ATP-TM-SP

OPERATOR MANUAL

FOR THE

ADVANCED TARGET POINTER ILLUMINATOR

AIMING LIGHT (ATPIAL)

Rev. 3 26 February 2013

SAFETY SUMMARY

GENERAL

This manual contains operating instructions and

maintenance procedures which may cause injury or death to

personnel, or damage to equipment if not properly followed.

Prior to performing any task, the WARNINGs, CAUTIONs

and NOTEs included in that task shall be reviewed and

understood.

DEFINITIONS

Highlights an essential operating or maintenance

procedure, practice, condition or statement, which,

if not strictly observed, could result in injury to, or

death of, personnel or long term health hazards.

Highlights an essential operating or maintenance

procedure, practice, condition or statement, which,

if not strictly observed, could result in damage to,

or destruction of, equipment or loss of mission

effectiveness.

Highlights an essential operating or maintenance

procedure, condition or statement.

WARNING

CAUTION

NOTE

i

SAF ETY PRECAUTIONS

Visible

Infrared

AL

AL

DL

AH

IH

DH

Class1

3R

3R

3B

3B

3B

3B

NOHD2

91m

14m

27m

203m

52m

209m

OD (unaided )4

0.7

0.1

0.7

1.6

1.8

1.8

NOHDe3

613m 0 204m

1.2km

80m

1.5km

OD (aided)4

0.7 0 0.6

1.5

1.7

1.8

NSHD

0 0 0 0 0

0

OD (skin)

0 0 0 0 0

0

The following general safety precautions supplement the

specific WARNINGs, CAUTIONs and NOTEs that appear

elsewhere in this manual.

WARNING

The Advanced Target Pointer Illuminator Aiming

Light (ATPIAL) emits both visible and invisible

laser radiation. Nominal Skin Hazard Distances

(NSHD) and Nominal Ocular Hazard Distances

(NOHD) for safe operation are listed in Table i-1.

Exposure to the ATPIAL’s laser beams within

these distances can cause irreversible damage to

the human eye.

Table i-1. Laser Safety Parameters.

1

Laser Safety Classification per IEC 60825-1, 2007

2

Nominal Ocular Hazard Distance without magnifying optics (in meters)

3

Extended Nominal Ocular Hazard Distance with standard 7x50

magnifying optics (in meters)

4

Optical Density (OD) expressed to the nearest tenth

ii

WARNING

• Do not stare into the laser beams.

• Do not look into the laser beams through

binoculars or telescopes.

• Do not point the laser beams at mirror-like

surfaces.

• Do not shine the laser beams into other

individuals’ eyes.

WARNING

Laser eye protection should be provided to

maintenance personnel, laser operators, and all

personnel at risk from laser radiation. Provided

protection should be appropriate for the Optical

Densities (OD) specified in Table i-1.

WARNING

Laser modes designated as Safety Class 3R (low

power) may be used for force-on-force training

only if opposing forces are beyond the NOHD

values shown in Table i-1.

WARNING

Laser modes designated as Safety Class 3B (high

power) shall NOT be used for force-on-force

training.

WARNING

The safety screw shall be installed in the lockout

position when the ATPIAL is in storage, being

returned to the armory, or distributed to field

personnel.

iii

WARNING

IR lasers are detectable by an enemy using night

vision devices. Detection is easier in smoky,

foggy, or rainy conditions. To reduce the risk of

detection by an enemy using night vision devices,

avoid prolonged activation of the IR lasers.

WARNING

Remove the ATPIAL from the weapon before

inspecting, cleaning, or performing other

maintenance functions.

WARNING

The ATPIAL is designed to be used with

destructive weapon systems. Improper operation

or misuse of the ATPIAL with these weapon

systems could lead to personal injury or death of

either the operator or other persons within

weapons range. Safe firearms handling

procedures must be practiced at all times.

WARNING

Ensure the Mode Selector is turned to the O (OFF)

position before attempting to install, remove, or

replace batteries.

WARNING

To prevent inadvertent activation of the laser(s),

the Mode Selector should be in the O (OFF)

position when not in use.

iv

WARNING

• Do not short circuit, puncture, disassemble,

crush, or incinerate battery.

• Do not attempt to recharge battery.

• Prior to use, inspect battery for cracks, dents,

leakage, or bulging. Never install a defective

battery in the ATPIAL.

WARNING

Lithium batteries can explode or cause burns if

disassembled, shorted, recharged, or exposed to

water, fire, or high temperatures (above 100°C or

212°F). Do not place loose batteries in a pocket

or other container containing metal objects. Do

not store batteries with hazardous or combustible

materials. Store in a cool, dry, ventilated area.

WARNING

Use of incorrect batteries poses a risk of fire or

explosion. Be aware that batteries do exist with

similar physical characteristics to the DL123A

battery, but with a different voltage and/or polarity

path. Ensure that only 3V lithium batteries with a

raised positive (+) terminal are installed in the

ATPIAL.

WARNING

Use of off-brand batteries poses a risk of fire or

explosion. Ensure that only 3V lithium batteries

produced by a well-known battery manufacturer

are installed in the ATPIAL. These batteries are

specifically designed for use in high performance,

high-drain devices, and contain built-in fault and

heat protection features.

v

WARNING

Failure to properly secure the ATPIAL to the rail

may lead to boresight repeatability and zeroing

issues. In extreme cases, the ATPIAL could fall

off the rail, thereby exposing the operator or other

personnel to the ATPIAL laser(s).

WARNING

Prior to conducting routine or periodic

maintenance on the ATPIAL, ensure the Mode

Selector is turned to the O (OFF) position.

WARNING

Isopropyl alcohol is flammable and toxic. To avoid

injury, keep away from open fire and use in a well

ventilated area.

CAUTION

Use of acetone or gun cleaning agents containing

perchloroethylene or methylene chloride may

permanently damage the ATPIAL system.

vi

TABLE OF CONTENTS

SAFETY SUMMARY ....................................................................... i

TABLE OF CONTENTS ............................................................... vii

LIST OF FIGURES ........................................................................ ix

LIST OF TABLES ........................................................................... x

CHAPTER 1 ...................................................................................... 1-1

INTRODUCTION .......................................................................... 1-1

SECTION I ................................................................................... 1-1

GENERAL INFORMATION .......................................................... 1-1

1.1 SCOPE ............................................................................. 1-1

1.2 MODEL NUMBER AND EQUIPMENT NAME ................. 1-2

1.3 MANUFACTURER ........................................................... 1-2

1.4 PURPOSE OF EQUIPMENT ........................................... 1-2

1.5 ABBREVIATIONS AND ACRONYMS .............................. 1-2

SECTION II .................................................................................. 1-4

EQUIPMENT DESCRIPTION ...................................................... 1-4

1.6 SYSTEM DESCRIPTION ................................................. 1-4

1.7 TECHNICAL SPECIFICATIONS ...................................... 1-5

1.8 MAJOR COMPONENTS .................................................. 1-6

1.9 FEATURES AND CONTROLS......................................... 1-8

CHAPTER 2 ...................................................................................... 2-1

OPERATING INSTRUCTIONS ................................................... 2-1

SECTION I ................................................................................... 2-1

PREPARATION FOR USE AND INSTALLATION ....................... 2-1

2.1 PREPARATION FOR USE ............................................... 2-1

2.2 BATTERY HANDLING ..................................................... 2-2

2.3 MOUNTING PROCEDURES ........................................... 2-3

2.4 BORESIGHT ADJUSTERS .............................................. 2-5

2.5 BORESIGHTING PROCEDURES ................................. 2-12

2.6 ZEROING PROCEDURES ............................................. 2-14

SECTION II ................................................................................ 2-16

OPERATING INSTRUCTIONS .................................................. 2-16

2.7 MODES OF OPERATION .............................................. 2-16

2.8 MODE SELECTION ....................................................... 2-17

2.9 MODE ACTIVATION ...................................................... 2-19

2.10 USING THE AIM LASERS ........................................... 2-22

2.11 USING THE IR ILLUMINATOR .................................... 2-24

2.12 LED STATUS INDICATOR .......................................... 2-27

vii

TABLE OF CONTENTS (Continued)

