Envirco BSC User Manual

Biological Safety Cabinet

4

’

Model Number 11228-001

User Manual

Envirco 101 McNeill Rd. Sanford, NC 27330 Phone: 1-800-884-8002 Fax: 1-800-458-2379

Catalog

I、Introduction 4

1.1 Specifications 5

II、Inst

allation 6

2.1 Position 6

2.2 Disassembly and handling 6

2.3 Assembly and installation 6

2.4 Check?? 7

III、Adjustment

s and testing 9

3.1 Adjustments on site 9

3.2 Tests and standards 9

3.2.1 Filter leakage test 9

3.2.2 Air adjustment of opening of work area 9

3.2.3 Downflow air velocity 10

3.2.4 Pressure test 10

3.3 Sterilization 10

IV、USE AND

MAINTENANCE 15

4.1 General operatingguidelines 12

4.1.1 Description: 12

4.1.2 Typical uses 12

4.1.3 Air filter system 12

4.1.4 Use instructions 12

4.1.5 Digital control circuit 13

4.1.6 Differential pressure indicator 14

4.1.7 Use of UV light 14

4.1.8 Use of electrical outlet 15

4.2 General maintenance 15

4.2.1 Running 15

4.2.2 Construction materials maintenance 15

4.2.3 Wipe down flows 16

4.2.4 Base plenum 16

4.2.5 Visual inspection 16

V、SER

VICE AND COMPONENTS 20

5.1 Main components replacement 16

5.1.1 Replacement of HEPA filter 17

5.1.2 Removal of filter 17

5.1.3 Filter installation 17

5.1.4 Motor replacement 21

2

5.2 Pressure monitor calibration 18

5.3 Major parts list 23

5.4 Fault finding hints 19

5.5 Attention to maintenance 21

VI、Inst

allations requiring connection to external exhaust systemError! Bookmark not defined.

6.1 Canopy/thimble connection 25

6.2 Hard connection 25

6.3 IFlow alarm monitoring system instructions 26

VII 、Label instructions 27

APPENDIX 1 Error! Book

DOWNFLOW/HAND INTAKE SETTINGS Error! Book

BIOHAZARD CABINETS-Class Error! Book

mark not defined.

mark not defined.

mark not defined.

FIGURE1 BASE FRAME ASSEMBLY 27

FIGURE 2 BOTH SIDE PANELS

_Toc265052624

FIGURE 4 MAIN PARTS Error! Book

mark not defined.

FIGURE 5 CONTROL PANEL 30

FIGURE 6 MEASUREMENT OF BIOHAZARD CABINET 28

FIGURE 7: AIR FLOW PATTERN AND PROTECTED AREA 30

FIGURE 8: FRONT ACCESS PANEL REMOVAL 30

FIGURE 9: GLASS CLIP 32

FIGURE 10: PRESSURE MONITOR CALIBRATION SETUP Error! Book

FIGURE 11: EXHAUST SYSTEM Error! Book

mark not defined.

mark not defined.

FIGURE 12: ELECTRICAL SCHEMATIC 33

VIII 、W

arranty

3

I、Introduction

Investigators and technicians concerned with microbiological safety have, for many years,

utilized specialized containment enclosures to limit their exposure to harmful pathogens. In

addition, it is recognized that exacting research, as well as routine pathology, is often

compromised by environmental contamination. The ENVIRCO Class II Biohazard Cabinet is

designed to limit the contamination exposure of both the worker and the work when handling

biohazard material. The Class II enclosure is an open-face cabinet with a high volume of air

circulated through an internal HEPA filter. Air is drawn into the open front of the cabinet and

exhausted through a HEPA filter. The controlled airflow direction and volume balance provide

protection for the worker, the work (sample), and against cross-contamination within the

cabinet.

This product has been tested to meet the requirements of CAN/CSA-C22.2 No.61010-1,

secondedition, including Amendment 1,or a later version of the same standard incorporating

the same level of testing requirements.

Important

Volatile, friable or poisonousradioactive substancesarenot allowed in the

non-exhaust-cover cabinet.

Sterilize the cabinet before turning off PAO test switch or wash water valve

Do not hinder airflow flowing out of HEPA filter.

Disconnect power before accessingthe operational board.

Maximum power of this equipment is 1000W.

Connect Only To Properly Grounded Outlet. Do Not Remove Ground Pin.

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

If needed, please use the emergency power cut-off, located on the front panel.

