Envirco MAC-T User Manual

OPERATION & MAINTENANCE MANUAL

Envirco Technical Support: 800-884-0002

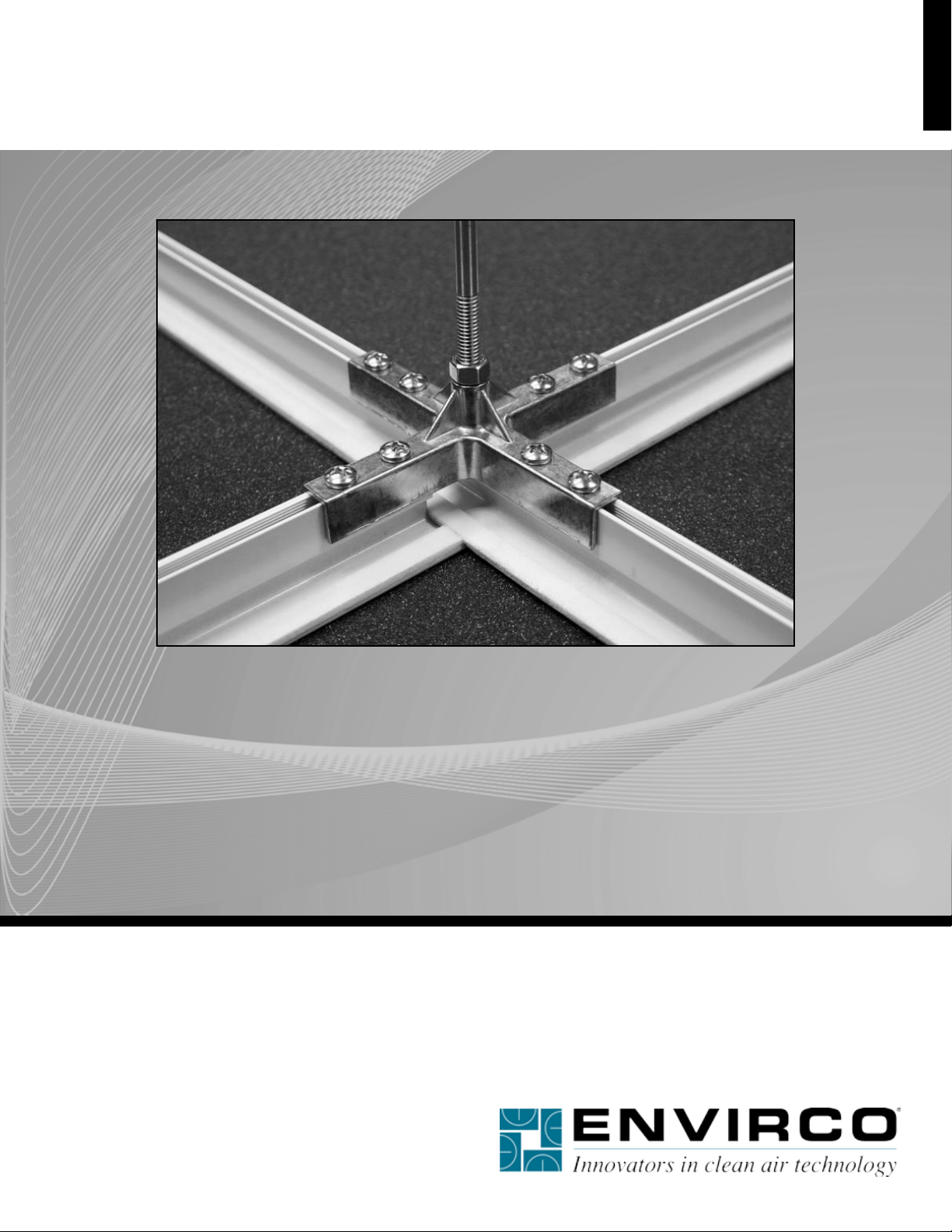

MAC-T Ceiling Grid System

2” Heavy Duty for Cleanroom

MAC-T Ceiling Grid System

2” Heavy Duty for Cleanroom

Installation & Service Manual

Table of Contents

Introduction ....................................................................................................................... 3

Tools ................................................................................................................................. 3

Uncrating, Inspection, and Inventory ................................................................................ 3

Notes ................................................................................................................................ 3

Part Numbers & Extrusion Guide Description .................................................................. 4

Diagram ............................................................................................................................ 5

Installation ........................................................................................................................ 6

Maintenance ..................................................................................................................... 7

Please read through instructions before beginning installation.

2 Innovators in Clean Air Technology | www.envirco.com | Operation & Maintenance

MAC-T Ceiling Grid System

2” Heavy Duty for Cleanroom

Installation & Service Manual

■ Introduction

Envirco offers the T-Grid 2” Gasket Seal Grid Cleanroom Ceiling System with superior materials that provides a structural grid

system and zinc alloy die-castings. The materials are packaged with care, but check for damage that may have occurred during

transit. Please inspect the shipment and quantity before beginning installation. Please notify us promptly if you experience any

problems at 800.884.0002.

The following information is provided by Envirco as a general guideline for the installation of the 2” T-Grid cleanroom ceiling

grid system. This information should be reviewed prior to commencing installation. The intent is to be as specic as possible

in detail for a typical project, yet general enough to be utilized by most installations. It is Envirco’s intent that the descriptions

are helpful and easy to understand. If there are any questions, comments, or special considerations, please contact Envirco

Technical Support at 800.884.0002.

Note: This narrative assumes that the job-site is clear and ready for the construction of cleanroom ceiling.

■ Tools

It is suggested that the following tools be used to erect this system:

• Laser or Suitable Leveling Instrument

• Phillips head Drive & Cordless Drill

• Circular Saw with Fine Toothed Carbide Tip Blade

• (triple toothed, negative rake, aluminum blade)

• Miter Saw with Fine Toothed Carbide Tip Blade

• (triple toothed, negative rake, aluminum blade)

■ Uncrating, Inspection, and Inventory

The Envirco ceiling system is packaged in the factory in a manner to protect each part during normal shipping and handling. It

is recommended by Envirco that the original packaging remain intact as much as possible until the individual parts are needed.

All extrusion components are packaged in boxes with protective paper between nished surfaces.

As the skids are received at the job-site, they should be placed in a location near the installation area, where they will not

become an obstacle, or require to be moved at a later time. The skids should then be opened, however leaving the internal

packaging unchanged. Pieces should be removed on an as needed basis and the packaging discarded. At this time, however,

the components should be visually inspected for obvious damage and an inventory taken to conrm that all parts are received

in good condition. Notify Envirco immediately of any discrepancies in quantity.

■ Fasteners Not Provided by Envirco

Envirco does not provide the attachment hardware for the existing structure or framework. All hardware required from the

turnbuckle to the existing support structure is not provided.

■ Special Notes

Due to expansion and contraction properties of aluminum, it is recommended that this system be installed in a temperature

that is as close as possible to that which the nished room will operate. Stock T-bar or wall angle with a length of over 4 feet is

cut with a tolerance of +/-.032”. Stock cross-tees less than 4 feet is cut to +/- .016”. The above stated tolerances are measured

at a material temperature of from 60 to 90 F. All eld cuts including perimeter miter cuts are to be performed by the installing

contractor.

3Innovators in Clean Air Technology | www.envirco.com | Operation & Maintenance

Loading...

Loading...