CHAPTER 3 ...................................................................................... 3-1

MAINTENANCE ........................................................................... 3-1

SECTION I ................................................................................... 3-1

MAINTENANCE AND TROUBLESHOOTING ............................. 3-1

3.1 TROUBLESHOOTING ..................................................... 3-1

3.2 INSPECTION / CLEANING .............................................. 3-3

3.3 CORRECTIVE MAINTENANCE ...................................... 3-4

SECTION II ................................................................................ 3-10

SERVICE / PACKING AND UNPACKING ................................. 3-10

3.4 RETURN INSTRUCTIONS ............................................ 3-10

3.5 WARRANTY INFORMATION......................................... 3-11

3.6 NON-WARRANTY INFORMATION ............................... 3-11

APPENDIX A.................................................................................... A-1

END ITEM COMPONENTS AND REPAIR PARTS ................... A-1

A.1 SCOPE ............................................................................ A-1

A.2 END ITEM COMPONENTS ............................................ A-2

A.3 REPAIR PARTS .............................................................. A-3

APPENDIX B.................................................................................... B-1

ACCESSORIES .......................................................................... B-1

B.1 SCOPE ............................................................................ B-1

viii

LIST OF FIGURES

Figure 1-1. ATPIAL Mounted to M4/M4A1 (Top Mount). ................ 1-1

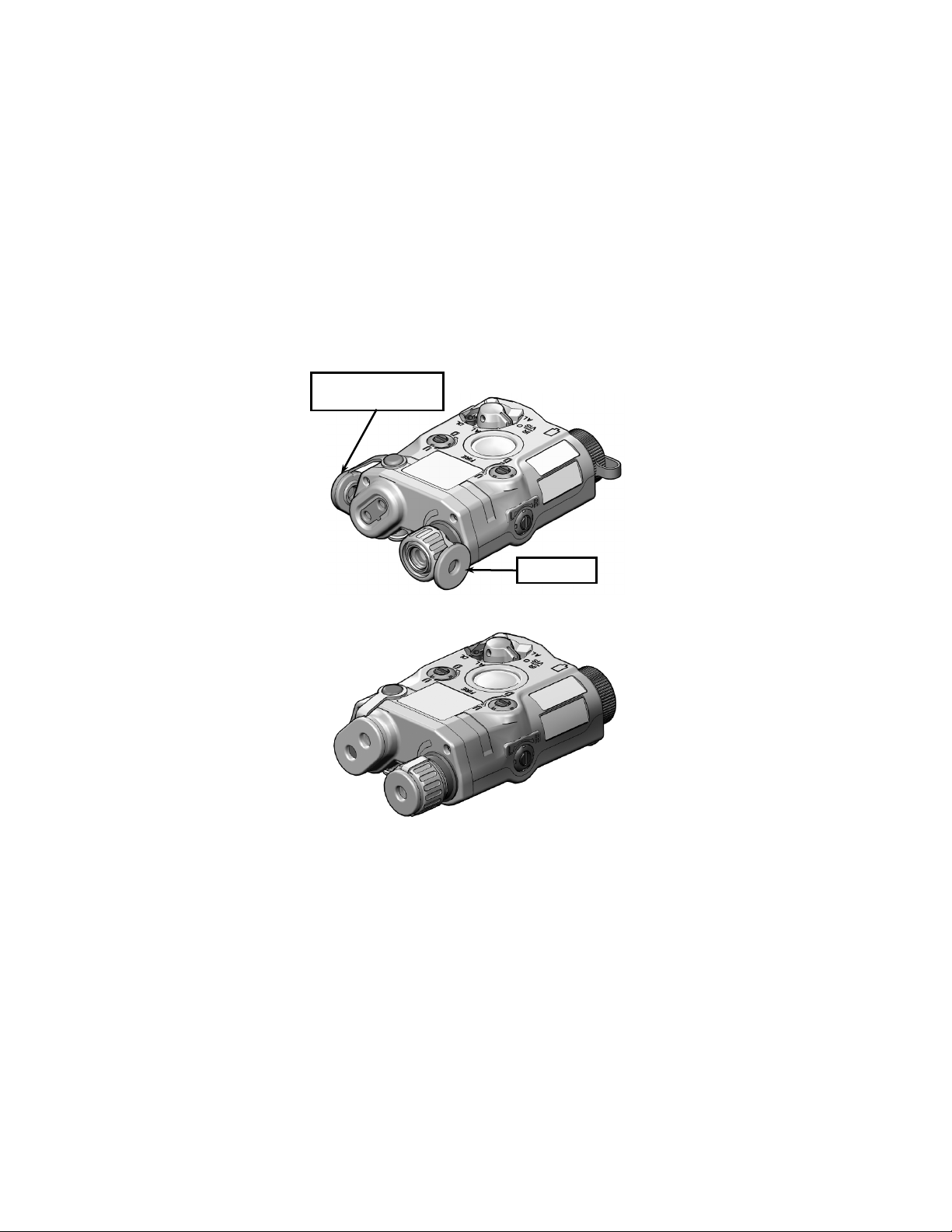

Figure 1-2. Major Components.

Figure 1-3. Features and Controls (Front View).

Figure 1-4. Features and Controls (Rear View).

Figure 2-1. Battery Installation.

Figure 2-2. Rail Grabber Bracket.

Figure 2-3. Boresight Adjusters.

Figure 2-4. Aim Laser Adjusters (Top Mounted).

Figure 2-5. Aim Laser Adjusters (Left Side Mounted).

Figure 2-6. Aim Laser Adjusters (Right Side Mounted).

Figure 2-7. Illuminator Adjusters (Top Mounted).

Figure 2-8. Illuminator Adjusters (Left Side Mounted).

Figure 2-9. Illuminator Adjusters (Right Side Mounted).

Figure 2-10. Mode Selector.

Figure 2-11. Safety Screw Shown Lockout Position.

Figure 2-12. Installation of the Remote Cable Switch.

Figure 2-13. Mounting the DBR.

Figure 2-14. DBR Activation Buttons.

Figure 2-15. Lens Caps Uninstalled.

Figure 2-16. Lens Caps Installed.

Figure 2-17. Pattern Generator Shapes.

Figure 2-18. IR Illuminator Focus Ring.

Figure 2-19. LED Status Indicator.

Figure 3-1. Battery Cap O-Ring.

Figure 3-2. Battery Cap / Battery Cap Lanyard.

Figure 3-3. Replacing IR Illuminator Diffuser Lens Cap.

Figure 3-4. Lens Cap Attachment Points.

Figure 3-5. Positioning the Lens Cap.

Figure A-1. End Item Components ................................................. A-2

Figure A-2. ATPIAL Assembly ........................................................ A-3

....................................................... 1-6

............................. 1-8

............................. 1-8

........................................................ 2-2

.................................................... 2-3

...................................................... 2-5

............................ 2-6

.................... 2-7

.................. 2-8

............................ 2-9

.................. 2-10

............... 2-11

.......................................................... 2-17

.................... 2-18

.................. 2-20

.................................................... 2-21

............................................ 2-22

............................................. 2-23

.................................................. 2-23

....................................... 2-24

......................................... 2-25

................................................ 2-27

...................................................... 3-5

.............................. 3-6

................. 3-7

........................................ 3-8

............................................. 3-9

ix

LIST OF TABLES

Table i-1. Laser Safety Parameters .................................................... ii

Table 1-1. Technical Specifications. ................................................ 1-5

Table 1-2. List of Major Components.

Table 1-3. List of Features and Controls.

Table 2-1. Shot Group Movement for Aim Lasers ........................... 2-6

Table 2-2. Shot Group Movement for Aim Lasers

Table 2-3. Shot Group Movement for Aim Lasers

Table 2-4. Beam Movement for the IR Illuminator

Table 2-5. Beam Movement for the IR Illuminator

Table 2-6. Beam Movement for the IR Illuminator

Table 2-7. Weapon Offsets.

Table 2-8. Modes of Operation.

Table 2-9. IR Illuminator Pulse Rates.

Table 2-10. LED Status Indicator.

Table A-1. List of End Item Components. ....................................... A-2

Table A-2. List of Repair Parts.

Table B-1. List of Accessories. ....................................................... B-1

............................................. 1-6

........................................ 1-9

........................... 2-7

........................... 2-8

........................... 2-9

......................... 2-10

......................... 2-11

........................................................... 2-13

..................................................... 2-16

........................................... 2-26

................................................. 2-27

....................................................... A-3

x

CHAPTER 1

INTRODUCTION

SECTION I

GENERAL INFORMATION

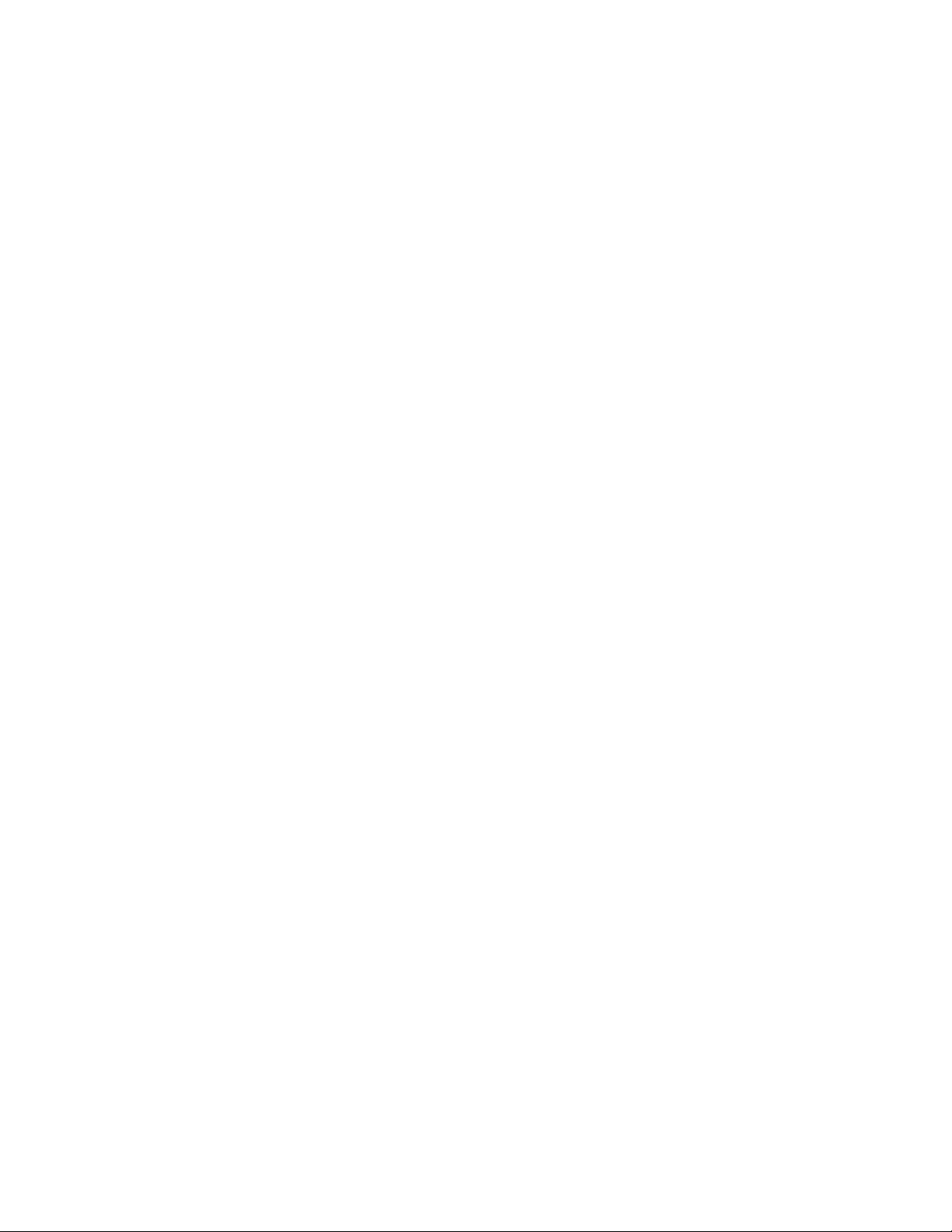

Figure 1-1. ATPI AL Mounted to M4/M4A1 (Top Mount).