4

Technical Specifications

Model: 11228 -001

Nominal Size: 4Ft.(1.2 meters)

Internal Dimensions: (WxDxH): 55.9″x 33.4″x 85

Internal Size: (W x D x H): 48″x 26.1″x25.6″ (1220 x 665 x 65

.8″ (1421 x 850 x 2180mm)

0 mm)

Average Airflow Velocity:

o Inflow:105fpm (0.53±0.015m/s)

o Downflow:66fpm (0.33±0.015m/s)

Airflow Volume:

o Inflow: 275cfm (465m³/h)

o Downflow67%: 571cfm (956 m³/h)

Exhaust, 33%: 275cfm (465 m³/h)

HEPA filter efficiency: >99.99% for particle size above 0.3 microns

Both filters are HEPA filters, H14.

Supply filter 1: 99.998% MPPS, Exhaust filter: 99.996%@ MPPS

Supply Filter 2: 99.998%MPPS, Exhaust filter : 99.996%@MPPS

Both filters are HEPA filters, H14.

Noise: ≤ 67dB(A)

Fluorescent lamp intensity: ≥650Lu

x

Ground resistance: ≤ 0.10Ω

Voltage Resistance: 2 seconds no breakdown with DC1200V

Cabinet Construction: Work area: 1.5mmstainless steel

Frame: cold-roll steel sheets with electrostatic coating

Working Environment: Use indoors only

Environmental temperature: 59°F– 95°F (15Ԩ-35Ԩ)

Relative humidity: ≤75

%;

Range of atmospheric pressure: 70kPa~106kPa

5

Power supply: AC 120V±10%, 60Hz ±1Hz

Serial number is on cabinet; see operational board mark.

II、Installation

2.1Position

The Biological safety cabinet should be positioned in an airflow-protected zone in order to

prevent the airflow from being adversely affected. This can be caused by ventilation

systems,air-conditioning or personnel movement.If the test shows that the interference of

other airflow overpasses the inlet speed into cabinet air flow, indoor infectious gas can enter

the biological safety cabinet work area. Therefore, it is necessary that the cabinet be

positioned correctly.The relationship between the safety cabinet exhaust air and indoor air

exhaust ventilation pipes should also be notedso that the air emission exhaustsfrom the top of

the cabinetand the cabinet itselfshould be positioned to avoid restrictions from its

exhaust.Biological safety cabinets should be in the downstream airflow direction;if possible,

the best way to install this cabinet is to reserve a 12” clearance on all four sides of the cabinet.

Pay special attention to the electrical line: every biological safety cabinet must adopt its

own exclusive line directly into the socket. Do not, under any circumstances, allow the use of

an extension cord without permission from the manufacturer to modify the powercord.

This biological safety cabinet can operate 24 hours a daysuccessively. All circuits and motors

are adequate and have protection measures.

2.2 Disassembly and handling

When the equipment is received,please check the box for outside damage conditions. Broken

glass or other damage should be notedupon receipt of equipment andcarrier should be

notified immediately.

1) If you do not receive return authorization, the equipment cannot be returned to the factory.

2) If the equipment is in cold weather transportation, it should be placed near the desired

location and left at room temperature for 24 hours prior toassembly.

3) First, remove all surface protection material. Read Item #7 below. Do not try to lift the

packageunder frame before the device is completely exposed.

4) When removing the packaging materials, carefully put assembly parts to one side. Excess

packaging tape residue can be wiped clean with alcohol.

5) Check all parts in the transport making sure there are no damaged parts. If damaged parts

are found, immediately report them to the transportation company. If there is damage, do not

open the packaging;the consigner may be asked to inspect the box.

6) Lift the Equipment off the packageunder frame and release the four stop blocks.

7) The security cabinet is very heavy and is equipped with highly efficient HEPA filters that

should be moved carefully. The safety cabinet should be transferred by a vehiclesuch as a

fork lift.

8) The cabinet should not be upside down during shipment under any circumstances.If so

