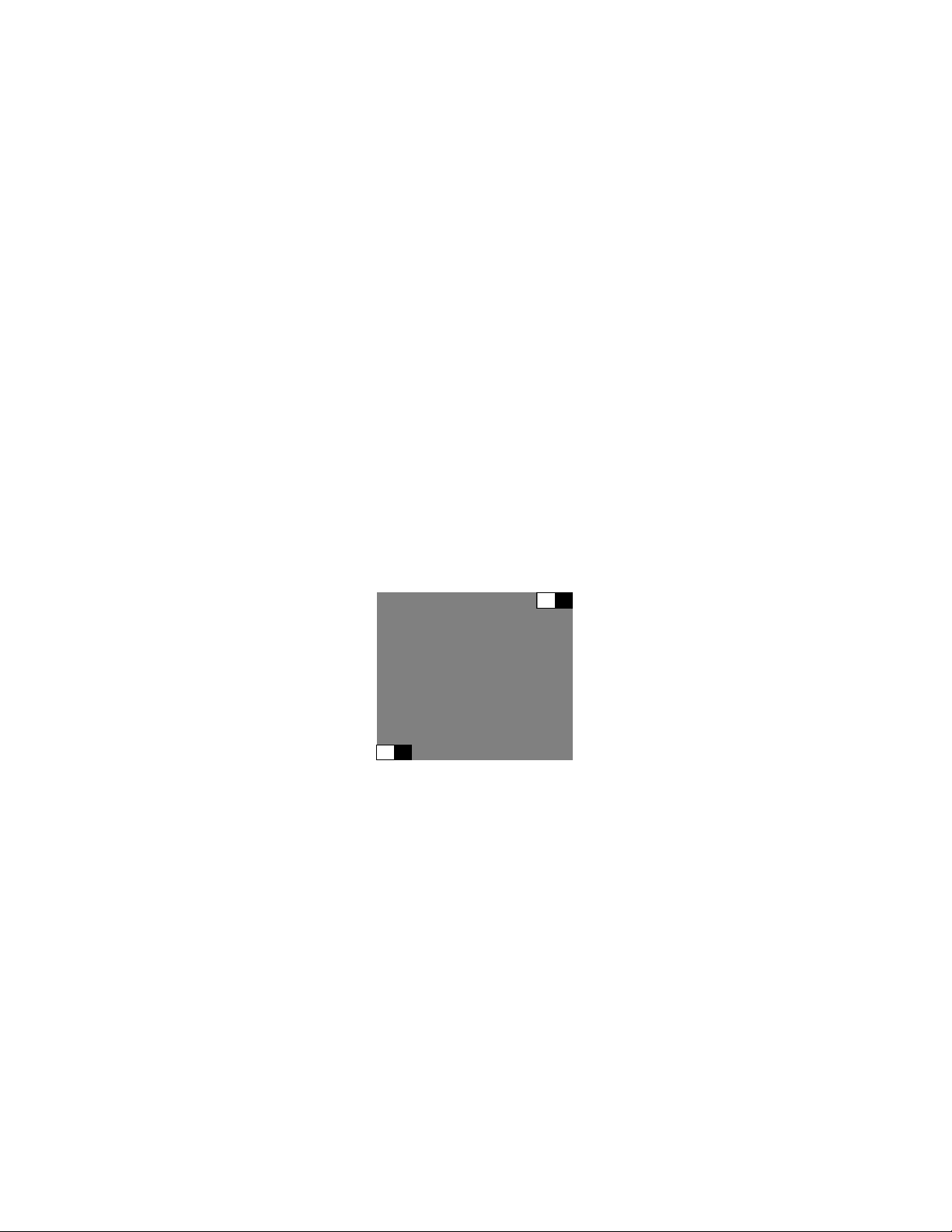

When the laser pointer is activated, a dot appears in the

center of the display reticle. Additionally, black and white

squares appear in the top right and bottom left corners of the

display as shown in Figure 2-11. Further indication that the

laser pointer is activated is provided by the green laser LED

shown in Figure 2-8.