1.1 SCOPE

This manual is intended for use by operators of the

Advanced Target Pointer Illuminator Aiming Light (ATPIAL).

It provides a system description, operational procedures, and

maintenance responsibilities. Complete familiarization with

this manual prior to using the equipment, will ensure safe

operation and maximum effectiveness of the ATPIAL.

1-1

1.2 MODEL NUMBER AND EQUIPMENT NAME

AH

(IR) Aim High (Mode Selector position)

AL

(IR) Aim Low (Mode Selector position)

Light

C

Celsius

CCW

Counterclockwise

CW

Clockwise

DH

Dual High (IR) (Mode Selector position)

This manual applies to the following ATPIAL models:

a. ATP-000-A18, ATPIAL, Tan

b. ATP-000-A22, ATPIAL, Black

1.3 MANUFACTURER

L-3 Communications Corporation

Warrior Systems Division

Insight Operations

9 Akira Way

Londonderry, NH 03053 USA

1.4 PURPOSE OF EQUIPMENT

The ATPIAL is a multifunction laser device that emits visible

or infrared (IR) light used for precise weapon aiming and

target / area illumination.

1.5 ABBREVIATIONS AND ACRONYMS

Abbreviations and acronyms used in this manual are as

follows:

ATPIAL Advanced Target Pointer Illuminator Aiming

DBR Dual Button Remote

1-2

1.5 ABBREVIATIONS AND ACRONYMS (Continued)

DL

Dual Low (IR) (Mode Selector position)

F

Fahrenheit

IH

(IR) Illuminator High (Mode Selector position)

ITAR

International Traffic in Arms Regulations

km

Kilometer

LBS

Laser Borelight System

m

Meter

MG

Machine Gun

mrad

Milliradians

mW

Milliwatts

MWS

Modular Weapon System

NOHD

Nominal Ocular Hazard Distance

NSHD

Nominal Skin Hazard Distance

NSN

National Stock Number

O

Off (Mode Selector position)

P

Program (Mode Selector position)

RMA

Return Material Authorization

TBD

To Be Determined

V

Volt

VIS

Visible Aim Laser

VIS-AL

(Visible) Aim Low (Mode Selector position)

IR Infrared

LED Light Emitting Diode

nm Nanometer

OD Optical Density

µW Microwatts

1-3

EQUIPMENT DESCRIPTION

SECTION II

1.6 SYSTEM DESCRIPTION

The ATPIAL is a multifunction laser device that emits visible

or IR light used for precise weapon aiming and target / area

illumination.

The Visible Aim Laser provides for active target acquisition

in low-light and close quarters combat situations without the

need for night vision devices.

The IR Aim and Illumination lasers provide for active, covert

target acquisition in low light or complete darkness when

used in conjunction with night vision devices.

The ATPIAL can be used as either a handheld illuminator /

pointer or can be mounted to weapons equipped with a

MIL-STD-1913 rail.

The ATPIAL is a ruggedized system designed for operation

in battlefield environments.

1-4

1.7 TECHNICAL SPECIFICATIONS

WEIGHT AND DIMENSIONS

Weight (with battery)

7.5 ounces

Length

4.6 inches

Width

2.8 inches

Height

1.6 inches

POWER / PERFORMANCE

Batteries

One 3V DL123A

* Battery Life

>6 Hours in DH (DUAL HIGH)

Waterproof

6m for one hour

LASERS

Visible Aim Laser

Beam Divergence

0.5 mrad (+ 0.3 / -0.35 mrad)

IR Aim Laser

Output Power HIGH

25 mW (+ 10%)

Beam Divergence

0.5 mrad (± 0.3 mrad)

Wavelength

820 – 850 nm

Range

>600m (LOW), >2000m (HIGH)

IR Illuminator

Output Power LOW

< 3.5 mW

Output Power HIGH

30 mW (+ 50 / -20%)

than 105 mrad

Wavelength

820 – 850 nm

Range

>2000m

Table 1-1. Technical Specifications.

Output Power

Wavelength 605 – 665 nm

Range >25m

Output Power LOW

Beam Divergence No less than 1 mrad to greater

4.0 mW (± 1.0 mW )

600 µW (± 100 µW)

* Performance will var y depending on actual environmental and

atmospheric conditions.

1-5

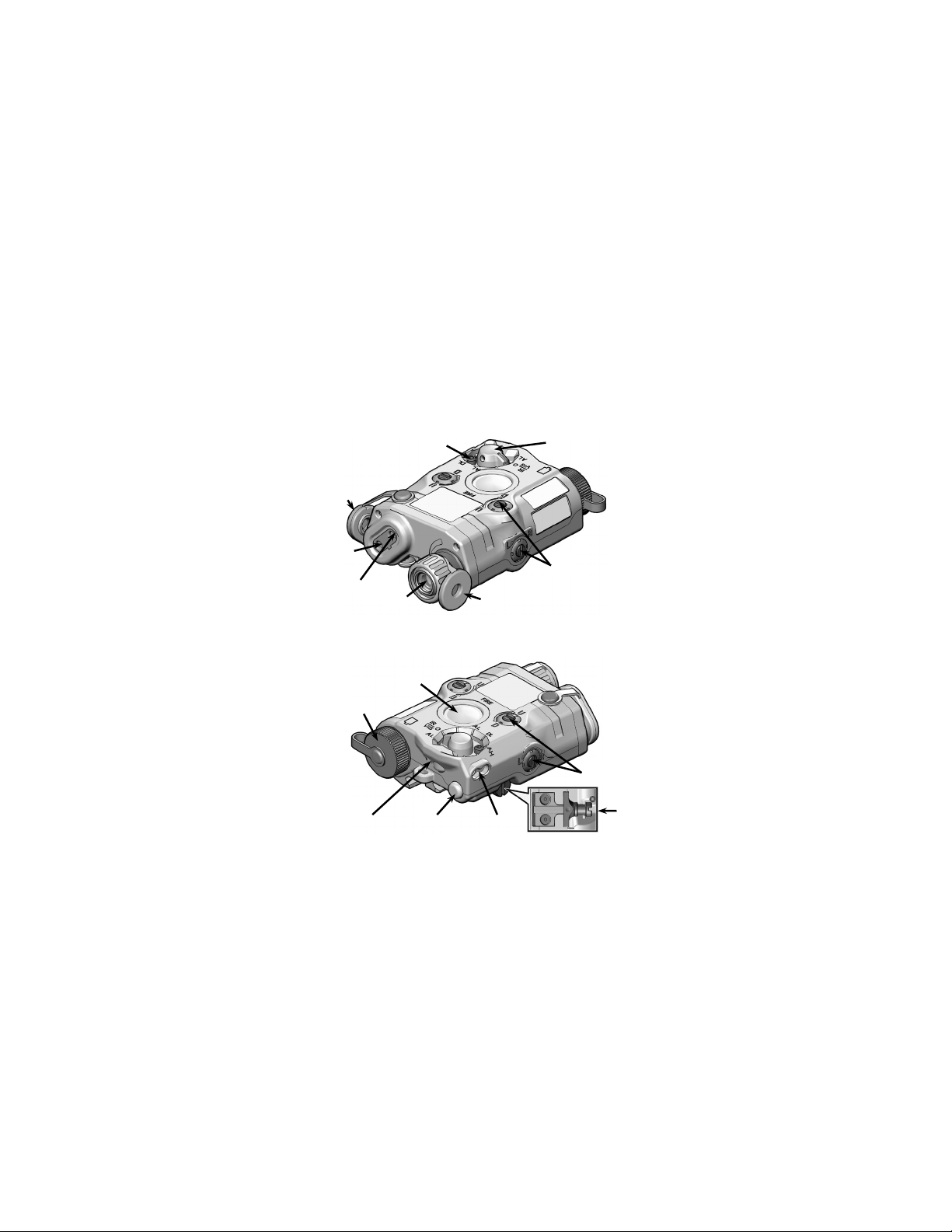

1.8 MAJOR COMPONENTS

Component

1

Soft Carrying

Case

Protects the ATPIAL and accessories

while in a field environment.

2

ATPIAL.

2

8 6 9 3 4

10

The ATPIAL system includes the components shown in

Figure 1-2. Table 1-2 provides a brief functional description

of each item. The “Key” column in Table 1-2 corresponds to

the label numbers in Figure 1-2.

1

5

Figure 1-2. Major Components.

Key

Table 1-2. List of Major Components.

Major

Function

7

Operator Manual Provides detailed operating and

maintenance procedures specific to the

1-6

1.8 MAJOR COMPONENTS (Continued)

Major

Component

3

Quick Reference

Provides at-a-glance operating

4

ATPIAL Assembly

A handheld or weapon mounted

aiming and target / area illumination.

5

3/32” Hex Head

Wrench

Used to remove / install the ATPIAL

safety screws.

6

Cable Switch to the weapon.

Loop (3)

to the weapon.

9

Battery, DL123A

One 3V lithium battery used to power the

ATPIAL.

10

Pattern

Five pattern generators that, when

over the aiming point of the laser.

Table 1-2. List of Major Components (Continued).

Key

Function

7

8

Guide

Strap, Retaining

(2)

Fastener Tape,

Remote Cable

Switch

Generators

(set of 5)

instructions for the ATPIAL.

multifunction laser device that emits

visible or IR light for precise weapon

May be used alone or in conjunction with

hook and loop fastener tape as an

alternate means of attaching the Remote

Used to secure the Remote Cable Switch

Allows for fingertip activation of the

ATPIAL without altering the operator’s

grip on the weapon.

individually installed over the aim lasers,

project a specific holographic design (i.e.,

circle, square, triangle, T-shape, cross)

1-7

1.9 FEATURES AND CONTROLS

4

6 7 8 9 1

2 3 14

13

12

15

5

Figures 1-3 and 1-4 show features and controls for the

ATPIAL. Table 1-3 provides a brief functional description of

each item. The “Key” column in Table 1-3 corresponds to

the label numbers in Figures 1-3 and 1-4.

