Envirco NSF Biohazard Cabinet User Manual

BIOHAZARD

CABINET

MANUAL

Model 10448 - EBC 47, 4-Foot Type A/B3

Model 10276, 6-Foot Type A

Model 10451, 6-Foot Type B3

Operation Manual

A Fedders Engineered Products Company

Biohazard Cabinet Manual NSF Std 49 (92) 011130

CAUTIONS AND WARNINGS

READ AND SAVE THESE INSTRUCTIONS

WARNING!

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

A. Read this manual completely before installing or operating the ENVIRCO Biohazard Cabinet.

B. Use this unit only in the manner intended by the manufacturer. If you have any questions,

contact the manufacturer:

ENVIRCO

101 McNeill Road

Sanford, NC 27330

Tel: (919) 775-2201

Tel: (800) 884-0002

Fax: (800) 458-2379

Email: info@envirco.com

ASIAN SALES

Building #1

200 Middle Suhong Road

Suzhou, Jiangsu

PRC 215021

Tel: (86) 512 6258 0031

Fax:(86) 512 6258 7180

Europe, Middle East & Africa (EMEA)

TRION Div of Ruskin Air Management Ltd

European Operations

The Cavendish Center Winnall Close

Winchester Hampshire

S023 OLB, UK

Tel: +44 (0) 1962 840465

Fax: +44 (0) 1962 828619

C. Before servicing or cleaning unit, switch power off at facility service panel and lock service

panel to prevent power from being switched on accidentally and follow proper procedures as

necessary.

D. The ENVIRCO Biohazard Cabinet is equipped with a three-wire grounding plug for your

protection against shock. Insert the plug into a properly grounded three-wire outlet. If only a

two-wire outlet is available, it must be replaced with a properly grounded three-wire outlet in

accordance with the National Electric Code, and local codes and ordinances. Installation

work and electrical wiring must be done by qualified person(s) in accordance with all

applicable codes and standards, including fire-rated construction. Only a qualified electrician

should do this work.

2

E. Caution: Do not, under any circumstances, cut or remove the grounding prong from the

plug.