Figure 2-11 Display with Laser Pointer Activated

|

― ▪ ―

|

2-19

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

SECTION III

SYSTEM MENU

2.15 MENU NAV IG ATION

With the WTM turned on, access the Main Menu by pressing

the PWR button. Menu items are then selected (underlined)

by scrolling with the UP / DOWN buttons. Pressing the PWR

button again activates the selected menu item. If the UP /

DOWN or PWR buttons are not pressed within

approximately 10 seconds, the Main Menu will disappear

and the WTM will revert to normal viewing mode. Once

activated, menu options will remain at the applied setting

(even if the WTM is turned off) until reset by the operator.

2.16 MAIN MENU

The Main Menu is shown in Figure 2-12. The following

paragraphs describe available menu options.

Figure 2-12 Main Menu

2-20

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

Toggle with:

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

2.16 MAIN MENU – Continued

ZOOM 1X / ZOOM 2X

Activating the ZOOM 1X / ZOOM 2X menu item toggles

between a 1x and 2x magnified viewed image.

Toggle with:

Figure 2-13 Menu – ZOOM 1X / ZOOM 2X

White Hot (WHOT) / Black Hot (BHOT)

Activating the WHOT / BHOT menu item toggles between

white hot and black hot polarity modes. When in WHOT

mode, objects with the hottest thermal signature will appear

white and those with the coolest thermal signature will

appear black. In BHOT mode, the reverse is true.

Figure 2-14 Menu – White Hot / Black Hot

2-21

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

2.16 MAIN MENU – Continued

Calibration (CAL)

The system menu provides one method of calibrating the

WTM. See section 2.9 for a more detailed description of the

calibration procedures.

NOTE

Failure to cover the objective lens prior to

calibrating the WTM may result in a distorted

picture or the presence of ghost images in the

eyepiece display.

Calibrating the WTM via the system menu is accomplished

as follows:

1. Install the objective lens cover over the objective lens.

2. Activate the CAL menu item as shown below.

3. The message “CALIBRATING” will appear as the unit

performs the calibration. Once complete (< 3 seconds),

the message will disappear and the WTM will revert to

normal viewing mode.

4. Remove the objective lens cover.

Figure 2-15 Menu – Calibration (CAL)

2-22

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

2.16 MAIN MENU – Continued

Picture (PIC)

Activating the PIC menu item takes a digital picture of the

viewed image. The image is automatically stored to flash

memory with a maximum capacity of approximately 150

pictures. When attempting to take more than the maximum

allowable number of pictures, the words “CAMERA FULL”

will appear in the eyepiece display.

No more pictures may be taken until one or more of the

stored pictures are deleted (see section 2.16, Review

(REV)).

Figure 2-16 Menu – Picture (PIC)

2-23

KEEP

DELETE

DELETE ALL!

EXIT

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

2.16 MAIN MENU – Continued

Review (REV)

Activating the REV menu item allows for review of stored

pictures.

Scroll with:

Figure 2-17 Menu – Review (REV)

Pressing the UP / DOWN buttons brings up the next /

previous stored picture. While in review mode, pressing the

PWR button again calls up the Review sub-menu shown

below.

Figure 2-18 Menu – Review Sub-Menu

2-24

2.16 MAIN MENU – Continued

1. Activating the KEEP sub-menu item returns the display to

the review picture mode.

2. Activating the DELETE sub-menu item permanently

removes the selected picture from flash memory and

returns the display to the review picture mode.

3. Activating the DELETE ALL! sub-menu item permanently

removes all stored pictures from flash memory and

returns the display to normal viewing mode.

4. Activating the EXIT sub-menu item returns the display to

normal viewing mode.

NOTE

The WTM does not “remember” the polarity or

zoom settings in place at the time a picture was

taken. When reviewing stored images through the

eyepiece display, they will appear with polarity and

zoom characteristics currently selected.

2-25

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

2.16 MAIN MENU – Continued

RS170 / VGA

Activating the RS170 / VGA menu item toggles between

these two display formats. VGA format is appropriate for

high-motion viewing. RS170 format is appropriate for all

other applications. See section 2.17, Viewing Live Imagery

for instructions on how to connect the WTM to an external

monitor for viewing live thermal imagery.