Figure 1-3. Features and Controls (Front View).

10

Figure 1-4. Features and Controls (Rear View).

1-8

11

1.9 FEATURES AND CONTROLS (Continued)

Control/

Indicator

1

Aim Neutral

When placed over the Aim Lasers, reduces

2

Safety Screw

When installed in the lockout position,

allows for access to all modes of operation.

3

Mode Selector

Allows the user to select the desired mode

of operation for the ATPIAL.

barrel of the weapon.

6

Infrared

Used with night vision devices to provide

area to be illuminated.

7

Laser

precision aim point or to mark targets.

Key

Table 1-3. List of Features and Controls.

Function

Density / Opaque

Lens Cap

(shown in lockout

position)

4

Illuminator

Adjusters

5

Illuminator

Diffuser Lens Cap

Illuminator /

Focus Ring

Infrared Aim

scatter from the IR Aim Laser, and blocks

emission of the Visible Aim Laser.

prevents the Mode S elector from being

turned to the high power laser settings (i.e.,

AH, IH, DH). Removal of the safety scr ew

Used to bring the illumination beam into

azimuth and elevation alignment with the

When installed over the IR Illuminator,

spreads the laser energy, allowing for

illumination of a wider area. This is useful

for illuminating a small room and is most

effective when used with the Focus Ring

adjusted to the widest beam (flood) setting.

IR illumination of the intended target area.

The Focus Ring is rotated to vary the

illumination beam spread from flood to

spot, based on the range and size of the

Used with night vision devices to provide a

1-9

1.9 FEATURES AND CONTROLS (Continued)

Control/

Indicator

8

Visible Aim Laser

Used to provide a precision aim point or to

9

Battery Cap /

Compartment

Provides secure housing for the 3V lithium

battery that powers the ATPIAL.

10

FIRE Button

Primarily used to activate the laser(s) that

Selector.

alignment with the barrel of the weapon.

Bracket

with a MIL-STD-1913 rail.

13

Safety Screw

Allows for secure storage of the safety

14

Remote Jack /

Provides an interface for the Remote Cable

moisture.

15

LED Status

Indicates when the ATPIAL is emitting

programming of the IR Illuminator.

Table 1-3. List of Features and Controls (Continued).

Key

11

12

Aim Laser

Adjusters

Rail Grabber

mark targets at close range during the day

or night, without the need of night vision

devices. It may also be used for boresighting the ATPIAL during daylight hours.

corresponds with the position of the Mode

Used to bring the Visible and IR Aim

Lasers into azimuth and elevation

Secures the ATPIAL to a weapon equipped

Function

Storage Location

Jack Plug

Indicator

1-10

screw after it has been removed from the

lockout position.

Switch. When installed, the jack plug

protects the remote jack from debris and

laser energy, when the battery power is

low, and displays the pulse rate during

CHAPTER 2

OPERATING INSTRUCTIONS

SECTION I

PREPARATION FOR USE AND INSTALLATION

2.1 PREPARATION FOR USE

Unpacking the Equipment

Open the soft carrying case and verify that all major

components listed in Table 1-2 are present. Check the

ATPIAL assembly to ensure the following additional items

are installed:

a. Battery Cap

b. Safety Screw

c. Remote Jack Plug

d. Aim Neutral Density / Opaque Lens Cap

e. Illuminator Diffuser Lens Cap

If any of the major components or items listed above are

missing, seek guidance from the equipment issuing

authority.

Inspection of the Equipment

Before use, inspect all pieces of equipment for any damage

such as cracks, loose parts, faulty cables, or other visible

defects. If any damage or defects are noted, seek guidance

from the equipment issuing authority.

2-1

2.2 BATTERY HANDLING

Battery Inspection

Before installation, inspect the 3V lithium battery for any

cracks, dents, leakage, or bulging. Never install a defective

battery in the ATPIAL.

Battery Installation

WAR NING

Ensure the Mode Selector is turned to the O (OFF)

position before attempting to install, remove, or

replace batteries.

CAUTION

Do not ship or store the ATPIAL with battery

installed.

Unscrew the battery cap and install one battery with the

positive terminal facing out as shown in Figure 2-1. Proper

battery orientation is clearly marked on the ATPIAL housing.

Replace and firmly tighten the battery cap.

2-2

Figure 2-1. Battery Installation.

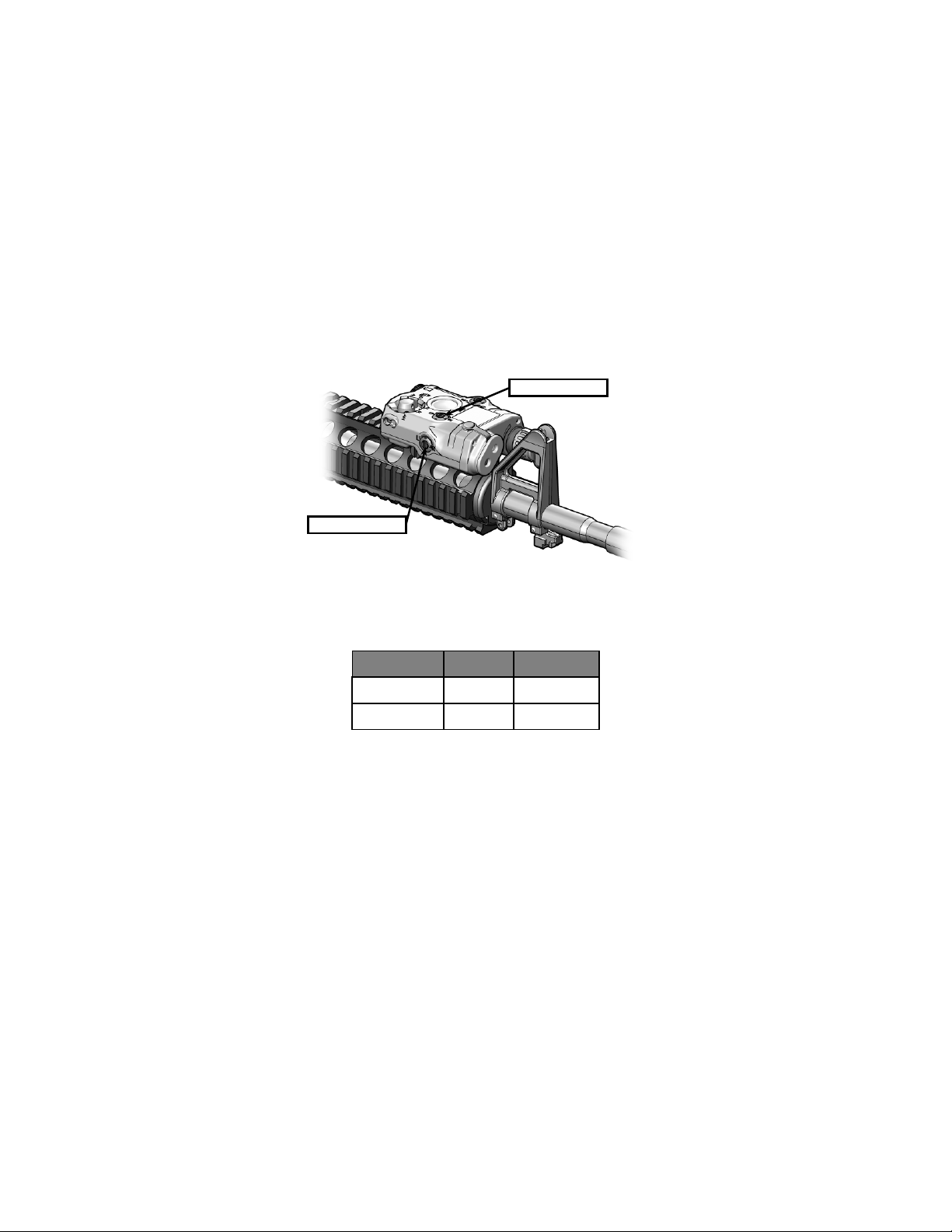

2.3 MOUNTING PROCEDURES

SCREW

Rail Grabber Bracket

The ATPIAL is equipped with an integral rail grabber bracket

(Figure 2-2) that is designed for direct attachment to

weapons with a MIL-STD-1913 rail.

RECOIL LUG

MOUNTING

Figure 2-2. Rail Grabber Bracket.

Mounting Configurations

The ATPIAL can be mounted on either the top or side rails of

the host weapon.

Mounting Instructions

WARNING

Failure to properly secure the ATPIAL to the rail

may lead to boresight repeatability and zeroing

issues. In extreme cases, the ATPIAL could fall

off the rail, thereby exposing the operator or other

personnel to the ATPIAL laser(s).

2-3

2.3 MOUNTING PROCEDURES (Continued)

WARNING

Be sure the weapon is CLEAR and SAFE before

proceeding.

NOTE

The ATPIAL may be placed at any position

(forward and aft) on the rail that is most

convenient for the operator. However, the entire

length of the mounting surface must be fully

supported (in direct contact) by the MIL-STD-1913

rail. If the ATPIAL is removed from the rail, the

operator must make note of the position at which it

was boresighted or zeroed, and return it to that

same position in order to ensure that zero is

retained.

1. Loosen the mounting screw on the rail grabber bracket

until the jaws have sufficient space to fit over the weapon

rail.

2. Hold the ATPIAL with the laser apertures facing in the

direction of the muzzle of the weapon.

3. Position the ATPIAL on the rail ensuring the recoil lug is

seated in the desired recoil groove of the rail.

4. While pushing down and forward on the ATPIAL, turn the

mounting screw clockwise as tightly as fingers allow. Use

a screwdriver or similar tool in the slot of the mounting

screw to turn it an additional 1/2 turn.

2-4

2.4 BORESIGHT ADJUSTERS

AIM LASER

The ATPIAL is equipped with boresight adjusters for

independent adjustment of the aiming and illumination

beams in both elevation and windage (azimuth).