contact the carrier

6

2.3 Assembly and install

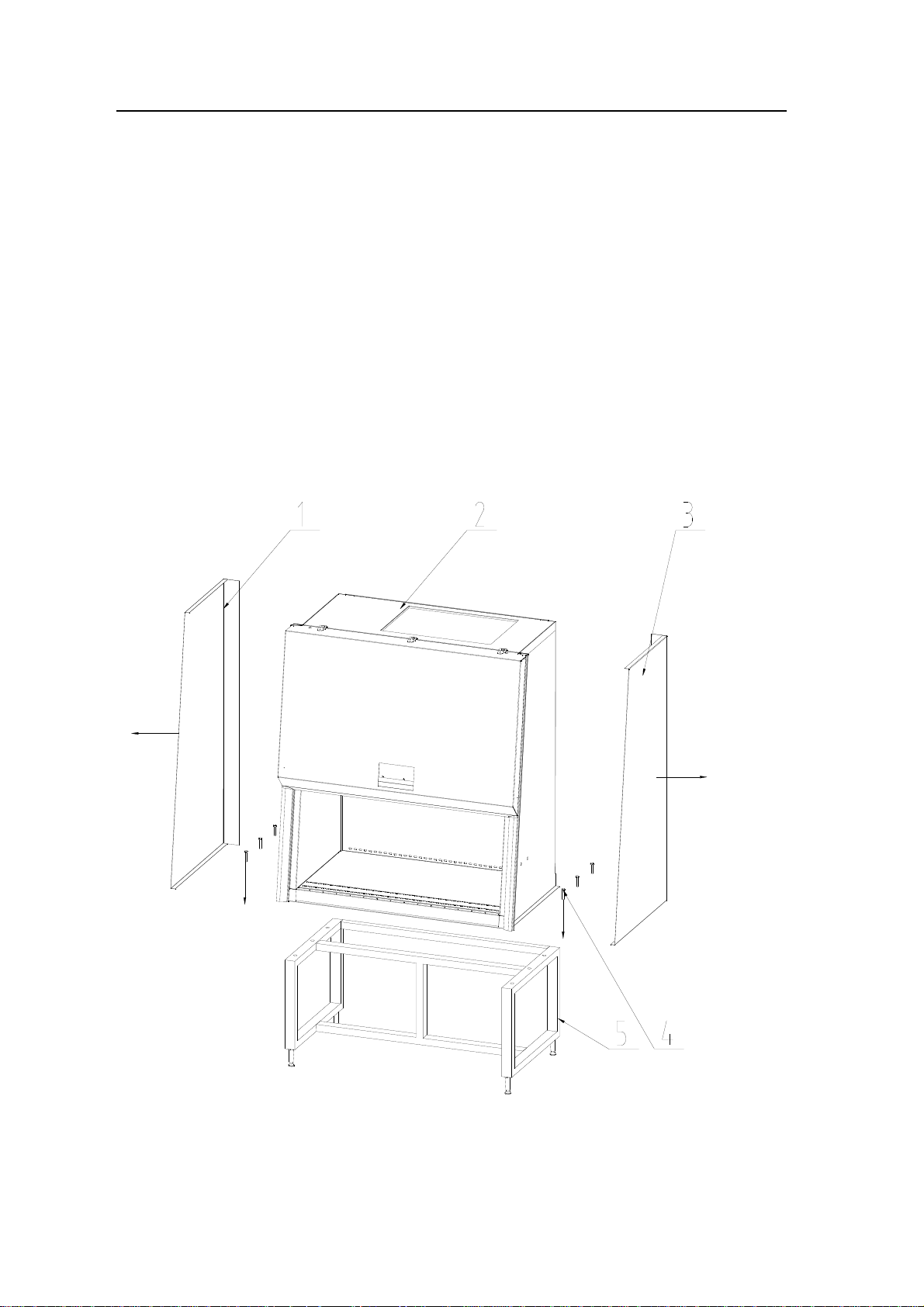

1) Assemble the under-frame, see installation Figure 1.

FIGURE 1: BASE FRAME ASSEMBLY

1. Seven M10×50 bolts

2. Horizontal support without hole is fastened with two M10×50 bolts

3. Horizontal support with hole is fastened with two M10×50 bolts

4. Left-side support

5. T-style support is fastened with three M10×50 bolts

6. Right-side support

7

2) Unload the two side panels see Figure 2.

3) Place cabinet onto under-frame and secure with bolts. Bolts are in the cabinet work zone

bag.Make the connection between the under frame and cabinet body (sees Figure 3), and

then mount side panels;

FIGURE 3: CONNECTION OF BASE AND CABINET BODY

1. RIGHT PANEL

2. CABINET

BODY

8

3. LEFT PANEL

4. M10 BOLT

5. BASE FRAME

4) Adjust under-frame and level the working surface to ensure the maximum stability on floor.

5) Remove the internal packing materials, empty all parts and clean all debris from inside of

the cabinet

Note: Any residual debris may lead to damage to the HEPA filters and fan.

6) Check packing list to ensure that all materials and accessories are included.

7) Check the internal and external safety cabinet carefully and inspect all components that

may have loosened during transport. If necessary, check for filter leakage. Check the front

panel fixed bolts; the bolts should not be too tight. If you need to check the air filter surface,

you can release the fixed wing nut bolt, remove from the front of the wing nut and then

carefully inspect.