Toggle with:

Figure 2-19 Menu – RS170 / VGA

NOTE

When viewing the WTM thermal image on an

external monitor, the RS170 video format must be

selected. Using the VGA video format for this

purpose will result in an extremely distorted image.

2-26

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

EXIT

AZ 0

EL 0

OFF

2.16 MAIN MENU – Continued

RETICLE

Figure 2-20 Menu – RETICLE

Activating the RETICLE menu item calls up the sub-menu

shown in Figure 2-21. The sub-menu controls the position of

the reticle in the eyepiece, and turns the reticle ON/OFF.

Figure 2-21 Menu – RETICLE Sub-Menu

1. Activating the EXIT sub-menu item returns the display to

the Main Menu while leaving the reticle turned on.

2. Activating the AZ sub-menu item moves the reticle along

the horizontal axis. Press PWR to select and use the

UP / DOWN buttons to move the center of the reticle left

or right.

2-27

2.16 MAIN MENU – Continued

3. Activating the EL sub-menu item moves the reticle along

the vertical axis. Press PWR to select and use the UP /

DOWN buttons to move the center of the reticle up or

down.

4. Activating the OFF sub-menu item toggles the reticle off

and returns the display to the Main Menu.

NOTE

When adjusting reticle position, AZ (azimuth) and

EL (elevation) values are displayed in the lower

left corner of the display. The numbers represent

“clicks” of the reticle. Azimuth and elevation

values can rapidly be returned to 0 by pressing the

UP / DOWN buttons simultaneously. When in

ZOOM 1X mode, the reticle is moved in 2-click

increments each time the UP / DOWN buttons are

pressed. The reticle is moved in 1-click

increments when in ZOOM 2X mode. Once

adjusted, the reticle position will remain at that

setting (even if the WTM is turned off) until

readjusted by the operator.

HAND / HELMET

Activating the HAND / HELMET menu item toggles between

these two display options to accommodate the WTM being

used as either a handheld or helmet-mounted device.

Toggling between the two options will rotate all text (not the

image) 180 degrees for readability purposes and ease of

use. The position of the reticle is unaffected and will remain

aligned to the laser.

2-28

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

ZOOM 1X

WHOT

CAL

PIC

REV

RS170

RETICLE

HAND

EXIT

2.16 MAIN MENU – Continued

Figure 2-22 Menu – HAND / HELMET

EXIT

Exit the Main Menu by activating the EXIT menu item. This

action saves all changes made and returns the WTM to

normal viewing mode.

Figure 2-23 Menu - EXIT

2-29

USB

CONNECTOR

DOWNLOAD

BUTTON

CABLE PLUG

BNC

CONNECTOR

SECTION IV

EXTERNAL VIEWING / IMAGE DOWNLOAD

2.17 IMAGE ADAPTER C ABLE

The WTM comes with an Image Adapter Cable that is used

to:

• connect the WTM to an external monitor for viewing

live thermal imagery, or

• connect to a personal computer (PC) so that

captured thermal images may be viewed and/or

downloaded.

The Image Adapter Cable is shown in Figure 2-24.

LED

Figure 2-24 Image Adapter Cable

2-30

2.17 IMAGE AD APTER CABLE – Continued

Viewing Live Imagery

Viewing live thermal imagery from the WTM on an external

monitor is accomplished by:

1. Remove the video jack plug (captive to the WTM) from

the video jack.

2. Plug the Image Adapter into the WTM by aligning the

white dot on the cable plug with the white dot on the jack.

Push the cable plug into the jack until it locks into place.

3. Attach the BNC connector to an external monitor or

television.

4. Follow the WTM startup procedures contained in section

2.13 and ensure RS170 video format is selected from the

Main Menu as described in section 2.16, RS170 / VGA.

5. Follow instructions provided by the manufacturer of the

monitor or television for viewing video from an external

device.

CAUTION

When the cable plug is inserted into the video

jack, it automatically locks in place. To remove it,

pull straight back on the cable plug. Do not

remove the cable plug by pulling on the cable.