ILLUMIN ATOR

ADJUSTERS

ADJUSTERS

Figure 2-3. Boresight Adjusters.

Aim Laser Adjusters

The ATPIAL Visible and IR Aim Lasers are co-aligned.

Therefore, a single set of adjusters moves both aiming

beams, and boresighting / zeroing can be accomplished

using either the Visible or IR Aim Laser.

Table 2-1 indicates the direction of adjuster rotation and

resultant shot group movement when the ATPIAL is top

mounted. Tables 2-2 and 2-3 indicate the direction of

adjuster rotation and resultant shot group movement when

the ATPIAL is side mounted (left / right).

2-5

2.4 BORESIGHT ADJUSTERS (Continued)

Shot Group

Movement

Windage

CCW

Left

TOP ADJUSTER

SIDE ADJUSTER

Figure 2-4. Aim Laser Adjusters (Top Mounted).

Table 2-1. Shot Group Movement for Aim Lasers

Adjuster Rotation

Top Adjuster

Elevation

Side Adjuster

(Top Mounted).

CW

CCW

CW

Up

Down

Right

2-6

2.4 BORESIGHT ADJUSTERS (Continued)

Shot Group

Movement

Elevation

CCW

Down

Side Adjuster

CW

Left

SIDE

TOP ADJUSTER

ADJUSTER

Figure 2-5. Aim Laser Adjusters (Left Side Mounted).

Table 2-2. Shot Group Movement for Aim Lasers

Top Adjuster

Windage

(Left Side Mounted).

Adjuster Rotation

CW

CCW

Up

Right

2-7

2.4 BORESIGHT ADJUSTERS (Continued)

Shot Group

Movement

Bottom Adjuster

CW

Down

Side Adjuster

Windage

CW

CCW

Right

Left

SIDE

BOTTOM

ADJUSTER

ADJUSTER

Figure 2-6. Aim Laser Adjusters (Right Side Mounted).

Table 2-3. Shot Group Movement for Aim Lasers

(Right Side Mounted).

Adjuster Rotation

2-8

Elevation

CCW

Up

2.4 BORESIGHT ADJUSTERS (Continued)

Beam

Movement

Windage

CCW

Left

SIDE ADJUSTER

Illuminator Adjusters

Table 2-4 indicates the direction of adjuster rotation and

resultant illumination beam movement when the ATPIAL is

top mounted. Tables 2-5 and 2-6 indicate the direction of

adjuster rotation and resultant illumination beam movement

when the ATPIAL is side mounted (left / right).

TOP ADJUSTER

Figure 2-7. Illuminator Adjusters (Top Mounted).

Table 2-4. Beam Movement for the IR Illuminator

Adjuster Rotation

Top Adjuster

Elevation

Side Adjuster

(Top Mounted).

CW

CCW

CW

Down

Up

Right

2-9

2.4 BORESIGHT ADJUSTERS (Continued)

Beam

Movement

Bottom Adjuster

Elevation

CW

CCW

Up

Down

SIDE

ADJUSTER

BOTTOM

ADJUSTER

Figure 2-8. Illuminator Adjusters (Left Side Mounted).

Table 2-5. Beam Movement for the IR Illuminator

Side Adjuster

Windage

2-10

(Left Side Mounted).

Adjuster Rotation

CW

CCW

Right

Left

2.4 BORESIGHT ADJUSTERS (Continued)

Beam

Movement

Top Adjuster

Elevation

CW

CCW

Down

Up

Windage

CCW

Right

TOP ADJUSTER

SIDE ADJUSTER

Figure 2-9. Illuminator Adjusters (Right Side Mounted).

Table 2-6. Beam Movement for the IR Illuminator

Side Adjuster

(Right Side Mounted).

Adjuster Rotation

CW

Left

2-11

2.5 BORESIGHTING PROCEDURES

The ATPIAL incorporates a factory preset feature that may

be used to quickly bring the co-aligned Visible and IR Aim

Lasers nearly parallel with the barrel of the host weapon.

CAUTION

Do not force the adjusters beyond their end of

travel. Forcing them will damage the adjusters or

internal components.

NOTE

To minimize laser travel as a result of weapon

shock, it is good practice to place a positive load

on the adjusters by ending all boresight adjuster

rotations with an approximate 1/2 turn in a CCW

direction.

To establish this preset, rotate both the Aim Laser boresight

adjusters to the full CCW end of travel, then rotate them

back CW three complete turns. Finally, place a positive load

on the adjusters by turning each adjuster 1/2 turn CCW.

The ATPIAL may also be boresighted to the host weapon

using a Laser Borelight System (LBS). Table 2-7 provides

10m Target Offsets for this purpose. Refer to the latest

version of the LBS Operator Manual for boresighting

procedures.

The following abbreviations and their definitions apply solely

to the last two columns of Table 2-7:

L Left R Right

U Up D Down

VIS Visible Aim Laser IR IR (Infrared) Aim Laser

2-12

2.5 BORESIGHTING PROCEDURES (Continued)

M4/M16A4

VIS 2.0R / 1.5U

VIS 2.5L / 1.5U

M4/M16A4

MWS

VIS 3.0L / 0.0

IR 4.0L / 1.0D

VIS 2.5R / 3.5U

IR 3.5R / 4.5U

M4/M16A4

MWS

VIS 3.0R / 4.5D

IR 4.0R / 3.5D

VIS 3.0L / 7.0U

IR 4.0L / 6.0U

M4/M16A4

VIS 2.0R / 4.5U

VIS 2.5L / 0.0

M4/M16A4

MWS w/M203

VIS 3.5L / 0.5U

IR 4.5L / 0.5D

VIS 2.5R / 2.5U

IR 3.5R / 3.5U

M4/M16A4

MWS w/M203

VIS 3.5R / 1.0D

IR 4.5R / 1.5D

VIS 4.0L / 5.0U

IR 5.0L / 6.0U

M249

Feed Tray

VIS 0.0 / 4.0U

VIS 3.0L / 4.0U

M249

Left Side

VIS 6.0L / 3.5D

VIS 1.5R / 11.0U

M249

Short Barrel

Right Side

Forward Rail

VIS 2.5R / 7.5D

IR 3.5R / 6.5D

VIS 3.5L / 14.5U

IR 4.5L / 13.5U

M249

Standard Barrel

Feed Tray

Cover

VIS 2.0R / 2.0U

IR 1.0R / 3.0U

VIS 1.5L / 4.0U

IR 0.5L / 3.0U

M249

Left Side

VIS 5.0L / 4.0D

VIS 4.5R / 11.0U

M249

Standard Barrel

Right Side

Forward Rail

VIS 4.7R / 9.5D

IR 5.7R / 8.5D

VIS 3.0L / 15.0U

IR 4.0L / 14.0U

Feed Tray

Cover

VIS 3.0R / 0.5U

IR 2.0R / 1.5U

VIS 2.0L / 5.0U

IR 1.0L / 6.0U

Left Side

VIS 4.0L / 5.0D

VIS 5.0R / 12.5U

Right Side

VIS 5.5R / 8.5D

VIS 4.0L / 16.0U

Weapon Mount

MWS

Table 2-7. Weapon Offsets.

Range

Zeroed To

Top Rail 300m

Left Rail 300m

Right Rail 300m

IR 1.0R / 2.5U

10m Boresight

Target Offset

Squares

25m Target Zero

Offset Squar es

IR 1.5L / 0.5U

MWS w/M203

Short Barrel

Short Barrel

Standard Barrel

M240B MG

M240B MG

M240B MG

Top Rail 300m

Left Rail 300m

Right Rail 300m

Cover

Forward Rail

400m

400m

400m

400m

Forward Rail

400m

400m

500m

Forward Rail

Forward Rail

500m

500m

IR 1.0R / 5.5U

IR 1.0L / 5.0U

IR 7.0L / 4.5D

IR 6.0L / 5.0D

IR 5.0L / 6.0D

IR 6.5R / 7.5D

IR 1.5L / 0.5U

IR 2.0L / 3.0U

IR 2.5R / 12.0U

IR 5.5R / 12.0U

IR 6.0R / 13.5U

IR 5.0L / 17.0U

2-13

2.6 ZEROING PROCEDURES

NOTE

The boresight adjusters move the aiming beams at

the rate of approximately 0.2 mrad per click. Two

clicks = 1 box on a standard 25-meter zeroing

target.

After establishing the factory preset or boresighting the

ATPIAL / weapon combination, the ATPIAL may be zeroed

to the weapon via live fire at a 25-meter range as described

below. Table 2-7 provides target offsets that must be

applied to the 25-meter zeroing target. Refer to Tables 2-1,

2-2, and 2-3 for adjuster rotation and resultant direction of

shot group movement.

NOTE

Direct sunlight may hinder the ability of the user to

effectively see the Visible Aim Laser on the target.

1. On a 25-meter zeroing target, mark the designated strike

point and designated strike zone for the weapon being

used (see Table 2-7).

2. Mount the target on an “E” silhouette or other suitable

surface at 25 meters.

3. Mount the ATPIAL to the weapon.

4. Rotate the Mode Selector to Visible Aim Low (VIS-AL)

position.

5. Activate the Visible Aim Laser in continuous mode by

double-tapping the FIRE Button.

6. Direct the Visible Aim Laser at the center of the target.

2-14

2.6 ZEROING PROCEDURES (Continued)

7. Fire a 3-round shot group and note the center of the shot

group relative to the designated strike point. Re-tighten

the rail grabber bracket.

8. Rotate the Aim Laser adjusters to move the center of the

shot group to the designated strike point.

9. Fire another 3-round shot group and again observe the

center of the new shot group relative to the designated

strike point.

10. When 5 out of 6 consecutive rounds are in the

designated strike zone, the ATPIAL / weapon

combination is zeroed.

11. Once the aiming beams are zeroed, rotate the Mode

Selector to the DL (DUAL LOW) or DH (DUAL HIGH)

position to observe both the IR aiming and illumination

beams. Rotate the Illuminator adjusters to center the

illumination beam over the IR aiming beam.