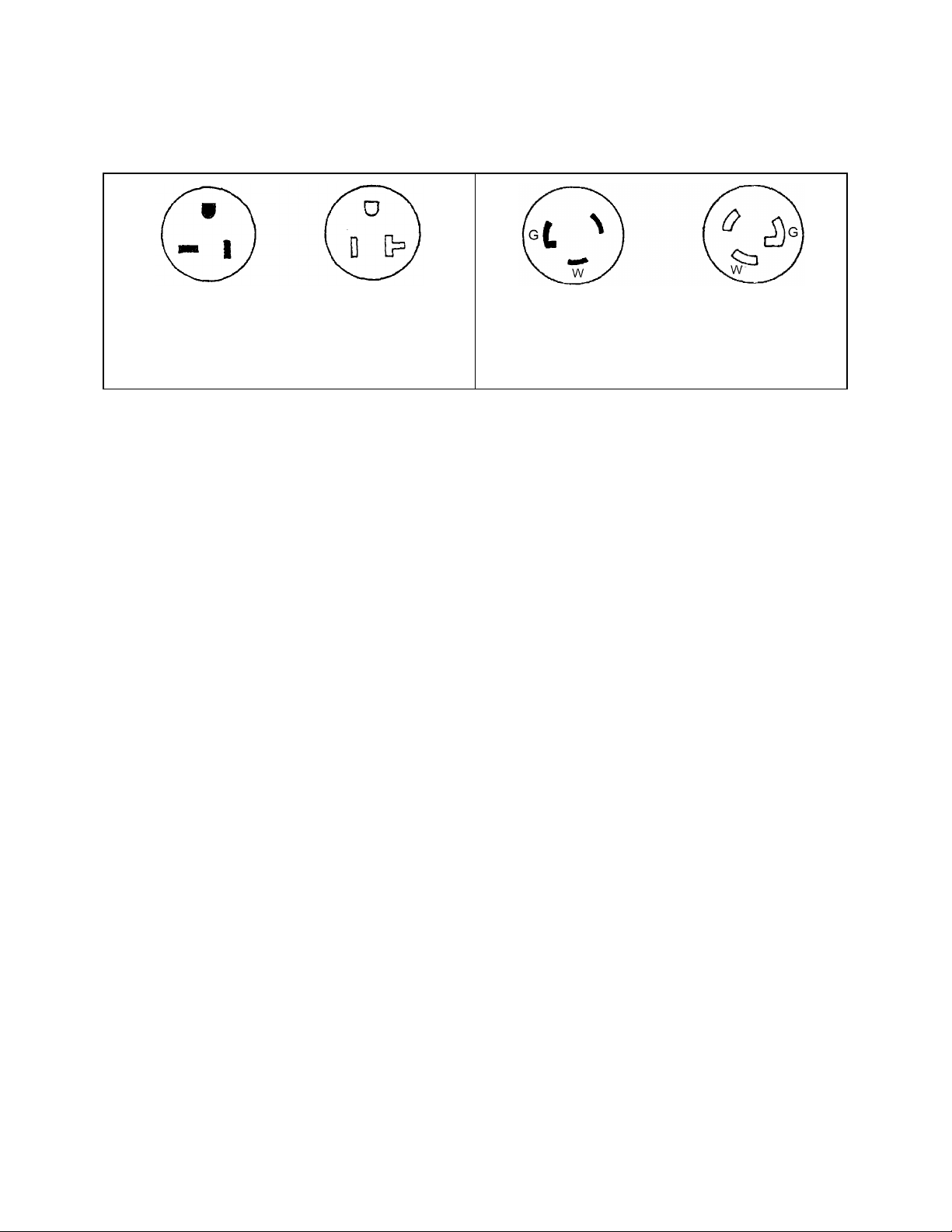

5-20 P

Plug

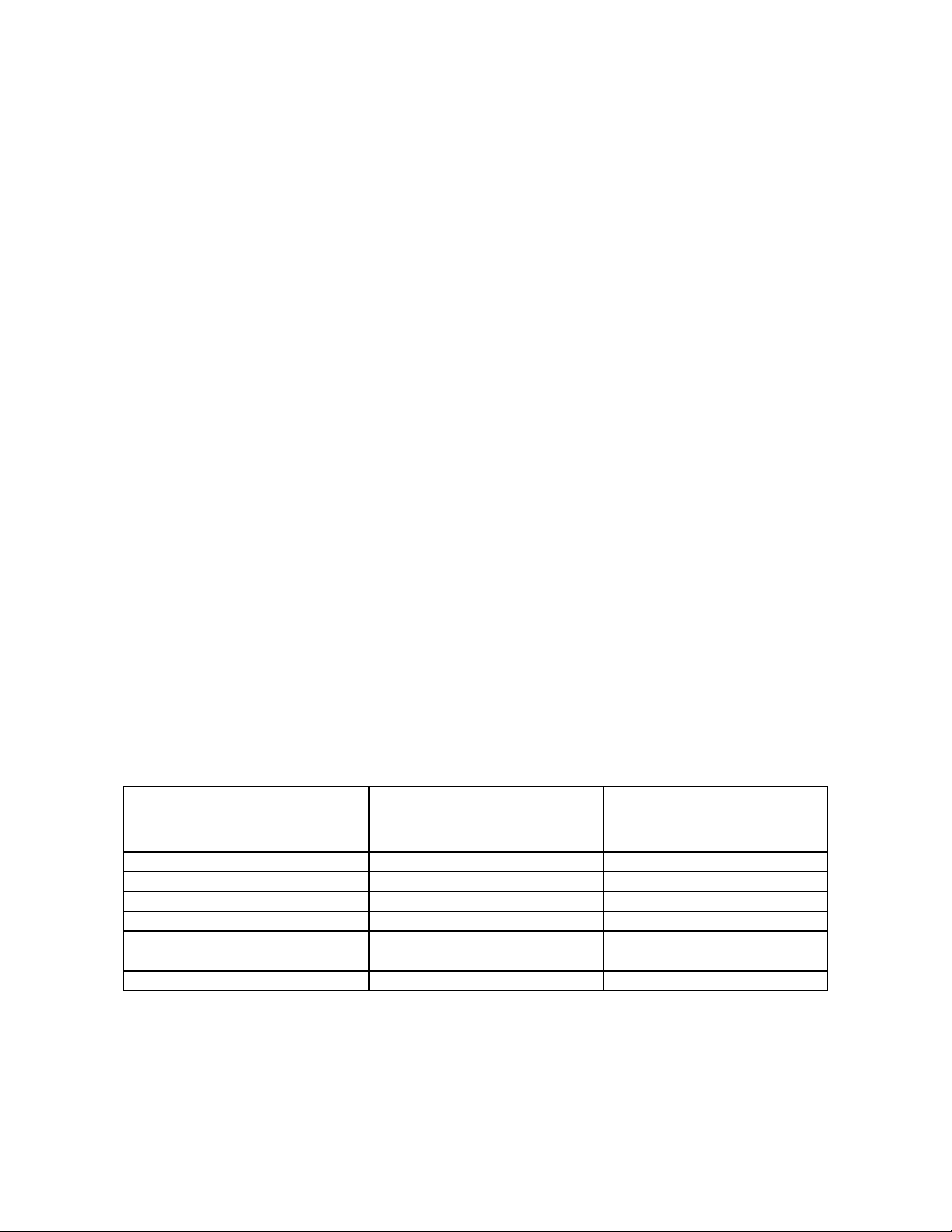

10448 - EBC 47, 4-Ft Type A/B3

5-20 R

Receptacle

5-30 P

Plug

10276, 6-Ft Type A

5-30 R

Receptacle

10451, 6-Ft Type B3

Figure 1: Plug and Receptacle Requirements

F. Unplug the power cord and decontaminate before servicing the cabinet or changing the

filters. Do not use extension cords. If the power cord or plug becomes frayed, cracked,

broken or otherwise damaged, replace it immediately.

G. Only an Authorized ENVIRCO Service Contractor should service the cabinet; however, the

owner can perform certain operations outlined in the manual. Do not attempt to perform any

procedures that are not specifically outlined in this manual.

H. Do not remove the caution labels from the equipment or the associated work area except for

the instruction label on the viewscreen.

I. Do not remove the front panel or HEPA filters from the ENVIRCO Biohazard Cabinet until the

cabinet has been decontaminated.

J. Keep this manual for future reference and for training new operators

3

TABLE OF CONTENTS

CAUTIONS AND WARNINGS...................................................................................................2

TABLE OF CONTENTS.............................................................................................................4

I. INTRODUCTION ............................................................................................................5

II. DEFINITIONS..................................................................................................................5

III. DESCRIPTION................................................................................................................6

IV. FEATURES.....................................................................................................................7

V. CABINET DIMENSIONS ...............................................................................................8

VI. SPECIFICATIONS..........................................................................................................9

VII. INSTALLATION............................................................................................................12

VIII. TESTING AND CERTIFICATION..............................................................................16