8) Check to make sure the work surface is firmly installed.

9) If the safety cabinet is equipped with water and air, connection to building or other services

must be in accordance with local codes.

10) Install the exhaust HEPA protection device on the exhaust filter: The protection device will

be placed around the filter opening, fixed with a nut.

NOTE: Do not, underany circumstances, put hand into exhaust filter.

11) Remove the four screws and lift out work surface panel. Remove the plug on the

down-board;secure the valve connecting the pieces to the down-board, connecting the drain

valve and making sure valve is in a closed drain position, (parallel to the ground).

12) The device is equipped with a HEPA exhaust protection device on the top. If the

equipment request is to connect to the external exhaust system (used in toxic, poisonous gas

or steam), be sure to refer to Chapter 6 of the external exhaust systems.

NOTE: The minimum distance between exhaust HEPA filter and the ceiling is 11.8”

(300mm). If the exhaust HEPA filter is blocked, sufficient air will not flow into the outlet

operating area. The inlet operating the open airflow speed should be checked on

location, when the exhaust HEPA filter is at the top of the clean room, less than 15.9”

(406mm).

13) Install ultraviolet and fluorescent lamp.

14) Installation of the main components, see Figure 4.

9

FIGURE 4: MAIN PARTS

1. Exhaust filter protector hood

2. Operational board

3. UV light

4. Control panel

5. Light

6. Power lock

7. Base frame

8. Emergency stop

10

2.4 Check

1) Connect the biological safety cabinet’s dedicated power line to power outlet on a 120V

power source, with a total power of 20 amps. The biological safety cabinet must be the only

equipment on the circuit; see the electrical equipment requirements data on the cover.

2) Turn the key on the front panel and press the power button located on the control panel.

There will be a delay on the fan in order to achieve the required speed. In order to prevent too

much current, the fan needs a delay of about 10-15 seconds in order to achieve full speed

before motor is running. Similarly, the fan also needsa 10-15 second delay to stop. Stable

voltage is provided by a built-in voltage regulator circuit for the motor/blower which helps to

eliminate air fluctuations. Please remember to turn fan of before shutting down.

3) Press the LIGHT button on control panel to turn on the lights. If the lamp is not bright, check

the lamptube or socket. It may have come loose between the lamp and lamp holder during

shipping.

4) Press the UV button on the control panel, turn on the UV lamp and check to make sure the

UV light is working properly.

NOTE: For safety purpose the UV lights will only operate when the glass dooris fully

closed.

5) Press key SOCKET button on the control panel and check the safety cabinet's internal

power socket. If the safety cabinet is equipped with two sockets, this button will control both.

11

III. Adjustments and Testing

3.1 Adjust on site

Before packing and transport, this safety cabinet has been tested and confirmed in our

factory; however, another test after installation must be performed. Only qualified personnel

can adjust this device and in order to ensure the accuracy of the on-site testing, this test

equipment must be calibrated. If you cannot implement this operation, please contact

ENVIRCO to provide a local on-site testing services company.

On site adjustment should include the following

- Check the safety cabinet inflow

- Check the safety cabinet internal decline airflow rate

- Check airflow inside the cabinet by using smoke simulator

- When the cabinet is connected to the building’s exhaust system, balance the air emission.

Toensure that your new equipment is accurate, perform an on-site inspection. The equipment

cannot be used without this pre-test, performed by qualified personnel.

Do not adjust the fan speed without fully testing decline of the wind speed and the inflow air.

The manufacturer has already set the correct air flow; no further adjustments should be

required. Do not change the valve set of the ratio between the exhaust and air supply unless a

qualified person thinks it is necessary to do.

3.2 Tests and standards

3.2.1 Filter leakage test

The standard aerosol testing for the integrity of the HEPA filtersis generally performed

annually. Qualified personnel must use a calibrated device when aerosol testing. A

referenced list will be provided by the factory.

:

NOTE: Place connection between supplyair and exhaust filters hose test for pressure

(the middle hose) photometer upper (PAO test point connection).

3.2.2 Air adjustment at the opening of the work area

The exhaust HEPA filter should be installed on the top of the biosafety cabinet. The air volume

exhausted is equal to the air volume entering from the work area opening. The average

velocity entering the opening of the work area has been identified during the design of the bio

safety cabinet. The test should conform to the rules of NSF49. The opening air velocity testing

data is in APPENDIX 1. To adjust the fan speed, adjustments should be according to the data

specified in APPENDIX 1.

12

Loading...

Loading...