2-15

OPERATING INSTRUCTIONS

VISIBLE AIM

Class 3R

The ATPIAL will not operate.

pulse rate.

AIM LOW

Class 3R

IR Aim Laser is selected at low

power.

DUAL LOW

Class 3B

IR Aim Laser and IR Illuminator

Class 3B

high power.

ILLUMINATOR

Class 3B

power.

SECTION II

2.7 MODES OF OPERATION

Table 2-8 describes the modes of operation for the ATPIAL.

Position Mode Remarks

VIS AL

Table 2-8. Modes of Operation.

Visible Aim Laser is selected.

2-16

O

P

AL

DL

AH

IH

DH

OFF

PROGRAM

AIM HIGH

HIGH

DUAL HIGH

Class 3B

Prevents inadvertent emission

of laser energy.

Programming mode is selected

to set the desired IR Illuminator

are both selected at low power.

IR Aim Laser is selected at

IR Illuminator is selected at

high power.

IR Aim Laser and IR Illuminator

are both selected at high

2.8 MODE SELECTION

MODE

SELECTOR

WARNING

The Class 3R lasers (low power) described in

Table 2-8 may be used in force-on-force training

only if opposing forces are beyond the NOHD

values shown in Table i-1.

WARNING

The Class 3B lasers (high power) described in

Table 2-8 shall NOT be used in force-on-force

training.

WARNING

To prevent inadvertent activation of the lasers, the

ATPIAL should be in the O (OFF) position when

not in use.

Modes of operation are accessed by turning the Mode

Selector to the desired position. The P (PROGRAM)

position allows for setting the desired IR Illuminator pulse

rate (see section 2.11, IR Illuminator Pulse Rate).

Figure 2-10. Mode Selector.

2-17

2.8 MODE SELECTION (Continued)

SAFETY SCREW

LOCKOUT POSITION

Safety Screw

WARNING

The safety screw shall be installed in the lockout

position when the ATPIAL is in storage, being

returned to the armory, or distributed to field

personnel.

A removable safety screw installed in the lockout position

prevents the Mode Selector from being turned to the high

power laser settings (i.e., AH, IH, DH). A 3/32” hex head

wrench is used to remove the safety screw when, for tactical

reasons, access to the high power laser settings is desired

(see section 3.3, Replacing Safety Screw). The safety screw

storage location allows for secure storage of the safety

screw after it has been removed from the lockout position.

SAFETY SCREW

STORAGE LOCATION

Figure 2-11. Safety Screw Shown Lockout Position.

2-18

2.9 MODE ACTIVATION

NOTE

The ATPIAL is equipped with a shut-down feature

that will automatically turn off any laser that has

been activated for five continuous minutes. To

reactivate, press (single tap) the FIRE Button.

Once the mode of operation has been selected, the ATPIAL

may be used in that mode by activating the system as

follows:

Momentary Operation

Pressing and holding the FIRE Button operates the ATPIAL

in the selected mode. The selected laser(s) will remain on

until the FIRE Button is released, or after five minutes of

continuous operation, whichever comes first.

Continuous Operation

Pressing the FIRE Button twice in rapid succession (doubletap) operates the ATPIAL in the selected mode. The

selected laser(s) will remain on until the FIRE Button is

pressed a third time (single tap), or after five minutes of

continuous operation, whichever comes first.

Remote Cable Switch

When installed, the Remote Cable Switch may be used to

provide the same functionality as the FIRE Button and is

operated in the same manner. The Remote Cable Switch

plugs into the remote jack as shown in Figure 2-12. It is then

secured to the weapon to best suit the operator’s firing

preference using the retaining straps and / or hook and loop

fastener tape.

2-19

2.9 MODE ACTIVATION (Continued)

CABLE

CAUTION

When the Remote Cable Switch is plugged into

the remote jack, it automatically locks in place. To

remove it, pull back on the cable sleeve. Do not

remove the Remote Cable Switch by pulling on the

cable itself.

NOTE

The ATPIAL comes with a jack plug installed in the

remote jack that must be removed and stored

before installing the Remote Cable Switch.

SLEEVE

Figure 2-12. Installation of the Remote Cable Switch.

2-20

2.9 MODE ACTIVATION (Continued)

Dual Button Remote

The optionally available Dual Button Remote (DBR) is

operated in the same manner as the standard Remote Cable

Switch. However, in addition to remote activation of the

ATPIAL, it also provides control over a second electrooptical device (e.g., M3X, etc.).

The DBR may be mounted on a MIL-STD-1913 rail as

follows:

1. Position the DBR with the recoil lug aligned with the

desired recoil groove of the weapon’s rail.

2. Hook the moveable jaw of the DBR under the rail (see

Figure 2-13).

3. Squeeze the DBR clamp to open the moveable jaw, and

“roll” the fixed jaw onto the weapon rail until it clicks into

place and is firmly secured.

MOVEABL E JAW

FIXED JAW

Figure 2-13. Mounting the DBR.

RECOIL LUG

2-21

2.9 MODE ACTIVATION (Continued)

The cables may then be plugged into the remote jacks of two

separate devices. The smooth Activation Button

corresponds to the cable with the raised, black plug end.

The embossed Activation Button corresponds to the cable

with the recessed, gray plug end (see Figure 2-14).

Figure 2-14. DBR Activation Buttons.

2.10 USING THE AIM LASERS

Modes of operation for the Visible and IR Aim Laser are

selected and activated as described in sections 2.8 and 2.9,

respectively.

Aim Neutral Density / Opaque Lens Cap

Under certain operating conditions, particularly at night, it

may be desirable to prevent inadvertent emission of visible

laser energy. The Aim Neutral Density / Opaque Lens Cap

is provided for this purpose. It also reduces scatter from the

IR Aim Laser. To use the lens cap, stretch it out and over

the front of the Aim Laser exit ports so that it is snug and

firmly in place. See Figures 2-15 and 2-16.

2-22

2.10 USING THE AIM LASERS (Continued)

ILLUMIN ATOR

AIM NEUTRAL DENSITY /

OPAQUE LENS CAP

OR PATTERN GENERAT OR

DIFFUSER

Figure 2-15. Lens Caps Uninstalled.

Figure 2-16. Lens Caps Installed.

2-23

2.10 USING THE AIM LASERS (Continued)

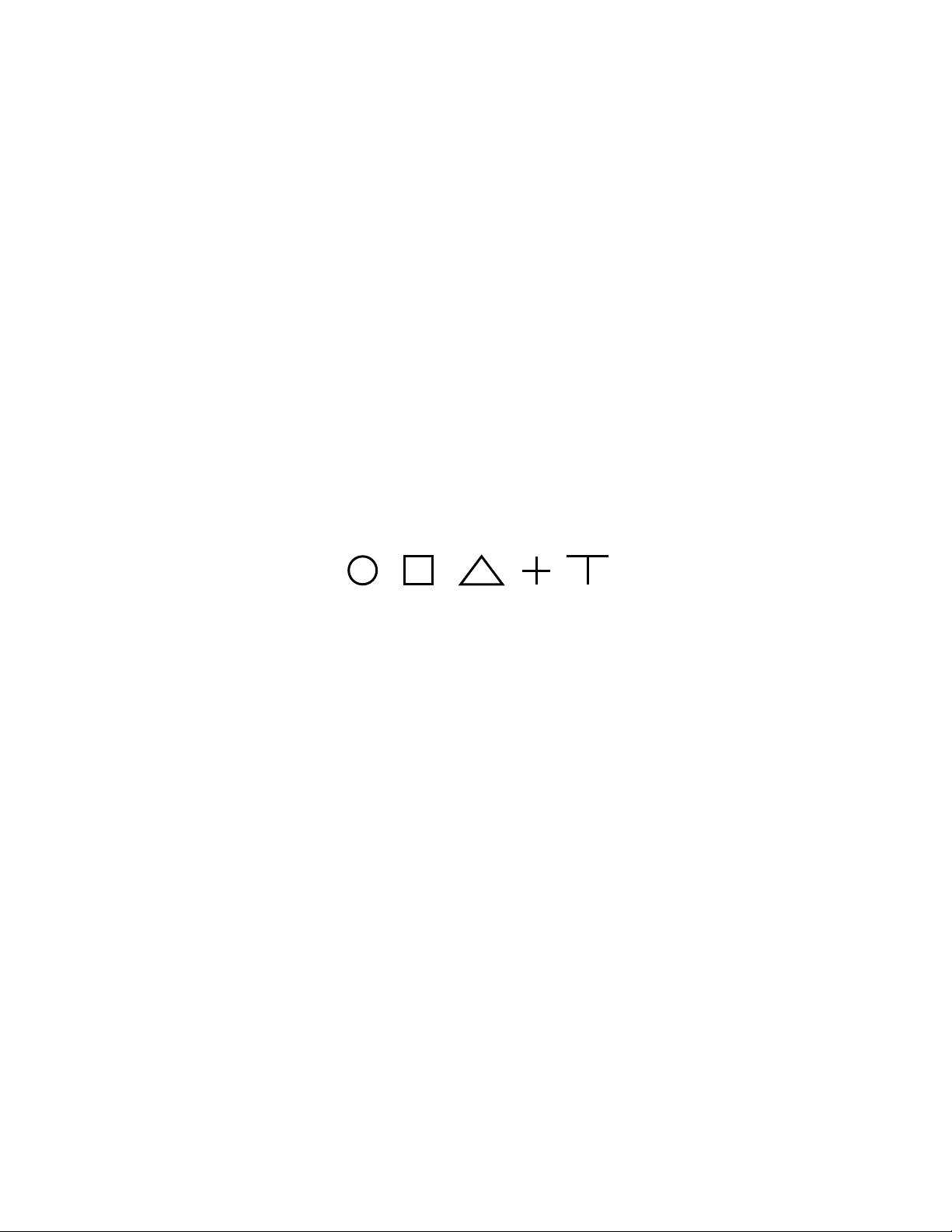

Pattern Generators

Five different Pattern Generators are supplied with the

ATPIAL for command and control purposes. When

individually installed over the Aim Lasers, they project a

specific holographic design over the aim point of the laser.