IX. 10448 - EBC 47 4-FOOT CABINET DRAWING ......................................................19

X. 10276 AND 10451 6-FOOT CABINET DRAWING.................................................20

XI. FILTER REPAIRS........................................................................................................21

XII. AIRFLOW ADJUSTM ENT..........................................................................................22

XIV. SUGGESTED WORKI NG PROCEDURES.............................................................25

XV. CABINET PRESSURE TESTING.............................................................................28

XVI. LABELING USED ON THE CABINET.....................................................................29

XVII. WIRING DIAGRAMS....................................................................................................30

XVIII. HEPA FILTER REPLACEMENT...............................................................................32

XIX. REPLACEMENT AND OPTIONAL PARTS............................................................33

XX. BIBLIOGRAPHY...........................................................................................................33

XXI. GLOSSARY...................................................................................................................35

XXII. RISK LEVELS, CLASSIFICATION ...........................................................................36

XXIII. MANUFACTURER'S LIMITED WARRANTY..........................................................37

4

I. INTRODUCTION

Investigators and technicians concerned with microbiological safety have for many

years utilized specialized containment enclosures to limit their exposure to harmful

pathogens. In addition, it is recognized that exacting research, as well as routine

pathology, is often compromised by environmental contamination. The ENVIRCO

Class II Biohazard Cabinet is designed to limit the contamination exposure of both

the worker and the work when handling biohazard material.

The Class II enclosure is an open face cabinet with a high volume of air recirculated

through internal HEPA filters. Air is drawn into the open front of the cabinet and

exhausted through a HEPA filter. The controlled airflow direction and volume

balance provides protection for the worker, the work (sample) and against cross

contamination within the cabinet.