2-31

2.17 IMAGE AD APTER CABLE – Continued

Retrieving Stored Images

Images stored in the WTM may be downloaded to the Image

Adapter Cable and converted to either a .tiff or .jpeg file

format (depending on model). Once downloaded, images

may then be viewed, saved, edited, and/or deleted by a PC

in the same manner as any files accessed through an

external drive. The Image Adapter Cable can store in

excess of 400 .tiff files. Storage capacity for .jpeg files is

considerably higher.

NOTE

The download process does not remove any of the

raw images from the WTM’s flash memory.

Deleting saved pictures from the WTM must be

accomplished as described in section 2.16,

Review (REV).

1. Plug the Image Adapter Cable into the WTM by aligning

the white dot on the cable plug with the white dot on the

video jack. Push the cable plug into the jack until it locks

into place.

2. Insert the Image Adapter’s Universal Serial Bus (USB)

connector into a free USB port on the computer. The PC

will recognize the Image Adapter as an external hard

drive and will normally open a Windows Explorer dialogue

box to display the contents of the drive.

3. Wait for the LED on the Image Adapter to turn solid

green. Other LED status indicators are described in

Table 2-5.

2-32

LED Indicator

Status Condition

Green (steady)

Powered and passed self test

Green flashing

Data transfer in progress

Red (steady)

Powered but failed self test

Red flashing

Operational error

2.17 IMAGE AD APTER CABLE – Continued

4. Press the Download Button. This action downloads all

images stored in the WTM’s flash memory, converts them

to .tiff (or .jpeg) format, and saves them to the flash

memory of the Image Adapter Cable. The LED on the

Image Adapter will flash green during this process.

NOTE

The Image Adapter creates a separate folder for

each of the WTM devices it has been connected

to. Initiating the download process from the same

WTM will cause the Adapter to overwrite the

existing folder. Renaming the folder prior to

downloading new images will preserve the content

of the original folder.

5. Wait for the LED on the Image Adapter to return to a

steady green state indicating that the transfer process is

complete. Open or refresh the Windows Explorer

dialogue box to view the contents of the Image Adapter’s

flash memory. Images may then be viewed, saved,

edited, and/or deleted in the same manner as any files

accessed through an external drive.

Table 2-5 LED Status Indicators

2-33

2-34

Malfunction

Probable Cause

Corrective A ction

1. No display is

a. WTM was not successfully

a. Ensure that the PWR

b. Batteries are improperly

installed.

b. Verify that the batteries

are properly installed.

c. Battery power is low.

c. Replace existing batteries

d. Objective lens cover is

installed.

d. Remove objective lens

cover.

e. Battery compartment

e. Clean the battery

CHAPTER 3

MAINTENANCE

OPERATOR MAINTENANCE

3.1 TROUBLESHOOTING

The procedures below will help correct some of the basic

problems that may arise with the WTM. If the equipment

malfunction is not listed, or the actions listed do not correct

the fault, refer to section 3.4 for additional guidance.

Table 3-1 Troubleshooting Procedures

SECTION I

present when

turning on the WTM.

activated.

corroded.

button has been pressed

twice as described in Table

2-3.

with fresh batteries.

compartment per section

3.2, Battery Compartment.

3-1

Malfunction

Probable Cause

Corrective A ction

2. Display is ON but

a. Objective lens cover is

installed.

a. Remove objective lens

cover.

b. WTM requires

b. Install the objective lens

section 2.9.

c. WTM needs to be

c. Adjust diopter and

d. WTM gain setting out of

alignment.

d. Adjust the gain setting

per section 2.11.

e. Viewed scene has no

e. Verify that the scene

3. Laser Pointer

a. Laser port requires

a. Clean the WTM laser port

Surfaces.

b. Battery power is low.

b. Replace existing batteries

with fresh batteries.

c. Battery com partment

c. Clean the battery

3.1 TROUBLESHOOTING – Continued

Table 3-1 Troubleshooting Procedures – Continued

no thermal images

are displayed.

appears weak or is

not visible down

range.

recalibration.

refocused.

thermal contrast.

cleaning.

corroded.

cover and perform a

calibration of the WTM per

objective focus.

being viewed has thermal

contrast.

per section 3.2, Optical

compartment per section

3.2, Battery Compartment

3-2

3.2 INSPECTION / CLEANING

The operator should inspect the WTM before each use and

after it has been in extreme conditions, such as prolonged

exposure to intense temperatures. The following procedures

will extend the life of the WTM and help ensure safe

operation.