The shapes are visible with the naked eye if using the Visible

Aim Laser, and with night vision devices if using the IR Aim

Laser. The Pattern Generators may only be used one at a

time and may not be used in conjunction with the Aim

Neutral Density / Opaque Lens Cap. See Figures 2-15 and

2-16.

Figure 2-17. Pattern Generator Shapes.

2.11 USING THE IR ILLUMINATOR

Modes of operation for the IR Illuminator are selected and

activated as described in sections 2.8 and 2.9, respectively.

Beam Size

To focus the beam of the IR Illuminator, rotate the Focus

Ring until the desired beam size is obtained. Direction of

rotation to achieve maximum divergence (flood) and

minimum divergence (spot) is clearly labeled on the ATPIAL

housing (see Figure 2-18).

2-24

2.11 USING THE IR ILLUMINATOR (Continued)

SPOT

FLOOD

Figure 2-18. IR Illuminator Focus Ring.

Diffuser Lens Cap

When installed over the IR Illuminator, the Diffuser Lens Cap

spreads the laser energy over an angle of at least 45

degrees, allowing for illumination of a wider area. It is most

effective when used in conjunction with the Illuminator Focus

Ring adjusted to the widest beam (flood) setting. To use the

Diffuser Lens Cap, stretch it out and over the front of the IR

Illuminator so that it is snug and firmly in place. See Figures

2-15 and 2-16.

2-25

2.11 USING THE IR ILLUMINATOR (Continued)

Pulse Rate

Mode Selector Position

Program

P

Continuous (no pulse)

AL

1 pulse per second

DL

2 pulses per second

AH*

4 pulses per second

IH*

8 pulses per second

DH*

IR Illuminator Pulse Rate

In addition to momentary and continuous modes of

operation, the IR Illuminator may be programmed to operate

in pulse mode at either 1, 2, 4, or 8 pulses per second.

NOTE

To access the programming mode, the Mode

Selector must be turned to the desired pulse rate

within 5 seconds of pressing the FIRE Button.

1. With the Mode Selector turned to the P (PROGRAM)

position, hold down the FIRE Button.

2. Turn the Mode Selector to the IR position that

corresponds to the desired pulse rate as shown in Table

2-9. The LED Status Indicator will display a flashing

green light that corresponds to the pulse rate (e.g., four

green flashes indicate a pulse rate of four pulses per

second).

* The safety screw must be removed to program these pulse rates.

Table 2-9. IR Illuminator Pulse Rates.

3. Release the FIRE Button, and the pulse rate will be

programmed. The set pulse rate will remain until it is

programmed differently.

2-26

2.12 LED STATUS INDICATOR

Color

Rate

Laser(s) activated or continuous IR

illumination

GREEN

1 flash per second

1 illuminator pulse per s econd

2 flashes per

second

4 flashes per

8 flashes per

second

RED

Steady

Laser(s) not activated, low battery power

Steady green with

seconds

Steady for 2

ORANGE

3 orange flashes

IR programming successful

INDICAT OR

An LED is incorporated into the body of the ATPIAL as

shown in Figure 2-19. A list of possible LED indications is

provided in Table 2-10.

LED STATUS

Figure 2-19. LED Status Indicator.

Indicator

GREEN Steady

GREEN

GREEN

GREEN

GREEN/RED

Table 2-10. LED Status Indicator.

RED

Indicator

second

1 red flash ev ery 5

seconds

ATPIAL Status

2 illuminator pulses per second

4 illuminator pulses per second

8 illuminator pulses per second

Laser(s) activated, low battery power

IR programming failed

2-27

2-28

CHAPTER 3

Malfunction

Probable Cause

Corrective Action

1. Laser(s) appear

a. Software overload.

a. Cycle power.

b. Mode Selector is in O

position.

b. Turn Mode Selector to

pressing the FIRE button.

c. Aim Neutral Density /

c. Uninstall the Aim Neutral

per Figure 2-15.

d. Laser port(s) obscured by

d. Clean las er port(s)

MAINTENANCE

MAINTENANCE AND TROUBLESHOOTING

Prior to conducting routine or periodic

maintenance on the ATPIAL, ensure the Mode

Selector is turned to the O (OFF) position.

3.1 TROUBLESHOOTING

The procedures below will help correct some of the basic

problems that may arise with the ATPIAL. If the equipment

malfunction is not listed, or the actions listed do not correct

the fault, refer to section 3.4 for additional guidance.

weak or are not

visible when

activated.

Table 3-1. Troubleshooting Procedures.

(OFF) or P (PROGRAM)

SECTION I

WARNING

desired position. Activate by

Opaque Lens Cap installed.

dirt, dust, or grime.

Density / Opaque Lens Cap

(section 3.2) .

3-1

3.1 TROUBLESHOOTING (Continued)

Malfunction

Probable Cause

Corrective Action

1 (cont). Las er(s)

e. Battery improperly

e. Verify battery is properly

f. Battery power is low.

f. Replace battery

g. Battery compartment /

g. Clean battery

(section 3.2) .

2. Laser(s) turn off

a. Software overload.

a. Cycle power.

b. Shut-down feature has

b. “Wake” the system by

Switch, or DBR.

c. Battery power is low.

c. Replace battery

d. Battery compartment /

d. Clean battery

(section 3.2) .

3. ATPIAL does not

a. Rail grabber assembly not

a. Verify rail grabber is

Table 3-1. Troubleshooting Procedures (Continued).

appear weak or are

not visible when

activated.

unexpectedly.

retain zero.

installed.

contacts corroded.

been initiated.

contacts corroded.

properly secured to weapon

rail.

installed (section 2.2).

(section 2.2) .

compartment / contacts

pressing (single tap) the

FIRE Button, Rem ote Cable

(section 2.2) .

compartment / contacts

properly secured to weapon

rail (section 2.3).

3-2

3.2 INSPECTION / CLEANING

The operator should inspect the ATPIAL before each use

and after it has been in extreme conditions, such as

prolonged exposure to intense temperatures. The following

procedures will prolong the life of the ATPIAL and help

ensure safe operation.

WARNING

Isopropyl alcohol is flammable and toxic. To avoid

injury, keep away from open fire and use in a well

ventilated area.

ATPIAL Housing

Inspect the ATPIAL housing for any signs of damage

including cracks, missing parts, and any other visible

defects. Rinse thoroughly with water or mild soap and

water, then wipe clean with a soft cloth. If necessary, clean

around buttons, switches, adjusters, and attachment points

using fresh water and a cotton swab.

Battery Compartment / Cap

Inspect the battery compartment for dirt, dust, or corrosion.

Dirt or debris that cannot be shaken loose from the battery

compartment may be removed using a cotton swab. Clean

the threaded portions of the battery cap and battery

compartment using a cotton swab dipped in isopropyl

alcohol. If necessary, clean battery contacts with a pencil

eraser or cotton swab dipped in isopropyl alcohol.

Periodically lubricate the battery compartment o-ring with

fluorinated grease. Replace the o-ring if it becomes cut,

nicked, or dried out (see section 3.3, Replacing Battery

Compartment O-Ring).

3-3

3.2 INSPECTION / CLEANING (Continued)

Laser Ports

Inspect the laser ports for dirt, dust, and grime. Remove any

large particles or loose dirt using air or a soft cloth. Fine

cleaning should be performed using lens tissue and lens

cleaning solution. Clean water, isopropyl alcohol, or general

purpose window cleaner may be used to remove stubborn

stains. Avoid using excessive force as this may scratch the

lenses.

Remote Jack

Inspect the remote jack for corrosion, dirt, and damage.

Gently remove any large particles of foreign matter and

clean the contacts using a cotton swab dipped in isopropyl

alcohol.

3.3 CORRECTIVE MAINTENANCE

The ATPIAL has no internal parts or assemblies replaceable

by the operator or organizational level personnel. See

section 3.4 for guidance regarding maintenance and/or

repair actions beyond those described in this manual.

3-4

3.3 CORRECTIVE MAINTENANCE (Continued)

GROOVE

Replacing Battery Compartment O-Ring

1. Unscrew the battery cap until it comes free of the battery

compartment threads.

2. Use the fingers of one hand to squeeze the battery

compartment o-ring while simultaneously pushing it out of

its retaining groove. Grasp the o-ring with fingers of the

other hand and pull it off the battery compartment

threads.

3. Use a cotton swab dipped in isopropyl alcohol to clean

the o-ring retaining groove of any dirt, grease, or debris.

4. Apply a thin, even coat of fluorinated grease to the

replacement o-ring.

5. Stretch the replacement o-ring over the battery

compartment threads and slip it into its retaining groove.

RETAININ G

Figure 3-1. Battery Cap O-Ring.

6. Reinstall the battery cap and tighten.

3-5

3.3 CORRECTIVE MAINTENANCE (Continued)

Replacing Battery Cap / Battery Cap Lanyard

1. Unscrew the battery cap until it comes free of the battery

compartment threads.

2. Use the fingers of one hand to squeeze the thin battery

compartment o-ring while simultaneously pushing it out of

its groove. Grasp the o-ring with fingers of the other hand

and pull it off the battery compartment threads.

3. Simultaneously stretch and pull the larger eye of the

battery cap lanyard off the battery compartment threads.

4. Pull the smaller eye of the battery cap lanyard off the

battery cap post.

Figure 3-2. Battery Cap / Battery Cap Lanyard.

5. Replace the battery cap and/or battery cap lanyard as

necessary.

6. Stretch smaller eye of the battery cap lanyard over the

post on the battery cap.

3-6

3.3 CORRECTIVE MAINTENANCE (Continued)

7. Simultaneously stretch and pull the larger eye of the

battery cap lanyard over the battery cap threads. Work

the lanyard until it is seated neatly in the groove closest to

the ATPIAL housing.

8. Stretch the o-ring over the battery compartment threads

and slip it into its retaining groove (see Figure 3-1).

9. Reinstall the battery cap and tighten.

Replacing IR Illuminator Diffuser Lens Cap

1. If applicable, remove the old lens cap by pulling it off the

ATPIAL housing.