II. DEFINITIONS

Class II, Type A Cabinets (formerly designated Type 1):

1. Maintain a minimum calculated average inflow velocity of 75 fpm through the

work area access opening.

2. Have HEPA filtered downflow air from a common plenum (i.e. a plenum from

which a portion of the air is exhausted from the cabinet and the remainder

supplied to the work area).

3. May exhaust HEPA filtered air back into the laboratory.

4. May have positive pressure contaminated ducts and plenums.

Type A cabinets are suitable for work with low to moderate risk biological agents in

the absence of volatile toxic chemicals and volatile radionuclides.

Class II, Type B3 Cabinets:

1. Maintain a minimum (calculated or measured) average inflow velocity of 100 fpm

through the work access opening.

2. Have HEPA filtered downflow air that is a portion of the mixed downflow and

inflow air from a common exhaust plenum.

3. Discharge all exhaust air to the outdoor atmosphere after HEPA filtration.

4. Have all biologically contaminated ducts and plenums under negative pressure,

or surrounded by negative pressure ducts or plenums.

Type B3 cabinets are suitable for work with low to moderate risk biological agents

treated with minute quantities of toxic chemicals and trace quantities of radionuclides

that will not interfere with the work if recirculated back with the downflow air.

5

Class II, Type A/B3 Cabinets:

1. Meets the requirements of Class II, Type A cabinets when the HEPA filtered

exhaust air is recirculated back to the laboratory.

2. Meets the requirements of Class II, Type B3 cabinets when the exhaust air is

vented to the outside atmosphere after HEPA filtration.

3. Confirms to the requirements for either the Type A or Type B3 cabinet outlined

above.

III. DESCRIPTION

The ENVIRCO Biohazard Cabinet is a Class II, Type A/B3 unit with HEPA filtered

air recirculation, front air barrier and self-contained exhaust. It provides a work area

for safe handling of low to moderate risk biohazard materials. It is designed

primarily for work in microbiology, virology, tissue culture, and sterility testing.

The Biohazard Cabinet

The cabinet protects the worker from airborne contaminants generated within the

work area. It protects the work from airborne contaminants generated in the

ambient air and protects against cross-contamination within the work area. The

cabinet is designed to comply with NSF1 Standard 49, Class II, Type A and/or B3

Biohazard Cabinetry and bears NSF seal of compliance.

NOTE: The Type A cabinet is suitable for work with low to moderate risk agents.

The Type B3 cabinet is suitable for use with chemical carcinogens and

low toxicity fumes or vapors.

1

NSF International, Ann Arbor, Michigan 48105

6

IV. FEATURES

1. The hinged viewscreen is constructed with safety glass and has a seven-

degree angle for comfortable viewing. The hinge enables easy loading and

unloading of work and allows maximum accessibility when cleaning the interior

work area.

2. The all stainless steel work area has a lift-out work tray and support for easy

cleaning.

3. The self-contained drain pan with external drain valve simplifies flushing and

cleanup of major spills.

4. The electrical and air, gas or vacuum outlets within the work area include all

internal plumbing.

5. The exhaust flow buzzer warns the operator in the event of loss of containment

function.

6. All of the controls, light tubes, and serviceable components are located outside

the contaminated area within a convenient, hinged front panel.

7. The heavy duty and stable work deck support provides extremely low vibration

transmission.

8. The leak-tight cabinet is designed to provide negative pressure. None of the

contaminated air plenums are at positive pressure with respect to the

laboratory.

9. The price of the cabinet includes initial on-site testing and certification of

proper performance by an Authorized Service Contractor.