WARNING

Prior to performing any inspection or maintenance

procedure, verify that batteries are not installed.

Batteries

Inspect the batteries for cracks, dents, leakage, or bulging.

If a battery shows signs of damage, remove and dispose of

properly. Replace batteries as required per section 2.2,

Battery Installation.

WTM Housing

Inspect the WTM housing for any signs of damage including

cracks, missing parts, and any other visible defects. Rinse

the WTM housing with water or mild soap and water and

then wipe dry with a soft cloth. Clean around buttons and

brackets with a cotton swab.

Battery Compartment

Inspect the battery compartment for dirt, dust and corrosion.

Dirt or debris that cannot be shaken loose from the battery

compartment may be removed using a clean cloth or cotton

swab.

3-3

Battery Cap

Inspect the battery cap for dirt, sand and grime. Thoroughly

clean the battery cap and o-ring by flushing with water and

wiping with a cotton swab. Periodically lubricate the o-ring

with fluorinated grease. Replace the battery cap assembly if

the o-ring becomes cut, nicked, or dried out.

Optical Surfaces

Inspect the laser port and optical surfaces of the WTM for

foreign material. Remove any large particles or loose dirt

using air or a soft cloth. Fine cleaning should be performed

using lens tissue. Clean water, alcohol, or general purpose

window cleaner may be used to remove stubborn stains.

Avoid using excessive force as this may scratch the lenses.

Video Jack

Inspect the video jack for corrosion, dirt and damage. Gently

remove any large particles of foreign matter and clean the

contacts with alcohol and a cotton swab.

Image Adapter Cable

Inspect the Image Adapter Cable for frayed wires, loose

connectors, and any other possible damage to the cable. As

required, clean the connectors with alcohol and a cotton

swab.

3-4

3.3 CORRECTIVE MAINTENANCE PROCEDURES

The WTM

has no internal parts or assemblies replaceable

by the user or organizational level personnel. Refer to

section 3.4 regarding maintenance and/or repair actions

beyond those described in this manual.

Replacing Neck Cord

No tools are required to perform this procedure.

1. Feed the ends of the replacement neck cord through the

channels of the WTM housing as shown in Figure 3-1.

Figure 3-1 Replacing Neck Cord

2. Tie a half knot in each end of the neck cord.

3. Pull back on the neck cord so that the half knots are snug

against the WTM housing.

3-5

3.3 CORRECTIVE MAINTENANCE PROCEDURES Continued

Replacing Battery Cap Lanyard

No tools are required to perform this procedure.

1. Unscrew the battery cap until it comes free of the battery

compartment threads.

2. Pull the battery cap lanyard over the battery compartment

threads.

3. Separate the lanyard from the battery cap.

4. Stretch smaller eye of the replacement lanyard over the

post on the battery cap.

5. Pull large end of replacement lanyard over battery cap

threads (see Figure 3-2). Work the lanyard down until it

is seated neatly in the groove closest to the WTM

housing.

Figure 3-2 Replacing Battery Cap Lanyard

6. Replace and tighten battery cap.

3-6

POST

SECTION II

SERVICE / PACKING AND UNPACKING

3.4 RETURN INSTRUCTIONS

For service, repair, or replacement, first e-mail

returns.insight@l-3com.com

or call toll-free 1-877-744-4803.

To assist with determining if the item is repairable, the

following information will be requested:

a. Serial number of the defective item;

b. Thorough description of the malfunction, defect, or

damage; and

c. If known, an explanation as to how the malfunction,

defect or damage occurred.

If the item is determined to be Beyond Economical Repair,

follow applicable replacement procedures through your

Property Officer. If it is determined that the item is under

warranty, or should be returned for repair, a Return Material

Authorization (RMA) number will be provided.