2. Stretch the looped end of the replacement lens cap

around the Illuminator Focus Ring.

3. Work the looped end down the Focus Ring toward the

ATPIAL housing, until it is seated neatly in its retaining

groove.

4. Flip the lens cap up and over the IR Illuminator.

Figure 3-3. Replacing IR Illuminator Diffuser Lens Cap.

3-7

3.3 CORRECTIVE MAINTENANCE (Continued)

ATTACHMENT

Replacing Aim Neutral Density / Opaque Lens Cap or

Pattern Generator

1. If applicable, pull both retaining straps off the Lens Cap

attachment points. Attachment points are located on both

the top and bottom sides of the ATPIAL housing.

POINTS

Figure 3-4. Lens Cap Attachment Points.

2. Examine the replacement lens cap. Note that one side is

flat and the other side is contoured. Also note that one of

the filters is glossy (Neutral Density) while the other is dull

(opaque).

3. Ensuring the flat side of the new lens cap will face out,

position the lens cap over the Aim Lasers as shown in

Figure 3-5. The glossy, Neutral Density filter must be

aligned with the IR Aim Laser.

3-8

3.3 CORRECTIVE MAINTENANCE (Continued)

GLOSSY

IR AIM LASER

Figure 3-5. Positioning the Lens Cap.

4. Stretch the eyes of the lens cap lanyard over the

attachment points.

5. Flip the lens cap over the IR Aim Lasers.

Replacing Safety Screw

1. Remove safety screw by using a 3/32 inch hex head

wrench. Turn counterclockwise.

2. Install replacement safety screw in the lockout or storage

location. Using a 3/32 inch hex head wrench, turn

clockwise to tighten.

3-9

SERVICE / PACKING AND UNPACKING

SECTION II

3.4 RETURN INSTRUCTIONS

For service, repair, or replacement, first e-mail

returns.insight@l-3com.com

or call toll-free 1-877-744-4803.

To assist with determining if the item is repairable, the

following information will be requested:

a. Serial number of the defective item;

b. Thorough description of the malfunction, defect, or

damage; and

c. If known, an explanation as to how the malfunction,

defect or damage occurred.

If the item is determined to be Beyond Economical Repair,

follow applicable replacement procedures through your

Property Officer. If it is determined that the item is under

warranty, or should be returned for repair, a Return Material

Authorization (RMA) number will be provided.

When returning the ATPIAL for service / repair, the following

procedures should be followed to prevent any additional

damage:

1. Be sure that the ATPIAL is free of all contaminants such

as dirt or any other foreign material.

2. Remove battery.

3. Place the ATPIAL in the soft carrying case.

3-10

3.4 RETURN INSTRUCTIONS (Continued)

Place the item and a copy of the test report or detailed

description of the failure in a suitable packing container.

Mark the package with “Field Return” and the RMA number.

Ship via fastest, traceable, pre-paid means to:

L-3 Communications Corporation

Warrior Systems Division

Insight Operations

9 Akira Way

Londonderry, NH 03053

3.5 WARRANTY INFORMATION

The ATPIAL is under warranty from defects in material and

workmanship for a minimum of one (1) year from the date of

manufacture. This warranty does not protect against

damage due to misuse, mishandling or battery leakage.

Additional warranty coverage may have been provided

through the contract or via subsequent contract extension.

Specific warranty terms can be obtained from your

procurement agent, Contracting Officer or L-3 Warrior

Systems, Insight.

3.6 NON-WARRANTY INFORMATION

Non-warranty repairs are subject to an evaluation fee. The

item will be tested and evaluated for failure, then customer

permission and payment terms are obtained prior to any

repairs being performed.

3-11

3-12

APPENDIX A

END ITEM COMPONENTS AND REPAIR PARTS

A.1 SCOPE

This Appendix lists end item components and repair parts

available for the ATPIAL.

INTENTIONALLY LEFT BLANK

A-1

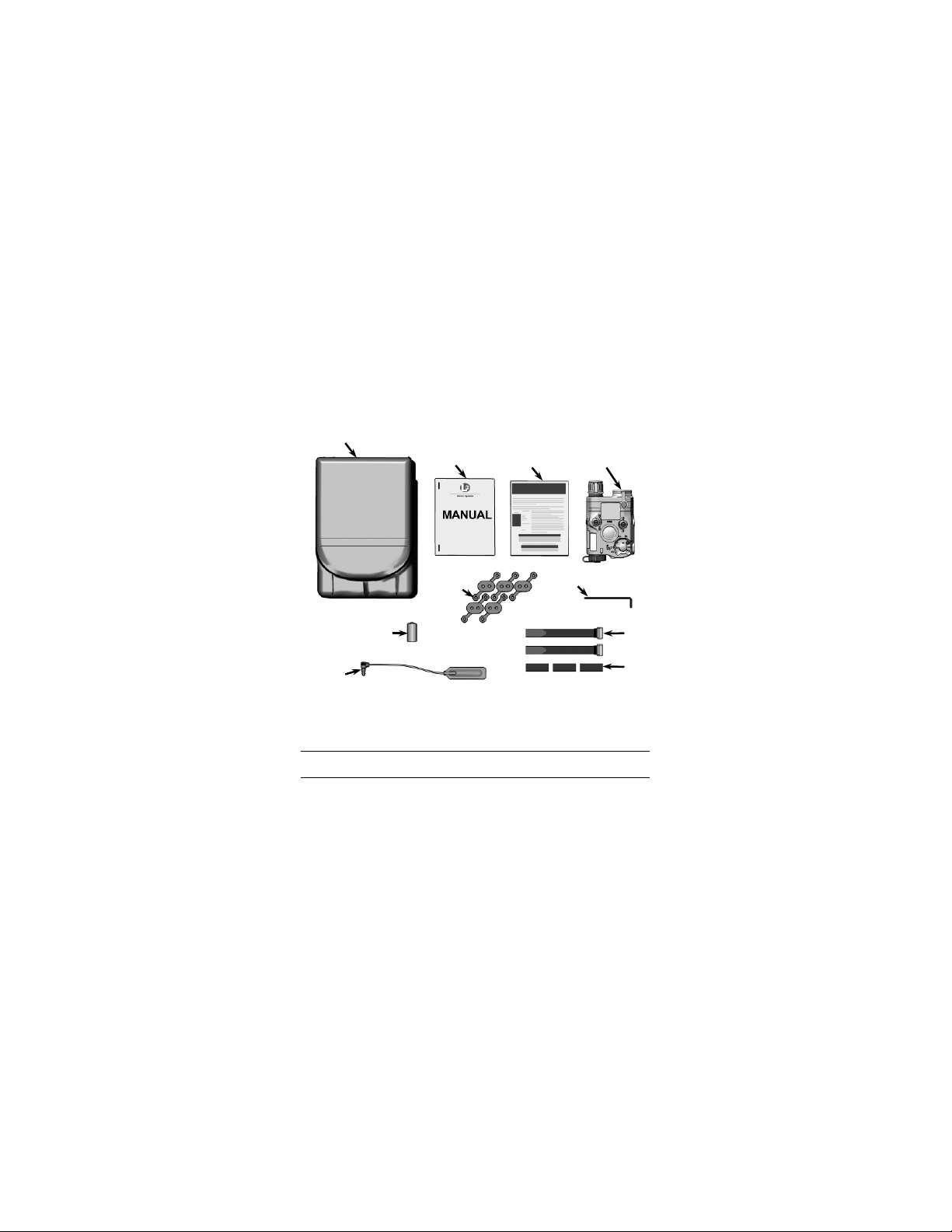

A.2 END ITEM COMPONENTS

ITEM

NO.

NATIONAL

STOCK NUMBER

PART

NUMBER

1

8105-01-368-6253

4B-949

Bag, Textile

1

2

N/A

ATP-TM-SP

Operator Manual

1

3

N/A

ATP-QRG-SP

Quick Reference Card

1

ATP-100-A17

ATPIAL Assembly, Tan

(see Figure A-2 for parts breakdown)

5

5120-01-578-7433

3/32 HEX KEY

3/32” Hex Key

1

6

5340-01-455-0062

ITP-809

Retaining Straps

2

7

8315-01-497-8154

ITP-044

Loop Tape

3

8

5995-01-454-7124

ITP-053

Remote Cable Switch, 12”

1

9

6135-01-351-1131

DL123ABK

Battery, DL123A

1

1240-01-545-6071

1240-01-536-9662

ATP-610

ATP-609

Pattern Generator Kit, Tan

Pattern Generator Kit, Black

1 2 5

7

8

3

4

10

6 9

Figure A-1. End Item Components.

Table A-1. List of End Item Components.

4 N/A

10

ATP-100-A21

ATPIAL Assembly , Black

A-2

DESCRIPTION QTY

1

1

A.3 REPAIR P ARTS

ITEM

NO.

NATIONAL

STOCK NUMBER

PART

NUMBER

1240-01-536-9660

1240-01-545-6070

ATP-630

ATP-630-A2

Aim ND / Opaque Lens Cap, Black

Aim ND / Opaque Lens Cap, Tan

2

5305-01-537-1811

MHW003-042ALBL

Safety Screw

1

4730-01-454-9944

HKL-313

Remote Jack Plug, Black

4

1240-01-536-9661

MFL-173

Lanyard, Battery Cap

1

6160-01-538-1792

IPM-252

Battery Cap, Black

6

5331-01-537-0498

AS-568A-018S70

O-Ring, Battery Compartment

1

1240-01-537-0486

ATP-420-A2

Lens Cap, Illuminator Diffuser, Tan

5 7 6

3

1

2

4

1

3

5

7

Figure A-2. ATPIAL Assembly.

Table A-2. List of Repair Parts.

4730-01-547-7145

6160-01-571-5425

1240-01-537-0486

HKL-313-02

IPM-252-02

ATP-420

DESCRIPTION QTY

Remote Jack Plug, Tan

Battery Cap, Tan

Lens Cap, Illuminator Diffuser, Black

1

1

1

1

A-3

Loading...

Loading...