7

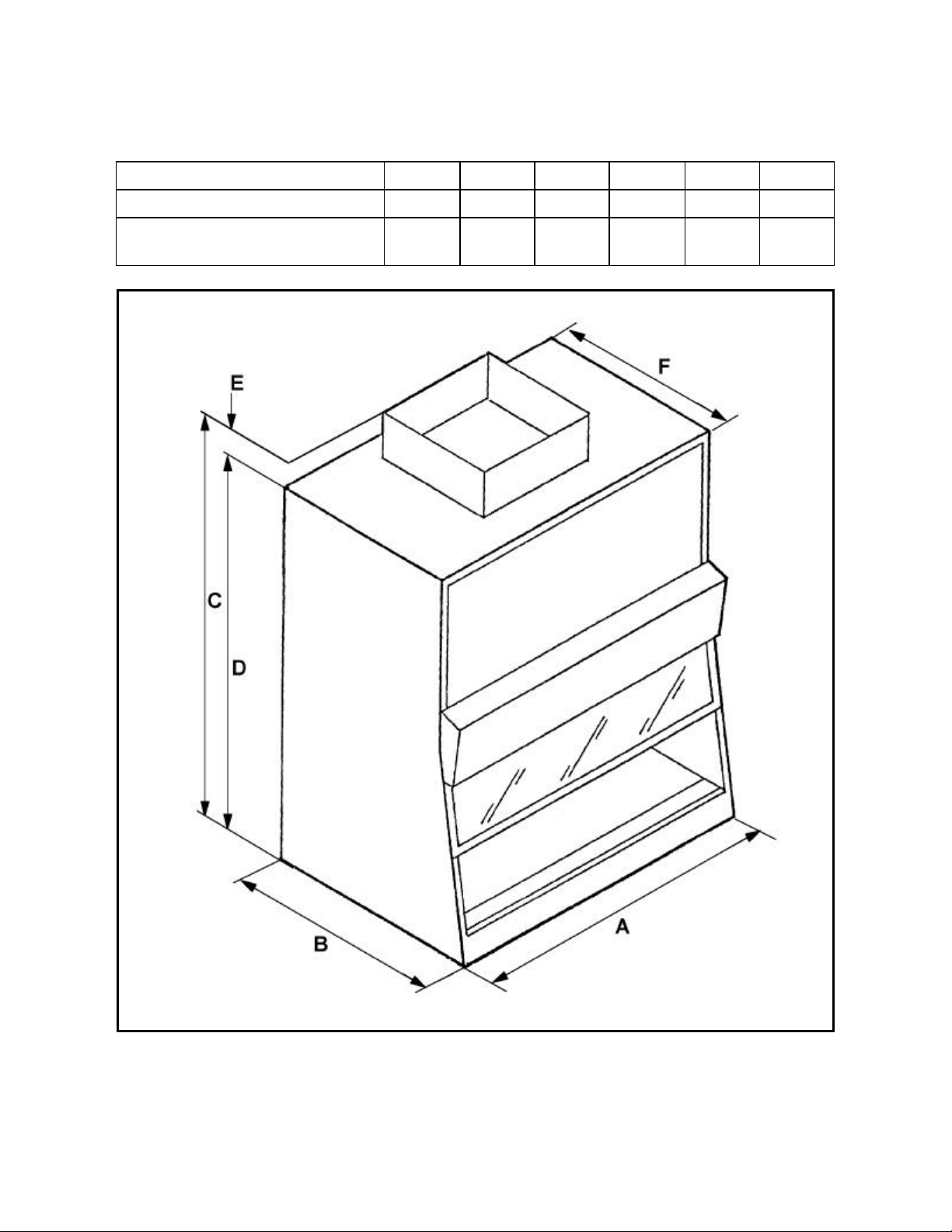

V. CABINET DIMENSIONS

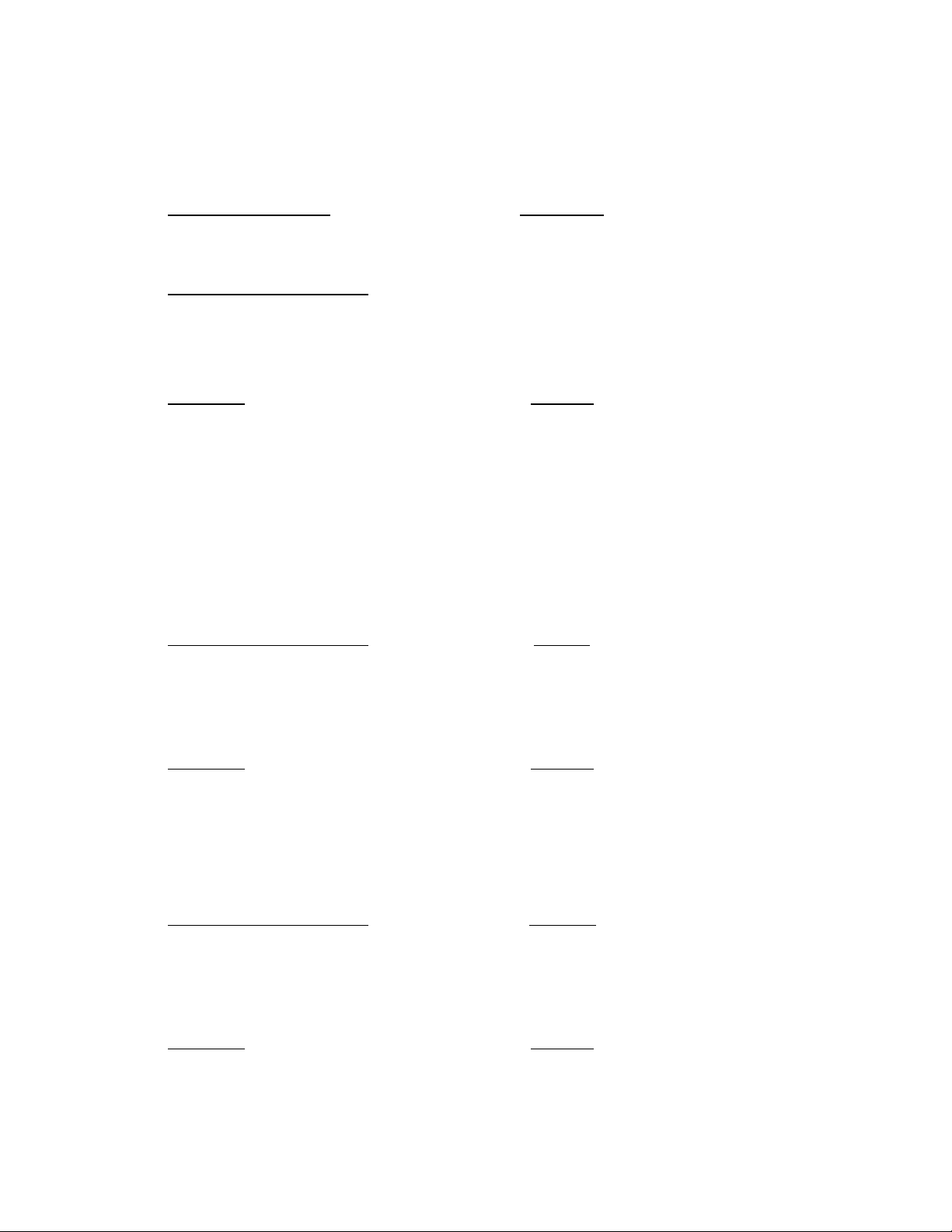

Model A B C D E F

10448 – EBC 47, 4-Ft Type A/B3 47.0” 32.5” 62.0” 58.0” 4.0” 28.5”

10276, 6-Ft Type A

10451, 6-Ft Type B3

70.0” 32.5” 62.0” 58.0” 4.0” 28.5”

Figure 2: Biohazard Cabinet Dimensions

8

VI. SPECIFICATIONS

Electrical:

10448 - EBC 47, 4-Ft Type A/B3: 115v, 60 Hz, 20 amp

10276, 6-Ft Type A: 115v, 60 Hz, 30 amp

10451, 6-Ft Type B3: 115v, 60 Hz, 30 amp

10448 - EBC 47, 4-Ft Type A/B3: Single power cord with a NEC 5-20p cap plug

10276, 6-Ft Type A: Single power cord with a NEC 5-30p cap plug

10451, 6-Ft Type B3: Single power cord with a NEC 5-30p cap plug

10448 - EBC 47, 4-Ft Type A/B3: One (1) 3/4 h.p. motor, thermally protected,

10276, 6-Ft Type A: Two (2) 1/3 h.p. motors, thermally protected,

10451, 6-Ft Type B3: Two (2) 1/3 h.p. motors, thermally protected,

All models have separate combination circuit breaker/switches for the motor(s),

lights and duplex electrical outlet.

automatic reset, SCR speed control

automatic reset, SCR speed control

automatic reset, SCR speed control

High Efficiency Particulate Air (HEPA) Filters:

Both the recirculating supply air and exhaust air filters remove all particles 0.3 µm and

larger in size with an efficiency of 99.99%. The HEPA filters are mounted with a

compression spring clamping system.

Physical:

Dimension 10448 – EBC 47, 4-Ft Type A/B3

Overall Height 62.0 in. (157.5 cm.) 62.0 in. (157.5 cm.)