When returning the WTM for service / repair, the following

procedures should be followed to prevent any additional

damage:

a. Be sure that the WTM is free of all contaminants

such as dirt or any other foreign material.

b. Remove batteries.

c. Place the WTM in the soft carrying case.

3-7

3.4 RETURN INSTRUCTIONS – Continued

Place the item and a copy of the test report or detailed

description of the failure in a suitable packing container.

Mark the package with “Field Return” and the RMA number.

Ship via fastest, traceable, pre-paid means to:

L-3 Communications Corporation

Warrior Systems Division

Insight Operations

9 Akira Way

Londonderry, NH 03053

3.5 WARR ANTY INFORMATION

The WTM is under warranty from defects in material and

workmanship for a minimum of one (1) year from the date of

manufacture. This warranty does not protect against

damage due to misuse, mishandling or battery leakage.

Additional warranty coverage may have been provided

through the contract or via subsequent contract extension.

Specific warranty terms can be obtained from your

procurement agent, Contracting Officer or L-3 Warrior

Systems, Insight.

3.6 NON-WARRANTY INFORMATION

Non-warranty repairs are subject to an evaluation fee. The

item will be tested and evaluated for failure, then customer

permission and payment terms are obtained prior to any

repairs being performed.

3-8

4

5

6

8

11

10

APPENDIX A

END ITEM COMPONENTS AND REPAIR PARTS

SCOPE

This Appendix lists end item components and repair parts for

the entire family of WTM configurations.

1

2

12

9

3

7

Figure A-1 End Item Components

A-1

ITEM

NATIONAL

PART

1

8105-01-585-6183

ATP-012

Soft Carrying Case

1

2

5855-01-559-9639

NVM-042

Helmet Adapter

1

3

N/A

WTM-TM-VISIR

Operator Manual

1

4

N/A

WTM-QRG-VISIR

Quick Reference Guide

1

5

6760-01-556-4306

7B626

Lens Tissue

1

6

5855-01-579-5690

WTM-030-A1

Image Adapter Cable

1

Picatinny (MIL-STD-1913)

Weapon Mount Adapter

8

5340-01-582-7719

WTM-010-A2

Weaver Weapon Mount Adapter

1

WTM Assembly (see Figure A-2

10

TBD

MTM-079

Eyecup

1

11

6135-01-351-1131

DL123ABK

Battery, 3V Lithium

2

Night Vision Filter /

SCOPE – Continued

Table A-1 List of End Item Components

NO.

STOCK NUMBER

NUMBER

DESCRIPTION QTY

7 TBD WTM-010-A1

9 N/A N/A

12 6760-01-556-3413 MTM-018

A-2

for parts breakdown)

Demist Shield

1

1

1

ITEM

NATIONAL

PART

1

5340-01-556-3418

EH-C0117

Video Jack Plug

1

2

5855-01-585-6619

WTM-512

Objective Lens Cover

1

3

TBD

WTM-365

Battery Cap

1

4

1240-01-536-9661

MFL-173

Retainer, Battery Cap

1

5

5331-01-537-0498

AS-568A-018S70

O-Ring, Battery Cap

1

6

TBD

WTM-061-A1

Lanyard, Objective Lens Cover

1

7

4020-01-585-6611

MTM-073

Neck Cord

1

2

3 6 5

4

SCOPE – Continued

1

NO.

7

STOCK NUMBER

Figure A-2 WTM Assembly

Table A-2 List of Repair Parts

NUMBER

DESCRIPTION QTY

A-3

A-4

The WTM

Is designed and produced by:

L-3 Communications Corporation

Warrior Systems Division

Insight Operations

Londonderry, NH 03053

Phone 603.626.4800 / Fax 603.626.4888

www.l3warriorsystems.com

This manual contains technical data whose export is gover ned

by the U.S. International Traffic in Arms Regulations (ITAR).

This information must not be transferred to a foreign person

without the proper authorization of the U.S. Government. Please

contact L-3 Warrior Systems for more information.

© 2011 L-3 Communications Corporation

Warrior Systems Division

9 Akira Way

USA

Loading...

Loading...