Overall Depth 32.5 in. (82.6 cm.) 32.5 in. (82.6 cm.)

Overall Width 47.0 in. (119.4 cm.) 70.0 in. (177.8 cm.)

Work Area Height 26.0 in. (66.0 cm.) 26.0 in. (66.0 cm.)

Work Area Depth 21.0 in. (53.3 cm.) 21.0 in. (53.3 cm.)

Work Area Width 45.5 in. (115.6 cm.) 68.5 in. (174.0 cm.)

Face Opening Height 8.0 in. (20.3 cm.) 8.0 in. (20.3 cm.)

Shipping Weight – Cabinet 550 lbs. (249.5 kg.) 750 lbs. (340.2 kg.)

10276, 6-Ft Type A

10451, 6 Ft Type B3

Lighting:

The light intensity at the work surface is between 80-150 foot-candles provided by two

(2) fluorescent light tubes controlled by a separate breaker switch.

9

Airflow

10448 - EBC 47, 4-Ft Type A/B3:

Direct Inflow Method Type A/B3

-Velocity 100 – 110 fpm

-Airflow 253 – 278 cfm

Calculated Face Velocity 115 – 125 fpm

Exhaust Volume 290 – 316 cfm

Exhaust Filter Area 1.07 sq. ft.

Front Access Area 2.53 sq. ft

Downflow Velocity

Uniform 72 – 82 fpm

or

Zoned

Zone 1 (Back) 67 – 77 fpm

Zone 2 (Center) 67 – 77 fpm

Zone 3 (Center) 80 – 90 fpm

Zone 4 (Front) 74 – 84 fpm

10276, 6-Ft Type A:

Calculated Face Velocity Type A

-Velocity 85 – 95 fpm

-Airflow 324 – 362 cfm

Exhaust Filter Area 2.33sq. ft.

Front Access Area 3.81 sq. ft.

Downflow Velocity

Zone 1 (Back) 54 – 64 fpm

Zone 2 (Center) 53 – 63 fpm

Zone 3 (Front) 67 – 77 fpm

10451, 6-Ft Type B3:

Calculated Face Velocity Type B3

-Velocity 100 – 110 fpm

-Airflow 381 – 419 cfm

Exhaust Filter Area 2.33sq. ft.

Front Access Area 3.81 sq. ft.

Downflow Velocity

Zone 1 (Back) 75 – 85 fpm

Zone 2 (Center) 75 – 85 fpm

Zone 3 (Front) 68 –78 fpm

10

NOTES:

1. In performing the velocity profile test, the front row of velocity readings

(behind the window) must be taken with the thermoanemometer probe

positioned perpendicular to the window with the probe head facing the

window.

2. Velocity readings for the middle row(s) and rear row must be taken with the

probe positioned parallel to the window.

3. In performing the calculated face velocity test, the exhaust transition collar

must be removed when taking air velocity readings with a thermal

anemometer probe. This is the manufacturer’s recommended method for

balancing the 10276 and 10451.

4. Direct Inflow Method is the manufacturer’s recommended method for

balancing the 10448-EBC 47.

Construction:

The all-steel, welded unitized construction is leak tight at 2.0-in. water gauge (500 Pa)

positive pressure. The exterior is finished with chemically resistant polyurethane

enamel. The work area is constructed of 304, 16 gauge stainless steel.

Color:

Blue and White.

11

VII. INSTALLATION

Cabinet Location

The cabinet should be placed in an area of the laboratory free from strong air

currents, heavy traffic and particulate microbial or chemical contamination. This will

reduce any disruption of the airflow patterns at the face opening and will prolong the

life of the HEPA filters.

The ceiling height above the cabinet should allow four (4) inches of clearance above

the exhaust area to allow free air passage.

Installation and Leveling

Caution: Do not remove the front panel. Removal will void the Factory Leak Tight

Air Seal Test.

Bench Top Installation

Set the cabinet on the bench top with five (5) inches overhanging in the front.

Thread the drain valve in place and tighten. Put the work deck support and pan

in place. Level the work deck by placing metal shims under the bottom of the

cabinet. Silicone caulking can also be applied to seal the area between the

bench top and the cabinet.

Figure 3: Bench Top Installation

12

Loading...

Loading...